TYPE R AUTOPILOT DRIVE UNIT SYSTEM PACKS

INSTALLATION MANUAL

OC15269 REV F 27 JULY 2012

POWERBOAT & SAILBOAT SYSTEMS

2 of 44

Subject to change without notice OC15269 REV F

Revision History

Revision Description

E Redesign in booklet format

F

See DCR # 0961

© 2012 Octopus Products Inc. All rights reserved.

The information contained in this document is the sole property of Octopus

Products Inc. Any reproduction in part or whole without the written permission of

Octopus Products Inc. is prohibited. Octopus Products Inc will nor be liable for

errors contained herein or for incidental or consequential damages in connection

with the furnishing, performance or use of this document.

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

CONTENTS

A Introduction

A1 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

A2 Compatibility Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

A3 Important Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

A3a Manual Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

A3b Manual Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

B Mechanical Installation

B1 Available Space - Physical Envelope & Orientation . . . . . . . . . . . . . . . . . .6

B1a Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

B2 Outboard Engined Boats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

B2a Engine compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

B2b Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

B2c Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

B3 Sterndrive Boats Mercruiser DHB 1994+. . . . . . . . . . . . . . . . . . . . . . . . . .12

B3a Engine compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

B3b Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

B3c Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

B4 Sterndrive Boats Volvo Gasoline & Diesel USA 1997 Onwards . . . . . . . .16

B4a Engine compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

B4b Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

B4c Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

B5 Sterndrive Boats Mercruiser Saginaw 1983-93 . . . . . . . . . . . . . . . . . . . . .20

B5a Engine compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

B5b Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

B5c Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

B6 Sterndrive Boats Volvo Diesel Europe. . . . . . . . . . . . . . . . . . . . . . . . . . . .24

B6a Engine compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

B6b Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

B6c Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

B7 Inboard Engined Boats & Sailboats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

B7a Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

B7b Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

B7c Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

B7d Quick Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

B7e Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

B8 Routing Steering Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

B8a Cable Length Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

B9 Connecting Steering Cable To Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

B10 Rudder Feedback Unit (RFB) Installation & Calibration . . . . . . . . . . . . . .35

B10a Universal RFB Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

B10b Calibration and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

B11 Interference Evaluation (Outboard Engines Only) . . . . . . . . . . . . . . . . . . .37

C Electrical Installation

C1 Connecting Drive To Autopilot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

C2 Rudder Feedback Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

C2a Connection - non Simrad autopilots . . . . . . . . . . . . . . . . . . . . . . .38

C2b Connection - Simrad autopilots . . . . . . . . . . . . . . . . . . . . . . . . . .39

D Appendix

D1 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

D2 General Maintenance Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

A INTRODUCTION

A1 System Overview

The Octopus Type R Remote Drive is a rotary mechanical autopilot drive system which

makes it simple and economical to fit an autopilot on smaller powerboats with

mechanical push-pull cable steering or small sailboats with a steering quadrant or tiller.

The type R drive unit incorporates a drive motor, solenoid clutch and integrated rudder

feedback (RFB) capability. Its design means that the drive can be mounted in a

convenient position, meaning it will fit a large number of boats which because of

design constraints or size were not practical to have an autopilot fitted before.

The system uses a steering cable and connection kit which is fitted in addition to

the existing manual steering cable for cable steered boats or directly to the steering

quadrant for sailboats. This allows the system to be easily installed on most types of

boat without having to interfere with the existing steering system. There are five Type

R packs available which include the drive unit, 6ft (1.8m) steering cable and relevant

connection kit:

Part Number Type Compatibility

MDRESYS-A* Sterndrive Mercruiser 1994 onwards, Volvo Gasoline engines

and Volvo Diesel engines USA 1997 onwards

* We recommend changing the steering cable for a 9ft version when installing on to a twin engined boat.

MDRESYS-B Sterndrive Mercruiser Saginaw 1983-93, Volvo Diesel engines

Europe 1994 onwards

MDRESYS-C Outboard Yamaha 70hp+

MDRESYS-D Outboard Mercury, Mariner, Suzuki

MDRESYS-E Inboard/Sailboat Up to 32ft (9.75m) / 13,200lbs (6,000kg) displacement

A2 Compatibility Information

• The Type R Remote Drive is recommended for use on vessels with a maximum

speed of 44mph (65km/h) and should not be fitted to vessels which can exceed this.

• It should not be fitted to boats where the engine max horsepower exceeds the

max horsepower rating for the vessel as stated on the vessel manufacturer’s tag.

• The existing steering system MUST be capable of being back driven. The Type R

Remote Drive cannot be fitted if the steering system is a NFB (no feed back) type.

• The drive is designed to produce a maximum cable push/pull of 300lbs (136kg),

which makes it suitable for the vast majority of cable steered vessels. However

some vessels fitted with push pull cable steering systems have very stiff steering

or steering which is heavily loaded in one direction due to hull design and engine

considerations. Generally speaking, the Type R drive will steer vessels that do not

require more than a 15lb force on the rim of a 14in diameter steering wheel to hold

a course, this equals 105in-lb of torque. If the steering wheel input torque exceeds

this figure we would recommend that the vessel be fitted with a hydraulic linear

actuator drive system instead.

4 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

A3 Important Safety Features

The Helmsperson should be made aware of the two following safety features before

using the Autopilot:

A3a Manual Release

The drive features a manual release in case the Autopilot is switched to manual

mode by mistake, which could result in a dangerous manoeuvre or violent movement of the steering wheel on a powerboat due to propeller action or trim forces.

While the drive is under consistent load from the boat’s steering system in one direction or no movement, the drive unit clutch will remain engaged when the Autopilot is

switched to manual mode.

To disengage the drive a small joggle action (turning the wheel/tiller from side to

side) will release the clutch and allow manual control.

IMPORTANT The helmsperson should always be ready to take manual control of

the boat when the Autopilot is returned to manual mode.

DOCKSIDE TESTING Due to the ‘Manual Release’ safety feature, when the vessel

is not in motion it might be necessary to joggle the wheel/tiller (move from side to

side) to engage or disengage the drive.

A3b Manual Override

IMPORTANT It is STRONGLY advised that the helmsperson be familiarized with

this manual override procedure before proceeding to sea.

In the event of uncontrolled automatic steering or any other emergency situation

where it is imperative that manual control be reassumed immediately, the helmsperson can override the steering action of the drive unit by exerting force on the steering wheel in the opposite direction to the drive. This action will cause the drive unit

thrust limit to “slip” allowing the helmsperson to take control.

NOTE The manual override does not disengage the autopilot - to resume full manual

control the autopilot should be switched to standby as soon as is practically pos-

sible.

5 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

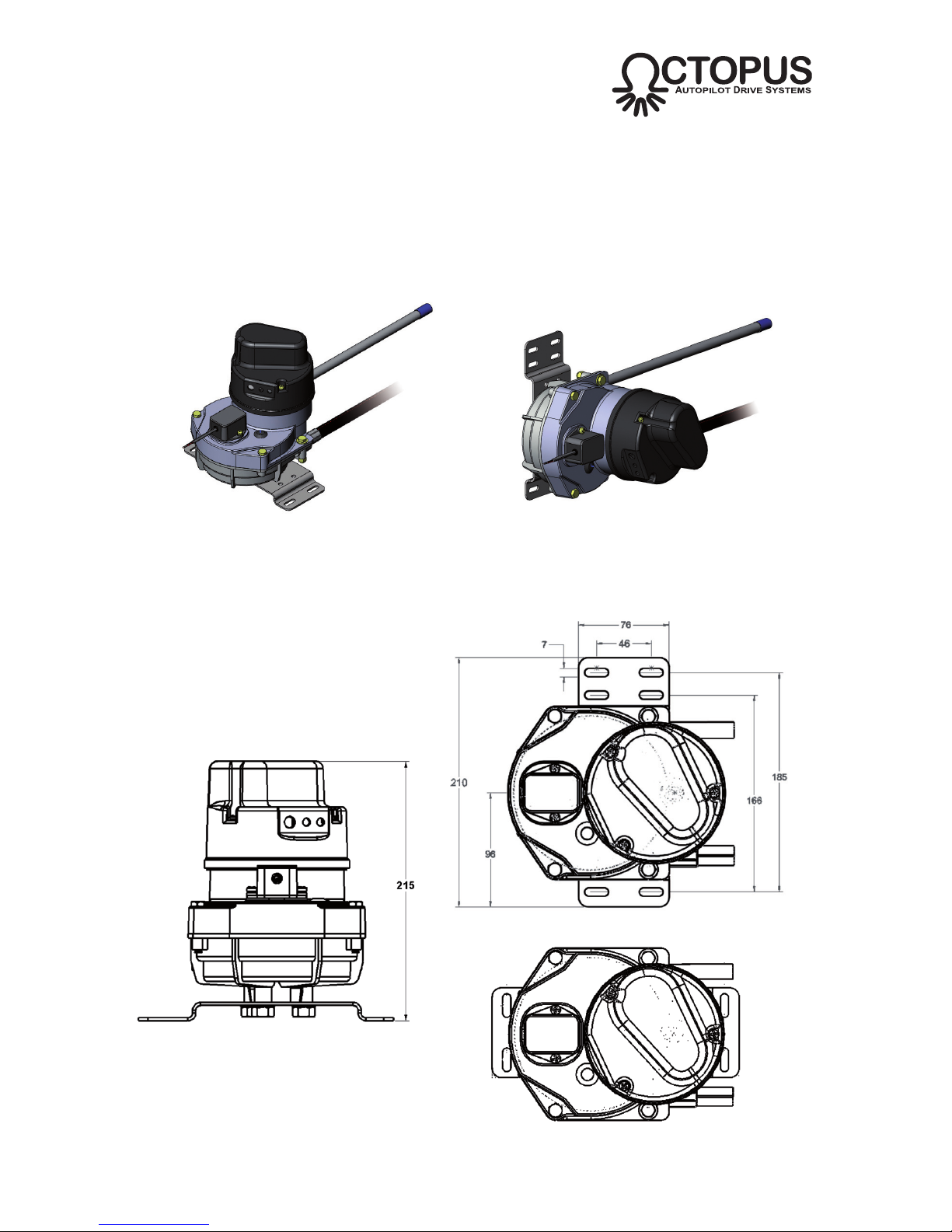

VERTICAL MOUNTHORIZONTAL MOUNT

Fig B1 - Mounting options

B MECHANICAL INSTALLATION

B1 Available Space - Physical Envelope & Orientation

The selected installation site should provide adequate space to accommodate the

drive unit including the entry and exit points for the steering cable. The drive can be

mounted at any angle. Note that no access for maintenance purposes is required.

The steering cable entry and exit ports are reversable, so the cable entry and exit

ports can be selected for the best installation arrangement on the particular vessel.

6 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B2 - Physical drive envelope

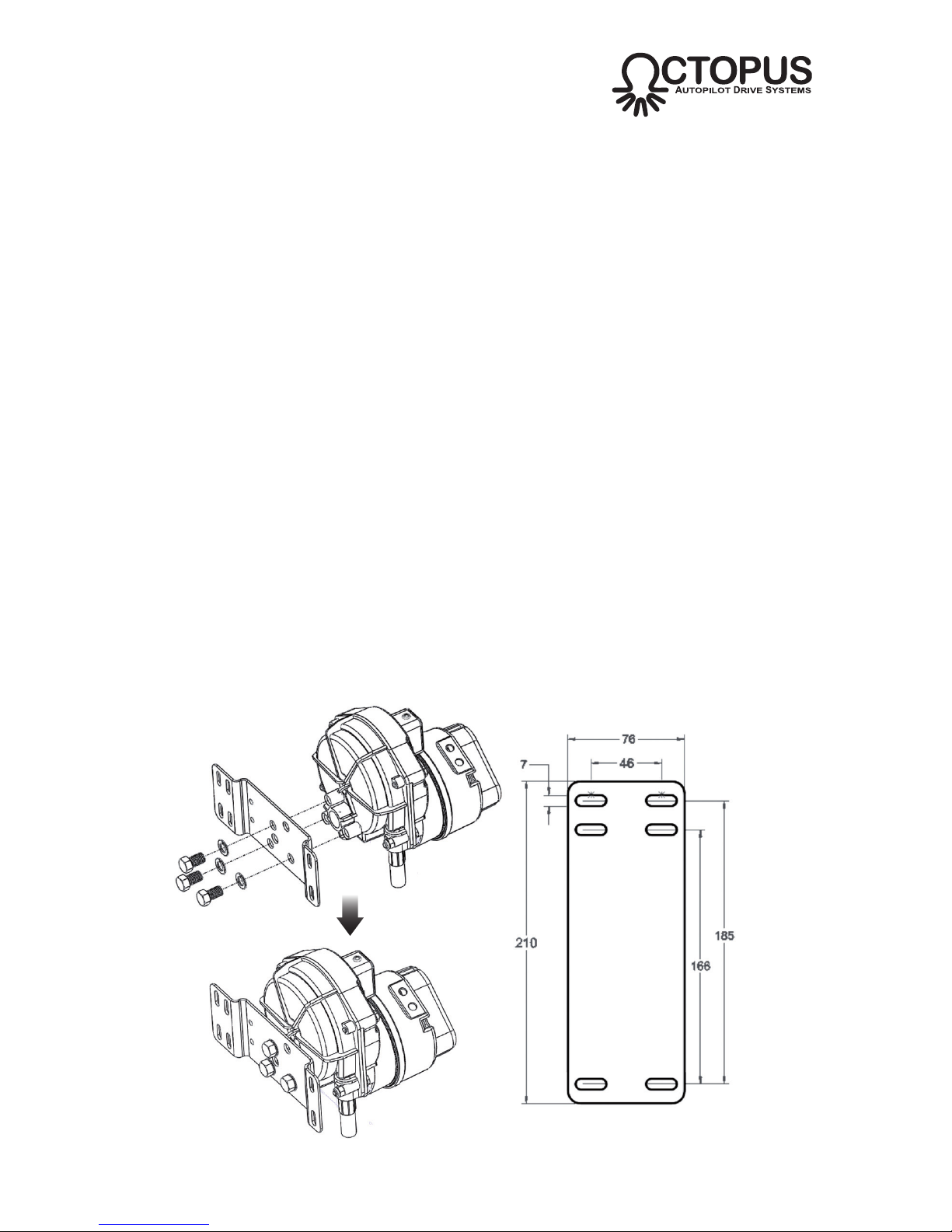

BASEPLATE PERPENDICULAR MOUNT

BASEPLATE PARALLEL MOUNT

NOTE If the ports are reversed, the steering action will also be reversed. This can

be compensated for by adjusting the autopilot software or the drive motor wiring.

B1a Drive Installation

The design of the Type R Autopilot Drive System gives a high degree of flexibility in

the location of the drive unit relative to the steering mechanism, however factors

such as the optimum steering cable route and also the length of the steering cable

(6ft / 1.8m standard, other lengths available) will influence the final location.

It is recommended that the steering cable connection is the final stage of the

mechanical installation, but it is advisable to take into account the points raised in

section B8 regarding steering cable routing when planning the drive unit location.

i) Position the drive unit in the final location. Verify that there is sufficient clear-

ance for the steering cable entry and the spent cable tube, as well as access

for the electrical connections.

ii) Although there are no loads transferred to the drive unit mounting when the

autopilot is in operation, the selected location should be sturdy enough to

support the drive unit.

iii)

The drive base plate can be fitted in two possible orientations - perpendicular

or parallel. Assemble the base plate to the drive using the most suitable ori-

entation for the installation and torque the fasteners to 30-35in-lb (3.4-4.0Nm).

iii) Mark out the fixing pattern from the drive base plate and drill appropriate

sized pilot holes into the mounting structure (Fig B3). The mounting holes

are suitable for 1⁄4in or 6mm fasteners.

iv) Position the drive unit and install using suitable fasteners. Ensure they are

tightened securely.

7 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B3 - Mounting plate drilling dimensions

B2 Outboard Engined Boats

The Outboard Installation Kits can be fitted to mechanical push-pull cable steered

vessels that are powered by MOST of the popular Yamaha (MDRESYS-C) and

Mercury/Mariner/Suzuki (MDRESYS-D) models of outboard engine. It is recommended for use on vessels with a maximum speed of 44mph and should NOT be fitted to vessels where the maximum horsepower of the engine exceeds the maximum

horsepower rating for the vessel as stated on the vessel manufacturer’s tag.

The installation kit allows the second steering cable for the Type R drive to be fitted

to the outboard steering system.

B2a Engine Compatibility

The MDRESYS-C kit is suitable for use on Yamaha 115-220 HP produced from

1984 onwards. The Yamaha engine has M6 (metric system) threaded fittings.

The MDRESYS-D kit is suitable for use on Mercury Black Max outboards from 1980

onwards, Mariner outboards from 1980 onwards, Mercury/Mariner 2.4 (all models)

and Suzuki DT75 – DT225 and DF60 – DF140. These engines have

1

⁄4in-28 UNF

threaded fittings.

B2b Supplied Parts

MDR-40 Type R Remote Rotary Autopilot Drive Unit

OC15SUK15A Yamaha Outboard Installation Kit (MDRESYS-C) OR

OC15SUK15B Mercury-Mariner-Suzuki Outboard Installation Kit (MDRESYS-D)

OC15109-6 6ft (1.8m) Secondary Steering Cable*

* Other lengths are available as optional accessories

B2c Installation

• Prepare the engine mounting site

i) Use the helm to centre the engine.

ii) Ensure that the area in front of the

tilt tube is clear of obstructing wires,

hoses etc. Reroute if necessary.

iii) There are four threaded holes on

the front face of the tilt tube (Fig B4),

ensure that these are free from paint

etc - retap if necessary:

MDRESYS-C M6 metric

MDRESYS-D

1

⁄4in-28 UNF

8 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B4 - Threaded mounting holes on front face

of tilt tube

Threaded

mounting holes

Tilt tube

• Remove steering link arm

i) To simplify the re-assembly proce-

dure, make a note of the connections

between the steering link arm and the

manual steering cable and engine tiller.

ii) Disconnect the steering link arm from

the manual steering cable and the

engine tiller.

iii) Retain the link arm and fixings etc for

later use.

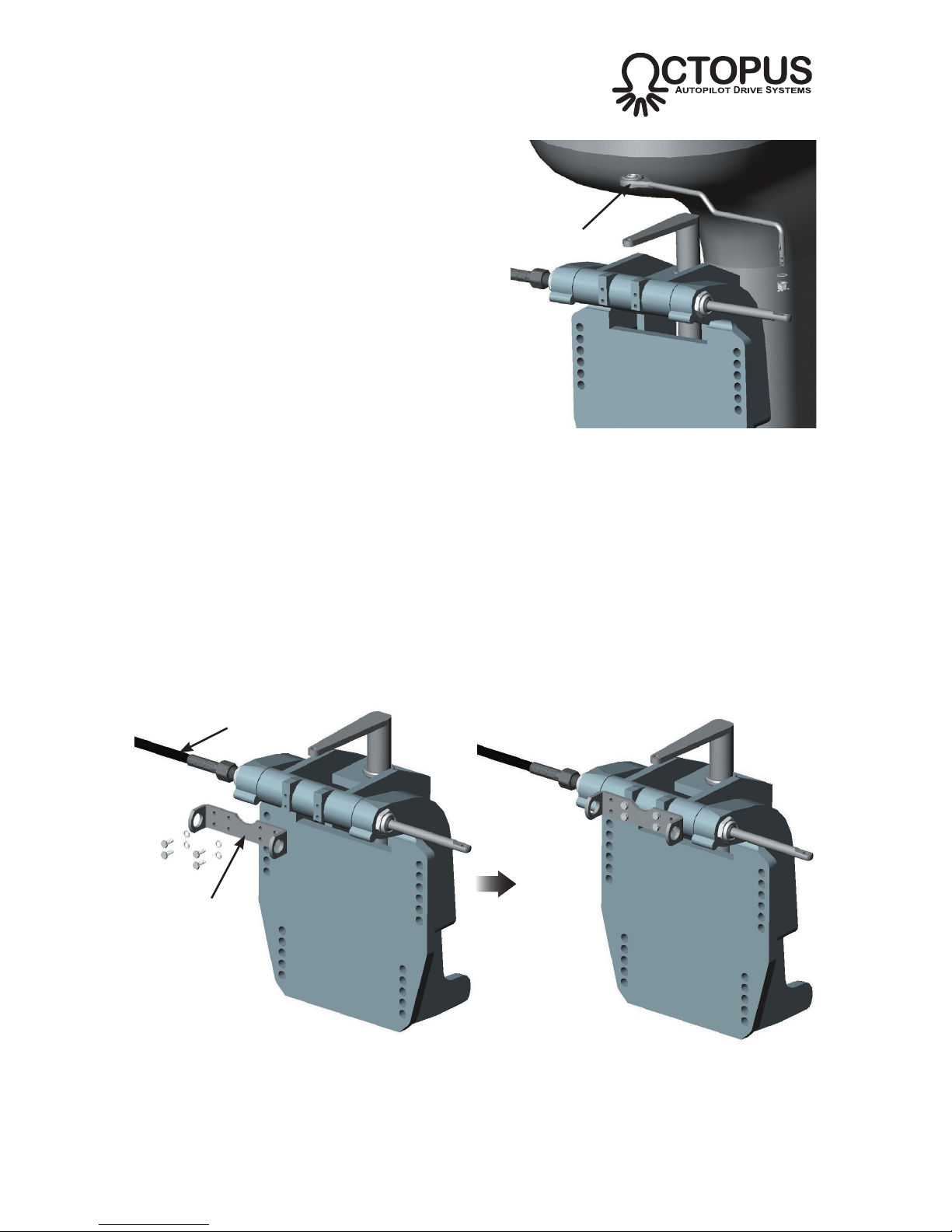

• Fit the secondary steering cable mount bracket to the engine tilt bracket

i) The bracket attaches to the four threaded mounting holes on the front face

of the tilt tube (Fig B6). Four M6/1⁄4in-28 UNF bolts and lockwashers are

supplied in the kit.

ii) Torque the bolts to 100in-lb (11Nm).

9 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B5 - Removing steering link arm

Steering

link arm

Fig B6 - Fitting the cable mount bracket

Primary

steering cable

Mount bracket

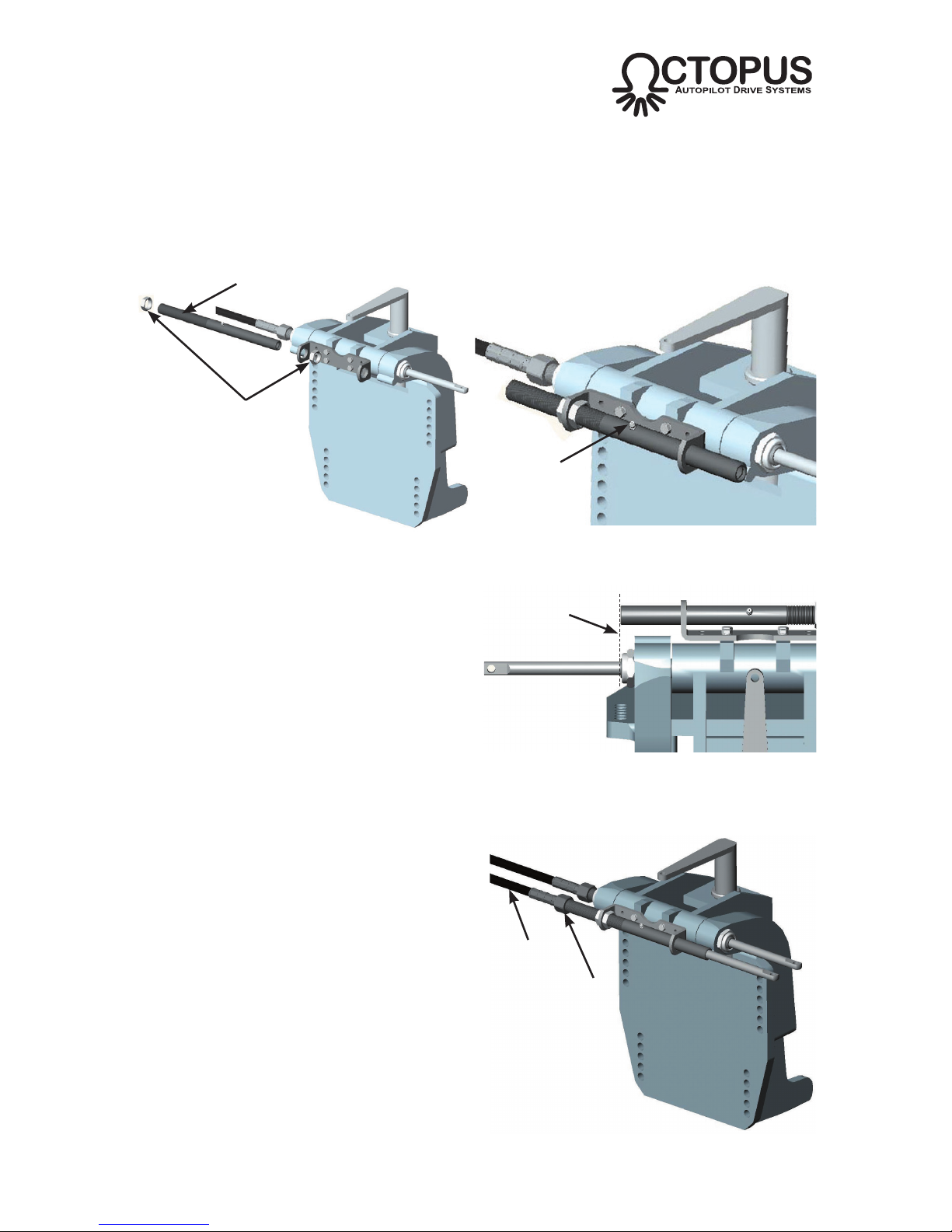

• Fit the cable guide tube to the cable mount bracket

i) Both the locknuts and the guide tube thread should be lubricated with marine

quality grease before assembly.

ii) Slide the guide tube into the cable mount bracket as shown (Fig B7).

10 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

iii) Adjust the position of the guide

tube so that the exit end of the

guide tube aligns with the exit end

of the engine tilt tube (Fig B8)

iv)Tighten the two locknuts and

torque to 175in-lb (20Nm).

Grease the fitting.

Fig B7 - Fitting the cable guide tube

Cable guide

tube

Locknuts

Fig B8 - Cable guide tube alignment

TOP VIEW

Align

Greaser

• Attach the secondary steering cable to the guide tube

i) Both the cable nut, the guide tube

thread and the inside of the guide

tube should be liberally lubricated

with marine quality grease before

assembly.

ii) Insert the rod end of the secondary

steering cable into the threaded end

of the guide tube (Fig B9).

iii) Hand tighten the cable nut and

torque to 175in-lb (20Nm). The nut

has an internal locking thread

which

increases the amount of torque required

initially as the thread is cut.

Fig B9 - Secondary steering cable

Cable

nut

Secondary

steering

cable

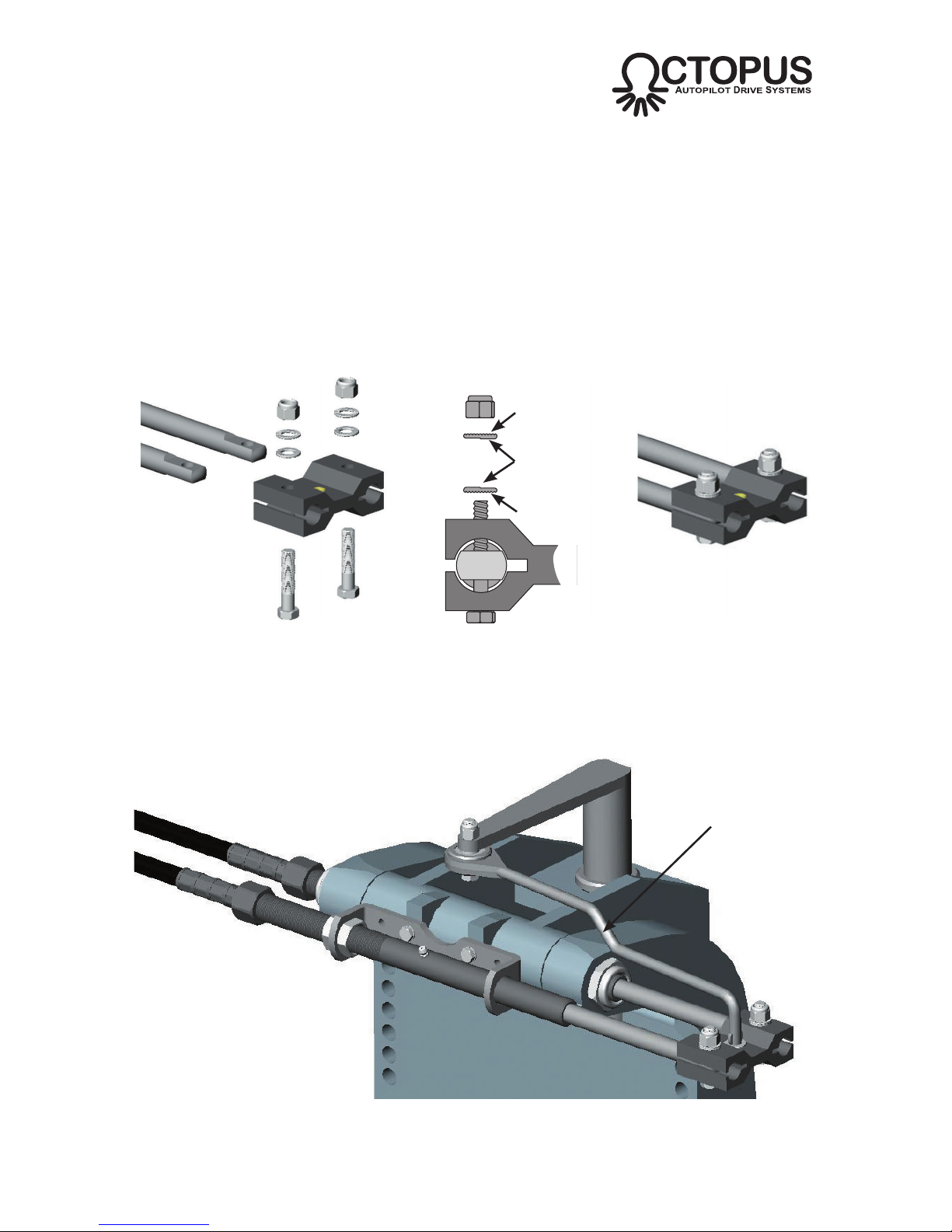

• Fit the dual block to the rod ends of the primary and secondary steering cables.

i) Disassemble the dual block assembly.

ii) Insert the two cable rod ends into the slots of the dual block.

iii) Align the crossholes and bolt through. The anti-vibration washers and nuts

supplied must be fitted in the correct order with the serrated face of the

washer in contact with the the nut face and the dual block face. The cam

face of the washers must be in contact with each other (Fig B10).

iv) Torque the nuts to 180-200in-lb (20-22Nm).

11 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B10 - Fitting dual block & correct washer orientation

Serrated face

Cam faces

Serrated face

• Reassemble the steering link arm.

i) Referring to the notes made when the steering was disassembled, reattach

the steering link arm between the engine tiller and the dual block (Fig B11).

Fig B11 - Fitting the steering link arm

Steering Link

Arm

• Refer to section B9 on connecting the secondary steering cable to the drive unit.

Primary

steering cable

Fig B12 - Mercruiser DHB 1994+ cylinder installation configuration

Secondary

steering cable

Octopus sterndrive

installation kit

Mercruiser DHB

steering cylinder

Octopus Type R

drive unit

B3 Sterndrive Boats Mercruiser DHB 1994+

The Octopus MDRESYS-A Type R Sterndrive pack can be fitted to mechanical

push-pull cable controlled sterndrive power assisted steering cylinders made by

Mercruiser (DHB).

The installation kit allows the second steering cable for the Type R drive to be fitted

to the sterndrive steering system.

B3a Engine compatibility

Mercruiser DHB steering cylinders are fitted to Alpha One Generation II and Bravo

Sterndrives from 1994 and newer.

B3b Supplied Parts

Type R Remote Rotary Autopilot Drive Unit

OC15SUK12B Sterndrive Installation Kit

OC15109-6 6ft (1.8m) Secondary Steering Cable

OC15109-9 9ft (2.75m) Secondary Steering Cable*

* Recommended for twin engine installations.

12 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

B3c Installation

• Prepare the steering cylinder

i) Use the helm to extend the steering

cylinder to full hard over as shown in

Fig B13 (it may be necessary to run

the engine to do this).

ii) Remove the cotter and clevis pins that

connect the primary steering cable

rod end to the steering cylinder clevis

bracket.

iii) Ensure that the flats on the steering

cylinder are vertically aligned (it may

be necessary to crack the nut on the

primary steering cable to adjust this,

the nut should then be re-torqued to

175in-lb / 20Nm).

• Fit the drive collar and spacer bush

i) Use the helm to retract the primary

steering cable to full opposite hard

over so the rod end disengages from

the cylinder clevis bracket (Fig B14a).

ii) Slacken the clamp screw and lock nut

on the fitting kit drive collar.

iii) Fit the spacer bush on to the steering

cylinder sleeve, ensure it is correctly

oriented - refer to Fig B14b.

iv) Slide the drive collar on to the steering

cylinder and over the spacer bush as

shown in the diagram. Do not tighten

the clamp screw at this stage.

v) Use the helm to extend the primary

steering cable back to full hard over

so that the rod end re-engages into

the cylinder clevis bracket.

13 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B13 - Steering cylinder in fully extended posi-

tion

Clevis

bracket

Clevis

pin

Flat must

be vertical

Cotter pin

Steering cylinder

fully extended

Steering cable fully

retracted

Spacer

bush

Drive collar

Drive collar &

Spacer bush

Steering cable

fully extended

Fig B14 - Fitting the drive collar and bush to the

steering cable sleeve

• Pre-fit the secondary steering cable to the guide tube/yoke assembly

i) Both the cable nut, the guide tube

thread and the inside of the guide

tube should be liberally lubricated with

marine quality grease before assembly.

ii) Insert the rod end of the secondary

steering cable into the threaded end of

the guide tube (Fig B15).

iii) Hand tighten the cable nut and torque

to 175in-lb (20Nm)*. Note that the

nut has an internal locking thread

which increases the amount of torque

required initially as the thread is cut.

* There should be NO movement between the

outer cable jacket and the guide tube when the nut

is fully tightened.

• Mount the connection kit and secondary steering cable to the steering cylinder.

This stage of the assembly will be easier if the Type R drive unit is not connected to the

secondary steering cable at this point, as fine adjustments to the drive collar positioning

are necessary and the backdrive friction from the drive unit will make this more difficult.

Connecting the drive unit should be the final stage of the mechanical assembly.

i) Remove the shoulder screw from the drive collar.

ii) Position the connection kit assembly above the steering cylinder and engage

onto the steering cylinder clevis bracket and drive collar as shown (Fig B16).

Ensure that the clevis pin is also locking the primary steering cable rod end

into the clevis bracket*. Lock in place using the hitch pin.

* If the clevis pin does not engage due to misalignment, adjust the manual steering helm slightly until

the hole in the primary steering cable rod end aligns with the holes in the clevis bracket.

14 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Guide tube/

yoke assembly

Fig B15 - Fitting the secondary

steering cable to the guide tube

Secondary

steering cable

iii) Adjust the position of the drive collar so that the shoulder screw hole aligns

with the hole in the secondary steering cable rod end.

iv) Fit the shoulder screw, torque to 55in-lb (6nm). The screw has a locking thread

which increases the amount of torque required initially as the thread is cut.

Fig B16 - Fitting connection kit to steering cylinder

Shoulder screw

v) Use the manual helm to set the steering to the midstroke position. Adjust the

position of the drive collar so that there is a 7.4in (188mm) gap between it

and the front face of the steering cylinder (Fig B17). Tighten the drive collar

clamp screw and torque to 175in-lb (19Nm). Tighten the drive collar lock nut

and torque to 45in-lb (5nm).

15 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B17 - Positioning the drive collar

7.4in (188mm)

when steering is centered

• Refer to section B9 on connecting the steering cable to the drive unit

16 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Primary

steering cable

Fig B12 - Mercruiser DHB 1994+ cylinder installation configuration

Secondary

steering cable

Octopus sterndrive

installation kit

Volvo steering cylinder

(model 3860883 shown)

Octopus Type R

drive unit

B4 Sterndrive Boats Volvo Gasoline & Diesel USA 1997 Onwards

The Octopus MDRESYS-A Type R Sterndrive pack can be fitted to mechanical

push-pull cable controlled sterndrive power assisted steering cylinders made by

Volvo for Gasoline engines and also Diesel engines in the USA since 1997.

The installation kit allows the second steering cable for the Type R drive to be fitted

to the sterndrive steering system.

B4a Engine compatibility

The installation kit supplied is compatible with Volvo 3860883, 3860726, 3862210,

3862513, 3860882, 3862456 and 3862514 steering cylinders.

B4b Supplied Parts

Type R Remote Rotary Autopilot Drive Unit

OC15SUK12B Sterndrive Installation Kit

OC15109-6 6ft (1.8m) Secondary Steering Cable*

OC15109-9 9ft (2.75m) Secondary Steering Cable*

* Recommended for twin engine installations.

17 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

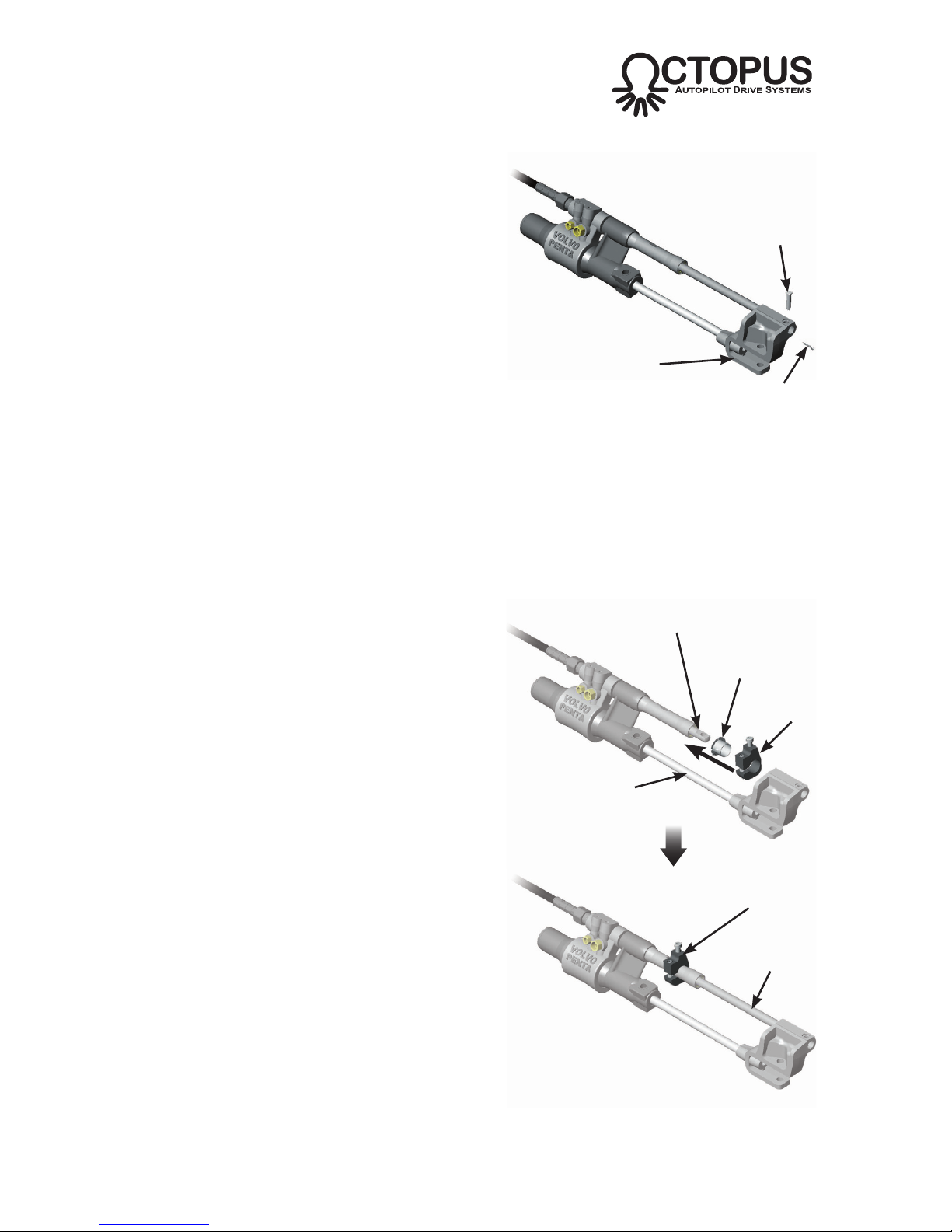

B4c Installation

• Prepare the steering cylinder

i) Use the helm to extend the steering

cylinder to full hard over as shown in

Fig B19 (it may be necessary to run

the engine to do this).

ii) Remove the cotter and clevis pins that

connect the primary steering cable

rod end to the steering cylinder clevis

bracket.

• Fit the drive collar and spacer bush

i) Use the helm to retract the primary

steering cable to full opposite hard

over so the rod end disengages from

the cylinder clevis bracket (Fig B20a).

ii) Slacken the clamp screw and lock nut

on the fitting kit drive collar.

iii) Fit the spacer bush* on to the steering

cylinder sleeve, ensure it is correctly

oriented - refer to Fig B20b.

* The spacer bush is not required on Volvo

models 3862513 and 3862514 which were fitted

from Sept 2003 onwards - the drive collar will clamp

directly onto the cable guide tube.

iv) Slide the drive collar on to the steering

cylinder and over the spacer bush as

shown in the diagram. Do not tighten

the clamp screw at this stage.

v) Use the helm to extend the primary

steering cable back to full hard over

so that the rod end re-engages into

the cylinder clevis bracket.

Fig B19 - Steering cylinder in fully extended

position

Clevis

bracket

Clevis

pin

Cotter pin

Steering cylinder

fully extended

Steering cable fully

retracted

Spacer

bush*

Drive

collar

Drive collar &

Spacer bush*

Steering cable fully

extended

Fig B20 - Fitting the drive collar and bush to the

steering cable sleeve

Fig B22 - Fitting connection kit to steering cylinder

Shoulder screw

18 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

• Pre-fit the secondary steering cable to the guide tube/yoke assembly

i) Both the cable nut, the guide tube

thread and the inside of the guide

tube should be liberally lubricated with

marine quality grease before assembly.

ii) Insert the rod end of the secondary

steering cable into the threaded end of

the guide tube (Fig B21).

iii) Hand tighten the cable nut and torque

to 175in-lb (20Nm)*. Note that the

nut has an internal locking thread

which increases the amount of torque

required initially as the thread is cut.

* There should be NO movement between the

outer cable jacket and the guide tube when the nut

is fully tightened.

• Mount the connection kit and secondary steering cable to the steering cylinder.

This stage of the assembly will be easier if the Type R drive unit is not connected to the

secondary steering cable at this point, as fine adjustments to the drive collar positioning

are necessary and the backdrive friction from the drive unit will make this more difficult.

Connecting the drive unit should be the final stage of the mechanical assembly.

i) Remove the shoulder screw from the drive collar.

ii) Position the connection kit assembly above the steering cylinder and engage

onto the steering cylinder clevis bracket and drive collar as shown (Fig B22).

Ensure that the clevis pin is also locking the primary steering cable rod end

into the clevis bracket*. Lock in place using the hitch pin.

* If the clevis pin does not engage due to misalignment, adjust the manual steering helm slightly until

the hole in the primary steering cable rod end aligns with the holes in the clevis bracket.

Guide tube/

yoke assembly

Fig B21 - Fitting the secondary

steering cable to the guide tube

Secondary

steering cable

iii) Adjust the position of the drive collar so that the shoulder screw hole aligns

with the hole in the secondary steering cable rod end.

iv) Fit the shoulder screw, torque to 55in-lb (6nm). The screw has a locking thread

which increases the amount of torque required initially as the thread is cut.

19 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

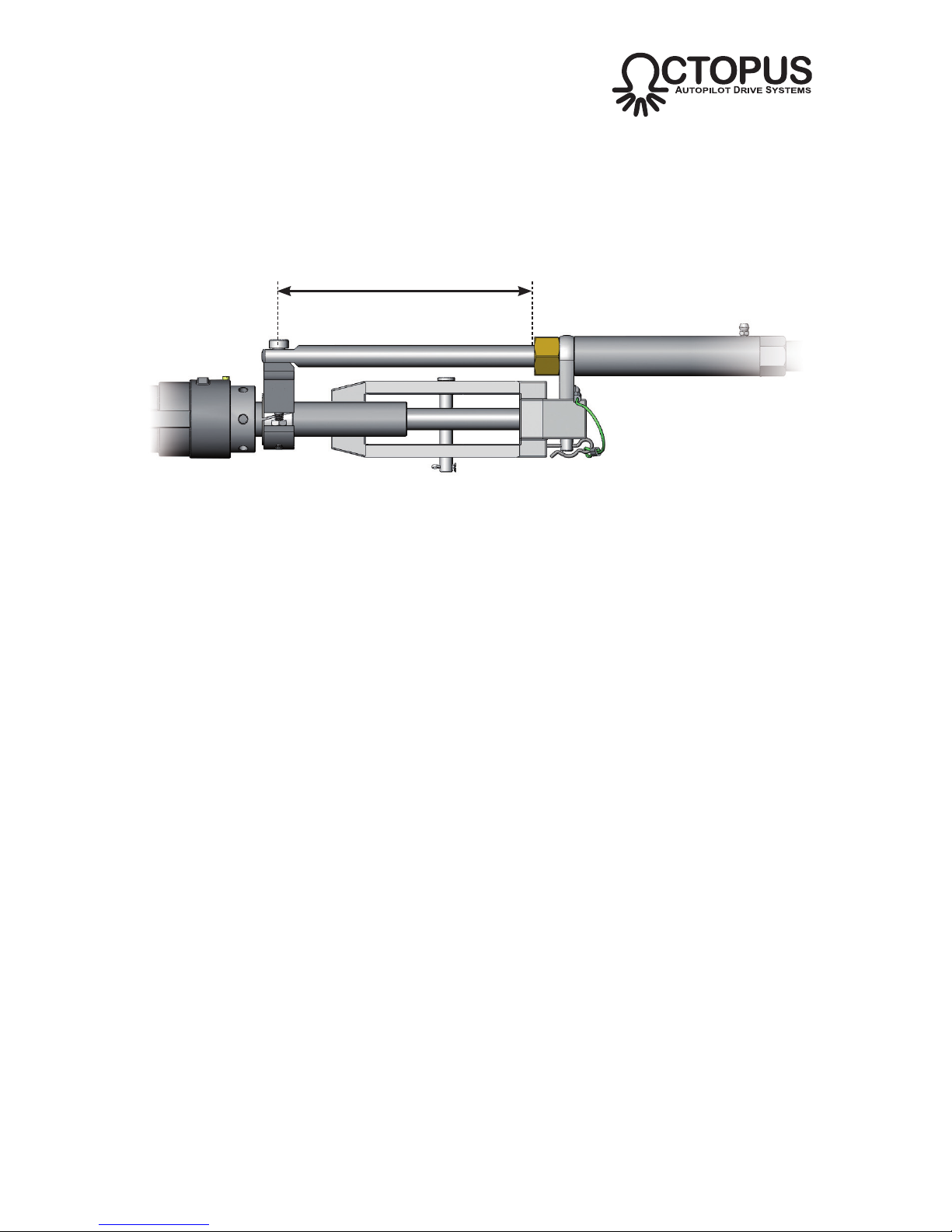

v) Use the manual helm to set the steering to the midstroke position. Adjust the

position of the drive collar so that there is a 7.3in (185mm) gap between it

and the front face of the steering cylinder (Fig B23). Tighten the drive collar

clamp screw and torque to 175in-lb (19Nm). Tighten the drive collar lock nut

and torque to 45in-lb (5nm).

Fig B23 - Positioning the drive collar

Guide Tube*

7.3in (185mm)

when steering is centered

* This diagram shows the earlier model Volvo cylinders, which featured a “necked” guide tube -

later models have a simpler parallel guide tube, which does not require the use of the Drive Collar

Spacer Bush.

• Refer to section B9 on connecting the secondary steering cable to the drive unit.

20 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Primary

steering cable

Fig B24 - Mercruiser Saginaw 1983-93 cylinder installation configuration

Secondary

steering cable

Octopus sterndrive

installation kit

Mercruiser Saginaw

steering cylinder

Octopus Type R

drive unit

B5 Sterndrive Boats Mercruiser Saginaw 1983-93

The Octopus MDRESYS-B Type R Sterndrive pack can be fitted to mechanical

push-pull cable controlled sterndrive power assisted steering cylinders fitted to

Mercruiser Alpha One Generation II and Bravo Sterndrives between 1983 and 1993

(Saginaw).

The installation kit allows the second steering cable for the Type R drive to be fitted

to the sterndrive steering system.

B5a Engine compatibility

Mercruiser Saginaw steering cylinders are fitted to Alpha One Generation II and

Bravo Sterndrives from 1983 to 1993.

B5b Supplied Parts

Type R Remote Rotary Autopilot Drive Unit

OC15SUK12C Sterndrive Installation Kit

OC15109-6 6ft (1.8m) Secondary Steering Cable*

* Other lengths are available as optional accessories

21 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

B5c Installation

• Prepare the steering cylinder

i) Use manual helm to set the steering

cylinder to the mid stroke position as

shown in Fig B25 (it may be neces-

sary to run the engine to do this).

ii) Remove the cotter and clevis pins

that connect the primary steering

cable rod end to the steering

cylinder clevis bracket.

• Fit the secondary steering cable to the guide tube

i) The cable nut, guide tube thread

and inside of the guide tube should

be liberally lubricated with marine

quality grease before assembly.

ii) Insert the rod end of the secondary

steering cable into the threaded

end of the guide tube (Fig B26).

iii) Hand tighten the cable nut and

torque to 175in-lb (20Nm)*. Note

that the nut has an internal locking

thread which increases the amount

of torque required initially as the

thread is cut.

* There should be NO movement between

the outer cable jacket and the guide tube

when the nut is fully tightened.

• Fit the two clamp assemblies to the guide

tube and cable assembly

i) The anti-vibration washers must

be fitted in the correct order on the

clamp assemblies, with the serrated

face of the washer in contact with

the nut face and the clamp face. The

cam face of the washers must be in

contact with each other (Fig B27).

iv) Slacken the nuts enough so that the

clamps can slide over the guide tube.

Locate the clamps in the GREEN

color coded slots as shown. Do not

tighten the nuts at this stage.

Fig B25 - Steering cylinder in mid stroke position

Clevis

bracket

Clevis

pin

Cotter pin

Guide tube

Fig B27 - Fitting the clamp assemblies

Secondary

steering cable

Fig B26 - Fitting the secondary steering cable

to the guide tube

Serrated faces

Cam faces

22 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

• Fit the clevis block to the secondary steering cable rod end

i) Remove the hitch pin from the clevis

block pin.

ii) Remove the nut, 2 x anti-vibration

washers and bolt from the clevis block.

ii) Insert the cable rod end into the slotted

hole in the clevis block. Ensure the

clevis block is correctly oriented as

shown, with the clevis pin pointing

down (Fig B28).

iv) Fit the bolt through the bottom of the

clevis block, through the cable rod end

and out the top of the block. Fit the

anti-vibration washers in the correct

order, with the serrated face of the

washer in contact with the the nut face

and the clevis block face. The cam

face of the washers must be in contact

with each other.

v) Tighten the locking nut and torque to

180-200in-lb (20-22.5Nm). The screw

has a locking thread which increases

the amount of torque required initially

as the thread is cut.

Clevis

block

Fig B28 - Fitting the clevis block to the

secondary cable rod end

Hitch

pin

Serrated

faces

Cam

faces

Rod

end

23 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

• Mount the connection kit and secondary steering cable to the steering cylinder.

This stage of the assembly will be easier if the Type R drive unit is not connected to the

secondary steering cable at this point, as fine adjustments to the drive collar positioning

are necessary and the backdrive friction from the drive unit will make this more difficult.

Connecting the drive unit should be the final stage of the mechanical assembly.

i) Position the connection kit assembly

above the steering cylinder as shown

(Fig B29). Hold the two clamp assem-

blies open so they will fit over the

manual steering cable guide tube, at

the same time ensure that both clamps

remain engaged in the GREEN color

coded slots of the secondary cable

guide tube.

ii) Lower the connection kit assembly

onto the cylinder and clevis bracket as

shown. Ensure that the clevis pin is

also locking the primary steering cable

rod end into the clevis bracket*. Lock

in place using the hitch pin.

* If the clevis pin does not engage due to misalign-

ment, adjust the manual steering helm slightly

until the hole in the primary steering cable rod end

aligns with the holes in the clevis bracket.

iii) Position the connection kit so that there is a minimal gap between the rear

clamp assembly and the primary steering cable guide tube lock nut (Fig B30).

Tighten the nuts on both clamp assemblies and torque to 100in-lb (11nm).

Fig B30 - Positioning the connection kit

Front clamp

assembly

Rear clamp

assembly

• Refer to section B9 on connecting the secondary steering cable to the drive unit.

Fig B29 - Fitting connection kit to steering

cylinder

Guide tube

lock nut

Minimal

gap

24 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Primary

steering cable

Fig B31 - Volvo Diesel (Europe) cylinder installation configuration

Secondary

steering cable

Octopus sterndrive

installation kit

Volvo 872215

steering cylinder

Octopus Type R

drive unit

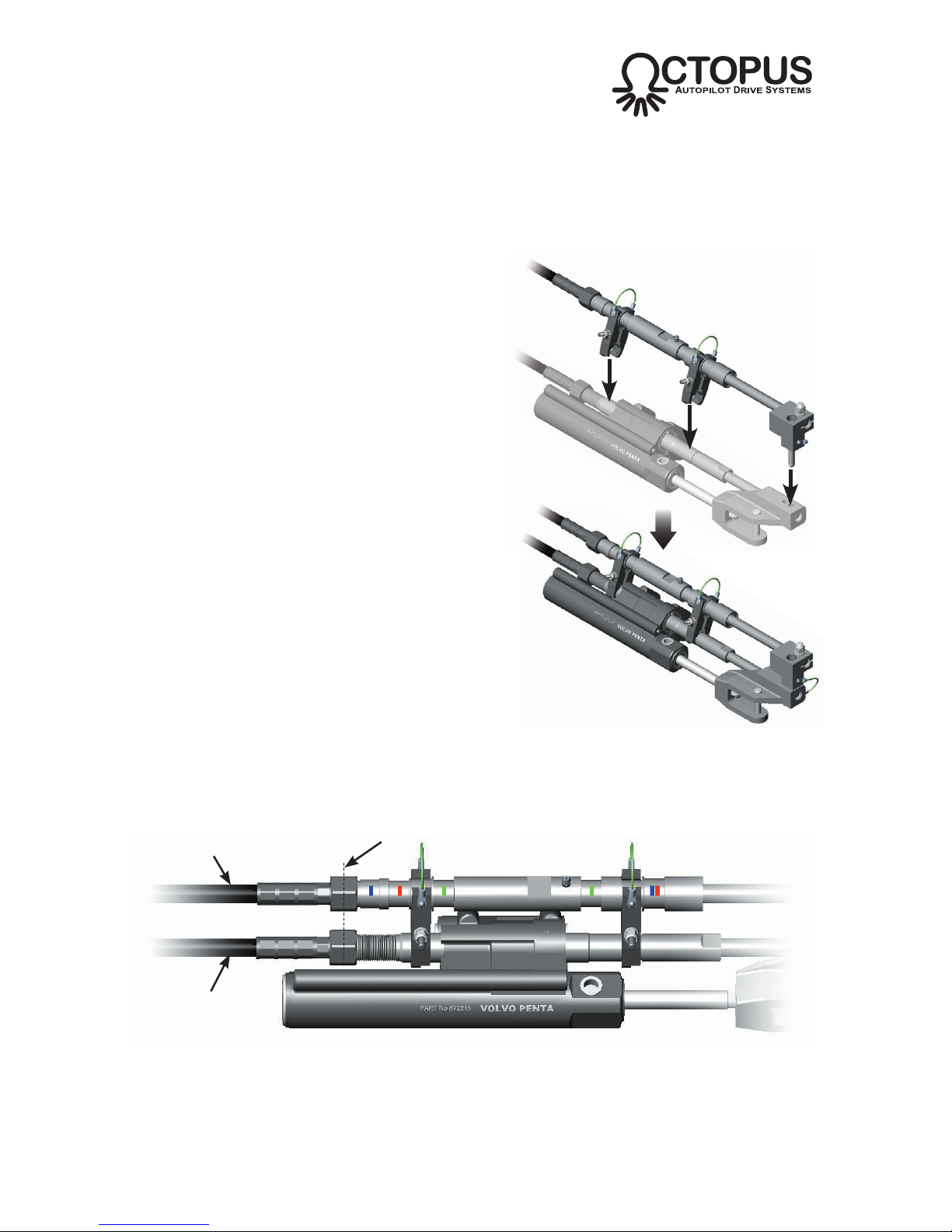

B6 Sterndrive Boats Volvo Diesel Europe

The Octopus MDRESYS-B Type R Sterndrive pack can be fitted to mechanical

push-pull cable controlled sterndrive power assisted steering cylinders made by

Volvo for Diesel engines in Europe.

The installation kit allows the second steering cable for the Type R drive to be fitted

to the sterndrive steering system.

B6a Engine compatibility

Volvo Diesel engines fitted with model 872215 sterndrive power assisted steering

cylinders.

B6b Supplied Parts

Type R Remote Rotary Autopilot Drive Unit

OC15SUK12C Sterndrive Installation Kit

OC15109-6 6ft (1.8m) Secondary Steering Cable*

* Other lengths are available as optional accessories

25 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

B6c Installation

• Prepare the steering cylinder

i) Use manual helm to set the steering

cylinder to the mid stroke position as

shown in Fig B32 (it may be neces-

sary to run the engine to do this).

ii) Remove the cotter and clevis pins

that connect the primary steering

cable rod end to the steering

cylinder clevis bracket.

• Fit the secondary steering cable to the guide tube

i) The cable nut, guide tube thread

and inside of the guide tube should

be liberally lubricated with marine

quality grease before assembly.

ii) Insert the rod end of the secondary

steering cable into the threaded

end of the guide tube (Fig B33).

iii) Hand tighten the cable nut and

torque to 175in-lb (20Nm)*. Note

that the nut has an internal locking

thread which increases the amount

of torque required initially as the

thread is cut.

* There should be NO movement between

the outer cable jacket and the guide tube

when the nut is fully tightened.

• Fit the two clamp assemblies to the guide

tube and cable assembly

i) The anti-vibration washers must

be fitted in the correct order on the

clamp assemblies, with the serrated

face of the washer in contact with

the nut face and the clamp face. The

cam face of the washers must be in

contact with each other (Fig B34).

iv) Slacken the nuts enough so that the

clamps can slide over the guide tube.

Locate the clamps in the YELLOW

color coded slots as shown. Do not

tighten the nuts at this stage.

Fig B32 - Steering cylinder in mid stroke position

Clevis

bracket

Clevis

pin

Cotter pin

Guide tube

Fig B34 - Fitting the clamp assemblies

Secondary

steering cable

Fig B33 - Fitting the secondary steering cable

to the guide tube

Serrated faces

Cam faces

26 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

• Fit the clevis block to the secondary steering cable rod end

i) Remove the hitch pin from the clevis

block pin.

ii) Remove the nut, 2 x anti-vibration

washers and bolt from the clevis block.

ii) Insert the cable rod end into the slotted

hole in the clevis block. Ensure the

clevis block is correctly oriented as

shown, with the clevis pin pointing

down (Fig B35).

iv) Fit the bolt through the bottom of the

clevis block, through the cable rod end

and out the top of the block. Fit the

anti-vibration washers in the correct

order, with the serrated face of the

washer in contact with the the nut face

and the clevis block face. The cam

face of the washers must be in contact

with each other.

v) Tighten the locking nut and torque to

180-200in-lb (20-22.5Nm). The screw

has a locking thread which increases

the amount of torque required initially

as the thread is cut.

Clevis

block

Fig B35 - Fitting the clevis block to the

secondary cable rod end

Hitch

pin

Serrated

faces

Cam

faces

Rod

end

27 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

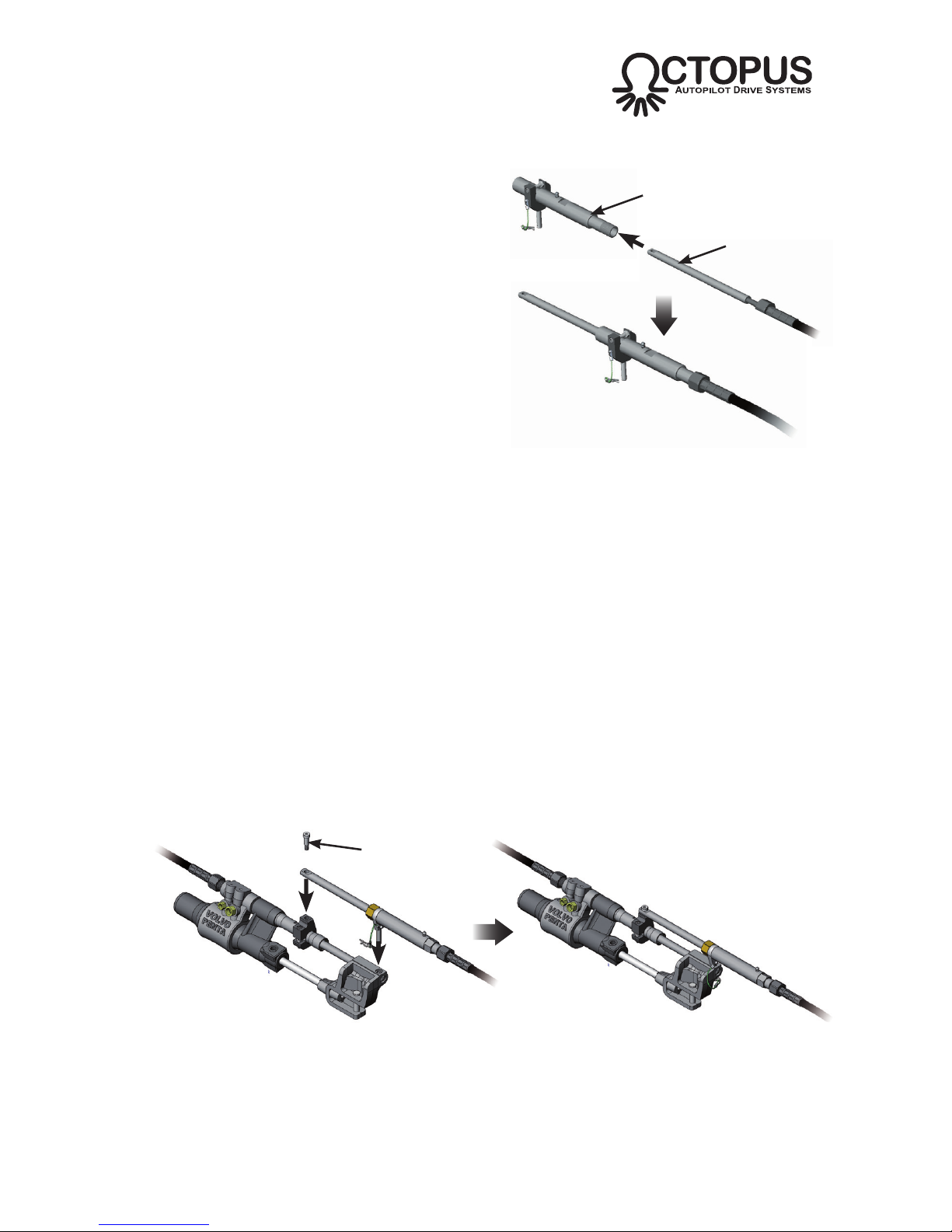

• Mount the connection kit and secondary steering cable to the steering cylinder.

This stage of the assembly will be easier if the Type R drive unit is not connected to the

secondary steering cable at this point, as fine adjustments to the drive collar positioning

are necessary and the backdrive friction from the drive unit will make this more difficult.

Connecting the drive unit should be the final stage of the mechanical assembly.

i) Position the connection kit assembly

above the steering cylinder as shown

(Fig B36). Hold the two clamp assem-

blies open so they will fit over the

manual steering cable guide tube, at

the same time ensure that both clamps

remain engaged in the YELLOW color

coded slots of the secondary cable

guide tube.

ii) Lower the connection kit assembly

onto the cylinder and clevis bracket as

shown. Ensure that the clevis pin is

also locking the primary steering cable

rod end into the clevis bracket*. Lock in

place using the hitch pin.

* If the clevis pin does not engage due to misalign-

ment, adjust the manual steering helm slightly

until the hole in the primary steering cable rod end

aligns with the holes in the clevis bracket.

iii) Position the connection kit so that the

primary and secondary steering cable

nuts are aligned (Fig B38). Tighten the

nuts on both clamp assemblies and

torque to 100in-lb (11nm).

Fig B37 - Positioning the connection kit

Align nuts

Secondary steering

cable

Primary

steering cable

• Refer to section B9 on connecting the secondary steering cable to the drive unit.

Fig B36 - Fitting connection kit to steering

cylinder

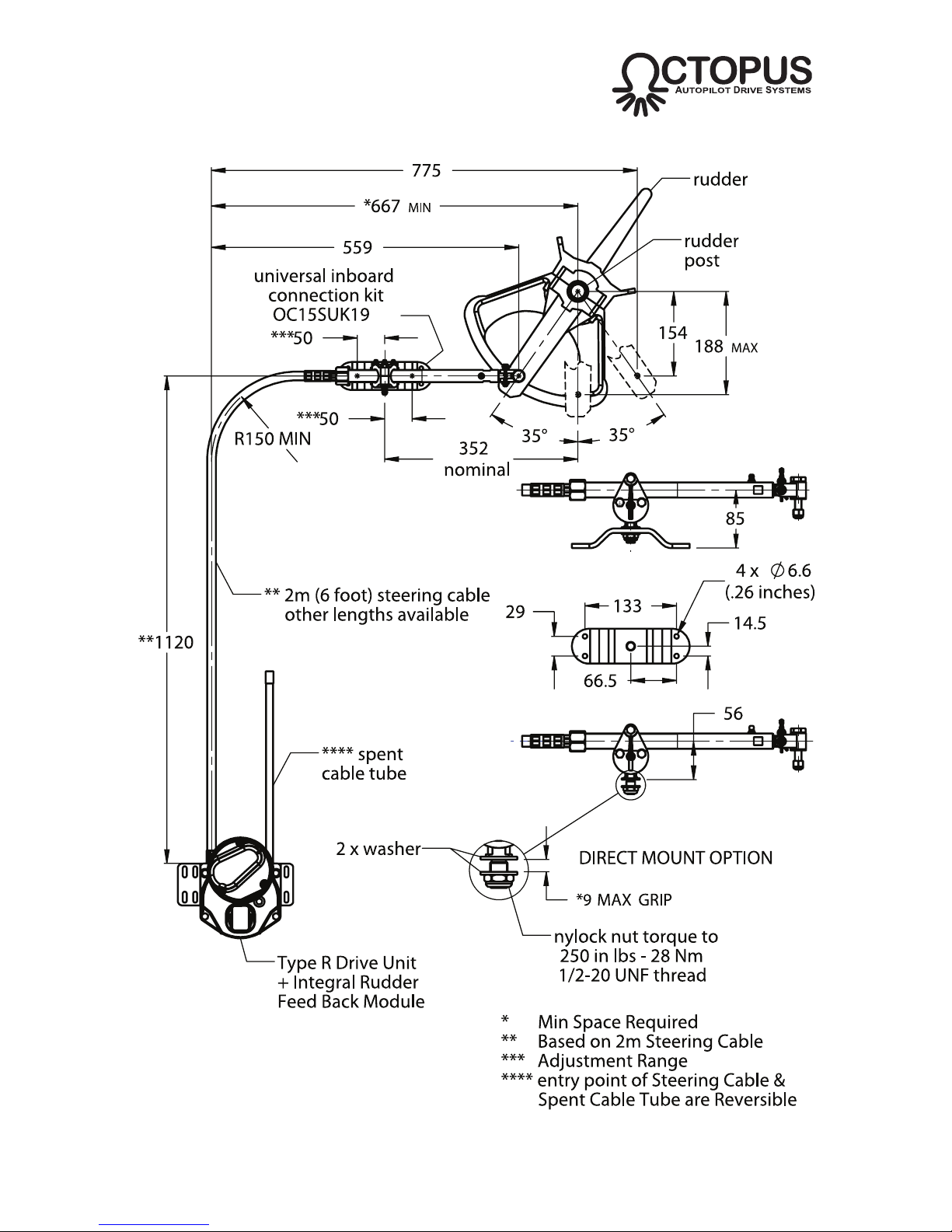

B7 Inboard Engined Boats & Sailboats

The Universal Inboard Installation Kit can be fitted to mechanically steered inboard

engined boats with access to a quadrant or tiller or smaller sailboats. It is recommended for use on vessels with a maximum speed of 44 mph.

The installation kit allows the second steering cable for the Type R drive to be fitted

to the boat’s steering quadrant or tiller.

B7a Compatibility

The MDRESYS-E kit is suitable for use on most sailboats and power boats with

mechanical steering less than 32ft (9.75m) in length and with a displacement of not

more than 13,200lbs (6,000Kg).

In all cases, the primary steering system must be capable of being back-driven with

a torque of less than 105in-lb (12Nm). If the amount of force required to maintain

course is greater than this, then the Type R drive is not suitable.

B7b Supplied Parts

Type R Remote Rotary Autopilot Drive Unit

OC15SUK19 Universal Inboard Installation Kit

OC15109-6 6ft (1.8m) Secondary Steering Cable

OC15109-9 9ft (2.75m) Secondary Steering Cable*

* Recommended for twin engine/rudder installations.

28 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B38 - Inboard installation configuration

Steering cable

Octopus universal

installation kit

Steering

tiller/quadrant

Octopus Type R

drive unit

Quick release

clevis bracket

B7c Installation

• Determine the mounting position of the installation kit (Fig B39)

This stage of the assembly will be easier if the Type R drive unit is not connected to the

secondary steering cable at this point, as fine adjustments to the drive collar positioning

are necessary and the backdrive friction from the drive unit will make this more difficult.

Connecting the drive unit should be the final stage of the mechanical assembly.

i) The kit must be mounted to a secure and stable surface that will be able to

withstand the forces generated by the drive and the rudder.

ii)

The kit has an 8.5in (216mm) stroke

and will need to be located so that the

rudder is at a 35º angle when in the

hard over position. This means the

steering cable attachment point will

typically be approx 7.4in (188mm) from

the rudder stock. Any further from the

rudder stock will reduce the amount

of rudder angle which the drive can

apply, which may adversely affect

the responsiveness of the autopilot.

Moving the mounting point closer

to the rudder stock will increase the

amount of force required to move the

rudder which may slow the lock-to-lock

time of the autopilot.

iii) The kit features a universal hub which offers 360º freedom of movement in

the horizontal plane and ±40º in the vertical plane. It can be mounted in any

orientation provided the kit is not forced beyond its rotational limits at any

point across the full steering range of the boat.

iv) The threaded guide tube offers up to ±3in (75mm) of lateral adjustment.

v) Ideally, the kit should be located so that the thrust from the steering cable is

perpendicular (ie at 90º) to the tiller at the mid-stroke position.

vi) The kit can be mounted with or without the base plate supplied.

vii) The clevis bracket can be mounted directly to the quadrant, or to a separate

tiller arm. An 0.375in (9.5mm) diameter hole will need to be drilled through

the tiller in order to attach the shoulder bolt supplied with the clevis bracket.

viii)Refer to the installation envelope diagram (Fig B40 overleaf) to ascertain the

best position for the kit.

29 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Universal hub

Threaded guide tube with

±3in (75mm) of adjustment

Clevis

bracket

Baseplate

Fig B39 - Universal installation kit

30 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B40 - Inboard kit installation envelope

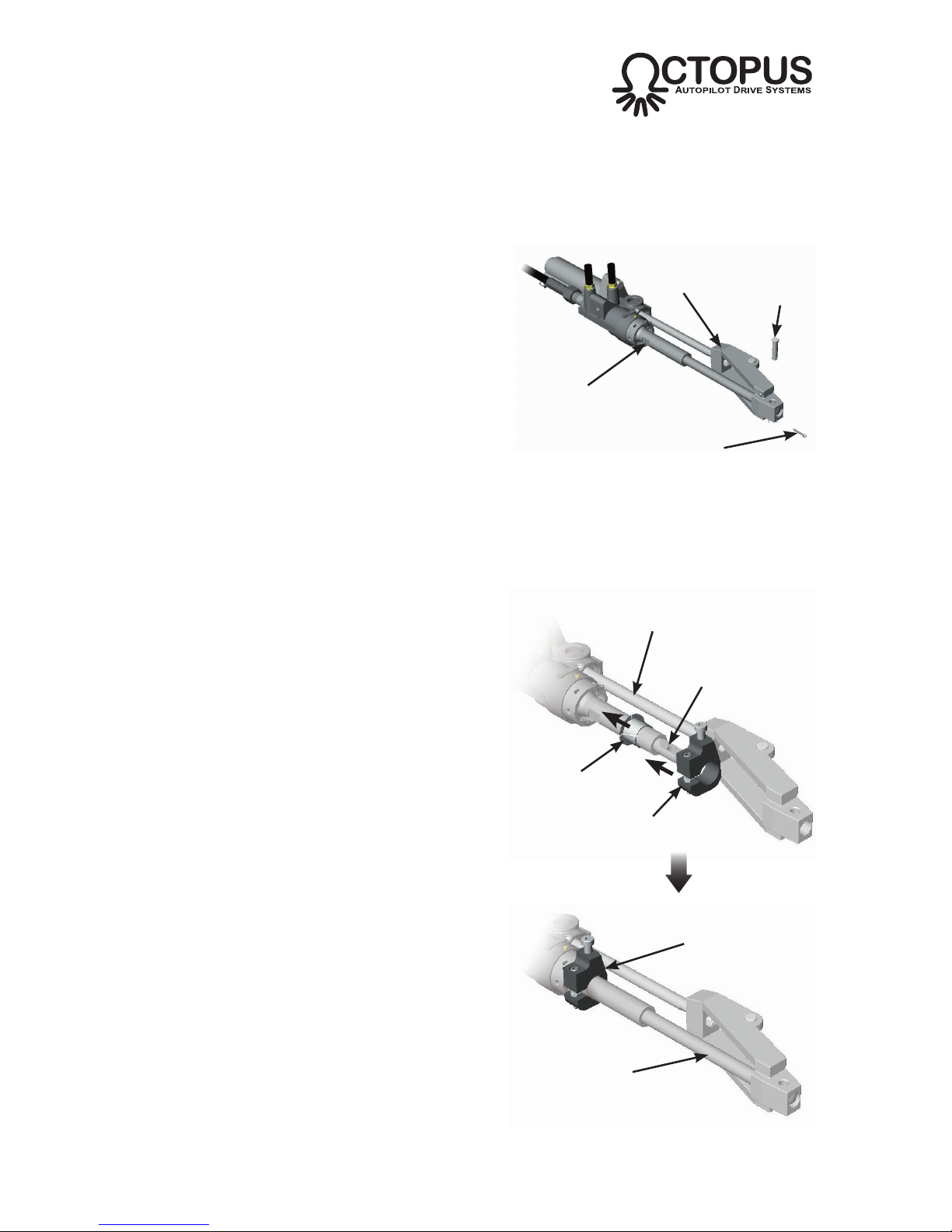

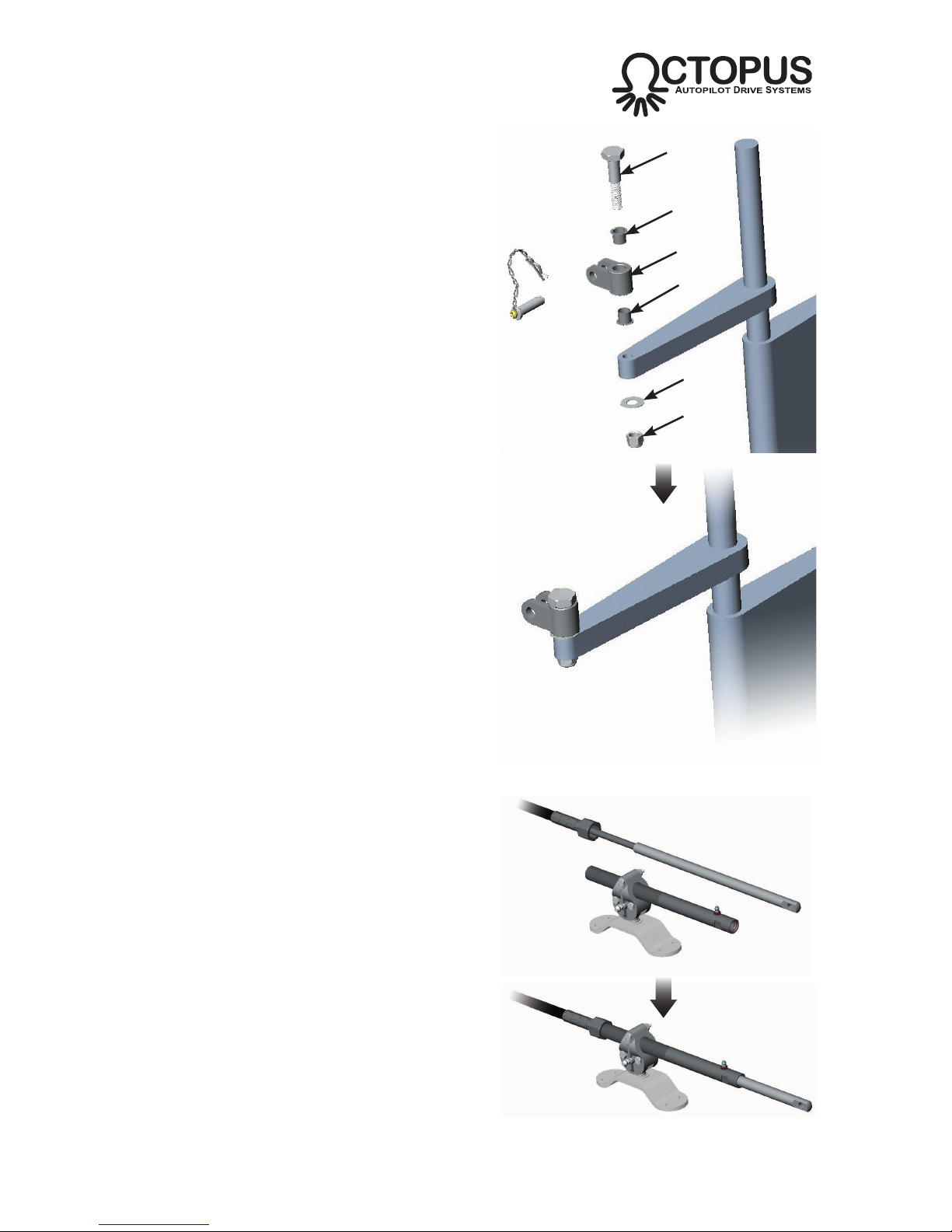

• Fit the clevis bracket to the tiller/quadrant

i) Use manual helm to set the rudder to

the centerline position.

ii) Using the information from the

installation envelope diagram, drill

an 0.375in (9.5mm) diameter hole

through the tiller/quadrant at a

distance of 6in (152mm) from the

rudder stock*.

* The clevis bracket can be mounted to a

separate tiller arm if a suitable location is not

available on the tiller/quadrant

ii) Fit the clevis bracket to the tiller as

shown in Fig B41, ensuring that the

plastic bushes, bracket, washer etc

are fitted in the correct order.

iii) Tighten the locking nut and torque to

180-200in-lb (20-22.5Nm). The screw

has a locking thread which increases

the amount of torque required initially

as the thread is cut.

iv) Remove the quick release locking pin

from the bracket.

• Fit the steering cable to the guide tube

i) The cable nut, guide tube thread and

inside of the guide tube should be

liberally lubricated with marine quality

grease before assembly.

ii) Insert the rod end of the steering

cable into the threaded end of the

guide tube (Fig B42).

iii) Hand tighten the cable nut and

torque to 175in-lb (20Nm)*. Note that

the nut has an internal locking thread

which increases the amount of torque

required initially as the thread is cut.

* There should be NO movement between the

outer cable jacket and the guide tube when the

nut is fully tightened.

31 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Shoulder

bolt

Bush

Bush

Clevis

bracket

Washer

Locknut

Fig B41 - Fitting the clevis bracket to the tiller

Fig B42 - Fitting the steering cable to the

drive tube

• Attach the steering cable to the tiller

i) Rotate the steering cable rod end so

that the hole is horizontally aligned.

ii) Position the steering cable rod end

into the clevis bracket (Fig B43).

iii) Insert the quick release locking pin

and lock in place using the hitch pin.

• Refer to section B9 on connecting the secondary steering cable to the drive unit.

B7d Quick Release

In an emergency situation the steering cable can be quickly disconnected from the

tiller by pulling out the hitch pin and then removing the locking pin.

B7e Specification

Maximum stroke .......................................................... 8.5in (216mm)

Peak Thrust ................................................................. 330Ibs / 136kg

Max Rudder Torque..................................................... 185ft-lb (250Nm)

Hard Over Time ........................................................... 12-15 seconds

Peak Power ................................................................. 60 watts 5 amps

Average Power ............................................................ 1.25 amps

Tiller arm radius ........................................................... 7.5in /190mm

Max displacement ........................................................ 13,200Ibs / 6,000kg

Max boat length ........................................................... 32ft / 10m

Voltage......................................................................... 12V DC

Clutch circuit power ..................................................... 850mA

32 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B43 - Attaching the steering cable to the tiller

Hitch pin

Quick release

locking pin

B8 Routing Steering Cable

When deciding on the routing path for the Type R drive steering cable, consideration

must be given to the following points:

i) There must be sufficient slack in the cable to allow for any movements of the

steering mechanism when steering from lock to lock - ensure that no part of

the cable is under stress at any point of steering, otherwise damage to the

cable may result over long term usage.

ii) The chosen route should use the minimum possible number of bends.

iii) If any bends are necessary, maximise the bend radius as much as possible.

It is recommended that bends have a radius of no less than 6in (150mm) and

that the combined total angle of all bends is no more than 270º.

B8a Cable Length Calculation

All Type R Drive System Packs are supplied as standard with a 6ft (1.8m) steering

cable, which should be suitable for most installations. If a suitable location for

mounting the drive unit is not available using this cable then other lengths are

available as separate accessories.

Use a length of rope or electrical cable to plan out the steering cable route and then

measure the total length required (Fig B44) :

(‘A’ Dimension + ‘B’ Dimension) – 4in for a 90º bend

Round up the result to the nearest full foot size and then refer to section D1 for the

appropriate custom cable order code.

33 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

6in (150mm)

minimum radius

‘B’ Dimension

‘A’ Dimension

Midstroke

Fig B44 - Preferred cable routing

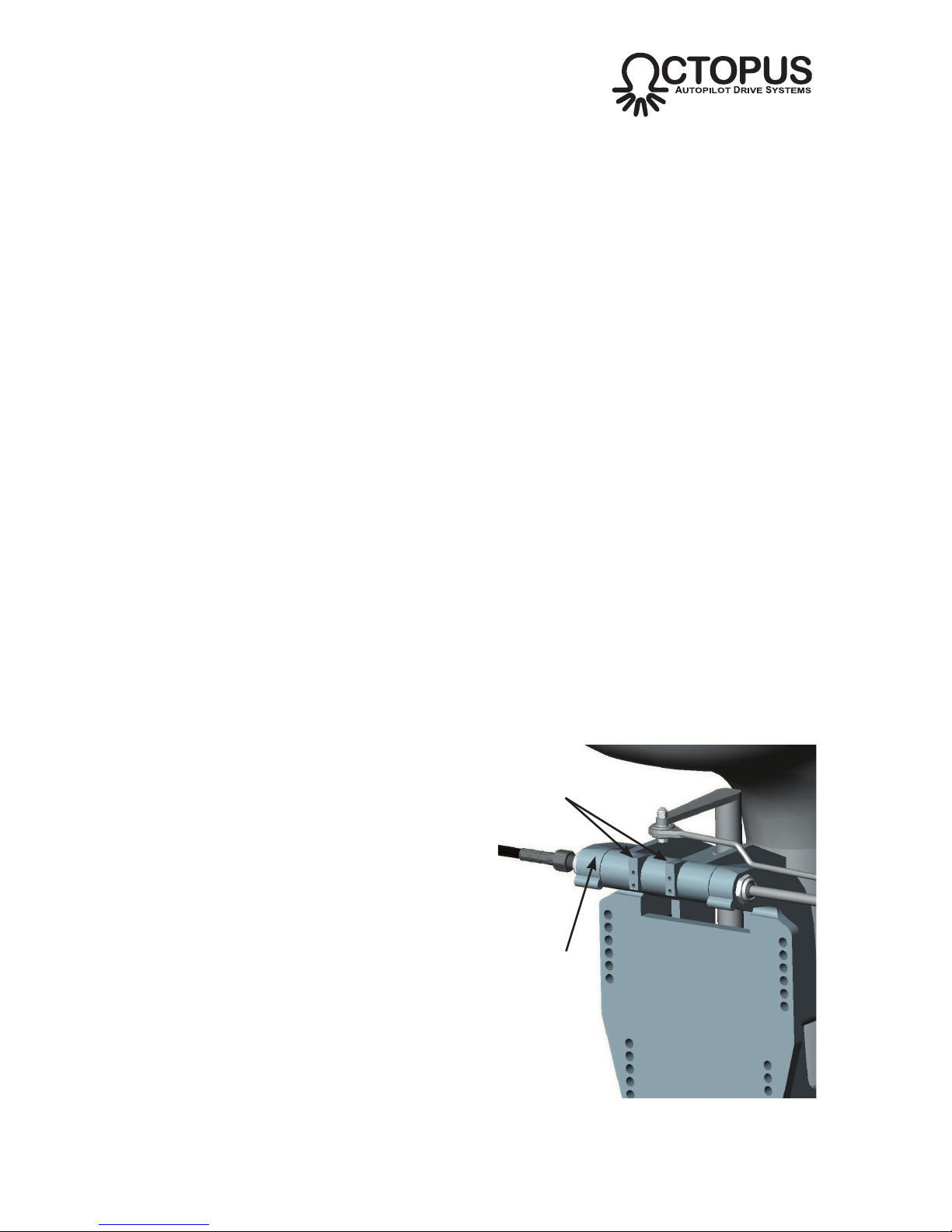

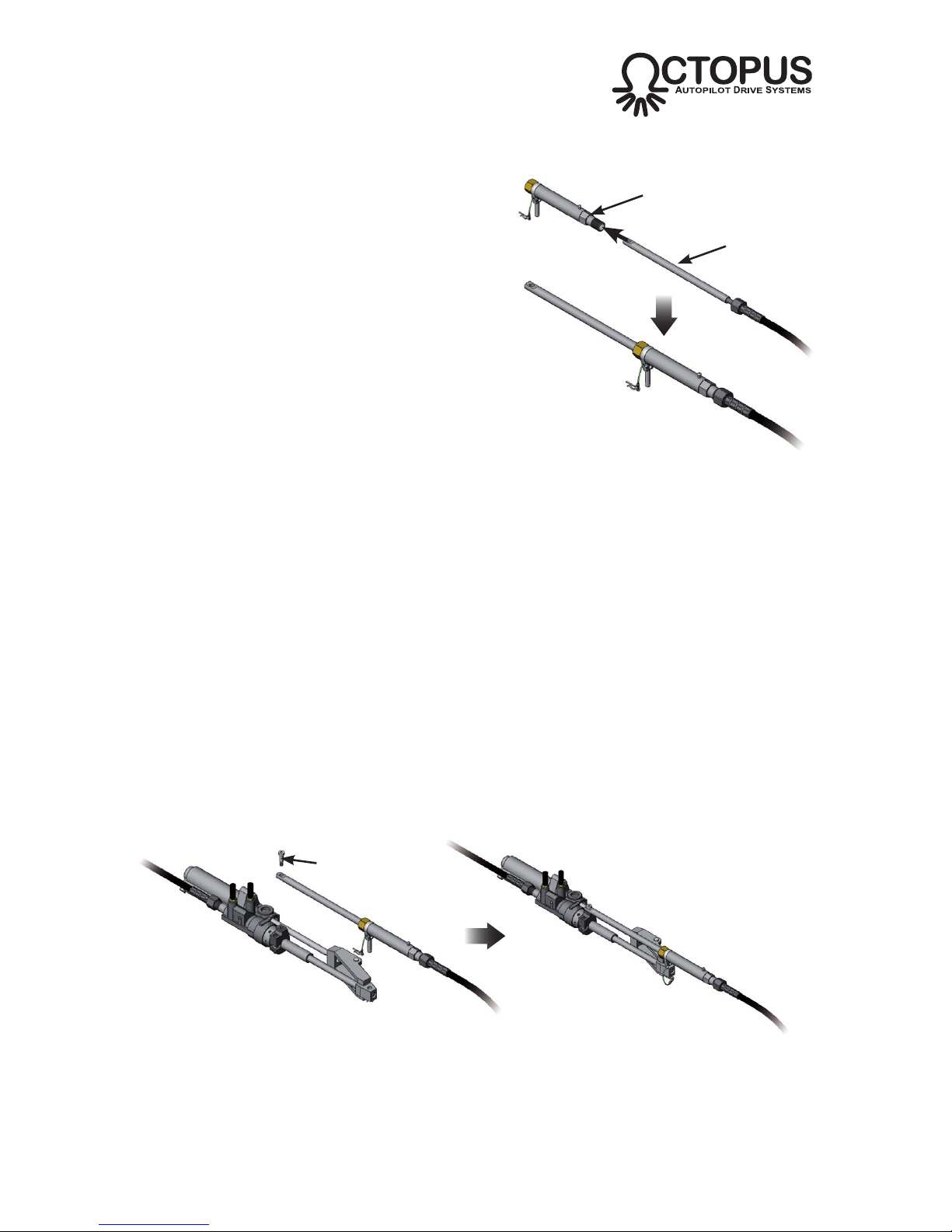

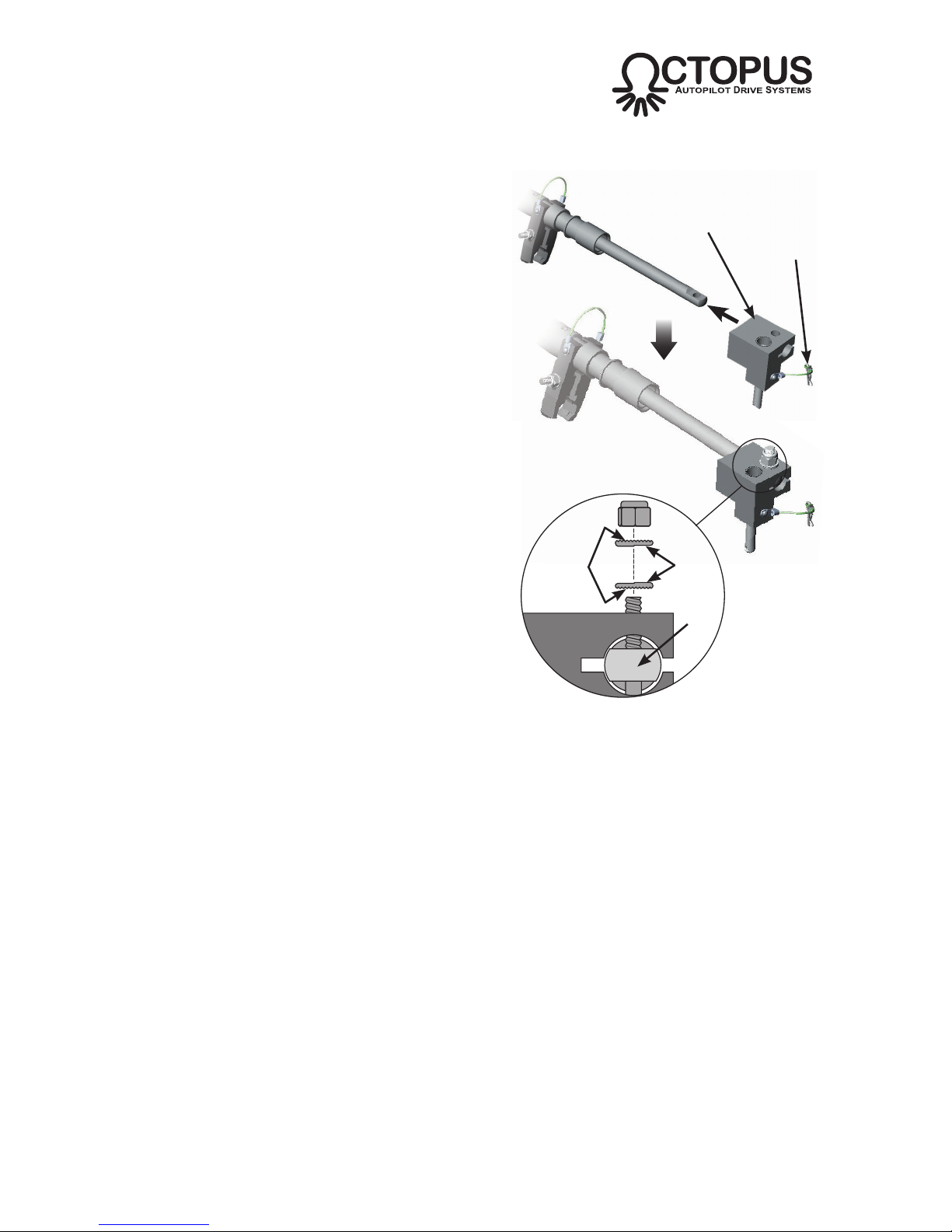

B9 Connecting Steering Cable To Drive

Either port can be use for the steering cable entry - select the most convenient for

the installation.

i) Remove the lock bolts, nuts and

washers from both ports (Fig B45).

ii) Insert the steering cable into the drive

port. Using moderate force, guide the

inner cable around the driving hub

and out of the opposite port.

iii) Push the steering cable jacket into

the port until the retaining collar butts

against the drive housing (Fig B46).

If required, the cable can be “driven”

into the drive by powering up the

clutch and drive.

iv) Insert the lock bolt to hold the cable in place.

v) If undue force is required to insert the cable, this may be caused by the end

of the inner cable fouling the outer face of the nylon guide. If this is the case,

remove the cable and inspect for sharp edges. If possible, twist the cable so

that the sharp edge is towards the inside of the radius, or use a file or burr

type tool to remove the sharp edges.

vi) Fit the spent cable tube to the opposite port and insert the lock bolt.

vii) Fit washers & nuts to both lock bolts, tighten & torque to 40-45in-lbs (4Nm).

34 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

Fig B45 - Remove cable locking bolts

Steering cable

outer jacket

Retaining

collar

Spent

cable tube

Fig B46 - Fitting steering cable and spent cable tube

B10 Rudder Feedback Unit (RFB) Installation & Calibration

Most autopilots require a rudder feedback device which is usually attached directly

to the rudder - this complicates installation in certain applications, particularly with

sterndrive and outboard engined boats. They are often exposed to the elements

and prone to damage due to

their location.

The optional Rudder Feedback

Unit is a simple solution which

attaches directly to the drive unit

itself and is calibrated using a

simple procedure.

A range of Rudder Feedback

units are available which are

compatible with most popular

autopilot systems (Fig B47).

B10a Universal RFB Setup

If a dedicated RFB is not available for a brand of autopilot, the OC15SUK27

Universal RFB should be suitable. This module is configured to the particular

autopilot using DIP switch settings:

35 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

ORDER CODE

AUTOPILOT

RESISTOR

OC15SUK27A COMNAV, SI-TEX

4k

OC15SUK27B RAYMARINE

5k

OC15SUK27D

SIMRAD 3k

OC15SUK27E

FURUNO, TMQ,

NAVMAN, GARMIN,

COURSEMASTER,

SI-TEX SP110

1k

Fig B47 - Rudder feedback compatibility

AUTOPILOT DIPSWITCH RESISTOR**

FURUNO, TMQ,

NAVMAN, GARMIN,

COURSEMASTER,

SI-TEX SP110

1k

RAYMARINE 5k

SIMRAD*

3k

COMNAV, SI-TEX 4k

* Simrad autopilots also require Signal Conversion Module OC15SUK83

** Fixed resistance measured between black and white wire. Resistance

between white and black wire is variable

DIP Switch

Fig B48 - Universal RFB DIP Switch Settings

36 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

B10b Calibration and Installation

The calibration routine should be performed after the drive unit has been fitted to the

vessel and wired up to the autopilot. The RFB should also be electrically connected

to the autopilot prior to calibration (refer to sections C1 and C2).

i) Remove the RFB module from the drive

housing (if already fitted) by removing

the two fixing screws.

ii) Center the rudder of the boat using the

manual helm (you may need to run the

engine to do this).

iii) Calibrate the RFB by aligning the two

red paint marks on the underside of the

unit (Fig B49).

iv) Remove the RFB blanking cap from the

drive unit housing (Fig B50a).

v) Fit the RFB to the drive housing and fix using the two screws provided (Fig B50b).

Ensure that the RFB driven gear is correctly engaged with the drive gear before

tightening the 2 screws.

vi) Refer to the autopilot manufacturer’s installation guide for instructions on any

additional software controlled RFB fine calibration and hardover limitation.

Align the two

red dots

Fig B49 - Calibrating the rudder feedback unit

Blanking

cap

Fig B50 - Installing the rudder feedback unit

37 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

B11 Interference Evaluation (Outboard Engines Only)

It is vital that an operating clearance check is performed between the second steering cable, outboard fitting kit and the existing hardware including hoses, electrical

cables and control cables before the system is connected to an autopilot system or

the boat is taken to sea. Two people will be required to carry out this evaluation.

i) While one person turns the steering wheel from full lock to full lock, the other

person should observe the outboard engine movement and ensure that there

is no physical interference between any parts across the full steering lock.

ii) With the outboard set to full lock left, tilt the engine to the full up position and

ensure that there is no physical interference between the parts at any stage.

Repeat this procedure with the outboard set to full lock right.

iii) It may be necessary to reroute hoses, electrical cables, control cables or

other hardware to avoid interference during operation. All hardware must be

well clear of the outboard fitting kit and second steering cable. Chafing may

occur if parts are permitted to come into contact.

38 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

C ELECTRICAL INSTALLATION

C1 Connecting Drive to Autopilot

As the Type R Autopilot Drive is designed

to work with most autopilot manufacturers’

equipment, the wiring colors or connection

references will differ slightly in each case.

However, drive to autopilot connections

are fundamentally the same for all makes

of autopilot. The Type R drive has a simple

four wire connection - two wires are for

the drive motor power feed, the other two

are for the clutch (Fig C1). Refer to the

autopilot manufacturer’s instructions for

wiring information.

Note that the Type R drive requires a 12V

input for both the motor drive and the

clutch. Do not use with a 24V system.

C2 Rudder Feedback Unit

C2a Connection - non-Simrad Autopilots

i) Connect the RFB Module wires to

autopilot junction box - refer to Figs

C2 and C3 for the correct wiring

color connections for common

autopilot brands.

ii) Setup and calibrate the RFB as

described in section B10.

DRIVE CABLE

AUTOPILOT

RED MOTOR +12V

BLACK MOTOR -12V (0V)

GREEN CLUTCH +12V

WHITE CLUTCH -12V (0V)

Fig C1 - Motor and clutch cable connections

Fig C3 - Rudder Feedback connections by manufacturer

rfb raymarine navman tmq

course-

master

comnav garmin

si-teX

sP110 sP70/80

red red orange red orange power red +ve pin 3

black green black blue blue common black -ve pin 1

white blue blue green brown poSition Yellow wip pin 2

Shield Silver black black n/a n/a n/a n/a n/a

Fig C2 - RFB cable connections

39 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

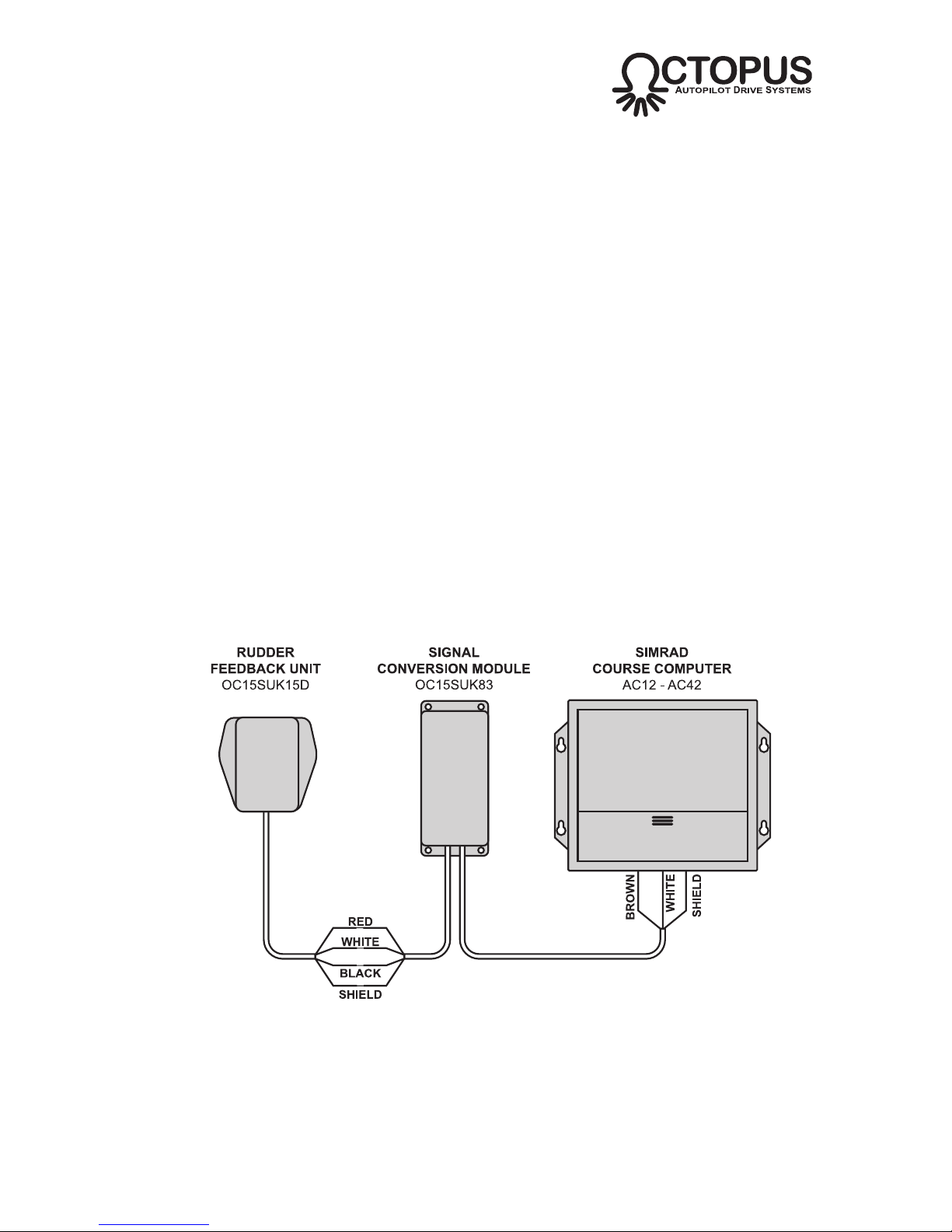

C2b Connection - Simrad Autopilots

The RFB Module OC15SUK27D MUST be used in conjunction with the Signal

Conversion Module OC15SUK83 when integrating with Simrad Autopilots.

i) IMPORTANT - all wiring connections must be made between the RFB

Module, the Signal Conversion Module and the Autopilot Course Computer

BEFORE powering up the Course Computer. Failing to follow this will result

in the RFB signal not being recognized by the Course Computer. If this

occurs perform the “Autopilot Reset” procedure (refer to Simrad autopilot

manual).

ii) Determine suitable site to mount the Signal Conversion Module. Shorten or

insert suitable extension cable as required to suit the installation.

iii) Connect the RFB Module, Signal Conversion Module and Autopilot Course

Computer together as shown in Fig C4. Use a marine grade electrical connection strip and ensure the wires are properly insulated and protected.

iv) Connect Octopus Signal Conversion Module output wires to Auto Pilot

Junction Box following Auto Pilot installation and wiring diagram.

v) Setup and calibrate the RFB as described in section B10.

Fig C4 - RFB connections - Simrad Autopilots

40 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

D APPENDIX

D1 Accessories

OC15SUK12B

OC15SUK12C

OC15SUK15A

OC15SUK15B

OC15SUK19

OC15109-6

OC15109-9

OC15109-12

OC15SUK27

OC15SUK27A

OC15SUK27B

OC15SUK27D

OC15SUK27E

OC15SUK83

Type B - Multi I/O Connection Kit – To Fit to Sterndrive

Power Assist Steering Cylinders for Mercruiser engines (from

1994) and Volvo Gas engines & Volvo Diesel engines USA

(from 1997)

Type C - Multi I/O Connection Kit – To fit to Sterndrive Power

Assist Steering Cylinders for Mercruiser Saginaw (up to

1993) and Volvo Diesel drives Europe (from 1994)

Yamaha 115-220 O/B Installation Kit – for Second Steering

Cable Connection to Outboard

Mercury-Mariner-Suzuki O/B Installation Kit – for Second

Steering Cable Connection to Outboard

Universal Connection Kit – for Custom Steering Cable

Connection to Tiller or Quadrant

Standard Steering Cable x 6 foot long

Standard Steering Cable x 9 foot long

Standard Steering Cable x 12 foot long

Rudder Feed Back Module – Universal Kit for all versions

of Autopilots

Rudder Feed Back Module – For Comnav & Sitex

Rudder Feed Back Module – For Raymarine

Rudder Feed Back Module – For Simrad

Rudder Feed Back Module – For Coursemaster, Furuno,

Garmin & TMQ

Simrad Signal Conversion Module – Required for Simrad

Autopilots

D2 General Maintenance Guide

• Grease the installation kit by applying a grease gun to the grease nipple on the guide

tube after installation and at regular intervals thereafter.

• Check the complete steering system and all fixings for security and integrity after a

few hours of operation and at frequent intervals.

• Keep all moving parts free from build-up of salt and other foreign material - this will

adversely affect their operation and create steering problems. Pay particular attention

to the installation kit hardware.

• Inspect all parts periodically for corrosion. Any parts affected by corrosion must be

replaced.

• Periodically remove the cable, clean the connector tube and thoroughly lubricate with

a waterproof grease. Inspect the cable for cracks, splits or other damage. DO NOT

cover cracks in the cable outer sheath with tape or other sealant; this will only delay

a failure of the cable. Always replace the cable.

• When replacing fixings, self-locking nuts must always be used.

• The cable is a consumable item which should be replaced at regular intervals. It is

recommended that the cable is replaced after 150 -200 hours of use or every two

seasons. Note that incorrect installation, high torques or lack of maintenance will

reduce the life of the cable. For extensive cruising and long passage making; it is

recommended that a spare cable is kept onboard.

41 of 44

Subject to change without notice OC15269 REV F

WWW.OCTOPUSDRIVES.COM

WWW.OCTOPUSEUROPE.COM

OC15269 REV F

Octopus Products Inc.

Vancouver, Canada

Tel 604 940 2010

Fax 604 952 2650

www.octopusdrives.com

www.octopuseurope.com

Loading...

Loading...