Page 1

XE–800 Single Board Computer

Reference Manual

Document #6515, rev. G07

CONTACT INFORMATION

Front Desk: 303–430–1500

Technical Support: 303–426–4521

FastHelp@octagonsystems.com

www.octagonsystems.com

1

Page 2

Copyright

OS Embedder™ is a trademark, and Octagon Systems Corporation®, and the

Octagon logo are registered trademarks of Octagon Systems Corporation. ROM–

DOS™ is a trademark of Datalight. Windows NT®, Windows XP® and Windows

CE.net® are registered trademarks of Microsoft Corporation. HyperTerminal ™ is

a copyright of Hilgraeve, Inc. CompactFlash™ is a trademark of San Disk

Corporation.

Disclaimer

Copyright 2004, 2005, 2006, 2007—Octagon Systems Corporation. All rights

reserved. However, any part of this document may be reproduced, provided that

Octagon Systems Corporation is cited as the source. The contents of this manual

and the specifications herein may change without notice.

The information contained in this manual is believed to be correct. However,

Octagon assumes no responsibility for any of the circuits described herein, conveys

no license under any patent or other right, and makes no representations that the

circuits are free from patent infringement. Octagon makes no representation or

warranty that such applications will be suitable for the use specified without

further testing or modification.

Octagon Systems Corporation general policy does not recommend the use of its

products in life support applications where the failure or malfunction of a

component may directly threaten life or injury. It is a Condition of Sale that the

user of Octagon products in life support applications assumes all the risk of such

use and indemnifies Octagon against all damage.

Technical Support

Carefully recheck your system before calling Technical Support. Run as many tests

as possible; the more information you can provide, the easier it will be for Technical

Support staff to help you solve the problem. For additional technical assistance, try

the following:

Technical Support telephone: 303–426–4521

E-mail Technical Support:

Applications Notes (via web):

fasthelp@octagonsystems.com

www.octagonsystems.com

Revision History

Revision Reason for Change Date

A Production Release 05 / 04

B Added “Excessive Thermal Stress” section

Clarified “Y” adapter for keyboard/mouse

C05 Update document number 01 / 05

D05 Clarify RTS signal for RS–485, corrected mating connectors 06 / 05

E05 Clarified IDE support and power supply requirements 11 / 05

F06 Removed reference to CD 08 / 06

G07 Clarified that Setup parameters must match configuration 10 / 07

08 / 04

2

Page 3

IMPORTANT!

Please read the following section before installing your product:

Octagon’s products are designed to be high in performance while consuming very

little power. In order to maintain this advantage, CMOS circuitry is used.

CMOS chips have specific needs and some special requirements that the user must

be aware of. Read the following to help avoid damage to your card from the use of

CMOS chips.

Using CMOS circuitry in industrial control

Industrial computers originally used LSTTL circuits. Because many PC

components are used in laptop computers, IC manufacturers are exclusively using

CMOS technology. Both TTL and CMOS have failure mechanisms, but they are

different. Described below are some of the failures that are common to all

manufacturers of CMOS equipment.

The most common failures on CPU control cards are over voltage of the power

supply, static discharge, and damage to the serial and parallel ports. On expansion

cards, the most common failures are static discharge, over voltage of inputs, over

current of outputs, and misuse of the CMOS circuitry with regards to power supply

sequencing. In the case of the video cards, the most common failure is to miswire

the card to the flat panel display. Miswiring can damage both the card and an

expensive display.

Multiple component failures: The chance of a random component failure is

very rare since the average MTBF of an Octagon card is greater than 11 years.

In a 7 year study, Octagon has never found a single case where multiple IC

failures were not caused by misuse or accident. It is very probable that multiple

component failures indicate that they were user-induced.

Testing “dead” cards: For a card that is “completely nonfunctional”, there is

a simple test to determine accidental over voltage, reverse voltage or other

“forced” current situations. Unplug the card from the bus and remove all

cables. Using an ordinary digital ohmmeter on the 2,000 ohm scale, measure

the resistance between power and ground. Record this number. Reverse the

ohmmeter leads and measure the resistance again. If the ratio of the

resistances is 2:1 or greater, fault conditions most likely have occurred. A

common cause is miswiring the power supply.

Improper power causes catastrophic failure: If a card has had reverse

polarity or high voltage applied, replacing a failed component is not an

adequate fix. Other components probably have been partially damaged or a

failure mechanism has been induced. Therefore, a failure will probably occur in

the future. For such cards, Octagon highly recommends that these cards be

replaced.

Other over-voltage symptoms: In over-voltage situations, the

programmable logic devices, EPROMs and CPU chips, usually fail in this order.

3

Page 4

The failed device may be hot to the touch. It is usually the case that only one IC

will be overheated at a time.

Power sequencing: The major failure of I/O chips is caused by the external

application of input voltage while the power is off. If you apply 5V to the input

of a TTL chip with the power off, nothing will happen. Applying a 5V input to a

CMOS card will cause the current to flow through the input and out the 5V

power pin. This current attempts to power up the card. Most inputs are rated

at 25 mA maximum. When this is exceeded, the chip may be damaged.

Failure on power-up: Even when there is not enough current to destroy an

input described above, the chip may be destroyed when the power to the card is

applied. This is due to the fact that the input current biases the IC so that it

acts as a forward biased diode on power-up. This type of failure is typical on

serial interface chips but can apply to any IC on the card.

Under-rated power supply: The board may fail to boot due to an under-

rated power supply. It is important that a quality power supply be used with

the XE–800 SBC that has sufficient current capacity, line and load regulation,

hold up time, current limiting, and minimum ripple. The power supply for the

XE–800 must meet the startup risetime requirements specified in the ATX

Power Design Guide, version 1.1, section 3.3.5. This assures that all the

circuitry on the CPU control card sequences properly and avoids system lockup.

Excessive signal lead lengths: Another source of failure that was identified

years ago at Octagon was excessive lead lengths on digital inputs. Long leads

act as an antenna to pick up noise. They can also act as unterminated

transmission lines. When 5V is switched onto a line, it creates a transient

waveform. Octagon has seen sub-microsecond pulses of 8V or more. The

solution is to place a capacitor, for example 0.1 µF, across the switch contact.

This will also eliminate radio frequency and other high frequency pickup.

Avoiding damage to the heatsink or CPU

WARNING!

When handling any Octagon Single Board Computer, extreme care

must be taken not to strike the heatsink (if installed) against another

object, such as a table edge. Also, be careful not to drop the Single

Board Computer, since this may cause damage to the heatsink or

CPU as well.

Note Any physical damage to the single board computer card is not covered under

warranty.

Excessive Thermal Stress

This card is guaranteed to operate over the published temperature ranges and

relevant conditions. However, sustained operation near the maximum temperature

specification is not recommended by Octagon or the CPU chip manufacturer due to

well known, thermal related, failure mechanisms. These failure mechanisms,

common to all silicon devices, can reduce the MTBF of the cards. Extended

operation at the lower limits of the temperature ranges has no limitations.

4

Page 5

Table of Contents

Technical Support ............................................................................................................................................. 2

Revision History ................................................................................................................................................ 2

Using CMOS circuitry in industrial control ........................................................................................................ 3

Avoiding damage to the heatsink or CPU............................................................................................................ 4

Excessive Thermal Stress ................................................................................................................................. 4

Table of Contents .................................................................................................................................................. 5

List of Figures........................................................................................................................................................ 9

List of Tables........................................................................................................................................................ 10

Overview: Section 1 – Installation ................................................................................................................. 11

Chapter 1: Overview.......................................................................................................................................... 12

Description .......................................................................................................................................................... 12

XE–800 SBC major hardware features.............................................................................................................. 12

CPU.................................................................................................................................................................. 12

SDRAM ............................................................................................................................................................ 12

On-board flash ................................................................................................................................................. 12

CompactFlash socket ...................................................................................................................................... 12

Hard disk and IDE port .................................................................................................................................. 12

USB ports ........................................................................................................................................................ 13

LPT and floppy ................................................................................................................................................ 13

Digital I/O ........................................................................................................................................................ 13

Ethernet........................................................................................................................................................... 13

Serial ports protected against ESD ................................................................................................................ 13

PC/104 and PC/104 Plus interface.................................................................................................................. 13

Video ................................................................................................................................................................ 14

Keyboard and mouse port ............................................................................................................................... 14

Real time calendar/clock with battery backup............................................................................................... 14

Setup information stored in EEPROM for high reliability ........................................................................... 14

Watchdog timer added for safety.................................................................................................................... 14

Hardware reset................................................................................................................................................ 14

5 Volt only operation lowers system cost ....................................................................................................... 15

Rugged environmental operation ................................................................................................................... 15

Size................................................................................................................................................................... 15

XE–800 SBC major software features................................................................................................................ 16

Diagnostic software verifies system integrity automatically ........................................................................ 16

Phoenix software BIOS ................................................................................................................................... 16

Octagon BIOS extensions................................................................................................................................16

Boot sequence .................................................................................................................................................. 16

Chapter 2: Quick start ...................................................................................................................................... 17

Component diagrams, connectors, jumpers and cables..................................................................................... 17

XE–800 SBC connectors and jumpers ............................................................................................................ 21

Custom cables.................................................................................................................................................. 22

Mounting the XE–800......................................................................................................................................... 23

Equipment required ........................................................................................................................................ 23

Hardware mounting ........................................................................................................................................ 24

XE–800 SBC power supply requirements ...................................................................................................... 25

Connecting a monitor and keyboard .................................................................................................................. 26

Monitor ............................................................................................................................................................ 26

Keyboard and mouse ....................................................................................................................................... 26

Installing an operating system........................................................................................................................... 27

OS on CD-ROM onto a hard drive or CompactFlash ........................................................................................ 27

Chapter 3: Setup programs.............................................................................................................................. 30

Operating systems other than DOS ................................................................................................................... 30

Setup.................................................................................................................................................................... 30

Main menu....................................................................................................................................................... 31

Hard drive submenus...................................................................................................................................... 32

5

Page 6

Advanced menu ............................................................................................................................................... 33

Advanced Chipset Control submenu .............................................................................................................. 34

I/O Device Configuration submenu ................................................................................................................ 35

PCI Configuration submenu ........................................................................................................................... 36

PCI/PNP ISA UMB Region Exclusion submenu............................................................................................ 36

PCI/PNP ISA IRQ Resource Exclusion submenu .......................................................................................... 37

PCI/PNP ISA DMA Resource Exclusion submenu ........................................................................................ 37

Boot menu........................................................................................................................................................ 38

Expanded Boot screen ..................................................................................................................................... 38

Exit menu ........................................................................................................................................................ 39

Chapter 4: Save and run programs................................................................................................................ 40

Save and run your programs on the XE–800 SBC ............................................................................................ 40

Saving programs and support files .................................................................................................................... 40

Adding your application.................................................................................................................................. 40

Overriding the autoexecution of your application ......................................................................................... 41

Overview: Section 2 – Hardware .................................................................................................................... 42

Chapter 5: Serial ports...................................................................................................................................... 43

Description .......................................................................................................................................................... 43

Mating receptacle ............................................................................................................................................ 43

Serial port configurations................................................................................................................................... 43

Setup menu for COM ports............................................................................................................................. 46

Function and use of serial ports......................................................................................................................... 46

COM1 as serial console device........................................................................................................................ 46

COM ports as RS–232 I/O............................................................................................................................... 46

COM2 as RS–422 and RS–485 networks ....................................................................................................... 47

RS–422 ............................................................................................................................................................. 47

RS–485 ............................................................................................................................................................. 47

Chapter 6: Console devices .............................................................................................................................. 49

Description .......................................................................................................................................................... 49

Selecting console devices .................................................................................................................................... 49

Monitor and keyboard console ........................................................................................................................ 49

Serial console................................................................................................................................................... 50

Chapter 7: CompactFlash, SDRAM, and battery backup........................................................................... 53

Description .......................................................................................................................................................... 53

CompactFlash ..................................................................................................................................................... 53

Creating a bootable CompactFlash ................................................................................................................ 53

SDRAM................................................................................................................................................................ 54

Battery backup for real time calendar clock...................................................................................................... 54

Installing an AT battery ................................................................................................................................. 54

Chapter 8: External drives............................................................................................................................... 55

Description .......................................................................................................................................................... 55

Hard disk controller............................................................................................................................................ 55

Master/slave designation for IDE devices...................................................................................................... 55

Installing a hard drive........................................................................................................................................ 57

Setup parameters and booting ........................................................................................................................... 57

Chapter 9: Bit-programmable digital I/O...................................................................................................... 58

Description .......................................................................................................................................................... 58

Interfacing to switches and other devices.......................................................................................................... 61

Opto-module rack interface ............................................................................................................................ 61

Organization of banks......................................................................................................................................... 63

Port addressing................................................................................................................................................ 63

I/O lines pulled low.......................................................................................................................................... 63

Configuring and programming the I/O ports..................................................................................................... 64

Programming the I/O ...................................................................................................................................... 64

Configuring the I/O ......................................................................................................................................... 64

Writing and reading from I/O ......................................................................................................................... 65

I/O output program examples......................................................................................................................... 65

I/O input program examples ........................................................................................................................... 66

Enhanced INT 17h function definitions............................................................................................................. 66

6

Page 7

Initialize I/O .................................................................................................................................................... 66

Write I/O .......................................................................................................................................................... 67

Read I/O ........................................................................................................................................................... 68

Chapter 10: CRTs and flat panels................................................................................................................... 69

Description .......................................................................................................................................................... 69

Video features ..................................................................................................................................................... 69

Connecting a monitor.......................................................................................................................................... 69

Connecting a flat panel display.......................................................................................................................... 71

Flat panels requiring bias voltage .................................................................................................................. 71

Connecting the flat panel to the XE–800 SBC............................................................................................... 71

Programming the video BIOS ............................................................................................................................ 73

Additional notes on video BIOS...................................................................................................................... 73

Chapter 11: Ethernet......................................................................................................................................... 74

Description .......................................................................................................................................................... 74

Chapter 12: PC/104 and PC/104 Plus expansion.......................................................................................... 75

Description .......................................................................................................................................................... 75

Chapter 13: USB ................................................................................................................................................. 76

Description .......................................................................................................................................................... 76

Overview: Section 3 – System management................................................................................................. 77

Chapter 14: Watchdog timer and hardware reset ......................................................................................78

Description .......................................................................................................................................................... 78

Timeout period (ranges) .................................................................................................................................. 78

Booting, power down, and strobing the watchdog timer ............................................................................... 78

Watchdog function definitions using enhanced INT 17h handler .................................................................... 79

Enable watchdog ............................................................................................................................................. 79

Strobe watchdog .............................................................................................................................................. 80

Disable watchdog............................................................................................................................................. 80

Hardware reset ................................................................................................................................................... 81

Chapter 15: Serial EEPROM............................................................................................................................ 82

Description .......................................................................................................................................................... 82

Enhanced INT 17h function definitions............................................................................................................. 82

Serial EEPROM .................................................................................................................................................. 82

Read a single word from the serial EEPROM................................................................................................ 82

Write a single word to the serial EEPROM ................................................................................................... 83

Read multiple words from the serial EEPROM............................................................................................. 83

Write multiple words to the serial EEPROM ................................................................................................ 84

Return serial EEPROM size ........................................................................................................................... 85

Chapter 16: System jumpers, user jumper, and BIOS recovery .............................................................. 86

System jumpers................................................................................................................................................... 86

System jumper................................................................................................................................................. 86

Extended BIOS jumper ................................................................................................................................... 87

Video jumper.................................................................................................................................................... 87

User jumper..................................................................................................................................................... 87

BIOS recovery jumper..................................................................................................................................... 87

BIOS programming using PHLASH.EXE...................................................................................................... 88

INT17 calls to read user jumper ........................................................................................................................ 88

Chapter 17: Troubleshooting........................................................................................................................... 90

Boot Block Recovery............................................................................................................................................ 90

Memory conflicts using operating system other than DOS .............................................................................. 90

No system LED activity...................................................................................................................................... 90

No CRT or flat panel video ................................................................................................................................. 90

Video is present but is distorted......................................................................................................................... 91

No serial console activity.................................................................................................................................... 92

Garbled serial console screen activity................................................................................................................ 92

System generates a BIOS message but locks up when booting ........................................................................ 92

System will not boot from CompactFlash .......................................................................................................... 92

System locks up on power-up; may or may not respond to reset switch .......................................................... 93

System locks up after power-down/power-up .................................................................................................... 93

LED signaling of “beep” codes ............................................................................................................................ 93

7

Page 8

Technical assistance ........................................................................................................................................... 97

Overview: Section 4 – Appendices.................................................................................................................. 98

Appendix A: XE–800 SBC technical data ...................................................................................................... 99

Technical specifications ...................................................................................................................................... 99

CPU.................................................................................................................................................................. 99

PCI bus clock ................................................................................................................................................... 99

BIOS................................................................................................................................................................. 99

SDRAM ............................................................................................................................................................ 99

On-board flash ................................................................................................................................................. 99

Hard drive........................................................................................................................................................ 99

CompactFlash socket ...................................................................................................................................... 99

USB .................................................................................................................................................................. 99

Serial I/O.......................................................................................................................................................... 99

Digital I/O ........................................................................................................................................................ 99

Keyboard and mouse ports.............................................................................................................................. 99

Video .............................................................................................................................................................. 100

Watchdog timer ............................................................................................................................................. 100

Real time clock............................................................................................................................................... 100

Expansion ...................................................................................................................................................... 100

Operating systems......................................................................................................................................... 100

PCI bus mastering......................................................................................................................................... 100

Power requirements ...................................................................................................................................... 100

Environmental specifications ....................................................................................................................... 100

Size................................................................................................................................................................. 100

Weight............................................................................................................................................................ 100

Excessive Thermal Stress ............................................................................................................................. 100

Mating connectors............................................................................................................................................. 101

Maps .................................................................................................................................................................. 101

Jumper settings ................................................................................................................................................ 104

Connector pin–outs ........................................................................................................................................... 105

Appendix B: Software utilities...................................................................................................................... 113

Introduction....................................................................................................................................................... 113

Support commands........................................................................................................................................ 113

GETVIDEO.EXE............................................................................................................................................... 114

I17HNDLR.EXE................................................................................................................................................ 114

PGMVIDEO.EXE.............................................................................................................................................. 115

PHLASH.EXE ................................................................................................................................................... 115

RESET.COM ..................................................................................................................................................... 116

Appendix C: Accessories.................................................................................................................................. 117

Warranty ............................................................................................................................................................. 118

Limitations on warranty................................................................................................................................... 118

Service policy..................................................................................................................................................... 118

Returning a product for repair ......................................................................................................................... 118

Returns.............................................................................................................................................................. 119

Governing law ................................................................................................................................................... 119

8

Page 9

List of Figures

Figure 2–1 XE–800 SBC component diagram (top) ..........................................................................18

Figure 2–2 XE–800 SBC component diagram (bottom) ....................................................................19

Figure 2–3 XE–800 SBC dimensions .................................................................................................20

Figure 2–4 Power connector, J8 .........................................................................................................24

Figure 2–5 Connecting a monitor and keyboard ...............................................................................26

Figure 2–6 Installing an operating system........................................................................................ 29

Figure 5–1 COM ports ........................................................................................................................44

Figure 5–2 VTC-20F cable and null modem adapter ........................................................................44

Figure 5–3 Typical RS–422 four-wire interface circuit.....................................................................47

Figure 5–4 Typical RS–485 4–wire interface circuit......................................................................... 48

Figure 5–5 Typical RS–485 2–wire half duplex interface circuit .....................................................48

Figure 6–1 Monitor and keyboard as console ....................................................................................50

Figure 6–2 The XE–800 SBC and a serial console ............................................................................52

Figure 8–1 XE–800 SBC with IDE device .........................................................................................56

Figure 9–1 Typical digital I/O configuration .....................................................................................60

Figure 9–2 Organization of banks......................................................................................................63

Figure 10–1 The XE–800 SBC and a VGA monitor ............................................................................70

Figure 10–2 The XE–800 SBC and a flat panel display......................................................................72

Figure 12–1 Typical PC/104 module stack ..........................................................................................75

9

Page 10

List of Tables

Table 2–1 XE–800 SBC connector functions....................................................................................21

Table 2–2 XE–800 SBC jumper functions........................................................................................21

Table 2–3 Power connector: J8 .........................................................................................................25

Table 5–1 Serial port configurations................................................................................................45

Table 5–2 COM1 and COM2 connector pin-outs (J15 connector) ................................................... 45

Table 5–3 J7 – COM2 connector pin-outs and pin-outs for 1.25 mm RS–422/485 cable ...............45

Table 5–4 COM2 jumper: W2 ...........................................................................................................46

Table 7–1 Battery Connector............................................................................................................54

Table 9–1 J6 and J14 arranged by function – digital I/O connectors .............................................58

Table 9–2 J6 and J14 arranged by pins – digital I/O connectors.................................................... 59

Table 9–3 Digital I/O opto-rack interface ........................................................................................62

Table 9–4 I/O port byte .....................................................................................................................64

Table 10–1 J3 – CRT connector..........................................................................................................70

Table 10–2 Flat panel connector: J1 ..................................................................................................72

Table 11–1 Ethernet LEDs.................................................................................................................74

Table 16−2 System configuration jumper: W1...................................................................................86

Table 17–1 BIOS beep codes...............................................................................................................94

Table A–1 XE–800 SBC Mating connectors ...................................................................................101

Table A–2 XE–800 SBC DMA map.................................................................................................101

Table A–3 XE–800 SBC I/O map ....................................................................................................102

Table A–4 XE–800 SBC interrupt map ..........................................................................................103

Table A–5 XE–800 SBC memory map ............................................................................................103

Table A−6 System configuration jumper: W1.................................................................................104

Table A–7 COM2 jumper: W2 .........................................................................................................104

Table A–8 J1 – flat panel connector................................................................................................105

Table A–9 J2 – PC/104-Plus connector ..........................................................................................106

Table A–10 J3 – CRT connector ........................................................................................................ 107

Table A–11 J4 – EIDE .......................................................................................................................107

Table A–12 J5 – COM2 connector pin-outs for RS–422/RS–485 .....................................................108

Table A–13 J6 and J14 – Digital I/O connectors ..............................................................................108

Table A–14 J7 – PC/104 connector....................................................................................................109

Table A–15 J8 – Power connector .....................................................................................................109

Table A–16 J9 – PS2 Keyboard Mouse .............................................................................................110

Table A–17 J10 – Battery Connector................................................................................................110

Table A–18 J11 – Ethernet connectors .............................................................................................110

Table A–19 J12 and J13 – USB connectors ......................................................................................111

Table A–20 J14 – Digital I/O 1..........................................................................................................111

Table A–21 J15 – COM1 and COM2 connector pin-outs .................................................................111

Table A–22 J16 – USB connector......................................................................................................111

Table A–23 J500 – CompactFlash ....................................................................................................112

Table C–1 Cables and accessories...................................................................................................117

Table C–2 Digital I/O accessories ...................................................................................................117

10

Page 11

Overview: Section 1 – Installation

Section 1 provides installation and programming instructions, startup options, and

system configuration program examples. The following chapters are included:

Chapter 1: Overview

Chapter 2: Quick start

Chapter 3: Setup programs

Chapter 4: Save and run programs

11

Page 12

Chapter 1: Overview

Description

The XE–800 is a Single Board Computer (SBC) in the EPIC™ form factor. It is

intended for higher-performance, low-power embedded control applications. The

XE–800 SBC integrates serial communications, IDE hard disk port, CompactFlash

socket, digital I/O, six USB ports, keyboard and mouse port, and video. The XE–800

SBC can be used in a stand-alone mode or expanded through a PC/104 or PC/104

Plus interface.

The XE–800 SBC comes with a BIOS loaded on a flash device for easy updates. It is

fully compatible with most popular operating systems.

XE–800 SBC major hardware features

CPU

The CPU is a high-performance, low-power AMD Geode GX1 processor with a clock

speed of 300 MHz. It uses the CS5530A companion chip for some of the peripherals.

The XE–800 SBC has an ISA bus speed of 8.33 MHz.

SDRAM

The memory socket can accept up to 256 MB capacity SO-DIMM modules.

On-board flash

On board is a 512 KB SMT boot flash that contains the BIOS.

CompactFlash socket

The CompactFlash socket accepts a Type I or Type II 3V CompactFlash card. The

CompactFlash appears as an IDE device to the system. It is implemented with an

ATA-4 compliant IDE controller, and appears in Setup as the Primary IDE device.

Hard disk and IDE port

The XE–800 has two ATA-4 compliant IDE controllers. The primary channel is

dedicated to the CompactFlash. The secondary channel supports two additional

IDE devices through a 2 mm, 44-pin connector. This connector supplies power to

the devices. Octagon Systems has a 44-pin to 40-pin Hard Drive Adapter cable

(part #4080 or #6246) to connect IDE devices with a 40-pin interface.

12

Page 13

USB ports

The CS5530A companion chip supports two USB 1.1 channels, accessed through a

10-pin header. USB 1.1 provides speeds up to 12 Mbps. The Octagon two-port USB

cable (part #6288) provides a direct connection from the 10-pin connector to two

USB devices. USB is available when using an operating system that supports USB.

There is no support from Octagon for DOS legacy USB.

Four additional 2.0 USB channels are supported by an on-board PCI-to-USB

controller. These channels are accessed through standard USB connectors. USB 2.0

provides speeds up to 480 Mbps.

All six channels are open HCI compliant.

Note that USB devices are hot-swappable when a device is plugged into a standard

USB connector, as pins on the connectors determine the order in which they make

contact. Devices are not hot-swappable when connected to a non-standard header.

You can hot swap a device on the four 2.0 connectors; through the USB connector

on the two-port USB cable; or through another USB connector wired to the 10-pin

header, but you cannot hot swap at the 10-pin header itself.

LPT and floppy

The XE–800 does not provide connectors for LPT parallel port or floppy disk drive.

These functions, if required, can be obtained through USB devices. For DOS

operating system they can be obtained through PC/104 or PC/104 Plus devices.

Digital I/O

The 48 digital I/O lines will interface with logic devices, switch inputs, LEDs and

industry standard opto module racks. The I/O lines are 0–5V logic compatible.

They can be individually programmed as inputs or outputs.

Ethernet

The XE–800 provides one 10/100BaseT Ethernet port and supports the IEEE 802.3

Ethernet standard.

Serial ports protected against ESD

The XE–800 SBC has two serial ports. COM1 and COM2 both provide RS–232C.

COM2 also supports RS–422 and RS–485 interfaces. COM1 and COM2 are routed

through a 20-pin connector for RS–232C. RS–422 and RS–485 are provided through

a separate 5-pin connector.

PC/104 and PC/104 Plus interface

The PC/104 interface accepts an 8- or 16-bit PC/104 expansion board. The PC/104

Plus accepts industry-standard PC/104 Plus boards. PC/104 expansion boards are

available from several manufacturers. Up to four PC/104 or PC/104 Plus expansion

boards may be stacked on the XE–800 SBC.

13

Page 14

Video

The XE–800 SBC supports CRT monitors up to 1280 x 1024 x 16 bpp (bits per

pixel) resolution, and flat panel displays with up to 1024 x 768 x 16 bpp resolution.

Keyboard and mouse port

The keyboard controller accepts an AT style keyboard and has a PS/2 connector.

The mouse port is combined with the keyboard port and is accessed with a “Y”

cable. Note that with some “Y” cables you may have to plug the mouse into the

keyboard icon, and the keyboard into the mouse icon; if the mouse and keyboard do

not function at power up, try switching them. A keyboard connects directly to the

XE–800 while a mouse requires the “Y” cable. Most operating systems do not

require a keyboard or a mouse; however, some operating systems do require both to

be connected for proper booting.

Real time calendar/clock with battery backup

The real time clock is fully AT compatible. An optional off-card battery powers the

real time clock when the 5 volt supply is removed.

Setup information stored in EEPROM for high reliability

Loss of Setup data is serious in industrial applications. Most PCs store Setup

information in battery-backed CMOS RAM. If the battery fails or is replaced

during routine maintenance, this information is lost. Without a keyboard and

monitor in embedded applications, time consuming re-initialization is required.

The XE–800 SBC stores the Setup information in EEPROM with 1024 words

available to the user. Software routines to use this available memory come with the

XE–800 SBC.

14

Watchdog timer added for safety

The watchdog timer resets the system if the program stops unexpectedly. The

watchdog is enabled, disabled and strobed under software control; it can also be

enabled or disabled in Setup. The time-out period is programmable from 2 ms to

120 seconds, with a variability of ±50%.

Hardware reset

A hardware reset ensures complete reset of the system and all attached

peripherals. A hardware reset can be done by any of the following methods:

An expired watchdog timer cycle

Depressing the reset switch

Cycling power

Power supervisor reset

Page 15

5 Volt only operation lowers system cost

5V ±5%

±12V supplied to PC/104 connector from the power connector; not required for

XE–800 SBC operation

+3.3V supplied to PC/104 Plus connector from the power connector; not

required for XE–800 SBC operation

Rugged environmental operation

Operating temperature –40° to 70°C @ 300 MHz, with no air flow

–40° to 80°C @ 300 MHz, with forced air flow

Nonoperating temperature –55° to 95°C, nonoperating

Relative humidity 5% to 95% noncondensing

Shock 40g, 3 axis

Vibration 5g, 3 axis

Size

115 mm x 165mm x 29.5 mm, EPIC™ form factor

15

Page 16

XE–800 SBC major software features

Diagnostic software verifies system integrity automatically

The XE–800 SBC has built-in diagnostic software that can be used to verify on-card

I/O and memory functions. On power-up, a series of tests is performed. If a problem

occurs, the failed test can be identified by a flashing LED or a beep code. The test is

performed automatically every time the system is reset or powered up. Memory

verification does not require software, test equipment, monitor, keyboard, disks, or

test fixtures. See the “Troubleshooting” chapter for a listing of tests and failures

and their descriptions.

Phoenix software BIOS

The XE–800 SBC has a Phoenix Software BIOS with Octagon BIOS extensions.

The BIOS extensions support the INT17 functions.

Octagon BIOS extensions

On-board BIOS extensions allow easy access to watchdog timer functions, serial

EEPROM, digital I/O, etc.

Boot sequence

An XE–800 SBC can be configured to boot from CompactFlash, a hard disk, or a

CD–ROM. Refer to Setup parameters and booting on page

57.

16

Page 17

Chapter 2: Quick start

This chapter covers the basics of setting up an XE–800 SBC system. The following

topics are discussed:

Component diagrams, connectors, jumpers and cables

Mounting the XE–800 SBC

Connecting a monitor and keyboard

Installing an operating system

Component diagrams, connectors, jumpers and cables

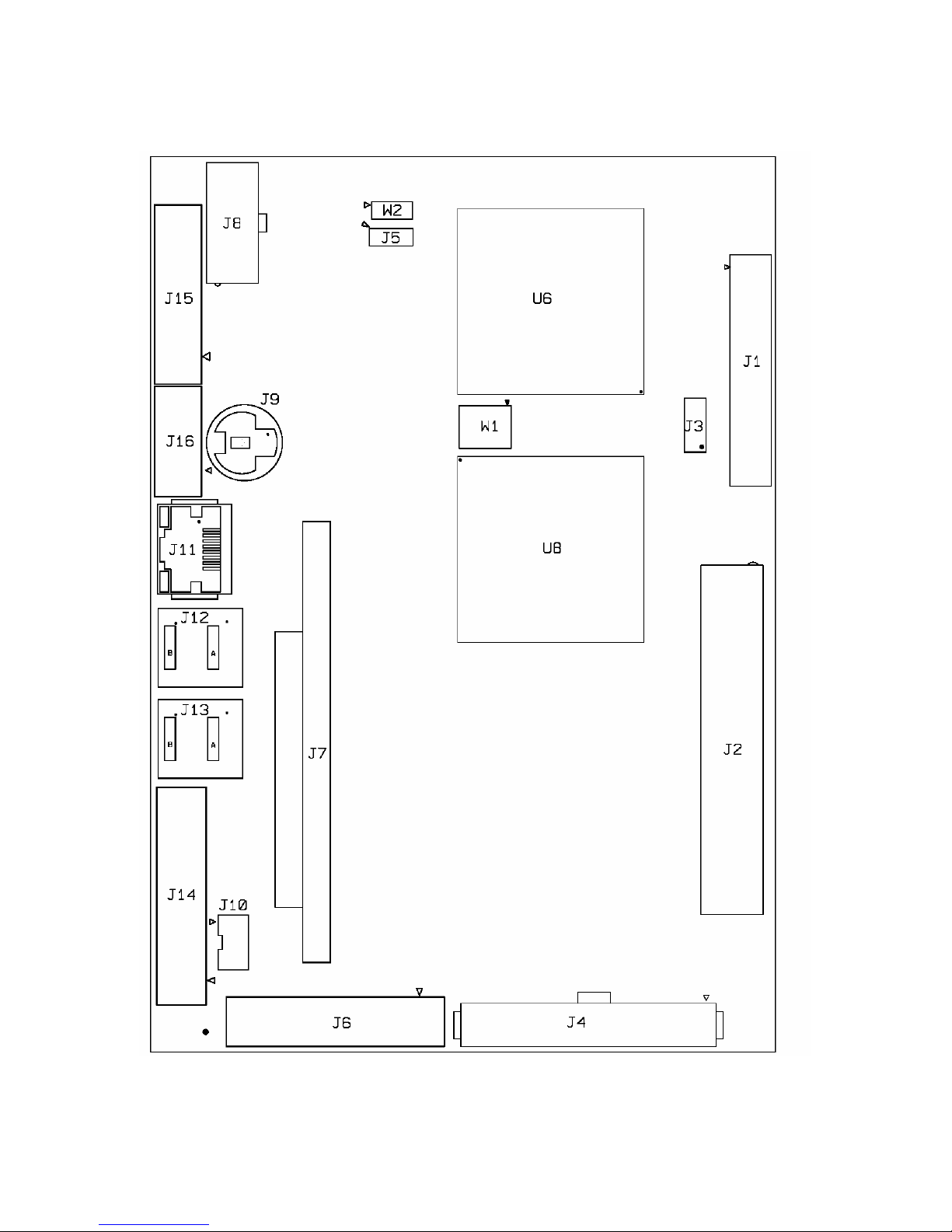

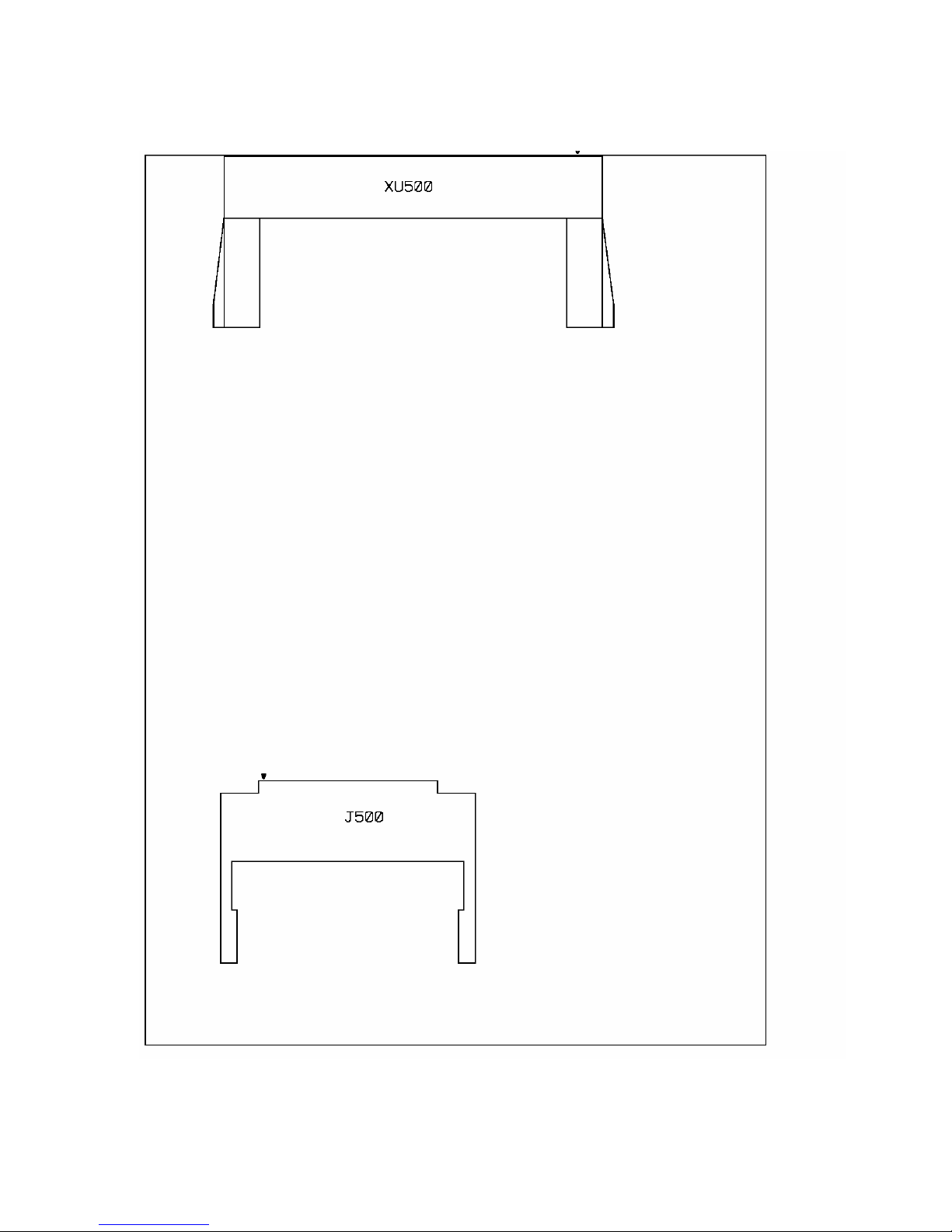

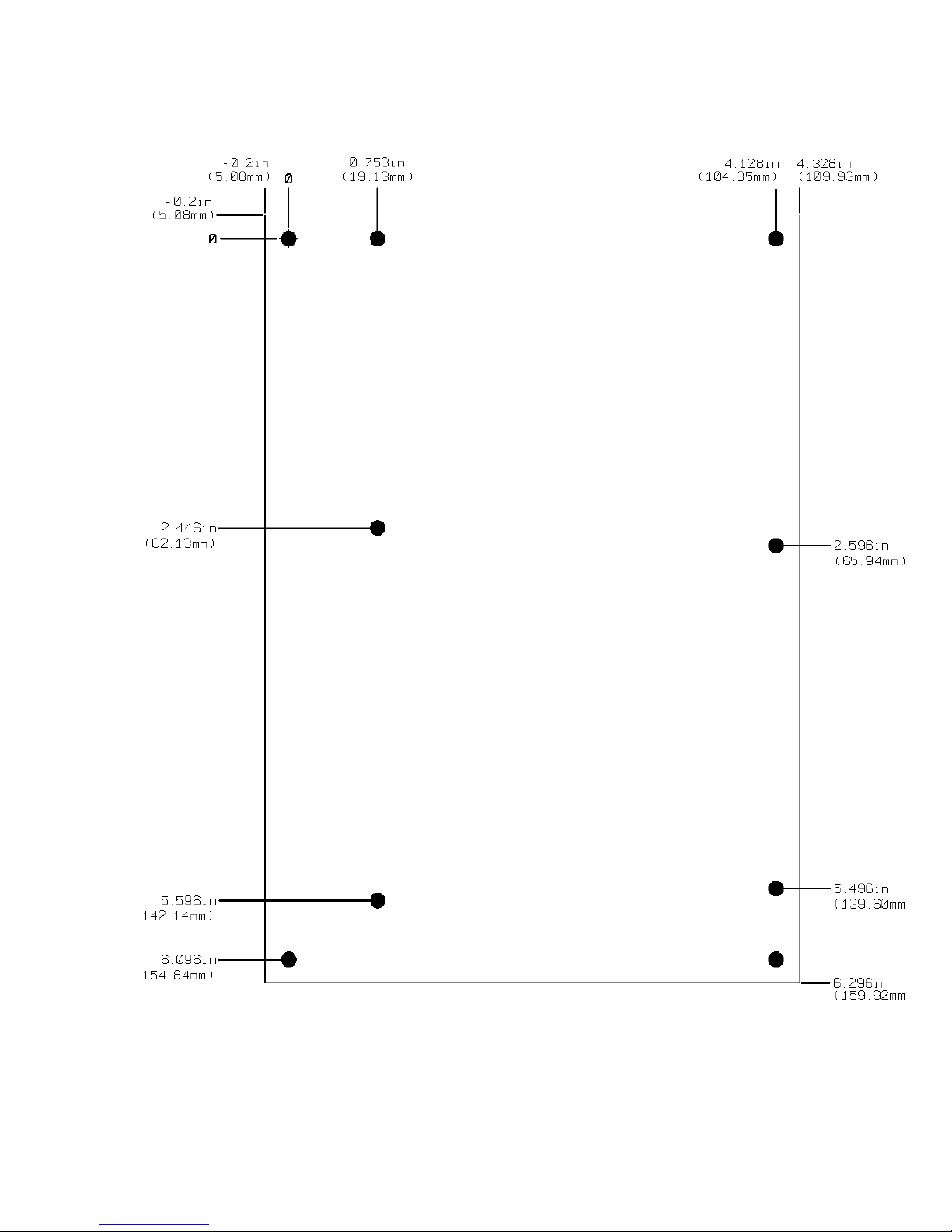

Figures 2–1 and 2–2 show the connectors and jumpers and their locations on the

XE–800 SBC. Figure 2–3 shows the dimensions of the XE–800 SBC in inches and

millimeters. The sections immediately following those figures describe the

connectors and jumpers, and some cables that you might require.

The XE–800 SBC contains static-sensitive CMOS components. To

avoid damaging your card and its components:

Ground yourself before handling the card

Disconnect power before removing or inserting a PC/104 or PC/104

Plus expansion board.

WARNING!

17

Page 18

Figure 2–1 XE–800 SBC component diagram (top)

18

Page 19

Figure 2–2 XE–800 SBC component diagram (bottom)

19

Page 20

Figure 2–3 XE–800 SBC dimensions

20

Page 21

XE–800 SBC connectors and jumpers

Table 2–1 lists the connector reference designators and function for each of the

connectors. Table 2–2 lists the jumper block reference designators and functions for

each of the jumper blocks. To view the physical location of each connector and

jumper block refer to the illustration on page

connectors see page

following section.

Table 2–1 XE–800 SBC connector functions

Connector Function

J1 Flat Panel Display

J2 PC/104 Plus

J3 CRT Video

J4 Hard drive/IDE

J5 COM2 RS–422/RS–485

J6 Digital I/O 2

J7 PC/104

J8 Power

J9 Keyboard/Mouse

J10 AT battery

J11 Ethernet

J12 USB3,4 (USB 2.0)

J13 USB5,6 (USB 2.0)

J14 Digital I/O 1

J15 COM1/2

J16 USB1,2 (USB 1.1)

J500 CompactFlash

XU500 SDRAM SODIMM

100. For information on cables you might require see the

18. For information on mating

Table 2–2 XE–800 SBC jumper functions

Jumper Function

W1 Display jumper / system

jumpers

W2 COM2 RS–422/RS–485

termination

21

Page 22

Custom cables

To conserve board real estate a few connectors on the XE–800 are non-standard or

provide alternate interfaces. The cables listed below connect to the XE–800 SBC

and provide industry-standard interfaces. For ordering information see page

COM PORT VTC-20F Cable This cable connects to the 20-pin COM1/2 port

and provides two DB-9 female connectors. A VTC-20M provides two DB-9 male

connectors.

1.25 mm COM2 RS-422/485 Cable This cable connects to the 5-pin header

for RS-422/485 on COM2 and provides a standard DB-9 interface.

2 mm VGA-12 Cable Provides a standard 15-pin VGA interface.

44-pin to 40-pin IDE Cable Converts the 44-pin IDE header to a 40-pin IDE

header.

Keyboard/Mouse “Y” Cable Connects to the PS/2 keyboard/mouse port to

provide keyboard and mouse interfaces. A keyboard will plug directly into the

XE–800 port.

Two-port USB Cable Converts the 10-pin header for USB1,2 into two

standard USB connectors.

117.

XE–800 ATX Power Cable Connects to the 10-pin ATX power connector and

provides a standard 20-pin ATX connector.

Caution

USB devices are hot-swappable when a device is plugged into a

standard USB connector, as pins on the connectors determine the

order in which they make contact. Devices are not hot-swappable

when connected to a non-standard header. You can hot swap a

device through the USB connector on the two port USB cable, or

through another USB connector wired to the 10-pin header, but you

cannot hot swap at the 10-pin header itself.

22

Page 23

Mounting the XE–800

WARNING!

The XE–800 contains static-sensitive CMOS components. To avoid

damaging your card and its components:

Ground yourself before handling the card and observe proper ESD

precautions

Disconnect power before removing or inserting a PC/104 or PC/104

Plus expansion board

Equipment required

To install the XE–800 SBC you will need the following equipment (or equivalent):

XE–800 SBC

+5V power supply – see the XE–800 SBC power supply requirements section.

You might also need an XE–800 ATX power cable, part #6537.

A device with an operating system. The device could be a CompactFlash, hard

disk, or CD ROM. The operating system can be Windows NT, Windows CE.net,

Linux, QNX, or DOS. Note: Windows 2000 and Windows XP/XP

Embedded will run with known issues, however, new driver

development is not supported by the CPU manufacturer.

PS/2 style keyboard

SVGA monitor

2 mm VGA-12 Cable, part #6392

VTC-20F Cable, part #4866 (for serial console)

Null modem adapter, #2740 (for serial console)

Windows HyperTerminal or equivalent terminal emulation software (for serial

console)

Your PC (for serial console)

Hardware components required to mount the XE–800 SBC (included):

9 threaded hex standoffs (4–40 x ¾”)

9 screws (4–40 x 3/16”)

9 internal star lock washers (#4)

9 nuts (4–40)

Refer to the XE–800 SBC component diagram, figure 2–1 on page

location of various connectors, and to the mounting hole diagram, figure 2–3 on

20, for mounting the XE–800 SBC system.

page

18, for the

23

Page 24

Hardware mounting

1. Use the standoffs, washers, and screws and place them in the nine holes on the

XE–800 SBC board. Refer to Figure 2–3 for the center-to-center mounting hole

dimensions and for the location of the designated holes used for mounting the

hardware.

WARNING!

All nine standoffs, screws and washers must be used to secure the

XE–800 SBC. The standoffs ensure full support of the board.

WARNING!

Verify that the washers and standoffs do not touch any of the

component pads adjacent to the mounting holes. Damage will occur

at power-up.

2. Connect a 5V power source to the XE–800 SBC. Refer to the Power Supply

Requirements section, page

Refer to Figure 2–4 and Table 2–3.

Note The +12V, –12V, and +3V signals are routed to the PC/104 and PC/104 Plus bus

only.

Make sure the power supply is OFF when connecting the power

cable to the XE–800 SBC board. Damage to the XE–800 SBC may

occur if the power is ON when connecting the power cable.

Accidentally crossing the wires, i.e., plugging +5V wires into the

ground connector or the ground wires into the +5V connector will

damage the XE–800 SBC.

25. The power supply connector is located at J8.

WARNING!

WARNING!

Figure 2–4 Power connector, J8

1

5

24

J8

6

10

Page 25

Table 2–3 Power connector: J8

Pin Function Function Pin

1 nc nc 6

2 GND +5v 7

3 GND +5v 8

4 +12V –12V 9

5 +3V GND 10

XE–800 SBC power supply requirements

The XE–800 SBC is designed to operate from a single +5 VDC supply, connected at

J8. The connector is a 10-pin ATX PC power supply connector, and connects to a

10-pin ATX power supply, or with an adapter cable, to a standard 20-pin ATX

power supply. The typical current requirement for the XE–800 SBC is listed in the

Technical Data appendix. If you are using the PC/104 or PC/104 Plus interface, you

may also require ±12 VDC and/or +3V.

The user should consider factors such as the power cable conductor gauge, number

and length of conductors, mating connectors, and the power requirements of

external devices such as hard drives, floppy drives, displays, mouse, and keyboard.

It is important that a quality power supply be used that has sufficient current

capacity, line and load regulation, hold up time, current limiting, and minimum

ripple.

The power supply for the XE–800 must meet the startup risetime requirements

specified in the ATX Power Design Guide, version 1.1, section 3.3.5. This assures

that all the circuitry on the XE–800 sequences properly and avoids system lockup.

Also, select a power supply that discharges quickly. If large power supply output

capacitors are used, powering the system down and then up may lock up the XE–

800 SBC. If the power supply does not drain below 0.7V, the CMOS components on

the XE–800 SBC will act like diodes and forward bias, potentially damaging the

XE–800 SBC circuitry.

The proper selection of a quality power supply ensures reliability and proper

functioning of the XE–800 SBC.

25

Page 26

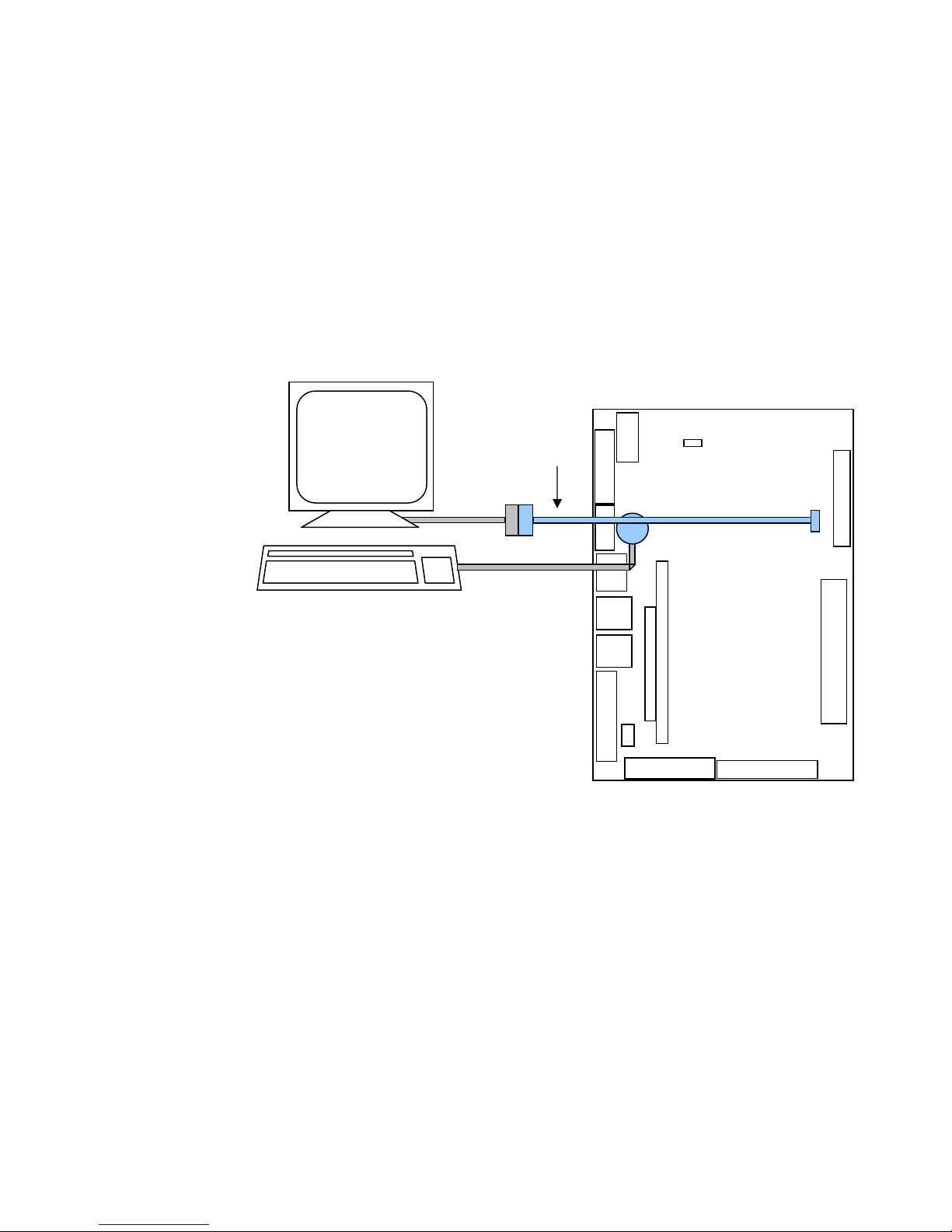

Connecting a monitor and keyboard

Figure 2–5 shows the XE–800 SBC with a monitor and keyboard. The following

sections describe how to connect these items.

WARNING!

The video connector is not keyed, and can be plugged in incorrectly.

Ensure that pin 1 of the cable is connected to pin 1 of the connector

(indicated by the dot). Incorrect connection could damage your

equipment.

Figure 2–5 Connecting a monitor and keyboard

VGA Monitor

PS/2 Keyboard

2 mm VGA-12 cable

XE–800 SBC

Dot indicates

pin 1

.

Monitor

The XE–800 SBC interfaces to a standard SVGA monitor through the J3 connector

using a 2 mm VGA-12 cable. Connect one end of the 2 mm VGA-12 cable into J3

and connect the other end to a SVGA monitor cable.

Note The video jumper, W1[5–6], must be installed to use a monitor. This jumper is

installed by default.

Keyboard and mouse

The XE–800 SBC accepts an AT style keyboard and has a PS/2 type connector,

located at J9. The mouse port shares the keyboard connector.

To use a keyboard, plug the keyboard directly into J9. To connect a mouse, use a

laptop-style “Y” connector, available at computer stores, that splits the signals into

26

Page 27

keyboard and mouse connectors.

Note With some “Y” cables you may have to plug the mouse into the keyboard

icon, and the keyboard into the mouse icon; if the mouse and keyboard do

not function at power up, try switching them.

Installing an operating system

The XE–800 SBC does not come with an installed operating system. You can install

an operating system onto a hard drive or CompactFlash. Octagon Systems has OS

Embedder™ kits available for several operating systems. These kits directly

support the unique features of Octagon products, such as digital I/O, watchdog

timer, etc., eliminating the need to write special drivers. Other software kits may

also be available. Contact Octagon Systems for information concerning the

software development kits.

To install an operating system you will need:

2 mm VGA-12 video cable, #6392

PS/2 style keyboard

VGA monitor

CD-ROM drive

Operating system media

Hard drive or CompactFlash to install the operating system onto.

If installing onto a hard drive, an IDE cable with master and slave connectors.

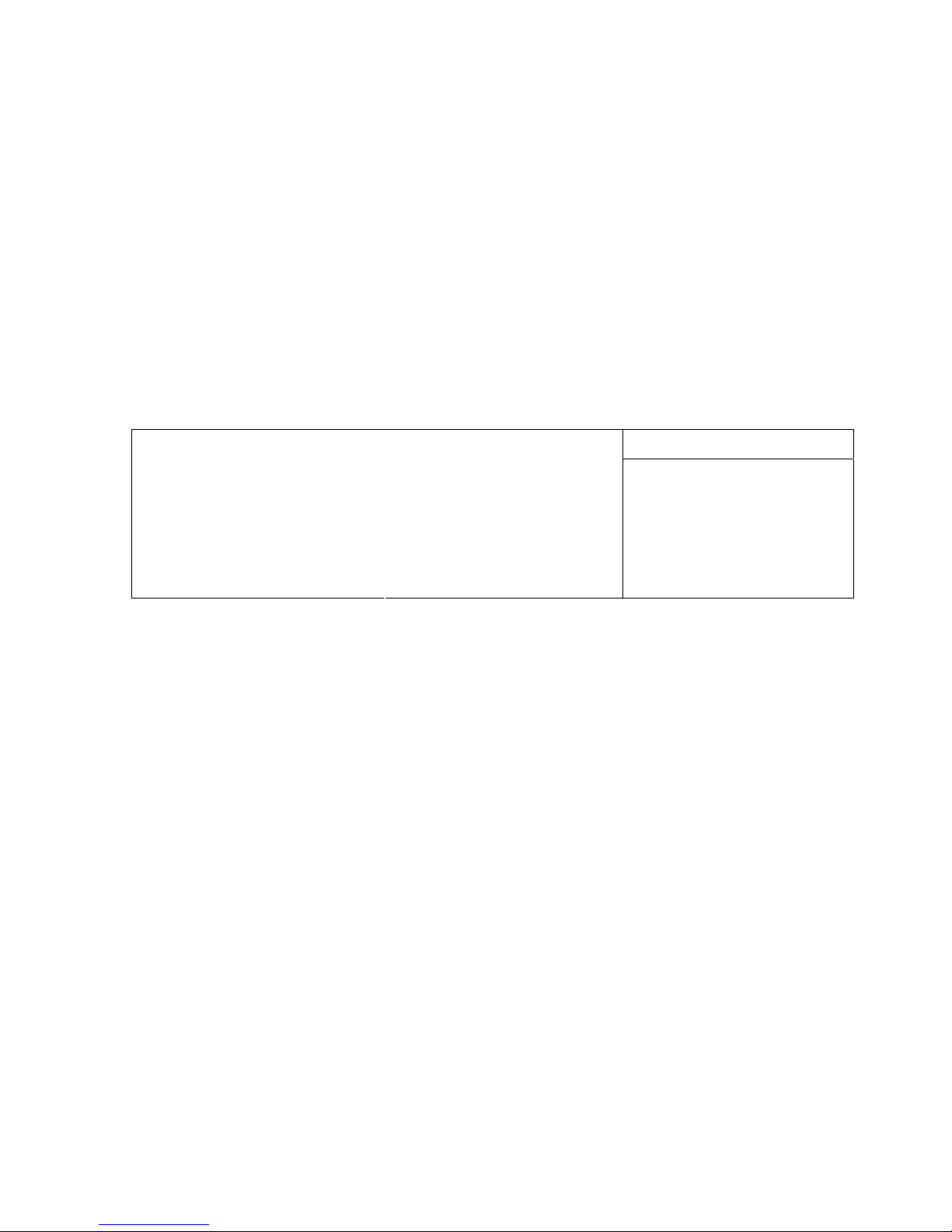

OS on CD-ROM onto a hard drive or CompactFlash

Refer to Figure 2–6 on page 29 for the following:

1. Attach the 2 mm VGA-12 video cable to J3.

2. Connect the PS/2 keyboard to J9, a VGA monitor to the VGA-12 video cable,

and a CD-ROM drive to J4. Configure the CD-ROM drive as a master.

3. If using a hard drive, configure it as a slave device and install it on the IDE

cable connected to J4.

Note IDE devices have a jumper or a switch that designates whether the device is a

master or a slave device. If only one device is connected to a port, it must be

configured as a master. If two devices are connected, one must be configured as a

master and one as a slave. The XE–800 does not use the CS signal (Cable Select) to

designate master or slave on a multi-connector cable. You can use BIOS Setup to

designate either the master or the slave as a boot device.

4. If using a CompactFlash, install it into the CompactFlash socket.

27

Page 28

5. Apply power to the XE–800 SBC system. A logon message similar to the one

below will appear on your PC monitor:

Copyright 1985-2003 Phoenix Technologies Ltd.

All Rights Reserved

Octagon Systems: XE–800 V1.00

Build Time: 01/27/04 16:59:27

CPU =Cyrix MediaGXm300 MHz

638K System RAM Passed

130048K Extended RAM Passed

System BIOS shadowed

6. Enter Setup by pressing the F2 key during BIOS POST sequence (this occurs

between the memory test and bootup).

Main Advanced Boot Exit

System Time:

System Date:

Legacy Diskette A:

Legacy Diskette B:

> Primary Master

> Primary Slave

> Secondary Master

> Secondary Slave

>Memory Cache:

>Boot option:

System Memory:

Extended Memory:

F1 Help ^v Select Item -/+ Change Values F9 Setup Defaults

Esc Exit <> Select Menu Enter Select > Sub-Menu F10 Save and Exit

PhoenixBIOS Setup Utility

[00:00:36]

[01/01/1988]

[Disabled]

[Disabled]

[None]

[None]

[3253MB]

[None]

640 KB

130048 KB

Item Specific Help

<Tab>, <Shift-Tab>, or

<Enter> selects field.

Note Your display message may be slightly different

7. Configure the CD–ROM as a master device in BIOS Setup, and change the boot

sequence to CD-ROM drive first.

8. Insert the operating system media into the CD-ROM drive.

9. Reboot the system. The system should boot to the CD-ROM.

10. Follow the on-screen dialog to load the operating system. Refer to the OS

documentation for further information.

28

Page 29

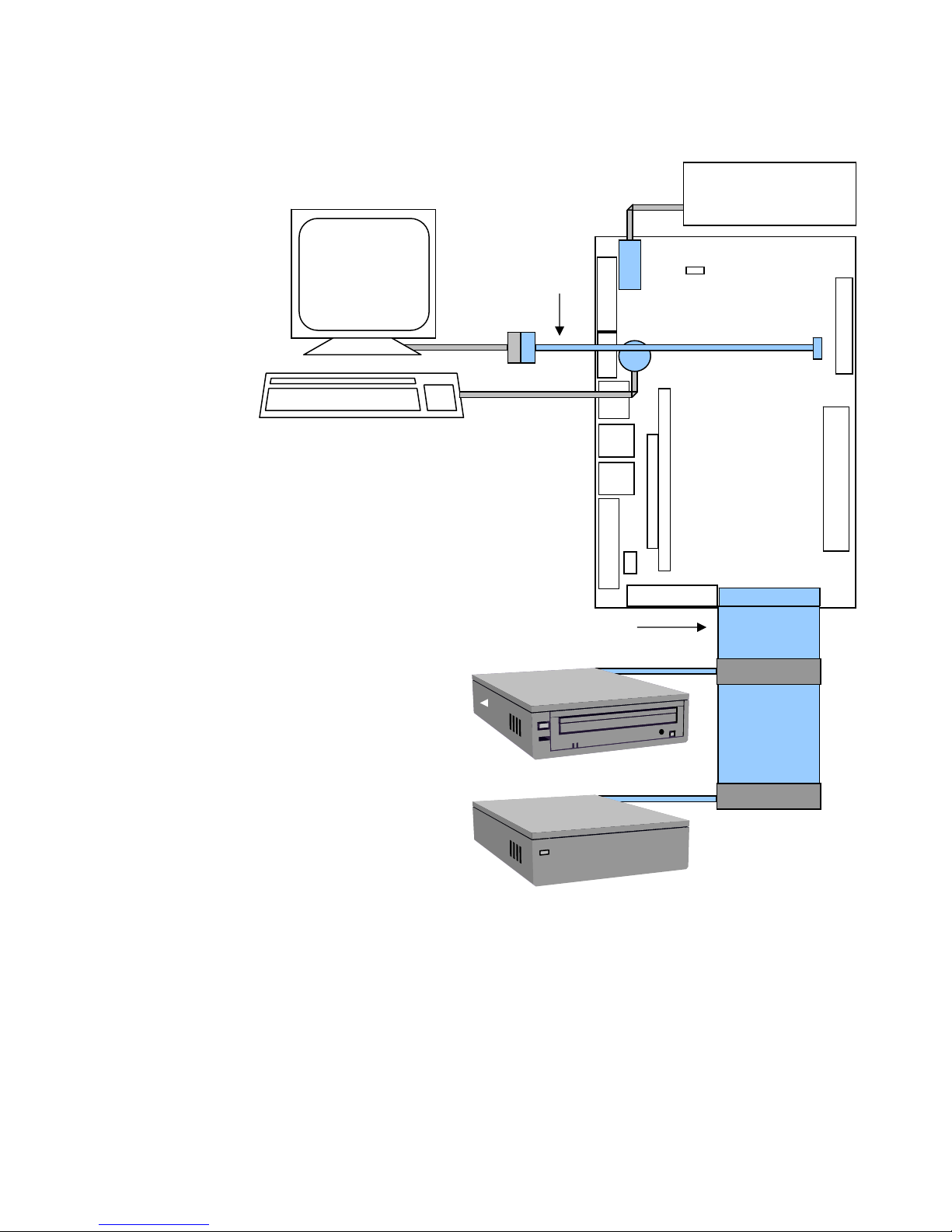

Figure 2–6 Installing an operating system

VGA Monitor

PS/2 Keyboard

CompactFlash installed into

CompactFlash socket on back of board

2 mm VGA-12 cable

Power Supply

XE–800 SBC

Dot indicates

pin 1

.

IDE ribbon cable for two devices, or

one device directly into J4

CD-ROM

and / or

Hard Drive

29

Page 30

Chapter 3: Setup programs

This chapter discusses running the Setup configuration program on the XE–800

SBC. Setup configures devices set up by the BIOS such as serial ports, floppy

drives, etc.

Operating systems other than DOS

If you are using an operating system other than DOS the X jumper should be

removed. The X jumper maps the INT17 extended BIOS into the 0xD80000xDFFFF memory. This can cause problems with applications or hardware running

on other operating systems if they attempt to use this memory range. Removing

the X jumper frees this memory for use by other operating systems.

Setup

Setup can be entered by pressing the “F2” key during the BIOS POST sequence

(this occurs between the memory test and boot).

Also, by removing the “S” jumper W1[1–2], you will force the setup to revert to the

factory programmed defaults shown in the following menus. This allows the user

to reconfigure the setup.

Note The Setup defaults might vary slightly from those shown in the following menus

depending on the BIOS revision on your card.

The system will display the XE–800 SBC PhoenixBIOS Setup Utility Main menu.

Select the submenu by using the up/down arrows, then press <ENTER> (when

using a monitor connected to the XE–800 SBC). For a serial console configuration,

Ctrl + E is up and Ctrl + X is down.

30

Page 31

Main menu

The Main menu allows you to set the basic system configuration.

Main Advanced Boot Exit

System Time:

System Date:

Legacy Diskette A:

Legacy Diskette B:

> Primary Master

> Primary Slave

> Secondary Master

> Secondary Slave

>Memory Cache:

>Boot options:

System Memory:

Extended Memory:

F1 Help ^v Select Item -/+ Change Values F9 Setup Defaults

Esc Exit <> Select Menu Enter Select > Sub-Menu F10 Save and Exit

System Time: Sets the time for the system clock.

System Date: Sets the date for the system clock.

Legacy Diskette A: Enables or disables a legacy floppy disk drive. Choices are Disabled, 360

KB 5 ¼”, 1.2 MB 5 ¼”, 720 KB 3 ½”, 1.44/1.25 MB 3 ½”, 2.88 MB 3 ½”. Note

that the XE–800 does not support a floppy drive directly. This feature

should be left disabled unless you are using a PC/104 floppy drive. This also

frees up INT6 for other applications.

Legacy Diskette B: Enables or disables a second legacy floppy disk drive. Note that Diskette A

must be enabled before Diskette B is accessible. The menu items for

Diskette B are then the same as for Diskette A. See note under Diskette A.

>Primary Master Accesses submenu for a Primary Master disk drive. Options are None, CD-

ROM, ATAPI Removable, Other ATAPI, User, and Auto. This channel is

hardwired to the CompactFlash, and cannot be used for other devices.

>Primary Slave Same as Primary Master. This channel is reserved and cannot be used.

>Secondary Master Same as Primary Master. Note that the XE–800 SBC only supports three

IDE devices total (CompactFlash and two Secondary devices.)

>Secondary Slave Same as Primary Master. Note that the XE–800 SBC only supports three