HIGH EFFICIENCY AIR/WATER HEAT PUMPS

OPERATING AND INSTALLATION

MANUAL

AIR 7

►

AI R 11

►

AIR 18

►

AIR 23

►

AIR 29

►

AIR 41

►

CONTENTS

PLEASE NOTE

OPERATION

1. Information on documentation 4

1.1 Safety information 4

1.1.1 Arrangement of safety information 4

1.1.2 Symbols and possible dangers 4

1.1.3 Keywords 4

1.2 Other symbols 5

1.3 Units of measurement 5

1.4 Specied performance data 5

2. Safety 5

2.1 Intended use 5

2.2 General safety information 5

3. Appliance description 6

3.1 Functionality 6

3.2 Appliance components 6

3.2.1 Indoor unit 6

3.2.2 Outdoor unit 7

3.2.3 Heat pump control unit 7

3.3 Name plate 7

4. Activating settings 8

4.1 Operating costs 8

4.1.1 Flow temperatures 8

4.1. 2 Ventilation 8

4.1. 3 Heating setback program 9

5. Maintenance and care 9

6. Problem solving 9

INSTALLATION

7. Safety 10

7.1 General safety information 10

7. 2 Regulations, codes and standards 10

8. Appliance description 10

8.1 Standard delivery 10

8.2 Hydraulic variants of the indoor unit 11

9. Preparing to install the appliance 13

9.1 Indoor unit installation location 13

9.1.1 Keep minimum clearances 13

9.2 Outdoor unit installation location 13

9.2.1 Keep minimum clearances 14

9.3 Foundations for the outdoor unit 14

9.3.1 Laying spot foundations 15

9.3.2 Laying strip foundations 16

9.3.3 Installing on at roofs 16

9.4 Preparing the refrigerant lines 17

9.4.1 Line lengths 18

9.4.2 Pipe diameter 18

9.4.3 Preparing the wall outlets 19

9.4.4 Preparing refrigerant lines passing through open air

20

9.4.5 Preparing underground refrigerant lines 20

9.5 Preparing the electrical connections 22

9.5.1 Heat pumps for three-phase alternating current 22

9.5.2 Heat pumps for single phase alternating current 23

9.5.3 Cables from main distributor to indoor unit 23

9.5.4 Cables from indoor to outdoor unit 23

9.5.5 Temperature sensor 23

9.5.6 Pumps and servomotors (230 VAC) 24

9.5.7 PSU signal contact 24

9.5.8 Smart Grid 24

10. Appliance installation 25

10 .1 Installation of indoor unit 25

10 .1.1 Delivery and transportation 25

10 .1.2 Positioning the appliance 26

10 .1.3 Disassembling the appliance casing 26

10 .1.4 Assembling the appliance casing 27

10.2 Installing the outdoor unit 28

10 . 2 .1 Delivery and transportation 28

10.2.2 Positioning the appliance 29

10.2.3 Disassembling the appliance casing 29

10.2.4 Installing the snow cover 29

10.2.5 Fitting the cylindrical silencer 29

10.2.6 Installing the SSP snow cover 30

10.3 Connecting the heat sink system 31

10 . 3 .1 Connecting the heating water 31

10.3.2 Safety valve drain 32

10.3.3 Filling the heating system 32

10.3.4 Diaphragm expansion vessel (DEV) 33

10.3.5 Flow metering 33

10.3.6 Cooling version 33

10.3.7 Connecting the DHW 33

10.4 Electrical connection 34

10 . 4 .1 General 34

10.4.2 Electrical connection of the indoor unit 34

10.4.3 Electrical connection of the outdoor unit 36

10.5 Connecting heat source system 37

10 . 5 .1 Connecting the refrigerant lines 37

10.5.2 Checking for leak tightness 38

10.5.3 Filling the refrigerant circuit with refrigerant 38

10.5.4 Insulating the refrigerant lines 38

11. Commissioning 39

11.1 Before switching on for the rst time 39

11. 2 Testing the control circuit 39

11. 3 Adjusting the ow rate 39

11. 4 Heat generator pump (HGP) 42

11. 5 Necessary conditions for commissioning 43

11. 6 Commissioning the system 44

11.7 Decommissioning 45

12. Troubleshooting 46

12 .1 Fault messages on the master controller 46

12.2 Reset high limit safety cut-out 48

13. Appliance maintenance 48

13 .1 Testing safety valve 48

13.2 Maintenance contract 49

14. Specication 50

14 .1 Heat pumps for three-phase alternating current 50

14 .1.1 Data table 50

14 .1.2 Output diagrams 54

14 .1.3 Details of energy consumption 60

14.2 Heat pumps for single phase alternating current 62

14 . 2 .1 Data table 62

14.2.2 Output diagrams 64

14.2.3 Details of energy consumption 66

14.3 Limits of use 67

14.4 System schematic diagrams 68

14.5 Voltage quality in island mode 84

14.6 Dimensions and connections 85

14 . 6.1 Indoor unit 85

14.6.2 Outdoor unit 86

15. Environment and recycling 90

16. Declaration of Conformity 91

17. ERP-Data 93

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 3

PLEASE NOTE | Information on documentation

i

PLEASE NOTE

f The appliance can be used by children over the age

of eight years and by people with reduced physical, sensory or mental abilities or with a lack of

experience and knowledge, if they are supervised

or instructed on the safe use of the appliance and

understand the dangers that can arise from its use.

Children must not be allowed to play with the appliance. Children must not be allowed to clean or

carry out user maintenance on the appliance without

supervision.

f Connection to the mains electricity supply must be

by means of a xed connection. It must be possible

to isolate the appliance from the mains supply with

a multi pole switch which has a gap of at least 3 mm

across all poles.

f You must not disconnect the mains supply even

outside the heating period. If the power supply is

disconnected, active frost protection of the system

cannot be guaranteed.

f You do not need to switch off the system for the

summer. The heat pump control unit changes over

automatically between summer and winter.

OPERATION

1. Information on documentation

The “Please note” and “Operation” sections are intended

for the appliance user and the qualied contractor.

The “Installation” section is intended for the qualied con-

tractor.

Unless otherwise stated, all the content of this documentation applies to the appliances listed on the title page. This

documentation describes appliances that are not always

standard items. There may therefore be differences to your

specic appliance.

Information

Read all of this documentation carefully before using the appliance and keep the documents safe.

Pass this documentation on to any new user.

1.1 Safety information

1.1.1 Arrangement of safety information

f Observe the minimum clearances in order to ensure

fault-free operation of the appliance and to allow for

maintenance work on the appliance.

f In bivalent mode, the return water from the second

heat generator can ow through the heat pump. Note

that the return water temperature must not exceed

65°C.

f Maintenance work such as checking the electrical

safety of the appliance may only be carried out by a

qualied contractor.

f We recommend an annual inspection (to assess the

appliance‘s actual condition) and if necessary maintenance (to reinstate it to its expected condition) by a

qualied contractor.

KEYWORD: Type of risk

The possible consequences of not observing the

safety information are shown here.

Instructions for action to remedy or remove

»

the source of danger are shown here.

1.1.2 Symbols and possible dangers

Symbol Type of risk

Injury

Electrocution

Burns

(burns, scalding)

Material damage

(appliance, consequential and environmental damage)

1.1.3 Keywords

Keyword Meaning

DANGER Failure to observe this information will result in seri-

WARNING Failure to observe this information may result in se-

CAUTION Failure to observe this information may result in

ous injury or death.

rious injury or death.

non-serious or minor injury.

4 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

OPERATION | Safety

i

i

1.2 Other symbols

► This triangular symbol is used as a bullet point.

These two arrows represent the symbol for an in-

»

struction. This shows that there is something you

must do. The actions required are described step by

step.

{{ These symbols show you the level of a software

menu. In this example, three menu levels are

indicated.

1.3 Units of measurement

Information

In these documents, unless otherwise specied,

all linear measurements (e.g. in tables and illustrations) are given in millimetres.

1.4 Specied performance data

The performance data of the appliance indicated in these

documents (text, tables and diagrams) have been calculated according to standardised measurement conditions.

However, these measurement conditions often do not

completely correspond to the plant-specic conditions applicable in the respective user‘s system. System-specic

factors that can affect the conditions include, for example,

the specic design of the system, the age of the system

and the actual ow rates. For this reason, the stated per-

formance data can differ from plant-specic performance

data.

2. Safety

2.1 Intended use

The appliance is intended for use in a domestic environment. It can safely be used by persons who have received

no instruction. The appliance can similarly be used in a

non-domestic environment such as commercial premises,

as long as it is used in the same instructed manner.

Any use of the appliance that is different from or goes

beyond this is not regarded as intended use. “Intended

use” also includes observing this documentation and the

documentation of any accessories used.

Information

Air pressure and air humidity will affect the operational reliability of the electrical components in the

heat pump system (dielectric strength). The location of the heat pump system must be no more than

1000 m above sea level.

2.2 General safety information

Observe the following safety information and instructions

for the appliance.

► Only qualied contractors should carry out the electri-

cal work and installation of this appliance.

► Commissioning and maintenance of the appliance

may be carried out only by OCHSNER Customer Service or by customer service partners authorised by

OCHSNER.

The stated performance data can be conrmed only if

the measurements taken for the appliance are carried out

according to the relevant standardised measurement conditions.

► The authorised contractor is responsible for compli-

ance with all relevant regulations during installation

and commissioning.

► Operate the appliance only when fully installed and

with all safety equipment tted.

► Protect the appliance from dust and dirt ingress dur-

ing building work. Use the plastic cover provided.

► Alterations to the appliance may be carried out only

by OCHSNER Customer Service or by customer service partners authorised by OCHSNER.

► Functions to protect the heat pump can be enabled

using the controller. However, since the controller is

not certied as a safety device, safety measures in

case of breakdown or damage to the heat pump (e.g.

additional external switching of the safety devices in

use) must comply with local regulations. In the case

of upgrades or updates to the controller software,

all function parameters of the heat pump must be

checked.

► Before commencing work on electrical connections

and installation, the heat pump system must be isolated and voltage-free.

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 5

OPERATION | Appliance description

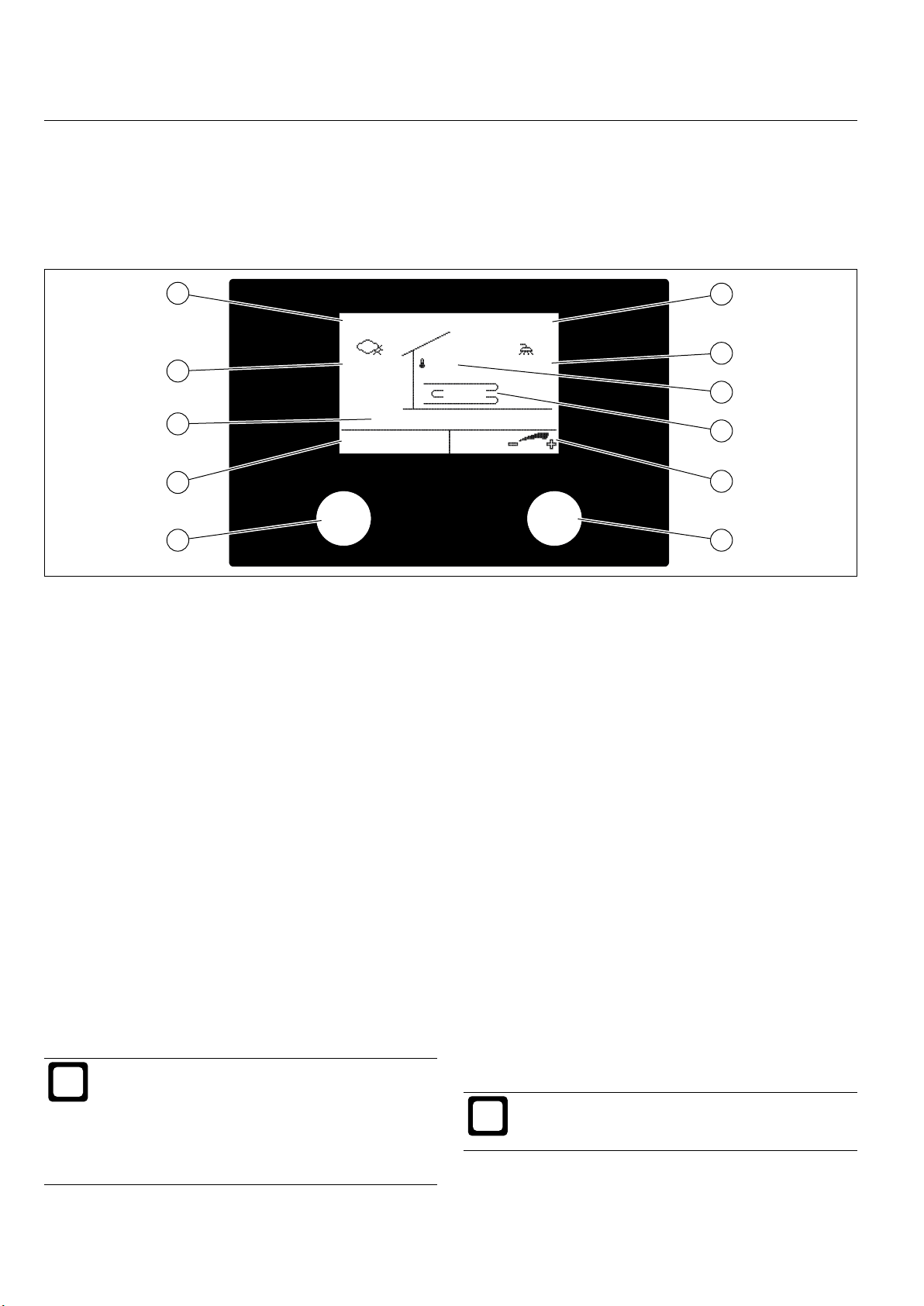

13_03_001

2

4

1

3

6

5

WARNING: Injury

The appliance may be used by children aged 8 and

up and persons with reduced physical, sensory or

mental capabilities or a lack of experience provided

that they are supervised or that they have been

instructed on how to use the appliance safely and

have understood the possible risks. Children must

not be allowed to play with the appliance. Children

must not be allowed to clean or carry out user

maintenance on the appliance without supervision.

3. Appliance description

The appliance is an air/water heat pump consisting of an

indoor unit and an outdoor unit. The appliance can be used

to heat a building and provide domestic hot water (DHW).

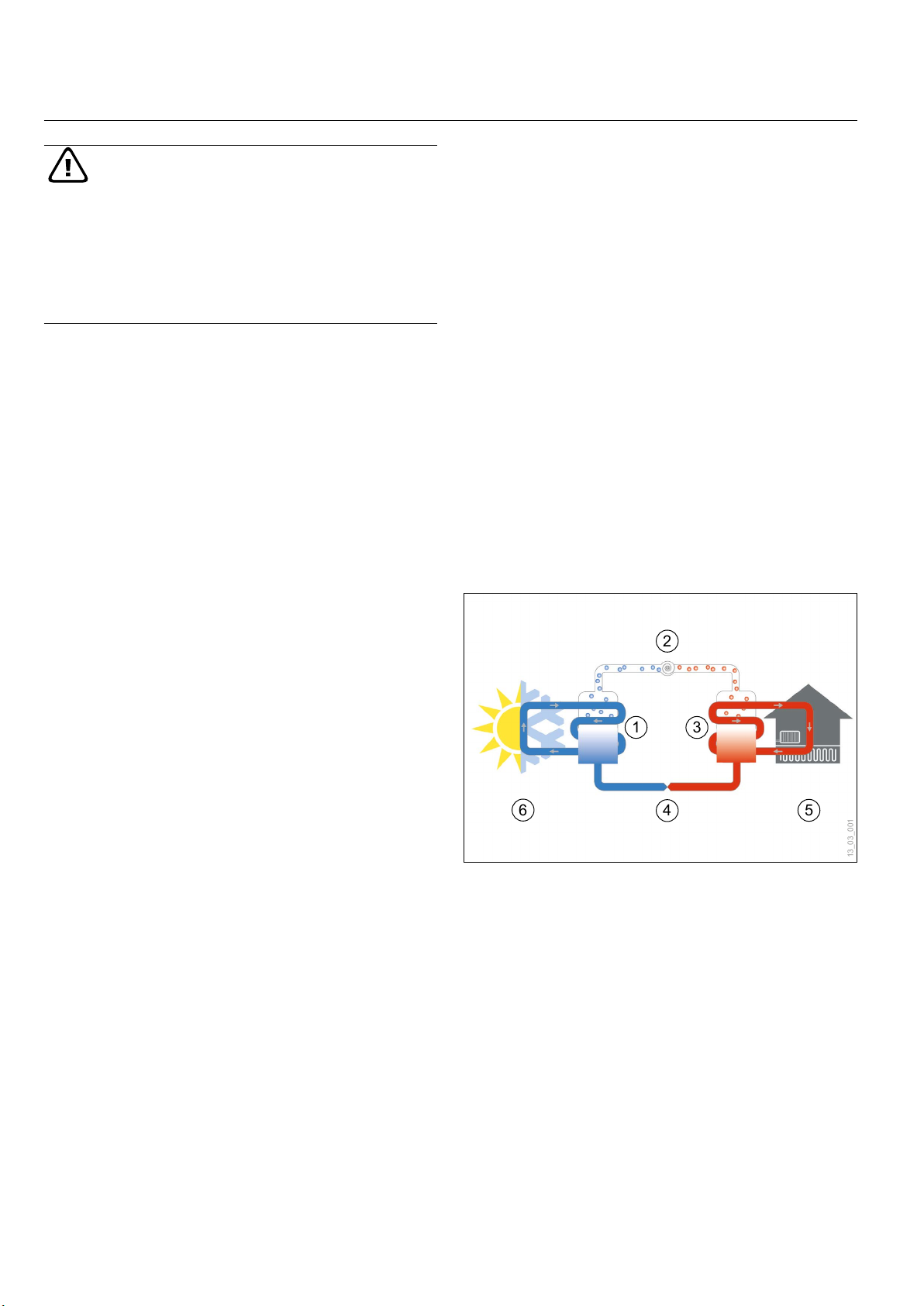

3.1 Functionality

An air/water heat pump extracts thermal energy from the

ambient air (low temperature) and transmits it together with

electrical drive energy in the form of useful heat (higher

temperature) to a heating and/or DHW circuit.

The heat pump consists of separated circuits linked together via heat exchangers:

► Heat source circuit (extracting heat)

► Refrigerant circuit

► Heat sink circuit (supply of heat to the central heating

and/or DHW)

The operating principle of an air/water heat pump:

1 Evaporator (n heat exchanger)

2 Compressor

3 Condenser (plate heat exchanger)

4 Expansion valve

5 Heat sink (heating, DHW)

6 Air as heat source

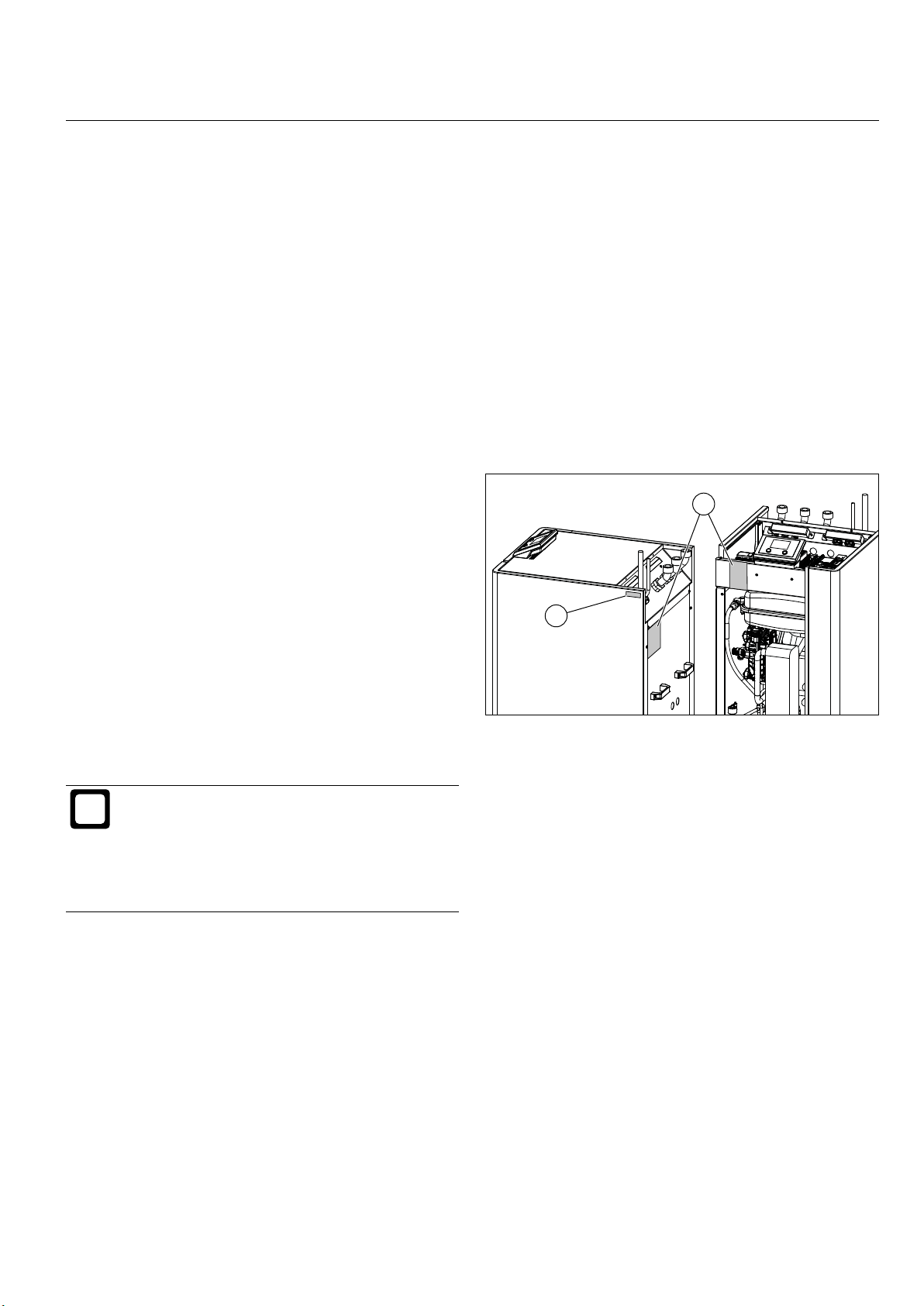

3.2 Appliance components

3.2.1 Indoor unit

6 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

The indoor unit is intended to be installed only inside the

building. The indoor unit contains the compressor, which

in terms of sound technology is acoustically decoupled a

number of times from the casing. The casing is acoustically

optimised and allows particularly quiet operation.

OPERATION | Appliance description

i

11_02_200_214_01_004

Compressor

The fully hermetically sealed compressor is designed for

high efciency heat pump applications. A suitable starting

current limiter for the compressor is installed in the indoor

unit.

Electric booster heater

The appliance is tted with an electric booster heater

(immersion heater). At low outdoor temperatures, the appliance operates in bivalent-parallel mode. The appliance

can also be combined with an additional heat generator.

Condenser

The condenser takes the form of a plate heat exchanger,

which is built of stainless steel and insulated on all sides

against condensation and heat loss.

3.2.2 Outdoor unit

The outdoor unit is intended to be installed outside. The

outdoor unit is designed as a horizontal split evaporator.

The indoor unit is connected to the outdoor unit with refrigerant lines, along with electrical control and power supply

cables.

► 1x direct circuit (heating and/or cooling)

► 1x mixed circuit (heating and/or cooling)

► 1x directly heated DHW cylinder (with electric booster

heater)

► 1x heat pump (heating and cooling)

► 1x additional heat generator (electric booster heater

or enable contact for external heat generator)

3.3 Name plate

Two name plates are attached to the indoor unit to identify

your heat pump. In addition, a label with the serial number

is attached to the right-hand casing panel of the appliance.

1

2

Evaporator

The evaporator is a part of the outdoor unit and consists

of copper pipes in a set of aluminium ns.

Information

With an air/water heat pump, frost may form on

the evaporator ns of the outdoor unit, depending

on the air temperature (below approx. +7°C), air

humidity and the operating point. The evaporator

ns are automatically de-iced again in the cyclical

defrosting mode of the heat pump.

Fan

The outdoor air is blown across the evaporator by a quiet

fan.

3.2.3 Heat pump control unit

The OCHSNER heat pump controller includes devices

for controlling heat pump heating systems with a cooling

function as well as DHW heating. In its standard version,

the heat pump control unit consists of the OTE controller

and the master controller, both of which are installed in

the indoor unit.

1 Name plate (back of indoor unit and front of control

box)

2 Serial number (right-hand casing panel)

The OTE controller can control the following system circuits

and heat generators:

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 7

OPERATION | Activating settings

i

i

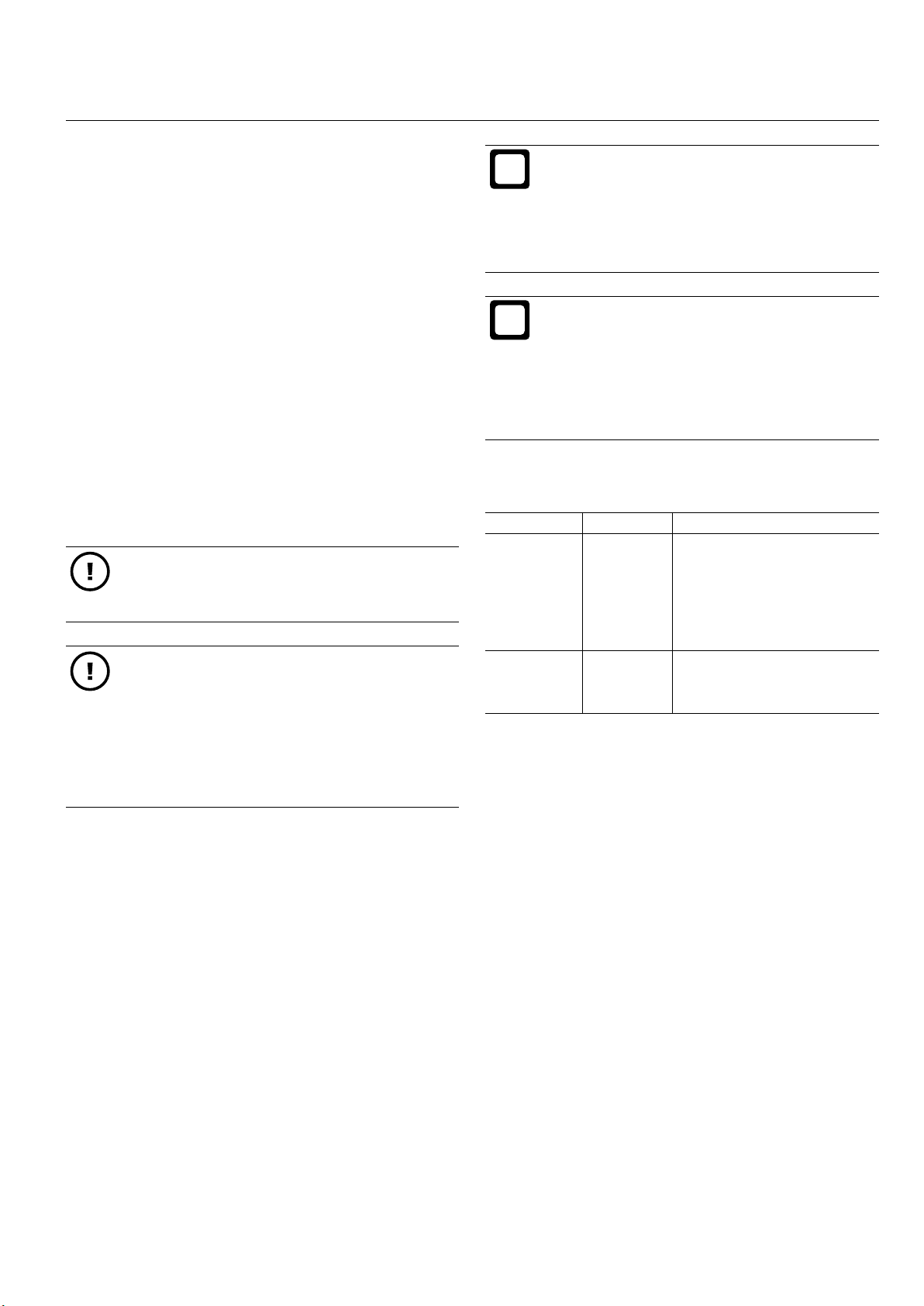

4. Activating settings

Settings are activated with the master controller on the

indoor unit (with graphic display or touchscreen), or via

a remote controller with touchscreen that is attached to

the wall.

5

Mo 09 .01.17 10:02

4

3

2

1 11

1 Button A:

Press to go back one menu step (ESC)

2 Displays function of Button A or fault message

3 Operating status

4 Outdoor temperature

5 Date

6 Time

7 DHW temperature

8 Actual room temperature

9 System temperature

10 Displays function of Button B

11 Button B:

Turn to select from menu or to change setting

Press to conrm (ENTER)

-12.5C 22°C 52.5°C

Heating mode

OCHSNER OTE

The master controller is mounted in an easily accessible

plastic cover on the top of the indoor unit. Two buttons

are provided for controlling the menu, with an illuminated

graphic display.

6

7

32.5°C

MENU

8

9

10

11_01_200_701_01_01_001

Pressing Button B on the right calls up the main menu

with a diagram of the heating system. Each heat consumer (heating circuit, DHW circuit) and each heat generator

(heat pump, electric booster heater, boiler etc.) has its own

menu and corresponding submenus.

Pressing Button A takes you back one step to the previous

menu.

You will nd further information on operating the heat pump

control unit in the control unit‘s operating instructions which

are also supplied with the heat pump.

Information

The heat pump has no separate on/off switch. In

an emergency, the system must be shut down via

the specied safety devices.

Ensure easy access to the safety devices. It

»

must be possible to perform an emergency

shutdown at all times.

8 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

4.1 Operating costs

In the rst two heating seasons, higher running costs are

to be expected (up to 50% more, depending on residual

moisture in the building). Enabling the screed drying program will also increase operating costs further.

4.1.1 Flow temperatures

For optimum operation of your heat pump, you should aim

for the lowest possible heating ow temperatures (and also

DHW temperatures). The maximum system temperature

for your heat pump should be restricted to 60°C.

Information

Increasing the room temperature by 1°C results in

an increase in consumption of 5-7%.

4.1. 2 Ventilation

Any ventilation should be intermittent, especially during

the heating period, and according to your own require-

OPERATION | Maintenance and care

i

i

ments. Intermittent ventilation is considerably more energy

efcient than permanent ventilation, and therefore saves

money. Avoid permanent ventilation.

4.1. 3 Heating setback program

From an energy efciency point of view, using a time pro-

gram to reduce the heating ow temperature is especially

not recommended for air/water heat pumps with low tem-

perature heating systems (such as underoor heating).

These systems are slow to respond and, due to the addi-

tional output from the system required following the end

of the setback phase, it is possible that the second heat

generator (boiler, electric immersion heater) will cut in. This

can lead to higher operating costs.

5. Maintenance and care

We recommend an annual inspection and if necessary

have your heat pump serviced by OCHSNER Customer

Service.

Material damage

Maintenance work on electrical components of the

heat pump may be carried out only by qualied

contractors.

Material damage

Abrasive tools must not be used to clean the evap-

orator ns in the outdoor unit.

Any dirt on the ns should be blown away

»

using compressed air (max. 8 bar), in the di-

rection of normal air ow.

If the ns are very dirty, contact your OCHS-

»

NER system partner or OCHSNER Customer

Service.

If it is necessary to clean the casing sections of the

»

indoor or outdoor unit, use only a damp cloth (with

water or a weak soapy solution). Do not use any abrasive or aggressive cleaning materials.

During the building phase, protect the indoor and

»

outdoor units from dirt and dust with a suitable cover.

Use the plastic cover provided.

Ensure that the heating circuit is lled with sufcient

»

water.

Ensure that any condensation beneath the outdoor

»

unit can drain away without freezing all year round.

Information

If the outdoor unit is covered with a thick layer of

snow, this can reduce system efciency.

Remove snow on and around the outdoor unit

»

as necessary.

If required, install the snow cover available as

»

an accessory for the outdoor unit.

Information

Ensure that the refrigerant circuit of your heat pump

is tested for leaks once a year (in acc. with Regulation (EU) no. 517/2014).

Ensure year-round access to soldered joints in

»

the refrigerant circuit.

Document the results of the leakage test in the

»

system test report.

6. Problem solving

Problem Cause Solution

Too little DHW

is available

or the central heating

system is too

cold.

The appliance

is leaking

water.

If you have a problem that you cannot resolve, contact

the system installer, a qualied contractor or OCHSNER

Customer Service.

Faults are displayed as”Er XXX”on the master controller of

the OTE control unit. If a fault occurs, contact your system

installer. The system installer knows your hydraulic system

and how it operates. The causes of faults can often be

found in the settings or in the hydraulics.

Before contacting the installer, make a note of the serial

number and the heat pump model. The serial number and

heat pump model of your appliance are shown on the name

plate. The name plates are attached to the back of the

appliance on the outside and behind the front appliance

casing panel (control box outer side).

► Customer service hotline for Austria:

Tel: +43 (0) 504245 - 499

Email: kundendienst@ochsner.at

The power

supply to the

appliance has

been cut off

The drain

for the safety valve is

blocked.

Check the safety device on the

main distributor board for your

house. Switch the safety device

back on. If the safety device triggers again after being switched

back on, contact a qualified contractor or OCHSNER Customer

Service.

Clean the safety valve drain. See

„Safety valve drain“ on page 32.

Ensure that the outdoor unit (both the top and the un-

»

derside) is kept free from snow, leaves and twigs and

other foreign bodies.

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 9

► Customer service hotline for Germany:

Tel: +49 (0) 69 256694 - 495

Email: kundendienst@ochsner.de

► Customer service hotline for Switzerland:

Tel: +41 (0) 800 100 - 911

Email: kundendienst@ochsner.com

INSTALLATION | Safety

i

INSTALL ATION

7. Safety

Only a qualied contractor should carry out installation,

commissioning, maintenance and repair of the appliance.

7.1 General safety information

We guarantee trouble-free function and operational reliability only if the original accessories and spare parts intended

for the appliance are used.

7. 2 Regulations, codes and standards

Information

Observe all applicable national and regional regulations and instructions.

8. Appliance description

8.1 Standard delivery

The standard delivery of your appliance includes the following components.

► 1x indoor unit:

The following components are installed in the indoor

unit:

AIR 7

AIR 11

AIR 18

Hydraulic variant M2-1 M2-2 M2-3 M2-4 M4-1 M4-2 M4-3 M4-4

Starting current limiter + + + + + + + +

Flow meter (heat sink

side)

Circulation pump (heat

sink side)

Internal flexible hose + + + + + + + +

Safety valve + + + + + + + +

Master control unit + + + + + + + +

OTE heat pump con-

troller

Diaphragm expansion

vessel 24 l

3-way switching mod-

ule (DHW)

Electric booster heater

8.8 kW

+ + + + + + + +

+ + + + + + + +

+ + + + + + + +

+ + + + - - - -

+ + - - + + - -

+ - + - + - + -

AIR 23

AIR 29

AIR 41

► 1x outdoor unit:

Evaporator, expansion valve, fan

► 3x connection pipes (45°):

For vertical or horizontal connection to the heating

system.

► 1x outdoor temperature sensor (TA)

► 1x contact sensor for a mixed circuit (TMK)

► 2x pocket sensors for a heat pump buffer tank

(TPO, TPM)

► 1x pocket sensor for a DHW cylinder (TB)

► 1xfoundationxingkitfortheoutdoorunit

10 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

INSTALL ATION | Appliance description

11_02_200_202_01_019

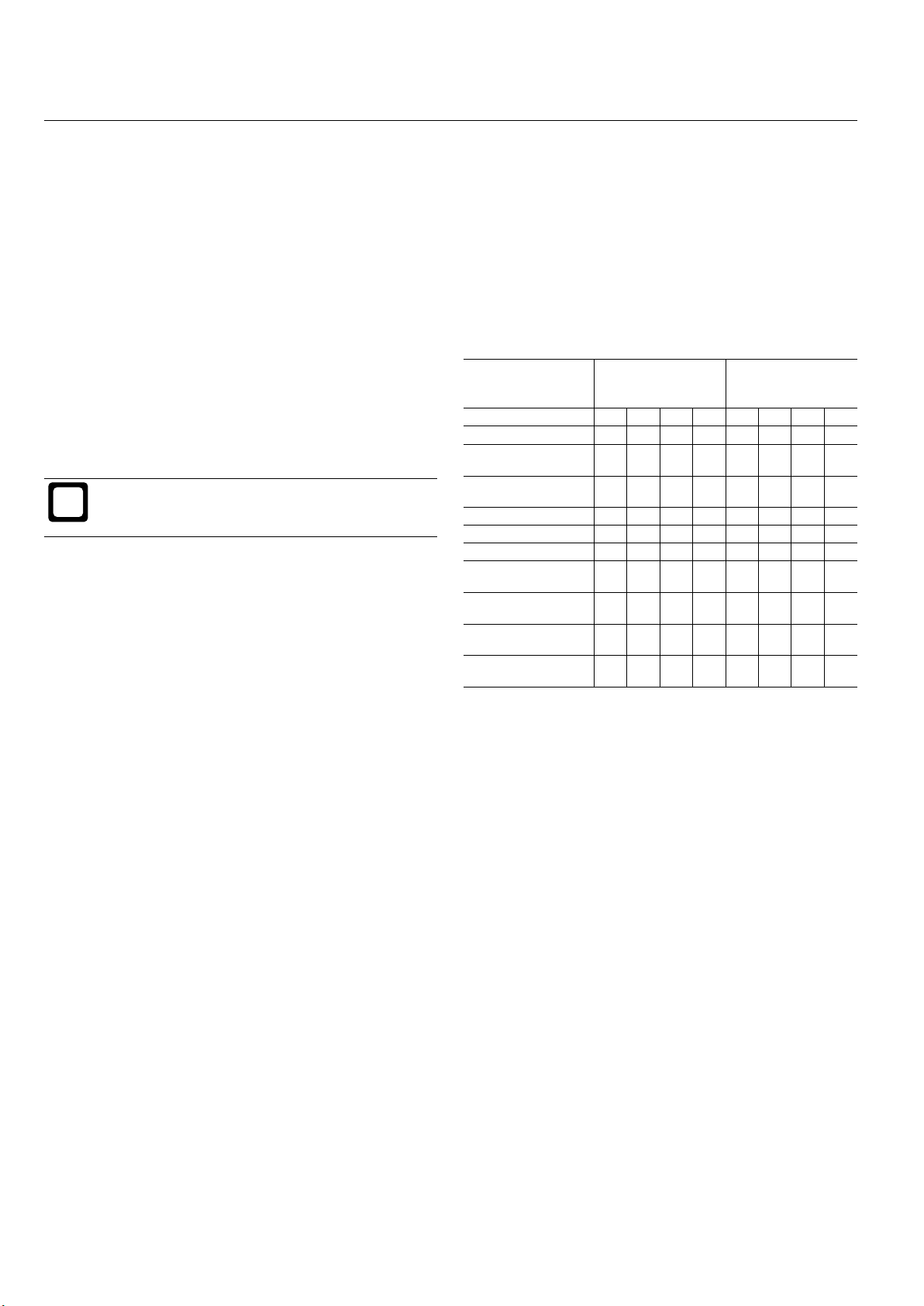

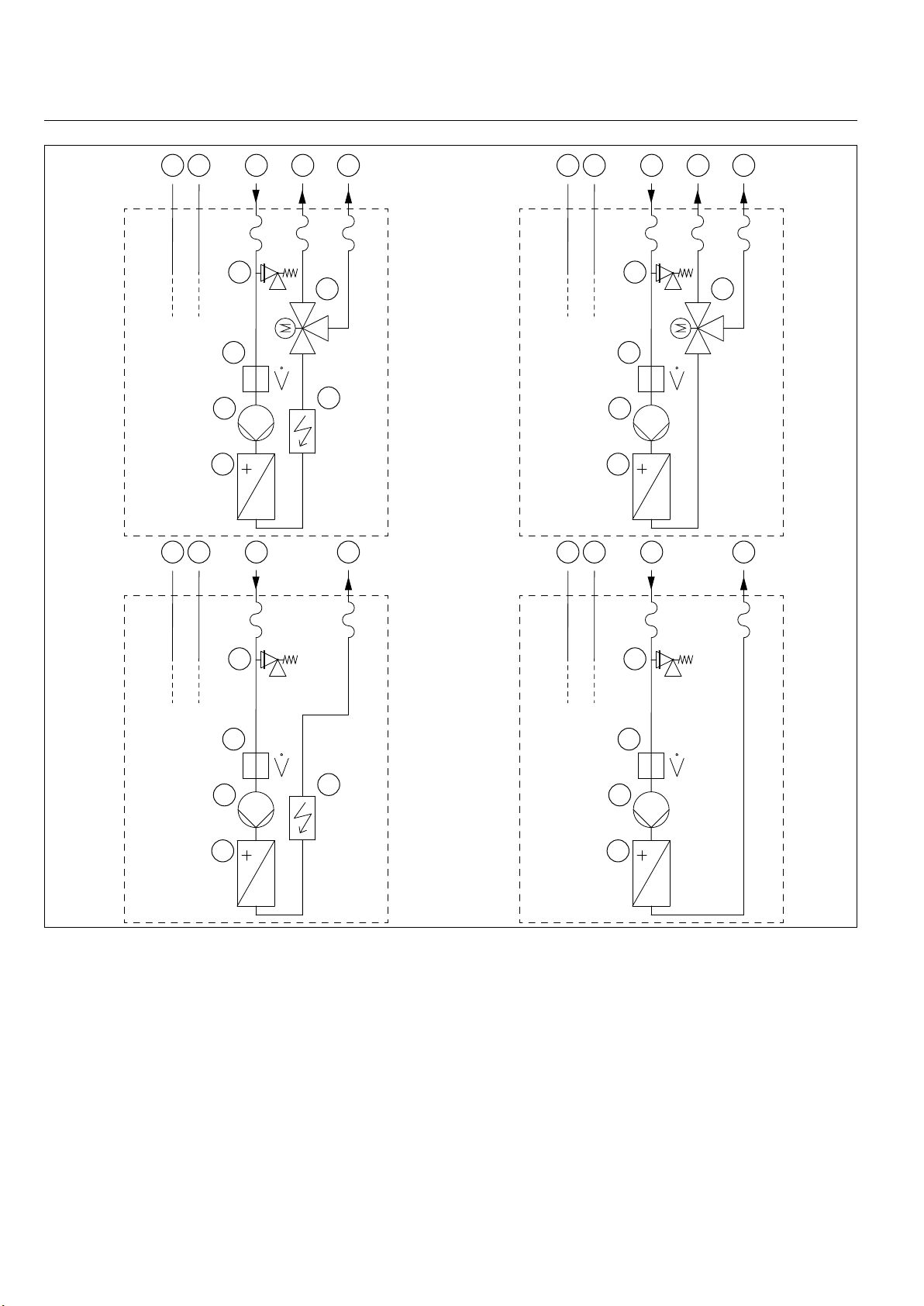

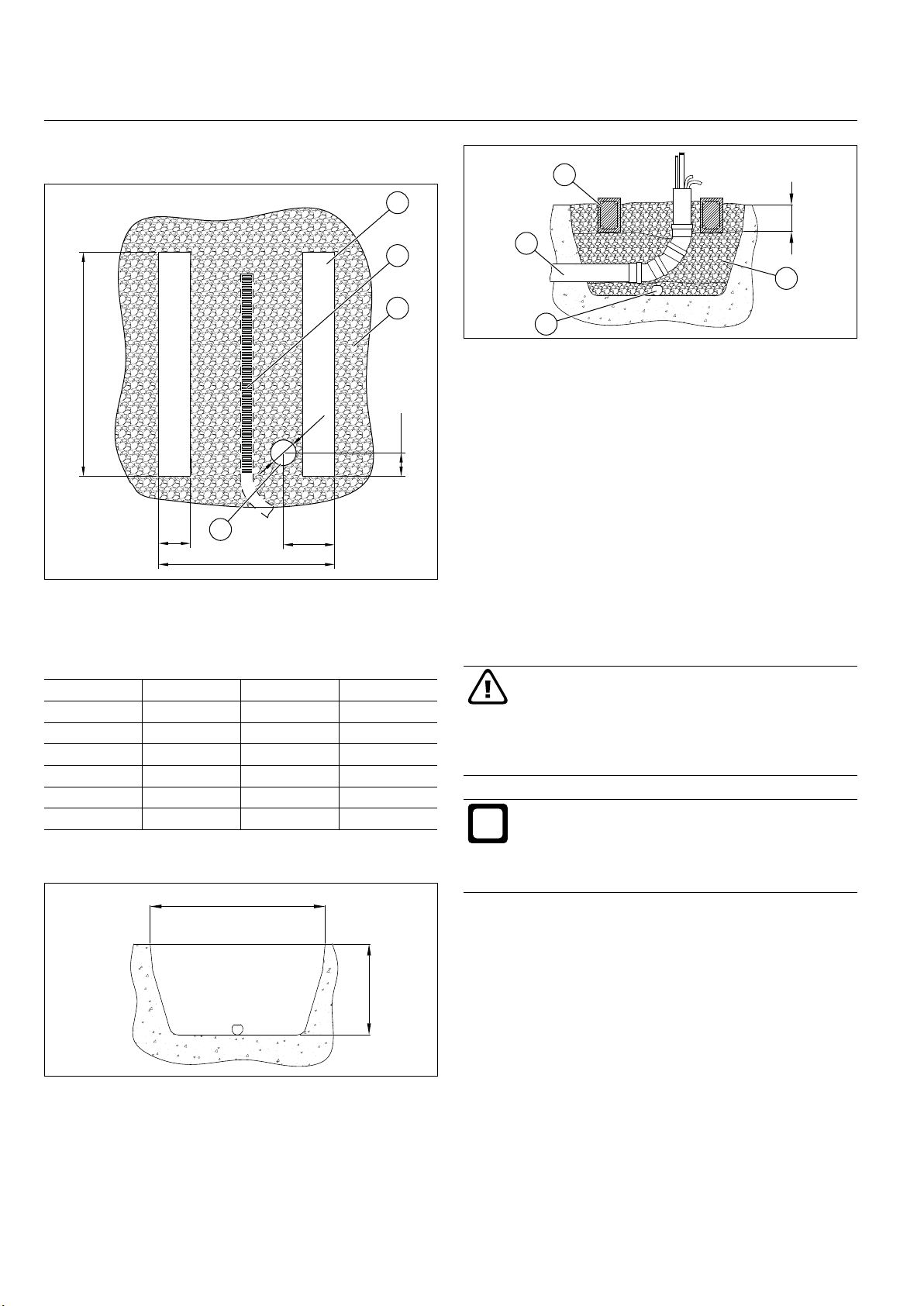

8.2 Hydraulic variants of the indoor unit

The indoor unit is available in eight different hydraulic

variants that are illustrated schematically below. Possible

system congurations for the hydraulic versions of the indoor unit are illustrated in „System schematic diagrams“

on page 68.

M2-3

43 521

43 521

M2-2M2-1

7

8

9

6

12

3 521

10

11

7

8

9

6

12

3 521

10

M2-4

7

6

12

1 Suction gas line

2 Liquid line

3 Heating water/DHW return

4 DHW ow

5 Heating water ow

6 Heat generator pump

7 Diaphragm expansion vessel

8 3-way switching module

9 Flow meter

10 Safety valve

11 Electric booster heater

12 Heat exchanger (heat sink side)

11

7

9

6

10

12

9

10

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 11

INSTALLATION | Appliance description

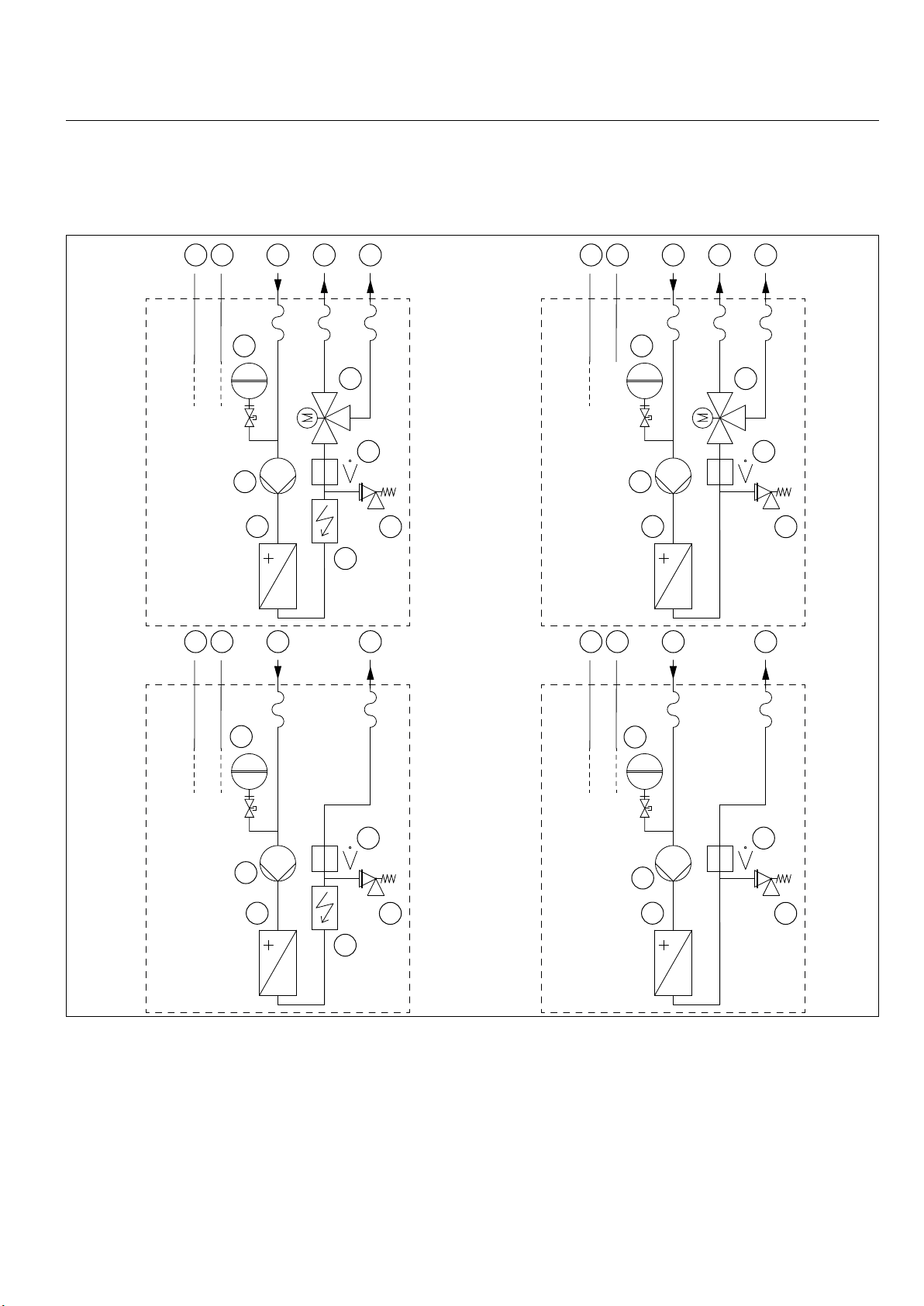

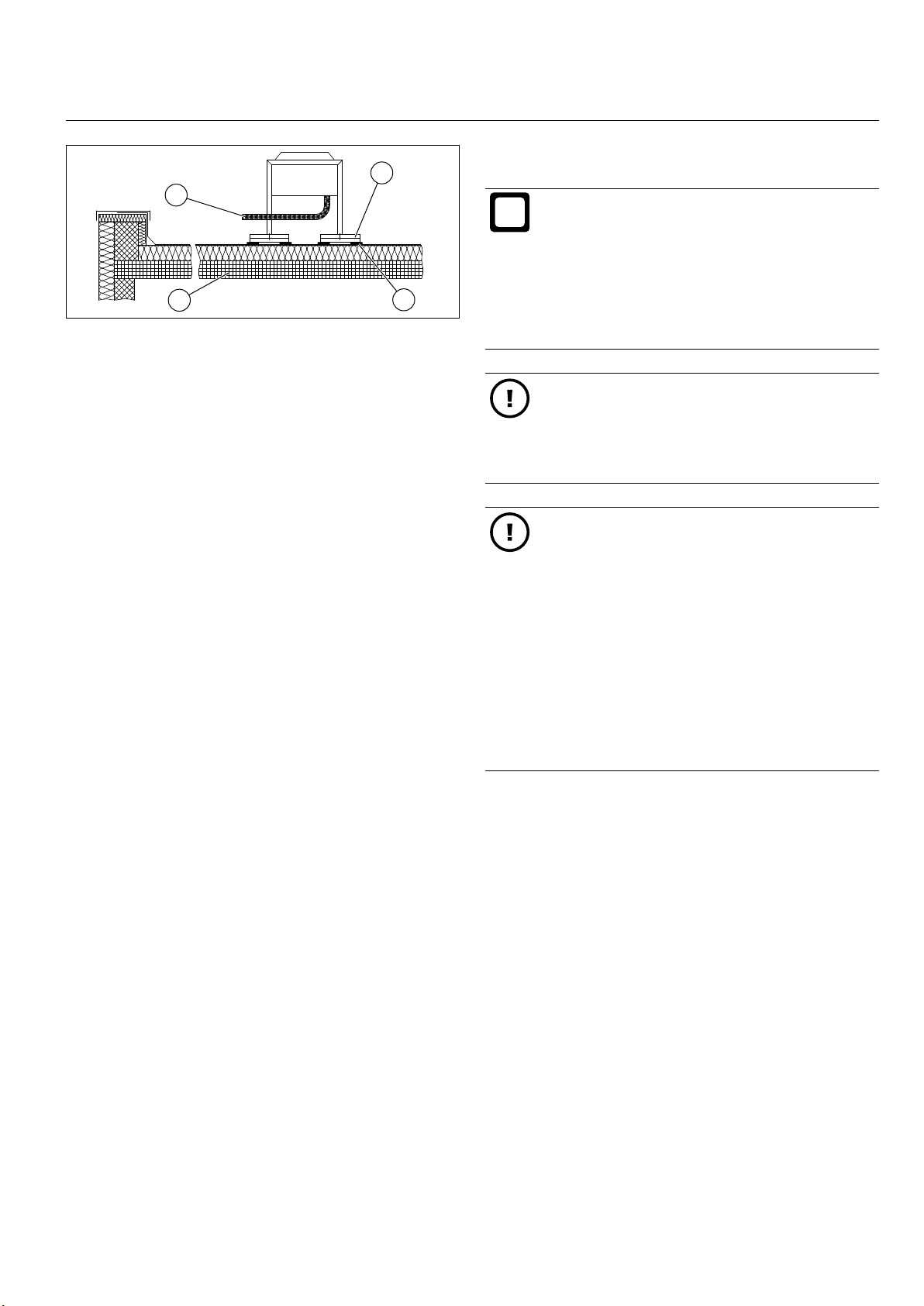

43 521

43 521

M4-2M4-1

6

7

8

9

10

11

21

3 5

6

7

8

9

11

3 521

M4-4M4-3

6

8

9

11

1 Suction gas line

2 Liquid line

3 Heating water/DHW return

4 DHW ow

5 Heating water ow

6 Safety valve

7 3-way switching module

8 Flow meter

9 Heat generator pump

10 Electric booster heater

11 Heat exchanger (heat sink side)

10

6

8

9

11

11_02_200_202_01_020

12 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

INSTALL ATION | Preparing to install the appliance

i

11_05_200_214_01_001

i

i

9. Preparing to install the appliance

Before installing the indoor and outdoor units, preparatory

work needs to be carried out by qualied contractors.

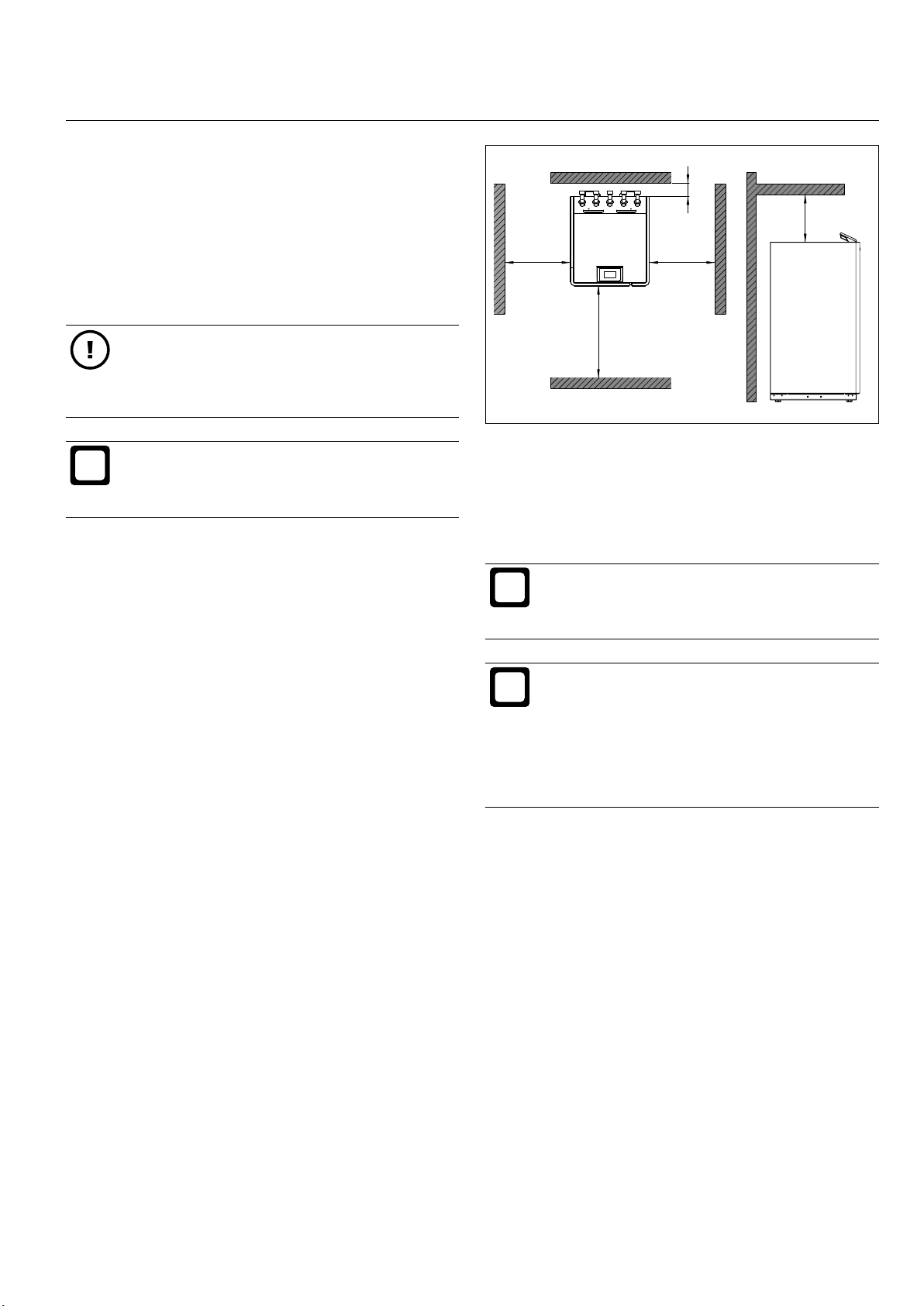

9.1 Indoor unit installation location

Material damage

The indoor unit is intended to be installed only inside the building. It must not be installed in rooms

with high levels of humidity (permanently above

70%).

Information

Plan the installation sites for the outdoor and indoor

units such that the pipework carrying the refrigerant is as short, straight and simple as possible.

B

A ≥ 1000 mm

B ≥ 500 mm

C ≥ 500 mm

D ≥ 50 mm

E ≥ 500 mm

D

E

C

A

The installation location for the indoor unit must meet the

following requirements:

► A dry and frost-free room

► Sound optimised environment

► A horizontal, adequate load bearing oor (for weight

of indoor unit, see „Specication“ on page 50)

► Not situated directly below or above bedrooms

► Max. room temperature 30°C

► The installation room must not be subject to a risk of

explosions arising from dust, gases or vapours.

9.1.1 Keep minimum clearances

Observing the specied minimum clearances for the indoor

unit ensures:

► Correct installation of the appliance

► Fault-free operation

► Ability to carry out maintenance on the appliance.

9.2 Outdoor unit installation location

Information

Plan the installation sites for the outdoor and indoor

units such that the pipework carrying the refrigerant is as short, straight and simple as possible.

Information

When laying refrigerant lines in the ground, schedule the work so that the pipe liner can be laid

together with the already inserted refrigerant lines

in the trench between the outdoor and indoor units.

- If the pipe liner is laid empty, inserting the re-

frigerant lines afterwards will be difcult if not

impossible.

The outdoor unit is intended to be installed only out of

doors. Please note the following with regard to the installation location of the outdoor unit:

► Select the outdoor unit installation location such that

the appliance is safely accessible from all sides all

year round.

► Avoid installing it in a hollow or ditch (a “pool” of cold

air).

► An optional snow cover is available to protect the

outdoor unit fan in case of heavy snowfall. Where

necessary, ensure that a snow cover is installed

(according to installation site and local weather

conditions).

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 13

INSTALLATION | Preparing to install the appliance

i

i

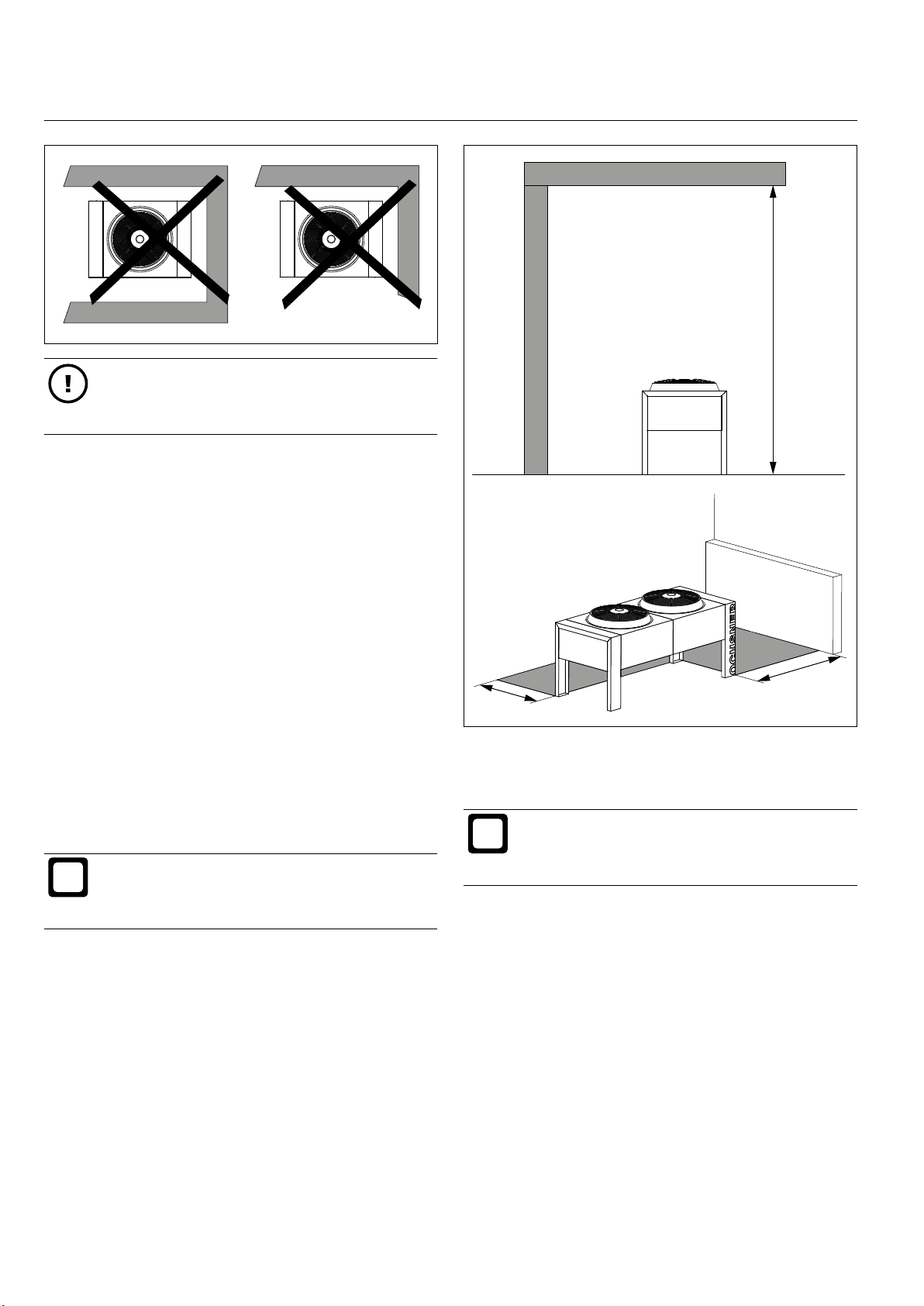

Material damage

The air ow through the evaporator must not be

obstructed by surrounding buildings. A reduced air

ow rate can lead to loss of efciency in the system.

Please note the following with regard to installation in

coastal areas:

► The standard design of outdoor unit must be installed

at least 1 km from the sea.

► Outdoor units with special coating, suitable for coast-

al locations, must be installed at least 200 m from the

sea.

► The installation location selected should always be on

the leeward side of the building (the side facing away

from the sea).

Please note the following with regard to sound emissions

from the outdoor unit:

► Avoid installing on reverberant ooring.

► Avoid installing between building walls. The walls can

increase the noise level.

► Avoid installing next to bedrooms.

Information

Plants and cultivated areas around the outdoor

unit, subject to minimum clearances, can reduce

the noise level of the outdoor unit.

11_05_200_504_002

C

A ≥ 3000 mm (minimum clearance to roof)

B ≥ 1000 mm (minimum clearance to a wall)

C 100 mm or ≥ 1000 mm (minimum longitudinal clear-

ance to a wall)

Information

The minimum clearance between two outdoor

units (e.g. connected in cascade) is 1000 mm on

all sides.

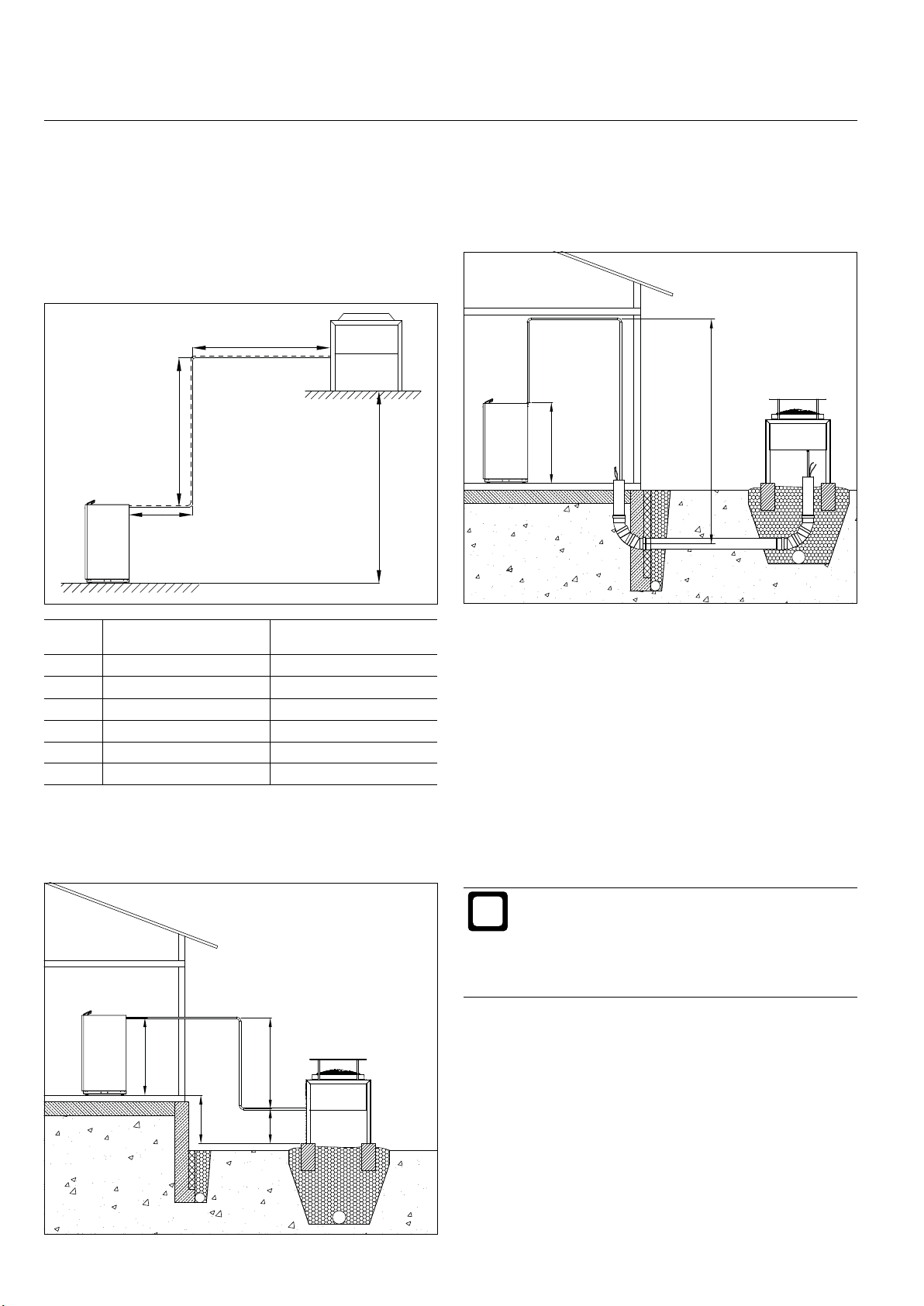

9.3 Foundations for the outdoor unit

A

B

11_05_200_504_001

9.2.1 Keep minimum clearances

Observing the specied minimum clearances for the outdoor unit ensures:

► Correct installation of the appliance

► Fault-free operation

► Ability to carry out maintenance on the appliance.

It is permissible to install the outdoor unit under a roof if the

space around the unit is permanently open on three sides.

14 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

A permanent foundation is required beneath the outdoor

unit. The foundations must meet the structural require-

ments of the outdoor unit (see Specication).

Provide for frost-free drainage (e.g. a gravel bed con-

»

nected to a drain) for condensation that forms on the

outdoor unit.

Where refrigerant lines are to be laid in the ground,

»

ensure correct positioning of the pipe liner when laying the foundations.

Use underground waste pipes (with a smooth inner

»

surface) for the pipe liner.

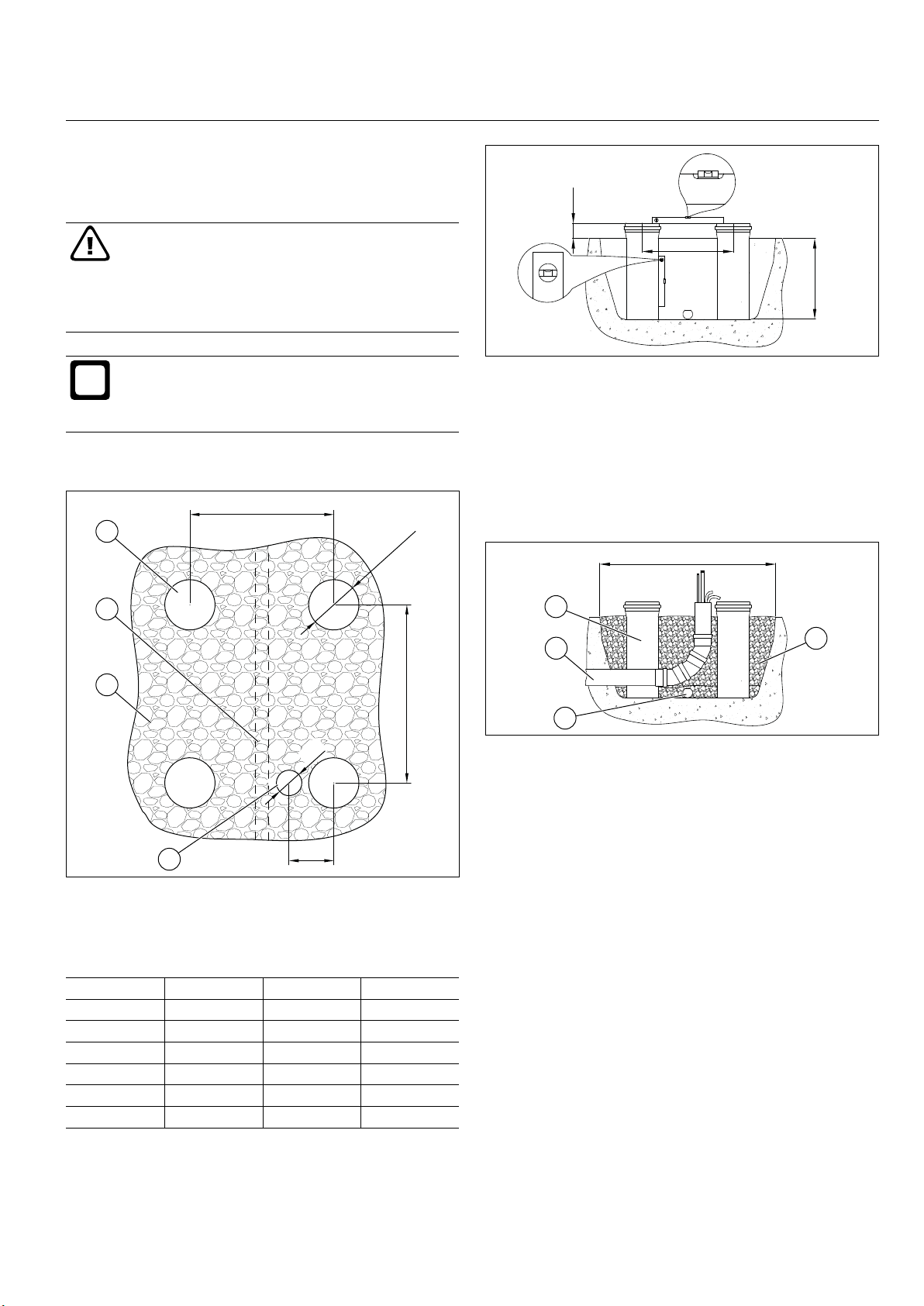

INSTALL ATION | Preparing to install the appliance

i

11_04_200_504_003

11_04_200_504_004

Ensure that the outdoor unit is adequately secured,

»

paying regard to the wind load occurring at the installation location.

CAUTION: Risk of slipping

If drainage for condensation is inadequate, ice can

build up in winter in the area around the outdoor

unit.

Ensure drainage for condensation is sufcient

»

even at low temperatures.

Information

Insulation used beneath the soil must be made of

a closed-cell material. Otherwise, the thermal insulation of the material will be impaired.

100

900

Dig out the foundation trench.

»

Place in position four underground waste pipes

»

(Ø ≥ 250 mm).

≥ 800

9.3.1 Laying spot foundations

900

4

Ø250

3

2

C

1

1 Pipe liner for the connecting lines (where installed

underground)

2 Gravel bed

3 Drainage pipe (frostproof)

4 Spot foundation (with underground waste pipe)

B

A

Ensure correct horizontal and vertical positioning of

»

the underground waste pipes.

Place a drainage pipe along the base of the trench.

»

≥ 1800

1

2

3

1 Underground waste pipe

2 Pipe liner for underground connecting lines

3 Drainage pipe (frostproof)

4 Gravel bed

In the case of underground connecting lines, allow for

»

the pipe liner.

11_04_200_504_001

Fill the foundation trench with coarse gravel. If the

»

pipe liner (with refrigerant lines) is to be installed at

a later point, in the case of underground connection lines, this must be allowed for in the foundation

trench.

4

Fill the underground waste pipes with concrete.

A B C

AIR 7 1110 270 ≥ Ø160

AIR 11 1110 270 ≥ Ø160

AIR 18 1110 270 ≥ Ø160

AIR 23 2040 300 ≥ Ø200

AIR 29 2040 300 ≥ Ø200

AIR 41 2040 330 ≥ Ø250

Use underground waste pipes when installing spot foundations. When installing spot foundations, we recommend

the following approach:

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 15

»

INSTALLATION | Preparing to install the appliance

i

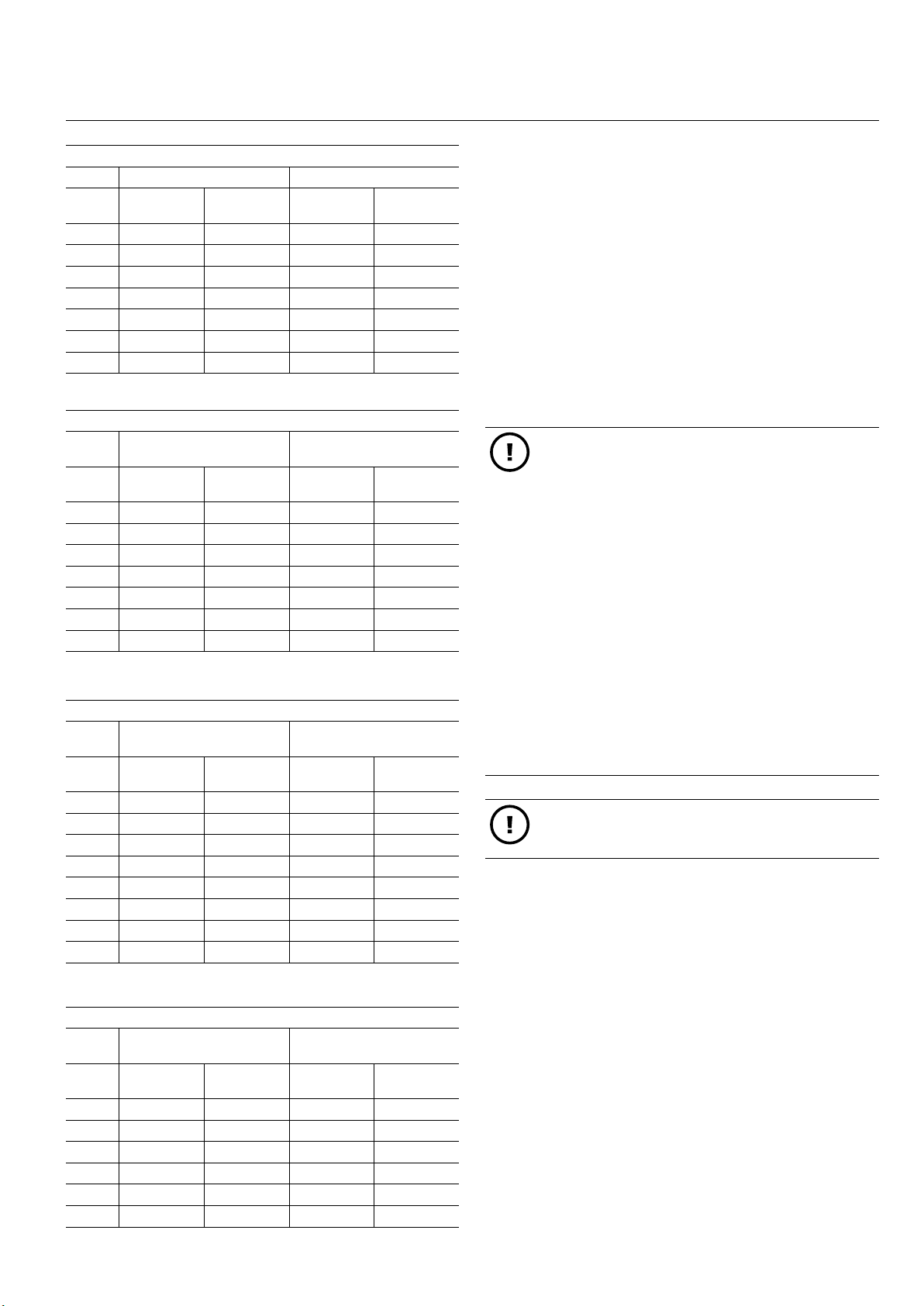

9.3.2 Laying strip foundations

4

3

2

A

C

150

200

1 Pipe liner for the connecting lines (where installed

underground)

2 Gravel bed

3 Drainage pipe (frostproof)

4 Strip foundations

AIR 7 1400 300 ≥ Ø160

AIR 11 1400 300 ≥ Ø160

AIR 18 1400 300 ≥ Ø160

AIR 23 2250 320 ≥ Ø200

AIR 29 2250 320 ≥ Ø200

AIR 41 2250 350 ≥ Ø250

When laying strip foundations we recommend the following

approach:

1

1100

A B C

≥ 1600

B

1

2

3

1 Reinforced strip foundation

2 Pipe liner for underground connecting lines

3 Drainage pipe (frostproof)

4 Gravel bed

In the case of underground connecting lines, allow for

»

the pipe liner.

Fill the foundation trench with coarse gravel. If the

»

pipe liner (with refrigerant lines) is to be installed at

a later point, in the case of underground connection lines, this must be allowed for in the foundation

11_04_200_504_002

trench.

Construct the two reinforced strip foundations.

»

9.3.3 Installing on at roofs

WARNING: Risk of falling

Working on a at roof without fall protection constitutes a risk.

When working on a at roof, observe the laws

»

relating to occupational safety in your region.

Always be aware of the open edge.

»

Information

Avoid installing the outdoor unit on the roof above

residential buildings or on car ports attached to residential buildings, due to the risk of structure-borne

noise transmission.

Loads and stresses on roof structure

≥ 300

4

11_04_200_504_006

Note that when outside temperatures are very low,

»

ice can form beneath the outdoor unit.

≥ 800

11_04_200_504_005

Dig out the foundation trench.

»

Place a drainage pipe along the base of the trench.

»

16 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

In terms of roof structure loads, allow for an ice load

»

of 400 kg/m² in addition to the dead weight of the

outdoor unit.

INSTALL ATION | Preparing to install the appliance

i

3

2

1

1 Flat roof

2 Refrigerant lines in open air (enclosed in thermal in-

sulation with UV protection)

3 2x concrete slabs attached with exible adhesive (per

leg of the outdoor unit). The outdoor unit is afxed to

the concrete slabs

4 Anti-vibration mounts

When installing the outdoor unit on a freestanding car port,

a garage roof or a storage space roof, please note the

following:

Ensure that the outdoor unit is adequately secured,

»

paying regard to the wind load occurring at the installation location.

Take account of the concentrated load arising from

»

the dead weight of the outdoor unit (including the

roof xings) and the surface load caused by possible

build-up of ice.

Ensure suitable structure-borne sound separation be-

»

tween the outdoor unit and the installation points on

the roof.

4

9.4 Preparing the refrigerant lines

Information

If the appliance, the refrigerant lines, the pipe xings and the wall outlets are not installed correctly,

structure-borne sounds can be transmitted to the

building.

Ensure that the refrigerant lines are in-

»

11_06_200_202_006

stalled in a way that ensures insulation from

structure-borne noise. The system installer

carrying out the work is responsible for this.

Material damage

Use only copper pipes suitable for refrigerant

(D IN 12735-1). Thin-walled pipes run the risk of

bursting.

Please observe the stipulated diameters and

»

wall thicknesses of the copper pipes.

Material damage

Incorrect or premature opening of the pipe connections and cutting of the refrigerant lines can allow

dirt and moisture to enter the refrigerant circuit.

Do not open the connections on the indoor

»

or outdoor units until just before installing the

refrigerant lines.

Cut the refrigerant lines with a suitable pipe

»

cutte r.

Prevent swarf from contaminating the pipe

»

connections and refrigerant lines.

Once cut, ll the refrigerant lines with a sub-

»

stance such as nitrogen.

Keep the refrigerant lines closed until just be-

»

fore installation.

Pipe connections for the refrigerant lines (suction gas and

liquid lines) are supplied soldered closed, both for the indoor unit and the outdoor unit. Appropriate copper pipes

for refrigerant lines are supplied sealed at both ends and

lled with nitrogen.

Please note the following with regard to routing of the refrigerant lines:

Keep to a minimum the distance between the indoor

»

and outdoor units, in order to minimise heat loss from

the refrigerant lines.

Select the installation sites for the indoor and outdoor

»

units such that the maximum permissible line lengths

and height differentials are not exceeded.

Avoid routing the lines in the vicinity of bedrooms.

»

The refrigerant in the lines can generate noise under

certain operational conditions.

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 17

INSTALLATION | Preparing to install the appliance

i

9.4.1 Line lengths

Observe the maximum permissible line lengths for

»

the refrigerant lines.

Where the outdoor unit is positioned higher than the

»

indoor unit, observe the maximum permissible height

differential between the two units.

C

B

A

Where a line routed along the ceiling is used in

»

conjunction with an underground connection line,

observe the maximum permissible height differential

between the highest and lowest points of the refrigerant lines.

1223

D

11_06_200_202_001

≤ 3500

11_06_200_202_002

A + B + C

(sum of line lengths)

AIR 7 ≤ 20 m ≤ 10 m

AIR 11 ≤ 20 m ≤ 10 m

AIR 18 ≤ 20 m ≤ 10 m

AIR 23 ≤ 20 m ≤ 10 m

AIR 29 ≤ 20 m ≤ 10 m

AIR 41 ≤ 16 m ≤ 5 m

Where the outdoor unit is positioned lower than the

»

indoor unit, observe the maximum permissible height

differential between the highest and lowest points of

the refrigerant lines.

1180

(max. height differential)

≤ 3500

D

9.4.2 Pipe diameter

The pipe diameter data for refrigerant lines shown below

applies as long as the following are observed:

► A maximum of eight 90° pipe bends

► With pipe diameters of < 35 mm, use a suitable pipe

bending tool to create the pipe bends

► With pipe diameters of ≥ 35 mm, use type 5002 pipe

bends

► Bending radii of ≥ 1 m are treated as straight runs

Information

Refrigerant lines with a pipe diameter of ≥ 35 mm

are created from rigid copper pipes in 5 m lengths.

With underground refrigerant lines, provide an

»

assembly shaft at connection sites to facilitate

soldering and maintenance work.

≤ 2970

18 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

650

11_06_200_202_003

INSTALL ATION | Preparing to install the appliance

Pipe diameter of the refrigerant line

Refrigerant line up to 6 m Refrigerant line up to 8 m

Liquid line Suction gas

line

AIR 7 10 18 10 18

AIR 11 12 18 12 18

AIR 18 12 22 12 22

AIR 23 12 22 16 2x22

AIR 29 16 2x22 16 2x22

AIR 41 16 42 16 42

AIR 41 16 4x22 16 4x22

Pipe diameter of the refrigerant line

Refrigerant line up to

10 m

Liquid line Suction gas

line

AIR 7 10 18 10 18

AIR 11 12 22 12 22

AIR 18 12 22 12 2 x18

AIR 23 16 2x22 16 2x22

AIR 29 16 2x22 16 2x22

AIR 41 16 42 16 42

AIR 41 16 4x22 16 4x22

Pipe diameter of the refrigerant line

Refrigerant line up to

14 m

Liquid line Suction gas

line

AIR 7 10 18 10 18

AIR 11 12 22 12 22

AIR 18 12 2 x18 12 2x22

AIR 23 16 2x22 16 2x22

AIR 29 16 2x22 16 35

AIR 29 16 2x22 16 3x22

AIR 41 16 42 16 42

AIR 41 16 4x22 16 4x22

Liquid line Suction gas

line

Refrigerant line up to

12 m

Liquid line Suction gas

line

Refrigerant line up to

16 m

Liquid line Suction gas

line

9.4.3 Preparing the wall outlets

Whether the refrigerant lines between the indoor and

outdoor units are to be routed above or below ground, ap-

propriate and plant-specic wall outlets need to be created

through the outer wall of the building.

Ensure that the wall outlets are constructed in an ap-

»

propriate, plant-specic manner.

Take the construction of the wall (tiles, concrete) into

»

account.

Take the prevailing groundwater situation into

»

account.

Material damage

Incorrectly created wall outlets can cause signicant damage to property, due to water (seepage,

condensation, floodwater) penetrating into the

building or stonework. Where the wall outlets are

created below ground level, the breach must be

appropriate to local conditions at the site (e.g.

non-accumulating or accumulating seepage water,

groundwater under pressure).

Use a suitable pipe liner or wall sleeve for the

»

wall outlet.

Tie the external end of the wall outlet in to the

»

external waterproof seal of the building.

Ensure that the pipe liner is arranged with a

»

slight fall (at least 2%) to the outside.

On both the outside and inside edge of the

»

wall, use appropriate ring seals to seal the

space between the wall sleeve and the refrigerant lines and electrical cables passing

through.

Material damage

PU foam is not suitable as a sealant for the pipe

li ner.

Pipe diameter of the refrigerant line

Refrigerant line up to

18 m

Liquid line Suction gas

line

AIR 7 10 18 10 18

AIR 11 12 22 12 22

AIR 18 12 2x22 12 2x22

AIR 23 16 2x22 16 2x22

AIR 29 16 35 16 35

AIR 29 16 3x22 16 3x22

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 19

Refrigerant line up to

20 m

Liquid line Suction gas

line

INSTALLATION | Preparing to install the appliance

i

i

i

i

9.4.4 Preparing refrigerant lines passing through open

air

3

2

1

6

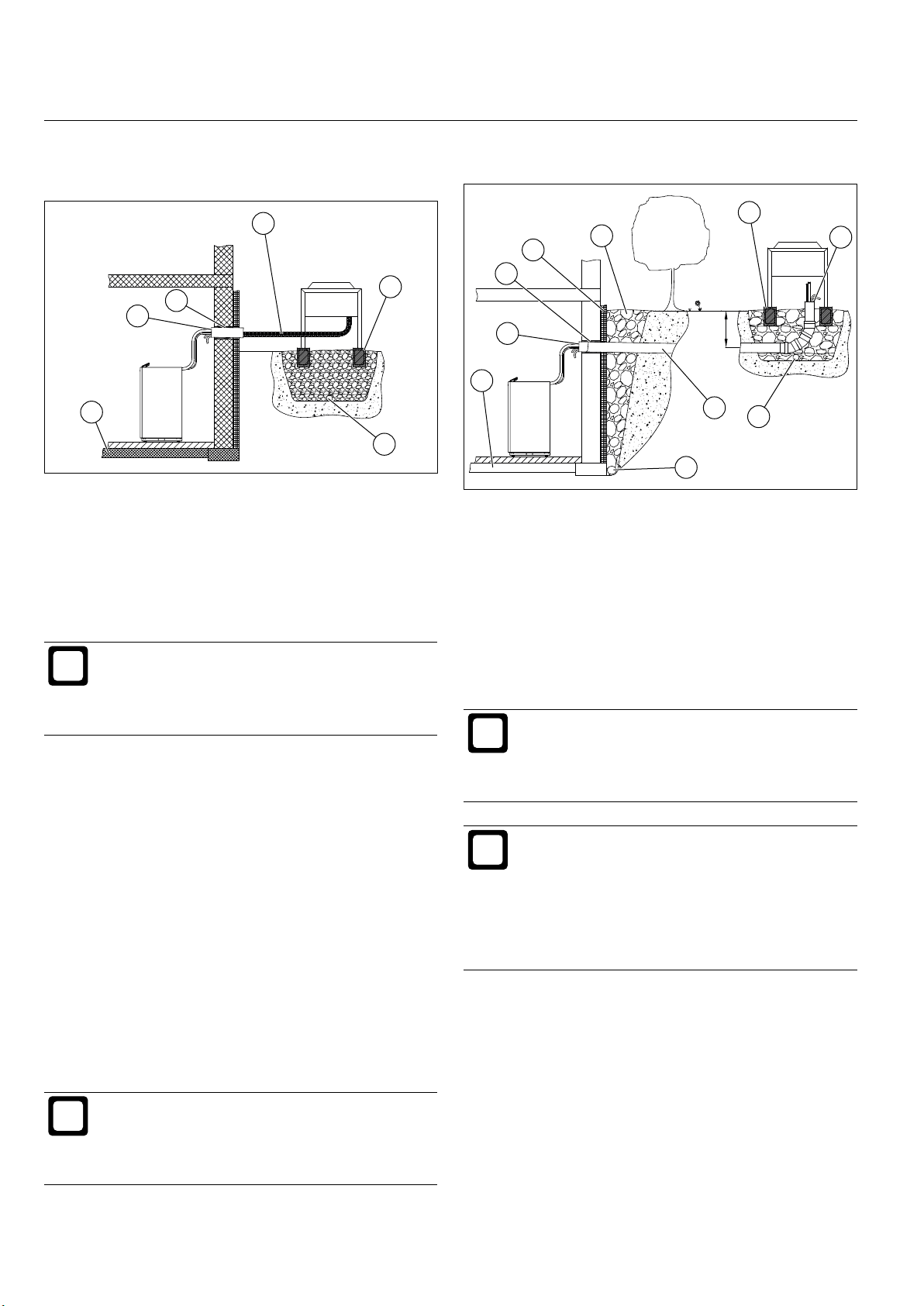

1 Appropriately sealed wall outlet (particularly where

there is a risk of ooding)

2 Appropriate sealing of the refrigerant lines as they

pass through the wall outlet

3 Refrigerant lines in open air (enclosed in thermal in-

sulation with UV protection)

4 Reinforced strip foundation

5 Drainage pipe (frostproof)

6 Foundation

Information

All solder sites on the copper pipework of the refrigerant line must be accessible all year round for

maintenance purposes (in accordance with Regulation (EU) no. 517/2014).

Run the refrigerant lines between the indoor and out-

»

door units.

4

5

9.4.5 Preparing underground refrigerant lines

5

3

2

1

10

11_06_200_202_005

1 Appropriately sealed wall outlet

2 Appropriate sealing of the refrigerant lines as they

pass through the pipe liner

3 Insulation

4 Gravel

5 Reinforced strip foundation

6 Appropriate sealing at the end of the pipe liner (be-

tween refrigerant lines and pipe liner)

7 Drainage pipe (frostproof)

8 Pipe liner (with min. 2% fall to outside)

9 Drain

10 Foundation

Information

All solder sites on the copper pipework of the refrigerant line must be accessible all year round for

maintenance purposes (in accordance with Regulation (EU) no. 517/2014).

4

~ 600

8

7

9

6

11_06_200_202_004

Allow some surplus length in the refrigerant lines

»

between the connections at the indoor and outdoor

units.

Ensure that the wall outlets are sealed in an appropri-

»

ate, plant-specic manner.

Use suitable sound-insulating pipe xings to secure

»

the refrigerant lines.

Insulate the refrigerant lines with suitable insulating

»

material where they pass through open air between

the indoor and outdoor units, to prevent formation

of condensation. When passing through open air

outside, the insulating material must also have UV

protection.

Information

Where the refrigerant lines run horizontally through

open air, use suitable supports. Take steps to prevent open refrigerant lines from being walked or

driven on.

Information

When laying refrigerant lines in the ground, schedule the work so that the pipe liner can be laid

together with the already inserted refrigerant lines

in the trench between the outdoor and indoor units.

- If the pipe liner is laid empty, inserting the re-

frigerant lines afterwards will be difcult if not

impossible.

20 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

INSTALL ATION | Preparing to install the appliance

i

1

Ensure that the wall outlets are appropriate and

»

plant-specic, and that the pipe liner is appropriately

sealed.

Ensure that the open end of the pipe liner at the

»

outdoor unit is properly sealed. For sealing the refrigerant lines in the pipe liner, use for example an

appropriate ring seal or a UV-resistant, permanently

exible sealing compound.

Any exposed refrigerant lines outside the pipe liner

»

must also be protected from a build-up of condensation with appropriate insulating material. Out of doors,

the insulating material must also have UV protection.

Information

Insulation used beneath the soil must be made of

a closed-cell material. Otherwise, the thermal insulation of the material will be impaired.

2

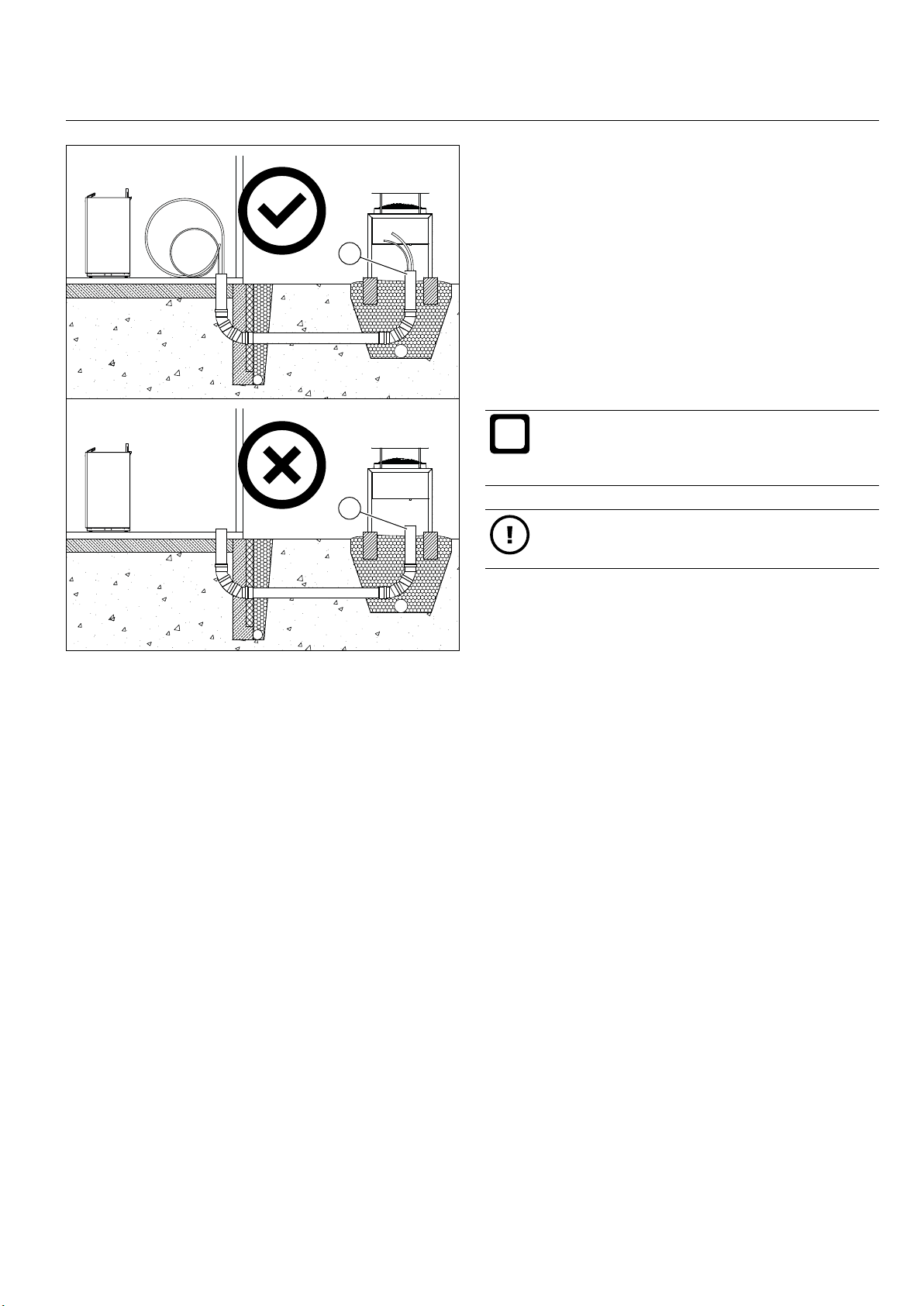

1 Where the pipe liner has two 90° bends, it must be

laid together with the refrigerant lines.

2 If the pipe liner is laid empty, it will not be possible to

insert the refrigerant lines afterwards.

For the underground pipe liner, use rigid waste pipes.

»

Use a pipe liner of a suitable diameter for the sys-

»

tem-specic refrigerant lines and the planned pipe

bends (see „Foundations for the outdoor unit“ on

page 14).

For 90° bends in the pipes, use either 3x 30° bends

»

or 6x 15° bends (depending on the diameter of the

pipe liner and the depth at which it is laid).

At the point where the refrigerant lines are connected

»

to the outdoor unit, create a suitable trench.

11_06_200_202_007

Material damage

PU foam is not suitable as a sealant for the pipe

li ner.

Dig a straight trench between the wall outlet and the

»

trench at the outdoor unit.

Lay the pipe liner, with the refrigerant lines already

»

inserted, into the trench between the outdoor and indoor units.

Lay the electrical control leads and power supply

»

cables in a suitable electrical conduit. The optional

OCHSNER cable harness is suitable for laying direct

into the ground.

Allow some surplus length in the refrigerant lines

»

between the connections at the indoor and outdoor

units.

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 21

INSTALLATION | Preparing to install the appliance

i

i

i

9.5 Preparing the electrical connections

WARNING: Electrocution

All electrical connection and installation work must

be carried out according to the applicable national

and regional regulations.

WARNING: Electrocution

Before commencing work on electrical connections

and installation, the heat pump system must be

isolated and voltage-free.

WARNING: Electrocution

Work on electrical connections and installation may

be conducted only by qualied contractors.

Material damage

This appliance contains frequency converters (e.g.

EC circulation pumps, EC fan motors). Leakage

currents may arise in normal operation. In the event

of faults, these components may cause DC fault

currents. An incorrectly selected RCD may trip during normal operation or, in the event of a fault, may

not trip at all or only trip after a delay.

Make sure that the power supply for this

»

appliance is separate from the domestic installation.

If local conditions require the installation of an

»

RCD, use type B AC/DC-sensitive RCDs.

► For the integral electric booster heater (8.8 kW), a

suitable high limit safety cut-out (HLSC) is installed in

the indoor unit.

Information

The main power circuit for the compressor has

no upstream power contactor on the machine

side. Control devices and equipment to disconnect and shut down all supply voltages across

all poles, which must be provided on the system

side, must meet the technical safety requirements

of EN 60204-1 sections 5 and 13.4.5, as well as the

international regulations in the IEC 60947 series.

Material damage

Protect the main power circuit (compressor), the

control circuit (control unit) and the electric booster

heater separately from one another.

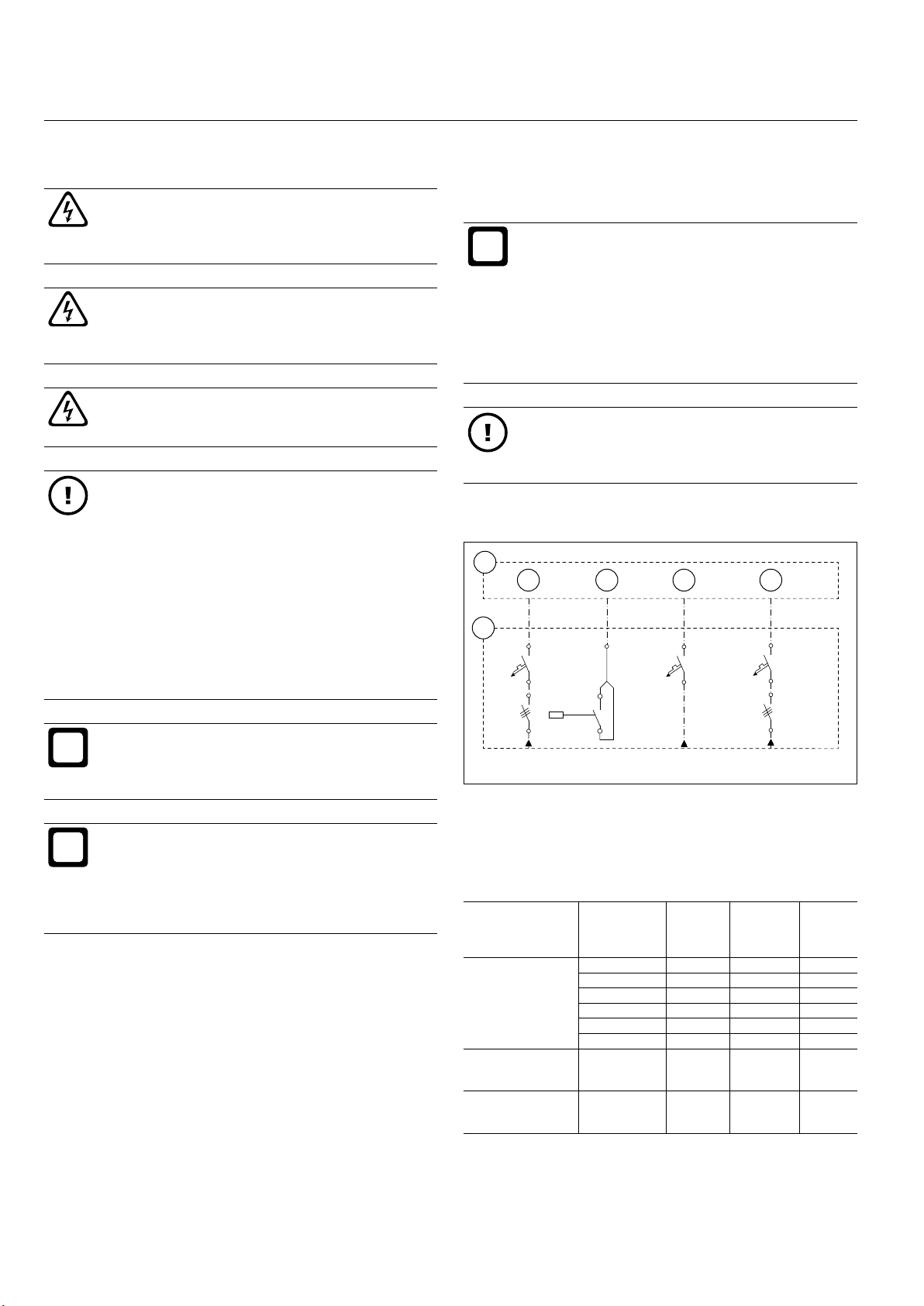

9.5.1 Heat pumps for three-phase alternating current

1

3 4 5 6

2

C13A B16A

Information

It is essential that the regulations of the responsible

power supply utility (PSU) and the applicable EN

standards be observed.

Information

The values specied in this documentation for

circuit protectors and cable cross-sections are

standard values. The contractor carrying out the

work is responsible for plant-specic sizing of safety equipment and cable cross-sections.

► For the electrical connection, use the system principle

schematic appropriate to your heat pump system from

section „System schematic diagrams“ on page 68.

► The outdoor unit takes its power supply from the in-

door unit. The supply cable for the fan in the outdoor

unit is protected by an internal C10A circuit breaker in

the indoor unit.

► In the case of a fault, the protection on the main pow-

er circuit (compressor) and electric booster heater

must break the circuit across all poles.

3 x 400 VAC 1 x 230 VAC 3 x 400 VAC

1 Heat pump indoor unit control box

2 Main system distributor board

3 Supply to main power circuit (compressor)

4 PSU signal contact

5 Supply to control circuit (OTE controller)

6 Supply to electric booster heater

Description Typ e Max.

Main power circuit

(compressor and

fan)

Electric booster

heater

Control circuit

(control unit)

AIR 7 C11A 13.5 5.4 C10A

AIR 11 C 11A 20.0 7.9 C10A

AIR 18 C11A 32.0 11. 4 C16A

AIR 23 C12A 50.5 16.8 C20A

AIR 29 C12A 49.5 21.1 C25A

AIR 41 C12A 63.5 24.8 C25A

AIR 7 C11A

–

AIR 41 C12A

AIR 7 C11A

–

AIR 41 C12A

starting

current

[A]

Max. operating

current

[A]

– 14 B16A

– 6 C13A

11_02_200_202_01_010

Fuse

► All power supply cables must be protected against

surges and short circuits.

22 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

INSTALL ATION | Preparing to install the appliance

i

i

Material damage

Operating a three-phase motor (compressor,

pumps, fans) for long periods using an incorrectly

phased three-phase supply will damage the motor.

Ensure that all three-phase motors are

»

connected to a three-phase supply with a

clockwise rotating eld.

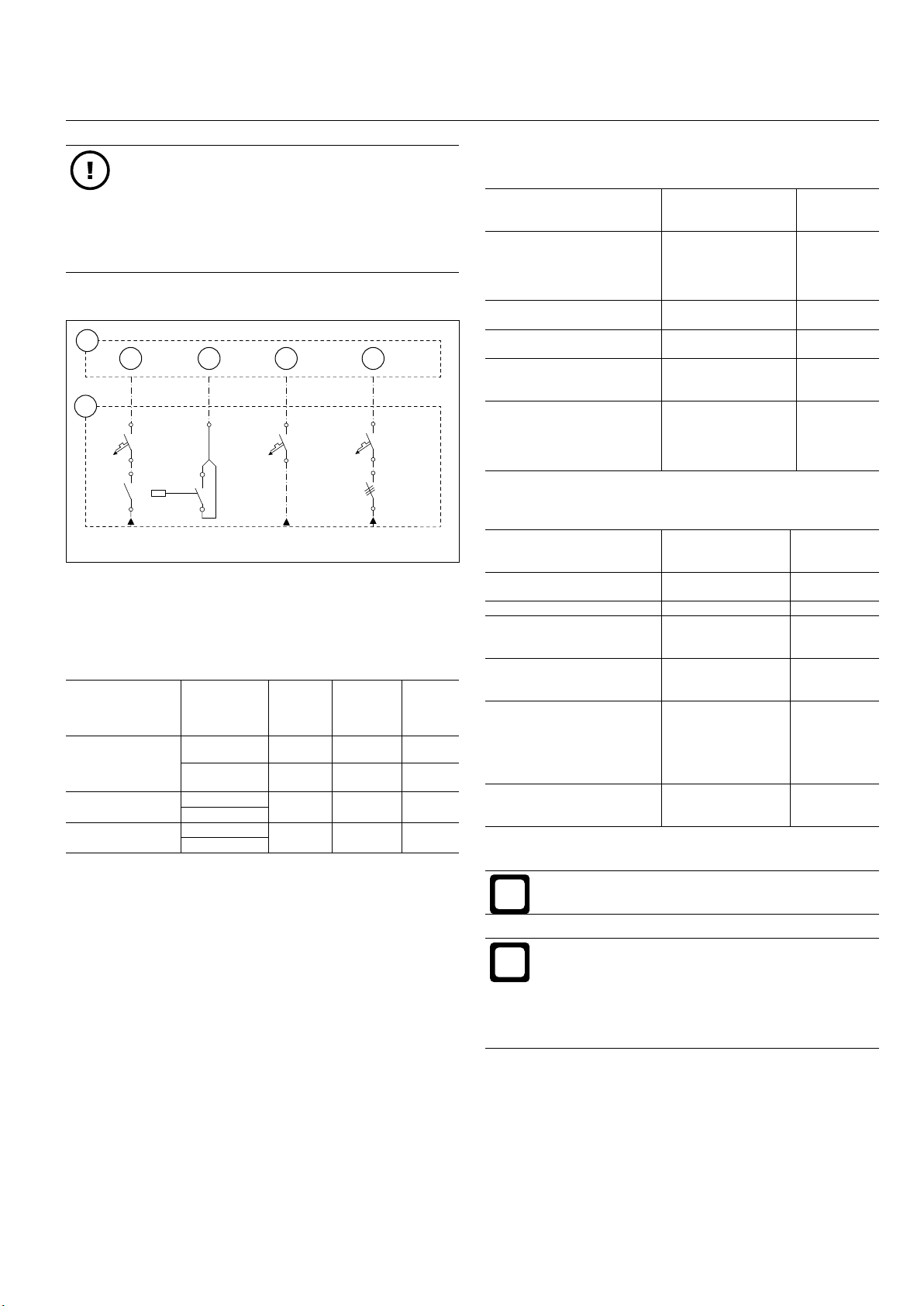

9.5.2 Heat pumps for single phase alternating current

1

3 4 5 6

2

C13A B16A

1 x 230 VAC 1 x 230 VAC 3 x 230 VAC

1 Heat pump indoor unit control box

2 Main system distributor board

3 Supply to main power circuit (compressor)

4 PSU signal contact

5 Supply to control circuit (OTE controller)

6 Supply to electric booster heater

Description Typ e Max.

Main power circuit

(compressor and

fan)

Electric booster

heater

Control circuit

(control unit)

AIR 11 C 11B 48.5 20.8 C25A

AIR 18 C11B 80.0 30.0 C40A

AIR 11 C 11B – 12.8 B16A

AIR 18 C11B

AIR 11 C 11B – 6 C13A

AIR 18 C11B

starting

current

[A]

Max. operating

current

[A]

Fuse

9.5.3 Cables from main distributor to indoor unit

Description Wires Min. cable

Supply to electric booster

heater

(8.8 kW electric immersion

heater)

Control circuit supply 1x 2 30 VAC

Supply to pumps and servomotors

Sensor leads

(system temperature sensors)

Bus leads

(eBus connections from

OTE controller to remote

controllers or auxiliary

modules and in cascades)

3x 400 VAC

(L1/L2/L3/N/PE)

or

3x 230 VAC

(L/L/L/N/PE)

(L/N/PE)

1x 23 0 VAC

(L/N/PE)

2x

(shielding recommended)

Example:

Y(ST)Y 2x2x0.8

(shielded cable design

and twisted cable

pairs)

9.5.4 Cables from indoor to outdoor unit

Description Wires Min. cable

11_02_200_202_01_024

Fan power supply 1x 23 0 VAC

Fan alarm (TK) 2x 230 VAC 1.5 mm²

Fan speed

(0-10 VDC)

Defrost sensor (TQE, TQA) 4x

Pulse lead

(for stepper motor on electronic expansion valve)

Suction gas sensor S2

(for expansion valve controller)

(L/N/PE)

2x

(shielding recommended)

(shielding recommended)

4x

(shielding recommended)

Example:

ÖLFLEX® CLASSIC

100 CY

2x

(shielding recommended)

9.5.5 Temperature sensor

cross-section

2.5 mm²

1.5 mm²

1.0 mm²

1.0 mm²

0.8 mm²

cross-section

1.5 mm²

1 mm²

1 mm²

0.8 mm²

1 mm²

Information

The maximum line length for sensor leads is 50 m.

Information

Sensor leads must be routed separately from 230 V

and 400 V cables. If a minimum distance of 20 cm

cannot be maintained, then shielded cables should

be used. The shielding should be connected to the

earth rail of the heat pump.

Defrost sensors (TQA, TQE):

The two defrost sensors are factory-installed in the evaporator on the outdoor unit.

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 23

INSTALLATION | Preparing to install the appliance

i

i

Outdoor temperature sensor (TA):

nected directly to the OTE controller (1x 230 VAC power

supply).

Fit the outdoor temperature sensor at a height of ap-

»

prox. 2.5 m to the outside wall of the building (on the

north-west side). Make sure that the outdoor temperature sensor is not exposed to direct sunlight or wind,

as this will impair the control characteristics.

Information

Avoid tting the outside temperature sensor to the

casing of the outdoor unit or in the air ow from

the outdoor unit.

Buffer sensor (TPO, TPM):

In heat pump buffer tank, two buffer sensors are required.

The heat pump is switched on on the basis of readings

from the TPO and switched off on the basis of those from

the TPM.

Install a sensor pocket in the female socket provided

»

for the upper buffer sensor (TPO)

Install a sensor pocket in the female socket provided

»

for the lower buffer sensor (TPM)

DHW sensor (TB):

Material damage

A test run of the pumps and servomotors may be

conducted only on a system that has been prepared for commissioning. The hydraulics must be

fully connected.

9.5.7 PSU signal contact

Tariff switching on the heat pump system

In the case of tariff switching (with interrupted power delivery), the heat pump is temporarily shut down by the power

supply utility (PSU).

Uninterrupted tariff

In the case of tariff switching with uninterrupted power

delivery, the heat pump is temporarily shut down by the

power supply utility. A PSU signal contact is provided for

this purpose on the indoor unit. To activate the function,

remove a cable bridge in the control box and connect the

PSU signal contact cable (see „Electrical connection of the

indoor unit“ on page 34).

OCHSNER DHW cylinders are tted with appropriate female sockets for installing the sensor.

Install the DHW sensor in the top one-third of the

»

DHW cylinder (or at the very least in the top half). The

lower the selected position of the DHW sensor, the

larger the switching hysteresis (5-15 K) will need to

be.

Information

Ensure that the DHW sensor is correctly positioned

and extends beyond the cylinder insulation into the

interior of the DHW cylinder. This is the only way in

which the temperature can be captured correctly.

Mixer sensor (TMK):

If, in addition to a direct heating circuit, your system also

has a heating circuit with mixing valve, then a mixer sensor

must be installed. The mixer sensor is supplied with the

heat pump, as a contact sensor including band clamp and

heat conducting paste.

Install the mixer sensor immediately downstream

»

of heating circuit circulation pump 2 for the heating

circuit with mixing valve, on a (metal) pipe made of a

good heat-conducting material.

Shutdown by means of a tariff contactor

In the case of shutdown by means of a tariff contactor installed on behalf of the customer (sealed by the PSU), the

power supply to the heat pump compressor is disconnected. Here, it is essential to connect an auxiliary contact to

the tariff contactor (N/C contact) of the PSU signal contact

on the indoor unit.

Night tariff

Where tariff switching takes place within the meter (night

tariff), the PSU signal contact is not connected.

9.5.8 Smart Grid

For the Smart Grid function, special descriptions are available on request from your OCHSNER Customer Service

department.

9.5.6 Pumps and servomotors (230 VAC)

Pumps (heating circuit pumps, DHW charging pump) and

servomotors (switching module, mixing valve) are con-

24 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

INSTALL ATION | Appliance installation

i

i

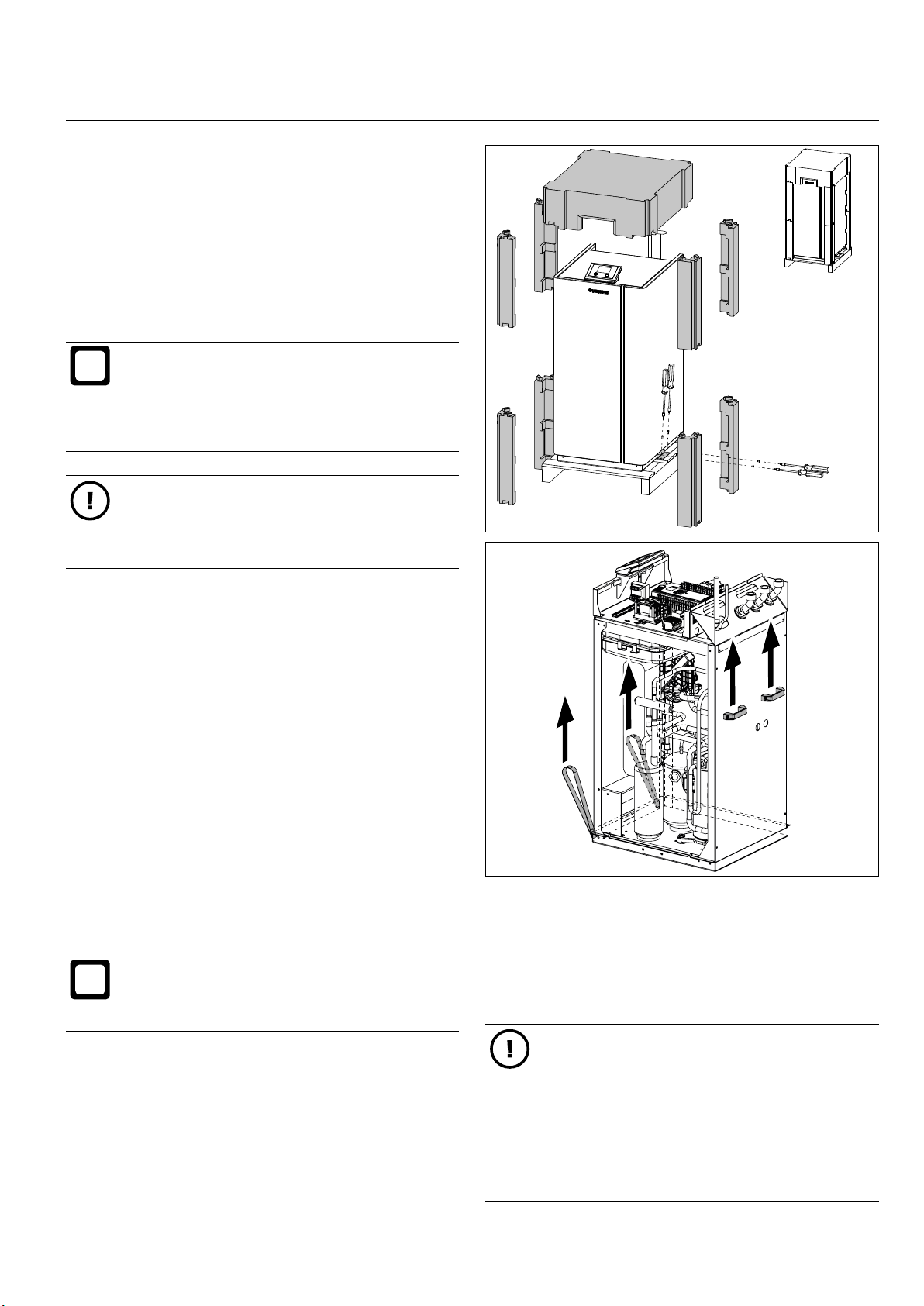

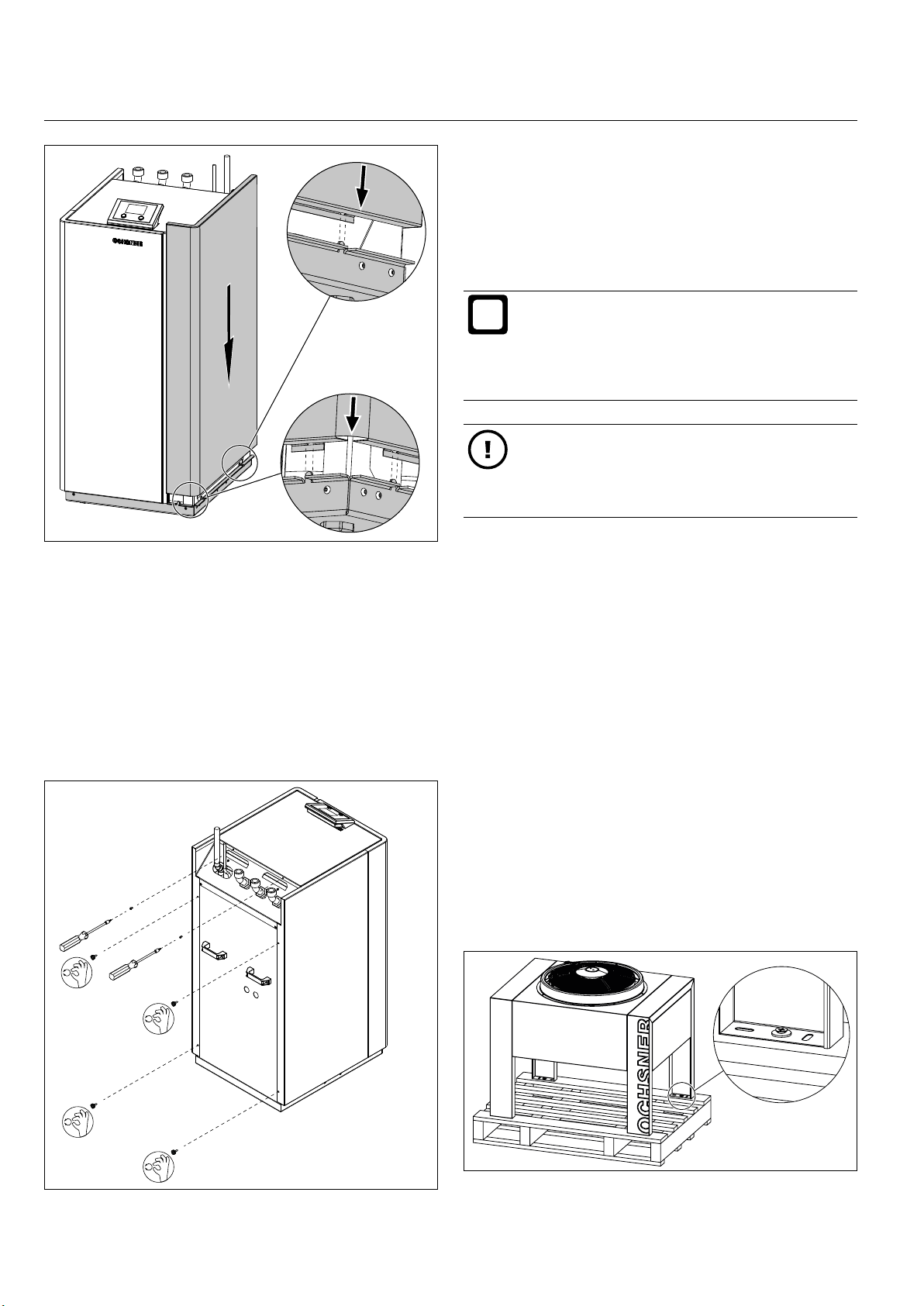

11_02_200_214_01_005

11_02_200_214_01_001

10. Appliance installation

10.1 Installation of indoor unit

10 .1.1 Delivery and transportation

The appliance is delivered on a one-way pallet, wrapped

in lm. The appliance casing is assembled on delivery.

Information

Should you notice any transportation damage to

the appliance, you must report such damaged immediately when the delivery is unloaded. Claims

for transportation damage cannot be made subsequently.

Material damage

Protect the appliance from damage by using

»

transport belts.

When transporting, protect the appliance from

»

impact.

► The appliance is secured to the one-way (recyclable)

pallet of the transport packaging with screws.

► The transport packaging or one-way pallet is suitable

for transportation using a forklift truck.

► For level transportation to the installation location, the

appliance may remain in the transport packaging.

► Leave the appliance in the transport packaging or on

the one-way pallet for lifting and moving by crane or

forklift.

► The standard packaging of the appliance does not

provide protection against the weather or sea water.

► The appliance may be stored and transported only at

temperatures of between -20°C and +45°C.

► The appliance must be stored in its transport

packaging.

Information

If the route to the installation location is difcult,

the transport packaging should be removed and

the appliance casing disassembled.

Please note the following when removing the transport

packaging:

Remove the transport packaging.

»

Undo and remove the eight woodscrews on the two

»

transport xing brackets (left and right) securing the

appliance to the one-way pallet.

Use the pre-installed transport aids (2 lifting slings at

»

the front and 2 lifting handles at the rear) to lift and

transport the appliance.

Transport the appliance in an upright position. Over

»

short distances, you may transport the appliance

carefully at an angle of up to 30°.

Material damage

Note the following points when carrying the appliance with the pre-installed transport aids:

- When lifting and carrying the appliance, make

sure that all 4 transport aids are pulled evenly

and at the same time.

- Ensure that the appliance casing is not damaged during transport.

- The transport aids are not suitable for lifting by

crane.

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 25

INSTALLATION | Appliance installation

i

Material damage

When being transported with the appliance casing disassembled, sensitive components will be

exposed.

Take care transporting the appliance.

»

10 .1.2 Positioning the appliance

After the appliance has been placed in position,

»

remove the two lifting slings at the front of the

appliance.

Undo and remove the two mounting bolts and remove

»

the two lifting slings.

Then screw the two mounting bolts back into the ap-

»

pliance frame.

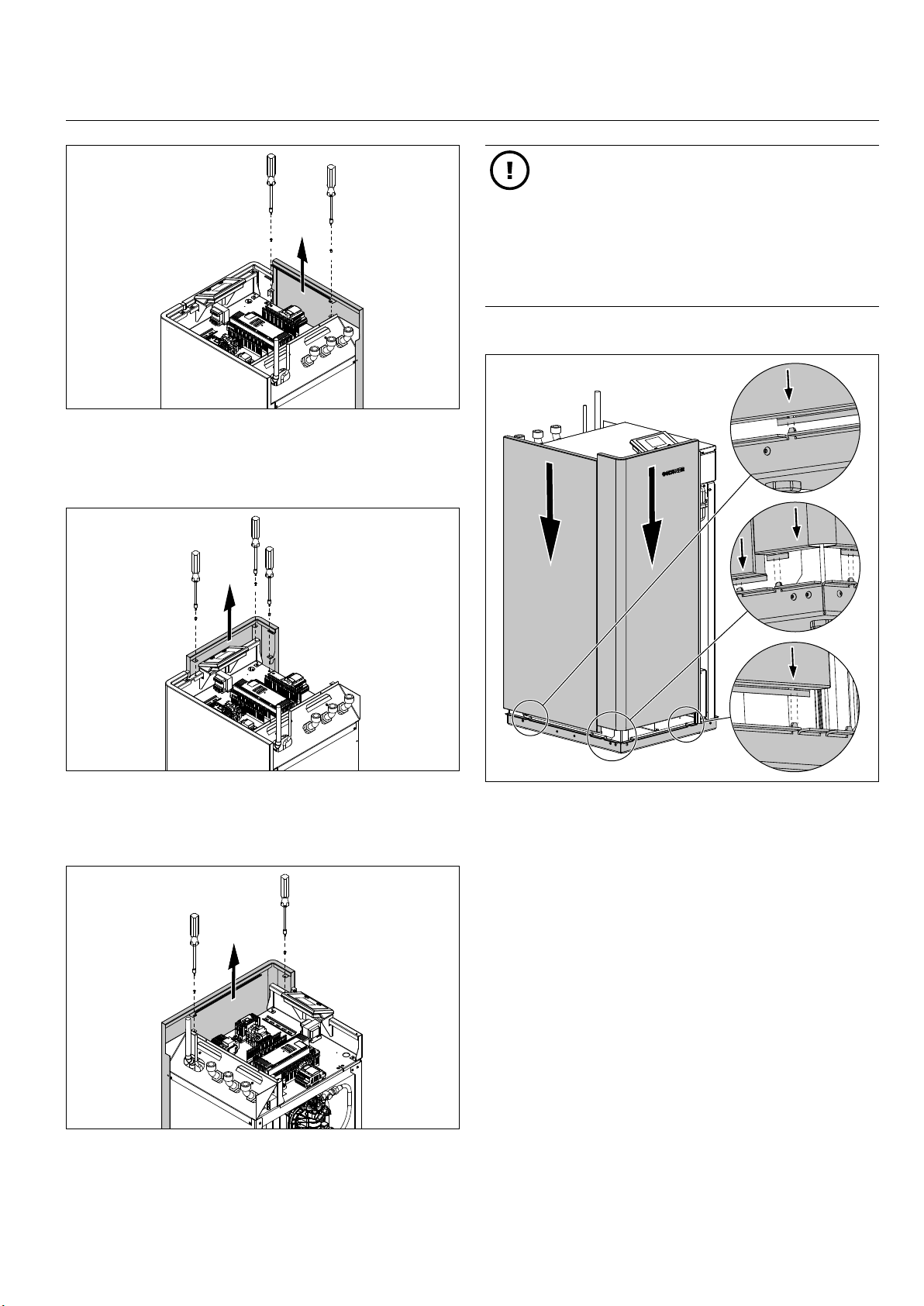

10 .1.3 Disassembling the appliance casing

11_02_200_214_01_002

Position the appliance at the intended installation

»

location.

Use the pre-installed transport aids (2 lifting slings at

»

the front and 2 lifting handles at the rear) to slide and

tilt the appliance.

Observe minimum clearances.

»

Ensure the appliance is horizontal. To compen-

»

sate for minor unevenness in the oor, use the four

height-adjusting plastic glides on the underside of the

appliance.

Information

On the underside of the indoor unit, there are four

plastic glides with rubber mounted threaded pins

(without nuts). Discrepancies in oor height of up

to 6 mm can be compensated for.

1

2 3

Undo and remove the four knurled screws for the ap-

»

pliance casing panel at the rear of the appliance.

Undo and remove the two xing screws for the control

»

box cover, on the rear of the appliance.

11_02_200_214_01_006

Slide back the control box cover. Lift the control box

»

cover up and away.

11_02_200_214_01_003

1 Lifting sling

2 Mounting bolt

3 Appliance frame

26 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

11_02_200_214_01_007

INSTALL ATION | Appliance installation

11_02_200_214_01_012

Undo and remove the two xing screws for the left-

»

hand appliance casing panel, inside the control box.

Lift the left-hand appliance casing panel up and away.

»

Material damage

When the appliance casing has been disassembled, sensitive components are fully exposed.

Assemble the appliance casing as soon as

»

there is nothing that needs doing inside the

appliance.

During the building phase, provide the appli-

»

ance with additional protection from dirt and

dust with a suitable covering.

10 .1.4 Assembling the appliance casing

11_02_200_214_01_008

Undo and remove the three xing screws for the front

»

appliance panel, inside the control box.

Lift the front appliance casing panel up and away.

»

Undo and remove the two xing screws for the right-

»

hand appliance casing panel, inside the control box.

Lift the right-hand appliance casing panel up and

»

away.

11_02_200_214_01_009

Slide the left-hand and front appliance casing panels

»

down from the top along the frame of the appliance,

until the panels click into place at the bottom.

Ensure that both panels are fully engaged at the ve

»

positions along the bottom.

Secure both of these appliance casing panels with

»

screws at the xing points provided, inside the control

box.

11_02_200_214_01_010

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 27

INSTALLATION | Appliance installation

i

Slide the right-hand appliance casing panel down

»

from the top along the frame of the appliance, until

the panel clicks into place at the bottom.

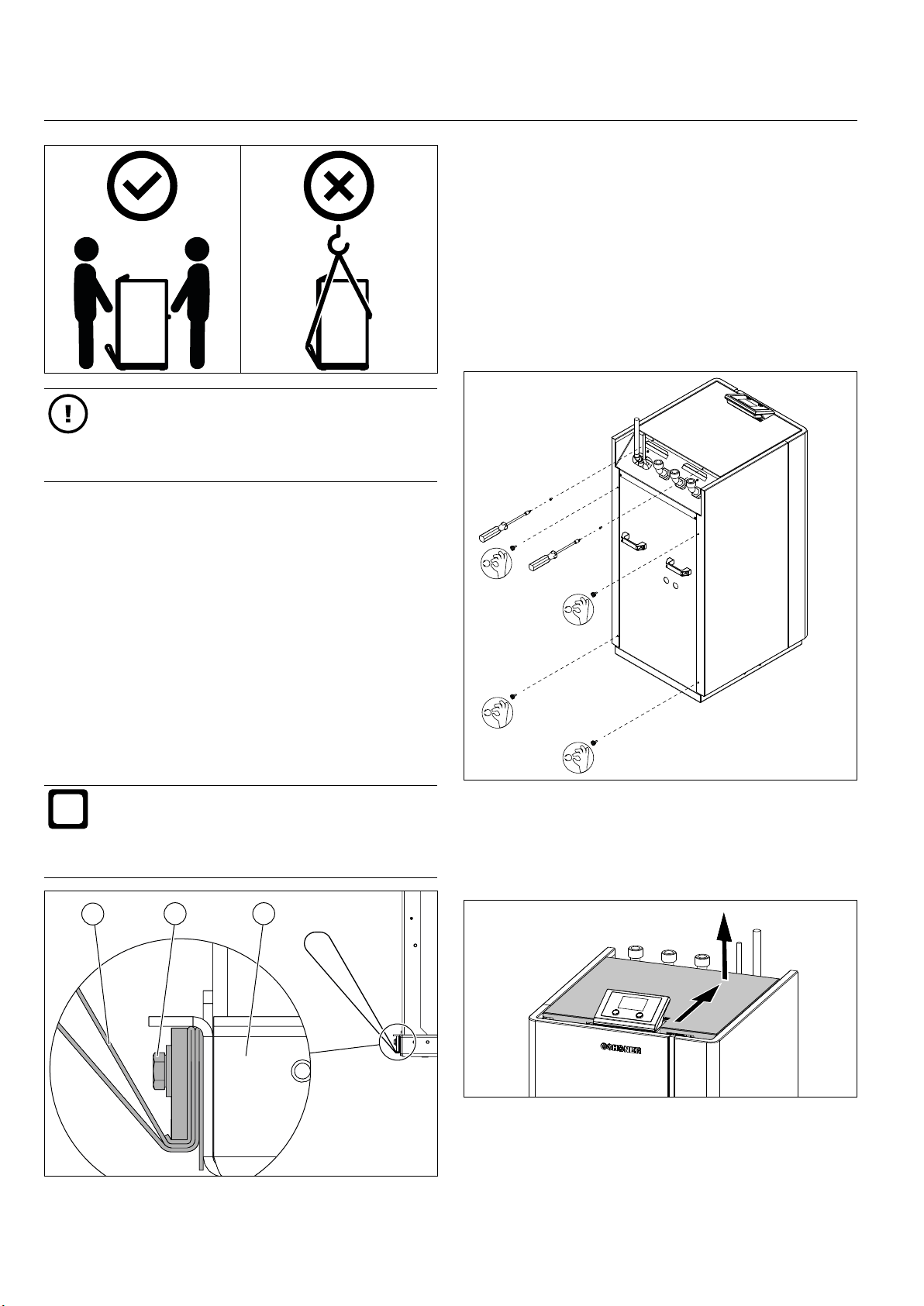

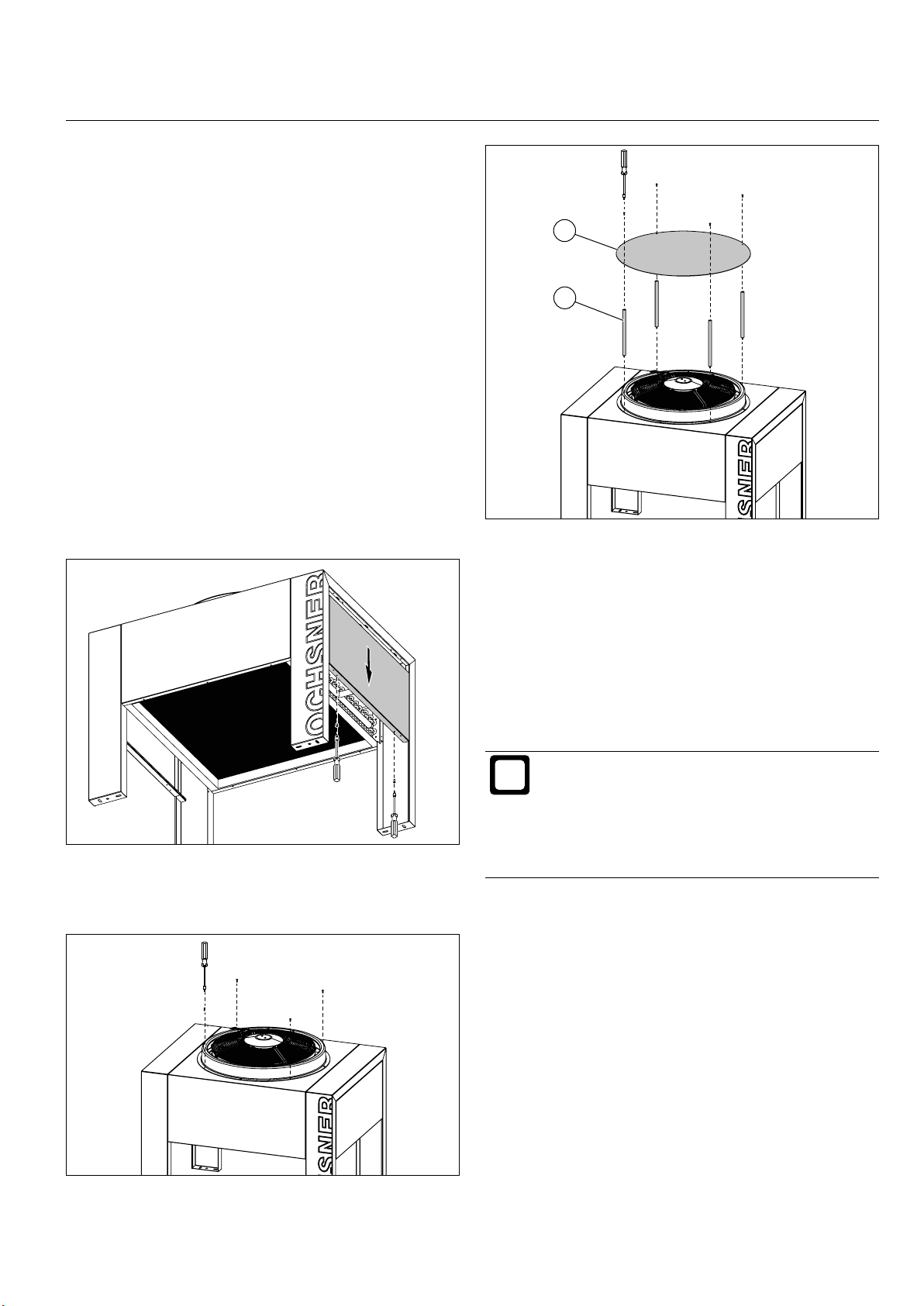

10.2 Installing the outdoor unit

10 . 2 .1 Delivery and transportation

The appliance is delivered on a one-way pallet, wrapped

in lm. The appliance casing is assembled on delivery.

Information

Should you notice any transportation damage to

the appliance, you must report such damaged immediately when the delivery is unloaded. Claims

for transportation damage cannot be made subsequently.

Material damage

Protect the appliance from damage by using

»

transport belts.

When transporting, protect the appliance from

»

impact.

11_02_200_214_01_011

► The appliance is secured to the one-way (recyclable)

pallet of the transport packaging with screws.

► The transport packaging or one-way pallet is suitable

for transportation using a forklift truck.

Ensure that the panel is fully engaged at the three

»

points along the bottom.

Secure the appliance casing with screws at the xing

»

points provided, inside the control box.

Secure the appliance casing with screws at the rear

»

of the indoor unit.

► For level transportation to the installation location, the

appliance may remain in the transport packaging.

► Leave the appliance in the transport packaging or on

the one-way pallet for lifting and moving by crane or

forklift.

► The standard packaging of the appliance does not

provide protection against the weather or sea water.

► The appliance may be stored and transported only at

temperatures of between -20°C and +45°C.

► The appliance must be stored in its transport

packaging.

Please note the following when removing the transport

packaging:

11_02_200_214_01_006

Remove the transport packaging.

»

28 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

11_02_200_504_01_007

INSTALL ATION | Appliance installation

11_02_200_504_01_006

i

Undo and remove the four woodscrews securing the

»

appliance to the one-way pallet.

10.2.2 Positioning the appliance

Position the appliance on the prepared foundations.

»

Secure the four legs of the outdoor unit on the foun-

»

dations, using four xing screws.

10.2.3 Disassembling the appliance casing

By removing the side casing panels on the outdoor unit,

you can gain access to the connection points for the refrigerant lines and to the terminal boxes for the electrical

control leads and power supply cables.

Undo and remove the two xing screws on the

»

underside.

Pull the side appliance casing panel down and away.

»

1

2

1 Round stainless steel plate

2 Mounting foot with threaded pin (4 pce, M5)

Attach the four mounting feet of the snow cover to the

»

outdoor unit, by screwing the threaded pins into the

four free screw holes in the ring-shaped casing part.

Attach the round stainless steel plate of the snow

»

cover to the four positioning feet (M5x12 mm, stainless steel).

10.2.4 Installing the snow cover

The snow cover for an outdoor unit fan can be retrotted.

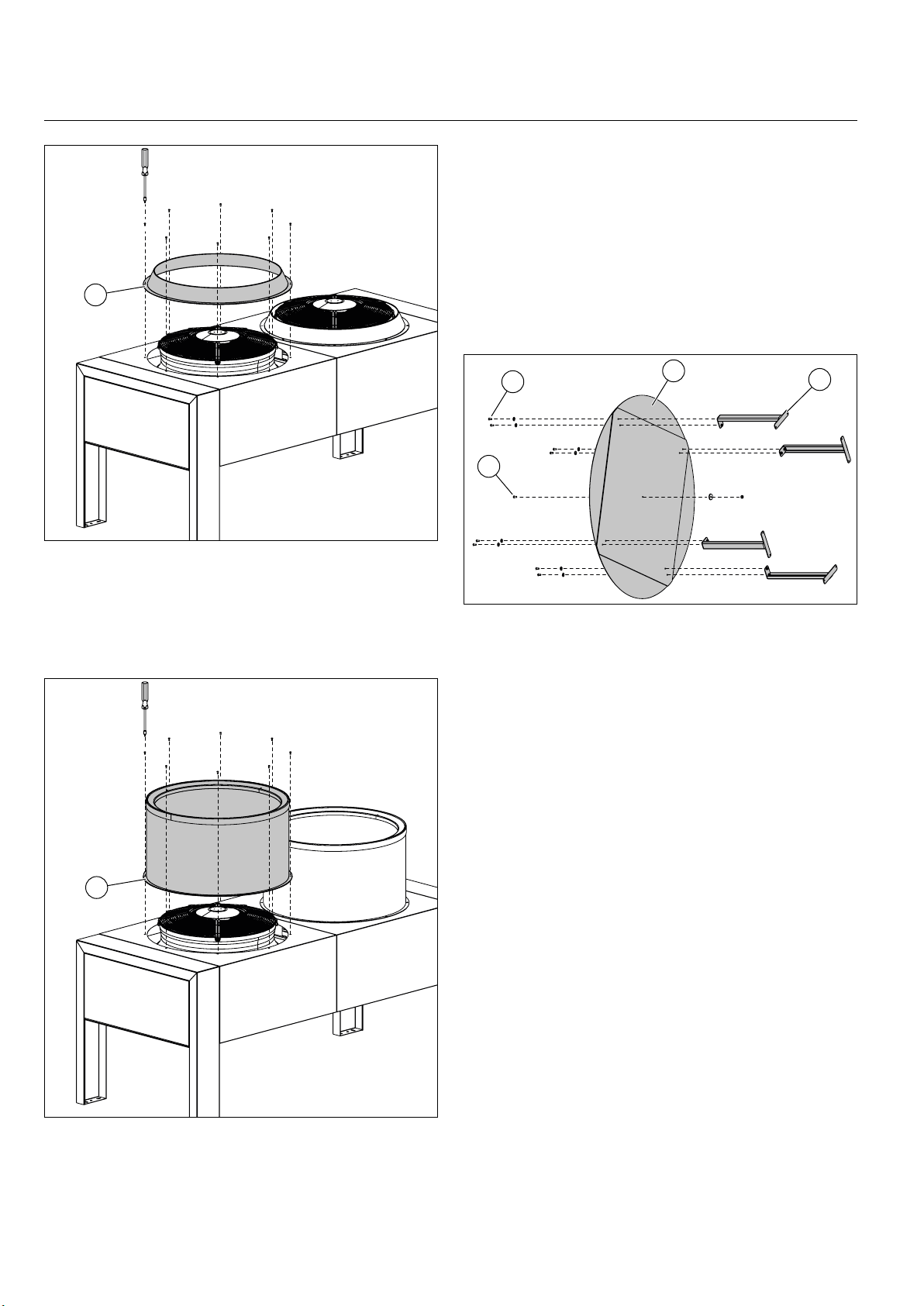

10.2.5 Fitting the cylindrical silencer

Information

The Super Silent Paket (SSP) exclusively available

ex works for a VHS-M outdoor unit reduces noise

by up to 3 dB. The Super Silent Paket consists of:

11_02_200_504_01_009

The cylindrical silencer from the super silent package

(SSP) can be retrotted. A retrotted cylindrical silencer

alone will reduce noise by about 1.5 dB.

11_02_200_504_01_005

- One cylindrical silencer per fan

- Reinforced casing insulation

- Shielded refrigeration technology

Undo and remove four of the eight xing screws on

»

the ring-shaped casing part for the fan (M5x12 mm,

stainless steel).

982000-AIR-M2-M4-EN03.1 | www.ochsner.com 29

INSTALLATION | Appliance installation

1

10.2.6 Installing the SSP snow cover

The SSP snow cover can be retrotted to an existing cy-

lindrical silencer on the outdoor unit.

Secure the four mounting feet to the round stainless

»

steel plate with screws (M5x12, 8 pcs).

Screw the safety bolt (M6x12, 1 pce) for the sound

»

absorbing mat into the centre of the stainless steel

plate.

1 Casing section for the fan

Undo and remove the eight xing screws (M5x12 mm,

»

stainless steel) on the ring-shaped casing part of the

fan.

Remove the ring-shaped casing part.

»

4

3

11_02_200_504_01_003

1 Round stainless steel plate with attached sound ab-

sorbing mat

2 Mounting foot with threaded rivet (4 pcs)

3 Safety bolt (M6x12, 1 pce) with washer and retaining

nut

4 Fixing screw (M5x12, 8 pcs) with plastic washer

Position the SSP snow cover on the upper edge of

»

the cylindrical silencer.

Ensure that the SSP snow cover is correctly aligned.

»

The cylindrical silencer has just one predrilled screw

hole for each mounting foot.

1

2

11_02_200_504_01_008

First, secure the four mounting feet of the SSP

»

snow cover to the cylindrical silencer, using the four

1

11_02_200_504_01_002

1 Cylindrical silencer

Position the cylindrical silencer over the fan. Ensure

»

that the assembly holes are correctly aligned.

Attach the cylindrical silencer to the casing panel of

»

the outdoor unit, using the eight xing screws (M5x12,

stainless steel).

30 www.ochsner.com | 982000-AIR-M2-M4-EN03.1

pre-drilled holes. Use self-tapping xing screws

(4.8x19 mm, stainless steel).

Secure the SSP snow cover through the remaining

»

four screw holes in the mounting feet that do not have

pre-drilled receiving holes. Use self-tapping xing

screws (4.8x19 mm, stainless steel).

INSTALL ATION | Appliance installation

i

i

i

i

11_02_200_202_01_016

1

Information

Ensure that the guard is easy to clean for maintenance purposes. A heavily soiled strainer can lead

to a high pressure safety shutdown or to a malfunc-

tion shutdown based on ow metering (heat sink).

Information

Ensure that the ow velocity in the pipe network

does not exceed 0.8 m/s, as this can cause increased noise emissions.

10 . 3 .1 Connecting the heating water

Before connecting the heat pump, ush the pipework

»

through with ltered ushing water in accordance with

standard procedures. Foreign bodies such as rust,

sealing material and swarf will impair the operational

reliability of the heat pump.

12

1 SSP snow cover

10.3 Connecting the heat sink system

Information

The hydraulic connection from the heat sink system

(WNA) to the heat pump may be made only by a

qualied contractor.

Information

For maintenance purposes, a cut-off valve should

be tted to every hydraulic line close to the connection point on the heat pump.

In the case of air/water heat pumps, an appropriately dimensioned heat pump buffer tank is essential, in order to

provide the necessary energy for defrosting the outdoor

unit.

► The pipe network and the pumps should be correctly

dimensioned for your heating system and according

to the technical data for your heat pump.

► A (manual) air vent valve must be tted at the highest

point in the pipework.

► At the lowest point in the pipework, t a drain pipe to

allow the system to be drained.

11_02_200_504_01_004

1 Heating water ow

2 Heating water/DHW return

Make the appropriate connections from the indoor

»

unit heating ow and heating return to the heating

system.

Ensure that the connection is tight.

»

When installing pipework, take care to prevent trans-

»

mission of vibration noise.

Quality of heating water

Use the corre ct ll water that is suit able for the compone nts

of your heating system. We recommend ll water prepared

according to Guideline VDI 2035-2.

A high pH value and low electrical conductivity in the ll