Océ User manual

Océ VarioStream 8000

Continuous Printing System

Océ Printing Systems GmbH

Copyright

Copyright

Copyright

All rights reserved, including rights of translation, reprinting, reproduction by

copying or any other method, of this document as a whole or parts thereof.

Offenders will be liable for damages.

All rights, including rights created b y patent grant or registration of a utility model

or design, are reserved.

Delivery subject to availability; right of technical modifications reserved.

Trademark protection

The designations Océ ColorStream

Web Buffer

TonerSafe

All hardware and software names used are trademarks of their respective owners.

©

2004 - 2008 Océ

®

, Océ VarioStream®, Océ VarioPrint®, Océ

®

, Océ PRISMA®production, Océ CustomTone®, and Océ

TM

are protected by trademark.

Training

We also offer courses in our Training Center for Océ VarioStream 8000.

Information:

Phone +49 8121 72 3940

Fax +49 8121 72 3950

Océ Printing Systems GmbH

ITC

Postfach 1260

85581 Poing

Germany

Order number A29246-X29-X-5-7680

Edition 2008-05

US

Table of Contents

Table of Contents

Chapter 1

Notes on printing system documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Notes on documentation for the printing system — overview . . . . . . . . . 12

Documentation signposts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Notes on Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Notes on the Help - Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Opening Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Navigating in Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Opening Direct Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Symbol conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Symbols in the text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Symbols in illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Other documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Manufacturer of the printing system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Statutory requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 2

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Security — overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Intended Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Flagging of safety directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Warning and information signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Accident and damage prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Accident and damage prevention — overview . . . . . . . . . . . . . . . . . . 35

Personal Representations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Transportation, assembly and installation, repair . . . . . . . . . . . . . . . . 40

Fire, disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Safety regulations and standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Safety regulations and standards — overview . . . . . . . . . . . . . . . . . . 42

CE Mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chapter 3

Description of the printing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Description of the printing system — overview . . . . . . . . . . . . . . . . . . . . 46

Device overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Equipment - overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3

Table of Contents

Front view of the printing system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Rear view of the printing system and main switch . . . . . . . . . . . . . . . 50

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Operating elements - overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Key control panel on the paper transporter. . . . . . . . . . . . . . . . . . . . . 53

Additional operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Operator Attention Light (OPAL) (optional) . . . . . . . . . . . . . . . . . . . . 57

Operating elements in the printing system . . . . . . . . . . . . . . . . . . . . . 59

Paper specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Paper feed options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 4

Operator panel description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Description of the Operator Panel — Overview . . . . . . . . . . . . . . . . . . . . 66

Toolbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Toolbar - overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Buttons and displays in the left-hand area . . . . . . . . . . . . . . . . . . . . . 68

Buttons and displays in the center area . . . . . . . . . . . . . . . . . . . . . . . 70

Frame toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Menu tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Menu tree — overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

'General' menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

'General' menus — overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

'User management' menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

'User' menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

'Security' menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

VarioStream menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

'VarioStream' menus — overview. . . . . . . . . . . . . . . . . . . . . . . . . . 81

'Displays' menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

'Configuration' menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

'Setup' menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

'Replace consumables ' me nu s. . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Menu display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Chapter 5

Working with the operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Working with the operator panel — overview. . . . . . . . . . . . . . . . . . . . . . 90

Managing user settings (Key Operator) . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Manage user settings (Key Operator) — overview . . . . . . . . . . . . . . . 91

Advanced password protection (optional extra for the Variostream 9000)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

'Add user'. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

'Delete user'. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Setting password/'General' tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Releasing and blocking menus and elements/'User rights' tab. . . . . . 97

4

Table of Contents

Setting language/'User profile' tab . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Managing user settings (Operator) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Manage user settings (Operator) — overview . . . . . . . . . . . . . . . . . . 99

Log on as user and request an access ticket . . . . . . . . . . . . . . . . . . 100

Changing password/'Password' tab . . . . . . . . . . . . . . . . . . . . . . . . . 101

Changing language/'User profile' tab . . . . . . . . . . . . . . . . . . . . . . . . 102

Log off as user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Selecting settings and entering values . . . . . . . . . . . . . . . . . . . . . . . . . 104

Applying or resetting settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Configuring operation mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Working with setups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Working with setups — overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Creating a new setup or changing a setup . . . . . . . . . . . . . . . . . . . . 108

Importing a setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Exporting a setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Managing resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Managing resources — overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Resource installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Delete resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Editing 'Replace consumables' menus on the operator panel . . . . . . . . 117

Chapter 6

Operating the printing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Operating the printing system — overview . . . . . . . . . . . . . . . . . . . . . . 122

Powering on the printing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

After printing has stopped, switch the printing system back to 'Ready' . 125

Inserting the paper web on single printing systems. . . . . . . . . . . . . . . . 126

Inserting the paper web on single printing systems - overview. . . . . 126

Preparing to insert the paper web. . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Preparing to insert the paper web - overview. . . . . . . . . . . . . . . . 127

Stopping the printing system and opening the doors. . . . . . . . . . 128

Preparing the paper transporter. . . . . . . . . . . . . . . . . . . . . . . . . . 129

Preparing the paper web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Inserting the paper web. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Inserting the paper web - overview . . . . . . . . . . . . . . . . . . . . . . . 133

Inserting paper web in paper input. . . . . . . . . . . . . . . . . . . . . . . . 134

Inserting paper web in vacuum box and paper transporter . . . . . 136

Completing the insertion of the paper web . . . . . . . . . . . . . . . . . . . . 140

Completing the insertion of the paper web - overview . . . . . . . . . 140

Close flaps, units, etc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Settings for different paper properties . . . . . . . . . . . . . . . . . . . . . 143

After inserting the paper web. . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Inserting the paper web in twin and triplex printing systems . . . . . . . . . 148

Inserting the paper web in twin and triplex printing systems - overview .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5

Table of Contents

Preparing to insert the paper web on twin or triplex printing systems 149

Paper guide in the inline turn bar . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Paper guide in the turning platform. . . . . . . . . . . . . . . . . . . . . . . . . . 156

Synchronization and positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Synchronization and positioning - overview . . . . . . . . . . . . . . . . . . . 163

Synchronization - Page integrity marks (PIM) for perforated paper . 164

Synchronization - Barcode synchronization mark for unperforated paper

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Positioning mark sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Positioning mark sensors - overview. . . . . . . . . . . . . . . . . . . . . . . . . 171

Positioning upper mark sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Positioning lower mark sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Calibrating mark sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Calibrating mark sensor - overview. . . . . . . . . . . . . . . . . . . . . . . . . . 176

Calibrating upper mark sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Calibrate lower mark sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Paper change settings on the printing system. . . . . . . . . . . . . . . . . . . . 181

Paper change settings on the printing system - overview. . . . . . . . . 181

Possible dirt after paper change . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Set rear paper web guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Set pressure roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Set loop puller force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Setting the position of the brake roller. . . . . . . . . . . . . . . . . . . . . . . . 187

Paper change settings on the operator panel . . . . . . . . . . . . . . . . . . . . 194

Paper change settings on the operator panel - overview . . . . . . . . . 194

Settings on the operator panel: 'Setup' . . . . . . . . . . . . . . . . . . . . . . 195

Settings on the operator panel: Paper with/without perforation. . . . . 196

Settings on the operator panel: Paper dimensions . . . . . . . . . . . . . . 197

Settings on the operator panel: Paper brake. . . . . . . . . . . . . . . . . . . 198

Settings on the operator panel: Fusing . . . . . . . . . . . . . . . . . . . . . . . 199

Synchronized roll change during a print job (twin/triplex). . . . . . . . . . . . 200

Replacing paper roll during a print job (twin/triplex) - overview. . . . . 200

Automatic start of roll replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Manual roll replacement before paper end or without external paper end

Paper guide in the inline turn bar - overview . . . . . . . . . . . . . . . . 150

Paper guide for reverse-side printing . . . . . . . . . . . . . . . . . . . . . . 151

Paper guide for front-side printing . . . . . . . . . . . . . . . . . . . . . . . . 154

Changing paper width in the inline turn bar . . . . . . . . . . . . . . . . . 155

Paper guide in the turning platform - overview. . . . . . . . . . . . . . . 156

Paper guide for reverse-side printing . . . . . . . . . . . . . . . . . . . . . . 157

Paper guide for front-side printing . . . . . . . . . . . . . . . . . . . . . . . . 160

Setting the position of the brake roller - overview. . . . . . . . . . . . . 187

Paper web runs to the rear in the printer . . . . . . . . . . . . . . . . . . . 188

Paper web runs to the front in the printer. . . . . . . . . . . . . . . . . . . 190

The brake roller setting has been lost . . . . . . . . . . . . . . . . . . . . . 192

6

Table of Contents

light barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Activate/deactivate function 'Automatic start' . . . . . . . . . . . . . . . . . . 204

Affixing the paper web. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Printing with another color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Printing with another color - overview. . . . . . . . . . . . . . . . . . . . . . . . 209

Replacing the toner feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Replacing the toner feed - overview. . . . . . . . . . . . . . . . . . . . . . . 210

Removing toner feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Installing toner feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Replacing the developer station . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Replacing the developer station — overview. . . . . . . . . . . . . . . . 217

Preparations for removing the developer station . . . . . . . . . . . . . 219

Removing the developer station. . . . . . . . . . . . . . . . . . . . . . . . . . 222

Final tasks for removing the developer station. . . . . . . . . . . . . . . 226

Preparations for installing the developer station . . . . . . . . . . . . . 228

Installing the developer station. . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Final tasks for installing the developer station . . . . . . . . . . . . . . . 234

Converting the printing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Converting the printing system - overview . . . . . . . . . . . . . . . . . . . . 237

Select configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Start conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Replacing the toner feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Replacing developer station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Changing the photoconductor drum . . . . . . . . . . . . . . . . . . . . . . . . . 243

Replace fuser roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Complete conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Powering off the printing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Chapter 7

Cleaning the printing system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Cleaning the printing system — overview . . . . . . . . . . . . . . . . . . . . . . . 250

Cleaning agents and devices, cleaning intervals. . . . . . . . . . . . . . . . . . 252

Clean the paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Clean transfer roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Clean plastic strips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Clean fuser station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Clean soft fuser roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Clean the developer station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Cleaning the sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Cleaning the sensors — overview. . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Cleaning the toner mark sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Cleaning the toner dust sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Cleaning the paper edge sensor in the fuser station. . . . . . . . . . . . . 281

Clean paper edge monitoring sensor (with inserted paper) . . . . . . . 283

Cleaning the toner suction system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

7

Table of Contents

Clean corotrons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Clean LED print head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Cleaning the filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Clean screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Cleaning the printing system generally . . . . . . . . . . . . . . . . . . . . . . . . . 294

Chapter 8

Replacing consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Replacing consumables — overview. . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Order numbers and packaging units for consumables. . . . . . . . . . . . . . 297

Monthly requirement for consumables. . . . . . . . . . . . . . . . . . . . . . . . . . 299

Toner bottle identification with Océ TonerSafeTM. . . . . . . . . . . . . . . . . 302

Replacing the developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Replacing the developer — overview . . . . . . . . . . . . . . . . . . . . . . . . 306

Empty developer station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Fill developer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Completing the replacement of the developer. . . . . . . . . . . . . . . . . . 318

Replacing the fuser oil bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Replacing the fuser oil bottle - overview . . . . . . . . . . . . . . . . . . . . . . 319

Removing the fuser oil bottle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Inserting the fuser oil bottle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Replacing waste oil container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Replacing the waste oil container — overview . . . . . . . . . . . . . . . . . 324

Removing waste oil container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Installing waste oil container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Change toner bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Filling toner box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Replacing the waste toner bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Replacing the waste toner bottle - overview . . . . . . . . . . . . . . . . . . . 332

Removing the waste toner bottle. . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Inserting the waste toner bottle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Chapter 9

Replacing expendables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Replacing expendables — overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Order numbers and packaging units for expendables . . . . . . . . . . . . . . 339

Monthly requirement for expendables . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Replacing the active filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Replacing the active filter - overview. . . . . . . . . . . . . . . . . . . . . . . . . 345

Remove active filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Insert active filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Replacing the pressure roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Replacing the pressure roller - overview. . . . . . . . . . . . . . . . . . . . . . 351

Remove pressure roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Install pressure roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

8

Table of Contents

Replacing the corotron s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Replacing the corotrons - overview. . . . . . . . . . . . . . . . . . . . . . . . . . 360

Preparing corotron replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Remove charge corotrons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Install charge corotrons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

Remove torn charge corotron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

Remove discharge corotrons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

Install discharge corotrons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Remove torn discharge corotron. . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Complete corotron replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Replacing the heating element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Replacing the heating element - overview . . . . . . . . . . . . . . . . . . . . 371

Remove heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

Installing the heating element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

Replacing the fine filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Replacing the fine filter - overview . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Remove fine filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

Install fine filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

Replacing the fuser roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

Replacing the fuser roller - overview. . . . . . . . . . . . . . . . . . . . . . . . . 385

Preparing to replace the fuser roller and removing the heating element

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 386

Remove fuser roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

Install fuser roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

Installing the heating element and completing replacement of the fuser

roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

Replacing the photoconductor drum . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

Replacing the photoconductor drum - overview . . . . . . . . . . . . . . . . 399

Removing the photoconductor drum. . . . . . . . . . . . . . . . . . . . . . . . . 400

Install photoconductor drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

Running in the photoconductor drum. . . . . . . . . . . . . . . . . . . . . . . . . . . 406

Replacing the cleaning brush. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Replacing the cleaning brush — overview . . . . . . . . . . . . . . . . . . . . 407

Remove cleaning brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Inserting the cleaning brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

Replacing the cleaning belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

Replacing the cleaning belt - overview . . . . . . . . . . . . . . . . . . . . . . . 413

Remove cleaning belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

Install cleaning belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 416

Replacing the transfer rol ler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 418

Replace/clean transfer roller - overview . . . . . . . . . . . . . . . . . . . . . . 418

Remove transfer roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

Install transfer roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

Replacing the waste col l ec tor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

Replacing the dirt bin - overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

9

Table of Contents

Remove dirt bin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

Install dirt bin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

Chapter 10

Correcting problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Correcting problems — overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

Processing messages on the operator panel. . . . . . . . . . . . . . . . . . . . . 431

Permitting or blocking remote access . . . . . . . . . . . . . . . . . . . . . . . . . . 435

Correct fusing errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 436

Clogged toner suction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

Clogged toner suction - overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

Vacuum out the toner feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

Remove toner from the clogged toner feed hose . . . . . . . . . . . . . . . 439

Substandard print quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

Substandard print quality - overview. . . . . . . . . . . . . . . . . . . . . . . . . 443

Substandard print quality Cause and correction . . . . . . . . . . . . . . . . 444

Chapter 11

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Technical data - Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

Technology and printing speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

Electrical values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

Mechanical conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Environmental conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

Appendix A

Your comments on this user guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

Your comments on this user guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 456

10

Chapter 1

Notes on printing system

documentation

11

Notes on documentation for the printing system — overview

Notes on documentation for the printing system — o verview

Introduction

The purpose of this documentation is to ensure that all printing system-related work

is carried out safely and correctly. It contains safety directives that must be strictly

observed.

Each section is divided into small, easy-to-understand subject areas. Overviews at

the beginning of th e sections help you to f ind the precise information you are looking

for quickly.

Overview

Here, you will find information on the following topics:

■ Documentation signposts on page 13

■ Notes on the Help - Overview on page 15

■ Symbols in the text on page 24

■ Symbols in illustrations on page 25

■ Other documents on page 26

■ Manufacturer of the printing system on page 27

■ Statutory requirements on page 28

12 Chapter 1 Notes on printing system documentation

Documentation signposts

Introduction

Documentation available to you on the Océ VarioStream 8000 includes a printed

user guide and help on the operator panel. This help is updated with every new

version of the operator panel software.

Security

This section gives you all necessary information on how to safely and efficiently

operate the printing syst em.

Description of the printing system

This section shows the structure of the printing system, describes the operating

elements and explains the printing principle. Y ou will also f ind information on paper

types and how to handle the paper.

Documentation signposts

Operator panel description

This section describes the individual areas of the operator panel with the most

important menus, buttons and icons.

Working with the operator panel

This section explains how you manage all user settings, how you select or enter

parameters on the operator panel, how you collect special settings for frequently

recurring print jobs using setups, how you manage resources for printing operation

and how you replace consumables and expendables using the operator panel.

Operating the printing system

This section describes ho w to power the printing system on and of f and the procedure

for inserting, affixing and removing the paper web, and also contains all other

information that you will need to operate the printing system.

Cleaning the printing system

This section shows you how often to clean the different components and how to carry

out this cleaning.

13

Documentation signposts

Replacing consumables

This section describes in detail all the steps required to replace consumables. It also

provides the order numbers and package units for all consumables.

Replacing expendables

This section describes in detail all the steps required to replace expendables. It also

provides the order numbers and package units for all expendables.

Correcting errors

This section shows you how to locate and remedy errors using the messages

displayed on the operator panel. It also describes ho w you ca n enable remote access

to allow remote diagnosis by Service during print operation. You will also find

information on how to correct any fusing errors.

Technical data

This section contains the most important technical data for the printing system.

You can use the ruler for controlling the paper path synchronization to assign the

marks on the paper input to certain form lengths.

14 Chapter 1 Notes on printing system documentation

Notes on Help

Notes on the Help - Overview

Introduction

This section shows you how you can quickly and easily access the information that

you currently require for your wo rk with the printing system.

There are two ways you can access help topics:

■ Help button on the toolbar and subsequent navigation via contents, index or

search

■ Direct Help via the F1 key

Overview

Notes on the Help - Overview

Here, you will find information on the following topics:

■ Opening Help on page 16

■ Opening Direct Help on page 21

Navigating in the Help:

■ Contents on page 18

■ Index on page 19

■ Search on page 20

Symbol conventions

■ Symbols in the text on page 24

■ Symbols in illustrations on page 25

15

Opening Help

Opening Help

To open Help

[1]

Proceed as follows:

1. Click on the following button in the frame toolbar:

[1]

The Help window opens. The navigation area is displayed initially:

[2]

The width of the navigation area can be changed with the mouse.

16 Chapter 1 Notes on printing system documentation

Function of the buttons in the Help window

[2]

Button Function

[3]

Hides or displays the navigation area with the following tabs:

[4]

■ Contents on page 18

■ Index on page 19

■ Search on page 20

When the navigation area is hidden, more space is available to

view the help topics.

[5]

Switches between the last help topics (backwards or forwards).

[6]

Switches from any help topic directly to the Help start page.

[7]

Closes Help.

Opening Help

17

Contents

Navigating in Help

Contents

Structuring in main groups

The Help is divided into separate main groups:

■ 'General'

■ 'VarioStream'

■ 'Paperpath Manager'

■ Any devices for paper post-print processing

To call up Help topics via the contents

[3]

Proceed as follows:

1. Click on the 'Contents' tab.

2. Click on the buttons for specific help levels to fade them in and out

[8]

3. Click on a help topic

18 Chapter 1 Notes on printing system documentation

Index

Introduction

Entries on the 'Index' tab are sorted alphabetically. Any number of secondary

keywords can be attached to a primary keyword.

To select information via the Index

[4]

Proceed as follows:

1. Click on the "Index" tab.

2. Scroll through the index entries

or

enter text (including partial words) into the 'Search' field and press Enter.

Example:

[9]

Index

3. Click on a help topic

19

Search

Search

Introduction

You can access the full text search function via the "Search" tab. The full text search

is used to find one or more specific words in the entire Help. Uppercase or lowercase

is not relevant for the search. Partial words cannot be found.

To call up information via the full text search

[5]

Proceed as follows:

1. Click on the 'Search' tab.

2. Enter the text in the 'Search' input field.

3. Press Enter.

The search results are listed by the title of the corresponding help topic, and

are sorted by lev el of matches and the frequency in which the w ord appears

in the help topic. Example:

[10]

The circle in the first column indicates the level of matching. The more

filled the circle is, the better the result matches the te xt that was searched for .

The number in the second column of the search result indicates how often

it occurs in the Help topic.

4. Click on a help topic

20 Chapter 1 Notes on printing system documentation

Opening Direct Help

Introduction

Context-sensitive Direct Help provides detailed information on all:

■ Menus

■ Operating elements in me nus

■ Errors and warnings

[6]

[11]

Note

When calling up the Direct Help, ensure that you ha v e selected the element

for which you wish to call up the Help text.

The selected element can be identified by the blue frame. In the following

example, the 'Edit user' menu in the fi rst illustration is only highlighted, b ut

has not been selected for the use of Direct Help. In the second illustration it

is selected.

If the element is not selected correctly, pressing the F1 button will only display the start page instead of the respective Help page.

Opening Direct Help

Selected element without a blue frame:

[12]

Selected element with a blue frame:

[13]

21

Opening Direct Help

To call up the Direct Help

[7]

Proceed as follows:

[14]

1.

Select menu

or

[15]

[16]

2. Press F1.

The Help window opens. The navigation area is initially hidden, e. g.:

[17]

select operating element

or

select message

22 Chapter 1 Notes on printing system documentation

Function of the buttons in the Help window

[8]

Button Function

[18]

Hides or displays the navigation area with the following tabs:

[19]

■ Contents on page 18

■ Index on page 19

■ Search on page 20

When the navigation area is hidden, more space is available to

view the help topics.

[20]

Switches between the last help topics (backwards or forwards).

[21]

Switches from any help topic directly to the Help start page.

[22]

Closes Help.

Opening Direct Help

23

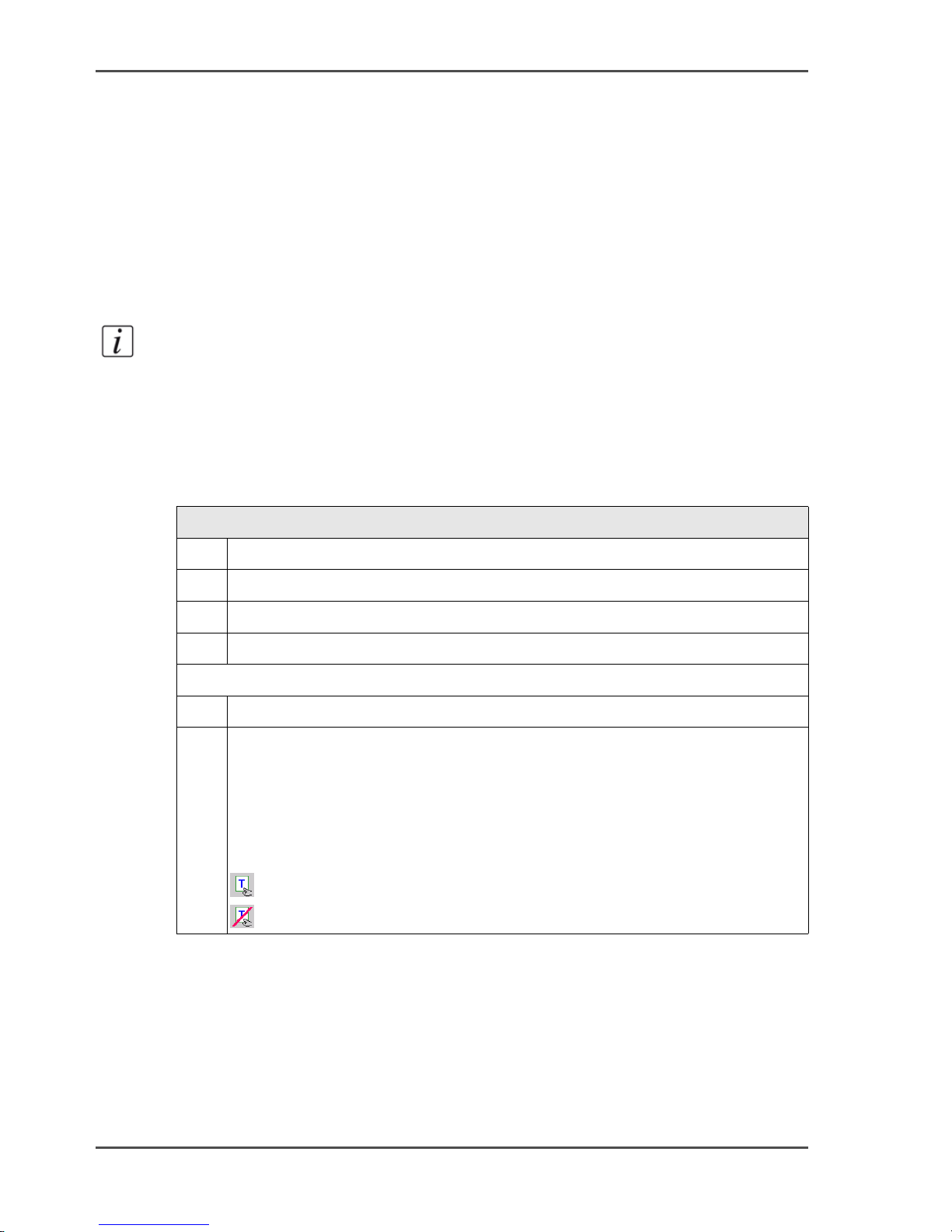

Symbols in the text

Symbol conventions

Symbols in the text

Display of operating elements on the operator panel

The operating element description is shown in inverted commas on the operator

panel, e.g.

'Configuration' menu.

Notes

Note:

This symbol indicates notes - tips for operating the Océ VarioStream 8000.

Safety directives

Symbols are used for the safety directives, as well as different alert words depending

on the degree of danger: see Flagging of safety directives on page 32.

24 Chapter 1 Notes on printing system documentation

Symbols in illustrations

Introduction

If not otherwise indicated, diagrams and illustrations of actions depict the starting

position of the respective component for the described action.

T o ease understandin g, the illustrations on ly depict the components t hat are directly

relevant to the immediate context.

Arrows

Arrows denote the positions where you should perform an action or observe

something in particular. The colors of the arrows denote t he type of acti ons and t he

sequence in which they are performed:

[9]

Arrow Meaning

[23]

[24]

[25]

[26]

Black arrow: Direction arrow

Perform this action first

Grey arrow: Direction arrow

Perform this action next

If further actions are depicted in an illustration, the numbers

on the arrows indicate the sequence of these further actions.

Symbols in illustrations

[27]

White arrow: Note arrow

An action should be performed in this area.

25

Other documents

Other documents

In addition to the user guide

Unless otherwise indicated, the following documents are also provided for ev e ry

printing system, in addition to the user guide:

[10]

Title Order number

Safety information A29246-X30-X-n-79 (multi-lingual)

Paper specification German: A29249-X4-X-n-59

Note:

The respective edition of the document is indicated in the order number by the digit

"n", for example:

Edition 3: n = 3.

English: A29249-X4-X-n-7659

26 Chapter 1 Notes on printing system documentation

Manufacturer of the printing sy stem

Océ VarioStream 8000

The printing system Océ VarioStream 8000 was manufactured by:

Océ Printing Systems GmbH

Postfach 1260

85581 Poing

Germany

Manufacturer of the printing system

27

Statutory requirements

Statutory requirements

Technical changes

The information, data and instructions in this documentation were up-to-date at the

time of going to press. The right of technical modifications due to further

development of the printing system is reserved. For this reason, the information,

illustrations and descriptions in this documentation cannot gi ve rise to any cla ims for

modifications or additions to printing systems that have already been shipped and

accepted.

Liability

No liability is accepted for damages resulting from:

■ Failure to comply with the doc umentation

■ Errors due to improper handling

■ Work performed incorrectly on the printing system

■ Use of non-original expendable parts, replacement parts and accessories

■ Use of non-original consumables

■ Unauthorized modification and retrofitti ng of the printing system by the agent or

the agent’s personnel.

28 Chapter 1 Notes on printing system documentation

Chapter 2

Security

29

Security — overview

Security — overview

Security

This section gives you all necessary information on how to safely and efficiently

operate the printing system.

Safety directives

In addition to the safety directives in the section Accident and damag e pre vention —

overview on page 35, the safety directives in the contin uous text of this

documentation must also be observed.

Please also observe the safety directiv es in the documentation for any pre-processing

and post-processing devices that may be connected.

Overview

You will find information on the following topics:

■ Intended Purpose on page 31

■ Flagging of safety directives on page 32

■ Warning and information signs on page 33

■ Accident and damage prevention — overview on page 35

■ Safety regulations and standards — overview on page 42

30 Chapter 2 Security

Intended Purpose

Océ VarioStream 8000

The printing system shall only be considere d as being use d for its intended purpose

if the notices and instructions in this documentation are strictly observed Océ

VarioStream 8000:

■ The printing system is intended solely for printing materials that comply with the

paper specification (see Other documents on page 26).

■ The printing system must only be operated with the recommended consumables

(see Order numbers and packaging units for consumables on page 297).

■ The printing system must only be operated under the presc ribed conditions of use

(see Technical data - Overview on page 448).

Any use of the printing system that does not comply with the above requirements can

cause damage to the printing system or property as well as injury to persons.

Intended Purpose

31

Flagging of safety directives

Flagging of safety directives

Definition

The following notational con v entions are use d for the safety directi ves in the text of

the manual:

[11]

Symbol Alert word

Type or source of danger and consequences of failure to observe the

safety directives

Instructions on avoiding danger

Different alert words are used for the safety directives, depending on the degree of

danger.

Two classes of safety directives

Caution:

Wa rns against dangers that could lead to injuries.

Attention:

Warns against situations that could lead to damage to the printing system or

disruptions to operation.

Example of a safety directive

Attention:

Fluid can get inside the printing system. This could cause irreparable damage to

the electrical and mechanical components.

Do not place cleaning fluids on top of or in the immediate vicinity of the printing

system. Take care to prevent fluids from seeping into the printing system.

32 Chapter 2 Security

Warning and information signs

Flagging of danger points

The following signs are af fi xed inside the pr inting system at pote ntial danger points:

[12]

Sign Meaning

[28]

Wa rning: Live electric parts

There are live e lectric pa rts behi nd protective covers bearing

this sign. These protective covers may only be removed by

authorized Océ Service personnel.

Warning and information signs

[29]

Warning: Rotating parts

In these areas, body parts (especially fingers), unprotected

long hair and loose hanging clothing (e. g. ties, jewelry , loose

belts...) can be pulled in by the rotating parts of the printing

system, trapped and pinched.

[30]

Warning: Hot components

In order to preven t burns, you must observe the cooling periods and other directives specified in the documentation for all

work in these areas.

[31]

Observe documentation

For all work in this area, you must observe the relevant instructions in the documentation.

[32]

Disposal

This icon means that separate, prop er disposa l of the co mponents at the end of the product service life is obligatory in the

EU Member States. The black bar shows that the regulation

enters into force at midnight on August 13, 2005. Directive:

Directive/2002/96/EC.

[33]

The "Environmental Protection Use Period (EPUP)", applicable in the People's Republic of China, amounts to 20 years

for the printing system.

Through this EPUP, consumables and expendables are not recorded according to regulations, th e liability for defects is not

affected and no special written guarantee is given for the

printing system.

33

Warning and information signs

Additional warning and information signs on the Océ VarioStream 8000

[13]

Sign Meaning

[34]

Warning regarding crushing

In these areas there is a risk of crushing limbs.

[35]

Warning of turning parts

In these areas, body parts (especially fingers), unprotected

long hair and loose hanging c lothing (e. g. ties, jewelry , loose

belts...) can be pulled in by the rotating parts of the printing

system, trapped and pinched.

[36]

The PC drum is light-sensitive

Store the PC drum away from direct exposure to light and

sunlight.

[37]

Wear gloves

Always wear the gloves provided when working with the

photoconductor drum.

[38]

Do not touch the photoconductor drum surface.

When working with the photocondu ctor drum, never touch its

surface.

[39]

34 Chapter 2 Security

Only grasp the PC drum by the inside.

When working with the photoconductor drum, only hold it on

the inside.

Accident and damage prevention — overview

Accident and damage prevention

Accident and damage prevention — overview

Overview

You will find information on the following topics:

■ Personal Representations on page 36

■ Operation on page 37

■ Transportation, assembly and installation, repair on page 40

■ Fire, disposal on page 41

35

Personal Representations

Personal Representations

Agent

An agent is any individual or legal entity (corporate body) that uses or commissions

the use of the printing system.

Operator

The Operator

■ is trained directly on the printing system as to how to operate it and has been

instructed on the tasks assigned to them. They are familiar with the contents of

the documentation.

■ is aware of the potential dangers of improper handling of the printing system.

■ has been informed about necessary safety installations, safety precautions and

operating conditions.

■ has been instructed or commissioned by the agent to operate the printing system.

■ can load defined setups.

Key Operator

The Key Operator

■ is an operator with a higher qualification assigned additional tasks b y the owner

■ can also display or hide menus for the diff erent operators and accordin gly adapt

■ can compile defined printing syste m configurations to create setups.

Service

Service are specialist staff from Océ who carr y out all work on and with the printing

system, which may not be carried out by the operator (e. g. work on the printing

system electrics).

(e. g. assignment of user rights and passwords).

the menu structure to the respective requirements.

36 Chapter 2 Security

Operation

Introduction

Observe the following instructions when operating the printing system:

Service personnel

Only operators, key operators and Service personnel may operate the printing

system.

The printing system must not be operated by persons under the influence of alcohol

or drugs, or by persons taking certain types of medication, such as psychotropic

drugs.

Before operating the printing system, carefully read through the documentation.

Please ask if you do not understand anything in the documentation (e. g. regarding

Service).

Operation

In cases of emergency, power off the printing system of f immediately with the mai n

switch. In the event of damage to the casing, power cable or operating elements, or

penetration of fluids or foreign bodies, call the appropriate Service representative.

Do not wear any loose hanging clothing (e. g. ties, sleeves, scarves), necklaces and

bracelets, loose belts, rings and unprotected long hair. These can catch in the drive

mechanisms or moving parts of the printing system and cause injury.

Safety covers

Do not attempt to remove safety covers yourself; do not manipulate safety

equipment such as the switches monitoring the safety covers, fuses etc., and do not

perform any work not intended to be performed by operators. Such action can cause

accidents and may also damage the printing system.

Safe operation of the printing system is guaranteed only when the outer paneling is

fully mounted. Only properly and fully affixed casing ensures:

■ Protection from electrical shocks

■ Protection against injury from mechanical parts, e.g. cuts, drawing in, crushing

■ Protection against the spread of fire

■ Sufficient cooling of the printing system.

Keep all doors, trims, flaps and cov ers closed while the printing system is in

operation. This ensures that limit values for electromagnetic co mpatibility are not

exceeded. Noise emission is also minimized.

37

Operation

Cleaning

Always use an industrial vacuum cleaner with a grounded suction tube, rubber

nozzle and filter set for f ine dust. An explosion-proof ind ustrial vacuum cleaner must

be used for large toner quantities because there can be a high build-up of static

charge when draining toner spill.

When cleaning the printing system, observe the instructions in the following sections

as well:

■ Cleaning the printing system — overview on page 250

■ Cleaning agents and devices, cleaning intervals on page 252

Foreign bodies, noises

Ensure that no objects (e. g. necklaces, paper clips or staples, coins, etc.) or liquids

enter the printing system, as this could cause electrical shocks or short circuits. Do

not place objects on the printing system, and especially do not place containers with

fluid, such as drinking bottles, glasses, cups or vases on top of or in the immediate

vicinity of the printing system.

Should the printing system emit any unusual or noticeable noises or smells, power

off the printing system and contact your Service engineer.

Cooling, heat, emissions

Do not obstruct the cooling ducts. Failure to do so may result in overheating or

combustion while the device is in operation.

Ensure that there is an adequate supply of cool and fresh air in the printing system

assembly room (see Cooling and fresh air, air purity on page 454).

Do not obstruct the operating and service clearance areas in any way by means of

other devices or objects.

During operation, the inner area of the fuser module in the printing system becomes

very hot (greater than 500°C/932°F). Before doin g an y w ork on or aro und the fu ser

module always allow it to cool down for the specified length of time. Failure to

observe the directives in this documentation could result in burns.

The ozone produced when the photoconductor and transfer belts are loaded is

suctioned off within the printing system and then transformed into oxygen through

a catalytic filter system. The life c ycle of the f ilter system is designed so that it does

not have to be replaced during the lifetime of the printing system.

In print operation the ozone concentration is

concentration (MAC) of 0.1 ppm (0.2 mg/m3). With proper ventilation, harmful

below the maximum allo wable work place

38 Chapter 2 Security

concentrations do not occur even if the f ilter system fails entirely . For ventilation, see

Cooling and fresh air, air purity on page 454.

Consumables and expendables

Observe the safety directives given in the manual for:

■ Toner

■ Developer

■ Fine filter

■ Photoconductor drum

■ Fuser station and fuser oil

■ Cleaning agents

Keep all consumables for the printing system out of the reach of children. Store

consumables away from containers used for food and drink.

Optical wave guide

Operation

If your printing system has an optical wave guide connection:

Never look directly down a glass fiber cable or glass fiber cable connection. The

laser beams in fiber optic devices can injure your eyes.

Laser

If the printing system includes a laser:

Never look directly into a la ser beam or laser opti cs. Nev er mov e a tool into the area

of the laser beam so that you do not unintentionally dif fract the laser beam. The laser

beams in fiber optic devices can injure your eyes.

Remote control via LAN

If you operate the printing system from a remote operator panel:

The access ticket ensures that only one user at a time can access the printing system.

Warning and information signs

Observe all warning and information signs on and in the printing system (see

Warning and information signs on page 33).

39

Transportation, assembly and installation, repair

Transportation, assembly and installation, repair

Transport

The printing system may only be transported by Service personnel or author ized

transport companies.

Assembly and installation

Observe the following instructions when assembling and installing the printi ng

system:

■ The printing system may only be assembled and installed by Service personnel.

■ The printing system must have a dedicated electrical connection or type B plug

connection (complying with VDE directives, EN 60950).

■ Do not route the lines and cables in such a way that they can be stepped on or

tripped over.

■ All printing system accessories and options must comply with statutory

regulations and directives for safety, electromagnet ic compatibi lit y,

telecommunications terminal devices as well as with the specifications published

by Océ Printing Systems GmbH.

■ The installation of other accessories may constitute a violation of these

requirements and directives, and may also damage the printing system.

■ Consult Service personnel for details on which accessories and options are

permitted for the printing system.

■ With the exception of optical wave guide connections, all data, signaling,

process, measurement and control lines mapping the printing system with other

devices must be properly grounded.

■ Data transmission lines should neither be connected nor disconnected during

electrical storms.

Repairs

Repairs to the printing system must only be carried out by Service personnel. Access

to locked areas and areas which can only be opened with special tools is reserv ed for

Service personnel. Opening the device without authorization and improperly

effected repairs may put operators at considerable risk.

The access ticket used by the Service technician ensures that the printing system

cannot be used via an LAN from a remote operator panel during repair work.

40 Chapter 2 Security

Fire, disposal

Fire

Observe the following instructions:

■ As is the case in any fire, toxic gaseous emissions can occur in the event of fire

in the printing system.

■ Self-contained breathing apparatus must be worn when fighting fire or smoke

emission. Instructions to this effect should be deposited at the fire alarm center

and with the local fire department.

■ Fire can cause toxic arsenic gas to develop on the photoconductor drum.

■ These security measures apply particularly in case of fire in locations where a

number of photoconductor drums are stored.

Disposal

Océ operates a system by which expendables and consumables can be returned for

environmentally sound disposal.

■ Keep all used parts and consumables that are to be returned for disposal for

collection by Service or the contracted shipping company . These will be recycled

or disposed of appropriately by Océ Printing Systems GmbH or a contracted

disposal company.

Fire, disposal

When disposing of a photoconductor drum, please observe the following:

■ Before touching the drum, always put on the gloves provided with the drum.

■ Should flaking of the photosensiti v e coating on the drum occur , carefully collect

the flakes or fragments of the coating.

■ Store the photoconductor drum and any flakes of coating in the original drum

packaging.

■ The drums and coating are hazardous waste and require special disposal. They

should be disposed of by Service or a contracted shipping company. Keep this

carton and its contents out of the reach of children.

■ Wash you r hands afterwards.

41

Safety regulations and standards — overview

Safety regulations and standards

Safety regulations and standards — overview

Introduction

The printing system Océ VarioStream 8000 complies with the relevant safety

requirements for information technology equipment. It meets the following national

and international safety regulations and standards:

Applicable guidelines

[14]

EN 60721 - Part 1 - Environment al conditions for products

- Climatic environmental conditions

- Use, transport and storage conditions

- Test criteria

EN 60721 - Part 2 - Environment al conditions for products

EN 60721 - Part 3 - Environment al conditions for products

ISO 2784 - Continuous paper for data processing

Safety standards

[15]

73/23/EEC Low Voltage Directive

IEC 60950 Safety of information technology equipment including

- Mechanical environmental conditions

- Use, transport and storage conditions

- Test criteria

- Permitted noise emissions from devices

- Dimensions

- Guide holes

EC directive for ha rmonization of the legal require ments

of member states regarding electrical equipment for use

within certain voltage limits (modified by EC Directive

93/68/EEC)

electrical business equipment

EN 60950 (Europe) Safety of information technology equipment, including

42 Chapter 2 Security

office devices, in connection with the CE mark

Safety regulations and standards — overview

UL 60950 (USA) Safety of information technology equipment including

electrical business equipment

CAN-CSA Standard

C22.2 No. 60950

(Canada)

General device safety is verified by:

■ VDE/GS

■ TÜV/GS

■ BG/GS

Electromagnetic Compatibility

[16]

89/336/EWG EMVDirective

EN 55024 Europe

EN 55022 / Class A

FCC Part 15 Subpart B

Class A

Standard for safety of information technolog y equipment

including electrical business equipment

EC Directive for harmonizatio n of the legal requirements

of member states regarding Electromagnetic Compati bility (modified b y Directi v e 91/263 /EEC, 92/31/EEC, a nd

Directive 93/68/EEC)

USA

C108.8-M1983 (Class A)Canada

Environmental Standards

[17]

2002/95/EC RoHS Directive

2002/96/EC WEE Directive

Overview

You will find information on the following topics:

■ CE Mark on page 44

EC directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment

= RoHS Directive (binding since 06/30/2006)

EC directive on waste electrical and electronic equipment = WEEE Directive (binding since 06/30/2006)

43

CE Mark

CE Mark

Océ VarioStream 8000

[40]

The printing system Océ VarioStream 8000 fulfills the requirements of the EC

directives 89/336/EWG, "Electromagnetic Compatibility" and 73/23/EWG "Low

Voltage Directive".

The CE Mark indicates that the printing system complies with these EC directives.

The printing system is a Class A product (EN 55022). This product may cause radio

interference in a domestic environment. In this case, the agent may be required to

take appropriate meas ures to correct the interference at his or her own expense.

The printing system can cause the po wer supply to fluctuate if the po wer network is

not in order. According to EN 61000-3-11, the printing system should only be used

on premises that have a network with a continuous current-carrying capacity of 100

A per phase or are supplied by a distribution network of 400/230 V.

The agent must ensure that the printing system is operated in a power supply network

that meets these requirements. If necessary, consult the power company to ensure

that the continuous current-carrying capacity of the power system at the connection

point to the public power grid is sufficient to connect the device.

44 Chapter 2 Security

Chapter 3

Description of the printing

system

45

Description of the printing system — overview

Description of the printing system — overview

Description of the printing system

This section shows the structure of the printing system, describes the operating

elements and explains th e printing principle. You will also find information on paper

types and how to hand le the paper.

Overview

You will find information on the following topics:

■ Equipment - overview on page 47

■ Operating elements - overview on page 52

■ Paper specifications on page 60

46 Chapter 3 Description of the printing system

Device overview

Equipment - overview

Introduction

This section describes all the assemblies that are relevant to the operator.

Overview

Here you will find information on the following topics:

■ Front view of the printing system on page 48

■ Rear view of the printing system and main switch on page 50

Equipment - overview

47

Front view of the printing system

Front view of the printing system

Front view

[41]

1 2 3 4

12

11

10

5

9

78

[18]

6

Number Description

1 Front door of fuser station

2 Cover hood

3 Operator Attention Light (OPAL) (optional)

4 Screen

5ON button

6 Keyboard and mouse

7 Right door

8 Left door

9 Front door of paper tension unit

10 Flap of paper tension unit

11 Additional operator panel

12 Side door of fuser station

48 Chapter 3 Description of the printing system

Internal view of front side

[42]

1 2 43

Front view of the printing system

5

6

[19]

Assembly Description

1 Fuser station

2Heating saddle

3 Discharge corotron cartridge

4 Buttons for paper transport

5 Cleaning brush

6 Charge corotron cartridges

7 Photoconductor drum

8 Developer station

9 Paper transporter

10 Vacuum box

8 7910

49

Rear view of the printing system and main switch

Rear view of the printing system and main switch

Back view

[43]

[20]

Number Description

1Main switch

2 Left door

3 Center door

4 Right door

50 Chapter 3 Description of the printing system

Rear view of the printing system and main switch

Internal view of rear side and main switch

[44]

9

8

1

2 3

[21]

Assembly Description

1 Waste oil container

2 Fuser oil container

3 Fuser station

4 Container for toner supply bottle

5 Container for fine filter

6 Toner dust indicator

7 Container for waste toner bottle

8Main switch

9 Paper feed

67 5 4

51

Operating elements - overview

Operating elements

Operating elements - overview

Overview

This section contains information on the following topics:

■ Key control panel on the paper transporter on page 53

■ Additional operator panel on page 54

■ Operator Attention Light (OPAL) (optional) on page 57

■ Operating elements in the printing system on page 59

52 Chapter 3 Description of the printing system

Key control panel on the paper transporter

Key control panel on the paper transporter

Manual paper web transport

This key control panel can be accessed after opening the printing system cover hood.

It has three keys for manual transport of the paper web.

Note:

To be able to transport the paper web by pressing the button, the printing system

must be in the 'Stop' status.

[22]

Button Function

EJECT Moves the paper web at print speed while the key is pressed. The pa-

per web is not printed.

ADVF (ADV anced F orward)

Moves the paper slowly forwards while the button is being pressed.

The paper speed increases the longer you press the button.

ADVR (ADV anced R everse)

Moves the paper slo wly backwards while the b utton is being pressed.

The paper speed increases the longer you press the button.

53

Additional operator panel

Additional operator panel

Additional operator panel position

The additional operator panel is located on the pa per output side at the tension rolle r

unit.

[45]

The buttons and LEDs on the additional operator panel

[46]

54 Chapter 3 Description of the printing system

Additional operator panel

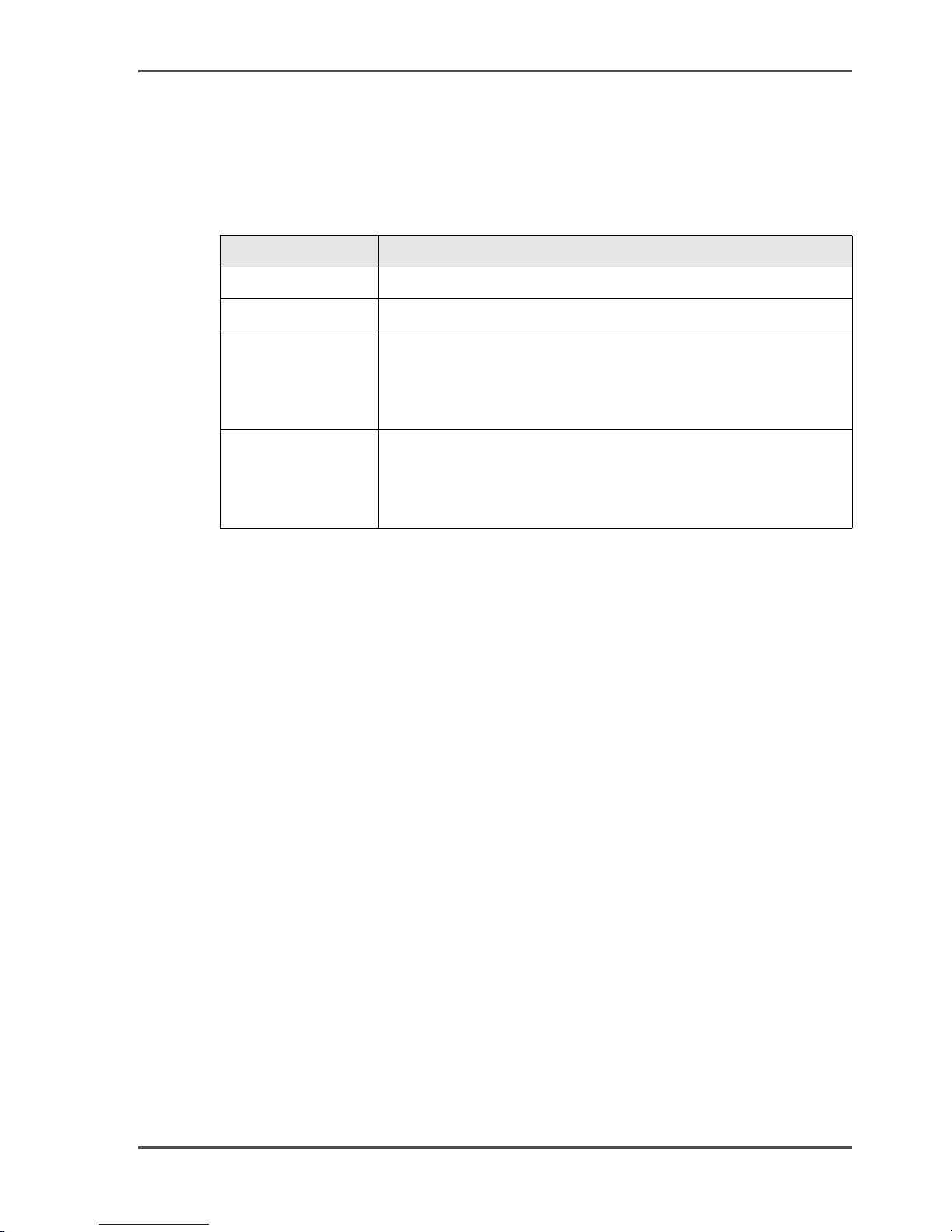

[23]

Button Function LED display

READY Switches the printing system to ready

for operation from the 'Stop' or error

states.

Note:

F or twin or triple x operation,

all printing systems are

ready to operate after pressing this button on one of the

printing systems.

EJECT Transports the paper web in the relevant

printer forward at print speed while the

button is pressed. The paper web is not

printed. Already printed pages will still

be fused.

Depending on how long this button is

pressed, single or several pages can be

advanced. The paper path always stops

at the beginning of the pap er, depend ing

on the selected form length.

The button can only be pressed in the

'Stop' status.

The green LED lights up

after pressing the READY

button.

The yellow LED lights up

while the key is pressed.

Note:

F or twin or triple x operation,

the paper web can tear if the

EJECT button on the se cond

or third printer is pr essed for

too long and insufficient paper was transported fr om the

first or second printer respectively.

C-EJECT Executes a Common-EJECT in twin

and triplex operation on all printers in

the printing system.

No LED display

55

Additional operator panel

Button Function LED display

[47]

Switches the tension rollers on. Pressing

the key again switches them off.

After a running time of approx. 10 seconds, the tension rollers are automatically switched off (not during paper

insertion).

This key has no function during the

preparation phase of the printing system.

The button can only be pressed in the

'Stop' status.

No LED display

STOP Switches the printing system to the

'Stop' status or cancels a current function.

The operator panel displays the 'Stop'

status.

Before the printing system stops, the

pages prepared on the PC drum are

transferred to the paper. The paper stops

at the start of a page.

Characters on the paper between paper

transporter and fuser station are not yet

fused.

The printing system is made operational

again by pressing the READY button.

Note:

F or twin or triple x operation,

pressing the STOP b utton on

one of the printing systems

stops all printing systems. If

a stop condition also appears

on another printing system,

the STOP LED also lights up.

The red LED lights up.

56 Chapter 3 Description of the printing system

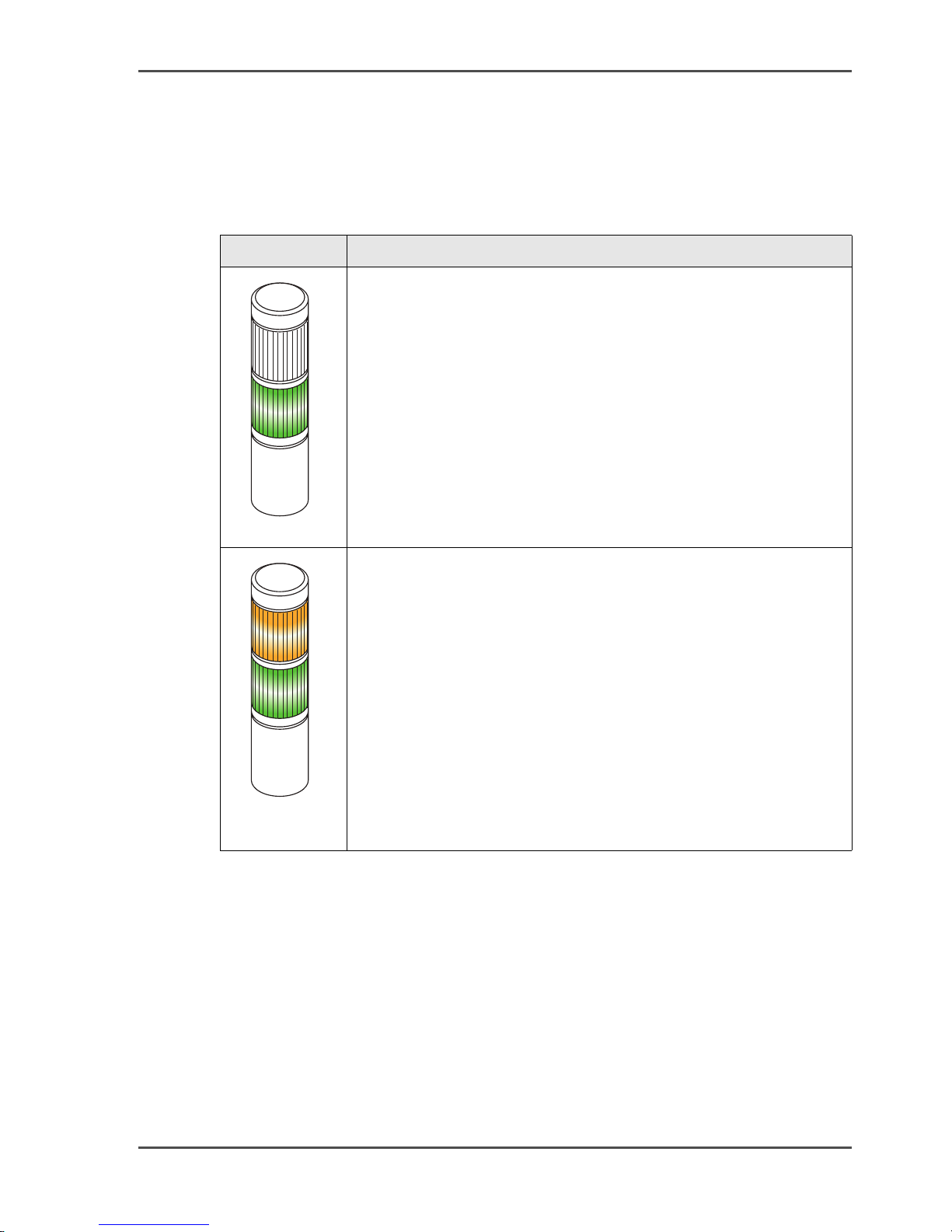

Operator Attention Light (OPAL) (optional)

Operator Attention Light (OPAL) (optional)

Displays

The most important displays are summarized in the following table:

[24]

Display Meaning

[48]

The printing system is in the 'Ready' status.

Service can set the printing system so that the Operator Attention

Light (OPAL) only lights up green in the 'Printing' status.

There is no warning.

(green)

[49]

(flashing

green/orange)

There is a warning in the 'Ready' status.

57

Operator Attention Light (OPAL) (optional)

Display Meaning

[50]

The printing system is in the 'Stop' st atus.

(orange)

[51]

An error occurred in the 'Ready' status

or the printing system has stopped because there is a warning.

(flashing orange)

58 Chapter 3 Description of the printing system

Operating elements in the printing system

Operating elements in the printing system

Example

All operating elements for normal, incident-free printing operation are designed in

blue-green, e.g.:

[52]

59

Paper specifications

Paper specifications

General information

The paper should comply with the paper specification for continuous printing

systems (see Other documents on page 26) and must be stored according to climatic

regulations in order to achieve higher availability of the printing system.

Non-compliance with the paper specifications can cause damage to the printing

system and may also result in the release of substances from the paper that can

contaminate the environment or have a detrimental effect on health. Océ Printing

Systems GmbH accepts no liability for such damages.

The printing system is designed to process a wide range of paper types. Ho wever , the

operational properties of the printing system and the print quality also depend on

factors such as:

■ Paper quality

■ Grammage

■ Moisture content

■ Dimensional stability

■ Smoothness, etc.

Before using new media, ensure that they comply with the paper specifications. If in

doubt, please contact the paper laboratory at:

Océ Printing Systems GmbH

SWS SI 4

Postfach 1260

85581 Poing

Germany

Paper types

All media that comply with the requirements of the electrophotographic printing

method can be used in all specified formats and paper weights.

Using other paper qualities may result in reduced operational results, lower

availability and possibly also higher usage of consumables and expendables.

Paper handling

The climate (temperature and relative humidity) of the storeroom and processing

room is of major importance in ensuring optimum paper processing. Unsuitable

conditions can, for example, giv e the paper an excessive curl, make it bumpy , or alter

its electrical resistance.

60 Chapter 3 Description of the printing system

Paper specifications

Observe the following guidelines to ensure that the original high quality of the paper

is not impaired in any way.

■ Store the paper in its packaging until it is used.

■ Do not store paper on the floor or next to walls, or in the vicinity of water pipes,

radiators, ventilators, windows (sunlight) etc.

■ Do not store paper in rooms in which the ambient conditions are subject to

constant change.

■ Before you use the paper, store it (in its packaging) near the printing system for

a few days if possible, or at least for 24 hours, to equalize temperature between

paper and room temperature.

■ Do not unpack more paper than you need.

■ Always use opened boxes of paper first. If you have to store open packs over a