Ocmis Irrigazione MR, MRR, MR/1, R1AT15 Instruction Manual

30/11/2015

EN

Models:

MR - MR/1

Models:

MRR - R1AT15

INSTRUCTIONS AND WARNING MANUAL

HOSE REEL TRAVELLING RAINGUNS

MUMR-R1.02 .EN

II

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

Chapter 0

All rights reserved in all countries

Requests for additional copies of this document or technical information on the same, should be sent to:

OCMIS IRRIGAZIONE S.p.A.

Headquarters and Production Facility

41014 CASTELVETRO (MO) ITALIA

Via S.Eusebio, 7

Tel. +39 059 702150

Fax. +39 059 702153

www.ocmis-irrigazione.it

info@ocmis-irrigazione.it

The text and images have been edited with the utmost care, however the Manufacturer reserves the right to amend and/or update the information

herein to correct any typographical errors and/or inaccuracies, without prior notice or obligation.

The content of this manual is strictly technical and is the property of the Manufacturer.

This manual is supplied in paper format.

No part of this manual may be translated and/or adapted and/or reproduced in another form and/or by mechanical, electronic means, by photocopying,

recording or other, without prior written authorisation from the Manufacturer.

The prohibition of copying, disclosing, etc. also applies to the electronic format.

The company protects its proprietary rights according to the law.

Documentation drawn up in compliance with the defi nitions under item 1.7.4 of EC directive 2006/42/EC (Directive on the approximation of the laws

of Member States relating to machinery).

The Manufacturer would like to thank you for purchasing one of its products and recommends reading this manual and all manuals and documents

listed in chapter 9.

In this manual you will fi nd all the information necessary for the proper handling of the machine supplied.

The user is therefore kindly requested to strictly adhere to the warnings herein and to read the manual in its entirety.

Furthermore, we urge you to directly contact the Manufacturer for any spare parts, suggestions on selecting any special equipment or simply for

instructions on the machine you have purchased.

Referencing this manual is supported by the general table of contents shown on the fi rst page and by the Manual layout, which allows topics to be

located immediately.

The chapters are arranged according to a structure that makes the required information easier to fi nd.

A special note at the beginning of the chapter highlights the fact that it deals with topics and provides information of specifi c interest to skilled personnel.

The documentation supplied with the machine consists of the following Instructions and Warning Manual as well as the manuals for the equipment,

machines, partly-completed machinery and components listed in chapter 9 which are an integral part of this manual and for which the same

recommendations/requirements set out herein apply.

The instructions contained in this manual are: TRANSLATION OF ORIGINAL INSTRUCTIONS.

III

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

Chapter 0

ORGANISATION OF THE DOCUMENTATION

The instruction and warning manual is organised as follows:

a) General machine manual, the chapter structure of which is set out below

Operating instructions manual

Chapter 0

Contents

• Contents of the manual

Chapter 1

General information

• Manual composition

• Warranty

• Terminology and abbreviations used

• General remarks

Chapter 2

Technical specifi cations and Layout

• Technical specifi cations

• Identifi cation code

• General Layout

Chapter 3

Description

• Description of the machine and installed

parts

• Confi guration by type

Chapter 4

Safety

• Technical standards applied

• Certifi cation of the machine

• Safety devices applied to the machine

• Disconnection of power sources

• Residual risks and warning plates

Chapter 5

Transport and Installation

• Packaging and transport

• Assembly and placement

• Connections

• Checks and inspections after installation

Chapter 6

Use and Operation

• Preliminary information

• Procedures for operating

• Operator interface devices

Chapter 7

Maintenance

• General maintenance information

• Personnel in charge of maintenance

• Maintenance plan

• Cleaning

• Maintenance procedures

Chapter 8

Troubleshooting - Diagnostics - Solutions

• Troubleshooting

• Diagnostics and Solutions

Chapter 9

List of annexes

• Reference to diagrams, manuals and

relevant documentation for component

equipment which makes up the supplied

machine

Chapter 10

Lists of Spare Parts

• Lists of machine spare parts recommended

by the Manufacturer for the machine

b) Specifi c Manuals for the main Process Units designed by the Manufacturer.

c) Instruction manuals drawn up by the respective OEMs for the main trade systems purchased by the Manufacturer and integrated into the machine.

d) Circuit diagrams (oil hydraulic, electrical, etc.), spare part list, setting up charts, etc.

IV

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

Chapter 0

CONTENTS

1 GENERAL INFORMATION ........................................................................................................................................ 1

1.1 WARNINGS FOR THE BUYER ........................................................................................................................................... 1

1.2 INTRODUCTION ................................................................................................................................................................. 2

1.3 MANUFACTURER'S ADDRESS ......................................................................................................................................... 3

1.4 SAFETY RULES SET OUT IN THE MANUAL..................................................................................................................... 3

1.5 GLOSSARY OF TERMS USED .......................................................................................................................................... 3

1.6 PERSONNEL QUALIFICATIONS ........................................................................................................................................ 5

1.7 SYMBOLS USED WITHIN THE MANUAL .......................................................................................................................... 5

1.8 SYMBOLS USED WITHIN THE MANUAL .......................................................................................................................... 6

1.9 DESCRIPTION OF PERSONAL PROTECTION EQUIPMENT (PPE) ................................................................................ 9

1.10 MANUAL LANGUAGE ....................................................................................................................................................... 10

1.11 MACHINE HANDLING ......................................................................................................................................................10

1.12 WARRANTY ..................................................................................................................................................................... 10

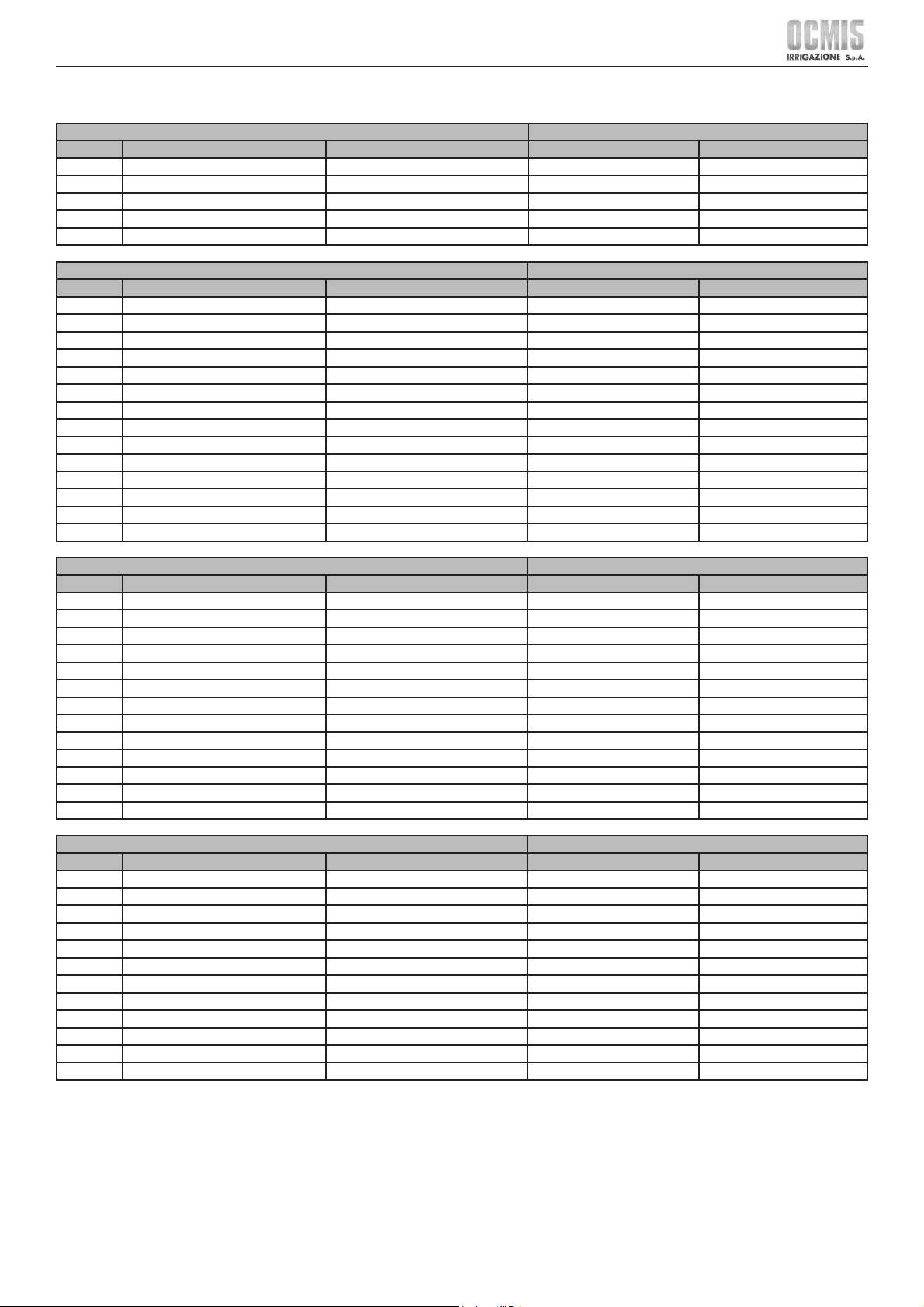

2 TECHNICAL DESCRIPTION OF THE MACHINE .....................................................................................................11

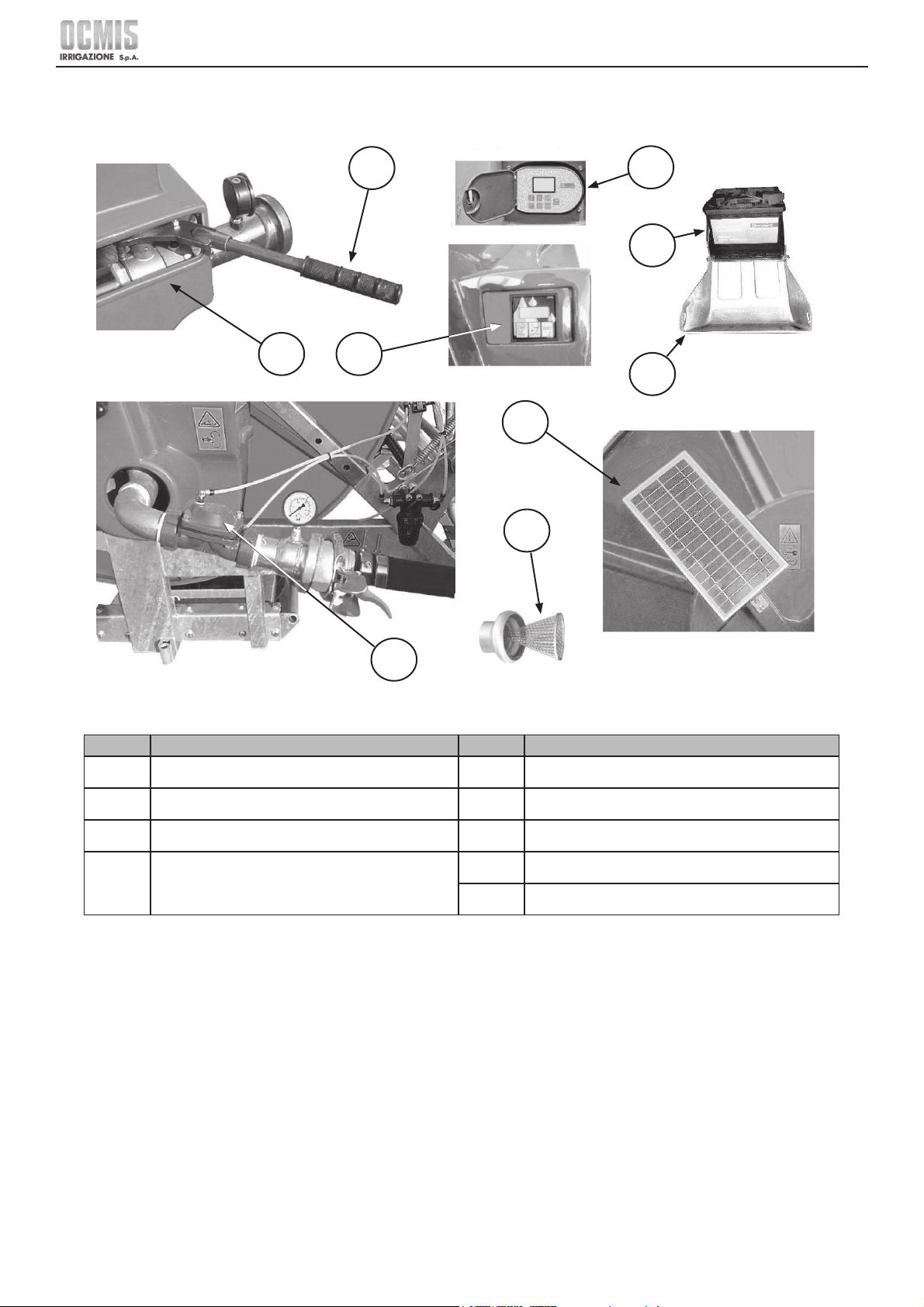

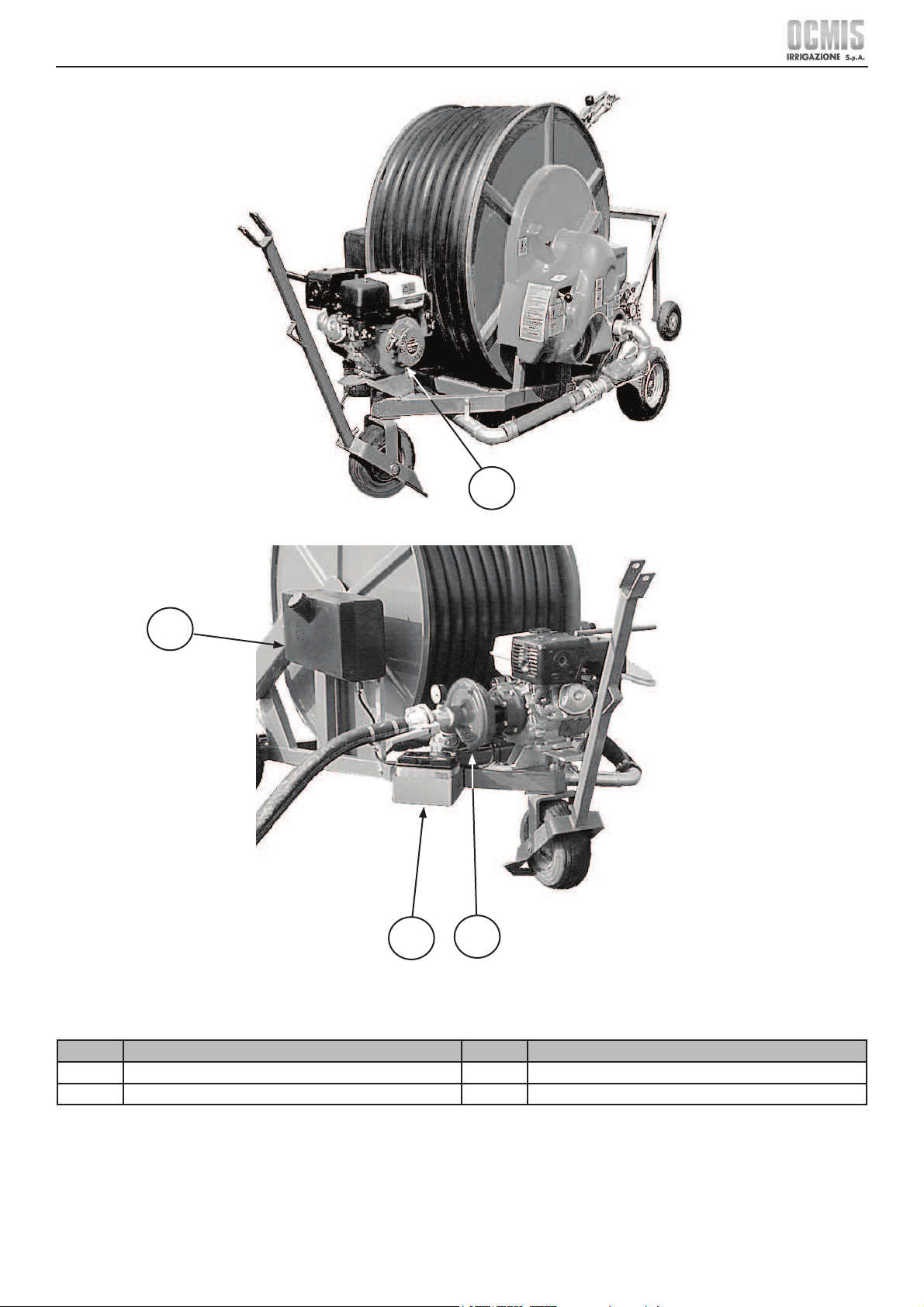

2.1 DESCRIPTION OF MAIN PARTS ..................................................................................................................................... 11

2.2 DESCRIPTION OF OPTIONAL PARTS ............................................................................................................................ 14

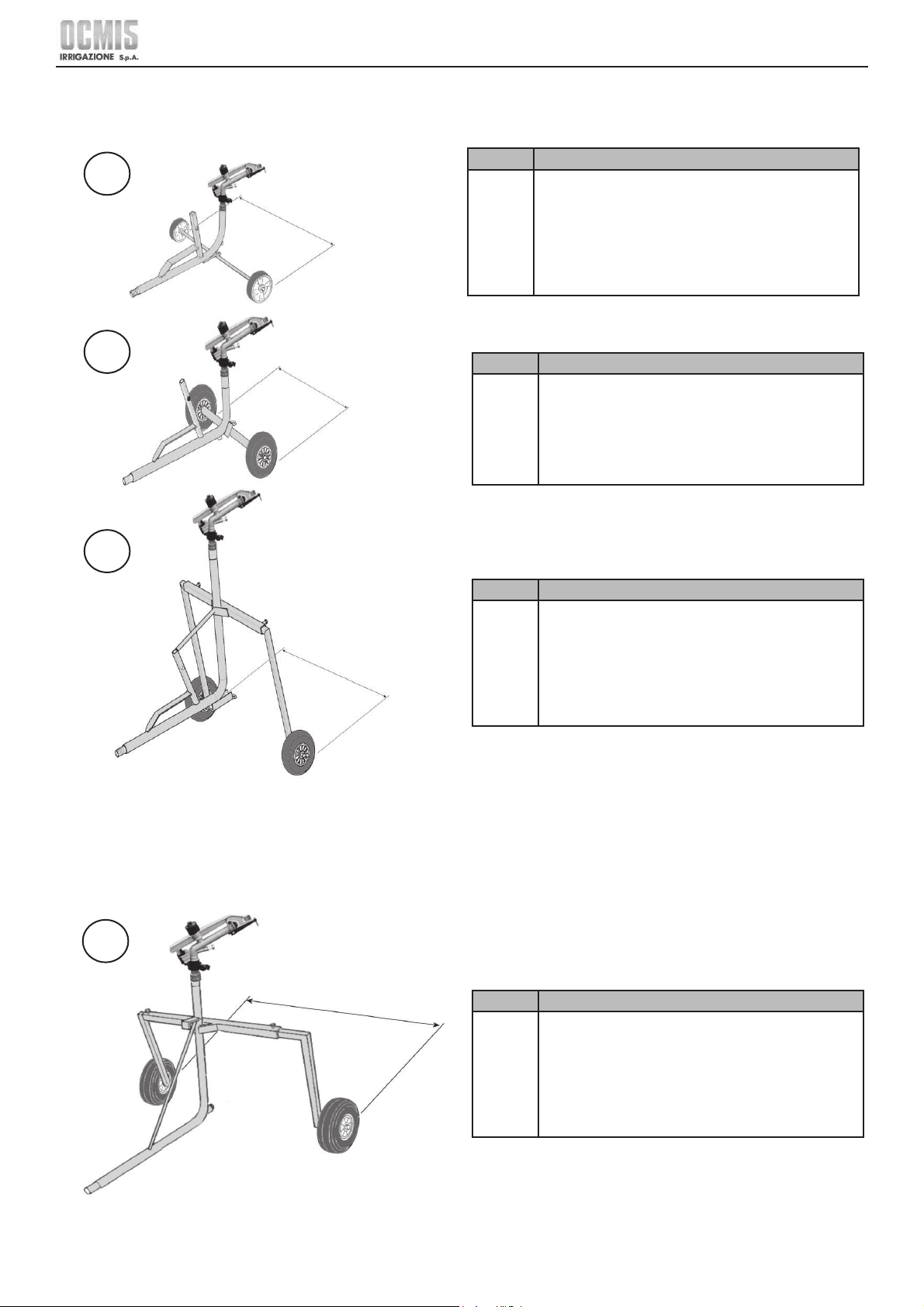

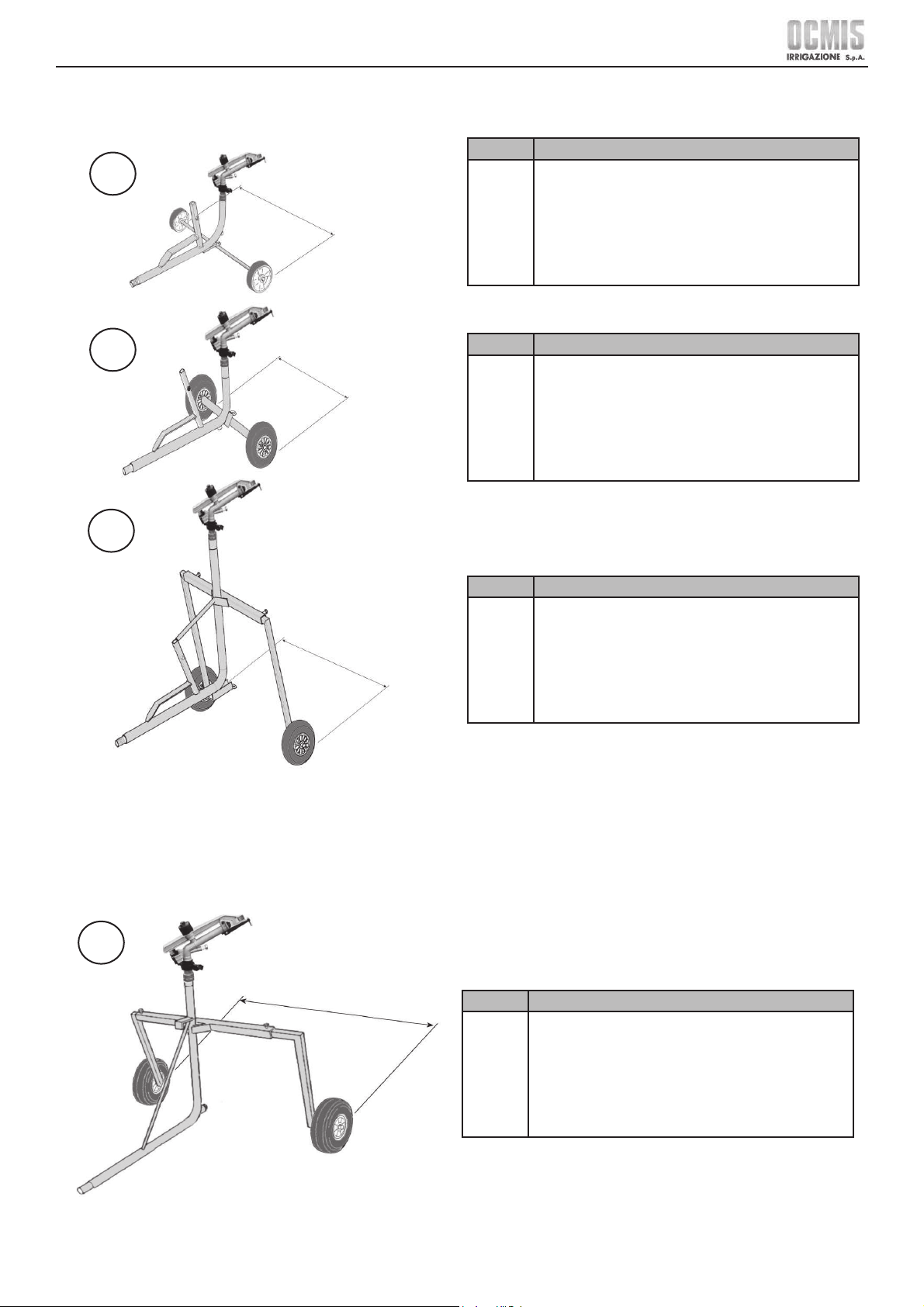

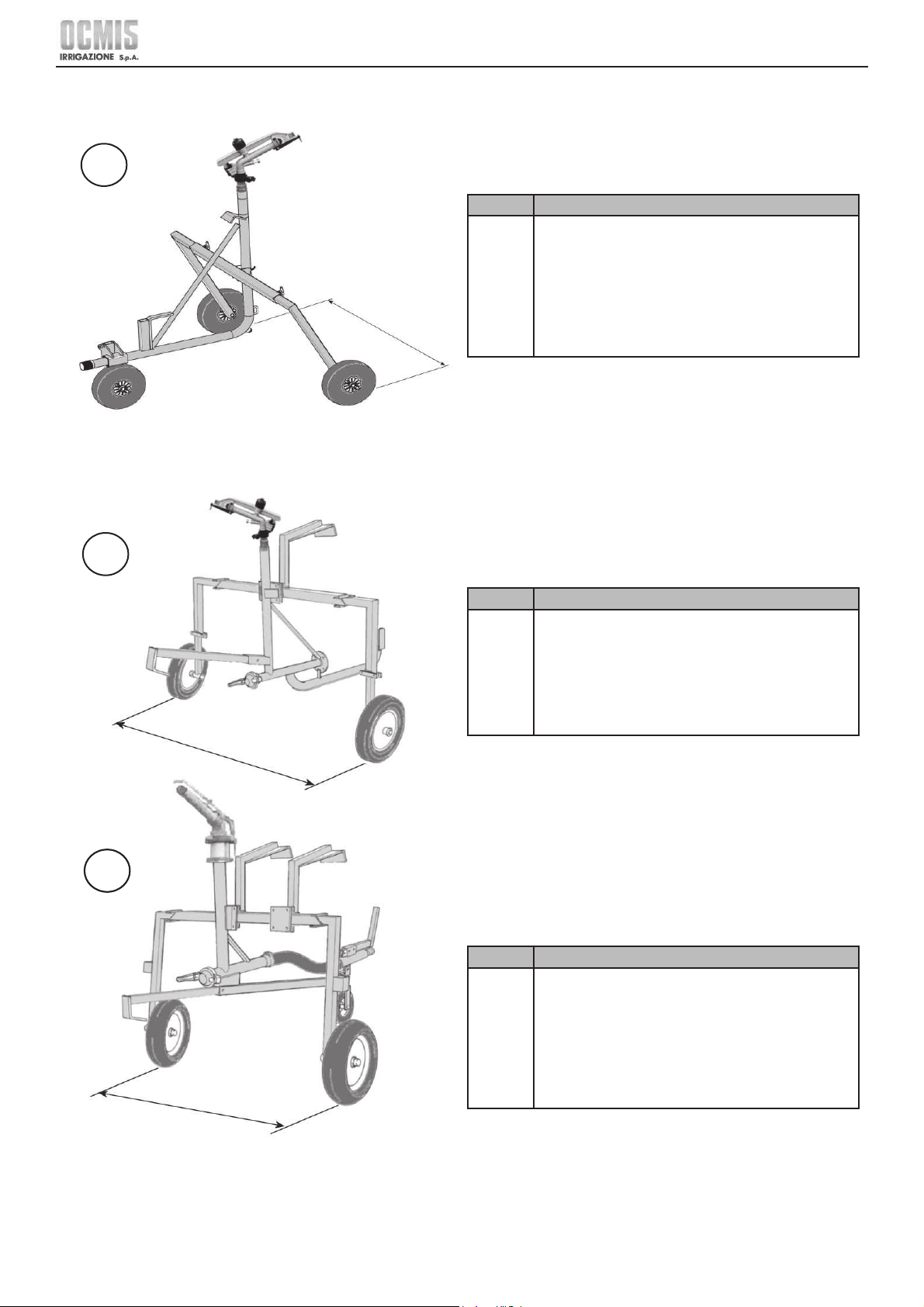

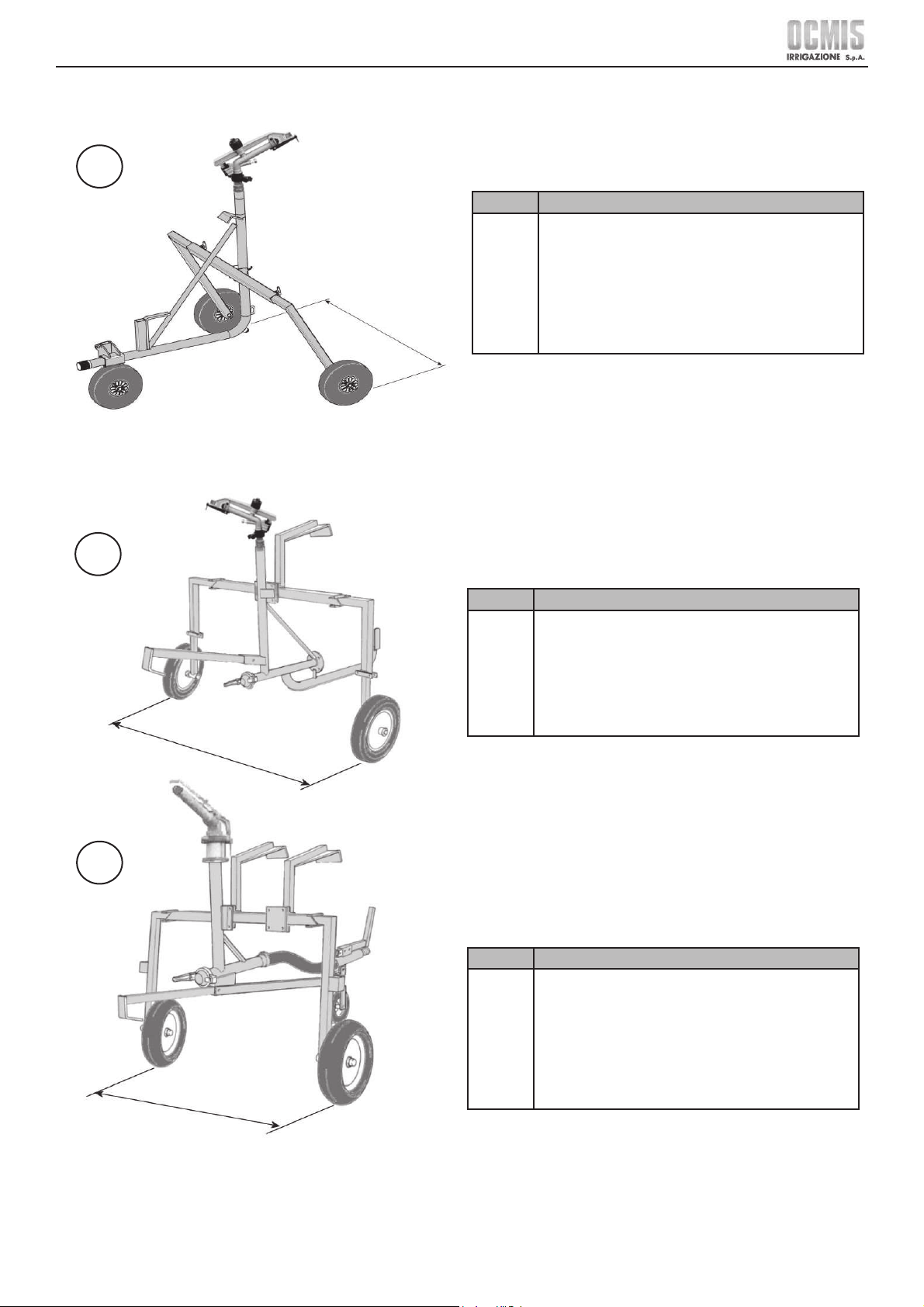

2.3 DESCRIPTION OF RAINGUN TROLLEYS ....................................................................................................................... 16

2.3.1 DESCRIPTION OF MAIN PARTS AND WHEEL WIDTH .................................................................................................................... 16

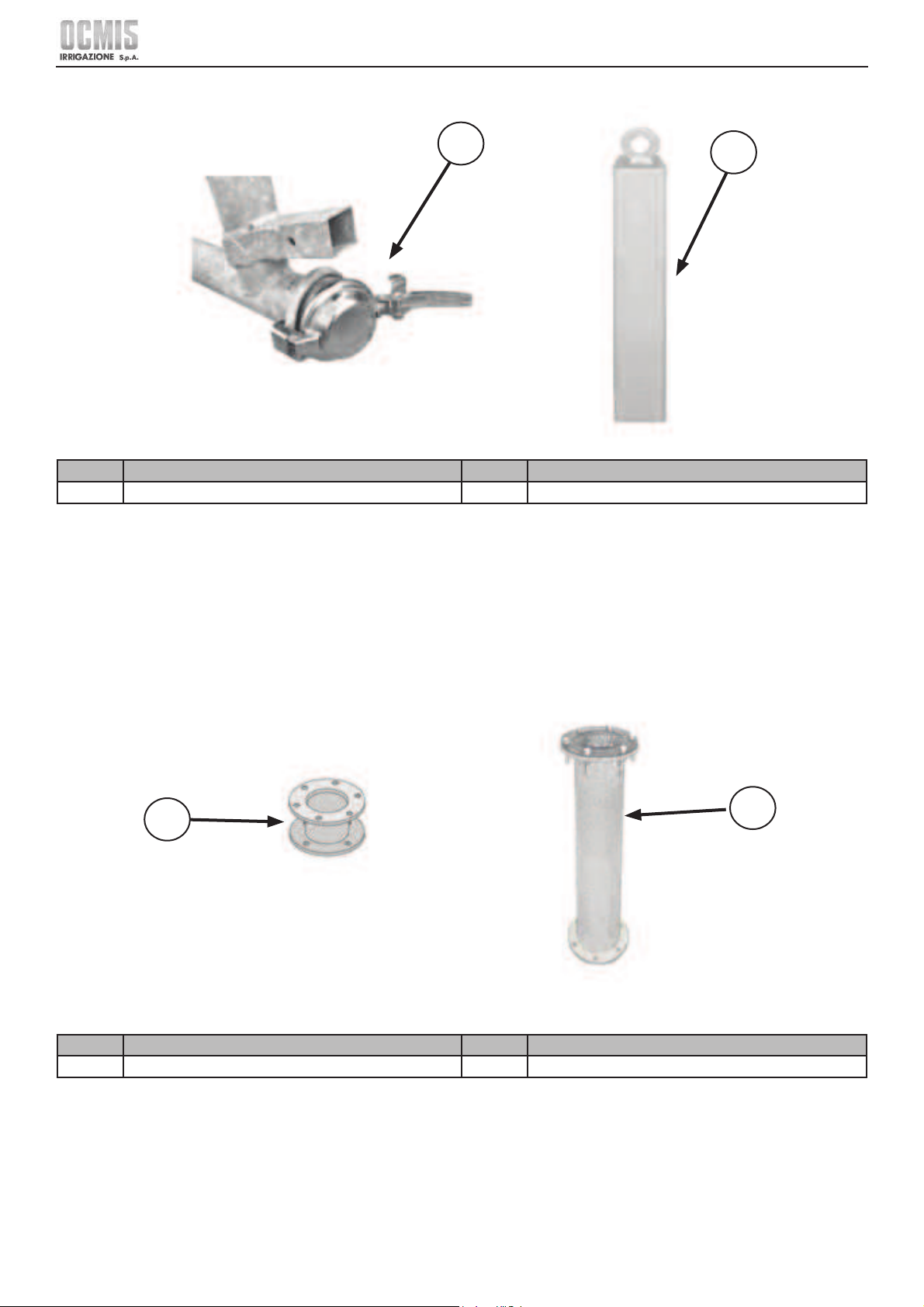

2.3.2 DESCRIPTION OF THE MAIN ACCESSORIES................................................................................................................................. 20

2.3.3 DESCRIPTION OF OPTIONAL ACCESSORIES ................................................................................................................................ 20

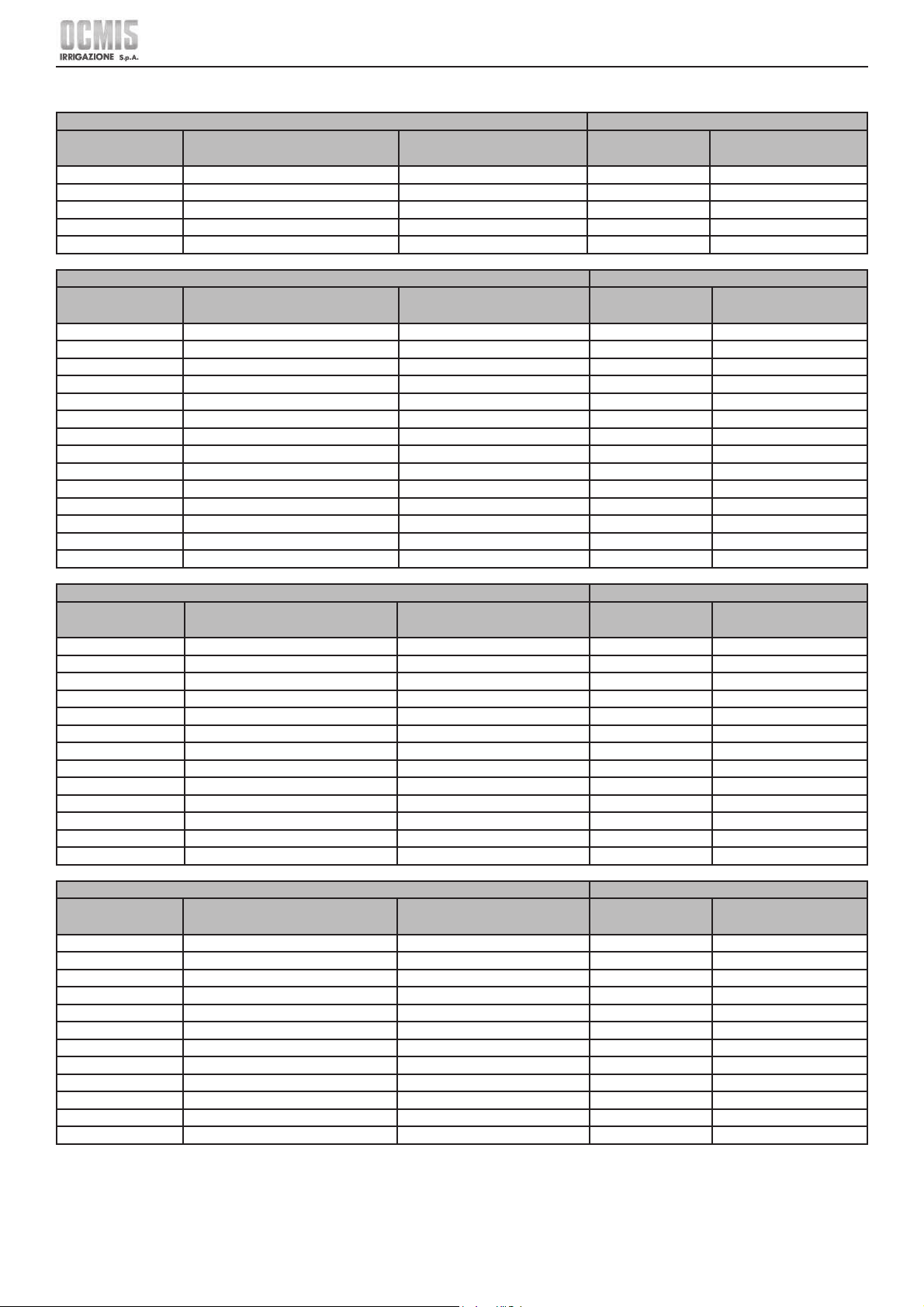

2.4 TECHNICAL DATA ............................................................................................................................................................21

2.4.1 MACHINE WEIGHTS BASED ON MODEL ........................................................................................................................................ 21

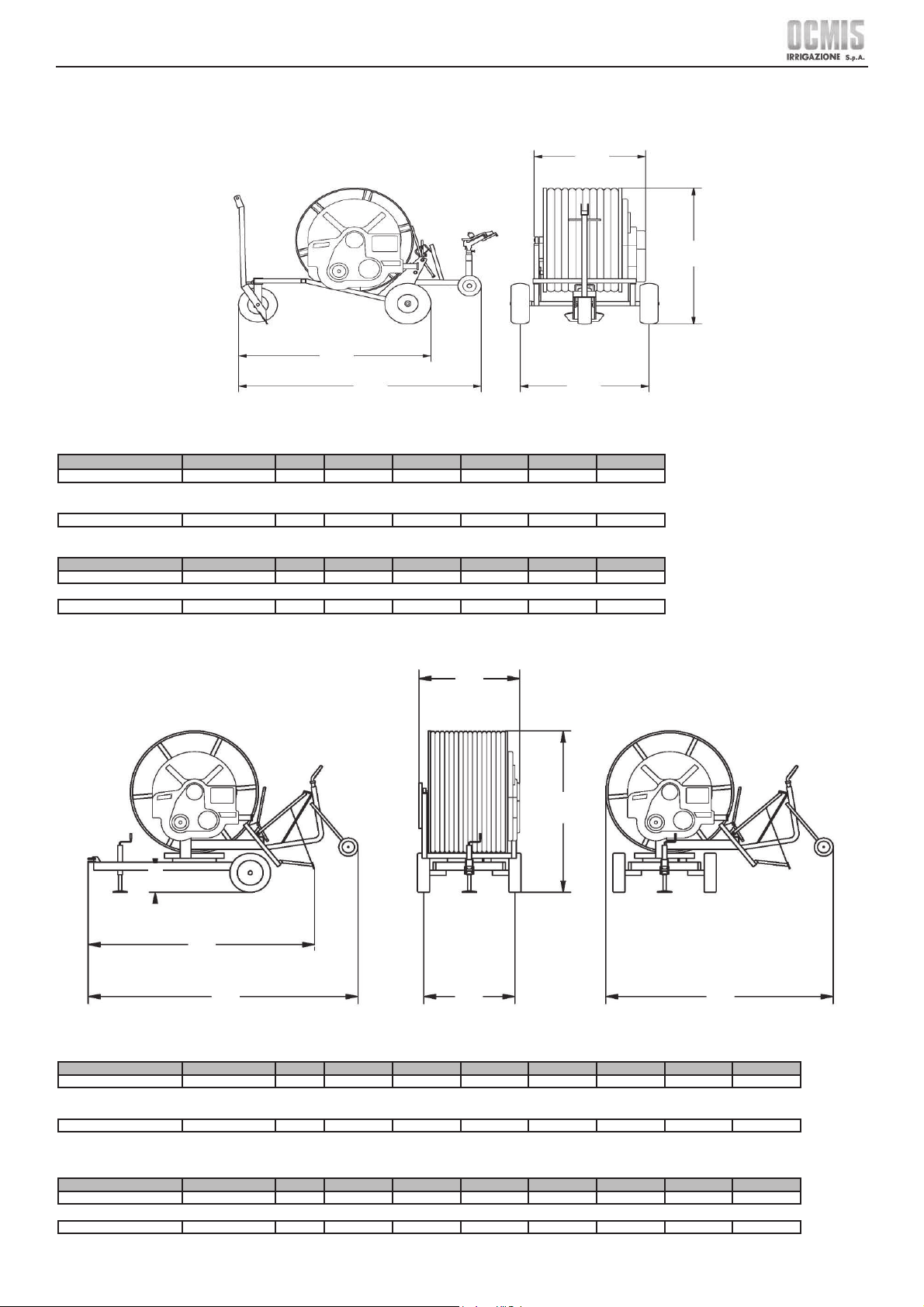

2.4.2 DIMENSIONS OF MACHINES WITH 2 WHEELS .............................................................................................................................. 23

2.4.3 WHEEL SIZE AND TECHNICAL SPECIFICATIONS .......................................................................................................................... 24

2.4.4 RAINGUN TROLLEY WHEEL SIZE AND TECHNICAL SPECIFICATIONS ....................................................................................... 24

2.4.5 NOISE LEVEL ..................................................................................................................................................................................... 24

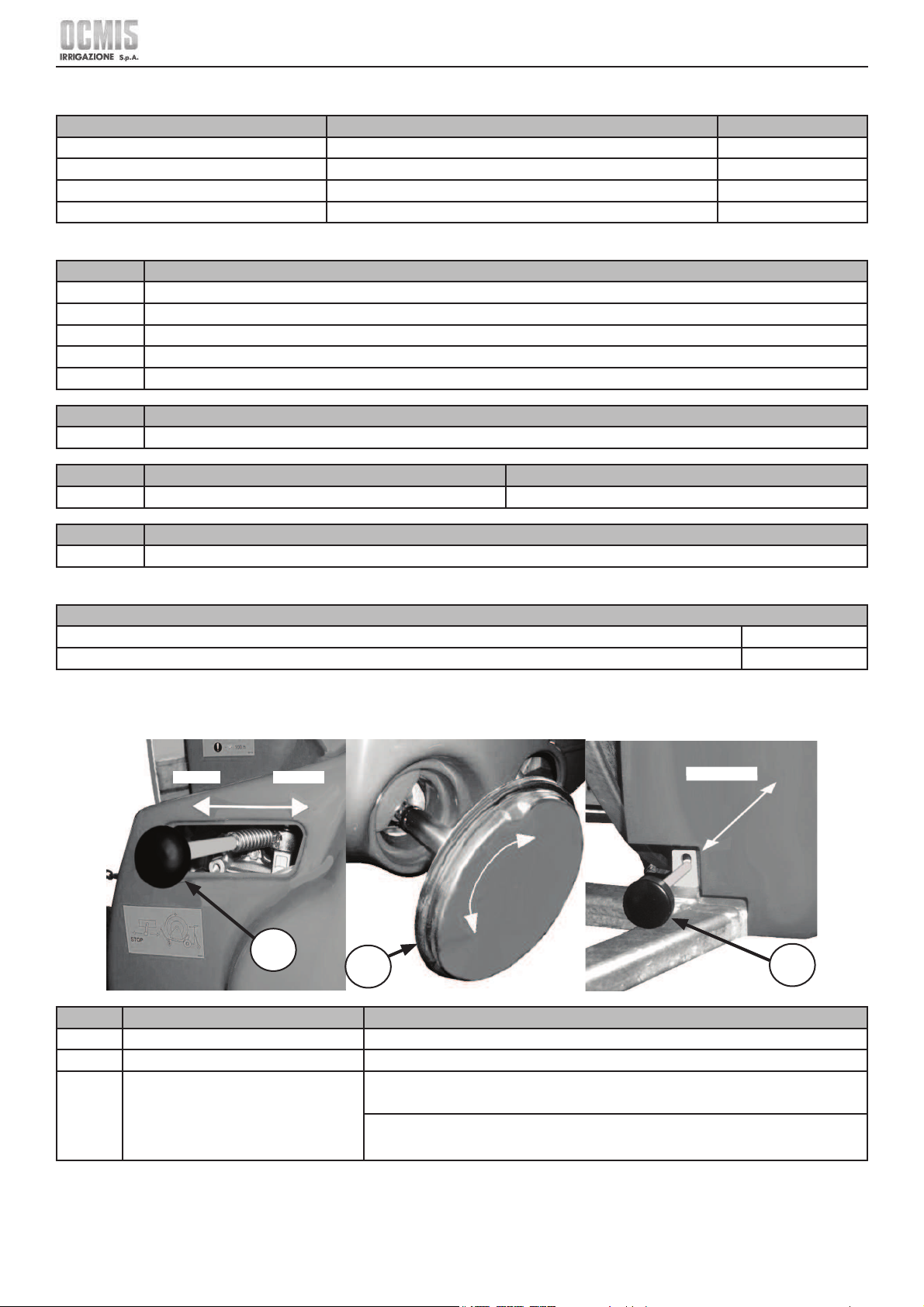

2.5 DESCRIPTION OF CONTROLS ....................................................................................................................................... 24

2.5.1 MECHANICAL CONTROLS ON THE MACHINE ............................................................................................................................... 24

2.5.2 COMPUTER CONTROLS ................................................................................................................................................................. 26

3 MACHINE DESCRIPTION ....................................................................................................................................... 27

3.1 INTENDED USE ................................................................................................................................................................ 27

3.2 UNAUTHORISED USE .....................................................................................................................................................27

3.3 MACHINE DESCRIPTION ................................................................................................................................................28

3.4 STANDARD OUTFITTING FOR THE MACHINE .............................................................................................................. 29

3.5 ACCESSORIES THAT MAY BE SUPPLIED WITH THE MACHINE.................................................................................. 29

4 SAFETY ................................................................................................................................................................... 31

4.1 GENERAL INFORMATION ................................................................................................................................................ 31

4.1.1 PERSONNEL TRAINING .................................................................................................................................................................... 31

4.1.2 DIRECTIVES APPLIED AND TECHNICAL STANDARDS OF REFERENCE ..................................................................................... 32

4.1.3 CERTIFICATION OF THE MACHINE ................................................................................................................................................. 32

4.1.4 INTENDED USES AND APPLICATION LIMITS.................................................................................................................................. 35

4.1.5 HAZARDOUS AREAS ........................................................................................................................................................................ 35

4.1.6 ENVIRONMENTAL OPERATING CONDITIONS ................................................................................................................................ 35

4.1.7 VIBRATIONS....................................................................................................................................................................................... 36

4.1.8 NOISE ................................................................................................................................................................................................. 36

4.1.9 ELECTROMAGNETIC EMISSIONS ................................................................................................................................................... 36

4.2 DISPOSAL OF WASTE MATERIALS ................................................................................................................................ 37

4.2.1 INSTRUCTIONS FOR SPECIAL WASTE ........................................................................................................................................... 37

4.3 SAFETY DEVICES APPLIED TO THE MACHINE ............................................................................................................ 37

4.3.1 CONTROL LEVERS ........................................................................................................................................................................... 37

4.3.2 FIXED GUARDS ................................................................................................................................................................................. 38

4.3.3 POWER DISCONNECTION ............................................................................................................................................................... 39

4.4 RESIDUAL RISKS ............................................................................................................................................................. 39

4.4.1 IMPACT AND CRUSHING: ................................................................................................................................................................. 39

4.4.2 SHEARING: ........................................................................................................................................................................................ 39

4.4.3 FIRE: ................................................................................................................................................................................................... 39

4.4.4 EXPLOSIVE ATMOSPHERE: ............................................................................................................................................................. 40

4.4.5 BLINDING: .......................................................................................................................................................................................... 40

4.4.6 ENTANGLEMENT: .............................................................................................................................................................................. 40

4.4.7 FALLING, FLYING OBJECTS: ............................................................................................................................................................ 40

4.4.8 SLIPPING: .......................................................................................................................................................................................... 40

4.4.9 WHIPLASH EFFECT: .......................................................................................................................................................................... 41

4.4.10 TRIPPING: .......................................................................................................................................................................................... 41

4.4.11 CIRCUIT FAILURES: .......................................................................................................................................................................... 41

4.4.12 LOSS OF STABILITY: ......................................................................................................................................................................... 41

4.4.13 LIGHTING: .......................................................................................................................................................................................... 41

4.4.14 BURN/SCALDING HAZARD: .............................................................................................................................................................. 41

4.4.15 LIGHTNING - ELECTROCUTION HAZARD: ...................................................................................................................................... 41

4.4.16 NOISE: ................................................................................................................................................................................................ 42

4.4.17 VIBRATIONS:...................................................................................................................................................................................... 42

V

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

Chapter 0

4.4.18 RISKS DUE TO HANDLING: .............................................................................................................................................................. 42

4.4.19 RISKS CAUSED TO PUBLIC OR PRIVATE ROAD CIRCULATION OR OTHER PRIVATE AREAS; ................................................. 42

4.5 ADDITIONAL DANGER WARNINGS ................................................................................................................................ 43

4.6 ADDITIONAL WARNINGS AND REQUIREMENTS .......................................................................................................... 44

4.7 WARNING NOTICES ........................................................................................................................................................ 46

4.8 POSITION AND MEANING OF THE OPERATION PICTOGRAMS ................................................................................. 47

4.9 POSITION AND MEANING OF THE WARNING PICTOGRAMS ..................................................................................... 48

4.10 CONSIDERATIONS AND SAFETY WARNINGS FOR OILS AND LUBRICANTS ............................................................50

4.10.1 CLASSIFICATION AND DESCRIPTION OF THE DEGREE OF HAZARDOUSNESS OF PRODUCTS ............................................ 50

4.10.2 FIRST AID MEASURES ...................................................................................................................................................................... 50

4.10.3 FIRE PREVENTION MEASURES ...................................................................................................................................................... 50

4.10.4 MEASURES FOR ACCIDENTAL SPILLAGE ...................................................................................................................................... 50

4.10.5 HANDLING AND PERSONAL PROTECTION .................................................................................................................................... 50

4.10.6 TOXICOLOGICAL INFORMATION ..................................................................................................................................................... 50

4.10.7 ENVIRONMENTAL INFORMATION ON STORAGE AND DISPOSAL ............................................................................................... 50

5 INSTALLATION ........................................................................................................................................................ 51

5.1 GENERAL INFORMATION ................................................................................................................................................ 51

5.2 TERMS OF SUPPLY ......................................................................................................................................................... 51

5.2.1 PACKAGING AND TRANSPORT........................................................................................................................................................ 51

5.3 PREPARATION OF THE OPERATING ENVIRONMENT .................................................................................................. 51

5.3.1 GENERAL INFORMATION ................................................................................................................................................................. 51

5.3.2 PROFESSIONAL PROFILES AND MANDATORY PPE ..................................................................................................................... 52

5.3.3 CHOICE OF PREMISES AND ASSESSMENT OF INSTALLATION REQUIREMENTS ..................................................................... 52

5.3.4 LOADING, UNLOADING, LIFTING AND HANDLING PROCEDURES .............................................................................................. 52

5.3.5 HOOKING LIFTING POINTS .............................................................................................................................................................. 53

5.4 ASSEMBLY AND PLACEMENT ........................................................................................................................................ 55

5.5 LUBRICATION OF MACHINE PARTS .............................................................................................................................. 55

5.6 CHECKS AND INSPECTIONS PRIOR TO STARTING UP ............................................................................................... 56

5.6.1 GENERAL CHECKS ON MECHANICAL ASSEMBLIES .................................................................................................................... 56

5.6.2 CHECK ON SAFETY SYSTEMS ........................................................................................................................................................ 56

5.7 DECOMMISSIONING ........................................................................................................................................................ 57

6 USE AND OPERATION - GENERAL INFORMATION.............................................................................................. 58

6.1 PROFESSIONAL PROFILES AND MANDATORY PPE .................................................................................................... 58

6.2 CHECK PRIOR TO STARTING WORK ............................................................................................................................. 58

6.2.1 PREOPERATIVE INSPECTION ......................................................................................................................................................... 58

6.2.2 FUNCTIONAL TESTS WITH REELED IN HOSE AND MACHINE STATIONARY .............................................................................. 59

6.2.2.1 TESTS ON MANUAL AND/OR OIL HYDRAULIC ACTUATIONS FOR MACHINE PLACEMENT FUNCTIONS ................................59

6.2.2.2 TESTS ON OPERATION CONTROLS WITH MACHINE STATIONARY ............................................................................................ 59

6.2.3 OPERATING SITE INSPECTION ....................................................................................................................................................... 65

6.3 REMOVAL FOR PLACEMENT IN THE FIELD .................................................................................................................. 65

6.3.1 TOWING THE MACHINE .................................................................................................................................................................... 65

6.4 PLACEMENT OF THE MACHINE IN THE FIELD ............................................................................................................. 66

6.5 CHECKS TO BE PERFORMED WITH UNWOUND HOSE AND PRIOR TO STARTING IRRIGATION ........................... 67

6.6 STARTING WORK ............................................................................................................................................................ 68

6.6.1 ADJUSTMENT OF AUTOMATIC SPEED CORRECTION .................................................................................................................. 68

6.6.2 QUICK HOSE WINDING .................................................................................................................................................................... 69

6.7 END OF WORK AND PREPARING TO TOW ................................................................................................................... 69

6.8 USE OF THE MECHANICAL OR ELECTRICAL SLOW CLOSING INLET VALVE (OPTIONAL FEATURE) .................... 70

6.8.1 ADJUSTMENT OF SLOW CLOSING INLET VALVE .......................................................................................................................... 70

6.8.2 OPERATION TO BE PERFORMED ON THE MACHINE PRIOR TO MOVING IT, IF IT IS EQUIPPED WITH SLOW CLOSING INLET

VALVE ................................................................................................................................................................................................. 70

6.9 USE OF THE MECHANICAL OR ELECTRICAL DISCHARGE VALVE (OPTIONAL FEATURE) ...................................... 70

6.10 BOOSTER UNIT WITH MOTOR PUMP MR - MR/1 - MRR ............................................................................................. 71

7 MAINTENANCE ...................................................................................................................................................... 74

7.1 GENERAL INFORMATION ................................................................................................................................................ 74

7.1.1 PROFESSIONAL PROFILES AND MANDATORY PPE ..................................................................................................................... 74

7.2 PERSONNEL IN CHARGE OF MAINTENANCE .............................................................................................................. 75

7.3 GENERAL SAFETY PRECAUTIONS................................................................................................................................75

7.3.1 DANGER NOTES ............................................................................................................................................................................... 75

7.3.2 WARNING NOTES ............................................................................................................................................................................. 77

7.4 RECOMMENDATIONS CONCERNING MAINTENANCE ................................................................................................. 77

7.4.1 OPERATIONS CONNECTED WITH EXTENDED DOWNTIMES ....................................................................................................... 77

7.4.2 MACHINE CHECK PROCEDURE WITH MOTOR OFF...................................................................................................................... 78

7.4.2.1 HYDRAULIC SYSTEM OIL ................................................................................................................................................................. 78

7.4.2.2 PIPING ................................................................................................................................................................................................ 78

7.4.2.3 FUEL SUPPLY SYSTEM ....................................................................................................................................................................78

7.4.2.4 BATTERY CHECK ..............................................................................................................................................................................79

7.4.2.5 TYRES ................................................................................................................................................................................................ 79

7.4.2.6 WHEEL RIMS ..................................................................................................................................................................................... 80

7.4.2.7 SCREW TIGHTENING TORQUES ..................................................................................................................................................... 80

7.5 DESCRIPTION OF THE MAINTENANCE PLAN .............................................................................................................. 81

7.6 CLEANING OPERATIONS ................................................................................................................................................ 81

VI

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

Chapter 0

7.7 LUBRICATION PLAN ........................................................................................................................................................82

7.7.1 RECOMMENDED LUBRICANTS: OILS AND GREASES .................................................................................................................. 82

7.7.2 REQUIRED LUBRICANT AMOUNTS ................................................................................................................................................. 82

7.7.3 MACHINE PARTS TO BE LUBRICATED WITH GREASE ................................................................................................................. 83

7.8 MAINTENANCE PLAN ...................................................................................................................................................... 85

7.8.1 FILLING IN CRITERION ..................................................................................................................................................................... 85

7.8.2 LIST OF MAINTENANCE SHEET AND FREQUENCY ...................................................................................................................... 86

7.8.2.1 EVERY 200 HOURS ........................................................................................................................................................................... 86

7.8.2.2 BEFORE STORAGE AT THE END OF THE SEASON ....................................................................................................................... 86

7.8.2.3 EVERY YEAR BEFORE THE START OF THE IRRIGATION SEASON ............................................................................................. 87

7.8.3 MAINTENANCE INFORMATION ON OPTIONAL ACCESSORIES .................................................................................................... 87

7.8.3.1 DISCHARGE VALVE ........................................................................................................................................................................... 87

7.8.3.2 SLOW CLOSING INLET VALVE ......................................................................................................................................................... 87

7.8.3.3 INTERNAL COMBUSTION ENGINE .................................................................................................................................................. 87

7.8.3.4 BATTERY ............................................................................................................................................................................................ 87

7.8.3.5 PHOTOVOLTAIC PANEL .................................................................................................................................................................... 87

8 GENERAL DESCRIPTION OF FAILURES .............................................................................................................. 88

8.1 LIST OF FAILURES - CAUSES - SOLUTIONS ................................................................................................................. 88

9 ANNEXES ................................................................................................................................................................ 91

10 SPARE PARTS ......................................................................................................................................................... 91

10.1 SPARE PART ORDER ...................................................................................................................................................... 91

1

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 1 - General information

GENERAL

INFORMATION

CH. 1

1 GENERAL INFORMATION

1.1 WARNINGS FOR THE BUYER

The manual, like the CE certifi cate of conformity, is an integral part of the machine and must always accompany it each time it is transferred or resold.

It is the user's responsibility to maintain this documentation intact, to allow it to be referenced throughout the entire service life of the machine.

In the event of loss or destruction, a copy may be obtained from the Manufacturer, specifying exactly the model, serial number and year of production.

The manual refl ects the state of the art at the time of supply. The undersigned company reserves the right to make any amendment to its products it

may deem appropriate, without being obliged to upgrade manuals and machines for previous production batches.

The Manufacturer disclaims any liability for production faults and damage caused by the machine to property, persons and animals in the following

cases:

• Misuse of the machine or use with functions other than those for which it has been constructed.

• Use by unsuitable or unauthorised personnel.

• Faults in oil hydraulic, water supply, etc.

• Non compliance with technical power supply specifi cations.

• Insuffi cient or poor periodic maintenance.

• Incorrect installation at the site or location it is intended for.

• Use of inadequate hoses or delivery hoses and/or hoses unsuitable for the pressures the machine has been designed for.

• Modifi cations or procedures not agreed with and/or authorised by the Manufacturer.

• Use in a non-Agricultural setting.

• Use of non-original parts or parts that are not specifi c to the model.

• Use by persons under the age of 18.

• Total or partial failure to comply with these instructions.

• Use not complying with the machine safety laws and/or with the safety standards set forth by specifi c European and/or national laws in force.

• Use of trailer or transfers on public roads without Road Use Approval.

• Exceptional events.

Responsibility for the application of the safety requirements set out below lies with the user, who must ascertain that authorised personnel:

• are qualifi ed to perform the required activity

• are familiar and strictly comply with the requirements herein

• are familiar with and apply general safety rules applicable to the machine and those in force at the utilisation site

• are familiar with the safety rules concerning the risks arising from treatment of the products the machine is intended for.

It is a mandatory requirement for the technical maintenance personnel to have read and understood this manual and the documentation

set out in chapter 9 which is an integral part thereof, to be familiar with and skilled in the basic principles of mechanics, hydraulics, water

engineering and electricity, to be familiar with connection and wiring procedures and with the symbols used in mechanical and fl uid power

diagrams, and to be experienced in using equipment and machinery.

Failure to comply with the safety standards may cause injury to personnel and damage the components and control unit of the machine.

Reading this manual, albeit comprehensively, cannot in any case replace adequate operator expertise.

The user may contact the Manufacturer at any time to request information additional to that contained herein, as well as to contribute proposed

improvements.

CAUTION

We hereby remind you that the documentation provided by the Manufacturer solely concerns the machine supplied to the user

by the Manufacturer and not the overall system/assembly within which it may be installed and used.

DANGER

Due to the process features, improper machine use and installation involve signifi cant risks and are forbidden.

CAUTION

It is the user's unequivocal responsibility to complement the instructions herein with any operating procedures in force in the

place of the machine's use and to provide all additional information to the personnel in charge of machine use and maintenance.

2

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 1 - General information

This manual is an integral part of the machine it refers to and contains the required information for:

• Properly raising operator awareness of relevant safety issues;

• Machine handling under safe conditions;

• Thorough knowledge of its operation and limitations;

• Its proper use under safe conditions;

• Performing maintenance procedures in a correct and safe manner;

• Dismantling the machine under safe conditions and complying with applicable standards protecting workers' health, safety and the environment.

Operators must be carefully trained on operation and proper use of the installed safety devices.

DANGER

The machine must be exclusively used by skilled operators trained on the procedures, and it is to be used complying with the

recommendations herein.

The user is also responsible for ensuring that - in the event this document should undergo any amendments by the Manufacturer - only updated

Manual versions are actually present at the utilisation sites.

All the manuals and documentation set out in chapter 9 are an integral part of this manual.

DANGER

Hazardous use of the machine may cause severe injury to the operator and/or persons near the operations area.

It is therefore indispensable to adhere to the provisions of this manual.

Operators and personnel in charge of maintenance must read this manual before starting work.

The manual must be kept on board the machine, for referencing and periodic review by all personnel who need to operate it.

The machines in question CANNOT be towed on public roads unless they are provided with proper Road Use Approval issued

and recognised by the Body responsible for issuing the Registration Document in the country where they are used.

When the machines are provided with Road Use Approval for towing on public roads, it is indispensable to adhere to the rules

and requirements set out in the Registration Document issued by the Body responsible of the country where they are used.

1.2 INTRODUCTION

In order to assure the utmost operating reliability, the Manufacturer has performed careful selection of the materials and components to be employed

in constructing the machinery, submitting it to proper testing before delivery. Its good performance over time depends on proper use and adequate

preventive maintenance, according to the instructions herein and in the documentation supplied with the machine.

All construction elements, coupling and control parts have been designed and constructed with a degree of safety such as to be able to withstand

abnormal strain or at any rate higher than those specifi ed.

The materials are of the best quality and their treatment in the company, storage and use in the shop are constantly monitored, in order to assure the

absence of damage, deterioration or malfunction.

Despite all design and construction solutions, for the aims of correct use, safety, durability and reliability of the machine, it is crucial to carefully follow

the Manufacturer's instructions and install and use the same in accordance with these instructions and with the legal requirements in force in the

country/site of use of the machine.

The purpose of this manual is to provide technical information to the personnel in charge of using and maintaining the machine produced by the

Manufacturer.

The instructions herein are aimed at operators with adequate knowledge in the fi eld of mechanics, hydraulics, water engineering and electrics.

The instruction and warning manual contains the information required to understand the methods for installing, operating and properly using the

machine, specifi cally: technical description of the various functional assemblies, safety equipment and systems, operation, use of the instrumentation

and interpretation of any diagnostics signals, main procedures and information concerning maintenance operations.

For proper use of the machine it is assumed that the work environment complies with applicable regulations on health and safety.

CAUTION

Before proceeding with machine installation or making it operational, using or performing maintenance on the machine, read this

manual very carefully and faithfully follow the instructions and recommendations herein.

Training is also recommended for the above personnel in order to assure perfect familiarity and knowledge of the machine.

3

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 1 - General information

1.3 MANUFACTURER'S ADDRESS

INSTRUCTIONS TO REQUEST SERVICING

The machine is a product serviced worldwide with direct coordination with the Manufacturer's technical support.

The undersigned Company is always available to meet Customer needs concerning any kind of information or clarifi cation on installation, use,

maintenance, etc.

The Customer should ask questions in a clear language, with references to this manual and always provide the details shown on the machine's

identifi cation data plate.

Any request for information or servicing at the Customer's premises or for clarifi cations concerning technical aspects of this document must be sent to:

OCMIS IRRIGAZIONE S.p.A.

Headquarters and Production Facility

41014 CASTELVETRO (MO) ITALIA

Via S.Eusebio, 7

Tel. +39 059 702150

Fax. +39 059 702153

www.ocmis-irrigazione.it

info@ocmis-irrigazione.it

In particular, the Customer must provide the following data to the manufacturer:

• type of machine, serial number, year of installation

• faults detected

• exact address of the site/facility where the machine is installed

• contact person.

1.4 SAFETY RULES SET OUT IN THE MANUAL

The safety requirements, instructions, rules and relevant notes, set out in the various chapters of the manual, have the purpose of defi ning behaviour

and a set of obligations one should adhere to in performing the various activities, in order to operate under safe conditions for personnel, the

equipment and the surrounding environment.

The safety rules herein are aimed at all authorised personnel, instructed and assigned to perform the following various operations:

• transport

• installation

• operation

• use

• handling

• maintenance

• cleaning

• decommissioning and dismantling

which represent the intended methods of use for the machine in question.

SUPPLEMENTARY INFORMATION

Please refer to chapter 4 for further information concerning training.

1.5 GLOSSARY OF TERMS USED

The manuals employ technical terminology or terminology having a meaning different from common usage.

below is an explanation of the terms and abbreviations used:

HAZARD: (Annex I, 1.1.1 Directive 2006/42/EC).

a potential source of injury or damage to health;

DANGER ZONE: (Annex I, 1.1.1 Directive 2006/42/EC).

any zone within and/or around the system where the presence of an exposed person represents a risk for that person's health and safety;

EXPOSED PERSON (Annex I, 1.1.1 Directive 2006/42/EC).

Any person wholly or partially in a danger zone;

RISK: (Annex I, 1.1.1 Directive 2006/42/EC).

a combination of the likelihood and severity of an injury or damage to health that may arise in a hazardous situation;

GUARD: (Annex I, 1.1.1 Directive 2006/42/EC).

a part of the machinery used specifi cally to provide protection by means of a physical barrier;

4

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 1 - General information

PROTECTIVE DEVICE: (Annex I, 1.1.1 Directive 2006/42/EC).

a device (other than a guard) which reduces the risk, either alone or in conjunction with a guard;

INTENDED USE: (Annex I, 1.1.1 Directive 2006/42/EC).

the use of the machinery in accordance with the information provided in the instructions for use;

MISUSE: Use of the machinery in a way not intended in the instructions for use, but which may result from readily predictable human behaviour;

RESIDUAL HAZARD: Hazard that has not been possible to eliminate or reduce by design, against which the guards are not (partially or totally)

effective;

The Manual (chapter 4) contains the residual hazards and information, instructions and warnings/requirements for managing Residual Risks, the

responsibility for which must lie with the user (Ref. UNI EN ISO 12100:2010).

HOSE REEL TRAVELLING RAINGUN: Type of movable irrigation machine equipped with a fi xed structure with a hose reel, onto which a fl exible

hose is wound through which irrigation water fl ows, towing a movable trolley onto which the distribution system is secured, generally consisting of a

long range raingun (Ref. 3.1 EN 908).

LONG RANGE RAINGUN: Large-sized raingun used on hose reel travelling rainguns and on other systems (Ref. 3.2 EN 908).

WINDING: One of the operations performed by the hose reel travelling raingun while it is irrigating. The hose reel travelling raingun progressively reels

in all the fl exible polyethylene hose onto the drum, allowing the long range raingun to move evenly through the plot to be irrigated. When the long range

raingun reaches the machine, reeling in is completed and the machine stops (Ref. 3.3 EN 908).

GUIDE SYSTEM: Side hose guide device to wind it evenly with close-knit loops (Ref. 3.4 EN 908).

GUIDE SYSTEM ACTUATION DEVICE: Mechanism that powers the guide system assuring even winding of the hose in layers (Ref. 3.5 EN 908).

COVER AREA: Range of various turret positions corresponding to all possible orientations (Ref. 3.6 EN 908).

For a comprehensive description of the terminology used please refer to the defi nitions contained in annex I of machine directive 2006/42/EC and

standards EN ISO 12100 and EN 908.

PERSONAL PROTECTION EQUIPMENT (PPE): Personal protection equipment refers to any equipment intended to be worn and/or used by the

worker for the purpose of protecting them from one or more risks likely to threaten their safety or health during work, as well as any item or accessory

intended for that purpose.

Personal protection equipment does not include the following:

• Ordinary work clothes and uniforms not specifi cally designed to protect the worker's health and safety;

USER: User (entrepreneur / fi rm) refers to whoever employs the machine for the intended use, or entrusts its use to skilled and suitably trained

persons.

MAN MACHINE INTERACTION: Any situation where an operator interacts with the machine in any operating stage at any time during its service life.

MACHINE STATUS: The machine status includes operating modes, e.g. running, dead-man control, stop, etc., the condition of the safety devices

fi tted on the machine such as the guards included, the guards bypassed, the emergency stop, the type of insulation from energy sources, etc.

In this manual, the term operator or personnel in charge is used to refer to the person or persons authorised to perform machine installation as well

as those intended to commission it, operate it and carry out maintenance in compliance with the classifi cation set out herein.

The defi nition of machine as set forth under art.2 of directive 2006/42/EC and included below should be deemed as consisting of the whole: hose reel

on frame with wheeled traveller, equipped with polyethylene hose and raingun trolley with or without optional accessories.

The term Manufacturer used in this manual refers to the company specifi ed under paragraph 1.3.

5

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 1 - General information

1.6 PERSONNEL QUALIFICATIONS

The symbols shown in the table are used in the Manuals next to the notes in bold to indicate important information/requirements concerning the

required professional qualifi cation.

PROFESSIONAL ROLES

Symbol Description

OPERATOR: User's personnel trained and qualifi ed for the use and operation of the machine for production purposes for the

activities it has been constructed and supplied for.

They must be able to perform all the required procedures for proper machine operation and for their own safety and that of any

assistants.

They must have proven experience in proper use for this type of machine for the work involved.

In the event of any doubts they must report any fault to their supervisor.

They are not authorised to perform any maintenance activity.

LIFTING AND HANDLING EQUIPMENT DRIVER: Personnel qualifi ed for the use of equipment for lifting and handling materials

and machines (strictly adhering to instructions issued by the Manufacturer), in compliance with applicable laws in force in the

machine user's country.

MECHANICAL MAINTENANCE TECHNICIAN: Qualifi ed technician able to run the machine as the operator, to work on

mechanical parts, internal combustion engine, oil hydraulic and water systems for adjustments, maintenance, repairs, and who is

also able to read water and hydraulic diagrams, technical drawings and spare part lists.

In extraordinary cases, they are authorised to operate the machine with reduced safety devices.

They are not qualifi ed to work on live electrical installations (if present).

Where necessary, they may issue instructions to the operator for proper use of the machine for production purposes.

ELECTRICAL MAINTENANCE TECHNICIAN: Qualifi ed technician able to run the machine as the operator, to work on electrical

adjustments and systems for maintenance, repairs, and replacement of worn parts.

They are also able to read wiring diagrams and to check the correct functional cycle.

They are able to work on live electrical boards, junction boxes, control equipment, etc. only if they are suitable (Instructed Person)

(See EN50110-1).

Where necessary, they may issue instructions to the operator for proper use of the machine for production purposes.

MANUFACTURER'S TECHNICIAN: A technician qualifi ed by the Manufacturer and/or their distributor for complex operations, as

they are familiar with the machine's construction manufacturing cycle.

This person must act according to the user's requirements.

Their skills must be, as the case may be, in mechanics and/or electrics and/or electronics and/or software.

1.7 SYMBOLS USED WITHIN THE MANUAL

Certain symbols are used within the manual to draw the reader's attention and highlight certain particularly signifi cant aspects of the content.

The following table describes the meaning of the various symbols used.

Symbol Meaning Notes

Danger Indicates a danger with injury hazard for the user, even fatal.

Pay the utmost attention to blocks of text marked by this symbol.

Caution Represents an alert to possible deterioration or damage to the machine, equipment or other

personal property belonging to the buyer/user.

Pay attention to blocks of text marked by this symbol.

Warning

Note

Indicates a warning or note on key functions or useful information.

Pay attention to blocks of text marked by this symbol.

Supplementary information The blocks of text that contain ancillary information are introduced by this symbol.

This information is not directly related to the description of a function or steps of a procedure.

They might be references to other ancillary documentation such as attached operating

instruction manuals, technical documents or to other sections in this manual.

Avoid damaging the material Remark referring to a strong risk of damaging a part, for instance by using the wrong tool or

assembling according to an incorrect procedure.

Special tool Indicates that use of a special tool or equipment is required for the operation.

Visual observation Indicates that the reader must perform a visual observation. This symbol is also found in

operating instructions. The user is required to read a measurement fi gure, to check a signal,

etc.

6

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 1 - General information

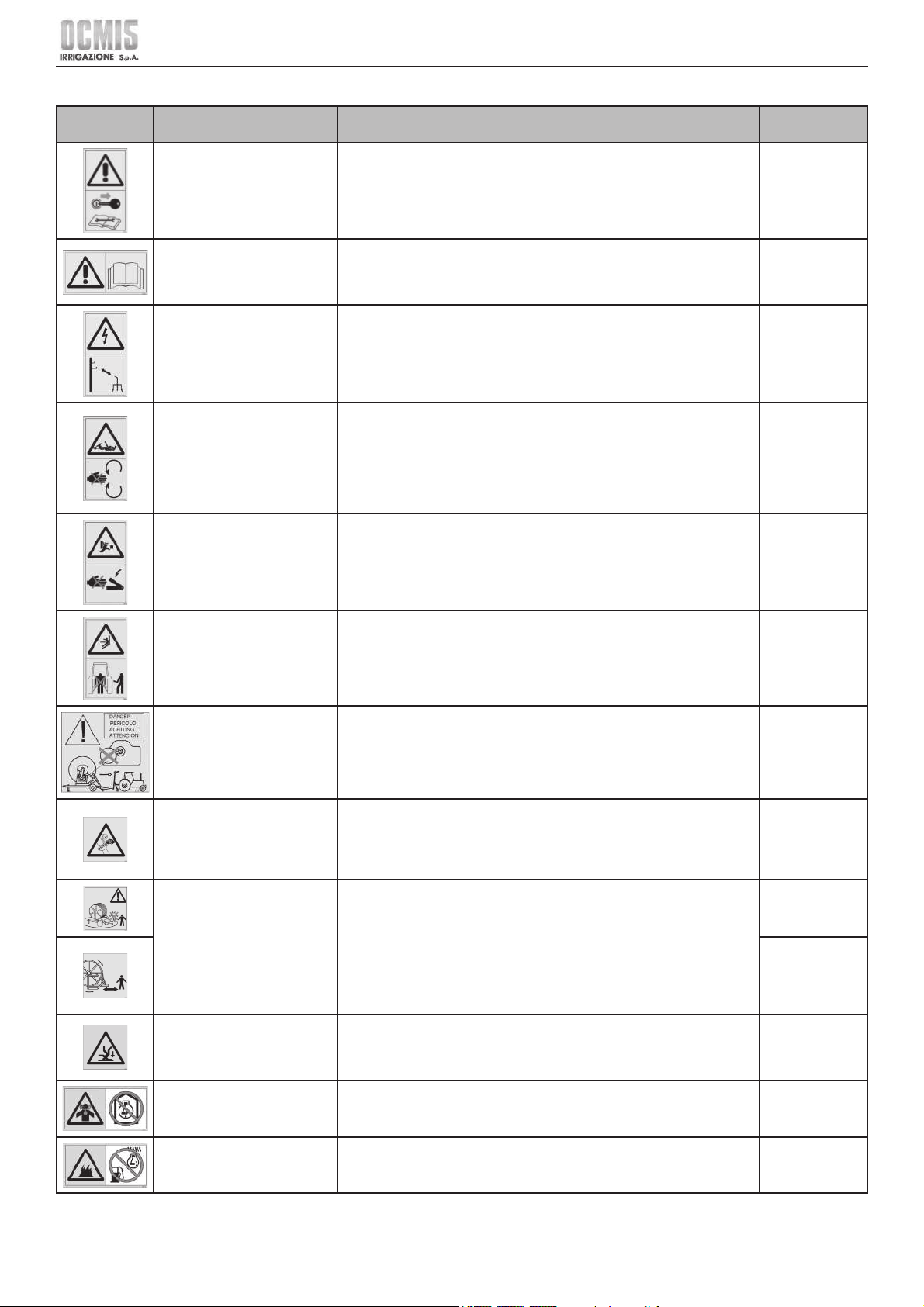

1.8 SYMBOLS USED WITHIN THE MANUAL

Symbol Meaning Notes

Code

Manufacturer

Obligation to stop the machine

before performing maintenance

and/or repair operations on it.

Indicates a mandatory requirement for the maintenance personnel to

read and understand the instruction manual provided before performing

maintenance activities on the machine or its units.

Obligation to stop the machine before performing maintenance operations.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

60201

Obligation to read the

instruction manual before

starting and using the machine.

Indicates a mandatory requirement for the operating personnel in charge

of running the machine or its units to read and understand the instruction

manual provided before performing operating activities on the machine or

its units.

60203-O

Electrocution hazard. Indicates a danger with injury hazard for the personnel in charge/user.

Obligation to keep a safe distance between the hose trolley and the power

lines or substations and not to aim the water jet at power lines.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

CE7/1

Entanglement hazard. Indicates a danger in area/s with moving parts.

It is forbidden to put your hands close to the moving power take off shaft or

to the trolley that places the hose on the reel.

Only use CE certifi ed power take off shafts, with adequate guards and

which are in a good state of repair.

The personnel in charge/user must pay the utmost attention to the signs

and areas displaying this symbol and remain at a safe distance.

60200

Shearing hazard, keep your

hands away.

Indicates a danger with injury hazard, even fatal, for the personnel in

charge/user.

Pay the utmost attention to the signs and areas displaying this symbol and

do not access areas thus signalled unless the area in question has had

supply lines and/or power pre-emptively removed.

60209

Crushing hazard, do not stand

between the machine and the

tractor.

Indicates a danger with injury hazard for the user.

It is mandatory to comply with the safety distances and never to stand

between the tractor and the machine.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

60208

Impact / entanglement hazard.

Moving parts. Do not leave the

handwheel on when unwinding

the hose with the tractor.

Indicates a danger with injury hazard for the personnel in charge/user.

It is forbidden to leave the handwheel on when the irrigation hose is

unwound with the tractor.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

CE8

Danger - pressurised hoses Indicates a danger with injury hazard for the personnel in charge/user.

It is mandatory to wear appropriate clothing such as shoes, overalls, face

protection shields, gloves, etc.

Pay the utmost attention to signals and areas where this symbol is displayed

and keep away from these areas.

60204

Automatic operation machine

with moving parts.

Indicates a danger with injury hazard for the personnel in charge/user.

Do not stand within the operating range of the machine especially during

rotation on the vertical axis.

Do not go near the rear of the machine, where the hose is wound onto the

rotating reel.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

CE45

60202

Slipping and falling hazard. Indicates a danger with injury hazard for the personnel in charge/user.

Prohibition to climb on the machine.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

60215

Carbon monoxide hazard. Caution - the engine releases carbon monoxide, which is a toxic and

poisonous gas.

Do not operate the engine in closed premises.

60214

Fuel. Fuel is extremely fl ammable. Turn off the engine and let it cool before

refuelling.

The same requirement applies before performing any maintenance activity.

60216

7

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 1 - General information

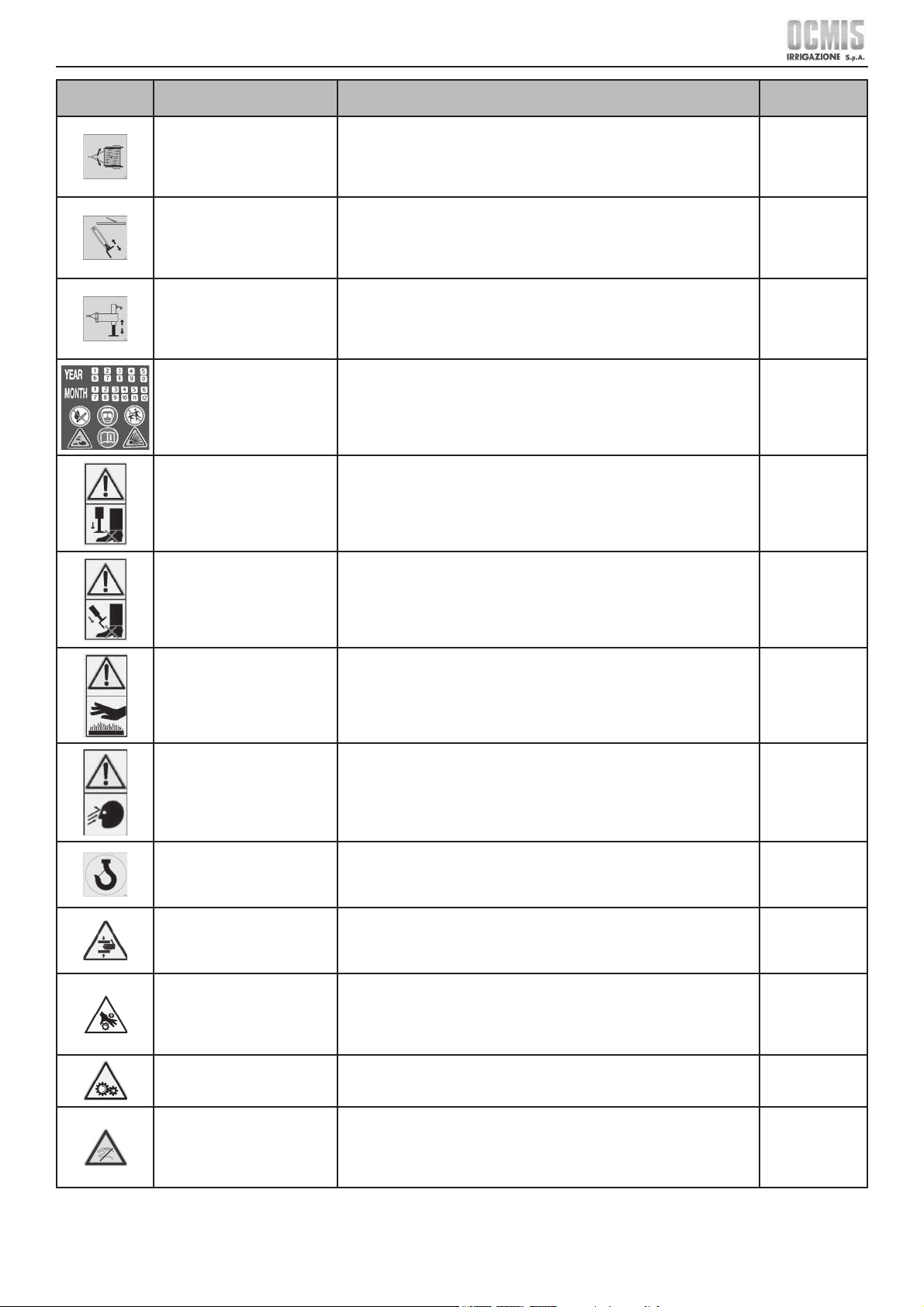

Symbol Meaning Notes

Code

Manufacturer

Indicates a hazard connected

to the hydraulic turret rotation

function.

Indicates the function performed by the lever on the distributor.

It is mandatory to keep a safe distance from the machine during turret

rotation.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

CE4

Indicates a hazard connected

to the rear hydraulic anchors

function.

Indicates the function performed by the lever on the distributor.

It is mandatory to keep a safe distance from the anchors, and ensure no

one can come into contact with them.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

CE2

Indicates a hazard connected

to the front hydraulic leg

function.

Indicates the function performed by the lever on the distributor.

It is mandatory to keep a safe distance during the operation of the leg

stabiliser, and ensure no one can come into contact with it.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

CE3

Indicates year and month

of construction with related

warning, danger and prohibition

symbols

Indicates a prohibition for the personnel in charge/user concerning the

battery compartment and requirements to be complied with in handling the

battery.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

See BATTERY

manual

Foot crushing hazard under the

front stabiliser leg.

Indicates a danger with injury hazard for the personnel in charge/user.

It is mandatory to keep a safe distance during the operation of the leg

stabiliser, and ensure no one can come into contact with it.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

60210

Foot crushing hazard under the

rear stabilisers.

Indicates a danger with injury hazard for the personnel in charge/user.

It is mandatory to keep a safe distance during the operation of the rear

stabilisers, and ensure no one can come into contact with them.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

60211

Hazardous temperature Indicates a danger with injury hazard for the personnel in charge/user.

It is mandatory to wear appropriate clothing such as shoes, overalls, high

temperature gloves, etc.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

60212

Hazard of being thrown from

the high pressure water jet

Indicates a danger with injury hazard for the personnel in charge/user.

It is mandatory to wear appropriate clothing such as shoes, overalls, face

protection shields, gloves, etc. and to always stand clear of the water jet

exiting the machine. Pay the utmost attention to signals and areas where

this symbol is displayed and keep away from these areas.

60213

Indicates the position where

the hooks for lifting the machine

need to be inserted

Indicate the hooking points with chains or wire ropes fi tted with hooks.

Indicates a mandatory requirement on the equipment to be used.

Pay attention to these plates and only use permissible lifting/handling

systems using cranes and/or overhead travelling cranes of suitable capacity.

60210

Limb crushing hazard. Indicates a danger with injury hazard for the personnel in charge/user.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

Entanglement hazard. Indicates a danger with injury hazard for the user.

It is mandatory to wear appropriate clothing such as shoes, overalls, gloves,

etc.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

Danger of moving parts. Indicates a danger in area/s with moving parts.

The personnel in charge/user must pay the utmost attention to the signs

and areas displaying this symbol and remain at a safe distance.

Keep hands clear.

Do not touch.

Indicates a danger with injury hazard for the personnel in charge/user.

It is mandatory to wear appropriate clothing such as shoes, overalls, gloves,

etc.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

8

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 1 - General information

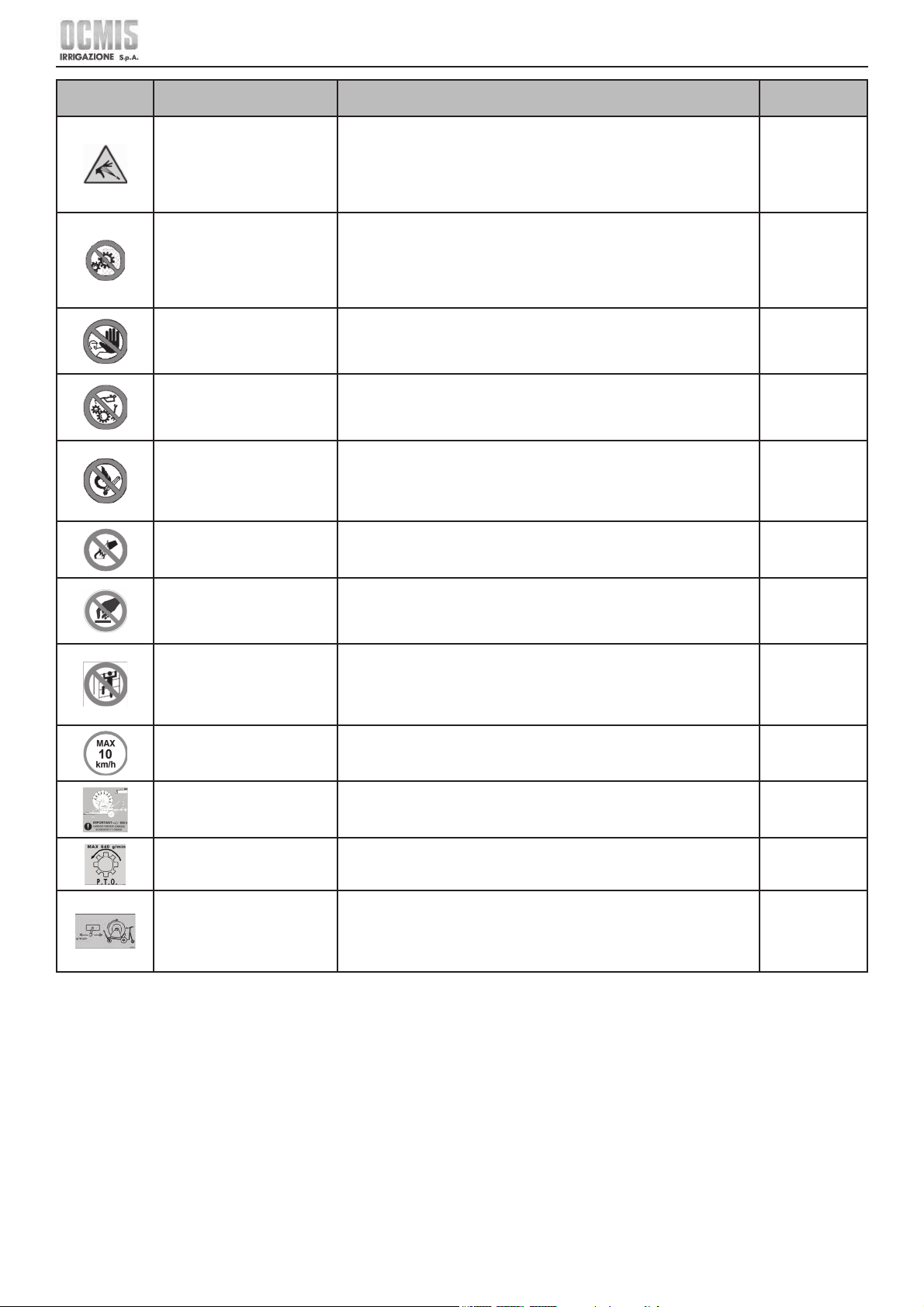

Symbol Meaning Notes

Code

Manufacturer

Risk of cutting or violent impact

with high pressure fl uid.

Indicates a hazard with risk of injury, even fatal, to the user, due to impact

with high pressure fl uid.

It is mandatory to wear appropriate clothing such as shield, shoes, overalls,

gloves, etc.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

It is forbidden to remove the

protective casings.

Indicates a prohibition for the personnel in charge/user to remove the

guards installed on the machine/plant.

It is strictly forbidden to operate the machine without the protective casings

it is supplied with.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

Prohibition to approach and go

beyond the barrier/area when

machine is in operation.

Indicates the prohibition for the personnel in charge/user to approach and

go beyond the area where this sign is displayed.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

It is forbidden to lubricate with

parts in motion.

Indicates the prohibition for the personnel in charge/user to lubricate

machine/plant parts with moving parts.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

It is forbidden to smoke

near engines or electrical

or hydraulic control units or

anywhere near the machine.

Indicates the prohibition for the personnel in charge/user to smoke near

engines or electrical control units and in any case in any area where this

sign is displayed.

All prohibitions in force in the country of use of the machine/plant remain

valid, as well as internal facility or plant provisions set out by the employer.

It is forbidden to aim water jets

at electrical equipment.

Indicates a prohibition to use or aim water jets at electrical equipment and

in any case in all areas where this sign is displayed.

Do not touch. Indicates the prohibition for the personnel in charge/user to touch the areas

of the machine where this symbol is displayed.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

It is forbidden to climb on parts

of the machine.

Indicates the prohibition for the personnel in charge/user to climb on the

machine or its parts, including the raingun trolley where this symbol is

displayed.

Pay the utmost attention to the signs and areas where this symbol is

displayed.

60190

Speed limit for machines

without Road Use Approval.

Indicates a prohibition to exceed the set speed for machines without Road

Use Approval.

It is strictly forbidden to exceed the indicated speed limit.

60027

Warning: periodically grease

the teeth of the crown gear

Indicates to grease every 100 hours of work all the teeth of the crown gear

located on one side of the machine.

60105

Warning: rotation direction and

maximum RPMs of PTO shaft

Indicates PTO rotation direction and maximum 540 RPMs.

CE6

Indicates the type of function

performed by the machine in

the two positions of the control

lever

Indicates an operating mode of the control lever in the two permissible

positions:

• with the lever to the left, the functions are STOP, hose UNWINDING or

QUICK WINDING;

• with the lever to the right, the function is OPERATION.

99000015

9

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 1 - General information

1.9 DESCRIPTION OF PERSONAL PROTECTION EQUIPMENT (PPE)

The personnel in charge of operation, use and maintenance must use the personal protection equipment that allows them to decrease all possible

risks arising from the various permissible activities on the machine, such as:

• head protection helmet.

• safety glasses or face mask to protect against chips, dust or oil jets, or debris resulting from the process.

• masks to protect against any vapours, inhalation, etc. arising from work hazards.

• safety gloves, shoes and boots as needed and according to the type of products used in the process in question.

• ear protectors.

CAUTION

The clothing of whoever operates or performs maintenance on the machine must comply with the essential safety requirements

set forth by EC directives 89/656/EC and 89/868/EC and with the laws in force in the country of installation.

CAUTION

It is the end user's unequivocal responsibility to ensure that the personnel in charge are duly instructed on the residual risks

connected to the process and use the proper PPE, as well as assessing the need for any required integration.

DANGER

During handling and maintenance operations, personnel must wear appropriate work clothing to prevent accidents.

In order to prevent mechanical risks such as entrainment, entrapment and the like, it is forbidden to wear accessories such as

bracelets, watches, scarves, rings or chains during work and maintenance operations.

DANGER

In performing work that might give rise to fl ying splinters or hazardous materials for oneself or other persons operating nearby,

the operator must arrange screens or other appropriate safety devices or obtain them from those responsible.

Symbol Meaning Notes

Code

Manufacturer

Use of the protective helmet is

mandatory.

Indicates a mandatory requirement for maintenance personnel to use the

protective helmet.

PPE to be always used when performing machine maintenance.

Use of protective shield

or protective goggles is

mandatory.

Indicates a mandatory requirement for personnel to use the protective

shield.

PPE to be always used when performing machine maintenance.

Use of protective shield or goggles is mandatory in the event of fl ying

objects or materials hazard.

It is mandatory to protect one's

hearing.

Indicates a mandatory requirement for personnel to use earmuffs or ear

plugs to protect their hearing.

PPE to be used at all times when operating the machine and/or at the

processing site or during maintenance.

It is mandatory to use protective

and insulating gloves.

Indicates a mandatory requirement for the personnel to use protective and

insulating gloves.

PPE to be used at all times when operating the machine and/or at the

processing site or during maintenance.

It is mandatory to use safety

shoes.

Indicates a mandatory requirement for personnel to use protective

footwear.

PPE to be used at all times when operating the machine and/or at the

processing site or during maintenance.

It is mandatory to wear

appropriate work clothing.

Indicates a mandatory requirement for personnel to wear appropriate and

protective work clothing.

PPE to be used at all times when operating the machine and/or at the

processing site or during maintenance.

NOTE

The PPE set out herein must be supplemented by the user according to the processing site (type and materials to be processed,

etc.), to set requirements and according to the provisions in force in the country of use.

SUPPLEMENTARY INFORMATION

The various chapters of this manual contain the detailed description of the “pictograms” and “PPE” specifi cally provided for the

machine supplied. This paragraph only lists and explains the meanings of the “pictograms” and “PPE”.

10

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 1 - General information

1.10 MANUAL LANGUAGE

The original manual was drawn up in Italian and translated into the language indicated on the manual's cover.

Any translations into additional languages must be done starting from the original instructions.

The Manufacturer is only responsible for the information contained in the Original Instructions; translations into other languages cannot be fully

verifi ed, hence should an inconsistency be found, refer to the text in the original language or contact our Technical Documentation Department.

1.11 MACHINE HANDLING

Handling of the machine is only allowed to authorised personnel, suitably instructed or at least possessing a suffi cient technical knowledge and

experience.

The personnel in charge of machine operation and maintenance must be aware of the fact that knowledge and application of safety regulations is an

integral part of their job.

Specifi cally, it is the User/Customer's unequivocal responsibility:

• To ensure the utilisation site complies with statutory provisions in force in the country of use.

• To check and arrange for the required transit and escape routes and operating and maintenance clearances around the machine.

• Carefully read this manual and the manuals listed in chapter 9.

• Know what guards, safety and emergency stop devices the machine is equipped with, and their location and operation.

DANGER

Unauthorised personnel must not access the machinery's operating area or the control system.

It is forbidden to disengage or partially remove guards and safety devices protecting from hazardous parts.

the same rule applies to signs (warning, danger, prohibition plates, etc.).

It is strictly forbidden to open boards, battery compartments and/or control and power units during operation or immediately

after switching off.

DANGER

The safety guards and devices must be maintained in perfect working order so that they operate correctly. In the event of a fault

or malfunction, they must be immediately repaired or replaced.

DANGER

Unauthorised use of trade components and accessories belonging to the safety guards and devices may cause malfunctions and

lead to hazardous situations for the operating personnel.

NOTE

Most accidents and injuries occurring in workplaces and specifi cally on farms are caused by failure to comply with certain simple

and fundamental rules of prudence and safety. That is why, in most cases, they may be avoided by operating with the necessary

caution and prudence.

In the event of failure to comply with the instructions herein, any possible accident cannot be wholly ruled out with this type of

machine, however well designed and constructed.

A watchful and prudent operator is the best guarantee against accidents.

DANGER

• Incorrect operation and maintenance of the machine may be hazardous and lead to serious injury or death.

• The operator using the machine and the personnel in charge of its maintenance must read this manual in its entirety, before

starting to operate the machine.

• Certain actions concerning machine operation and maintenance may cause severe accidents unless they are undertaken in

the manner described by this manual.

• The procedures and precautions described in this manual only apply to the intended and stated uses for the machine.

• In no case must the machine be used for actions strictly forbidden in this manual.

NOTE

Strict compliance with a single and elementary safety rule is enough to prevent a high number of serious injuries.

That rule is:

Never perform any cleaning, lubrication or maintenance operation while the machine is moving and/or water is pressurised.

1.12 WARRANTY

The warranty applied by the Manufacturer is set out in the contractual documents, to which you should refer.

11

Ocmis Irrigazione S.p.A. – INSTRUCTION AND WARNING MANUAL – Translation of Original Instructions

MUMR-R1.02 .EN - 31/07/2015

CHAPTER 2 - Technical specifi cations and layout

TECHNICAL SPECIFICATIONS AND

LAYOUT

CH. 2

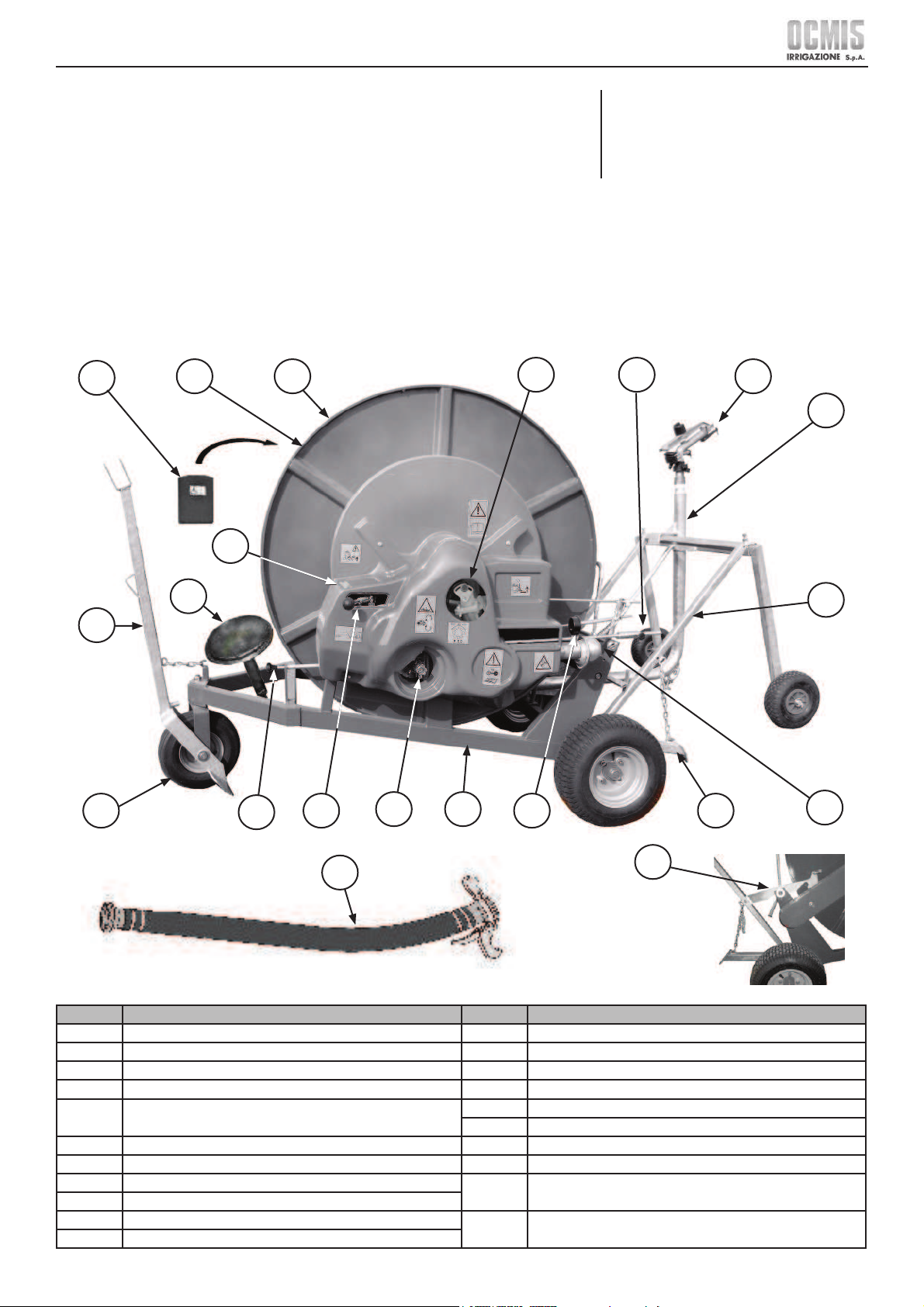

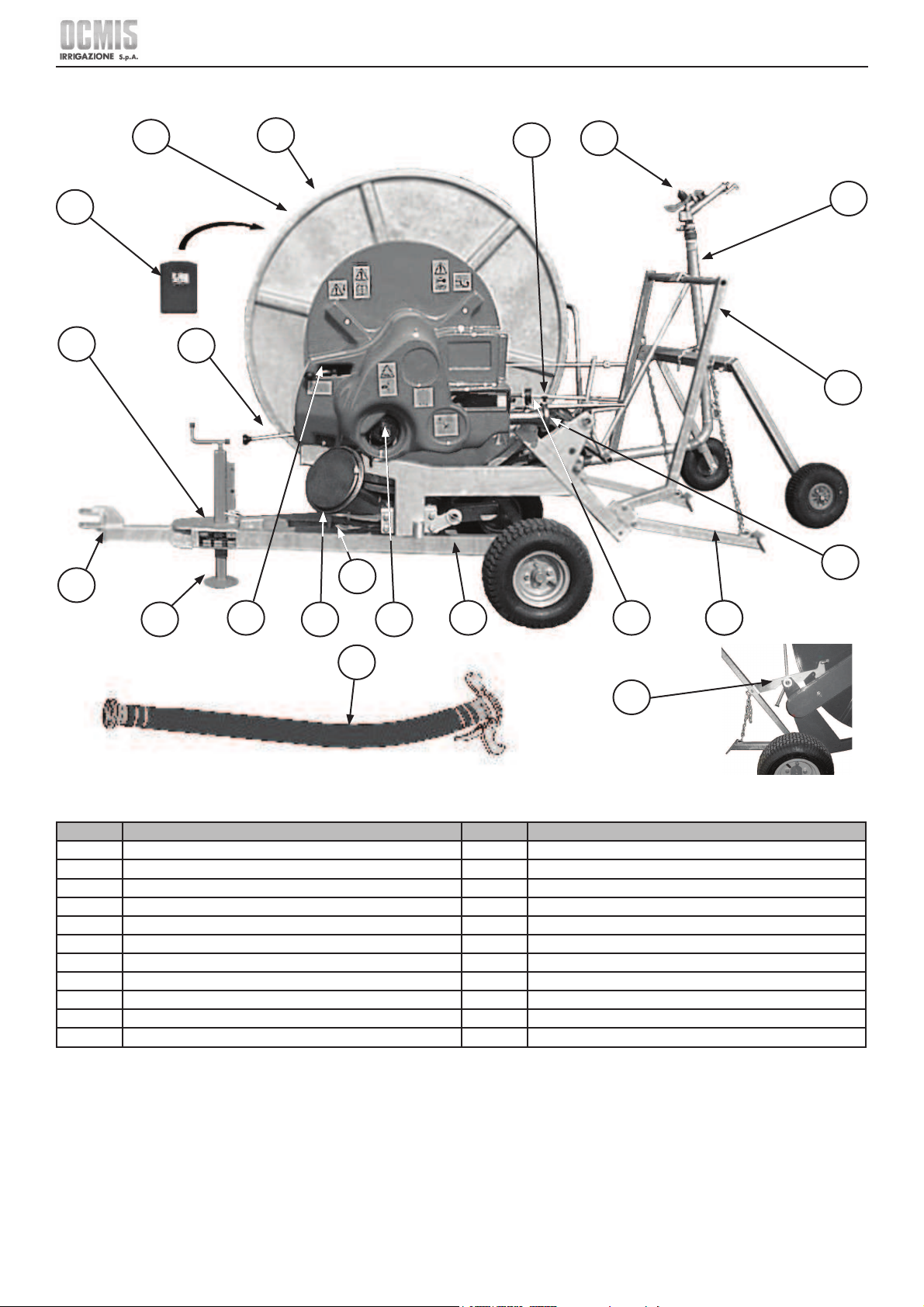

2 TECHNICAL DESCRIPTION OF THE MACHINE

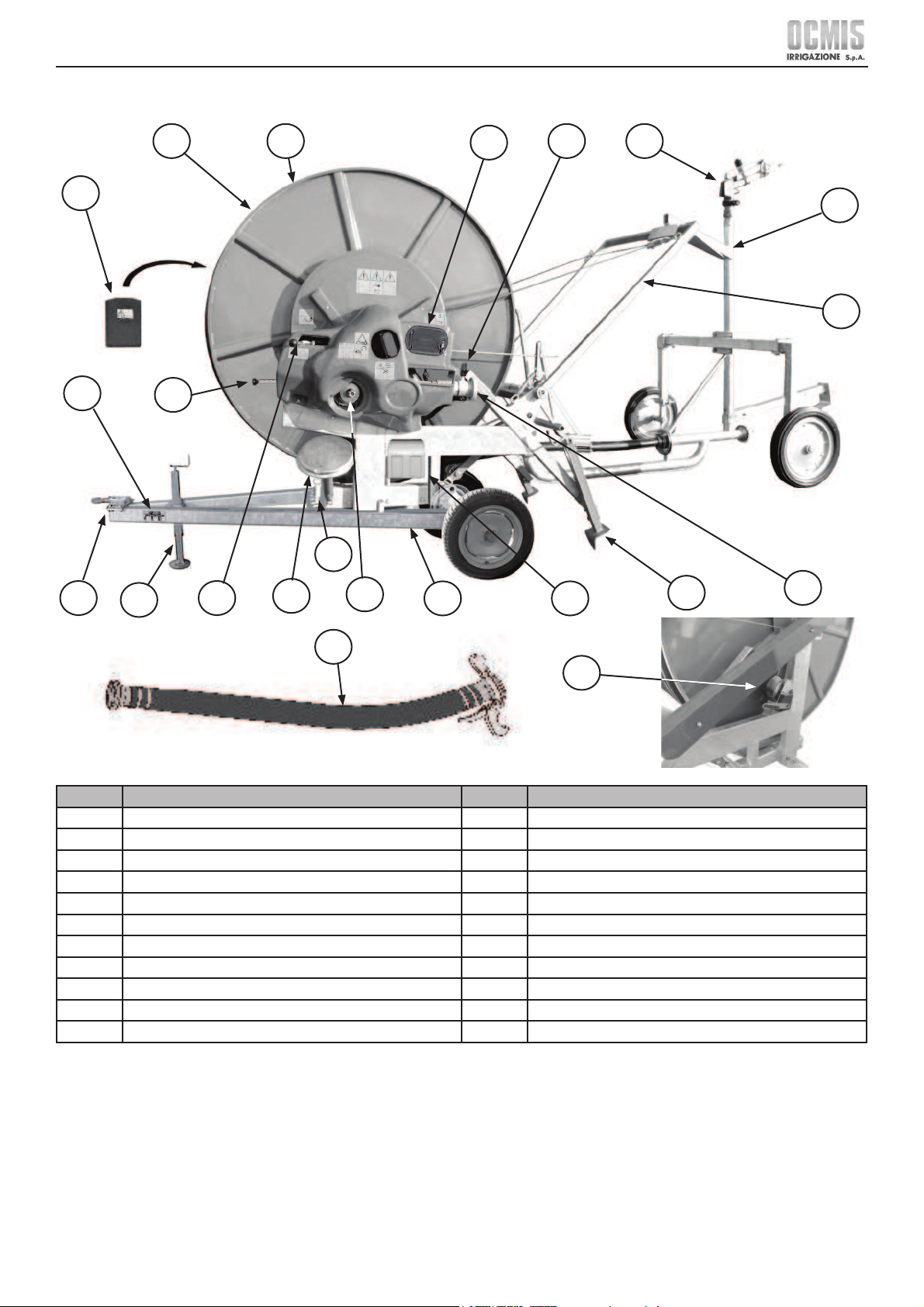

2.1 DESCRIPTION OF MAIN PARTS

The hose reel travelling raingun is a farm machine which is towed for moving it and is used for irrigating fi elds and plots of land after it has been put

in place.

The suitable drawbar “eye” must be used for moving the machine and placing it in the fi eld. The machine consists of the following assemblies/sections,

shown in the Drawing below.

MR-MR/1

Ref. Description Ref. Description

1 Reel 12 Water pressure gauge

2 PE irrigation hose 13 Rear anchors

3 Document holder 14 Water inlet

4 Identifi cation plate 15 Trolley loading frame

5

Handwheel for manual winding

(optional feature)

16 Raingun trolley

17 Irrigator (Raingun)

6 Tow bar 18A By-pass adjustment lever (for MR40-43)

7 Front pivoting wheel 18B By-pass adjustment rod (for MR50#63)

8 Ratchet rod

19

Hooking lever for trolley loading frame

(standard for MR50#63)

9 Turbo-gearbox lever

10 Quick winding power take off

20 Water supply hose

11 Frame

12

3

19

6

4

7

8

9

10 11