Ocean Aire AIR BOSSR410A, AIR BOSS PAC60, AIR BOSS PAC12 User Manual

ENGINEERING, INSTALLATION AND SERVICE MANUAL

PAC60

PAC12

AIR BOSS

Portable Air-Cooled Spot Cooler

R410A Models

TABLE OF CONENTS PAGE

GENERAL DESCRIPTION …................................. 1

PRODUCT DATA AND SPECIFICATIONS............ 2

UNIT DESCRIPTION

Standard Features.................................. 3

Applications / Operation.......................... 4

Electrical.................................................. 5

Condensate............................................. 6

Accessories………................................... 7 - 13

Installation................................................ 14

Thermostat............................................... 15

SERVICE

Replacement Parts Procedure................. 16

Troubleshooting Guide............................. 17

Preventive Maintenance........................... 18

DIAGRAMS

Unit Interior................................................ 19

Piping Schematic....................................... 20

Wiring Diagrams......................................... 21 - 26

Use of Extension Cords............................. 27

Three Phase Monitor................................. 28

FORWARD

This manual provides the user with basic details for the installation

and operation of the Oceanaire Air Boss spot cooler. It is recommended to read and fully understand the instructions outlined within

this manual, before operating the Air Boss unit.

As with all commercial air conditioning equipment, it is recommended

to have the Air Boss sized and installed by a licensed specifying

engineer and contractor, in accordance with all local and state codes.

The length of service received can be extended by following the

installation and preventive maintenance instructions.

NOTICE

In our ongoing process of continuous improvement, the items and

procedures described in this manual are subject to change without

notice. Please note model and serial number of the Air Boss unit

when contacting the factory

.

NOMENCLATURE

P AC 24 1 2

PORTABLE VOLTAGE

AIR-COOLED PHASE 1 or 3

NOMINAL CAPACITY

CAPACITY RATING

NOMINAL CAPACITY 12..........12,000 BTU/HR

18..........18,000 BTU/HR

24..........24,00 BTU/HR

36..........36,000 BTU/HR

60……...60,000 BTU/HR

GENERAL DESCRIPTION

The Oceanaire AIRBOSS is a portable air-cooled spot cooler designed for

permanent or temporary cooling applications. The entire air conditioning

unit has been built in an attractive sheet metal cabinet, equipped with heavy

-duty casters for mobility. All Air Boss models come with a 10-foot power

cord for electrical connection and added mobility in service. These spotcoolers are designed to direct air to specific areas or objects through a discharge grill located on the upper-front of the unit, while rejecting heat from

the top of the unit. The Air Boss models range in cooling capacities from

12,000 BTU/HR to 60,050 BTU/HR to satisfy most space cooling

requirements.

The Air Boss is a self-contained unit with the entire cooling system,

evaporator and condenser fan motors and electrical components neatly

arranged in a gray polyester powder coated metal cabinet. When connected to the proper source of electrical power, a 24-volt thermostat controls

the Air Boss unit to provide the desired level of comfort and cooling.

A wide variety of accessories and factory installed options are available for

the Air Boss units allowing for improved performance and versatility.

WARRANTY CARD

It is important that the warranty card be filled out completely and

returned to the factory within fourteen (14) days of installation of the

unit in order to receive the benefits of the warranty.

1

2

AirBos

s

Deluxe Air-Cooled Portable Air Conditioners

Specifications subject to change without notice

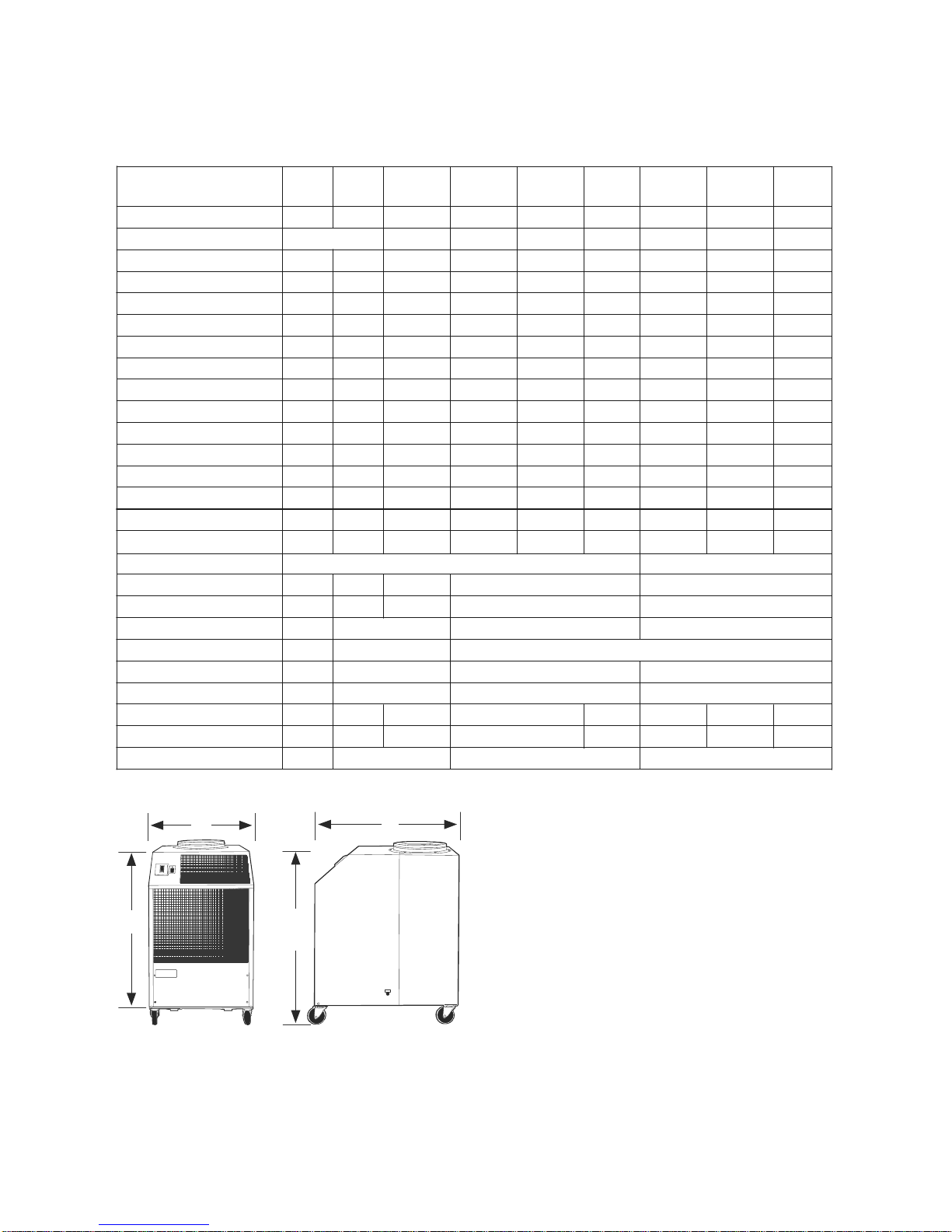

MODEL: PAC

121 1

1811

2412 3612 3632 3634 6012 6032 6034

Cooling Capacity

1

11,800

16,800

24,020 36,050 36,050 36,050 60,050 60,050 60,050

Voltage (V/Phase) at 60Hz 115/1

208-230/1 208-230/1 208-230/3 460/3 208-230/1 208-230/3 460/3

Cooling Amps

6

10.4

14.1

14.9 18.1 17.2 8.7 32.0 20.4 14.8

Cooling Watts

6

1180

1670

2700 3620 3620 3620 6000 6000 6000

In Rush Current (Amps)

77.5

100.5

90 140 122 122 169 140 140

Plug Type

5-15P

5-20P

6-20P 6-30P L15-30P L16-20P 6-50P L15-30P L16-20P

EER

3

10.0

10.0

8.9 10.0 10.0 10.0 10.0 10.0 10.0

Compressor HP

1

1 1/2

2333555

Compressor RLA

9.5

12.3

10.5 13.6 8.8 5.0 27.6 18.1 9.0

Compressor LRA

50

63

48 83 77 35 158 137 62

Evap CFM

4

400

600

810 1310 1310 1310 1950 1950 1950

Evap Motor HP

1/8

1/8

1/3 1/3 1/3

1/3

111

Evap Motor Watts

200

210

350 375 375 375 550 550 550

Condenser CFM

580

930

1010 1390 1390 1390 2200 2200 2200

Condenser Motor HP

1/8

1/8

1/3 1 1 1 1 1 1

Condenser Motor Watts

280

450

330 460 460 460 750 750 750

Condensate 5 Gallon Condensate Tank - STANDARD (Pump Optional) Pump -STANDARD (20 ft. Lift)

Sound Level

5

54 60

65 69 78

R-410A Charge Oz.

18 40

37 66 80

(A) Height with Casters (in.)

37

44 1/2

51

52

(B) Width (in.)

20 24

27

(C) Depth (in.) 25 30

35 39

(D) Height w/o Casters (in.) 32 1/2

39 1/2 45

46

Net Weight (lb.)

180

260

260

365

485 485 515

Shipping Weight (lb.)

200

285

285

405

525 525 555

Shipping Volume (cu. ft.)

19

28 40 48

380

420

SPECIFICATIONS

1. Cooling Capacity is total BTUH at 80ºDB/67ºWB return air,

95ºF Outdoor at high fan speed

2. Time Delay fuses/circuit breakers are recommended

3. EER is determined at high fan speed, with condenser

discharge air ducted into another area

4. CFM with free discharge

5. Sound Pressure, dB at 5 feet, commercial operation

6. Amps & Watts at 208 Volts

May operate down to 55º if equipped with hot gas bypass

(Factory installed)

Ambient operating range 65º to 105º

50 Hz MODELS AVAILABLE - CONSULT FACTORY

Note: Condenser inlet air plenum adds

13 inches to dimension “C”

D

B

A

C

STANDARD FEATU RES

CABINET

The AirBoss Series cabinet is constructed of 18 gauge steel with a gray polyester powder

coated finish that will compliment any decor. The entire cabinet is insulated with a soundabsorbing insulation for cool, quiet comfort. All units come equipped with handles and

swivel casters for portability and convenient set-up.

ELECTRONIC THERMOSTAT

All Air Boss unit are equipped with a non-programmable electronic thermostat. When

power is connected to the unit, the thermostat will control the Air Boss to cool a space to

the desired temperature. The thermostat is also capable of controlling the fan to operate

automatically (when needed) or continuously. To protect the compressor from shortcycling, there is a built-in, 4-minute time delay in the thermostat.

FAN SPEED CONTROL

A two position rocker switch, located next to the thermostat, provides the user with the

option of running the evaporator fan in high-speed or low-speed.

CONDENSATE RESERVOIR/PUMP

Air Boss units come equipped with a means for handling the condensate generated dur-

ing the cooling process. All models except the 5-ton models come equipped with a

Condensate Reservoir Tank, that captures the condensate from cooling. The tank can

then be easily removed from the unit and emptied as required.

The 5-ton Air Boss models come equipped with an Automatic Condensate Pump that

disposes of the condensate. The pump comes with a 25 foot long vinyl hose that allows

for the disposal of the condensate water to a drain. The automatic pump is capable of a

20ft lift, to handle just about any installation requirement.

CONDENSATE ALARM LIGHT

On the front of all Air Boss models, there is a Condensate Alarm Light (RED) located near

the thermostat. For models less than 5-tons, the light indicates that the condensate tank

is full and needs to be emptied. In the 5-ton Air Boss units (model PAC60) the light indicates a condensate pump over-flow condition where the pump is either disabled, or incapable of rejecting the condensate water, and must be serviced.

FILTERS

All Air Boss units are equipped with washable filters at the air intakes. 1/8” mesh air filters

located behind the evaporator return air grill serve to filter the air before it is cooled. A

1/2” aluminum mesh filter serves to protect the condenser coil from dust build-up. Both

filters can be easily removed and cleaned.

HIGH PRESSURE SAFETY SWITCH

Located on the back of the Air Boss unit is a manual re-set high pressure switch, used for

the protection of the compressor. If the condensing pressure exceeds the limit setting, the

cut-out shuts down the compressor, while the evaporator fan remains running. The compressor can be re-started, once the condensing pressure has lowered, by depressing the

“RESET” button.

POWER CORDS

All Air boss units come with power cords, convenient connection and portability. All units

except the 5-ton models, and 3-phase models are equipped with LCDI for added safety

devices.

3

4

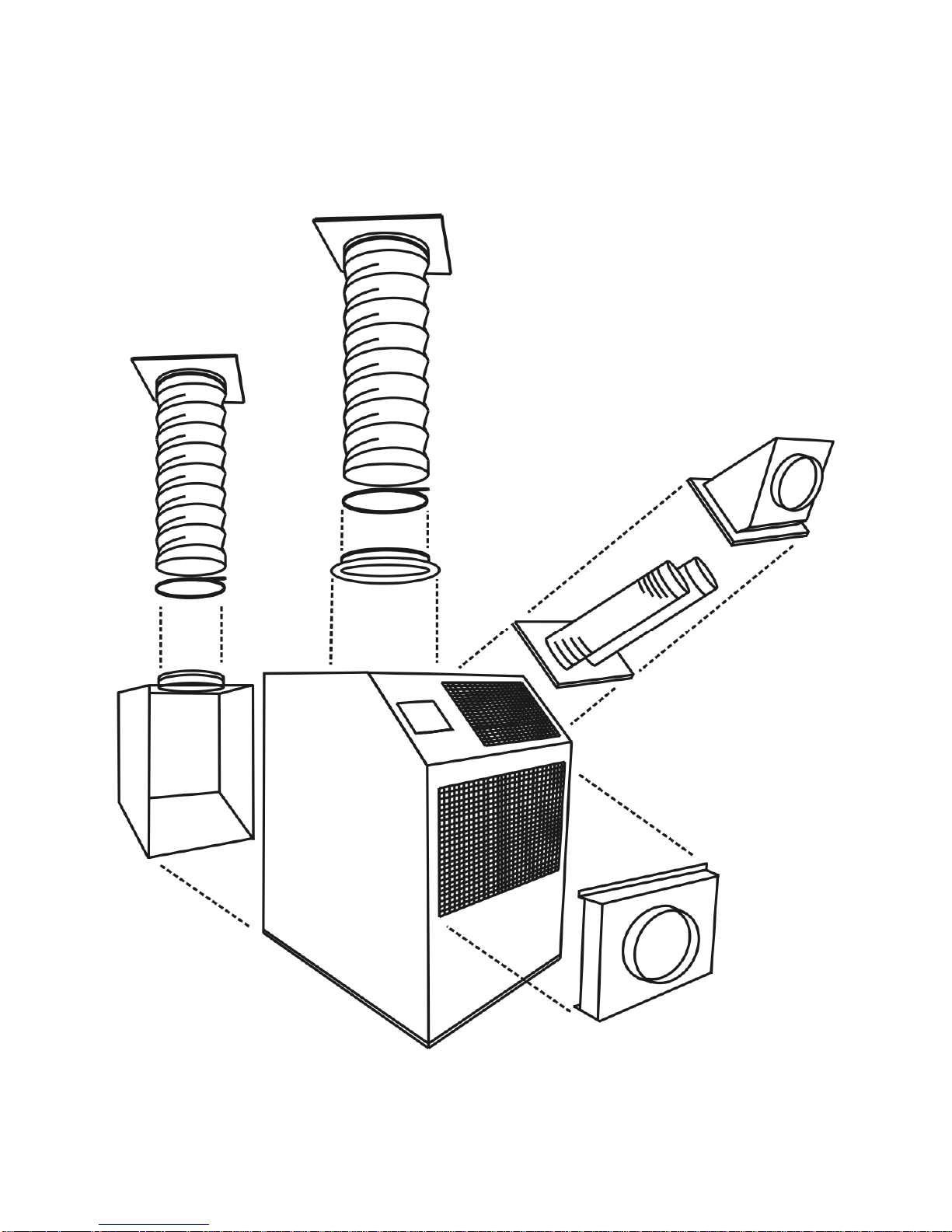

APPLICATIONS

SPOT COOLER

The Air Boss can be used in an open environment to cool specific objects or "spots".

Spot Cooling is a convenient and economical way to provide air conditioning where

cooling the entire space is impractical. Cool air is discharged from the unit and is directed

where it is needed. Nozzle kits can be used to improve direction of the cooling airflow.

AREA COOLER

When the Air Boss is installed in an area that is not totally enclosed, the condenser hot air

exhaust duct directs condenser air out of the area, allowing the evaporator air to cool the

specific space.

ROOM AIR CONDITIONER

When ducted, the OceanAire AirBoss can be used as a room air conditioner to cool an

enclosed space. Using the condenser return air plenum (DCP) and ceiling discharge kit

(CK) and ceiling panel kits CK-PL accessories, the Air Boss can operate as a room air

conditioner with the condenser air isolated form the conditioned space.

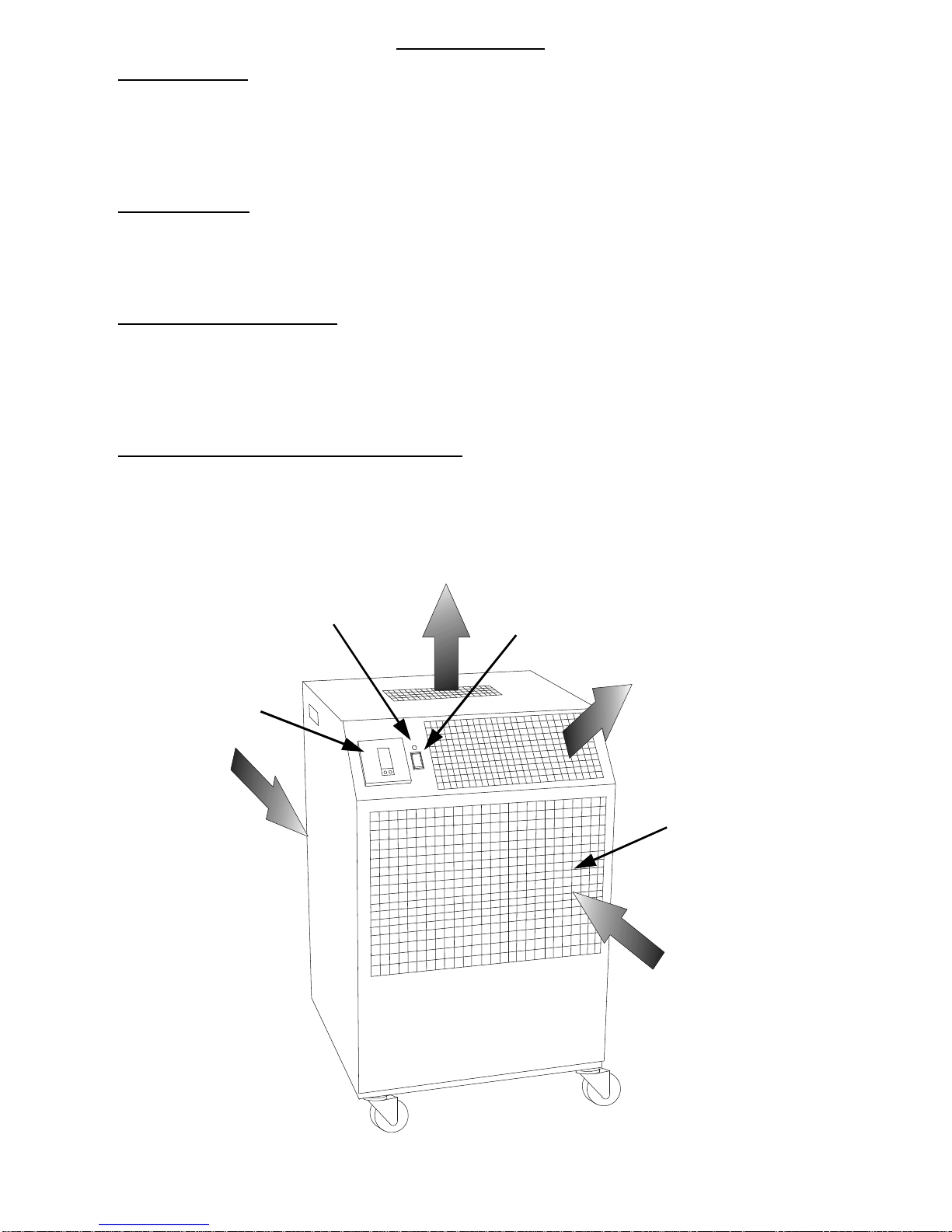

AIR BOSS—OPERATION / DESCRIPT ION

CONDENSER

AIR INLET

(Back of Unit)

CONDENSER FAN DISCHARGE

“HOT”

EVAPORATOR

FAN DISCHARGE

“COOL”

RETURN AIR

GRILL

AND FILTER

CONDENSATE

ALARM LIGHT

FAN SPEED

SWITCH

ELECTRONIC

THERMOSTAT

AIR BOSS—FRONT VIEW

SERVICE CORD

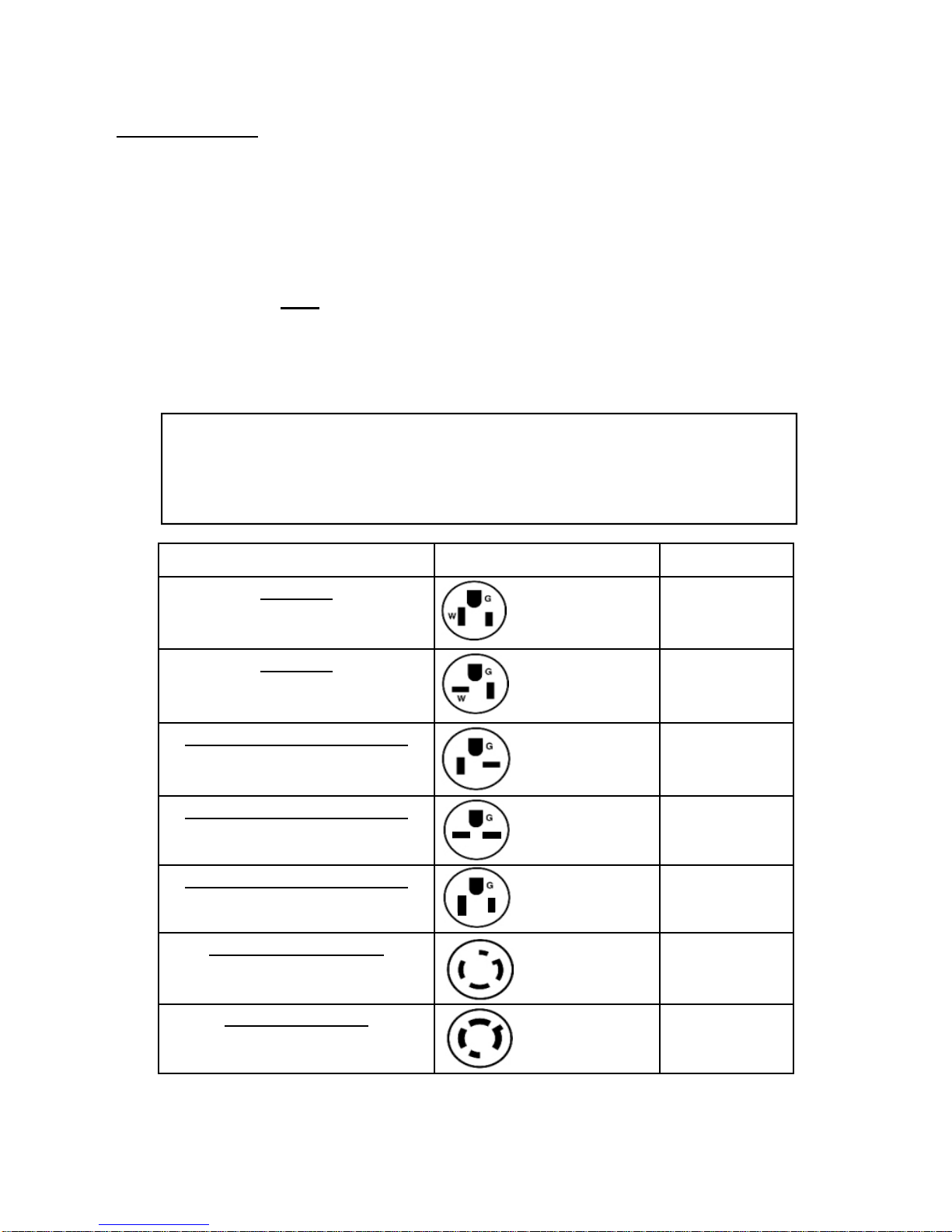

All AirBoss Series units are equipped with the standard ten foot long service cord with

plug configurations and receptacle requirements as shown in this chart. PAC1211,

PAC1811, PAC2412 and PAC3612 units come with LCDI (Leakage Current Detection

& Interruption) devices that serve as a means of electrical protection.

CAUTION—DO NOT

USE THE LCDI AS AN ON/OFF SWITCH FOR THE UNIT

All 3-phase models are equipped with locking plugs for added connection reliability.

Refer to the chart below for plug and receptacle details for all Air Boss models.

A DAMAGED LCDI POWER SUPPLY CORD MUST BE

REPLACED WITH A NEW POWER SUPPLY CORD

OBTAINED FROM OCEANAIRE, AND NOT REPAIRED

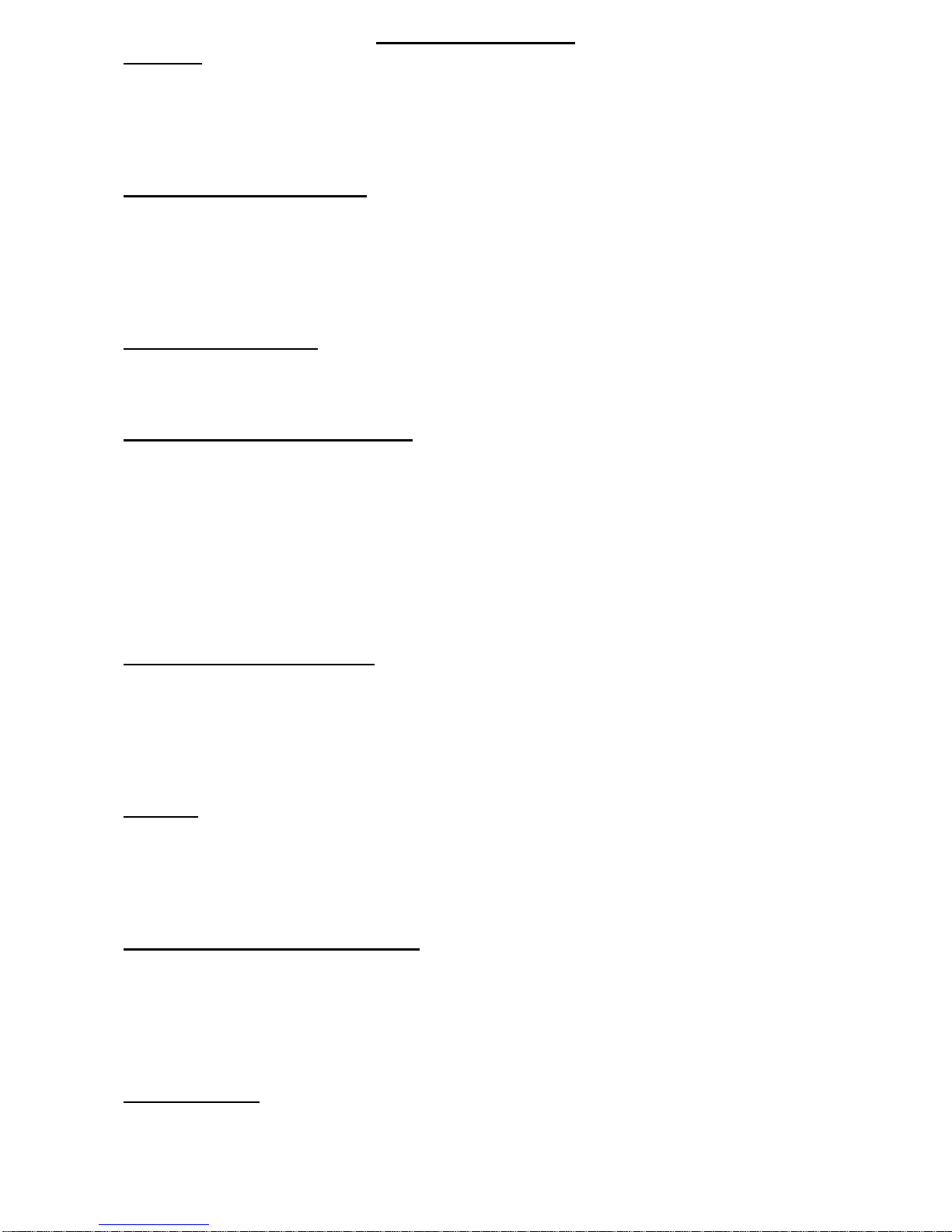

UNIT/MODEL PLUG CONFIGURATION RECEPTACLE

115 VOLT

PAC1211

115 VOLT

PAC1811

208-230 VOLT SINGLE PHASE

PAC2412

208-230 VOLT SINGLE PHASE

PAC3612

208-230 VOLT SINGLE PHASE

PAC6012

208-230 VOLT 3-PHASE

PAC3632

PAC6032

460 VOLT 3-PHASE

PAC3634

PAC6034

15A-125 VOLT

NEMA 5-15P

20A-125 VOLT

NEMA 5-20P

20A-250 VOLT

NEMA 6-20P

30A-250 VOLT

NEMA 6-30P

50A-250 VOLT

NEMA 6-50P

30A-250 VOLT

NEMA L15-30P

20A-460 VOLT

NEMA L16-20P

NEMA-5-15R

NEMA 5-20R

NEMA 6-20R

NEMA 6-30R

NEMA 6-50R

NEMA L15-30R

NEMA L16-20R

5

6

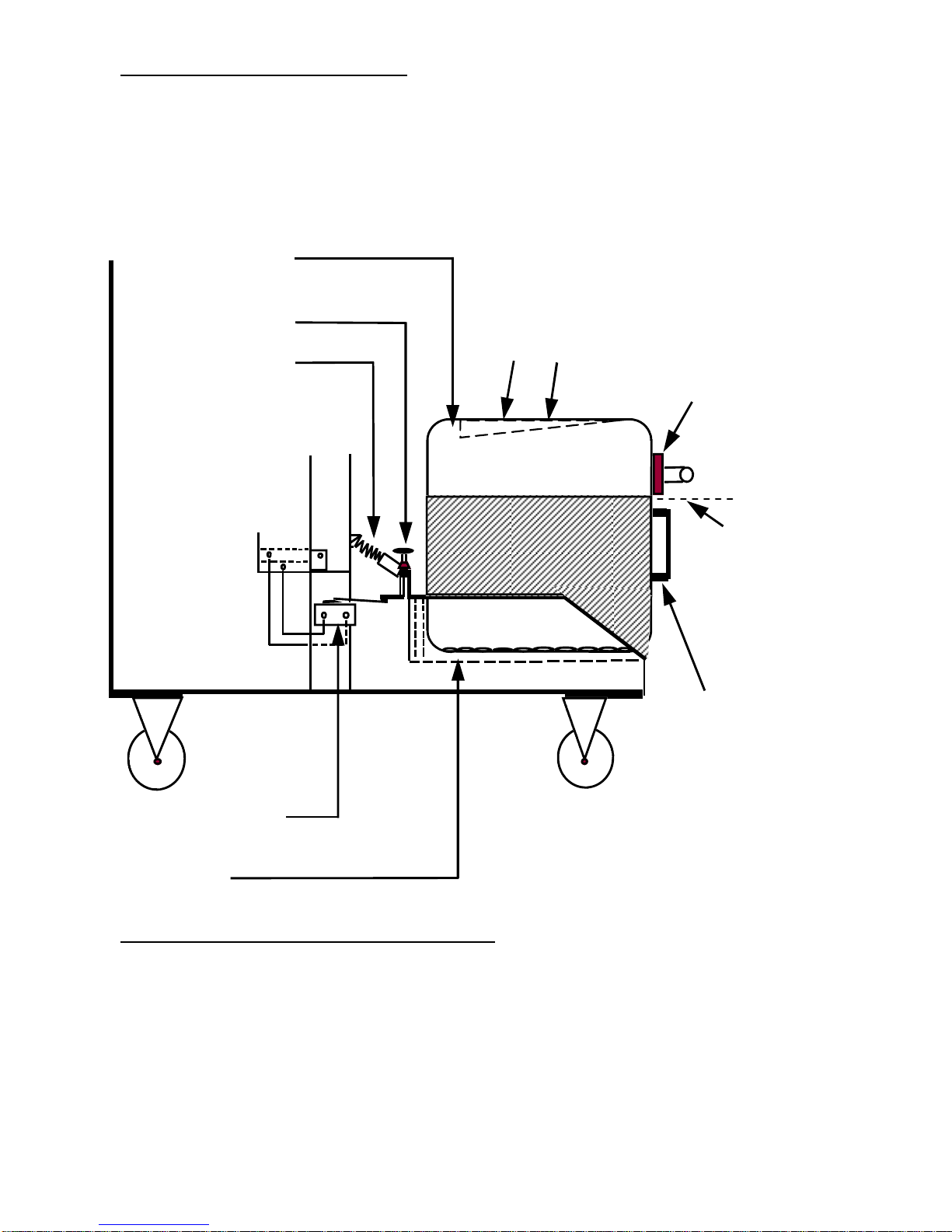

CONDENSATE RESERVOIR TANK

For Air Boss Models PAC12, PAC18, PAC24 and PAC36, a 5-gallon polyethylene tank is

provided standard, to collect condensate. The tank is located in the lower, front section

of the unit. A high water level cut-out switch is used to stop the compressor and

condenser fan automatically when the tank's pre-set water level has been reached. The

evaporator fan will continue to run, circulating air.

TANK LEVEL ADJUSTMENT INSTRUCTIONS

An adjustment screw is provided to vary the cut-off of the tank full switch. If a lighter (less

weight) level of water is desired, turn the adjusting screw clockwise. Do not exceed 6 full

turns counter-clockwise.

CAUTION, TURN UNIT OFF: BEFORE ADJUSTING SET SCREW

BEFORE REMOVING TANK TO EMPTY CONDENSATE

Turn screw clockwise to lower water level. Less water makes tank lighter and easier to

remove.

NOTE: Max. and Min. water levels shown are those at which the unit will shutdown and

not restart until the condensate tank has been drained.

Condensate Tank

*Tank Water Level

Adjusting Screw

Spring

Handle

For PAC36 —

Condensate

drains

through a

corrugated

hose into

tank cap

High Water Level

Cut-Out Switch

Condensate

Tank Tray

Max W ater

Level

4" From Top

For PAC12, PAC18

and PAC24 —

Condensate water

drops from drain pan

into trough on tank

7

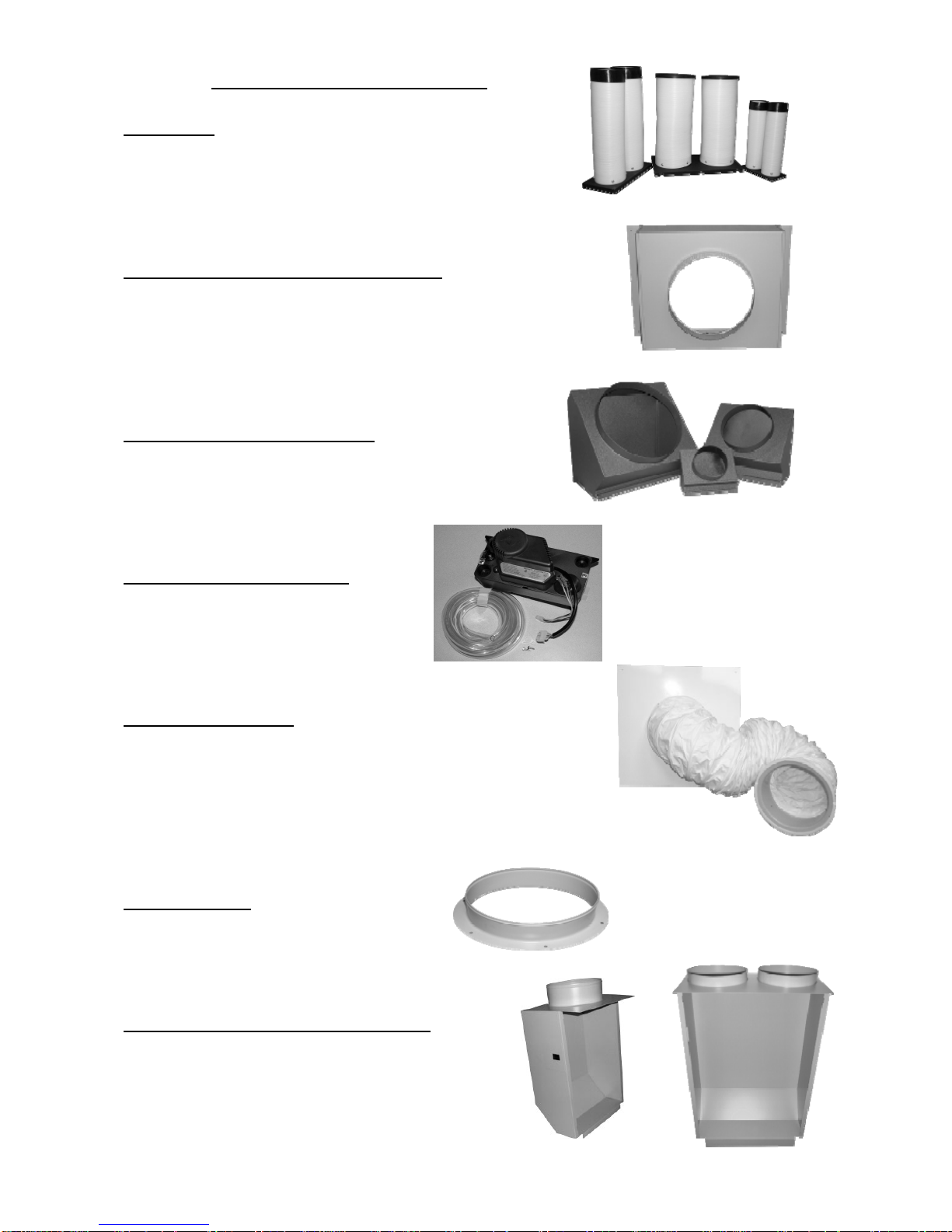

CK-12PL

(2 Req’d for

2DCP-4

CK-12

CK-16

2DDA-6

2DDA-10

2DDA-16

2NK-1

2NK-2

2NK-3

DEP-10

2DEP-12

DEP-16

2DCP-1

2DCP-2

2DCP-4

AIR BOSS UNIT

ACCESSORIES

PAC – AIR BOSS ACCESSORIES

NOZZLE KIT

2NK-1 (2 X 4-Inch) PAC12

2NK-2 (2 X 6-Inch) PAC18, 24

2NK-3 (2 X 8-Inch) PAC36, 60

EVAPORATOR RETURN AIR PLENUM

DEP-10 (10-Inch Round) PAC12

2DEP-12 (12-Inch Round) PAC18, 24

DEP-16 (16-Inch Round) PAC36, 60

DISCHARGE DUCT ADAPTER

2DDA-6 (6-Inch Round) PAC12

2DDA-10 (10-Inch Round) PAC18, 24

DDA-16 (16-Inch Round) PAC36, 60

CONDENSATE PUMP KIT *

PC-1P 115V Models

PC-2P 230V Models

* Not Required for PAC60’s

CEILING PANEL KIT

CK-12 PAC12, 18, 24

CK-16 PAC36, 60

CK-12PL CK-12 without Duct Flange

CKP-12 2 X 2 Ceiling Panel w/12-Inch Dia. Flange

CKP-16 2 X 2 Ceiling Panel w/16-Inch Dia. Flange

DUCT FLANGE

DF-12 12-Inch Duct Flange

DF-16 16-Inch Duct Flange

CONDENSER RETURN AIR PLENUM

2DPC-1 PAC12

2DCP-2 PAC18, 24

2DCP-4 PAC60

8

Loading...

Loading...