Page 1

NOTICE

The drivers and utilities for Octagon products, previously provided

on a CD, are now in a self-extracting zip file located at the Octagon

Systems web site on the product-specific page. Download this file to a

separate directory on your hard drive, then double click on it to extract

the files. All references in this manual to files and directories on the CD

now refer to files in the Utilities zip file.

Page 2

O C T A G O N S Y S T E M S

Embedded PCs For Extreme Environments

PC-500 User’s Manual

5170 (0403)

Page 3

DiskOnChip® is a registered trademark of M-Systems. Micro PC™, PC SmartLink™,

Octagon Systems Corporation

of Octagon Systems Corporation. QuickBASIC

Corporation. QNX

®

is a registered trademark of QNX Software Systems Ltd.

®

, the Octagon logo and the Micro PC logo are trademarks

®

is a registered trademark of Microsoft

ROM-DOS™ is a trademark of Datalight. Windows™ and Windows NT™ are trademarks of Microsoft Corporation. PICO FA™ is a trademark of Phoenix Technologies

Ltd.

Copyright 1997, 1998, 2003—Octagon Systems Corporation. All rights reserved.

However, any part of this document may be reproduced, provided that Octagon

Systems Corporation is cited as the source. The contents of this manual and the

specifications herein may change without notice.

The information contained in this manual is believed to be correct. However, Octagon

assumes no responsibility for any of the circuits described herein, conveys no license

under any patent or other right, and makes no representations that the circuits are free

from patent infringement. Octagon makes no representation or warranty that such

applications will be suitable for the use specified without further testing or modification.

Octagon Systems Corporation general policy does not recommend the use of its products

in life support applications where the failure or malfunction of a component may directly

threaten life or injury. It is a Condition of Sale that the user of Octagon products in life

support applications assumes all the risk of such use and indemnifies Octagon against

all damage.

Technical support: 303-426-4521

Telephone: 303-430-1500

Web site: www.octagonsystems.com

FAX: 303-426-8126

Page 4

PC-500 user’s manual Notice to user

IMPORTANT!

Please read the following section before installing your product:

Octagon’s products are designed to be high in performance while consuming

very little power. In order to maintain this advantage, CMOS circuitry is

used.

CMOS chips have specific needs and some special requirements that the user

must be aware of. Read the following to help avoid damage to your card from

the use of CMOS chips.

≡ Using CMOS circuitry in industrial control

Industrial computers originally used LSTTL circuits. Because many PC

components are used in laptop computers, IC manufacturers are exclusively using CMOS technology. Both TTL and CMOS have failure

mechanisms, but they are different. Described below are some of the

failures which are common to all manufacturers of CMOS equipment.

However, much of the information has been put in the context of the

Micro PC.

Octagon has developed a reliable database of customer-induced, field

failures. The average MTBF of Micro PC cards exceeds 11 years, yet

there are failures. Most failures have been identified as customerinduced, but there is a small percentage that cannot be identified. As

expected, virtually all the failures occur when bringing up the first

system. On subsequent systems, the failure rate drops dramatically.

n Approximately 20% of the returned cards are problem-free. These

cards, typically, have the wrong jumper settings or the customer has

problems with the software. This causes frustration for the customer and incurs a testing charge from Octagon.

n Of the remaining 80% of the cards, 90% of these cards fail due to

customer misuse and accident. Customers often cannot pinpoint the

cause of the misuse.

n Therefore, 72% of the returned cards are damaged through some

type of misuse. Of the remaining 8%, Octagon is unable to determine the cause of the failure and repairs these cards at no charge if

they are under warranty.

Page 5

Notice to user PC-500 user’s manual

The most common failures on CPU cards are over voltage of the power

supply, static discharge, and damage to the serial and parallel ports.

On expansion cards, the most common failures are static discharge, over

voltage of inputs, over current of outputs, and misuse of the CMOS

circuitry with regards to power supply sequencing. In the case of the

video cards, the most common failure is to miswire the card to the flat

panel display. Miswiring can damage both the card and an expensive

display.

n Multiple component failures - The chance of a random compo-

nent failure is very rare since the average MTBF of an Octagon card

is greater than 11 years. In a 7 year study, Octagon has never

found a single case where multiple IC failures were not caused by

misuse or accident. It is very probable that multiple component

failures indicate that they were user-induced.

n Testing “dead” cards - For a card that is “completely nonfunc-

tional”, there is a simple test to determine accidental over voltage,

reverse voltage or other “forced” current situations. Unplug the card

from the bus and remove all cables. Using an ordinary digital

ohmmeter on the 2,000 ohm scale, measure the resistance between

power and ground. Record this number. Reverse the ohmmeter

leads and measure the resistance again. If the ratio of the resistances is 2:1 or greater, fault conditions most likely have occurred.

A common cause is miswiring the power supply.

n Improper power causes catastrophic failure - If a card has had

reverse polarity or high voltage applied, replacing a failed component is not an adequate fix. Other components probably have been

partially damaged or a failure mechanism has been induced. Therefore, a failure will probably occur in the future. For such cards,

Octagon highly recommends that these cards be replaced.

n Other over-voltage symptoms - In over-voltage situations, the

programmable logic devices, EPROMs and CPU chips, usually fail in

this order. The failed device may be hot to the touch. It is usually

the case that only one IC will be overheated at a time.

n Power sequencing - The major failure of I/O chips is caused by the

external application of input voltage while the Micro PC power is off.

If you apply 5V to the input of a TTL chip with the power off, nothing will happen. Applying a 5V input to a CMOS card will cause the

current to flow through the input and out the 5V power pin. This

current attempts to power up the card. Most inputs are rated at

25 mA maximum. When this is exceeded, the chip may be damaged.

n Failure on powerup - Even when there is not enough current to

destroy an input described above, the chip may be destroyed when

the power to the card is applied. This is due to the fact that the

input current biases the IC so that it acts as a forward biased diode

on powerup. This type of failure is typical on serial interface chips.

Page 6

PC-500 user’s manual Notice to user

n Hot insertion - Plugging cards into the card cage with the power on

will usually not cause a problem. (Octagon urges that you do not

do this!) However, the card may be damaged if the right sequence

of pins contacts as the card is pushed into the socket. This usually

damages bus driver chips and they may become hot when the power

is applied. This is one of the most common failures of expansion

cards.

n Terminated backplanes - Some customers try to use Micro PC

cards in backplanes that have resistor/capacitor termination networks. CMOS cards cannot be used with termination networks.

Generally, the cards will function erratically or the bus drivers may

fail due to excessive output currents.

n Excessive signal lead lengths - Another source of failure that was

identified years ago at Octagon was excessive lead lengths on digital

inputs. Long leads act as an antenna to pick up noise. They can

also act as unterminated transmission lines. When 5V is switch

onto a line, it creates a transient waveform. Octagon has seen

submicrosecond pulses of 8V or more. The solution is to place a

capacitor, for example 0.1 µF, across the switch contact. This will

also eliminate radio frequency and other high frequency pickup.

≡ Avoiding damage to the heatsink/CPU

WARNING!

When handling any Octagon CPU card, extreme care must be

taken not to strike the heatsink against another object, such

as a table edge. Also, be careful not to drop the CPU card,

since this may cause damage to the heatsink/CPU as well.

Epoxy adhesive bonds the heatsink to the CPU chip. When

the heatsink is struck, the epoxy adhesive does not allow the

heatsink to separate from the chip. The force of the blow to

the heatsink then causes the legs of the CPU chip to separate

from the PCB. This force damages both the CPU chip and

the PCB.

Note Any physical damage to the CPU control card is not covered under

warranty.

Page 7

Notice to user PC-500 user’s manual

Page 8

PC-500 user’s manual Contents

Contents

Abbreviations and terms used in this manual ............................................ xiii

Conventions used in this manual .....................................................................xv

About this manual

Overview: Section 1 – Installation

Chapter 1: Overview ........................................................................................... 1-1

Description.......................................................................................................1-1

PC-500 major hardware features ..................................................................1-1

CPU .........................................................................................................1-1

Up to 48 MB DRAM...............................................................................1-1

Solid-state disks .....................................................................................1-2

Serial ports protected against ESD ......................................................1-3

Local bus SVGA, flat panel interface, and GUI accelerator ...............1-3

Adjustable display bias supply .............................................................1-3

Industrial I/O using EZ I/O...................................................................1-4

Speaker, keyboard, and mouse ports ....................................................1-4

PC/104 16-bit interface..........................................................................1-4

Ethernet..................................................................................................1-4

SCSI ........................................................................................................1-4

PC-500 major software features ....................................................................1-5

Advanced power management and system management input ........1-5

Diagnostic software verifies system integrity automatically .............1-5

SETUP information stored in EEPROM for high reliability..............1-5

Phoenix BIOS .........................................................................................1-6

“Instant DOS” operating system ..........................................................1-6

Programmable video BIOS....................................................................1-6

On-board flash file system.....................................................................1-6

Octagon BIOS extensions......................................................................1-6

Interrupt routing: In system and programmable...............................1-6

Floppy and hard disk ports ...................................................................1-6

Boot sequence .........................................................................................1-7

Multifunctional printer port..................................................................1-7

Watchdog timer added for safety ..........................................................1-7

Real time calendar/clock with battery-backup ....................................1-7

I/O connectors.........................................................................................1-7

Keypad and LCD display support for low cost operator interface .....1-7

Hardware reset.......................................................................................1-8

5 Volt operation lowers system cost......................................................1-8

Rugged environmental operation .........................................................1-8

Size ..........................................................................................................1-8

Chapter 2: Quick start ....................................................................................... 2-1

Installing the PC-500 .....................................................................................2-1

Reference designators.....................................................................................2-6

PC-500 power supply requirements ..............................................................2-8

Running a demo program...............................................................................2-9

Logon message .......................................................................................2-9

What’s next....................................................................................................2-10

iii

Page 9

Contents PC-500 user’s manual

Chapter 3: SETUP programs ............................................................................ 3-1

Introduction.....................................................................................................3-1

SETUP .............................................................................................................3-1

Running SETUP over the console port ................................................3-4

SETUP example.....................................................................................3-8

SETSSD ...........................................................................................................3-9

PMISETUP......................................................................................................3-9

SETIRQ.EXE...................................................................................................3-9

Chapter 4: Save and run programs ................................................................ 4-1

Save and run your programs on the PC-500 ................................................4-1

Saving programs and support files................................................................4-1

Adding your application ........................................................................4-2

Autoexecuting your application ............................................................4-2

Overriding the autoexecution of your application...............................4-2

Overview: Section 2 – Hardware

Chapter 5: Serial ports....................................................................................... 5-1

Description.......................................................................................................5-1

Serial port options...........................................................................................5-1

Description of serial ports ..............................................................................5-2

Conflicting COM port addresses ...........................................................5-2

COM1 ......................................................................................................5-2

COM2 ......................................................................................................5-3

COM3 through COM5 interrupt/status port .......................................5-3

COM3 ......................................................................................................5-5

COM4 ......................................................................................................5-5

COM5 ......................................................................................................5-6

Null modem cable ...........................................................................................5-6

Mating receptacle...................................................................................5-6

Building your own cable ........................................................................5-7

Function and use of serial ports ....................................................................5-9

COM1 as serial console device ..............................................................5-9

COM1 through COM4 as RS-232 I/O...................................................5-9

COM5 as RS-485 transmitter control ..................................................5-9

RS-485 network.............................................................................................5-10

iv

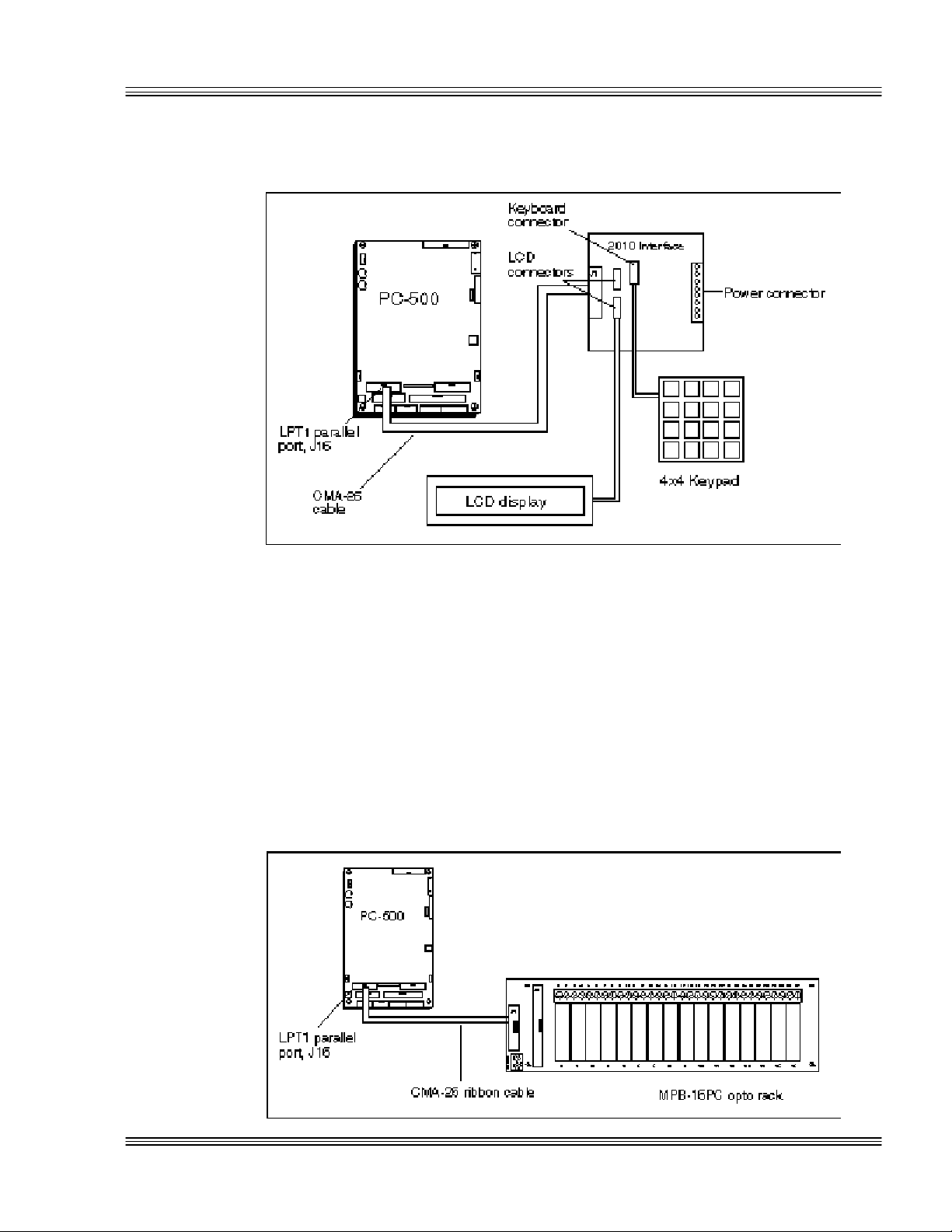

Chapter 6: LPT1 parallel port .......................................................................... 6-1

LPT1 parallel port ..........................................................................................6-1

Printer..............................................................................................................6-1

Installing a printer ................................................................................6-1

Display .............................................................................................................6-2

Installing a display ................................................................................6-2

Keypad .............................................................................................................6-2

Installing a keypad ................................................................................6-2

Opto rack .........................................................................................................6-3

Chapter 7: Console devices ............................................................................... 7-1

Description.......................................................................................................7-1

Selecting console devices ................................................................................7-1

Local bus SVGA .....................................................................................7-1

Serial console..........................................................................................7-1

Keyboard.................................................................................................7-3

Page 10

PC-500 user’s manual Contents

Speaker ...................................................................................................7-3

Mouse ......................................................................................................7-3

Enabling/disabling the video BIOS ...............................................................7-3

Re-establishing communications when the console is not working ...7-5

Chapter 8: SSDs, DRAM, and battery backup ............................................. 8-1

Description.......................................................................................................8-1

SSD0 (optional) ...............................................................................................8-1

Selecting SSD0 device type ...................................................................8-1

SSD0 replaced with an SRAM device............................................................8-1

SSD0 replaced with a flash device.................................................................8-2

Selecting an SSD BIOS .........................................................................8-2

SSD0 replaced with an EPROM/OTPROM .........................................8-3

SSD1.................................................................................................................8-3

DRAM...............................................................................................................8-3

Battery backup for SSD0 SRAM and real time calendar clock...................8-4

Installing an AT battery........................................................................8-4

Chapter 9: External drives................................................................................ 9-1

Description.......................................................................................................9-1

Floppy disk controller .....................................................................................9-1

Power requirements...............................................................................9-1

Installing a floppy disk drive ................................................................9-1

Hard disk controller ........................................................................................9-2

Booting with ROM-DOS .................................................................................9-2

Chapter 10: IRQ routing and opto IRQs......................................................10-1

Interrupt routing...........................................................................................10-1

Opto IRQs ......................................................................................................10-3

Interrupt routing matrix defaults ...............................................................10-3

Programming.................................................................................................10-3

Master disable ...............................................................................................10-4

Chapter 11: EZ I/O .............................................................................................11-1

Description.....................................................................................................11-1

Pulling the I/O lines high or low..................................................................11-2

Organization of ports ....................................................................................11-2

Port addressing ....................................................................................11-3

Base I/O address ..................................................................................11-3

Configuring and programming the EZ I/O ports........................................11-4

Programming the EZ I/O.....................................................................11-4

Configuring the EZ I/O ........................................................................11-4

Writing and reading from EZ I/O .......................................................11-5

EZ I/O output program examples .......................................................11-5

EZ I/O input program examples .........................................................11-6

Enhanced INT 17h function definitions......................................................11-6

Initialize EZ I/O ...................................................................................11-6

Write EZ I/O .........................................................................................11-7

Read EZ I/O ..........................................................................................11-8

Opto-module rack interface..........................................................................11-9

Interfacing to switches and other devices.................................................11-11

Chapter 12: LED signaling and “beep” codes ............................................12-1

Description.....................................................................................................12-1

v

Page 11

Contents PC-500 user’s manual

Chapter 13: CRTs and flat panels .................................................................13-1

Description.....................................................................................................13-1

Video features................................................................................................13-1

Video options .................................................................................................13-1

Programming the video BIOS......................................................................13-2

Connecting the monitor/display...................................................................13-4

Analog monitor.....................................................................................13-4

Flat panel display ................................................................................13-5

Flat panels requiring bias voltage......................................................13-5

LCD bias control examples ........................................................13-6

LCD bias control examples ........................................................13-7

Flat panel considerations .............................................................................13-7

Flat panel interface voltage select: W8 .............................................13-7

Inverted shift clock signal voltage level select: W9 ..........................13-7

Chapter 14: PC/104 expansion........................................................................14-1

Description.....................................................................................................14-1

Chapter 15: SCSI................................................................................................15-1

Description.....................................................................................................15-1

Reprogramming the video BIOS..................................................................15-1

Chapter 16: Ethernet ........................................................................................16-1

Description.....................................................................................................16-1

Overview: Section 3 – System management

Chapter 17: Watchdog timer and hardware reset ....................................17-1

Description.....................................................................................................17-1

Enhanced INT 17h function definitions......................................................17-1

Enable watchdog ..................................................................................17-1

Strobe watchdog...................................................................................17-2

Disable watchdog .................................................................................17-2

Hardware reset..............................................................................................17-3

Chapter 18: Serial EEPROM and CMOS RAM ...........................................18-1

Description.....................................................................................................18-1

Enhanced INT 17h function definitions......................................................18-1

Serial EEPROM ............................................................................................18-1

Read a single word from the serial EEPROM ...................................18-1

Write a single word to the serial EEPROM.......................................18-2

Read multiple words from the serial EEPROM ................................18-3

Write multiple words to the serial EEPROM ....................................18-4

Return serial EEPROM size................................................................18-4

CMOS RAM ...................................................................................................18-5

Read extended CMOS RAM ................................................................18-5

Write extended CMOS RAM ...............................................................18-6

Check CMOS battery...........................................................................18-7

Copy contents of serial EEPROM to extended CMOS RAM ............18-7

Copy contents of extended CMOS RAM to serial EEPROM ............18-8

vi

Chapter 19: Transferring files/remote disks ..............................................19-1

Transferring files between the PC-500 and your PC.................................19-1

Transferring files to the PC-500 ..................................................................19-2

Page 12

PC-500 user’s manual Contents

Transferring files from the PC-500 .............................................................19-2

Downloading files to the PC-500 using PC SmartLINK ...........................19-3

Remote disks..................................................................................................19-5

Downloading files to the PC-500 using REMDISK/REMSERV.......19-5

PC-500 with one serial cable......................................................19-5

Chapter 20: Managing SSDs ...........................................................................20-1

PICO FA flash file system ............................................................................20-1

Defining SSDs using SETSSD.....................................................................20-1

Using PFORMAT to format an SSD ...........................................................20-2

Formatting SSD1 .................................................................................20-2

Using SYS to make an SSD bootable..........................................................20-3

Adding operating system startup files (using SYS) ..........................20-3

Changing boot SSD.......................................................................................20-4

Autoexecuting your application ..........................................................20-4

Using SETSSD and TESTRFA to test an SSD...........................................20-4

Making copies of the PC-500 SSD ...............................................................20-5

Programming copies of the PC-500 SSD.....................................................20-5

Programming a new BIOS into SSD1.........................................................20-6

Programming the video BIOS into an SSD ................................................20-6

Chapter 21: User-defined jumper..................................................................21-1

User-defined jumper .....................................................................................21-1

Read jumpers........................................................................................21-1

Chapter 22: CPU power management..........................................................22-1

Description.....................................................................................................22-1

Power management overview ......................................................................22-1

Hardware controlled modes..........................................................................22-2

Device power management ..........................................................................22-2

System power management.........................................................................22-3

How to initiate the SUSPEND/RESUME option ..............................22-4

How to initiate the STANDBY option ................................................22-6

Save to disk....................................................................................................22-7

How to initiate the save to disk option...............................................22-8

Power management configuration...............................................................22-9

Enabling power management .............................................................22-9

System timers.....................................................................................22-10

Doze timer enable and resets............................................................22-10

IDLE timer resets ..............................................................................22-11

RESUME from STANDBY ................................................................22-12

RESUME from SUSPEND................................................................22-13

Remote suspend/resume inputs ........................................................22-13

First Suspend/Resume Pulse: ..................................................22-14

Second Suspend/Resume Pulse:...............................................22-14

External PMI interrupt .....................................................................22-14

Thermal management .......................................................................22-15

Bitblt engine .......................................................................................22-15

PMISETUP..................................................................................................22-16

Chapter 23: Troubleshooting..........................................................................23-1

Technical assistance......................................................................................23-3

vii

Page 13

Contents PC-500 user’s manual

Overview: Section 4 – Appendices

Appendix A: Technical data............................................................................. A-1

Technical specifications................................................................................. A-1

Jumper settings.............................................................................................. A-6

Connector pinouts .......................................................................................... A-9

Tie wrap holes .............................................................................................. A-18

Appendix B: Software utilities ....................................................................... B-1

Introduction.................................................................................................... B-1

GETBIOS.EXE ............................................................................................... B-2

GETIMG.EXE................................................................................................. B-2

GETIMGH.EXE ............................................................................................. B-3

HIMEM.SYS................................................................................................... B-4

I17HNDLR.EXE............................................................................................. B-5

LCDBIAS.EXE ............................................................................................... B-6

LPT1CON.COM ............................................................................................. B-7

PFORMAT.EXE.............................................................................................. B-7

PGMBIOS.EXE .............................................................................................. B-8

PGMIMG.EXE................................................................................................ B-9

PGMIMGH.EXE........................................................................................... B-10

PGMVIDEO.EXE ......................................................................................... B-11

PHDISK.EXE ............................................................................................... B-12

PICOFA.SYS ................................................................................................ B-13

PMISETUP.EXE .......................................................................................... B-14

REMDISK.EXE............................................................................................ B-15

REMQUIT.COM ........................................................................................... B-17

REMSERV.EXE............................................................................................ B-17

RESET.COM................................................................................................. B-19

SCONSOLE.EXE ......................................................................................... B-19

SETIRQ.EXE................................................................................................ B-20

SETSSD.EXE ............................................................................................... B-20

SETUP.COM................................................................................................. B-22

TESTRFA.EXE............................................................................................. B-23

TRANSFER.EXE ......................................................................................... B-24

VDISK.SYS................................................................................................... B-26

viii

Appendix C: Third party support .................................................................. C-1

Using QNX on the PC-500 ............................................................................ C-1

Programming QNX into SSD1............................................................. C-1

Using M-Systems DiskOnChip (DOC) ......................................................... C-1

Booting from the DOC drive ................................................................ C-2

Appendix D: Accessories .................................................................................. D-1

Warranty

Page 14

PC-500 user’s manual Contents

List of figures

Figure 2-1 PC-500 component diagram...................................................2-2

Figure 2-2 PC-500 center-to-center hole dimensions..............................2-3

Figure 2-3 Power connector: P8, P9 ........................................................2-4

Figure 5-1 Null modem adapter and VTC-20F cable .............................5-7

Figure 5-2 Custom null modem cable for the PC-500 ............................5-8

Figure 5-3 PC-500 serial devices..............................................................5-9

Figure 5-4 RS-485 two-wire (half duplex) transmission ......................5-11

Figure 6-1 LPT1 as a printer port............................................................6-1

Figure 6-2 LPT1 as a display or keypad port..........................................6-3

Figure 6-3 LPT1 and an opto rack ...........................................................6-3

Figure 7-1 The PC-500 and a serial console............................................7-2

Figure 7-2 VTC-20F cable and null modem adapter ..............................7-2

Figure 7-3 Changing ROM Enable flowchart..........................................7-4

Figure 10-1 Interrupt routing matrix ......................................................10-2

Figure 11-1 Typical EZ I/O configurations ..............................................11-1

Figure 11-2 Organization of ports ............................................................11-3

Figure 11-3 MPB-16PC opto rack hookup ...............................................11-9

Figure 11-4 PC-500 interfacing with an STB-26 terminal board........11-11

Figure 13-1 The PC-500, a VGA monitor, and an AT/PS-2 compatible

keyboard ................................................................................13-3

Figure 13-2 The PC-500 and a VGA monitor ..........................................13-4

Figure 13-3 The PC-500 and a flat panel display ...................................13-5

Figure 14-1 Typical PC/104 module stack...............................................14-1

Figure 19-1 Downloading files using TRANSFER.EXE.........................19-4

Figure B-1 Cabling diagram for a standard cable................................ B-16

ix

Page 15

Contents PC-500 user’s manual

List of tables

Table 2-1 Power connector: P8, P9 ........................................................2-5

Table 2-2 PC-500 connectors...................................................................2-6

Table 2-3 TTL and RS-485 interface: W1 .............................................2-6

Table 2-4 RS-485 termination select jumper: W1 ................................2-6

Table 2-5 BIOS and boot option jumper: W2........................................2-7

Table 2-6 EZ I/O pull-up/pull-down, user option jumper: W3 .............2-7

Table 2-7 Auxiliary option jumper: W4.................................................2-7

Table 2-8 SSD0 device configuration: W5, W2[7-8]..............................2-8

Table 3-1 PC-500 SETUP parameters ...................................................3-2

Table 5-1 COM port options....................................................................5-1

Table 5-2 Conflicting COM port addresses ............................................5-2

Table 5-3 COM1 available addresses (IRQ 4 dedicated) ......................5-3

Table 5-4 COM2 available addresses (IRQ3 dedicated) .......................5-3

Table 5-5 Register 0A9h..........................................................................5-4

Table 5-6 Reading the interrupt status port: Register 0A9h ..............5-4

Table 5-7 Interrupt status port (138h, 158h, 338h*, and 358h) ..........5-5

Table 5-8 COM3 available address and IRQ routing............................5-5

Table 5-9 COM4 available address and IRQ routing............................5-5

Table 5-10 Available addresses for COM5 (IRQ 5 default, routable) ....5-6

Table 5-11 COM5: J17, RS-485 or TTL interface....................................5-6

Table 5-12 Custom RS-232 null modem cable for the PC-500:

First COM port........................................................................5-7

Table 5-13 Custom RS-232 null modem cable for the PC-500:

Second COM port ....................................................................5-8

Table 5-14 RS-485 transmitter control: COM5 at location 320h........5-10

Table 5-15 RS-485 termination select jumper: W1 ..............................5-10

Table 5-16 RS-485 and TTL interfaces ..................................................5-10

Table 7-1 Video BIOS disabling and enabling options in SETUP

(C0000h-C7FFFh, C8000h-CFFFFh ROM Enable).............7-4

Table 8-1 SSD0 device selection jumpers: W5, W2[7-8]........................8-1

Table 8-2 Selecting an SSD BIOS: W2[5-6] ..........................................8-2

Table 8-3 SSD0 device configuration: W5, W2[7-8]..............................8-4

Table 8-4 Battery connector: J8.............................................................8-4

Table 10-1 Interrupt status port (ISP) map setting

at I/O location 0A9h..............................................................10-4

Table 11-1 EZ I/O connector: J11 ..........................................................11-2

Table 11-2 EZ I/O pull-up/pull-down jumpers: W3 ..............................11-2

Table 11-3 EZ I/O port address...............................................................11-3

Table 11-4 Reading the EZ I/O port .......................................................11-4

Table 11-5 EZ I/O port byte ....................................................................11-5

Table 11-6 EZ I/O opto-rack interface..................................................11-10

Table 12-1 Ethernet LEDs ......................................................................12-1

Table 12-2 Additional error codes for Phoenix BIOS ............................12-4

Table 13-1 Video controller and associated CRT, flat panel,

and PC-video circuitry ..........................................................13-2

Table 13-2 Flat panel interface voltage select: W8 ..............................13-7

Table 13-3 Inverted shift clock signal voltage level select: W9 ...........13-8

Table 16-1 Ethernet LEDs ......................................................................16-1

Table 22-1 Remote suspend/resume: J10............................................22-14

Table 22-2 Enhanced mode, CPU clock speed: W2[3-4] .....................22-16

Table A-1 PC-500 memory map ............................................................. A-3

x

Page 16

PC-500 user’s manual Contents

Table A-2 PC-500 I/O map...................................................................... A-4

Table A-3 I/O map (Latched registered outputs via OctaGlue:

Address at X0A8h) ................................................................. A-5

Table A-4 I/O map (Configuration inputs via OctaGlue:

Address at X0A9h) ................................................................. A-5

Table A-5 COM1 available addresses.................................................... A-5

Table A-6 COM2 available addresses.................................................... A-6

Table A-7 Available LPT1 port addresses ............................................. A-6

Table A-8 TTL and RS-485 interface: W1 ............................................ A-6

Table A-9 RS-485 termination select jumper: W1 ............................... A-6

Table A-10 BIOS and boot option jumper: W2....................................... A-7

Table A-11 EZ I/O pull-up/pull-down, user option jumper: W3 ............ A-7

Table A-12 Auxiliary option jumper: W4................................................ A-7

Table A-13 SSD0 device configuration: W5............................................ A-8

Table A-14 Flat panel voltage select: W8 ............................................... A-8

Table A-15 Inverted shift clock signal voltage level select: W9 ............ A-8

Table A-16 PC/104 signal assignments: J1 ............................................ A-9

Table A-17 Keyboard connector: J2 ...................................................... A-10

Table A-18 Mouse connector: J3............................................................ A-10

Table A-19 Speaker connector: J4......................................................... A-10

Table A-20 Flat panel connector: J5 ..................................................... A-11

Table A-21 VGA connector: J6............................................................... A-11

Table A-22 PC video connector: J7........................................................ A-12

Table A-23 Battery connector: J8.......................................................... A-12

Table A-24 Ethernet connector: J9........................................................ A-13

Table A-25 OPTOA and OPTOB: J10................................................... A-13

Table A-26 EZ I/O connector: J11 ......................................................... A-13

Table A-27 SCSI connector: J12............................................................ A-14

Table A-28 AT and industrial serial for COM1 and COM2: J13........ A-15

Table A-29 AT and industrial serial for COM3 and COM4: J14........ A-15

Table A-30 Floppy drive connector: J15 ............................................... A-16

Table A-31 LPT1 as printer connector: J16 ......................................... A-16

Table A-32 RS-485 and TTL interfaces for COM5: J17 ...................... A-17

Table A-33 IDE hard rive connector: J18 ............................................. A-17

Table A-34 Power connector: P8, P9 ..................................................... A-18

Table D-1 PC-500 mating connectors ....................................................D-1

Table D-2 Cables and terminal board....................................................D-2

Table D-3 Memory devices......................................................................D-2

Table D-4 LCD displays and keypads....................................................D-3

Table D-5 Opto rack and modules..........................................................D-3

Table D-6 Miscellaneous part numbers .................................................D-3

xi

Page 17

Contents PC-500 user’s manual

xii

Page 18

PC-500 user’s manual Abbreviations and terms used in this manual

Abbreviations and terms used in

this manual

Throughout this manual, the following symbols and terms are used:

Autoexecution Automatic execution of a program on powerup or

reset.

BIOS Basic Input Output System. Detailed instructions

that activate peripheral devices. See ROM-DOS.

BIOS drive The solid-state disk which contains the system BIOS

and ROM-DOS.

bpp bits per pixel

Console port Video card or COM1 where BIOS and DOS messages

appear and keyboard input is available.

DRAM Dynamic Random Access Memory devices. DRAMs

provide volatile memory with unlimited read and

write cycles.

Expansion card The expansion cards add I/O functions to the Micro

PC system, such as analog input/output, digital

input/output, motion control, and display.

EZ I/O This digital I/O chip supplies 24 I/O lines which can

be individually programmed as 5V input or 5V

output.

Flash Electrically erasable PROM which allows at least

100,000 write cycles.

h The suffix “h” denotes a hexadecimal number. A

decimal number has no prefix or suffix. For ex-

ample, 1000h and 4096 are equivalent.

KB Kilobyte (1,024 8-bit bytes).

MB Megabyte (1,048,576 8-bit bytes).

Memory device The type of static RAM, DRAM, flash memory, or

EPROM specified for either volatile or nonvolatile

memory.

PC/104 An expansion bus used for holding 8- and 16-bit

expansion expansion cards.

PC SmartLINK A serial communications software package designed

by Octagon for use with the PC-500 single board

computer. Refers to all versions of PC SmartLINK.

xiii

Page 19

Abbreviations and terms used in this manual PC-500 user’s manual

PC Video A feature on the PC-500 which imports an external

video source into the virtual graphics array (VGA)

system. This feature allows for advanced video

connections including video overlays.

PICO FA Phoenix’s flash file system used to access SSDs from

DOS as a read/write DOS drive.

ROM Read Only Memory devices. ROMs provide nonvola-

tile memory, have a limited number of write cycles,

and include EPROMs and EEPROMs.

ROM-DOS Operating system included in Micro PC ROM.

Single board A printed circuit board that contains a complete

computer computer: CPU, memory, I/O, and clock. The single

board computer controls the operation of all the

expansion cards.

Solid-state disk A simulated disk which uses a high speed solid-state

(SSD) memory device. For example, flash memory,

EEPROM, or static RAM.

Static RAM Static Random Access Memory device. Static RAMs

provide volatile memory with unlimited read and

write cycles. They may be used with a backup

battery.

TTL compatible Transistor transistor logic compatible; 0-5V logic

levels.

Virtual drive A disk created in DOS or extended memory which

emulates an actual disk. The virtual drive provides

temporary storage for files. When power to the

computer is turned off the virtual drive disappears.

W[ - ] Denotes a jumper block and the pins to connect.

XMODEM A communications protocol which allows transfer of

files between two computers.

XON/XOFF A communications protocol for asynchronous connec-

tions. The receiver can pace the sender by sending

the XOFF and XON characters to stop and continue

the data flow.

+5V Safe +5V at the I/O connectors that is protected by a

0.75A fuse.

xiv

Page 20

PC-500 user’s manual Conventions used in this manual

Conventions used in this manual

This section explains the format used for notes, warnings, and command

entry.

≡ Notes and warnings

Special notes and warnings appear in this manual. Each one has a

different meaning and format. They are as follows:

Note A note is supplementary or background information. At other times, it

is a hint or reminder that makes a task easier or quicker.

WARNING!

A warning gives vital information. Failure to heed a warning may cause system failure, equipment damage, or bodily

harm to the system operator.

≡ Command format and procedures

For some commands, you will only enter a single keyword (for example,

reset). For most commands, however, you will enter several keywords

followed by one or more parameters for which you must supply values.

Commands must be entered in a specific format. To indicate the format,

this manual uses a series of conventions that are explained below. The

conventions cover the rules for issuing all commands, including the most

complex ones. Most commands, however, are much simpler.

The command format looks like this:

command [type_this | or_ this] input {optional_input}

Follow these rules and conventions:

n Information which appears on your screen is shown in a different

type face, for example:

PhoenixBIOS(TM) A486 Version 1.03

Copyright (C) 1985-1994 Phoenix Technologies, Ltd.

All Rights Reserved

Octagon Systems Corp. PC500 CPU

n Commands that you must key in are shown in Courier Bold, for

example:

C:> RESET

xv

Page 21

Conventions used in this manual PC-500 user’s manual

n Italicized refers to information that is specific to your particular

system or program, e.g.,

Enter filename means enter the name of your file.

n Paired angle brackets are used to indicate a specific key on your

keyboard, e.g., <ESC> means the escape key; <CTRL> means the

control key; <F1> means the F1 function key.

n All addresses are given in hexadecimal, for example, 328h.

xvi

Page 22

PC-500 user’s manual About this manual

About this manual

The PC-500 user’s manual provides information about installing and

configuring the PC-500. This manual is divided into four sections:

n Section 1 – Installation

Chapter 1: Overview

Chapter 2: Quick start

Chapter 3: SETUP programs

Chapter 4: Save and run programs

n Section 2 – Hardware

Chapter 5: Serial ports

Chapter 6: LPT1 parallel port

Chapter 7: Console devices

Chapter 8: SSDs, DRAM, and battery backup

Chapter 9: External drives

Chapter 10: IRQ routing and opto IRQs

Chapter 11: EZ I/O

Chapter 12: LED signaling and “beep” codes

Chapter 13: CRTs and flat panels

Chapter 14: PC/104 expansion

Chapter 15: SCSI

Chapter 16: Ethernet

n Section 3 – System management

Chapter 17: Watchdog timer and hardware reset

Chapter 18: Serial EEPROM and CMOS RAM

Chapter 19: Transferring files/remote disks

Chapter 20: Managing SSDs

Chapter 21: User-defined jumper

Chapter 22: CPU power management

Chapter 23: Troubleshooting

n Section 4 – Appendices

Appendix A: Technical data

Appendix B: Software utilities

Appendix C: Third party support

Appendix D: Accessories

Page 23

About this manual PC-500 user’s manual

Page 24

PC-500 user’s manual Overview of Section 1

Overview: Section 1 – Installation

Section 1 provides installation and programming instructions, startup

options, and system configuration program examples. The following

chapters are included:

Chapter 1: Overview

Chapter 2: Quick start

Chapter 3: SETUP programs

Chapter 4: Save and run programs

Page 25

Overview of Section 1 PC-500 user’s manual

Page 26

PC-500 user’s manual Overview

Chapter 1: Overview

≡ Description

The PC-500 Mobile Industrial Computer™ (MIC) is a high performance,

single board PC in Octagon’s semi-custom product line. The PC-500

integrates serial communication, industrial digital I/O, a floppy and

local bus hard disk port, a multifunctional parallel port, and a local bus

video which supports monitors and flat panels. This single board computer has an interrupt routing matrix, two solid-state disks, a PC/104

interface, a SCSI-2 interface host port, and a 10Base-T Ethernet port.

The PC-500 also supports various CPU types including 586/133 MHz

and can have up to 16 MB of on-board DRAM with an expansion of

48 MB by adding a 32 MB DIMM module. This board is supplied with

DOS 6.22 in ROM but will also execute other operating systems such as

Windows™, Windows NT™, and QNX

same functional blocks as the Micro PC™, the circuitry has been fully

proven as reliable and the software is compatible with the software in

the Micro PC series.

®

. Since the PC-500 uses the

Specified to your engineering needs, the PC-500 can be ordered as a

semi-custom board in OEM quantities. The stocked version of the

PC-500 is listed below with the standard and optional features. The

standard version can be used for system development and an optional

version of the PC-500 is usually application specific.

≡ PC-500 major hardware features

CPU

The high performance 586 CPU comes in two versions. One version is a

120MHz586 and the other is a 133MHz586. Both versions operate at

3.3V for low power consumption. The PC-500 has a local bus speed of

33 MHz and an ISA bus speed of 8.33 MHz.

Up to 48 MB DRAM

The standard unit is supplied with 1 MB of fast, EDO surface mount

DRAM. The use of EDO DRAM increases performance by 20% which, in

most cases, eliminates the need for an expensive L2 cache. The PC-500

can contain up to 16 MB of on-board DRAM. Up to 32 MB of additional

DRAM can be added through an optional DIMM module, which makes a

total of 48 MB DRAM. Two holes are on-board the PC-500 to secure the

DIMM module in high vibration environments. All surface mount

1-1

Page 27

Overview PC-500 user’s manual

DRAM and DIMM modules from Octagon meet the full PC-500 temperature range. Customers who need a 0° to 70°C range can install

commercially available DIMM modules onto the PC-500.

n 1 MB EDO surface mount standard

n 16 MB EDO surface mount optional

n SO-DIMM socket installed standard

n SO-DIMM socket not installed optional

Solid-state disks

SSD0

A 32-pin DIP socket accepts either a 5V flash, SRAM, or 512 KB/1 MB

EPROM. The socket exhibits high retention force and affords a gas

tight contact. SSD0 optionally contains the BIOS drive and ROM-DOS

6.22 in ROM. By default, the optional SSD0 contains a 192 KB backup

BIOS with a 320 KB or a 512 KB drive area. Flash file system software

is included which allows the SSDs to emulate hard disk operation.

SSD0 options include:

n SSD0 socket installed standard

n SSD0 socket not installed optional

n SSD0 socket/EPROM installed optional

For information on changing the device type, refer to the W5 SSD0

table in the Quick start chapter. You can also install compatible

PROMs into SSD0 through the supplied utility programs found on the

PC-500 utility disk. You can format the flash while in the socket.

EPROM usage, however, requires off-card programming from either a

master flash or a master EPROM.

SSD0 also supports a battery back up voltage. The PC-500 is capable of

supplying a battery voltage to SSD0 with SRAM installed.

SSD1

SSD1 is used for storage of the applications program. A standard 2 MB

5V flash is soldered on-card. The flash programmer is built-in which

allows on-card programming of the device. The PC-500 includes flash

file system software, which permits the SSDs to emulate hard disk

operation. Automatic “wear leveling” ensures that no single section of a

chip will reach its life span (100,000 times), while other sections will

scarcely be used. A 1 MB device reserves 192 KB for BIOS and 832 KB

for a drive area, a 2 MB device reserves 192 KB for BIOS and 1856 KB

for a drive area.

1-2

n 2 MB EPROM standard

n 1 MB EPROM optional

n SSD1 not installed optional

Page 28

PC-500 user’s manual Overview

Serial ports protected against ESD

The PC-500 can have either two or five serial ports. All five serial ports

are standard, while COM3 through COM5 can be optionally omitted

from the PC-500. COM1 through COM4 are RS-232 and have the full

8-wire PC signal or they can optionally have 4-wire industrial RS-232

serial port lines. The 4-wire industrial RS-232 lines support RxD, TxD,

RTS, CTS and the DTR pin with a 1K pull-up to 5V. The interface to

COM5 is 2-wire industrial RS-485 also configurable to 2-wire TTL.

COM1 through COM5 have the following specifications:

n IEC1000, level 3, ESD protection specification

— Contact discharge ±6 kV

— Air-gap discharge ±8 kV

n Backdrive protection

n 16C550 compatible

n Up to 115.2K baud

n 16 byte FIFO buffers

n RS-232 voltages generated on-card

n COM1 through COM5 standard

n Omission of COM3 through COM5 optional

Local bus SVGA, flat panel interface, and GUI accelerator

The video system on the PC-500 uses the advanced 65550 video chip

from Chips & Technologies. It supports CRT, LCD and EL displays

with resolutions to 1024 x 768 bpp. Displays from CGA through SVGA

are supported. The 65550 is also a graphics accelerator with real time

PC-video being supported. Since the video circuitry operates on the

local bus at the full processor speed, programs like Windows execute

very rapidly. The video section has 2 MB of video RAM for high resolution displays and simultaneous CRT and flat panel operation.

The PC-500 supports both 3.3V and 5V flat panel displays. It has a 12V

connector for powering the backlighting on the displays and a 3.3V at

100mA connector to power the newer generation displays that use 3.3V

logic.

n Local bus flat panel video present standard

n No local bus flat panel video present optional

Adjustable display bias supply

An on-board voltage converter eliminates the need for a separate bias

supply for the LCD contrast control. The on-board power converter is

factory configurable and can be made to be compatible with most LCD

displays. The standard default range for the power converter is from

+23V to +29V.

n + Bias voltage 23V to 29V standard

n – Bias voltage/other range optional

n No bias supply optional

1-3

Page 29

Overview PC-500 user’s manual

Industrial I/O using EZ I/O

The PC-500 is supplied with 24 lines of industrial I/O, using the Octagon EZ I/O digital I/O chip. Each EZ I/O line is programmable as an

input or output. The lines are 5V compatible and can sink and source

15mA. The EZ I/O port can drive the Octagon MPB series opto-isolation

module (Opto 22, G4 style) racks directly, controlling AC and DC loads

to 240V at 3A.

Speaker, keyboard, and mouse ports

The speaker connector is PC compatible and is a standard feature. The

keyboard controller accepts an AT style keyboard and has a PS-2 type

connector. The keyboard port is standard. The mouse port is optional

and conforms to the PS-2 standard. Neither the keyboard nor the

mouse are required for operation.

n Mouse port included standard

n Mouse port not included optional

PC/104 16-bit interface

This interface is a standard feature on the PC-500 and accepts an 8- or

a 16-bit PC/104 expansion board. PC/104 expansion boards are available from several manufacturers. As many as three PC/104 expansion

boards may be stacked on the PC-500.

Ethernet

The PC-500 provides a 10Base-T Ethernet port, located at J9. This

interface is a standard feature on the PC-500 and supports the IEEE

802.3 Ethernet standard. The Ethernet controller IC chip provides the

following:

n 16-bit ISA interface

n 4 KB on chip buffer

n Integrated 10 Base-T transceiver interface

n Four LEDs for status and diagnostic purposes

The PC-500 Ethernet interface supports the 10Base-T physical interface. This port operates at 10 MHz and uses twisted-pair wiring cable,

which is built in a star configuration. The 10Base-T physical interface

terminates at the standard, 8-position RJ-45, latching phone jack and is

vertically accessed.

1-4

SCSI

The PC-500 has a SCSI-2 host interface, located at J12. This device is a

16-bit ISA bus compatible part and has a sustained data rate of 10 MB

per second in the fast SCSI-2 synchronous transfer mode. It also has

parity generation and checking, noise filters, a low power mode, and ISA

bus RAM buffers.

Page 30

PC-500 user’s manual Overview

n SCSI-2 host interface, included standard

n SCSI-2 host interface, not included optional

≡ PC-500 major software features

Advanced power management and system management

input

Power management can be used to reduce power consumption or to

freeze the state of the program on the occurrence of a power management interrupt. Power consumption can be reduced by more than 60%.

This reduces the heat load and extends the battery life in mobile applications. There are opto-isolated system management and suspend/

resume inputs with 4-6V ranges. A system management input (SMI)

will cause the PC-500 to save its current status. When the system is

signaled to restart, execution resumes at the point the system last

stopped. The following are functions in the advanced power management and SMI:

n Suspend/resume by SMI input and software — halts CPU

n Wake up through various interrupts including keyboard, SMI

and serial port

n Slow CPU by dividing clock

n Contextual save to disk.

Diagnostic software verifies system integrity automatically

The PC-500 has built-in diagnostic software that can be used to verify

on-card I/O and memory functions. On powerup, a series of tests is

performed. If a problem occurs, the failed test can be identified by the

color sequence on an on-board, bicolored LED. The test is performed

automatically every time the system is reset or powered up. Software,

test equipment, monitor, keyboard, disks, or test fixtures are not required for memory verification. See the LED signaling “beep” codes

chapter for a complete listing of tests and failures and their descriptions.

SETUP information stored in EEPROM for high reliability

Loss of SETUP data is serious in industrial applications. Most PCs

store SETUP information in battery-backed CMOS RAM. If the battery

fails or is replaced during routine maintenance, this information is lost.

Without a keyboard and monitor in embedded applications, time consuming re-initialization is required. The PC-500 stores the SETUP

information in EEPROM with 1,536 bytes available to the user. Software routines to use this available memory come with the PC-500.

1-5

Page 31

Overview PC-500 user’s manual

Phoenix BIOS

The PC-500 has a Phoenix AT BIOS with power management and

Octagon BIOS extensions. The AT BIOS supports up to four EIDE

drives.

“Instant DOS” operating system

Datalight ROM-DOS v6.22 operating system is in flash. This means

that this version is always present on powerup. The system boots and

operates the same way as a desktop PC. Since all software and hardware are included, the system is fully operational “out of the box.”

Programmable video BIOS

The flash contains a video BIOS, which controls the on-board SVGA

controller. To support other flat panels, you can reprogram a new video

BIOS. By default, the video BIOS supports a CRT and Sharp monochrome dual drive flat panel in simultaneous mode.

On-board flash file system

The Phoenix PICO FA flash file system controls the on-board SSDs,

which allows read/write DOS access to the flash/SRAM. SSD0 can also

use EPROM. For certain types of flash, the flash file system uses “wear

leveling” to spread the usage and maximize the lifetime of these devices.

Octagon BIOS extensions

On-board BIOS extensions allow easy access to digital I/O, serial

EEPROM, LCD bias control, watchdog timer functions, etc.

Interrupt routing: In system and programmable

Software is on-board the PC-500 to change the interrupt routing and

some other features. The software allows more flexible use of interrupts on the PC-500 and outboard systems such as PC/104 expansion

boards.

Floppy and hard disk ports

The floppy disk port supports two drives with either 720 KB or 1.44 MB

capacities. The floppy port is terminated with a 34-pin IDC connector.

The EIDE hard drive port is terminated with a 44-pin, 2 mm connector.

+5V is supplied to the hard drive through the EIDE connector and is

optionally supplied to the floppy drive through the IDC connector.

1-6

Page 32

PC-500 user’s manual Overview

Boot sequence

A PC-500 can be configured to boot from the on-card, solid-state disk, an

external floppy or hard disk.

Multifunctional printer port

The PC-500 incorporates the latest enhanced parallel port.

n Unidirectional

n Bidirectional

n IEEE 1284, ECP and EPP modes

n 24 mA of drive current

n Backdrive protection

The following represent applications in the multifunctional parallel port:

n LPT1 for PC compatible printers

n 17 general purpose digital I/O lines

n Up to a 4 x 4 matrix keypad

n 4-line alphanumeric display

n MPB-16PC, 16-position opto-module rack.

Watchdog timer added for safety

The watchdog timer resets the system if the program stops unexpectedly. The watchdog is enabled, disabled and strobed under software

control. The time-out is 1.6 seconds (typical).

Real time calendar/clock with battery-backup

The real time clock is fully AT compatible and uses the standard DOS

calls. An optional off-card battery powers the real time clock when the

5 volt supply is removed. A connector is provided for the external battery. The real time clock also provides the user with 128 bytes of userdefined CMOS-RAM.

I/O connectors

With the exception of the mouse, keyboard, and IDE, all I/O connectors

can be latched to prevent connector movement during shock or high

vibration.

Keypad and LCD display support for low cost operator

interface

For embedded applications, the parallel printer port or the EZ I/O port

can interface with a 16-key matrix keypad and a 2- or 4-line LCD display. The PC-500 is supplied with software that provides keypad scanning and display operation. Supplied display and keypad drivers in C

support these devices.

1-7

Page 33

Overview PC-500 user’s manual

Hardware reset

A hardware reset can be done by any of the following methods:

n Issuing the RESET software command (using the watchdog

function)

n Depressing the reset switch

n Cycling power

n Configuring the opto channel for RESET.

A hardware reset ensures complete reset of the system and all attached

peripherals. An expired watchdog timer cycle also causes a hardware

reset to occur.

5 Volt operation lowers system cost

The PC-500 operates from a single 5V ±5% supply. Located across the

power supply, the 6.2V, 5W zener diode protects against reverse voltage

and limits over voltage. The power supply generates the RS-232 voltages

on-board. The locking power connector is a standard PC power header

connector.

n 5V ±5%, 1.0A to 2.0A (dependent upon processor, speed and I/O

devices), less than 500 mA in standby

n +12V, -12V and -5V supplied to PC/104 connector and display

connector, not required for PC-500 operation

n A standard PC power supply may be used. See the Power supply

requirements section in the Quick start chapter for more information

on power supply selection and criteria.

Rugged environmental operation

n Operating temperature -40° to 70°C, operating with

adequate airflow

n Nonoperating temperature -55° to 90°C, nonoperating

n Relative humidity 5% to 95% noncondensing

n Altitude -100 to 10,000 m

n Shock 10g, 3 axis

n Vibration 3g, 3 axis

Note Forced air cooling is required above 45°C if power management is not

used.

1-8

Size

5.75" x 8.0" x 0.9375"

Page 34

PC-500 user’s manual Quick start

Chapter 2: Quick start

This chapter covers the basics of setting up a PC-500 system and tells you:

n How to install and power on the PC-500 and run a demo program

n How to use a serial console instead of the on-board SVGA video.

Follow the mounting procedures for the PC-500. To establish a serial

console link, go to the Serial console section in the Console devices chapter.

≡ Installing the PC-500

To install the PC-500 you will need the following equipment

(or equivalent):

n PC-500 Mobile Industrial Computer

n +5V power module

n AT compatible keyboard with PS/2 connector

n VGA monitor

n VGA-12 cable

1. Refer to the PC-500 component diagram (Figure 2-1) for the location of

various connectors, before installing your PC-500 system.

WARNING!

The PC-500 Mobile Industrial Computer contains static sensitive CMOS components. Do the following to avoid damaging

your card and its components:

nn Ground yourself before handling the PC-500 card

nn Disconnect power before removing or inserting a PC/104

expansion board

nn When programming a memory device, place the device in

the socket before applying power.

Hardware components required to mount the PC-500 (not included):

n 8 threaded hex stainless steel standoffs (4-40 x 3/8")

n 8 screws (4-40 x 1/4")

n 8 internal star lock washers (4-40)

2. Use the #4 standoffs, washers, and screws and place them in the eight

holes on the PC-500 board. Refer to Figure 2-2 for the center-to-center

mounting hole dimensions and for the location of the designated holes used

for mounting the hardware.

2-1

Page 35

Quick start PC-500 user’s manual

Figure 2-1 PC-500 component diagram

2-2

Page 36

PC-500 user’s manual Quick start

Figure 2-2 PC-500 center-to-center hole dimensions

2-3

Page 37

Quick start PC-500 user’s manual

WARNING!

Before the PC-500 is powered on for bench testing, all eight

standoffs, screws and washers should be secured to the

board. The standoff pieces will ensure full support of the

PC-500 not only on all four sides, but also in the middle of

the board. These hardware pieces will reduce the circuit

board flex when the PC/104 expansion board and/or the SSD0

are inserted. Flexing of the PC-500 board should be avoided,

since it can cause problems with the copper circuit traces

Figure 2-4 PC-500, keyboard, and monitor and the surface

mounted components.

3. The power supply connector is located at P8, P9. Make certain to connect the ground wires (typically black) to all ground connectors at P8,

P9 on the PC-500. Refer to Figure 2-3.

WARNING!

Accidently crossing the wires, i.e., plugging +5V wires into

the ground connector or the ground wires into the +5V connector will damage the PC-500.

Figure 2-3 Power connector: P8, P9

Note By removing the keys on the PC-500, it is possible to key your power