Page 1

2560

2560

EN

Part No. C1260-0001

C1260-0002

www.ocon.com

Page 2

Copyright © 2015

All rights reserved.

Original Instructions: English

All rights reserved throughout the world. No part of this document may be stored in a retrieval system,

transmitted, copied or reproduced in any way, including, but not limited to, photocopy, photograph,

magnetic or other record without the prior agreement and permission in writing of the Vitec Group Plc.

Disclaimer

The information contained in this manual is believed to be correct at the time of printing. Vitec Videocom

Ltd reserves the right to make changes to the information or specifications without obligation to notify any

person of such revision or changes. Changes will be incorporated in new versions of the publication.

We are making every effort to ensure that our manuals are updated on a regular basis to reflect changes

to product specifications and features. Should this manual not contain information on the core functionality

of your product, please let us know. You may be able to access the latest revision of this manual from our

website.

Vitec Videocom Ltd reserves the right to make changes to product design and functionality without

notification.

Trademarks

OConnor® is a registered trademark of the Vitec Group Plc.

All product trademarks and registered trademarks are the property of The Vitec Group Plc.

All other trademarks and registered trademarks are the property of their respective companies.

Published by:

Vitec Videocom Ltd

Supports Technical Publications Department

Western Way, Bury St Edmunds

Suffolk IP33 3TB

United Kingdom

Email: technical.publications@vitecgroup.com

Page 3

Contents

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

About this User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Front View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Box Contents C1260 - 0001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the Head and Payload . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting the head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Levelling the Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lock Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting the Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fitting the Pan Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Balancing the Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fore / Aft Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Payload Weight and C of G Height Adjustment . . . . . . . . . . . . 14

Numeric Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting the Centre of Gravity (C of G) . . . . . . . . . . . . . . 15

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operating the Pan and Tilt Locks . . . . . . . . . . . . . . . . . . . . . . . 16

Pan and Tilt Fluid Drag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjust Lock Levers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Technical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

General Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1

Page 4

Safety

Important information on the safe installation and operation of

this product. Read this information before operating the product.

For your personal safety, read these instructions. Do not operate

the product if you do not understand how to use it safely. Save

these instructions for future reference.

Warning Symbols Used in These Instructions

Safety cautions are included in these instructions. These safety

instructions must be followed to avoid possible personal injury and

avoid possible damage to the product.

WARNING!

Where there is a risk of personal injury or injury to others,

comments appear supported by the warning triangle symbol.

Where there is a risk of damage to the product, associated

equipment, process or surroundings, comments appear

supported by the word ‘CAUTION’.

Health and Safety

WARNING! Risk of personal injury or injury to others. All

personnel must be fully trained and adhere to correct manual

handling techniques and Health & Safety regulations. It is

the responsibility of the local organisation to enforce safe

working practices at all times.

Mounting, Installation and Operation

WARNING! Risk of finger entrapment. Do not place fingers

between the platform and body of the fluid head.

WARNING! Avoid trapping fingers when collapsing and

extending tripod legs.

WARNING! DO NOT fit the head to a tripod that cannot

support the combined mass of the head and its full payload.

WARNING! Toppling hazard. Do not leave unattended.

Keep out of reach of children.

WARNING! The product must always be secured.

CAUTION! Always lock the vertical and horizontal brakes

when the camera is mounted but not in use or when levelling

the fluid head on the tripod.

CAUTION! Hold the camera securely when mounting or

dismounting from the fluid head and when making

adjustments to the tripod height or footprint.

CAUTION! Always hold the pan bar when making

adjustments to the counterbalance or camera position. Do

not use the pan bar to lift or move the tripod and fluid head.

CAUTION! Only attach camera accessories to the pan bar.

Do not attach heavy items to the pan bar.

CAUTION! Always remove the camera before transporting.

WARNING! Before fitting or adjusting the camera or payload

the tilt lock pin must be engaged. See “Installation” on

page 9.

2

Page 5

Safety / About This Guide

Maintenance

WARNING! The fitting of non-approved parts and or

accessories, the carrying out of non-approved alterations or

servicing can be dangerous and could affect the safety of the

product. It may also invalidate the terms and conditions of the

product warranty.

CAUTION! When replacing the battery, use only the same or

an equivalent type of battery recommended for use with the

product.

About this User Guide

This guide describes the installation, configuration and operation of the

OConnor 2560 fluid head.

The 2560 features OConnor's step-less counterbalance system as well

as ultra-smooth pan and tilt fluid drag designed for cine style shooting.

A collapsible counterbalance crank handle and numerical readout

make counterbalancing the payload easy. The platform and brake

arrangements mean that all of the controls are on the camera

operator's side of the head (left side) for an improved operation

experience.

Additionally the platform has a marking scale and four rosette handle

mountings. The platform release lever has a one touch finger and

thumb actuated safety release catch, while still requiring conscious

effort for safety.

OConnor's fluid drag system allows an extremely quick pan movement

from one position to another, recovering instantly without any spring

back.

Variants

Two variants of the 2560 are available.

Basic Kit C1260 - 0002:

Supplied as a basic head with no accessories.

The C1260-0002 is supplied with a protective plastic base,

secured with 4 x Allen bolts, which must be removed and

swapped for a 150mm spherical and tie down or Mitchell

and tie down before use.

Full Kit C1260 - 0001:

Supplied as a full kit, see Box Contents C1260 - 0001 on page 6.

3

Page 6

Components

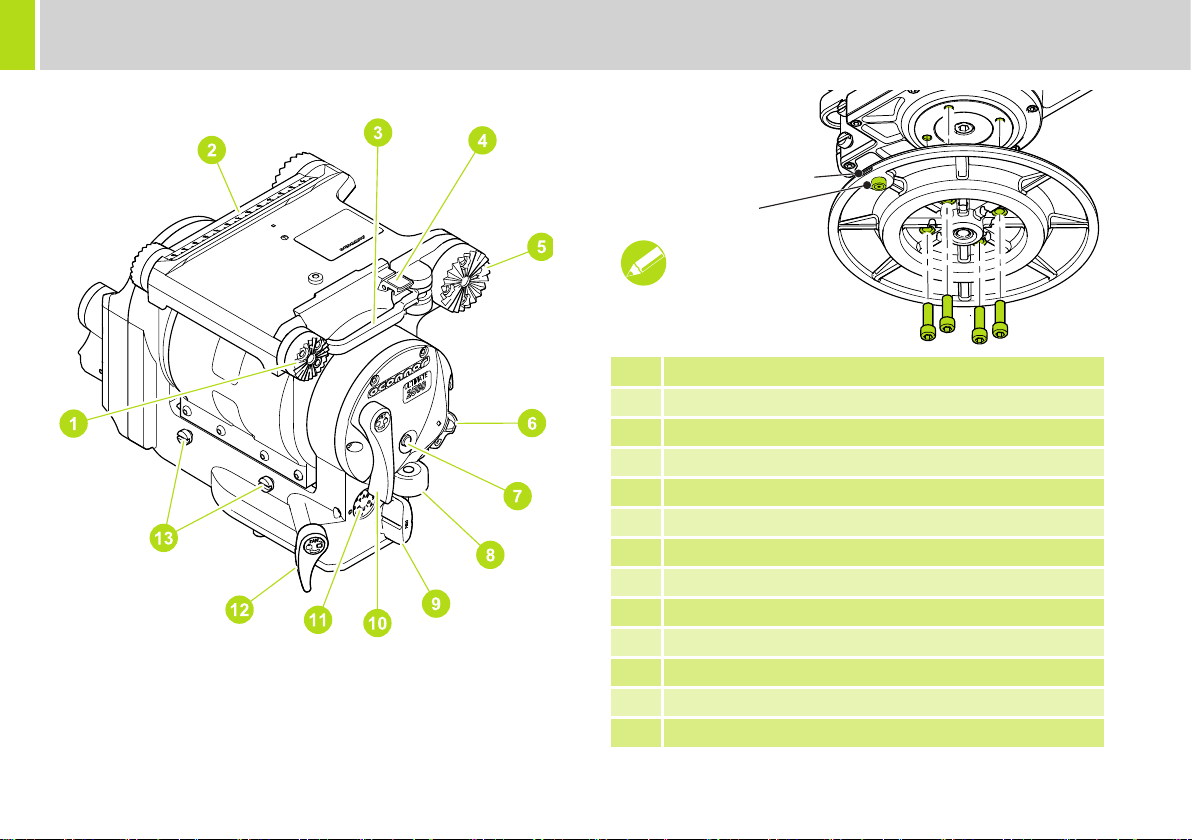

Front View

Mitchell Key marker

Mitchell Key

Attach either Mitchell

Base (shown) or

150mm ball base using

4 x Hex screws

1 Front end handle / accessory mounting rosette

2 Slide plate scale

3 Platform release lever

4 Platform release lever safety catch

5 Rear large pan handle / accessory mounting rosette

6 Tilt centre lock

7 Bubble illumination button

8 Bubble level

9 Pan fluid drag adjustment knob

10 Tilt lock lever

11 Pan fluid drag display

12 Pan lock lever

13 Front box mounting screws

4

Page 7

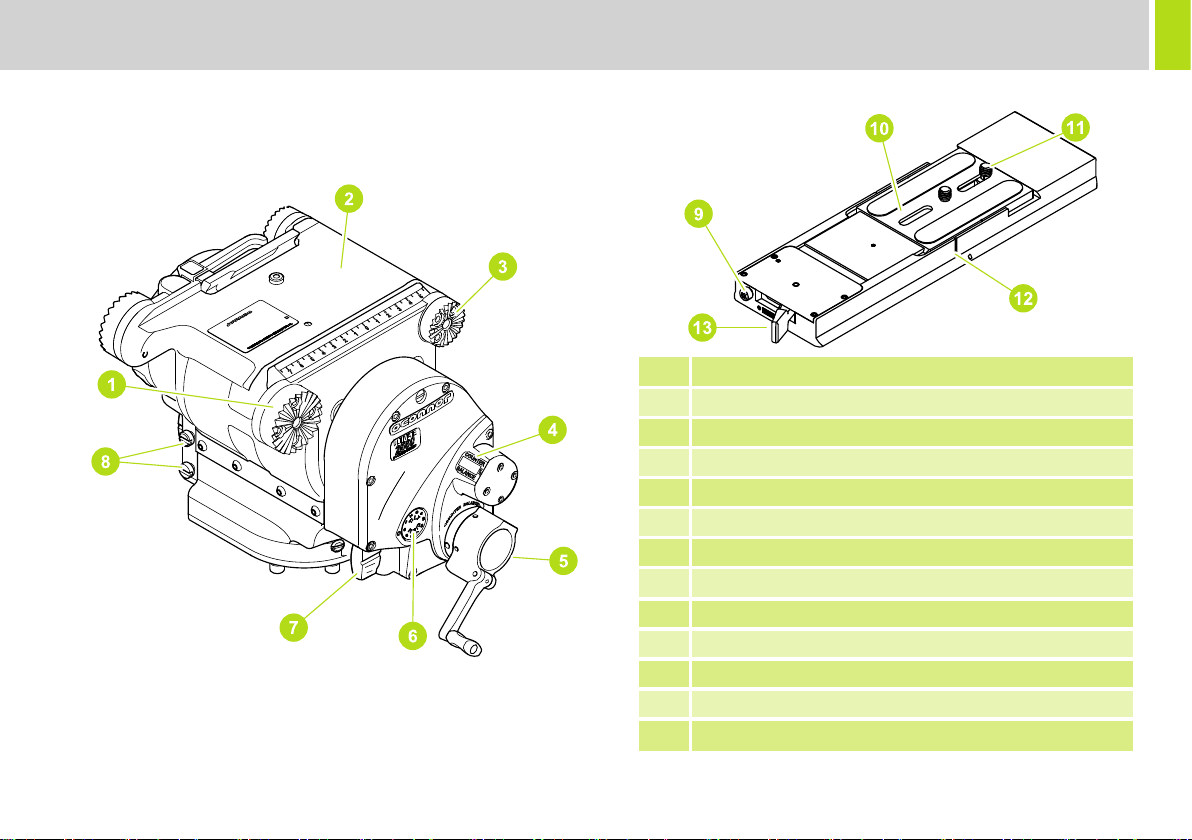

Components

Rear View

Euro Style Quick Release Plate

1 Rear large pan handle / accessory mounting rosette

2 Platform

3 Front small pan handle / accessory mounting rosette

4 Counterbalance numerical display

5 Folding counter balance adjustment crank

6 Tilt fluid drag display

7 Tilt fluid drag adjustment knob

8

Eyepiece leveller mounting screws

9 Camera plate clamp release lever

10 Camera mounting plate

11 Camera fixing screws

12 Slide plate marker

13

Camera plate clamp lever

5

Page 8

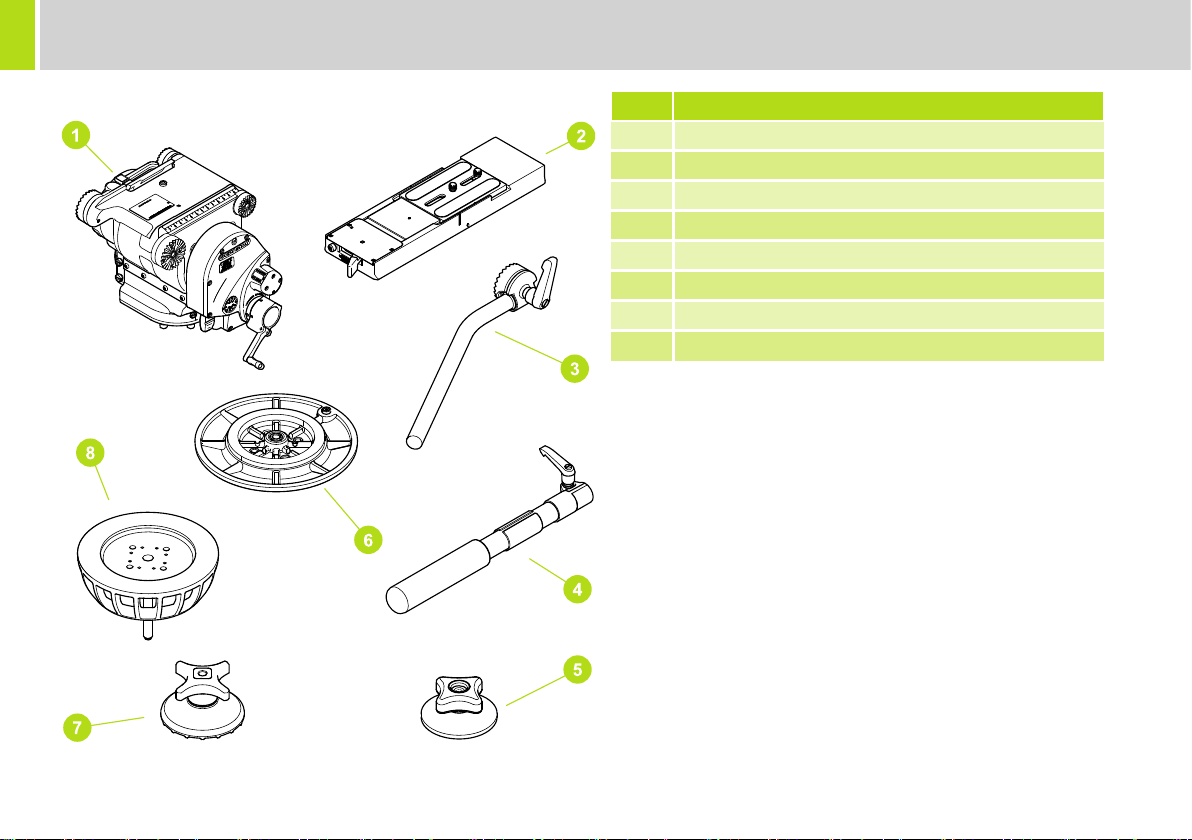

Components

Box Contents C1260 - 0001

Item Description

1 2560 head

2 Euro style quick release plate

3 Pan handle

4 Pan extension handle

5 Mitchell tie down

6 Mitchell base assembly

7 150mm tie down

8 150mm base assembly

*Variant C1260-0002 consists of head only.

6

Page 9

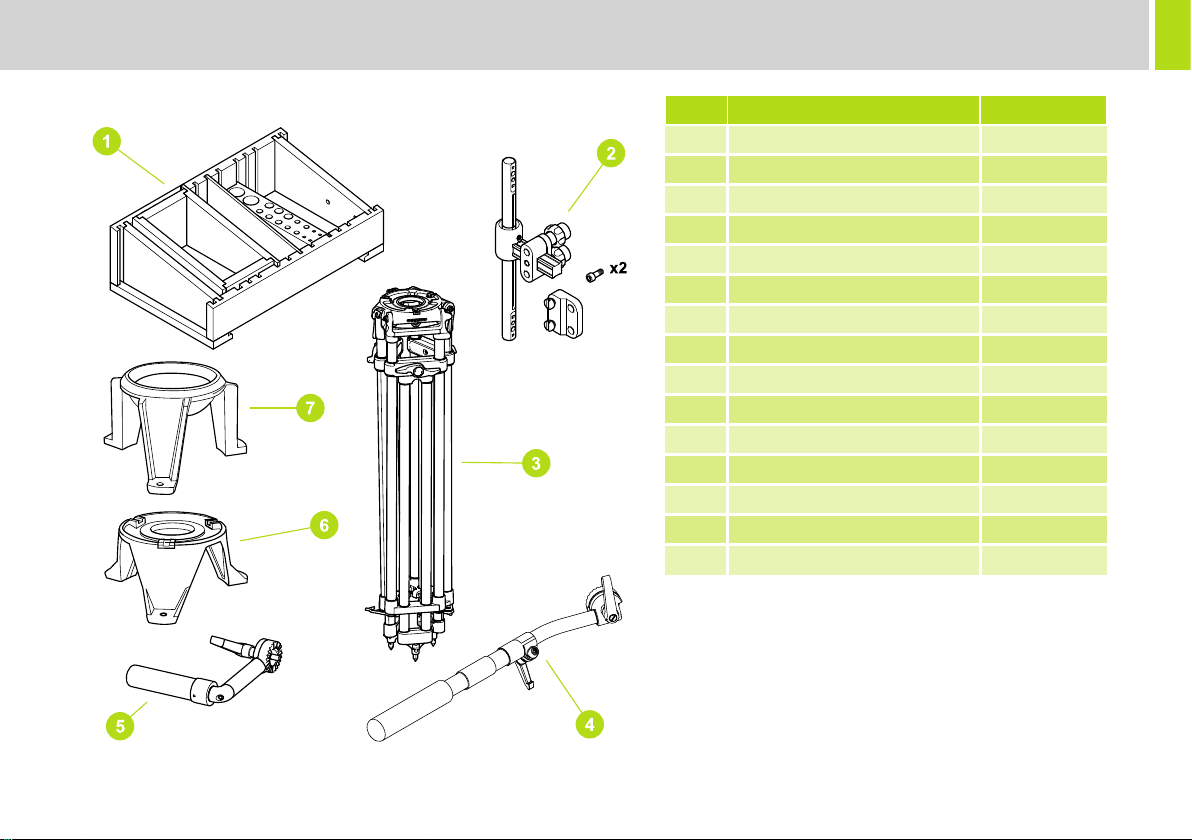

Components

oconner

Optional Accessories

Item Description Part No.

1 Assistants box CSE-MFB100

2 Eye piece leveller C1504-1000

3 Tripods

Cine HD Mitchell C1221-0001

Cine HD 150mm ball base C1221-0003

Cine HD Baby Mitchell C1221-0002

Cine HD Baby 150mm ball base C1221-0004

4 Pan handle 08409

5 Front handle C1260-1010

6 High hat Mitchell C1250-0001

7 High hat 150mm C1250-0002

OConner plate (Not shown) 08283

Arri plate dovetail (Not shown) 2575 - 210

Arri platform plate (Not shown) C2575 - 0240

Large pan handle (Not shown) 2575 - 107

7

Page 10

Installation

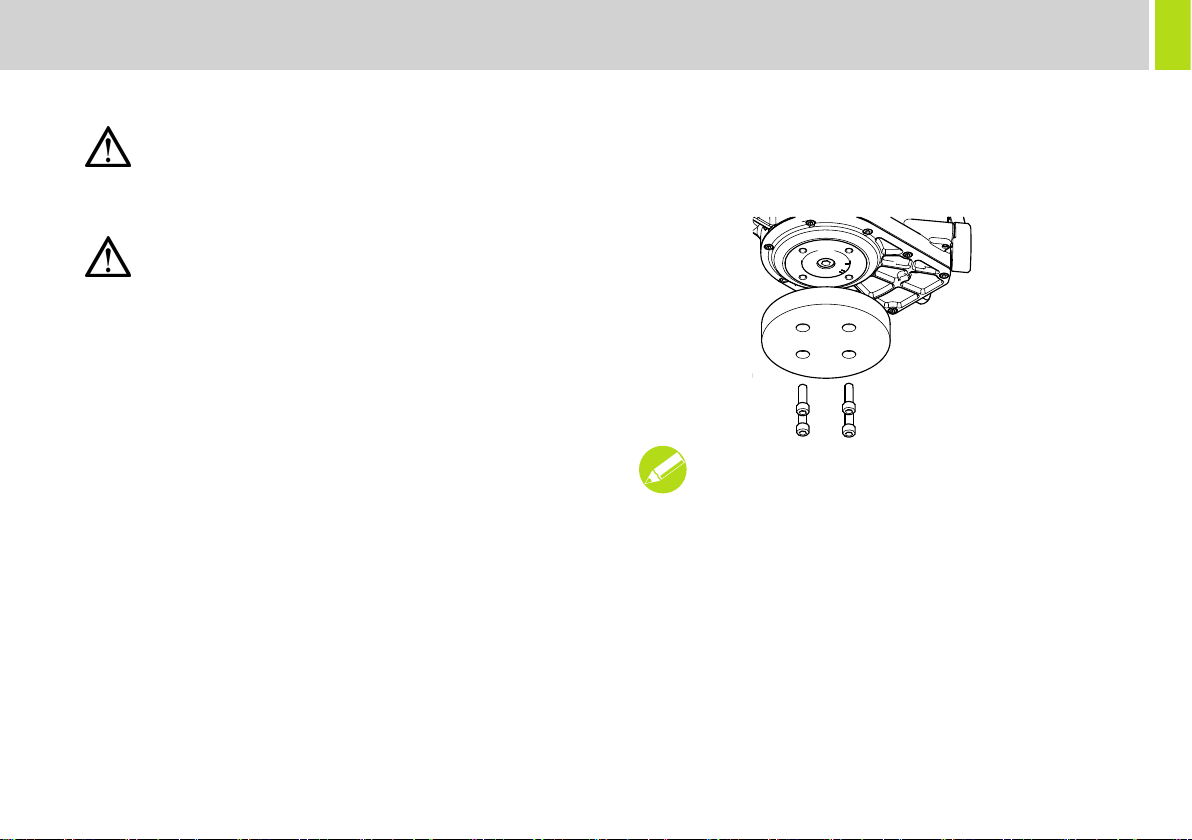

Mounting the head

The 2560 is installed onto standard tripods using either the Mitchell

base and tie down or the 150mm ball base and tie down as required.

WARNING! Do Not fit a head to a tripod that cannot support

the combined mass of the head and its full payload.

WARNING! If required use a mid-level or floor spreader to

ensure that the tripod legs are spread sufficiently; this ensures

that the C of G remains within the footprint of the tripod.

Refer to the tripod instructions supplied with the tripod for

correct fitting procedure.

Levelling the Head

After securely mounting the head on to the tripod, center the bubble

level to set the level.

If necessary, in poor light conditions:

1. Press the button illumination bubble (the light will remain on for 20

seconds).

2. Press the button again within 20 seconds to turn the light off.

Ball Base

Loosen the bowl clamp. Move the fluid head to center the level bubble.

Tighten the bowl clamp and re-check the level.

Mitchell Base

Levelling is achieved by adjusting the legs on the tripod until the level

bubble is centred.

8

Page 11

Installation

9

Page 12

Mounting the Camera

The camera is attached to the head by means of a side loading platform

mechanism.

WARNING! Before fitting or adjusting the camera or

payload the tilt lock pin must be engaged. See “Installation”

on page 9.

1. Release side loading platform if fitted.

2. Attach the mounting plate securely to the bottom of the camera in

the desired position.

3. Engage the tilt lock pin.

4. Release the safety catch and pull out the platform release lever.

5. Slide the camera mounting plate on to the platform towards the

right side of the head until an audible "click" is heard. When the

platform hook engages the camera mounting plate, the plate is

captive, but not locked.

6. Engage the base plate with the mounting plate. Slide the camera

and plate to the required position and lock by closing the platform

release lever.

10

Page 13

Fitting the Pan Handle

Pan Handle / accessory mounting rosettes are located at the front and rear of the head, on both the left and right sides.

Installation

11

Page 14

Installation

Fore/Aft Balance

Ensure that the head is level before balancing. The camera and

payload should be fitted on the head, so that the load is

balanced. This can be achieved by moving the camera

forwards (Fore) or backwards (Aft) on the cradle.

WARNING! When balancing the payload, it is

important to be aware of the potential danger that an

unbalanced payload will fall away suddenly. Maintain a

firm hold on the payload until the balance is set

correctly.

WARNING! The payload balancing procedure requires

the assistance of another person.

CAUTION! The camera, handles and all accessories

must be fitted in their operational position before

balancing the head. Any equipment fitted or adjusted

later can unbalance the head.

Turn the counterbalance crank to set the

1

counterbalance to 50%.

Depending on the payload weight, it may be necessary to

increase or decrease this setting to enable the payload to

be correctly balanced fore and aft.

50%

T

I

L

T

2

1

12

Set the tilt fluid drag adjustment knob to 0.

2

Page 15

Hold and steady the camera, then disengage the

3

tilt lock and observe how it moves and where it

stops.

If the camera cradle stops in a horizontal

position (camera pointing directly forward),

the balance is correct.

Reposition the camera as required on the head and

4

secure in position. The horizontal balance is correct

when the camera cradle comes to rest in a

horizontal position.

Installation

If the camera tilts backwards (points upward), then the camera must be

moved towards the front of the head (fore).

If there is insufficient movement in the sliding plate

to achieve balance, remove camera and plate from

the head, reattach the mounting plate to the

camera in the required position, remount the

camera and plate, repeat the balancing procedure.

If the camera tilts forward (points downwards), then the camera must be

moved towards the rear of the head (aft).

13

Page 16

Installation

Payload Weight and C of G Height Adjustment

WARNING! For safe and reliable operation the head and all

mounted equipment must be correctly balanced.

If the correct numerical balance setting of the payload is

known, tilt the platform to the horizontal position and turn

the counterbalance crank until the display shows the

correct setting

Maximum and minimum payloads that can be balanced are dependent

on the weight of the camera and accessories and on the centre of

gravity (C of G) height. The graph below shows the range of loads and

C of G heights that can be maintained in balance. The counterbalance

can be adjusted all the way to zero (no counterbalance) and the head

can still be tilted ±90º.

2560 Counterbalance

mm

in

16

406

356

14

12

305

254

10

8

203

Above Platform

152

6

Camera Centre of Gravity

102

4

51

2

0 102030405060708090100110120

lbs

5

Kg

914182327323641455054

Camera Weight

Numeric Display

The numeric display indicates the setting of the counterbalance

mechanism on a scale of 0-99%. Adjust the counterbalance crank

clockwise to increase the counterbalance setting and counter clockwise

to reduce it.

The display has a three color coded band offering advance warning of

cranking to the end limits.

CAUTION! When cranking into the red zone be careful to

stop before reaching either 0 or 99% as damage could

occur.

14

Page 17

Adjusting the Counter Balance

CAUTION! Risk of damage to equipment. Be prepared

to prevent the camera from falling away suddenly

Installation

1

2

Tilt the camera approx. 45°

upward and release it.

If the camera stays in the same

position when released, the

camera is correctly balanced

with the C of G on the tilt axis.

If the camera continues to move

towards the horizontal after

releasing the camera cradle,

reduce the counterbalance.

T

I

L

T

T

I

L

T

3

If the camera keeps falling back towards the vertical position

when released, increase the counterbalance.

Tilt the camera over the TDC, it should remain stationary at

any angle.

If the camera angle falls or rises, repeat the alignment

procedure until balance is achieved.

After adjusting the counterbalance, it may be necessary to

check that the fore and aft balance remains satisfactory.

Readjust the position of the camera horizontally on the

camera plate as required.

After balancing, exercise the head through both axes to

confirm that it operates smoothly.

The sliding plate is marked and the platform has

graduations. Make a note of the "balanced" position to

simplify rebalancing this particular payload.

15

Page 18

Operation

Operating the Pan and Tilt Locks

The pan and tilt friction locks are operated by levers on the left of the head. The locks should be applied whenever the camera/head is left unattended.

16

After prolonged use, if the lock does not fully engage at the end of the lock lever travel, refer to Adjust Lock Levers on page 19.

The levers are designed so they can be released simultaneously with one hand.

Page 19

Operation

Pan and Tilt Fluid Drag

The pan drag adjustment knob is located on the lower right rear of the head, and the tilt drag adjustment knob on the lower left of the head. Both controls

are continuously adjustable from 0 to 9. To increase drag, turn the knob clockwise, towards a higher setting. To decrease drag, turn the knob

counter-clockwise, towards a lower setting.

17

Page 20

Maintenance

Battery Replacement

The battery illuminates the bubble level. It should be replaced

whenever the illumination becomes inadequate.

1. Use a coin or flat blade screwdriver to unscrew the battery cover.

2. Carefully pull the battery out of its compartment.

3. Fit a replacement CR 2032 3v battery in the compartment,

ensuring that the positive side (+) of the battery faces outermost.

4. Replace the battery cover and tighten using a coin or flat blade

screwdriver.

5. Press the bubble level illumination button and verify that the

bubble level is lit for approximately 20 seconds.

18

Page 21

Maintenance

Adjust Lock Levers

If the pan and/or tilt friction locks do not fully engage at the end of the

lock lever travel, adjust the lever position as follows:

1 Shaft

2 Tilt lock lever

3 Screw

4 Lock label

1. Rotate the lock lever to the “locked” position.

2. The lock lever is attached by means of a screw. Carefully peel off

the lock label to expose the screw. Using a 2.5 mm Allen key

remove the screw.

3. Pull the lock lever off the hexagonal shaft, rotate it approx. 30°

away from the “locked” end of travel, and reinstall it.

4. Tighten the screw. Reapply the lock label.

30°

19

Page 22

Maintenance

Cleaning

We encourage regular cleaning of the product. During normal use the

only cleaning required should be a regular wipe over with a lint-free

cloth.

Cover the head when not in use. Dirt accumulated during storage or

periods of non-use may be removed with a vacuum cleaner.

CAUTION! Salt water will damage the head! If product

comes into contact with salt water, immediately rinse with

distilled water and dry with compressed moving air.

Storing the Head

• When shooting is finished the head should be stored in the case.

• Store in a dry area.

• You may leave the counterbalance and drag settings at the end of

a shoot.

• For long term storage, we advise that the counterbalance is

adjusted towards 100%.

CAUTION! Never force the counterbalance when

resistance is felt near 0 or 100%.

20

Page 23

Physical Data

Technical Specification

Height

20.3 cm (8 in.)

Depth

19.1 cm (7.5 in)

*Maximum payload

40.72 kg (90 lb) See

chart on page 14

Storage temp.

-40°C to +60°C

(-40°F to +140°F)

Bubble level

Illuminated

Width

28.7 cm (11.3 in.)

Weight

7.3 kg (16.2 lb)

Tilt

±90º throughout entire

counterbalance

range, zero to max.

Operating Temp.

-40°C to +60°C

(-40°F to +140°F)

Battery

Type: 1 x CR 2032 3v

*Capacity:

For maximum payload capacity please use balance graph on page 14.

As a reference below are the maximum capacities if CofG distance

above platform is:

@102mm (4 in) 37.7 kg (83 lb.)

@152mm (6 in) 29.5 kg (65 lb.)

@ 203mm (8 in) 24.1 kg (53 lb.)

21

Page 24

General Notices

Declaration of Conformity

Vitec Videocom Limited declares that this product has been

manufactured in accordance with BS EN ISO 9001:2008 and is in

compliance with the essential requirements and other relevant

provisions of the Machinery Directive 2006/42/EC. A copy of the

Declaration of Conformity is available upon request.

Environmental considerations

European Union Waste of Electrical and Electronic

Equipment (WEEE) Directive (2002/96/EC)

This symbol marked on the product or its packaging indicates that this

product must not be disposed of with general household waste. In

some countries or European Community regions separate collection

systems have been set up to handle the recycling of electrical and

electronic waste products. By ensuring this product is disposed of

correctly, you will help prevent potentially negative consequences for

the environment and human health. The recycling of materials helps

conserve natural resources.

Visit our website for information on how to safely dispose of this product

and its packaging.

In countries outside the EU:

Dispose of this product at a collection point for the recycling of electrical

and electronic equipment according to your local government

regulations.

Disposal of waste batteries

Any batteries included with this product must not be treated as

household waste. By ensuring these batteries are disposed of correctly,

you will help prevent potentially negative consequences for the

environment and human health, and help conserve natural resources.

Read ‘Battery Replacement’ section in this manual for instructions on

how to remove the battery from the product safely. Hand the battery

over to the applicable collection point for recycling waste batteries.

22

Page 25

Page 26

Page 27

Page 28

Publication part No. C1260-4980/2

OConnor

™

A Vitec Group brand

www.ocon.com

Loading...

Loading...