Page 1

Océ

User manual

Arizona T220UV

Océ Arizona T220UV User Guide

Page 2

Order number 3010102780

Edition Revision C

US

Page 3

Table of Contents

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Product Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 2

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 3

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Safety Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

UV Lamp Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Arizona T220UV Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Safety Awareness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table of Contents

Chapter 4

User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Operator Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 5

How to Operate the Arizona T220UV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Training Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

How to Switch the Printer On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

How to Set Up a Print Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Select a Print Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Change Print Job Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Change Print Job Parameter Options . . . . . . . . . . . . . . . . . . . . . . . . . 53

How to Use the Media Vacuum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

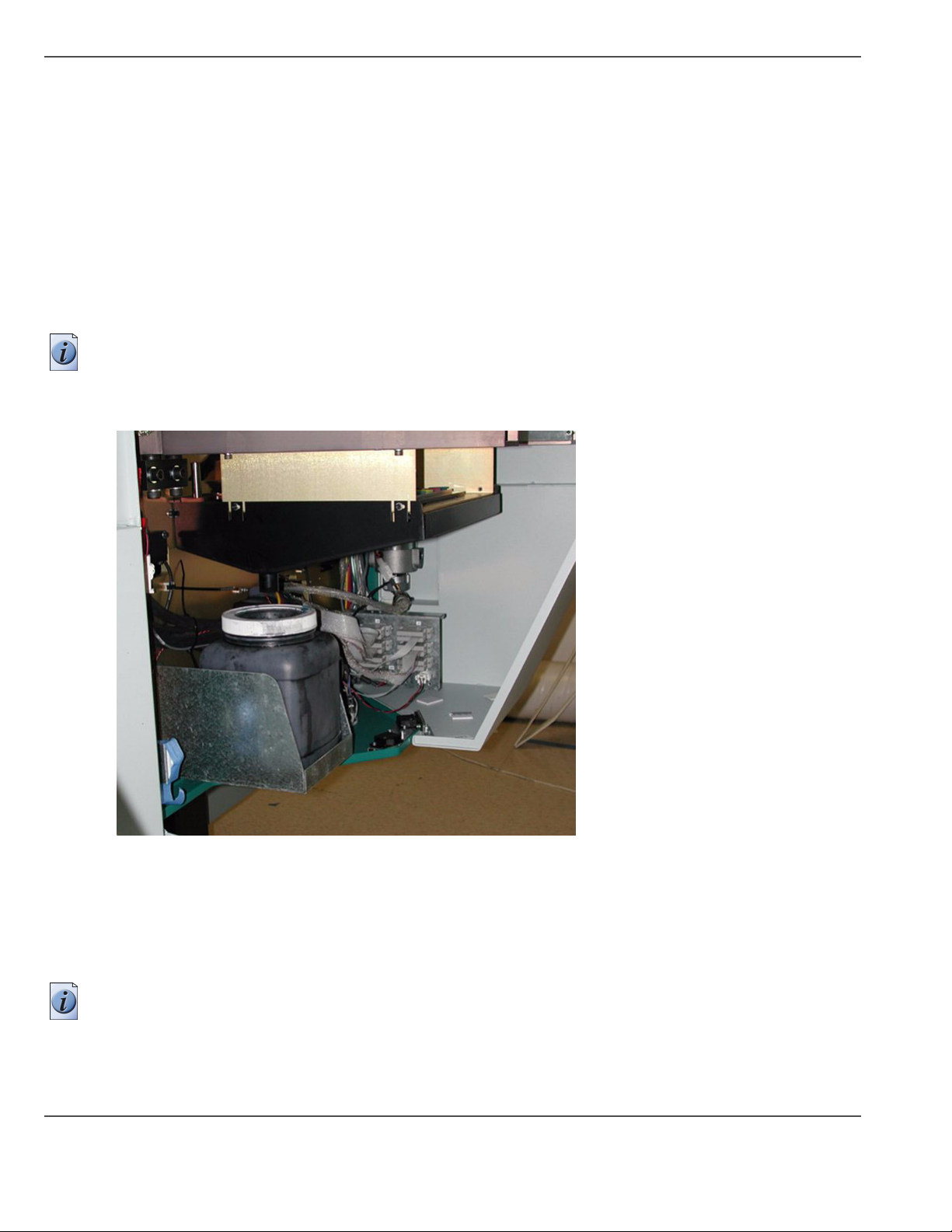

The Media Vacuum System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

How to Maintain Print Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

How to Reduce Banding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Diagnostic Stripe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Standard Nozzle Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Diagnostic Nozzle Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Application Hints and Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Chapter 6

Ink System Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Océ T220UV Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

How to Change an Ink Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

How to Scan Ink Barcodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

How to Empty the Waste Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

How to Change Blot Cloth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3

Page 4

Table of Contents

Chapter 7

Media Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

How to Handle Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

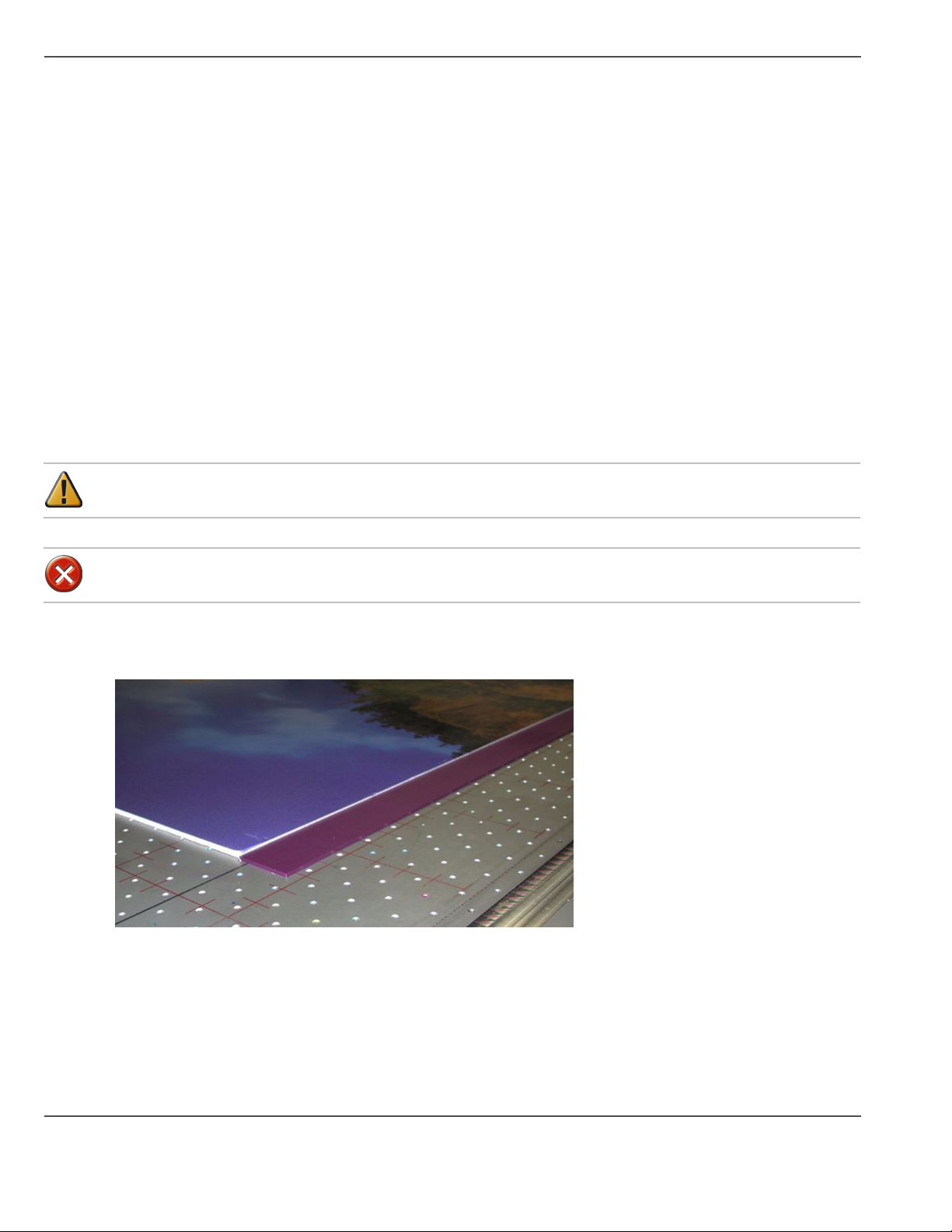

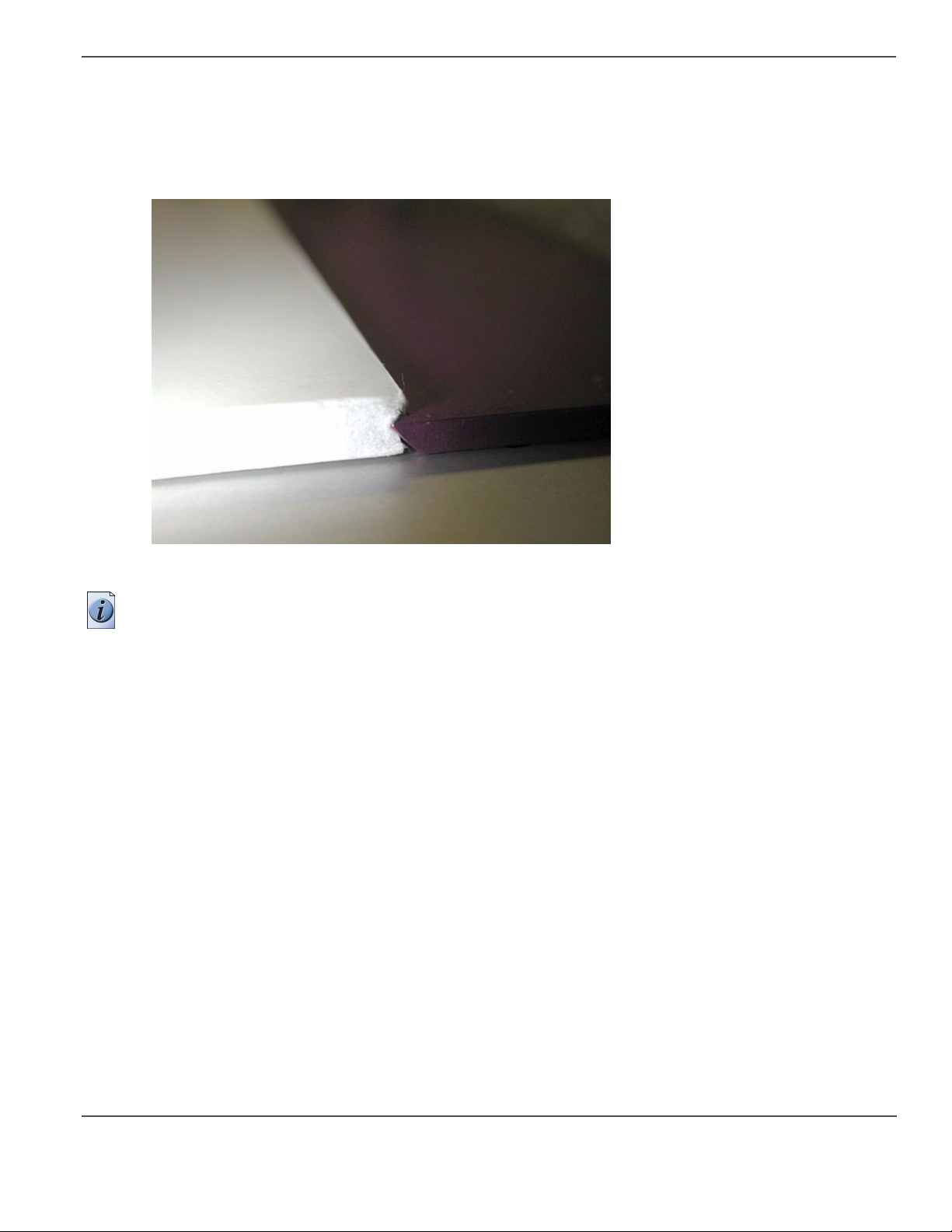

How to Use Media Holder Strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Use A Spoilboard Sheet to Reduce Artifacts . . . . . . . . . . . . . . . . . . . . . . 83

Chapter 8

Error Handling and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Troubleshooting Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

System Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

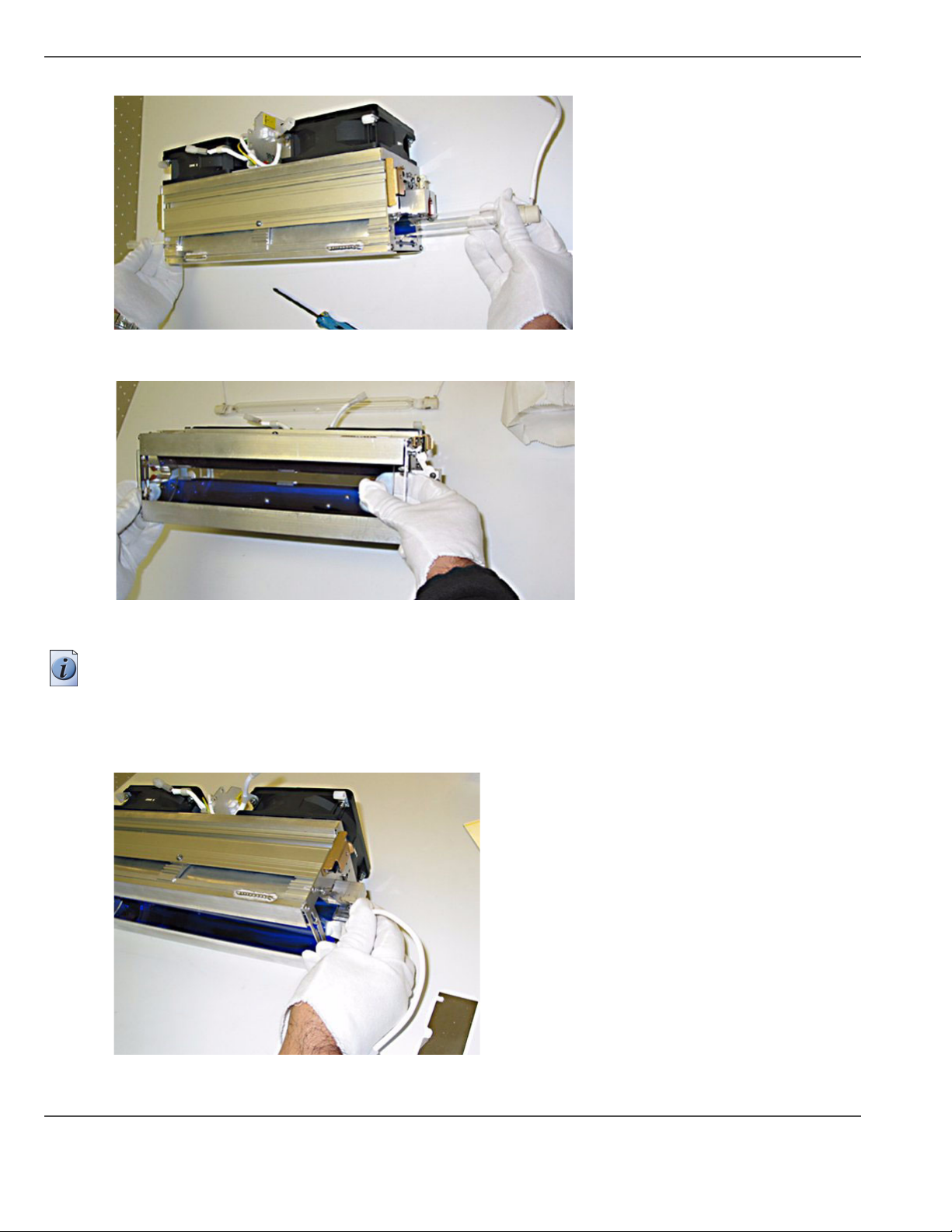

T220UV Lamp Bulb Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Chapter 9

Printer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Maintenance Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

As Required Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Remove Ink and Ink Waste . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Clean Carriage Underside. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Swab Printheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Monthly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Clean Gantry Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

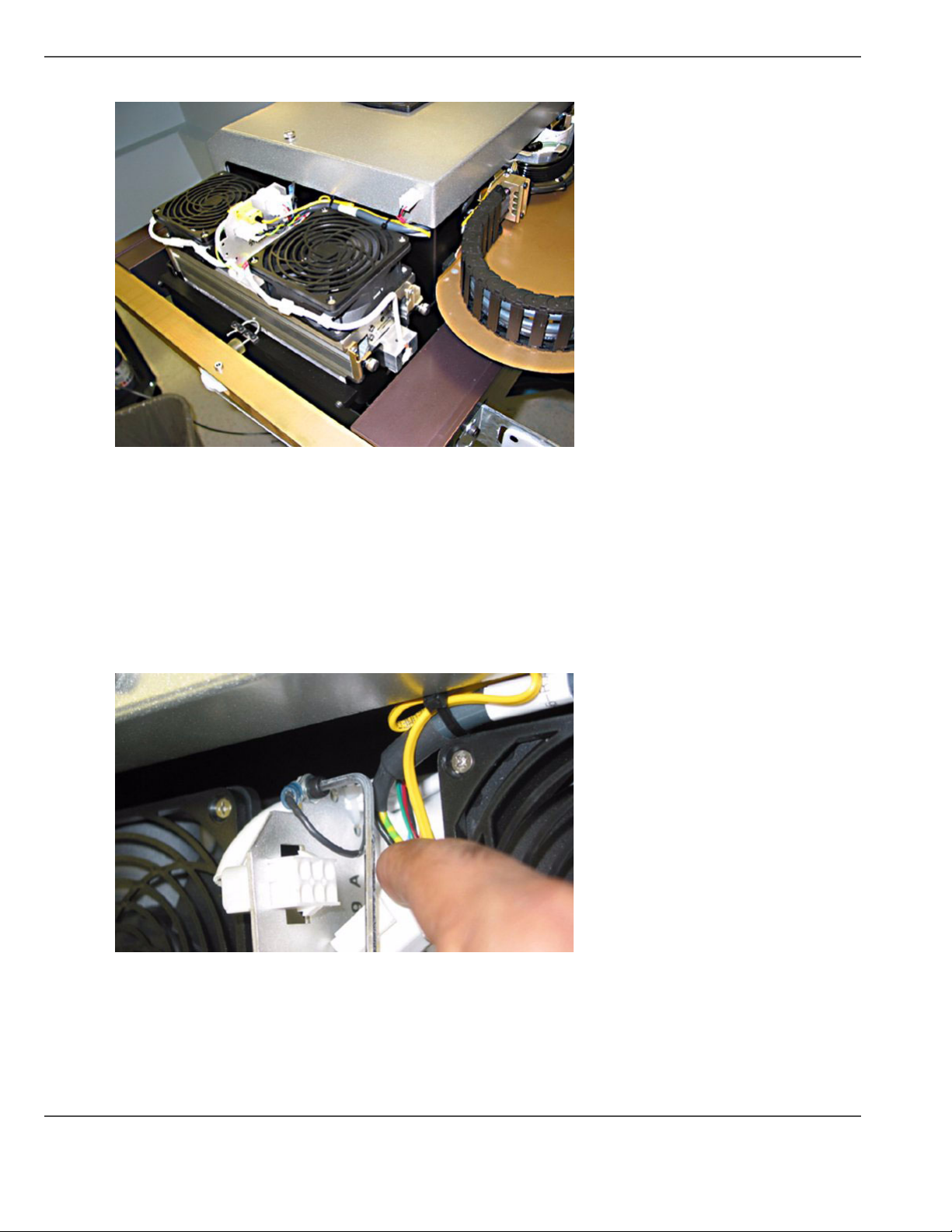

Clean Gantry Door Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Clean Ozone Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Change Auto-Drain Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Clean Linear Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Change the Electronics Bay Air Filter . . . . . . . . . . . . . . . . . . . . . . . . 112

Gantry Brushes (Every Two Years). . . . . . . . . . . . . . . . . . . . . . . . . . 113

Appendix A

Special Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

How to Install Special Prints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

How to Print the Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

How to Print the Table Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Appendix B

Safety Systems and Machine Safeguarding . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Arizona T220UV Safety Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Interlock System Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

4

Page 5

Chapter 1 Introduction

5

Page 6

Preface

Preface

Summary

This User Guide introduces you to the Océ Arizona T220UV flatbed inkjet printer. It will orient you to the many

features and procedures that enable you to print quality images on various media.

Copyright

© 2004 Océ Display Graphics Systems. All rights reserved.

This document contains information proprietary to Océ, to its subsidiaries, or to third parties to which Océ may have

a legal obligation to protect such information from unauthorized disclosure, use or duplication. Any disclosure, use,

or duplication of this document or of any of the information contained herein for other than the specific purpose for

which it was disclosed is expressly prohibited, except as Océ may otherwise agree to in writing. Due to continuing

research and product improvements, features or product specifications may change at any time without notice.

Océ DGS on the Internet

For further information on documentation and support for your Arizona T220UV or for information on other Océ

Display Graphics Systems products, please visit our web site:

Web: http://www.dgs.oce.com

Safety Information

This manual contains three sections with details on safety when handling ink and using the printer:

■ "Ink Safety" offers advice in the proper handling of UV inks;

■ "UV Lamp Safety" presents warning about the dangers of exposure to UV light; and

■ "Safety Interlocks" explains the safety features built in to the printer that prevent exposure to UV light.

Also, where applicable, cautions and warnings are used throughout this manual to draw your attention to safety

precautions to be taken.

Customer Support

Océ maintains a comprehensive support structure for its Arizona T220UV customers. Upon installation of your

printer, you will be provided with the name of the sales and service office responsible for your account. Record this

information, along with the serial number of your Arizona T220UV. Always report service problems to the office

assigned to your account at installation.

6 Chapter 1 Introduction

Page 7

Customer Service

When you call our customer service number you will be provided with telephone technical support. Outside of

office hours, you can leave a message and your call will be returned the next working day. When you call, identify

yourself as an Arizona T220UV customer and provide the following information:

• The serial number of your Arizona T220UV

• Your company name and your name

• Your telephone number

• Nature of the problem

If we are unable to resolve your problem over the telephone, field engineers can be dispatched to your site to

conduct repairs. Service visits are paid for by the customer, either under a maintenance agreement, by purchase

order or prepayment. Time and material rates are charged for any service not covered under a maintenance

agreement. Before calling to report a problem, gather as much information about the problem as possible and have

it ready to provide to the customer care center engineer. The more information you can provide initially, the more

quickly the problem can be corrected.

Responsibilities of the T220UV Operator

The operator of the Arizona T220UV must be properly trained. Océ provides training for the operator in the use of

the Arizona T220UV hardware and software at the time of installation. It is the customer's responsibility to ensure

that only properly trained personnel operate the printer.

Preface

Operators of the Arizona T220UV should be fully versed in the operation of Onyx PosterShop® . For any operator

unfamiliar with its operation, Onyx PosterShop® training is required. On-site or off-site training courses are

available; contact Onyx Graphics Corporation for more information:

http://www.onyxgfx.com/support_training.html

The operator or other trained personnel are expected to handle all user maintenance as detailed in the User Guide,

and also replacement of consumable parts (except print heads). If your site has a technician in charge of printer

maintenance, that person is the optimal candidate. While any trained operator may perform routine maintenance,

the best maintenance results from familiarity with the printer's internal operation and history.

The Arizona T220UV printer requires some daily maintenance. Periodic cleaning must be scheduled for some

components on a weekly basis. A few minutes spent cleaning ensures the highest quality prints. Several areas

require maintenance to ensure the highest print quality, and the printer design gives you easy access to all these

areas. Refer to the Arizona T220UV User Guide for details.

It is the responsibility of the operator to try to eliminate simple problems before calling a service representative.

But knowing when to call for service is also important. An untrained operator must not attempt to service the printer

as this may cause further damage. When you have determined that a service call is required, call as soon as possible.

See the Maintenance section for more details.

7

Page 8

Preface

Responsibilities of the T220UV Service Technician

Field service technicians must have Océ Arizona T220UV service training. The service technician is responsible

for all repairs, upgrading and modification requested by the customer or mandated by the Océ Service and Support

Group.

Service personnel are furnished with proper tools for the installation and maintenance of the Arizona T220UV

printer. In addition to the T220UV tools and custom kits, each engineer will have basic tools for proper maintenance

and servicing.

An Océ help desk consultant initially screens all customer calls. This means that a trained Océ Arizona T220UV

specialist with system training handles the calls and helps you understand your problem or situation. This process

minimizes the number of print quality issues that are not directly related to hardware. All hardware problems are

dispatched to field service technicians. If an on-site visit is required, the help desk technician can recommend parts

which then can be ordered, thus increasing efficiency in the service cycle.

Statement of Foreseen Use

The Océ Arizona T220UV flatbed inkjet printer uses piezo printing technology and UV curable inks to produce

outdoor-durable output. It can print directly onto rigid and flexible substrates up to 62 inches wide by 120 inches

long by 2 inches thick (1.6 m x 3 m x 5 cm).

The Océ Arizona T220UV holds substrates stationary while the print head assembly moves across to create the

print, eliminating image skew problems associated with rigid stock feed systems. It can print full bleeds, saving

time and labor costs in finishing.

With four print heads per color, the Océ ArizonaT220UV can produce prints at a production speed of up to 180

square feet (16.7 m2) per hour. It includes the unique Océ ColorBlend® super-CMYK technology, for an apparent

resolution of 600 dpi. The Océ Arizona T220UV uses UV curable pigmented inks, and can print directly onto a

variety of uncoated rigid or flexible substrates such as foam-core style mounting board, PVC sheets, styrene,

aluminum-plastic composites and vinyl.

Note: "Océ ColorBlend" is a registered trademark of Océ Display Graphics Systems, Inc.

8 Chapter 1 Introduction

Page 9

Product Compliance

Introduction

Electromagnetic Compatibility:

This equipment generates, uses and radiates radio frequency energy and if not installed and used as designed or

intended, may cause interference to radio communications. This equipment has been tested and found to comply

with the limits for a Class A computing device. This equipment has been designed to provide reasonable protection

against such interference when operated in residential and commercial environments. Operation of this equipment

in a residential area may cause interference, in which case the user, at his own expense, is required to take whatever

measures are required to correct the interference.

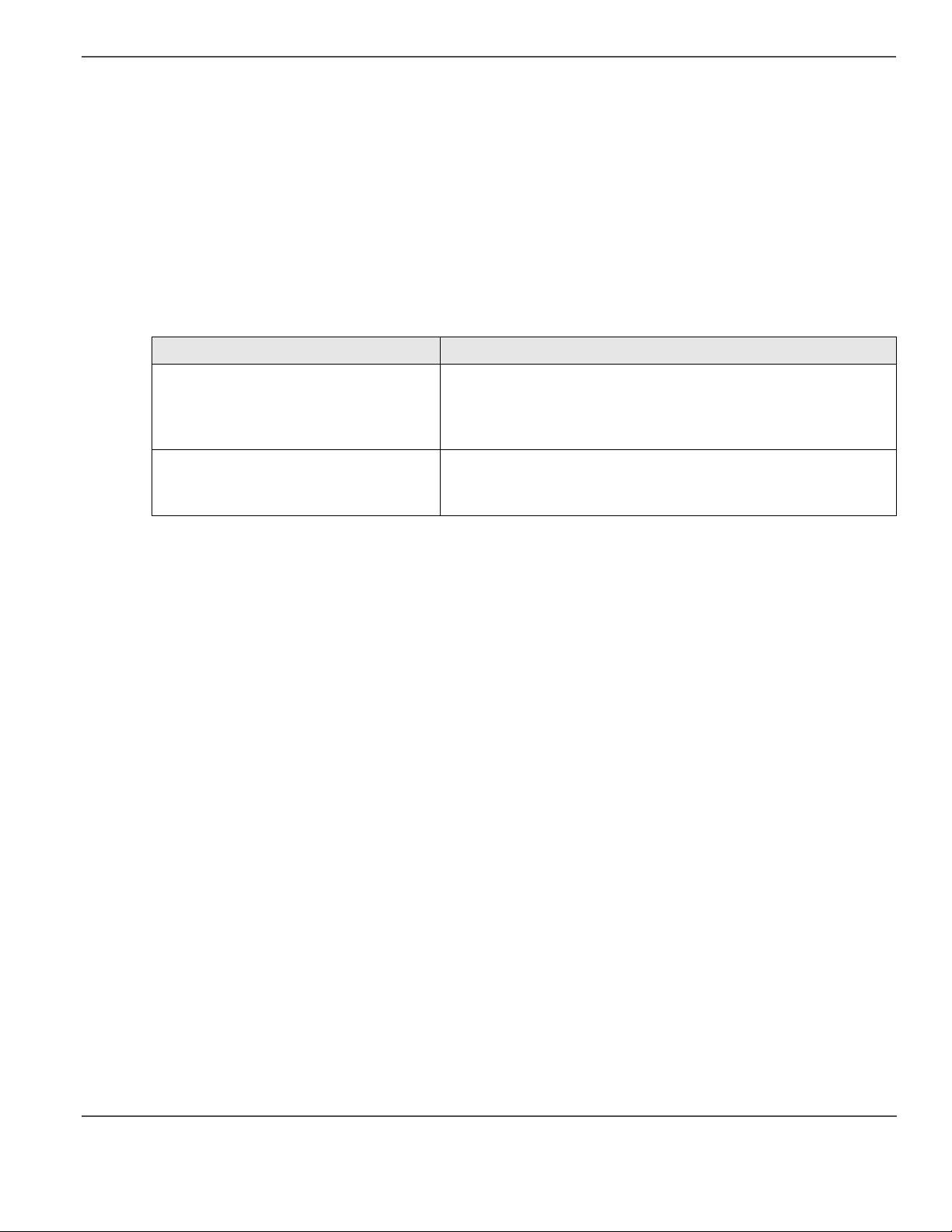

The Arizona T220UV complies to the following Agencies and Standards:

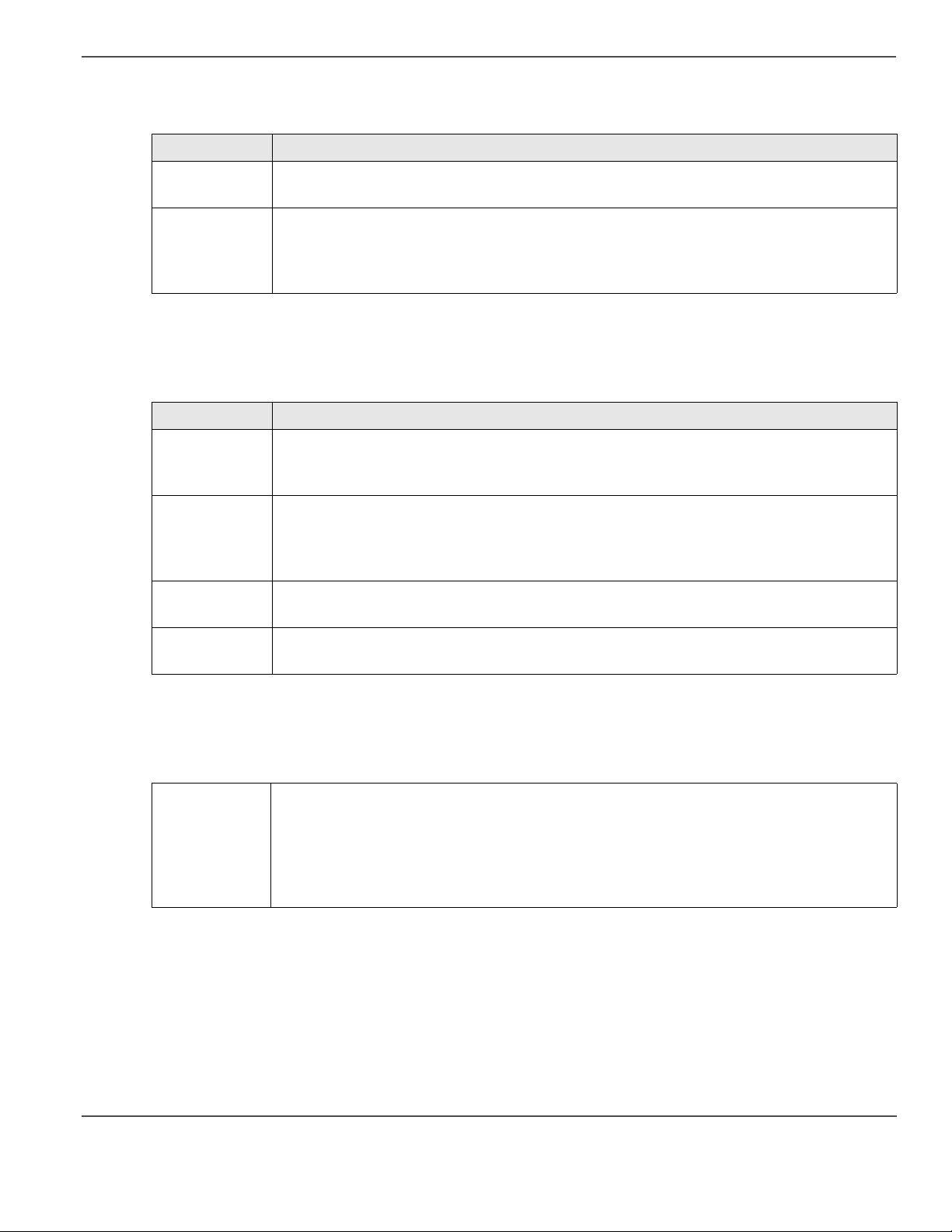

[1]

[1] Compliance Specifications

Specification Directive Number

Product Compliance

EMC

(Directive 89/336/EEC)

Electrical Safety

(Low Voltage Directive 73/23/EEC)

Compliance Category

This device complies with Class A emmision limits.

This equipment is considered to be information technology equipment for use in a light industrial setting. The

equipment falls under the scope of the Machinery Directive due to the movement associated with the gantry

carrying the printer head carriage assembly. As such, a full risk assessment per EN 1050 and a full mechanical and

machinery assessment per 292-2 + A1 Annex 1 was performed. As the equipment is primarily information

technology equipment (large format printer receiving data from a computer terminal), and is within the scope of

EN 60950 (mains operated ITE equipment under 600V including plotters and photoprinters - clause 1.1.1, EN

60950: 2000), a full electrical evaluation was performed per EN 60950:2000.

Noise Measurement Test Summary

Tested according to EN13023:2003, EN11204, ISO3744:1994(E)/ISO3746:1995(E) and declared according to

ISO4871:1984(E)

Measurements taken at the sample in 5 different locations, Printer in normal operation with Vacuum Pump, exceed

75dB (maximum measured value: 76.8dB). For all locations, provide noise protection enclosure or remove pump

from location.

Complete report is available upon request:

Colin Soutar

Health, Safety and Environment

Océ Display Graphics Systems (ODGS)

13231 Delf Place Building #501

Richmond, British Columbia.

Canada V6V 2C3

Email: colin.soutar@dgs.oceusa.com

EN61000-6-4

EN61000-6-2

EN61000-3-3 1995+A1

EN55011

EN60950: 2000(A1 thru A4, A11)

IEC 60950, UL60950, CAN/CSA 22.2 No. 60950-00

EN60204-1:2001

9

Page 10

Product Compliance

Manufacturer:

Oce Display Graphics Systems (ODGS)

13231 Delf Place - Building #501

Richmond, British Columbia

Canada V6V 2C3

Contact: Colin Soutar

Email: colin.soutar@dgs.oceusa.com

http://www.oceusa.com/

http://www.dgs.oce.com/ (

Direct Dial (604) 232-2345

Fax (604) 273-2775

Alternate Manufacturer:

Océ Display Graphics Systems (ODGS)

San Jose Office (RasterGraphics)

2811 Orchard Parkway San Jose, California

U.S.A. 95134

Ph: 408 232 4000

Fx: 408 232 4100

Representatives Marketing the Arizona T220 in Europe:

Océ-Deutschland GmbH

Solinger Straße 5-7

45481 Mülheim/Ruhr

Germany

Telephone: (49) 2084 8450

Fax: (49) 2084 80950

E-mail: ves@oce.de

Web site: http://www.oce.de/

Océ (UK) Ltd.

Langston Road Loughton, Essex IG10 3SL

United Kingdom

Telephone: (44) 870 600 5544

Fax: (44) 870 600 1113

E-mail: salesinformation@oce.co.uk

Web site: www.oce.co.uk

10 Chapter 1 Introduction

Page 11

Chapter 2 Product Overview

11

Page 12

General Description

General Description

Introduction

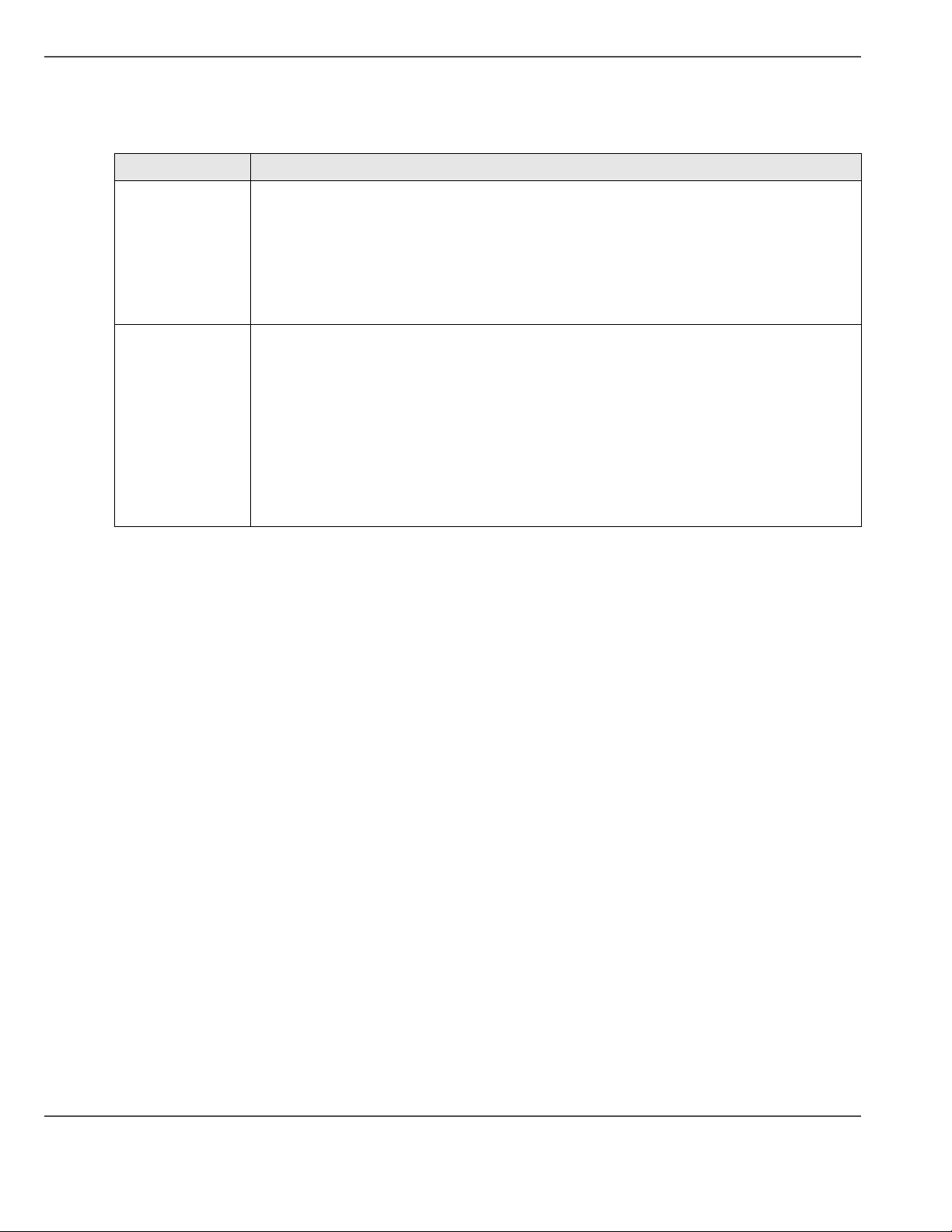

The Arizona T220UV is a six-color digital inkjet printer capable of producing large format images on various rigid

and flexible stock materials. The printer consists of a large vacuum table and moving gantry. The material is held

flat and stationary on the vacuum table during printing. The gantry contains a carriage that sweeps across the table

as the gantry moves in steps along the length of the table to print an image on the media. The Arizona T220UV

must be operated in accordance with certain environmental and safety requirements noted in this document.

Illustration

[1]

[1] Arizona T220UV Printer

Viewing Specifications (8 pass mode only)

Note: This viewing specification is based on the Océ reference print, imaged on the provided Indoor/Outdoor

Poster Grade Paper (Part # 3010102610).

Banding artifacts - not visible from 8 feet (Texture or Regular Banding).

Non-Banding artifacts - not visible from 3 feet (fisheyes, orange peel).

12 Chapter 2 Product Overview

Page 13

Océ ColorBlend® Six-Color Printing

Océ ColorBlend® technology uses the printer’s fifth and sixth ink stations to provide the appearance of continuous

tone color. It does this by adding lighter density cyan and magenta inks to the basic four CMYK (cyan, magenta,

yellow and black) inks to create a smoother appearance in the light and midtone colors, a wider color gamut and

crisper detail. The result is near-photographic quality output without the requirement of extremely high resolution

or true continuous tone.

[2]

[2]

Note: Océ ColorBlend is a registered trademark of Océ Display Graphics Systems, Inc.

General Description

13

Page 14

Product Features

Product Features

Introduction

The Arizona T220UV prints directly onto rigid media using an original flatbed technology. The printer holds the

media stationary on the table while printing is in progress. In addition to the benefits of stationary positioning, the

use of UV ink technology on rigid material eliminates finishing processes such as mounting and lamination.

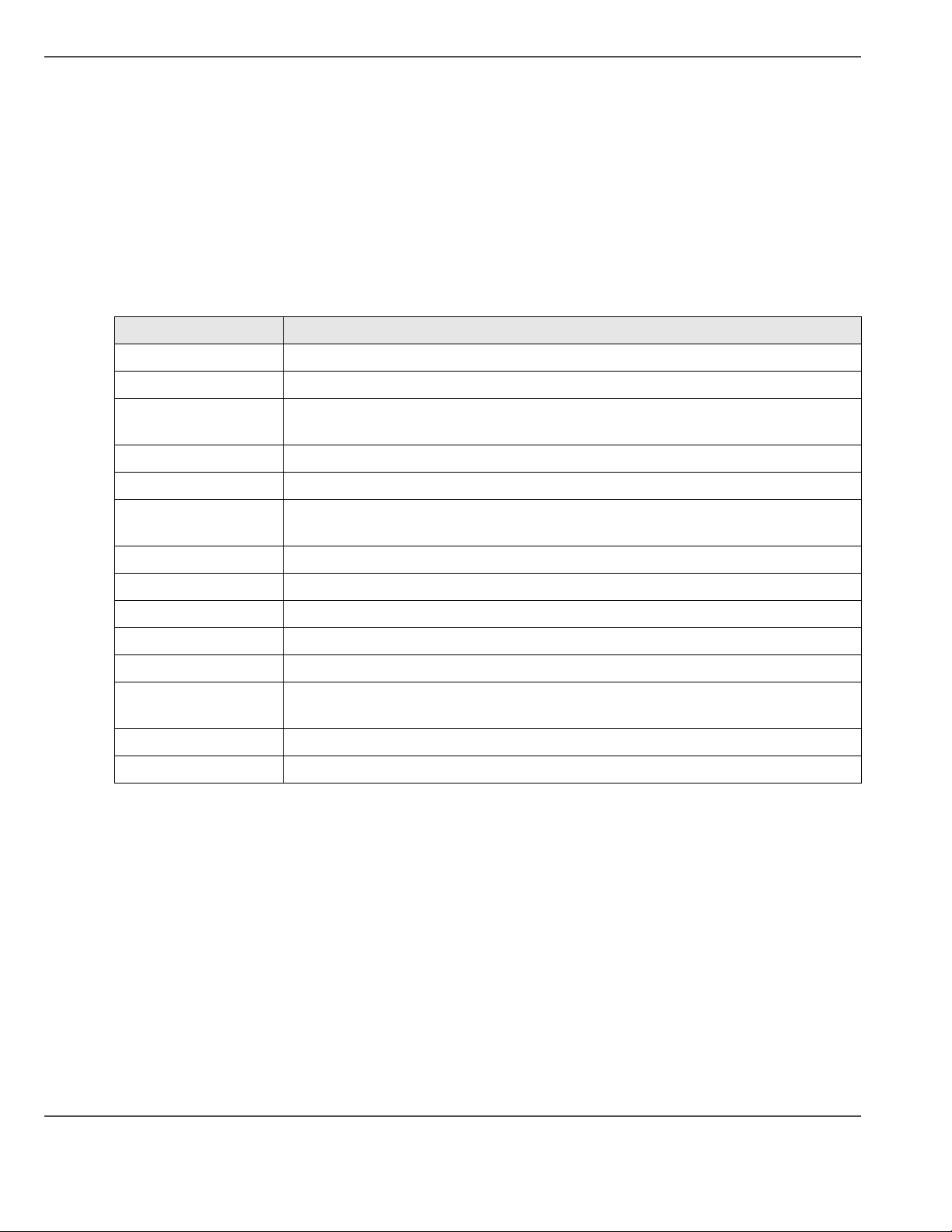

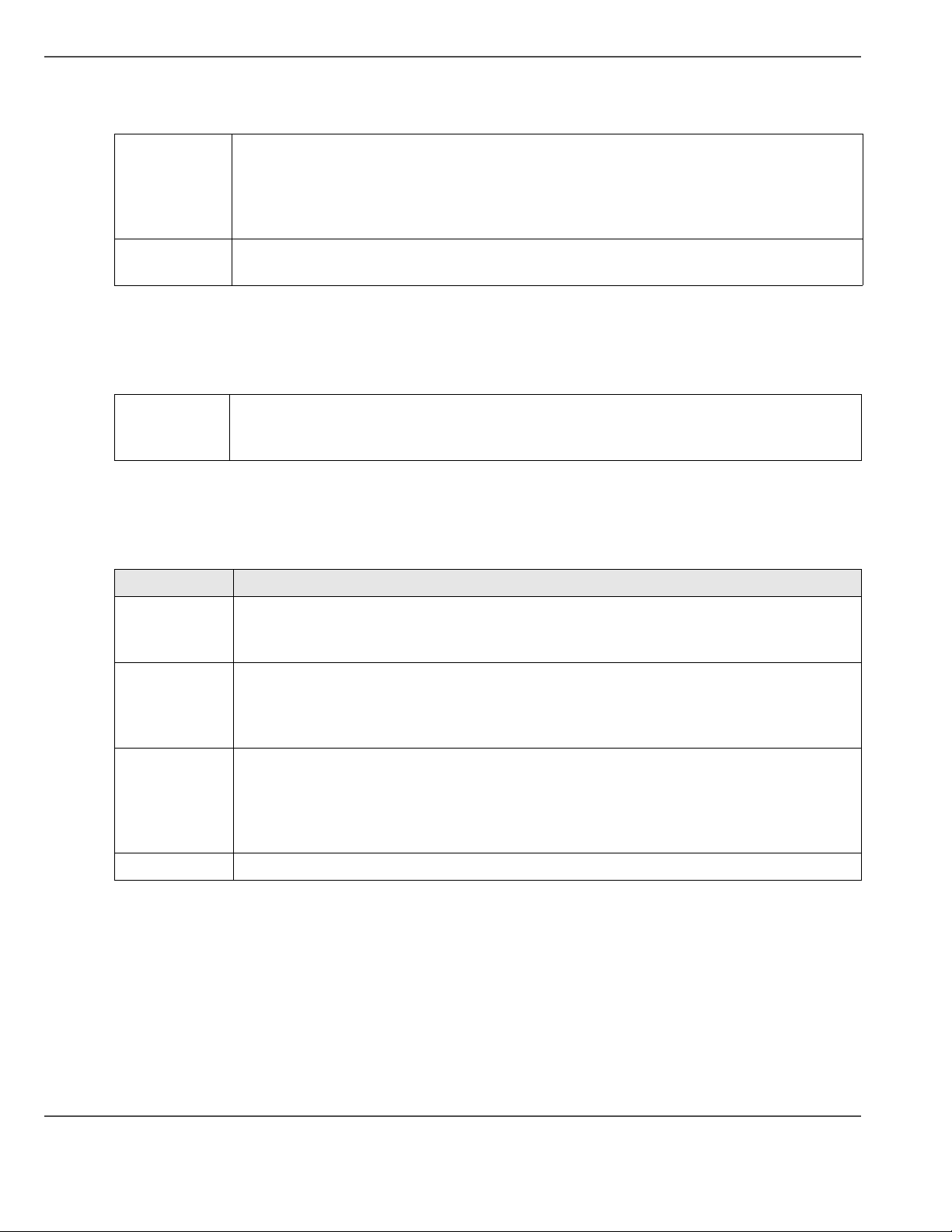

T220UV Specifications

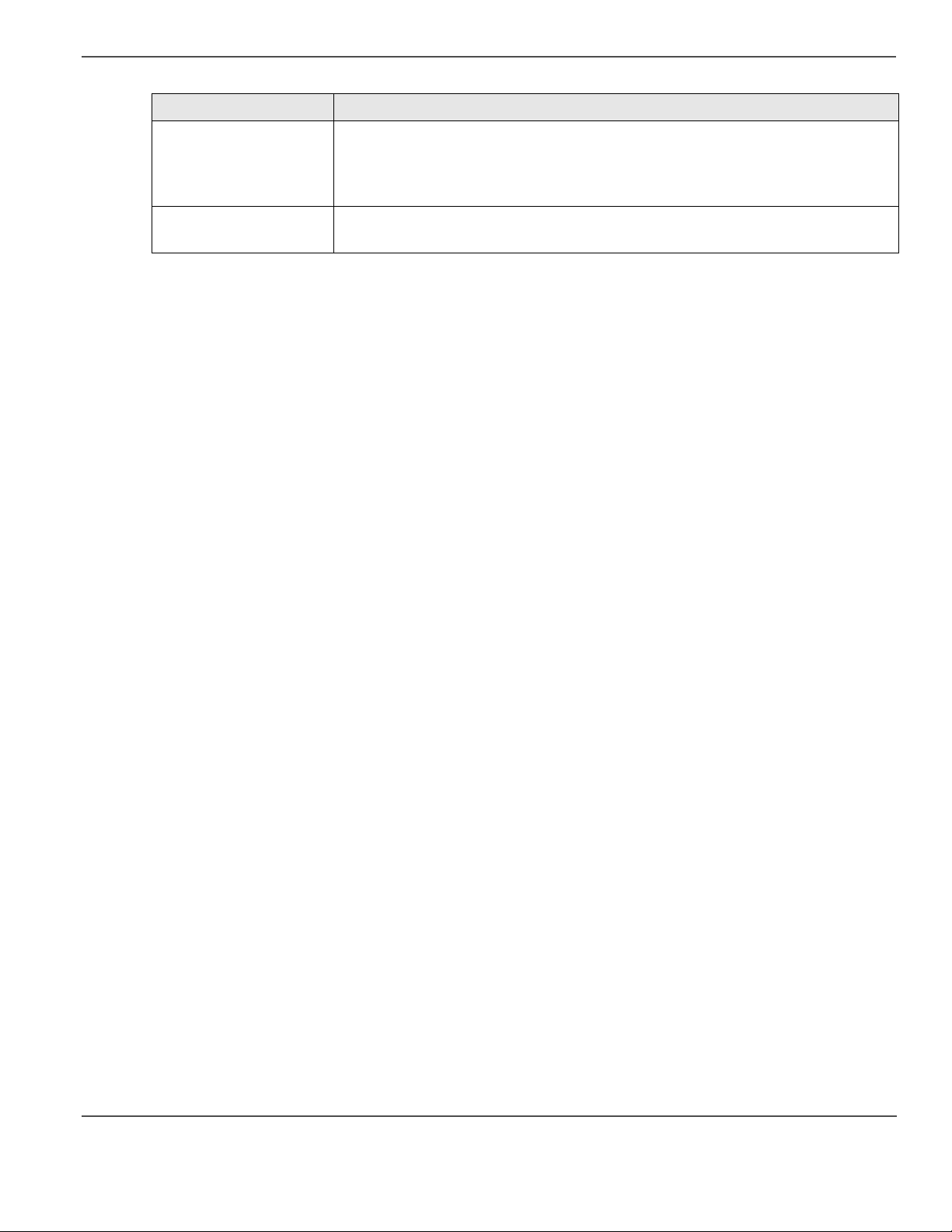

[3]

Feature: Specification:

Minimum Media Size 6" wide x 6" long (15cm x 15cm)

Maximum Media Size 62" wide x 120" long (158cm x 305cm)

Maximum Media

Thickness

Resolution 309 dpi (600 apparent dpi)

Nozzle Drop Volume 65 picoliter

Productivity 4 pass mode: 180 sq.ft./hr. (16.7 sq.metres/hr.)

Ink Colors Black, Cyan, Light Cyan, Magenta, Light Magenta, Yellow

Print Heads Piezoelectric (504 nozzles per color) Xaar/MIT

Curing System UV curing lamp

Table Protection Replaceable liner to protect table from UV inks

Weight 2300 lbs. (1043 kg.)

Dimensions Table: 70.5" x 168" (180 cm x 427 cm)

Hardware Interface Standard Centronics Parallel, LVD, SCSI-2, Ethernet TCP/IP and RS-232 Serial Ports

Software Onyx PosterShop 6.0 or greater

Air Requirements

Pressure: .........80 to 100 psi per minute

2" (5.8cm) thick

8 pass mode: 90 sq.ft./hr. (8.4 sq.metres/hr.)

Gantry: 36" x 120" (91 cm x 305 cm)

Flow: .........1cfm per minute

Air supplied to the printer must pass through the supplied Air Preparation Unit that contains the following:

■ Air Filter – 5 micron element c/w auto drain;

■ Coalescing Filter – 99.97% efficiency c/w auto drain; and

■ Regulator c/w gauge.

14 Chapter 2 Product Overview

Page 15

Printer Electrical Configuration

The T220UV printer operates in the following two configurations:

Delta (USA) Configuration:

Voltage: 230VAC +/-10%, 3 Phase

Frequency: 50 or 60 Hz

Current: 25AMPS maximum steady state

Power: 15kW max.

Circuit Breaker 30 Amps

Wye (European) Configuration:

Voltage: 400VAC +/-10%, 3 Phase

Frequency: 50 or 60 Hz

Current: 25AMPS maximum steady state

Power: 15kW max.

Circuit Breaker 30 Amps

Vacuum Pump Configuration

The vacuum pump operates over the following range of voltages and frequencies:

230 Volts @ 60HZ

Voltage: 230 VAC +/-10%, 3 Phase

Current: 13 AMPS maximum steady state

Power: 6 kW max.

Circuit Breaker 20 Amps

400 Volts @ 60Hz

Voltage: 400 VAC +/-10%, 3 Phase

Current: 8 AMPS maximum steady state

Power: 6 kW max.

Circuit Breaker 15 Amps

190 Volts @ 50 Hz

Voltage: 190 VAC +/-10%, 3 Phase

Current: 16.5 AMPS maximum steady state

Power: 8 kW max.

Circuit Breaker 20 Amps

380 Volts @ 50 Hz

Voltage: 380 VAC +/-10%, 3 Phase

Current: 8 AMPS maximum steady state

Power: 7kW max.

Circuit Breaker 15 Amps

Product Features

Note: ODGS recommends that the AC power outlet for the vacuum pump be located within 8 feet of the power inlet

on the pump.

Important: Unplugging the power cord from the wall socket is the only way to isolate the entire machine.

15

Page 16

Product Features

16 Chapter 2 Product Overview

Page 17

Chapter 3 Safety Information

17

Page 18

Safety Guidelines

Safety Guidelines

Introduction

Read all of the material in this section and review the MSDS documents before handling any UV ink or using the

T220 UV printer.

Caution: Both UV inks and the curing lamps can be harmful if not properly handled. Follow these

guidelines carefully in order to ensure maximum safety.

Personal Safety

The operator should wear butyl rubber gloves, a protective apron, a NIOSH-approved respirator (half-mask organic

vapor respirator), and Safety glasses with side shields when handling inks.

Personal Safety

The Arizona T220UV printer has an integrated safety interlock system that stops all machine motion when a

situation that might compromise operator safety occurs. Thus, opening any of the gantry doors (except during

authorized procedures), tripping the hinged gate on the gantry cover, or activating an Emergency-Stop button will

switch the Safety Monitoring Relay input circuits. This results in the system isolating the power to both the motion

control motors and the T220UV curing system (lamps). For a general description of how the safety interlock system

works, see “Safety Interlocks” and for a detailed technical description see Appendix B.

Handling UV Inks

Read and practice safety guidelines as outlined in the Material Safety Data Sheet (MSDS) for each ink. Post these

documents in the work area as required by prevailing law. MSDS for all six inks are provided when you purchase

inks. The following is a summary of the important safety aspects of the MSDS that are common to all UV inks.

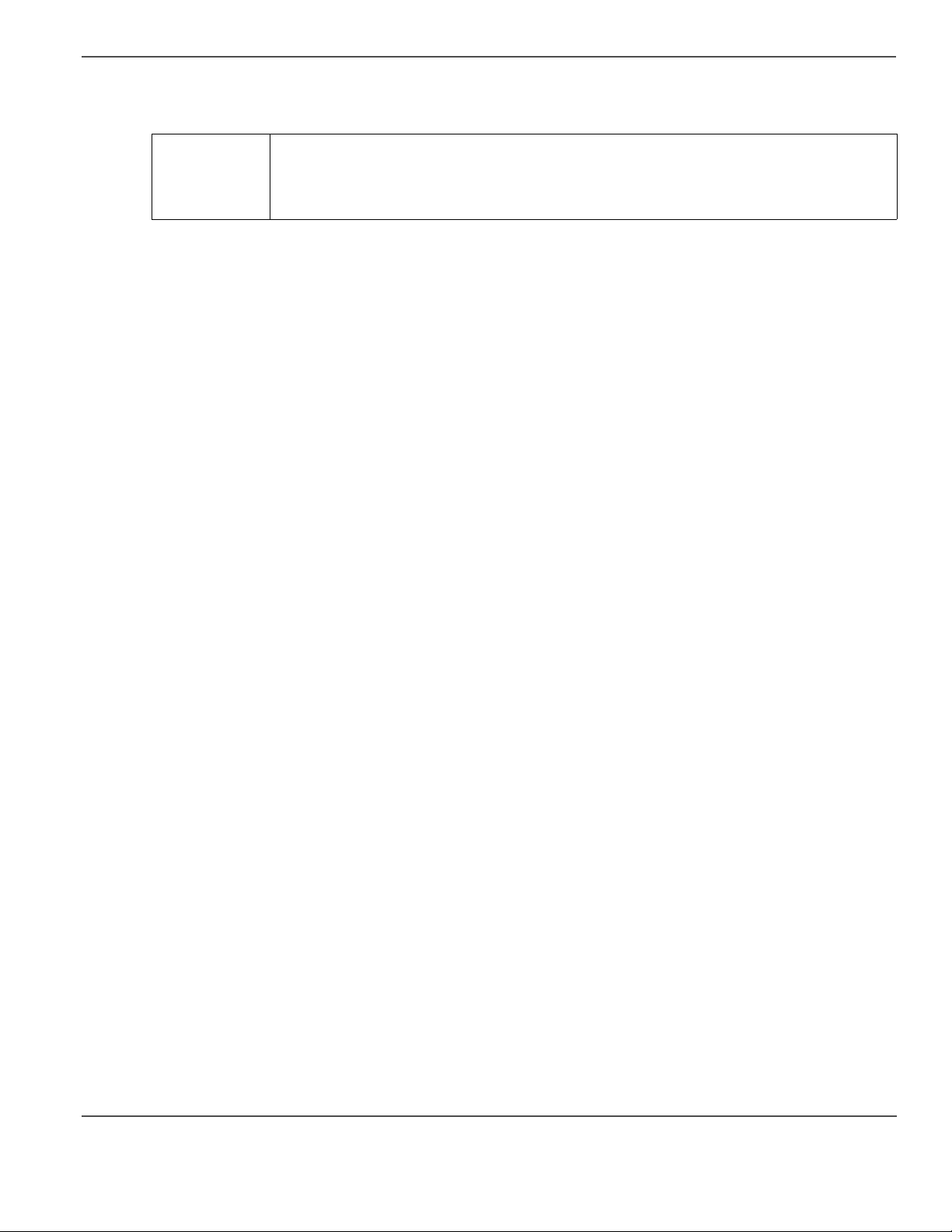

Immediate Health Effects of Exposure to Ink

[4]

[4] Immediate (Acute) Health Effects by Route of Exposure

Exposure by: Effect:

Inhalation: Can cause severe respiratory irritation, dizziness, weakness, fatigue, nausea, headache and

Skin Contact: Can cause severe irritation, defatting, and dermatitis. Irritation effects may last for hours or days

Eye Contact: Corrosive to eye tissue. Can cause severe irritation, tearing, and burns that can quickly lead to

Ingestion: Severely irritating to mouth, throat, and stomach. Can cause abdominal discomfort, nausea,

possible unconsciousness.

but will not likely result in permanent damage.

permanent injury including blindness.

vomiting and diarrhea.

18 Chapter 3 Safety Information

Page 19

Safety Guidelines

Long-Term Health Effects

[5]

[5] Long-Term (Chronic) Health Effects

Exposure by: Effect

Inhalation: Upon prolonged and/or repeated exposure, can cause severe respiratory irritation, dizziness,

weakness, fatigue, nausea, headache and possible unconsciousness.

Skin Contact: Upon prolonged or repeated contact can cause severe irritation, defatting, and dermatitis. May

cause lingering affects but not likely to result in permanent damage if the exposure is

eliminated. Upon prolonged or repeated exposure, harmful if absorbed through the skin. May

cause severe irritation and systemic damage

First-Aid Measures

[6]

[6] First-aid Measures

Exposure by: Remedy

Inhalation: Remove to fresh air. If breathing is difficult, have a trained individual administer oxygen. If not

breathing, give artificial respiration and have a trained individual administer oxygen. Get

medical attention immediately.

Eyes: Immediately flush eyes with plenty of water for at least 20 minutes retracting eyelids often.

This corrosive material can cause immediate and permanent eye damage. Tilt the head to

prevent chemical from transferring to the uncontaminated eye. Get immediate medical

attention and monitor the eye as advised by your physician.

Skin Contact: Wash with soap and water. Remove contaminated clothing, launder immediately, and discard

contaminated leather goods. Get medical attention immediately.

Ingestion: Severely irritating. Do not induce vomiting. Seek medical attention immediately. Drink 2

glasses of water or milk to dilute.

Dealing With Spilled Ink

[7]

[7] Accidental Release Measures

Personal

Precautions and

Equipment:

Exposure to the spilled material may be severely irritating or toxic. Follow personal protective

equipment recommendations found in Section VIII of this MSDS. Personal protective

equipment needs must be evaluated based on information provided on the MSDS sheet and the

special circumstances created by the spill including; the material spilled, the quantity of the

spill, the area in which the spill occurred, and the expertise of employees in the area responding

to the spill. Never exceed any occupational exposure limits.

19

Page 20

Safety Guidelines

Handling and Storage

[8]

[8] Handling & Storage

Handling

Precautions:

Toxic or severely irritating material. Avoid contacting and avoid breathing the material. Use

only in a well ventilated area. As with all chemicals, good industrial hygiene practices should

be followed when handling this material. Avoid contact with material, avoid breathing dusts or

fumes, use only in a well ventilated area. Wash thoroughly after handling. Do not get in eyes,

on skin or clothing. Remove contaminated clothing and wash before reuse.

Storage

Conditions:

Store in a cool dry place.

Isolate from incompatible materials.

Exposure Controls

[9]

[9] Exposure Controls

Engineering

Measures

Local exhaust ventilation or other engineering controls are normally required when handling or

using this product to avoid overexposure. It is recommended that facilities storing or using this

material be equipped with an eyewash and safety shower.

Personal Protection

[10]

[10] Personal Protection

Area Strategy

Respiratory

Protection:

Follow a respiratory protection program that meets 29 CFR 1910.134 and ANSI Z88.2

requirements whenever work place conditions warrant the use of a respirator. Respiratory

protection may be required in addition to ventilation depending upon conditions of use.

Eye Protection: Wear safety glasses with side shields when handling this product. Wear additional eye

protection such as chemical splash goggles and/or face shield when the possibility exists for

eye contact with splashing or spraying liquid, or airborne material. Do not wear contact lenses.

Have an eye wash station available.

Skin Protection: Avoid skin contact by wearing chemically resistant gloves, an apron and other protective

equipment depending upon conditions of use. Inspect gloves for chemical break-through and

replace at regular intervals. Clean protective equipment regularly. Wash hands and other

exposed areas with mild soap and water before eating, drinking, and when leaving work. Use

of protective coveralls and long sleeves is recommended.

Gloves: Wear impervious material.

20 Chapter 3 Safety Information

Page 21

Disposal of UV Ink

[11]

[11] Disposal Considerations

Safety Guidelines

Disposal

Methods:

Dispose in accordance with Federal, State, Provincial and Local regulations. Material may be

compatible with industrial waste incineration or inclusion in a fuel blending program. This

characterization is subject to approval by your waste management contractor. This material

should be recycled if possible.

21

Page 22

UV Lamp Safety

UV Lamp Safety

Introduction

The Arizona T220UV printer is designed so that direct light from lamps is not visible and bounce (reflected) light

is minimized. UV lamps radiate harmful ultraviolet rays, which can cause serious burns to skin and eyes. While

thermal burns are felt immediately, UV burns are not felt for several hours. Short exposure to lamp radiation can

cause severe burning of skin and eyes. UV burn of the eyes affects the cornea and takes several days to heal. UV

burn is identical to "Welder's burn" and will feel like sand in the eyes that cannot be washed out. The discomfort is

transitory. Extreme caution must be taken - high power UV radiation can cause blindness.

Limited exposure to UV radiation will evoke erythema on normal skin. Such erythema is transitory and will not

produce blistering, nor tanning, as only a small amount of radiation penetrates the Malpighian layer. Extreme

caution must be taken since high power UV radiation can cause severe burns to the skin.

Note: The Arizona T220UV printer has a built-in interlock safety system that shuts down the UV lights if the gantry

doors are opened. This ensures that the operator is not exposed to potentially harmful UV rays from the lamps. The

section “Safety Interlocks” explains the interlock system and how it protects the operator from UV exposure.

Statement of UV Safety

UV Lamps: Superficial eye damage and burning of the skin can occur with even brief exposure to UV light. Serious

injuries can result from prolonged exposure, especially if unshielded. Some UV lamps operate at very high

temperatures (approximately 800° C). For this reason, never touch a lamp which has been in operation. Let the lamp

cool before attempting any maintenance, and then use extreme care in handling the bulbs. Most bulbs contain a small

amount of metallic mercury which is toxic when ingested, handled, or breathed. Therefore, if bulbs are broken, care

should be taken to clean up the spill immediately.

The UV Lamps emit dangerous levels of UV light. Arizona T220UV operators must limit their exposure to

UV/Blue light escaping from beneath the gantry hinged gates. The UV Radiation Hazards of the machine have been

measured according to EN12198 and are at safe levels outside the machine.

Gantry Cover Brush: The Brushes are used as a UV Shield to prevent stray UV light escaping from the front and

back of the gantry, while still allowing adequate media clearance. The brushes must be replaced if they become

contaminated or deformed by any means. The brushes must be replaced at least every two years, or sooner if they

become contaminated or deformed in any way.

Emmision Compliance

Effective UV-irradiance Emmision Category of AzT220UV According to 7.1 of EN12198-1:2000 Category (1)

Effective Irradiance respective the Effective Radiance Emmision Category of AzT220UV According to 7.1 of

EN12198-1:2000 Category (1)

22 Chapter 3 Safety Information

Page 23

Handling UV lamps

Bare skin contact with the UV lamps must be avoided. Replacement lamps must be wiped with the supplied

cleaning solution before placing in service. Compounds from the skin when heated on lamps operating at 600 to

850C will form permanent etching (devitrification) on the quartz surface decreasing UV energy transmission. A

contaminated lamp eventually may overheat, causing premature failure.

When unpacking the lamps, the carton should be opened fully so lamp can be lifted out of packaging with no

twisting or pulling. Unpacking should take place in an area large enough to eliminate the possibility of inadvertently

striking lamp against walls, pillars, pipes, beams or press machinery.

Ozone Safety

Tri-atomic oxygen or ozone (O3) is the only by-product of the UV lamp. It is formed by oxygen being exposed to

254nm wavelengths of UV energy. Ozone is effectively eliminated in the printing area by exhausting air from the

cooling system of the T220UV. Such exhausting involves no danger as the hot gas is very unstable and breaks down

to oxygen rapidly in ducting. Also, the Arizona T220UV printer is equipped with ozone filters located above the

fans in the gantry. These filters ensure that ozone is kept to a minimal safe level.

UV Lamp Safety

23

Page 24

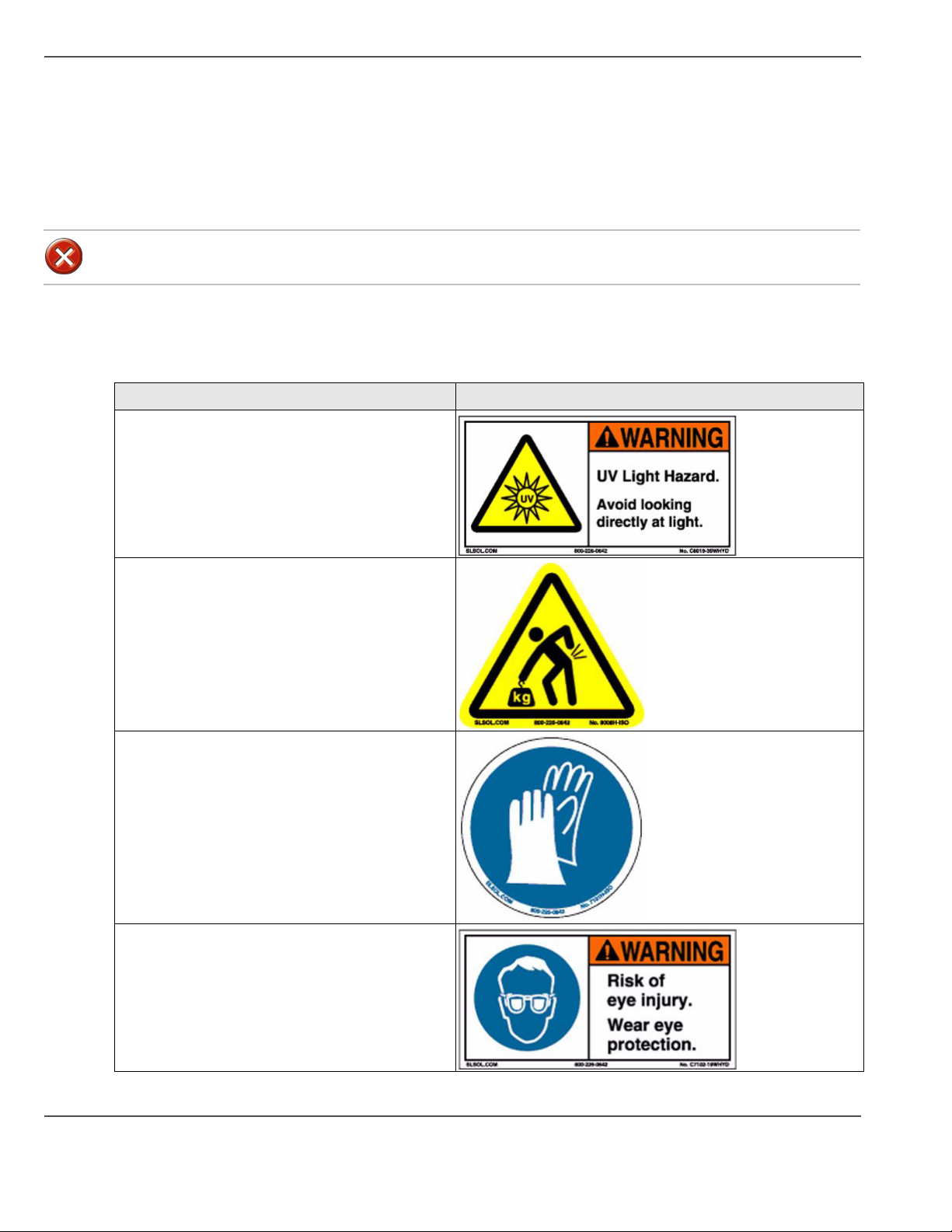

Arizona T220UV Safety Labels

Arizona T220UV Safety Labels

Introduction

The safety labels are placed at strategic locations on the printer to warn the operator of possible dangers and hazards.

It is important to be aware of the meaning of these labels to ensure safe operation of the printer.

Caution: Read and understand all of the safety label descriptions in the table below before operating the

printer.

Safety Labels

[12]

[12] Safety Labels (1 – 3)

Description Label

Warning: UV Light Hazard. Avoid looking

[3]

directly at light. # 3012002359

Located on gantry door to remind operator that

looking at the UV light source is dangerous.

Lifting Hazard, Heavy Object - #3012002361

[4]

Located on the ballast platform to remind service

technicians that the ballast is heavy and to use due

care if any lifting is required.

Wear Safety Gloves - # 301222360

[5]

Located on the ink enlcosure tray as a reminder to

always wear gloves when handling ink.

Warning: Risk of Eye Injury. Wear Eye

Protection - #3012002360 - Located on the ink

enclosure tray as a reminder that the UV-curable

ink is harmful to the eyes and skin. Always wear

glasses and gloves when handling ink.

24 Chapter 3 Safety Information

[6]

Page 25

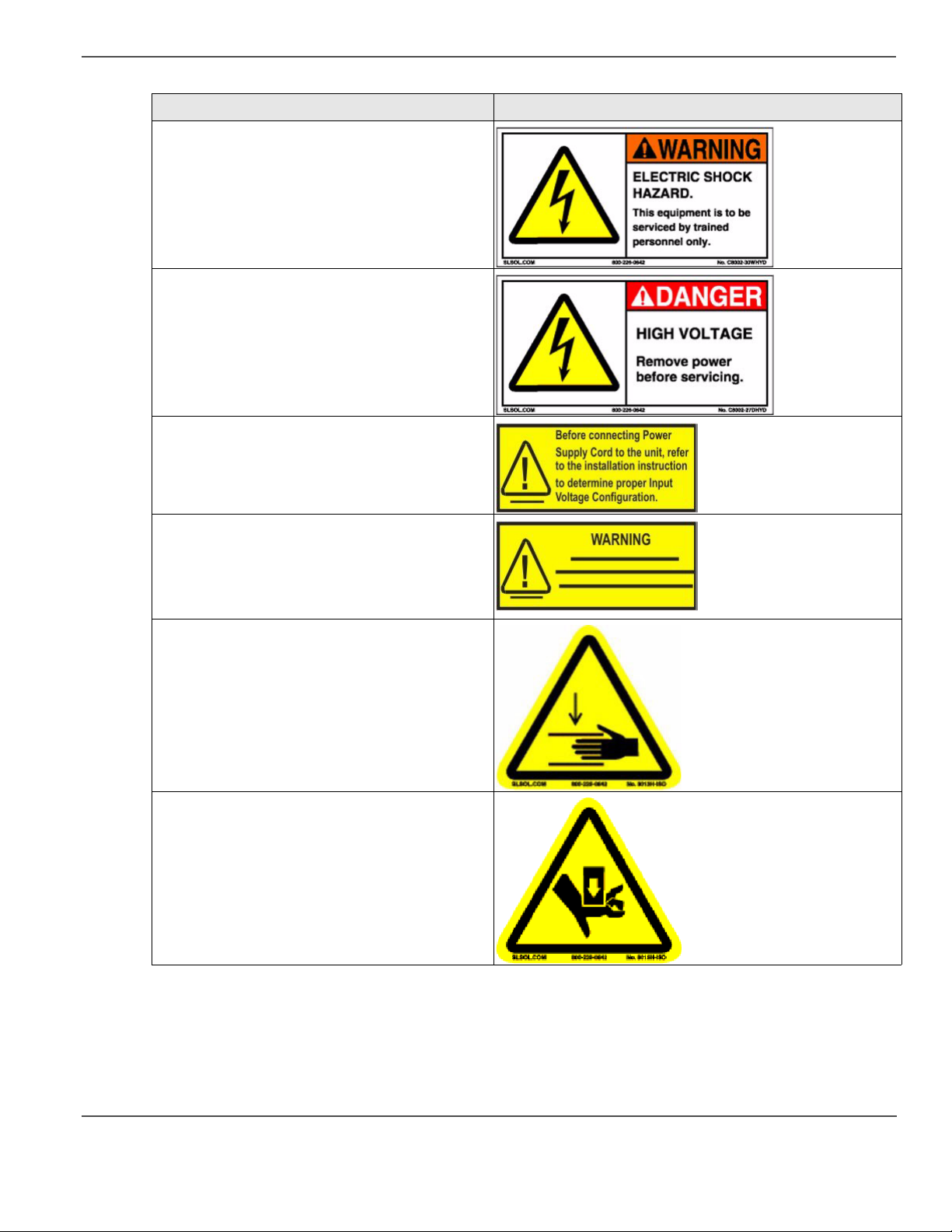

Arizona T220UV Safety Labels

[12] Safety Labels (2 – 3)

Description Label

Warning: Electric Shock Hazard This

[7]

equipment is to be serviced by trained

personnel only. - # 3010100961

Located on the door to the electronics enclosure.

This door must be kept locked and only opened by

a trained technician.

DANGER High Voltage: - # 3010100724

[8]

Remove power before servicing. Located inside

the electronics enclosure. AC power cable should

be disconnected before servicing any electrical

components.

Before connecting Power Supply Cord to the

[9]

unit, refer to the installation instruction to

determine proper Input Voltage Configuration

WARNING - # 3010100315 HIGH LEAKAGE

[10]

CURRENT EARTH CONNECTION

ESSENTIAL BEFORE CONNECTING

SUPPLY.

Located above the AC power cable

[11]

Pinch Point - # 3010100726

Located on the bracket endplate and the plate end

cap.

Crush Hazard - # 3010100725

Located on the gantry end covers

[12]

25

Page 26

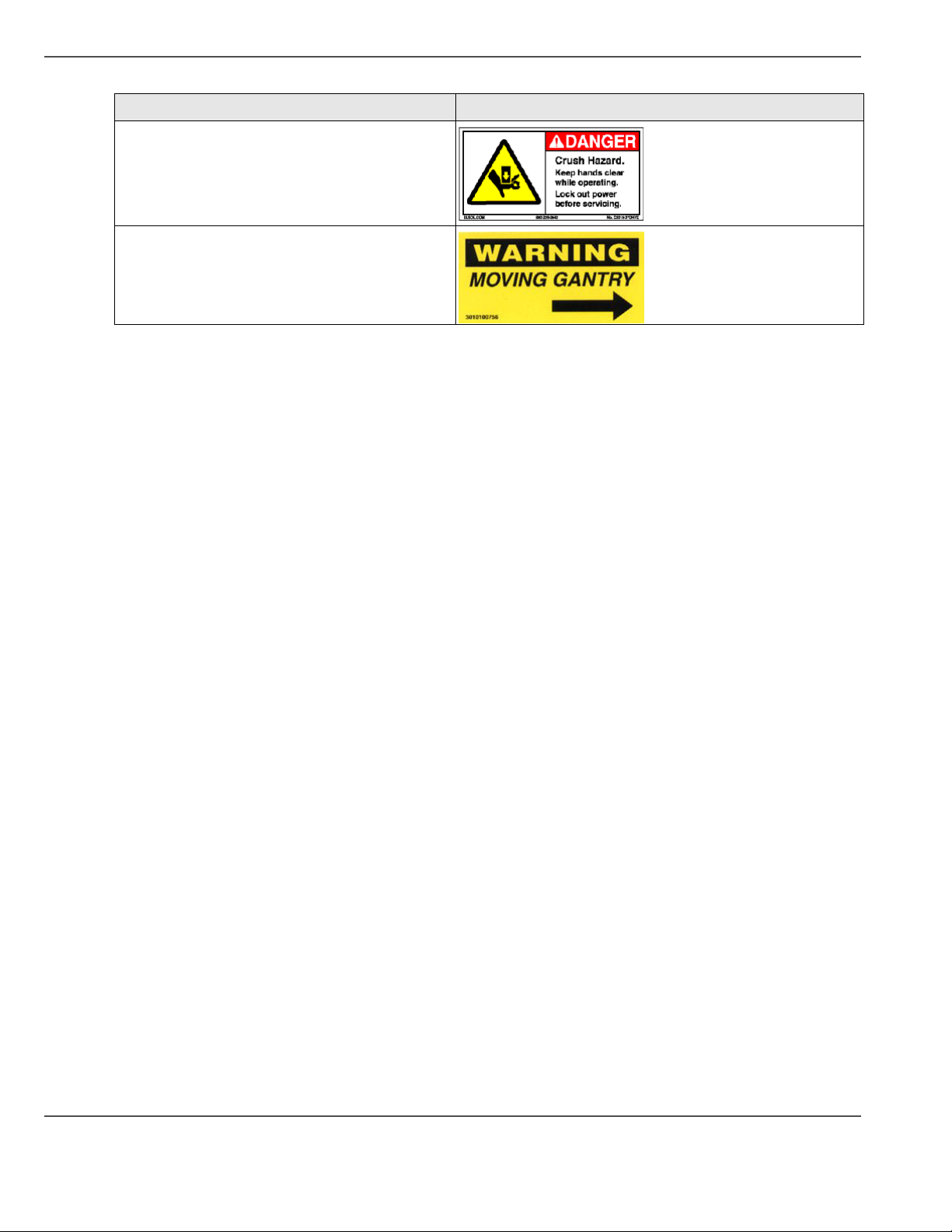

Arizona T220UV Safety Labels

[12] Safety Labels (3 – 3)

Description Label

Danger Crush Hazard: - # 3010100725 Keep

[13]

hands clear while operating. Lock out power

before servicing

Located on the endplate of the gantry where the

carriage rests on the capping station.

Warning Moving Gantry - # 3010100756 -

[14]

Located on the table to identify the risk involved

with the gantry moving during printing.

26 Chapter 3 Safety Information

Page 27

Safety Awareness

Introduction

This section contains two sets of principles that must be followed to assure maximum safety when operating the

Arizona T220UV printer. The first set uses negative examples to show you residual risks that must be avoided in

order to prevent injury to the operator. The second set of principles illustrates some of the residual risks that are

inherent in the operation of the Arizona T220UV printer. These are situations or physical aspects of the printer that

may present a potential danger to the operator, but would compromise the capabilities of the printer if changed.

Therefore, they are pointed out as a precaution that the operator must be aware of when using the printer.

Attention: The photos in the following table illustrate residual risks that must be avoided when operating the

Arizona T220UV printer.

Situations to Avoid

Avoid the actions and situations presented in the following table.

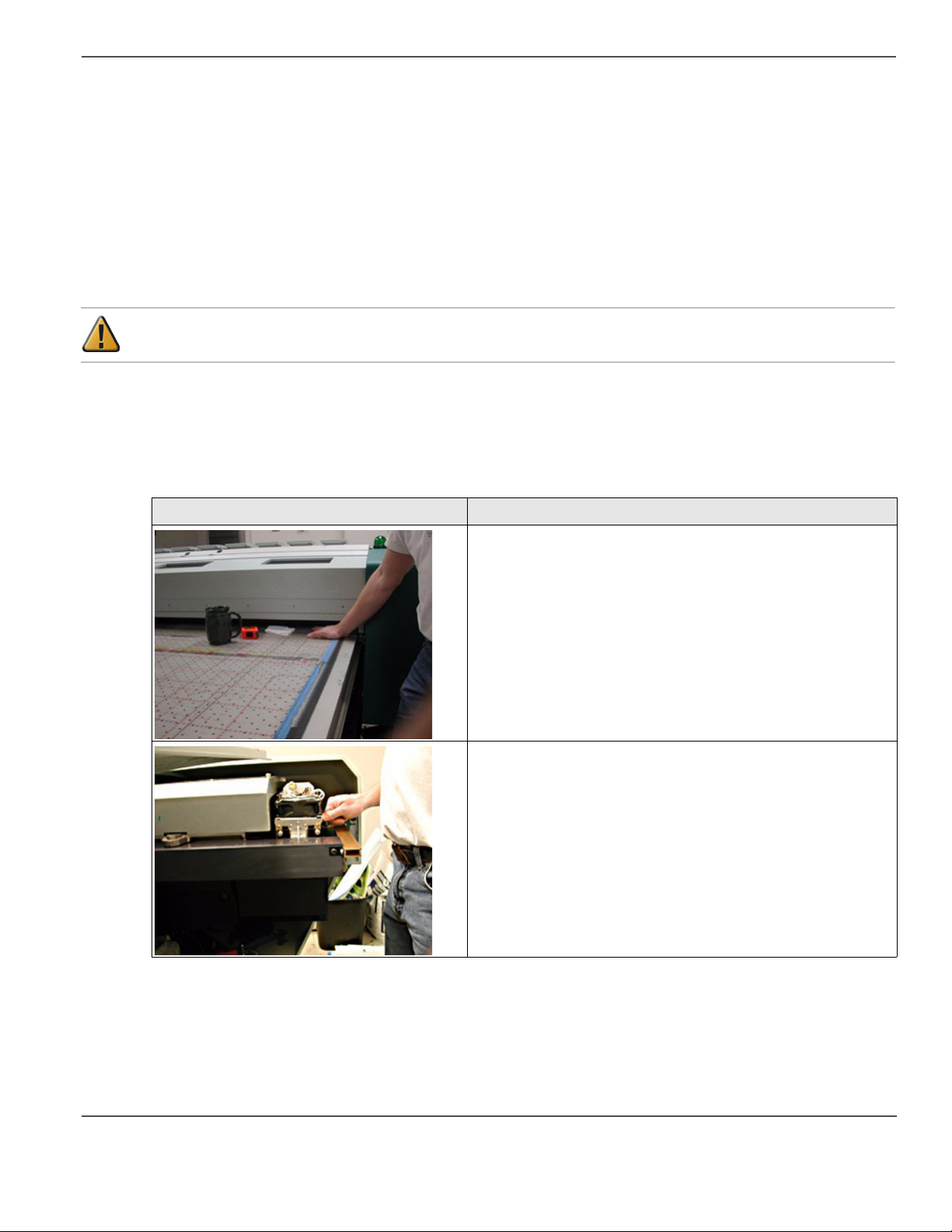

[13]

[13] How NOT to use the Arizona T220UV (1 – 2)

Safety Awareness

Avoid these Situations For Your Personal Safety

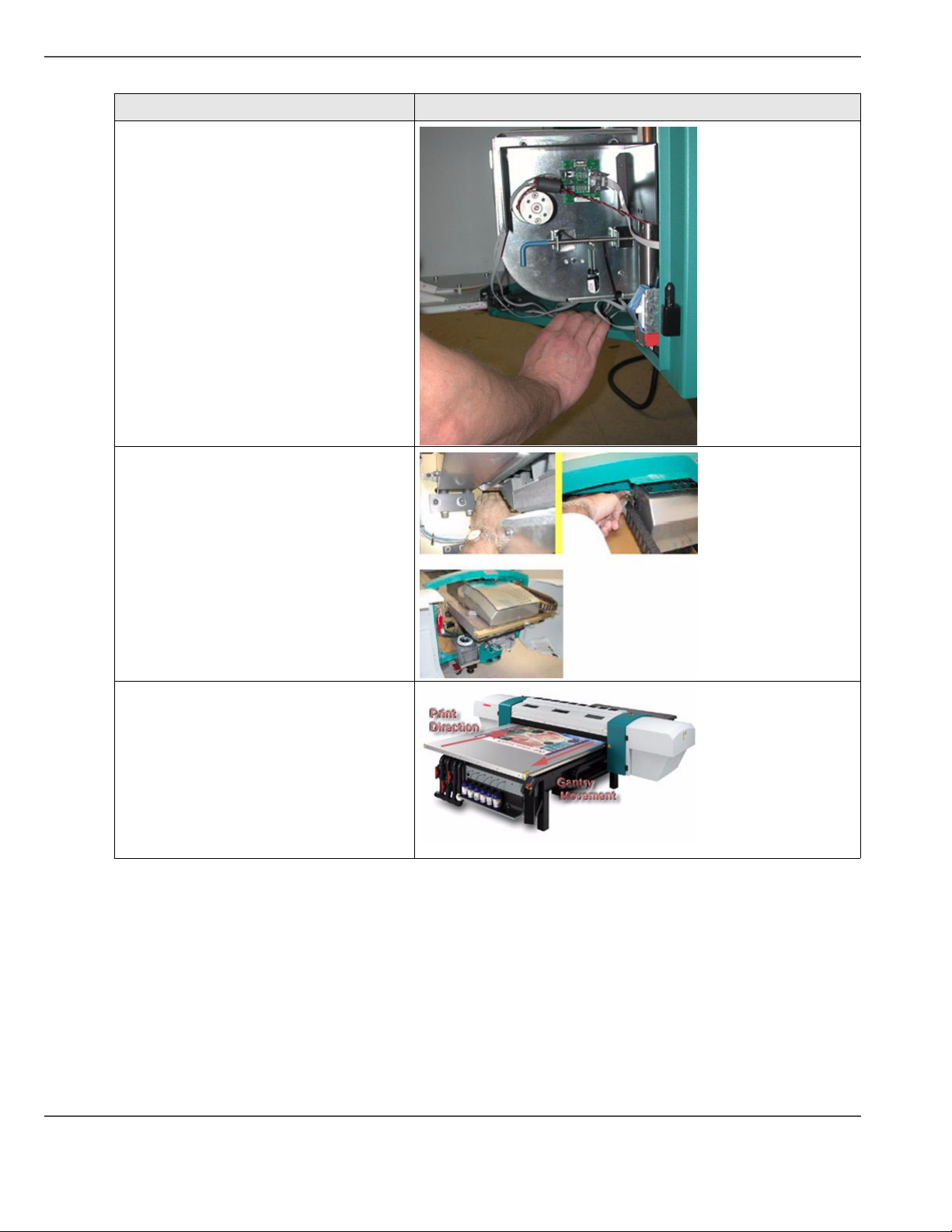

[15]

Do not place your hand under the gantry when the printer is

powered on. Do not leave any objects on the table printing

surface, except for media that you will print on. Also make sure

the media is less than 2 inches (50.8 mm) in thickness.

[16]

Do not push or force the carriage to move manually. Always use

the “Access Carriage” command in the Operator menu to move

the carriage to the blot station if you need to access the area

under the carriage.

27

Page 28

Safety Awareness

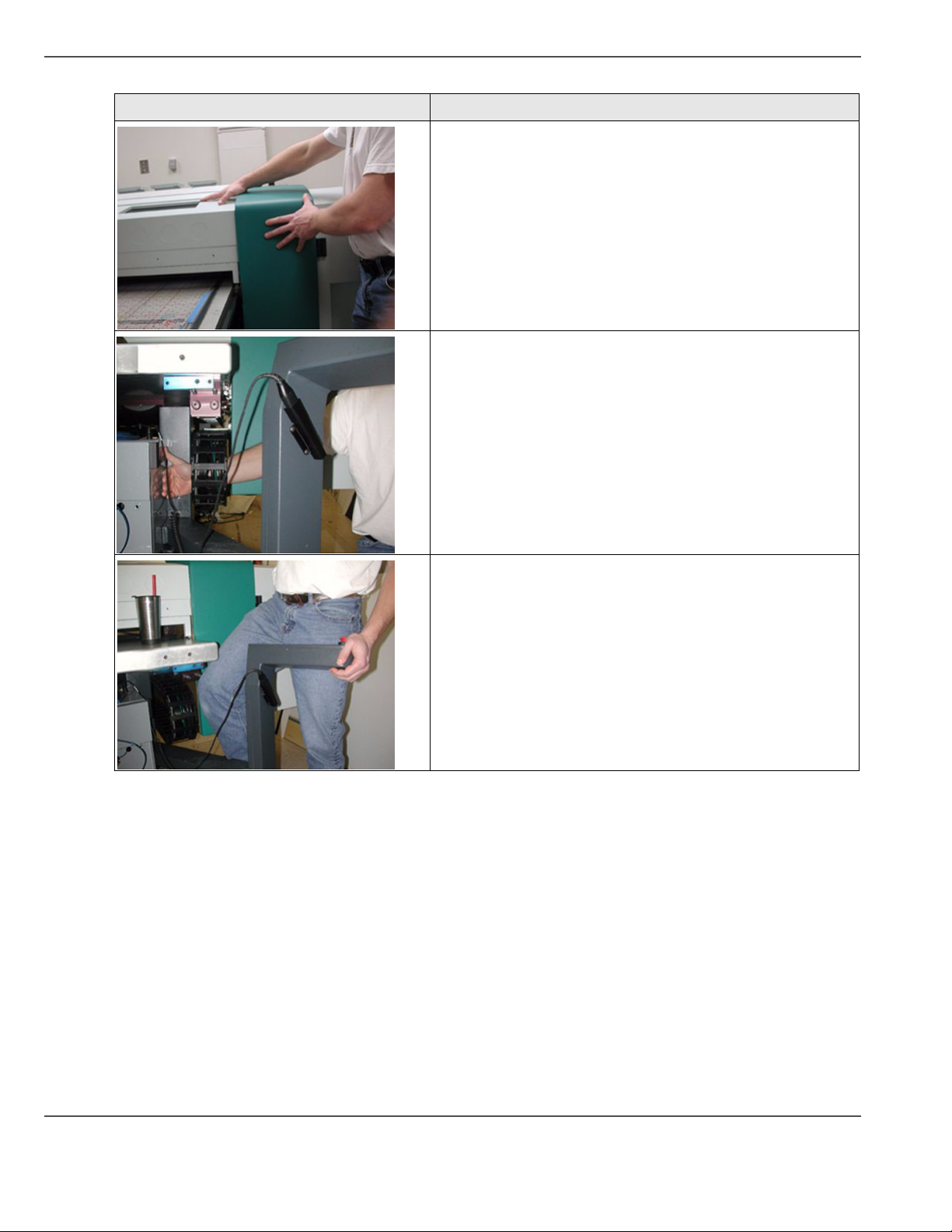

[13] How NOT to use the Arizona T220UV (2 – 2)

Avoid these Situations For Your Personal Safety

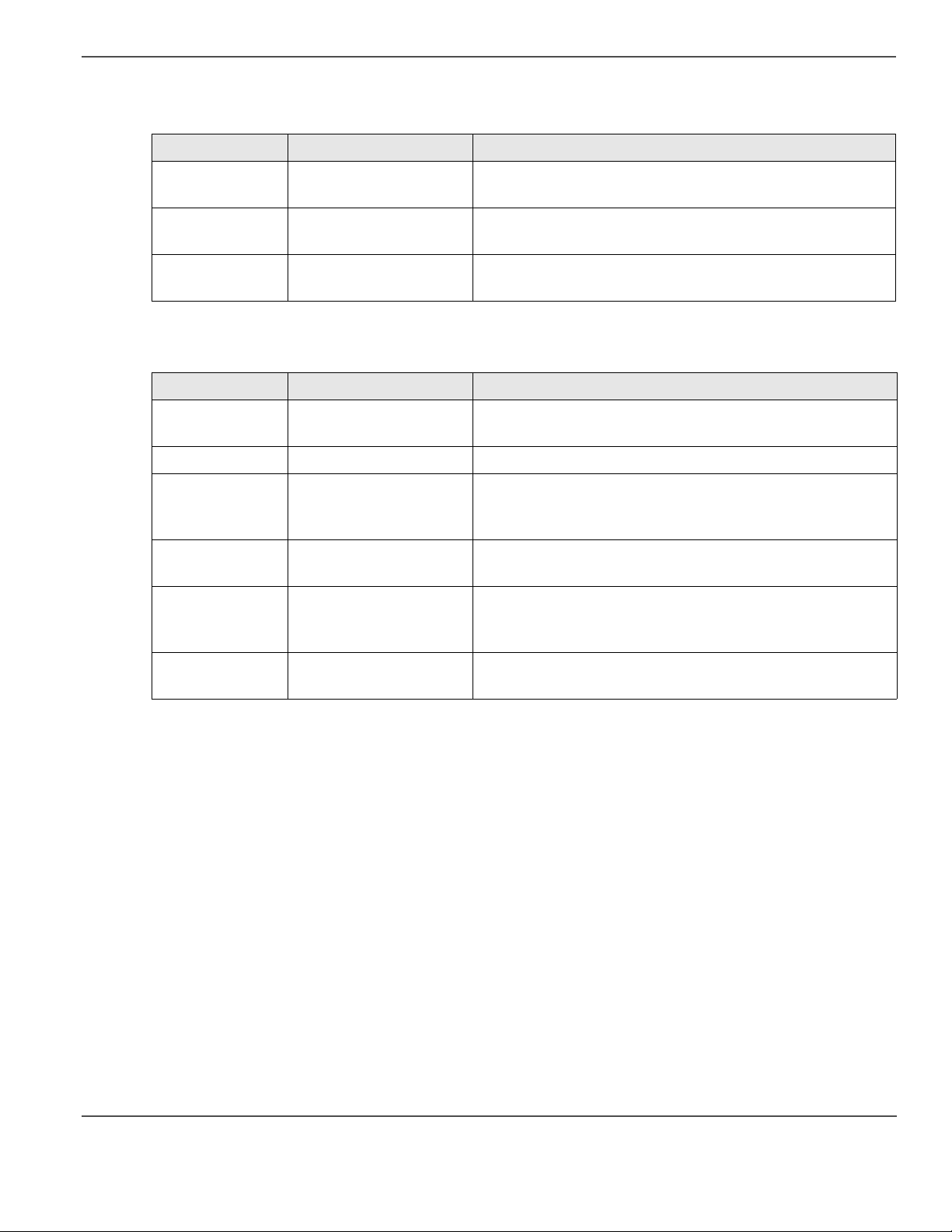

[17]

[18]

Do not push or force the gantry to move manually. Always use

the “Move Gantry” command in the Operator menu to move the

gantry along the table surface in increments of 1 foot (305mm).

Do not place you hand or arm in the end section of the IGUS

track unless power is turned off and locked out (See “Locking

Out the Power Switch”)

[19]

Do not stand at the Control Panel or close to the table when the

gantry is actively printing.

28 Chapter 3 Safety Information

Page 29

Residual Safety Risks

The Arizona T220UV is engineered to minimize machine components and operating procedures that may

compromise operator safety. However, in order to maintain some machine operations and functionality, certain

compromises are required. The following table documents some of these residual hazards. By making the operator

aware of the potential risks, we hope to ensure maximum safety in the operation of this printer.

Note: In all of these cases, the risk is reduced by slowing down the gantry in all non-print and hazardous areas.

A hinged and interlocked gate across both sides of the Gantry also reduces the risk.

Caution: there may be a time lag between when a print job is issued and when the gantry movement actually begins.

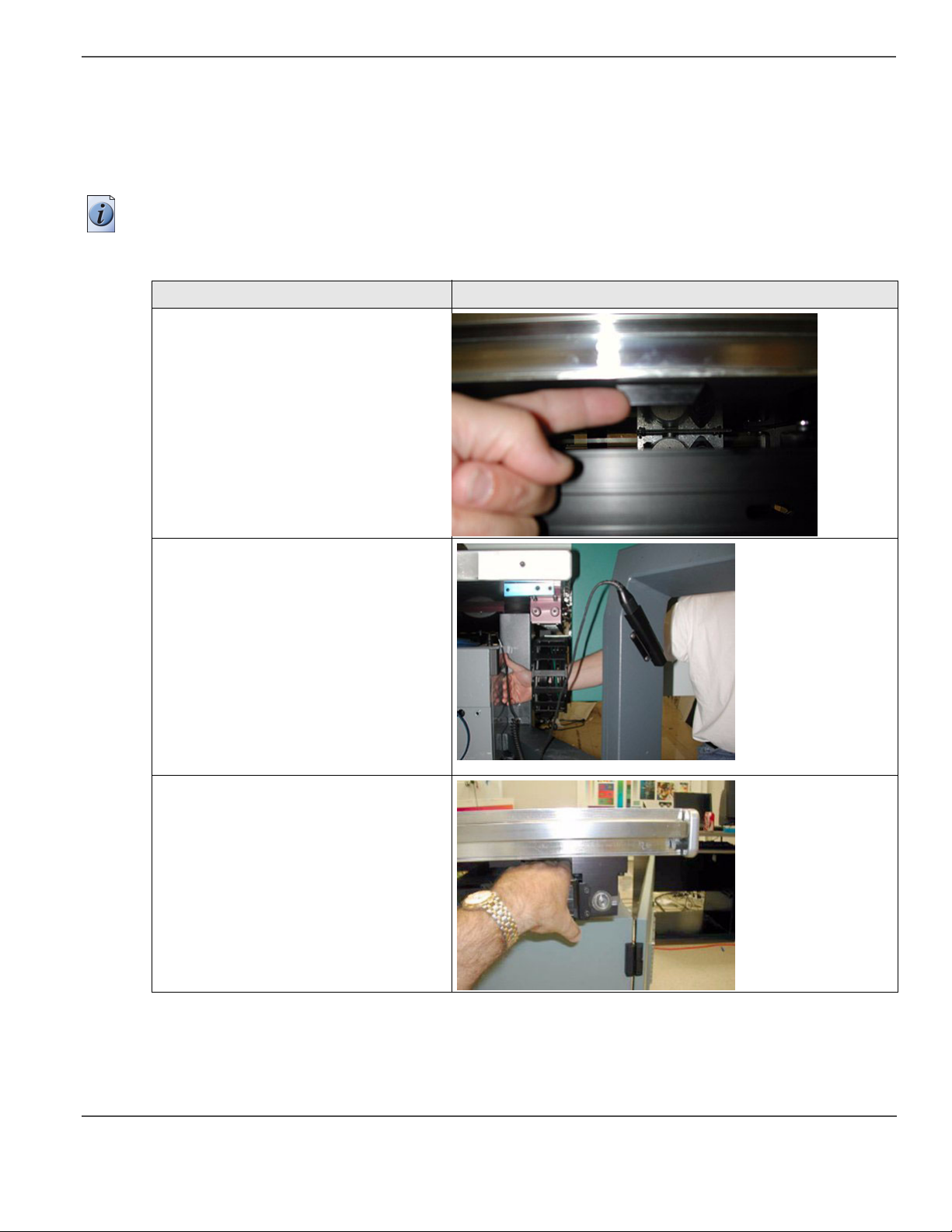

[14]

[14] T220UV Residual Risks (1 – 4)

Safety Awareness

Risk Area Crushing/Shear Hazard

[20]

A crushing/pinch hazard is created by the

gantry and the home and away position tabs.

This is reduced by rounding off the corners

of the tab.

[21]

A crushing/pinch hazard is created by the

cable track and the frame of the machine.

A crushing/shear hazard is created by the

gantry and the frame of the machine.

[22]

29

Page 30

Safety Awareness

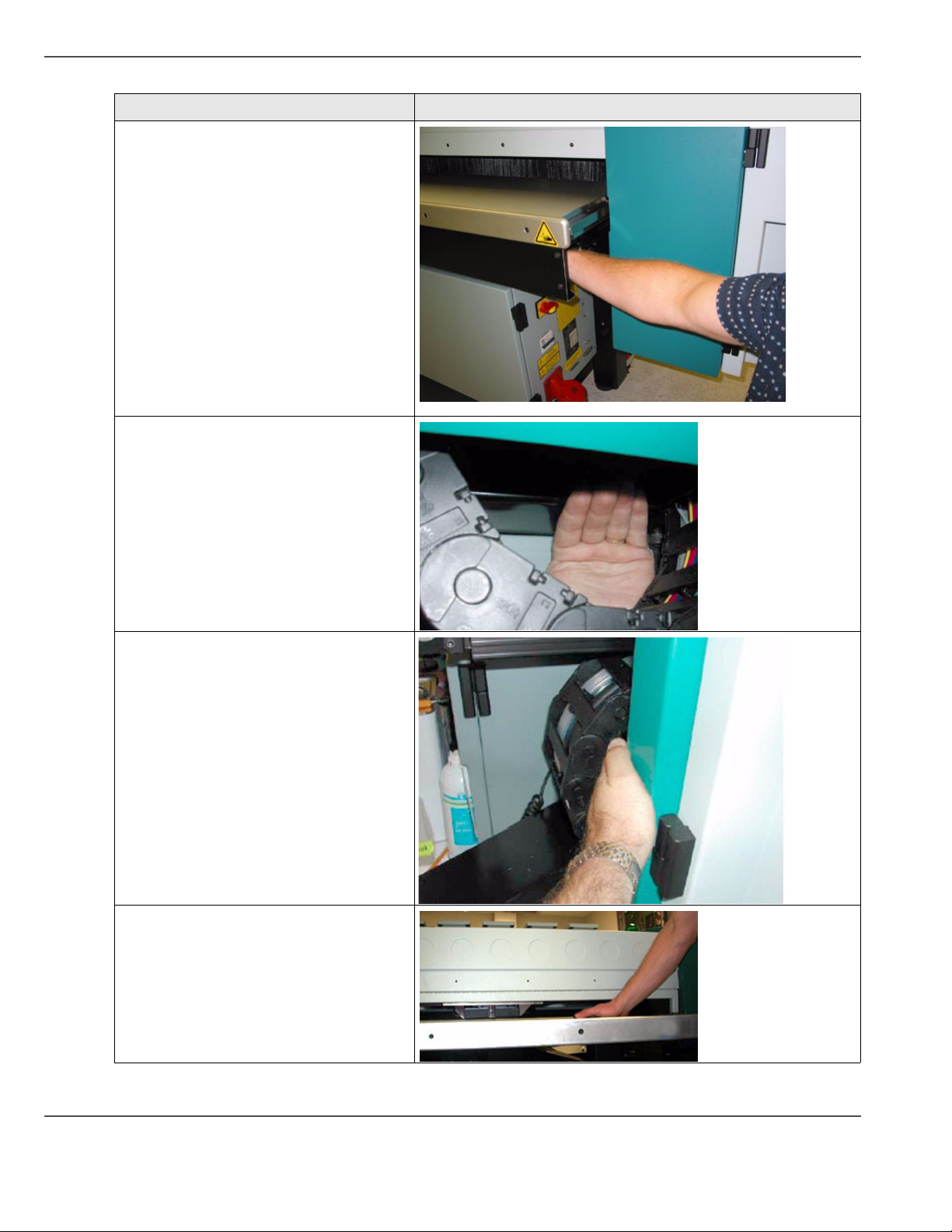

[14] T220UV Residual Risks (2 – 4)

Risk Area Crushing/Shear Hazard

[23]

A crushing/shear hazard is created by the

gantry-driver cover and the gantry door of

the machine.

x

[24]

A crushing/shear hazard is created by the

gantry cable web and the frame of the

machine.

A crushing/pinch hazard is created by the

gantry cable web and the gantry.

A shearing hazard is created by the carriage

and the gantry frame from the back side

entry.

[25]

[26]

30 Chapter 3 Safety Information

Page 31

[14] T220UV Residual Risks (3 – 4)

Safety Awareness

Risk Area Crushing/Shear Hazard

[27]

[28]

A crushing/pinch hazard is created by the

gantry and the frame end at these various

positions.

A crushing/pinch hazard is created by the

gantry and the frame rails from the

underside.

[29]

[30]

31

Page 32

Safety Awareness

[14] T220UV Residual Risks (4 – 4)

Risk Area Crushing/Shear Hazard

[31]

A crushing/pinch hazard is created by the

blotting station.

[32]

A crushing/pinch hazard is created by the

carriage assembly at these locations.

Note: the carriage assembly cannot move if

the gantry doors are open.

An impact hazard is created by the

movement of the gantry across the table

surface.

[33]

32 Chapter 3 Safety Information

Page 33

Chapter 4 User Interface

33

Page 34

Operator Control Panel

Operator Control Panel

Introduction

The control panel consists of a two line LCD display screen, a key pad, status LED’s and an emergency stop button.

A bar code wand, used for scanning ink bottle labels, is stored under the control panel. The Arizona T220UV

operator control panel provides access to the printer’s menu system.

Illustration

[34]

[35]

[34] Arizona T220UV Control Panel

[35] Key Pad, Display Screen, and Status LEDs

34 Chapter 4 User Interface

Page 35

Control Panel Keypad

The function keys on the keypad

[15]

[15] Control Panel Function Keys

Label Function

ONLINE Allows the operator to pause the printer during printing. “Online” is denoted by a solid or

CANCEL Allows the operator to cancel a print in Progress. Allows the operator to exit lower menus

MENU Allows access to the main menu.

BACK Allows you to move back to the previous menu Selection.

-+ Allows changes in menu selection. Allows increase or decrease in numerical values.

ACCEPT Allows operator to confirm menu selection.

VACUUM Allows operator to turn on vacuum supply to the table in order to hold media in place.

Status Lights

The status lights on the control panel have the following fuctions.

Operator Control Panel

flashing green status LED. Allows the operator to exit lower menus and return to the top

level menu.

and return to the top level menu.

[16]

[16] Control Panel Status Lights

Label Function

ERROR Indicates a printer problem has occured

CHECK Flashes in conjunction with operator alert messages (for example, Blotting cloth low or

INK Indicates a low ink level condition. Display will indicate which color ink to replace with a

Control Panel Display

The operator control panel displays the online screen whenever it is not displaying the menu system or presenting

error messages. If you are in the menu system and you press the ONLINE button, the panel displays the online

screen thus confirming you are no longer in the menu system.

The top left corner indicates the current status of the UV lamps. When the lamps are activated the display shows

the percentage of power achieved with an estimate of the time needed to reach operating (curing) temperature.

When the lamps are hot enough the display shows Lamp 100% and printing can begin. After a print is completed,

or if the lamps are turned off in the menu, the display shows "Cooling".

The top right corner of the online screen alternates between displaying the UV lamp temperature (when the lamps

are on) and the status of the vacuum system (either ON or OFF).

empty).

new bottle.

35

Page 36

Operator Control Panel

Gantry Beacon (BG Model Only)

Whenever the gantry is preparing to move, the green warning beacon located on the top right end of the gantry

illuminates to alert the operator. This is a safety feature that is meant to let the operator know that the table must

be clear of all objects except the media that will be printed on and also to stay clear of the gantry path when it does

begin printing.

Reset Button (BG Model Only)

This blue button on the control panel next to the red Emergency Stop button resets the printer after an interlock is

triggered by an open door. It also resets the printer after the Emergency Stop button is pushed. This is for the BG

version only. The regular T220UV printer uses the ACCEPT key to perform a system reset.

Safety Interlocks

The Interlock system is a safety shutdown feature that includes the Emergency Stop button and a system that detects

when the gantry doors are open. Interlock ensures that the gantry doors are not opened except during approved

printing or maintenance procedures. At all other times, opening the gantry doors results in a error message on the

operator display panel and a shutdown of the printer’s electrical system. A reboot is required to recover from an

interlock situation.

Note: Opening gantry doors — other than when authorized by the operator control panel display — or pushing the

Emergency Stop, results in a complete shutdown of the printer’s operating system. The only recovery soluton is a

printer reboot.

Emergency Stop

If a situation requires an immediate shutdown of all printer activity, press one of the three Emergency Stop buttons.

To recover from an emergency shutdown, resolve the problem that prompted the shutdown and then release the

Emergency Stop by twisting it slightly clockwise. Then press the ACCEPT button to restart the printer.

Note: There are three Emergency Stops, one on the control panel and one on each end of the gantry. When you

need an immediate shutdown, it is also possible to open the one of the gantry doors to initiate an interlock

shutdown.

Anytime an Emergency Stop is pressed, the lamps, the 48-volt (carriage and gantry motion) and the 24-volt (all

other motors) lines are disabled, effectively stopping all printer activity.

Note: For safety, lamp power is always disabled when a door is open. Printing is not possible with lamps off (doors

open).

36 Chapter 4 User Interface

Page 37

The following table shows what happens when the Emergency Stop is pressed.

[17]

[17] Results of a Emergency Stop

When Then Message

When system idle Requires a reboot. "E-STOP/INTERLOCK OPEN"

"check and press ACCEPT to restart"

During Print All stop, requires a reboot "E-STOP/INTERLOCK OPEN"

"check and press ACCEPT to restart"

Any other motion All stop, requires a reboot "E-STOP/INTERLOCK OPEN"

"check and press ACCEPT to restart"

When a door is opened (interlock triggered) - UV lamps are always turned off:

[18]

[18] Doors Opened During Normal Operation

When Then Message

During boot up Intervention required. "Close All Doors"

"and press ACCEPT key"

When system idle Nothing. "DOOR IS OPEN"

Operator Control Panel

Start up print

gantry movement

Gantry stopped,

intervention required.

During print All stop, intervention

required.

End of print gantry

movement

Access carriage

from menus

Gantry stopped,

intervention required.

Access/Park occurs only

if doors closed.

"SYSTEM ERROR

[press ACCEPT to restart]"

"GANTRY MOTOR or ENCODER"

"Door open while printing"

"close all doors and press ACCEPT"

"SYSTEM ERROR

[press ACCEPT to restart]"

"GANTRY MOTOR or ENCODER"

"Close All Doors"

"and press ACCEPT key"

37

Page 38

Operator Control Panel

Arizona T220UV Lamp Control

The UV lamps are necessary for drying the ink. When the lamps are on it is essential to follow the safety precautions

indicated in “UV Safety” on page 9, since the UV light is potentially harmful if safety protocol is not followed.

This section explains the different states of the lamps and how they relate to the operation of the printer.

[19]

[19] UV Lamp States

Stage Description

Lamp off When the printer is idle, the carriage is parked, and the lamp is inactive, the status of the lamp

will be displayed as "Off".

Lamp cooling When the lamp is off, but has been used recently, the lamp will go into a "cooling" state

waiting for the illuminator sensors to drop below 31C (88F).

Lamp warmup When a print is requested and the lamp is currently off, the lamp will strike and go into a

"warmup" state.

Lamp power XX% When the lamp is running, the target "power" will display in percent.

Start of a print: Once the lamps are struck, it generally takes about 2 minutes in a warm up state for the lamps to

reach their target power level. When the lamps attain their target power level, the print will not begin until the

illuminator temperature reaches 125C (257F). There is a 7-minute warm up time-out, which will cause the print to

abort and give an error message.

If the lamps begin at their idle power level and are set to go to their print power level, this change only takes a few

seconds.

After a print: When the carriage is parked, the lamps will go into an idle power mode currently defaulted to 30%.

The lamps will remain at this power level until the idle timeout occurs, currently defaulted to 10 minutes. Both of

these settings are menu adjustable. After the time-out period, the lamps will be turned off.

38 Chapter 4 User Interface

Page 39

Menu Structure

Introduction

There are three main menus accessed by pressing the MENU key pad. Once you have entered the menu system,

press the MENU key to advance the display to the next menu option. Press the ACCEPT key to access a menu’s

displayed option.

Print Queue

■ Print Jobs

Operator

■ Maintenance

■ Test Prints

■ Special Prints

■ Print Parameters

■ Delete Files

■ Units, Set Clock

■ About Printer

Menu Structure

Configure I/O

■ SCSI Port

■ Parallel Port

■ Serial Port

The Operator and Configure I/O menus have various submenus as indicated above. This section will provide

specific details of those submenus. The Print Queue has no submenus, but does provide various menu options to

modify a print job after it is selected. A detailed map of the whole menu structure is available in the Special

Prints/Menu Tree Print submenu. Refer to Appendix A for instructions to locate and print this map.

Print Queue Menu

The Print Queue menu allows the operator to select a job for printing from all jobs stored on the printer’s hard drive.

Print jobs are prepared using Onyx PosterShop software and then transferred to the printer, where they appear in

the Print Queue. The Print Queue menu provides the option to change the media thickness, image horizontal and

vertical offsets, if desired. It also offers the option to change Print Parameters such as number of copies and number

of overprints, but only if these parameters are activated in the Operator menu (see “Print Parameters” ). The details

of these Print Queue options are provided in the section “Select a Print Job” .

39

Page 40

Menu Structure

Operator Menu

The Operator menu has six submenus: Maintenance, Test Prints, Print Parameters, Units, Set Clock, and About

Printer. The details of these submenus and how to access them are provided below.

Maintenance Menu: The Maintenance Menu consists of various commands that support maintenance activities for

the printer. The commands are explained in the table below.

[20]

[20] Maintenance Menu (1 – 2)

Menu Title Function

TURN ON/OFF

UV LIGHTS

Turn the UV lights ON if you want them to start warming up before you start a print job.

This reduces the wait time between issuing a print job and the time it actually starts. Turn

the UV lights OFF if you know that you will not issue more print jobs (for example, at the

end of the day). This speed up the process of cooling down the lamps.

HIGH PURGE

NOZZLES

LONG PURGE

NOZZLES

RECOVERY

PURGE

This is used to clear contaminants out of the nozzles. Contaminants can be either

environmental particles or dried ink.

This is used primarily to clear the printheads. It lasts longer but has less force than a high

purge

This command is used as a troubleshooting tool to restore a printhead that will not respond

to a high or long purge.

NOZZLES

BLOT HEADS Blotting heads is the process of pressing the print heads into an absorbent cloth. This is

necessary to remove any ink which may have accumulated on the print head nozzle plates.

SPIT HEADS This command is used to evaluate the condition of the printheads. When it is initiated the

carriage moves to the blotting station. All printheads then fire into the blot cloth. The

carriage then returns to its previous state of operation. The operator can then observe the ink

patterns created on the blot cloth from the spit. If the patterns are not forming clean lines of

equal length, it can be an indication of blocked nozzles.

FILL

RESERVOIR

This command manually fills one or more ink reservoir with ink. This is generally only used

if ink-fill is turned Off and the user wants to manually ensure that the ink reservoirs are full

of ink. The system stops the filling when the ink reservoir level sensor indicates that the ink

reservoir is full.

MOVE GANTRY Allows you to place the gantry at any location over the table in increments of 1 foot (30.5

ACCESS

CARRIAGE

PA RK

CARRIAGE

RAISE

CARRIAGE

BLOT CLOTH

DISPLAY

40 Chapter 4 User Interface

cm).

This command raises the carriage to the currently-set media height and moves the carriage

over to the blotting station. This is useful to gain access to the underside of the carriage in

order to manually clean the print heads.

This command moves the carriage to the capping station and lowers the carriage onto the

foam pads (called 'capping'). It is necessary to perform this step any time the operator has

been doing manual maintenance and wishes to park and cap the carriage.

This command raises the carriage to currently-set media height then moves the heads over

the drain, which allows the carriage to be moved manually for service access.

Allows you to determine when to start displaying the Blot Cloth Low message based on the

percentage of blot cloth remaining.

Page 41

Menu Structure

[20] Maintenance Menu (2 – 2)

Menu Title Function

LAMP USAGE Allows you to check both UV lamps for the total number of strikes and the length of time

the lamps were on so that you can monitor usage over time. It also allows you to reset the

usage statistics when you replace a lamp.

BARCODE

PRACTICE

Allows you to practice scanning barcodes without using new bottles of ink so you can get a

feel for the barcode wand. Practice barcodes can also be entered manually using the keypad

(See “Scanning Ink Barcodes” on page xx).

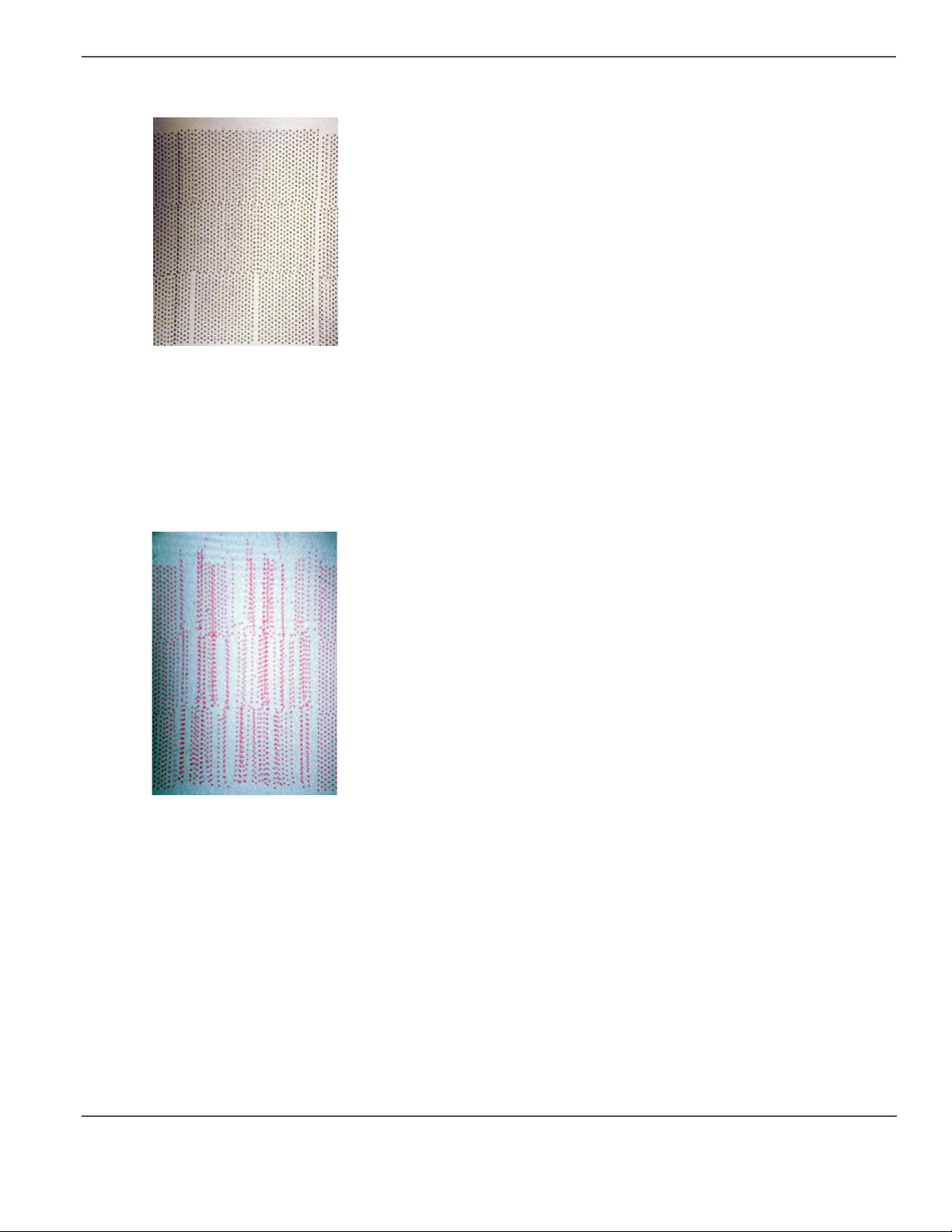

Test Prints Menu - The Test Prints menu allows you the option of printing three documents stored in the Arizona

T220UV printer:

• Nozzle print (Diagnostic and Standard)

• Configuration print

• Color bars print

In the nozzle prints, breaks in the line indicate which heads are misfiring. Performing a High Purge or Recovery

Purge on the ink colors that show misfiring can help to clear the affected heads. For a more detailed explanation of

how to use the nozzle print for diagnostic purposes, refer to (see ‘How to Reduce Banding’ on page 57).

[21]

[21] Test Prints Menu

Component Function

NOZZLE PRINT The Nozzle Print menu provides you with a visual representation of how the print heads are

firing.

COLOR BAR The Color Bars menu prints a set of color bars. The eleven color bars start with Light

Magenta and end with Black.

CONFIGURATIO

N PRINT

The Configuration Print menu provides the operator and Océ Display Graphics Systems

service technicians with machine-settings data if the unit must be diagnosed or recalibrated.

A current configuration print for your printer should be stored for reference.

41

Page 42

Menu Structure

Special Prints Menu - The Special Prints menu gives you access to the Menu Tree print and the Table Grid print,

either metric or imperial version.

[22]

[22] Special Prints Menu

Component Function

Menu Tree Print The Print Menu Tree menu generates a print which is a graphical illustration of the

Grid Print The Table Grid is used to position media for printing. It is printed directly on the printer

T220UVsystem menu tree. This 32 x 56 inch poster illustrates the Operator, Print Queue,

and Configuration menu thus providing you with an overview of the menu system. It also

contains Safety Guidelines, a summary of the Maintenance Schedule, and Application Tips.

If the print does not show up in the Special prints menu, or of you want to check for an

updated version, the Menu Tree Print must be downloaded from the ODGS web site and then

copied to the printer. For detailed instructions, see Appendix A.

table. This ensures that printed production jobs are registered with exact pixel placement. If

necessary, the grid can be cleaned off the table and reprinted. The grid file comes in two

versions: metric and imperial units.

Either the Imperial and Metric grids appear as a menu selection - Operator / Special Prints.

Which one appears depends on what was loaded (see below). Before printing the grid, make

sure that you set the height to 0 (zero) and also when the display prompts to set the pre-fire

strip catcher height, remove any media or other spacing material from the slot in the catcher.

If the Grid does not appear as a menu option, it must be downloaded from the ODGS web

site and then copied to the printer. For detailed instructions, see Appendix A.

Print Parameters Menu

The Print Parameters menu lets you set Enable Job Parameter Changes. If this is set to ON, you can decide which

of the following options are presented to the operator prior to printing (See “Print Job Parameter Options” on page

32):

■ BiDirectional Printing - either in both directions or just right to left

■ # of Copies - print up to 100 copies of an image

■ # of Overprints - prints the image on the media up to 3 times.

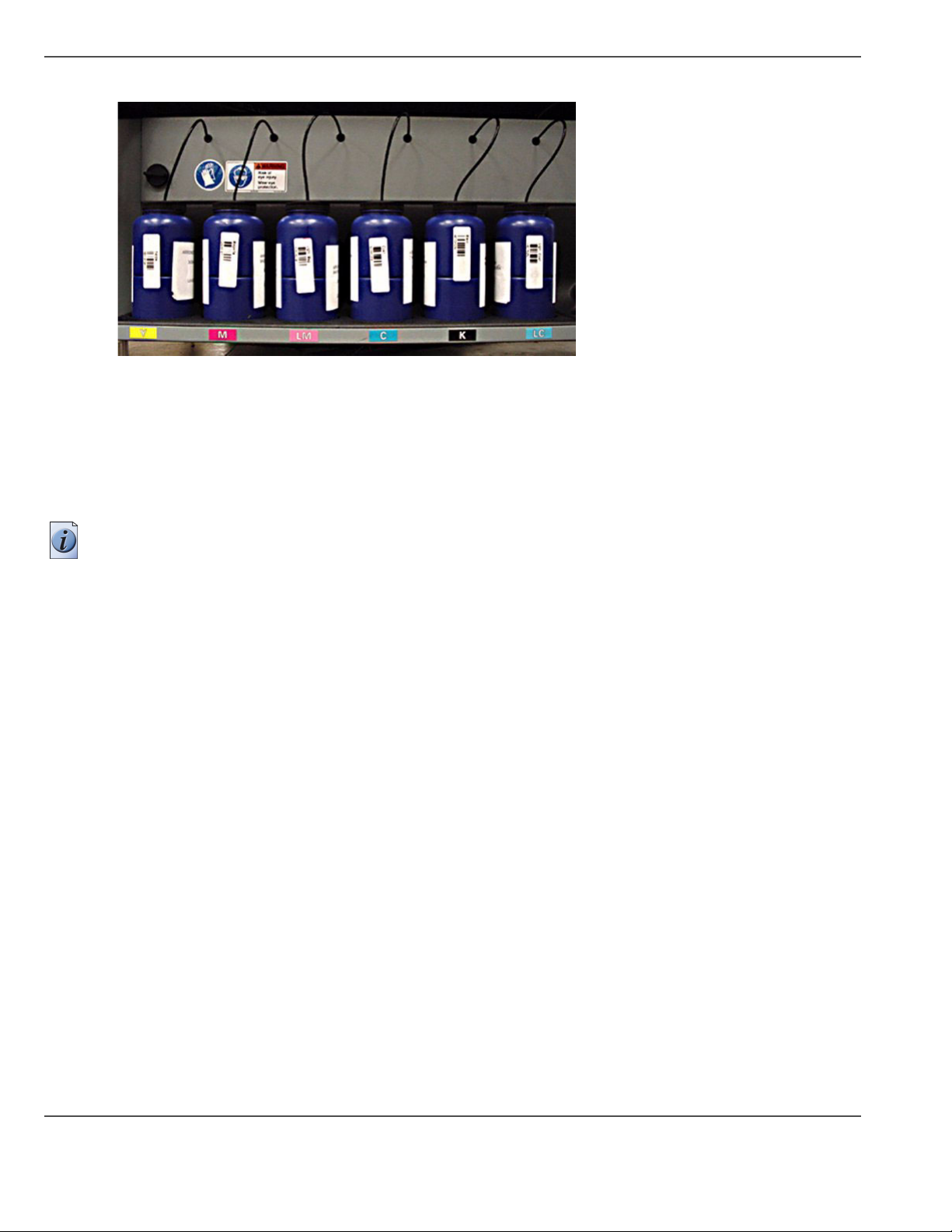

Ink Menu

The Ink Menu lets you view approximately how much ink is left in each bottle and also to install new ink bottles,

if required.

42 Chapter 4 User Interface

Page 43

Menu Structure

Delete Files

The printer’s hard drive has a capacity of 70 gigabytes for storing print jobs. When the drive is full, the oldest file

is automatically removed to make more space available. The Delete Files menu lets you delete all print job files

stored on the drive. It is not possible to select particular files for deletion - using this option deletes all files (print

jobs) on the drive.

Units Menu

The Units menu allows you to choose between Imperial (English) and Metric units. All control panel menus display

the preferred units. The Units menu is part of the Operator submenu.

Set Clock Menu

The Set Clock menu allows you to set the date and time. When the date and time are set, they are printed in the

statistics output.

About Printer Menu

Displays amount of media printed, firmware revision, firmware build date, firmware build time, serial number, and

boot ROM version. The About Printer menu allows you to view the current printer specifications on the printer

control panel. The same information is available in the configuration print.

Configure I/O Menu

The Arizona T220UV printer can accept input through two types of ports, Centronics parallel, and low-voltage

differential (LVD) SCSI-2 communication ports. They are built into the printer. The Active menu allows you to

select the type of port - Parallel or SCSI.

Parallel Port

The printer uses a standard Centronics-type parallel data cable to allow access for service and diagnostic purposes.

LVD-SCSI-2 Port Configuration

Océ Display Graphics Systems recommends that you use the Adaptec 29160 68- pin LVD-SCSI-2 card in the

computer that connects to the T220UV printer. The printer ships with a standard 32 foot (10 meter) 68-pin SCSI-2

data cable. It uses the ultra SCSI settings under this menu to support/enhance the transfer speed of your computer

platform when printing to the Arizona T220 printer.

Note: NEVER connect or disconnect SCSI cables with the printer powered On. Disconnecting powered

connections can make printer hard drives unusable.

If you have any error messages on the computer or printer display pertaining to the SCSI port, or if print jobs are

not transferred to the Print Queue, check that the SCSSI settings are exactly as indicated here:

Active: SCSI

SCSI Address: 5

Timeout: 60 seconds

Ultra SCSI: ON

Interface Cable: LVD

43

Page 44

Menu Structure

44 Chapter 4 User Interface

Page 45

Chapter 5 How to Operate the Arizona T220UV

45

Page 46

Training Requirements

Training Requirements

Introduction

Before operating the Arizona T220UV printer, make sure you have read and understood the section “Safety

Guidelines”.

Océ Operator Training

For optimal safety and print quality, the Arizona T220UV printer operator must be trained by a qualified Océ

service personnel. Océ training provides a general orientation to the Arizona T220UV printer safety and operating

procedures. This training involves both the User and Maintenance Training modules.

PosterShop Training

Maximum performance from the Arizona T220UV printer requires a properly trained operator. Océ Service and

Support Group trains the operator in the use of the Arizona T220UV hardware and software at installation.

However, this is not a substitute for formal PosterShop® training.

Operators of the Arizona T220UV should be fully versed in the operation of Onyx PosterShop® . For any operator

unfamiliar with its operation, Onyx PosterShop® training is required. On-site or off-site training courses are

available; contact Onyx Graphics Corporation for more information: Visit

http://www.onyxgfx.com/support_training.html

46 Chapter 5 How to Operate the Arizona T220UV

Page 47

How to Switch the Printer On

Introduction

You must switch on both the Arizona T220UV printer and the Postershop computer before you can print. This

section describes how to switch the printer on. Refer to the Onyx Postershop documentation for information on how

to install and run the Postershop computer.

Before you begin

Before you apply AC power to the printer, make sure that loose objects such as clothing, tools and cleaning

materials are not interfering with the printer mechanisms. Position the power cord so that it does not pose a hazard

when walking around or accessing the doors on the printer. The Arizona T220UV has an AC power circuit breaker

that functions as an On/Off switch, and it has an AC power lock-out switch, (it also has an AC power plug, referred

to as the Disconnect Device - see below). All of these power-related items are located on the blot station side of

the electronics enclosure.

Caution: THE SOCKET OUTLET MUST BE INSTALLED NEAR THE EQUIPMENT AND BE

EASILY ACCESSIBLE. Ensure that you follow the guidelines in the Arizona T220UV Site Preparation

document before plugging the printer AC power plug into the socket.

How to Switch the Printer On

Attention: Unplugging the power cord from the wall socket is the only way to isolate the entire machine.

47

Page 48

How to Switch the Printer On

Illustration

[23]

1 - Lockout Device 2 - On/Off Switch 3 - AC Power (Disconnect Device)

[36]

4 - SCSI Connector 5 - Parallel Cable 6 - Serial Cable

[36] AC Power, Connections & Disconnect Device

To Power ON

1. Ensure the red AC power plug is properly seated; and

2. Turn on the AC power circuit breaker On/Off switch.

Attention: After powering the printer On, leave it running continuously, even when at idle, because the printer

automatically runs maintenance routines to keep it at its optimum operating specifications. Failure to leave the

printer powered on may result in ink draining out of the ink reservoirs.

48 Chapter 5 How to Operate the Arizona T220UV

Page 49

How to Lock Out the Power Switch

Attention: Some maintenance and service procedures require locking out the On/Off switch to ensure

operator safety. When the switch is locked out it is impossible to supply power to the printer.

1. Turn the Lock-out switch to the Off position.

2. Apply a lock and a tag-out label to the switch for the duration of any service or maintenance procedures.

Illustration

[24]

1 - Lock-Out / Tag-Out Device with Lock

[37]

How to Switch the Printer On

2 - Circuit Breaker On/Off Switch

[37] Lock-Out / Tag-Out and AC Power Switch

49

Page 50

How to Switch the Printer On

Disconnect Device

Attention: The red AC power plug is the disconnect device for the Arizona T220UV printer. For maximum

safety, if the printer is moved or if any service or repair work is conducted, the disconnect device must first be

unplugged from the printer.

1. To unplug it, first press down on the release flange with your thumb.

[38]

2. This flips up the safety cover and allows you to pull the disconnect device out of its socket.

[38] Unplugging the Disconnect Device

Note: the vacuum pump, which is separate from the printer, also uses a disconnect device that looks and functions

in a manner identical to the one on the printer.

50 Chapter 5 How to Operate the Arizona T220UV

Page 51

How to Set Up a Print Job

Select a Print Job

Introduction

The section explains how to select an image to print on the Arizona T220UV.

Note: The image for the print job must first be sent to the printer using Onyx Postershop to prepare a digital image

for printing.

Attention: Do not print on mirrors or any other highly reflective media as UV light is reflected off such

media. This results in curing the ink in the heads and thus damaging them.

Choose the Print Job

1. Press the MENU button on the control panel to enter the menu system. The Print Queue menu is always the first

main menu option.

2. Press ACCEPT to enter the Print Queue menu. The LCD panel displays the most recent job sent to the print queue

by the host computer (i.e., PosterShop).

You have four possible choices:

■ Press CANCEL to quit viewing the print queue and proceed to the next main menu option which is the Operator

menu.

■ Press MENU or BACK to return to the Print Queue menu.

■ Press the + or - keys to cycle through all avaliable print jobs.

■ Press ACCEPT to confirm that you want to proceed with the print job that is currently displayed.

Select a Print Job

3. Press ACCEPT and the control panel display shows the following information for the selected print job.

Note: Thickness and offsets values are retained from the previous time these values were entered. Ensure that they

are appropriate to the current media and print job. If not, use the method described below to change them.

Print the Print Job

1. Press ACCEPT to continue the print job.

When you press ACCEPT, the display advances to the Place Media menu, the last step prior to actual printing.

Change the Job Settings

1. Alternately, press the + or - key if you want to change media thickness, UV power, horizontal or vertical image

offsets, or print job parameters (if Parameters is enabled).

When you press + or - keys, the display advances to the New Media Thickness display, as indicated in the next

section.

51

Page 52

Change Print Job Settings

Change Print Job Settings

Introduction

The following three settings may be altered only if the operator chooses to change them when the print information

for a particular job is displayed by pressing the + or - keys:

• Media Thickness

• UV Power Setting

• Horizontal and Vertical Offsets

Purpose

If you pressed + or - when the print job information was displayed, you can change settings in the print job.

When to do

The desired media thickness is first set when you prepare the image in PosterShop and then verified at the control

panel prior to printing. As a precaution against damaging the printheads, there is a media touch rotary switch

located on the lead edge of the carriage used to detect any obstacles higher than the media on the table. If anything

on the table is sitting too high, including the media, the media touch rotary switch will cause the gantry to stop and

the control panel will alert the operator of the problem.

Note: Do not rely on media thickness specifications listed on the media supply box. Always measure the media

with a digital caliper (see below) to be sure of the correct height.

In the second menu display you can change the power setting of the UV lamps. A higher setting results in faster

drying of the ink but also applies more heat to the media.

The third menu display allows you to change first the horizontal and then the vertical offsets. This determines where

the image is printed on the media.

Required tool

ODGS recommends that the operator measure the media thickness with a set of calipers.This ensures optimum

conditions for achieving the best possible print quality by placing the print nozzles at the optimal height above the

media. Since the clearance between the media and the print heads is only 2mm (0.08 in.), altering the clearance has

a negative impact on the bi-directional alignment.

52 Chapter 5 How to Operate the Arizona T220UV

Page 53

Change Media Thickness

1. Use the ACCEPT key to move through the displayed digits. The selected digit has an underline indicating it can

be increased or decreased using the + or - keys.

2. When the digit you want is displayed, press ACCEPT and the underline moves to the next digit.

3. When you are at the last digit, pressing ACCEPT advances to the Offests menu.

Note: Use the MENU key to move to the next digit if no changes are required for a particular field.

Change UV Power Setting

1. Use the ACCEPT key to move through the displayed digits. The selected digit has an underline indicating it can

be increased or decreased using the + or - keys.

2. When the digit you want to use is displayed, press ACCEPT and the underline moves to the next digit.

3. When you are at the last digit, pressing ACCEPT advances to the Place Media display if Print Parameters were

NOT enabled in the Operator/Print Parameters menu.

Note: If Display Print Parameters is set to OFF in the Operator/Print Parameters/ Statistics menu, the control

panel display shows the message “Place media on the table” and the print job can begin.

Change Print Job Parameter Options

Change Horizontal and Vertical Offsets

1. Use the ACCEPT key to move through the displayed digits. The selected digit has an underline indicating it can

be increased or decreased using the + or - keys.

2. When the digit you want to use is displayed, press ACCEPT and the underline moves to the next digit.

3. When you are at the last digit, pressing ACCEPT advances to the Place Media display if Print Parameters were

NOT enabled in the Operator/Print Parameters menu.

Note: If Display Print Parameters is set to OFF in the Operator/Print Parameters/ Statistics menu, the control

panel display shows the message “Place media on the table” and the print job can begin.

Change Print Job Parameter Options

Introduction

The print job parameter options consist of three functions that support printing. If a particular option was enabled

in the Operator\Enable Job Parameters Change menu, and if the operator decides to change the settings of a selected

print job, then its associated screen is displayed in the following order.

■ BiDirectional Printing - either in both directions or just right to left

■ # of Copies - print up to 100 copies of an image

■ # of Overprints - prints the image on the media up to 3 times

53

Page 54

Change Print Job Parameter Options

Purpose

The Operator\Print Parameters menu lets you set Enable Job Parameter Changes to ON or OFF. If this is set to ON,

you can decide which of the three options are presented to the operator prior to printing. If this is set to OFF, then

the options will not appear in the display when the operator chooses to change the other settings in a selected print

job.

Note: Use the MENU key to move to the next option if no changes are required for a particular parameter.

Change Print Direction

1. Press + or - to change the printing direction. Options are Single or Bidirectional — single means that the nozzles

will print only in the right to left direction, while bidirectional prints in both directions.

2. Press ACCEPT when the printing option you want is displayed.

Change Number of Copies

1. Press + or - to change the number of copies printed. Options are 1 to 100. Use the ACCEPT key to move through

the displayed digits. The selected digit has an underline indicating it can be increased or decreased using the + or

- keys.