Page 1

octagon v2.16 Page 1

OCTAGON

USER GUIDE

Pellet Burner

Series Octagon

Model bio 3 – Fbio 3

3’’

Page 2

octagon v2.16 Page 2

Page 3

octagon v2.16 Page 3

CONTENTS

SECTION

CONTENTS

PAGE

1

Letter of thanks

3 2 Instructions for use

4 3 Burner’s operating principles

5 4 Burning phases

7 5 Choosing the right burner

8 6 Safety rules

9

6.1

Safety installation instructions to licensed technicians

9 7 Package

10

7.1

Package contents

11

7.2

Pellet burner parts

12 8 Spare parts

13 9 Burner fuel

15

9.1

Technical characteristics of wood pellet according ΕΝ 14961-1

16

10

Fuel feeding - Auger

17

11

Fuel tank

18

12

Burner installation

19

12.1

Installation steps

19

13

Electrical installation - Sensors

20

14

Burner display screen

21

15

1st level - Configuration of the burner

22

15.1

Display symbols and keyboard buttons

22

15.2

Basic configuration of burner

24

15.2.1

Power rating

24

15.2.2

Boiler water temperature

25

15.2.3

Fuel

25

15.2.4

Time

26

15.2.5

Programming

26

15.2.6

Filling of the auger

26

16

2nd level - Configuration of the burner

28

16.1

Access to programming

28

16.1.2

Display of individual parameters of combustion regulation

29

17

Power adjustment of burner

30

18

Troubleshooting

32

18.1

Additional error notifications

33

19

Tables

34

19.1

Table 1, Configuration values, Auger-Fan with pellets of category 2

34

19.2

Table 2, Table of Parameters

36

20

Maintenance and checks to be performed by end user

37

21

Warranty

38

22

Maintenance log

40

23

Brief instructions for initial adjustments and operation

41

24

Certificates

43

25

Quality control checklist

44

Page 4

octagon v2.16 Page 4

Page 5

octagon v2.16 Page 5

1. LETTER OF THANKS

Thank you for choosing the pellet burner of OCTAGON.

We would like to reassure you for the high quality of our product which we trust will

fully satisfy your requirements.

OCTAGON will always be at your service maximizing the value of your purchase.

For a better future,

more sustainable,

more affordable.

Please read carefully the section under the heading “OPERATION OF THE BURNER” to

ensure proper understanding of the operating principles of the pellet burner.

Management & Production of OCTAGON

Page 6

octagon v2.16 Page 6

2. INSTRUCTIONS FOR USE

The device can be used by persons over eighteen (18) years of age with full physical, neurological

and mental capabilities and persons with no previous experience and skill or persons being

trained for the use of the device but always under the supervision of person responsible for their

safety.

Do not allow children to play with the device.

The cleaning of the device should not be done by children without the supervision of an adult.

Page 7

octagon v2.16 Page 7

3. BURNER’S OPERATING PRINCIPLES

First start

The pellet burner has predetermined configurations of maximum and minimum power rating by

the manufacturer.

The authorized trained technician who will fire up the burner has the option – if necessary – to

reduce the maximum power of the burner to fit the power of the boiler or a specific user’s

requirement.

Operation of the burner

First check

Once the start command is given by the user, the burner performs a series of checks to the

whole system in order to ensure that all parameters permit its smooth and safe start.

To this effect the burner checks immediately a number of parameters e.g. the water

temperature or the exhaust gas temperature. The values of all parameters should be within a

predetermined and acceptable range as indicated by the manufacturer to enable start of the

burner.

Combustion of the burner

After the controller performs the first check, the auger feeds the pellet burner with a specific

quantity of pellet and ignition is generated with the use of an electrical heating element.

Burning

When the flame sensor “detects” - within a specific time frame - that the flame’s intensity is

sufficient then the pellet burner will proceed to the BURNING PHASE aiming to the maximum

power level.

Should the flame sensor does not confirm the required intense of flame within the specific time

frame then the starting process is stopped and an “error” notification is displayed which is

accompanied with the code diagnosing the type of error (see §18 “Troubleshooting”).

Page 8

octagon v2.16 Page 8

The innovation of Octagon pellet burner bio lies with two crucial elements relating to

combustion:

a. The operation of the burner is totally proportional, within the predefined parameters,

subject to automatic adjustment of the level of power (self adjustment). In this way the

pellet burner will provide always the power required by the system and will achieve the

maximum possible fuel economy

And,

b. The pellet burner will control the burning process by the constant and excellent control

of the boiler’s backpressure and the chimney draft. The control of the fan ensures not

only the extraction of the exhaust gas but mainly minimizes the possibility of “backfire”

from the supply pipe.

Gradual reduction of combustion level

As soon as the burner achieves the predefined water temperature it will automatically reduce its

power so as to remain functional within the set temperature range and below the upper safety

limit. At this point the burner operates with the necessary, minimum power meeting the

required thermal need.

END OF BURNING

The smooth termination of burning is achieved by ensuring the complete burning of any

remaining fuel in the combustion chamber. This is achieved by continuous monitoring of the

flame through the flame sensor which drives the fan that will continue to work in order to burn

all residual pellets in the flame tube.

Thereafter, the fan continues at maximum speed for a period of time so as to clean the burning

chamber from the ashes and preparing it for the next fire up.

Page 9

octagon v2.16 Page 9

4. BURNING PHASES

Everything described in the previous chapter, OPERATING PRINCIPLES, is outlined in the cycle

below which is divided in four sections:

A. FIRE UP, yellow colour

The burner checks whether there is flame in the burning chamber, in case of a KEEP FIRE status,

so as to offer the minimum required power to the system. Whatever the status of the burning

chamber may be, the burner will proceed with full ignition of the fuel intensifying the flame until

the threshold of burning phase is reached.

B. BURNING

The power of the burner rises progressively whilst it performs constant checks to all parameters

of the combustion in order to allow the maximum desired thermal performance with utmost

economy.

C. FIRE DOWN

When the water temperature approaches the set threshold then the burner regulates POWER to

achieve balance in the system. Gradually, the reduction in burning will lead the system to KEEP

FIRE or OFF status.

D. KEEP FLAME OR OFF

The burner at this phase is put in stand-by mode either turned off or keeping the flame. In both

cases it can be put back to FIRE UP status.

OCTAGON Hellas

Page 10

octagon v2.16 Page 10

5. CHOOSING THE RIGHT BURNER

In order to make to right choice of burner - both technically and practically - you need to take

under consideration certain basic parameters:

1. The burner is designed to burn wood pellets ONLY. The use of any other type of pellet

such as agro-pellets (pellet made of agricultural by-products) without the approval of the

manufacturer is explicitly prohibited.

2. Make sure that your boiler is designed to burn pellets. The manufacturer of the boiler

will indicate the appropriate type of fuel and will provide relevant information for proper

combustion including the following:

Output power for the particular fuel. This should be equal to or less than the

maximum rated power of the burner as indicated on the name plate of the burner.

Minimum chimney draft.

Regulation of the burner’s damper.

Exhaust gas temperature.

3. Additionally, please note that:

The minimum capacity of the combustion chamber should be 0,06 m

3

in respect of

models bio 2 and 1 and 0,12 m3 in respect of model bio 3 in order to achieve the

maximum power of the burners.

For the unhindered opening of the boiler door both the door and the burning

chamber of the boiler should have minimum width as follows:

o Thirty (30) cm in respect of model bio 2

o Forty (40) cm in respect of model bio 3

The minimum length of the burning chamber should be:

o Forty (40) cm in respect of model bio 2

o Fifty two (52) cm in respect of model bio 3

The length of the flame should be at least five (5) cm below the above mentioned

values.

The space in front of the boiler should be free in an arc 90° towards the same

direction to which the door opens and at a distance of at least a hundred (100) cm to

ensure unhindered door opening when necessary.

The burner should be installed ONLY in horizontal position.

POINTS TO REMEMBER

The technician responsible for the installation and the first fire up of your burner is

obliged to provide you with a “Combustion Certificate” which includes the following:

The type of the burner

The type of the boiler

The exhaust gas temperature

The content in CO and CO2.

Page 11

octagon v2.16 Page 11

6. SAFETY RULES

The pellet burner is an electric/electronic device that operates with 230 V – 50 HZ. According to

applicable legislation its installation, connection, regulation, operation and service should be

done by trained personnel authorized by the local authorities.

It is expressly forbidden for anyone to modify parameters of 2nd level of configuration except for

trained licensed technicians.

The private individual and end user of the pellet burner may operate and adjust the burner ONLY

in so far as the basic commands of the burner are concerned and ONLY using the display and

programming touch screen situated on the metal casing of the pellet burner.

6.1. SAFETY INSTALLATION INSTRUCTIONS TO LICENSED TECHNICIANS

Please ensure that the boiler standards comply with applicable legislation. The boiler must be

connected with the hydraulic system and the chimney.

Measure the chimney draft and make sure that it is in line with the requirements of the

manufacturer of the boiler.

Please adhere to all instructions concerning start up and make sure to use only approved and

certified materials.

Never open the door of the boiler while the burner is in operation.

The burner conforms to European Directive ΕΝ 15270

and is CE marked.

ATTENTION

Always ensure that the boiler’s flame damper is

open to allow optimum level of draft.

NEVER fire up the burner when the flame damper

is closed as there is serious DANGER of the flame

returning to the burner.

Page 12

octagon v2.16 Page 12

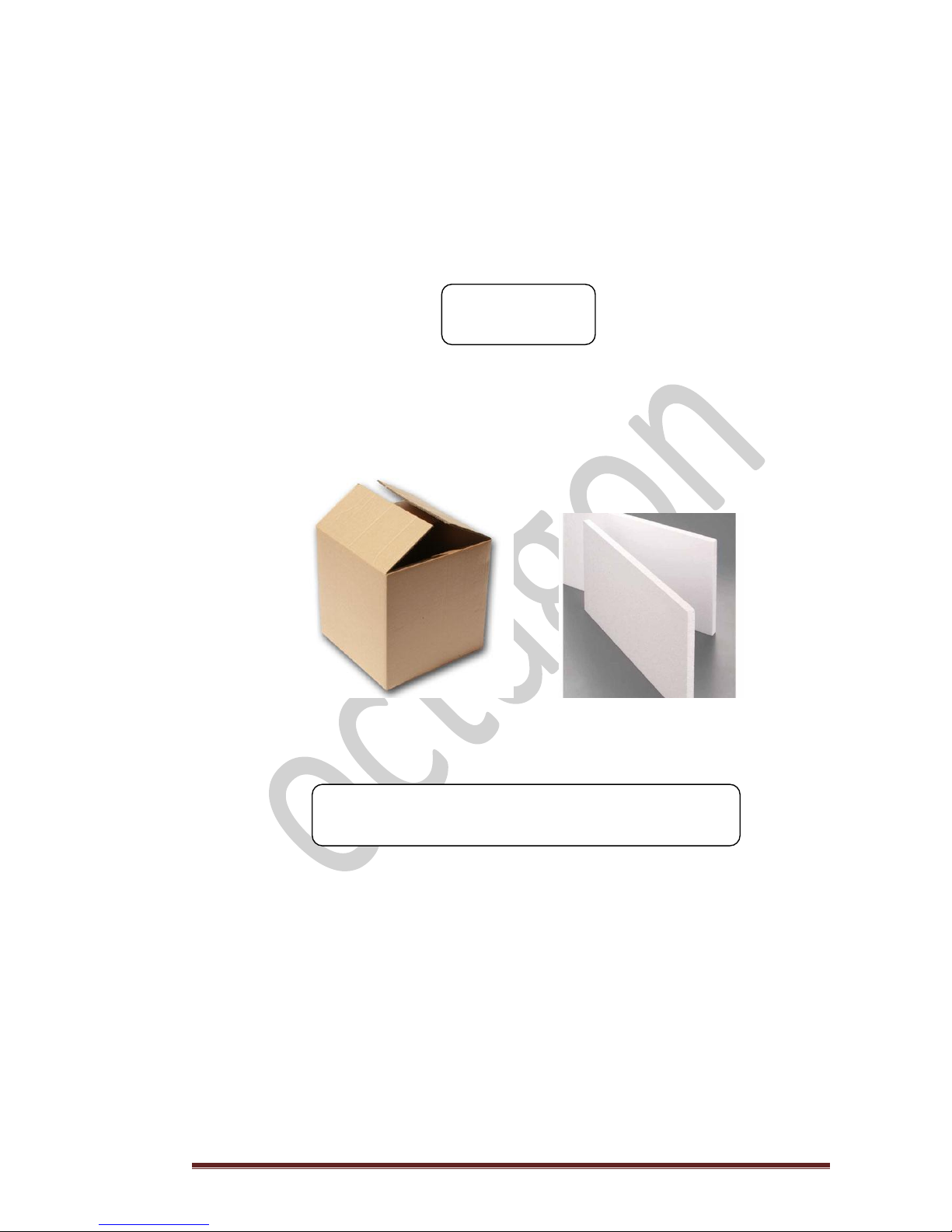

7. PACKAGE

The pellet burner will be packed in hard cardboard box of dimensions 60 cm X 40 cm X 40 cm

(Length / Width / Height) and will bear an adhesive label showing the model of the burner as

follows:

Model

Special care is given to the packing of the burner to make sure that it will be delivered to you

safely and free of any damage. The product is wrapped in thick polystyrene sheets and placed in

a plastic bag.

ALWAYS STORE THE PACKED PELLET BURNER IN CORRECT

HORIZONTAL POSITION AWAY FROM MOISTURE.

bio 2

Page 13

octagon v2.16 Page 13

7.1 PACKAGE CONTENTS

Each package contains:

o A user guide manual with information in respect of installation,

operation and maintenance.

o A burner with its metal casing and the display screen, connected with its

stainless steel burning chamber.

o A stainless steel pipe 2” for the feeding of the fuel.

o A certificate of quality control including the date of production of the

burner at the last part of the manual.

T h e a u g e r i s s u p p l i e d t o g e t h e r w i t h e a c h b u r n e r .

FOR SAFETY REASONS THE DISPLAY SCREEN IS NOT

CONNECTED TO THE ELECTRONIC CONTROL UNIT OF THE

BURNER. THE CONNECTION SHOULD BE EXECUTED BY THE

LICENSED TECHNICIAN.

DO NOT FORGET TO CHECK THAT ALL PARTS OF

THE BURNER ARE FIRMLY CONNECTED.

Page 14

octagon v2.16 Page 14

7.2 PELLET BURNER PARTS

The pellet burner consists of the following parts:

1) A steel metallic casing electrostatically painted (green).

2) An electronic display and programming touch screen.

3) A connection cable of the screen to the central control unit.

4) A stainless steel frame body with flange for fixing the burner to the boiler.

5) One (1) centrifugal fan of 40 W.

6) An electronic central control unit (plc).

7) An electric heating element of 250 W.

8) A flame sensor.

9) Electric connector.

10) A stainless steel feeding tube 2” with insulating flange.

11) A bimetallic contact thermostat, STB, with manual reset placed in the 2” stainless steel

feed tube.

12) Three (3) cable glands for the accommodation of the connection cables.

13) A high heat resistant stainless steel flame tube for the combustion of the fuel.

14) A high heat resistant stainless steel combustion rack.

15) A screw to hold the rack.

16) A mineral insulation of twenty five (25) mm for the flange.

17) Internal insulation of five (5) mm for the flame tube to the casing.

18) A boiler water temperature sensor.

19) An exhaust gas temperature sensor.

A metallic auger moving the pellets from the fuel tank to the burner via electric motor

of 50 W.

This is packed with a polyurethane flex hose to be connected with the stainless steel

feeding tube.

Page 15

octagon v2.16 Page 15

8. SPARE PARTS

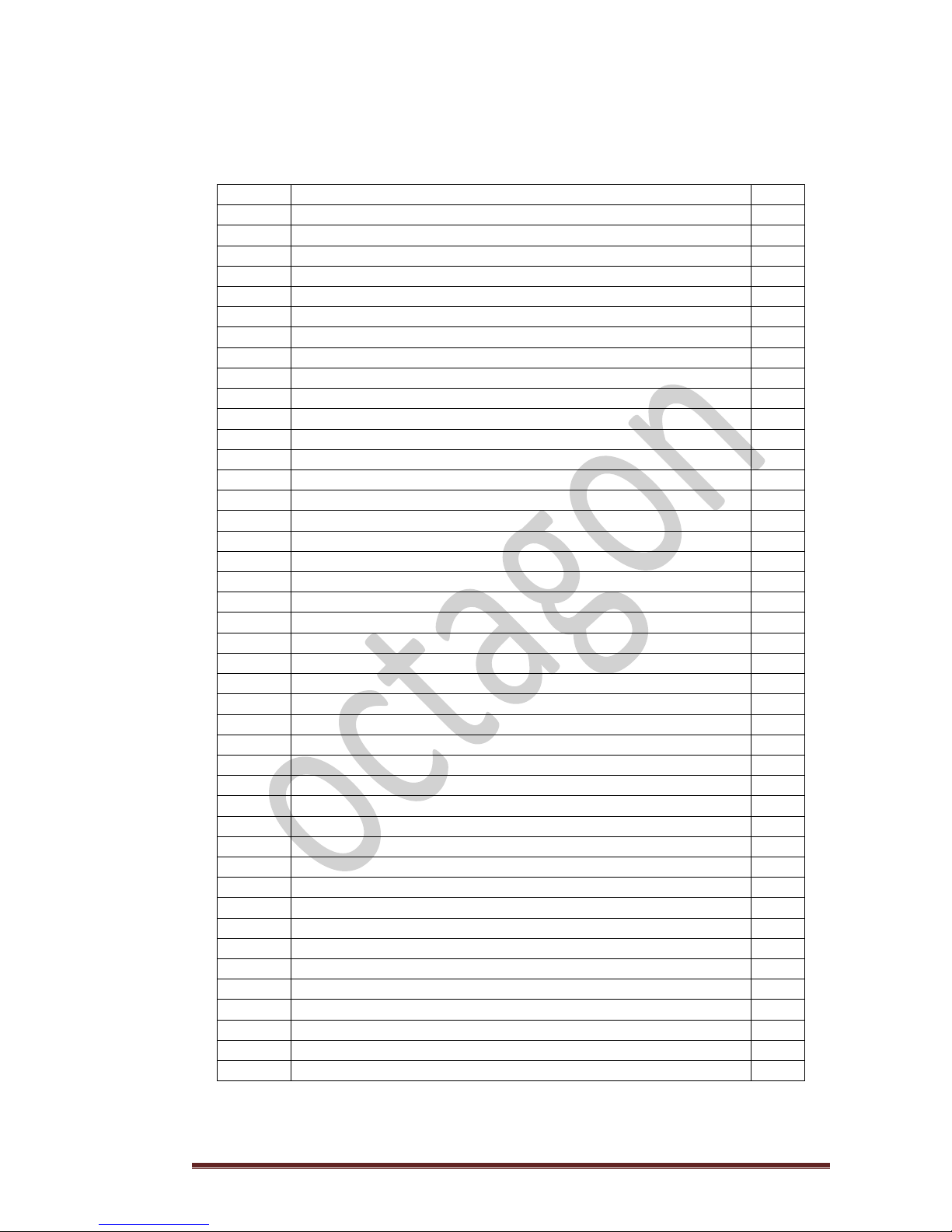

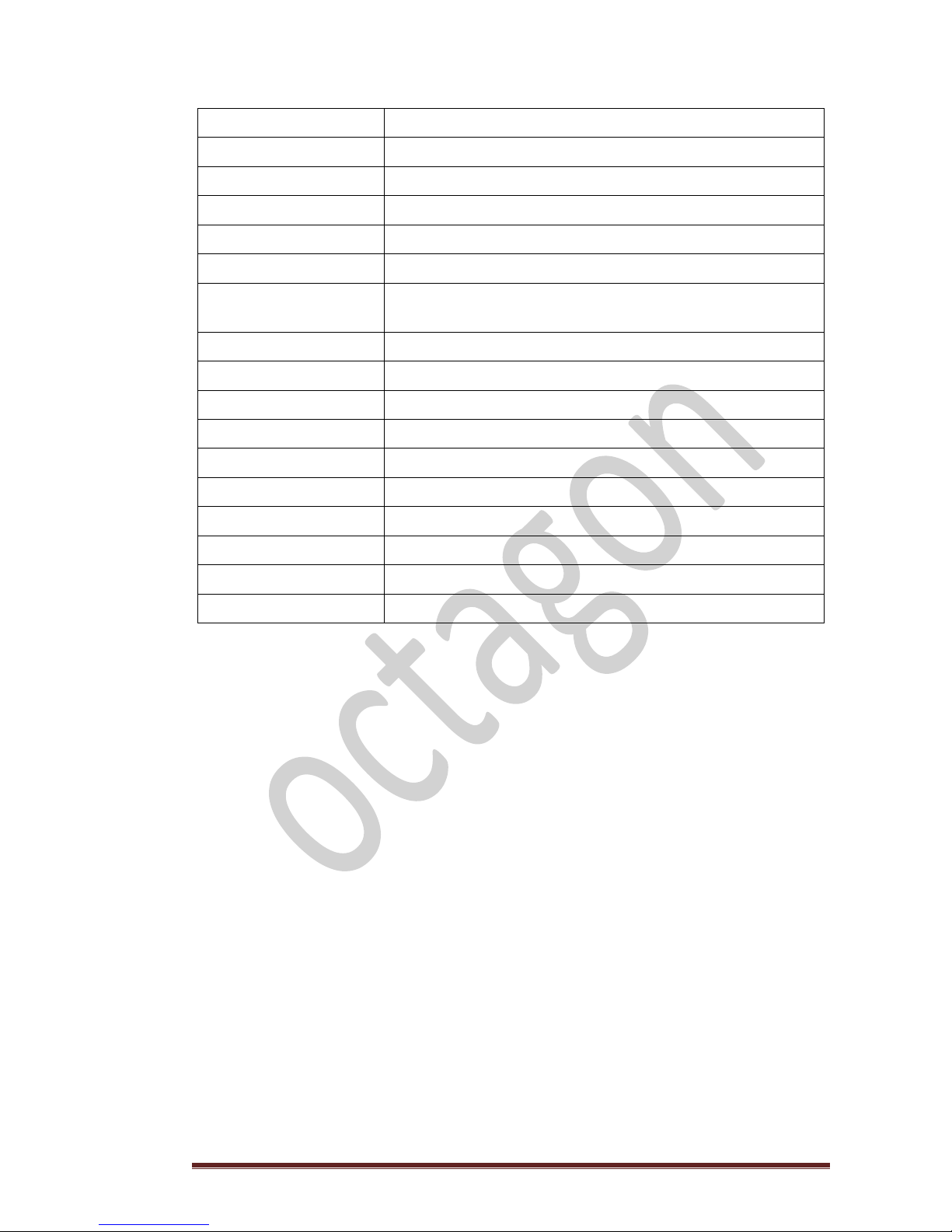

The table herebelow contains a list of spare parts of a pellet burner by OCTAGON HELLAS

including relevant reference numbers. The reference number should be quoted when an order is

placed.

REFERENCE NUMBER

DESCRIPTION OF SPARE PART

Μ001-1001-1

Steel casing of pellet burner bio 2

Μ001-1001-2

Steel casing of pellet burner bio 3

D100-1100-1

Electronic touch screen LCD

D100-1200-1

Connection cable of screen to the central control unit 1 m.

D100-1200-2

Connection cable of screen to the central control unit 2,5 - 5 m.

D100-1300-1

Wall mounted stainless frame for touch screen

Ρ100-1021-1

Plastic frame for touch screen

Μ001-1100-0

Auger set series OCTAGON , 2 1.2''

Μ001-1100-1

Auger set series OCTAGON , 3''

M001-1400-1

Steel casing for auger motor bio2 & bio3

Ρ100-1011-1

PU flex hose feeding pellet 60 mm (diameter) per m

Ε100-1110-10

Auger motor series OCTAGON

Ε100-1030-1

Cable set for auger

Α100-1001-1

High heat resistant stainless steel flame tube for bio 2

Α100-1001-2

High heat resistant stainless steel flame tube for bio 3

Α100-1011-1

High heat resistant grate for bio 2

Α100-1011-2

High heat resistant grate for bio 3

A100-1021-1

Mineral insulation for the flange 25 mm (thickness) for bio 2

A100-1021-2

Mineral insulation for the flange 25 mm (thickness) for bio 3

F100-0101-2

Internal insulation gasket for flame tube 5 mm for bio 2

F100-0101-2

Internal insulation gasket for flame tube 5 mm for bio 3

A100-1101-1

Stainless steel flanged feeding tube 2’’

F100-0101-1

Insulating flange for stainless steel feeding tube 2''

Page 16

octagon v2.16 Page 16

S100-1001-1

Flame sensor BRAHMA , FC 8R

S100-1010-1

Electric heating element 250 W

S100-1020-1

Boiler water temperature sensor

S100-1030-1

Exhaust flue gas temperature sensor 1,5 m (length)

S100-1030-2

Exhaust flue gas temperature sensor 3 m (length)

S100-1050-1

Bimetallic contact thermostat with manual reset, STB , for the

2''stainless steel feeding tube

E100-1110-11

Fan with flange series OCTAGON 40 W

D100-1001-1

Electronic central control unit (plc)

Page 17

octagon v2.16 Page 17

9. BURNER FUEL

The pellet burners of OCTAGON, are designed to burn wood pellets.

The pellets are very small chips of wood along with other logging residues which are compressed

mechanically in order to take a cylindrical shape of around 6 - 8 mm diameter and less than 40

mm of length.

The type of wood used in this process as well as the percentage that each wood contributes to

the final mixture will determine a number of important parameters including the following:

Thermal output (heating power as a value of kW/kg or Kcal/kg or KJ/kg)

Combustion quality (rate of solid residues of burning process)

Cost per kg

The correct regulation of the combustion air in the pellet burner minimizes ash content and

maximizes thermal output. The acceptable rate of ash content is specified by EN 14961-1

(Chapter 7.1, page 14).

It is very important for the proper functioning of the burner as well as fuel economy that the

pellet burner to be fed with certified wood pellet that conforms to European standards and be

supplied from producers who are well established in the market.

The thermal power of wood pellets must be in excess of 4,6 kW/kg so that the final result should

satisfy all the parameters of proper combustion together with your expectations in economy.

DO NOT BUY WOOD PELLETS OF UNKNOWN ORIGIN AND QUALITY.

IT IS TO YOUR BEST INTEREST TO USE ALWAYS THE BEST QUALITY OF PELLETS.

Page 18

octagon v2.16 Page 18

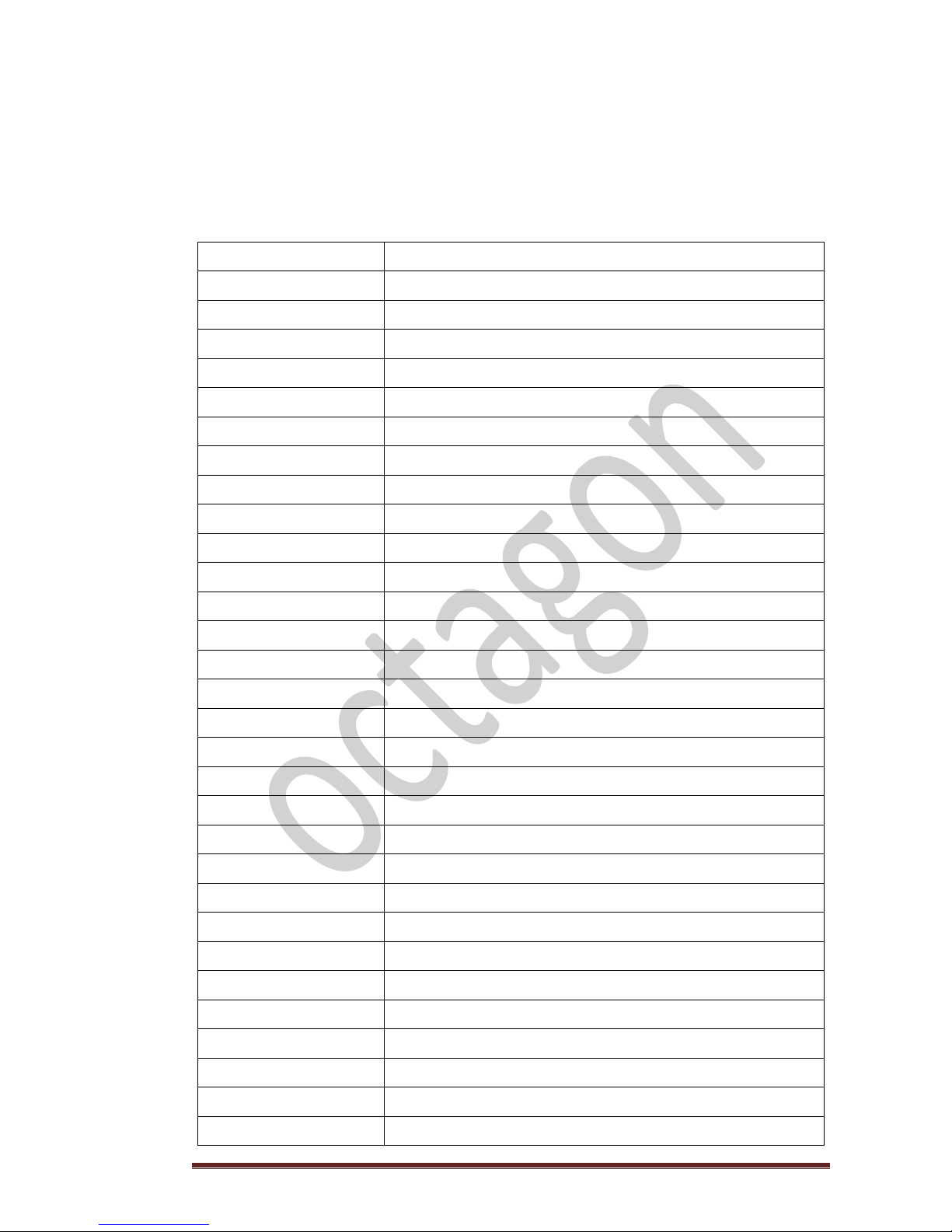

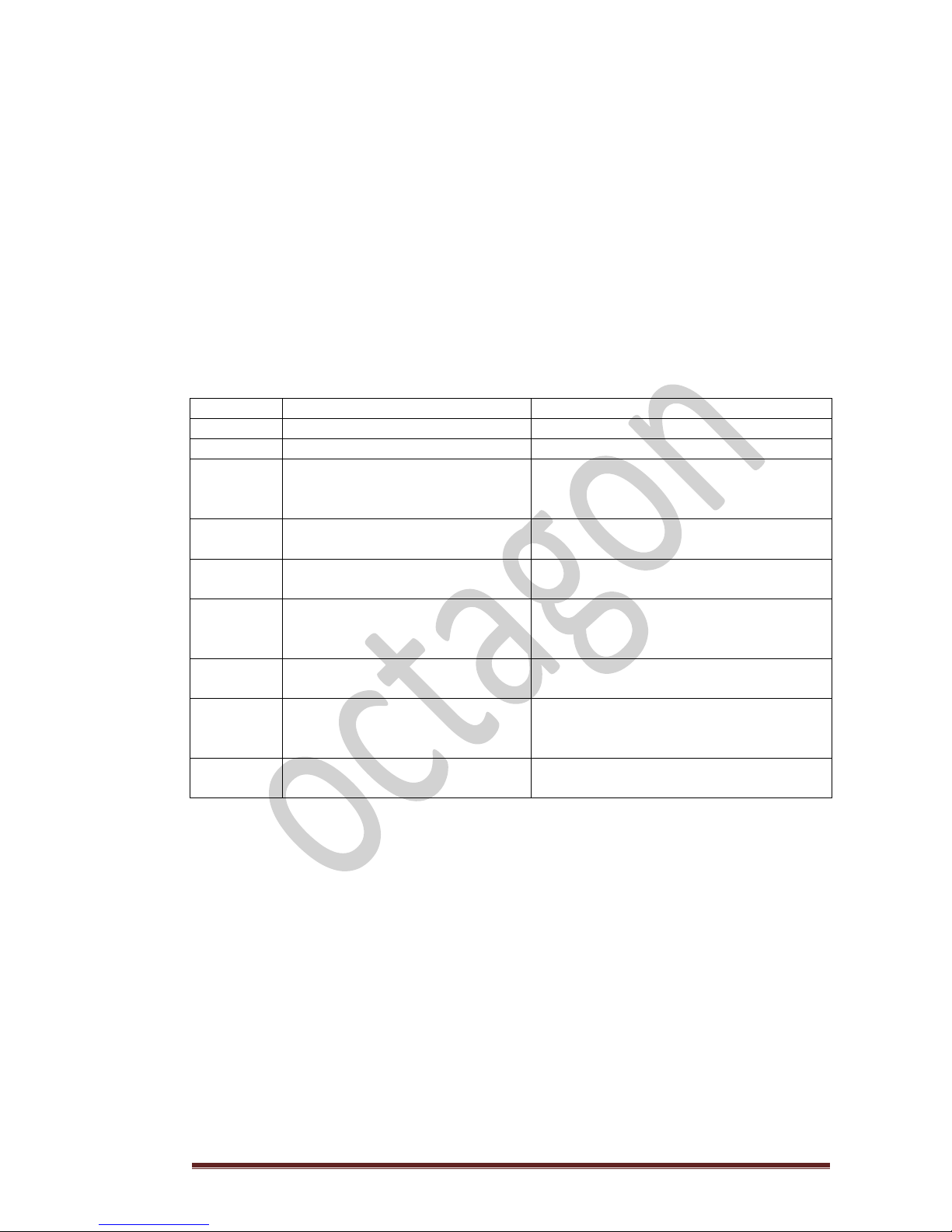

9.1 TECHNICAL CHARACTERISTICS OF WOOD PELLET ACCORDING ΕΝ 14961-1

The European standard ΕΝ 14961-1, which specifies the technical characteristics of wood pellets,

has not yet been finalized. Upon completion it will become mandatory to all European Union

member states. As at today (September 2012) every member state has its own standards.

SIZE

MEASUREMENT UNIT

VALUE

DIAMETER

mm

6 - 8

LENGTH

mm

3,15 - 40

DENSITY

kg/m3

≥ 600

FINES

w-% dry

≤ 1

MOISTURE CONTENT

w-% dry

≤ 10

ASH CONTENT

w-% dry

≤ 0,7

THERMAL POWER

MJ/kg

16,5 - 19

Sulphur

w-% dry

≤ 0,03

Nitrogen

w-% dry

≤ 0,3

Chlorine

w-% dry

≤ 0,02

Arsenic

mg/kg

≤ 1

Cadmium

mg/kg

≤ 0,5

Chrome

mg/kg

≤ 10

Copper

mg/kg

≤ 10

Mercury

mg/kg

≤ 0,1

Lead

mg/kg

≤ 10

Zinc

mg/kg

≤ 100

Nickel

mg/kg

≤ 10

Additives

%

≤ 2

Page 19

octagon v2.16 Page 19

10. FUEL FEEDING - AUGER

The feeding of the pellet burner is achieved using a metal auger which rotates via a motor and

transfers pellet from the fuel tank to the burner.

Between the feeder and the inox feeding tube of the burner, a polyurethane flex hose is used.

Relevant hose is flame retardant for safety reasons in case of gases and flames return from the

combustion chamber through the inox feeding tube to the fuel tank (reverse path). In this case

the tube will melt by the high temperature creating a disruption of the gases direction from the

burner to the fuel tank.

The slope of the auger should be within the range of 40 - 45 degrees.

Relevant slopes are achieved by OCTAGON fuel tanks of 200 and 350 litres. In case of different

slope please contact the manufacturer for instructions as this will interfere with the proper

supply of the fuel.

Never leave the fuel tank without pellets as then you will be required to fill the auger manually

(see §15.2.6 “Filling the auger”).

MAKE SURE THAT THE PLASTIC PIPE IS OUTSTRETCHED WITHOUT CURVES

THE OPERATION OF THE BURNER MAY BE INTERRUPTED

CORRECT POSITION WRONG POSITION

Minimum

height 40 cm.

Page 20

octagon v2.16 Page 20

11. FUEL TANK

The fuel tank plays an important role in the proper and undisturbed feeding of the burner.

OCTAGON has designed a fuel tank - with special interior - that fully meets the requirements of

the burner by ensuring steady and safe operation of the auger and allowing maximum utilization

of the stored pellets.

DO NOT USE HOMEMADE FUEL TANKS

AS THIS WILL JEOPARDIZE

THE PROPER OPERATION AND FEEDING OF THE BURNER

Diagram of fuel tank of 200 liters (usable volume)

Page 21

octagon v2.16 Page 21

12. BURNER INSTALLATION

12.1 INSTALLATION STEPS

1. Ensure that the boiler room is in line with local regulations paying special attention to

ventilation.

2. Ensure that the boiler is connected to the hydraulic network and that the exhaust flue

gas system is tightly connected.

3. Measure the chimney draft and make sure that it complies with the “minimum chimney

draft” according to the manufacturer of the boiler.

4. Secure the flame damper of the boiler (if any) to the proper position.

Only after having satisfied the above terms you may proceed with burner installation.

5. Remove the steel metallic casing of the burner including the display screen.

6. Ensure that the burning chamber of the burner is tightly connected to the flange of the

burner. If required, please tighten the screws.

7. Tighten the stainless steel flange of the burner against the door of the boiler.

8. Place the stainless steel feeding tube with the flange and tighten it.

9. Place the sensors of the burner:

Exhaust gas sensor to the flue duct connecting the boiler with the chimney

Boiler water temperature sensor

Other sensors

Bimetallic contact thermostat to the stainless steel feeding tube

10. Make electrical connections of the burner (see §13 “Electrical installation – Sensors”)

11. Fill the auger with pellets (see §15.2.6 “Filling the auger”)

12. Connect the flex hose feeding the pellets.

13. Connect the cable of the display screen with the electronic part of the burner.

14. Place and screw tightly the metal casing of the burner.

YOUR BURNER IS READY TO START UP

The burner regulates on its own both primary and

secondary air required for the burning process.

Page 22

octagon v2.16 Page 22

13. ELECTRICAL INSTALLATION – SENSORS

The electrical connections of the burner as well as the adjustment of the burner are only allowed

to trained licensed technicians for safety reasons. The safety electric connector of the burner has

twelve (12) numbered connections.

As soon as all cables pass through the corresponding cable glands then cables should be

connected as follows:

CONNECTION 1

POWER SUPPLY - Phase 230 V AC – 50 Hz (Live).

The polarity of the current is very important and this connection should

be connected with the phase of the current otherwise there will be a

malfunction and/or damage to the electronic board.

CONNECTION 2

POWER SUPPLY - Neutral

CONNECTIONS 3 -4

AUGER.

CONNECTIONS 5 – 6

WATER PUMP.

The current intensity of the water pump should not exceed 0,7 A

otherwise, an electrical relay should be inserted.

CONNECTIONS 7 - 8

EXTERNAL THERMOSTAT (Dry contact)

CONNECTIONS 9 - 10

SAFETY SWITCH (water’s safety thermostat )

The connections 11 and 12 will remain unused for future connections with peripheral devices to

the burner.

Install the connection line of the burner to a general switch so that the poles of the current

(L&N) can be disconnected should this be required.

CAUTION

THE EXTERNAL COMMAND OF THE BURNER (THERMOSTAT,

AUTONOMY TABLE) IS DRY CONTACT. IN CASE OF CURRENT

(230 V) YOU HAVE TO INSERT AN ELECTRICAL RELAY

SENSORS

BLACK PLASTIC = BOILER WATER TEMPERATURE SENSOR

Put some thermal oil in the boiler thermometer pocket to achieve thermal conductivity.

SILVER METALLIC = CHIMNEY SENSOR

Secure the sensor to the flue with aluminum tape or high temperature silicon.

Page 23

octagon v2.16 Page 23

14. BURNER DISPLAY SCREEN

KEYBOARD BUTTONS AND DISPLAY SYMBOLS

Alarm

Servicing

Indicator Timer Fuel

Temperature

Alarm IR Sensor Fan Time

Cleaning Power

Alarm

No

Fuel Set up

Cancel

Increase / Decrease + _

Light

Signal of operation

Power ON /OFF Enter

< Menu buttons >

Page 24

octagon v2.16 Page 24

15. 1ST LEVEL - CONFIGURATION OF THE BURNER

The 1st level of configuration is user friendly and easily accessible to the end user of the burner.

This configuration mainly introduces the end user to basic information of the device and allows

him to modify settings such as time or screen brightness.

15.1 DISPLAY SYMBOLS AND KEYBOARD BUTTONS

DISPLAY SYMBOLS

At the top of the display screen there are a number of symbols which indicate the basic

functions of the burner (Image No. 1, page 21).

The symbols are displayed in three colours:

GREEN indicating FUNCTION

RED indicating ERROR

ORANGE indicating SETTING FUNCTION

MENU < > command allows us to choose one of the “basic functions” of the burner (1st level of

configuration and operation). All basic functions are displayed in green colour in the following

order from left to right:

POWER is displayed by a “flame” symbol and the screen indicates AUTO which means that the

burner is operating automatically and proportionally in accordance with its settings.

TEMPERATURE is displayed by a “thermometer” symbol and the screen indicates the

temperature of the boiler water in οC (Celsius scale) at all times

FUEL is displayed by an “open container” symbol and the screen indicates the category of pellet

with which the burner operates i.e. 1, 2 ή 3.

Page 25

octagon v2.16 Page 25

TIME is displayed by a “clock” symbol and the screen indicates the current time in hours and

minutes i.e. 13:12.

PROGRAMMING is displayed by a “gear” symbol and the screen indicates OFF.

The programming belongs to the 2nd level of configuration of the pellet.

DESCRIPTION OF KEYBOARD BUTTONS

BUTTON

DESCRIPTION

Power ON/OFF button is used for turning the combustion system on or off.

Press and hold the button for one (1) second.

Menu buttons are used for navigating the first level menu context. The

currently selected menu context is indicated with the corresponding icon at

the top. In addition, these buttons are used in the edit mode.

Edit buttons are used for navigating the submenus and increasing /

decreasing values in the edit mode, when the selected value blinks.

Enter button is used for entering the edit mode and confirming the set values,

or selecting the additional submenus.

Cancel button is used for discarding the changes and returning up one level in

the menu. If you press and h old this button for more than three (3) seconds,

the last error or alert code is displayed.

The advanced keyboard of bio-burner is also equipped with the beeper, which provides the

keyboard feedback signals. The following sound signals are available:

Short high tone: sounds when navigating the menu and editing the settings

Long low tone: sounds in case of an invalid operation (wrong button pressed)

Long high tone: in case of and alert, this tone sounds with the user defined loudness, and in

case of an error, this tone sounds with 100% loudness. For description of alerts and errors,

refer to §18 “Troubleshooting”.

Page 26

octagon v2.16 Page 26

15.2 BASIC CONFIGURATION OF BURNER

After the electric connection is made you may proceed with the installation of the burner. By

keeping the button ON / OFF pressed for one (1) second the indication ON will be displayed on

the screen and the burner will automatically begin operation. This means that the burner will

proceed to the phase “FIRE UP”.

15.2.1 POWER RATING

The burner has been set by the manufacturer to work automatically (i.e. analog power control)

at maximum power of 35 kW/h and 70 kW/h in respect of bio 2 and bio 3 respectively.

Additionally, there is the option to operate the burner at a different power rating but relevant

adjustment can only be performed by a licensed technician using the 2nd level of configuration.

(see §15.2.5 “Programming”).

The burner could also operate at all times at a user defined (NOT analog) power rating through

appropriate adjustment at 1st level of configuration. The minimum and maximum power rating

together with intermediate values, as defined by the manufacturer, are included in the table

below:

POWER

bio 2

bio 3

P5 (Max)

35 kW/h

70 kW/h

P4

28 kW/h

56 kW/h

P3

21 kW/h

42 kW/h

P2

15 kW/h

27 kW/h

P1 (Min)

8 kW/h

12 kW/h

If you wish to reduce the maximum power rating of the burner by removing its analog feature

then you should follow the next steps:

Navigate through the MENU button < > to the POWER (flame symbol).

Press ENTER. The indication AUTO will appear on the screen blinking.

Press the EDIT buttons +, - to choose the desired power rating, 4, 3, 2, ή 1.

Press ENTER to set the desired power rating. The command will be stored and the selected

power rating will be displayed on the screen.

Page 27

octagon v2.16 Page 27

15.2.2 BOILER WATER TEMPERATURE

Navigate through the MENU button < > to the TEMPERATURE (thermometer symbol).

PRESS ENTER. The screen will show the predefined boiler water temperature.

Press the EDIT buttons +, - to choose the desired boiler water temperature.

Press ENTER to set the desired boiler water temperature. The command will be stored and

you can move on.

15.2.3 FUEL

The FUEL button indicates the category of the pellet that bio burner is adjusted to.

The categories of the pellet are three (3) :

Category 1: Pellet with thermal power 5,4 kW/kg

Category 2: Pellet with thermal power 5 kW/kg

Category 3: Pellet with thermal power 4,6 kW/kg

If you wish to change category pellet then:

Navigate through the MENU button < > to the FUEL (open container symbol).

Press ENTER. The number indicating the current pellet category will appear on the screen

blinking.

Press EDIT buttons +, - to choose the desired category.

Press ENTER to set the desired pellet category. The command will be stored and the selected

pellet category will be displayed on the screen.

All burners of OCTAGON HELLAS are initially

adjusted to pellet Category 2

The burner will adjust the AUGER and FAN to the new

parameters automatically.

You simply need to define the pellet category in use.

Page 28

octagon v2.16 Page 28

15.2.4 TIME

Navigate through the MENU button < > to the TIME (clock symbol).

Press ENTER. The indication 00:00 will appear on the screen. The first part will be blinking.

Press the EDIT buttons +, - to insert the time in hours (0 to 24).

Press the Menu button < > to move to the second part.

Press the EDIT buttons +, - to insert the time in minutes (0 to 60).

Press ENTER to set the time. The command will be stored and you can move on.

15.2.5 PROGRAMMING

The programming has thirteen (13) submenus. These are:

1

OFF, useful only to the technician. (Always set to OFF).

2

SCREEN BRIGHTNESS (1 to 5)

3

CHANGING DISPLAY STATUS OF LCD SCREEN

Press 1 for continuous rotation of display values

Press 2 for screen display of boiler water temperature

Press 3 for screen display of the time / water temperature

4

BEEPER VOLUME

5

HARDWARE TYPE AND SCREEN, useful only to the technician.

6 MANUAL ACTIVATION OF AUGER

A particularly useful command for the filling of auger with fuel either at first start

up or after emptying the fuel tank.

7

UNLOCK OF PROGRAMMING to new parameter settings

This is ONLY allowed to a qualified licensed technician giving him access to

modify predefined settings Νο 8 to 13

8

SYSTEM PARAMETERS e.g. fan speed

9

d In , to be adjusted only with manufacturer’s approval

10

Α In, display of sensors’ current values (see §16.1.2)

11

DIGITAL OUTPUT, to be adjusted only with manufacturer’s approval

12

STATISTICS OF BURNER’S USE (manufacturer)

13

ERROR LOG REPORT (manufacturer)

Navigate through the MENU button < > to the PROGRAMMING (gear symbol).

The indication OFF will appear on the screen.

Press EDIT buttons +, - to choose the setting you wish to modify e.g. [ 2 ]* and press ENTER.

A number indicating the screen brightness e.g. 3 will appear on the screen.

Press EDIT buttons +, - to choose the desired brightness and press ENTER.

The end user is only allowed to modify parameter settings 2, 3, 4 and 6 at the 1st level of

configuration of the burner.

Page 29

octagon v2.16 Page 29

15.2.6 FILLING THE AUGER

The filling of the auger is performed after you have first disconnected the flex hose from the

stainless steel tube of the burner and place a bucket to its end to collect the outgoing pellets.

Those pellets can be placed back to the fuel tank once you have finished.

Navigate through the MENU button < > to the PROGRAMMING (gear symbol).

The indication OFF will appear on the screen.

Press the EDIT buttons +, - to go to number [ 6 ] and press ENTER.

The screen will display horizontal dots - - - - .

Keep ENTER button pressed constantly while the dots are blinking.

The auger starts to operate and transfers the pellets to the burning chamber. The duration

of this operation is approx. 30 seconds (30’’). On completion of the operation the auger

stops and OFF indication appears on the screen. This process is repeated one more time by

keeping the ENTER button pressed and wait for another thirty seconds (30’’). This will ensure

that auger has been filled successfully.

When OFF indication appears on the screen again you can move on.

To make sure that the auger has been fully loaded with

pellet please fill in the fuel tank with minimum three

(3) bags of pellet (45 kg in total) and activate the auger

for at least ten (30) minutes.

Page 30

octagon v2.16 Page 30

16. 2nd LEVEL - CONFIGURATION OF THE BURNER

The 2nd level of configuration of the burner is ONLY allowable to trained licensed technicians.

Access to this level of configuration is strictly forbidden to end users as there is a serious risk of

deregulation of the burner.

16.1 ACCESS TO PROGRAMMING

Navigate through the MENU button < > to the PROGRAMMING (gear symbol).

The indication OFF will appear on the screen.

When indication OFF appears on the screen and you press ENTER then the indication OFF will start blinking.

Press EDIT buttons +, - to move to indications Hi or Lo.

Hi: enables deactivation of ON/OFF button

Lo: enables deactivation of ENTER button

Above options are used only by the service personnel in case of cleaning the screen and/or keyboard of the

burner etc.

Press once any of the EDIT buttons +, - a number in brackets will appear on the screen

e.g. [ 2 ]

Press the EDIT button + to go to number [ 7 ] and press ENTER.

A four (4) digit number will appear. Add up the four digits plus one e.g. number [ 2025 ] =

= 9 +1 = 10 and press ENTER.

Press EDIT buttons +, - to insert the sum (in our example above the sum is 10) and press

ENTER. The ON indication will appear on the screen.

Now you have full access to the 2nd configuration level including the parameter settings

of burning allowable by the manufacturer.

Press EDIT buttons +, - go to number [ 8 ] and press ENTER. When “Par” indication appears

on the screen press ENTER. The screen will display P 000.

Press the EDIT buttons+, - to insert the code of the parameter you wish to change e.g.

number 28 refers to the Fan speed 5 (max. speed).

Press ENTER. The screen will display a blinking number e.g. 155 indicating the fan speed.

Press the EDIT buttons+, - to choose the new fan speed e.g. 156 and press ENTER. The new

fan speed 5 will be 156 i.e. higher than the previous setting.

See Table of parameters in Table 2, §19.2

Page 31

octagon v2.16 Page 31

16.1.2. DISPLAY OF INDIVIDUAL PARAMETERS OF COMBUSTION

REGULATION

The screen provides us with information on the current values of the various parameters.

It is particularly useful during the first fire up and when you wish to perform a system check.

Repeat steps detailed in previous section to go to setting number 10 and press ENTER.

Press EDIT buttons +, - to display values for the following parameters:

t 03, EXHAUST GAS TEMPERATURE

t 04, for the manufacturer

t 01, BOILER WATER TEMPERATURE

t 02, for the manufacturer

t 05, for the manufacturer

F 01, FUEL TANK SENSOR (if any)

Press, BURNING CHAMBER PRESSURE SENSOR (BURNING CHAMBER DRAFT)

Page 32

octagon v2.16 Page 32

17. POWER ADJUSTMENT OF BURNER

Before you change the maximum power of the burner you should first understand its analog

function and as an example we will look into the operation of model bio 2 of maximum power

(Ρ5), nominal power 35 kW/h and minimum power (Ρ1) of 8 kW/h.

In analog power the intermediate power ratings Ρ2, Ρ3, Ρ4 are automatically defined in such a

way that the distance between two consecutive power ratings is always equal.

The minimum power Ρ1 remains unchanged, unless you wish to modify it.

E.g. When you wish to reduce power rating from 35 down to 32 kW/h , the burner will

automatically redefine the remaining three (3) power ratings by calculating the distance of the

“step” the as follows = (32-8)/4 = 6

In the above example the power ratings are redefined as follows:

Ρ5 = 32 kW/h (new default value)

Ρ4 = 26 kW/h

Ρ3 = 20 kW/h

Ρ2 = 14 kW/h

Ρ1 = 8 kW/h

POWER REDUCTION

In order to reduce the power of the burner you should also redefine the values of the AUGER

and FAN at maximum power 5. To this effect you need to consult two tables:

o TABLE 2, TABLE OF PARAMETERS (see §19.2) for selection of the parameter to be

modified

o TABLE 1, CONFIGURATION VALUES, AUGER-FAN WITH PELLETS OF CATEGORY 2

(see §19.1) for reference values of the AUGER and FAN.

The parameter that defines the AUGER at POWER 5 is No. 18,

Whereas,

The parameter that defines the FAN at POWER 5 is No. 28.

After unlocking and accessing the PROGRAMMING (see §16.1) the ON indication will appear on

the screen.

Press EDIT buttons +, - go to number [ 8 ] and press ENTER. When “Par” indication appears

on the screen press ENTER. The screen will display P 000.

Press the EDIT buttons+, - to insert the code of the parameter you wish to change

e.g. number 28 refers to the Fan speed 5 (max. speed).

Press ENTER. The screen will display a blinking number e.g. 145 indicating the fan speed.

Press the EDIT buttons+, - to choose the new fan speed e.g. 138 and press ENTER.

The new fan speed 5 will be 138 i.e. lower than the previous setting.

In the same way you may redefine the value of AUGER in order to operate the burner at a

default power rating.

Page 33

octagon v2.16 Page 33

The values of the fan in TABLE 1 (see §19.1) are indicative and may need to

be revised by you.

Each system “burner -boiler-chimney” has its own characteristics and it

might require new adjustments of fan values. The shortage of air fan may

cause - in addition to poor combustion – an overload of fuel in the burner’s

flame tube and malfunction of the whole system.

To avoid this situation ALWAYS use flue gas measuring instruments at

first fire up of the burner.

Page 34

octagon v2.16 Page 34

18. TROUBLESHOOTING

The keyboard of the burner provides notifications and warnings for alerts and errors,

which can occur during operation. The alarm icons indicate a problem. An alert

notification is indicated with the blinking icons, errors are indicated with continuously lit

icons. In case of an alert, the combustion system is still operational, in case of an error

the combustion system is seriously malfunctioning and the service personnel should be

contacted.

Each alert and error has a code, which can be used to identify the problem. To display

the code, press and hold the Escape button. In case there is no information on the

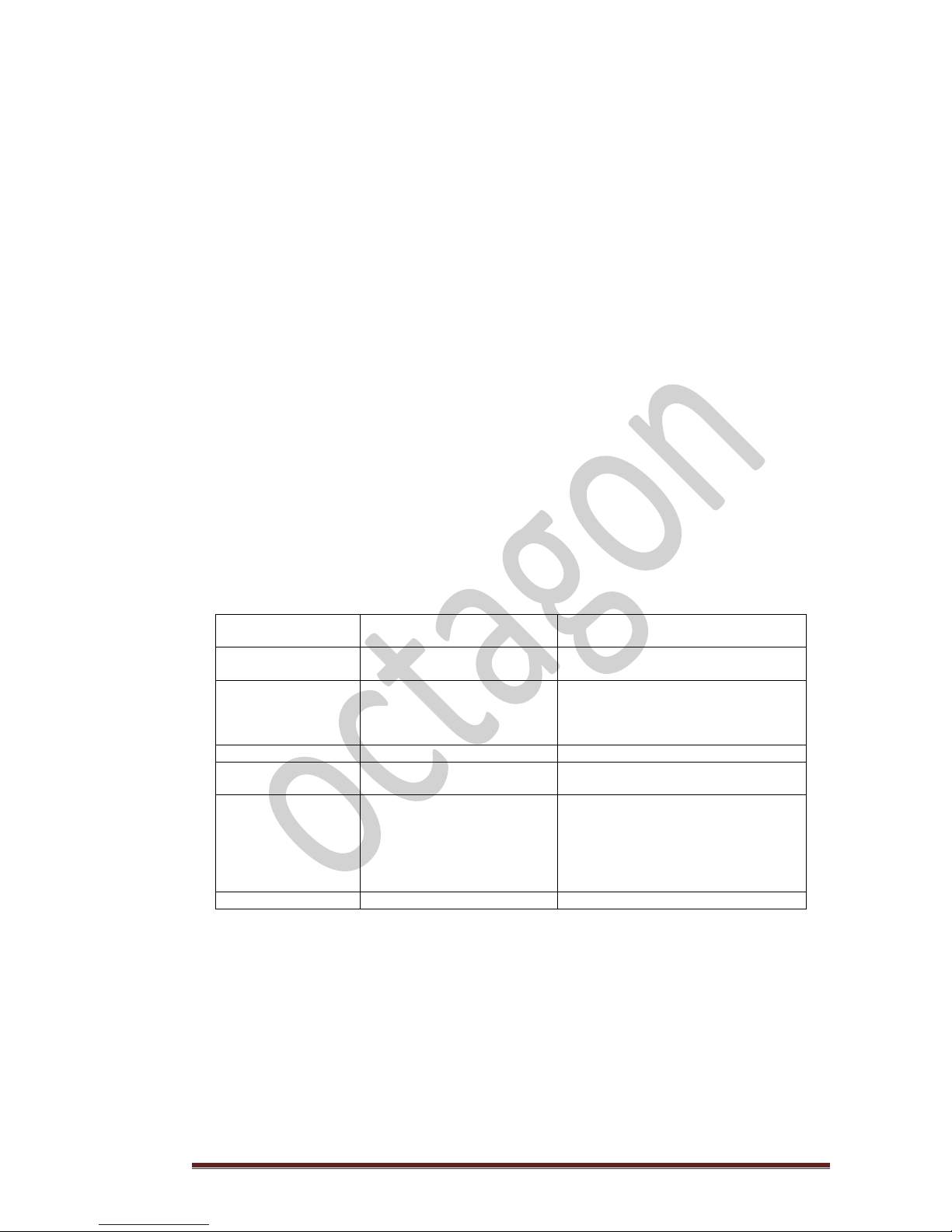

alert/error code, the display shows:

CODE

INDICATION

CAUSE / SOLUTION

Α001

Icon NO FUEL is blinking

Refill the fuel container.

Icon NO FUEL is on

A. Shortage of fuel in the fuel container.

B. Improper fuel (high humidity),

C. Wrong installation of auger.

Α002

Icons of CLEANING and SERVICE

blinking simultaneously

Time to service is up. Call service personnel

for maintenance of the burner.

Α003

Icon CLEANING is blinking or on

The burning chamber or chimney are dirty

and require cleaning.

Α004

Icon SERVICE is on

Call service personnel to change the

battery as it is getting low. The burner is

still operational.

Α005

Icon SERVICE is blinking

The fan sensor malfunctioned. Call the

service personnel.

Α006

Icons NO FUEL and SERVICE are

blinking

Burning chamber or fuel container door is

open. Check and close the burning

chamber or fuel container door

Α007

Icon SERVICE is blinking

The pressure sensor malfunctioned. Call

the service personnel.

Page 35

octagon v2.16 Page 35

18.1 ADDITIONAL ERROR NOTIFICATIONS

Indication: Icon SERVICE is on

The combustion system malfunctioned and is not operational.

This can be due to:

Code E001: Keyboard error

Code E002: IR communication error

Code E003: RF communication error

Code E004: MB communication error

Code E101: Fire error or water overtemperature

Code E105: NTC2 error

Code E106: NTC3 error

Code E107: TC2 error

Code E108: Security switch error (STB safety thermostat is triggered, press to reset)

Code E109: Pressure switch error (safety switch between contacts 9 – 10 is triggered)

Code E110: NTC1 error

Code E111: TC1 error

Code E112: Fuel overtemperature

Code E115: General error

Solution: Note the error code and contact the service personnel

During power supply fail, the settings of the burner remain active due to internal battery.

In case of a power supply failure internal electronics operate as follows:

DURATION OF POWER

SUPPLY FAILURE

OPERATION BEFORE THE POWER

SUPPLY FAILURE

OPERATION AFTER THE POWER SUPPLY

FAILURE

LESS THAN TWO (2)

MINUTES

FIRE UP PHASE

The burner continues normally.

BURNING PHASE

The burner checks the air / water

temperature and continues in the

BURNING PHASE, or restarts in the FIRE UP

phase.

OFF

OFF

MORE THAN TWO (2)

MINUTES

FIRE UP PHASE

The burner continues normally.

BURNING PHASE

The burner checks the flue gases

temperature. If the flue gases temperature

dropped below predefined value of

PARAMETER 56, the combustion system

restarts in the FIRE UP phase, otherwise it

continues in the BURNING phase.

OFF

OFF

Page 36

octagon v2.16 Page 36

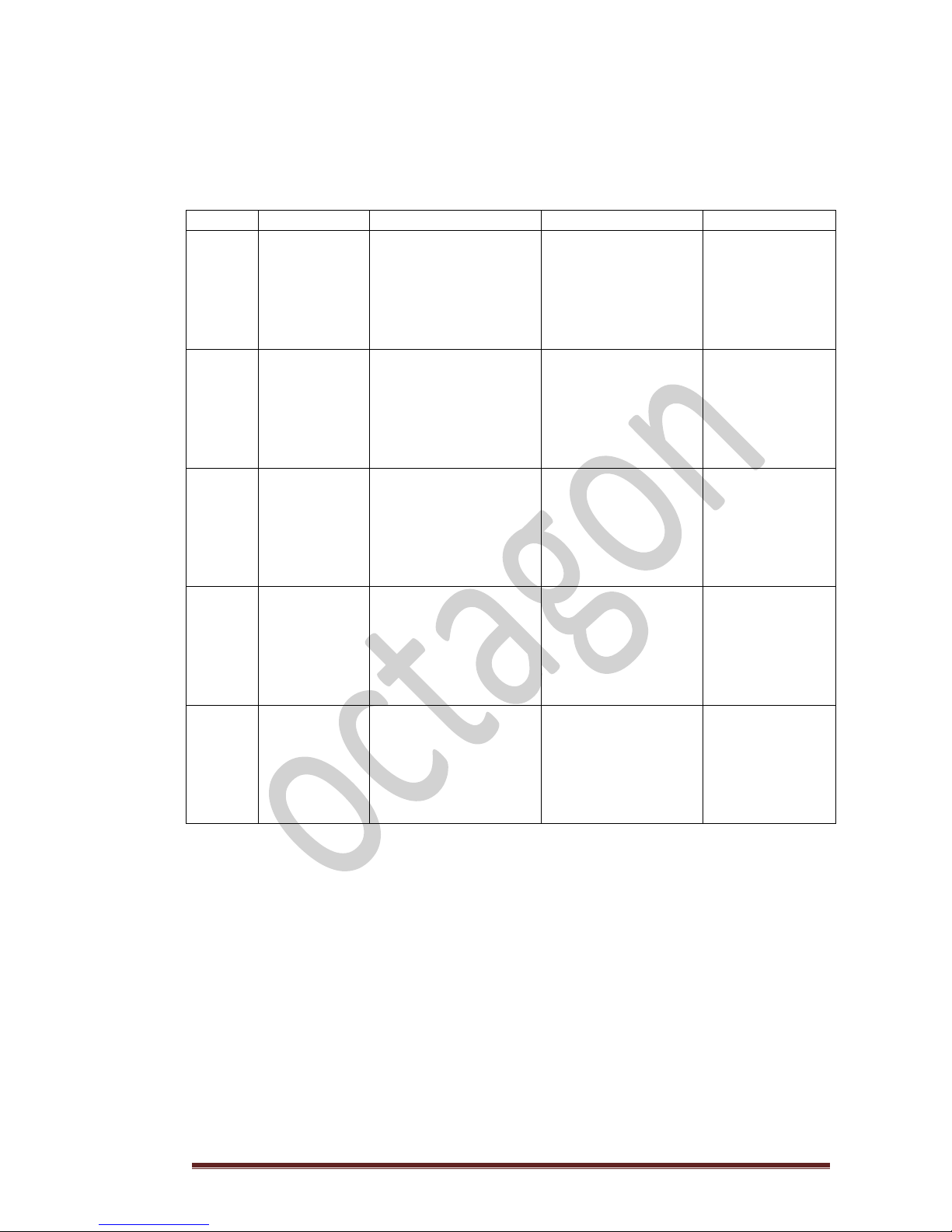

19. TABLES

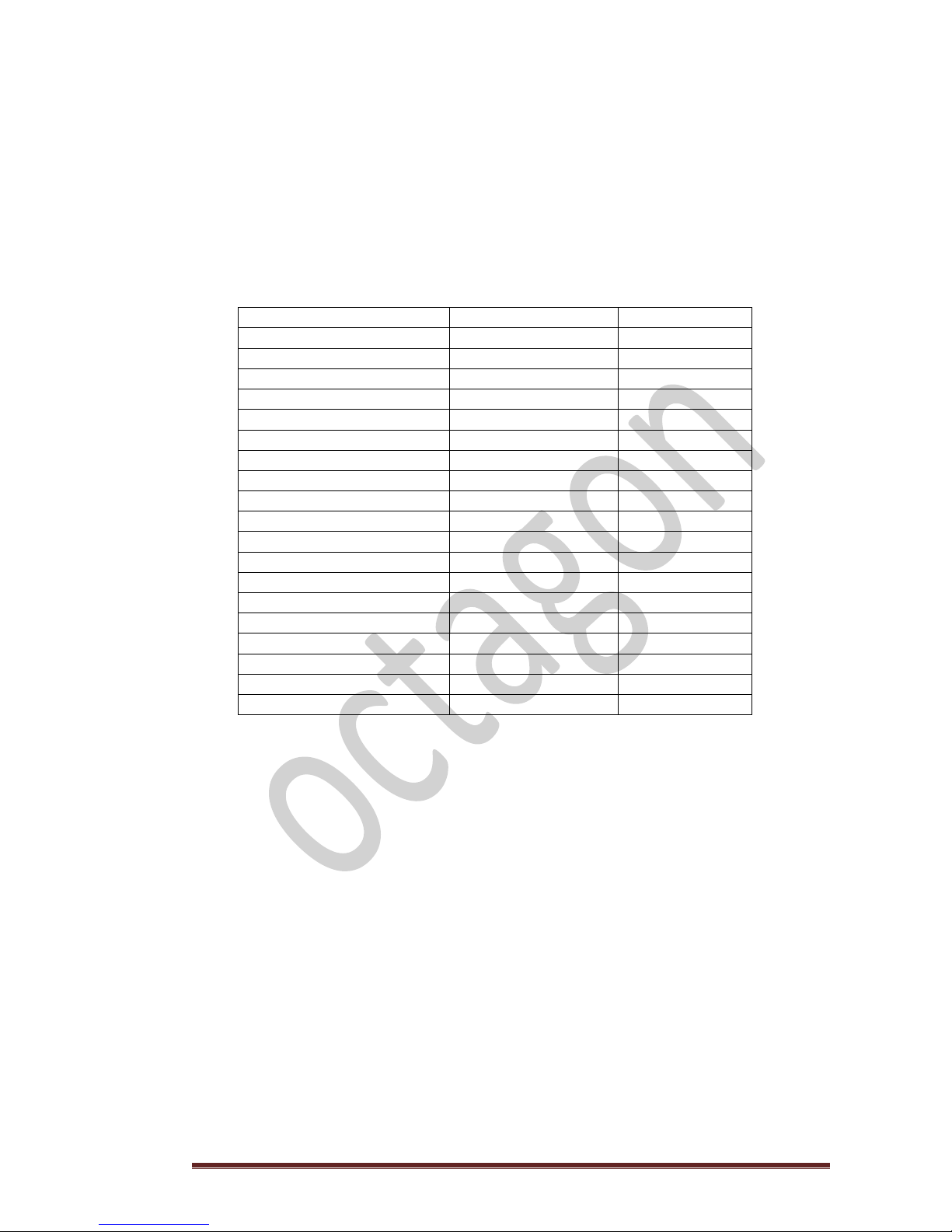

19.1 TABLE 1 3’’ AUGER

CONFIGURATION VALUES, AUGER-FAN WITH PELLETS OF CATEGORY 2,

HEATING POWER = 5 kW/kg

400 gr/min

POWER

ON

AUGER

VALUE

FAN VALUE

5

kW/h

Kw*h/kg

bio3

8 8 9 9

10

10

11

11 12

12

104

13

13

105

14

14

107

15

15

108

16

16

110

17

17

111

18

18

112

19

19

114

20

20

115

21

21

117

22

22

118

23

23

119

24

24

121

25

25

122

26

26

124

27

27

125

28

28

126

29

29

128

30

30

129

31

31

131

32

32

132

33

33

133

34

34

135

35

35

136

36

36

138

37

37

139

38

38

140

39

39

142

40

40

143

41

41

145

Page 37

octagon v2.16 Page 37

42

42

146

43

43

147

44

44

149

45

45

150

46

46

151

47

47

153

48

48

154

49

49

156

50

50

157

51

51

158

52

52

160

53

53

161

54

54

163

55

55

164

56

56

165

57

57

167

58

58

168

59

59

170

60

60

171

61

61

172

62

62

174

63

63

175

64

64

177

65

65

178

66

66

179

67

67

181

68

68

182

69

69

184

70

70

185

If you are using pellet of a different category to that of the burner, you should

make the appropriate selection using the display and programming touch

screen.

The burner will AUTOMATICALLY adjust the necessary parameters in line with

the selected category of the pellet.

Ensure that fan is operating at the correct speed using measurement

instruments.

Page 38

octagon v2.16 Page 38

19.2. TABLE 2

TABLE OF PARAMETERS

In so far as the 2nd level of configuration is concerned access to the parameters included in the

table below is allowed. The remaining parameters belong to 3rd level of configuration and can be

modified only in liaison with and subject to agreement of the manufacturer.

PARAMETER

DESCRIPTION

INDICATIVE

VALUE OF

PARAMETER

bio 2

3

Heat Up Phase Feeder OFF

Time: 0,5’’second

5

4

Heat Up Phase Feeder ON

Time: 11,5’’ seconds

115

10

Power 1 = Feeder ΟΝ

12

18

Power 5 = Feeder ΟΝ

38

19

Fan Speed in FIRE STOP sequence

97

20

Fan speed in TEST FIRE sequence

98

24

Fan speed at POWER 1

95

28

Fan speed at POWER 5

145

50

Difference of degrees at start up of burner (51-50)

5

51

Desired Water / Air Temperature of boiler water

75

53

Safety limit of boiler water temperature (51+53)*

5

67

Water pump turn ON temperature in (oC).

35

68

Water pump turn OFF temperature in (oC).

30

70

Heat Up sequence duration (in seconds)

55

92

Defines one of the three pellets fuel quality types

2

IMPORTANT

If the boiler water temperature exceeds the safety limit set (sum of parameters 51 and 53

plus 1 oC) for more than one (1) minute the burner will automatically switch to FIRE STOP phase.

Page 39

octagon v2.16 Page 39

20. MAINTENANCE AND CHECKS TO BE PERFORMED BY END USER

As with all electronic devices, the burner also requires maintenance and cleaning service

annually in order to ensure long term operability as well as optimum fuel economy. Do not

neglect the annual service, it is possible that malfunctions may go unnoticed for several time

leading to fuel wastage and costly damages.

WEEKLY CLEANING

The end user has also the obligation to inspect frequently the combustion system and keep both

the boiler and the flame tube of the burner clean from ashes and combustion residues. The

frequency shall be determined empirically since each system or type of pellet produces different

wastage in solid form (ashes etc). We recommend that cleaning be performed at least twice (2) a

week in the beginning. During these weekly cleanings you should:

A. Remove all ashes from the interior of the boiler as well as the exhaust gas outgoing

routes using a special brush.

B. First unscrew the bolt holding the combustion grate and then remove it cleaning any

ashes and solid combustion residues.

C. Check inside the flame tube and remove any visible ashes and solid combustion

residues. Place back the combustion grate in position and tighten the screw again. Close

the door of the boiler. Your system is ready to operate.

MONTHLY CLEANING

Once a month we recommend that you clean:

D. The inclined metallic, stainless steel surface where pellet is loaded. Remove the plastic

tube with your hands, unscrew the stainless steel feeding tube 2’’ and clean with a cloth

the angled surface of the burner that leads to the burning chamber. You can also use a

flat metallic scraper.

E. Detach the plastic tube and shake it well so that any dust and debris that may have been

deposited inside the tube to be removed.

F. Unscrew and detach the flame sensor from the body of the burner. Check the glass

surface and wipe it thoroughly with a dry cloth of soft texture (not paper).

ANNUAL CLEANING

G. Once a year and before the beginning of winter, clean the fuel tank from any dust and

pellet deposits. It is essential that the fuel tank always contains clean and dry pellet. If

moisture is present in pellet then do not use it as it is unsuitable for combustion.

H. Make sure by a visual check that the system “burner – boiler – chimney” is fully

tightened. Otherwise please call immediately the service technician to repair the system.

Page 40

octagon v2.16 Page 40

Page 41

octagon v2.16 Page 41

21. WARRANTY OF PELLET BURNER OCTAGON

The European Directive 99/44/CE, sets out the specific responsibilities and obligations of the ultimate seller of the

product to the ultimate buyer for any possible defects. The European Directive can be found on the website at:

http://europa.eu/legislation_summaries/consumers/protection_of_consumers/l32022_en.htm

ΟCTAGON, is not the ultimate seller of the pellet burner; however, it accepts and undertakes the responsibility of the

ultimate seller through its additional warranty granted to OCTAGON HELLAS approved and certified sales network.

SCOPE AND DURATION OF THE WARRANTY

OCTAGON hereby guaranties the good operation of the product sold and agrees to provide spare parts free of charge

for the purpose of repairing any defective part of the burner for a period of twenty four (24) months after the date of

delivery to the ultimate buyer.

As the date of delivery shall be considered the date included in the proof of purchase (Receipt or Invoice) and MUST

accompany this warranty.

The purchase of this product should have taken place within three (3) years from the date of production as included in

the special labelling of the burner (the adhesive label on the casing of the burner).

WHEN IS THE WARRANTY VALID

The warranty is hereby granted subject to the following prerequisites:

The installation of the burner must be carried out by a licensed technician in accordance with local authority

regulations, good engineering practices and the technical manual of the manufacturer.

The burner must undergo proper service by specialized personnel and an entry be made accordingly in the

Maintenance log, included herebelow, and be signed.

The actual duration of the warranty will not be altered by intermediate service repairs.

EXCLUSIONS

This warranty will NOT cover:

Cost of carriage of the spare parts and repair works.

Damage or wear as a result of violent acts on the burner or malfunction of the power supply.

Damage caused as a result of substandard fuel quality and/or unsuitable chimney.

Incorrect installation by unlicensed technicians.

Non compliance with local authority regulations, good engineering practice and installation instructions of

the manufacturer.

Non fulfillment of the annual service.

Use of spare parts not approved by the manufacturer.

Natural forces and disasters.

RESPONSIBILITY

The licensed technician is totally and exclusively responsible for installation and compliance with local

authority regulations, good engineering practice and installation instructions of the manufacturer.

The terms of this warranty are unique and nobody can alter them, add or remove any part thereof.

This warranty is a supplement to and does not replace the European Directive 99/44/CE.

This guaranty will be validated after it has been completed and a copy be sent to the representative firm of your

country within 10 days from the date of purchase of the burner.

MODEL : DATE OF PURCHASE :

SERIAL NUMBER :

SIGNATURE AND STAMP OF THE SELLER SIGNATURE OF THE BUYER

Page 42

octagon v2.16 Page 42

Page 43

octagon v2.16 Page 43

22. MAINTENANCE LOG

SECTION

DATE

NAME OF TECHNICIAN

REMARKS

SIGNATURE

1st

2nd

3rd

4th

5th

Page 44

octagon v2.16 Page 44

23. BRIEF INSTRUCTIONS FOR INITIAL ADJUSTMENT AND OPERATION

1. ELECTRICAL CONNECTION

CONNECTION 1

POWER SUPPLY - Phase 230 V AC – 50 Hz (Live).

The polarity of the current is very important and this connection should

be connected with the phase of the current otherwise there will be a

malfunction and/or damage to the electronic board.

CONNECTION 2

POWER SUPPLY - Neutral

CONNECTIONS 3 -4

AUGER.

CONNECTIONS 5 – 6

WATER PUMP.

The current intensity of the water pump should not exceed 0,7 A

otherwise, an electrical relay should be inserted.

CONNECTIONS 7 - 8

EXTERNAL THERMOSTAT (Dry contact)

CONNECTIONS 9 - 10

SAFETY SWITCH (e.g. open boiler door sensor)

2. FILLING OF THE AUGER 1

ST

LEVEL CONFIGURATION

BUTTON

INDICATION

SCREEN DISPLAY

>

PROGRAMMING

OFF + [ 6 ]

[ 6 ]

ENTER

- - - - - - - -

Keep pressed ENTER button to start the filling of the auger in process circles of thirty second

(30’) each. On completion of each circle the indication OFF appears on the screen. Repeat the

process cycle as required.

3. SELECTION OF PELLET CATEGORY (only if pellet is not 5kW/kg)

BUTTON

INDICATION

SCREEN DISPLAY

< >

FUEL

2

ENTER 2

+, -

1 ή 3

SELECTED VALUE

ENTER

SELECTED VALUE

4. ACCESS TO PROGRAMMING, 2

nd

LEVEL CONFIGURATION

BUTTON

INDICATION

SCREEN DISPLAY

< >

PROGRAMMING

OFF

ENTER OFF + [ 7 ]

[ 7 ]

ENTER

4-DIGIT NUMBER

Add up the four digits plus one

BUTTON

INDICATION

SCREEN DISPLAY

ENTER

SUM

SUM

ENTER ΟΝ

You have now access to 2nd level configuration.

Page 45

octagon v2.16 Page 45

5. MODIFICATION OF THE MAXIMUM POWER OF THE BURNER IN TWO STEPS

5.1. ADJUSTMENT OF FAN SPEED, 2

nd

CONFIGURATION LEVEL

The speed levels per power rating are subject to the following parameters:

FAN SPEED

PARAMETER

Fan speed during phase FIRE STOP

19

Fan speed during phase TEST FIRE

20

Fan speed at Power 1

24

Fan speed at Power 5

28

ADJUSTMENT OF SPEED (CONTINUATION OF Νο 4), ACCESS TO PROGRAMMING

BUTTON

INDICATION

SCREEN DISPLAY

ΟΝ

+, -

PARAMETERS

[ 8 ]

ENTER

PARAMETER SETTINGS

Par - - - -

+, -

PARAMETER SETTINGS

DESIRED PARAMETER

ENTER

SELECTED VALUE

5.2. ADJUSTMENT PELLET FEEDING-AUGER, 2

nd

CONFIGURATION LEVEL

This procedure is the same as with the adjustment of the fan.

By adjusting only the ON time of the auger, the burner will calculate automatically the OFF time.

Choose parameter.

AUGER OPERATION

PARAMETER

Power 1 = Auger ON

10

Power 5 = Auger ΟΝ

18

Page 46

octagon v2.16 Page 46

24. CERTIFICATES

Declaration of conformity

Manufacturer : OCTAGON

Address : Koumoundourou 53 – 182 33 Attiki –

Hellas

declares that this unit is complies with the :

• EN 60335-1:2012 , EN 60335-2-102:2006

+A1:2010

Harmonized to the LVD European directive

2006/95/EC (Low voltage Directive)

• EN 61000-6-1:2007, EN 61000-6-3:2007

Harmonized to the EMC European directive

2004/108/EC

• EN 15270:2007

Quality Manager

Dimitris Papakonstantinou

CЄ12

Page 47

octagon v2.16 Page 47

25. QUALITY CONTROL CHECKLIST

We herby confirm that the burner passed successfully all manufacturing steps

and quality control tests and is delivered to you ready to use.

MODEL OF BURNER ………………………………………………

POWER RATING kW/h

Ρ5……..

Ρ4……..

Ρ3……..

Ρ2……..

Ρ1……..

Electronic controller

Touch screen bio-burner

Boiler water temperature sensor

Flue gas temperature sensor

Flame sensor

Bimetallic safety thermostat

Heating element

Fan

Auger motor

Electric connections

Metallic parts

DATE OF PRODUCTION: …………………………….

PRODUCTION ENGINEER: ………………………………………………………………...

Loading...

Loading...