OceanAire OWC1811 Operation Manual

....

PAGE

General Information ................................................ 1-2

Product Data & Specifications ................................................ 3

UNIT DESCRIPTION

Standard Features ................................................ 4-5

Accessories ................................................ 6

Unit Construction ................................................ 7-8

Installation ................................................ 9-10

Parts Replacement Procedure ................................................ 11-12

Troubleshooting Guide ................................................ 13-15

Preventive Maintenance ................................................ 15-16

DIAGRAMS

Piping Schematic ................................................ 17

Wiring Diagram ................................................ 18

Warranty ................................................ 19

GENERAL DESCRIPTION

Air Conditioners are designed for applications where outside air is not available and spot cooling is

needed. The cord connected AquaCooler Models range from 13,780 BTU/HR to 60,100 BTU/HR floor

mount configuration to satisfy any space requirements. All models are provided with casters for

portability.

These models are thoroughly self-contained with the entire refrigeration system, water valve,

condensate pump, fan motor and electrical components neatly arranged in a platinum texture polyester

powder coated metal cabinet. Only power, condenser water supply and discharge and condensate drain

piping are required for installation.The 24 volt programmable electronic controller, provides the desired

comfort. The high counterflow efficiency design of the water-cooled condenser operation allows proper

amount of water flow to achieve the desired high and low refrigeration system pressures. Condenser

water is regulated by a refrigeration system head pressure actuated water regulating valve.

GENERAL REQUIREMENTS

A MINIMUM WATER PRESSURE OF 20 PSIG IS REQUIRED to actuate the water regulating valve

and allow water to flow into the condenser coil. The condenser water temperature leaving the unit

should not exceed 112° F. Ignoring this compliance will void the warranty on the refrigeration system.

IMPORTANT AquaCooler Air Conditioners are designed and engineered for the comfort of the

end user. The length of service received can be extended by following the installation and preventive

maintenance instructions. It is important that the warranty card be filled out completely and returned to

the factory within fourteen (14) days of installation of the unit in order to receive the benefits of the

warranty.

UNIT MODEL CAPACITIES

12780 BTU/HR COOLING

18840 BTU/HR COOLING

23950 BTU/HR COOLING

36100 BTU/HR COOLING

60,300 BTU/HR COOLING

NOMENCLATURE

O WC 24 1 2

OCEANAIRE VOLTAGE

WATER-COOLED SINGLE PHASE

CAPACITY SELECTION

CAPACITY SELECTION

NUMBER CODE 12..........13780 BTU/HR

18..........18840 BTU/HR

24..........23950 BTU/HR

36..........36100 BTU/HR

60..........60100 BTU/HR

2

Feb 20, 2001

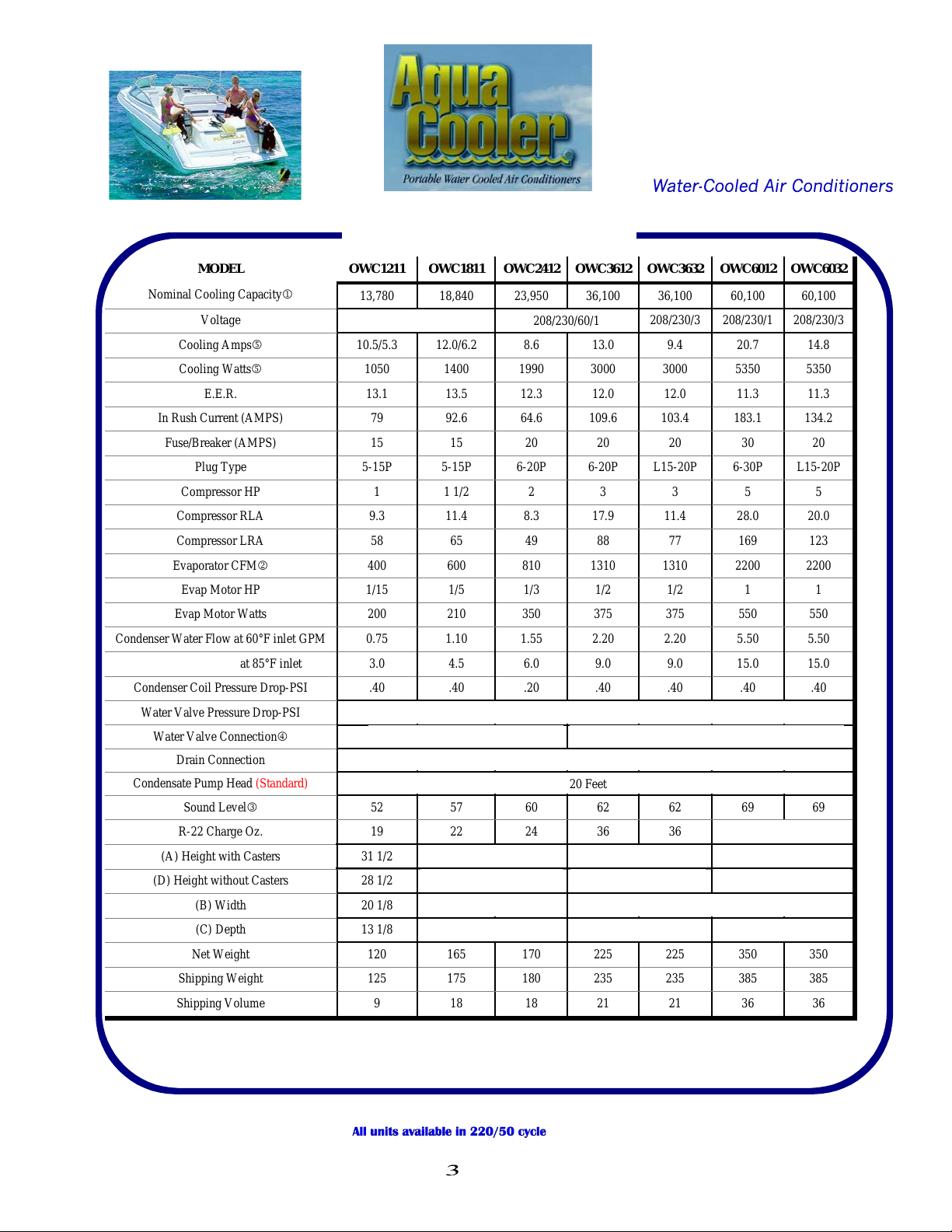

Specifications

MODEL OWC1211 OWC1811 OWC2412 OWC3612 OWC3632 OWC6012 OWC6032

Nominal Cooling Capacity1

Voltage 208/230/3 208/230/1 208/230/3

Cooling Amps5 10.5/5.3 12.0/6.2 8.6 13.0 9.4 20.7 14.8

Cooling Watts5 1050 1400 1990 3000 3000 5350 5350

E.E.R. 13.1 13.5 12.3 12.0 12.0 11.3 11.3

In Rush Current (AMPS) 79 92.6 64.6 109.6 103.4 183.1 134.2

Fuse/Breaker (AMPS) 15 15 20 20 20 30 20

Plug Type 5-15P 5-15P 6-20P 6-20P L15-20P 6-30P L15-20P

Compressor HP 1 1 1/2 2 3 3 5 5

Compressor RLA 9.3 11.4 8.3 17.9 11.4 28.0 20.0

Compressor LRA 58 65 49 88 77 169 123

Evaporator CFM2 400 600 810 1310 1310 2200 2200

Evap Motor HP 1/15 1/5 1/3 1/2 1/2 1 1

Evap Motor Watts 200 210 350 375 375 550 550

Condenser Water Flow at 60°F in let GPM 0.75 1.10 1.55 2.20 2.20 5.50 5.50

at 85°F inlet 3.0 4.5 6.0 9.0 9.0 15.0 15.0

Condenser Coil Pressure Drop-PSI .40 .40 .20 .40 .40 .40 .40

Water Valve Pressure Drop-PSI

Water Valve Connection4

Drain Connection

Condensate Pump Head (Standard)

Sound Level3 52 57 60 62 62 69 69

R-22 Charge Oz. 19 22 24 36 36

(A) Height with Casters 31 1/2

(D) Height without Casters 28 1/2

(B) Width 20 1/8

(C) Depth 13 1/8

Net Weight 120 165 170 225 225 350 350

Shipping Weight 125 175 180 235 235 385 385

Shipping Volume 9 18 18 21 21 36 36

13,780 18,840 23,950 36,100 36,100 60,100 60,100

13

208/230/60/1

2.0

3/8 MF

20 Feet

68

28 1/4

15 1/2 39

115/60/1 or 208/230/60/1

3/8 MF 5/8 MF

37 1/2 47 52 1/4

34 1/2 42 1/2 46 1/2

24 1/4

1Nominal Capacity is net BTU/HR at 80°F DB/67°F WB return air or 85°F EWT to 95°F LWT (#GPM/Ton). 2CFM with free discharge. 3Sound Pressure, dB at 5 feet Com. Config.

4Size 3/8 valve used on model 12, 18, 24 (3/8 MF Fitting) 5/8 valve used on models 36 and 60 (5/8 MF fitting)

5Amps & Watts at 208 volts

Specifications subject to change without notice.

STANDARD FEATURES

SERVICEABILITY

All AquaCooler Series units are designed with removable panels to provide full service accessibility.

Turn to page 11 “Part Replacement Procedure” for removal of the correct panel when replacing a part.

AUTOMATIC WATER VALVE

All units are equipped with a direct-acting, refrigeration system head pressure actuated water regulating

valve. This valve, factory set for 94° - 100° leaving water temperature (LWT), flows only the amount of

water required to achieve the desired refrigeration system operating pressure. Units used for closed loop

operation may be ordered without the water valve. If, however, the temperature of the return water is

questionable in a closed loop, the water valve may be helpful and left in the system with little pressure

drop.

ATTRACTIVE CABINET

The AquaCooler Series cabinet is constructed of 18 gauge galvanized steel with a platinum texture poly-

ester powder coated finish that will compliment any decor. The entire cabinet is insulated with a sound

absorbent insulation for cool, quiet comfort. The base pan is 14 gauge galvanized steel and remains dry

and free from odor and fungal growth.

HIGH PRESSURE SAFETY SWITCH

All units incorporate a manual re-set high pressure switch for maximum protection of the refrigeration

system and compressor. The cut-out pressure setting is 375 ± 5 PSIG for all models except OWC36

which uses 425± 5 PSIG. If the pressure exceeds this setting, the compressor stops and can be re-started

by depressing the “RESET” button located on the back panel of the unit. The high pressure control’s capillary line is attached to a schrader valve. This allows replacement of a defective control without recovering the refrigerant.

High Pressure Switch Reset Button

Water Cooled Condenser

Power Cord

Caster

Compressor

Electrical Box

Control Board

4

STATE-OF-THE-ART CONTROLS

The AquaCooler units maintain the desired temperature by setting the 24 volt State-Of-The-Art programmable electronic controller. Turn to page 10 for simplified operating instructions.

The thermostat has a setting range from 55° F to 85° F ± 1° F and also has a Celsius readout. A six speed

push-button regulates the evaporator motor if manual control is desired. In automatic mode, fan speed is

automatically reduced as temperature approaches set point. This provides maximum cooling with minimum air flow noise.

The Moisture Mode helps to control relative humidity and minimize compressor operation. A de-icing cycle helps prevent evaporator coil icing. The nonvolatile memory retains program and set points without

batteries.

A three digit display reads “CON” to indicate condensate alert and/or high pressure cut-out.

BUILT-IN CONDENSATE PUMP

Every unit is equipped with a condensate pump designed as an automatic condensate removal pump for

water dripping off the evaporator coil. The pump is capable of pumping against a 20 ft. head and is controlled by a float/switch mechanism which turns the pump “on” when approximately 2 1/2 inches of water

collects in the tank, and automatically switches “off” when the tank drains to a level of approximately

1 1/4 inches. A built-in pump safety switch turns off the air conditioner if the condensate line becomes

plugged or motor/pump failure should occur. An in line check valve is standard. The entire base pan

stays dry.

CONDENSER COIL

The water cooled copper/steel tube-in-tube type condenser coil is designed for a maximum water side

working pressure of 400psi. Optional cupro-nickel condenser coils are available for severe duty and saltwater/brine applications. Low pressure drop and efficient design (high EER’s) fully utilizes the heat transfer capability of this compact coil.

FILTER

All units are equipped with a 1/4 inch thick, throw away foam air filter located behind the return air grille

that can easily be removed and replaced. Just lift and pull the grille out and remove the filter.

SERVICE CORD

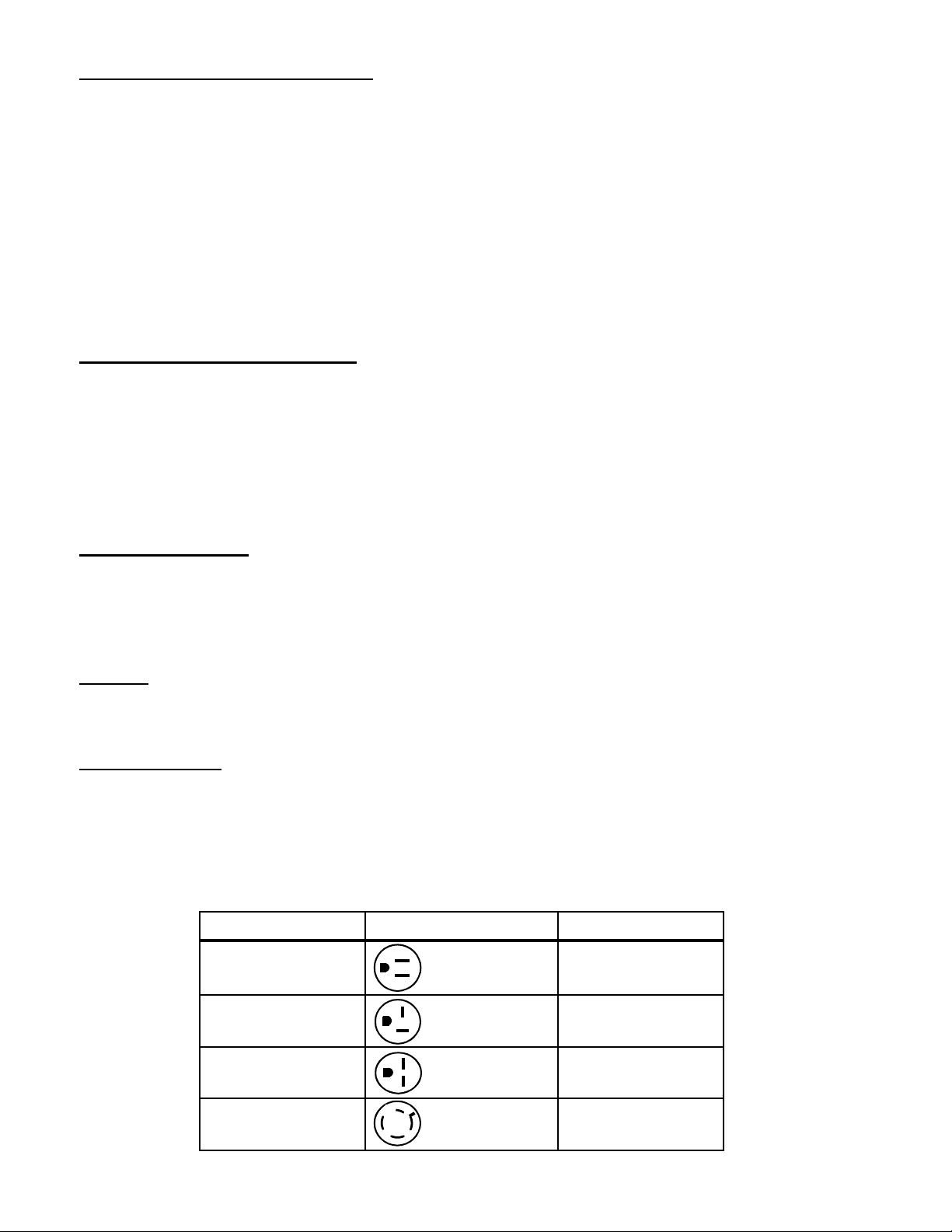

All AquaCooler Series units are equipped with the standard ten foot long service cord with plug configurations and receptacle requirements as shown in the chart below.

ELECTRICAL SERVICE PLUG CONFIGURATION

UNIT MODEL PLUG CONFIGURATION RECEPTACLE

OWC-12-18

115 V

OWC24-36

208/230 V

OWC6012

208/230 V

OWC6032

208/230

3 Phase

NEMA-L15-20P

15A-125V

NEMA 5-15P

20A-250 V

NEMA 6-20P

30A-250 V

NEMA-6-30P

20A-250 V

5

NEMA 5-15R

NEMA 6-20R

NEMA-6-30R

NEMA-L15-20R

Loading...

Loading...