OCEANSERVER COMPASS MANUAL

Digital Compass Users Guide, OS5000 Series

P/N: 90-05000-00

REVISION 3.0

2007,2008 OceanServer Technology, Inc, 151 Martine St, Fall River, MA 02723 USA

www.ocean-server.com

Sales@ocean-server.com or support@ocean-server.com

1

OCEANSERVER COMPASS MANUAL

Table of Contents

Introduction to the Tiny Compass Family...........................................................3

OS Compass Design Features ..........................................................................5

Specifications ..................................................................................................... 6

Electrical Connector and pin assignment...........................................................7

Cables................................................................................................................ 8

Communicating with the compass, RS-232 or USB...........................................9

Output Sentence Formats ................................................................................ 10

Format Type 0x01: “$C” format....................................................................... 11

Format Type 0x02: “$OHPR” Sentence ..........................................................12

Format Type 0x03: “$HCHDT” Sentence........................................................12

Format Type 0x04: “comma delimited” Sentence ...........................................12

Output Parameter Selection Table................................................................... 12

Terminal Emulation Programs for Communicating with the Compass ............. 13

Compass Command Summary Table ..............................................................14

Compass Mounting Guidelines ........................................................................16

Calibrating the Compass.................................................................................. 19

Installing Windows Demo Utility ....................................................................... 25

Basic Commands to Configure the OS5000 ....................................................28

Depth or other sensor Connection for OS5500-USG.......................................29

2

OCEANSERVER COMPASS MANUAL

Introduction to the Tiny Compass Family

The OceanServer precision 3-Axis Tilt Compensated compass products use

state of the art technology to provide outstanding performance and ease of use in

a low cost design.

The OS5000 family of compasses is a new class of sensor component providing

best in class performance for under $200.00 (USD) in low volume.

Features:

• Precision compass accuracy, 0.5 degrees nominal, 0.1 resolution

• Roll & Pitch full rotation (<1 degree (0-60 degrees))

• Tilt-compensated (electronically gimbaled)

• Tiny size, 1”x1”x0.3”, less than 2 grams weight

• Low Power Consumption, <30ma @3.3V

• Hard and soft-iron compensation routines

• Optional support for a high resolution Depth or Altitude sensor (24

• Serial Interface:

• Rugged design

• ASCII sentence output, in several formats, NMEA checksum

• High Data Update Rate to 40HZ

• Support for True or Magnetic North Output

• Precision components

bit AD)

o RS232, USB or TTL

o Baud rate programmable 4,800 to 115,000 baud

o 10,000 G shock survival

o -20C to 70C operating temperature, -40C to 85C non-op

o 3 Axis magnetic sensors from Honeywell

o 3 Axis Accelerometers from ST Microelectronics

o 24 bit differential Analog to Digital converters from Analog

Devices

o 50 MIPS processor supporting IEEE floating point math

1

3

OCEANSERVER COMPASS MANUAL

OS5000-S -- Signals: RS-232 Levels: 3-Axis Compass, 1” x 1” size with full RS-232

support, single connector on the top side of the module.

OS5000-T -- Signals: TTL Levels: 3-Axis Compass, 1” x 1” size offers TTL only

support, single connector on the topside of the module

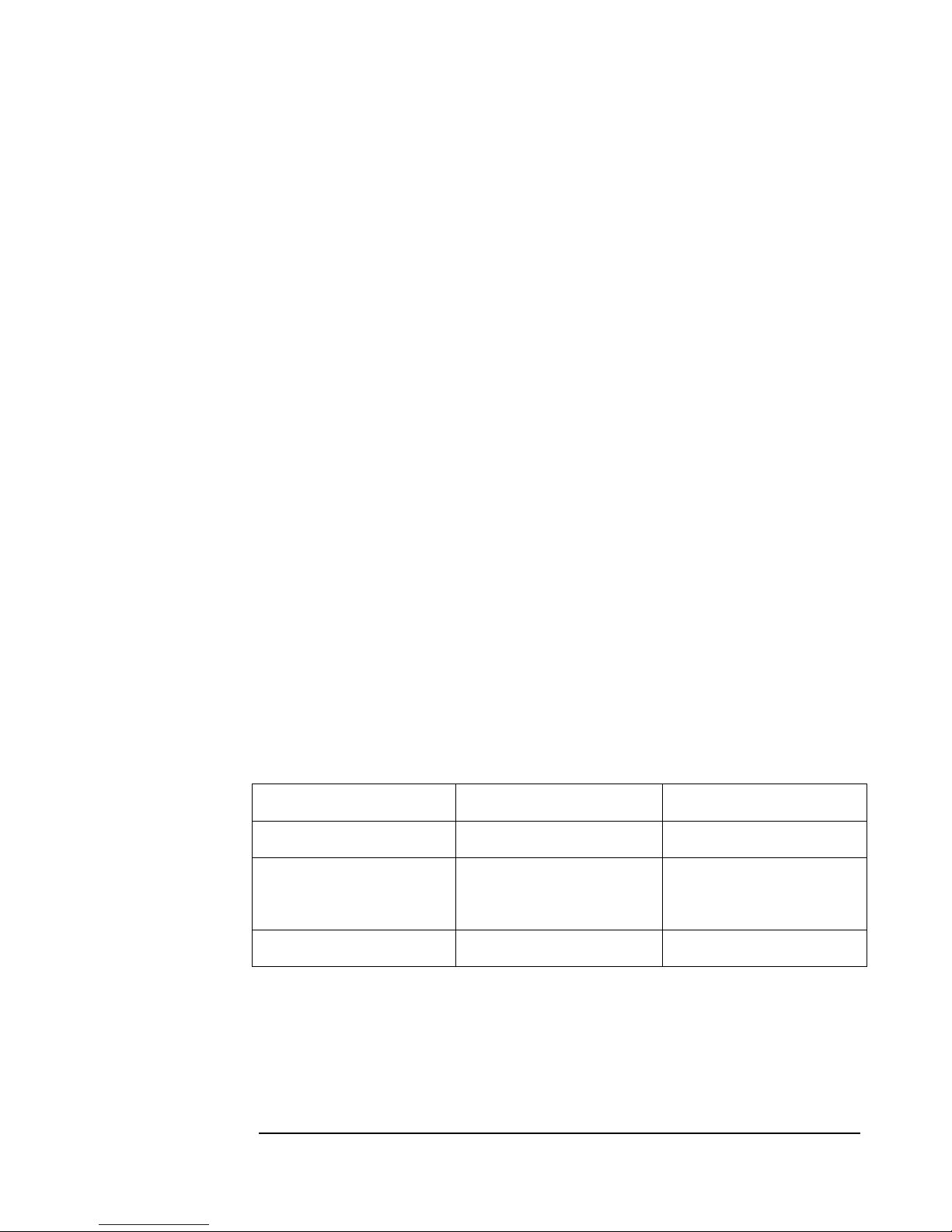

OS5000-US -- Signals USB or RS-232: 3-Axis tilt compensated compass, 1” x 1”.

Has both Serial & USB direct interface and has connectors on both sides of the

module.

Always mount compass with 7 pin side 1 up even when using USB connector.

Additional Note: the OS5500-USG version supports pressure measurement for depth

(not shown; utilizes same PCB and connectors as OS5000-US above).

4

OCEANSERVER COMPASS MANUAL

OS Compass Design Features

Hardware Variants:

OS5000-S (RS232 Only), OS5000-US (RS232 & USB), OS5000-T (TTL

Only), OS5500-USG (Standard Features of –US Compass with Depth)

Magnetic Sensors:

Honeywell two-axis AMR sensor for X, Y plane sensing

Honeywell z-axis AMR sensor

Accelerometer, tilt sensor:

Three-axis STM accelerometer

Microprocessor:

50 MIPS processor that supports IEEE floating point operations for accurate

tilt compensation.

AD Conversion:

24 bit Sigma-Delta converters with differential inputs

All Models are RoHS Compliant Additional Note:

The OS5000 family of compasses is the next generation of compasses offered by

OceanServer Technology. The table below gives a cross reference to previous

generation parts:

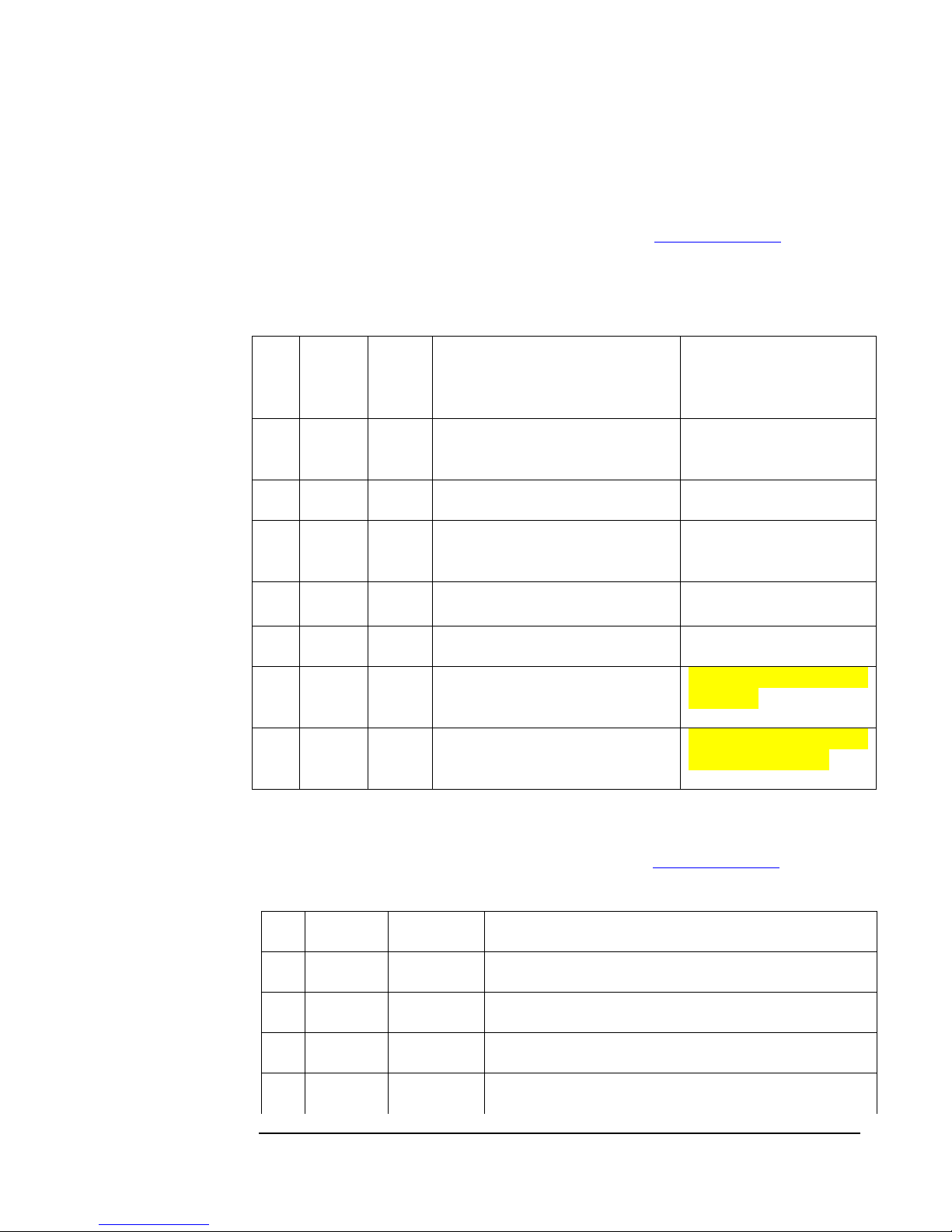

Previous Generation Part Replacement Part Comments

OS1000 OS5000-S Direct Replacement

One part replaces both units

OS1500 and 3500 OS5500-USG

OS3000 OS5000-US Smaller 1’x1’ form factor

depth connected via Serial port

connector

5

OCEANSERVER COMPASS MANUAL

Specifications

Parameter Value

Azimuth accuracy 0.6 deg RMS, 0.1 deg resolution

Inclination (pitch and roll)

< 1 deg, 0.1 deg resolution

accuracy

Inclination range +/- 80 degrees, (output for full rotation at decreased

accuracy)

Temperature range -40C to +85C operating,

Humidity: 20-80% RH non-condensing

Shock (Operating) 3,000 G, 0.5 ms, 10,000 G 0.1ms

Data Refresh Rate 0.01 Hz to 40Hz sentence output rate

Size 1” x 1” x 0.3” module

Weight ~ 2 grams

Supply Voltage 3.3V – 5VDC (Will operate with up to 15VDC)

Power consumption 30 ma @3.3V (-S variant)

Serial Data Interface RS-232C levels, TTL and USB 2.0 based on Variant

Sentence Format NMEA0183 Style, four sentence formats, supporting xor

Magnetic Compensation

Routines

35 ma @5V (-US variant, in USB mode)

4800 – 115000 baud, 8 bit, 1 stop, no parity (19200 default)

parity ($HCHDT, $OHPR, $C, comma delimited.

Supports Acceleration & Magnetic sensor output in X,Y,Z

Hard Iron and Soft Iron calibrations supported, note: Soft iron

(V1.4 or later firmware)

6

OCEANSERVER COMPASS MANUAL

Electrical Connector and pin assignment

:OS5000-S, OS5000-US (TOP, Side 1 Serial Connector) and OS5000-T 7 pin, Molex

1.25mm connector (Molex: 51021-0700) – Available on. www.Mouser.com

pins and tool to make custom cables.

Additional OS5000-T

Pin Color Signal Description

(TTL version compass

along with

notes)

1 White P-in Pressure Input from Transducer

same

(OS5500-USG only)

2 Black GND Ground same

3 Red Vin-

Unreg

DC Power Input, DC voltage

in the range of 3.3V - 5V

same

4 Orange NC RESERVED - Do Not Connect same

5 Black GND Ground – Use with RS232 same

6 Green Tx RS-232 Transmit (DB9-F pin: 2) Voltage Level TTL, 3V

drive level

7 Blue Rx RS-232 Receive (DB9-F Pin: 3 ) Voltage Level TTL, 3V or

5V tolerant on input

:OS5000-US USB and OS5500-USG, Bottom, side 2, 6 pin, single row header, Molex

1.25mm connector (Molex:

53261-0671) – Available on www.Mouser.com along with

pins and tools to make custom cables

Pin Color Signal Description

Green USB D+

1

White USB D -

2

Red

3

Black

4

5V Regulated USB Power

Ground USB Power

7

OCEANSERVER COMPASS MANUAL

Reserved

5

6

Reserved

Must be no connect

Must be no connect

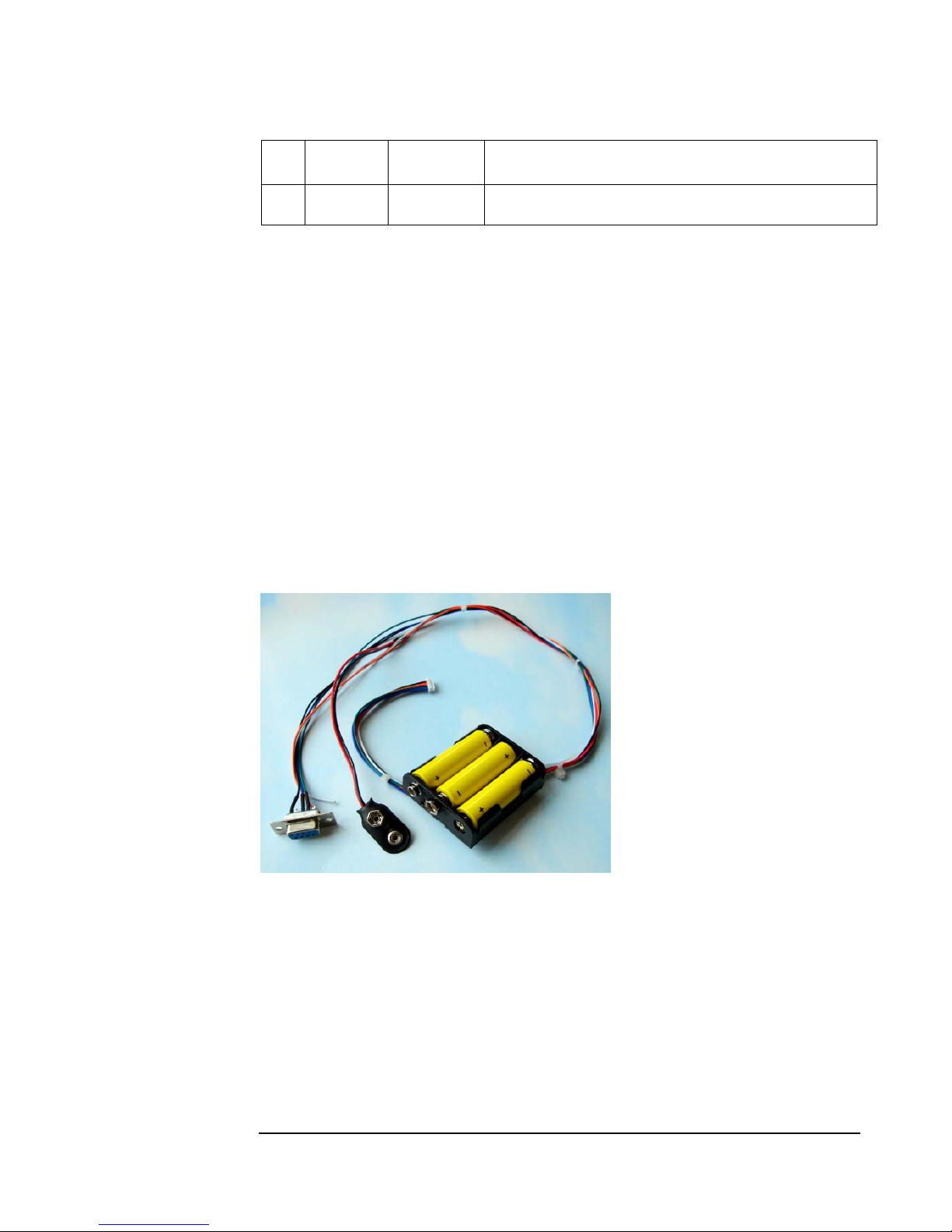

Cables

OceanServer offers a variety of cables, which come with the compass evaluation kits or

can be ordered separately. OS5000-US will auto detect whether the Serial or USB cable

has been plugged in. (No jumper required)

Standard Cables:

19-00061-24, 24" OS5000-S Demo Kit Cable with Serial connection, Pressure and

3.6V battery power connection (picture below) Demo cable provides 3.6V battery

connection. Cable Note: this cable is a quick way to get the compass running for

evaluation. It is highly recommended that you operate the compass from 3.3V since

the module has a linear regulator and any voltage higher than 3.3V heats up the module

and wasting power and heating up the OS5000 module.

8

OCEANSERVER COMPASS MANUAL

19-00062-24, 24" OS5000-S/-T Series Pigtail Cable, 7 Pin connector, blunt cut (below)

19-00116-00, Aprox. 6’ OS5000-US Demo Kit Cable with USB to 6 Pin connector

Communicating with the compass, RS-232 or USB

The USB compass requires device drivers to present itself to the system as an asynch

serial port, i.e. COMn: port on Windows. There are drivers supporting MAC OS and

Linux variants on the www.silabs.com web site, CP2101 bridge drivers. We provide

basic drivers and manuals on our web site for windows www.ocean-

9

OCEANSERVER COMPASS MANUAL

server.com/compass/. At this point all compass designs present themselves as serial

port devices at a baud rate, 8 bits, 1 stop bit (ASYNCH).

Using a windows system open up a TeraTerm terminal emulator port to the compass

device. The factory default baud is 19200, 8, 1, N. This change has been made so

Windows OS does not mistakenly recognize the compass as a serial mouse. The baud

rate can be changed back to 9600 using the <Esc> B command

Output Sentence Formats

Figure: Compass output for each of the four supported output formats. The command

<esc>* lets you select the bit mask for the desired sentence format.

The compass is programmed with an output rate and it sends sentences at this fixed

rate. The rate is programmed with the <esc>R command. Values lower than 1 per

second use a negative number, -100 is 0.01hz, -10 is 0.1 hz, -2 is 0.5hz. Values greater

than 0 are in sentences per second, HZ. A value of 10 is 10hz, 40 is 40hz and so on. If

you program a rate of 0 the compass will cease output but still respond to <esc>

commands.

10

OCEANSERVER COMPASS MANUAL

Format Type 0x01: “$C” format

$Chhh.hPpp.pRrr.rTtt.tMx0.000My0.000Mz0.000Ax000.0Ay000.0Az000.0*cc

$C212.4P2.5R-14.0T28.4Mx107977.90My-79422.00Mz173.27Ax0.045Ay-

0.245Az0.977*3A

This sentence format provides a text tag in front of each data type so the user program

can parse them accurately regardless of which data elements are activated. In effect

every data element has leads with its unique name.

Possible fields reported in the sentence (use the <esc>Xnnnnn<space> command to

configure the desired fields for output.

Hhh.h Heading in degrees, corrected for Declination if one is entered

Ppp.p: Pitch angle, “P” precedes the pitch angle in degrees

Rrr.rr Roll angle, “R” precedes the roll angle in degrees

Ttt.t: Temperature of the compass board, crude measure taken from the core

microprocessors internal sensor. Used for relative measurements of environments not

accurate. We provide a single point calibration offset using the <esc>+ command.

Standard Factory Format for OS5000-S, OS5000-US or OS5000-T

The standard setting below is <esc>*1<space> command

Example: $C320.5P0.2R-18.3T19.0*3C

Mx,My,Mz Magnetic field strength reported on each sensor. The units are calibrated to

milliguass by the user setting the local horizontal field strength before a full calibration.

Ax,Ay,Az Acceleration measured on all three sensors. The units are in “G” for each

sensor. You can also output the vector length (acceleration scalar) which will be close

to 1G

*cc This is the end of line character, the cc is the HEX X-OR sum of the characters

between the $ and the *. This is the NMEA standard format.

OS5500-USG Example: $C328.3P28.4R-12.4T21.1D21.01*<checksum> <cr><lf>

• Compass heading: 328.3 degrees

• Pitch angle: 28.4 degrees

• Roll angle: -12.4 degrees

11

OCEANSERVER COMPASS MANUAL

• Temp: 21.1 degrees

• Depth: 21.01 feet [This is only output on the OS5500-USG ]

Format Type 0x02: “$OHPR” Sentence

$OHPR value1,value2,value3,value4….*cc

The $OHPR sentence is activated with the <esc>*2<space> command. It provides a

comma-delimited list of all of the parameters selected for output with the <esc>X

command.

Format Type 0x03: “$HCHDT” Sentence

$HCHDT,212.4,T*2C

The NMEA0183 standard true heading sentence is supported for output. The

$HCHDT sentence is activated with the <esc>*4<space> command. To have the

heading be true the user must program the compass with the local declination value

using the <esc>Qnnnn<space> where nnnn is the degress times 10 for local heading

offset. Example <esc>Q125<enter> will offset the heading 12.5 degrees for every

value reported.

Format Type 0x04: “comma delimited” Sentence

value1,value2,value3,value4,….

This sentence outputs the data as a simple comma delimited list of the requested

values. This sentence is activated by the <esc>*8<space> command and it outputs all

data elements selected in the <esc>Xmask<space> command. This sentence format

is only available with firmware version 1.4 or later.

Output Parameter Selection Table

(Note: not all compasses support all features)

Order Bit value (base 10) Parameter Name

1 1 Azimuth

2 2 Pitch Angle

12

OCEANSERVER COMPASS MANUAL

3 4 Roll Angle

4 8 Temperature

5 16 Depth (feet)

6 32 Magnetic Vector Length

7 64 3 axis Magnetic Field readings, x,y,z

8 128 Acceleration Vector Length

9 256 3 axis Acceleration Readings, x,y,z

10 512 reserved

11 1024 2 axis Gryo Output, X,y

12 2048 Life Counter, incrementing counter , used in

Testing

13 4096 Reserved

Table: The output order and bit values for each of the possible output fields is

shown in the above table. The <esc>X

The <esc>Xmask<space> command uses a decimal mask. If you want heading, roll

and pitch active add the Bit Values up for the fields. I.e. 1+2+4=7, now use the

command <esc>X7<space> to enable these three fields. Remember the mask is

decimal so just add the bit field values up from the table.

Terminal Emulation Programs for Communicating

with the Compass

Hyperterm Issues: OceanServer compasses will usually show up as an additional

Hyperterm port when properly connected to a system. If the compass cannot be

communicated/programmed check to confirm the Hyperterm port has the correct

settings (baud is 9600, 8, 1, N (older compasses) or 19200 with firmware v1.1 or later).

If the settings are correct it could be a Hyperterm system issue and you may want to

download a different terminal program. One possible program is TeraTerm:

TeraTerm (Support Forum)

13

OCEANSERVER COMPASS MANUAL

http://www.neocom.ca/forum/viewtopic.php?t=436

The install for version 4.51 and can be locate at

http://www.neocom.ca/freeware/TeraTerm/teraterm_utf8_451.exe

A windows version of Tera Term installer is located at www.ocean-

server.com/compass/

Compass Command Summary Table

The compass is configured and calibrated using a set of commands sent to it via its

serial port connection. The general format of all commands to the compass are sending

it the ESCAPE command key, ASCII=27 decimal, noted as <esc> in this manual.

Type1: <esc>Kvalue<space>

Type2: <esc>K

Where type 1 is the format for a command that has a value supplied. Note all values

are decimal integers examples: 10000, -1000, 2345. If the value needs a floating point

number such as heading we send it multiplied by 10.. Example: <esc>Q123<space> is

a value of 12.3 for heading.

The second type, Type2 is commands that immediately have some action. One

example is the calibrate command, <esc>C

Note1: Entering Commands -- Push the escape <Esc> key prior to a key command.

The command keys are CASE sensitive so if it asks for a “R” a “r” will not work.

Note2: Some command changes require the compass to be power cycled for changes

to take affect. Example, BAUD RATE CHANGE.

Key

Command

<Esc> B Set new baud rate, 0-6, change takes effect after power cycle.

Description of the command

0=4800,1=9600,2=14400, 3= 192000, 4=38400,5=57600,6=115200

<Esc> R Set the compass output rate, -50 to +40. Rate is in samples per second

and negative are seconds per sample. .i.e. 20=20 samples/second, 10=10 seconds per sample. A rate of 0 will stop output

14

OCEANSERVER COMPASS MANUAL

<Esc> X Fields to Display, bit mask of 5 bits (entered in decimal). 31=all active.

Sum up the values, Azimuth=1, Pitch=2, Roll=4,Temp=8,depth=16.

<Esc> Q Enter Declination angle to create offset for compass Azimuth. Value is

10x degrees. Example: -103=-10.3 degrees, 152=15.2 degrees.

<Esc> C Calibrate the compass in the platform. Level the platform and prepare

to rotate it very slowly. When the output reports “XxYy” it is finding

new calibration data, keep rotation until you see only “.”’s output. You

MUST keep the platform level while you rotate. Validate the Roll and

Pitch angles are < 1 degree in the output string R0.x, P0.x before starting

<Esc> Z Rotate your platform 90 degrees on it’s side. This will place the Z axis in

the same “earths” magnetic field the “C” calibration saw for the x,y

sensors. Perform once complete and slow rotation.

<Esc> H

Help Menu

or ?

<Esc> A Moving average filter on roll, pitch and heading. Enter the number of

samples to include in the average. This combined with output rate will

determine the period of the filter. Example: averaging = 5 output rate =

10 is half second period

<Esc> V Displays the firmware version installed on this device

<Esc> + Calibrate Temperature, offset in O.1C, example <esc>+-131<enter>

will subtract 13.1 from the reported temperature. Temperature is a crude

sensor and should not be used if accuracy is required, it is a good relative

measure of changes in the electronics rack.

<Esc> U Calibrate Raw Magnetic output, milliguass of horiz field requires new

calibration. The value you enter is the local horizontal field strength of

the earth’s magnetic field. After you enter this and do a calibration the

compass will output 3 axis magnetic sensor values in milliguass. The

local H field strength can be estimated using the NOAA world magnetic

model for you local area.

<Esc> D Digital Filter Value for AD conversion, higher=longer filter time. The

<Esc> * Change Output Sentence Formats, bit mask, 1,2,4,8 are valid values.

default value is 3, using a higher value will add lag to the measurements

but filter noise.

Format 8 requires firmware version 1.4.

15

<Esc> % Change Escape Character for compass, default=27=ESC *careful* This

is used to change the compasses ESCAPE character for applications

where the compass may be on a shared output line and the system may

send ASCII=27 characters. If you change it you will not be able to talk

to the compass unless you can send the new character.

<Esc> F Restore Factory Defaults and calibration

<Esc> T Accelerometer Calibration, requires accurate placement of the compass

in 6 orthogonal angles. This is a factory test and generally never

required to be done in the field.

<Esc> $ Soft Iron Compensation. The values are 0=disable, 1=enable,

2=generate calibration. When you enter generate (2) you need to have

the system with the compass in installed and freshly calibrated, (via the

<esc>C,<esc>Z commands). You will need to align the system to

cardinal points according to a magnetic compass, N,S,E,W in an area

free of magnetic disturbance.

Note: You must have deviation set to 0 before this operation,

<esc>Q0<enter>

The soft iron compensation method uses the deviation coefficient

finding method described by Archibald Smith to the Royal Society in

1855. Soft Iron Compensation is supported with firmware version 1.4.

<Esc> S Degauss every 'n' sentences. This sets the frequency of the sensor

degauss and offset operations. The default value is something around 1

second. The quicker you degauss the lower the compass lag is when

moving it quickly.

Important Note: Some commands may not be available in earlier firmware releases.

Compass Mounting Guidelines

In general you should mount the compass in a location in your vehicle or device that

has the least disruption to the earths magnetic field.

1) Mount away from permanent magnets such as motors. The fields fall off as

inverse square of the distance so doubling the distance reduces the field

strength by ¼.

2) Mount the compass away from moving magnetic fields such as wires carrying

current, moving magnets, generators, etc.

3) Mount the compass as far as possible from batteries and ferrous materials such

as soft iron.

16

4) Mount all compasses component side up (side 1 with arrow), level or true to

platform level with the arrow pointing forward. This is also the case when

using the USB connector on the OS5000-US.

5) Mount the compass in a mechanically stable location so this it moves with the

vehicle or device but doesn’t vibrate.

6) Metals such as aluminum, brass or copper do not block magnetic fields but

currents can still flow through them that could create unwanted local magnetic

fields. Metals such as iron and steel will distort the magnetic field.

OceanServer ships compasses with plastic standoff but users should insure that

the compass has sufficient distance from ferrous objects that could bend the

earth’s magnetic field and disrupt compass accuracy.

Aircraft Note: Most all electronic compasses use gravity to detect level and tilt with

accelerometers to measure tilt (including OceanServer compasses). The tilt angles are

determined by measuring the earth’s static gravitational vector. Since, dynamic and

static acceleration are indistinguishable when used in aircrafts with high acceleration

and banking turns, the dynamic acceleration will introduce an error in both roll and

pitch angle reported by the compass as well as heading errors. Only level headings will

be accurate when aboard a plane and vibration needs to be considered. Strong

vibration also applies acceleration to the compass and can cause errors if the amplitude

of the acceleration is significant as compared to the earth’s 1G acceleration due to

gravity

Mounting Location Example:

In one real world example if the compass is mounted 2 inches from a paddle wheel

the compass will see up to 90 degrees of offset in heading due to the magnets moving!

Since the magnetic field falls off as the inverse square of the distance moving the

compass a small distance can make large improvements in the accuracy.

Mounting Distance (inches) Error (heading degrees)

-------------------------------- ------------------------------

2” 90 degrees

5” 10 degrees

9” 1.6 degrees

11” 0.2 degrees

17

Y

X

So moving the compass 10+ inches from these moving magnets we were able to

remove all of the significant error introduced in your reading.

$C288.6P-0.2R-0.1T26.6*20

$C288.4P-0.2R-0.2T26.6*21

$C288.6P-0.2R-0.2T26.6*23

^^^^ Notice: Level in roll and pitch

CMD:C

Bridge offset

Calibrate X,Y <space> when done

XyxXyXyXYXyXyX.XXYxYY.xYxYxYxYxYxYxYxY.xYxYxYxYxYxYxY.xYxYxYxYxYxYxYx.YYxYxYxYx

xYY.YYYYYYYY.YYXYXXYXYXX.XXXXXXX.XXXXXXXX.XXXXXXXX.X.yyy.......yy.yy.y.yyyy.yy.....

XXX.XXX.X...Y.YYY.YY.YY.........xxx.x....................Flash Write

$C346.7P1.5R-0.1T26.9*06

$C335.7P-0.3R-90.0T26.9*10

$C335.7P-0.4R-88.4T26.9*1A

$C335.7P-0.4R-90.0T26.9*17

^^^^ Notice: Platform rolled 90 degrees, pitch 0

CMD:Z

Bridge offset

Calibrate Z <space> when done

zZzz.zZZZZZZZZZZZZZ.ZZZZZZZZZZZZZZ.ZZZZZZZZ..zzzz.zzzzzzzzzzzzzzzz.zzzzzzzzzzzzzzzz.zz

zzzzzzzzzz..........Z..Z................Flash Write

$C69.6P-0.4R-90.0T27.0*24

$C69.7P-0.4R-88.4T27.0*28

OS5000 Mounting hole locations (stand-offs shipped with compasses).

18

t

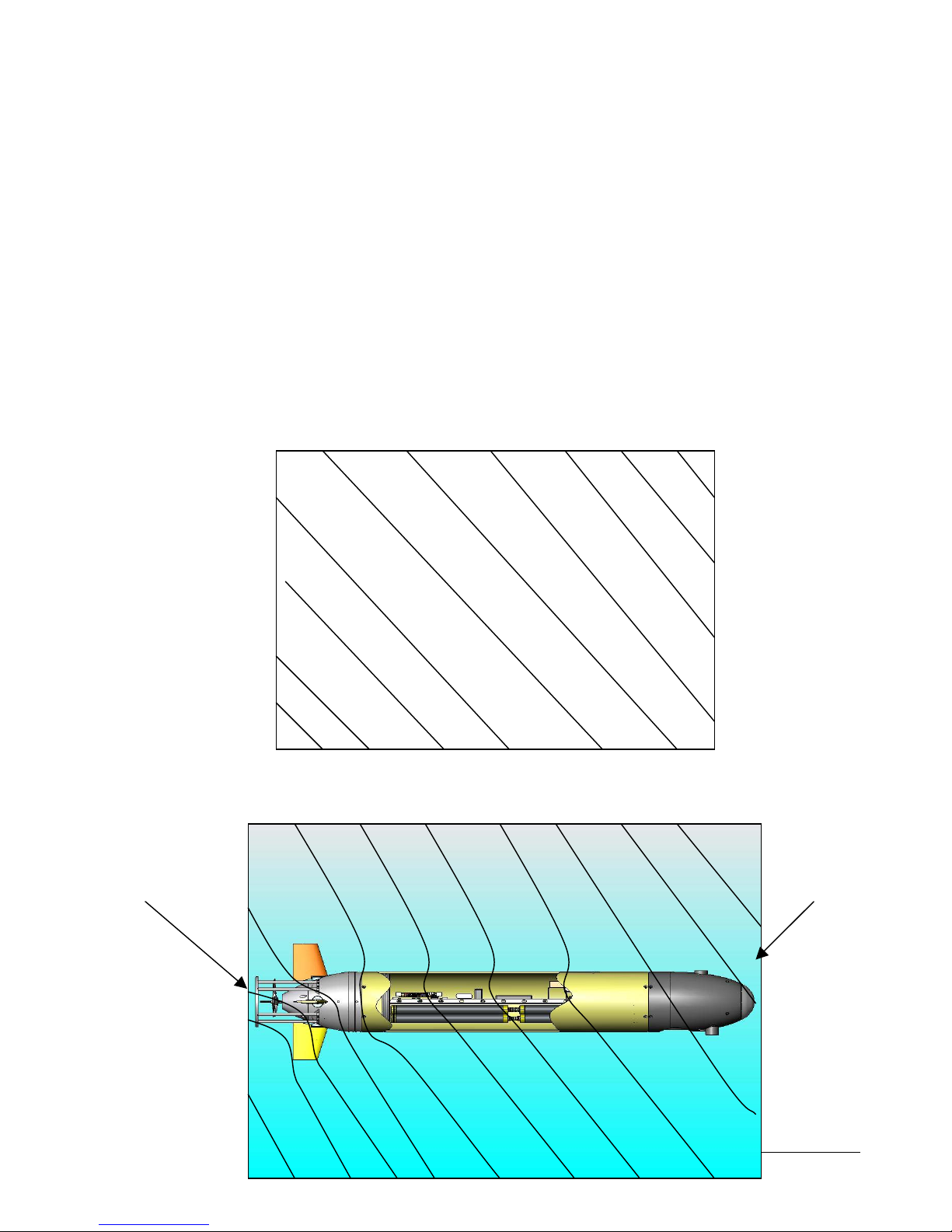

Calibrating the Compass

Compasses operate by measuring the earth’s magnetic field and locating magnetic

north. When mounted in real platforms or devices there are other local magnetic fields

or materials that disrupt or offset the earth’s magnetic field. Sources to be aware of are

ferrous metal, electric currents and permanent magnets in electric motors. There are

two sources of magnetic field distortion: “Soft-iron” and “Hard-iron”. “Soft-iron”

effects are caused by un-magnetized ferrous materials in the area of the compass.

“Hard-Iron” effects are caused by magnetized ferrous materials near the compass.

“Hard-Iron” can be cancelled out by going through the rotational calibration

(described bellow). “Soft-iron” effects should be addressed during the design in phase

and compasses should be located away from such items to minimize impact to the

sensor. OceanServer compasses with firmware version V1.4 and later include a soft

iron calibration option.

Ferrous Material in Tail

Plus an Electric Motor

Creating Magnetic

Field Disturbance

Not an Ideal Place for

Compass Placement

Magnetic Field Examples:

Undisturbed Magnetic

Compass Placemen

Field

Non-Ferrous Bow

Least Magnetic

Field Disturbance

Best Place for

Compass

Placement

19

Users will need to calibrate the compass.

Step 1: Select appropriate location and install OceanServer Compass in device

IMPORTANT NOTE: Compasses require users to hit the < Esc > key prior to

each programming/calibration step. This has been added to prevent accidental

programming.

Step 2 Open a Hyperterm window to take two separate measurements (X-Y together,

followed by Z) for calibration. The Virtual terminal settings for the compass serial port:

19200 baud, 1 stop, no parity. We recommend TeraTERM free software. A Nema

string of data will begin outputting when connected properly (ie…“$C328.3P28.4R-

12.4T21.1D21.01)

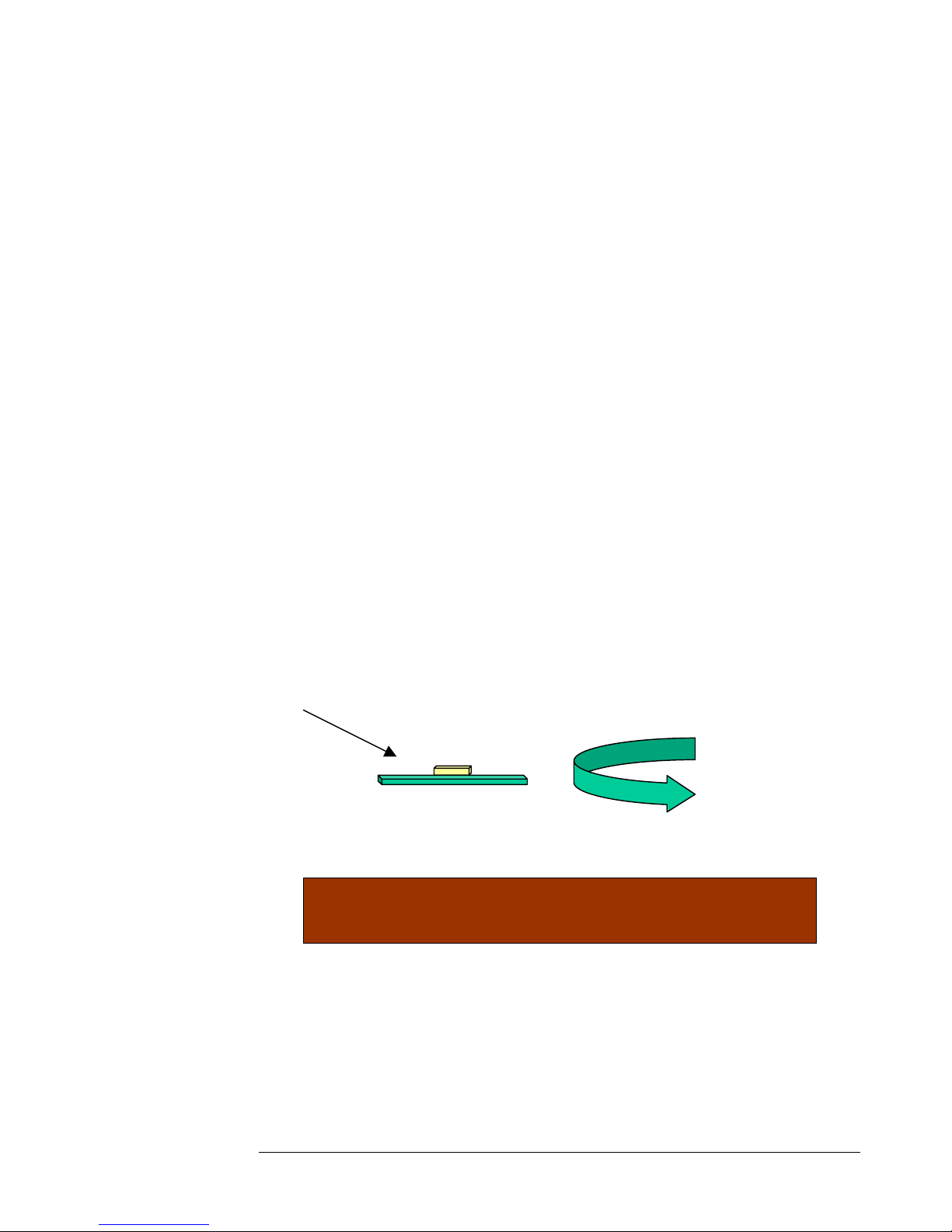

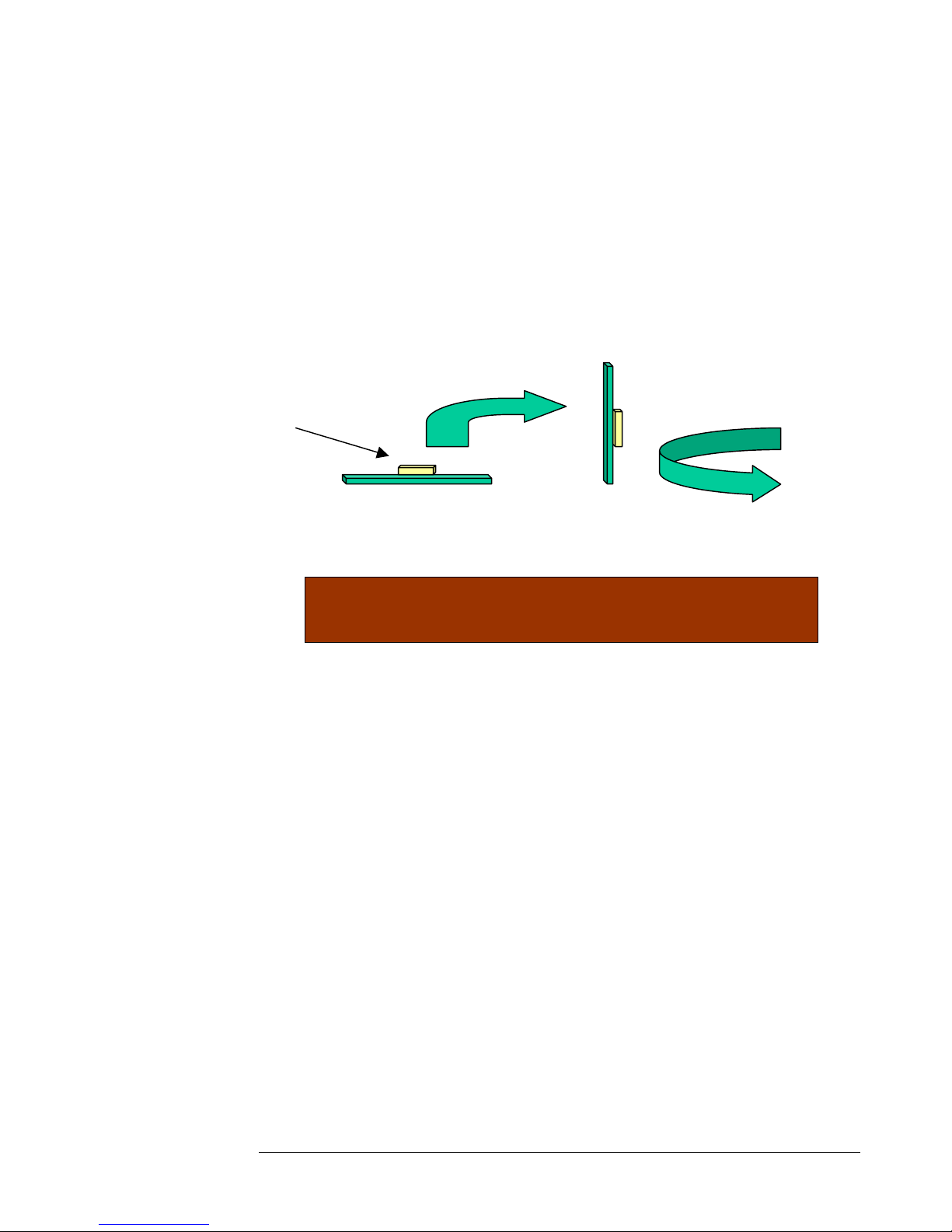

Step 3 (Calibrating X, Y):

a. Check that the platform is level, observe Pitch (P0.x) and Roll (R0.x) data

and confirm they are less than 1 degree. Next, fully rotate the platform to make

sure it will remain level during the calibration process. The area should be

clear of soft and hard iron objects that could disrupt the earths magnetic field,

cars, motors, wires with current, magnets, etc.

Compass looking into

Back connector

b. Calibrating X, Y: Enter <Esc> key, next enter uppercase “C” key and slowly

rotate the device at least one complete rotation for at least 20 plus seconds.

Note: the device should be kept as level as possible to calibrate the X, Y

magnetic sensing elements. Terminate sequence with SPACE bar key after you

have slowly rotated the device and observed the following output “…..” this

indicates you have found the “X,Y” max and “X,Y” min values.

Rotate 360 Degrees

Parallel to the Earth

X, Y Calibration

Ground

20

w

c. Final X,Y Note: If the platform is not level during the calibration procedure

just abort (by hitting the SPACE bar) and re-run it. (i.e. Hit space and start at

step a above).

Step 4 (Z Calibration): Rotate device (90 degrees) so it is turned on its side

Compass looking into

back connector

Rotate 90 degrees

Next rotate 360 degrees

hile at 90 degree angle

a. Roll the platform 90 degrees, The area should be clear of soft and hard iron

objects that could disrupt the earths magnetic field, cars, motors, wires with

current, magnets, etc. You want the calibration to be done in the same place as

the “C” calibration as it needs to see the same earth’s magnetic field

b. Enter Z Calibration mode. Push <esc>Z on the keyboard. Slowly rotate the

device 360 degrees (at least one complete rotation). This step should take 20

plus seconds when you just get “…” you have found the “Z” max and “Z”

min values. Terminate the sequence by hitting the SPACE bar. Important

Note: The “Z” command should be done in the same location to calibrate and

align the Z axis sensor to the X, Y. This is important for tilt compensation.

Errors in heading, when the device is tilted, will result from no Z axis

calibration

Z Calibration

Ground

Note: If the platform is not level during the calibration procedure just abort it and

re-run it. (i.e. Hit space and start at step 3 above). Compasses can also be

calibrated in the latest version of the OceanServer Windows Demo program. The

basic steps are the same as described above. The feature can be found under the

“program” button.

21

Optional Soft Iron Calibration

The above mentioned (C,Z) calibration routines do not compensate for soft iron

effects. Soft iron, batteries, wires with moving currents and other high permeability

materials in the near field cause these. These are generally far weaker than hard iron

effects. Choosing a good compass mounting location with distance from soft iron

structures should be attempted. In cases where the sensor will be impacted by soft

iron you should run the soft iron calibration (available starting with firmware version

1.4).

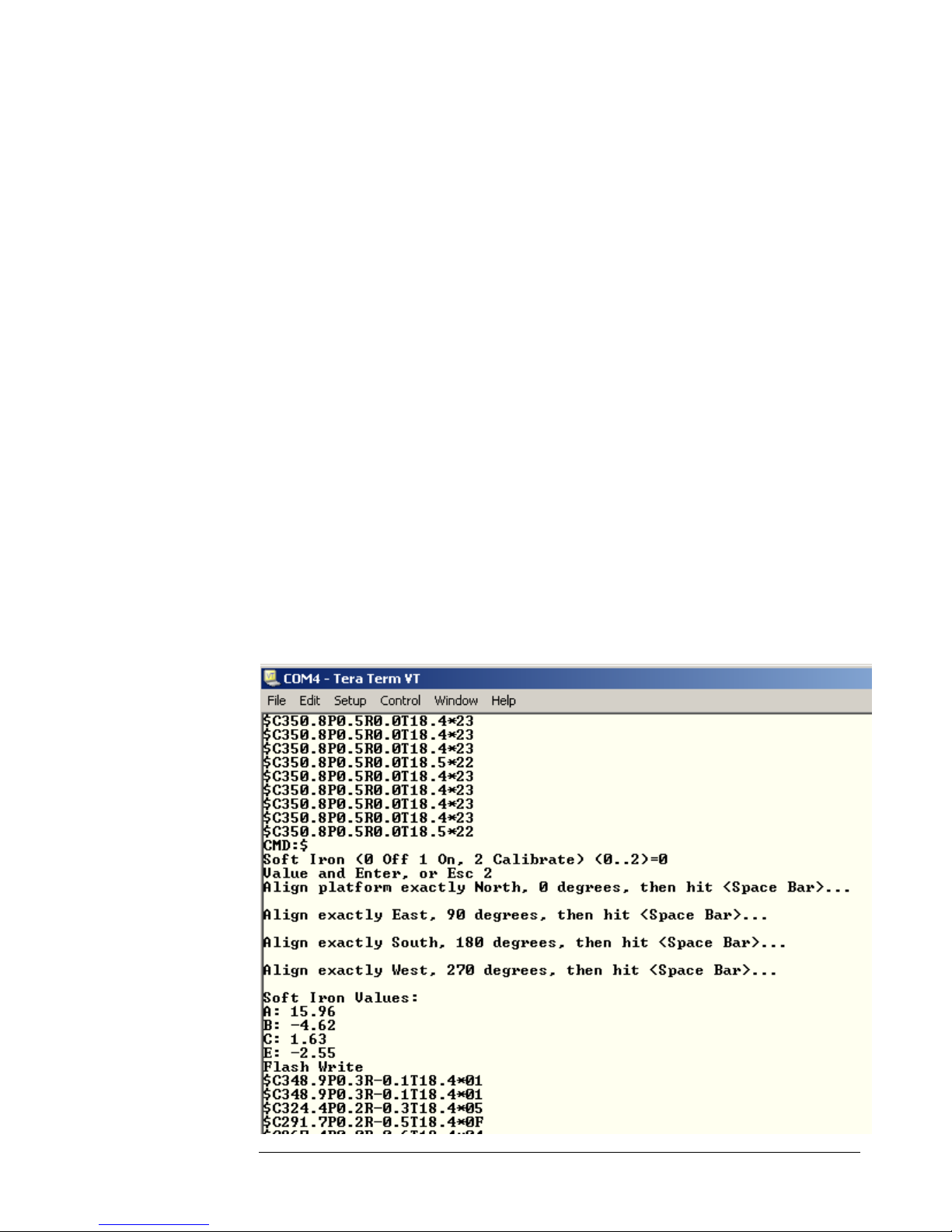

The soft iron compensation routine is started by hitting the <Esc> $ key command.

You want to select option 2 and follow the screen prompts (see example screen shot

below).

Important setup steps prior to running soft iron calibration:

Before starting the calibration, you need to have the system with the compass installed

and freshly calibrated, (via the <esc>C,<esc>Z commands). You must have

declination set to 0 before soft iron calibration begins, check setting by <esc>Q and

make change to 0 if necessary then hit <enter>. You will need to align the system to

the four cardinal points according to an accurate reference magnetic compass, 0 North,

90 East, 180 South, 270 West in an area free of magnetic disturbance. Once you have

your device or system properly aligned, starting at 0 North, you want to start the soft

iron correction with the <esc>$ command followed by entering 2. Actual calibration

routine shown below.

22

After you run through the calibration process, you will see the correction values

generated by the process. At this point, the soft iron calibration is completed. You

should go back and check the cardinal points with your system. You should see your

system more inline with the cardinal points.

If the compass is still not reporting accurate information compared to the known good

reference compass you should run through the calibration process again and carefully

check each step. In some cases, the magnetic field may be too disturbed for accurate

calibration and distance from soft iron is the best solution.

Compass Settings Relating to Filtering Measurements (Not Required for

Most Applications):

------------------------------------------------------------------------------Since the OS5000 family of digital compasses use a fast 3-axis accelerometer to

sense the gravity (1G) static vector to determine its Roll and Pitch angle you may

need to filter out other dynamic acceleration introduced by your platform. These

accelerations will decrease the accuracy of the Roll and Pitch estimation using

Euler angles. Introducing filtering will improve the accuracy if the platform

acceleration is dynamic and can be filtered out.

Note: The future OS5000-USG compass will introduce rate Gyros and Kalman

filters which can remove most short-term dynamic acceleration effects. This

product is in development and should be released in the future.

1) Analog to Digital Converter Decimation Filter

The analog to digital converter is an AD7799 24 bit Sigma delta converter. It has

an internal decimation filter that sets the filter period and the sampling update

rate.

The lower the setting the faster the update rate can be. If your using a

40hz output rate you should set this value from 3 to 2.

<esc>D (1-9) enter ! to change the update rate

1: 470 Hz, 4ms settling time

2: 242 Hz, 8ms settling time

3: 123 Hz, 15 ms settling time (factory default)

4: 62 Hz, 32 ms settling time

5: 50 Hz, 40 ms settling time

6: 39 Hz, 48 ms settling time

7: 33.2 Hz, 60 ms settling time

8: 19.6 Hz, 101 ms settling time, 90 dB rejection of 60Hz noise

9: 16.7 Hz, 120 ms settling time, 90 dB rejection of 50Hz noise

Use the higher values if you have large electrical or vibration noise you need to

filter out, at a much lower update rate.

23

(2) Averaging of readings, n Sample in the average

This will be a moving average filter of the magnetic readings and the

accelerometer readings. A value of 1 sample is no filtering, the default is 6 with an

output rate of 10 samples per second. The output rate of samples per second

combines with the number of samples in the average to give you the lag in

response time of the output.

(3) Output rate of the compass sentences, n samples per second.

Values that are negative are for less than one sample per second. You can set this

from -40 (1 sample every 40 seconds) to -2 (1 sample every 2 seconds). If the

values are positive this is number of samples per second. The range is 1 (1 sample

per second) to 40 (40 samples per second, 40 hz).

<esc>R n <enter> ! change the output rate of the compass to n

If your using output rates of greater than 20 hz you should change the D filter

value to 2 or 1.

Temperature Calibration (not required)

----------------------------------The OS5000 reports its temperature from the sensor inside of the modules 50

MIPS microprocessor. It is affected slightly by the operating voltage of the

module. It may require a linear offset to make it align with ambient temperature.

Using the command <esc>+ ttt <enter> you can offset this temperature. Enter

the value in degrees Cx10.. Example: 25 will add 2.5 degrees C to the

measurement. -92 will deduct 9.2 degrees C. Note: This calibration step is not

required and is for users looking for better temperature accuracy.

Calibration of Raw Magnetic readings in milliguass (not required)

------------------------------------------------------------------------You can set the milligauss of the Horizontal earths magnetic field using the

<esc>U mmmm <enter>. This is milliguassx10. Example 1794 for 179.4

milligauss. You can use the NOAA provided web model using your latitude and

longitude and nanoTesla Horizontal for the earth’s field in your local area.

Convert this to milligauss (divide by 100). Make this change in compass settings

before you calibrate the compass and the magnetic vector output will be in

milliGuass. NOAA Link:

http://www.ngdc.noaa.gov/seg/geomag/jsp/IGRFWMM.jsp?defaultModel=WMM

M210.12,Mx121.21,My12.12,Mz171.1

M=Vector Intensity

Mx=X component

My=Y component

Mz=Z component

Acceleration Raw Output Data

------------------------------------------

24

The acceleration raw data in G's can be output. The format is as follows:

G1.001,Gx0.621,Gy0.212,Gz0.754

G=Gravity vector, will be close to 1 if no dynamic acceleration present

Gx=X axis component of acceleration in G's

Gy=Y axis component of acceleration in G's

Gz=Z axis component of acceleration in G's

The "G" vector overall length will tell you if the platform is stable or experiencing

dynamic acceleration. Any dynamic acceleration changes the vector length from

near 1 to a lower or higher value.

Configuring the output sentence of the compass (Not Required)

---------------------------------------------------------------------

The <esc>X {decimal} <enter> command will let you set the bit mask of what

values the compass outputs. If you enter the max value of 4095 (all 12 bits set)

the compass will output all values. Use the Compass Demo program to help your

set this field on the compass. The program can be downloaded from:

www.ocean-server.com/compass/

Installing Windows Demo Utility

The windows demo utility is located on the web. Download the

CompassDemo5000.zip file and open it. This installer will put the compass demo

program on your system.

www.ocean-server.com/compass/

25

Main Screen:

Configuration Screen

26

Program Screen (allows for calibration, custom screen displays and other settings)

USB Drivers for the OceanServer OS5000-US family of compasses

You must download the USB drivers for windows directly from our web site.

These are only required if your using the USB interconnect option on the

OS5000-US compass. Remember if you have an OS5000-US it supports either

RS-232 serial or USB by selecting the correct cable. There are two connectors on

the module. The serial connector is on the TOP side and is 7 pin, the USB cable is

6 pins and on the bottom side of the module.

The standard USB dirvers can be downloaded from www.silabs.com

CP210x VCP Drivers Drivers for Windows, Mac and Linux

27

Our demo program runs on Windows only but on all other operating systems you

can open a terminal program to the virtual serial port and talk/listen to the

compass with it's NMEA strings.

If you would like a method to test the OS5000-T (TTL only) with a RS232 com

port on a PC, Black Box Networks offers a RS232 to TTL converter (PN#

IC1157A). Link:

http://www.blackbox.com/Catalog/Detail.aspx?cid=308,1421,1547&mid=4062

Basic Commands to Configure the OS5000

1) Mount the compass in the best location away from ferrous materials

2) Configure the compass firmware (hit <Esc> key prior to any command key)

a. Talk to the compass using a terminal program such as “Tera term”,

Settings: 19200,8,1,N to the device (9600 with firmware v1.0 ).

b. “<esc>V” Check firmware version

c. “<esc>B” Set compass baud rate (Active after power cycle)

d. “<esc>C” calibrate X,Y (rotate 360+ in 15+seconds, level X,Y)

e. “<esc>Z” Calibrate X (tip platform on side, rotate 360+)

f. “<esc>Q” Set the Declination value if you want “True magnetic

output” – This will offset for the delta between magnetic north and

true north.

g. “<esc>R” set the output rate for your application

h. “<esc>*” set user sentence format, 1,2,4,8

28

i. “<esc>$” soft iron calibration, align system to N,S,E,W magnetic

j. “<esc>A” Set averaging to smooth the readings

Note: These are the most common commands used (configurations will vary).

Depth or other sensor Connection for OS5500-USG

OS5500-USG connection with MSI pressure transducer, sensor outputs 1.-5V.

OceanServer compass has internal series divider to change voltage range to .5-2.5V

(3K+3K ohm series)

Note: See page 7 for assignment of pins 3-7.

OS5500-USG commands: <esc> M nnnn <enter> enter max pressure for sensor PSI <esc>P<space> set

zero depth, pressure output via 24 bit AD, resolution in 0.01 feet. Note: Depth assumes fresh water, no

internal density correction. If M0<enter> is set the device will output the sensor voltage for use with nondepth sensors. One example would be an altitude sensor for airborne applications.

Remember the OS5500 pressure input (white wire) has an internal voltage divider to allow an external 0-5V

signal to be input to the AD converters 0 – 2.5V input. The resistance values are two 3K resistors in series to

ground (6K resistance to ground.). The output of your sensor must consider this divider in it’s output drive

circuit.

29

Customer Support

Send technical questions to: support@ocean-server.com

Or call us at 508-678-0550 during normal business hours.

OceanServer Technology, Inc, 151 Martine St, Fall River, MA 02723 USA

Copyright © 2008 by OceanServer Technology, Inc. All Rights Reserved.

30

Loading...

Loading...