Ochsner GMLW, GMLW 9, GMLW 14, GMLW 19, GMLW 25 Installation And Operating Instructions Manual

...

Installation and Operating Instructions

GMLW

Heat Pump

Heating/Cooling/Hot Water

Contents:

Installation and Operating Instructions Heat

Pump ................................................................... 2

1 Notes on the documentation .................. 4

2 Safety instructions ................................. 4

2.1 CE Labelling ................................................... 5

3 Appliance description ............................. 5

3.1 Function ......................................................... 5

3.2 Heat Pumps GMLW ....................................... 5

3.3 Guarantee ...................................................... 5

4 Installation ............................................. 6

4.1 Delivery .......................................................... 6

4.2 Transport ........................................................ 7

4.3 Installation location ......................................... 7

4.3.1 Installation of split outdoor unit ....................... 7

4.4 Connecting the heating system ...................... 8

4.4.1 Cooling operation ........................................... 9

4.5 Heat source connection .................................. 9

4.5.1 Wall conduit .................................................... 9

4.5.2 Refrigerant pipework ...................................... 9

4.5.3 Leak check ..................................................... 9

4.5.4 Insulation ........................................................ 9

4.6 Electrical connection .................................... 10

4.6.1 Supply voltage to heat pump ........................ 10

4.6.2 Evaporator wiring ......................................... 11

4.6.3 Cable cross sections .................................... 11

4.6.4 Sensor wiring ................................................ 12

4.6.5 Pumps, motors 230 VAC .............................. 12

4.7 Utility control contact .................................... 12

4.7.1 Switch off via tariff relay:............................... 13

4.7.2 Switch off via ripple control ........................... 13

5 Commissioning ..................................... 13

5.1 Required on-site personnel: ......................... 13

5.2 Check list for commissioning ........................ 14

6 Operating the system ........................... 14

6.1 Safety functions ............................................ 14

6.2 Running costs............................................... 14

7 Maintenance ......................................... 15

7.1 Service work ................................................. 15

7.2 Service and Maintenance ............................. 15

7.3 Trouble shooting ........................................... 16

ANNEX ............................................................... 18

Technical Data GMLW ............................................... 19

Technical Data GMLW plus ........................................ 20

Evaporator connection pipework ................................. 21

Dimensions sheet ....................................................... 22

Operation data MLLENIUM evaporator ..................... 23

Declaration of conformity ............................................ 24

Installation and Operating Instructions Heat Pump

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 2 of 25

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 3 of 25

1 Notes on the documentation

The following pointers are valid for the whole of

the documentation.

Storage:

This instruction Manual must be kept within

easy access close to the heat pump.

Symbols:

The precautionary pointers below will be used

in this document..

Pointer which, if not heeded, can mean danger

to life and limb, and can also lead to material

damage. These pointers must be heeded without fail.

Pointer which, if not heeded, can lead to an

appliance malfunction and to material damage

(to system components, building, ...). These

pointers must be heeded.

Tips which are intended to aid the job in hand,

or mean additional information for the user.

WARNING

CAUTION

POINTER

2 Safety instructions

Read this manual carefully before you begin to

commission/adjust the heat pump!

Converting or altering the appliance is not allowed. Work on the

appliance (repairs, alterations) may

only be carried out by the manufacturer or by a specialist authorised

by the manufacturer.

All circuit breakers in the heating

system are to be turned off before

any work is carried out on the

terminal strips or electrical connections (wiring). The heating

system comprises the control, the

additional modules and the components connected to the control

(energy generator, pumps, nonself-resetting safety thermostat,

etc.).

Contact with the terminal strips,

wires connected to them, or nonconnected wires by persons or by

means of electrically conductive

materials is prohibited, as the

terminal strips could be live (danger of contact with live circuit).

The control, additional modules,

terminal strips and control wiring

may also be being supplied with

live voltage by means of external

switching (non-self-resetting

safety equipment, etc) when the

control is not connected, or no

line voltage is on the control

The commissioning as well as the

maintenance of the appliances may

only be carried out by personnel

which are authorised by OCHSNER.

The installation of the appliances

and their electrical wiring may only

be carried out by a specialist according to local regulations and codes of

practice.

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 4 of 25

Safety functions for the heat pump

may be activated with the control.

As the control is, however, not certified as a safety appliance, safety

mechanisms against failure of, or

damage to the heat pump must adhere to local safety regulations (e.g.

through supplementary external

switching of the safety appliances

used)..

If upgrades/updates to the control

software are carried out, all parametered functions of the heat pump are

to be controlled once again

2.1 CE Labelling

The product you have purchased conforms to

the technical regulations valid at the time of

manufacture, and is CE-conform.

3 Appliance description

3.1 Function

The heat pump converts low-temperature

warmth (for instance, the heat in the soil) into

warmth of a higher temperature (water for heating).

The heat pump extracts from the ambient:

• Soil

• Ground water

• Air

the solar energy stored therein and yields this,

plus the driving energy (electricity) to the heating and hot water circuits in the form of heat.

The system consists of separate circuits which

are connected by means of heat exchangers.

3.2 Heat Pumps GMLW

Heat pumps of the type GMLW are split appliances, where the compressor unit is installed

inside, and the evaporator outside the building.

The compressor unit is suitable for

indoor-installation

door installation.

The heat extraction (from the heat source circuit) takes place usually from the ambient air by

means of a finned-tube heat exchanger.

The GMLW heat pumps function at low temperatures in bivalent-parallel operation. The

heat pump can, however, be combined at any

time with a further heat generating system.

and NOT for out-

3.3 Guarantee

All OCHSNER heat pumps carry a guarantee of

24 months, if the installation and operating instructions are adhered to and the system data

sheet is filled out and stored correctly.

The concept and design of the system is to be

carried out according to current Ochsner –

guidelines and the valid technical regulations.

For flat laying for the heat source ground, the

responsibility for the design of the extraction

area lies with the system planner, taking the

local conditions on site into account.

No guarantee will be given for any defects to

the heat pump which are caused by the heat

source system, the heating system itself, faulty

adjustment of the control and regulation elements or by elementary occurrences (lightning,

flood damage,......)

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 5 of 25

The heat pump is to be commissioned by OCHSNER factory customer service engineers. The correct construction and function of

the heating system, the heat

source and the electrical installation is the be ensured by the installer. Otherwise, no guarantee

or warranty claims will be recognised.

The electrical heating rods and circulation

pumps carry a guarantee period of 12 months.

Parts subject to wear and tear such as protective anodes, filters, signal lamps etc. are excluded from guarantee and warranty claims.

Increased effort due to appliances that are incorrectly located or mounted shall be invoiced

with the guarantee work.

Read this instruction manual carefully before you start commissioning the heat pump!

4 Installation

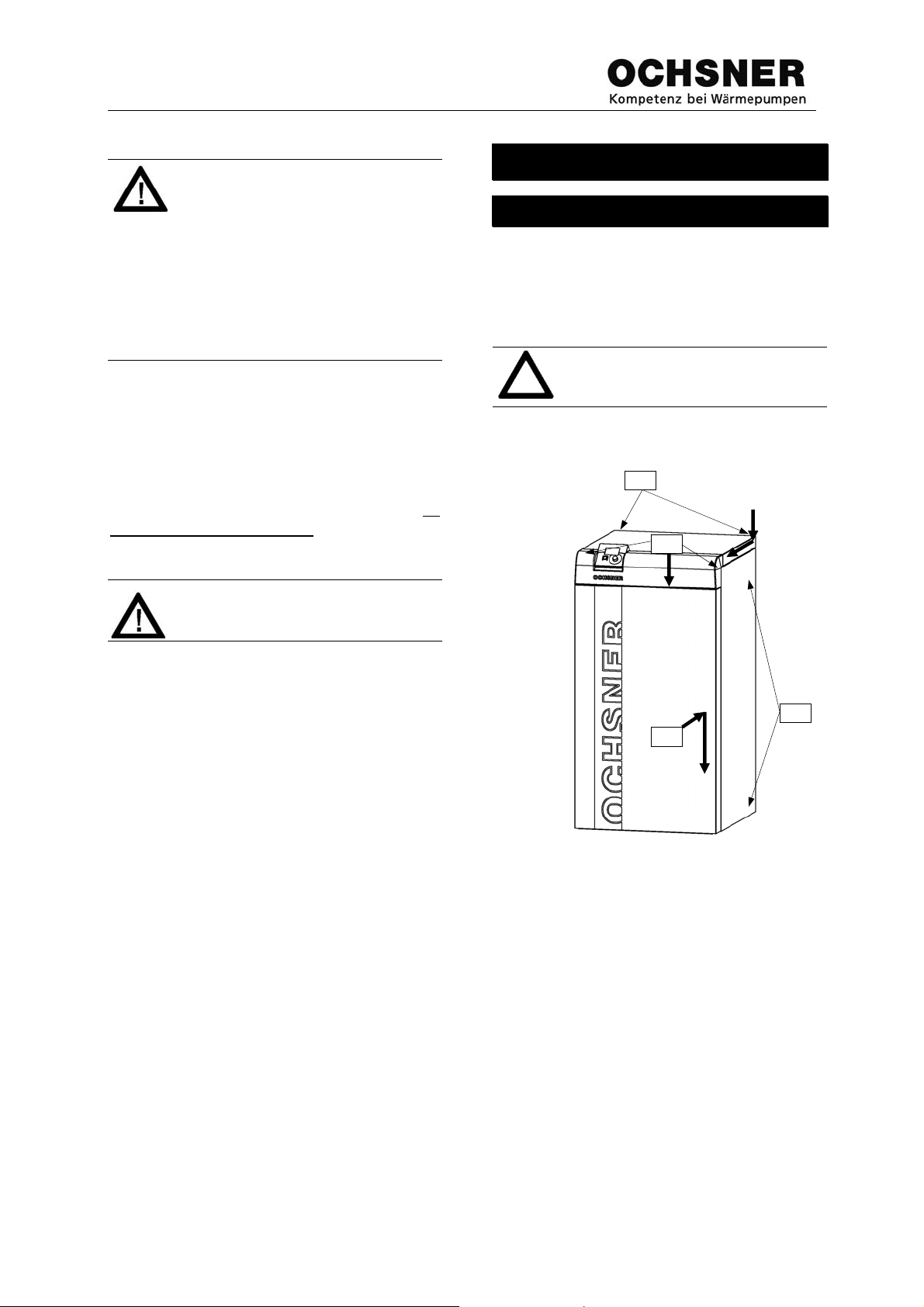

4.1 Delivery

The heat pump is delivered on a non-returnable

palette and pack in cling-film. The cladding is

supplied in the heat pump packaging.

ARA License Nr. 7910

Any transport damage must be immediately reported upon delivery!

The complete cladding must only be fitted after

the heat pump has been entirely connected up.

4

3

1

2

Fig. 1: Casing

1. Mount the left and right hand side panels to

the base frame using the Velcro fasteners.

2. Mount the front panel on to the lugs on the

side panels.

3. Slide the plastic cover into the slots provided

on the front panel and screw to the side

panels using the 2 screws provided.

4. Position the top panel on the side panels,

slide it towards the plastic cover until it slots

home. Screw the top panel to the rear panel

using the 2 screws provided.

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 6 of 25

4.2 Transport

The heat pump is to be transported and stored

in a packaged condition. Careful transport at an

angle of 45° is allowed over short distances.

Ambient temperatures of –20°C to +45°C are

allowed both for transport and storage. The

standard packaging affords no protection

against weather and sea-water.

Transport damage can only be recognised if

this is made known to the driver of the delivery

vehicle during unloading.

4.3 Installation location

The GMLW heat pump can be installed in any

and frost free room.

dry

The installation must

face. The location of the appliance is to be selected such that operation and maintenance

are possible at any time.

(Clearance from the rear of the heat pump to

the wall - min. 50 cm, clearance from the side

of the heat pump to the wall - 30 cm, clearance

from the front of the heat pump to the wall - 70

cm).

The heat pump must

from the floor.

Reverberant rooms can lead to increased noise

sensitivity. A possible noise transfer to adjoining rooms cannot be ruled out and must be

considered during the design.

4.3.1 Installation of split outdoor unit

The installation of the split outdoor unit

rator) is only permissible in the open air and is

to be carried out in such a way that the air-flow

is not hindered on any side.

take place on a level sur-

be decoupled acoustically

(evapo-

A maximum of one side may face a wall. A

minimum clearance of 1m must be ensured.

min. 1 m

Fig. 2: Minimum clearance to a wall

Evaporator

A minimum of 3m clearance above the unit is to

be ensured. Installing the unit in a hollow is not

permitted.

min. 3 m

Evaporator

Fig. 3: Minimum clearance to a ceiling

The distance from the heat pump to the evaporator is usually up to 10m (horizontal). The

maximum permissible difference in height (top

edge of evaporator) is 7m. Larger distances are

to be agreed with the factory in advance.

The following points are to be heeded w hen

installing the evaporator:

• avoid

installing on hard floors which could

transmit vibration

• installing between two walls could lead to an

increase in noise level

Pointer for the installation:

The higher the performance rating of

the heat pump, the louder the noise

made by the compressor.

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 7 of 25

• avoid

• plants and vegetated surfaces can reduce

• in closed rooms, the noise level is depend-

• a frost-protected drainage is to be con-

installing the evaporator alongside

bedrooms

the noise level

ent on the volume of the room and its re-

verberation time.

structed in order to drain off the condensate

accruing. In order to guarantee this, it is

usual to make a collection sump (not supplied) below the evaporator (see Fig. 4) If it

is not possible to make a collection sump

with drainage, a gravel bed is to be made

under the evaporator, In winter ice can form

in the drainage area..

If the condensate drainage is not

executed as recommended, ice

could build up of the surfaces around

the evaporator!

4.4 Connecting the heating system

The heat pump’s hydraulic connection made only be carried out by a

specialist according to local regulations!

All heat pump connections are to be carried out

in a flexible fashion. Acoustic bridges are to be

avoided when installing the pipework. The sizing of the pipe network as well as the selection

of the circulation pump depend upon the heating system in place.

Make sure the following design fundamentals are considered:

The rate of flow in the pipe network

must not exceed 0,8 m/s

(noise/resistance).

In order to ensure a comfortable and

disturbance-free operation, a temperature difference of 5K between

the heating system flow and return is

to be maintained.

When designing the heating system

circulation pump/buffer charge

pump, take the internal pressure difference in the heat pump condenser

into account (see technical data)!

Integrated heating circulation pumps

are designed as buffer charge

pumps (technical data – see annexe). The rate of flow in the pipe

network must not exceed 0,8 m/s

(noise/resistance).

For air/water heat pumps the installation of a

suitably sized decoupling tank (separation tank,

buffer tank) absolutely necessary in order to be

able to provide the necessary energy to be able

to defrost. A manual bleeding valve must be

installed at the highest point in the pipework.

.

If this is not done, there is a danger that the

heat pump will not reach the declared catalogue rating and under certain conditions will be

shut off by means of the high-pressure

switch,Æ ERROR report (see operation instructions OTE).

It must be ensured that no foreign bodies can

get into the pipework (dust, dirt, etc.).

A sieve filter

pipework to the heat pump in order to trap any

dirt. Make sure that the dirt collector

clean for maintenance purposes.

A clogged filter will substantially effect the heat

dissipation and can lead to switch-off by the

high-pressure safety mechanism!

Valves and thermometers

both the flow and return pipework, so that the

heat pump water flow rate and the running conditions can be continuously monitored.

A drain pipe

in the pipework so that the system can be

drained.

The heating system pipework is to be sized

according to the technical data of the heat

pump. Sample hydraulic standard schematics

can be found in Annex A.

can be inserted into the return

is easy to

are to be installed in

is to be installed at the lowest point

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 8 of 25

4.4.1 Cooling operation

For cooling operation, all system components

(pipework, fittings) must be insulated against

condensate forming by means od suitable insulating materials. This holds especially for the

flow pipework from the heat pump to the buffer

tank/distributor.

4.5 Heat source connection

4.5.1 Wall conduit

Conduits through external walls are to be executed with lined pipework. These are to be laid

with a slight slope

This is the only way to guarantee that condensate/rain water gathering can be properly disposed of through the house drainage system,

and no dampness can get into the brickwork. It

is also very important that the feed pipe on the

outside of the building is surrounded by gravel

and is bevelled from the top to the bottom

from inside to out!

Fig. 4: Wall conduit into free air

Fig. 5: Wall conduct into ground

Fig. 6: Foundation

This hinders the water from entering the building in the event of heavy rainfall. After placement, the pipe should be sealed with foam or if

necessary a special sealing compound.

4.5.2 Refrigerant pipework

The refrigerant pipework should always be positioned to the side of the heat pump (left or

right). Connections to rear should only be carried out in exceptional cases, as the connection

is made considerably more difficult!

4.5.3 Leak check

The leak check is to be performed and documented by OCHSNER Customer Service during the commissioning process.

4.5.4 Insulation

All exposed refrigeration lines are to be well

insulated to prevent build-up of condensation

and thermal losses.

Insulation installed underground

must be a closed-pore material. The

insulation properties of the insulation

will otherwise be negatively influenced

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 9 of 25

4.6 Electrical connection

The regulations of the energy utility and the relevant EN-standards

are to be adhered to without fail.

The values indicated in the Appendix for fuseprotection are given solely as reference values.

The implementation of proper safety measures

is the sole responsibility of the electrician connecting the heat pump. In cases of system

damage occurring due to falsely installed safety

devices, OCHNSER provides no guarantee!

4.6.1 Supply voltage to heat pump

The protection for the main electrical circuit is to

be provided by a three pole circuit breaker

which, in case of failure, shuts off all poles

(amperage found in Appendix, Technical Data).

The supply cable must also be protected

against overload and short-outs.

The control circuit should also employ an allpole shut-off circuit breaker. The main and

control circuits must be separate circuits.

.

Control voltage X3

supply X1,X2

Fig. 7:El. connection to heat pump

We recommend that the control voltage and the

main supply have their own FI switch so that, if

there is a short-circuit in the house installation,

the heating system remains in operation.

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 10 of 25

A

Due to the fact that the Scroll-compressors are

3-phase models, they will run in one or the

other direction, depending upon how the terminal L1, L2 and L3 are connected. To check for

correct connection, test whether, when switching on, the pressure on the suction side falls,

and that on the high-pressure side increases.

If the compressor is running in the wrong direction, the pressure on the suction side will increase, the noise level can also be higher than

if the compression is running in the right direction and the motor draws much less current

than stated in the technical data.

All 3-phase motors (compressors,

pumps, fans) MUST be connected to

a RIGHT-HAND ROTARY FIELD

.

Longer continuous operation in the

wrong direction will lead to damage.

OCHSNER takes no liability for this.

Connection work which entails

opening the connection boxes is

to be carried out by an authorised

contracting company, due to the

fact that current-carrying components can endanger life!

4.6.2 Evaporator wiring

The motors and sensors on the evaporator are

supplied from the indoor unit. For this, the following cables must be run from the indoor unit

to the evaporator:

Motors/Sensors Cable

3-phase supply to fan, incl.

signal contact, winding protec-

7 x 1.5

tion

De-ice sensor (TQA, TQE)

4 x 0.75

Electronic expansion valve 4 x 0.75

1

Rotation speed control for fan

2 x 0.75

If a delta-connection is necessary for operation

for technical reasons, special attention must be

paid to the operating currents and particularly to

setting of the motor-protection relays.

Power for a back-up electrical heating element

is to be provided using a separate external

power supply limiter.

4.6.3 Cable cross sections

Commercially available cables are to be used

to wire up actuators and sensors. Following

guidelines are to be heeded.

Position

min. Xsection

Supply cables 230V~: (Pumps,

valve motors)

lways size connecting cables

1.5 mm²

according to local conditions.

Sensor cables: (external sensor,

etc.) Sensor cables must always be

run separately (min. 20 cm) from

230V/400V cables.

0.75 mm²

The max. cable length must not

exceed 50 m.

Bus cables: (Room remote controls, auxiliary modules) must always be run separately (min. 20

cm) from 230V/400V cables. Above

1.0 mm²

50 m cable length, choose 1.5 mm².

The max. cable length must not

exceed 200 m.

Table. 2: Chart cable sizing

Table. 1: List of cables to evaporator

All cables/wiring must be suitable for laying

outdoors and must laid so that they are UVprotected.

1

Only for version with rotational speed control

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 11 of 25

4.6.4 Sensor wiring

De-icing sensors:

2 de-icing sensors (TQA, TQE) are to be installed in the fin-packet of the evaporator. (See

the wiring diagram for the exact positioning of

the sensors) For this, a 4-pole cable is to be run

from the indoor unit to the evaporator. The sensors are then connected together with the 4pole cable in a terminal box which is protected

against moisture (not supplied with heat pump).

The external sensor

(TA) of the control system

is to be installed at approximately 2.5 m height

on the outer side of the building wall (North or

West side). Care must be taken that the thermometer is not exposed to direct solar radiation

or wind; as such placement influences the operational characteristics of the control system.

The heat generator sensor

(TPO) is normally

included with the heat pump at delivery. If a

buffer storage tank or a low loss header is to be

implemented, the sensor is to be mounted internally in the storage device. Placement

should occur in the top

third of the tank. If there

is no low loss header, the heat generator sensor (TPO) will not be installed. See separate

Instruction „Wiring diagram“

The hot water sensor

(TB) is included with the

heat pump at delivery. Placement should occur

in the bottom third, to max. the middle of the

tank. OCHSNER hot water tanks have suitable

sleeve fittings for this installation.

Should a mixing circuit be installed additionally

to the heating circuit, then the mixing circuit

sensor (TMK) is included in the delivery along

with strapping and heat conducting paste. The

sensor is to be installed directly after the mixing

circuit pump.

Do not expose the sensor terminals

to a voltage > 10 V. This may damage or destroy the control.

4.6.5 Pumps, motors 230 VAC

Pumps (heating circuit pumps, water charging

pumps) as well as motors (mixing valves, etc.)

are to be wired directly to the control.

Warning: A test-run may only be

undertaken on a fully-prepared system that is ready for commissioning!

(Hydraulically connected, correct

compressor rotation ensured).

4.7 Utility control contact

In the case of tariff switching (interrupted power

supply) the heat pump will be temporarily

switched off by the utility. A control input (bridge

on terminal EVU, terminal strip X3) is present in

the control. If the tariff switching takes place in

the meter (Night Tariff), the EVU contact must

not be activated.

Fig. 8: Tariff switching contact on terminal X3

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 12 of 25

4.7.1 Switch off via tariff relay:

For switching by means of a tariff relay (sealed

by the utility on site) the 3-phase power supply

to the heat pump is switched off. The heat

pump signal contact must

be executed via the

auxiliary contact on the tariff relay.

4.7.2 Switch off via ripple control

For switching by means of a ripple control receiver (open contact), the heat pump will NOT

be separated from the 3-phase supply.

5 Commissioning

Commissioning requests are to be made to

OCHSNER Customer Service. Fixed commissioning appointments should be made two

weeks in advance.

To undergo the commissioning process, the

following work should be complete:

- The heating and hot-water systems must

be completely installed, filled, bled, and hydraulically adjusted.

- - The electric connection from the main

circuit 3x400V/50Hz, (control circuit

230V/50Hz) and other electrical installations on the building site are complete.

Confirmation of proper field rotation, no

provisional modifications!

Details: see check list supplied in packaging!

Work to be completed by OCHSNER:

- Installation and connection of refrigerant

lines (except collector installation)

- Leak check on refrigeration lines

- Evacuation of the refrigerant lines

- Insulation of the refrigerant lines (only in the

internal area of the system)

- Filling of the system with the proper amount

of refrigerant

- Setting of safety devices

- Inspection of the operation cycle

- Preparation of a commissioning protocol

- Setting of control system for basic opera-

tion

- System orientation, explanation for operator

(if present at commissioning)

5.1 Required on-site personnel:

Electrician, installer and future caretaker/operator MUST

orientation.

Other necessary work performed, such as

bleeding the piping network of air, electrical

wiring, etc., that do not fall within the realm of

the Ochsner firm’s duties will be invoiced separately.

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 13 of 25

be present for the system

adjustment

ob

5.2 Check list for commissioning

Adhere to the following sequence:

1) Check heating system circuit: Systempressure, expansion vessel function,

bleeding valves, quantity adjustment

2) Check whether all non-return valves

are open

3) Check power supplies and circuit

breakers

4) Check refrigerant circuit

5) Check the electrical connections to the

system components, including all required safety equipment, according to

the wiring diagram.

6) Switch on 3-phase supply to the heat

pump.

7) Control 3-phase supply and right-hand

rotary field

8) Switch on control voltage supply

9) Configure the system by means of the

commissioning (IBN) assistant

10) Store the sensor configuration

11) Relay test on the output terminals

12) Adjust the system according to user requirements and document these settings

13) Hand over system to operator

6 Operating the system

The heat pump operation takes place by means

of the basic operating panel. This is easily accessible in a plastic housing mounted on the

heat pump.

The user has 2 knobs and a lit display at his

disposal (Fig. 9)

Display

ESC-knob

Fig. 9:Basic control panel (Master remote control)

The heat pump has no separate

OFF switch. In emergency the system MUST

be switched off by means

of the specified circuit breakers.

The circuit breakers MUST

reachable as to ensure a switching

off at any time

kn

be so

6.1 Safety functions

Following safety features are implemented from

both Hard- and Software:

- Electric control and safety devices for the

compressor

- High pressure safety pressostat

- Start delay to avoid compressor chopping.

- Frost protection function

6.2 Running costs

Pointer:

For optimum heat pump operation,

the lowest possible flow temperature

to the heating circuit should set.

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 14 of 25

An increase of the room temperature

by 1°C means a 5-7% increase in

energy consumption.

Generally, higher operation costs can be expected in the first heating season, depending

upon the residual moisture (up to 50%) in the

building materials

7 Maintenance

7.1 Service work

The heat pump operates maintenance free. It

must, however, be ensured that:

- the evaporator is free from leaves and twigs

or any other foreign bodies,

- the condensation can drain off,

- the heating circuit contains enough water

Pointer:

On request, OCHSNER can offer a

maintenance contract. If interested,

please contact our customer service

department.

7.2 Service and Maintenance

The following services are to be carried out by

our customer service:

- Control of the refrigeration cycle

- Testing and repair (re-working) of electrical

connections

- Testing of safety devices (Pressostats,

thermostats

- Inspection of switch contacts

- Commissioning protocol

- Service and maintenance log entries

- Review of control parameters

-

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 15 of 25

7.3 Trouble shooting

Should a defect or problem arise, despite the selection of parts of highest quality and the painstaking

care put into production, please notify your contracting partner or the OCHSNER customer service department with the heat pump model and product number at the following numbers.

Customer service Austria: Tel.: 0043(0)504245 -14

E-Mail: kundendienst@ochsner.at

Customer service Germany: Tel.: 0049(0)3628 58 108 - 0

E-Mail: kundendienst@ochsner.de

The heat pump model and product number can be found on the heat pump rating plate which is located

on the rear of the unit.

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 16 of 25

Error / Warning Possible Cause Recommended Action

2. Energy provider error - High

Pressure (ER 36)

One or more circulation pumps not

see also Pos. 5.

Air in heating circuit Bleed heating circuit

3-way valve defect Replace

Return-valve does not open Loosen, replace

For external hot-water heating option:

-Heat exchanger too small Enlarge heat exchanger

-Heat exchanger chalked or silted Contact cust omer service, clean, decalcify

Control set too high Lower shut-off temperature (55°C maximum)

Loose connections at terminals Tighten connections at terminals

3. Energy generator error - Low

Pressure (ER 37)

Evaporator heavily iced, too little defrost

Energy dispersion not guaranteed /

Heating loop over-regulated

functioning

RPM (speed level) of heating circulation

pump to low

Air temperature too low Activate auxiliary heat source (e.g. elec.

energy available

Open barriers to flow (valves)

Reset function

Increase pump RPM (level switch), delta

t=5K, supply/return

element)

Enlarge buffer storage tank, install electrical

heating element with larger capacity

Refrigerant loss Contact Customer Service

Refrigerant circuit defect Contact Customer Service

Buffer pump defect Contact heating installer, free/replace pump

4. Evaporator iced despite defrost

function (ER 47)

Too little defrost energy available Enlarge buffer storage tank, install electrical

5. Heating system not warm, heat

pump and buffer storage hot

see also Pos. 2

6. Heat pump runs, but heating

capacity is insufficient

7. Heat pump provides hot-water but

heating is late or non-exist e nt

Poor weather conditions Remove ice with the help of warm water or

Energy discharge interrupted/not

sufficient

Too high heating demand Reduce heating demand

Heat source overloaded Reduce heating demand

Machine is set for boiler-priority Check hot water control settings

Building condition (e.g. insulation

properties) insufficient

Scroll-Compressor rotates in the wrong

direction. Warning: Turn of heat pump

immediately

Hot water thermostat set too high Lower switch in temperature

Control is set to summer operation Set controller for heating operation

Heat exchanger (hot water) too small Enlarge surface area of heat exchanger

Heat exchanger (hot water) chalked Contact installer, clean, decalcify

Refill refrigerant

Repair or replace

air. Never remove ice mechanically

heating element with larger capacity

Repair or replace circulation pump,

bleed heating circuit, open gate valve, open

regulator, set circulation pump speed to a

higher level

Install insulation to heat pump design

conditions

Contact electrician to change wiring, test to

ensure proper rotation direction

Table. 3: Trouble shooting chart 1

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 17 of 25

Trouble shooting, continued

8. Hot water temperature not

reached

9. Heat pump runs constantly but

brings little warmth, oily substance

on unit

10. Operation condition (Utility

block)

11. Phase failure

Heat exchanger (hot water) too small Enlarge surface area

Heat exchanger (hot water) chalked Contact instal l e r, clean, decalci fy

Wrong sensor positioning Position correctly

Pipework too small Install larger pipes

Hot water sensor defect Repair or replace

Hot water charge pump defect Repair or replace

Performance of boiler pump to low Set pump performance higher

3-way valve defect Repair or replace

Refrigerant leak: Connections in the

refrigerant circuit not tight/leak-proof

Utility blocking time active

Compressor rotates in the wrong

direction

(at relay K7 the LED DEF is lit)

Phase failure

(at relay K7 the LED DEF is lit)

Phase shifting

(at relay K7 the LED ASY is lit)

Table. 4: Trouble shooting chart 2

Shut-off heat pump, contact customer

service

Contact electrician to change wiring, test to

ensure proper rotation direction

Contact electrician to test the electricit y

supply

Contact electrician to test the electricit y

supply, the phase shift can be adjusted by

up to 20%, but CAUTION, if damage

occurs through this, the guarantee is void!

Only instructed persons are allowed to correct failures and to change the settings !

The controller basic adjustment takes place in the context of commissioning via the specialist. For possible corrections and program attitudes the operator/responsible person is responsible!

Further error reports Æ see Operating Instructions for control

ANNEX

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 18 of 25

Technical Data GMLW

Performance Data normal mode GMLW 9 GMLW 14 GMLW 19 GMLW 25

Heating Capacity L7/W35 9,9 15,1 20,2 27,0 kW

Power Consumption L7/W35 2,2 3,4 4,6 6,3 kW

Coefficient of Perfomance L7/W35 4,5 4,4 4,4 4,3

Drawn Current L7/W35 4,7 7,7 9,7 12,3 A

Heating Capacity L2/W35 8,5 12,7 17,0 22,4 kW

Power Consumption L2/W35 2,0 3,25 4,35 5,9 kW

Coefficient of Perfomance L2/W35 4,2 3,9 3,9 3,8

Drawn Current L2/W35 4,6 7,5 9,8 12,1 A

Heating Capacity L2/W50 7,8 11,5 15,6 21,4 kW

Power Consumption L2/W50 3,25 4,7 6,4 8,7 kW

Coefficient of Perfomance L2/W50 2,4 2,4 2,4 2,45

Drawn Current L2/W50 6,0 9,0 11,8 15,0 A

Performance Data reverse mode

Cooling Capacity L30/W18 5,9 8,9 12,1 15,1 kW

Waste heat Cpacity L30/W18 8 12,0 16,4 20,4 kW

Power Consumption L30/W18 2,0 3,1 4,3 5,3 kW

Coefficient of Performance L30/W18 3 2,9 2,8 2,8

Drawn Current L30/W18 4,3 6,8 9,0 12,8 A

Compressor

Type

Number 1111units

Max. Operating Current 8,0 13,0 16,0 20,0 A

Max. Starting Current 31 45 68 90 A

Max. Starting Current w/ Di scharge 16 23 34 45 A

Evaporator

Type

Building Mater i a l

Number 1111units

Max. Operating Pressure Antifreeze 30 30 30 30 bar

Relative Humidity 80% 80% 80% 80%

Air Volume Flow Rate 4000 4000 8000 8000 m³/h

Workin g F luid Temperature Di fference 5,0 5 , 0 5,0 5,0 K

Operating Range -15/+40 -15/+40 -15/+40 -15/+40 °C

Fan Power Consumption 140 140 280 280 W

Noise pressure level

Weight 94 94 126 141 kg

Condenser

Type

Building Mater i a l

Number 1111units

Max. Operating Pressure Water 6666bar

Max. Operating Pressure Antifreeze 30 30 30 30 bar

Internal Pressure Differenze 0,07 0,1 0,17 0,2 bar

Working Fluid Volume Flow Rate 1,7 2,6 3,5 4,64 m³/h

Durchmesser Anbindeleitung 27,41 33,90 39,34 45,29 mm

Static Pressure Head w/out redirect valve max. 0,247 0,071 0,112 - bar

Fitting Diameter (minimum) 28 35 42 54 mm

Working Fluid Temperature Difference 5555K

Operating Range 55 55 55 55 °C

Workin g F luid

Rated Press ur e 45 45 45 45 bar

Refrigeration Cycle

Number of Refrigeration Cycles 1111units

Working Fluid R 407C R 407C R 407C R 407C

Defrost Function

Unit Data/ Electriacal Information

Voltage/ Frequency 400/50 400/50 400/50 400/50 V/Hz

Power Factor (cosine Phi) 0,68 0,64 0,68 0,74

Fuse Protec tion 10 16 20 25 A

Hood Color

Housing Color

Weight 120 130 143 156 kg

Built-in Heating Circulation Pump yes yes yes no

(in a distance of 10m)

Full-hermetic / Scroll

Finned Heat Exchanger

Copper / Aluminium

26 26 29 29 dB(A)

Flat Plate Heat Exchanger

Stainless Steel 1.4401

Water

Hot gas / Reversal System

cement grey RA L 70 3 0

grey/white RAL 9002

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 19 of 25

y

Technical Data GMLW plus

Performance Data normal mode

Heating Capacity L7/W35 10,0 14,1 19,8 26 34,8 kW

Refrigerating Capacity L7/W35 7,8 11,1 15,4 20,4 27,7 kW

Power Consumption Compressor L7/W35 2,2 3 4,4 5,6 7,1 kW

Power Consumption Fan L7/W35 0,14 0,115 0,23 0,23 0,60 kW

Power Consumption L7/W35 2,3 3,1 4,4 5,8 7,7 kW

Coefficient of Perfomance L7/W35 4,4 4,5 4,5 4,5 4,5

Drawn Current L7/W35 4,6 6,4 8,6 11,8 16,3 A

Heating Capacity L2/W35 8,6 11,7 16,8 22,1 29,5 kW

Refrigerating Capacity L2/W35 6,5 8,8 12,6 16,8 22,7 kW

Power Consumption Compressor L2/W35 2,1 2,9 4,2 5,3 6,9 kW

Power Consumption Fan L2/W35 0,14 0,115 0,23 0,23 0,60 kW

Power Consumption L2/W35 2,2 3,0 4,3 5,6 7,5 kW

Coefficient of Perfomance L2/W35 3,9 3,9 3,9 3,9 3,9

Drawn Current L2/W35 4,5 6 8,3 11,6 16,1 A

Heating Capacity L2/W50 8,1 10,7 15,9 19,7 27,0 kW

Refrigerating Capacity L2/W50 5,3 7 10,3 12,6 17,6 kW

Power Consumption Compressor L2/W50 2,8 3,7 5,6 7,1 9,4 kW

Power Consumption Fan L2/W50 0,14 0,115 0,23 0,23 0,60 kW

Power Consumption L2/W50 2,9 3,8 5,7 7,3 10,0 kW

Coefficient of Perfomance L2/W50 2,8 2,8 2,8 2,7 2,7

Drawn Current L2/W50 5,2 7,2 1 0 13,6 19,2 A

Performance Data reverse mode

Cooling Capacity L30/W18 9,9 8,7 13,3 14,8 28,4 kW

Waste heat Cpacity L30/W18 12,7 11,9 18,2 20,3 20,9 kW

Power Consumption L30/W18 2,9 3,2 4,9 5,5 8,1 kW

Coefficient of Performance L30/W18 3,4 2,7 2,7 2,7 3,5

Drawn Current L30/W18 5,9 6,5 8,9 13 16,0 A

Compressor

pe

T

Number 11111units

Power settings 1 1 1 1 1 units

Max. Operating Current 6,0 9,6 13,8 17,7 23,2 A

Max. Starting Current 28,0 45 49,5 70 90,0 A

Max. Starting Current w/ Discharge 14,0 23 25 35 45,0 A

Evaporator

Type

Building Material

Number 11111units

Max. Operating Pressure Antifreeze 30 30 30 30 30 bar

Relative Humidity 80% 80% 80% 80% 80%

Air Volume Flow Rate 4000 4000 8000 8000 9800 m³/h

Working Fluid Temperature Difference 4,0 5,0 5,0 5,0 4,0 K

Operating Range -18/+40 -15/+40 -15/+40 -15/+40 -18/+40 °C

Fan Power Consumption 140 140 280 280 600 W

Noise pressure level

Weight 94 94 126 141 159 kg

Condenser

Type

Building Material

Number 11111units

Max. Operating Pressure Water 6 6 6 6 6 bar

Max. Operating Pressure Antifreeze 30 30 30 30 30 bar

Internal Pressure Differenze 0,07 0,09 0,16 0,17 0,22 bar

Working Fluid Volume Flow Rate 1,7 2,5 3,4 4,4 6 m³/h

Durchmesser Anbindeleitung 27,53 33,25 38,77 44,10 51,36 mm

Static Pressure Head w/out redirect valve max. 0,247 0,071 0,112 - - bar

Fitting Diam et er (minimum) 28 4 2 42 54 54 mm

Working Fluid Temperature Difference 5 5 5 5 5 K

Operating Range 65 65 65 65 65 °C

Working Fluid Water Water Water Water Water

Rated Pressure 45 45 45 45 45 bar

Refrigeration Cycle

Number of Refrige ration Cycles 1 1 1 1 1 unit s

Working Fluid R 407C R 407C R 407C R 407C R407C

Defrost Function

Unit Data/ Electriacal Information

Voltage/ Frequency 400/50 400/50 400/50 400/50 400/50 V/Hz

Power Factor (cosine Phi) 0,72 0,72 0,76 0,69 0,71

Fuse Protection 16 16 20 25 25 A

Hood Color

Housing Color

Weight 117 130 143 166 160 kg

Built-in Heati ng Ci rculation Pump yes yes yes no no

(in a distance of 10m)

GMLW 9 Plus

26 26 29 29 37,5 dB(A)

GMLW 14 Plus GMLW 19 Plus GMLW 25 Plus

Full-hermetic / Scroll

Finned Heat Exchanger

Copper / Aluminium

Flat Plate Heat Exchanger

Stainless Steel 1.4401

Hot gas / Reversal System

cement grey RAL 7030

grey/white RAL 9002

GMLW 35 plus

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 20 of 25

Evaporator connection pipework

Artikel Nr. WP-Type Bögen 90°

Anzahl

284050 GMLW 9 2 bis 8 12 18 12 18 12 22 12 22

284060 GMLW 9 plus 2 bis 8 12 18 12 18 12 22 12 22

284100 GMLW 14 2 bis 8 12 22 12 22 12 22 12 2x18

284110 GMLW 14 plus 2 bis 8 12 22 12 22 12 22 12 2x18

284150 GMLW 19 2 bis 8 12 22 16 2x22 16 2x22 16 2x22

284160 GMLW 19 plus 2 bis 8 12 22 16 2x22 16 2x22 16 2x22

284200 GMLW 25 2 bis 8 16 2x22 16 2x22 16 2x22 16 2x22

284210 GMLW 25 plus 2 bis 8 16 2x22 16 2x22 16 2x22 16 2x22

284260 GMLW35plus 2 bis 8 16 42 16 42 16 42 16 42

Anzahl

Artikel Nr. WP-Type Bögen 90°

284050 GMLW 9 2 bis 8 12 22 12 22 12 22 12 22

284060 GMLW 9 plus 2 bis 8 12 18 12 18 12 22 12 22

284100 GMLW 14 2 bis 8 12 2x18 12 2x22 12 2x22 12 2x22

284110 GMLW 14 plus 2 bis 8 12 2x18 12 2x22 12 2x22 12 2x22

284150 GMLW 19 2 bis 8 16 2x22 16 2x22 16 2x22 16 2x22

284160 GMLW 19 plus 2 bis 8 16 2x22 16 2x22 16 2x22 16 2x22

284200 GMLW 25 2 bis 8 16 2x22 16 35 16 35 16 35

284210 GMLW 25 plus 2 bis 8 16 2x22 16 35 16 35 16 35

284260 GMLW35plus 2 bis 8 16 42 16 42

Anbindeleitung bis

FlüssigL. Saugg.L FlüssigL. Saugg.L FlüssigL. Saugg.L FlüssigL. Saugg.L

16 4x22 16 4x22 16 4x42 16 4x42

Anbindeleitung bis

FlüssigL. Saugg.L FlüssigL. Saugg.L FlüssigL. Saugg.L FlüssigL. Saugg.L

Table. 5: Dimension pipework to the evaporator

6m

Anbindeleitung bis

8m

14m

Anbindeleitung bis

16 4x42 16 4x42

16m

16 3x22 16 3x22 16 3x22

Anbindeleitung bis

Anbindeleitung bis

10m

18m

Anbindeleitung bis

Anbindeleitung bis

12m

20m

The pipework specified in the Table is valid:

• for differences in height up to 10 m, when the evaporator is positioned higher than the heat pump.

• for a maximum of 8 bends which are to be made using tooling (for 35mm pipe bend Type 5002)

• Bending radii of 1m are considered to be straight stretches!

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 21 of 25

Dimensions sheet

GMLW 9 – GMLW 19

GMLW 9 plus – GMLW 19 plus

1150

EA

VLH

RLQ

VLQ

920

OCHSNER

600

VLH

RLH

VLQ

RLQ

EA

GMLW 25 – GMLW 25 plus

GMLW 35 plus

1150

Vorlauf Heizung/Heating Supply

Rücklauf Heizung/Heating Return

Vorlauf Quellenergie/Heat Source Supply

Rücklauf Quellenergie/Heat Source Return

Elektroanschluss/Electrical Connection

RLH

621

155

650

85

385

5/4"

5/4"

EA

RLQ

VLH

VLQ

621

RLH

OCHSNER

600

VLH

RLH

VLQ

RLQ

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 22 of 25

Vorlauf Heizung/Heating Supply

Rücklauf Heizung/Heating Return

Vorlauf Quellenergie/Heat Source Supply

Rücklauf Quellenergie/Heat Source Return

EA

Elektroanschluss/Electrical Connection

650

38585

5/4"

5/4"

155

Operation data MLLENIUM evaporator

MSV 14:

MSV 19-35:

Operating data:

Heat pump type

Evaporator Type

Flow rate [m3/h] 4000 8000 8000 9800

Number of fans

Power consumption [W] 65 130 130 400

Noise level (in 10m distance

to the fan) [dB(A)]

Weight [kg ] 93 136 164 169

GMLW 9 plus GMLW 19 plus GMLW 25 plus GMLW 35 plus

MSV 14 MSV 19

1 2 2 2

22 25 25 32

MSV 25 MSV 35

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 23 of 25

A

Declaration of conformity

European Communit y –Manufacturer Disclosure

The signatory

Ochsner Wärmepumpen GmbH

Werk: A 3350 Haag

Ochsnerstrasse 1

certifies that the following indicated device(s) introduced into the market by Ochsner fulfill the

requirements of the harmonised EU-directives, EU-safety standards and EU-standards relating to the

specific product.

ny modification to device(s) that have not been approved by us effectively voids this statement.

Description of the appliance(s):

Heating heat pump with R134a

Heating heat pump with R407C

Hot water heat pump with R407C

Hot water heat pump with R134a

Heat Pump Type(s):

GMDW 5 – 9, GMDW 12 – 30

GMDW 6plus – 11plus, GMDW 13plus –

18plus

GMDW 8 V X –GMBW 11 3 V X

GMSW 6 – 11 GMSW 15 - 38 OSWP

46-96

GMSW 7 VX – GMSW 18 VX

GMSW 6plus – 10plus, GMSW 12plus –

17plus

GMSW 38R, OSWP 46R-96R

GMWW 6 – 11, GMWW 15 – 38, OWWP 4696

GMWW 8plus – 13plus, GMWW 15plus –

23plus

GMWW 38R, OWWP 46R-96R

GMWW 10 VX – GMWW 18 VX

GMLW 9 – GMLW 25 GMLW 9plus –

GMLW 35plus, OLW 6 – OLW 18, OLW

12plus, OLW 18plus

GMLW 14 VX – GMLW 19 VX

IWWP 110 – 220 SC IWWP 160 – 1900 Sv

ISWP 110 – 220 SC ISWP 160 – 1900 SV

Domestic hot water heat pumps:

Europa Mini EWP

Europa Mini IWP

Europa 500 IW

Europa 303/313

Europa 303.1/313.1

Ochsner Wärmepumpen GmbH Haag, 18.01.2008

European Community Guidelines:

EC – Machine Guidelines (98/37/EWG)

EC – Low Voltage Guidelines (73/23/EWG)

EG – EMV Guidelines (89/336/EWG)

Harmonized European Standards:

EN 378 1994

EN 60529 1992

EN 292/T1/T2 1991/1995

EN 294 1992

EN 349 1993

EN 60335/T1/T2-40 1 99 5/1998

EN 55014 1993

EN 55014-1/A1 1997

EN 55014-2 1997

National standards / Guidelines:

DIN 8975 1986

VBG 20 1993

DruckbehV 1993

DIN 8901 1995

BA_GMLW OTE bis V3.4 SHORT_EN_20090408_V1 Page 24 of 25

We reserve the right to change technical data without notice!

Industriestrasse 28 B-4700 Eupen Tel.:+32(0)87 59 16 50 Fax:+32(0)87 59 16 55 info@accubel.be www.accubel.be

This instruction describes machines, which are not always in the scope of supply in series. Therefore

deviations to your heat pump are quite possible.

System installer company:

.............................................................................................................................

Address ...................................................................................................................................................

...................................................................................................................................................

Tel. .........................................................................................................................................................

Service engineer ....................................................................................................................................

OCHSNER

Wärmepumpen GmbH

Autobahnstr.2

A 3350 Haag

Tel. +43 (0) 5 042458

Fax. +43 (0) 5 04245-30

www.ochsner.at

kontakt@ochsner.at

OCHSNER

Wärmepumpen GmbH

Elxlebenerweg 10

D 99310 Arnstadt

Tel. +49(0)3628 / 58 108 - 0

Fax +49(0)3628 / 58 108 - 18

www.ochsner.de

kontakt@ochsner.de

ACCUBEL S.A.

Industriestrasse 28

B - 4700 EUPEN

+32 (0)87 59 16 50

Tel.

32 (0)87 59 16 55

Fax +

www.accubel.be

info@accubel.be

52 fo 52 egaP 1V_80409002_NE_TROHS 4.3V sib ETO WLMG_AB

Loading...

Loading...