Page 1

Océ CS

5050/5070

User Manual

Page 2

Océ-Technologies B.V.

Trademarks

Products in this manual are referred to by their trade names.

In most, if not all cases, these designations are claimed as

trademarks or registered trademarks of their respective

■

companies.

Copyright

Océ-Technologies B.V. Venlo, The Netherlands © 1999

All rights reserved. No part of this work may be reproduced, copied, adapted,

or transmitted in any form or by any means with out w ritte n pe rm issi on from

Océ.

Océ-Technologies B.V. makes no representation or warranties with re spe ct to

the contents hereof and specifically disclaims any implied warranties of

merchantability or fitness for any partic ul ar purpose.

Further, Océ-Technologies B.V. reserves the right to revise this publication and

to make changes from time to time in the content h ereof without obligation to

notify any person of such revision or changes.

Edition 1.0

GB

Page 3

Contents

Chapter 1

Introduction

Printing with Océ CS 5050/5070 10

Graphic reproductions 10

Easy to use 11

Choice of appropriate inks and media 11

Obtaining quality reproductions 12

Choice of print mode 12

Original image type 12

Original image clarity and colour 13

Scanner type 13

Scan reso lution 14

Post-scanning im age correction and shar pening 14

Ink cartridge pr eparation and alignm ent 15

Chapter 2

Getting started

Using the control panel 18

Start-up checklist 18

Locating the cont rol panel 18

Accessing the menu functions 19

Setting the langua ge 19

Loading media 20

Using the powe r m edia feed and take-up system 20

Loading roll medi a 21

Using the take-up roll 21

Setting drying time 23

Loading sheet me di a 23

Moving the carriage 23

Installing the cu tter 2 4

Filling the ink reservoirs 25

Installing ink cartridges 27

Placing the cartridges 27

Priming the ink delivery lines 27

Printing a colour test 32

Printing the prime pattern 33

Calibrating cartridges 35

Defining calibration units 36

Contents 3

Page 4

Chapter 3

Cartridge recognition 37

Calibrating the colour deadband 38

Calibrating the paper axis 39

Operating the printer 40

Printing options

Main menu at a glance 42

Using the default settings 43

Choosing print mode options 46

Selecting re solution (dpi) 47

Selecting a colour mode 48

Selecting quality modes 48

Setting the number of print passes 49

Setting the carriage speed 49

Selecting the print direction 50

Choosing "feed media" options 51

Detecting the "end of media" 51

Using the media counter 52

Choosing paper options 54

Media standards 54

Rollfeed media: sizes and maximum printing areas 55

Sheet media: si zes and maximum printing ar eas 57

Setting margins 59

Setting auto-load delay 60

Selecting auto -cut 60

Saving media 61

Selecting auto-wipe 6 1

Applying ink redu ct i on 61

Selecting ink preh eat 62

Turning on the dryer 63

Setting the dry time 63

Adjusting the LCD cont r as t 63

Saving user options 64

Chapter 4

Printing with HP-GL/2

Overview 66

Accessing the HP-GL/2 menu options 66

Selecting the palette 67

Setting the "Control" function 67

Rotating a print 68

4 Océ CS 5050/ 5070 User Manual

Page 5

Chapter 5

Making reprints 68

Nesting 69

Applying the ink limit 70

Printing an HP-GL/2 test file 70

Printer maintenance and storage

Ink reservoir and cartridge maintenance 72

Refilling ink reservoirs 72

Changing ink types 73

Removing and storing ink cartridges 73

Removing the reservoirs 74

Installing new car tr i dges 75

Refilling ink cartridges 75

Purging ink delivery lines 77

Periodic cleaning 78

Materials to use for cleaning 79

Cleaning the ink cartri dge jet plate 80

Cleaning the service station 81

Replacing the service station wipers 82

Cleaning the slide shaft 84

Cleaning the en coder strip 84

Maintaining the Océ Prime tool 86

Transporting or storing your printer 87

Accessing pri nt er information 87

Chapter 6

Error handling and troubleshooting

Error handli ng 90

Unrecognised cartridge 90

Checking the quality of ink cartridges 91

Getting cartridge information 91

Running the prime test 91

Compensating for electrically defective jets 93

clearing clogged jet s 93

Compensating manually for clogge d je ts 94

Troubleshooting 96

Troubleshooting areas 96

Isolating problem s 96

Printer behaviour 97

Print quality 101

Data transfer 104

5

Page 6

Appendix A

Appendix B

Appendix C

Application software 104

Calling for assistance 106

Glossary

Quick reference card

Using the “Quick Reference Card” 112

Supplies

Caring for inks and media 116

Inks and ink cartridges 116

Caring for your media 117

Inks for Océ CS 50 50/5070 printers 118

Océ Standard Colour Inks accessory kits 118

Océ Standar d C ol o ur Inks replacement cartridges 118

Océ Outdoor I nks accessory kits 119

Océ Outdoor Colour Inks replacement cartridges 119

Media for Océ CS 5050/5070 printers 120

Miscellaneous Océ CS 5050/5070 accessories 121

Appendix D

Technical specifications

Océ CS 5050/5070 printer specifications 124

Appendix E

Safety information

Instructions for safe use 128

Safety data sheets 130

Appendix F

Miscellaneous

Notation conventions 132

Reader’s comment sheet 133

6 Océ CS 5050/ 5070 User Manual

Page 7

Addresses of local Océ organisations 135

Index 137

7

Page 8

8 Océ CS 5050/ 5070 User Manual

Page 9

Océ CS 5050/5070

User Manual

Chapter 1 Introduction

The Océ CS 5050 an d 5070 ar e wide-forma t colour prin ters

that provide profess iona l quality prin ts wit h all the

brilliance and gloss of liquid ink. The Océ CS 5050/5070

printers reduce production time while main tain ing

exceptional graphics quality.

9

Page 10

Printing with Océ CS 5050/5070

The Océ CS 5050/5070 wide-format inkjet printers can reproduce graphics up

to the length of a roll of media. Large format colour printing combines the

technical sophistication of the Océ CS 5050/5070 series with the unique

qualities of Océ proprietary inks and media (coated canvas, vinyl, film, paper,

etc.)

Graphic reproductions

The Océ CS 5050/5070 addresses the following printing needs:

Posters

■

Banners

■

DTP

■

Packaging prototypes■ Point of purchase

■

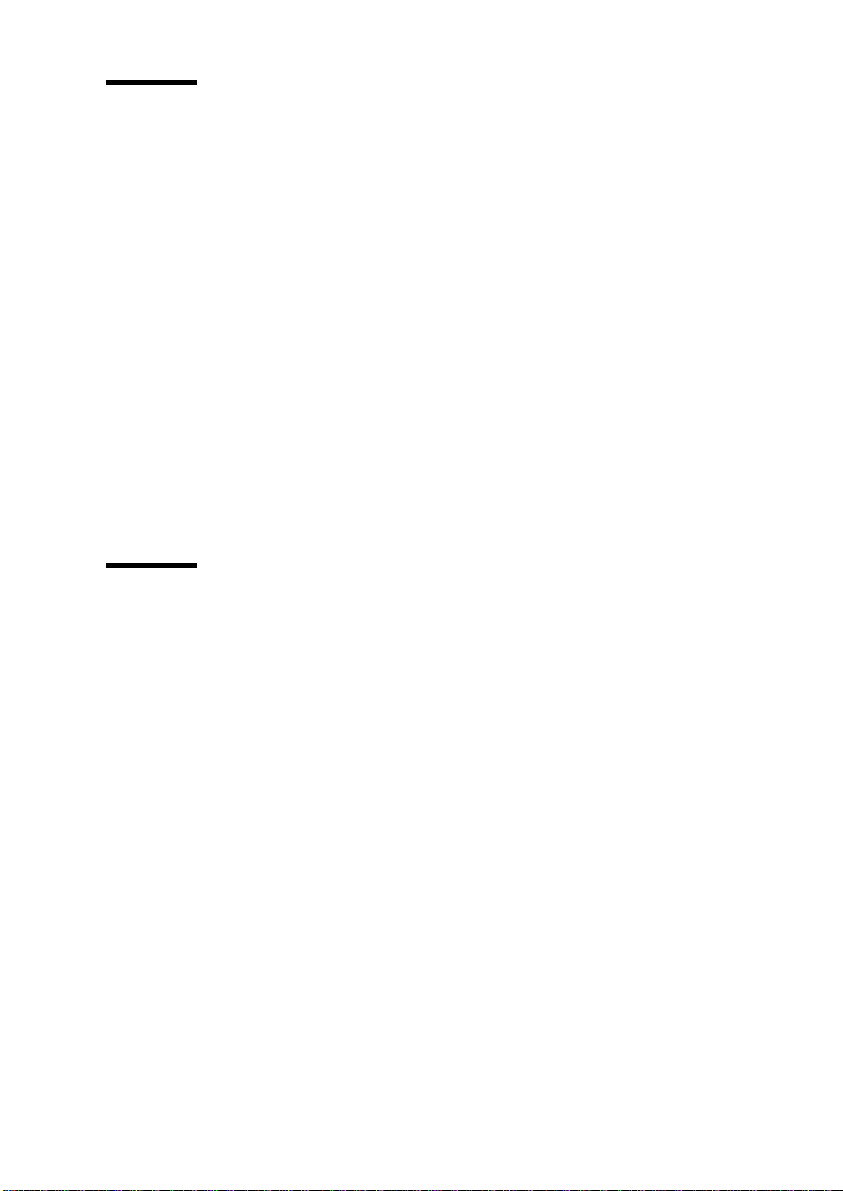

[1] Rear-view Océ CS 5050/5070 printer

Signs

■

Displays

■

Imposition proofing

■

Fine art

■

Proofing

■

Textile design

■

Exhibits

■

10 Océ CS 5050/5070 User Manual

Page 11

Easy to use

Continuous-feeding ink system

colour to ensure that there is an adequate ink supply for large print jobs. Simply

check the transparent plastic reservoirs and refill them if necessary prior to

printing. In addition, the printer’s dual ink system speeds up the process of

switching between different types of ink.

Acceptance of raster-oriented data in HP RTL format

begins immediately after the printer receives the first complete line of HP R TL

data. Depending on the software used, it is possible to reproduce millions of

colours, yielding high-quality results for full-colour images or 3-dimensional

renderings.

The printers use 500 ml rese rvoirs for each

Choice of appropriate inks and media

Océ inks and media are developed specifically to w ork together to achie v e the

widest range of colours available, for high colour fidelity . For details about the

appropriate types of media for different print jobs, see ‘Media for Océ CS

5050/5070 pr inters’ on page 120.

In this mode, printing

Introduction 11

Page 12

Obtaining quality reproductions

Depending on the print mode you use, inkjet printing can produce a wide

variety of print qualities. Hence, before starting a print job, it is essential that

you understand what the required output quality will be, based on the future

use of the reproduced graphic, as well as the time and cost involved in

achieving that required print quality.

Several factors can affect the quality of reproduced graphics. Use the following

guidelines to obtain optimal print quality with the Océ CS 5050/5070.

Choice of print mode

There are printing modes, each of which compromises between image quality

and speed. When pri nting he avy r enderin gs, maps, or art gra phics, ch oose one

of the quality printing modes. Certain types of media also require quality

printing modes.

To select the appropriate printing mode for a specific print job, refer to

‘Selecting quality modes’ on page 48.

Original image type

The type of original image influences the quality of the final print.

For best results, use an original transparency (not a duplicate) with extremely

■

crisp edge definition.

Print film photos are not quite as good, because they are removed one level

■

from the original film. Also, because of the emulsion process used to make

photo prints, edge definitions tend to be lost.

Colour prints must be of very good quality to produce acceptable scaled

■

prints.

Some digital photo files may be unacceptable for large format printing, as

■

they only contain a small fraction of the information contained in a film

transparency.

12 Océ CS 5050/5070 User Manual

Page 13

CD images in TIFF or EPS format of 28MB or more are preferable for high

■

quality prints. A v oid compressed image files such as GIF or JPEG, since these

files can lose valuable data after compression. However, if you must use a

compressed file, take into account the following:

Choose the JPEG format in case some quality loss is acceptable. (The

■

compression factor determines the final image quality.)

Choose LZW if quality loss is not acceptable.

■

When using LZW, the compression factor will be very low on photo

Note:

images.

Original image clarity and colour

The quality of the original transparency, photograph, or digital file determines

the input as well as output clarity and colour of the image. By using a good,

clear original, you can maintain the image quality throughout the printing

process.

An out-of-focus photograph will result in a fuzzy inkjet print, despite the

■

after-effects of sharpening corrections.

V ariations in film, speed, grain, or developing process can affect the lightness

■

or darkness of the image for which colour corrections cannot compensate.

Scanner type

It is essential to understand the required (output) print quality of an image, and

to use the appropriate scanner to scan that image into a digital file. Use a

scanner that can achieve enough colour fidelity and edge clarity to meet the

overall print requirement. An image scanned using a low-performance scanner

will lose detail, clarity, and colour.

Introduction 13

Page 14

Scan resolution

Choosing the right resolution for the output print size (as well as the amount

of scaling needed after scanning) determines the best scan resolution for each

image. A resolution that is too low will diminish the print quality (insuff icient

detail). A resolution that is too high slows down the raster image processor

(OGSL) without adding quality to the image.

Use the following guidelines to set end resolution:

150 dpi for sharp, deta i le d i mage s intended for close vie wi ng

■

100 dpi for vie wi n g fr om a sign ificant distance

■

Keep text and logos as vector information (i. e. Postscript fonts and formats),

■

which will always print at the printer’s resolution.

Most scanners can interpolate or “imitate” high-resolution scanning. However ,

do not use the interpolated resolution of your scanner to compute the image

size. Instead, use the scanner’s highest true optical resolution to maintain

image quality.

Post-scanning image correction and sharpening

Before printing a scanned image, you must perform some basic image

corrections and sharpening to ensure a high-quality, wide-format colour print.

Tonal correction

If necessary, remov e the colour cast from the midtones of an

image using a function such as “Auto" levels in PhotoShop. This function

allows you to re-adjust the black and white points in the image and redistribute

the intermediate colours proportionately. In most cases, this correction is

suff ic i ent for properly expo sed images. However, in very dark night sc e nes or

in very white snow backgrounds, you must make a manual correction by

adjusting the histogram.

Sharpening

T o improv e the edge details of an image, use the “Unsharp Mask

filter” in Photoshop. This can digitally refocus an image that has become

blurred from scanning or interpolation. A small over-estimation of the filter

effect can be diffused in the printing process; ho wev er , a lar ge ov er-estimation

can give the image a hard, pixelated appearance.

14 Océ CS 5050/5070 User Manual

Page 15

Ink cartridge preparation and alignment

Cartridge maintenance and alignment are key factors in printer performance,

which in turn affect colour, accuracy, and image quality. Use the following

recommendations to keep your cartridges in optimal working condition:

Keep the printer wiping stations clean so that the heads stay clean.

■

Align and check cartridges to make sure all nozzles work properly.

■

T o achie ve the best possible accuracy, use a loupe to evaluate the registration

■

of test patterns.

Re-align all cartridges when you adjust, move, or replace a cartridge, since

■

even small, one-pixel errors can affect both colour and image quality.

Introduction 15

Page 16

16 Océ CS 5050/5070 User Manual

Page 17

Océ CS 5050/5070

User Manual

Chapter 2 Getting started

This section expla ins t he i nitia l i ns talla tio n of the Oc é C S

5050/5070:

■

using the control panel

■

loading media

■

filling ink reservoirs

■

installing, priming, and calibrating ink cartridges

■

calibrating the colour deadband and the paper axis

17

Page 18

Using the control panel

Before printing, make sure that you are familiar with the start-up checklist and

the control panel’s main menu functions.

Start-up checklist

To start the CS 5050/5070, check the following:

Be sure that the power cord is plugged into the wall socket.

■

Be sure that the printer connects to your computer using a parallel cable.

■

Turn on the printer before attempting to print.

■

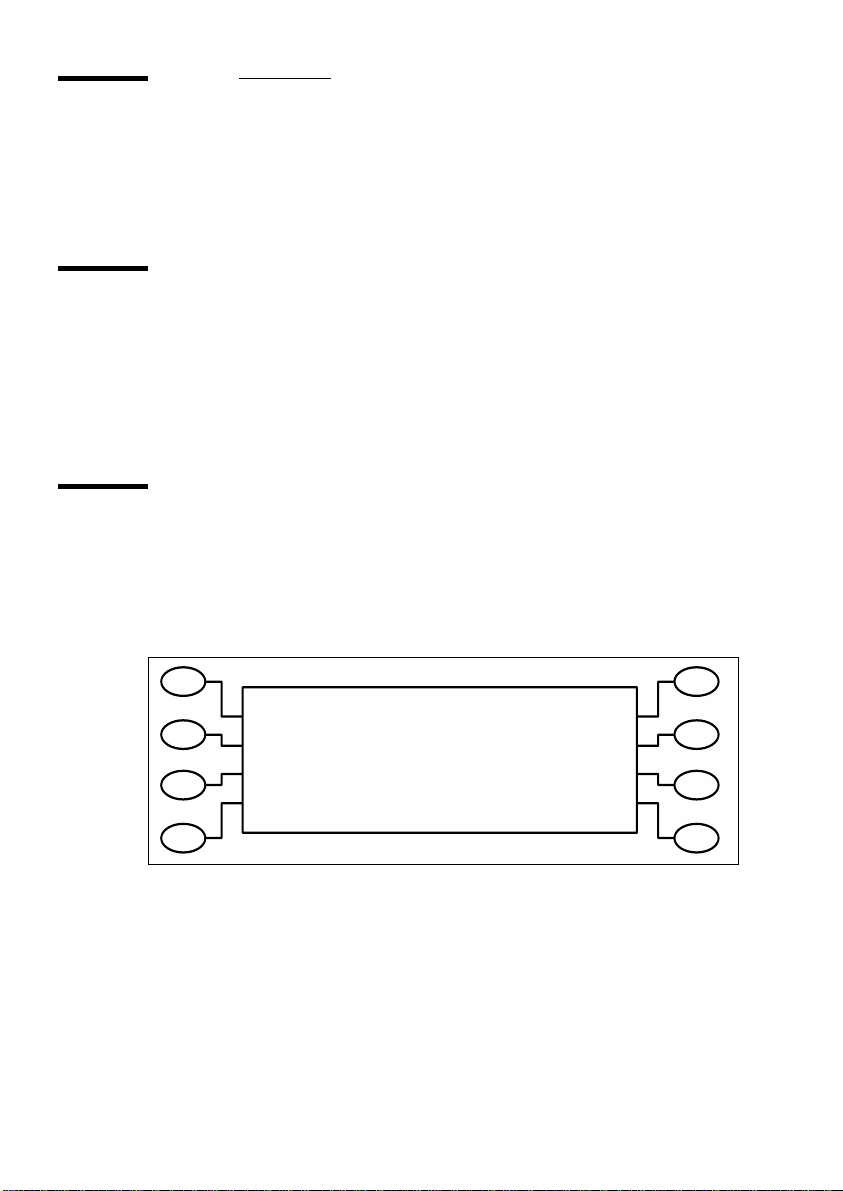

Locating the control panel

The control panel is located on the right-hand side of the printer. It includes

eight buttons and a display which indicates modes and settings, as illustrated

below. For a complete summary of all printer options, see ‘Main menu at a

glance’ on page 42.

Load Media

Cut

Pause

Reset

[2] Océ CS 5050/5070 control panel

18 Océ CS 5050/5070 User Manual

Feed Media Menu

Set Up Menu

Utility Menu

Page 19

Accessing the menu functions

There are two types of menus:

■ action menus

perform.

■ selection menus

▼▼▼▼

To select menu functions

To select a function, press the button displayed next to the function.

1

The display lists options available for the selected function.

Press the

2

When the selection you want is displayed, press the button for that option and

3

press

Depending on t he t y pe of menu, you can return to t he pr evious menu le vel by

4

pressing the

Press

5

Press the

6

Next Option

.

OK

OK

consecutively to return to the main menu.

Exit

Cancel

Setting the language

The Océ CS 5050/ 5070 can display menu items in English, German, French,

Italian, Portuguese, Korean, Japanese, and simplified or traditional Chinese.

▼▼▼▼

To set a language

Press

1

2

3

Setup/User settings/Language

Select the language you want.

Press OK.

provide a list of additional menus or immediate tasks to

let you view and modify printer settings.

or

Exit

or

button.

Prev. Option

buttons to display the selections.

button to restore the previous setting and exit the menu.

.

Getting started 19

Page 20

Loading media

You can use either roll media or cut sheets. The printer is set for roll media as

its default. T o ensure straight paper loading and avo id skewing, hold the media

parallel to the platen line. Use the loading lines on the platen as a guide. The

printer has sensors which detect the presence of media and activate the feed

and take-up mechanisms.

The roll media core must have an inside diameter of 5 cm and a maximum

outside diameter of 15 cm (about 6 inches). If your media has an inside

diameter of 8 cm, use the core adapter provided. If you want to store prints on

the take-up roll, you will need to have extra cores available.

Caution:

60" (1,52 m) wide. The media roll may be heavy, so have someone help you

to load it. Before printing, check that you have a take-up roll cor e available

that is the same width as the media roll core you are loading.

Attention:

damaged part of the roll prior to loading, to prevent the media from

jamming in the printer. Load only media with an edge that is perfectly

horizontal into the printer. Make sure not to leave fingerprints on the

printing side of glossy media pap er.

The Océ CS 5050/5070 printers (60” version) can use media up to

If your roll media has wrinkled or damaged edges, cut off the

Using the power media feed and take-up system

The power media feed and take-up system facilitates long, unattended print

jobs by automatically unwinding and rewinding media as prints are generated.

It includes a feed roll, a take-up roll, and sensors which prevent media from

touching the floor.

When the unit is first switched on, the feeder may turn for a few seconds. If the

take-up turns, i t indicates that the sensor is blocked. Clear anything blocking

the sensor before proceeding.

20 Océ CS 5050/5070 User Manual

Page 21

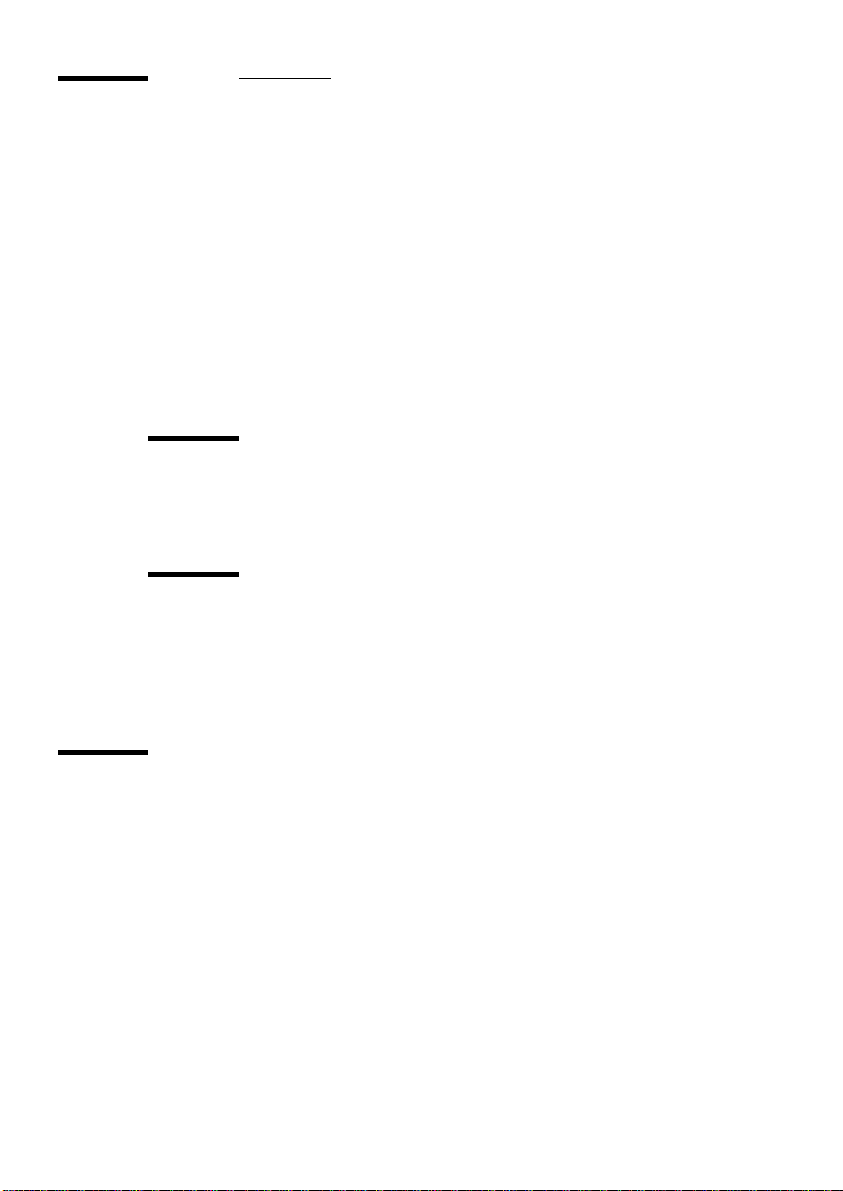

Loading roll media

▼▼▼▼

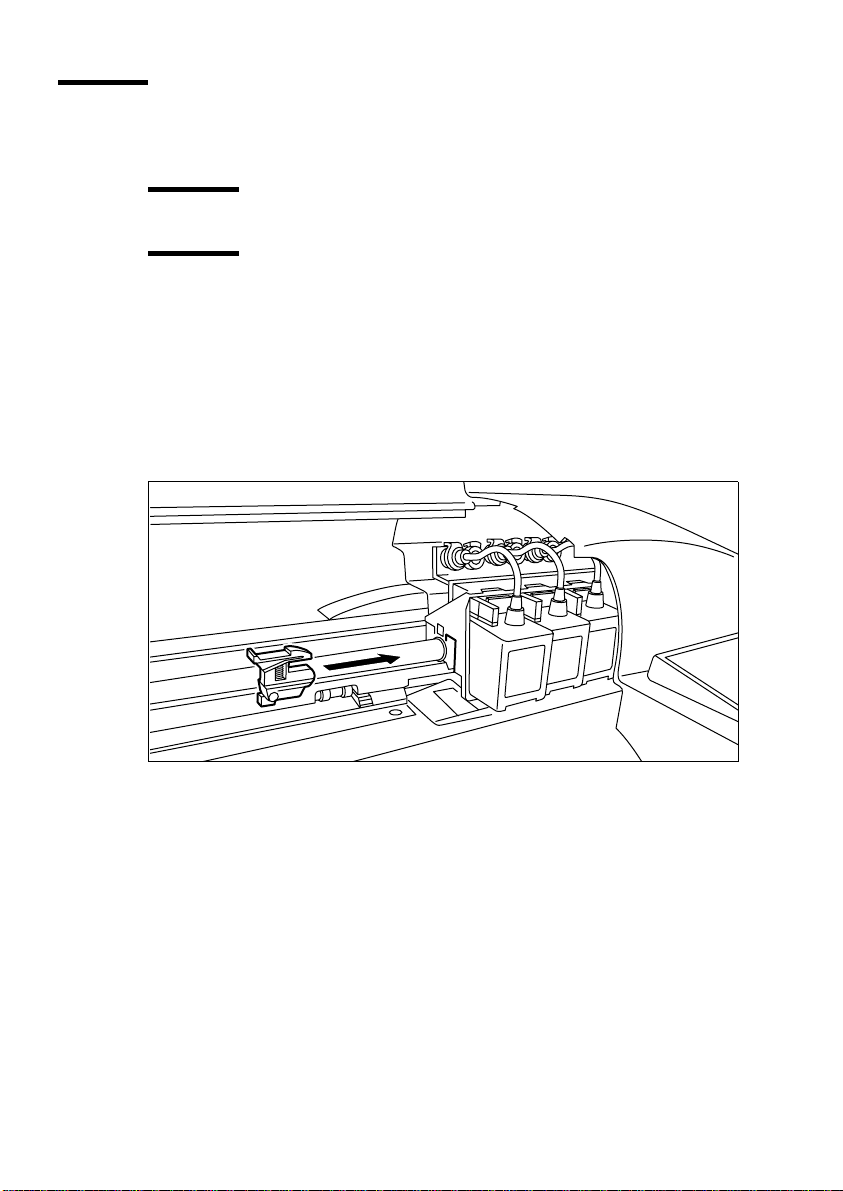

To load roll media

Slide the rolled media onto the media (upper) roller, feeding in the paper as

1

shown.

Slide the media guide into the roll core, and tighten the guide to secure the roll

2

by turning the knob clockwise.

Standing behind the printer, insert the media's leading edge into the back of the

3

printer. The printer automatically detects the presence of the media and

advances it.

Press

4

Load Media

[3] Loading media

to move the media into printing position.

Using the take-up roll

The take-up roll facilitates unattended print jobs by automatically winding

printed media onto a core. In this mode, the automatic cutter is disabled. When

using this option, be sure that the media sensor on the printer's right leg is not

blocked.

▼▼▼▼

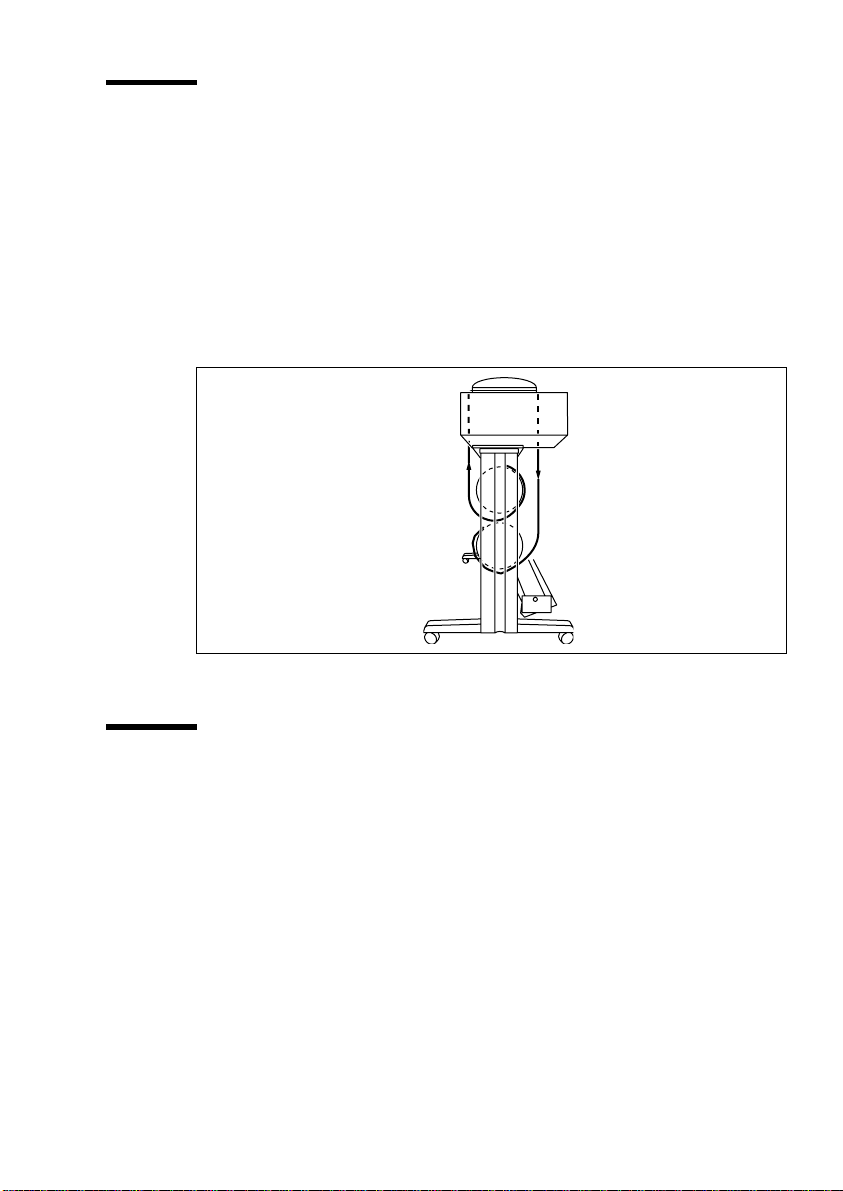

To install the take-up roll

Install an empty core onto the take-up guides. Be sure that the core width

1

matches the width of the media you are using.

Slide the roll guide onto the media core, and secure it by tightening the locking

2

mechanism. If you mo v e d the sens or mo unt ing br ac ke t be fore loa din g the rol l

media, be sure to return it to its normal position.

Getting started 21

Page 22

Since media cores can be narrower than the media, position the media guide at

3

3 mm (1/8”) from the end of the core and lock it into place.

4

Press

Feed Media/Forward

to advance enough media to allow its leading edge

to come to the centre of the take-up roll.

[4] Locking the take-up roll

Using at least three pieces of tape, attach the leading edge of the media to the

5

take-up roll at the left, right, and centre of the core.

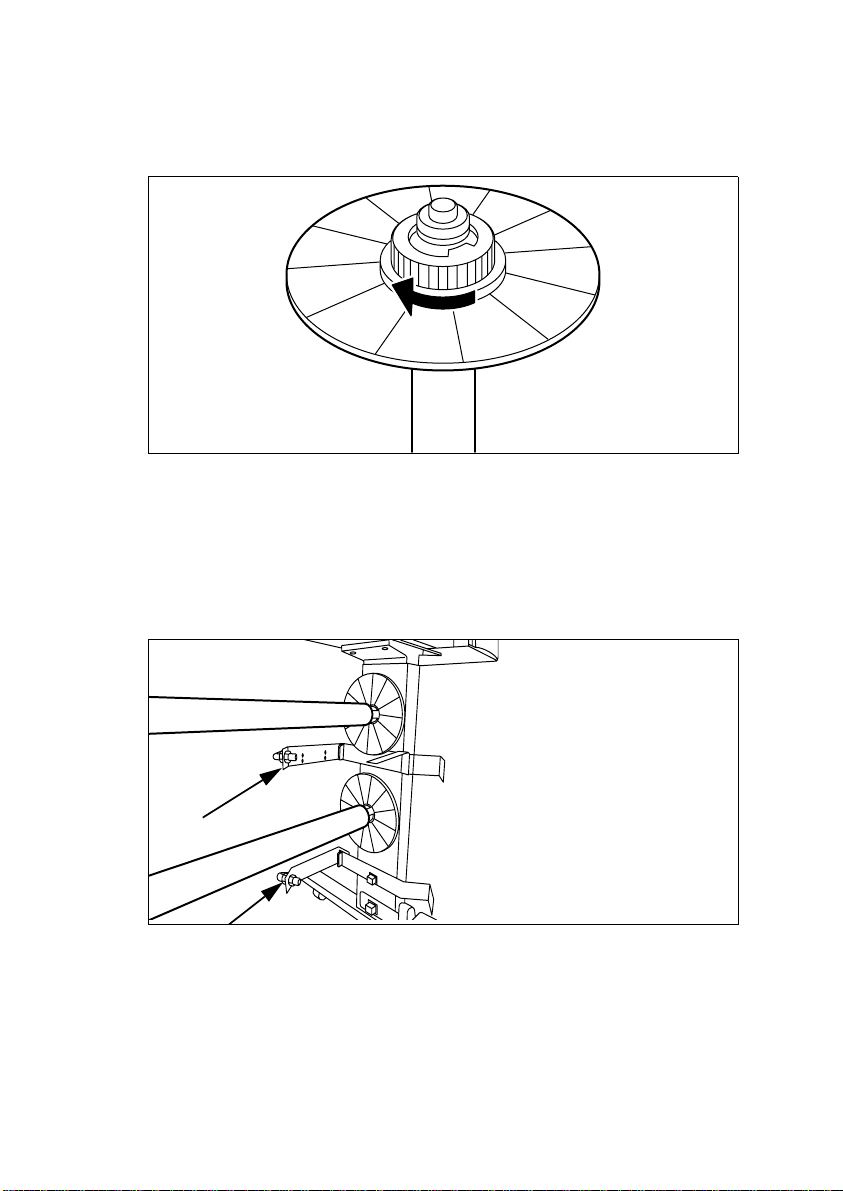

As printing progresses, the media loops down to the front of the take-up core

6

until the sensor detects it on the printer stand leg. The take-up rolls then

activate to roll the media.

Be sure not to block the sensor!

Note:

[5] Sensors on the printer stand

▼▼▼▼

22 Océ CS 5050/5070 User Manual

To set the take-up mode

Press

1

2

Setup /Paper Opti on

Press OK. This enables the take-up roll and disables the cutter.

, then

Supply Type/Take-up

.

Page 23

▼▼▼▼

To unload the take-up roll

Press the

1

Remove the roll from the printer.

2

Release the adjustable roll guide.

3

Slide the take-up roll out of the printer.

4

button to cut the media.

Cut

Setting drying time

Depending on the ambi ent humidity , temp erature, and amo unt of ink cover age,

it is recommended that you use the dryer when printing a long print (see

‘Setting the dry time’ on page 63). Position the dryer so that the fans blow on

the media. Set a sufficient drying time to let the ink dry before the media rolls

up to the take-up core. The number of dryers that switch on automatically

depends on the width of the loaded media.

Loading sheet media

▼▼▼▼

To load sheet media

Press

1

2

3

4

Setup/Paper Options

Press

Supply Type/Sheet

Press OK.

Load the sheet from the back of the printer, aligning it with the alignment mark

on the platen.

Make sure that the media is flat and under the rollers. The printer automatically

5

senses the media's presence and forwards it until it reaches the start position on

the platen.

Moving the carriage

When not in use, the cartridges remain in the service station at the right side of

the printer. This de vice seals the ink jets to pre vent them from drying out. W ith

the power on, always use the

carriage away from the service station when you install, change, adjust, or

clean the ink cartridges or the service station.

.

.

Utility/Access Cartridges

button to move the

Getting started 23

Page 24

Installing the cutter

With an installed cutter, the printer cuts the media automatically after printing.

Caution:

Attention:

Be careful when handling the cutter to avoid injury.

For normal media, do not use an external kni fe or c utter to cut,

as this can damage the platen and prevent the media sensors from working

properly. However, for heavy media such as canvas, use the "Feed media"

menu to advance the media through the printer before cutting with scissors.

▼▼▼▼

To install the cutter

Press

1

Utility/Access Cartridges

to move the carriage to the left, and out of the

service station. The cutter fits in the printer on the left side of the carriage.

Press down the lever of the old cutter to remove it from the carriage.

d

2

[6] Installing the cutter

Push the new cutter into the slot until it clicks into place.

3

Press the

4

Utility/Access Cartridges

station. This ensures that the cutter blade is in the start/rest position.

If the cutter becomes worn, it can cause the carriage to jam or can cause

Note:

a ragged media cut. In extr eme cases, you might see an err or messag e stating:

"Carriage Axis Failure" (see ‘Carriage axis failure’ on page 98).

24 Océ CS 5050/5070 User Manual

to move the carriage back into the service

Page 25

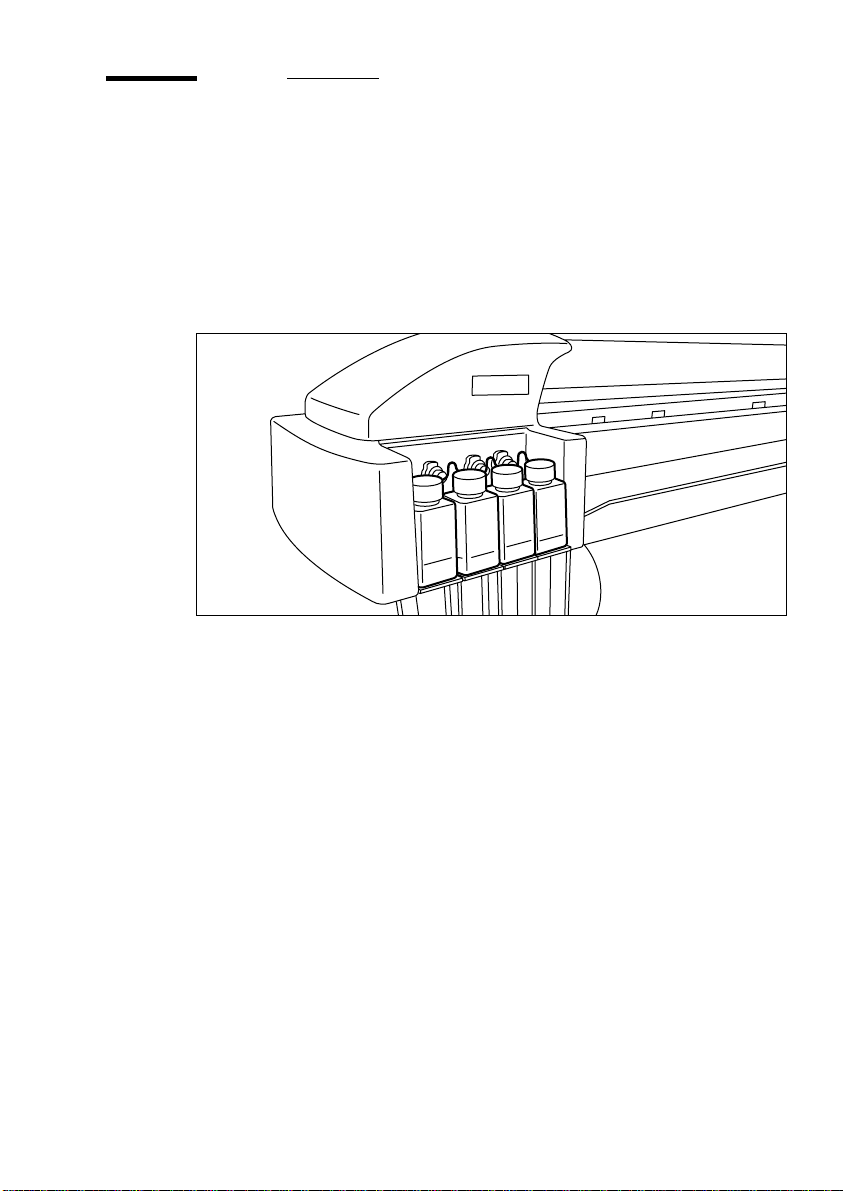

Filling the ink reservoirs

The Océ CS 5050/5070 can handle long, uninterrupted print jobs because each

of its four reservoirs holds 500 ml of ink. The ink reservoirs are located at the

printer's left side. Use Océ inks for best results.

When running at carriage speeds faster than th e default, the ink levels in

Note:

the reservoirs should be no more than 300 ml.

[7] Filling the ink reservoirs

To place the ink reservoirs in the right order, see the sticker on the

Note:

carriage. Observe the ink o rder from left to right a s follows: yellow, magenta,

cyan, black.

▼▼▼▼

To fill the ink reservoirs

Open the cover on the left side of the printer to access the ink reservoirs.

1

Unscrew the cap of one reservoir.

Open only one reservoir at a time to prevent mixing with other ink

Note:

colours.

Remove cap from the bottle.

2

Make sure that you are using the same type of ink in all the reservoirs and

3

cartridges.

Fill the reservoir up to 375 ml, or no more than 1/2 inch (about 1.2 cm) from

4

the top of the reservoir.

Make sure that there is no excess ink on the reservoir cap.

5

Replace the cap on the reservoir.

6

Getting started 25

Page 26

Attention:

Do not over-tighten the reservoir cap in order to maintain

adequate air pressure for correct ink flow to the cartridges.

Repeat these steps for the remaining reservoirs, then close the cover.

7

Attention:

A complete second set of connec tions is provided with

colour-coded quick-connect fittings for changing to another type of ink. Be

sure that each reservoir is connected to th e sam e colour fitting.

26 Océ CS 5050/5070 User Manual

Page 27

Installing ink cartridges

The process of installing new ink cartridges involves the following phases:

Placing the cartridges on the carriage

■

Priming the ink delivery lines

■

Printing a colour test

■

Attention:

The Océ CS 5050/5070 works onl y wi th O cé pre-filled ink

cartridges. Using other cartridges can dam age the printer a nd/or prevent

the printer from printing.

Placing the cartridges

When you place the cartridges, follow these precautions closely:

Do not remove the blue tape from the cartridge until instructed to do so.

■

Do not touch the jet area or the flex contact area of the cartridge.

■

Work with only one colour at a time to avoid mixing.

■

Make sure that the ink delivery lines are not twisted.

■

▼▼▼▼

To place a cartridg e

With the printer powered on, press

1

carriage into position for cartridge installation or replacement.

The cartridges are pre-filled and pre-primed. Remove the cartridge from the

2

sealed bag and remove the shipping cap.

Place it bottom first into the correct slot on the carriage.

3

Do not remove the blue tape from the jet plate.

Note:

Tilt the cartridge up until it clicks into place. Make sure the cartridge is firmly

4

installed.

Utility/Access Cartridges

to move the

Priming the ink delivery lines

After filling the ink reservoirs, prime each of the four ink delivery lines to

establish ink flow between the reservoirs and cartridges. Use the Océ 5350

Prime tool for this purpose. The Prime tool is a battery operated ink priming

Getting started 27

Page 28

device used to draw ink through the ink delivery lines and for priming

cartridges.

Perform this procedure after you have set up the printer for the first time. It is

not necessary when refilling the reservoirs or replacing ink cartridges.

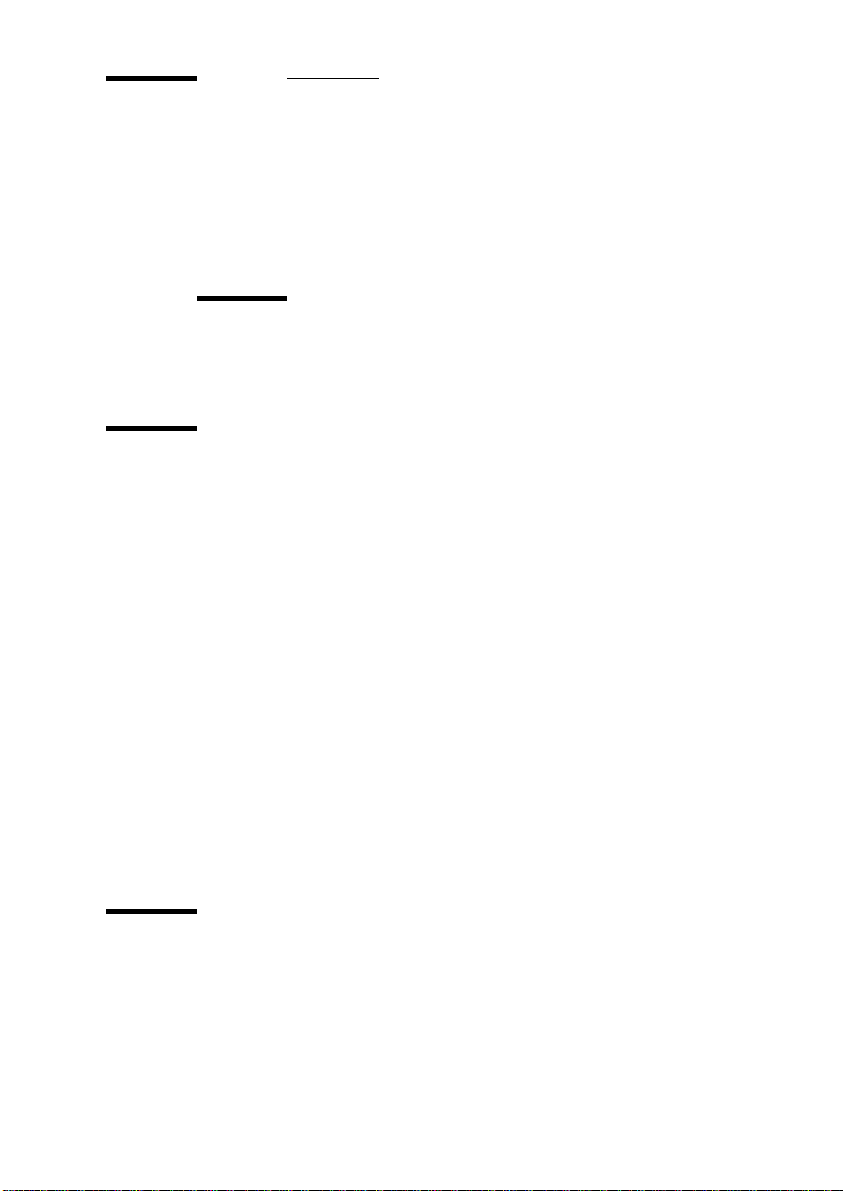

[8] Océ CS 5050/5070 Prime tool

When priming delivery lines, be sure to wipe off any excess ink from the

Note:

Océ 5350 Prime tool before going on to the next colour to avoid colour mixing.

▼▼▼▼

To prime the delivery lines

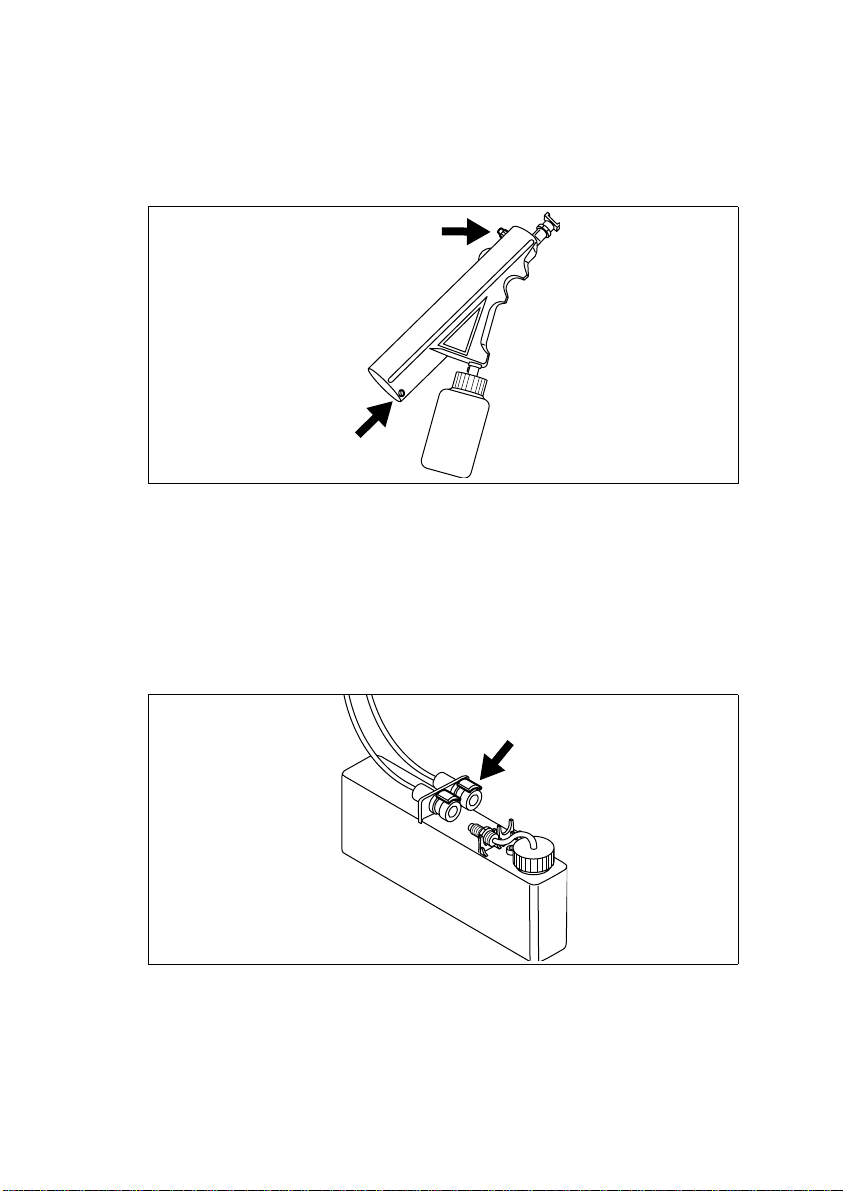

Fill the ink reservoirs (do not exceed maximum lev el line). Attach the reservoir

1

to the appropriate ink delivery line by quickly pressing connect tab and

snapping reservoir into place.

[9] Quick-connect fitting

For the right order in which to place the ink reservoirs, see the sticker

Note:

on the carriage.

28 Océ CS 5050/5070 User Manual

Page 29

Obtain the Océ CS 5050/5070 Prime tool.

2

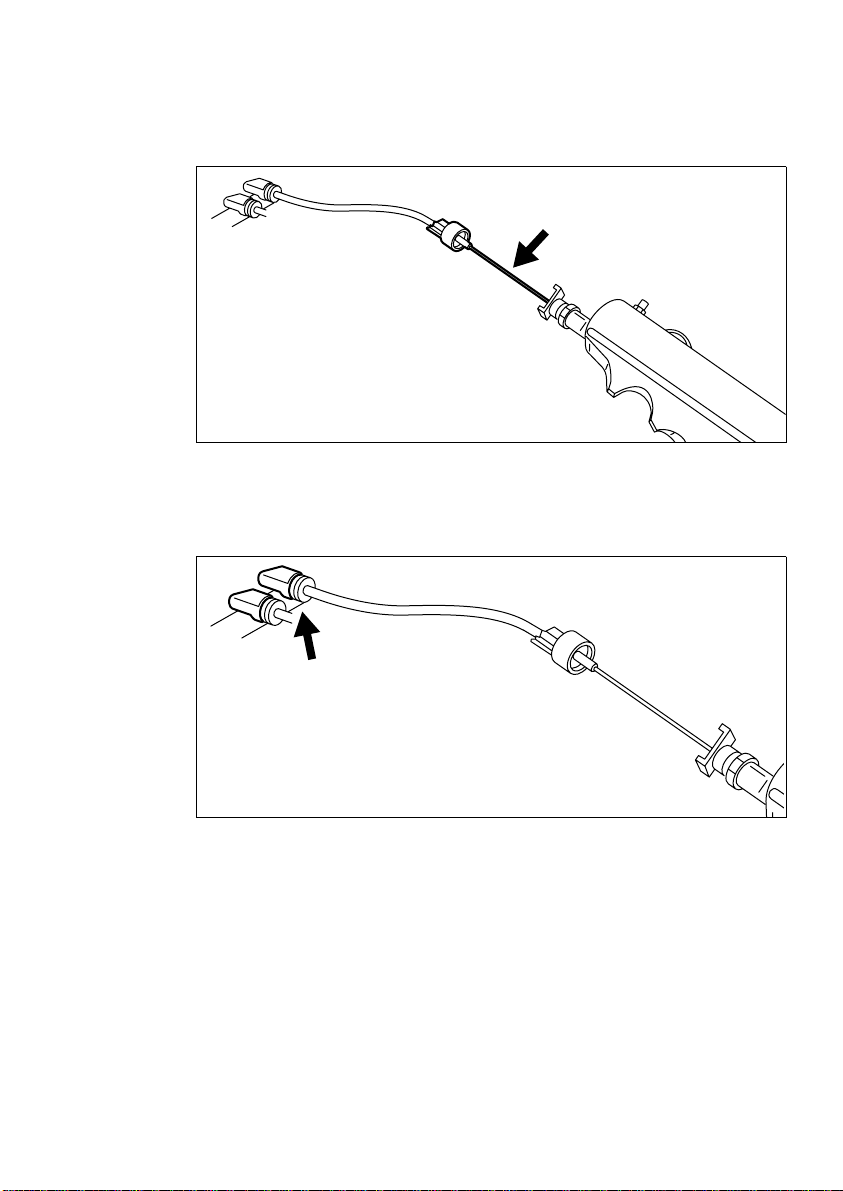

Prime each tubing/chain ink line by inserting the cartridge needle into the end

3

of the Prime tool and pressing the button several times until a solid stream of

ink is present throughout the tubing.

2298

[10] Inserting the needle into the small opening of the Prime tool

With your other hand, simultaneously press the quick-connect fitting tab (blue

4

or grey) and pull on the connect fitting to release the cartridge tube assembly

from the electronics cover.

[11] Quick-connect fitting tab

Getting started 29

Page 30

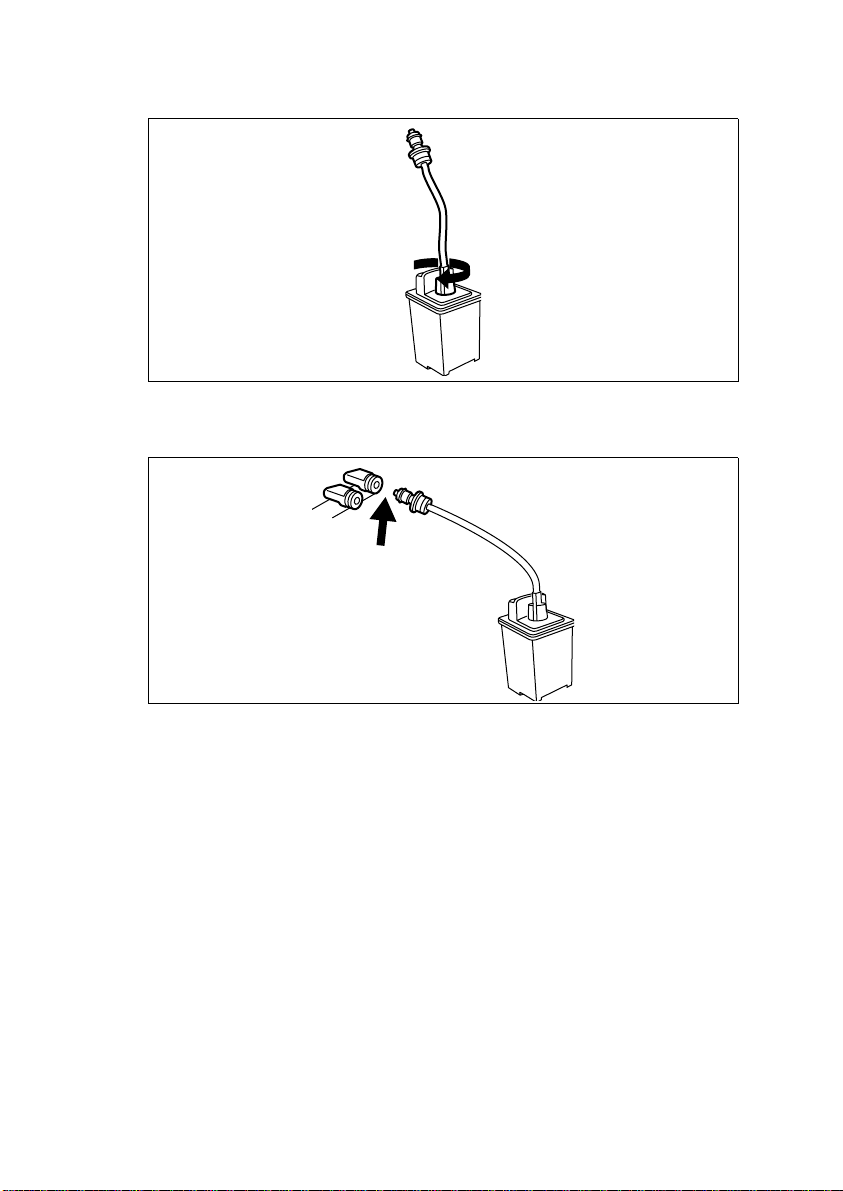

Remove the cartridge needle from the Prime tool and insert it into the cartridge

5

opening; turn it clockwise and tighten securely.

[12] Removing the cartridge needle

Re-attach cartridge tubing assembly to the quick-connect fitting.

6

[13] .Re-attaching cartridge tubing assembly

30 Océ CS 5050/5070 User Manual

Page 31

Remove the blue tape from the cartridge jet plate.

7

Do not raise the cartridge 30 degrees above electr onics cover or turn

Note:

the cartridge upside-down during th e tape removal or priming process.

[14] Removing the blue tape from the cartridge jet plate

Attach the Prime tool to the cartridge jet plate and prime cartridge with pulses

8

by pressing the activation button repeatedly.

A helpful method is to break the seal with th e jet plate af ter e ach

Note:

pulse to improve the priming success rate.

[15] Attaching the Prime tool to the cartridge jet plate

Getting started 31

Page 32

Blot the jet plate with a lint-free towel or cloth.

9

[16] Blotting the jet plate

Insert the cartridge into the carriage, making sure it snaps into place properly.

10

[17] Inserting the cartridge into the carriage

Printing a colour test

An initial colour test checks for correct cartridge priming, to ensure that all

colours print in a uniform and solid pattern.

▼▼▼▼

32 Océ CS 5050/5070 User Manual

To print the colour test

Check that the printer has media loaded.

1

Press

2

3

4

5

6

7

Setup menu/Print Mode menu

Press

Quality mode/Photo

Select

Utility menu/Service menu/Diagnostics/Colour Test

Set the colour test percentage to 75%.

Press OK. The colour test prints.

Check that all colour bands print a solid pattern, indicating a correct priming

of cartridges. Run the colour test again if you do not obtain a solid pattern.

.

.

.

Page 33

Printing the prime pattern

The prime pattern is printed to check that the ink cartridges fire properly and

to detect any clogged or electrically defective jets.

▼▼▼▼

To print the prime pattern

With the media loaded, press

1

2

Select

Prime

.

Utility

menu

T e sting pattern prints. The test pattern consists of four coloured bands (black,

cyan, magenta and yellow), a series of lines and a CMYK header, indicating

the compensating print modes for damaged jets. (See ‘Compensating for

electrically defective jets’ on page 93.)

▼▼▼▼

To interpret the pri me tes t

The bands should be smooth, without dark streaks or white lines. The lines

■

should not look fuzzy or contain gaps.

[18] The upper test pattern of a prime test

Within the printed test pattern, each jet is represented by a short horizontal

■

line. Together, these short horizontal lines form a “stair step” pattern.

Electrically defective jets appear as solid bars for which you can compensate.

■

Clogged jets appear as gaps or misdirected lines in the “stair step” pattern,

■

which must be cleared manually.

The print modes for which compensation is available are shown above the

■

test pattern.

Getting started 33

Page 34

In the example above, the prime test shows that there are three electrically

■

defective jets and one clogged jet. The header indicates that you can

compensate for the electrically defective jets in the 4-pass mode. But you

must clear the clogged jet manually. See ‘clearing clogged jets’ on page 93

for further information.

If all jets appear to be defective, reinstall the cartridges.

Note:

34 Océ CS 5050/5070 User Manual

Page 35

Calibrating cartridges

For best results, perform a calibration each time you install a new cartridge.

▼▼▼▼

To print a colour calibration test

With paper loaded, press

■

Utility/Colour Calibration menu/ Calib Print Test

.

The printer draws a series of three patterns as follows:

Current Heads (Y, M, C)

shows yellow , magenta, and cyan “+” which represent

the horizontal and vertical alignment between the cartridges.

Yel low

[19] Current Heads (Y, M, C)

Magenta

Cyan

Black

If the coloured “+” lines up horizontally and vertically with the black

alignment marks, no adjustment is required.

Colour Vertical Head-To-Head Calibration

checks for vertical alignment.

Colour Black

[20] Colour Vertical Head-to-Head Calibration

Getting started 35

Page 36

Colour Horizontal Head-To-Head Calibration

checks for horizontal alignment.

Three lines similar to the examples below are printed with the following colour

combinations: yellow/magenta, magenta/cyan, and cyan/black.

.... - 3

[21] Colour Horizontal Head-to-Head Calibration

- 2

The numbers below each set of lines represent the different horizontal and

vertical alignment values.

▼▼▼▼

To adjust colour calibration values

Examine the patterns to determine which value shows the best horizontal and

1

vertical alignment between cartridges. These are the values you will set in the

printer menu.

Press

2

3

4

5

6

Cyan -Vertical

Enter the value which represents the best alignment for cyan vertical.

Press OK.

Repeat for Magenta and Yellow vertical.

Repeat procedure for Cyan, Magenta, and Yellow horizontal.

.

Defining calibration units

You can set the calibration units to English or Metric.

▼▼▼▼

To set calibrati on un its

Select

1

2

Setup/User Setup/Units Select

Choose

English

or

Metric

- 1

0

1

2

3 ....

.

.

36 Océ CS 5050/5070 User Manual

Page 37

Cartridge recognition

The Océ CS 5050/5070 printe r is designed to use only Océ CS 5050/5070

cartridges. To avoid potential damage to the printer, a

feature checks for properly installed Océ cartridges. This function activates

when the printer receives a print request (i.e., image data, prime, etc.).

If the system detects a problem, the “Unrecognised Cartridge(s)” error

message displays on the control panel, and the printer beeps three (3) times.

You must clear this error before the printer can proceed with the print job.

cartridge recognition

▼▼▼▼

To clear cartridge recognition error

1

Press

Access Cartridges

to move the carriage to the correct position for

replacement of the ink cartridges.

Make sure that there are four installed Océ cartridges.

2

Replace any invalid cartridge.

3

Press OK.

4

This error can also occur with incorrectly installed Océ cartridges, due

Note:

to poor electrical connections between the cartridge and the carriage unit.

Getting started 37

Page 38

Calibrating the colour deadband

When printing in bi-directional mode, the velocity of the carriage can cause

certain dots to miss the target area on the media. To alle viate this problem, use

the

colour deadband compensation

colour deadband test pattern lets you check the velocity deadband values and

adjust them for best printing results.

feature to fine-tune dot placement. The

▼▼▼▼

To print the colour deadband test pattern

Press

1

2

3

Setup/Utility

Select

Calibration/Colour Db test

100 92 84 76 68 60 52 44 36 28 20 12

[22] Colour deadband test pattern

For each colour, examine the vertical lines and select the set of straightest lines.

.

. The following pattern prints out:

( FAST K=44, C=52, M=52, Y=52, SLOW=1)

Note the compensation number at the bottom of the set of lines you have

selected.

Compare with the existing compensation values printed in the lower right

4

corner of the test pattern. If any of these differ from the values you selected,

enter the new compensation values by pressing the button corresponding to the

colour deadband you want to ch ange.

Use the

5

Next

and

Previous option

buttons to scroll to the desired compensation

value.

38 Océ CS 5050/5070 User Manual

Page 39

Calibrating the paper axis

External factors such as room temperature, storage temperature, and humidity

can have a deforming effect on media. A paper axis calibration corrects minor

paper length fluctuations, and carried out using a precision ruler at least 33

inches (838.2 mm) long.

▼▼▼▼

To print the paper axis test

Load the media that you want to use. Check that the length is at least 36 inches

1

(91 cm) long.

Press

2

3

Utility/Calibration/Paper Axis Test

Remove the media from the printer and measure the distance between the

. The printer prints two marks.

witness marks. The distance between the marks should be exactly 838.2 mm

(33.00 ”).

If the distance between the marks is different from that shown on the display,

4

press

Paper Axis

Press OK.

■

The OGSL software can convert units from inches to metric, and vice

Note:

to enter the value of the distance you have just measured.

versa. See your software documentation for instructions.

Getting started 39

Page 40

Operating the printer

While the printer prints, you can stop it momentarily and then resume printing,

or cancel a print.

▼▼▼▼

▼▼▼▼

To pause the printer while printing

Press

1

Press it again to resume printing.

2

Note:

To cancel a print

Cancel the print job from the computer using the appropriate command fo r

■

.

Pause

Banding might oc c ur.

your software application.

▼▼▼▼

To clear the buffer after cancelling a print

Press

■

Reset

.

40 Océ CS 5050/5070 User Manual

Page 41

Océ CS 5050/5070

User Manual

Chapter 3 Printing options

This section explains the available printing options:

■

Menu functions

■

Default printer settings

■

Print modes

■

Media standards and options

■

Saving user options

41

Page 42

Main menu at a glance

Main menu Menu options Subsequent options (in italics) or function

Load

media

Cut Cuts media

Pause Stops print job temporarily

Reset Clears print buffer after job cancellation

Feed

Media

Setup

Print mode

Forward

Media counter

Display counter

Backward

End of media

Paper options

User setup

Ink option

Moves media into/away from platen

Advances media to the front of printer

Tracks the length of media remaining on a roll

Shows and prints the length of media remaining on a roll

Moves media to the back of printer

Detects when media no longer advances through the printer

Colour mode, Quality mode, Dots per inch, Print passes,

Carriage speed, Print direction, Exit

Supply type, Media standard, Margins, Auto-load delay, Auto-cut, Save media, Auto-wipe, Exit

Select user, Save user, Unit select, Language, Init. settings,

Print settings, LCD contrast, Exit

Ink reduction, Ink preheat, Dryer, Dry time, Exit

Serial comm

HPGL/2 menu

Exit

Utility Prime

Access cartridge

Display settings

Print settings

Colour Calib

menu

Calibration menu Use Calib XY, Paper axis test, Colour Db menu, Open jet

Service menu

(diagnostics used

by technical support)

42 Océ CS 5050/5070 User Manual

Baud rate, Data bits, Parity bits, Exit

Palette select, Control, Rotation, Nesting menu, Reprints,

Ink limit, Exit

Returns to the main menu

Prints the prime pattern

Moves carriage away from service station

Displays information such as paper width and height, on

time, cumulative plot time

Prints information about media size, f irmware version, RAM

size, plot hours

Prints the colour calibration test pattern values, sets the colour values determined by the test pattern .

menu, Paper axis

Calibration, Diagnostics, About, Cartrid ge Informa tio n

Page 43

Using the default settings

The following table shows the factory default printer settings. You can print

these settings for reference.

▼▼▼▼

To print settings

Press

■

Setup/User

and

Setup/Print Settings

to get a listing of current settings.

Be sure to have pa per lo ade d be for e you st art .

▼▼▼▼

To return to factory default settings

Press

■

Setup/User Set up/Init

Settings buttons. All saved user settings return to

default settings.

Printing options 43

Page 44

User Settings Default Other optio ns

COLOUR MODE

QUALITY MODE

Colour Mono, Grey

Photo Draft, Quality, User,

Production

DOTS PER INCH 600 300

PRINT PASSES

CARRIAGE SPEED

PRINT DIRECTION

4 1, 2, 3, 4, 8, 10

10 1-10

Bi Uni

AUTO-LOAD DELAY 6 1-12 seconds

MEDIA ST ANDARD

All US ENGR, US ARCH,

ISO A, M_DIN.

GRAPHICS, MET

OVER A, ISO B, SPECIAL

MARGIN

AUTO CUT

SAVE MEDIA

AUTO WIPE

CALIB XY

SELECT USER

SAVE USER

UNITS SELEC T

Normal Expanded

ON OFF

ON OFF

ON OFF

ON OFF

11 TO 8

11 TO 8

English Metric

LANGUAGE English German, French, Ital-

ian, Spanish, Portuguese, Japanese,

Chinese, Korean

INK PREHEAT

2 OFF, 1-7

INK REDUCTION 0 12.5 %, 25%, 37.5%,

50%

DRYER

DRY TIME

OFF ON

0 0:10, 0:20, .... 60.:00

44 Océ CS 5050/5070 User Manual

Page 45

User Settings Default Other options

BAUD RATE

PARITY BIT

System settings Default Other options

SUPPLY TYPE

LCD CONTRAST

Calibration settings Default Other options

DEADBAND

SLOW DEADBAND

CYAN VERTICAL

MAGENTA VERTICAL

YELLOW VERTICAL

CYAN HORIZONTAL

MAGENTA HORIZONTAL

YELLOW HORIZONTAL

PAPER AXIS

9600 19200, 38400

None Even, odd

Take-up (5070) Roll, Sheet

81-16

44 0 .... 120

0 -2 ... +2

0 -9 ... +9

0 -9 ... +9

0 -9 ... +9

0 -9 ... +9

0 -9 ... +9

0 -9 ... +9

33.00 32 - 34

Printing options 45

Page 46

Choosing print mode options

Your printer offers several print modes which compromise between speed and

quality.

The print mode choice depends on factors such as software application, colour

vs. monochrome printing, and media type. Each print mode directly affects the

printing speed and the quality of the printed image. The following print mode

options are available:

Colour modes

■

Print quality modes

■

Print passes

■

Carriage speed

■

Print direction

■

DPI mode

■

The following table summarises the default print mode settings. It is not

necessary to set all the parameters, unless you want to create a user-defined

print mode.

Mode DPI Uni or bi-di-

rectional

DRAFT

PRODUCTION

QUALITY

PHOTO

USER

600 x

600

600 x

600

600 x

600

600 x

600

600 x

600

BI 1 10

BI 2 10

BI 3 10

BI 4 10

User-defined via the contr ol panel

Passes Carriage speed

46 Océ CS 5050/5070 User Manual

Page 47

Selecting resolution (dpi)

Select your image resolution based on the viewing distance and user

specifications. This resolution is not the same resolution as in the resulting

rasterised file created with OGSL. For best results, make sure that the printer

resolution (dpi) matches the image resolution of the file you are printing.

Even though a rasterised image at 6 00 dpi is four times la rger than the

Note:

same image at 300 dpi, the printing speed does not change (if other settings are

the same.) The printer always prints at 600 dpi, even if the print mode menu

setting displays 300 dpi. This setting refers to the resolution at which your

image was created, and not the actual resolution at which it prints.

OGSL automatically corrects for imag es with differ en t input r esolutions.

Note:

RIP

resolution

300 dpi

300 dpi

600 dpi

600 dpi

▼▼▼▼

To choose resolution

Press

1

2

Setup menu/Print mode menu/Dots per inch

Select

Printer dpi setting Result of printed output image

300 dpi 1 input pixel

prints as 4 output

pixels.

600 dpi 1 input pixel

prints as 1 output

pixels.

300 dpi 1 input pixel

prints as 1 output

pixels.

600 dpi 1 input pixel

prints as 1 output

pixels.

or

300

resolution.

600

The printed image

is the size of the

original.

The printed image

is 1/4 the original

size.

The printed image

is 4 times the original size.

The printed image

is the size of the

original.

.

Printing options 47

Page 48

Selecting a colour mode

Colour mode gives you the option of printing in colour or monochrome.

▼▼▼▼

To choose a colour mode

Press

1

Setup/Print Mode/Colour Mode

Choose

2

Press OK.

3

Colour

or

Mono

Selecting quality modes

You can select five print quality modes, depending on the type of image you

are printing (i.e. line art or photographs).

A single-pass mode that optimises printing speed over quality. Useful as

Draft

a check for position, layout, colour, etc., but not for finished quality images.

Production

paper. Use it for line drawings or images with small areas of fill and large areas

of white space.

Note: Draft

modes are not r ecommended for printing ima ges, because bleeding may occur

in areas of heavy fill or dark shading.

Quality

on paper media.

A two-pass mode that gives fast, average-quality prints on bond

and

Production

A three-pass mode that gives fast, better-than-average-quality prints

.

.

modes are suitable for line drawings (CAD). These

A four-pass mode that optimises quality over printing speed, used for

Photo

high-quality continuous-tone images.

User-defined

This option lets you select the number of print passes, the print

direction, and the carriage speed.

Use multi-pass modes for continuous tone images, blends, and solid fills.

Note:

Because these modes split inking into three or four passes, it reduces print

anomalies such as banding (stripes through fills) and over-inking. Howe ver, it

takes longer to print. Experiment with different modes to pick the best one for

your needs.

48 Océ CS 5050/5070 User Manual

Page 49

▼▼▼▼

To choose print quality

Press

1

2

3

Setup/Print Mode /Quality Mode

Choose the print quality.

Press OK.

Setting the number of print passes

The number of passes indicates how many times the cartridges must f ire to lay

down the ink for a complete scan line. When you choose multiple passes, the

jets fire a fraction of the dots on each pass. The result is less ink in each pass.

If you're printing an image with heavy fill or shading, setting the print mode to

an option that lays down less ink (e.g., three pass) can help prevent running and

bleeding.

The 10-pass print mode can handle difficult print jobs that involve high

contrast solid fills and blends. This mode can give higher output quality from

older cartridges, hence extending the life of your cartridges.

.

▼▼▼▼

To change the number of passes

Choose

1

2

3

Setup/Print Mode/Print Passes

Choose

single, two, three, four, six, eight, or ten

Press OK.

Setting the carriage speed

The carriage speed determines the number of dots that print (per second) as the

carriage moves over the media.

▼▼▼▼

To set the carriage spee d

Press

1

2

3

Setup/Print Mode/Carriage speed.

Choose the speed from 1 to 10.

Press OK.

.

passes.

Printing options 49

Page 50

Selecting the print direction

The print direction determines whether the inkjets fire on both passes of the

carriage over the print area (bi-directional), or simply on the return pass

(unidirectional).

■ Unidirectional

printing can reduce ru nn ing a nd i nk blee d i ng if you have an

image with solid fills and blends.

■ Bi-directional

printing can decrease your printing time if printer speed is

more important.

▼▼▼▼

To change the print direction

Press

1

Setup/Print Mode/P rint Direction

Choose

2

Press OK.

3

Unidirectional

or

Bidirectional

.

.

When printing in bi-directional mode, the velocity of the carriage can cause

certain dots to miss the target area on the media. To alle viate this problem, use

the

colour deadband compensation

feature to fine-tune dot placement. The

colour deadband test pattern lets you check the velocity deadband values and

adjust them for best printing results (see ‘To print the colour deadband test

pattern’ on pag e 38).

50 Océ CS 5050/5070 User Manual

Page 51

Choosing "feed media" options

The printer’s "Feed media" options allow you to:

set the "end of media" detection

■

use the media counter to estimate the remaining media length

■

Detecting the "end of media"

When the media jams or does not unroll properly from the feeder roll, it cannot

advance through the printer. However, the carriage sensor still detects the

presence of media and printing progresses. This damages the print job because

the printer continues to lay down ink on the same portion of media.

The "End of media/Feeder stop" option can limit the damage in these cases.

When the printer detects an abnormally long absence of the media loop

between the feeder roll and the platen, it automatically enters the "pause"

mode, as if you had manually pre ssed "Pause" on the control panel menu.

The printer beeps 3 times every 20 seconds, and remains in the "pause" mode

until you either:

manually press "Pause" to resume printing ("Pause" is a toggle function)

■

manually press "Reset" to abort printing . Abort the print job from the

■

software application as well.

When you use this setting, keep in mind the following principles:

This setting does not work with cut sheets as the selected media

■

This setting is a machine setting and therefore activates each time you switch

■

on the printer, until you manually turn it off from the control panel menu

You cannot store this setting as a user setting

■

You cannot change this setting once printing begins

■

When you manually press "Pause" to resume printing, the "Feeder stop"

■

detection disables for the remainder of the print

When activated, the "Feeder stop" detection restarts at the beginning of each

■

print

Printing options 51

Page 52

▼▼▼▼

To set the "Feeder st op"

Press

1

2

3

Feed Media/End of Media

Choose

Feeder Stop

Press OK.

Using the media counter

The media counter gives you a means of "estimating" the length of media left

on a roll.

When you install a new roll (or used roll of media with a kno wn length), you

■

enter the length in the media counter on the control panel.

As the printer uses up the media, this value decreases and displays on the

■

control panel.

When you remove the media roll, you can print the estimated remaining

■

length on the roll, and enter this value in the media counter the next time you

use this roll.

.

.

▼▼▼▼

▼▼▼▼

▼▼▼▼

▼▼▼▼

To enter a media length value

Press

1

2

3

1

2

1

2

3

1

2

3

Feed Media/Media counter

Enter the media length.

Press OK.

To display the media length value

Press

Feed Media/Display counter

Press

To print the media length value on the roll

Press

Press

Press

To reset the media counter to 0

Press

Press

.

Exit

Feed Media/Display counter

Print counter

.

Exit

Feed Media/Media counter

Reset counter

.

.

Press OK.

.

. The current value appears.

.

.

52 Océ CS 5050/5070 User Manual

Page 53

When you use this setting, keep in mind the following principles:

Reset the media counter to 0 to avoid confusion when not in use

■

The media counter does not decrease below 0

■

This setting is a machine setting and therefore activates each time you switch

■

on the printer, until you manually turn it off from the control panel menu

You cannot store this setting as a user setting

■

Printing options 53

Page 54

Choosing paper options

The following paper options are available:

Supply Type

■

Margins

■

Media standards

When you print an image, you determine its size from the software application.

Make sure that you have loaded a media wide enough to accommodate the

image size; the printer automatically defines the print area based on the width

of the loaded media. If length is a problem, use roll media. If the media width

is smaller than the image size, the image may be truncated.

▼▼▼▼

To choose the media standard

Press

1

Setup/Paper Option/Media Standard

Choose the size of media you are loading.

2

Press OK.

3

Save Media

■

Auto-Load Delay

■

.

Auto-Wipe

■

Auto-Cut

■

54 Océ CS 5050/5070 User Manual

Page 55

Rollfeed media: sizes and maximum printing areas

Paper size Normal Print Area Expanded Print Area

Graphic (U.S. Offset)

8.5” x 11.0” 7.3” x 9.8” 8.1” x 10.6”

A

11.0” x 17.0” 9.8 ” x 15.8” 10.6” x 16.6”

B

17.0” x 22.0”

C

19.0” x 25.0”

20.0” x 28.0”

22.0” x 26.0”

22.0” x 34.0”

D

23.0” x 35.0”

24.0” x 29.0”

25.0” x 38.0”

32.0” x 44.0”

34.0” x 44.0”

E

35.0” x 45.0”

36.0” x 45.0”

40.0” x 50.0”

48.0” x 65.0”

50.0” x 65.0”

54.0” x 65.0”

60.0” x 65.0”

U.S. Architectural

9.0” x 12.0” 7.8” x 10.8” 8.6” x 11.6”

A

12.0” x 18.0” 10. 8” x 16.8” 11.6” x 17.6”

B

18.0” x 24.0” 16. 8” x 22.8” 17.6” x 23.6”

C

24.0” x 36.0” 22. 8” x 34.8” 23.6” x 35.6”

D

36.0” x 48.0” 34. 8” x 46.8” 35.6” x 47.6”

E

U.S. Engineering

8.6” x 11.0” 7.3” x 9.8” 8.1” x 10.6”

A

11.0” x 17.0” 9.8 ” x 15.8” 11.6” x 16.6”

B

17.0” x 22.0” 15. 8” x 20.8” 16.6” x 21.6”

C

22.0” x 34.0” 20. 8” x 32.8” 21.6” x 33.6”

D

15.8” x 20.8”

17.8” x 23.0”

18.8” x 26.0”

20.8” x 24.0”

20.8” x 32.8”

21.8” x 33.0”

22.8” x 27.0”

23.8” x 36.0”

30.8” x 42.0”

32.8” x 42.8”

33.8” x 43.0”

34.8” x 43.0”

38.8” x 48.0”

46.8” x 63.0”

48.8” x 63.0”

52.8” x 62.4”

58.8” x 62.4”

16.6” x 21.6”

17.6” x 24.6”

18.6” x 27.6”

20.6” x 25.6”

21.6” x 33.6”

21.6” x 34.6”

22.6” x 28.6”

23.6” x 37.6”

30.6” x 43.6”

33.6” x 43.6”

33.6” x 44.6”

34.6” x 44.6”

38.6” x 49.6”

46.6” x 64.6”

48.6” x 64.6”

53.6” x 62.8”

59.6” x 62.8”

Printing options 55

Page 56

Paper s ize Normal Print Area Expanded Print Area

34.0” x 44.0” 32.8” x 42.8” 33.6” x 3.6”

E

ISO-A

210 x 297 mm 180 x 267 mm 200 x 287 mm

A

4

297 x 420 mm 267 x 390 mm 287 x 410 mm

A

3

420 x 594 mm 390 x 564 mm 410 x 584 mm

A

2

594 x 840 mm

A

625 x 880 mm

1

841 x 1189 mm 811 x 1159 mm 831 x 1179 mm

A

0

METRIC-DIN

250 x 337 mm 220 x 307 mm 240 x 327 mm

A

4

337 x 460 mm 307 x 430 mm 327 x 450 mm

A

3

460 x 634 mm

A

610 x 860 mm

2

634 x 881 mm

A

860 x 1220 mm

1

881 x 1229 mm

A

1000 x 1414 mm

0

1189 x 1682 mm

ISO-B

250 x 353 mm 220 x 288 mm 240 x 298 mm

B

564 x 810 mm

595 x 815 mm

430 x 604 mm

580 x 795 mm

604 x 851 mm

830 x 1155 mm

851 x 1199 mm

970 x 1349 mm

1158 x 1617 mm

584 x 830 mm

615 x 825 mm

450 x 624 mm

600 x 805 mm

624 x 871 mm

850 x 1165 mm

871 x 1219 mm

990 x 1359 mm

1179 x 1627 mm

3

353 x 500 mm 323 x 470 mm 343 x 490 mm

B

3

500 x 707 mm 470 x 677 mm 490 x 697 mm

B

2

707 x 1000 mm 677 x 970 mm 697 x 890 mm

B

1

56 Océ CS 5050/5070 User Manual

Page 57

Sheet media: sizes and maximum printing areas

Paper size Normal Print Area Expanded Print Area

Graphic (U.S. Offse t)

8.5” x 11.0” 7.3” x 9.0” 8.1” x 9.4”

A

11.0” x 17.0” 9.8 ” x 15.0” 10.6” x 15.4”

B

17.0” x 22.0”

C

19.0” x 25.0”

20.0” x 28.0”

22.0” x 26.0”

22.0” x 34.0”

D

23.0” x 35.0”

24.0” x 29.0”

25.0” x 38.0”

32.0” x 44.0”

34.0” x 44.0”

E

35.0” x 45.0”

36.0” x 45.0”

40.0” x 50.0”

48.0” x 65.0”

50.0” x 65.0”

U.S. Architectural

9” x 12.0” 7.8” x 10.0” 8.6” x 10.4”

A

12.0” x 18.0” 10. 8” x 16.0” 11.6” x 16.4”

B

18.0” x 24.0” 16. 8” x 22.0” 17.5” x 22.4”

C

24.0” x 36.0” 22. 8” x 34.0” 23.6” x 34.4”

D

36.0” x 48.0” 34. 8” x 46.0” 33.6” x 46.6”

E

U.S. Engineering

8.5” x 11.0” 7.3” x 9.8” 8.1” x 9.4”

A

17.0” x 22.0” 9.8 ” x 15.0” 10.6” x 15.4”

B

17.0” x 22.0” 15. 8” x 20.0” 16.6” x 20.4”

C

22.0” x 34.0” 20. 8” x 32.0” 21.6” x 32.4”

D

34.0” x 44.0” 32. 8” x 42.0” ”33.6” x 42.4”

E

15.8” x 20.0”

17.8” x 23.0”

18.8” x 26.0”

20.8” x 24.0”

20.8” x 32.0”

21.8” x 33.0”

22.8” x 27.0”

23.8” x 36.0”

30.8” x 42.0”

32.8” x 42.0”

33.8” x 43.0”

34.8” x 43.0”

38.8” x 48.0”

46.8” x 63.0”

48.8” x 63.0”

16.6” x 20.4”

18.6” x 23.6”

19.6” x 26.6”

21.6” x 24.6”

21.6” x 32.4”

22.6” x 33.6”

23.6” x 27.6”

24.6” x 36.6”

31.6” x 42.6”

33.6” x 42.4”

34.6” x 43.6”

35.6” x 43.6”

49.6” x 48.6”

47.6” x 63.6”

49.6” x 63.6”

Printing options 57

Page 58

Paper s ize Normal Print Area Expanded Print Area

ISO-A

210 x 297 mm 180 x 247 mm 200 x 257 mm

A

4

297 x 420 mm 267 x 370 mm 287 x 380 mm

A

3

420 x 594 mm 390 x 544 mm 410 x 554 mm

A

2

594 x 840 mm 564 x 791 mm 564 x 801 mm

A

1

841 x 1189 mm 811 x 1139 mm 831 x 1149 mm

A

0

METRIC-DIN

250 x 337 mm 220 x 287 mm 240 x 297 mm

A

4

337 x 460 mm 307 x 410 mm 327 x 420 mm

A

3

460 x 634 mm 430 x 580 mm 450 x 694 mm

A

2

634 x 881 mm 604 x 831 mm 624 x 841 mm

A

1

881 x 1229 mm 851 x 1179 mm 871 x 1189 mm

A

0

ISO-B

353 x 500 mm 323 x 450 mm 343 x 460 mm

B

3

500 x 707 mm 470 x 657 mm 490 x 667 mm

B

2

707 x 1000 mm 677 x 950 mm 697 x 960 mm

B

1

58 Océ CS 5050/5070 User Manual

Page 59

Setting margins

IMAGE

Y ou can set margins to

Normal

or

Expanded

. Any part of the image that extends

outside the margin will be clipped.

The

Expanded

setting enlarges the print area and decreases the margins. When

using this setting, make sure that you align the media accurately using the

guide on the right of the platen so that the ink doesn’t exceed the edge of the

media.

The following tables give the margin sizes for cut sheet and roll feed media:

Cut sheet media On three sides Fourth (bottom) side

Normal

Expanded

15 mm (0.6”) 35 mm (1.4”)

5 mm (0.2”) 35 mm (1.4”)

IMAGE

[23] Cut sheet normal margins and expanded margins

Rollfeed media All sides

Normal

Expanded

Printing options 59

15 mm (0.6”)

5 mm (0.2”)

Page 60

0.59"(15mm)

m

m

0.59"(15mm)

0.59"(15m

0.197"(5mm)

0.197"(5mm)

0.197"(5m

IMAGE

0.59"(15mm)

[24] Roll sheet normal margins and expanded margins

▼▼▼▼

To set margins

Press

1

2

3

Setup/Paper Option/Margins

Choose

Press OK.

Normal

or

Setting auto-load delay

Auto-load delay is the time lapse between the moment the printer senses the

presence of the media and when it actually starts feeding the media. This gives

you time to reposition the media manually if necessary. The default is 6

seconds, selectable from a range of 1-12 seconds.

▼▼▼▼

To set auto-load delay

Press

1

2

3

Setup/Paper Option/Auto-load delay.

Choose the delay time.

Press OK.

Only stored in memory in combination with a user-defined setting.

Note:

Expanded

IMAGE

0.197"(5mm)

.

.

Selecting auto-cut

With the

Auto-cut

the media when printing completes. To ensure that the image is dry before

cutting, turn on the dryer and/or specify a dry time. You can also select to cut

the media manually from the printer control panel at any time.

Auto-cut is disabled when the paper feed option is set to

Note:

60 Océ CS 5050/5070 User Manual

option activated (by default), the printer automatically cuts

“take-up”

.

Page 61

▼▼▼▼

To set auto-cut

Press

1

Choose On or

2

Press OK.

3

Saving media

Setup/Paper Option/Auto-Cu

.

Off

t.

With the

Save media

enough to print the image. When not activated, the printer advances the full

print area of the loaded media. For example, if a 36 inch roll is loaded, the

printer advances the entire print area for a standard 36 x 48" sheet, even if the

printed image is only 30 inches long.

▼▼▼▼

To turn off Save Media

Press

1

2

3

Setup/Paper Option/Save Media

Choose

Off

.

Press OK.

Selecting auto-wipe

The printer automatically wipes the cartridge jet plates periodically during

printing (by default). However, you can de-activate this setting if you are

having problems with banding.

Not wiping the cartridge jet plates can cause inkjet clogging.

Note:

▼▼▼▼

To turn off the wiper

Press

1

2

3

Setup/Pape r Option/Auto-Wipe

Choose

Off

.

Press OK.

option activated (by default), the media advances only far

.

.

Applying ink reduction

Ink reduction lets you reduce the percentage of ink laid down by the printer.

This option applies to vector-based images only, and has no effect on

continuous tone (raster) images. This is useful for images with large amounts

of printed area, and limits bleeding or over-saturation of the media. However,

Printing options 61

Page 62

because it changes the appearance of colours, it is recommended to run a small

test print.

▼▼▼▼

To apply ink reduction

Press

1

2

3

Setup/Ink Option/Ink Re duc tion

Choose a reduction percentage Press OK.

Selecting ink preheat

Although cartridge heat settings are optimised for Océ media for printing in a

standard office environment, they can vary depending on the ambient

temperature where the printer is located and the type of ink or media used.

Adjusting the ink preheat settings (after applying other corrective measures)

can help solve problems with banding, poor fills, or over dot gain.

The default ink preheat values depend on the type of ink used, which the printer

reads from the chip at the back of each cartridge. You can either increase or

decrease the temperature from the default value by pressing (+) or (-)

respectively. When you reach the limits of the temperature range, the panel

displays

modify when changi ng to another type of ink.

Use the following tips to select preheat settings:

Turn down the heat for a smaller dot size in a hot or humid environment.

■

Turn up the heat in a cold or dry en vironment for a larger dot size. Ho we v er,

■

too high a setting can cause the ink to run or sputter.

Note:

or

MAX

Adjusting the preheat settings will influence the printed colours.

.

12.5, 25%, 37.5, or 50%

. The printer saves the new settings, which you must

OFF

.

▼▼▼▼

62 Océ CS 5050/5070 User Manual

To select an ink preheat setting

Press

1

2

3

Setup/Ink Option/Ink Preheat

Choose a preheat setting.

Press OK.

.

Page 63

Turning on the dryer

The dryer is installed at the base of the printer stand and is designed to dry the

ink. When activated, the dryer fans turn on at the be ginning of a print and stay

on for 10 minutes unless you set a specific dry time.

▼▼▼▼

To turn on the dryer

Press

1

2

3

Setup/Ink Option/Dryer

Choose On.

Press OK.

Setting the dry time

Unattended prints require drying time to prevent the ink from smearing when

the image touches the take-up roll or previously printed images. Different

media can require different drying time depending on the ambient temperature

and humidity . Dry time values range from 10 seconds to 60 minutes. When this

time expires, the printer rolls or cuts the image before printing the next image

in the buffer.

▼▼▼▼

To set the dry time

Press

1

2

3

Setup/Ink Option/Dry Time

Choose a time from 10 seconds to 60 minutes.

Press OK.

Adjusting the LCD contrast

The LCD contrast option lets you adjust the brightness of the control panel

(with default setting 9). The contrast values range from 1-16, with 16 as the

least contrast.

.

.

▼▼▼▼

To set LCD contrast

Press

1

2

3

Setup/User Setup/LCD Contrast

Choose the contrast value.

Press OK.

Printing options 63

.

Page 64

Saving user options

You can save the most frequently used options to avoid reconfiguring the

printer each time you print an image. You can define up to eight different

configurations and save them under a user setting number ranging from 1-8.

Select the desired user setting number before sending an image to the printer.

You can save settings for the following options:

Cut On or Off

■

Media Standard

■

Auto load delay

■

Baud Rate

■

Auto-Wipe On or Off

■

Monochrome or Colour

■

Drying Time

■

Quality Mode

■

Print Mode

■

Margins

■

Parity

■

Dryer On/Off

■

▼▼▼▼

▼▼▼▼

64 Océ CS 5050/5070 User Manual

To save user-defi ned se ttin gs

Press

1

2

3

1

2

3

Setup/User Setup/Save User

Scroll to the number under which you want to save the user settings.

Press OK.

To use a previously saved user setting

Press

Setup/User Setup/Select User

Scroll to the number of the user setting you want.

Press OK.

.

.

Page 65

Océ CS 5050/5070

User Manual

Chapter 4 Printing with HP-GL/2

This section explains th e printi ng pa rameters generally

used with vecto r-based files, such as palet te sele ction,

printer control, rotation, reprints, nesting, and ink li mit.

HP-GL/2 and HP RTL are trademarks of the Hewlett-Packard Co. AutoCAD is a

Note:

trademark of Autodesk, Inc.

65

Page 66

Overvie w

The "Draft" and "Production" modes are the most suitable printing modes for

line drawings or drawings with light solid fills, typically created by

computer-aided design.

When printing vector data, you can either control certain options from your

software application or assign the control to the printer settings. The following

section explains the HP-GL/2 print settings on the Océ CS 5050/5070.

Accessing the HP-GL/2 menu options

The following menu options are available from the HP-GL/2 menu:

Palette select

■

Control

■

Rotation

■

Nesting menu

■

Reprints

■

Ink limit

■

▼▼▼▼

66 Océ CS 5050/5070 User Manual

To access the HP-GL /2 men u

In the main menu, press

■

Setup menu/HP-GL/2 me nu

.

Page 67

Selecting the palette

The "Palette select" option lets you choose either the HP-GL/2 or AutoCAD

palette. Each palette allows 256 colours with 8 predefined colours, as shown

below:

Pen number HP-GL/2 AutoCAD

0 White White

1Black Red

2 Red Yellow

3 Green Green

4 Yellow Cyan

5Blue Blue

6 Magenta Magenta

7 Cyan Black

▼▼▼▼

To choose a palette

From the main menu, press

1

Choose either HP-GL/2 or AutoCAD.

2

Press OK.

3

Setting the "Control" function

Set the control to establish whether it is the software application or the printer

control panel that determine certain printing functions. Control overrides the

following functions in the HP-GL/2 header file:

"Repeat Plot" (RP): when you set control to the printer, the printer will

■

ignore RP commands in the print file and make only one print. On the

control panel you can use the "H P-GL/2/Repri nts" menu to speci fy

additional copies.

"Enable Auto Cutter" (EC): when you set control to the printer, the printer

■

will ignore EC commands in the print file, and will not automatically cut

after each print. On the control panel, you can enable automatic cutting or

initiate a command for a single cut.

Printing with HP-GL/2 67

Setup menu/HP-GL/2 menu/Palette select

.

Page 68

Do not override software control when sending merged raster/vector

Note:

data to the printer.

▼▼▼▼

To set control

From the main menu, press

1

Choose either

2

Press OK.

3

Rotating a print

The printer automatically prints an image with the long side on the paper axis.

To fit multiple images and save media, you can use the "Rotation" (RO)

function to rotate vector files counter-clockwise 90 degrees at a time.

Only HP-GL/2 files support rotation. RTL files do not support rotation.

Note:

When you use this setting, keep in mind the following principles:

If you specify a rotation that does not fit on the media or contains raster

■

images, the file will not rotate.

If you set the rotation value to "Auto", the algorithm automatically rotates the

■

print if this procedure will save media, regardless of whether or not you hav e

enabled "Nesting".

If you set the rotation value to "0", the print does not rotate.

■

"Control" does not override the RO command in the print file.

■

▼▼▼▼

To rotate a print

From the main menu, press

1

Choose the rota tion angle (0, 90, 180, 270, Auto).

2

Press OK.

3

Software

Setup menu/HP-GL/2 menu/Control

or

.

Printer

Setup menu/HP-GL/2 menu/Rotation

.

.

Making reprints

You can print up to 99 copies of a specific vector f ile. When you set "Reprint"

to 0, only one copy prints.

▼▼▼▼

68 Océ CS 5050/5070 User Manual

To make reprints

From the main menu, press

1

Choose the number of reprints (0 to 99).

2

Press OK.

3

Setup menu/HP-GL/2 menu/Reprints

.

Page 69

Nesting

The "Nesting" function can save media by printing multiple prints across the

horizontal width of the media. It also reduces the time required to print

multiple prints.

When you enable this function, the printer accumulates HP-GL/2 files in a

"nest". Printing begins when one of the following occurs:

The "nest" is full, when no other image can fit across the media

■

The "Nesting Wait Time" is up. This is the length of time during which the

■

printer idles and waits for the current nest to fill.

The printer runs out of memory

■

The printer receives a print f ile with d ifferent print settings than those in the

■

"nest", such as:

Print quality

■

Number of passes

■

Print direction

■

Speed

■

Colour mode

■

DPI

■

Dry time

■

Margins

■

Wipe on/off