Page 1

O-Box WM Set

Standard - C1243-0001

Deluxe - C1243-0002

User Guide

User Guide

Page 2

!

Caution

WARNING!

!

If the sunshade is damaged or torn, DO NOT touch the damaged

surfaces. Dispose of safely.

Ÿ DO NOT attempt to move the camera by pulling the flags.

Ÿ DO NOT lift the O-Box WM by the flags, the flag brackets or the O-Grips.

Ÿ DO NOT overload the O-Box WM as a carrying or rigging point.

Ÿ Ensure the lock levers on the flag brackets and the 3-system rod bridge

are firmly tightened.

Ÿ Ensure screws are sufficiently tight when attaching rod brackets or studio

adapter brackets.

Ÿ NEVER use solvents or oil-based cleaners to clean the O-Box WM.

Use mild detergents only. Wipe surfaces with a damp, lint-free cloth.

Ÿ ALWAYS use genuine OConnor parts and accessories with the O-Box WM.

Ÿ When using the O-Box WM as a clamp-on mattebox and/or handheld mount,

DO NOT subject the lens to forces that may damage it.

Particular care should be taken when using still photography lenses intended

for autofocus photography.

Copyright © 2013 The Vitec Group plc

All rights reserved throughout the world. No part of this document may be stored in a retrieval system, transmitted, copied or reproduced in any way, including,

but not limited to, photocopy, photograph, magnetic or other record without the prior agreement and permission in writing from the Vitec Group plc.

Page 3

Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The O-Box Wide Mini . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

In the box - standard set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

In the box - deluxe set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Assembly

assembling the filter frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

assembling the flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

assembling the clamp rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

assembling the universal rings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

assembling the bellows ring (donut) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

mounting onto camera rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Setup options

Cine Follow Focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

O-Grips Handgrip System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Contents

3

Page 4

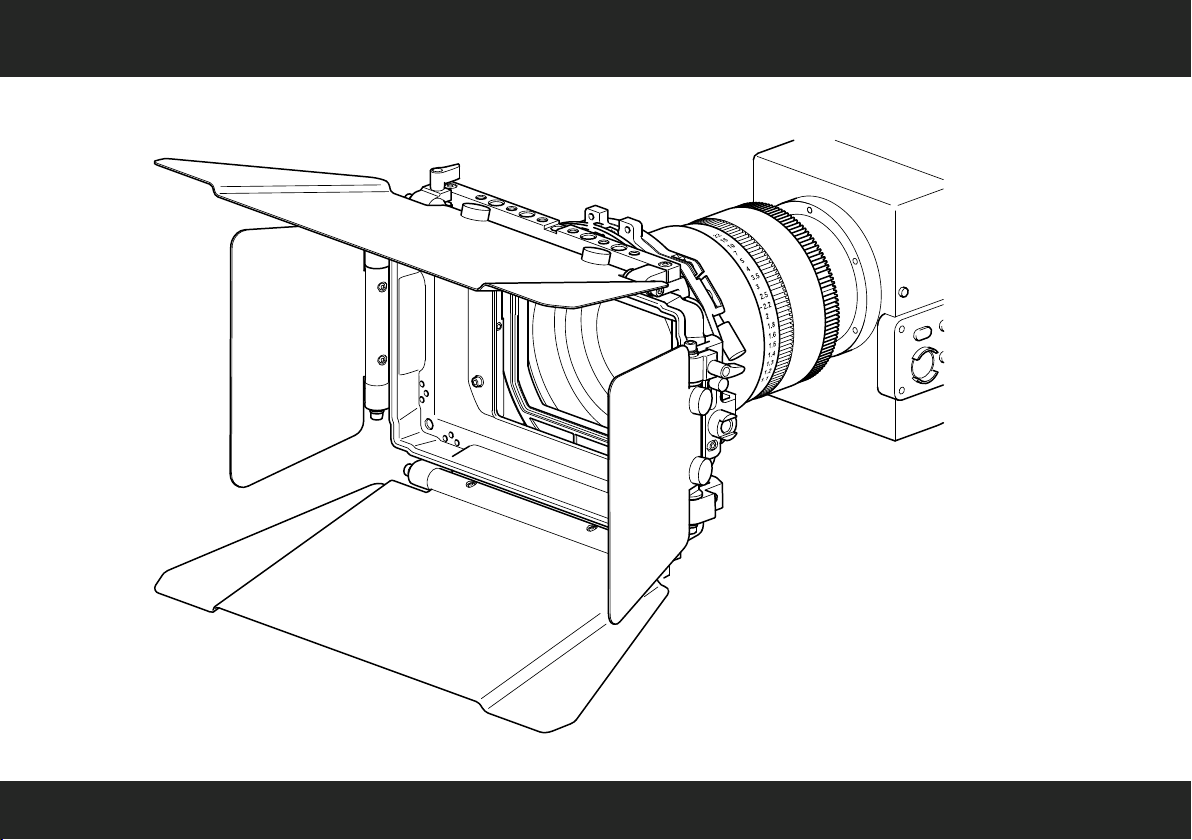

The O-Box Wide Mini

4

Page 5

Congratulations on the purchase of your new OConnor O-Box WM Set!

We want you to get the most from your new O-Box WM compact mattebox and therefore encourage you to

read this user guide to familiarize yourself with its many features, some of which may be new to you. It also

covers essential safety information.

Features and benefits of your new O-Box WM

The O-Box Wide Mini, the first mattebox from OConnor, offers a host of innovative features:

Ÿ highly shock-resistant and durable design

Ÿ large rear clamping interface for lens diameters up to 150 mm

Ÿ clamp rings featuring collet design for high compressibility with no light leaks

Ÿ utility bar or “cheese stick” with provisions for attachment of O-Grips and other

mounting/rigging hardware such as ringlights, top lights, or monitors

Ÿ interface to O-Grips 3-system rod bridge to save rod space in studio configurations

Ÿ easy serviceability

Special features

The OConnor O-Box WM is a compact, two-stage mattebox designed around the 16:9 wide-angle format. The

O-Box WM can be combined with an OConnor Follow Focus, up to six O-Grips and up

to three filters, offering highly flexible configurability and many diverse filtering possibilities in a very compact

package.

New accessories

Oconnor have teamed up with our friends at CINEPARTS to introduce two unique Universal Rings for the

O-Box WM range. Based on an exclusive CINEPARTS design endorsed by OConnor, each ring is

manufactured from aircraft aluminum and holds a seamless high-tech fabric inner that will flex over a variety of

lens diameters. The Universal Rings are supplied in two sizes: 150 to 80 mm, and 114 to 55 mm. These

handy new additions can replace multiple hard reduction rings and are perfect for today's versatile shooter

working with a range of lenses.

5

Page 6

Specifications

O-Box WM Set (C1243-0001) / O-Box WM Deluxe Set (C1243-0002)

O-Box WM

Weight (incl. top flag bracket, LWS rod bracket) . . . . . . . . . . . . . . . . . . . . 0.7 kg (1.54 lbs)

Dimensions (HWD) . . . . . . . . . . . . . . . . . . . . . . . 210 x 242 x 84 mm (8.3 x 9.5 x 3.3 in.)

Height, incl. bottom flag bracket . . . . . . . . . . . . 211 x 242 x 84 mm (8.3 x 9.5 x 3.3 in.)

Width, incl. side flag brackets . . . . . . . . . . . . . 210 x 300 x 84 mm (8.3 x 11.8 x 3.3 in.)

Depth, incl. bellows ring . . . . . . . . . . . . . . . . . 210 x 242 x 106 mm (8.3 x 9.5 x 4.2 in.)

Maximum lens diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø150 mm (Ø5.9 in.)

Top or bottom flag

Dimensions (width at widest point) . . . . . . . . . . . . . . . . . . . . 166 x 337 mm (6.5 x 13.3 in.)

Filter frames (sets of 2)

to hold square filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 x 4 in.

to hold rectangular filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 x 5.65 in.

Overall dimensions (per frame) . . . . . . . . . . . . . . . . . . . . . . . . . 151 x 145 mm (6 x 5.7 in.)

LWS rod bracket

for standard camera rods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø15 mm (0.6 in.)

Specifications are subject to change without notice

6

Page 7

Specifications

O-Box WM Deluxe Set (C1243-0002)

Side flags (set of 2)

Dimensions (width at widest point) . . . . . . . . . . . . . . . . . . . . . 115 x 172 mm (4.5 x 6.7 in.)

Side flag brackets (set of 2)

Dimensions (HWD) . . . . . . . . . . . . . . . . . . . . . . . . 105 x 57 x 36 mm (4.1 x 2.2 x 1.4 in.)

Bellows ring (Donut)

Dimensions (width at widest point) . . . . . . . . . . . . . . . . . . . . . 115 x 172 mm (4.5 x 6.7 in.)

Maximum lens diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø114 mm (Ø4.4 in.)

Reduction ring

Maximum lens diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø110 mm (Ø4.3 in.)

Universal rings (set of 2)

(150 - 80 mm)

Outer diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø150 mm (Ø5.9 in.)

Minimum lens diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø80 mm (Ø3.1 in.)

(114 - 55 mm - threaded)

Outer diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø114 mm (Ø4.4 in.)

Minimum lens diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø55 mm (Ø1.9 in.)

Specifications are subject to change without notice

Only

7

Page 8

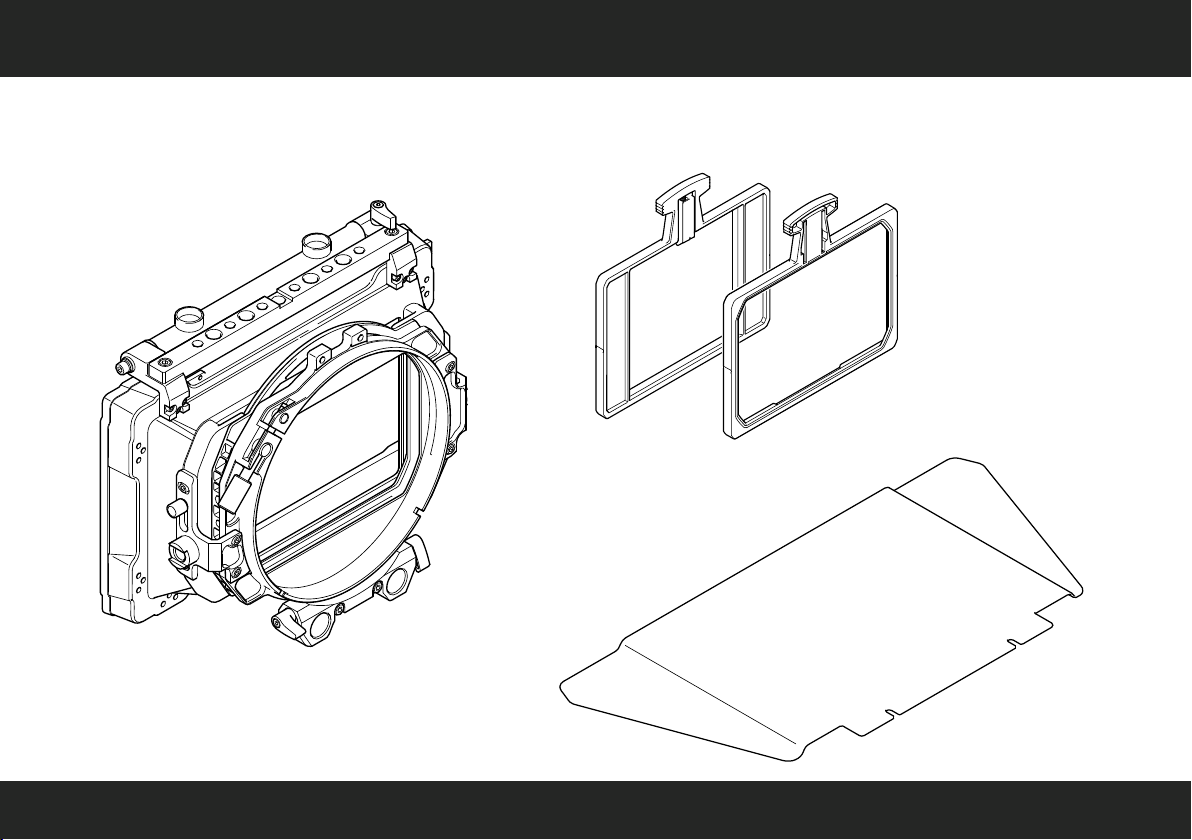

In the box - standard set

O-Box WM Set

C1243-0001

O-Box Wide Mini

Filter Frames 4"x 4"

Set of 2

Filter Frames 4"x 5.65"

Set of 2

Top or Bottom Flag

8

Page 9

In the box - deluxe set

O-Box WM Deluxe Set

C1243-0002

O-Box Wide Mini

Filter Frames 4"x 4"

Set of 2

Filter Frames 4"x 5.65"

Set of 2

Side Flags (Wings)

Set of 2

Side Flag Brackets

Set of 2

9

Page 10

In the box - deluxe set

Bellows Ring

(Donut)

Top or Bottom Flag

Reduction Ring

(114 to 110 mm)

Universal Rings

Set of 2

10

Page 11

Clamp Rings

C1243-1123

C1243-1124

C1243-1125

C1243-1126

Accessories

Studio Adapters

C1243-1118 (19 mm)

C1243-1119 (15 mm)

(for use with rod bridge)

Side Flags (Wings)

Set of 2

C1243-1122

Side Flag Brackets

Set of 2

C1243-1121

Part no.

C1243-1123

C1243-1124

C1243-1125

C1243-1126

Clamp Ring size

(for standard lenses)

150 to 114 mm

150 to 110 mm

150 to 95 mm

150 to 80 mm

11

Page 12

Accessories

Part no.

C1243-2171

C1243-2172

C1243-2173

Reduction Rings

C1243-2171

C1243-2172

C1243-2173

Reduction Ring size

(for use with bellows ring)

114 to 110 mm

114 to 95 mm

114 to 80 mm

O-Grips 3-System

Rod Bridge

C1244-1002

Bellows Ring

(Donut)

C1243-1117

Matching OConnor accessories:

Cine Follow Focus CFF-1 Set

C1241-0001

O-Grips Handgrip System

C1244-1001 (single module)

Bottom Flag Bracket Set

C1243-1127 (flag req.)

12

Page 13

Universal Rings

C1243-1128

C1243-1129

Accessories

Top or Bottom Flag

C1243-2149

Part no.

C1243-1128 150 to 80 mm

Part no.

C1243-1129 114 to 55 mm

Universal Ring size

(for standard lenses)

Universal Ring size

(for use with bellows ring)

13

Page 14

Components

top or bottom flag

sunshade

(mattebox)

side flag

(asymmetric)

flag axle

side flag bracket

knurled flag screws

(hollow)

fixing screw

(for rotatable stage)

O-Grip

mounting point

lock lever

top or bottom bracket

(with utility bar or “cheese stick”)

filter stages

(front / rear)

rear clamping

interface

(Ø150 mm)

bellows ring or “donut”

(optional)

LWS rod bracket

14

Page 15

Assembly – assembling the filter frames

1

Push up the filter spring. Align the

filter in the frame, then release the

spring to fix the filter in place.

A

4" x 4"

B

4" x 5.65"

A

A

OR

rear stage

OR

front stage

B

B

2

Slide the assembled filter frame

Two filter stages are available between the sunshade

and the rear clamping interface: one fixed and one

rotatable stage. Slowly push the filter frame down,

until it audibly ‘clicks’ into place. If you can feel

mechanical resistance, slacken the red fixing screw

a few turns (see step 3).

3

Turn the red fixing screw on the filter stage

clockwise to secure the filter frame in position.

The rear filter frame can be rotated 360°.

Push the head of the filter frame to the left

or right. Tighten the large silver fixing

screw on the front filter stage to

lock the rotation.

into the filter stage.

15

Page 16

assembling the flags

1

If required, turn the lock lever anti-clockwise to unlock the flag axle.

Adjust the axle so the hollow knurled screws point upward.

Turn the knurled screws anti-clockwise a few turns to slacken.

Align the cutouts at the bottom of the flag with the screw threads,

then push the flag into position and tighten the screws.

Adjust the angle of the flag as desired, then tighten the lock

lever clockwise to fix the flag in the desired position.

2

A set of two side flags and two flag brackets

are available as optional accessories. Attach a

flag bracket on either side of the sunshade;

use a 2 mm Allen or hex key and secure the

bracket with the six screws and two rectangular

nuts supplied.

3

Repeat the steps outlined above for the

bottom/top flag also for the side flags

(see step 1). Adjust each flag’s position

as desired, then tighten the lock lever

firmly to fix in position.

16

Page 17

1

Choose a clamp ring to suit your camera lens.

Turn the knurled screw anti-clockwise to widen the

rear clamping interface. The clamp ring uses a

collet design making it easier to compress.

Squeeze the ring adapter slightly, then carefully fit

it into the clamping interface.

assembling the clamp ring

Use the clamp ring to mount the O-Box directly onto the camera lens.

This type of setup is used when carrying the camera on the shoulder

or when mounting it without camera rods. Four standard-size clamp

rings are available (see page 8).

For more information about lens diameters visit OConnor Labs online

at the OConnor website (see OConnor > Labs > ‘Lens Diameters’).

2

Fit the clamp ring over the camera lens. Turn the

knurled screw clockwise to secure the clamp ring to

the lens ensuring that it is firmly attached and that

the mattebox cannot slip.

17

Page 18

assembling the universal ring

Use the universal ring to mount the O-Box directly onto the camera

lens. This type of setup is used when the LWS rod bracket is mounted

to the mattebox.

For more information about lens diameters visit OConnor Labs online

at the OConnor website (see OConnor > Labs > ‘Lens Diameters’).

1

Turn the knurled screw anti-clockwise to widen the

rear clamping interface. Carefully fit the universal

ring into the clamping interface.

18

Turn the knurled screw clockwise to secure the

2

universal ring to the clamping interface. Finally,

using the LWS rod bracket mount the assembled

mattebox on the camera rods and push until it

engages with the camera lens.

Page 19

assembling the bellows ring (donut)

The O-Box WM can be fitted with an optional bellows ring

or “donut” and a reduction ring or universal ring for use

with camera lenses with smaller lens diameters (see page

12 and 13). The donut can accommodate an optional

rotatable round filter (Ø138 mm).

This configuration is suitable for camera rods.

2

Insert the front of the donut into the

clamping interface and push in as far

1

Slacken the large knurled screw on the

rear clamping interface a few turns to

widen the clamping ring. If a round filter

is used, unscrew the retaining ring at the

front of the donut, insert the filter in the

ring groove, then reassemble the donut.

as the tooth profile. Turn the knurled

screw clockwise, until it firmly holds

the donut in the interface.

A

B

3

Insert either the reduction ring [A] or the

universal ring [B] into the donut thread,

then turn clockwise to fix in position.

Finally, using the LWS rod bracket mount

the assembled mattebox on the camera

rods and push until it engages with the

camera lens.

19

Page 20

mounting onto camera rods

The O-Box WM can be fitted with a 15 mm or 19 mm studio adapter

and a 3-system (O-Grips) rod bridge to suit standard camera rods

(see page 9) supporting lightweight to heavy accessory loads.

Turning the lock levers clockwise secures the mattebox on the rods.

For more information about rod adapters visit OConnor Labs online

at the OConnor website (see OConnor > Labs > ‘Rod Standards

Explained’).

20

Remove the LWS bracket (see page 19).

Align the studio adapter and—using a 3 mm

Allen or hex key—tighten the two cap head

screws to secure the adapter.

Mount the 3-system rod bridge. Align the

bridge mounting holes with the adapter

rods, then push the bridge forward onto the

rods. Turn the lock levers clockwise, tighten

firmly to secure the bridge in position.

Page 21

Cine Follow Focus

For precision movement control

the O-Box WM can be partnered

with the Cine Follow Focus.

21

Page 22

adjusting the LWS rod bracket

1

The O-Box WM comes with an LWS rod bracket

attached. Mount the O-Box WM onto camera rods

above the camera using a 3 mm Allen or hex key

to unscrew the two screws holding the LWS rod

bracket and remove the bracket.

The O-Box WM mattebox can be attached to a

camera fitted with an OConnor Follow Focus with

the camera rods mounted above or below the

camera lens. The complete O-Box WM mattebox

assembly, including a suitable lens adapter, is then

mounted flush on camera rods using the 15 mm

LWS rod bracket.

22

2

Attach the LWS rod bracket at the top of the rear

clamping interface. Use the two screws to secure

the bracket in place.

Page 23

O-Grips Handgrip System

The O-Box WM can be equipped with

up to six O-Grips (A), where the system

setup includes a studio adapter and a

3-system O-Grips rod bridge.

The standard setup with a 15 mm LWS

rod bracket offers four mounting points

for O-Grips (B).

A

B

For more information consult the OConnor O-Grips Handgrip System User Guide (publication

part no. C1244-4980) supplied with the product or visit the OConnor website (see page 19).

23

Page 24

OConnor Offices worldwide

ASIA

CHINA

Room 706, Tower B

Derun Building

YongAn Dongli A No. 8

Jianwai Ave.

Chaoyang District

100022 Beijing, China

Tel.: +86 10 8528 8748

Fax: +86 10 8528 8749

JAPAN

P.A. Building 5F

3-12-6 Aobadai

Meguro-ku

Tokyo 153-0042

Japan

Tel.: +81 3 5456 4155

Fax: +81 3 5456 4156

SINGAPORE

6 New Industrial Road

#02-02 Hoe Huat Industrial

Building

Singapore 536199

Tel.:

+65 6297 5776

Fax:

+65 6297 5778

EUROPE

FRANCE

171 Avenue des Gr sillons

92635 Gennevilliers CEDEX

France

Tel.: +33 8 20 82 13 36

Fax: +33 8 25 82 61 81

GERMANY

ä

Geb ude 16

Planiger Stra e 34

55543 Bad Kreuznach

Germany

Tel.: +49 671 483 43 30

Fax: +49 671 483 43 50

Erfurter Straße 16

85386 Eching

Germany

Tel.: +49 89 321 58 200

Fax: +49 89 321 58 227

UK

William Vinten Building

Western Way

Bury St Edmunds

Suffolk IP33 3TB

United Kingdom

Tel.: +44 1284 752 121

Fax: +44 1284 750 560

Sales Fax: +44 1284 757 929

é

ß

www.ocon.com – sales@ocon.com

HEADQUARTERS

2701 N. Ontario St.

Burbank, CA 91504

USA

Tel.: +1 818 847 8666

Fax: +1 818 847 1205

USA

16 Progress Drive

Shelton, CT 06484

USA

Tel.: +1 203 929 1100

Fax: +1 203 925 2684

BRAZIL

Vitec Group Brazil

Vitec Brazil Tecnologias Ltda.

Rua Quintana, 950 – cj. 32

Brooklin

São Paulo, 04569-011

Brazil

Tel.: +55 11 5102 4001

Page 25

Page 26

Connor

O

A V

™

itec Group brand

C1243-4980/2

Loading...

Loading...