Page 1

intro.fm Page i Wednesday, October 31, 2007 9:06 AM

Océ CS7400 Series

User Manual

0706443 Rev B

Page 2

Océ Display Graphics Systems Inc.

13231 Delf Place, Suite 501

Richmond, BC V6V 2C3

Canada

© 2007 MacDermid ColorSpan, Inc. All rights reserved.

Printed in the United States of America.

No part of this document may be reproduced, copied, adapted, or transmitted in

any form or by any means without express written permission from MacDermid

ColorSpan, Inc.

MacDermid ColorSpan, Inc. makes no representations or warranties with respect

to the contents of this manual. Further, it reserves the right to revise or change

this publication without obligation to notify any person of such changes.

ColorSpan, ColorMark, and VideoNet are trademarks or registered trademarks of

MacDermid ColorSpan, Inc. All other products mentioned in this manual are

trademarks or registered trademarks of their respective companies.

Telephone: +1 604 273 7730

Fax: +1 604 273 2775

http://www.oce.com

MacDermid ColorSpan provides no recommendation, warranty or representation

regarding combining a MacDermid ColorSpan printer with a cutter. Should any

MacDermid ColorSpan printer be combined with a cutter, such combination

should only be made in the sole discretion of the customer, at the customer's

sole risk, and MacDermid ColorSpan disclaims any liability for such combination.

Any combination by a customer of a MacDermid ColorSpan printer with a cutter

should be made in such a way as to avoid infringment of US Patent No.

5,537,135. MacDermid ColorSpan disclaims any liability for such combination.

Page 3

Regulatory Statements

FCC-A This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

his or her own expense.

This equipment must be installed exactly as instructed in this manual using only

the components supplied. If a supplied component ever needs to be replaced, it

must be replaced with the same part supplied by the manufacturer. It is your

responsibility to follow these instructions in order to maintain compliance with the

FCC regulations. Changes or modifications not expressly approved by ColorSpan

Corporation could void your authority to operate this equipment. In particular, this

device must be operated with shielded cables to maintain FCC compliance.

A booklet is available from the Federal Communications Commission entitled,

How to Identify and Resolve Radio-TV Interference Problems (#004-000-00345-

4). Write to the U.S. Government Printing Office, Washington, DC 20402.

DOC (Canada) This digital apparatus does not exceed the Class A limits for radio noise for digi-

Telecommunications

Network Statement

tal apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Normes de Sècuritè (Canada)

Le présent appariel numérique n’émet pas de bruits radioélectriques dépassant

les limites applicables aux appareils numériques de la Classe A prescrites dans le

réglements sur le brouillage radioélectrique édictés par le Ministére des Communications du Canada.

The ColorSpan VideoNet port on this device is not intended to be connected to a

public telecommunications network. Connection of this device to a public telecommunications network in a European Community Member State will be in violation of national law implementing Directive 91/263/EEC on the approximation

of laws of the Member States concerning telecommunication terminal equipment,

including the mutual recognition of their conformity.

Der VideoNet port ist nicht dafür vorgesehen an ein öffentliches Telefonnetz

angeschlossen zu werden. Der Anschluß dieses Gerätes an ein öffentliches

Telefonnetz in einem Mitgliedstaat der EU, verstößt gegen nationale Gesetze zur

Ausführung der Direktive 91/263/EEC, die sich mit der Annäherung von

Gesetzen von Mitgliedstaaten beschäftigt, betreffend Telekommuniktionsanlagen

und die gegenseitige Anerkennung ihrer Konformität.

Regulatory Statements iii

Page 4

Related

Documentation

• Release Notes — describes new versions of the printer’s

embedded software and other new information not included

in this user manual.

• Material Safety Data Sheets — information for safe han-

dling of the inks and printhead flush used with the printer.

For instructions on using a third-party RIP with the printer, refer

to the documentation that accompanies it.

iv Related Documentation

Page 5

Table of Contents

Regulatory Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

FCC-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

DOC (Canada). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Telecommunications Network Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Getting Started

Operating Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Connecting the RIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Step 1: Install the VideoNet Card and Cable. . . . . . . . . . . . . . . . . . . . . . . .1-4

Step 2: Install the VideoNet Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Step 3: Install the RIP Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Important Operating Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Français. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Italiano. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Daily Shutdown Not Recommended . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Quick Tour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Special Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

Printheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

Ink System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

Media Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Performance and Ease-of-Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Table of Contents v

Printing

Configure Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Configure Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Load New Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Unload Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Reload Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Media Wizard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Load and Print on Rigid Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Load and Print on Roll-Fed Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Loading Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Unloading an Empty Ink Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Loading a Full Ink Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Printing Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Pause-Swapping Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Page 6

Calibrating the Moveable Fence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Checking Jet Health . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Print Prime Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Map Out Missing Jets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

UV Lamp Operation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Replacing UV Lamp Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Using the Control Panel

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Front Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Calibrate Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Printer Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

User Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Print Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Service Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Warnings & Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Calibrating the Printer

When to Calibrate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

AutoJet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

AutoTune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Quality Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Auto Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Manual Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Media Feed Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Manual BiDi Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Manual X Head Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Manual Jet Mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Report Individual Bad Jets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Clear Individual Bad Jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

View Current Bad Jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Clear All Bad Jets for a Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Clear All Bad Jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Print Jet-Out Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Default Registration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Service Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Calibrating the Head Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Calibrating the Media Thickness Sensor . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Calibrating the Service Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

vi Table of Contents

Page 7

Technical Specifications

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Electrical Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Supplies and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Troubleshooting

Troubleshooting Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Warranty Claims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Océ Technical Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Help From Océ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

If All Else Fails... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Index

Table of Contents vii

Page 8

viii Table of Contents

Page 9

Chapter 1

Getting Started

This chapter shows you how to get started using your printer. It includes

these topics:

• Operating Requirements (page 1-2)

• Important Operating Notes (page 1-8)

• Quick Tour (page 1-17)

• Special Features (page 1-20)

Getting Started 1-1

Page 10

Operating

Requirements

Choose a location for the printer before you unpack it. Keep the

following requirements in mind:

Electrical • Use the supplied power cord. Plug it directly into a grounded

electrical outlet. Do not lengthen the power cord with an

extension cord; the resulting drop in voltage could damage

the printer.

• Make sure the line voltage meets the requirements: See

Appendix A, Technical Specifications, for details.

• To maintain vacuum to the printheads during printer power-

down or unexpected power outages, use the auxiliary 24 volt

power supply (included in the accessory kit with universal

power adapters). Connect the 24 VDC jack on the vacuum/

pressure assembly to either of two options:

• 1. UPS — customer-supplied uninterruptable power sup-

ply, output 100-240 VAC, 50/60 Hz, minimum of 15 watts

of power, provides battery backup to the vacuum system

in the event of a power failure.

• 2. Wall outlet — 100-240 VAC, 50/60 Hz, provides tem-

porary power to the vacuum system when it is necessary

to power down the printer for service. See Appendix A,

Technical Specifications, for details.

• Connect printer to its own electrical circuit. Do not connect

the RIP, auxiliary power supply, or UPS into the same circuit

as the printer.

1-2 Operating Requirements

Page 11

Environmental • Make sure the room is well ventilated, with a temperature

and relative humidity within specifications (see “Specifications” on page A-2). Optimal printing occurs within these

ranges.

• The high power UV light emitted by the curing lamps reacts

with oxygen and produces ozone. This formation tends to be

greatest during lamp start-up. The printer should be operated in a well-ventilated area to avoid minor effects such as

headaches, fatigue, and dryness of the upper respiratory

tract. Normal air movement will mix the ozone with fresh air,

causing it to revert back to oxygen.

• Store media and ink in an area with similar temperature and

humidity conditions as the printer.

• Locate the printer so that it can be connected to the print

server (RIP) with the included cable. Optionally, you can

locate the computer that is running the RIP in the cubby in

the printer stand.

• Locate the printer on a flat, level floor.

• Locate the printer where its normal operating noise will not

disturb quiet work areas.

• DO NOT install the printer near humidifiers, refrigerators,

fans, water faucets, heaters or similar equipment.

• DO NOT install the printer in areas where the temperature

changes abruptly, such as near air conditioners, in the path

of direct sunlight, or near open doors or windows.

• DO NOT expose the printer to flames or dust.

Operating Requirements 1-3

Page 12

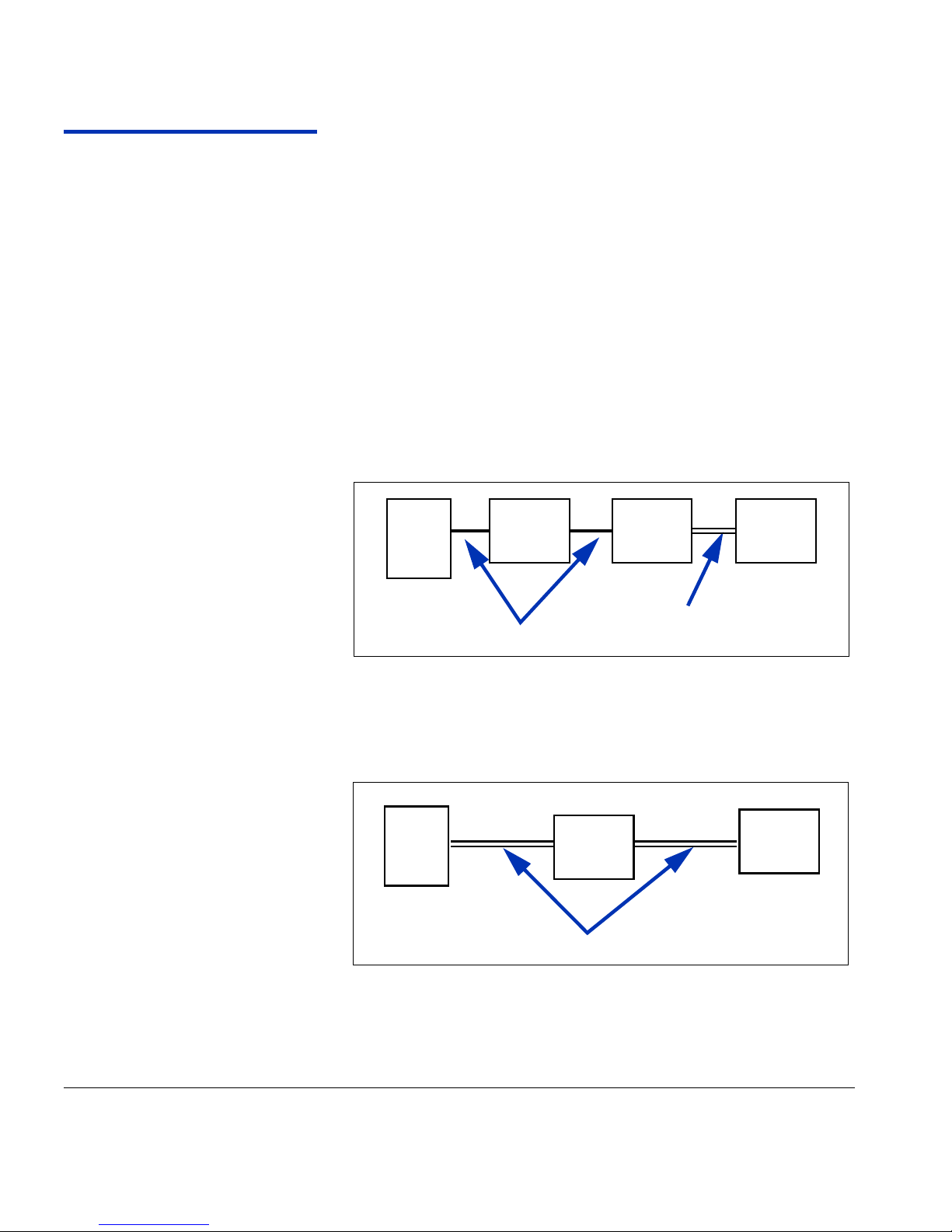

Connecting the RIP To connect the printer to a RIP, follow this procedure:

Step 1: Install the VideoNet

Card and Cable

1. Power off the computer you will be using to run the RIP.

2. Install the VideoNet printer interface card into an available

PCI expansion slot.

3. Connect the printer to the interface card.

4. Connect the user workstation(s) to the RIP.

You can connect your workstation to the RIP via a local area

network or directly using a single cable.

• To connect to the print server via a network hub, use a

standard straight-through Category 5, 10/100Base-T

cable.

User

Work-

Station

Cat 5 Straight-Through Cable

Network

Hub

RIP

Cat 5 Crossover Cable (“VideoNet”)

Printer

5. To connect a single workstation to the RIP without a network, use a Category 5, 10/100Base-T crossover cable,

such as the ColorSpan VideoNet cable, part number

0502323.

User

Work-

Station

Cat 5 Crossover Cable (“VideoNet”)

1-4 Connecting the RIP

RIP

Printer

Page 13

6. Power on the computer.

After Windows starts, it detects the new interface card and

installs the driver software.

Step 2: Install the VideoNet

Protocol

The VideoNet networking protocol is used to communicate with

the printer. These instructions assume a familiarity with

Microsoft Windows XP administrative functions. If necessary,

consult your network or computer administrator or consultant for

assistance.

Caution The VideoNet protocol is not compatible with Novell

NetWare. Do not install VideoNet if you are using

Novell NetWare.

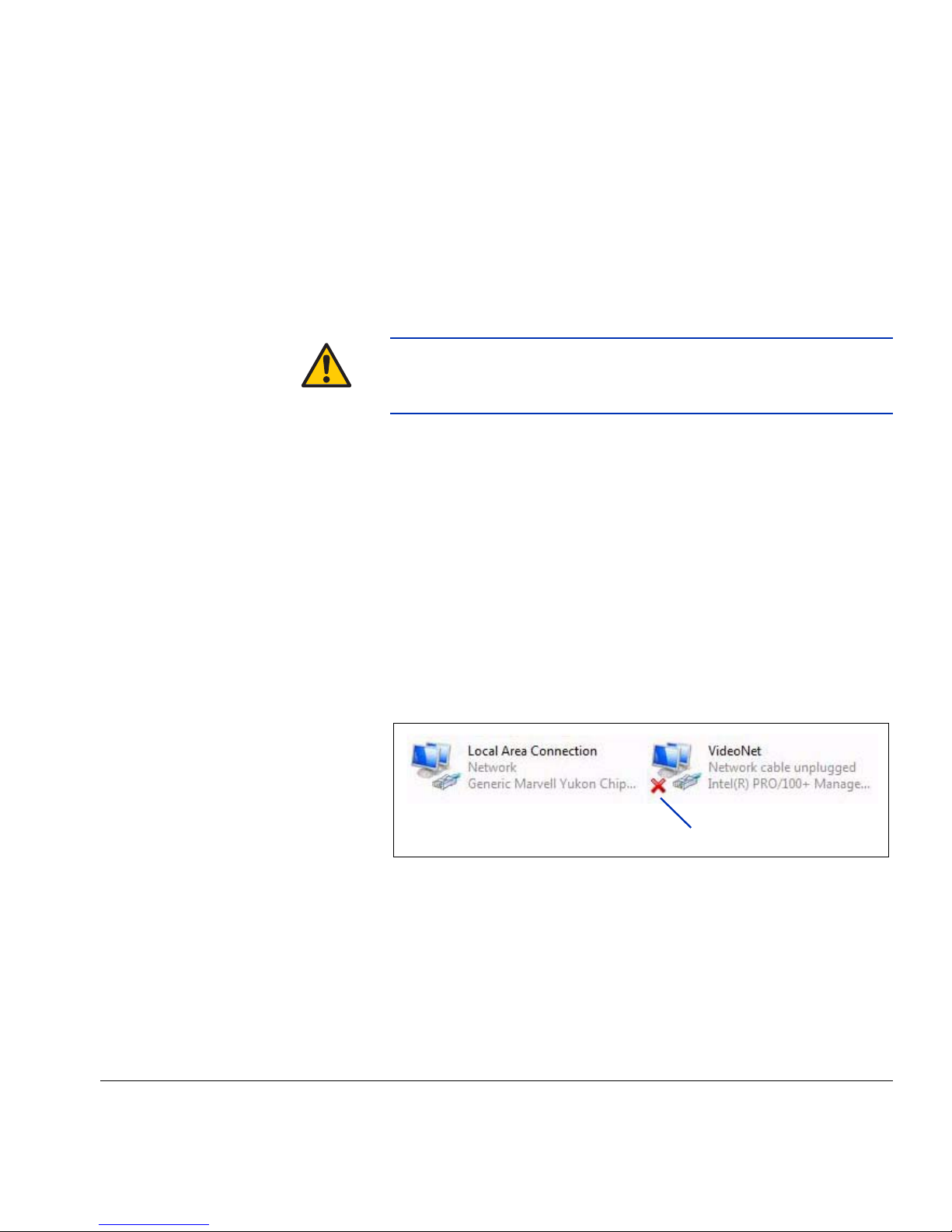

1. Display the Local Area Connection icons.

On the Windows Start menu, click Control Panel. From the

Control Panel, click Network & Internet Connections. From

Network & Internet Connections, click Network Connections.

You should see two icons, one representing your office LAN,

the other representing the VideoNet connection.

It can be difficult to determine which icon represents which

connection. One way to determine this is to unplug the

VideoNet cable and observe which icon shows a red “X”

(see the following figure).

Connecting the RIP 1-5

Disconnected cable indicated by red “X”

Fig. 1-1. Identifying the VideoNet connection

2. To avoid confusion in the future, rename the Local Area

Connection icons to “LAN” and “VideoNet.”

3. Right-click the VideoNet icon.

4. Click Properties.

Page 14

5. Click the Install button.

6. Select Protocol.

7. Click the Add button.

8. Click Have Disk...

9. Click Browse.

10. Browse to the folder on the ColorSpan DVD (for example,

D:\Videonet\Windows XP).

This displays a file named videonet.inf in the File Name

field.

11. Select Open.

The Install from disk dialog box reappears.

12. Click OK.

A window appears, listing the ColorSpan VideoNet Driver.

13. Highlight ColorSpan VideoNet Driver, then click OK.

Windows installs the VideoNet protocol. After the install has

completed, the Network Properties for chosen card will be

displayed.

Note If Windows displays the message, “The software

you are installing for this hardware has not passed

Windows Logo testing to verify its compatibility with

Windows,” click the Continue Anyway button. ColorSpan software has been thoroughly tested with all

supported Windows operating systems.

14. Un-bind protocols from the office network card.

Uncheck the VideoNet protocol from this card by clicking

once on the check box. Use the identifying information in

this tab to verify that you are configuring your office LAN settings, not the VideoNet card settings.

15. Click OK to close the window.

1-6 Connecting the RIP

Page 15

16. Right-click the VideoNet connection icon, then click

Properties.

17. The window should now display all services and protocols

assigned to the VideoNet card.

18. Uncheck all protocols except ColorSpan VideoNet by clicking on the boxes with check marks in them.

Step 3: Install the RIP

Software

19. Install and configure the RIP software as outlined in the documentation supplied with it.

Connecting the RIP 1-7

Page 16

Important Operating

Notes

• UV CURE INK IS PERISHABLE. Unlike other

inks used in wide format printing, UV cure ink

has a limited shelf life. Plan to rotate your ink

stock and use it promptly by the date printed

on the ink box.

• DO NOT POWER DOWN THE PRINTER. Constant vacuum

at the printheads is required to prevent ink from flowing from

the printheads when not printing.

Caution When the UV lamps are switched off, they undergo

a controlled cool-down cycle. Sudden removal of

power from hot lamps, such as disconnecting the

power cord or from a power outage, can result in

overheating and permanent damage. The lamps

should be switched off only via the printer software.

• The media supply may be wound either print-side out or

print-side in.

• The default head height set to 0.085 inches (2.2 mm) above

the media. (The space below the carriage will measure to

0.070 inches due to the printhead protection frame around

the outside of the carriage.)

• The Media Wizard stores a set of operational parameters for

predefined and user-defined media types. When you load a

new media type, select an existing Media Wizard set, or create a custom set. Media Wizard parameter sets can be

selected at any time from the control panel. (See “Media

Wizard” on page 2-9 for details.)

• Enable AutoTune during long periods of unattended print-

ing. AutoTune runs AutoJet at user-defined intervals to

ensure that all jets are either working or substituted with

working jets. (See “AutoTune” on page 4-4 for instructions.)

• Wear cotton gloves when loading media to prevent finger-

prints that could show after printing.

• DO NOT rest or store a media roll on end, or you could

cause edge creases that could strike the printheads during

printing.

• DO NOT reprint over any output that has not completely

cured. The rubber pinch rollers could be damaged by wet

ink. If ink does get onto the pinch rollers, clean them with a

1-8 Important Operating Notes

Page 17

minimal amount of isopropyl alcohol and dry them thoroughly before printing.

• DO NOT set heavy objects on the power cord or printer

cable; do not bend the cables or force them into contorted

positions.

• DO NOT place heavy objects anywhere on the printer.

Important Operating Notes 1-9

Page 18

Safety Warnings • UV light — the ultraviolet (UV) curing lamps emit high power

UV light. The printer must be operated with all safety shielding installed to protect the operator from eye and skin damage. When operated according to manufacturer’s

instructions, safety glasses or other protective clothing are

not necessary.

• Mechanical hazards — Keep fingers away from carriage

and media path. Do not exceed the maximum weight load of

the input or output tables, as printed on the label.

• Ink — read and practice safety guidelines as outlined in the

Material Safety Data Sheet (MSDS) for the ink, and post the

document in the work area as required by prevailing law.

Avoid any contact with skin and eyes. Provide adequate

general and local exhaust ventilation. Avoid breathing

vapors. Respirator protection may be required under exceptional circumstances when excessive air contamination

exists. None of the component substances have established

exposure standards per OSHA, NIOSH or ACGIH.

• Electrical — WITH THE POWER SWITCH IN THE OFF

POSITION, POWER MAY STILL BE SUPPLIED TO THE

PRINTER COMPONENTS. To completely cut power from

the printer, you must unplug the power cord from the power

outlet.

• Ozone — the high power UV light emitted by the curing

lamps reacts with oxygen and produces ozone. This formation tends to be greatest during lamp start-up. The printer

should be operated in a well-ventilated area to avoid minor

effects such as headaches, fatigue, and dryness of the

upper respiratory tract. Normal air movement will mix the

ozone with fresh air, causing it to revert back to oxygen.

• Hazardous waste — THE PRINTER ELECTRONICS

ASSEMBLY CONTAINS A LITHIUM BATTERY DEVICE.

THERE IS A DANGER OF EXPLOSION IF THE BATTERY

IS INCORRECTLY REPLACED. The battery must be

replaced only by authorized service providers, and must be

replaced only with the same or equivalent type. Dispose of

this lithium battery device in accordance with local, state (or

province), and Federal (or country) solid waste requirements.

1-10 Important Operating Notes

Page 19

Deutsch • UV-Licht – die ultravioletthärtenden Lampen strahlen

Hochleistungs-UV-Licht ab. Der Drucker muss mit allen

installierten Sicherheitsabschirmungen betrieben werden,

um den Bediener vor Augen- und Hautschäden zu schützen.

Sicherheitsbrillen oder andere Schutzkleidung ist nicht

erforderlich, wenn gemäß den Herstelleranweisungen gearbeitet wird.

• Mechanische Risiken – Halten Sie die Finger fern vom

Laufwagen und von der Medienzuführung. Überschreiten Sie

nicht die maximale Gewichtsauslastung der Eingabe- oder

Ausgabetische, die auf dem Etikett aufdruckt sind.

• Tinte – lesen und beachten Sie die Sicherheitsrichtlinien,

wie sie im Material- Sicherheitsdatenblatt (MSDS) für die

Tinte dargestellt sind und bringen Sie das Dokument, wie

von der aktuellen Rechtsprechung gefordert, im Arbeitsbereich an. Vermeiden Sie jeden Kontakt mit Haut und Augen.

Stellen Sie ausreichende generelle und lokale Absaugvorrichtungen bereit. Vermeiden Sie das Einatmen von

Dämpfen. Eine Atemschutzmaske könnte unter

außergewöhnlichen Umständen, wenn erhöhte Luftverschmutzung besteht, erfoderlich sein. Keine der Bestandteile

haben Gefahrenstandards nach OSHA, NIOSH oder ACGIH

etabliert.

• Ozon – das Hochleistungs-UV-Licht, das von den Aushär-

tungslampen abgegeben wird, reagiert mit Sauerstoff und

produziert Ozon. Diese Entwicklung ist am größten, während

die Lampe hochgefahren wird. Der Drucker sollte in einem

gut gelüftetem Umfeld betrieben werden, um geringfügige

Auswirkungen, wie Kopfschmerzen, Müdigkeit und Austrocknen der oberen Atemwege zu vermeiden. Die normale Luftbewegung vermischt das Ozon mit Frischluft, wodurch es

wieder zu Sauerstoff umgewandelt wird.

Español • Luz UV — Las lámparas de curado ultravioleta (UV) emiten

luz UV de alta intensidad. La impresora debe ser manejada

con filtros de seguridad instalados para proteger al operador de posibles daños en ojos y piel. Si la operativa del

equipo se ajusta a las instrucciones del fabricante no será

necesario el uso de gafas de seguridad ni vestimenta de

protección.

• Riesgos mecánicos — Mantener los dedos fuera del cam-

ino tanto del cabezal como del soporte. No debe excederse

Important Operating Notes 1-11

Page 20

el peso máximo de carga de las mesas de entrada y salida,

según lo especificado en la etiqueta.

• Tinta - Lea y ponga en práctica las recomendaciones de

seguridad recogidas, en la Hoja de Datos de Seguridad del

Material (Material Safety Data Sheet - MSDS), para la tinta y

exponga dicho documento en el área de trabajo, tal y como

requiere la legislación vigente. Evite todo contacto con piel y

ojos. Asegúrese de disponer de una adecuada ventilación y

extracción tanto general como local. Evite la inhalación de

vapores. Un respirador de protección puede llegar a ser necesario, bajo circunstancias excepcionales, cuando exista

una excesiva contaminación del aire. Ninguna de las sustancias componentes tienen estándares de exposición establecidos por OSHA, NIOSH o ACGIH.

• Eléctrico — CON EL INTERRUPTOR DE POTENCIA EN

POSICIÓN "OFF", LA POTENCIA PUEDE SEGUIR

SIENDO SUMINISTRADA A LOS COMPONENETES DELA

IMPRESORA. Para cortar totalmente el suministro de corriente a la impresora, deberá desenchufar los cables de

potencia de las tomas.

• Ozono — La luz UV de alta intensidad emitida por las lám-

paras de curado reacciona con el oxígeno y produce ozono.

Esta reacción tiende a ser de mayor relevancia durante el

proceso de arranque de lámparas. La impresora deberá ser

operada en un área bien ventilada para evitar pequeños

efectos secundarios como dolor de cabeza, fatiga y

sequedad de las vías respiratorias superiores. El movimiento normal del aire mezclará el ozono con aire fresco,

haciendo que reaccione de forma inversa, a oxígeno.

• Residuos Peligrosos — EL GRUPO ELECTRÓNICO DE

LA IMPRESORA CONTIENE UNA BATERÍA DE LITIO.

EXISTE RIESGO DE EXPLOSIÓN SI LA BATERÍA ES

REEMPLAZADA DE FORMA INCORRECTA. La batería

debe ser reemplazada únicamente por personal técnico

autorizado y sólo por otra igual o equivalente. Deshágase de

esta batería de litio según los requisitos de tratamiento de

residuos sólidos establecidos por su localidad, provincia y

país.

1-12 Important Operating Notes

Page 21

Français • Lumière UV — Les lampes à séchage ultraviolet (UV) dif-

fusent une puissance de lumière UV importante. L'imprimante doit être utilisée en tenant compte de toutes les

mesures de sécurité mises en place pour protéger l'opérateur de blessures aux yeux et sur la peau. Quand vous utilisez l'imprimante, les lunettes de protection et vêtements de

protection ne sont pas nécessaire.

• Risques mécaniques — Garder les mains éloignées du

chariot et du chemin papier. Ne pas dépasser le poids maximum pour des tableaux en entrée et en sortie, comme

indiqué sur la fiche.

• Encre — Concernant les encres, lire et respecter toutes les

mesures de sécurité comme indiqué dans le Material Safety

Data Sheet (MSDS) et placer ce document dans l'espace de

travail comme requis par la loi. Eviter tout contact avec les

yeux et la peau. Mettre en place une ventilation générale et

locale adéquate. Eviter de respirer les vapeurs. Des protections respiratoires peuvent être nécessaires dans des circonstances exceptionnelles lorsque qu'une contamination

excessive de l'air existe. Aucun des composant standard n'a

été établi comme une menace our OSHA, NIOSH ou

ACGIH.

• Electricité — Lorsque la touche ON/OFF est sur la position

OFF, l'électricité est quand même fournie aux composants

de l'imprimante. Pour éteindre totalement l'imprimante, il faut

débrancher le câble électrique de la prise.

• Ozone — L'émission importante de lumière UV émise pour

le séchage par les lampes réagit à l'oxygène et produit de

l'ozone. Cette réaction tend à être plus importante au

moment du démarrage des lampes. L'imprimante doit être

utilisée dans un espace ventilé pour éviter des réactions

mineures de type maux de tête, fatigue, sécheresse de la

partie supérieure de l'appareil respiratoire. Un mouvement

normal de l'air mixe l'ozone avec de l'air frais pour revenir à

de l'oxygène.

• Déchets hasardeux — Le système électronique de l'impri-

mante contient une batterie en lithium. Il y a un danger

d'explosion si la batterie n'est pas correctement remplacée.

La batterie doit être remplacée par du personnel autorisé par

le fournisseur et doit être remplacée par un type de batterie

identique ou équivalent. Se débarrasser de cette batterie en

Important Operating Notes 1-13

Page 22

lithium en accord avec la réglementation de gestion des

déchets locale, régionale ou gouvernementale.

Italiano • Luce Ultravioletta (UV) — Le lampade UV, emettono raggi

ultravioletti ad alta intensita'. Bisogna operare il plotter con

tutti i filtri di protezione installati, per proteggere l'operatore

da eventuali esposizioni dannosi agli occhi e alla pelle. Se ci

si attiene alle disposizioni e istruzioni d'uso del fabbricante,

non sono necessary occhiali o ulteriori materiali aggiuntivi di

protezione.

• Rischi parti meccaniche in movimento — Tenere le dita e

le mani lontano dal movimento del supporto delle testine di

stampa. Non eccedere il peso massimo consentito sui tavoli

di supporto, come specificato sulle etichette.

• Inchiostri — Leggere attentamente le istruzioni e le racco-

mandazioni degli inchiostri contenute nella documentazione

(Material Safety Data Sheet-MSDS) e metterlo in chiara

esposizione all'interno dell' area di lavoro come prevede la

normativa di legge. Evitare qualsiasi contatto con gli occhi e

la pelle. Assicurarsi che l'ambiente di lavoro sia sufficentemente ventilato. Evitare di respirare le emissioni di vapori.

L'uso di una maschera di protezione potrebbe essere necessaria in una situazione eccezionale con un eccessiva contaminazione dell'aria. Nessuna delle sostanze contenute

negli inchiostri tiene emissioni standard come descritte da

OSHA, NIOSH o ACGIH.

• Sistema elettrico — Anche se l'interruttore di accensione si

trova nella posizione spenta (OFF) potrebbe comunque

fornire tensione a componenti del plotter. Per staccare totalmente la tensione elettrica, scollegare completamente I cavi

di alimentazione dalle relative prese.

• Ozono — La elevate intensita' ultravioletta delle lampade

UV, reagisce con l'ossigeno e produce ozono. Questo processo tende ad essere piu' elevato nella fase di riscaldamento delle lampade. Il plotter deve operare in un area ben

ventilata, per evitare leggeri disturbi, tipo mal di testa, affaticamento e irritazione delle vie respiratorie superiori.Con

l'emissione di aria fresca, l'ozono reagisce e si ritrasforma in

ossigeno.

1-14 Important Operating Notes

Page 23

• Residui pericolosi — All' interno del gruppo elettrico del

plotter, si trova una batteria al litio il quale se non sostituita in

maniera corretta puo' rischiare di esplodere. Per tale motivo,

solamente personale tecnico specializzato deve eseguire

tale operazione. Per lo smaltimento della batteria usata o

danneggiata, verificare le modalita' locali, provinciali o nazionali in materia.

Important Operating Notes 1-15

Page 24

Daily Shutdown Not

Recommended

DO NOT POWER DOWN THE PRINTER. Power is required to

maintain vacuum to the printheads, which keeps ink from seeping out. If power is unexpectedly removed from the printer, printhead vacuum will be lost and ink will leak from the printheads.

The amount of ink lost will be limited to the ink currently in the

printheads, not the ink in the ink supply boxes which has not yet

been pumped to the printheads.

Since automatic head maintenance cannot occur when the

printer is powered down, keep the printer powered on at all times

if possible. If automatic head maintenance does not occur for an

extended period, manual purging may be necessary to restore

the printheads to working condition.

See page A-4 for information on using the included auxiliary

power supply for the vacuum/pressure system.

The printer will automatically enter a Sleep mode when it has

been idle for a user-defined period of time (see page 3-5 for

details).

1-16 Important Operating Notes

Page 25

Quick Tour

1

3

10

9

8

11

13

2

4

5

12

7

6

14

21

20

18,19

Quick Tour 1-17

17

16

Fig. 1-2. Major parts of the printer

15

Page 26

1. UV-shielded access cover

2. Touch-screen control panel

3. Integrated output table

4. Output media fence

5. Electronics box (inside enclosure)

6. Ink supply boxes

7. Profiler docking station

8. Media load (lower pinch rollers)/unload (raise pinch rollers)

switch

9. Media advance foward/backward switch

10. Fixed input media fence

11. Exhaust fans

12. Service station (inside enclosure)

13. Adjustable input media fence

14. Shelf for optional placement of the RIP

15. Printhead maintenance vacuum (inside enclosure)

16. Integrated input table

17. Electric power inlet

18. VideoNet port

19. Port for optional foot switch

20. Power On/Power Standby switch

21. Vacuum/Pressure system auxiliary power inlet

1-18 Quick Tour

Page 27

12 3

4

7

5

10

14

15 16

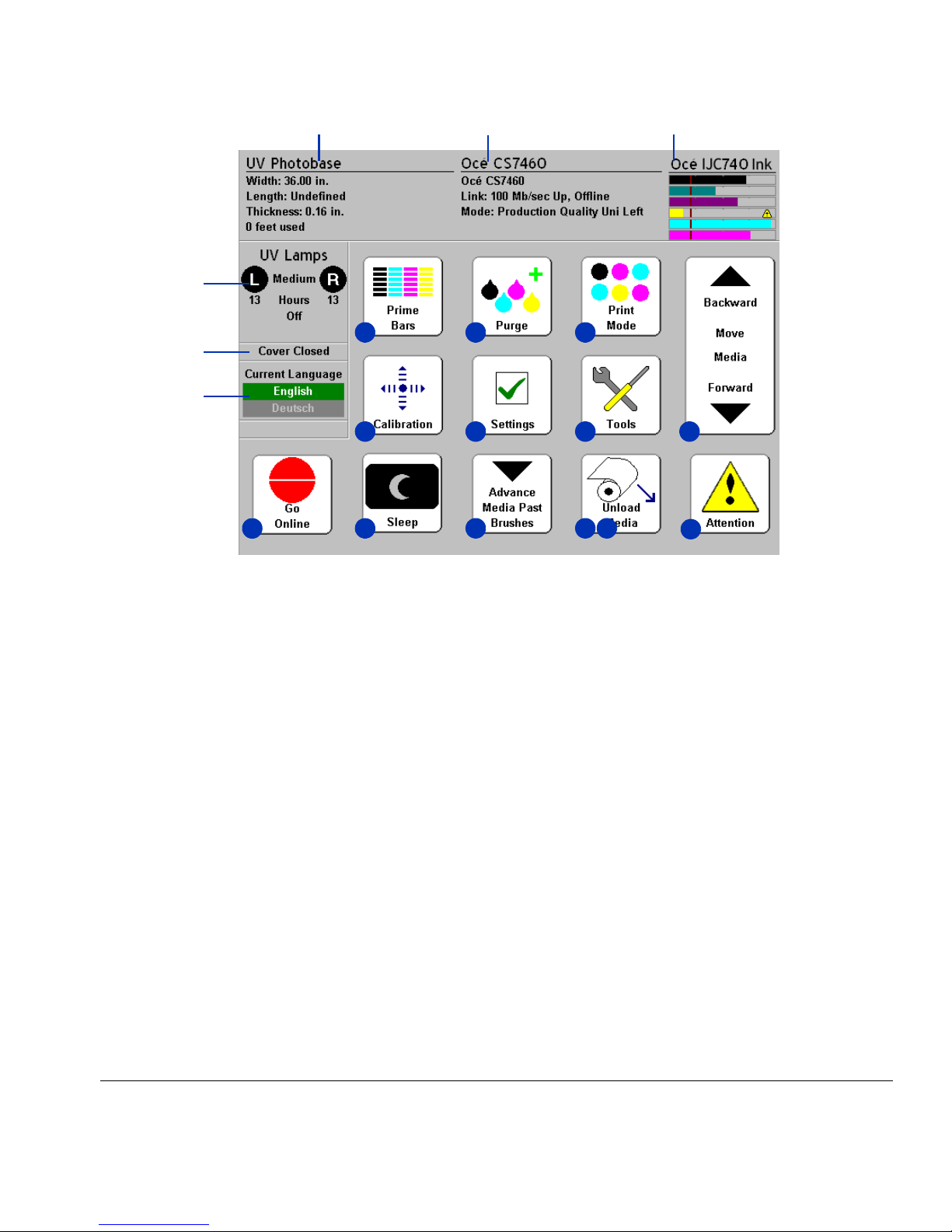

Fig. 1-3. Front Page screen

1. Media information

2. Printer status

3. Ink levels

4. UV lamps status (L=left side, R=right side)

8

11

9

12

17618

11. Settings

12. Too ls

13. Move media forward/backward

14. Go Online/Go Offline switch

13

19

5. Covers status (open or closed)

6. Language selector (if installed)

7. Print prime bars

8. Purge printheads

9. Print mode

10. Calibrate

Quick Tour 1-19

15. Sleep/Wake switch

16. Advance Media Past Brushes

17. Load New Media/Reload Media (visible

when media is not loaded)

18. Unload (visible when media is loaded)

19. Attention messages

Page 28

Special Features

Printheads • Printheads — variable drop size, piezoelectric printheads,

Ink System • Off-Head System (OHS) — 1-liter bulk ink boxes with inte-

Media Handling • Integrated media roller tables — integrated front and rear

192 jets per head.

grated filters. No-drip quick connectors simplify ink box

replacement.

• Onboard vacuum/pressure (VP) system — provides vac-

uum to maintain negative printhead pressure, and air pressure to purge the printheads or ink tubes without removing

them from the printer.

• Patent-pending automated printhead service station —

fully maintains the health of the printheads while idle or in

service, without operator intervention.

roller tables that fold up to feed rigid media sheets, or down

to use the rollfed media supply. The tables extend outward

from 36 to 60 inches (91.4 to 152.4 cm) to support board

lengths up to 96 inches (244 cm).

• Automatic head height — automatic head height adjust-

ment and patent-pending shuttered UV lamps allow the

printer to accept rigid sheet-fed media up to 1.0 inch (25

mm) thick.

• Automatic media width sensing — automatically detects

the width and position of the media loaded, for precise image

placement.

• Built-in static charge abatement — ionizer bars help dissi-

pate static electric charge from synthetic media, while the

electrically-conductive platen discharges static build-up on

the bottom surface of the media

• AutoEdge — automatically aids the loading of rigid sheets

by detecting the leading edge.

• Rollfed media supply spool — accepts rollfed media up to

54 inches (137.2 cm) wide on 3-inch cores.

• Rollfed media edge holders — integrated clips hold down

the edges of rollfed media to prevent curling.

1-20 Special Features

Page 29

• Advanced pinch roller design — the molded pinch rollers

are self-aligning to prevent media skew. Any individual pinch

roller can be snapped up and out of the way to avoid interfering with the edge of the media.

• Adjustable media fence — keeps the media feeding

straight, prevents skewing.

Calibration The Advanced Automation Eye uses a high-resolution imaging

sensor, photodiode, and embedded software to align the printheads, detect and replace missing jets, linearize output, and

color profile media (with supported RIP).

Performance and

Ease-of-Use

• AutoSet

TM

calibration — uses a high-resolution digital

imaging sensor to automatically align printheads bidirectionally for precise positioning of inkjet pixels, and runs AutoJet.

• AutoJet

TM

calibration— compensates for lost or misfiring

jets by locating them and using substitute jets without slowing printing speed.

TM

• AutoTune

scheduling — runs AutoJet at user-defined

intervals, for highest quality during unattended printing.

Optionally, if unsubstituted non-working jets are found, printing stops until the problem is corrected.

• Automatic color calibration — uses an onboard photo-

diode to linearize output over the entire density range (with

print server or RIP support).

• Media Wizard — stores and recalls a set of operating

parameters by media type and print mode, for optimal printing performance. Includes a set of predefined settings for

standard media; user may add settings for other media.

• Speed/quality print modes — provided to meet speed and

quality requirements.

Special Features 1-21

• Edge-to-edge printing — margins on rigid media can be set

to zero for edge-to-edge printing, providing “full bleed” prints

without trimming.

• Fine Text — prints at half the normal head speed to improve

the output quality of fine text and line art.

• Sharp Edge — reduces overspray at the edges of images

and blocks of color.

• Simplified control panel interface — touch-screen control

panel with graphical Front Page interface presents fre-

Page 30

quently-used functions. A menu provides access to less-frequently used functions and troubleshooting help.

• User assistance — control panel features online help, inter-

active procedures, and diagnostics to assist the user “onthe-fly,” reducing training and troubleshooting time.

1-22 Special Features

Page 31

Chapter 2

Printing

This chapter shows you how to set print mode and media options, load

ink and media, and print:

• Configure Printing (page 2-2)

• Configure Media (page 2-6)

• Load and Print on Rigid Media (page 2-10)

• Load and Print on Roll-Fed Media (page 2-15)

• Loading Ink (page 2-19)

• Printing Tips (page 2-21)

• Checking Jet Health (page 2-24)

Printing 2-1

Page 32

Configure Printing The printer can print in several different modes for the combina-

tion of quality, resolution, and speed that you require.

Addressable Resolutions and Maximum Print Speeds

Print Modes

DPI Model High Quality Production Billboard

1200x600 CS7440 / CS7460

CS7445 / CS7465

600x600 CS7440 / CS7460

CS7445 / CS7465

600x300 CS7440 / CS7460 n/a

CS7445 / CS7465 n/a

24 sf/h (2.25 m

48 sf/h (4.5 m2/h) 97 sf/h (9 m2/h) 194 sf/h (18 m2/h)

48 sf/h (4.5 m2/h) 97 sf/h (9 m2/h) 194 sf/h (18 m2/h)

97 sf/h (9 m2/h) 194 sf/h (18 m2/h) 388 sf/h (36 m2/h)

“Jet replacement” is the printer’s ability to locate and replace inkjets that are clogged or misfiring in High Quality and Production

modes. Jet replacement is not available in Billboard mode.

The current print mode is shown on the Front Page of the control

panel. To change the print mode, follow these instructions.

2

/h) 48 sf/h (4.5 m2/h) 97 sf/h (9 m2/h)

194 sf/h (18 m

388 sf/h (36 m2/h)

2

/h)

n/a

n/a

1. On the control panel, press the Print Mode key.

The print mode menu appears, with these options

• Billboard

• Production

• High Quality

2. Press a print mode to select it.

A menu appears with these options:

• Bidirectional

• Unidirectional Left (left to right)

• Unidirectional Right (right to left)

:

2-2 Configure Printing

Page 33

The printer can print in both directions (bidirectional) or in

one direction only (unidirectional). Unidirectional printing can

occur in either direction. Printing occurs at about half the

speed of the corresponding bidirectional print mode. Unidirectional printing eliminates the bidirectional misalignment

that occurs when printing on media that is not perfectly flat.

3. Press a direction option to select it.

A message appears reporting that the printer has changed

the media settings according to the loaded media type and

the new print mode selected. The print mode also determines which options appear in step 4.

4. Press the (Proceed) key.

After you select an option, in Production and High Quality

modes, a menu appears with these options (in Billboard

mode, go to step 5):

• Normal — prints at full speed.

• Fine Text — prints at half the normal head speed to

improve the output quality of fine text and line art by eliminating overspray.

Caution Printing in Fine Text mode, which prints at 50% of

the speed of the "normal" Production and High

Quality modes, may expose the media to excessive

heat from the UV lamps, which could result in bowing of the center of the media, and possible contact

with the printheads. Thinner rigid media such as

fluted polypropylene (Coroplast) are susceptible. To

avoid warping, set a media delay in Printer Set-

tings > Printing Delay, or in a custom Media Wizard parameter set for Fine Text printing.

• Sharp Edge — reduces overspray at the edges of

images and blocks of color.

Configure Printing 2-3

Page 34

The following table shows the print mode and resolution

combinations supported by each of these modes:

600x600 600x300 1200x600

Normal BB, PQ, HQ PQ BB,PQ,HQ

Fine Text PQ, HQ — PQ, HQ

Sharp Edge PQ, HQ PQ PQ, HQ

BB=Billboard; PQ=Production Quality; HQ=High Quality

The Unsupported Setup Job Handling menu appears.

5. Select an option.

The printer does not print jobs at 600x300 dpi resolution in

High Quality or Billboard mode. If it receives a 600x300 print

job from the RIP when the printer is set to either of these

modes, the job will be handled according to the option you

select:

• Prompt With Options — the control panel will ask

whether to print the job in Production mode or cancel the

job.

• Use Production Quality — the job will be printed in Pro-

duction mode.

• Cancel Job — the job will not be printed.

6. Press an option to select it.

The UV lamps settings appear.

7. Configure the UV lamps operation by pressing the High,

Medium, or Low option.

• For standard media listed in the Media Wizard, leave the

lamp settings at their default values, then adjust as

needed.

• Faster print modes require higher lamp settings to ensure

sufficient curing.

• If the ink is not curing, increase the setting. The lamps

will gradually lose curing effectiveness, so increasing the

setting eventually may become necessary. (For infomation about UV lamp life, see “Replacing UV Lamp Bulbs”

on page 2-26.)

2-4 Configure Printing

Page 35

• If the media is wrinkling or warping from the heat of the

lamps, lower the setting.

When you select a lamp setting, the shutter aperture screen

appears.

8. Adjust the shutter apertures, or press Press (Proceed) to

continue.

You can select the aperture (opening amount) for each shutter, and/or completely close one of the shutters, during printing. This enables you to reduce the warping of rigid media

by reducing the amount of light and heat emitted by the

lamps. The aperture can also be set by touching the UV

lamps info panel (see “Front Page” on page 3-3).

The UV lamp shutters are vertical when completely opened,

and rotate to change the aperture. An aperture setting of 0

degrees is completely open; 20 degrees is half open, 40

degrees is the maximum closed setting. You cannot set both

shutters to closed while printing. During printing, the lamp

icons on the control panel are dynamically shaded to indicate the aperture setting. The icons will change as the carriage direction changes if the leading and trailing aperture

settings are different from each other.

9. Press (Proceed) to save the settings and return to the

Front Page, or (Cancel) to restore the previous print

mode settings.

10. Select a print resolution at the RIP.

Configure the RIP to rasterize print jobs at the desired resolution. Refer to the RIP documentation for instructions. See

the table on page 2-2 for a list of resolutions supported by

each print mode.

Configure Printing 2-5

Page 36

Configure Media Before the printer will accept a print job, it must be configured for

a specific media type. The currently-configured media type, if

any, is displayed in the upper left corner of the control panel.

You can load a new media type (see the following procedure), or

reload the previously loaded media (see “Reload Media” on

page 2-9).

Load New Media 1. To load a different media type from the type displayed on the

control panel, from the Front Page screen, press the Load

Media or Load New Media key.

The Select Media to Load menu appears. The list of media

ends with the option Create Media Type.

Tip Start by using one of the standard media types. If

you are not using a standard media type, select the

standard media type that most closely matches the

media you are using. Then only if necessary, create

a new media type using the standard type you

selected as a starting point, and adjust it as needed.

2. Press a media name, or Create Media Type.

2-6 Configure Media

Page 37

Fig. 2-1. Media settings screen

• If you pressed a media name, a list of settings appears

(see Fig. 2-1). From this screen you can change the

Media Settings, change the Print Mode, Select Media

again, or Proceed to loading the media. To load media,

press the (Proceed) key and go to “Load and Print on

Rigid Media” on page 2-10 or “Load and Print on Roll-Fed

Media” on page 2-15.

• If you pressed Create Media Type, the control panel

prompts you to press the (Proceed) key to create a

new media type, or (Cancel) to return to the Media

Wizard screen.

If you press the (Proceed) key, the control panel displays

an alphanumeric keyboard so you can enter a name for the

media you are creating.

3. Enter the media name, then press the Enter key to continue.

A list of default settings appears. To change any of the settings, press the Media Settings key to display a menu of

settings you can change:

Configure Media 2-7

• Media Name

• Media Feed Method — Roll or Cut Sheet.

• Platen Vacuum Control — this option turns on the vac-

uum fans, and displays and keys on the control

panel. Press and to raise or lower the fan speed.

Page 38

Observe the media as the fan speed changes. If the

media is lifting off the platen, increase the fan speed. If

the media advance seems impeded by the vacuum,

decrease the fan speed.

After you save your changes by pressing the (Proceed) key, the Leading Edge Static Control screen

appears. This feature reduces overspray in areas of fine

text in the first 0.6 inches (15 mm) leading edge of a rigid

media print. Disable if the media is not being held sufficently onto the platen.

• Printing Delay — press the and keys on the con-

trol panel to increase or decrease the delay (seconds per

print swath). To increase throughput, decrease the delay.

• Media Edge Holders — if Yes, you will be prompted dur-

ing the media load sequence whether you are using the

media edge holders for rollfed media. If No, you will not

be prompted.

• Media Out Sensor — the sensor is used to detect the

trailing edge of cut-sheet media so that printing can be

stopped before running out of media. The sensor should

be disabled only for media types it cannot detect, or if the

sensor is malfunctioning.

• Measure Media Width — select Automatically to mea-

sure the media with the digital imaging sensor (camera),

or Manually to position the printhead carraige at the right

and left edges of the media, or when loading transparent

media, the edges of which cannot be detected by the

printer.

4. Press (Proceed) to load the media, or press (Cancel)

to discard your changes.

• To load media, go to “Load and Print on Rigid Media” on

page 2-10 or “Load and Print on Roll-Fed Media” on page

2-15

2-8 Configure Media

Page 39

Unload Media To unload media (raise the pinch rollers and switch off the platen

vacuum), press the Unload Media key on the Front Page screen,

or press the Load/Unload switch on the back of the printer to the

Unload position.

Reload Media If the control panel displays the media type you intend to use,

press the Reload Media key (or press the Load/Unload switch to

the Load position, or press the optional foot switch).

• If you are reloading roll-fed media, see “Load and Print on

Roll-Fed Media” on page 2-15.

• If you are reloading rigid media, press either the Reload

Sheet or Reload and Print key. Reload and Print switches

the printer Online after it is complete, so it can immediately

accept the next print job. Reload Sheet does not switch the

printer Online. Then see “Load and Print on Rigid Media” on

page 2-10.

Media Wizard To view or change the settings for the currently-loaded media,

press the media listing area (upper left corner) of the Front Page

screen. This displays the Media Wizard.

The Media Wizard also lets you create a new media type, delete

an existing media type, view the settings for any media type, or

change the order in which the media are listed in the Media

Wizard.

Configure Media 2-9

Page 40

Load and Print on

1. If loaded, unload any roll-fed media.

Rigid Media

2. If necessary, slide the roll-fed media edge holders out of the

way of the media path.

3. Open the input and output media tables, and unfold and lock

the legs into position. For longer media, pull out the table

extension. For longer, lightweight media (such as FomeCor), pull out the media supports.

Fig. 2-2. Rigid media tables with extensions and supports

4. Perform the Configure Media process (see “Configure

Media” on page 2-6), then press the (Proceed) key on the

control panel.

The Select Media Length menu appears.

5. Select a predefined media length on the control panel, or

select Input Manually and type in the length.

6. The printer displays a message telling you that your

changes are being saved.

7. Press the (Proceed) key on the control panel.

If the printer’s current head height off the media is different

from the Media Wizard’s head height setting for the selected

media, the printer prompts you to change one or the other.

• Pressing Yes uses the value from the wizard, pressing

No uses the printer’s current head height, pressing

Change Head Height allows you to change the printer’s

current head height.

2-10 Load and Print on Rigid Media

Page 41

The following screen appears.

Fig. 2-3. Load media screen

8. Unlock the adjustable media fence by loosening the locking

knob, and slide it to the right (toward the service station end

of the printer).

Locking knob

Rail

Fence

Fig. 2-4. Adjustable fence

9. Load the sheet of media onto the input table, sliding it to the

left (toward the ink boxes) until the media is flush against the

fixed media fence.

Load and Print on Rigid Media 2-11

Page 42

10. Slide the adjustable media fence against the right side of the

media. Then lock it in place.

At this point you can also adjust the speed of the vacuum

fans, or switch them on or off. If the sheet is warped or not

being held down, increase the vacuum fans or raise the

pinch rollers.

11. If the edge of the media you are using is directly below a

pinch roller, raise that pinch roller by pushing it up and then

pushing the latch toward the rail to engage it (see Fig. 2-5

below). To lower the pinch roller, push it up and the latch will

disengage, then lower the roller to the platen.

Latch

Pinch roller assemblies Media thickness sensor

Fig. 2-5. Pinch rollers

12. Move the media edge holders (for roll-fed media) out of the

media path, and make sure that the output door is closed.

13. Press the (Proceed) key on the control panel, or the

Load/Unload switch on the back of the printer to the Load

position, or the optional foot switch (if installed). This causes

the printer to:

• Measure the media thickness

• Measure the media width

• Find the leading edge of the media

2-12 Load and Print on Rigid Media

Page 43

After briefly displaying the measured width of the media, the

control panel displays the media and margin measurements

(see Fig. 2-6):

• To change the margins, press the Margin Settings key.

Note The minimum Trailing Margin is 6 inches (15.2 cm),

to enable the pinch rollers to advance the media.

Fig. 2-6. Rigid sheet measurements

14. Press the (Proceed) key.

The control panel displays the message, “Media loaded successfully,” and asks whether to save the Media Feed Number (MFN) for the current media type.

• To load the new MFN, press the

9 (Yes) key.

• To discard the new MFN and used the previously-saved

MFN, press the (No) key.

• To perform a media feed calibration or enter a different

MFN, press the Calibrate Media Feed key (For

instructions, see “Media Feed Calibration” on page 4-9.)

The Front Page screen appears.

15. Press the Go Online key.

Load and Print on Rigid Media 2-13

Page 44

16. Send a print job from the RIP.

For multiple copy jobs, the printer control panel will prompt

for the next sheet a short time before the previous sheet is

done printing. Load the subsequent sheet as before, and

press the (Proceed) key, or press the Load/Unload switch

to the Load position, or press the optional foot pedal switch.

The printer prints on the next sheet and will use the same

option settings on all of the copies in the print job.

Tip To display the Media Wizard and view or change

media and margin settings for the currently loaded

media, touch the media info panel in the upper left

corner of the Front Page screen.

2-14 Load and Print on Rigid Media

Page 45

Load and Print on

Roll-Fed Media

1. If opened, retract the rigid media input and output table

extensions, and fold the table legs, tables, and adjustable

media fence down into their storage positions.

Fig. 2-7. Tables stored for roll-fed printing

2. Load the media onto the supply spool.

Remove the removeable collet from the spool, load the roll

of media onto the spool, and replace the collet. You can print

on either side of the media by loading the spool with the

media feeding off the top or bottom of the roll.

Tip To prevent fingerprints from showing on printed out-

put, wear gloves while handling the media.

Removeable collet

Pin

Fixed collet

Fig. 2-8. Media spool

Load and Print on Roll-Fed Media 2-15

Page 46

3. Load the supply spool onto its bracket.

Insert the end of the spool with the pin into the left spool

holder, then insert the other end of the spool into the right

spool holder.

4. Unspool enough media to reach past the pinch rollers, and

smooth out the media across the platen.

5. Configure the media (see “Configure Media” on page 2-6).

6. Press the (Proceed) key on the control panel.

If the printer’s current head height off the media is different

from the Media Wizard’s head height setting for the selected

media, the printer prompts you to change one or the other.

• Pressing Yes uses the value from the wizard, pressing

No uses the printer’s current head height, pressing

Change Head Height allows you to change the printer’s

current head height.

7. Enter media length on the control panel.

If you do not know the media length, press the Esc key. This

will disable the printer from alerting you when the media

supply is running low.

8. Press the (Proceed) key.

9. The printer displays a message telling you that your

changes are being saved.

10. Press the (Proceed) key.

The printer raises the pinch rollers, then asks whether you

are using the media edge holders.

The media edge holders are clips that are integrated into

slots that run the length of the platen. They hold down the

edges of roll-fed media during printing. When you tell the

software that you are using the media edge holders, the

software allows for them when measuring the media width

2-16 Load and Print on Roll-Fed Media

Page 47

and calculating margins, to prevent printing on the media

edge holders.

Fig. 2-9. Media edge holder (left shown)

11. Press the

9 (Yes) or (No) key.

• If you press Yes, the printer prompts you to position the

edge holders at the sides of the media. Then position the

edge holders.

• If you press No, go to step 12.

12. Press the (Proceed) key, or the Load/Unload switch on

the back of the printer to the Load position, or the optional

foot pedal switch (if installed).

The printer measures the media and lowers the pinch rollers.

The control panel displays the message, “Media loaded successfully,” and asks whether to save the Media Feed Number (MFN) for the current media type.

• To load the new MFN, press the

9 (Yes) key.

• To discard the new MFN and used the previously-saved

MFN, press the (No) key.

Load and Print on Roll-Fed Media 2-17

• To perform a media feed calibration or enter a different

MFN, press the Calibrate Media Feed key (For

instructions, see “Media Feed Calibration” on page 4-9.)

The Front Page screen appears.

13. On the Front Page screen, press the Go Online key.

14. Send a print job from the RIP.

Page 48

Tip To display the Media Wizard and view or change

media and margin settings for the currently loaded

media, touch the media info panel in the upper left

corner of the Front Page screen.

2-18 Load and Print on Roll-Fed Media

Page 49

Loading Ink The amount of ink in the ink supply box is tracked by the printer

software and recorded on its corresponding profiler. The control

panel displays a bar graph with the ink levels in each ink box.

When the control panel shows that the ink is low, replace the ink

box with a full ink box of the same color.

Fig. 2-10. Press the bar graph for detailed ink status

Note You may want to wear gloves (latex or nitrile) and

have a paper towel handy to catch the drops of ink

that may fall from the ink tube connection during this

procedure.

Connector

Filter

Fig. 2-11. Ink supply box

Loading Ink 2-19

Page 50

Unloading an Empty

1. Remove the profiler.

Ink Box

2. Grasp the metal connector where the ink tube enters the

printer, and push it up to release the ink supply tube.

3. Lift the box out of its holder and turn the box upside down so

the ink tube is pointing up.

4. Remove and dispose of the ink box (refer to the MSDS for

proper disposal procedures).

Loading a Full Ink Box 1. Open the new ink box and locate the supply connector.

2. Locate and remove the profiler, and set aside until step 5.

3. Invert and install the ink box into position in the holder, so

the ink supply tube is at the bottom of the box.

4. Insert the ink tube connector into the metal connector on the

printer.

The position for each ink color is shown on a label below

each ink box and next to the profiler docking station.

5. Install the profiler in the corresponding docking station slot.

2-20 Loading Ink

Page 51

Printing Tips • Rigid cut-sheet media — use only flat, unwarped, undam-

aged sheets, with parallel opposite edges and 90

Load the media from the back of the printer; loading from the

front will cause interference with the UV blocking brushes.

• Curing continues for 24-48 hours — the UV ink will con-

tinue to cure for a day or two after printing. Maximum durability and adhesion is achieved after the ink is fully cured.

° corners.

• Pausing printing — to pause printing, press the

key. While printing is paused, you can:

• Change media settings (vacuum, print delay).

• Pause-swap inks (see “Pause Swapping Ink,” below).

Caution Synthetic media commonly used for inkjet printing

can build up a static charge, especially in environments with low relative humidity. This charge can

pose an electrostatic discharge (ESD) hazard to

persons, the printer, and other equipment. It can be

safely discharged by draping a grounded chain or

tinsel over the top of the stack of media.

(Pause)

Pause-Swapping Ink You can replace one or more ink boxes during a print by pausing

the printer:

1. On the printer control panel, press the

(Pause) key.

2. Remove the old profiler.

This signals to the printer that the ink box is being replaced.

3. Disconnect and remove the old ink box.

4. Install and connect the new ink box.

5. Install the profiler that was included with the new ink box.

6. Repeat steps 2 through 5 for any other ink boxes you want

to replace.

7. On the printer control panel, press the

Printing Tips 2-21

(Resume) key.

Page 52

Calibrating the

Moveable Fence

The moveable fence is calibrated at the factory to be parallel to

the top surface of the media, at a height just above the top of the

table rollers (lower than the thickest media that will be used on

the printer).

If the moveable fence needs to be recalibrated, follow this

procedure:

1. Place a piece of rigid media under the pinch rollers, and

align it against the stationary fence.

2. Slide the moveable fence next to the edge of the media and

observe its position relative to the top surface of the media.

3. If the fence is not parallel to the top edge of the media, use a

2.5 mm hex wrench to turn the position screw (shown below)

until the moveable arm is parallel with the media.

2-22 Printing Tips

Fig. 2-12. Location of position screw

Page 53

4. Using a 5 mm hex wrench, loosen the two set screws

(shown below) that secure the vertical position of the moveable fence.

Fig. 2-13. Height adjustment screws

5. Place a long, flat, thin metal ruler on top of one column of

table rollers.

6. Place the moveable fence arm on top of the metal ruler.

7. Press down on the arm until moveable arm is flat against the

ruler.

8. Tighten both set screws.

The arm may move while tightening the set screws. Recheck the position after tightening.

9. Push the moveable arm back and forth across the width of

the table to make sure that the arm does not contact the

rollers.

Tip To prevent thin flexible media from slipping under

the fence, the fence can be lowered to just under

the top surface of the rollers. In this case, use

extreme care when moving the fence across the

width of the media, to avoid striking the rollers.

Printing Tips 2-23

Page 54

Checking Jet Health Under most conditions, AutoJet jet substitution and the printer’s

automated printhead service station keeps the printheads clean

and operating without your intervention. Should operator cleaning of the printheads become necessary, the printer also provides several printhead-cleaning tools to accomplish this.

If you notice a decrease in print quality, one or more inkjets may

be clogged. To check jet health and recover clogged jets, follow

these procedures:

1. Purge

2. Print Prime Bars or Print Recover Jets Pattern

3. Map out missing jets with AutoJet or Manual Jet Mapping

These procedures are explained in the following paragraphs.

Purge When printing prime bars does not recover missing jets, you can

purge the printheads with air. Then print another Prime Bars to

verify that all jets are working.

Print Prime Bars 1. From the control panel Front Page screen, press the Prime

Bars key.

The control panel displays a prompt asking you to enter the

total width of the prime bar pattern you wish to print.

2. Enter a width for the prime bar pattern by pressing the

and keys.

3. Press the (Proceed) key to continue.

The printer prints the prime bar pattern. The prime bars will

show correctly working jets with a solid line, and missing jets

with no line.

Alternatively, you can select Maintenance > Print Recover

Jets Pattern from the menu, which prints a special pattern

designed to recover missing jets, followed by a set of prime bars.

2-24 Checking Jet Health

Page 55

Map Out Missing Jets If the Prime Bars reveal blank lines after a Purge, the corre-

sponding jets should be mapped out. When all missing jets have

been substituted, printed output will appear as if all jets are

working.

You can map jets out temporarily (“soft bad jets”) or permanently

(“hard bad jets”). For instructions, see “AutoJet” on page 4-3 or

“Manual Jet Mapping” on page 4-18.

When AutoJet detects a missing jet, it attempts to replace it with

a working jet on the same or another printhead (in Production

and High Quality modes). In this way, printing occurs with all jets

for maximum quality.

Optionally, you can print a Jet-Out Lines pattern to see which

jets have been subsitituted.

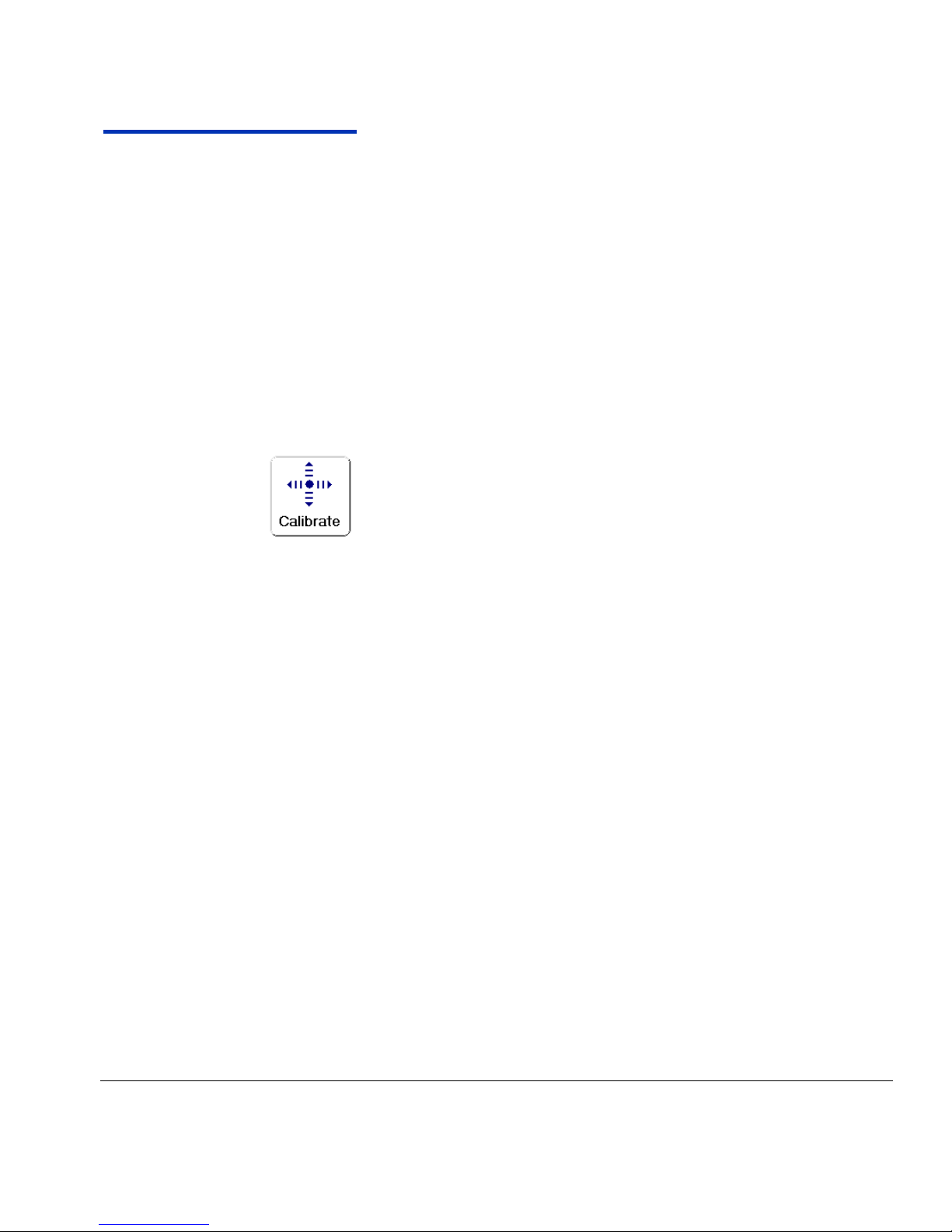

1. From the control panel Front Page screen, press the Calibrate key.

The Calibrate menu appears.

2. Press Manual Calibrations.

The Manual Calibrations menu appears.

3. Press Print Jet-Out Lines.

The Jet-Out Lines pattern prints. Substituted jets are marked

with a black square.

Checking Jet Health 2-25

Page 56

UV Lamp Operation

and Maintenance

The printer’s two UV lamps (on the left and right sides of the

printhead carriage) emit the high-intensity ultraviolet light that is

necessary to cure the UV ink.

The lamps have a limited life, during which the amount of UV

light emitted slowly decreases, eventually reaching a level that

will no longer cure the ink. There are measures you can take to

extend the service life of the lamps, but they will eventually have

to be replaced.

WARNING UV light hazard. Excess exposure to high-intensity

UV light can result in photokeratitis (also known as

snow blindness or welder’s flash). AVOID LOOKING

DIRECTLY AT THE UV LIGHT.

VORSICHT UV Licht hoher Intensität. Bitte vermeiden Sie es,

direkt in die Lampen zu schauen.

Caution Failure to allow the lamps to cool down properly, as

described on the control panel, will damage the

lamps.

Operating Tips When the lamps do not cure output sufficiently in Billboard Qual-

ity Mode, switch to Production Quality Mode. When the lamps do

not cure the output in Production Mode, switch to High Quality

Mode (Front Page > Print Mode).

If the lamps are not curing the ink with the lamps set to Low,

increase the setting to Medium or High (Front Page > Print

Mode > Select Print Mode > Select Print Direction > Print

Mode Options > Lamp Modes).

If the lamps are still not curing printed output after taking these

steps, replace the bulbs.

Replacing UV Lamp Bulbs The UV lamp bulbs will gradually lose their intensity and there-

fore their ability to cure the ink. The control panel will display a

warning message when one or both of the bulbs have been

operated for 500 hours, but the bulbs may continue to cure

printed output for up to 1000 hours. To view the number of hours

that each lamp has operated, advance to the System Informa-

2-26 UV Lamp Operation and Maintenance

Page 57

tion page where this is listed (on the Front Page, touch the

printer status message to reveal the System Information pages).

Replacing the bulbs as a pair is recommended. If the total operating time for the right and left bulbs is significantly different,

printing artifacts may be visible due to uneven ink curing. When

you replace the bulbs, be sure to reset the operating time

counter (Tools > Maintenance > Reset UV Lamp Hours).

Detailed instructions for replacing the bulbs are included with the

replacement bulbs.

Note The UV lamps contain heavy metals and other ele-

ments that should be disposed of as hazardous

waste. They should be taken by any hazardous

waste service or facility that accepts mercury lamps.

UV Lamp Operation and Maintenance 2-27

Page 58

2-28 UV Lamp Operation and Maintenance

Page 59

Chapter 3

Using the Control Panel

This chapter describes the functions of the control panel.

• Overview (page 3-2)

• Front Page (page 3-3)

• Menu Tree (page 3-6)

• Menus (page 3-7)

Using the Control Panel 3-1

Page 60

Overview The touch-screen control panel shows you the printer’s current

status, and enables you to interact with the printer when changing media and ink, respond to an error condition, or configure

options.