Page 1

Océ CS6407

Read this User’s Guide (including Safety Information)

carefully before use of this printer and handle it properly.

After reading, keep it for later use.

Basic Operation Guide

1

Documentnumber

Wide Format Solvent Inkjet Printer

Océ CS6407

Océ Technologies B.V.

Introduction For your basic operation Maintenance When encountering a problem Appendix

Page 2

Océ CS6407 Wide Format Solvent Inkjet Printer Basic Operation Guide

Edition 1, April 2010

Copyright

© 2010, Océ-Technologies B.V. Venlo, The Netherlands.

All rights reserved. No part of this work may be reproduced, copied, adapted, or transmitted in any form or by any

means without written permission from 'companyname'.

Océ-Technologies B.V. makes no representation or warranties with respect to the contents hereof and speci cally

disclaims any implied warranties of merchantability or tness for any particular purpose.

Further, Océ-Technologies B.V. reserves the right to revise this publication and to make changes from time to

time in the content hereof without obligation to notify any person of such revision or changes.

Trademarks

Océ®, Océ CS6407® are registered trademarks of Océ-Technologies B.V.

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft® Corporation in the United

States and / or other countries.

Products in this publication are referred to by their general trade names. In most, if not all cases, these

designations are claimed as trademarks or registered trademarks of their respective companies.

Note:

Visit Océ on the internet at www.oce.com for the latest information.

Page 3

3

Introduction

Océ 6407 Wide Format Solvent Inkjet Printer (hereafter simply called the Printer.) is equipped with built-in USB

interface that adopts solvent ink and supports media of up to 74-inch width.

The Océ 6407 Wide Format Solvent Inkjet Printer Basic Operation Guide describes:

- The Printer’s features and main components

- Information required for the operation

- Basic operations to turn the Printer on and o and to handle the media and ink system

To operate the Printer safely and properly, before starting the operation be sure to read the following.

- Safety precautions

- Delivery products

- Manual legend (notation rules)

Keep this guide near the Printer so that you can quickly access it at any time.

Page 4

Océ 6407 Basic Operation Guide

4

To perform your rst printing

Basic Operation Guide

Read the Basic Operation Guide before your rst Printer operation.

This guide describes the basic handling and daily operation of

media, printing, and maintenance.

To print on other media

To perform double-sided printing

To perform the Printer’s maintenance

To replace the Printer’s ink pack

To replace the Printer’s waste ink bottle

To recover error messages

To clear media jams

How do the two Guides work?

Océ CS6407

Read this User’s Guide carefully before use of this printer and

handle it properly.

After reading, keep it for later use.

Basic Operation Guide

1

Documentnumber

Wide Format Solvent Inkjet Printer

Océ 6407

Océ Technologies B.V.

P.29

P.50

P.54

P.58

P.86

P.84

P.76

P.75

Page 5

5

Advanced Operation Guide

Read the Advanced Operation Guide so that you can operate

the Printer eectively.

This Guide describes the Printer’s ne setting and adjustment to

maximize the Printer’s performance.

To clear banding, white lines, and bleeding

To operate the Printer with ne settings

To print on cut-sheet media

To change heater temperature while printing

To turn the Printer o

To create a new media preset

To switch between 4-color and 8-color modes

Océ CS6407

Read this User’s Guide carefully before use of this printer and

handle it properly.

After reading, keep it for later use.

Wide Format Solvent Inkjet Printer

Advanced Operation Guide

Océ 6407

Océ Technologies B.V.

P.66

P.26

P.42

P.52

P.8

P.36

P.60

Page 6

Océ 6407 Basic Operation Guide

6

TABLE OF CONTENTS

Introduction

3

Safety precautions

7

General warning and cautions

8

Regulation Notices (country dependent)

10

Handling precautions

12

Components delivered with this product

15

Manual legend (Notational rules)

16

Operating conditions

19

Introduction

20

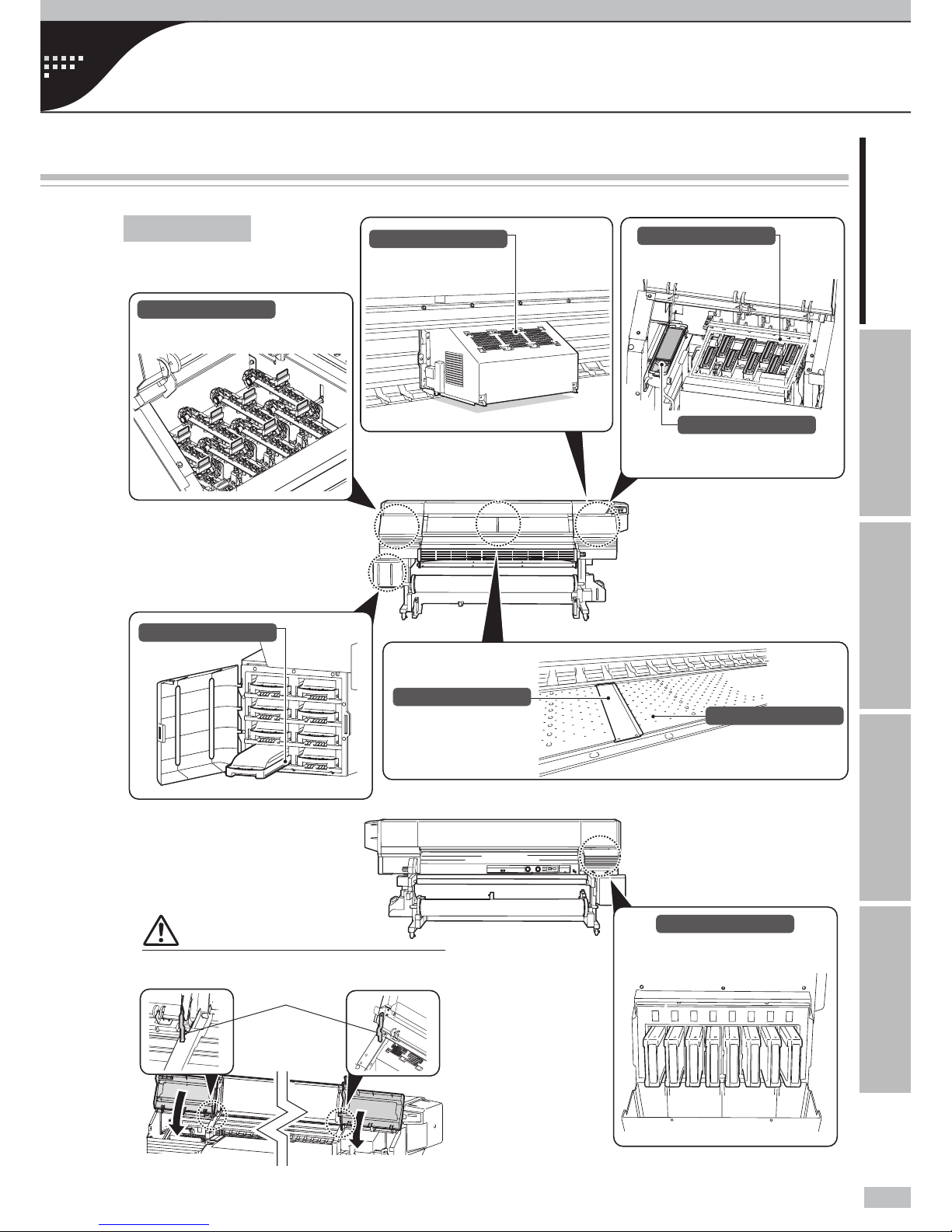

Appearance / Main components and their

functions

20

Printer rear (supply side)

20

Printer interior

21

Operation panel

22

Printer heater unit

23

Online and o ine

24

Online

24

Offline

24

Supported media

25

Vinyl

25

Banner

25

Mesh banner

25

Backlit banner (FF)

25

Solvent printing coated paper

25

For your basic operation

26

Precautions to prevent media jams

27

Basic operation for printing

29

Printing workflow overview

29

Procedure to remove media roll from the Printer

43

Media at take-up side

43

Media at supply side

46

Procedure to remove scroller flange from media roll

48

To print on other media

50

To print on Vinyl, Mesh banner, Backlit banner (FF), or

Solvent printing coated paper

50

To take up media in LOOSE winding mode

52

To perform double-sided printing

54

Maintenance

58

Daily maintenance

58

Check the wiper blade for contamination and replenish

wiper cleaning liquid

60

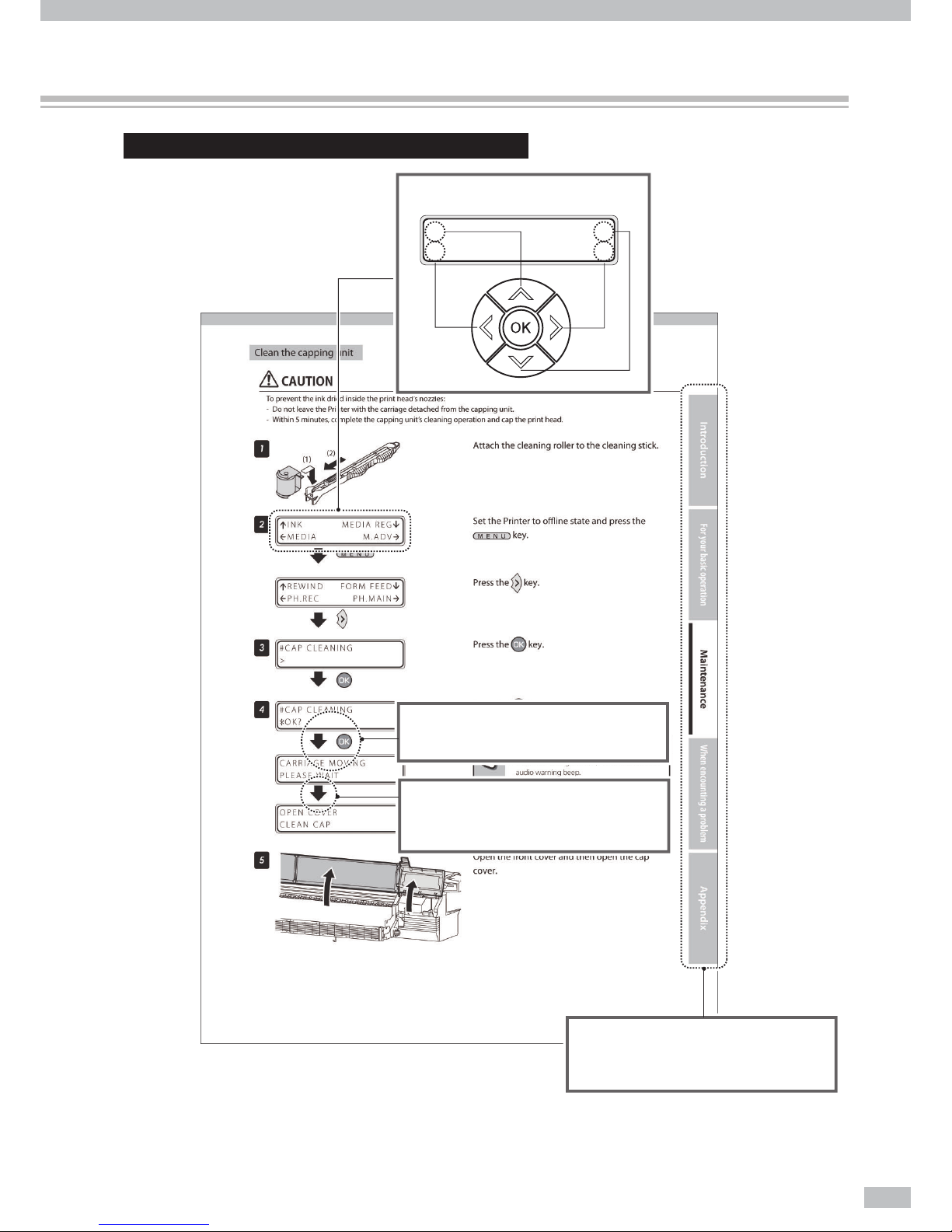

Clean the capping unit

61

Replenish spittoon absorber liquid

63

Check the waste ink bottle

64

Clean the carriage

64

Cleaning the madia edge guard

67

Performing normal cleaning

68

Print the nozzle print pattern

68

Cleaning

70

Clean the exterior

70

Clean the front cover and front paper guide

70

Carriage cleaning

70

After today’s operation

71

When encountering a problem

72

Check your problem

72

How to clear media jams

75

When an error message is displayed

76

Out of ink while printing

80

The media was skewed.

81

Warning messages

82

Move the Printer

83

Replace a waste ink bottle

84

Install and replace an ink pack

86

Replace a spittoon case

88

Replace a wiper blade

90

Appendix

92

Basic speci cations

92

Consumables

93

Addresses of lacal Océ organisations

95

Index

98

Page 7

7

The following symbols are used in the Guides to ensure the Printer’s proper operation and to prevent the Printer

from being damaged. Follow the instructions marked with these symbols:

This symbol ( ) denotes items that require special care while

executing a certain procedure or operation.

This symbol ( ) denotes items that are forbidden.

This symbol ( ) denotes items you should follow to prevent

accidents or injury.

Example of symbols :

WARNING

CAUTION

Failuretofollowtheguidelinesmarkedwiththis

symbolcouldresultinseriouspersonalinjuryor

death.

Failuretofollowtheguidelinesmarkedwiththis

symbolcouldresultinminorpersonalinjuryor

damagetotheproduct.

Safety precautions

Page 8

Océ 6407 Basic Operation Guide

8

Be sure to read warnings below before use.

WARNING

Use the power supply voltage speci ed on the

nameplate. Avoid overloading the printer’s

electrical outlet with multiple devices.

Be sure the printer is well grounded. Failure

to ground the printer may result in electrical

shock, re, and susceptibility to electromagnetic

interference.

Always hold the power cord by the plug when

connecting and disconnecting from the power

outlet.

Never pull on the cord because this may damage

it and create risk of re and electric shock.

Do not use a conversion plug.

Do not disassemble or repair the Printer by

yourself. Do not reinstall the printer in a new

location. Call your service representative.

DO NOT damage, break, process, or heat the

power cable. If it is damaged, replace it with a

new one. Using a damaged power cable may

cause re or electric shock.

NEVER use the Printer in a place of extreme

humidity or any place where it can possibly be

splashed by any liquids. If any liquid gets into the

Printer, it could lead to re, electric shock, or a

breakdown.

Do not allow metal or liquids to touch the

internal parts of the Printer. Doing so may cause

re, electric shock, or other serious hazards.

DO NOT disconnect or connect the power cord

with wet hands. Doing so may lead to electric

shock.

Power OFF the printer, unplug the power cord

from the power outlet, and contact your service

representative in any of the following cases.

Using the printer continuously in an abnormal

state may result in an accident or re.

- Smoke, strange noise or smell is generated

from the Printer or the Printer is overheated.

- There is smoke or an unusual smell coming

from the printer.

- The Printer is making an unusual noise during

normal operation.

- A piece of metal or a liquid (not part of

cleaning and maintenance routines) touches

internal parts of the Printer.

- An error requiring service by a service

representative occurs.

Ink used in the ink packs and subcartridges is

combustible. Do not use or store near open

ames, sparks, or other sources of ignition.

Avoid contact between skin, eyes, and clothing

and the Printer’s following consumables: ink,

storage liquid, cleaning liquid, cap cleaning

liquid, wiper cleaning liquid, and waste ink.

- Immediately wash skin with soapy water.

- Use an approved eye wash station if ink is

splashed into eyes and consult a doctor if

necessary. If an approved eye wash station is

unavailable, flush eyes with cold water and

consult a doctor Remove clothing soaked with

ink from contact with skin.

Do not swallow ink. If swallowed, do not induce

vomiting and seek immediate medical attention.

DO NOT place the printer on an unstable table or

at a slant place. If it falls, it maylead to injury.

General warning and cautions

The following symbols are used in the Operation Guides to ensure the proper use of the Printer and to prevent

the Printer from being damaged. Follow the instructions marked with these symbols.

WARNING

Failure to follow the guidelines marked with this symbol could result in serious personal

injury or death.

CAUTION

Failure to follow the guidelines marked with this symbol could result in minor personal

injury or damage to the product.

General warnings

Page 9

9

To ensure safe operation of the Printer, pay attention to all the warnings and cautions contained

throughout this manual.

Do not touch heater surfaces in the media path.

This may cause burns.

Keep ink packs, subcartridges, and waste ink

bottles out of the reach of children.

General cautions

CAUTION

Ensure to read cautions below before use.

Operate the Printer carefully near the Printer's

movable parts, so that your hands or your

clothes are not caught in the Printer.

Install and operate the printer in a wellventilated area. Otherwise the operator may

feel sickish. In such a case, take a rest in a wellventilated place.

Handle media rolls with care. They can be

heavy and di cult to move in con ned spaces.

In some cases, two people should move and

install media rolls. Dropping a media roll could

cause personal injury or damage to the printer.

Carrying with dolly is recommended.

Page 10

Océ 6407 Basic Operation Guide

10

Regulation Notices (country dependent)

Radio Interference suppression (all countries except USA)

Warning: This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

FCC approval (USA- only)

Note: This system has been tested and found to comply with the limits for a class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the system is operated in a

commercial environment. This system generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

ICES-003; Interference-causing equipment (Canada- only)

This Class A digital apparatus complies with Canadian ICES-003. Cet appareil

numérique de la classe A est conforme à la norme NMB-003 du Canada.

End of Life; WEEE (EU- only)

The symbol "the crossed-out wheeled bin" indicates that at end-of-life of the equipment

separate collection is required in the EU Member States. The black bar speci es that the

appliance is put on the market after 13 August 2005. Reference: Directive 2002/96/EC.

Contact your local Océ -organization for further information.

General information (All countries)

Caution labels and notations (All countries)

You can nd the power-marking label near the mains entrance. If connection to a

di erent mains voltage is required, contact Customer Service.

Do not remove caution labels or caution notations. If a label or notation is soiled,

please clean the label or notation. If you cannot make label or notation legible, or if the

label or notation is damaged, please contact your service representative.

Page 11

11

Space requirements and operation precautions (All countries)

The required operating space of this product will be communicated to each customer

by the local sales representative during the Site Survey.

Please refer to the corresponding Safety Data Sheets for speci c safety information,

including the dimensions of the product, the recommended room volume and

ventilation rate. You can download the Safety Data Sheets from the support site of

your product at http://global.oce.com/support/.

Operating environment (All countries)

The environmental requirements for correct operation of the machine are as follows:

Operating temperature (T): 15 °C (59 °F) to 30 °C (86 °F)

Relative Humidity (RH): 30 % to 70 %

Page 12

Océ 6407 Basic Operation Guide

12

Handling precautions

The precautions below are recommended to avoid damage to the Printer and its components.

Power supply

1. Install the Printer near the socket. To pull out the power plug in an emergency, the power socket must

be reached easily.

2. Do not share the power supply with the noise generating devices such as a motor.

3. Use the power supply voltage speci ed on the nameplate.

4. Monthly turn o the Printer and check the following:

- The power plug is inserted into the socket securely.

- No dust is accumulated between the plug terminals and socket. When dust is found, clean the area

with a dry cloth.

Printer

1. Do not place anything on the top of the printer. Do not rest your elbows on the Printer. Especially be

careful not to block the printer's exhaust outlet shown by the gure below.

2. Do not apply shock or stress to the Printer.

3. During the print operation, do not open the front cover, nor set the pressure control knob to “Open.”

Otherwise the printer operation is terminated.

4. Do not clean the cover’s surface with benzene or paint thinner. This may damage the Printer’s paint.

Clean the cover’s smear with a soft cloth. If the cover is considerably smeared, wipe it o with a cloth

moistened with water-diluted neutral detergent. If it is not cleaned, the smear may a ect the Printer’s

surface painting.

5. Always use the SIIT-speci ed attachments and options. The other products may degrade the image

quality, damage the Printer, and disable the maintenance.

6. Never touch the print head nozzles. They can be easily damaged or clogged.

Regular inspection and maintenance

Make sure you observe the appropriate maintenance guideline.

1. Clean the capping unit and wiper blade every day.

2. Everyday check visually the remaining wiper cleaning liquid is the speci ed quantity or more.

3. Clean the print head every two months with the head cleaning kit (IP7-125).

4. If you leave the Printer o for more than 2 weeks, perform the service cleaning.

5. If, after the service cleaning, you leave the Printer for a long time and again you start the print operation

with the Printer, be sure to perform the head wash and charge the ink system.

Consumables

1. SIIT ink packs should be installed before the “Install By” date printed on the pack. The other ink may

damage the Printer, and the Printer repair fee is borne by you.

2. To ensure the quality, validated date is printed on the SIIT ink pack, storage liquid, and cleaning liquid.

Use the consumables before they expire. The expired consumables may cause deterioration in print

quality or the Printer’s malfunction.

3. Put used ink packs into a plastic bag and dispose of them as industrial waste. Observe local regulations

Page 13

13

for disposal of consumables.

4. Unpack the SIIT ink pack package only when they are installed. Do not store SIIT ink packs in direct

sunlight. Store the SIIT ink packs in a cool, dry place. This prevents deterioration of the ink during

storage.

5. Do not disassemble the ink packs and subcartridges. They are intended for single use only.

6. Do not drop the ink packs and subcartridges. Avoid shock to them. The drop or shock may cause an ink

leakage.

Media

Supported media

The Printer supports the solvent inkjet media of the types below. Note that the print condition may change

depending on the environmental conditions and the media production batch. So you are recommended to test

the print with the media beforehand.

For details, contact your service representative.

z Vinyl

z Banner

z Mesh banner

z Backlit banner (FF)

z Solvent printing coated paper

Precautions on storing media

At storing media, packed or unpacked, avoid direct sunlight and water stained. To avoid dust put the

media into a box or a bag, and keep it in a cool and dark place.

Avoid a rapid temperature change to prevent a dew condensation.

Do not store media upright. The media stored upright may be deformed to be telescopic due to its

weight, or may deform its edge.

Do not pile up the roll media.

Precautions on disposing of media

Dispose of media or printout in compliance with all local, state, and federal regulations.

Precautions on using media

Do not subject the unpacked media to the temperature and humidity change. Before loading the

media on the Printer, leave the media in the operating environment for three hours or more. Note that

the ambient humidity change may a ect the media by turning on or o the air conditioner.

The media may be curled in a lower temperature, and wrinkled in a higher temperature. Keep the

temperature around 23°C and the humidity around 50% when you use the media.

Do not use a part of media when the part is scratched, wrinkled, turned, or with obstructions. Never use

the damaged media, as the right and left edges of the media are especially critical to feed media on the

Printer. Besides, do not drop the media and avoid water stained, which may degrade the image quality,

and cause the Printer’s malfunction.

Do not touch the printed image but the margin part. The image quality may be degraded by your

insensible sebum and sweat.

When the media is wound telescopically at loading on the Printer, correct the slippage before using.

Page 14

Océ 6407 Basic Operation Guide

14

Precautions on handling printouts

Do not touch the printed surface of the media before the ink dries, or especially 24 hours after printed.

Handle the printout by securing the margins.

Do not scratch the printout to avoid the color lost or transferred. To avoid the printout’s color

transferred, do not put the printed media on the other printed media with their printed surface facing

each other.

Do not put the printed media on the printout from copier or laser printer. The printouts’ ink or toner

may stick the two printouts.

Note that an ink on the printed surface may come o if the surface is rubbed hard or scratched.

The printed image may bleed or be lost if the water-stained printout is scratched hard or left.

Other precautions

Media loses its color and quality with age. Check the media condition and select the media with better

condition.

Cut the media carefully, as its paper dust may cause bubble surface at laminated.

When adhesive-backed media is applied, some adhesive agent may be left on the platen, which

may cause a media jam. So clean the agent completely with a soft cloth moistened with the neutral

detergent.

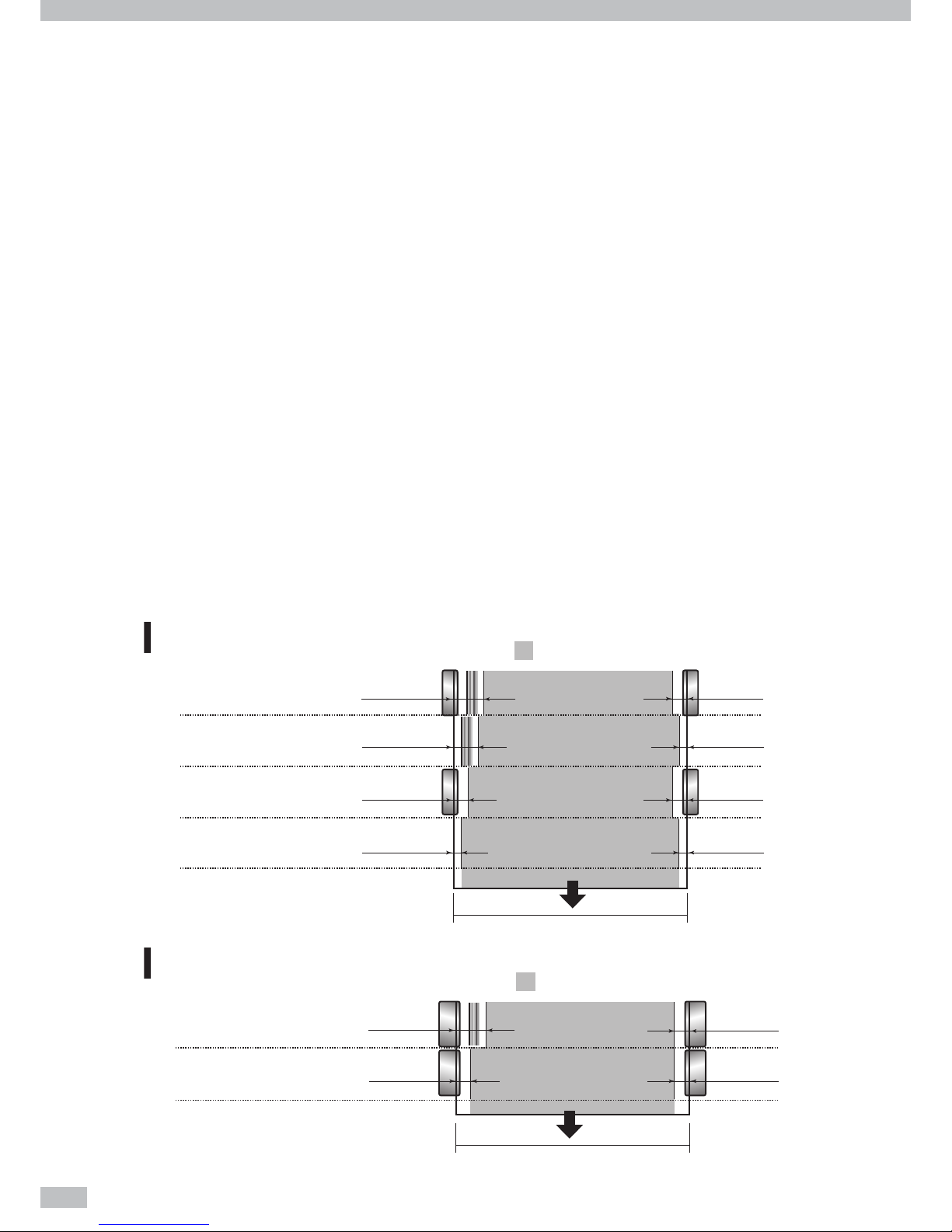

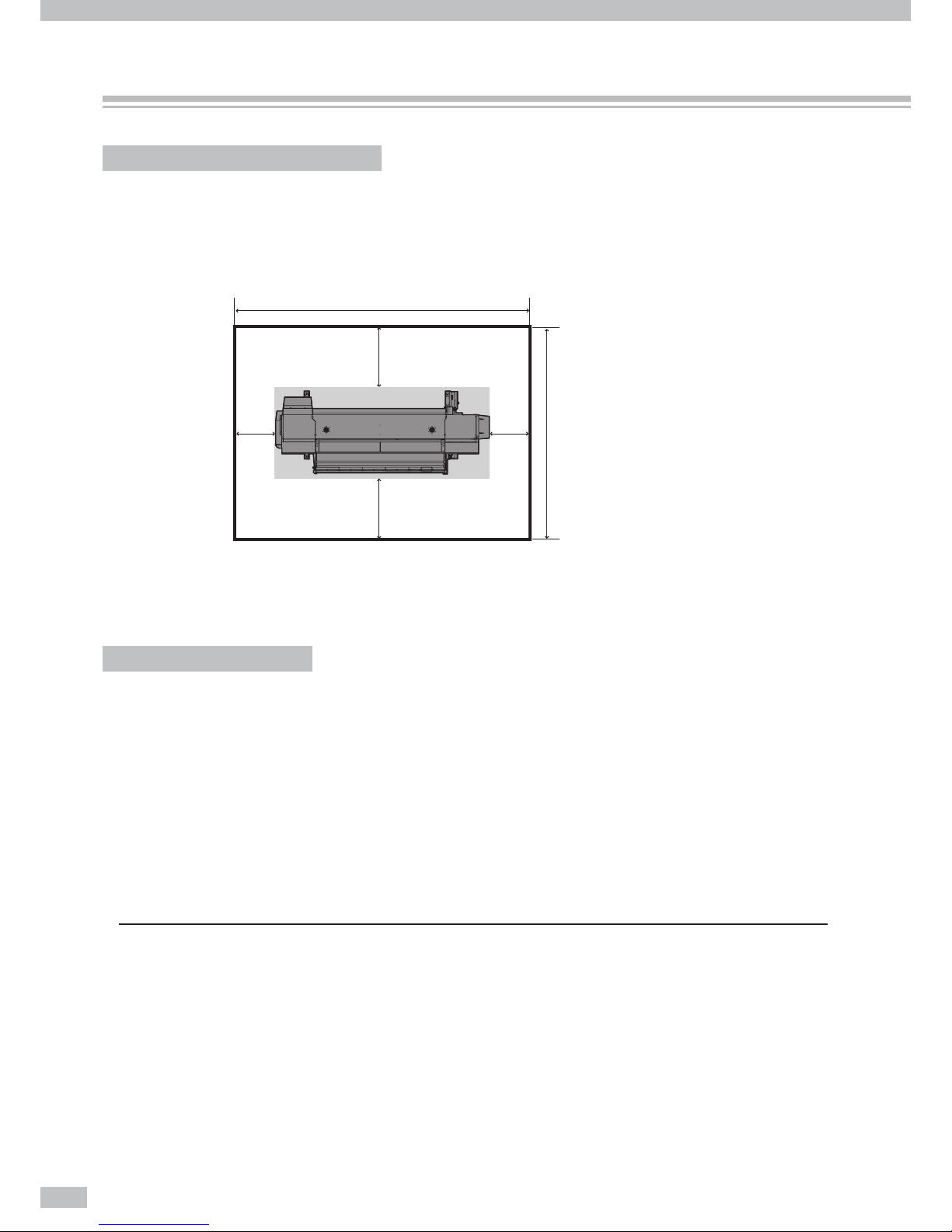

Available area on media

The available area on media in scanning direction depends on media width, media edge guards application,

and stripe bar presence. With the media edge guards and stripe bar applied, your available area is decreased by

34.9mm in right and 10.0mm in left. The available are is decreased more when the optional product below is

applied:

- Wide type media edge guards for platen sheet

Media width

Media width

Printable area

Color stripe :YES

Printable area

Media edge guards :YES

Color stripe :NO

Media edge guards :YES

41.9mm

15.0mm 15.0mm

15.0mm

Without wide type media edge guards for platen

sheet

ޓ

With wide type media edge guards

34.9mm

29.9mm

10.0mm 10.0mm

10.0mm

5.0mm 5.0mm

5.0mm

Color stripe :YES

Media edge guards :YES

Color stripe :YES

Media edge guards :NO

Color stripe :NO

Media edge guards :YES

Color stripe :NO

Media edge guards :NO

Page 15

15

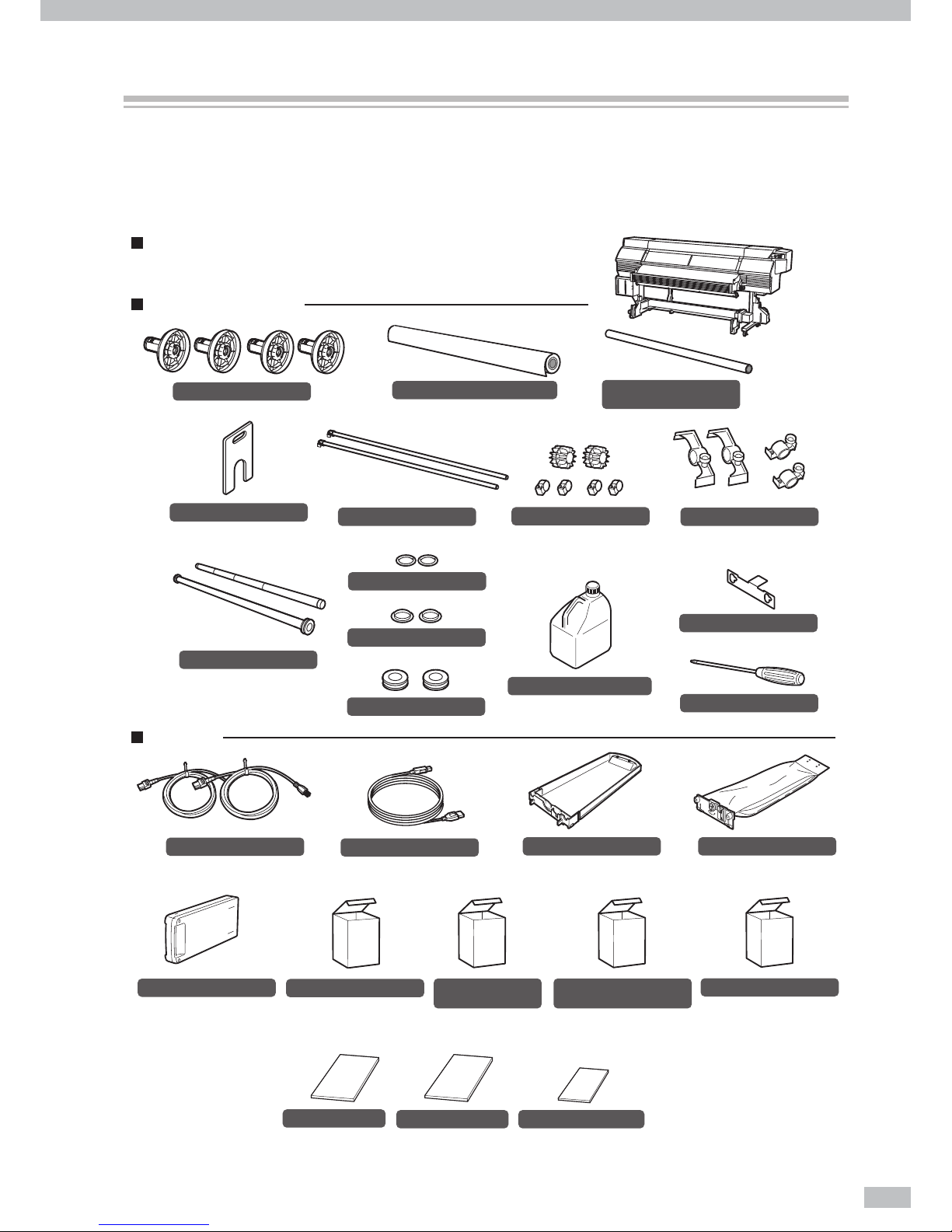

The following components are delivered with the Printer, and installed to the Printer at the Printer installation,

check that all the components below are delivered.

If any item is missing or damaged, contact Océ from whom you purchased the Printer or the nearest service

depot.

(Supply side) (Take up side)

Scloller flange

<4 pieces>

Flange spacer

<1 piece>

Flange holder

<1 piece>

Tension bar

(with ange: 1 piece)

(with no ange S: 2, ML: 1, L: 1)

<2 pieces>

Tension bar flange

<2 pieces>

Fixing ring

<2 pieces>

Tension bar flange with screw

<1 set>

Waste ink bottle IP6-109

<1 bottle>

Power cable

<2 pieces>

Subcartridge

<8 pieces>

Basic Operation Guide

(this guide)

<1 volume>

Advanced Operation Guide

<1 volume>

Quick reference guide

<1 volume>

Spittoon absorber

liquid

29953844

<1 set>

Spittoon absorber liquid(100 ml) : 3 bottles

Daily maintenance kit

29953842

<1 set>

• Cap cleaning liquid : 300 ml

• Wiper cleaning liquid : 200 ml

• Spittoon absorber liquid : 100 ml

• Cleaning roller : 30 pieces

• Cleaning swab : 10 pieces

• Dripper : 10 pieces

• Tweezers : 1 piece

• Cleaning stick : 1 piece

• Spittoon case : 1 piece

• Gloves : 30 pairs

• Bag : 1 piece

* Subcartridge consists of the colors below.

(1) Y, M, C, K, Lm, Lc, Gy, and Lgy (1pc for each)

for 8-color mode

(2) Y, M, C, and K (2pcs for each) for 4-color mode

<1 unit>

- with USB interface

- with the feed unit and take-up reel unit

Wiper cleaning liquid

purging set

(Required at the Printer relocation.)

Wiper cleaning liquid set

29953843

<1 set>

Wiper cleaning liquid (200 ml) : 3 bottles

USB 2.0 cable

<1 piece>

Ink tray

29951292

<8 pieces>

Dummy pack

<8 pieces>

Roll spacer

<2 pieces>

(with four xtures)

Scloller shaft

<2 pieces>

Flange shaft fixture

- Supply side <2 pieces>

- Take up side <2 pieces>

<4 pieces>

Phillips screwdriver

Roll media (for adjustment)

<1piece>

64-inch paper tube

(for take-up reel unit)

<1 piece>

Printer

Items packed with printer

Accessories

Components delivered with this product

Page 16

Océ 6407 Basic Operation Guide

16

The notational rules such as marks, keys, LCD, and LEDs used for explanation in this guide are as follows:

Marks

WARNING

- Boxes marked with a "WARNING" describe points of caution for avoiding serious personal

injury.

CAUTION

- Boxes marked with a "CAUTION" describe points of caution for avoiding injury to yourself

or damage to the Printer.

TIP:

- This mark o ers you the information to facilitate

the Printer operation.

Reference mark

This mark is followed by a reference section or page number.

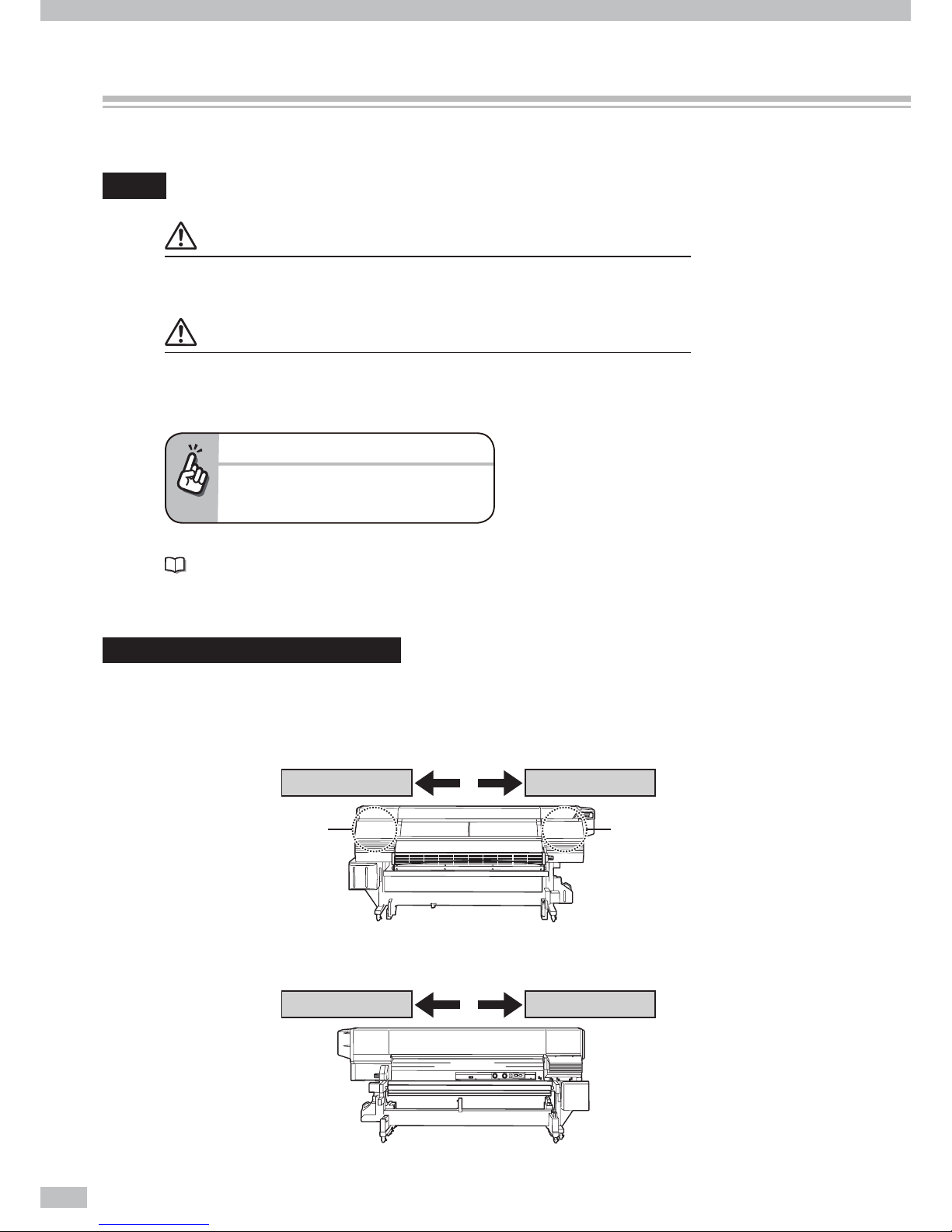

Capping unit side and wiping unit side

To identify the Printer’s right and left, this guide mentions the capping unit side and wiping unit side as follows.

Viewed from the Printer’s front (media teke-up side)

Viewed from the Printer’s rear (media supply side)

Capping unit sideWiping unit side

Capping unit side Wiping unit side

Capping unit is equipped.

Wiping unit is equipped.

Manual legend (Notational rules)

Page 17

17

This is the example page for the operation guidance.

INK MEDIA REG

MEDIA M.ADV

Operation Guide’s quick index

The quick index on the right edge is a

shortcut for users to access the target page.

Shows the LCD on the operation panel.

Shows that the LCD menu automatically

changes in the arrow direction without key

operation.

Shows that the LCD menu changes

in the arrow direction with key operation.

Page 18

Océ 6407 Basic Operation Guide

18

Installation and maintenance space

Adequate space is required around the Printer for supplies replacement of consumables and parts, print

processing, and ventilation during normal operation and maintenance.

Keep the space shown in the gure below.

4183mmormore

400

1000

1000

3275mmormore

(Front side)

400

Secure 2200 mm in horizontal direction.

(Unit: mm)

Environmental conditions

Operating temperature and humidity levels

Use the Printer within the temperature and humidity levels shown below.

Temperature: 15°C to 30°C (60°F to 80°F)

Humidity: 30% to 70%

To obtain better print quality, use the Printer within a temperature range of 20 to 25°C (68 to 77°F).

To ensure a stable and good print quality, the Printer slows down the print speed when the head

temperature exceeds 40°C (104°F).

NOTE

- If the Printer is not used at the operating temperature and humidity ranges, the print may be stopped or the print quality may be

degraded.

- It takes time for the Printer to reach the operating environment temperature and humidity.

- To ensure good print image quality, it is recommended to keep the room temperature 20 to 25°C, 68 to 77°F and use the Printer

after 1 hour.

Operating conditions

Page 19

19

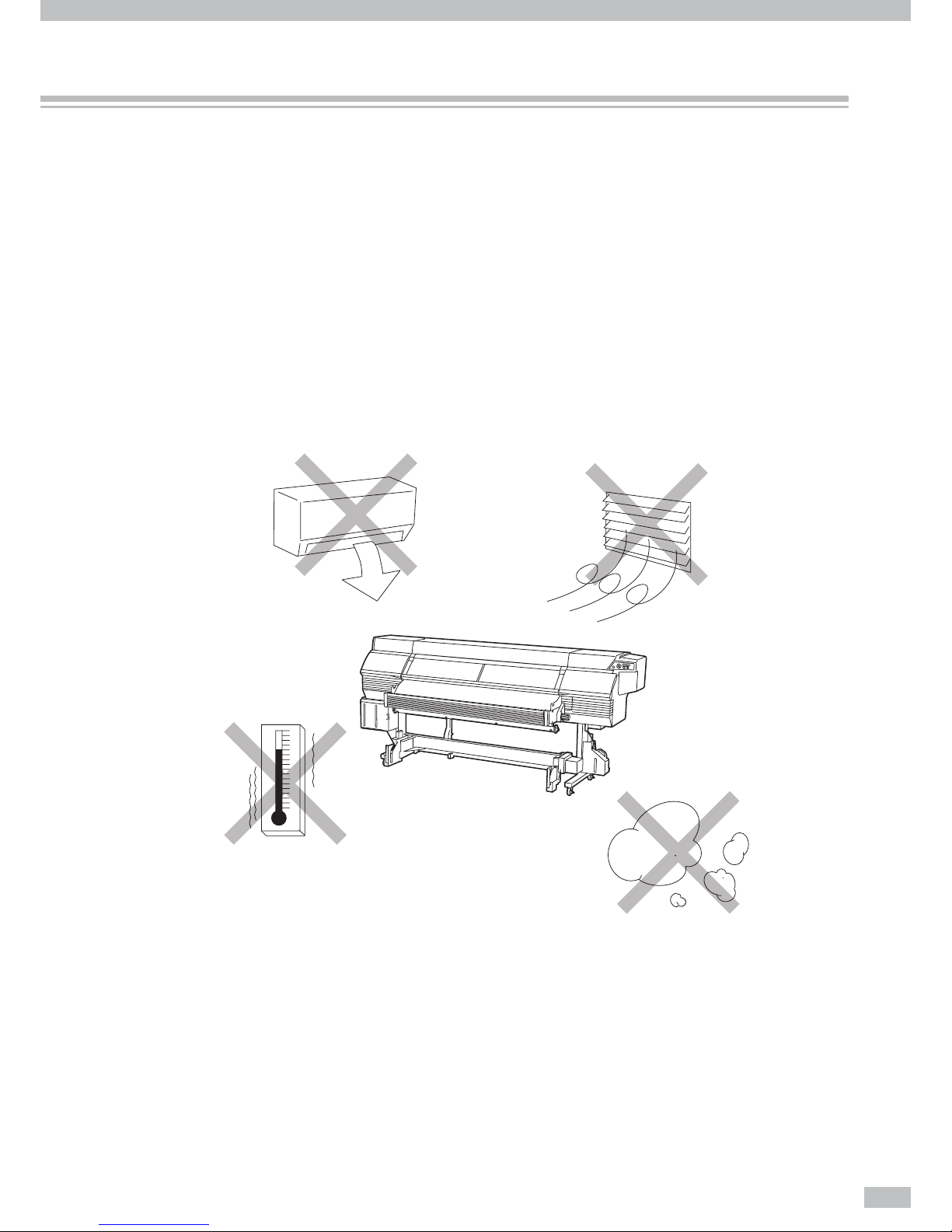

Places where the Printer must not be installed

Do not install the Printer in the following places.

Places near re

Places exposed to direct sunlight

Places subject to vibration

Places with excessive dust

Places subject to extreme changes in temperature or humidity

Places near an air conditioner or a heater

Places where the Printer may get wet

Places exposed to direct exhaust air from an air vent

Places near a diazo copier that may generate ammonia gas

Places with poor ventilation

Unstable places

Page 20

Océ 6407 Basic Operation Guide

20

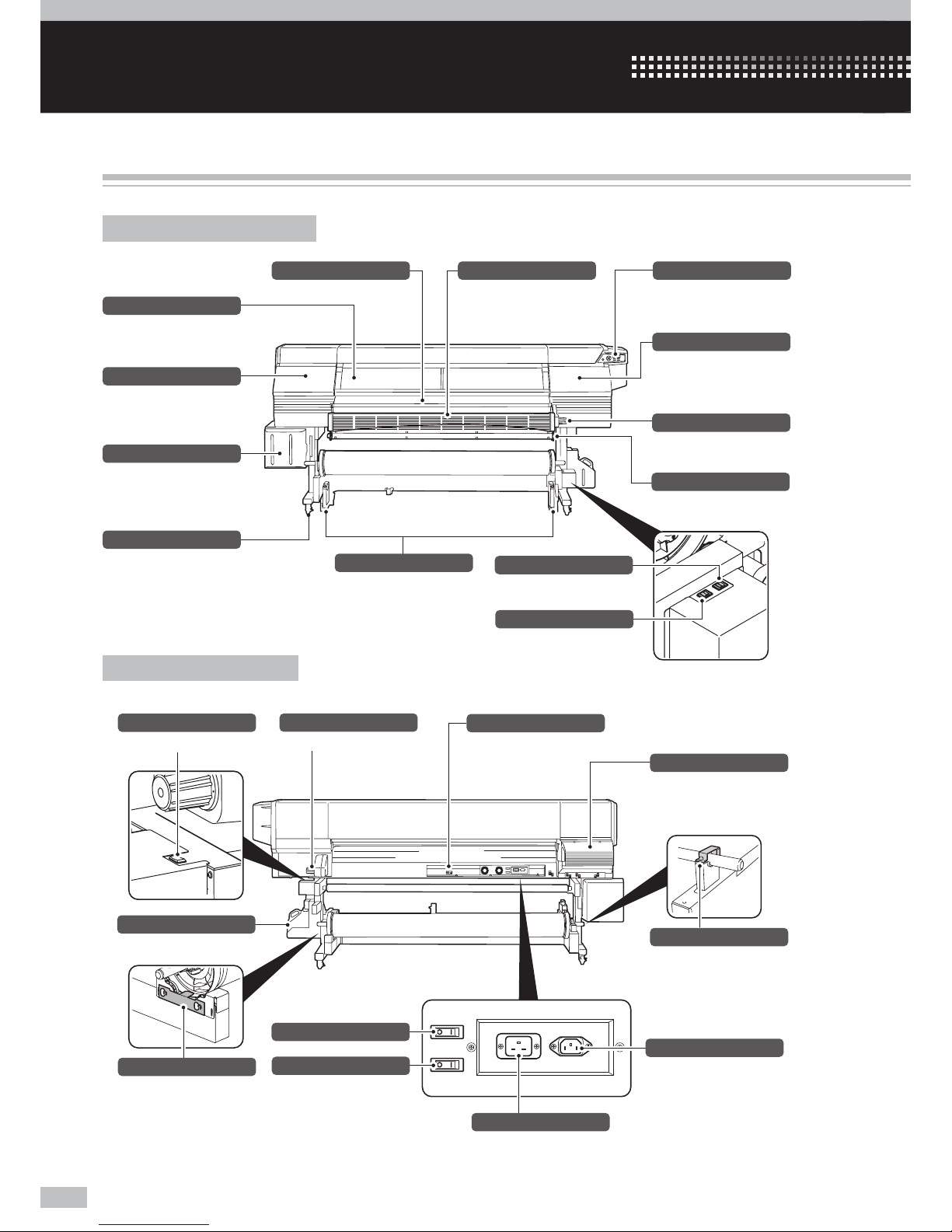

Appearance / Main components and their functions

Printer front (take-up side)

Operation panel

Provided with LEDS and LCD to

display printer status and keys to

set functions.

Media drying fan

Equipped to dry ink after printing.

Pressure control knob

Switches the media pressure force.

Take-up direction switch

Selects a media take-up direction.

Media advance/rewind switch

Advances or rewinds media.

Media advance/rewind switch

Advances or rewinds media.

Flange holder

Holds the scroller ange so that

the scroller ange would not lifted

during the print.

Shaft holder

Holds the scroller shaft so that the

scroller shaft would not be lifted

during the print.

Subcartridge cover

Covers the subcartridge insertion

slots.

On the LCD, subcartridge is

displayed as subtank.

Waste ink bottle unit

Contains a waste ink bottle

Capping cover

Opened when cleaning the

capping unit or the carriage.

Wiping cover

Opened when replacing the wiper

blade.

Protection bar

Placed to protect media surface

just after the print.

Front cover

Must be closed during printing.

Caster

Unlocked to move the Printer and

locked to immobilize it.

Tension bar guide

Applies tension to the media.

Tension bar

Placed to apply a proper tension to

media.

Printer power inlet

Printer power switch

Heater power inlet

Heater power switch

USB connector

Connected to the printer server.

Pressure control knob

Switches the media pressure force.

Ink box cover

An inlet to set ink (Note: Displayed

as “INK COVER” on the LCD.)

Printer rear (supply side)

Introduction

Page 21

21

Introduction For your basic operation Maintenance When encountering a problem Appendix

Appearance / Main components and their functions / Online and o ine / Supported media

Printer interior

Printer front (take-up side)

Printer rear (supply side)

Stopper

CAUTION

Be sure to unlock the stopper before closing the wiping

cover and capping cover.

Wiping unit

Removes foreign substances on

the print head’s nozzle surface.

Capping unit

Prevents the print head’s nozzles

from drying.

Spittoon case

For the stable printing, contains

the absorbers to hold excess ink

from print head.

Carriage

Houses the print heads inside, and

prints image with scanning media.

Ink tray

Supports ink pack setting.

Subcartridge

Provides with ink for printing while

ink pack is replaced.

On the LCD, Subcartridge is

displayed as subtank.

Media edge guard

Protects print heads from being

damaged by the curling or

feathering media edge.

Platen

Transports media.

The platen incorporates suction

fans and print heater to cure the

ink.

Page 22

Océ 6407 Basic Operation Guide

22

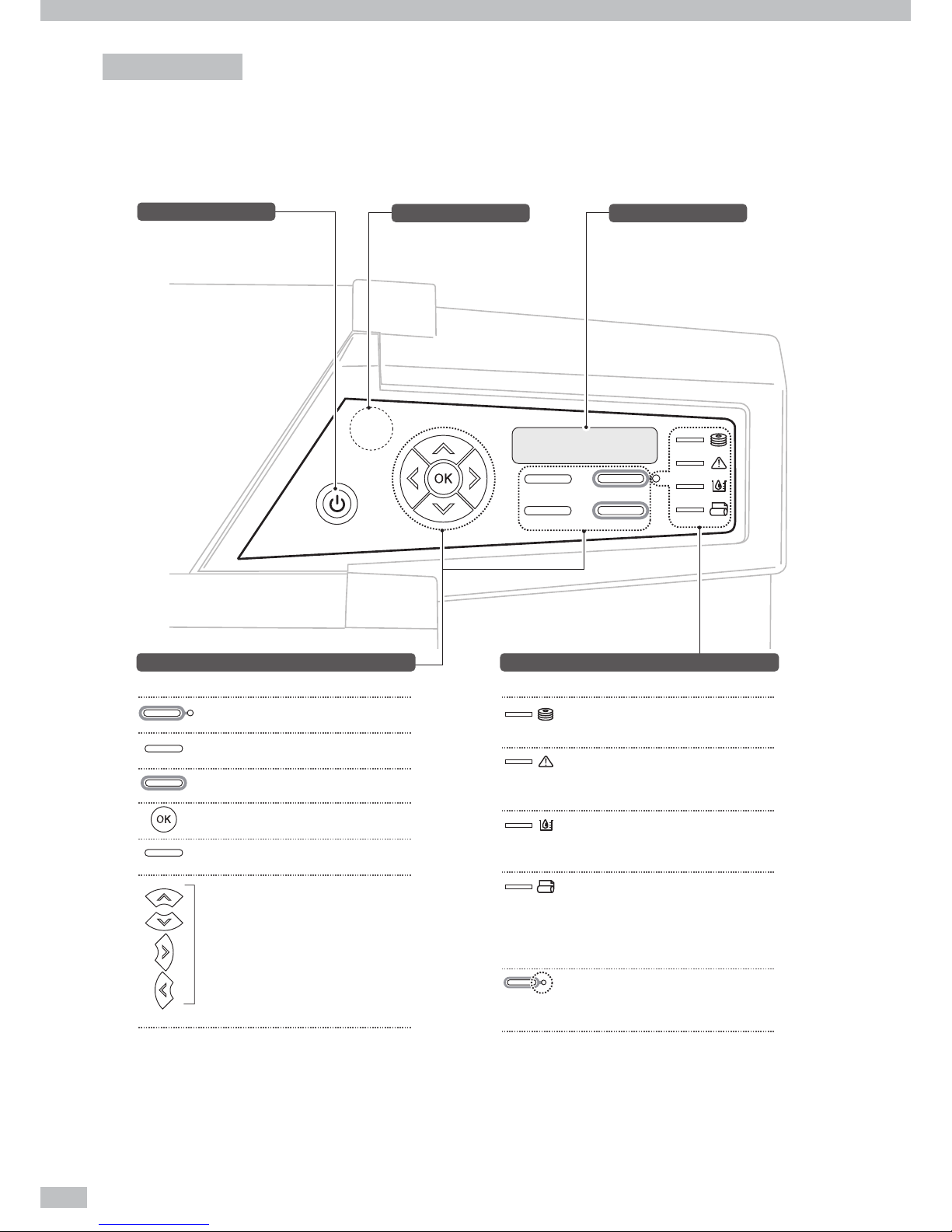

Operation panel

The keys, LEDs and LCD are laid on the Printer's operation panel of the Printer as shown below. In addition, the

operation panel is also equipped with a buzzer function for attention in case an error occurs or an invalid key is

input.

MENU

ONLINE

HEATER

CANCEL

ONLINE

HEATER

MENU

CANCEL

ONLINE

Power switch

Turns on or o the power of the

Printer.

LCD

Indicates printer status and menus.

Buzzer

Sounds when:

- An error occurred.

- Invalid key operation was made.

- The print head was not capped in

the daily maintenance.

LEDs

Indicates printer status with ON, OFF, and blinking.

Keys

Assists your menu operation and the Printer operation.

Data LED

(Green)

Error LED

(Orange)

Ink LED

(Green)

Media LED

(Green)

ONLINE LED

(Green)

Indicates data reception state.

Blink: Receiving data from the host computer.

OFF: No receiving data from the host computer.

Indicates whether an error has occurred.

ON: An error has occurred.

Blink: Warning state.

OFF: Normal (no error)

Indicates whether ink is remaining.

ON: Ink of all colors is present.

Blink: Ink near-end (Ink of any color is little.)

OFF: No ink.

Indicates whether media is remaining.

ON: Media is present (Either roll media or

cut-sheet media is loaded.)

Blink: Take-up reel unit's operation was

suspended.

OFF: No media (Neither roll media nor cut-sheet

media is loaded.)

Indicates online or offline state of the Printer.

ON: Online

Blink: Online pause mode

OFF: Offline

Selects online or offline of the Printer.

Switches between menu group screens, as

auxiliary parameter input.

Cancels entered parameters.

Determines the selected menu and parameters.

Enters heater control menu.

Selects a menu group and switches menu by

going up or down in a menu or option, or by

increasing or decreasing a value.

Page 23

23

Introduction For your basic operation Maintenance When encountering a problem Appendix

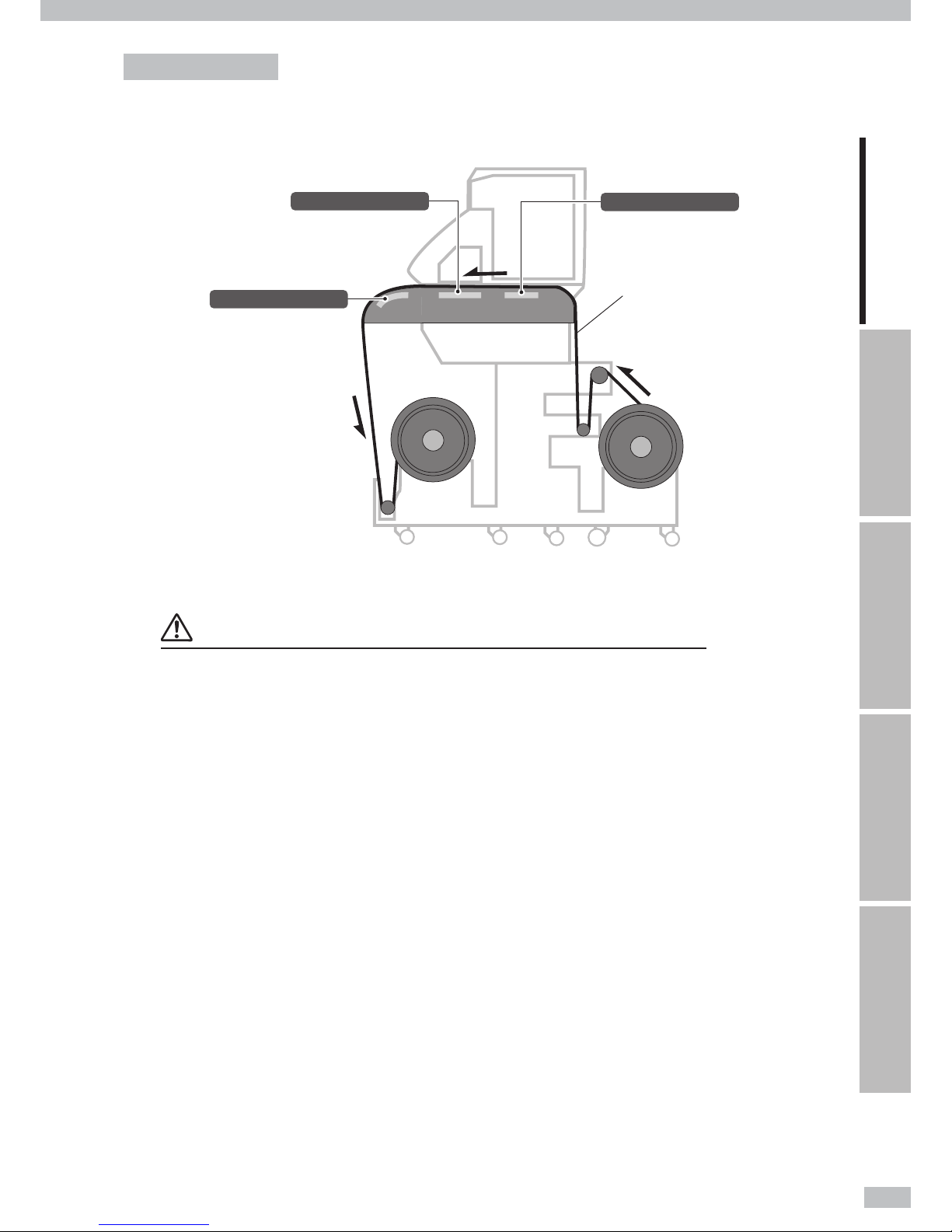

Printer heater unit

The printer is equipped with three heaters for ink fusing and image quality stabilization.

Preheater (rear)

Preheats media.

Media

Print heater (front)

Penetrates ink into media to fuse

the ink.

Afterheater (finishing)

Dries ink to stabilize print quality.

* These three heaters are controlled independently.

The temperature of each heater can be controlled from the operation panel and the host PC (RIP).

WARNING

- Do not touch these heaters to avoid burn as they become hot.

Page 24

Océ 6407 Basic Operation Guide

24

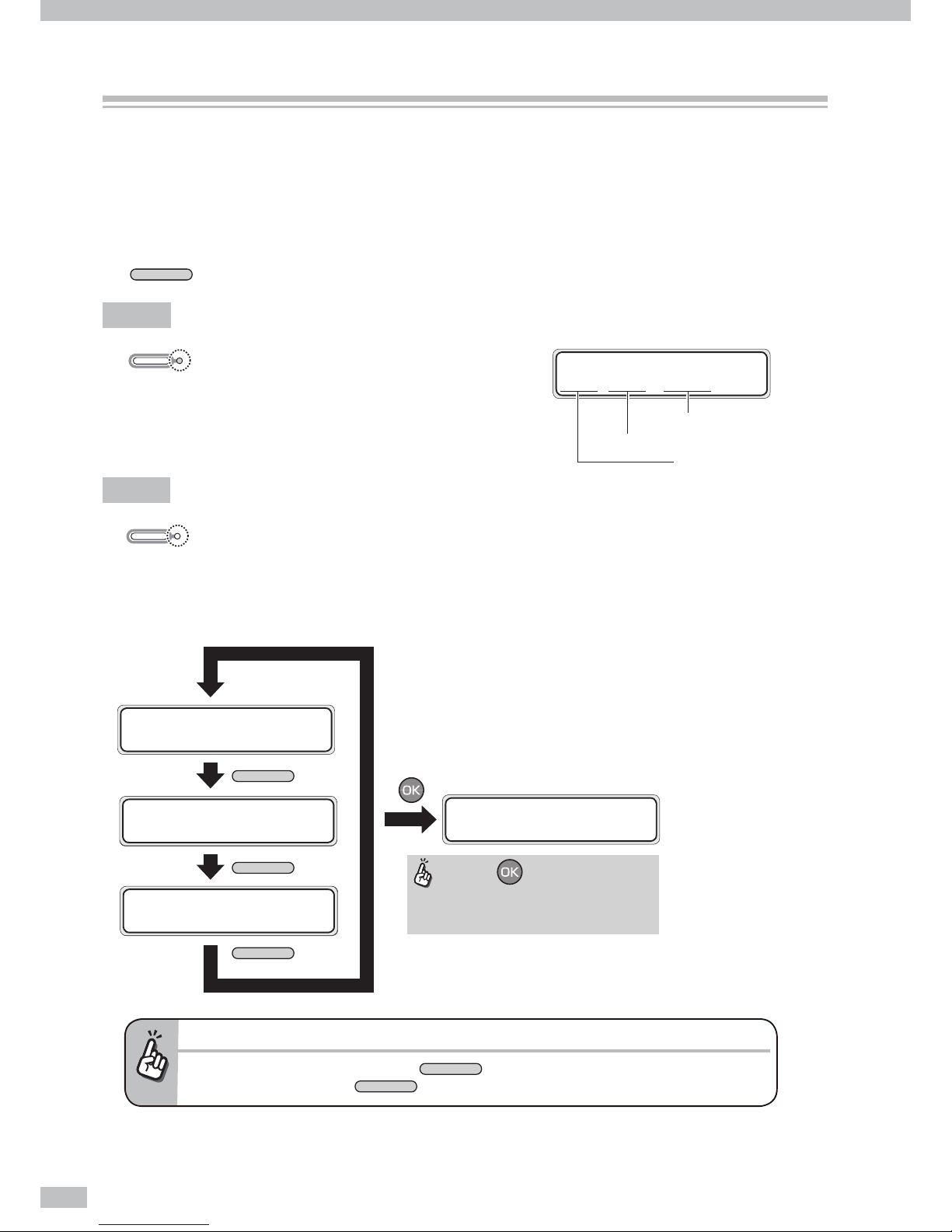

Online and o ine

The Printer operates in both online and o ine.

When the Printer is in online:

- The Printer prints the data sent from the computer’s Raster Image Process (RIP) software.

When the Printer is in o ine:

- The menu is operated with the operation panel keys.

The

ONLINE

key switches between online and o ine.

Online

When the online LED is on, the Printer is online.

O ine

When the online LED is o , the Printer is o ine.

The Printer in o ine displays the menu group on the LCD, and activates the menu operation.

The menu operation assists you to create new media presets, perform daily maintenance, and adjust the print

head settings.

When an operator call error is displayed...

- To activate the menu operation, press the

ONLINE

key.

* However, in some cases the

ONLINE

key does not activate the menu operation.

ONLINE

ON

ONLINE

OFF

MENU

MENU

MENU

When the key is pressed in any

menu group, the PH.REC MENU screen

opens.

INK MEDIA REG

MEDIA M.ADV

ハ゛ックフーィト゛ フィート゛

クリーニンク゛ サーヒ゛ス

ファンクション システム

メカチョウセイ ヒータ

REWIND FORM FEED

PH.REC PH.MAIN

PRINTER SETUP

ADJUST HEATER

#PH RECOVERY

>NORMAL

Online state (idle mode) display

Media name:PAPER

Media of 1625 mm (64 inches) width

Roll media is set

PRINTER READY

ROLL: 1625 / PAPER

Page 25

25

Introduction For your basic operation Maintenance When encountering a problem Appendix

Vinyl

Vinyl is media with PVC-material surface. As a general vinyl is adhesive-backed, by peeling the release paper on

the back you can stick the media easily. Depending on its gloss grade, the vinyl is classi ed into three: glossy vinyl

(with high gloss), matte vinyl (with no gloss), and semi-glossy vinyl (with medium gloss).

When the media is applied on some prints, a gray adhesive-backed vinyl is e ective to avoid the prints seen

through the top media.

For backlit purpose application, the PVC material surface is sometimes transparent or translucent.

Banner

Banner is polyester ber cloth media with double sides coated with synthetic resin lm such as PVC. As the

banner is water- and tear-resistant, it is applied for tent canvases, construction wrap sheets, and inkjet-printed

banner advertisements.

Depending on its gloss grade, the banner is classi ed into three: glossy banner (with high gloss), matte banner

(with no gloss), and semi-glossy banner (with medium gloss).

Mesh banner

Mesh banner is perforated banner media reinforced with mesh grid. As its open structure allows wind to

permeate, the mesh banner is wind- and tear-resistant, and will withstand heavy wind.

Backlit banner (FF)

Backlit banner, exible face (FF) is translucent, that is, semi-transparent banner media. With its translucency, it is

applied to the backlit sign inside a light box.

Compared with an acrylic sign, the backlit banner is lightweight and easy to handle, wind- and tear-resistant, and

of high safety and shutter proof withstanding wind pressure.

Solvent printing coated paper

Solvent printing coated paper is media with the printing surface coated on which solvent ink is cured vividly. Its

thickness depends on the product type.

When the media is applied on some prints, a blue back type is e ective to avoid the prints seen through the top

media.

Visit Océ on the internet at http://mediaguide.oce.com for the latest information.

Supported media

Page 26

Océ 6407 Basic Operation Guide

26

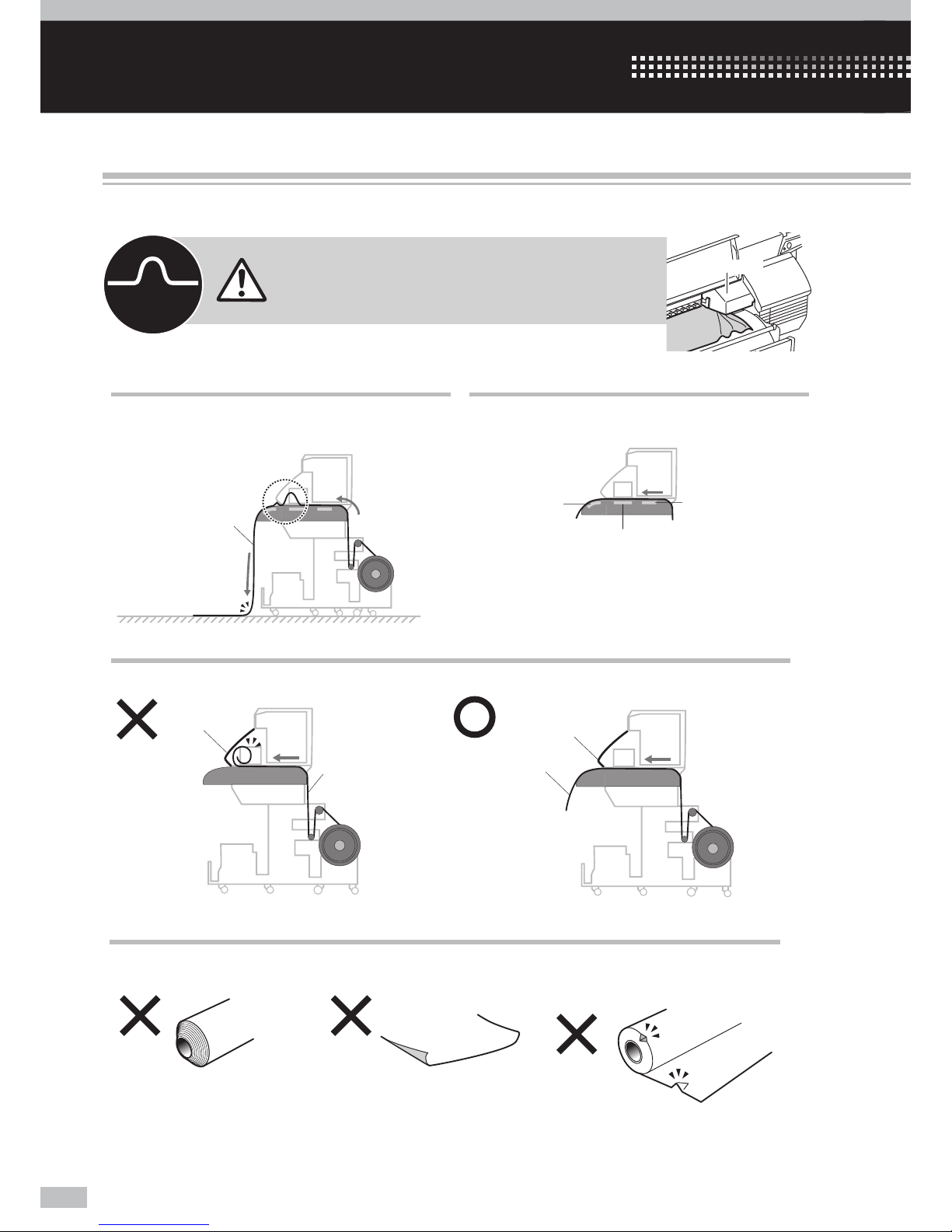

For your basic operation

Note that the media on the platen may bunch up

when the front media edge reaches the oor.

To avoid media wrinkle, turn o the preheater and

printheater.

At printing on paper-based media

At setting media

At printing without winding

If media waves, the sliding carriage may touch the

wave, which may damage the Printer.

Media bunches up.

Media

Media

wave

Carriage

Printheater

Preheater

OFF

OFF

Afterheater

Set the media so that the front media edge precedes the front cover.

Media

Front cover

Front cover

Media

OKNG

At visually checking media

Avoid using the media below.

The media was wound telescopically.

The right or left media edge curls. The media edge is deformed by, for

example, hitting media

NG NG

NG

Precautions to prevent media jams

The precautions below are recommended to prevent the main causes of media jams: media wave and skew.

Page 27

27

Introduction For your basic operation Maintenance When encountering a problem Appendix

Precautions to prevent media jams / Basic operation for printing / Procedure to remove media roll from the Printer / To print

on other media / To perform double-sided printing

At the both media supply side and media take-up side,

without a ange spacer, x the scroller ange to the

media by pressing it as far as it goes.

At taking up media in LOOSE winding mode

Set the tension bar at the media center.

If the media is not perpendicular to the paper tube, the media is taken up with skew, which may cause the

media wave on the platen.

At attaching media to the take-up paper tube,

Be sure to set the media perpendicular to the take-up paper tube.

Media

Tension bar

Paper tube

Tape

Perpendicular

Perpendicular

Paper tube

Tape

Paper tube

Tape

Paper tube

Tape

Media

Tension bar

Skew

OK

NG

OK

NG

At xing media to the take-up paper tube,

Stick the adhesive tape from center outward.

垂直

OK

NG

④②①

The tape is stuck from center outward.

The

media

slacks

③⑤

垂直

①②③

The tape is stuck from media edge.

④⑤

If media skews, the media edge is disengaged

from the media edge guard, which may cause

the media wave.

Media edge guard

Media

[Viewed from top]

Media

Media

Media

Media

The media is

tightened.

Flange spacer

Page 28

Océ 6407 Basic Operation Guide

28

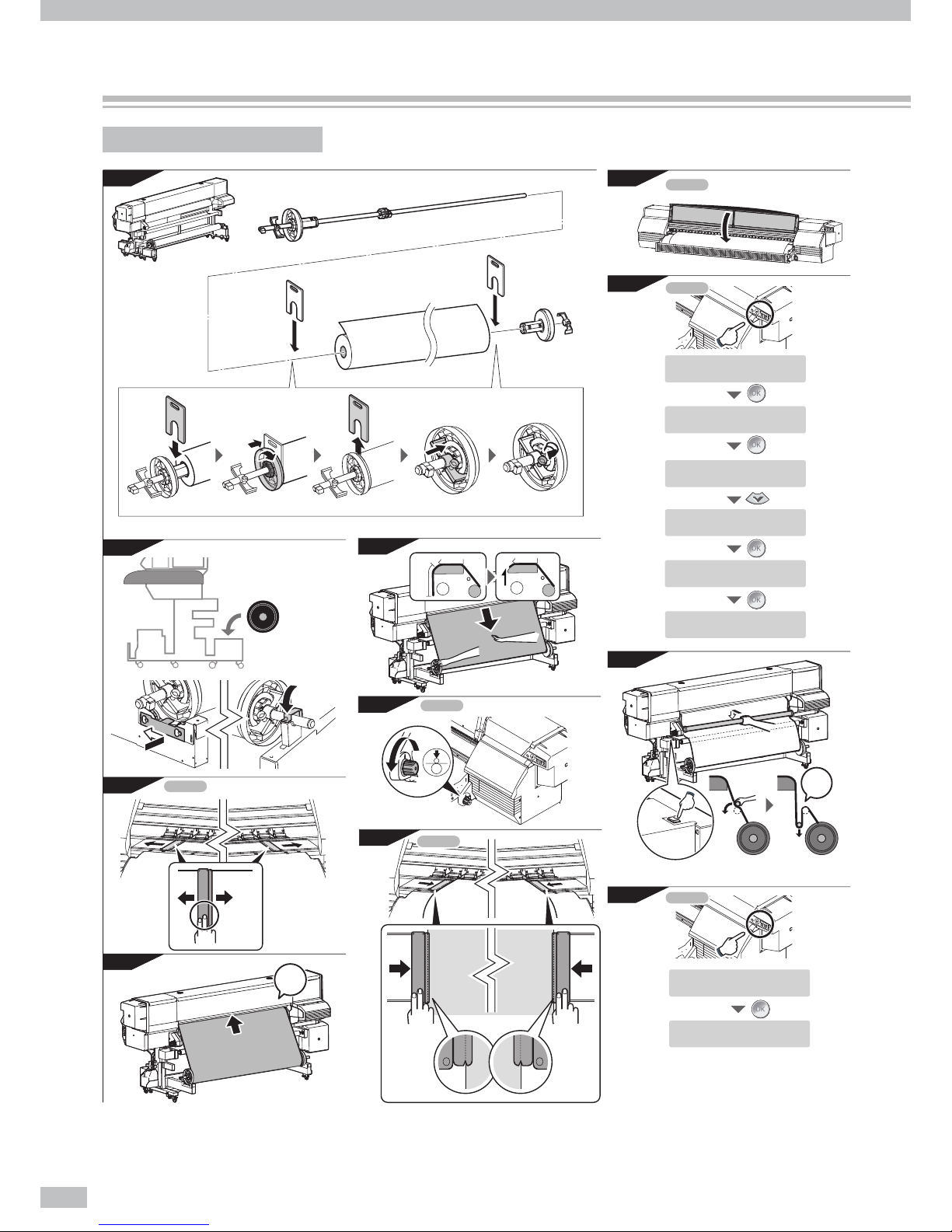

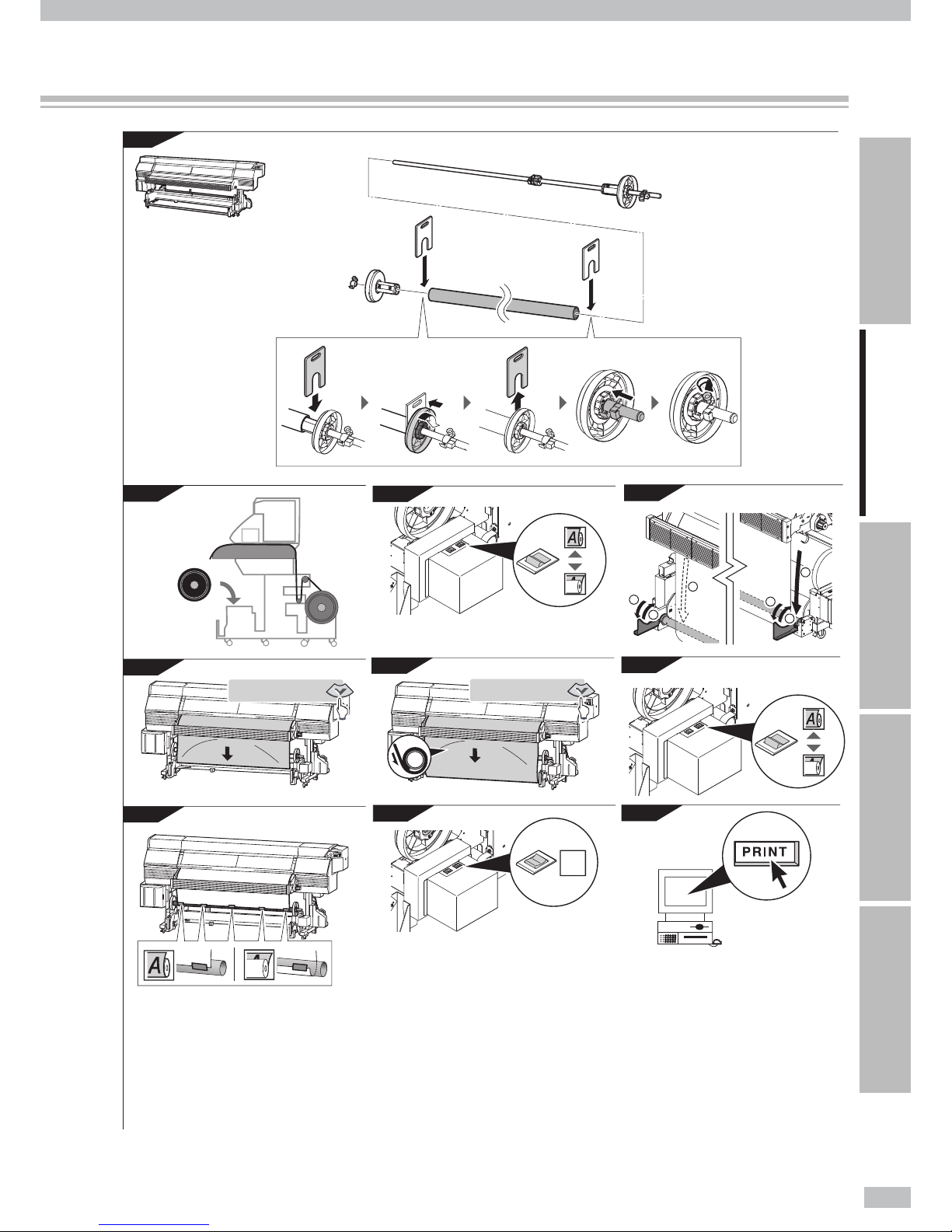

Basic operation for printing

Printing work ow overview

2

3

6

10

11

5

7

8

9

4

FRONT

REAR

REAR

REAR

1

1m

♪

FRONT

FRONT

FRONT

FRONT

FRONT

FRONT

CHECKEDGEGUARD

*O K ?

SELECTMEDIA

ROLL/SHEET:ROLL

…

SELECTMEDIA

MEDIA:Banner

SELECTMEDIA

MEDIA:PAPER

SETREMAININGMEDIA

****m

CHECK

SLACKENMEDIA

Blip

Blip

Feedmediafor

1m

moreaftertheblip.

♪

SETMEDIA

*O K ?

PREPARINGMEDIA

PLEASEWAIT

Page 29

29

Introduction For your basic operation Maintenance When encountering a problem Appendix

1

9

10

8

7

3

2

4

5

6

1

3

3

1

2

2

FRONT

FRONT

FRONT

FEEDINGMEDIA

FEEDINGMEDIA

OFF

Page 30

Océ 6407 Basic Operation Guide

30

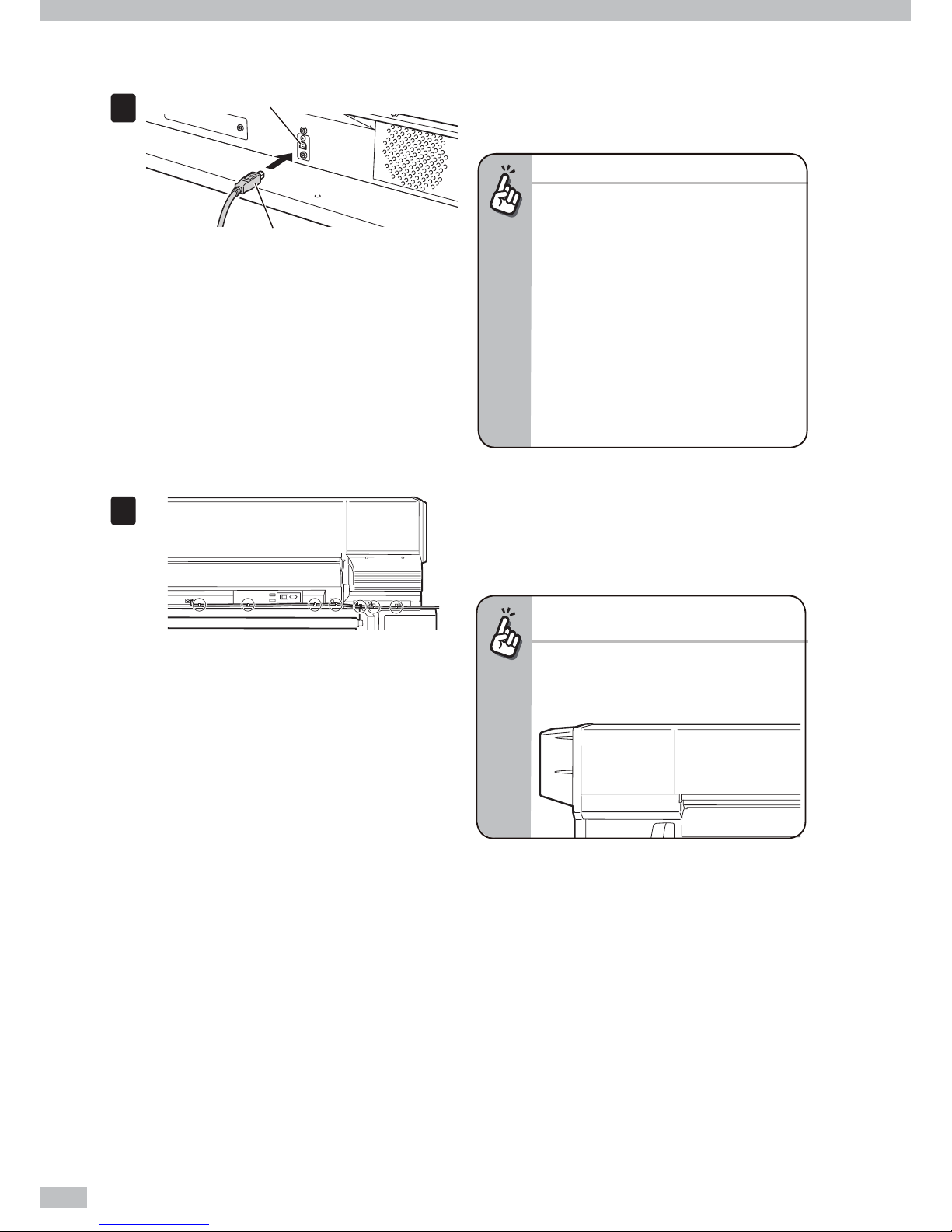

To connect USB cable.

1

USB connector

USB 2.0 cable (B-type connector)

Connect the Printer’s USB 2.0 cable to the USB

connector at the rear center of the Printer.

Important!

- Use the supplied USB 2.0 cable.

- For the USB connection and the related

system, use the USB-compliant hubs and

cables supporting USB 2.0. Note that a normal

operation may not be ensured if the habs,

cables, and the other related devices are not

USB-compliant.

- Use 5m cable or shorter. If the connection

length exceeds 5m, apply hubs to extend the

connection. The hub quantity must be ve

or less in total. Note that a normal operation

may not be ensured if a cable exceeding 5m is

applied, or if the cable connection exceeds 5m

without hubs.

2

Clamp the USB 2.0 cable to the Printer along

the wiping unit direction.

To protect the USB connector, clamp the USB 2.0 cable

to the Printer body as shown in the left gure.

To extend the cable along the capping unit

direction...

- As the gure below shows, x the cable at

some positions with adhesive tape. If the USB

cable is not clamped, the media feed sensor

may operate incorrectly.

Page 31

31

Introduction For your basic operation Maintenance When encountering a problem Appendix

Turn the Printer on.

With the procedure below, supply the power to the Printer’s two 200V power system.

CAUTION

- Do not use any power cable other than those supplied with the Printer.

- The supplied power cables are for 200 VAC only. Note that the plug shape di ers from that for 100 VAC.

- Be sure to secure the power cables with cable clamps. Otherwise, they may be caught by the feed unit resulting in

electric shock or damage to the Printer.

Turn the printer power and heater power switches on only before your rst operation. From the next operation, turn the

Printer on and o only by pressing the POWER switch on the operation panel.

1

Switch o (O) Power inlet

With the two power cords supplied with the

Printer, connect the Printer’s two power inlets

and the power supply’s two sockets.

Be sure to con rm that at the rear of the Printer the

printer power switch and heater power switch are set

to o , the side marked with O.

2

Clamp the two power cords to the Printer.

To protect the power cords, be sure to clamp them.

Printer power switch + Printer power inlet

Heater power switch + Heater power inlet

Supply side

Page 32

Océ 6407 Basic Operation Guide

32

3

Switch on (I)

Set the printer power switch and heater power

switch to on, the side marked with I.

4

MENU ONLINE

HEATER CANCEL

Power ON/OFF switch

Booting up...

INITIALIZING...

PLEASE WAIT

LOAD MEDIA

Press the power switch on the operation panel.

When the power switch is turned on, the Printer

performs the power-on self-diagnostic test and

displays the following message on the operation

panel.

If an error message appears...

- To recover the error, refer to “When

encountering a problem.”

- If the POWER LED on the operation panel does

not light even when the printer and heater

power switches at the rear of the Printer and

the power ON/OFF switch on the operation

panel are turned on, the power supply has a

problem.

CAUTION

Except for emergency, turn o the power while a message "PRINTER READY" is displayed. If the power is turned o

unnecessarily when the Printer is performing "INITIALIZING..."or "CLEANING," the ink may drool, the print head may be

damaged, or saved parameters may be lost.

To load media on the Printer

This section uses banner to explain the media loading procedure.

1

Put the media on the table.

Page 33

33

Introduction For your basic operation Maintenance When encountering a problem Appendix

2

Load a roll media onto the scroller ange and scroller shaft.

Check the flange

spacer’s correct position.

(3) Remove the ange spacer.

(2) Push the scroller ange until it

stops and turn the handle

clockwise until the ange is

xed to the paper tube.

(5) Cover the scroller ange’s

convex part with the ange shaft

xture, and push the ange shaft

xture as far as it goes.

(5) Turn the knob to x the scroller

shaft.

(1) Insert the ange spacer

between the scroller ange and

the media roll.

The ange spacer should

be inserted to the

position indicated by the

line B.

Be careful not to deform

it by applying too much

force.

Handle

Flange shaft fixture

Flange shaft fixture

Convex part

Flange shaft fixture

Flange shaft fixture

Fixture

A

B

Move the roll spacer to the media center, and fasten

the fixtures at the roll spacer’s both sides.

Pass the scroller shaft through the roll spacer with fixtures at its

both sides, scroller flange, and flange shaft fixture.

The roll spacer prevents the

paper tube from bending at

the center due to the media

weight.

Scroller flange

Scroller flange

Scroller shaft

Scroller flange

Scroller flange

Scroller flange

Roll spacer

Roll spacer

Flange spacer

Flange spacer

Flange spacer

Not required in LOOSE

winding mode.

Not required in LOOSE

winding mode.

For outer take-up mode

For inner take-up mode

Roll media

Roll media

Page 34

Océ 6407 Basic Operation Guide

34

3

Capping unit side

Wiping unit side

Knob screw

Flange holder

Shaft holder

Remove the ange holder, and open the shaft

holder.

To open the shaft holder, loosen the knob screw.

4

Printer rear

Load the media roll into the Printer’s rear side

(supply side).

CAUTION

- As the media is heavy, carefully carry it with a recommended dolly.

- On carrying the media with two persons, carefully carry it by manually holding the scroller shaft.

- Be careful not to catch your nger or hand between the Printer and the scroller shaft.

Recommended dolly

Scroller shaft

On carrying the media alone: On carrying the media manually by two persons:

5

Capping unit side

Wiping unit side

Knob screw

Flange holder Shaft holder

Set the ange holder, and close the shaft holder.

After closing the shaft holder, fasten the knob screw.

6

Front cover

Protection bar

Remove the protection bar and open the front

cover.

Page 35

35

Introduction For your basic operation Maintenance When encountering a problem Appendix

7

Wipingunitside

Cappingunitside

With pressing the media edge

guard’s your side part, move each

media edge guard.

Move the media edge guards to each side.

Move the media edge guards to each side so that they

are not under the media.

With pressing the media edge guard’s your side part,

move each media edge guard.

8

Take-up side

Pressure control knobs

Set the pressure to “Open” by rotating the

pressure control knob.

9

Paper feeder

Printer rear

Insert the media end into the paper feeder,

while smoothing out the media by hand to prevent

wrinkles.

If the media is curled

- If it is hard to insert the media end into the

paper feeder due to a curl of the media,

interpose an interleaf and insert the media

end under the interleaf as shown in the gure

below.

Interleaf

Interleaf

Media

Media

- Upward curl - Downward curl

10

Blip

Feed media for 1m more after the blip.

♪

Platen

Feed the media for 1m more after the blip.

In this state, smooth out the media toward the both

sides on the platen to make the media center tense.

Point to be checked

- If the media is set with a distortion or wrinkles,

it may cause a media jam or skew.

Page 36

Océ 6407 Basic Operation Guide

36

11

Feed back the media.

Feed back the media while pressing the center of the

media gently at the supply side.

Con rm that the front media edge precedes the

closed front cover by approx. 30 cm.

30cm

Front cover

Important!

- This step is important to set the media properly.

12

Supply side

Set the pressure to “Normal” by rotating the

pressure control knob counterclockwise.

Point to be checked again

- Check that the media on the platen has no

wave or wrinkle.

13

With pressing the media

edge guard’s your side part,

move each media edge

guard.

Align each media edge

guard’s notch to the media

edge.

(1) (2)

Notch

Set the media edge guards.

(1) With pressing the media edge guard’s your side part,

move each media edge guard to the media edge.

(2) Align each media edge guard’s notch to the media

edge.

Check that the media edge guards are not under the

media or thick media is not caught by having been

inserted forcibly.

CAUTION

- The print operation without media edge guards may

cause a media jam.

14

Close the front cover, and set the protection

bar.

15

CHECK EDGE GUARD

✻

OK?

Press the key.

Page 37

37

Introduction For your basic operation Maintenance When encountering a problem Appendix

16

SELECT MEDIA

ROLL/SHEET:ROLL

Press the key.

17

SELECT MEDIA

MEDIA:PAPER

• • •

SELECT MEDIA

MEDIA:Banner

Select [Banner] and press the key.

With the or keys, select a media preset for

the current media type.

18

SET REMAINING MEDIA

✻✻✻✻

m

CHECK

SLACKEN MEDIA

Enter the remaining media length and press the

key.

When you do not know the remaining media length,

press the key without entering the length.

19

Adjust the tension bar l ength.

To print in TENSION winding mode: Conform the tension bar length with the media width.

The table below lists the tension bar combination and the tension bar’s total length. Referring to the list, apply

the tension bar length nearest to the media width.

To print without winding: The table below lists the tension bar combination and the tension bar’s total length.

Referring to the list, apply the tension bar length nearest to the media width.

Tension bar length

16inches(41cm)

S

L

48inches(123cm)

16inches(41cm)

S

ML

26inches(66cm)

Examples of tension bar combinations

Applied size Tension bar's length

S 16 inch (41cm)

ML 26 inch (66cm)

S, S 32 inch (82cm)

ML, S 42 inch (107cm)

L 48 inch (123cm)

ML, S, S 58 inch (148cm)

L, S 64 inch (164cm)

L, ML 74 inch (189cm)

When the tension bar is almost same as the media width, or is slightly longer than the media width, set the

tension bar with screws to the tension bar.

Media

Tension bar

ange with

screw

Tension

bar ange

with screw

Tension bar

Page 38

Océ 6407 Basic Operation Guide

38

When the tension bar is clearly longer than the media width, set the tension bar anges and xing rings to the

tension bar.

Media

Tension bar ange

+

Fixing ring

Tension bar

Tension bar ange

+

Fixing ring

20

Create a slack area in the media.

♪

Blip

Media advance/rewind switch

Tension bar

Peel roller

(1) Press the tension bar to the peel roller’s

upper part.

(2) By pressing the media advance/rewind

switch, create a slack area in the media.

Then, with slightly pressing the tension bar

in the direction of the media rear side, install

the tension bar in the slack.

Slacken o to a level lower than the supply-side slack

sensor.

When the slack reaches the sensor detection area, the

operation panel blips.

Peel roller

Scroller ange

Supply-side slack sensor

CAUTION

- Do not rotate the peel roller, or the Printer may be

damaged.

- Be sure to rotate the peel roller with the media

advance/rewind switch.

21

SET MEDIA

✻

OK?

PREPARING MEDIA

PLEASE WAIT

Press the key.

Page 39

39

Introduction For your basic operation Maintenance When encountering a problem Appendix

To load media on the take-up reel unit

This section explains the procedure, taking in TENSION winding mode for instance.

1

Load a paper tube onto the scroller ange and scroller shaft.

(4) Push the ange shaft xture as far

as it goes.

Handle

Flange shaft fixture

Flange shaft fixture

Fixture

Move the roll spacer to the paper tube center, and

fasten the fixtures at the roll spacer’s both sides.

Pass the scroller shaft through the roll spacer with fixtures at its

both sides, scroller flange, and flange shaft fixture.

The roll spacer prevents the

paper tube from bending at

the center due to the media

weight.

Flange spacer

Flange spacer

(1) Insert the ange spacer

between the scroller ange and

the paper tube.

(2) Push the scroller ange until it

stops and turn the handle

clockwise until the ange is

xed to the paper tube.

(3) Remove the ange spacer.

(5) Turn the knob to x the scroller

shaft.

Check the flange

spacer’s correct position.

The ange spacer should

be inserted to the

position indicated by the

line B.

Be careful not to deform

it by applying too much

force.

A

B

Scroller flange

Flange spacer

Flange shaft fixture

NOTE:

- To wind the media in LOOSE

winding mode, without inserting

the ange spacer, push the scroller

ange as far as it goes.

Scroller flange

Scroller shaft

Roll spacer

Scroller flange

Roll spacer

Paper tube

Flange spacer

Not required in LOOSE

winding mode.

Not required in LOOSE

winding mode.

Page 40

Océ 6407 Basic Operation Guide

40

2

Take-up direction switch

OFF

OFF

Set the take-up direction switch to OFF.

CAUTION

- If the Printer processing proceeds to the next step with the take-up direction switch set to ON, your hand may be

caught as the scroller is not secured.

3

Tension bar hook

Tension bar

Hook the tension bar to the tension bar hook

beforehand.

4

Load the paper tube in the Printer.

5

By pressing the key, feed the media until

the front media edge is wound on the paper

tube.

FEEDING MEDIA

Page 41

41

Introduction For your basic operation Maintenance When encountering a problem Appendix

6

Tape

Paper tube

Attach the media passed through the Printer to

the paper tube.

(1) Check the take-up direction, remove the slack of the

media, and then make sure that the media position

is not deviated on the supply side and the take-up

side.

(2) Attach the media to the paper tube with adhesive

tape. Tape it rst at the center, and then at the right

and left sides, so that the tension is uniform across

the media width and that no wrinkles are found on

the media. The taped positions are recommended to

be three or more in total.

Inner take-up:

Media is taken up with its print

surface coming inside.

Outer take-up:

Media is taken up with its print

surface coming outside.

Points to be noted on winding media

- If the media is not installed straight to the paper tube, a skew of media may occur.

- When the take-up direction is set as Inner take-up, the taken-up media's diameter increases and the media

cannot backfeed after printing. Select [FWD ONLY] beforehand in MEDIA BACK MODE of MEDIA REG MENU.

(When the media backfeeds in [BACK&FWD] mode, the motor idles and may cause a trouble.)

7

Take-up direction switch

OFF

u Outer take-up

- OFF

v Inner take-up

Set the take-up direction switch according to

the take-up direction.

8

By pressing the key feed the media, and

wind one full turn of the media on the paper

tube.

FEEDING MEDIA

CAUTION

- If the tension bar is attached without winding the

media by one turn, the tape will peel o .

9

Take-up direction switch

OFF

OFF

Again set the take-up direction switch to OFF.

Page 42

Océ 6407 Basic Operation Guide

42

10

Press the key to feed enough media to

create a slack.

FEEDING MEDIA

Be sure to create a su cient slack so that you can

install the tension bar at the bottom of the tension bar

guide.

11

Open the tension bar guide’s cover.

12

Place the tension bar at the bottom of the

tension bar guide.

When the tension bar does not reach the

tension bar guide’s bottom

- When the tension bar does not reach the

tension bar guide’s bottom, feed the media

with the operation panel’s FEED menu. Con rm

that tension bar was placed securely at the

tension bar guide’s bottom.

13

Close the tension bar guide’s cover.

When the excessive media slack is created

- If the media slack is secured excessively, the

take-up reel unit may keep winding the media

for more than the prescribed time, and a takeup timeout error occurs. In such a case, turn o

the take-up direction switch, and then press the

switch again.

14

Take-up direction switch

OFF

u Outer take-up

- OFF

v Inner take-up

Set the take-up direction switch according to

the take-up direction.

15

Input the data in the RIP software.

Page 43

43

Introduction For your basic operation Maintenance When encountering a problem Appendix

Procedure to remove media roll from the Printer

Media at take-up side

1

Take-up direction switch

OFF

OFF

Turn o the take-up direction switch.

2

Open the tension bar guide’s cover.

3

Place the take-up side tension bar at the

tension bar hook.

4

Cutter groove

Open the front cover, and then cut the media.

You are recommended to cut the media by setting the

cutter blade along the cutter groove.

Platen

Cutter

Cutter groove

Sponge

Cutter guide

Media

CAUTION

- A net is spread out on the supply side and take-up side paper guides respectively, so that the media will not adhere to

the guides. Do not remove these nets.

- When cutting the media, be careful not to damage the paper guide net.

- Pay attention not to drop the printed media to avoid smearing the media.

Page 44

Océ 6407 Basic Operation Guide

44

5

CLOSE

COVER

ONLINE

Set the Printer to o ine state by pressing the

ONLINE

key.

6

Ç

INK MEDIA REGÈ

Å

MEDIA M.ADV

Æ

ROLL(Banner)

1625mm

Press the key.

The media advance/rewind switch is activated by

selecting the media and setting the take-up reel unit’s

take-up direction switch.

7

Advance/rewind switch

Wind the media by pressing the takeup-side

take-up reel switch.

If the wound media diameter is so large that the media touches the media drying fan

- Move the media drying fan’s position with the procedure below.

Protection bar

(1) Remove the protection bar, and then open

the front cover.

Media drying fan

Knob screw

(2) Loosen the right and left knob screws next

to the movable media drying fan.

Media drying fan

(3) Pull the media dryer fan toward you, and

turn it upward by 90 degrees.

When the media drying fan is turned upward,

it slightly goes down and is xed. To return the

fan to its original position, pull it up and turn

it downward by 90 degrees toward you, and

then push and secure it with the knob screws.

- Turn the media drying fan carefully so that the media drying fan connecting cable does not hung up on

the pressure control knob and surrounding sheet metals.

Page 45

45

Introduction For your basic operation Maintenance When encountering a problem Appendix

8

Remove the tension bar from the tension bar

hook.

9

Knob screw

Tension bar hook

Loosen the knob screw of each tension bar

hook and extend it laterally.

10

Remove the media from the Printer.

CAUTION

- As the media is heavy, carefully carry it with a recommended dolly.

- On carrying the media with two persons, carefully carry it by manually holding the scroller shaft.

Recommended dolly

Scroller shaft

On carrying the media alone: On carrying the media manually by two persons:

Page 46

Océ 6407 Basic Operation Guide

46

Media at supply side

1

CLOSE

COVER

ONLINE

Set the Printer to o ine state by pressing the

ONLINE

key.

2

Ç

INK MEDIA REG

È

Å

MEDIA M.ADV

Æ

ROLL (Banner)

1625mm

Press the key.

The advance/rewind switch switch is activated by

selecting media.

3

(1)

(2)

(2)

Tension bar

<LOOSE widing>

Printer rear (supply side)

Tension bar

S size tension bar

Advance/rewind

switch

Peel roller

Remove the supply-side tension bar.

(1) By pressing the media advance/rewind switch, lift

up the slack part.

(2) Remove the supply-side tension bar.

CAUTION

- Do not rotate the peel roller manually with force, or

the Printer may be damaged.

4

Supply side

Set the pressure to “Open” by rotating the

pressure control knob.

Page 47

47

Introduction For your basic operation Maintenance When encountering a problem Appendix

5

Rotate the scroller ange manually to take up

the media.

6

Capping unit side

Wiping unit side

Knob screw

Flange holder Shaft holder

Remove the ange holder, and open the shaft

holder.

To open the shaft holder, loosen the knob screw.

7

Remove the media roll from the Printer.

CAUTION

- As the media is heavy, carefully carry it with a recommended dolly.

- On carrying the media with two persons, carefully carry it by manually holding the scroller shaft.

Recommended dolly

Scroller shaft

On carrying the media alone: On carrying the media manually by two persons:

Page 48

Océ 6407 Basic Operation Guide

48

Procedure to remove scroller ange from media roll

1

Recommended dolly

Rest a media roll on the table or on the

recommended dolly.

2

(1) (2)

Knob screw

Remove the scroller shaft xture at one side.

(1) Rotate the knob screw.

(2) Pull out the scroller shaft xture from the scroller

shaft.

3

①

②

Handle

Remove the scroller ange.

(1) Rotate and loosen the handle.

(2) Pull out the scroller ange from the scroller shaft.

4

Handle

At the other side, rotate and loosen the scroller

ange’s handle.

5

Supporting the scroller ange, pull out the

scroller shaft.

Page 49

49

Introduction For your basic operation Maintenance When encountering a problem Appendix

memo

Page 50

Océ 6407 Basic Operation Guide

50

To print on other media

To print on Vinyl, Mesh banner, Backlit banner (FF), or Solvent printing coated paper

Vinyl

Mesh banner

Install an S-size tension bar at the

slack center position.

(backed)

Printer setting

Media type: Glossy

For glossy vinyl

Install a tension bar conforming

with the media width.

TENSION

winding mode

LOOSE winding

mode

Supply-side tension bar

Supply-side tension bar

SELECT MEDIA

MEDIA:Glossy

Media type: Banner

SELECT MEDIA

MEDIA:Banner

# MEDIA BACK MODE

>01:BACK&FWD

Supply-side tension bar’s size

S size

Winding mode

LOOSE winding mode

Printer setting

Supply-side tension bar’s size

Length conforming with the

media width

Winding mode

TENSION winding mode

Media type: Matte MEDIA BACK MODE: BACK & FWD

# MEDIA BACK MODE

>01:BACK&FWD

MEDIA BACK MODE: BACK & FWD

For matte vinyl

SELECT MEDIA

MEDIA:Matte

Media

Media

Page 51

51

Introduction For your basic operation Maintenance When encountering a problem Appendix

TENSION

winding mode

LOOSE winding

mode

Media

Media

Install an S-size tension bar at the

slack center position.

Supply-side tension bar

Install a tension bar conforming

with the media width.

Supply-side tension bar

Printer setting

Supply-side tension bar’s size

Winding mode

Printer setting

Supply-side tension bar’s size

S size

Winding mode

LOOSE winding mode

# MEDIA BACK MODE

>01:BACK&FWD

Length conforming with the

media width

TENSION winding mode

# MEDIA BACK MODE

>01:BACK&FWD

Aft 50 Prn 40 Pre 45

C) 50 C) 40 C) 45

Backlit banner (FF)

Solvent printing coated paper

Media type: BLT_B

SELECT MEDIA

MEDIA:BLT_B

MEDIA BACK MODE: BACK & FWD

MEDIA BACK MODE: BACK & FWD Afterheater: 50°C / Printheater: 40°C /

Preheater: 45°C

Page 52

Océ 6407 Basic Operation Guide

52

To take up media in LOOSE winding mode

CAUTION

- Apply the paper tube with the same length as the media width.

1

Paper tube

Scroller ange

Scroller shaft

Install the scroller shaft and scroller ange onto

the paper tube.

(1) Pass the scroller shaft through the roll spacer with

xtures at its both sides, scroller ange, and ange

shaft xture.

(2) Pass the scroller shaft through the paper tube.

(3) Insert the scroller anges into the paper tube’s both

edges as far as they go.

Scroller ange

Handle

(4) By rotating the handle x the scroller ange.

Knob screw

Flange shaft xture

(5) Cover the scroller ange’s convex part with the

ange shaft xture, and push the ange shaft xture

as far as it goes.

(6) Turn the knob screw to x the scroller shaft.

2

Take-up direction switch

OFF

Set the take-up direction switch to OFF.

CAUTION

- If the Printer processing proceeds to the next step

with the take-up direction switch set to ON, your

hand may be caught as the scroller ange is not

secured.

3

Install the paper tube into the Printer’s front side

(take-up side).

Page 53

53

Introduction For your basic operation Maintenance When encountering a problem Appendix

4

By pressing the key, feed the media until

the front media edge is wound on the paper

tube.

FEEDING MEDIA

5

Tape

Paper

tube

Install the printed media to the paper tube.

(1) Check the take-up direction, remove the slack of the

media, and then make sure that the media is not

deviated on the supply side and the takeup side.

(2) Attach the media to the paper tube with adhesive

tape. Tape it rst at the center, and then at the right

and left sides, so that the tension is uniform across

the media width and that no wrinkles are found on

the media. The taped positions are recommended to

be totally three or more.

Inner take-up:

Media is taken up

with its print surface

coming inside.

Outer take-up:

Media is taken up

with its print surface

coming outside.

Points to be noted on winding media

- If the media is not installed straight to the paper tube, a skew of media may occur.

- When the take-up direction is set as Inner take-up, the taken-up media's diameter increases and the media cannot

backfeed after printing. Select [FWD ONLY] beforehand in MEDIA BACK MODE of MEDIA REG MENU. (When the

media backfeeds in [BACK&FWD] mode, the motor idles and may cause a trouble.)

6

Take-up direction switch

OFF

u Outer take-up

- OFF

v Inner take-up

Set the take-up direction switch according to

the take-up direction.

7

By pressing the key feed the media, and

wind one full turn of the media on the paper

tube.

FEEDING MEDIA

8

Input the data in the software RIP.

Page 54

Océ 6407 Basic Operation Guide

54

To perform double-sided printing

At double-sided printing

- The Printer does not contain the structure to feed media with correctly applying the media advance adjustment value.

So the Printer cannot correctly align the rst side image with the second side image.

For convenience of explanation on the double-sided printing below, the side printed rst is referred to as the

"First side" and the side printed next is referred to as the "Second side." The following procedure is described for

the case to print the rst side of the media, reinstall the media to the roll feed unit for each media roll that wound

the media, and then print the Second side of the media.

First side printing

Second side printing

Move

Media roll moves

1

SELECT MEDIA

ROLL/SHEET:FACE

Load the media on the Printer.

For the procedure, see page 32.

At loading the media, on the operation panel select

[FACE] with the or keys.

Print the rougher side rst.

- With a single-sided-printing oriented banner,

the roughness grade is di erent between

the front and rear surfaces. To print on such a

banner, print on the rougher side rst as a rst

side.

2

F

o

u

r

f

u

l

l

t

u

r

n

s

Load the media onto the take-up reel unit.

For the procedure to load the media onto the take-up

reel unit, see page 39.

Wind four full turns of the media on the

paper tube.

- Since a margin of approximately 2.5 m or more

is required for the second side printing, wind

about four full turns of media to the take-up

reel unit in advance.

Page 55

55

Introduction For your basic operation Maintenance When encountering a problem Appendix

3

Start printing on the rst side of the media.

4

Reference dashed line

for cutting

Reference solid line to align print

position on rst and second sides

When printing is completed, open the front

cover and cut the media.

At the end of the rst-side printing, two lines are

printed. One line is a reference solid line to match print

positions on the rst and second sides. The other line

is a reference dashed line for cutting.

You are recommended to:

- To cut the media, insert the blade of a box

cutter into the gap between the platen and

the paper guide.

- To easily install the second side of media,

mark the position of the reference solid line

at the second side’s right and left edges.

CAUTION

- The drying time of printed media varies depending on printed images. Con rm that printed media has dried, and

then proceed to the next operation. Generally, dry the printed rst side for three hours or more (24 hours for highdensity print), and then start second side printing.

- Pay attention not to drop the printed media to avoid smearing the media.

5

Remove the supply side media roll from the

Printer.

See P. 43.

CAUTION

- As the media roll is heavy, carefully load or remove it

with a recommended dolly.

Recommended dolly

On carrying the media alone:

6

Move the media roll from

take-up side to supply side.

Remove the take-up side media roll from the

Printer, and move it to the supply side.

See P. 43.

Page 56

Océ 6407 Basic Operation Guide

56

Before starting the second-side printing...

- Go to the operation panel and change the settings of [#SUCTION FAN LEVEL] and [#MEDIA ADV MODE] in

accordance with the applied media. If the media is sticky or if the rst-side image may adhere to the platen,

the friction could be too high and the media advances irregularly. To solve it, set [#SUCTION FAN LEVEL] to

[LOW], and [#MEDIA ADV MODE] to [BACK & FWD1] or [BACK & FWD2].

#MEDIA ADV MODE

>01:BACK & FWD1

#MEDIA ADV MODE

>01:BACK & FWD2

Suction fan: [LOW]

Suction fan

MEDIA ADV MODE: [BACK & FWD1] or [BACK & FWD2]

To avoid the irregular media advance, set the

suction fan’s vacuum pressure to low.

[BACK & FWD1]

: At starting the print, the Printer moves the media back