BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 1 of 76

Operating and installation manual

OCHSNER AIR EAGLE 717

OCHSNER AIR EAGLE 414

OCHSNER AIR EAGLE 717 with MULTI TOWER (T200)

OCHSNER AIR EAGLE 414 with MULTI TOWER (T200)

Air/water heat pump

for Heating and DHW

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 2 of 76

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 3 of 76

Contents

1 General ......................................................... 4

1.1 Information on documentation ...................... 4

1.2 Safety regulations ........................................... 4

2 Appliance description ................................... 5

2.1 Heat pump ...................................................... 5

2.2 CE designation ................................................. 5

2.3 Scope of delivery ............................................. 5

2.4 Function .......................................................... 6

2.5 System overview ............................................. 6

3 Outdoor unit ................................................. 7

3.1 Choosing the installation location................... 7

Minimum wall clearances ................................ 8

Dimensions ....................................................... 8

3.2 Opening the outdoor unit ............................... 9

3.3 Main components ......................................... 10

3.4 Cable entries ................................................. 10

3.5 Foundation for the outdoor unit ................... 11

Strip foundation ............................................. 12

Spot foundation ............................................. 12

Concrete plinth .............................................. 13

Installing on flat roofs .................................... 13

4 Indoor unit .................................................. 15

4.1 Golf-Midi indoor unit .................................... 15

Main components .......................................... 15

Connections ................................................... 16

Choosing the installation location.................. 16

Venting the system ........................................ 18

Safety valve .................................................... 18

Expansion vessel/system pressure................. 18

4.2 T200 (MULTI TOWER) indoor unit ................. 19

Appliance description .................................... 19

Main components .......................................... 20

Choosing the installation location.................. 20

Hydraulic and refrigerant connections .......... 22

Transport and handling .................................. 23

Safety valve .................................................... 26

DHW connection and safety assembly........... 26

Filling the system ........................................... 27

Venting the system ........................................ 28

Using T200 with a heating circuit with mixing

valve ............................................................... 28

Cooling with T200 .......................................... 28

T200 maintenance ......................................... 29

5 Connection lines ......................................... 30

5.1 Refrigerant lines ............................................ 30

5.2 Conduit to house ........................................... 31

6 Electrical connection ................................... 32

6.1 Preparation ................................................... 32

6.2 Guidelines ..................................................... 33

6.3 Power connection details.............................. 33

6.4 PSU signal contact ......................................... 34

6.5 Uninterrupted tariff ...................................... 34

6.6 Shutdown by tariff contactor ........................ 34

6.7 Night tariff ..................................................... 34

6.8 Modbus wiring .............................................. 34

6.9 Sensor wiring................................................. 34

6.10 Pumps, drives 230 VAC.............................. 35

6.11 HLSC on the heating circuit ....................... 35

6.12 DHW booster heater .................................. 35

6.13 Wiring diagram .......................................... 36

6.14 Indoor unit wiring ...................................... 37

Golf-Midi indoor unit ..................................... 37

T200 (MULTI TOWER) indoor unit ................. 38

Outdoor unit wiring .................................................. 40

6.15 Wiring diagrams ......................................... 41

EAGLE 717 with Golf-Midi indoor unit ........... 41

EAGLE 717 with T200 indoor unit .................. 42

EAGLE 414 with Golf-Midi indoor unit ........... 43

EAGLE 414 with T200 indoor unit .................. 44

7 Heating system ........................................... 45

7.1 Quality of heating water ................................ 45

7.2 Pressure maintaining system ......................... 45

8 Commissioning ............................................ 46

8.1 Before starting ............................................... 46

8.2 Persons required on site ................................ 46

8.3 Setting the flow rate ...................................... 47

9 Operation .................................................... 48

9.1 Menus ............................................................ 48

9.2 Appliance function ......................................... 49

Heating circuit ................................................ 49

DHW ............................................................... 49

Anti-legionella function ................................. 49

Second heat generator .................................. 49

Screed drying program .................................. 49

9.3 System operation ........................................... 49

Running costs ................................................. 49

Flow temperatures ........................................ 49

10 Troubleshooting .......................................... 50

10.1 Error Codes OTE ......................................... 51

10.2 Dealing with faults ..................................... 52

10.3 Rectifying minor causes independently ..... 52

10.4 Cleaning and care ....................................... 52

11 Maintenance ............................................... 53

11.1 Customer service ....................................... 53

11.2 Maintenance contract ................................ 54

12 Environment and recycling .......................... 55

12.1 Disposal of transport packaging ................. 55

12.2 Decommissioning ....................................... 55

12.3 Disposal of the appliance ........................... 55

13 Specification ............................................... 56

13.1 Data table (with Golf-Midi indoor unit) ..... 56

13.2 Data table (T200 indoor unit) .................... 58

13.3 Pressure drop ............................................. 59

13.4 Pump curves............................................... 59

13.5 Limits of use ............................................... 59

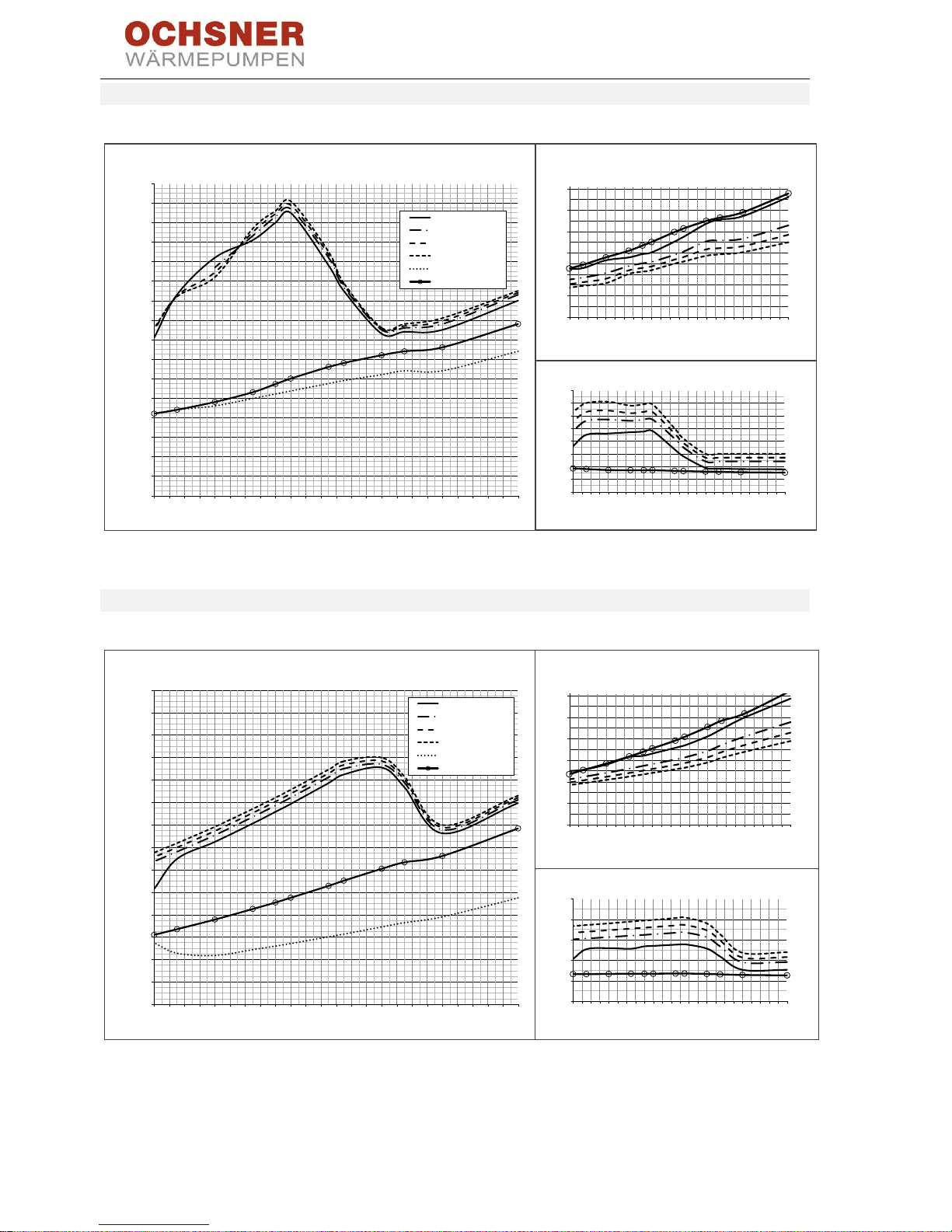

13.6 Performance diagrams EAGLE 717............. 60

13.7 Performance diagrams EAGLE 414............. 60

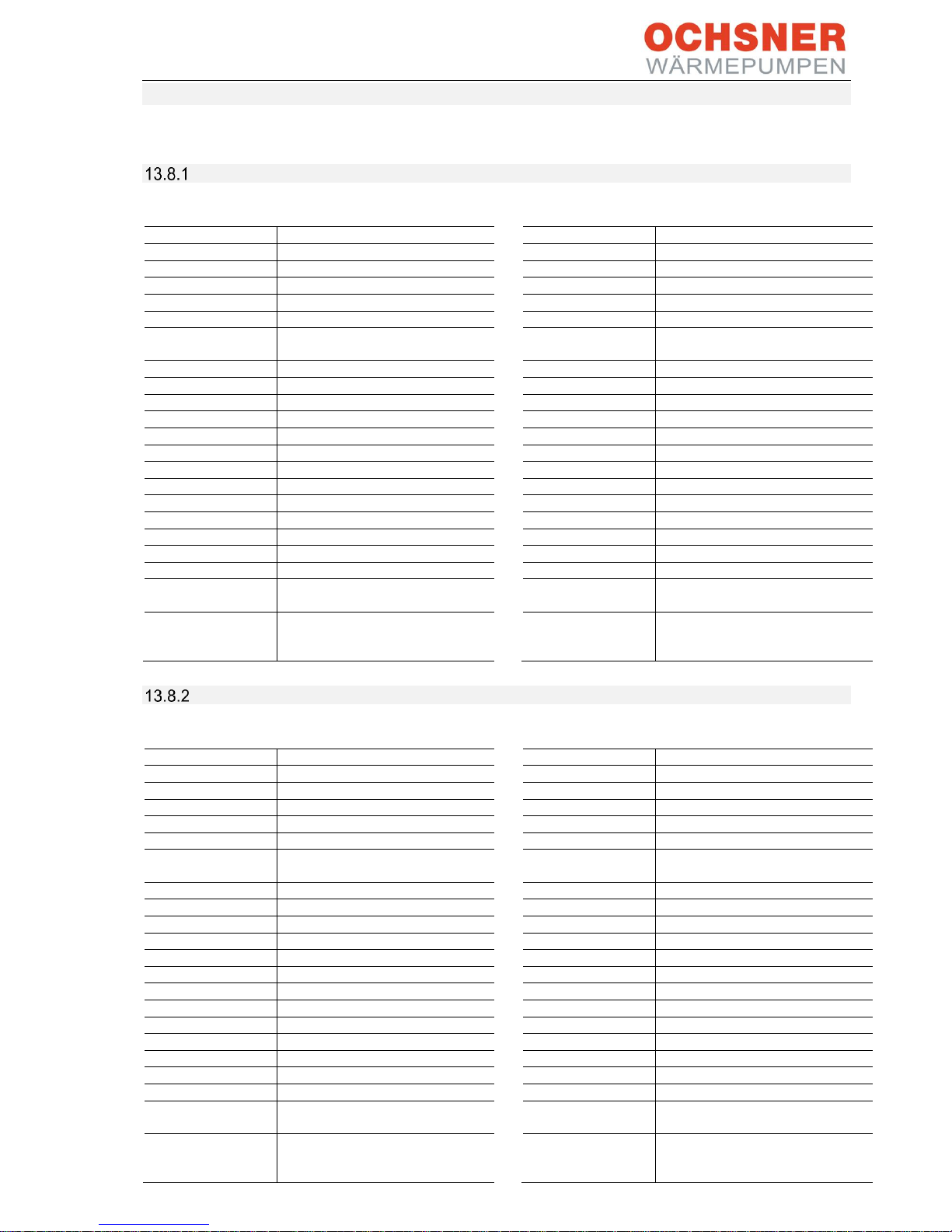

13.8 Details of energy consumption .................. 61

AIR EAGLE 414 ............................................... 61

AIR EAGLE 717 ............................................... 61

13.9 Electrical wiring diagrams EAGLE 717 ........ 62

13.10 Electrical wiring diagrams EAGLE 414 ........ 67

14 List of figures ............................................... 72

15 List of tables ................................................ 72

16 Declaration of conformity ........................... 73

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 4 of 76

1 General

1.1 Information on documentation

The following information is a guideline for the

complete documentation.

Please read your heat pump's operating manual

carefully from beginning to end. This will help you

to operate your heat pump better. This manual is

to be kept readily accessible near the heat pump.

The precautionary information provided below is

used in this document.

WARNING

Failure to observe this information

poses a risk of injury or death and may

lead to material damage. This

information must be observed without

fail.

CAUTION

Failure to observe this information may

lead to an appliance fault or material

damage. This information should be

observed.

PLEASE NOTE

CAUTION

Information for work on electrical

systems. This information must be

observed without fail. Caution - risk to

life!

1.2 Safety regulations

Read this manual thoroughly before

commissioning the heat pump or making settings!

The appliance must not be converted or

modified in any way. Work on the

appliance (repairs, modifications) may

only be carried out by the manufacturer

or bodies authorised by them.

Turn off all mains fuses of the system

before carrying out any work on plug-in

strips or electrical connections (wires).

Commissioning and servicing of the

appliances may only be carried out by

specialist personnel authorised by

OCHSNER.

Installation of the appliances and their

wiring may only be carried out by a

specialist in accordance with local

regulations.

The controller can be used to enable

functions to protect the heat pump.

However, since the controller is not

certified as a safety device, safety

measures in case of failure of or damage

to the heat pump (e.g. additional

external switching of the safety devices

in use) must comply with local

regulations.

In order to avoid malfunctions, fitting

the snow cover on the EAGLE outdoor

unit is mandatory. In the event of heavy

snowfall and after longer idle periods, it

may be necessary to remove the snow.

WARNING

Do not use the appliance as a step or

platform. Do not climb on the appliance

or place any loads on it.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 5 of 76

2 Appliance description

2.1 Heat pump

OCHSNER AIR EAGLE 717 and OCHSNER AIR

EAGLE 414 are air/water heat pumps configured

as split appliances.

The appliance extracts heat at a low temperature

from the outdoor air and releases it to the heating

water at a higher temperature. Heating water can

be heated to a flow temperature of up to 65°C.

The appliance is equipped with an electric

booster heater (DHC). In monovalent mode, the

electric booster heater is switched on when the

bivalent point is not reached to ensure heating

mode or the provision of high DHW

temperatures.

Special features of this heat pump:

• Output-dependent refrigerant circuit

• Variable speed compressor

• Refrigerant circuit controller

• OTE heat manager

• Split outdoor unit with compressor

Additional properties:

•

Suitable for underfloor and radiator

heating systems

•

Low temperature heating systems are

preferred

•

Heat can still be extracted from the

outdoor air at temperatures as low as 20°C

•

Corrosion protected - external cladding

components are made of powder coated

stainless steel

•

Includes all components and safety-

relevant devices required for operation

•

Contains non-flammable safety

refrigerant

Two different indoor units are available for the

air/water heat pump:

•

Golf-Midi indoor unit

•

T200 (MULTI TOWER) indoor unit

2.2 CE designation

The product you have purchased conforms to the

technical regulations valid at the time and is

compliant with CE standards.

2.3 Scope of delivery

The OCHSNER AIR EAGLE heat pump is delivered

in 2 sections.

Golf-Midi indoor unit:

The indoor unit is delivered without its casing

installed. The casing sections are in a separate

package on the same pallet.

Contents of packages:

• Name plate

• Cowl for outdoor installation

• Front panel

• Rear panel

• Side panels, left/right

• OTE controller sensor set

• Operating manual

Optional accessories:

• OTE sensor set for buffer

T200 (MULTI TOWER) indoor unit:

The following components are packed inside the

MULTI TOWER, next to the two pumps:

• Outside temperature sensor

• Adjustable feet

• Drain hose

• Operating manual

Gaskets for the hydraulic connection (heating

circuit flow/return, cold water, DHW) are

attached directly at the connections.

Outdoor unit:

The outdoor unit is shipped fully assembled. It is

transported on a pallet.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 6 of 76

2.4 Function

Heat is extracted from the outdoor air via the

heat exchanger (evaporator) on the air side. The

refrigerant is evaporated and compressed by a

compressor. This requires electrical energy. The

refrigerant is now at a higher temperature level

and releases the heat from the air to the heating

system via another heat exchanger (condenser).

During this, the refrigerant expands and the

process begins again. At air temperatures below

approx. + 7 °C air humidity condenses as ice on

the evaporator fins. This ice is automatically

removed (defrosting). In the defrost phase, the

fan shuts down and the heat pump circuit is

reversed. The heat required for defrosting is

drawn from the buffer tank or the heating circuit.

At the end of the defrost phase the heat pump

automatically returns to heating mode.

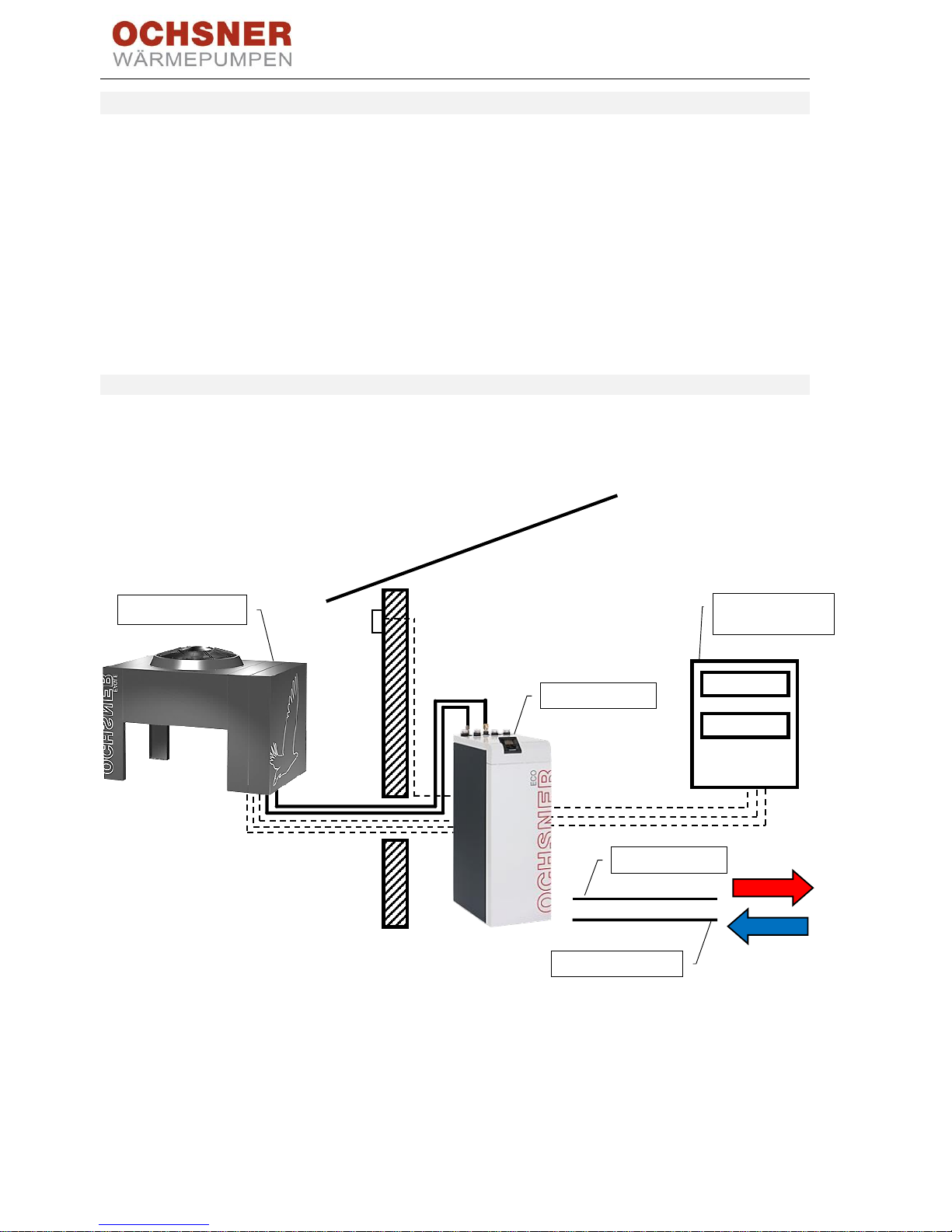

2.5 System overview

The heat pump consists of a split outdoor unit and

an indoor unit which is installed in the boiler room.

The connection to the heating system is made via

the flow and return of the heat sink side of the

heat pump.

Figure 1: System overview

EAGLE indoor

Primary/secondary

distribution

EAGLE outdoor unit

Heating return

Heating flow

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 7 of 76

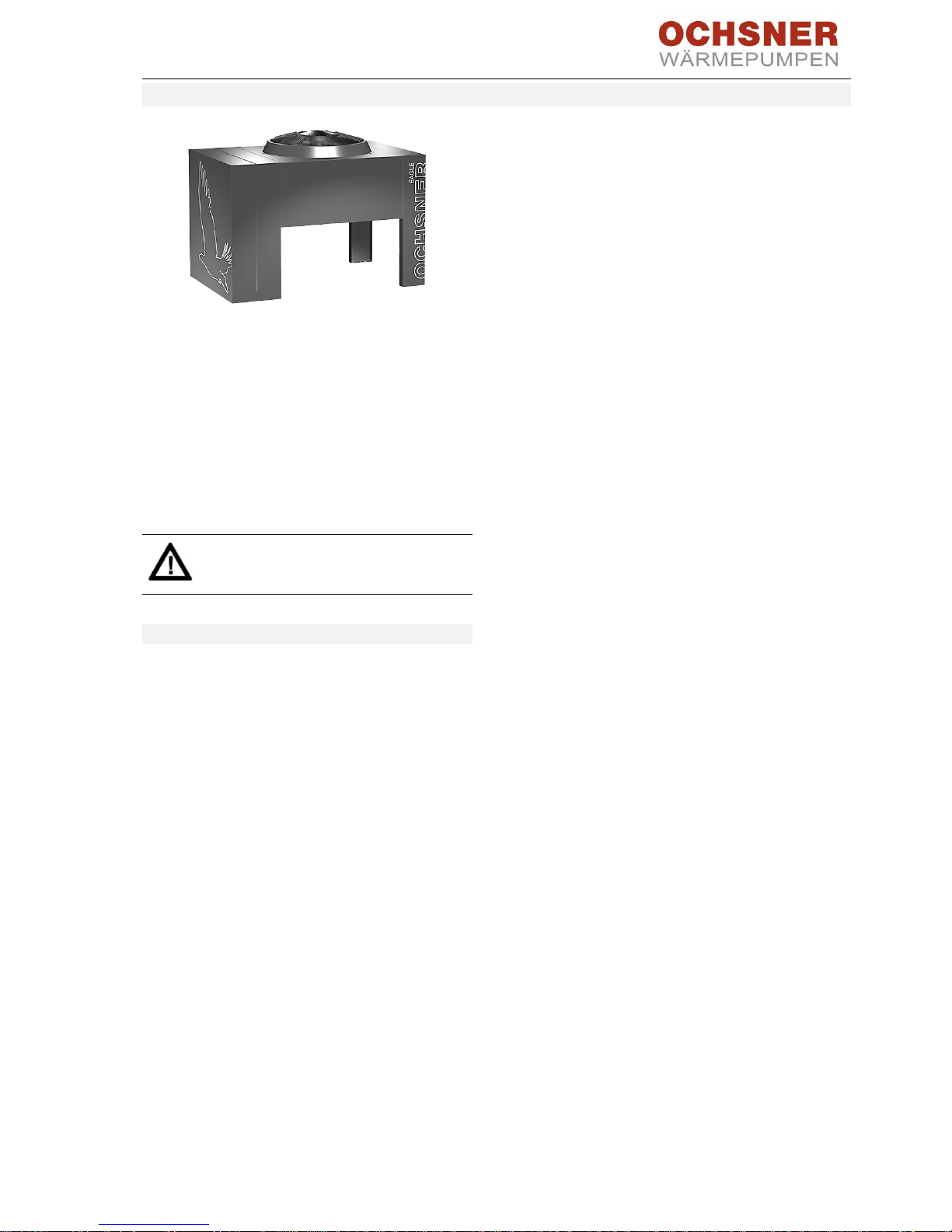

3 Outdoor unit

Figure 2: EAGLE outdoor unit

The EAGLE outdoor unit is installed outdoors on a

plinth provided on site. The outdoor unit consists

of a sound-insulated casing for the horizontal fan

and refrigerant circuit components, such as the

evaporator, compressor, expansion valves and

others. It should be installed as closely as possible

to the indoor unit. The minimum clearances to

walls and recesses should be observed for

installation.

CAUTION Risk of injury!

Never remove the grille from the fan.

3.1 Choosing the installation location

The heat pump can be installed at altitudes of up

to 1000 m above sea level.

High wind loads on the outdoor unit can cause

problems with defrosting in defrosting mode.

Avoid installation in an open and exposed location

with high expected wind loads (e.g. flat roof of a

house in a raised location).

Select an installation location where the appliance

is on the side of the building facing away from the

wind (leeward side).

Avoid acoustic reflections when installing the

EAGLE outdoor unit:

• Avoid installation on reverberant floors.

• Installation between two walls can lead to

increased sound levels.

• Avoid installation next to bedrooms.

• Plants and planted areas can reduce sound

levels.

Provide a frost-free drain for any condensate to

drain away. A gravel bed with drainage connection

underneath the evaporator is sufficient. In winter,

ice may form around the drain.

Please note the following with regard to

installation in coastal areas:

• The outdoor unit must be installed at least

1 km away from the sea.

• The installation location selected should

always be on the leeward side of the building

(the side facing away from the sea).

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 8 of 76

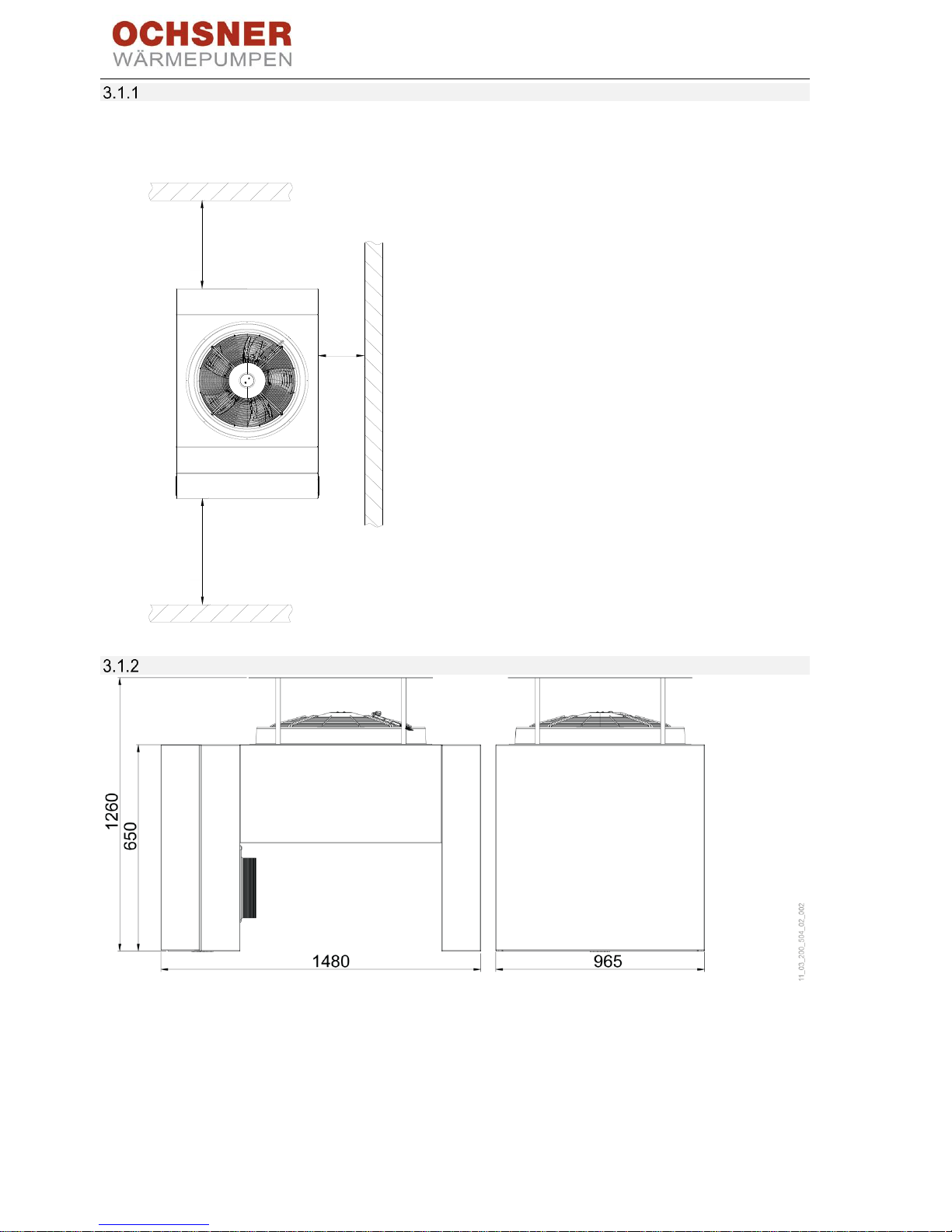

Minimum wall clearances

Do not place the outdoor unit in a recess. The

diagram shows the minimum wall clearances.

Figure 3: Outdoor unit minimum clearances (in mm)

Dimensions

Figure 4: Outdoor unit dimensions (in mm)

min. 1000

min. 500

min. 1000

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 9 of 76

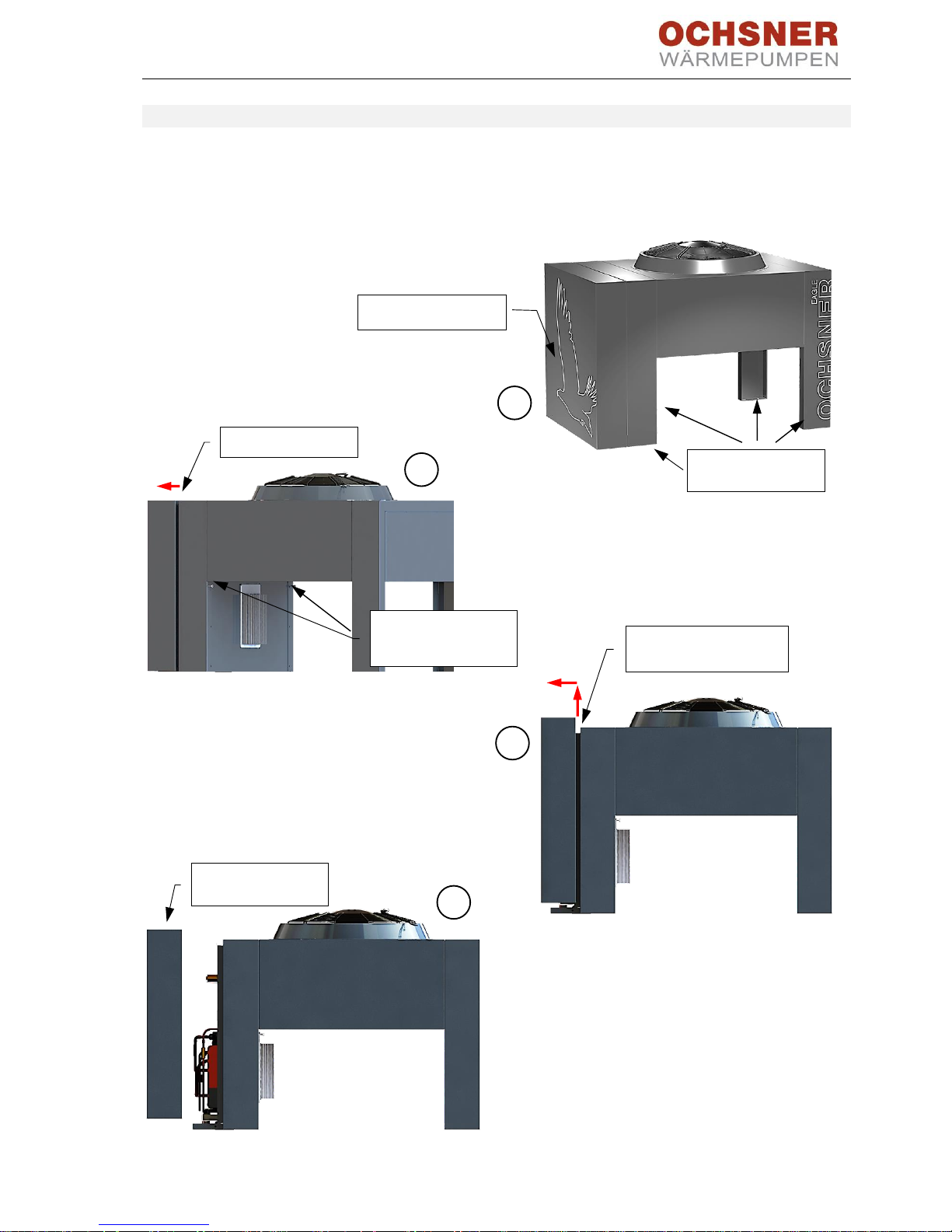

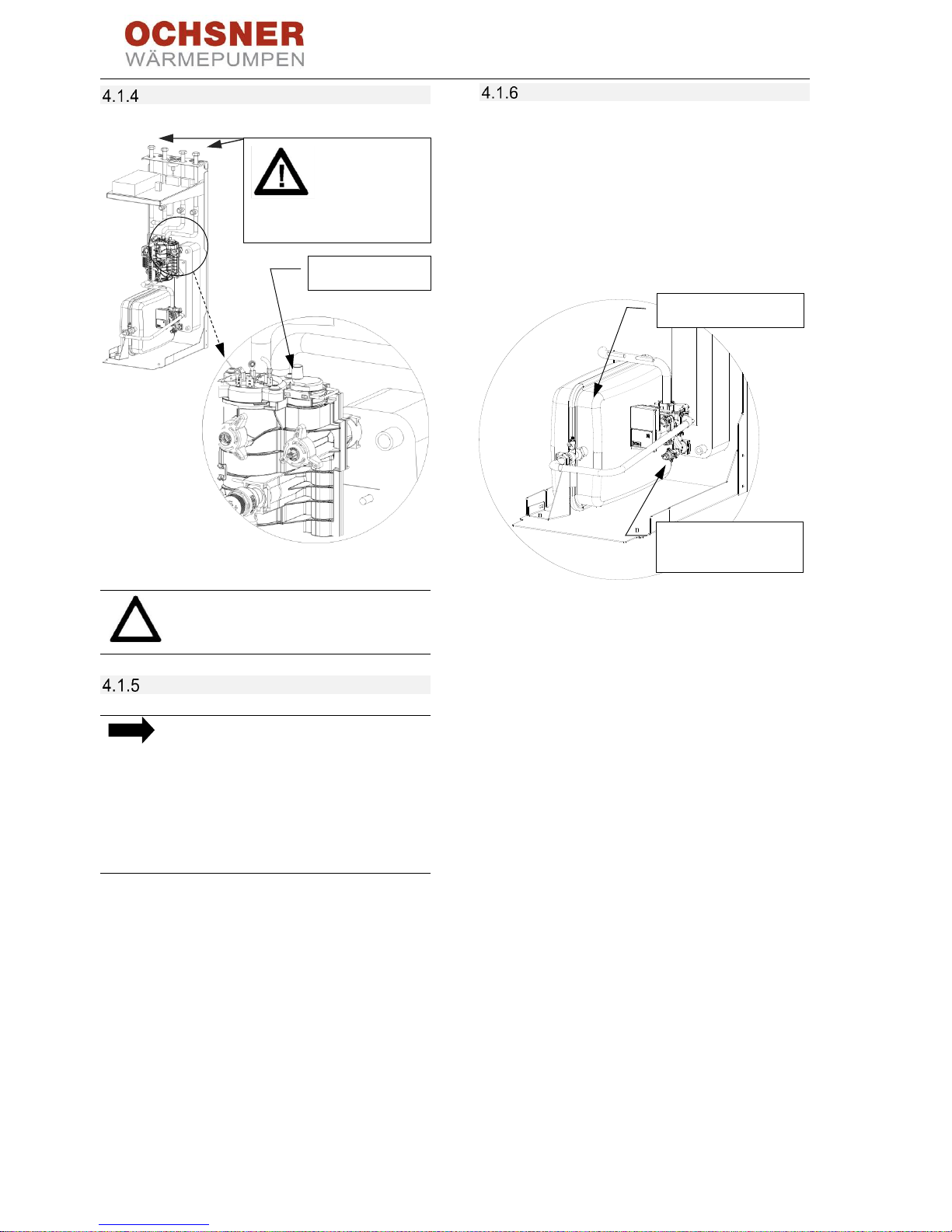

3.2 Opening the outdoor unit

The EAGLE outdoor unit is delivered as a closed

unit. It has to be opened for the connection of the

refrigeration and electric system. We recommend

securing the outdoor unit before removing the

casing cover.

Procedure:

1. Secure the outdoor unit

2. Undo screws on the cover

3. Lift cover out

4. Remove cover

Cover can now be

removed

4

3

Slide cover upwards out

of the bracket

2

Undo 2 hexagon

socket 6 screws

M8x200

Release cover

Secure the

outdoor unit

1

Casing cover

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 10 of 76

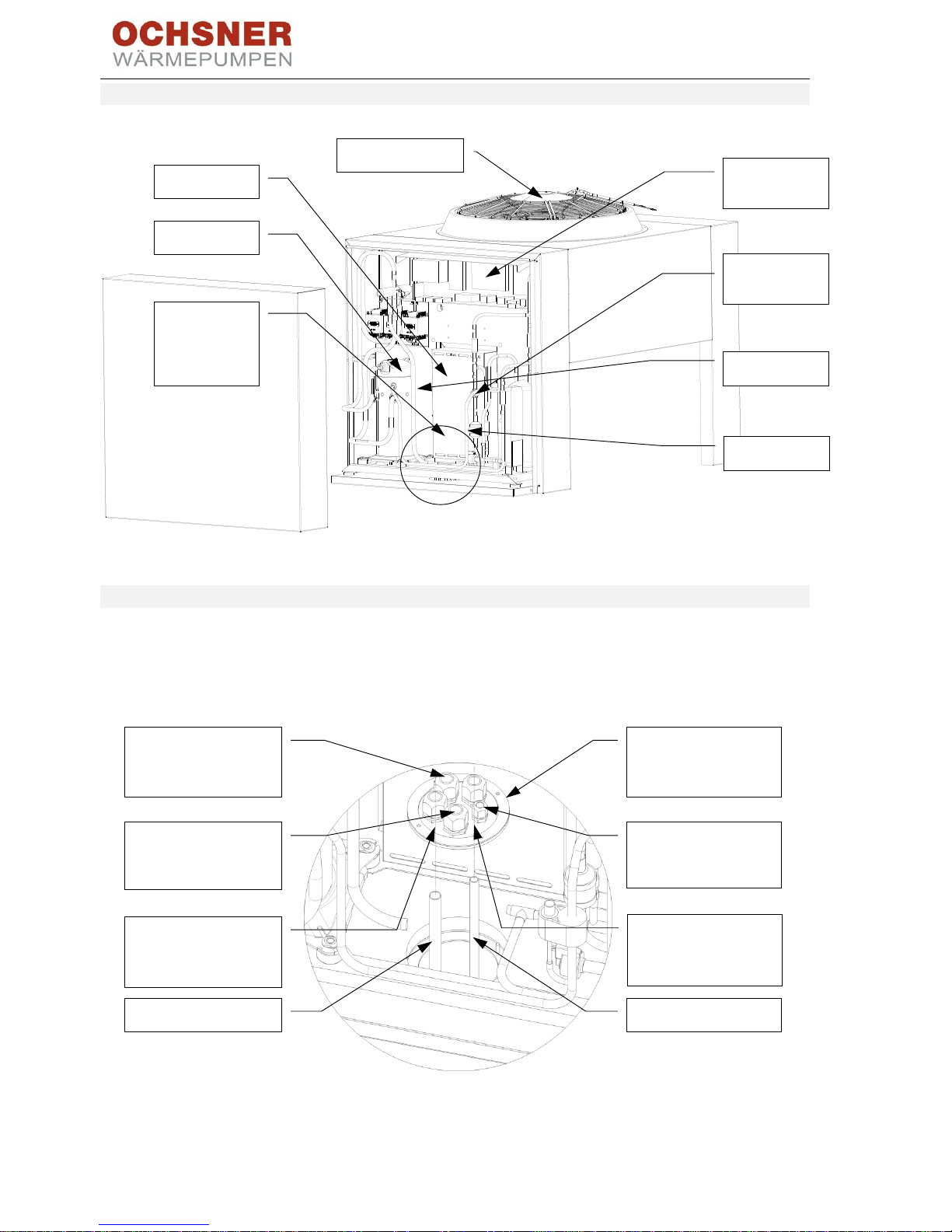

3.3 Main components

Figure 5: Outdoor unit main components

3.4 Cable entries

Remove the mounting plate to pass through the

hot gas and liquid pipes as well as the 3 supply

cables. After the outdoor unit has been

positioned, the pipes can be aligned and cables

passed through. When everything is ready, realign the mounting plate and tighten the cable

entries.

Figure 6: Outdoor unit conduits

Outdoor unit

control box

Compressor

Fan motor

Inverter

Refrigerant

circuit

Connection

line conduit

Cable entries

Liquid line

Hot gas line

Cable entries for control

cables

M25 x 1.5

Liquid line

Hot gas line

Conduits

Hot gas line

M25 x 1.5

Mounting plate

removed

Cable entry for BUS

cable

M16 x 1.5

Cable entry for power

supply

M25 x 1.5

Conduit

Liquid line

M25 x 1.5

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 11 of 76

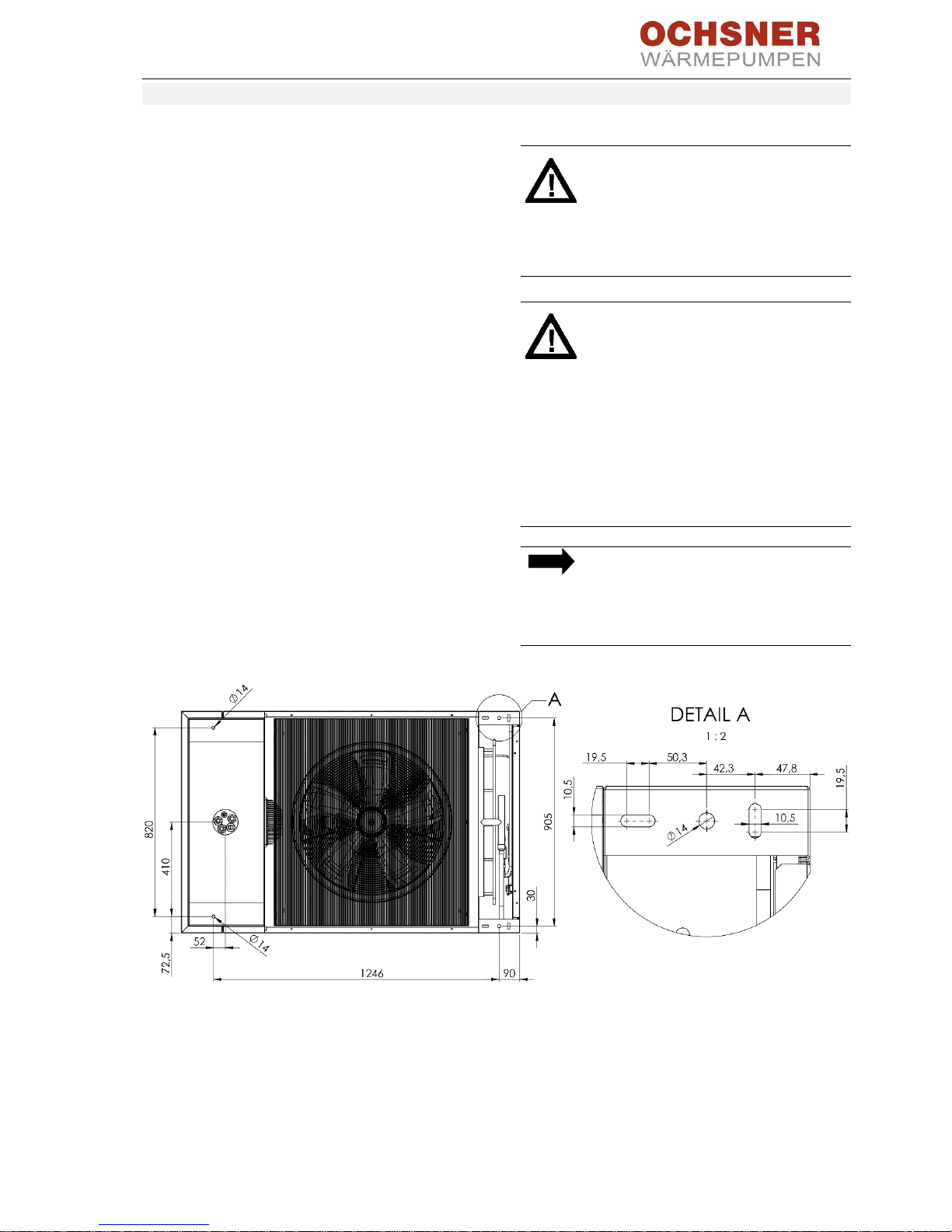

3.5 Foundation for the outdoor unit

A permanent foundation is required beneath the

outdoor unit. The foundation must meet the load

bearing requirements of the outdoor unit (see

section 13, Specification).

• Provide for frost-free drainage (e.g. a gravel

bed with a frost-free connection to a drain)

for condensation that forms on the outdoor

unit.

• Where refrigerant lines are to be laid in the

ground, ensure correct positioning of the

pipe liner when laying the foundations.

• Use rigid underground sewage pipes or

flexible, double-skinned cable ducts (smooth

on the inside) for the pipe liner.

• This must be done in accordance with the

relevant Building Codes of Practice and

regulations.

Take the expected wind loads at the

installation site into consideration.

Ensure that the outdoor unit is

adequately secured to the foundation

to prevent it from tipping over due to

wind loads.

CAUTION: Slipping hazard

If drainage for condensation is

inadequate, ice can build up in winter

in the area around the outdoor unit.

- Ensure drainage for

condensation is sufficient even

at low temperatures.

- Ensure that no ice is formed,

especially around walking

surfaces and entrances around

the outdoor unit.

NOTE

Insulation used beneath the soil must

be made of a closed-cell material.

Otherwise, the thermal insulation of

the material will be impaired.

Figure 7: EAGLE outdoor unit (view from below), fixing holes in the outdoor unit legs (dimensions in mm)

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 12 of 76

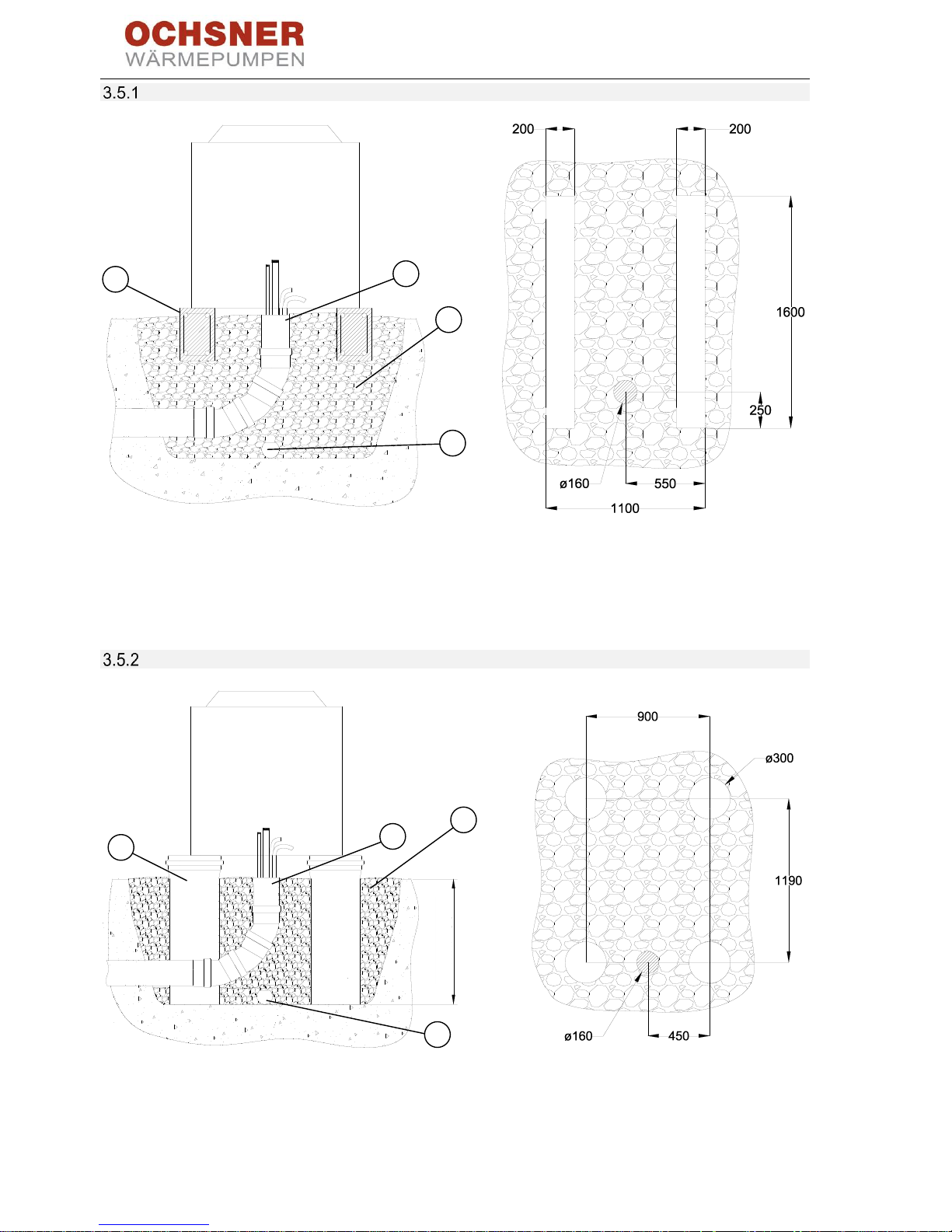

Strip foundation

1

Strip foundation

2

Pipe liner for the connecting lines (where installed underground)

3

Gravel bed

4

Drainage pipe (frostproof)

Figure 8: Strip foundation (dimensions in mm)

Spot foundation

1

Spot foundation

2

Pipe liner for the connecting lines (where installed underground)

3

Gravel bed

4

Drainage pipe (frostproof)

Figure 9: Spot foundation (dimensions in mm)

2

1

3

4

min. 800

2

1

3

4

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 13 of 76

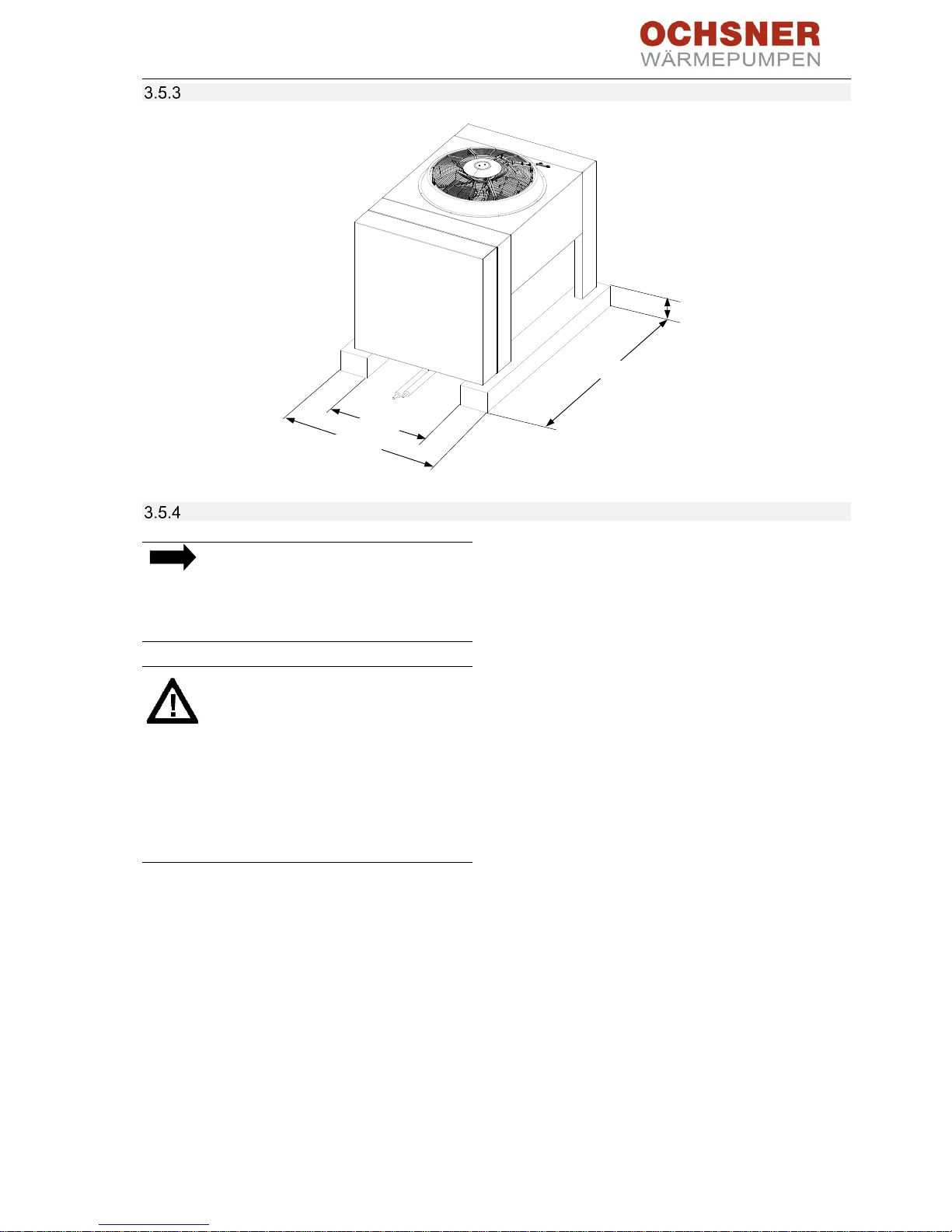

Concrete plinth

Figure 10: Installation on concrete plinth (dimensions in mm)

Installing on flat roofs

NOTE

Avoid installing the EAGLE outdoor unit

on roofs over living spaces or car ports

attached to living spaces due to the risk

of structure-borne noise transmission.

WARNING Risk of falling

Working on a flat roof without fall

protection constitutes a risk.

• When working on a flat roof,

observe the laws relating to

occupational safety in your

region.

• Always be aware of the open

edge.

Loads and stresses on roof structure

Note that when outside temperatures are very

low, ice can form beneath the outdoor unit.

In terms of roof structure loads, allow for an ice

load of 400 kg/m² in addition to the dead weight

of the outdoor unit.

When installing the EAGLE outdoor unit on top of

a freestanding car port, a garage or a storage

space, please note the following:

• Provide a suitable plinth for roof installation.

• Take the concentrated load arising from the

dead weight of the outdoor unit (subject to

the type of plinth) and the surface load

caused by possible build-up of ice into

consideration.

• Ensure suitable sound insulation between the

outdoor unit and the installation points on

the plinth.

• Use suitable anti-vibration pads between the

plinth and the outdoor unit legs (OCHSNER

accessory no. 290698) – see Figure 11.

• Provide sound insulation between the

outdoor unit legs and the plinth – see

Figure 11.

• Use suitable sound-insulating pipe fixings to

secure the refrigerant lines.

700

min. 1600

1100

200

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 14 of 76

1

Base

2

Anti-vibration mount

3

Rubber grommet

4

Washer

5

Fixing screw

Figure 11: EAGLE outdoor unit secured with structure-borne noise attenuating fixings

1

Flat roof

2

Refrigerant lines in open air with thermal insulation and UV protection

3

Base

4

Anti-vibration mount

Figure 12: Flat roof installation of EAGLE outdoor unit (dimensions in mm)

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 15 of 76

4 Indoor unit

The indoor unit is installed in the heating distribution room or any other suitable room. The indoor unit

contains the condenser and all hydraulic components required for operation with a water-filled heating

system. Observe the minimum clearances to the wall and recesses when installing the unit and ensure the

maximum room temperature does not exceed 30°C.

4.1 Golf-Midi indoor unit

Main components

Figure 13: Indoor unit detailed view

Indoor unit

control box

OTE controller

MFA module with

• 3-way switching valve

• Safety valve

• Electric auxiliary heater

8.8 kW

• Flow sensor

• Air vent

Circulation pump

Plate heat ex-

changer

Condenser

Expansion vessel

Service valve for

expansion vessel

Valve for filling and

draining

DHW

flow

Heating

flow

Heating

return

DHW

return

Bypass connection

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 16 of 76

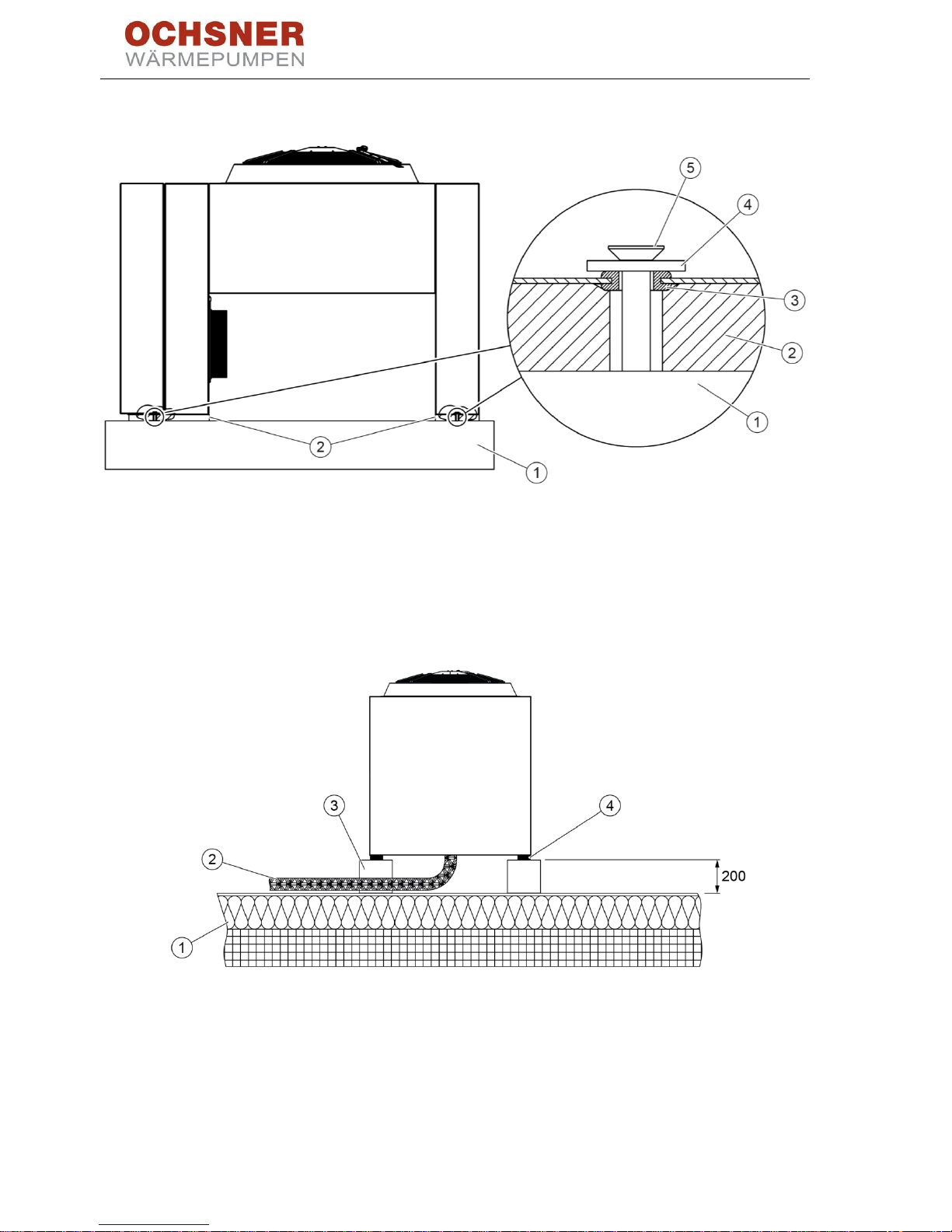

Connections

Figure 14: View from above

Choosing the installation location

4.1.3.1 Minimum wall clearances

Figure 15: Minimum wall clearances

Room

temperature

<30°C

Controller voltage

230 V~

Booster heater

400 VAC

Sensors <12 V

Liquid line

DHW heating

return

Heating

return

DHW heating

flow

Heating

flow

Hot gas line

Pressure gauge

b

bar

40 cm

min 40 cm

min 40 cm

min 100 cm

65 cm

min 5 cm

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 17 of 76

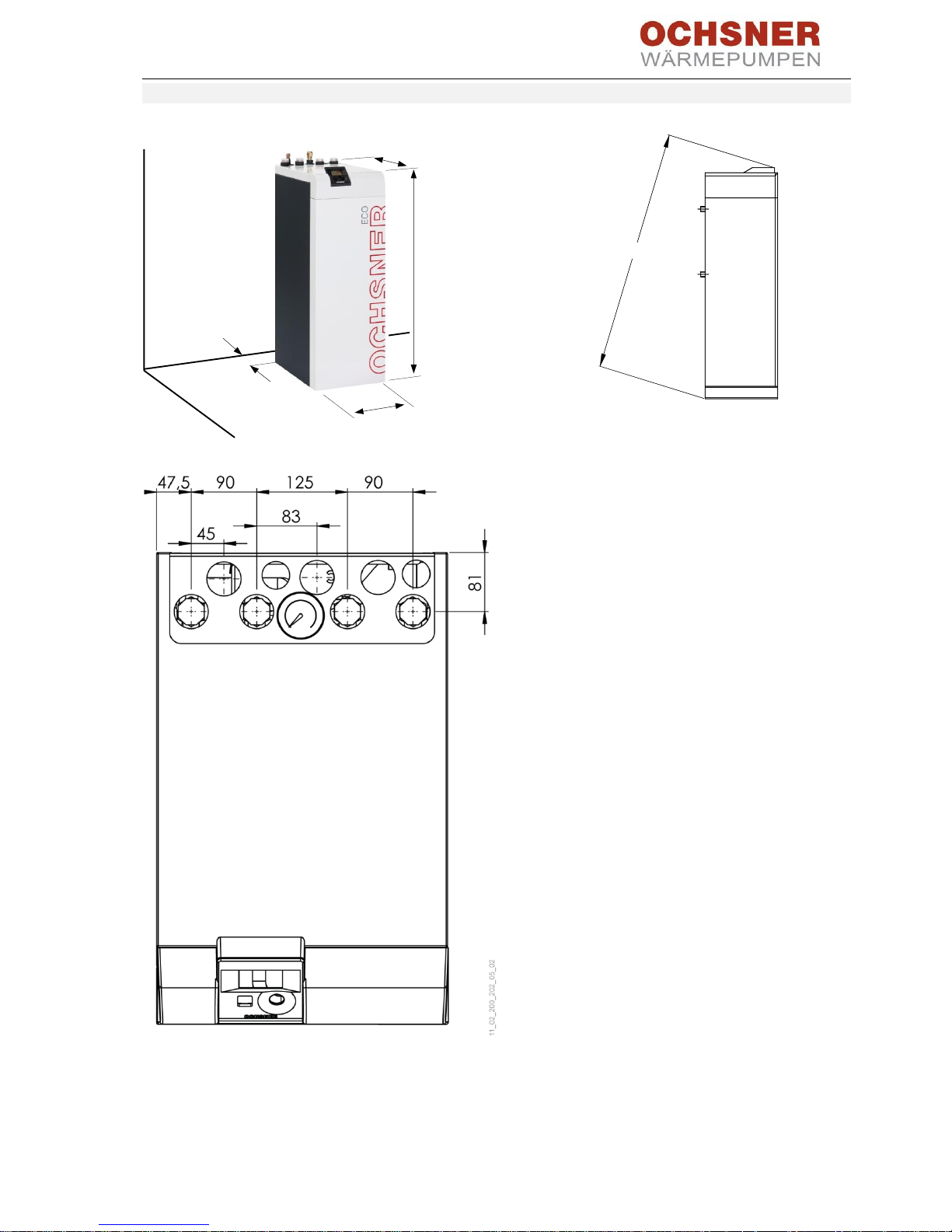

4.1.3.2 Dimensions

Figure 16: Indoor unit dimensions

Figure 17: Indoor unit tilt height

Figure 18: Indoor unit connection dimensions

min. 50 mm

1150 mm

400 mm

650 mm

approx. 132 cm

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 18 of 76

Venting the system

Figure 19: Indoor unit air vent valve

CAUTION

Close the valve cap after venting.

Safety valve

NOTE

Water will escape when the safety

valve is opened. Route the drain hose

into the sewage drain at the rear of the

indoor unit. The drain must not be

permanently connected to the sewage

drain! A funnel with a siphon must be

provided.

- Size the drain hose to ensure water can drain

freely when the safety valve is fully open.

- Ensure that the safety valve drain hose is open

to the atmosphere.

- Route the safety valve drain hose with a

continuous slope to the drain.

- Secure the drain hose to prevent movement

when water is running out.

Expansion vessel/system pressure

Preparation for filling:

A 24 l expansion vessel is installed in the heat

pump Golf-Midi indoor unit. In buffer systems or

systems with higher capacity, this expansion

vessel should be checked. If required, install an

additional expansion vessel in the system

(externally, not inside the appliance).

Figure 20: Draining and filling detailed view

Before filling the system, check the pre-charge

pressure in the expansion vessel. This must be

matched to the building height.

- Static head: Difference between highest and

lowest points in the system.

- Pre-charge pressure = static head + 0.3 bar

- System charge pressure = pre-charge pressure

+0.5 bar (when cold)

- Max. permissible operating pressure: 2.6 bar.

Select a safety valve with 3.0 bar.

See EN ISO 4126-1:2013-10-15, part 1: Safety

valves.

- Flush the heating system thoroughly before

filling.

- Only fill with water of potable quality.

CAUTION!

Replace plastic closures with

suitable plugs.

Air vent valve

Drain and fill opening

Expansion vessel

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 19 of 76

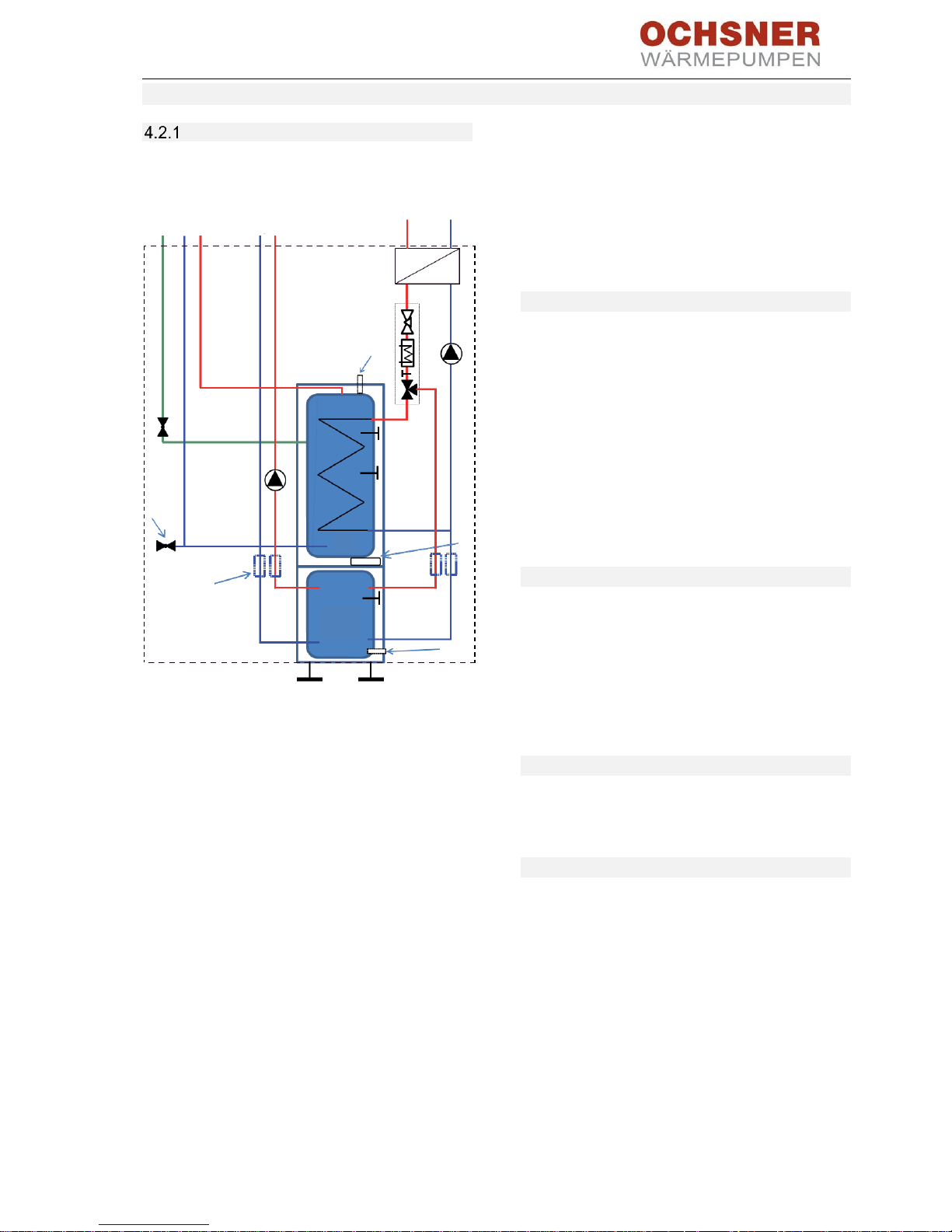

4.2 T200 (MULTI TOWER) indoor unit

Appliance description

The buffer tank and the DHW tank with heat

exchanger are arranged on top of each other and

can be separated for handling.

1

Heat pump

2

Hot gas

3

Liquid

4

Buffer charging pump

5

Multifunctional assembly (MFA)

6

Magnesium anode

7

Cable grommet

8

Drain stopcock

9

Heating circuit

10

DHW circulation

11

Cold water

12

DHW

13

Connecting hoses

14

Buffer tank

15

DHW tank

Figure 21: T200 hydraulic schematic

The appliance is fitted with a plastic foam outer

casing and a removable front panel. The appliance

is connected hydraulically and electrically to the

heat pump. All hydraulic connections are at the

top.

Further system components are integrated

alongside the DHW tank and the buffer tank:

Heat pump manager, tank charging pump, high

efficiency circulation pump for one direct heating

circuit, multifunctional assembly with safety valve

and 3-way switching valve, emergency/booster

heater for mono energetic operation.

4.2.1.1 DHW tank

The steel tank is fitted internally with a special

direct enamel and a sacrificial anode. The anode

with wear indicator protects the inside of the tank

against corrosion.

The heating water heated by the heat pump is

pumped through an internal indirect coil in the

DHW tank. The internal indirect coil transfers the

absorbed heat to the DHW. The integral heat

pump manager controls DHW heating to the

required temperature.

4.2.1.2 Buffer tank

The steel tank serves to hydraulically separate the

flow rates of the heat pump and the heating

circuit. The heating water heated by the heat

pump is transported to the buffer tank by the tank

charging pump. When there is a demand, the

heating water is supplied to the heating circuit by

the integral heating circuit circulation pump.

4.2.1.3 Heat pump manager (OTE)

The system is controlled via the integral OTE3 heat

pump manager. For adjustment options, see the

controller operating manual.

4.2.1.4 Multifunctional assembly (MFA)

The multifunctional assembly switches between

heating circuit and DHW heating.

10

11

12 9 2

1 3 5

6

8

7

13

8

4

14

15

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 20 of 76

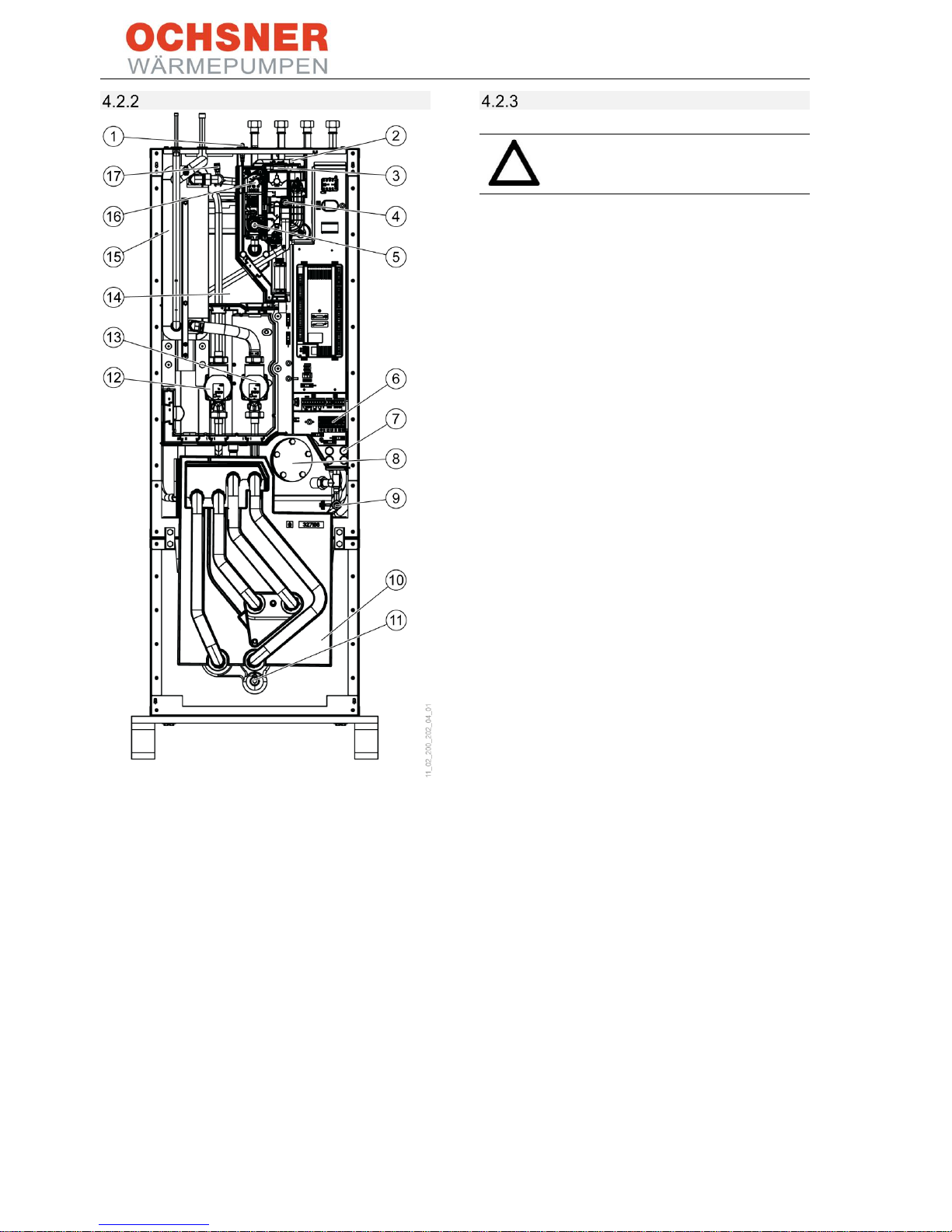

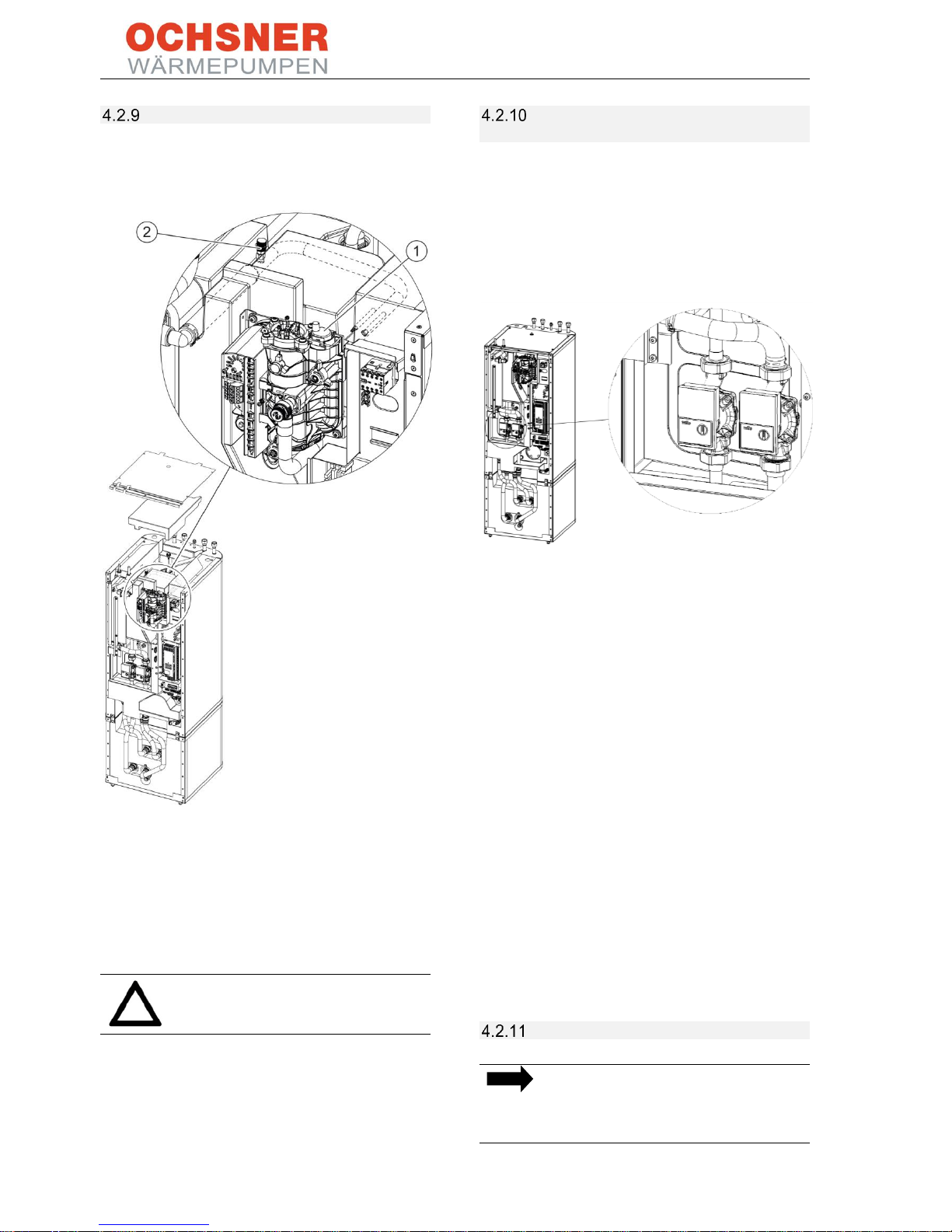

Main components

1

Magnesium anode

2

Air vent valve (MFA)

3

Electric booster heater 8.8 kW (MFA)

4

Safety valve (MFA)

5

3-way switching valve (MFA)

6

Electrical connection

7

Cable entries

8

Maintenance flange

9

Drain stopcock

10

Buffer tank (100 l)

11

Drain stopcock

12

Heating circuit pump

13

Buffer charging pump

14

DHW tank (168 l)

15

Condenser (plate heat exchanger)

16

High limit safety cut-out (MFA)

17

Air vent valve

Figure 22: Main components in T200 indoor unit

Choosing the installation location

CAUTION

Do not install the appliance in damp

rooms!

Install the appliance in a frost free and dry room

near the draw-off point. In order to reduce line

losses, keep the distance between the indoor unit

and the outdoor unit small.

Ensure that the floor has adequate load bearing

capacity and is sufficiently level (for weight, see

section 13, Specification). The room must not be

endangered by explosive dust, gases or vapours.

If installing the appliance in a boiler room with

other heating appliances, ensure that their

operation is not affected.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 21 of 76

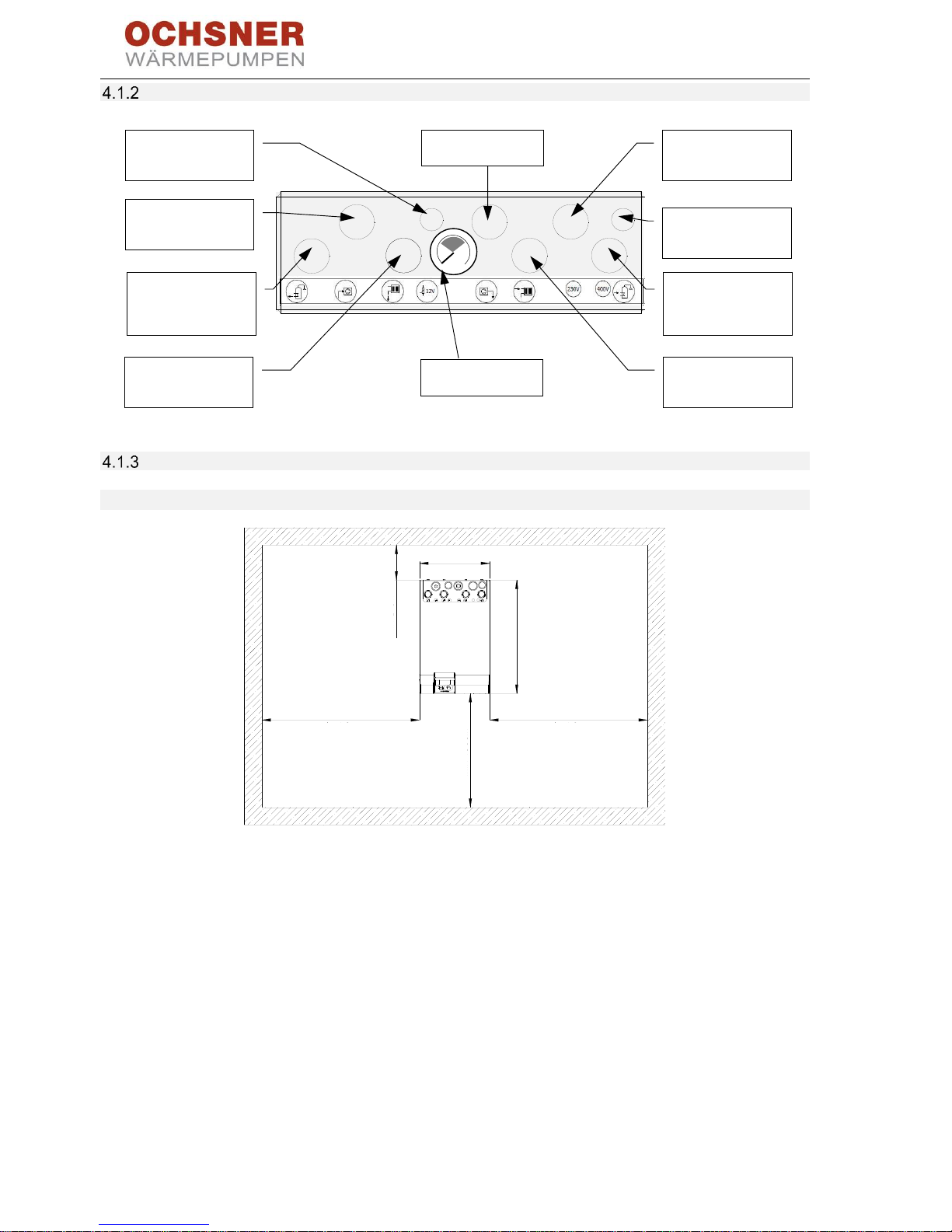

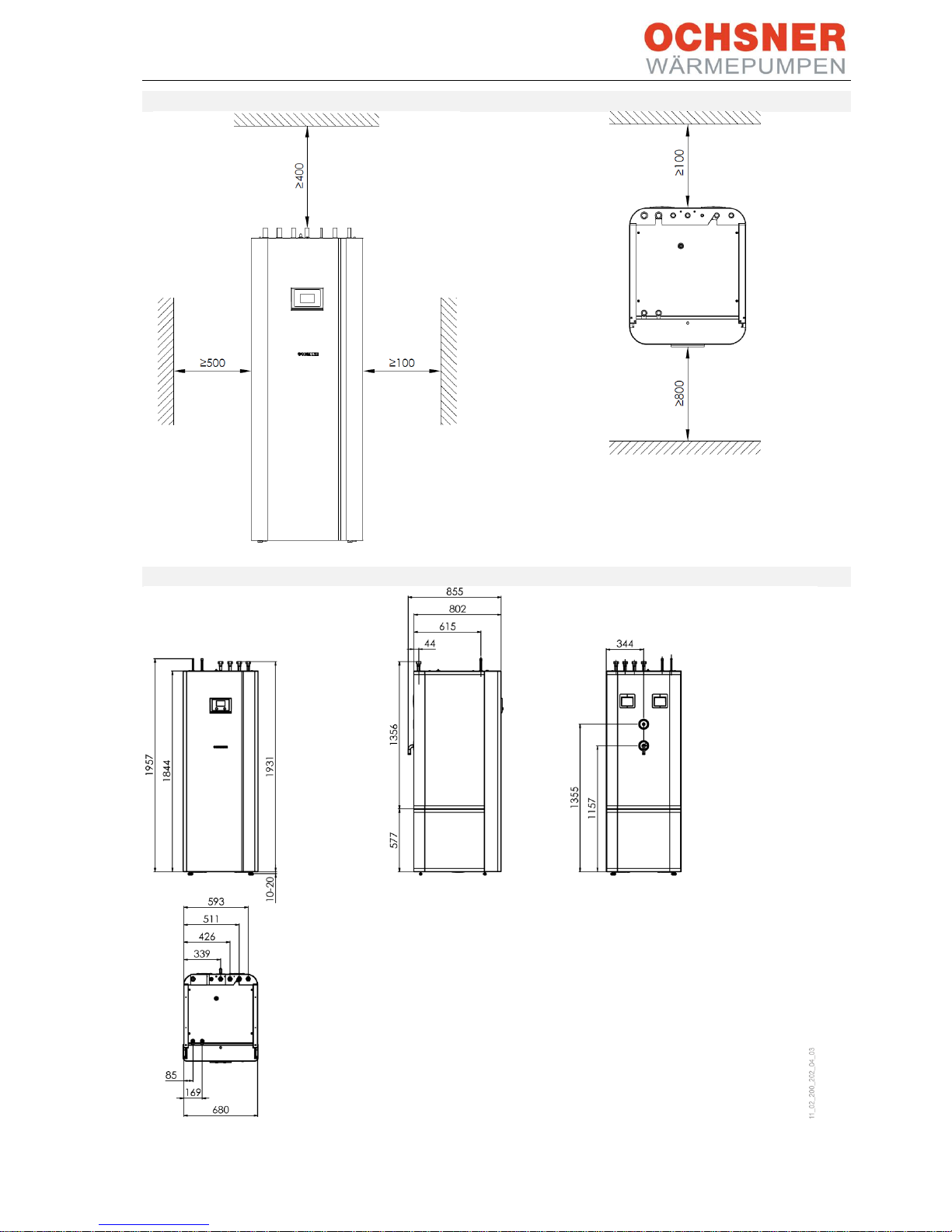

4.2.3.1 Minimum wall clearances

Figure 23: Minimum clearances (in mm)

Minimum clearances to the side can be either to

the right or the left.

4.2.3.2 Dimensions

Figure 24: Dimensions (in mm)

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 22 of 76

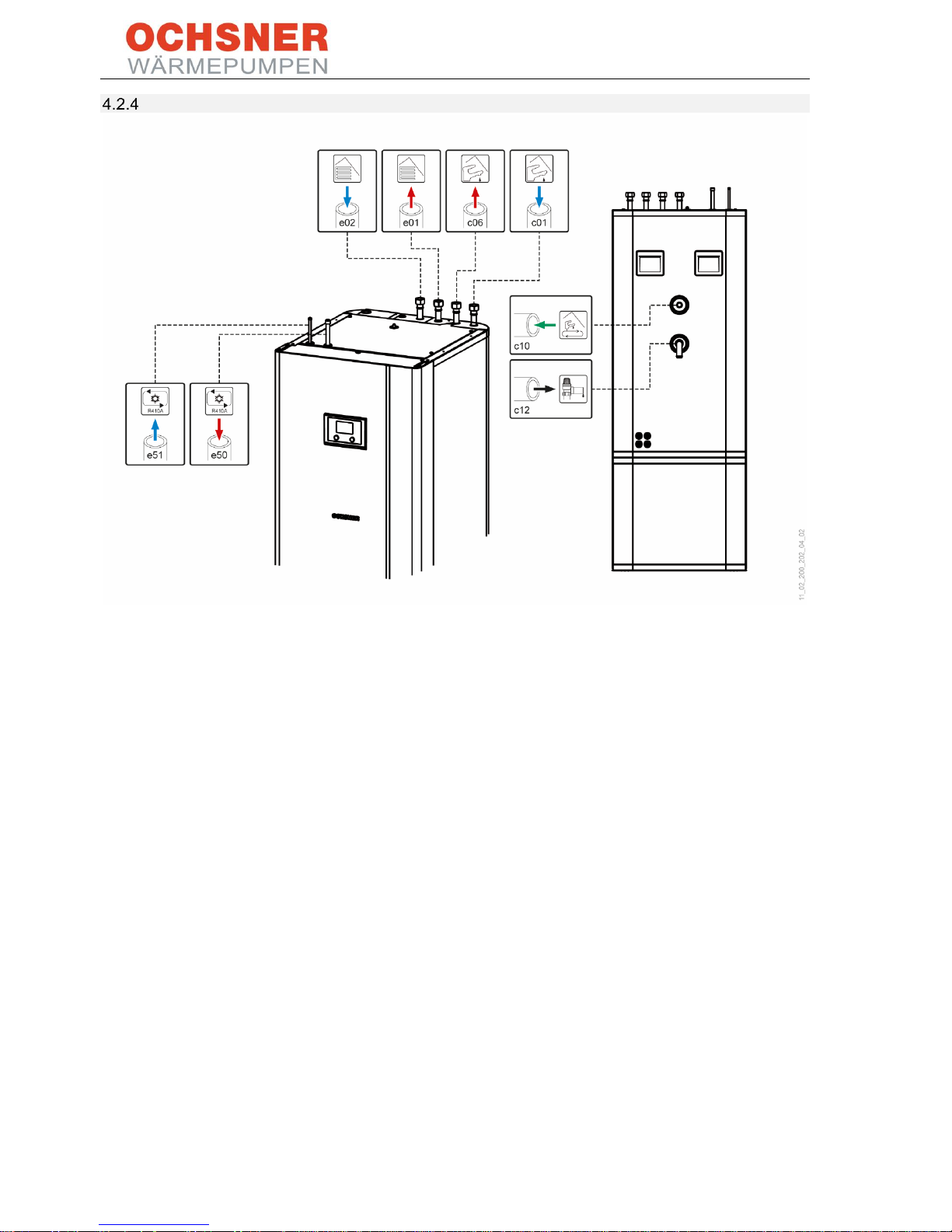

Hydraulic and refrigerant connections

e01

Heating circuit flow 1" union nut with flat gasket

e02

Heating return 1" union nut with flat gasket

e50

Hot gas line

e51

Liquid line

c01

Cold water inlet 1" union nut with flat gasket

c06

DHW outlet 1" union nut with flat gasket

c10

DHW circulation 12 mm copper

c12

Safety valve drain

Figure 25: Hydraulic connections and labels, T200 refrigeration

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 23 of 76

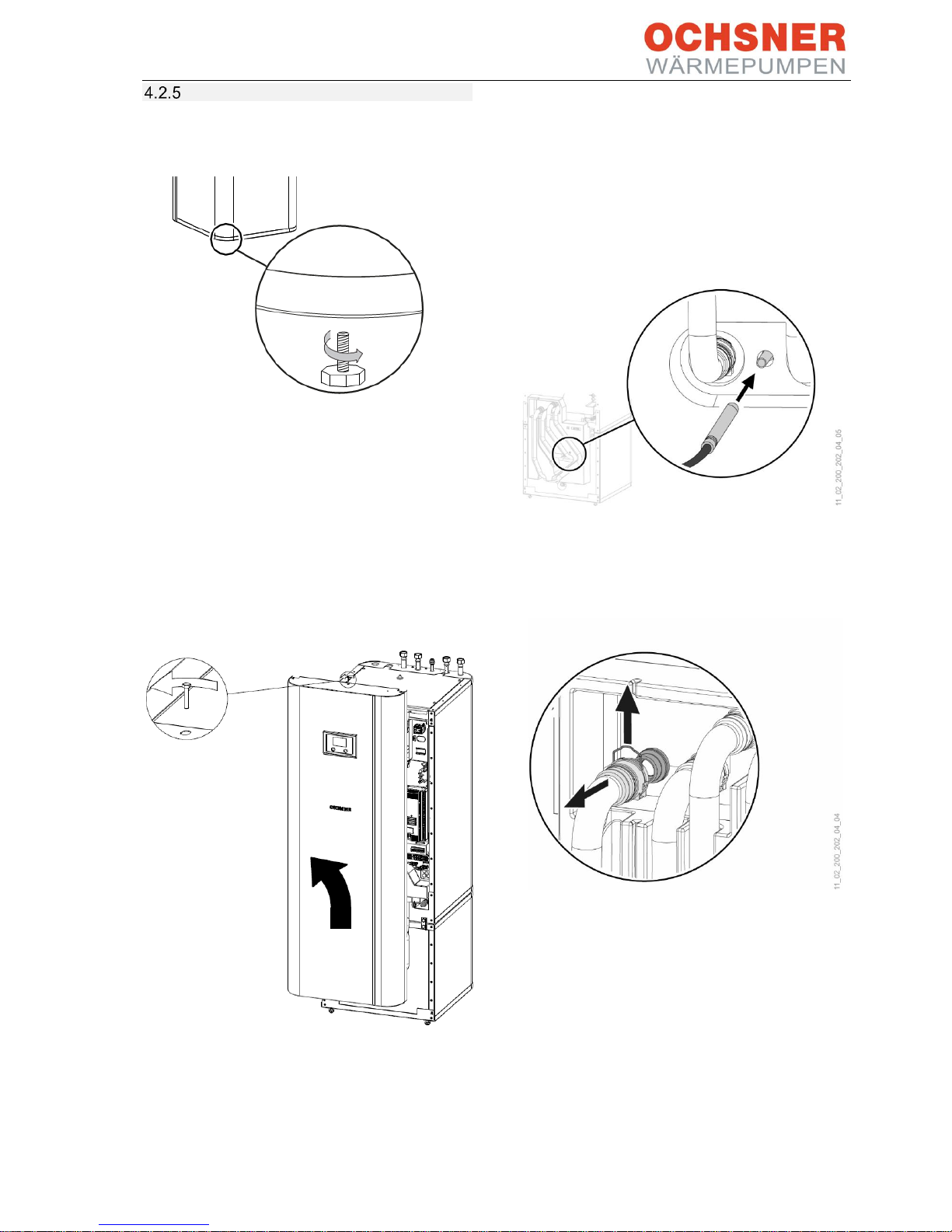

Transport and handling

- Remove the 4 screws from the non-

returnable pallet.

Figure 26: Removing the fixing screw

- Slightly tilt the appliance and screw in the

4 adjustable feet supplied.

- Lift the appliance from the pallet.

Should narrow doors or corridors impede

handling, the top and bottom sections of the

appliance can be separated as described in the

following sections.

Removing the front cladding:

- Remove the screw from the top centre of the

appliance.

- Unhook the front cladding towards the top.

- Disconnect the control panel plug and the

front panel earth wire.

Installing the front cladding

Install the front cladding in reverse order.

Separating the appliance sections:

Figure 27: Pull the sensor from the buffer tank.

- Pull out the sensor on the buffer tank.

- Remove the sensor cable from the guiding

groove in the insulation element.

Figure 28: Undoing the plug-in connectors

- Undo the plug-in connectors of the 4 hydraulic

connections. Pull out the spring clips fully

using a screwdriver.

- Pull off the hydraulic connections towards the

front.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 24 of 76

Figure 29: Removing the hydraulic hoses

- Remove the 4 hydraulic hoses and the thermal

insulation element.

Figure 30: Undoing the connecting screws

- Undo the 4 screws on the tabs at the front of

the appliance.

Figure 31: Separating the appliance sections 1

- Pull the top section towards the front.

Figure 32: Separating the appliance sections 2

- Tilt the top section towards the back. Use the

grip rail for better grip during transport.

Figure 33: Setting down the T200 top section

- Set the top appliance section on a pad or mat

to avoid damage.

Assembling the appliance sections:

Assemble the appliance sections in reverse order.

The positioning aids and dotted line markings

facilitate sliding the top appliance section into the

guide on the lower section.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 25 of 76

1

Grip rail

2

Guide pin

3

dotted line (perforation in the metal plate)

4

Guide groove

5

Positioning aid

Figure 34: Assembling the appliance sections 1

1

dotted line (perforation in the metal plate)

Figure 35: Positioning aid

- Place the top appliance section onto the

bottom appliance section at the dotted line.

Figure 36: Assembling the appliance sections 2

- Slide the top appliance section towards the

rear until it is flush with the bottom section.

When the appliance sections are assembled

correctly, the end position is given by the

guide groove and the guide pin.

- Fasten the tabs at the front of the appliance.

- Fit the thermal insulation element and the

4 hydraulic hoses.

- Fit the plug-in connectors of the 4 hydraulic

connections. Ensure that the spring clips

engage.

- Plug in the sensor on the buffer tank.

- Route the sensor cable in the guiding groove

in the thermal insulation element.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 26 of 76

Safety valve

1

Drain pipe

2

Mounting

3

Drain

Figure 37: Drain hose, safety valve

- Size the drain hose to ensure water can drain

freely when the safety valve is fully open.

- Ensure that the safety valve drain hose is open

to the atmosphere.

- Route the safety valve drain hose with a

continuous slope to the drain.

- Secure the drain hose to prevent movement

when water is running out.

DHW connection and safety assembly

CAUTION

Do not exceed the maximum pressure

(see section 13, Specification).

CAUTION

The appliance must be operated with

pressure fittings.

Cold water pipe:

Permitted materials are galvanised steel, stainless

steel, copper and plastic.

CAUTION

A safety valve is required.

DHW line:

Permitted materials are stainless steel, copper and

plastic.

Installing the DHW circulation line

A DHW circulation line with an external

DHW circulation pump can be connected at the

"DHW circulation" connection.

- Remove the sealing flap from the "DHW

circulation" connection.

- Connect the DHW circulation line.

Connection:

- Thoroughly flush the pipes.

- Install the DHW outlet pipe and the cold water

inlet pipe (see section 4.2.4 Hydraulic and

refrigerant connections).

- Install a type-tested safety valve in the cold

water inlet pipe. Note that, depending on the

supply pressure, a pressure reducing valve

may be additionally required.

- Size the drain pipe to ensure water can drain

freely when the safety valve is fully open.

- The safety valve drain opening must remain

open to the atmosphere.

- Route the safety valve drain pipe with a

continuous slope.

1

2

3

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 27 of 76

Filling the system

Filling the heating system:

Figure 38: Filling the heating system

- Fill the heating system via the drain valve.

- Vent the pipework.

NOTE

For easier filling, the 3-way switching

valve (multifunctional assembly) is set

to a position suitable for filling at the

factory. The cable from the switching

valve to the OTE controller has been

disconnected at the factory.

➔ Once the system is successfully

filled, connect the plugs PIN3/N/PE

and PIN4/N/PE on the OTE

controller.

Filling the DHW tank:

- Fill the DHW tank via the cold water

connection.

- Open all downstream draw-off valves until the

appliance is filled and the pipework is free

from air.

- Adjust the flow rate. Observe the maximum

permissible flow rate with fully opened valve

(see Specification). If necessary, reduce the

flow rate at the throttle on the safety

assembly.

- Carry out a leakage test.

- Test the safety valve.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 28 of 76

Venting the system

- To vent the system, temporarily open the air

vent valve (1) on the multifunctional

assembly.

There is another air vent valve underneath the

top appliance cladding.

- Remove the top appliance cladding.

- Remove the thermal insulation material

underneath.

- To vent the system, temporarily open the air

vent valve (2).

CAUTION

Close the air vent valves after venting.

Using T200 with a heating circuit with

mixing valve

To use the T200 (MULTI TOWER) indoor unit with

a heating circuit with mixing valve, the internal

heat circuit pump must be replaced with an

adaptor.

The heating circuit pump is the left-hand pump in

the upper section of the T200.

Adaptor:

The adaptor needs to have the following

dimensions:

- Connections 2 x 1½" MT, with flat gasket

- Length 180 mm

- Nominal diameter DN 25 (1")

The adaptor is available from OCHSNER as an

accessory with the item number 914383.

Subsequently, the heating circuit (or several) can

be set up externally.

Connect the components of the mixed circuit to

the following connections on the OTE controller:

- Mixer: PIN 15/16/N/PE

- Mixed circuit sensor: PIN 43/GND

- Mixed circuit pump: PIN 8/N/PE

Recommission the controller with heating circuit 2

in mixed configuration. In case of more than one

mixed circuit, an auxiliary module (order

no. 290197) is required.

Cooling with T200

NOTE

Only gentle cooling down to a flow

temperature of 18°C is permitted with

the T200 indoor unit!

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 29 of 76

T200 maintenance

CAUTION

Before any work is carried out, all

electrical connections to the appliance

must be isolated from the mains across

all poles.

Draining the buffer tank:

Figure 39: Draining the buffer tank

- Drain the buffer tank via the drain valve.

Draining the DHW tank:

CAUTION Risk of scalding

Hot water can escape when draining

the DHW tank.

- Close the shut-off valve in the cold water inlet

pipe.

- Open the DHW valves on all draw-off points.

Figure 40: Draining the DHW tank

- Drain the DHW tank via the drain valve.

Cleaning and descaling the DHW tank:

CAUTION

Do not use a descaling pump or

descaling agent to clean the tank.

- Clean the appliance via the inspection flange.

- For tightening torques and flange bolts, see

Specification.

Sacrificial anode:

CAUTION

If the wear indicator has changed from

a white to red colour, let a qualified

contractor check the sacrificial anode

and replace it if necessary.

1

white = anode OK

2

red = requires checking by qualified contractor

Figure 41: T200 DHW tank sacrificial anode

- Replace the sacrificial anode when it has been

used up.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 30 of 76

5 Connection lines

5.1 Refrigerant lines

NOTE

If the appliance, the refrigerant lines,

the fixing points and the wall conduits

are not properly installed, structureborne sound may be transmitted to the

building.

➔ Ensure the refrigerant lines are

secured in a way to minimise

structure-borne sound. The system

installer carrying out the work is

responsible for this.

WARNING

Work on the refrigerant circuit may be

carried out only by an authorised and

suitably qualified contractor.

o When handling refrigerant, wear

appropriate gloves, protective

clothing and protective glasses.

Always position the outdoor unit as closely to the

indoor unit as possible. The maximum length of

the connection line must not exceed a total length

of 25.0 m! Do not exceed a maximum difference in

height of 15.0 m.

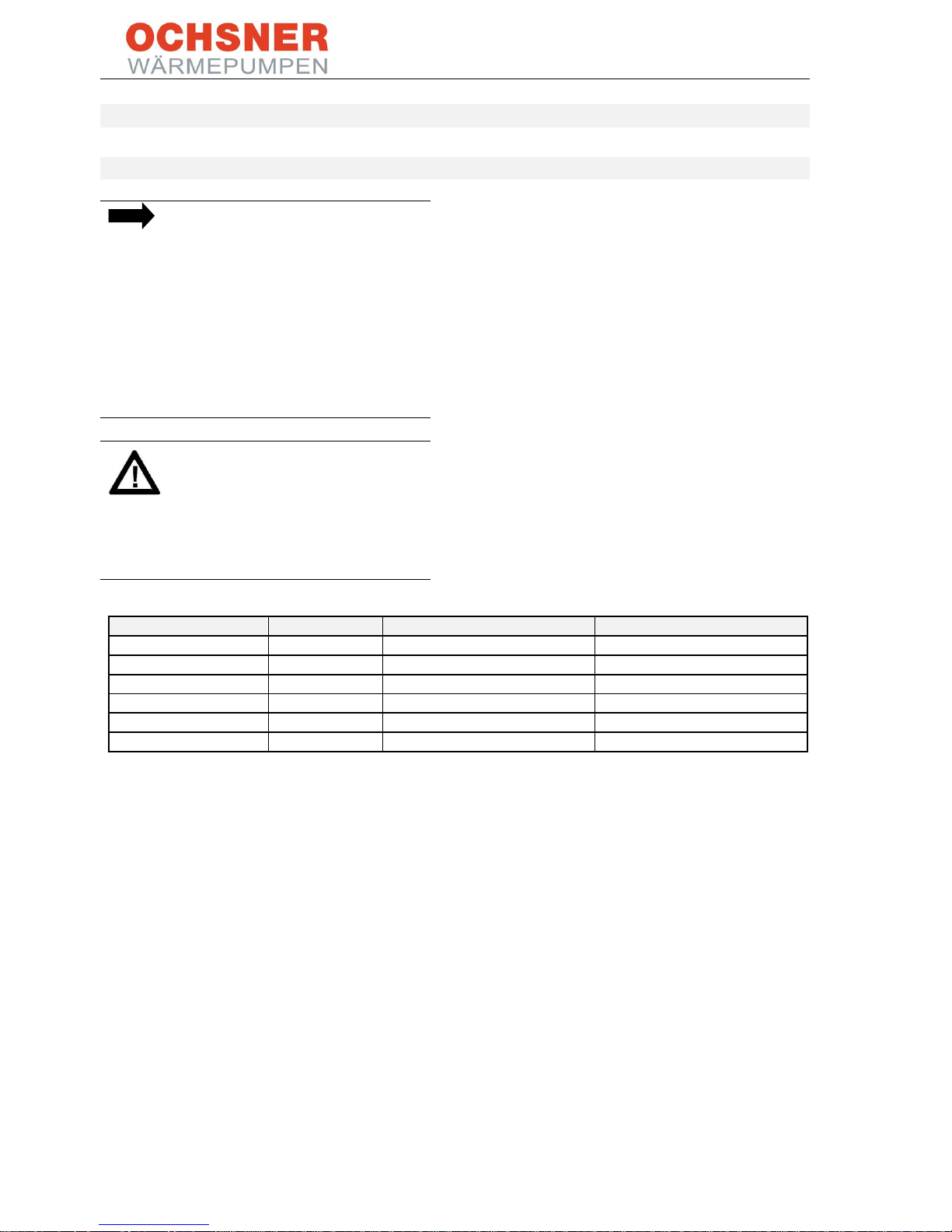

Unit

OCHSNER AIR EAGLE 414

OCHSNER AIR EAGLE 717

max. length m < 25

< 25

max. height differential

m

15

15

Refrigerant R410A

R410A

max. operating pressure

bar

45

45

Hot gas line

mm

12

16

Liquid line

mm

10

12

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 31 of 76

Figure 42: Max. height difference

Figure 43: Oil lift bends

A

Liquid line

B

Hot gas line (thicker copper pipe)

C

Oil lift bend in the hot gas line (min. bending radius 5x diameter)

5.2 Conduit to house

Figure 44: Conduit to house (dimensions in mm)

max. 15 m

A

C

max. 15 m

B

5 m

5 m

Drainage

gravel bed

Drainage pipe

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 32 of 76

6 Electrical connection

6.1 Preparation

CAUTION!

Before starting any wiring, isolate the

heating system from the power

supply.

DANGER of electric shock

All electrical connection and

installation work must be carried out

according to the relevant national and

regional regulations.

Connection work may only be carried

out by an approved contractor

according to this manual!

The listed fuse protection ratings and cable crosssections are guideline values only! The electrician

connecting up the heat pump is responsible for

selecting the correct safety devices. Cables should

be selected by the electrician taking into account

the output and cable lengths.

WARNING

Before commissioning, the necessary

fault protection measures on the

system and the earth connection must be checked

by a certified electrician. The main power circuit

for the compressor motor has no upstream

power contactor on the machine side. Control

devices and equipment to disconnect and shut

down all supply voltages across all poles, which

must be provided on the system side, must meet

the technical safety requirements of EN 60204-1

sections 5 and 13.4.5, as well as the international

regulations in the IEC 60947 series.

During maintenance or service work, shut down all

heat pump supply voltages on the system side and

observe safety regulations to EN 50110-1.

Failure to observe the technical safety

requirements or precautions may result in serious

injury or death.

Checklist:

• The specified voltage must be consistent with

the grid voltage. Pay attention to the

information on the type plate!

• For connection of the appliance, approval

must be obtained from the relevant power

supply utility.

• Fuse protection for the main power circuit

230 V/400 VAC should be provided via a

circuit breaker, which triggers a shutdown

across all poles in the event of a fault.

• If RCDs (FI) are used, they must trigger an

AC/DC-sensitive shutdown.

• The supply lines must be protected against

surges and short circuits.

• It is essential that the regulations of the

responsible PSU (power supply utility) and

the applicable EN standards are observed.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 33 of 76

6.2 Guidelines

Position

min. crosssection

Connection cables 230 VAC:

Always size connection cables

according to the local

conditions.

1.5 mm²

Control cable 230 VAC:

Pumps, actuators

min. 1.0 mm²

Sensor leads:

(outdoor sensors, etc.), sensor

leads are sensitive to EMC and

must always be routed

separately (min. 20 cm) from

230 V/400 V lines. If separation

is not possible, screened cables

should be used. Screening

should be connected to PE on

the heat pump

Max. line length 50 m!

2x 1.0 mm²

Bus leads:

Modbus from outdoor to

indoor unit, room remote

control units, eBus from OTE

controller to room remote

control units, auxiliary

modules, underneath each

other in cascades).

These lines must always be

routed in a screened version.

The screen should be earthed

to PE on the heat pump.

OCHSNER recommends the

following conventional cable:

Y(ST)Y) 2x2x0.8

CAUTION: Always use a

twisted wire pair!

Example: MODEBUS = A/B

Example: eBus = SIGNAL/GND

Do not connect GND to the

screen!

2x2x0.8 mm²

Table 1: Cable selection

6.3 Power connection details

According to the wiring diagram (see section 6.15,

Wiring diagrams) the 400 VAC and 230 VAC power

supplies should be provided separately. The

following power supplies must be provided:

Figure 45: Power supply

A

400 V (230 V) compressor supply

B

PSU signal contact (indoor unit control box)

C

230 V controller supply (indoor unit control

box)

D

400 V (230 V) electric booster heater (indoor

unit control box)

E

Option: 400 V (230 V) DHW auxiliary heater for

anti-legionella function.

The 230 VAC controller power supply to the

outdoor unit is via terminal strip X2 in the indoor

unit control box (L N PE). This ensures that the

outdoor unit and the indoor unit are in phase.

If it is not possible to comply with the

100 mm minimum clearances between

sensor leads and 230 V/400 V, then

screened cables should be used.

The listed fuse protection ratings are guide values

only! The electrician connecting up the heat pump

is responsible for selecting the correct safety

devices.

OCHSNER does not accept liability for faults

resulting from incorrectly designed safety devices!

*PSU = power supply utility

A

B C D

E

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 34 of 76

6.4 PSU signal contact

CAUTION!

There is a 230 VAC control voltage

present on the PSU signal contact!

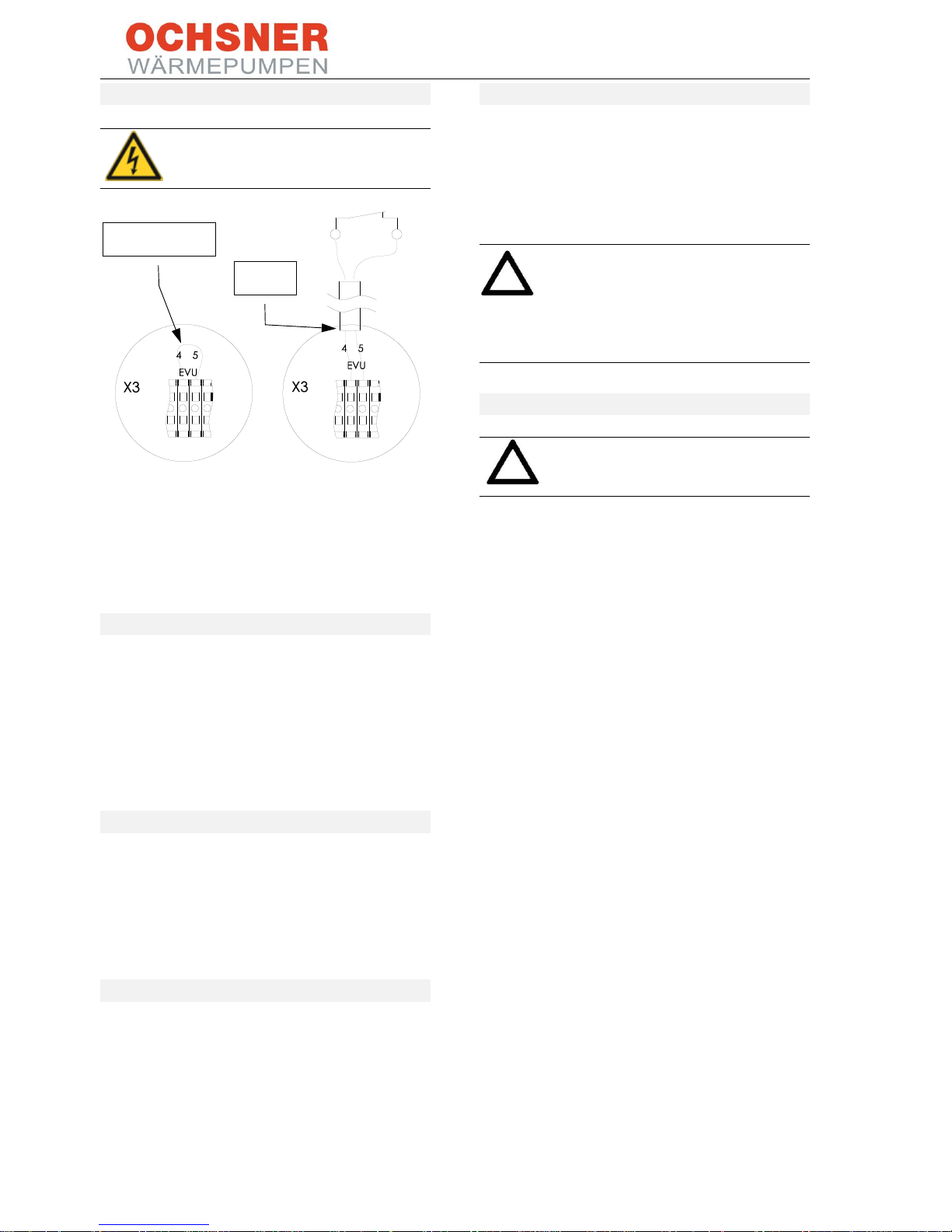

Figure 46: PSU signal contact

Remove the jumper and insert cables as shown in

the drawing. If the PSU signal contact is

interrupted, the compressor and the booster

heater (if installed) will immediately shut down.

6.5 Uninterrupted tariff

In the case of tariff switching without interrupted

power supply, the heat pump is temporarily shut

down by the power supply utility. The PSU signal

contact on the EAGLE indoor unit (terminal

strip X3) should be used for this. To enable the

function, remove the jumper and connect the

cables.

6.6 Shutdown by tariff contactor

In case of shutdown by a tariff contactor (sealed

by the PSU, installed on site), the heat pump

compressor power supply is disconnected. In this

case, the PSU signal contact must be switched via

an auxiliary contact on the tariff contactor

(N/C contact) (otherwise ERROR).

6.7 Night tariff

Where tariff switching takes place within the

meter (night tariff), the PSU signal contact is not

connected.

6.8 Modbus wiring

A Modbus connection is required between the

EAGLE outdoor and indoor units. Communication

between the bus subscribers requires a twisted

cable. Cables of type Y(ST)Y 2x2x0.8 mm² have

proved to be suitable.

CAUTION!

Always use a twisted wire pair.

MODBUS = A/B

eBus = SIGNAL/GND

Do not connect GND to the screen!

6.9 Sensor wiring

Never apply voltage to the sensor

terminals! This would destroy the

controller.

The type NTC5K temperature sensors of the OTE

controller are supplied with a cable length of

4.0 m. If this length is not sufficient, the leads can

be extended to the required dimension. Please

use 2x 1.0 mm² flexible cable.

During installation of the sensor cable, ensure that

the cable is not routed parallel to cables with

AC voltage >230 VAC.

Outdoor sensor TA

Install the outdoor sensor of the controller at a

height of approx. 2.5 m on the outside of the

building wall (facing north-west). Make sure that

the outdoor sensor is not exposed to direct

sunlight or wind, as this will impair the control

characteristics. Also avoid positioning it close to

the evaporator. There may be a risk of influence

on the control.

Mixer sensor TMK

If a mixer circuit is installed in addition to the

direct heating circuit, a mixer sensor must be

installed. The mixer sensor is a contact sensor and

is supplied with the heat pump including a band

clamp and heat conducting paste. Install the mixer

sensor directly downstream of the mixer circuit

pump. When using multi-skin or plastic pipes,

provide a suitable large metal bridge.

Remove jumper

230 VAC

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 35 of 76

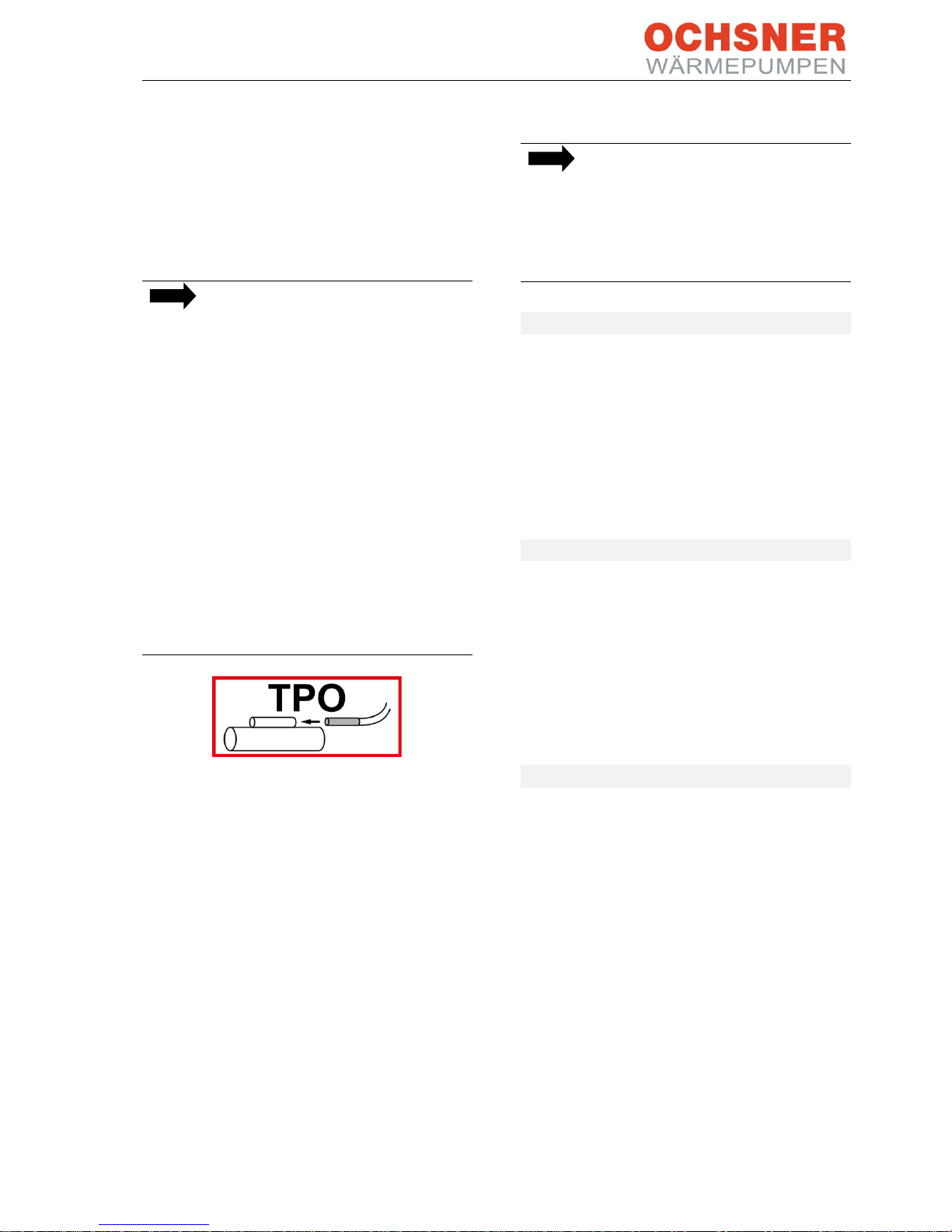

Buffer sensor (TPO, TPM)

Two buffer sensors are required in the buffer tank.

The heat pump is switched on based on readings

from the TPO and switched off based on those

from the TPM.

- Install a sensor pocket in the female socket

provided for the upper buffer sensor (TPO)

- Install a sensor pocket in the female socket

provided for the lower buffer sensor (TPM)

NOTE

In systems with direct heating circuit,

install the TPO sensor in the heating

flow of the heat pump indoor unit.

- Install the TPO sensor in the indoor

unit at the marked location on the

heating flow pipe, downstream

from the electric booster heater

(MFA).

- The required controller parameters

are set by OCHSNER customer

service or specialist personnel

authorised by OCHSNER.

In systems with a buffer tank, a bypass

or a low loss header or a heating

circuit with mixing valve, the TPO

sensor must not be installed in the

indoor unit.

Figure 47: Pipe marking in the heat pump indoor unit

DHW sensor TB

The DHW sensor is included in the delivery of the

heat pump. OCHSNER DHW tanks are fitted with

appropriate female sockets for installing the

sensor.

Install the DHW sensor in the top one-third of the

DHW tank (or at the very least in the top half). The

lower the selected location of the DHW sensor,

the larger the switching hysteresis (5-15 K) will

need to be.

NOTE

Ensure that the DHW sensor is correctly

positioned and extends beyond the

tank insulation into the interior of the

DHW tank. This is the only way in which

the temperature can be measured

correctly.

6.10 Pumps, drives 230 VAC

Pumps (heating circuit pumps, DHW charging

pump) and drives (mixer valves, etc.) are

connected directly to the controller.

A test run may only be carried out on a system that

has been prepared for commissioning! A relay test

can be performed on the OTE controller to check

the relevant outputs (actuators).

6.11 HLSC on the heating circuit

If an on-site high limit safety cut-out (HLSC) is

installed, it can be connected to the HLSC contact

on terminal strip X3. This shuts down the feed

pump. This only applies for hydraulic connection

versions 7.1 and 7.2. In all other versions, the HLSC

must be installed directly in the power supply of

the on-site heating circuit pump.

6.12 DHW booster heater

A separate contactor must be provided in the

electric distribution box for the optional electric

auxiliary heater in the DHW tank (anti-legionella

function). See electrical wiring diagram in section

13, Specification. This function is an option and

therefore not supplied with the heat pump.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 36 of 76

6.13 Wiring diagram

The following wiring should be prepared by the system installer for heat pump commissioning by OCHSNER

customer service:

BMK

Cable

Wires

Output/fuse

protection

From (source)

To (target)

1

W1

Power supply

controllers

230 VAC - L/N/PE

Fuse protection: C13A

Primary/second

ary distribution

Indoor unit

2

W2

Power supply

compressor

3x 400 VAC L1/L2/L3/N/PE

or 1x 230 VAC - L/N/PE

EAGLE 717: C16A

EAGLE 414: C20A

Primary/second

ary distribution

Indoor unit

3

W3

Power supply

booster heater

3x 400 VAC L1/L2/L3/N/PE

or 1x 230 VAC - L/N/PE

8.8 kW

3x 400 V, B16A across

all poles

1x 230 V, B40A

Primary/second

ary distribution

Indoor unit

4

W4

Power supply

compressor

3x 400 VAC L1/L2/L3/N/PE

or 1x 230 VAC - L/N/PE

EAGLE 717: C16A

EAGLE 414: C20A

Indoor unit

Outdoor unit

5

W5 Control cable

230 VAC - 23/24/L/N/PE

5x 1.5 mm²

Internal fuse

protection

Indoor unit

Outdoor unit

6

W7

MODBUS

2x 2x 0.8 mm² screened

Indoor unit

Outdoor unit

7

OTE

TA outdoor temperature

sensor

2x 1.0 mm² screened

Indoor unit OTE

Building

exterior wall

8

OTE

eBus to room remote

control (optional)

2x 2x 0.8 mm² screened

Indoor unit OTE

Room remote

control

9

OTE

Communication to

RoomTerminal (optional)

2x 2x 0.8 mm² screened

Indoor unit OTE

RoomTerminal

touchscreen

10

OTE

All required sensors TB,

TMK (optional)

2x 1.0 mm²

Indoor unit OTE

Heating system

11

OTE

All required actuators,

servomotors, pumps

230VAC

at least 1.0 mm²

Indoor unit OTE

Heating system

Table 2: Wiring diagram

Figure 48: Wiring overview

W2 cable 3x400 VAC or

1x230 VAC power supply,

compressor

W3 cable 3x400 VAC or

1x230 VAC power supply,

booster heater

Refrigerant lines

W4 cable 3x400 VAC or

1x230 VAC power supply, com-

pressor

W1 cable 230 VAC

Power supply

controllers

W5 control cable 230 VAC

W7 Modbus cable

1 4 5 6 2

3

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 37 of 76

NOTE

OCHSNER can provide a cable harness as an accessory for the electrical connection between

indoor unit (Golf-Midi or T200) and outdoor unit. The cable harness combines the Modbus

cable (W7), the control cable (W5) and the compressor supply (W4). For the MULTI TOWER (T200)

an external junction box (X11) must be provided next to the indoor unit.

6.14 Indoor unit wiring

CAUTION

Isolate the system from the power

supply before attempting any

electrical work!

CAUTION

Connecting cable cross-sections should

be sized according to local regulations.

Golf-Midi indoor unit

Terminal

Description

OTE pin

Description

X1

L1/L2/L3 (KM3)

Power supply

electr. booster heater 8.8 kW

(W2)

7

Heating circuit pump 1, direct (HCP 1)

N1/N2/N3/PE

8

Heating circuit pump 2, with mixer valve

(HCP 2)

X2

23/24/LS/N/PE

Control cable to outdoor unit (W5)

13/14

DHW charging pump ON/OFF (WWL)

X3

L/N/PE

Power supply OTE controller (W1)

15/16

Heating circuit mixing valve (MVH)

EVU

PSU signal contact

41/42

Control elements (eBus)

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 38 of 76

HLSC

External high limit safety cut-out

(heat sink)

43

Mixer sensor (TMK)

44

Outdoor temperature sensor (TA)

10

DHW auxiliary heater

46

DHW sensor (TB)

X11

L1/L2/L3/N/PE

Compressor power supply (W4, to

outdoor unit)

72

Default target value, building

management system (BMS)

MODBUS

B/GND/A

Modbus connection to outdoor unit

Note: If the X11 terminal is not provided in the indoor unit control box on site, provide an external junction box with

X11.

T200 (MULTI TOWER) indoor unit

The appliance control box is located behind the

front panel (see section 4.2.5).

Figure 49: T200 electrical connection

- Route all mains and sensor cables through the

cable entry into the appliance.

Figure 50: T200 indoor unit cable entry

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 39 of 76

T200 control box:

Terminal

Description

X1

L1/L2/L3

Power supply

electr. booster heater 8.8 kW

N1/N2/N3

X2

23/24/LS/N/PE

Control cable to outdoor unit

X3

L/N/PE

Power supply OTE controller

10

DHW auxiliary heater

1/2 (EVU)

PSU signal contact

1/2

External high limit safety cut-out

(heat sink)

Modbus

B/GND/A

Modbus connection to outdoor

unit OTE pin

Description

8

Heating circuit pump 2, with

mixer valve (HCP 2)

15/16

Heating circuit mixing valve

(MVH)

41/42

Control elements (eBus)

43

Mixer sensor (TMK)

44

Outdoor temperature sensor (TA)

72

Default target value, building

management system (BMS)

Figure 51: T200 indoor unit connection terminals

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 40 of 76

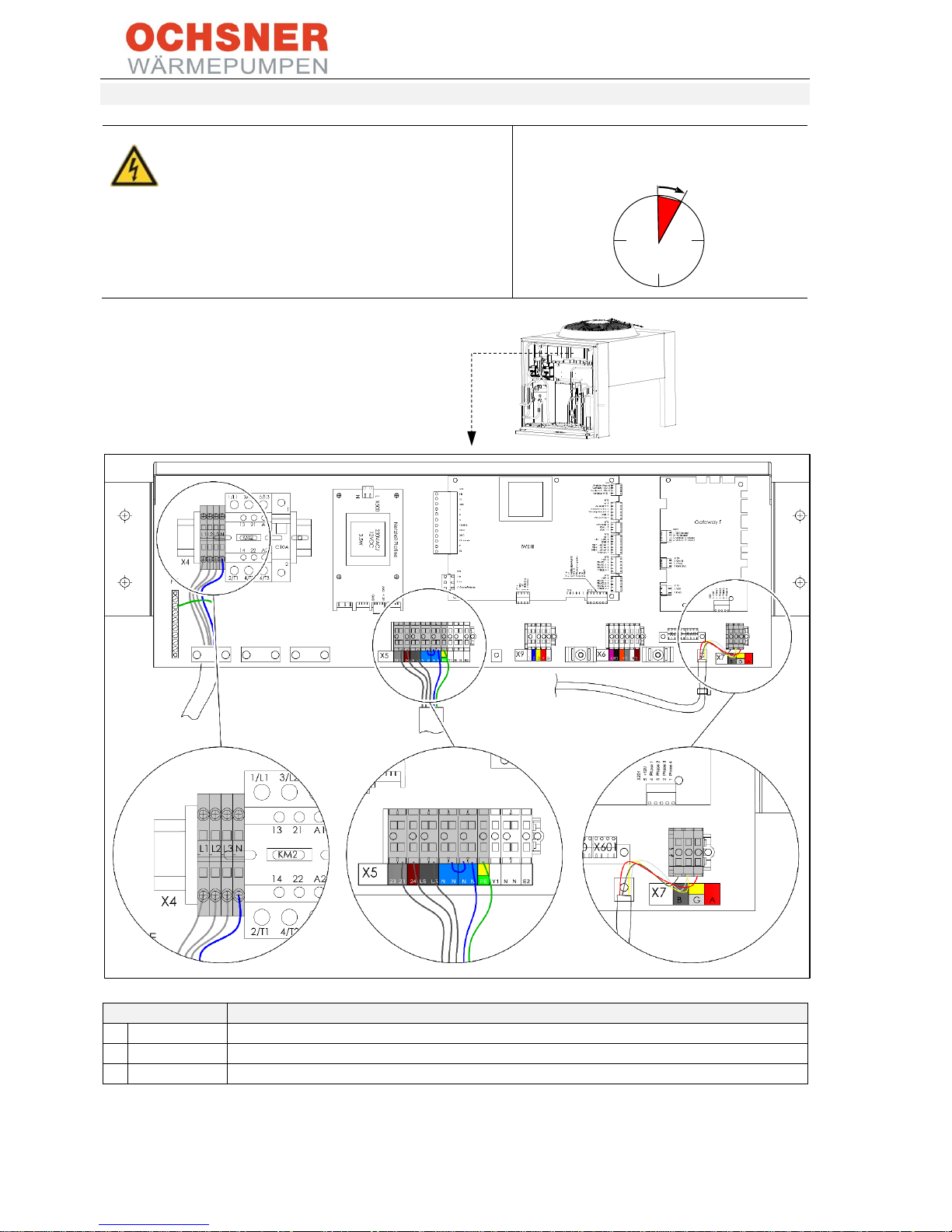

Outdoor unit wiring

CAUTION danger of death!

Prior to carrying out any work/repairs on the

outdoor unit, wait at least 4 minutes after

disconnecting the unit from the power supply, to

ensure all capacitors have been discharged.

From disconnection from power supply:

+4 minutes

Terminal

Description

X4

L1/L2/L3/N/PE

Compressor power supply (W4, to indoor unit)

X5

23/24/LS/N/PE

Control cable to indoor unit

X7

B/GND/A

Modbus connection to indoor unit

Figure 52: Outdoor unit wiring

4 minutes

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 41 of 76

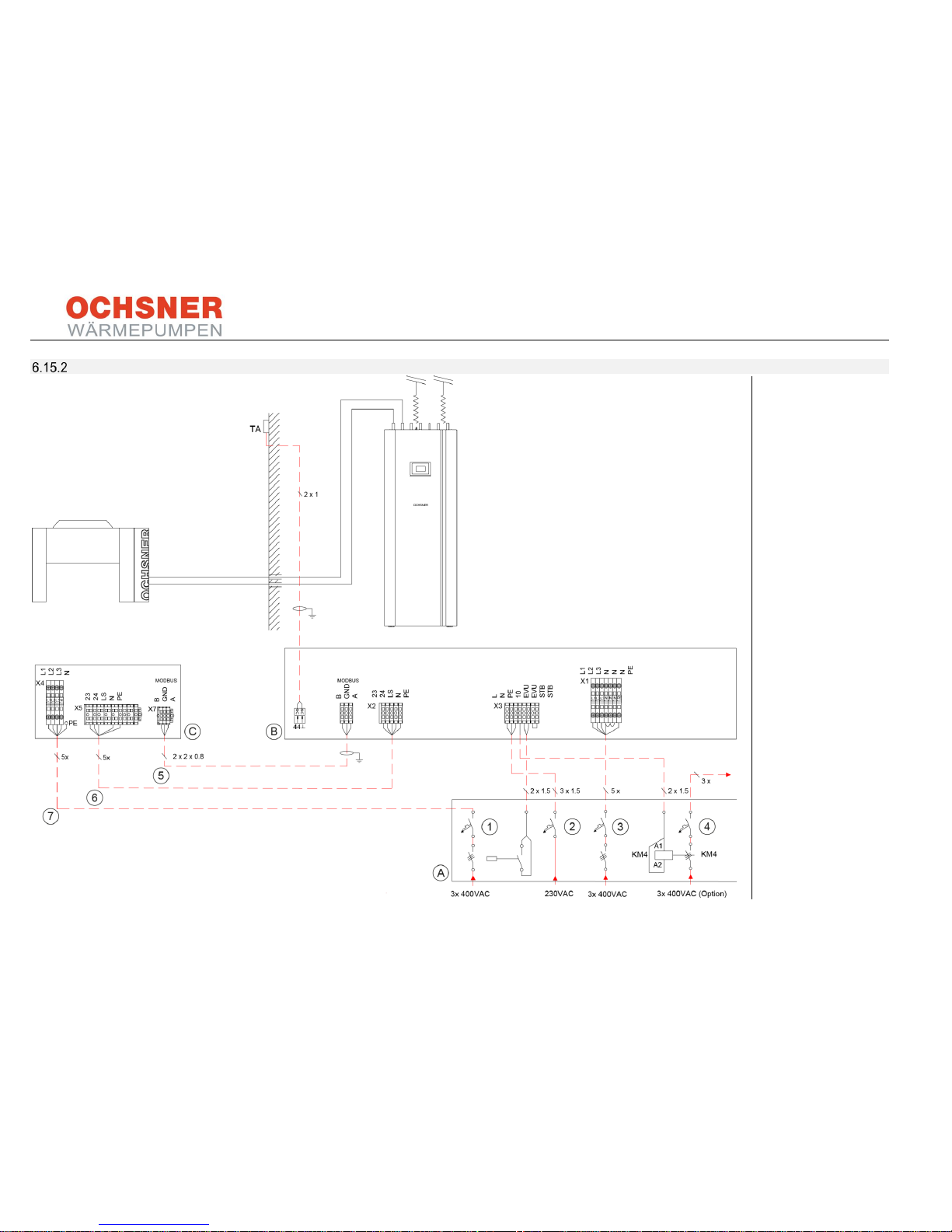

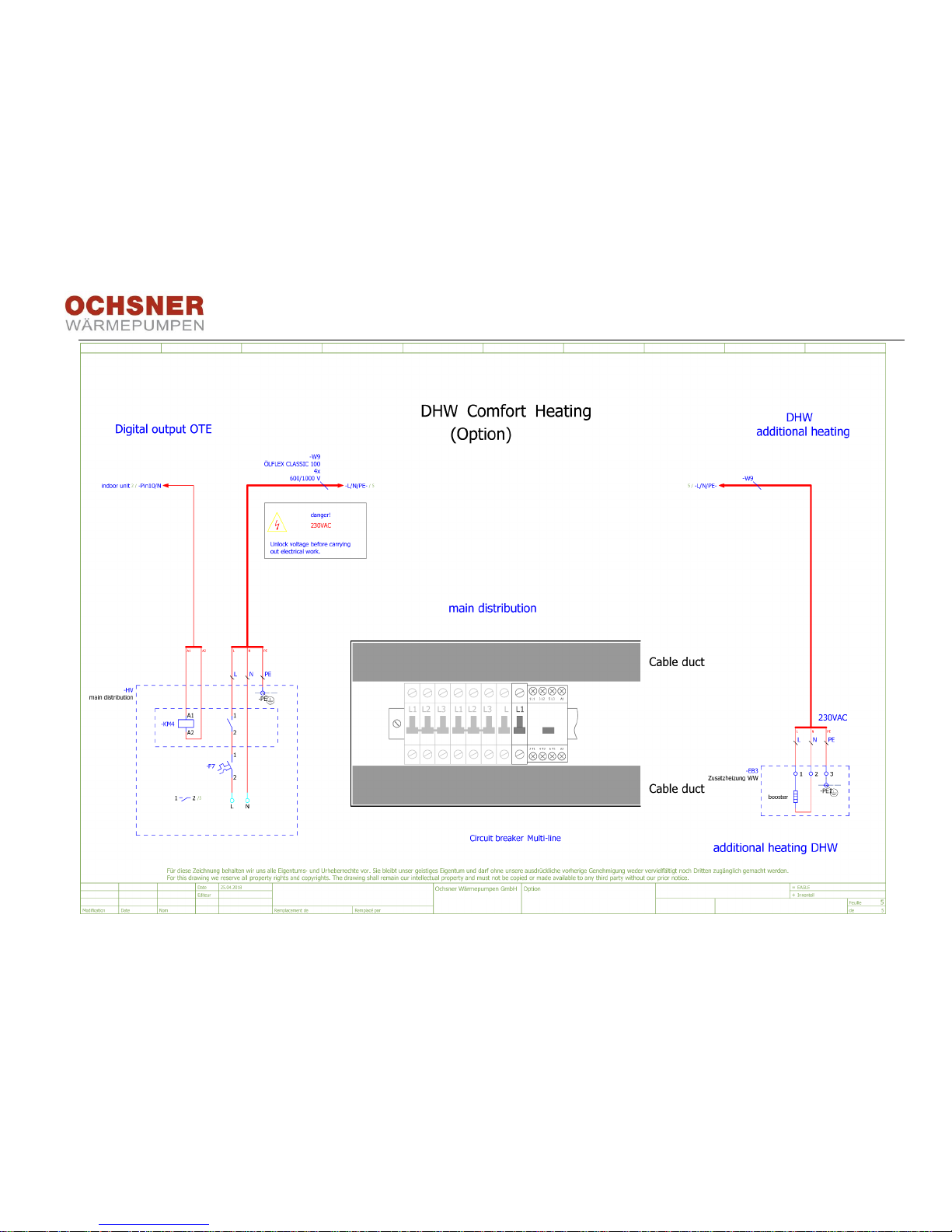

6.15 Wiring diagrams

EAGLE 717 with Golf-Midi indoor unit

A Main distributor

B Indoor unit control box

C Outdoor unit control

box

1 Compressor supply

(C16A across all poles)

2 Controller supply

(C13A)

3 Electric booster heater

supply

(B16A across all poles)

4 Option:

Supply for DHW

auxiliary heater for

anti-legionella function

5 Modbus cable

6 Control cable

7 Compressor supply

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 42 of 76

EAGLE 717 with T200 indoor unit

A

Main distributor

B Indoor unit control box

C Outdoor unit control

box

1 Compressor supply

(C16A across all

poles)

2 Controller supply

(C13A)

3 Electric booster heater

supply

(B16A across all

poles)

4 Option:

Supply for DHW

auxiliary heater for

anti-legionella function

5 Modbus cable

6 Control cable

7 Compressor supply

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 43 of 76

EAGLE 414 with Golf-Midi indoor unit

A

Main distributor

B Indoor unit control box

C Outdoor unit control box

1 Compressor supply

(C20A)

2 Controller supply

(C13A)

3 Electric booster heater

supply

a: 3x 400 V (B16A across

all poles)

b: 1x 230 V (B40A)

3a

Booster heater with

3-phase power supply

3b

Booster heater with

single phase power supply

4 Option:

Supply for DHW auxiliary

heater for anti-legionella

function

5 Modbus cable

6 Control cable

7 Compressor supply

8 Option:

Mains switch for EAGLE

outdoor unit

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 44 of 76

EAGLE 414 with T200 indoor unit

A

Main distributor

B Indoor unit control box

C Outdoor unit control box

1 Compressor supply

(C20A)

2 Controller supply

(C13A)

3 Electric booster heater supply

a: 3x 400 V (B16A across all

poles)

b: 1x 230 V (B40A)

3a

Booster heater with

3-phase power supply

3b

Booster heater with

single phase power supply

4 Option:

Supply for DHW auxiliary

heater for anti-legionella

function

5 Modbus cable

6 Control cable

7 Compressor supply

8 Option:

Mains switch for EAGLE outdoor unit

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 45 of 76

7 Heating system

The heating water and system pressure should be

checked regularly by the system operator and

corrected in case of deviations (pressure too

high/low). The flow rates at the heat sink system

(WNA) are monitored by the integral flow sensor.

The specified system maintenance intervals and

system checks must also be observed.

If major modifications or pipe breakages require

draining and subsequent replacing of a large

proportion of the heating water, this should be

done in the presence of OCHSNER customer

service or by an authorised OCHSNER authorised

partner (see enclosed logbook). In the case of nonroutine refilling (e.g. after modifications or pipe

breakages), a current water assessment must be

prepared, and, on the basis of this, the heat sink

system must be refilled, with additives if required,

by the installer.

7.1 Quality of heating water

Use the correct fill water that is suitable for the

components of your heating system. We

recommend fill water prepared according to

Guideline VDI 2035-2.

A high pH value and low electrical conductivity in

the fill water will reduce to a minimum the risk of

corrosion to iron and copper materials, as long as

there is also low oxygen content. This will also

minimise scaling (calcification).

Fill water characteristics

pH value at 25°C

8.5-10

Electrical conductivity at

25°C

< 100 μS/cm

Oxygen content

< 0.05 mg/l

Chloride

< 30 mg/l

Unsuitable fill water can damage your

system due to scaling and corrosion. If

necessary, ensure that the fill water is

professionally softened and

demineralised.

7.2 Pressure maintaining system

For the operational reliability of your

system in defrosting or cooling mode, it

is important that the hydraulic safety

and pressure maintaining devices are

sufficiently sized and inspected annually

according to the relevant standards.

CAUTION

The closures provided are only for

transport. Replace them with suitable

plugs if the DHW flow or return is not

being used!

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 46 of 76

8 Commissioning

8.1 Before starting

The heat pump has no separate ON/OFF switch. In

an emergency, the system must be shut down via

the specified circuit breaker. The circuit breaker

must be accessible so that an emergency

shutdown can be performed at any time.

Caution - risk to life

First-time start-up of electrical systems

is permitted only in the presence of a

qualified electrician.

Do not turn ON (or OFF) the power to the system,

until:

• Nobody can be put at risk

• All installation work on the heat pump is

completed

• All wiring is completed

• Voltages have been checked according to

the documentation

• The hydraulic system has been filled with

water

• The system has been fully vented

The supply voltage for the compressor must not

be turned on, until the refrigerant circuit and the

hydraulics have been filled with the correct

medium.

Once all conditions above have been checked and

met, the controller voltage of 230 VAC (fuse F1)

can be switched on for checking individual

functions.

Carefully check all sensors and their measurement

values for plausibility and all outputs used in your

hydraulic system for correct function.

CAUTION

Operating the heat pump with too little

or no refrigerant will damage the

appliance. Operating circulation

pumps without water in the system will

destroy the pump.

The heat pump must be commissioned by

OCHSNER customer service or an authorised

OCHSNER partner. The OCHSNER commissioning

guidelines apply. Operating the system without it

having been properly commissioned by factory

customer service will void all guarantee and

warranty rights.

8.2 Persons required on site

The electrician, installer and future system

maintainer or operator must be present during

commissioning for instruction.

Information for the system installer:

• The OCHSNER customer service engineer /

customer service partner makes the user

specific adjustments according to the

information in the system datasheet. If the

system installer is not present during

commissioning or if a fully completed system

datasheet is not available, the system is put

into operation using the control factory

settings. OCHSNER will accept no liability for

any faulty operation (heating curve too low,

bivalent point too high, etc.). Any claims

resulting from this will be charged to the

system installer.

• For the system to operate efficiently, it is

essential that hydraulic balancing is carried

out and the controller is adjusted according to

the system requirements.

• Special work, such as venting, electrical

connections, renewed instruction, etc., not

included in the scope of work provided by

OCHSNER will be charged separately.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 47 of 76

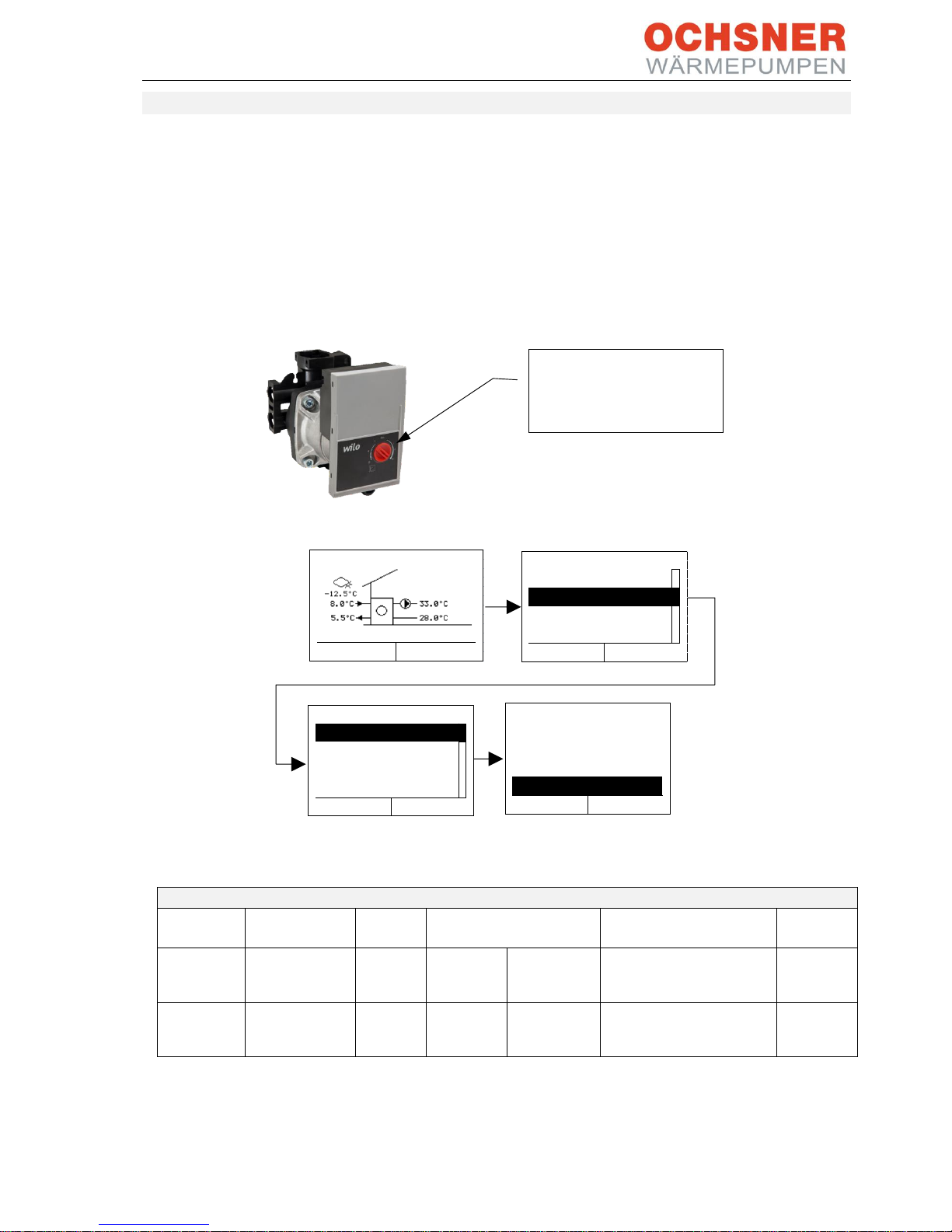

8.3 Setting the flow rate

The nominal flow rate must be ensured in each

operating mode (DHW charging, heating or

cooling mode via separate cooling/buffer tank,

etc.). The flow rate is measured via the installed

flow sensor and shown on the OTE controller

display. On the supplied circulation pumps, the

flow rate is adjusted via the adjusting screw.

To enable hydronic balancing according to the

relevant standards, in particular during combined

heating or heating/cooling and DHW heating

modes, the appropriate balancing valves must be

installed and the system regulated accordingly.

The measured flow rate is displayed on the heat

pump display and must correspond to the nominal

flow rate.

Figure 53: Setting the flow rate

Figure 54: Reading the flow rate

Heat consumption

Heat pumps

Circulation

pump

Item no.

Nominal flow rate,

heat sink

Internal

differential pressure

Residual

head

OCHSNER

AIR

EAGLE 717

PARA HPS

25/7.5 RKC

922586

1.8 m³/h

30 l/min

220 mbar

In DHW mode +30 mbar

380 mbar

(350 mbar)

OCHSNER

AIR

EAGLE 414

PARA HPS

25/7.5 RKC

922586

1.4 m³/h

23 l/min

160 mbar

In DHW mode +10 mbar

590 mbar

(580 mbar)

Table 3: Nominal flue rates

Adjust the flow rate by

turning the red adjusting

screw.

WAERMEPUMPE

Betriebswahl

Betriebsdaten

Einstellungen

Relaistest

ESC

ENTER

WAERMEPUMPE

ESC

ENTER

21-002

WAERMEPUMPE

Volumenstrom Wärmenut-

zung

27.4 l / min

ESC

ENTER

ESC

ENTER

23-010

Heizenergie MWh

0

23-003

Heizleistung

0

WAERMEPUMPE

21-002

Volumenstrom Wä

27

23-001

Heizenergie kWh

0

HEAT PUMP

HEAT PUMP

HEAT PUMP

Operation mode

Operating data

Settings

Relay test

Flow rate heat

Heating energy kWh

Heating energy MWh

Heating output

HEAT PUMP

Flow rate heat sink

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 48 of 76

9 Operation

Figure 55: Operation

The main display shows current temperatures, the operating state and the date and time. The "operating

state" display provides information about the entire system. All heat generators and/or consumers are free

from faults.

9.1 Menus

The OCHNSER AIR EAGLE is operated via the

master operating panel on the heat pump indoor

unit. There are 2 buttons (A and B) as well as an

illuminated graphic display for showing the

functions.

Pressing the right-hand button (A) calls up the

main menu with a diagram of the heating system

is illustrated.

Each heat consumer (heating circuits, DHW

circuits) and each heat generator (heat pump,

electric booster heater, boiler etc.) has its own

menu and submenus.

Pressing button (B) takes you back one step (ESC).

You can also purchase a RoomTerminal with

touchscreen.

Figure 56: Operation

For more information on how to operate the

controller, see the current OTE operating manual

which is supplied with every heat pump.

OCHSNER OTE

MENU

Sa 21.010.2015

08:10

Heizbetrieb

Time Date

Outdoor

temperature

Operating status

Button B

one step back

(ESC)

DHW temperature

System

temperature

Button A

Menu selection

and confirmation

ENTER

WARMWASSERKREIS

WAERMEPUMPE

Hauptmenü

HEIZKREIS 1

HEIZKREIS 2

ESC

Button A

Button B

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 49 of 76

9.2 Appliance function

Heating circuit

The heating circuits operate fully automatically

with weather compensation and summer/winter

changeover.

DHW

DHW heating is according to the default target

value. The efficiency of the system can be

increased with a DHW time program.

Anti-legionella function

To prevent legionella, the DHW has to be

periodically heated to a temperature of at least

60°C. The anti-legionella function is automatic and

can be controlled via a time program. Depending

on the system version, the electric booster heater

is activated.

Second heat generator

OCHNSER AIR EAGLE heat pumps are supplied

with an electric emergency/booster heater as

standard. The electric immersion heater is built

into the MFA module and is required to ensure the

operational reliability of your heating system.

Protect the supply voltage in the main distribution

box across all poles. The voltage is supplied via the

KM3 contactor and is automatically switched on

by the system.

Effect of the electric emergency/booster heater

in the heat pump flow:

• Mono energetic operation

The electric emergency/booster heater

guarantees heating mode and the provision of

high DHW temperatures when the bivalent

point is not reached.

• Emergency mode

Should the heat pump fail due to a fault, the

heating output is provided by the electric

emergency/booster heater.

For the operational reliability of your heating

system, ensure the power supply to the electric

booster heater at all times!

Screed drying program

In case of return temperatures <25°C (room

temperatures) the heat for drying has to be

provided by the electric emergency/booster

heater! At these low system temperatures the

heat for drying must not be provided by the heat

pump as the frost protection of the appliance can

no longer be guaranteed during the defrost cycle.

At the end of the drying out program, the electric

emergency/booster heater can be disconnected

as long as it is not required for the operation of the

appliance. Note that emergency operation is not

possible in the screed drying program.

9.3 System operation

Running costs

Depending on the residual building moisture,

increased running costs of up to 50% are to be

expected.

Flow temperatures

To ensure energy saving operation of the heat

pump, try to keep the heating flow temperature

(and also DHW temperatures) as low as possible.

For EAGLE heat pumps, the max. system

temperature should be limited to 60°C.

NOTE

Increasing the room temperature by

1°C results in an increase in

consumption of 5-7%.

BA_OCHSNER AIR EAGLE_414_717_V06_EN.docx Page 50 of 76

10 Troubleshooting

Let only trained specialist personnel carry out adjustments and troubleshooting! Standard settings for the

controller are made by customer service during commissioning. The operator and contracting partner is

responsible for additional corrections and program adjustments!

Fault/display

Cause

Solution

Heating system does

not heat up,

no fault

1. PSU shutdown

2. Energy transfer to the

heating circuits is

interrupted or too low

3. Power failure

4. DHW priority

Chick individual room controls, vent

heating circuit,

open valves,

check DHW circulation pump, increase

output level of the DHW circulation pump

Check fuses

Heat pump only

produces DHW but does

not heat or heats too

late

DHW target temperature is too

high

Check the DHW target temperature

Anti-legionella mode

Use time program

Install electric immersion heater for DHW

DHW circulation hydraulics