Page 1

1 Safety Precautions

Safety Precautions .............................................2

2 Basic Operations

Turning the Printer On and Off ...........................6

Loading the Roll ..................................................8

Loading the Sheet ............................................12

Printing from Windows ......................................14

3 Maintenance

Replacing Ink Tanks .........................................16

Cleaning the Printer ..........................................21

Checking for Nozzle Clogging ..........................25

Cleaning the Printhead .....................................26

Adjusting the Printhead Automatically ..............27

Adjusting the Feed Amount ..............................28

4 Troubleshooting

Responding to Messages .................................29

Troubleshooting if You Cannot Print .................37

Troubleshooting IfYou Cannot Print as Expected

..45

Clearing Jammed Roll Paper ............................48

Clearing Jammed Sheet ...................................52

5 Consumables

Consumables ....................................................54

6 Appendix

Index .................................................................56

Page 2

Safety Precautions

Follow the warnings and precautions below to use the printer safely. Do not perform any

operations or procedures other than as described in this manual. Doing so m a y result in

unexpected accidents and can cau

█Printer location

Do not set up the printer in any location exposed to alcohol, thinner, or other volatile liquids.

•

If these substances come into contact with electrica l components inside the printer, there

is a risk of fire or electrical shock.

█Power Supply

Never handle the power cable with wet hands. Doing so may cause electrical shock.

•

Insert the power cable securely and co mpletely into the power source. If the power cab le is not

•

inserted completely, this could cause a fire or electrical shock.

se a fire or electrical shocks.

Do not use any power cable other than the one

•

shock. Never use the power cable with any other electrical device.

Never cut the power cable or attempt to modify it, and never stretch it or bend it forcefully.

•

Never place a heavy object on the power cable. Damaged sections of the power cable could

cause a short circuit and may cause a fire or electrical shock.

Never connect the power cable to a power strip or any power source sha red by other electrical

•

devices. This could cause a fire or electrical shock.

Never knot the power cable or wrap it around itself. This could cause a fire or electrical shock.

•

Periodically disconnect the power cable and use a dry cloth to wipe away dust that has

•

collected on the plug and the area around the power outlet. Leaving the power cable plugged in

and not cleaned for a long period, especially in an ar e a subject to dust, oil, and humidity, could

cause the insulation material to deteriorate and lead to a fire.

█In an Em ergency

If the printer emits smoke or strange odors, continuing to use the printer may cause a fire or

•

electrical shock. Switch the p

outlet. Contact the nearest service center.

provided. This could cause a fire or electrical

rinter off immediately and remove the power plug from the power

2

Page 3

█Cleaning the Printer

Use a damp cloth to clean the printer. Use a damp cloth to cle

•

come into contact with any electrical component inside the printer, a fire or electric shock

may occur.

█Pacemakers

This printer genera tes a low-level magnetic field. Anyone wearing a pacemaker who

•

experiences discomfort while working around the printer should leave the area. Consult a

physician before continuing to work around the printer.

█Printer location

Never install the printer on an unstable or vibrating surface. If it falls over, this could cause

•

personal injury.

Never set up the printer in a location that is exposed to high humidity or large amounts of dust,

•

or exposed to direct sunlight, high temperature, or open flame. This could cause a fire or

electrical shock. Use the printer location in an environment where temperature and humidity

are within the ranges of 5 Degrees C to 35 Degrees C (41 Degrees F to 95 De grees F) and 10

to 90% RH (with no condensation).

Never place the printer on a heavy wool or shag carpet. The fibers may enter the printer

•

and cause a fire.

Safety Precautions

an the printer. If such materials

Keep the area around the power outlet clear of items so that you can disconnect the power

•

cable immediately if the printer starts operating abnormally. n the event of a printer malfunction,

remove the power cable from the outlet as s oon as possible to prevent fire and electrical shocks.

Never install the printer near large office equipment or any other type of electrical device that

•

emits a strong magnetic field. Never install the printer near large office equipment or any other

type of electrical device that emits a strong magnetic field.

█Moving the Printer

The weights of main printer units are as follows:

•

39 Kg

•

Moving the printer requ ires at least two people, one person on each side of the un it. Be careful

to avoid back strain and other injuries.

When moving the printer, firmly grasp the Carrying handles located on the bottom surface

•

at both sides. Holding the printer at other positions is dangerous and poses a risk of injury

and damage if the printer is dropped

3

Page 4

Safety Precautions

█Power Supply

Always grip the plug to remove the power cable from the powe

•

cable could damage the cable and lead to a fire or electrical shock.

Never use an extension cord. This could cause a fire or electrical shock.

•

Never use any power source other than 100–240 V. T his could cause a fire or electrical shock.

•

The printer operating conditions are described below. Use the printer under the following

conditions.

Power supp ly voltage: 100–240 V

Power supply frequency: 50/60Hz

█Cleaning the Printer

Always disconnect the power cable from the outlet before cleaning the printer. If the printer is

•

switched on accidentally, moving parts inside the printer may cause personal injuries.

█ Printhead, Ink Tanks and Maintenance Cartridge

Always store consumables in a safe location out of the reach of small children. If a child licks or

•

ingests ink accidentally, seek medical assistance immediately.

r outlet. Pulling on the power

█Other

Avoid dropping or shaking Printheads,in

•

stain clothing and the work area.

Never touch the electrical contacts o

•

extremely hot and can cause minor burns.

Never disassemble the printer or attempt repairs. There are high voltage parts inside the

•

printer that can cause a fire or elec

Never use flammable sprays around the printer. The gas of flammable sprays can cause a fire

•

or electrical shock, if it contacts high voltage points inside the printer.

Never insert your hand into the printer while it is printing. Moving parts inside the printer can

•

cause injuries.

Never place anything on the pr

•

any type of liquid container that contains flammable liquids (alcohol, benzene, etc.). If such

objects fall into the printer, this could cause a fire or electrical shock.

inter such as small metal objects (paper clips, staples), liquids,

k tanks, and maintenance cartridges. Spilled ink can

fthePrinthead after printing. The contacts become

trical shock.

4

Page 5

Safety Precautions

After removing the Cutter Unit, never touch the cutting edge. This could cause personal injury.

•

To prevent a fire hazard or dangerous electric shock, if a fo

•

into the printer, press the Power button immediately to switch the printer off, unplug the printer

power cable from the outlet, and then call for service. If you continue to use the printer, this

could cause a fire or electrical shock.

Connect the interface cable correctly. To avoid damage, before connection make sure that the

•

shape of the cable connector matches the connection point on the printer.

Do not block the vents on the top and right side of the unit while the p rinter is on.

•

Avoid placing papers or other light objects near the right-side vent

•

reign object falls into or a liquid spills

5

Page 6

Turning the Printer On and Off

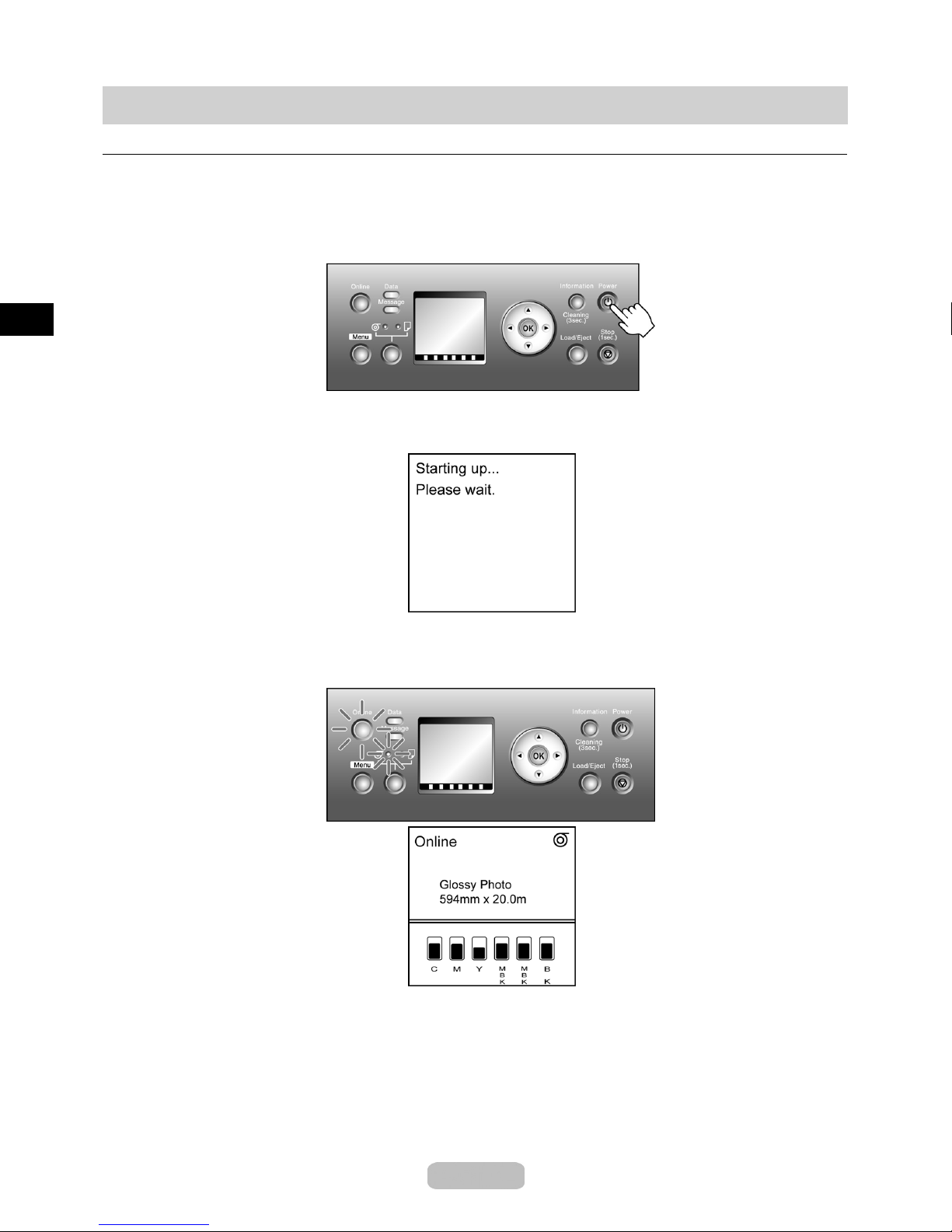

Turning the printer on

1

2

Press the Power button to turn on the printer.

The printer will now start up.

After the Display Screen shows the Océ logo,Startingup…Pleasewait.is

displayed.

The printer goes online in preparation for printing after startup, and the Online lamp

and paper source section lamp remain lit.

6

Page 7

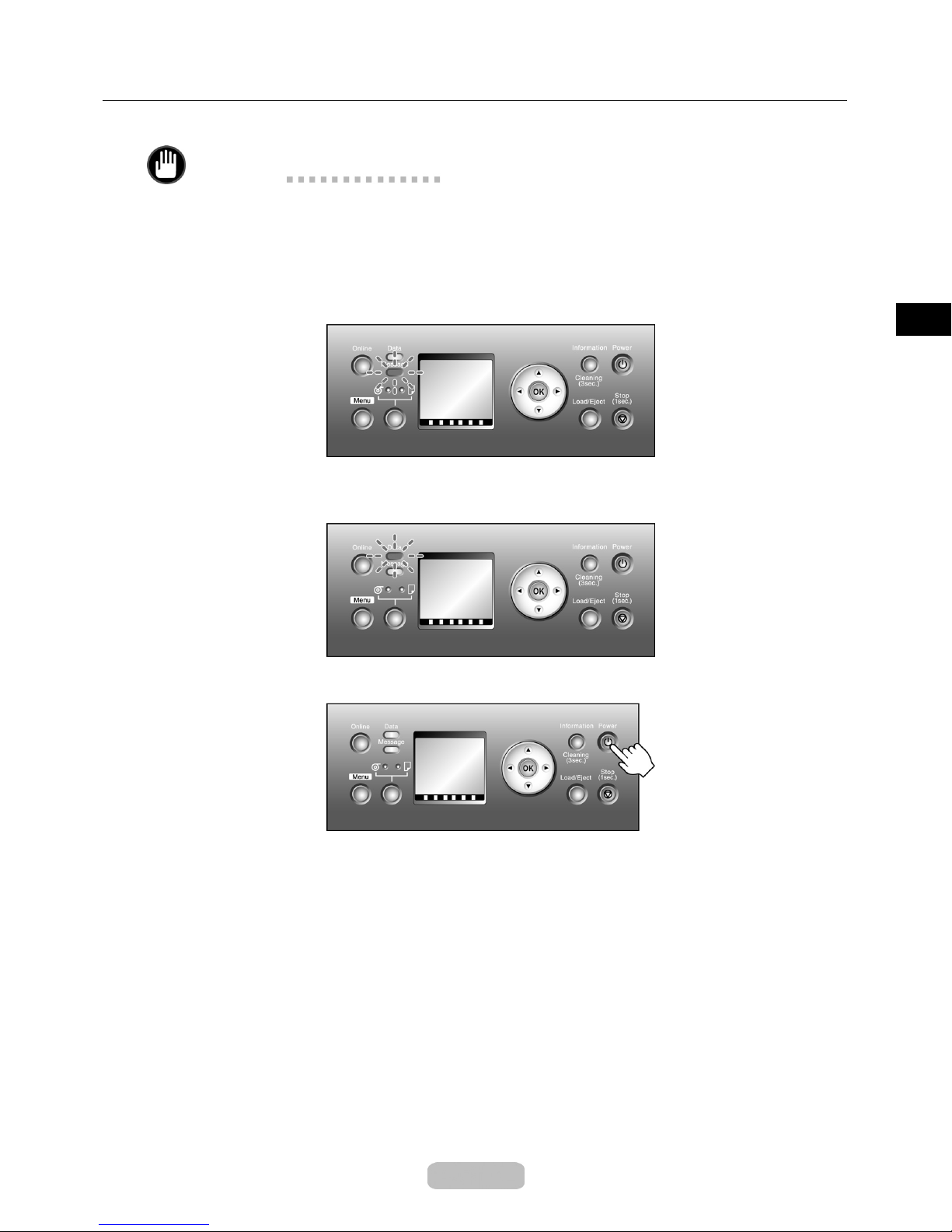

Turning the printer off

Important

Never turn the printer off or unplug it during a prin t job. This could damage the

•

printer.

Turning the Printer On and Off

1

2

Make sure no print jobs are in progress.

If the Message lamp is flashing, check the message on the Display Screen and

take action as necessary.

If the Data lamp is flashing, the printer is receiving a print job. Turn off the printer

only after printing is finished.

Hold down the Power button for more than a second.

After Shut Down.. Please Wait.. isshownontheDisplay S creen, the printer

shuts off.

7

Page 8

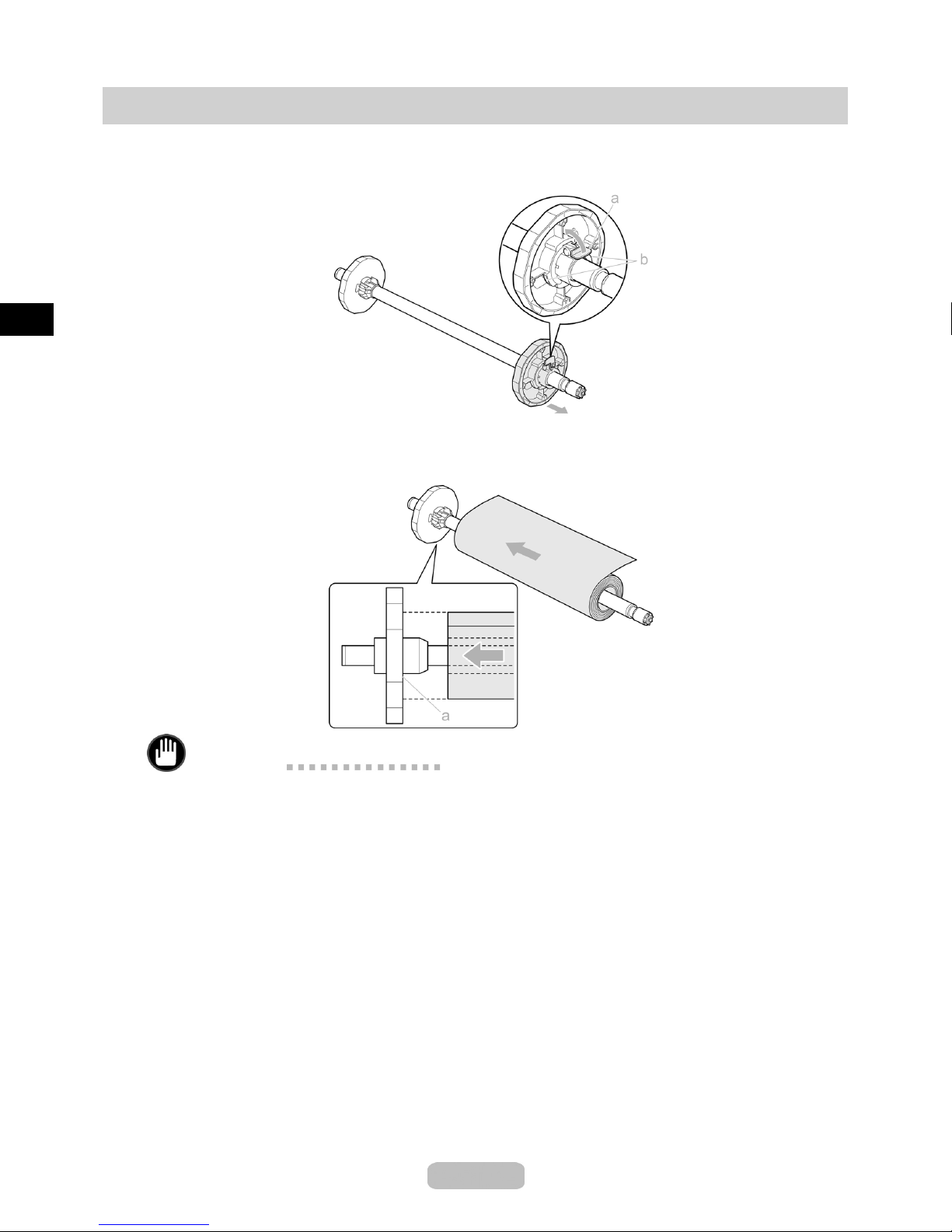

Loading the Roll

1

2

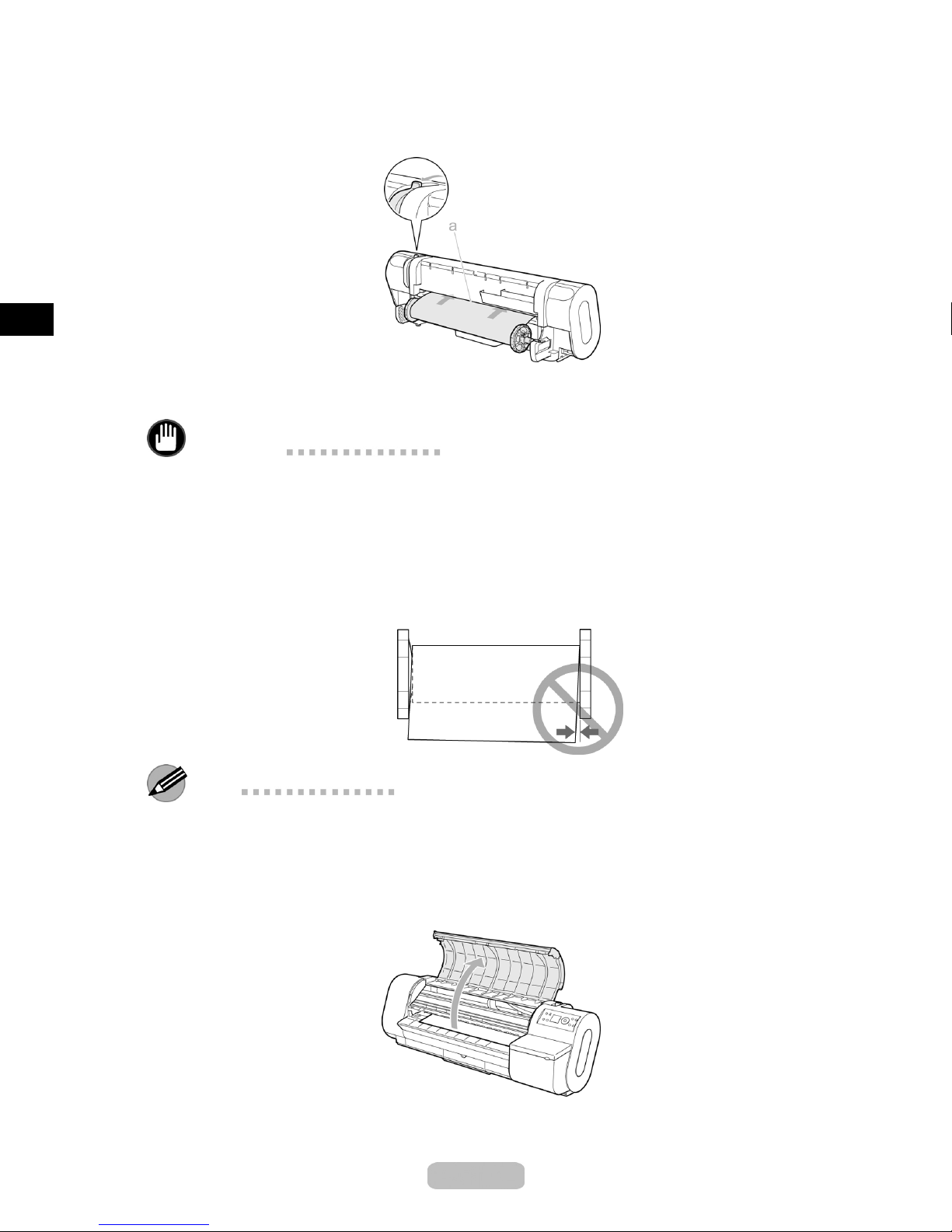

Lift the Holder Stopper lever (a) from the shaft side to unlock it. Holding the

Holder Stopper at the p osition indicated (b), remove it from the Roll Holder.

With the edge of the roll paper facing back as shown, set the roll with the Roll Holder

from the right. Insert the roll firmlyuntilittouchestheflange (a) of the Roll Holder.

3

Important

Insert the roll firmly so that there is no gap between the roll and the flange of the

•

Roll Holder. If there is a gap, it may cause feeding problems.

Insert the Holder Stopper from the right in the Roll Holder as shown. Holding it

at the position indicated (b), push it firmly in until the flange(a)oftheHolder

8

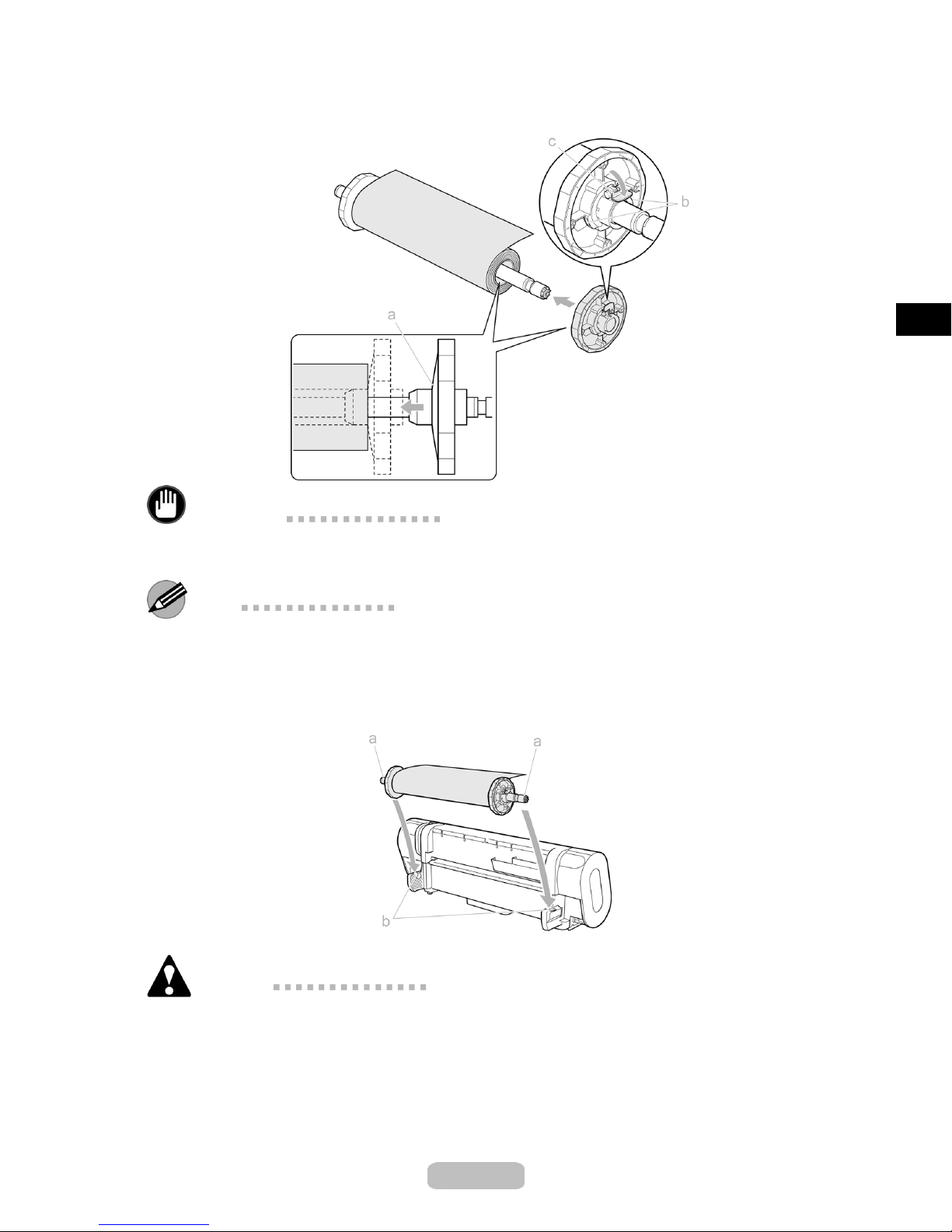

Page 9

Loading the R oll

Stopper touches the roll. Lock the Holder Stopper lever (c) by pushing it down

toward the shaft side.

4

Important

Insert the Holder Stopper firmly so that there is no gap between the roll and the

•

flange of the stopper. If there is a gap, it may cause feeding problems.

Note

Remove any loaded paper that will not be used.

•

If the Platen is dirty, clean inside the To p C o v e r .

•

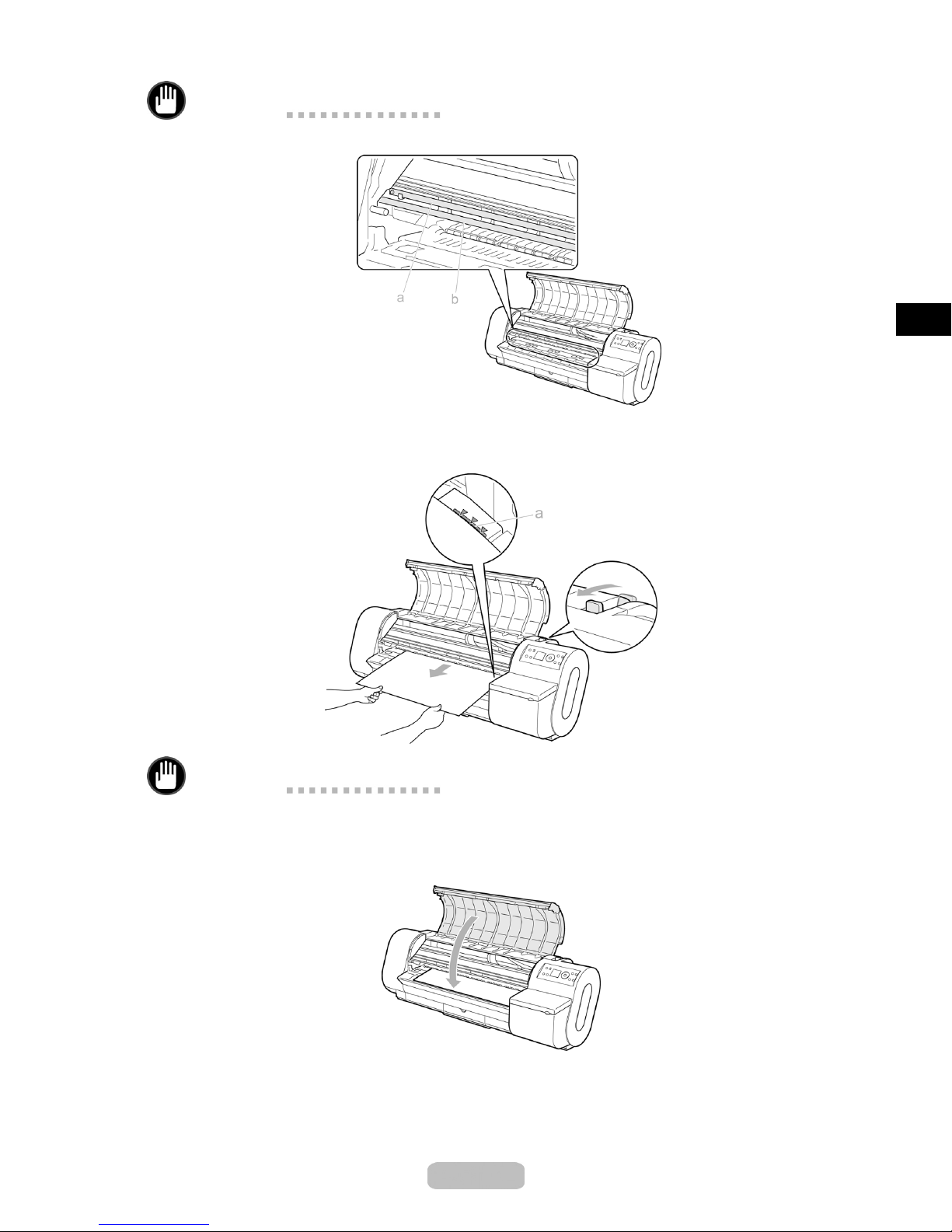

With the edge of the roll paper facing toward the printer, insert the Roll Holder shaft

(a)intotheguidegrooves(b)oftheRoll Holder Slot on both sides.

Caution

Be careful not to drop a roll and hurt yourself when loading it.

•

Be careful not to put your fingers between the guide grooves (b) and the Roll

•

Holder shaft (a) when loading roll, or may hurt yo u rs elf.

9

Page 10

Loading the Roll

5

Push the Release Lever back and pull out the roll paper evenly on both ends.

Insert the edge in the Paper Feed Slot (a) and advance the paper until vacuuming

paper starts.

After the paper reaches the Platen, it is automatically advanced and vacuuming

paper starts.

Important

Be careful not to soil the printing surface of rol

•

affect the printing qual ity.

If the paper is wrinkled or warped, straighten it out before loading it.

•

If i t is difficult to insert the rol l paper in the Paper Feed Slot, insert the left or rig ht

•

corner in the slot first, and then straighten the paper as you advance it.

Load the roll so that there is no gap between the right edge of the paper and the

•

Roll Holder.

l pap er as you pull it out. This may

Note

You can adjust the strength of vacuum holding paper against the Platen when the

•

Release Lever is open. If it is difficult to load paper, press the ▲ or ▼ button on

the Control Panel to adjust the strength. Set vacuum stronger by pressing the ▲

button or weaker with the ▼ button. Three settings are available.

6

Open the To p Cov e r .

10

Page 11

Important

Do not touch the linear scale (a) or Carriage Shaft (b).

•

Loading the R oll

7

8

Pull the roll edge gently and align it with the Paper Alignment Line (a). Lower the

Release Lever toward the front.

Important

Do not force the roll paper into alignment with the Paper Alignment Line (a) . This

•

may prevent the paper from being advanced straight.

Close the To p C o ver.

After you load a roll, the printer automatically shows a menu for selection of the paper

type on the Display Screen.

At this point, specify the paper type.

11

Page 12

Loading the Sheet

Note

If the Platen is dirty, clean inside the To p C o v e r.

•

After pressing the Load/Eject button, you can refer to instructions on the Display

•

Screen as you load the paper.

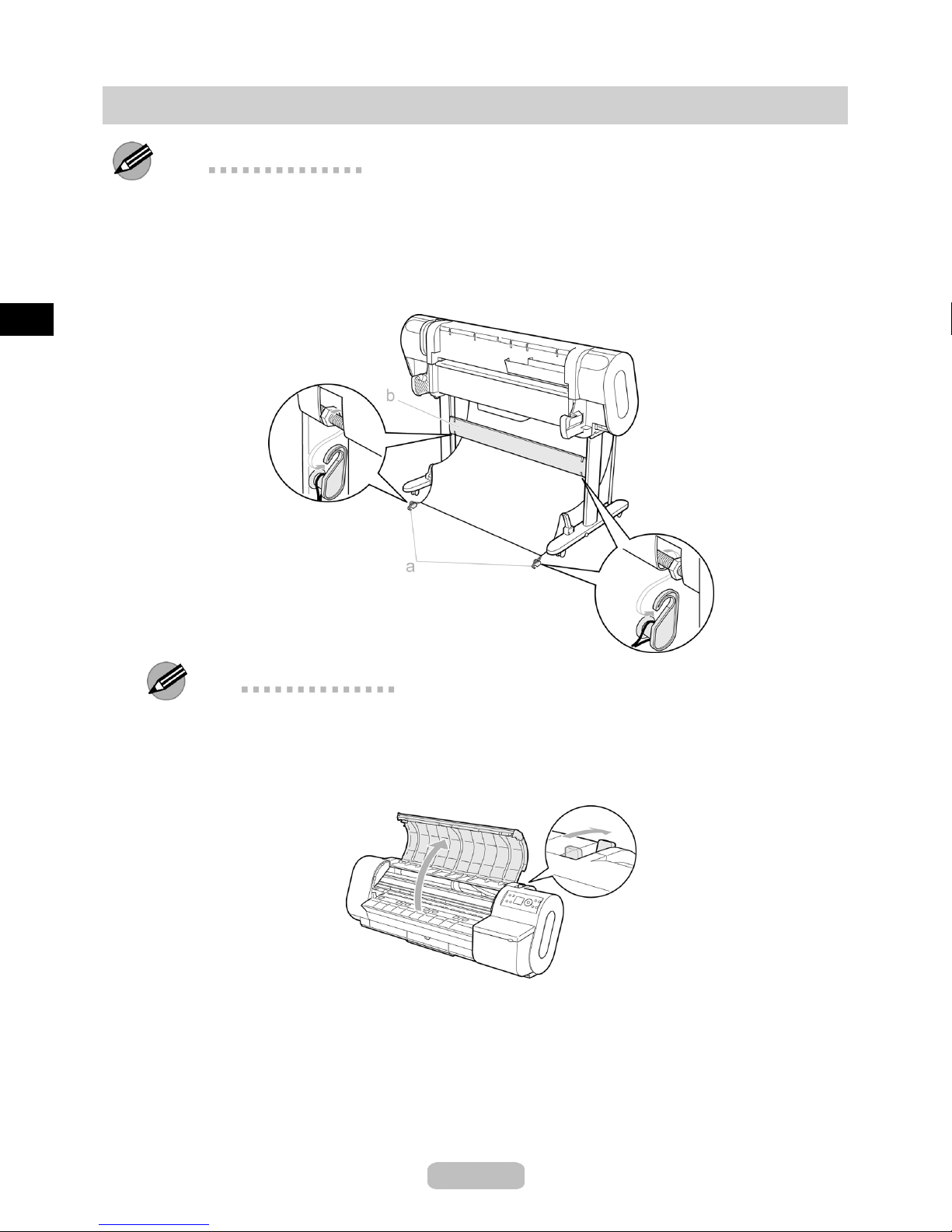

1

Remove the Roll Holder from the printer and remove Basket Fastener A (a) from

the Stand Stay (b).

Note

If you print on a lo ng sheet (longer than 914 mm [36 in]), the trailing edge may touch

•

the floor and become dirty. Before loading long paper, remove the Roll Hold er and

spread a clean cloth or paper on the floor.

2

Open the Top Cove r and push the Release Lever back.

12

Page 13

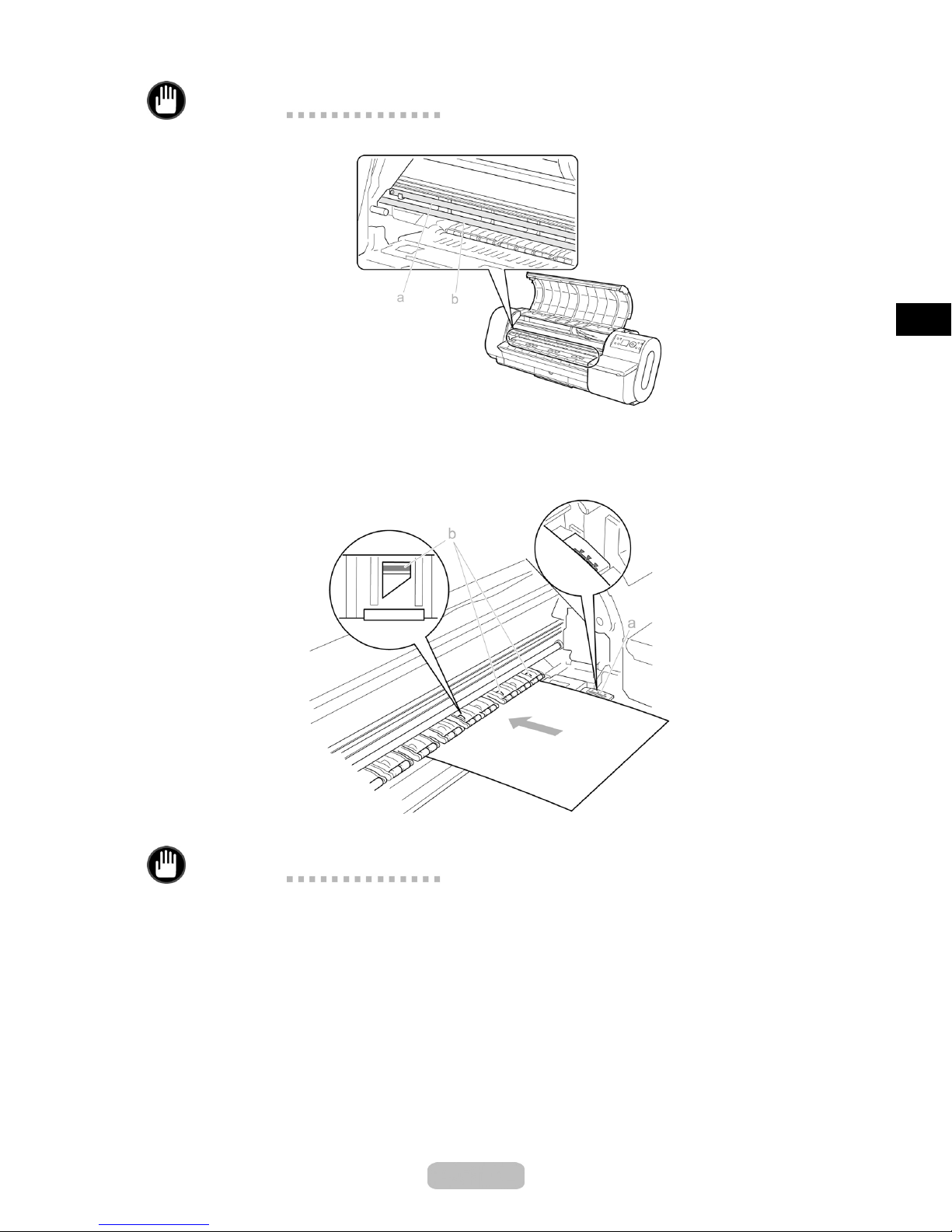

Important

Do not touch the linear scale (a) or Carriage Shaft (b).

•

Loading the Sheet

3

With a sheet lengthwise and printing-side up, insert it straight between the Platen

and the Paper Retainer. Align the sheet with the Paper Alignment Line at right

(a) and the Paper Alignment Line inside (b).

When inserted, sheets are automatically held by suction against the Platen.

Important

Load a sheet so that it is parallel to the Paper Alignment Line at right (a). Load ing

•

paper askew will cause an error.

Warped paper may rub against the Printhead. Straighten paper if it i

•

before loading it.

swarped

4

Lower the Release Lever toward the front and close the Top Cove r .

After you load the sheet, the printer automatically shows a menu for selection of

the paper type on the Display Screen.

At this point, specify the paper type.

13

Page 14

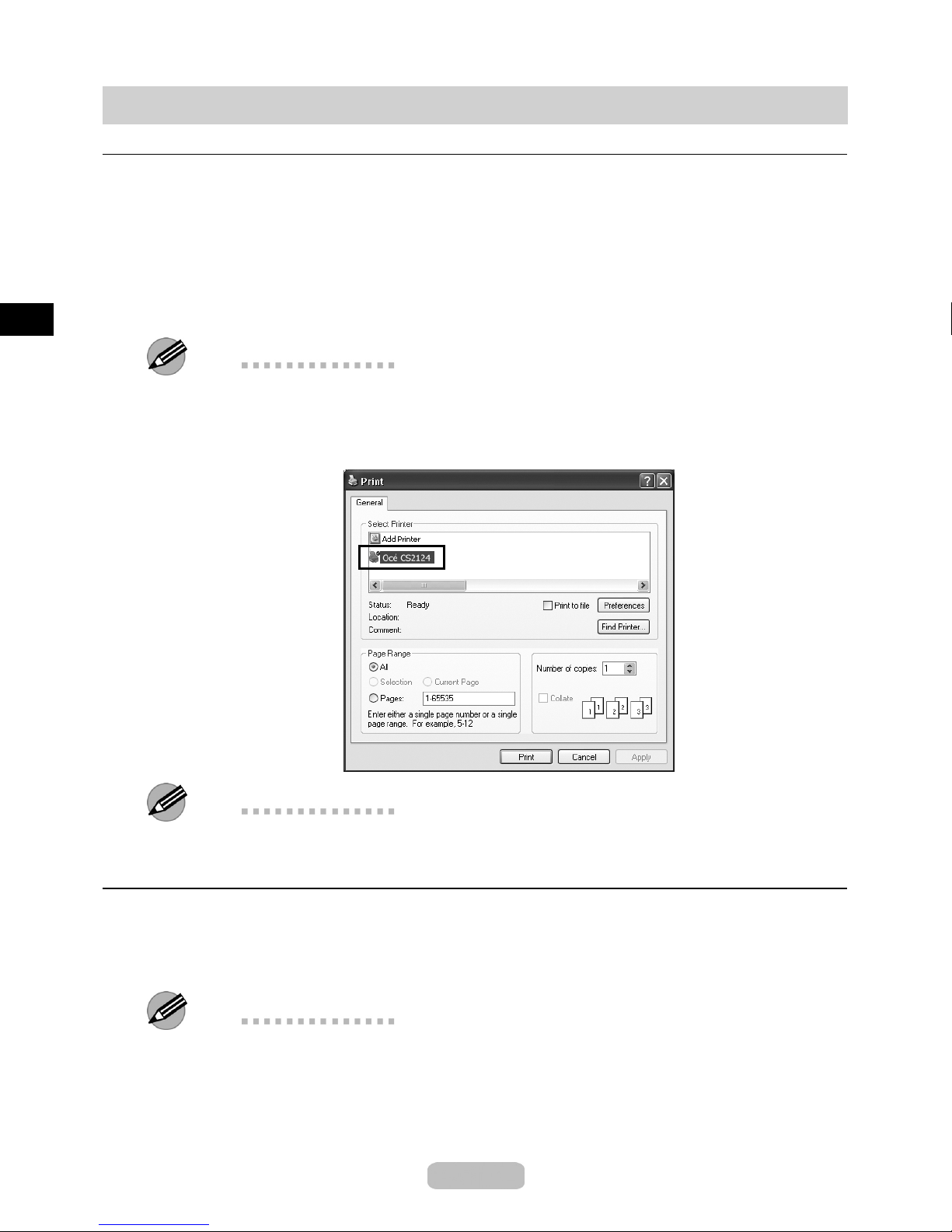

Printing from Windows

Printing

Print from the application menu.

1

2

In the application software, select Print from the File menu to display the dialog

box for printing conditions.

After confirming that the printer is selected in the dialog box, click Print or OK to

start printing.

Note

The appearance of the dialog box varies depending on the application software. In

•

most cases, the dialog box includes basic printing options and enables you to choose

the printer, specify the range of page s, numb er of copies, and so on.

Example: Print dialog box displayed by the application software

Note

If another printer is selected, select the printer you want to use under Select Printer

•

or in the dialog box displayed after clicking Printer.

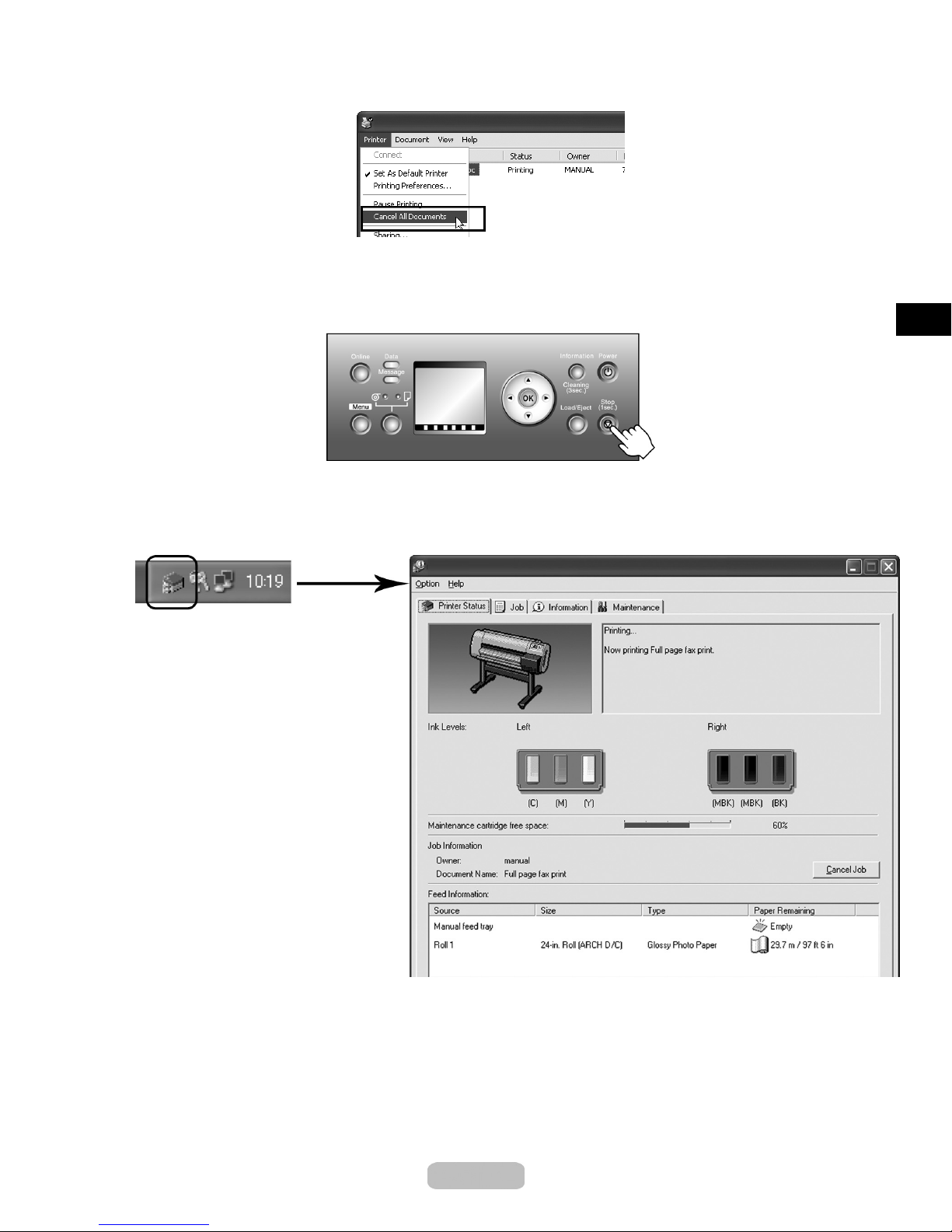

Canceling print jobs

You can cancel print jobs in the printer window.

1

Click the printer icon in the taskbar to display the printer window.

Note

You can also display this window by double-clicking the printer icon in the Printers

•

and Faxes (or Printers) folder, accessible through the Windows Start menu.

14

Page 15

Printing from Windows

2

3

1

Choose Cancel All Documents in the Printer menu to stop the pr

If the Display Screen of the Control Panel still indicates that the job is in progress

and the Data lamp continues flashing, hold down the Stop button for a second or

more to stop printing.

If the Data lamp is off and you cannot stop printing, do the following.

Double-click the taskbar icon to access t he GARO Status Monitor.

On the Printer Status sheet, click Cancel Job.

int processsing.

15

Page 16

Replacing Ink Tanks

Precautions when handling an Ink Tank

Take the following precautions when h andling an Ink Tank.

Caution

For safety, keep an Ink Tank out of the reach of children.

•

If ink is accidentally ingested, contact a physician immediately.

•

Important

Before removing an Ink Tank f ro m the pouch for installation, shake it gently seven

•

or eight times. If you do not shak e the Ink Tank, the ink may sediment, which may

affect printing quality.

Do not remove and shake an Ink Tank that has already been installed in the printer.

•

Ink may leak out.

Avoid dropping the Ink Tank after removing it from the pouch. O therwise, ink may

•

leak and cause stains.

TheremaybeinkaroundtheinkholesofInk Tank you remove. Handle an Ink

•

Tank carefully during replacement. The ink may stain clothing.

We recommend using up an Ink Tank in the course of printing within six months

•

after breaking the seal. Using an old Ink Tank may affect the printing quality.

Do not remove the Ink Tank if the printer is not used for a long period (a m onth

•

or more). Ink remainin g in th e pri nter m ay become clogged and cause of printing

problems.

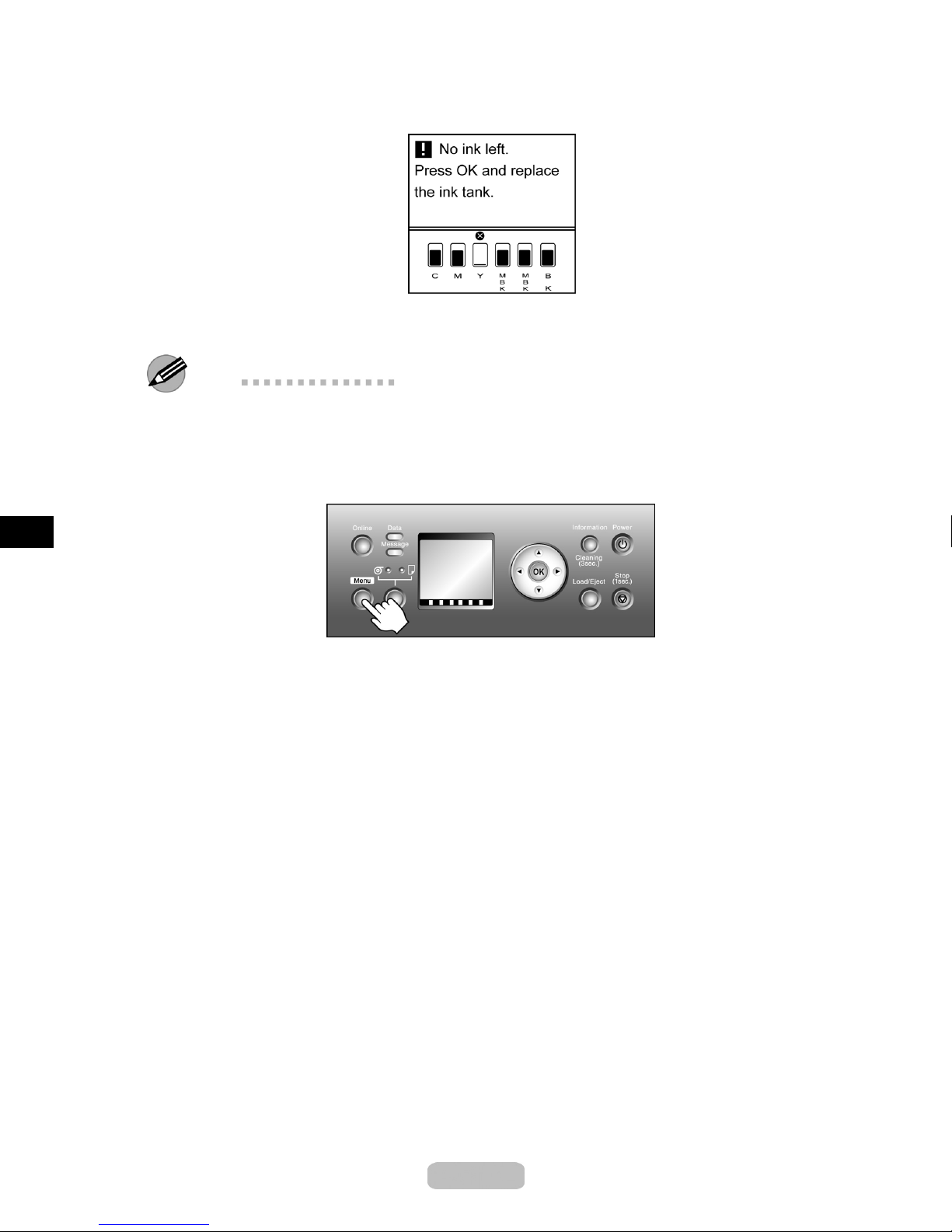

ReplacinganInkTank

1

Make sure no print jobs are in progress.

You can replace Ink Tank if the Display Screen indicates the printer is Online

or Offline, or if messages advise y ou to check the amount of ink left or replace

the Ink Tank.

16

Page 17

Replacing Ink Tanks

If a message prompts you to replace the Ink Tank,presstheOK button. Steps 2 and

3 are unnecessary in this case. Go to step 4 and remove the Ink Tank.

2

3

4

Do not remove an Ink Tank during i

printer, or during printhead cleaning.

nitialization immediately after turning on the

Note

Ink Tank replacement is possible even when print j

•

paper is being fed. In this case, the cancellation or feeding is paused during Ink

Tank replacement and resumed after replacement.

Press the Menu buttontodisplayMAIN M ENU.

Select Rep. Ink Tank→Ye s and press the OK button.

A message on the Display Screen advises you to open the Ink Tank Cover.Next,

remove the Ink Tank.

Open the Ink Tank Cover and check the Ink Lamp.

obs are being canceled or if

17

Page 18

The Ink Lamp flashes quickly if there is no ink left.

Replacing Ink Tanks

5

6

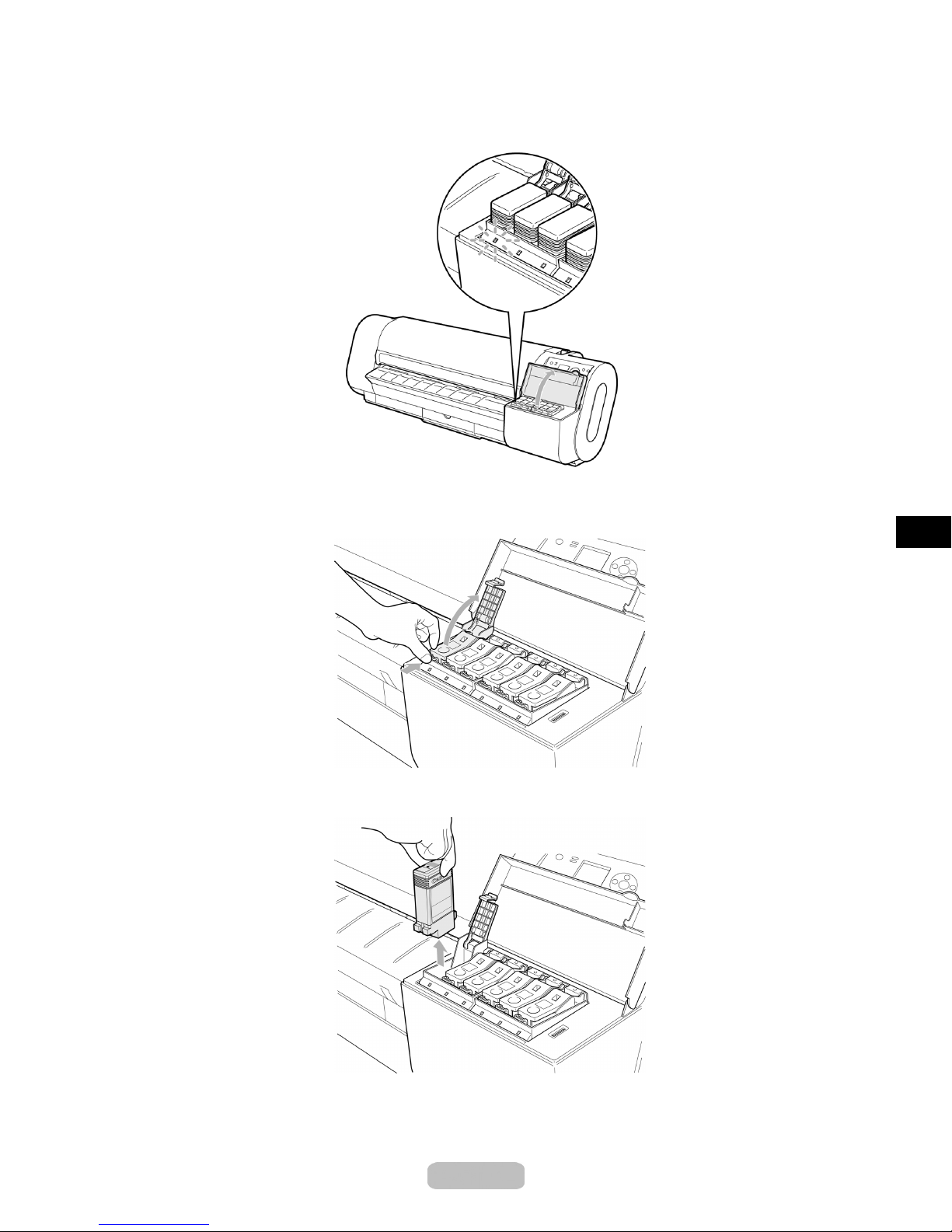

Press the tip of the InkTankLockLeverof the color for replacement and lift

the InkTankLockLeverto

Hold the empty Ink Tank bythegriptoremoveit,andpresstheOK button.

open it.

18

Page 19

Replacing Ink Tanks

Note

If there is still some ink left in the Ink Tank you removed, st

•

the ink holes (a) facing up. Otherwise, ink may leak and cause stains. Put the Ink

Tank in a plastic bag and seal it.

Dispose of the used Ink Tank according to local regulations.

•

ore the ink tank with

7

8

Before opening the pouch, shake the Ink Tank gently seven or eight times. Agitate

the ink in the Ink Tank by slowly turning the Ink Tank upside-down and right

side up several times.

Note

If you do not shake the Ink Tank, the ink may sediment, which may affect printing

•

quality.

Open the pouch and remove the Ink Tank.

Note

Never touch the ink holes or metal contacts. This may cause stains, damage the

•

Ink Tank, and affect printing quality.

Avoid dropping the Ink Tank after removing it from the pouch. O therwise, ink may

•

leak and cause stains.

Do not remove and shake an Ink Tank that has already been installed in the printer.

•

Ink may leak out.

19

Page 20

Replacing Ink Tanks

9

Press the OK button and insert the Ink T

figure,withtheinkholesdown.

ank into the holder facing as shown in the

Important

Ink Tank cannot be loaded in the holder if the colo

•

If the Ink Tank does not fit in the ho lder, do not force it into the holder. Make sure

the color of the InkTankLockLevermatches the color of the Ink Tank,and

check the orientation of the Ink Tank before re

r or orientation is wrong.

loading it.

10

11

12

Close the InkTankLockLeveruntil it clicks.

Make sure the Ink Lamp is lit in red.

Note

Ink Lamp flashes when there is l ittle ink left.

•

Close the Ink Tank Cover.

The printer returns to the mode before replacement of Ink Tank.

20

Page 21

Cleaning the Printer

Clean the printer regularly to maintain better printing quality and help prevent problems.

Aboutonceamonth,cleantheprintere

Cleaning the printer exterior

xterior.

1

2

3

Turn the printer off.

Unplug the power cord from the outlet.

Caution

Always turn off the printer and unplug the power cord before cleaning or

•

maintenance. Accidentally leaving the printer on poses a risk of injury if you

touch moving parts inside the p rinter.

Using a damp cloth that you have wrung out completely, wipe away any dirt or

paper dust from the Paper Feed Slot (a),powercordplug,andsoon. Drythese

partswithadrycloth.

Caution

Never use flammable solvents such as alcohol, benzene, or thinner. If these

•

substances come into contact with electrical components inside the printer,

there is a risk of fire or electrical shock.

4

Plug the power cord into the outlet.

21

Page 22

Cleaning the Printer

Cleaning inside the top cover

Clean inside the To p Cov e r about once a month to maintain better printing quality and

help prevent problems.

Also clean inside the Top Co v e r in the

If the printed surface or the underside of paper is dirty after printing

•

After you have used up a roll

•

After borderless printing

•

Afterprintingonsmallpaper

•

After printing on paper that generates a lot of cuttin g debris

•

If you have replaced the roll

•

following situations to ensure optimal operation.

Important

If the Platen inside the Top Cover becomes dirty, it may soil the underside of p aper.

•

Clean the Platen after borderless printing or printing on small paper.

1

2

Turn the printer off.

Unplug the power cord from the outlet.

3

Caution

Always turn off the printer and unplug the power cord before cleaning or

•

maintenance. Accidentally leaving the printer on poses a risk of injury if you

touch moving parts inside the p rinter.

Open the To p Cov e r .

22

Page 23

Cleaning the Printer

4

If paper dust has accumulated in the Vacuum holes on the Plate

Borderless Printing Ink Grooves (b), use the included Cleaning Brush (c) to

wipe it away.

n (a)orinthe

Important

Do not touch the linear scale (a) or Carriage Shaft (b).

•

Note

If the Cleaning Brush is dirty, rinse it in water.

•

5

Using a damp cloth that you have wrung out completely, wipe inside the To p Co v e r

to clean it. Wipe away any ink residue on the Top Cover Roller (a), all ov

er the

23

Page 24

Cleaning the Printer

Platen (b), the Paper Retainer (c), the Borderless Printing Ink Grooves (d), the

Ejection Guide (e), and the guide rail (f).

Important

Do not use a dry cloth to wipe inside the To p C o v er. This may create a static charge,

•

which may attract dust and affect the printing quality.

Never use flamm a ble solvents such as alcohol, benzene, or thinner. If these

•

substances come into contact with electrical com pon ents inside the printer, there is a

risk of fire or electrical shock.

6

7

Close the To p C o ver.

Plug the power cord into the outlet.

24

Page 25

Checking for Nozzle Clogging

If printing is faint or streaked in different colors, make sure the Printhead nozzles are clear

byprintingatestpatterntocheckth

Note

You can specify a number of pages in the printer’s Noz. Check Freq. menu for

•

automatic nozzle checking and cleaning every time you finish printing that quantity.

e nozzles.

1

2

3

4

Load unused paper.

Press the Menu buttontodisplayMAIN M ENU.

Select Te st P rint →Nozzle Check, and then press the OK button.

The printer goes online and prints a test pattern.

Check the printing results.

If the horizontal lines are not faint or incomplete, the nozzles are clear.

If some sections of the horizontal lines are faint or incomplete, the nozzles for those

colors are clogged.

If horizontal lines are faint or incomplete, follow the steps below and check again

for nozzle clogging.

1.

Clean the Printhead.

2.

Print a test pattern to check the nozzles.

Note

If you repeat these steps several times but the horizontal lines are still faint or

•

incomplete, contact your

Océ dealer.

25

Page 26

Cleaning the Printhead

Cleaning the Printhead may help clear nozzles that are clogged.

Note

You can specify a number of pages in the printer’s Noz. Check Freq. menu for

•

automatic nozzle checking and cleaning every time you fi

You can start Head Cleaning A by holding down the Information button for three

•

seconds or more.

Cleaning the Printhead

nish printing that quantity.

1

2

3

Press the Menu buttontodisplayMAIN M ENU.

Select Head Cleaning→ the type of cleaning, and then press the OK button.

Head Cleaning A

•

Use Head Clea ni ng A if printing is faint or contains foreign substances. This

method of cleaning consumes the least amount of ink. It takes a bo ut three minutes

to complete.

Head Cleaning B

•

Use Head Cleaning B if no ink comes out of the printhead, or if Head Cleaning A

does not solve the problem. It takes about four minutes to complete.

The printhead is cleaned, and the printer goes online.

Print a test pattern to check the nozzles, and determine whether cleaning has cleared

the nozzles.

Note

If printing does not improve after Head Cleaning A,tryHead Cleaning B.Ifthis

•

does not solve the problem, repeat Head Cleaning B two or three times. If this still

does not improve printing, the Printhead may have reached the end of its useful

life. Contact your

Caution

Do not remove the Maintenance Cartridge during cleaning.

•

Océ dealer.

26

Page 27

Adjusting the Printhead Automatical

If printed vertical lines are warped or colors are ou t of alignment, adjust the Printhead

alignment. Adjust the Printhead alignment automatically or manually by using a printed

test pattern.

Follow the steps below for standard automatic adjustment of the Printhead.

ly

1

2

3

Load unused paper.

If using sheets, load paper A4/Letter-sized or larg

at most.

er. You will need three sheets

Note

Always specify th e paper type when loading paper. Using paper that you have not

•

specified on the printer may cause feeding problems and affect the printing quality.

We recomme nd lo ading a type of paper that you use often.

•

Press the Menu buttontodisplayMAIN M ENU.

Select Adjust Printer→Auto Head Adj.→Advanced Adj.→Yes and press the

OK button.

A test pattern is printed for printhead adjustment.

After reading the pattern, the printer automatically adjusts the Printhead alignment.

Note

If adjustment is not possible using highly transparent film or similar media, try

•

another type of media. If you cannot adjust the printhead as desired using special

media, select Advanced A dj.

27

Page 28

Adjusting the Feed Amount

If printed images are affected by white streaks or dense color streaks, adjust the amount

that paper is fed.

Follow the steps below for standard automatic adjustment of the feed amount.

1

2

3

Load unused paper.

If using sheets, load paper A4/Letter-sized or larger. You will need two sheets at

most.

Note

Always specify th e paper type when loading paper. Using paper that you have not

•

specified on the printer may cause feeding problems and affect the printing quality.

We recomme nd lo ading a type of paper that you use often.

•

Press the Menu buttontodisplayMAIN M ENU.

Select Adjust Printer→Auto Band Adj.→Standard Adj.→Ye s and press the

OK button.

A test pattern is printed for band adjustment.

After reading the pattern, the printer automatically adjusts the feed amount and

goes online.

28

Page 29

Responding to Messages

Cross-references are given in the following format.

Information in the Reference Guide ( → P.XX)

Information in the User's Guide ( → CD "XX")

Messages regarding paper

Error Messages

Regular printing is selected,

but a roll is loaded.

No sheets present.

No sheets are loaded.

End of paper feed. Cannot

feed paper more.

Insufcient paper for job.

Cause

A print job for sheets was sent

when a roll is loaded.

A sheet is not loaded.

A sheet is not loaded.

You are pressing the ▲ button

on the Control Panel and

trying to rewind the roll

completely.

The printer has received a print

job longer than the amount of

roll paper left.

Corrective Action

Remove the roll.

(→ CD "Removing the Roll from the

Printer")

Hold down the Stop button for a

second or more to cancel printing.

Load paper of the type and size you

have specied in the printer driver.

(→P.12)

Hold down the Stop button for a

second or more to cancel printing.

Load paper of the type and size you

have specied in the printer driver.

(→P.12)

Hold down the Stop button for a

second or more to cancel printing.

Release the ▲ button.

Follow the steps below to replace

the roll.

Remove the roll.1.

Load a roll with enough paper left.2.

If no barcode was printed on the

3.

roll, specify the paper type.

Select the paper length, unless

4.

a barcode was printed on the

roll and you have deactivated

automatic detection of the

remaining roll paper.

Hold down the Stop button for a

second or more to cancel printing.

Press the Online button to resume

printing.

However, the roll paper will run out

during the print job, and you will not

be able to print all of the document.

29

Page 30

Responding to Messages

Error Messages

Cannot adjust with present

paper.

This paper cannot be used. The loaded paper is too large

Borderless print is not

possible with roll loaded.

Cause

The Printhead and feed

amount cannot be adjusted

when highly transparent lm is

loaded.

for the printer.

Paper that is too small for the

printer has been loaded.

The printer has received a print

job that cannot be printed using

borderless printing.

Corrective Action

We recommend loading a type of

paper that you often use, other than

lm, before adjusting the Printhead.

(→P.27)

Adjust the feed amount manually.

(→CD "Adjusting the Feed Amount

Manually")

Load paper of the correct size.

(→CD "Paper Sizes")

Load paper of the correct size.

(→CD "Paper Sizes")

Follow the steps below to change

the settings of the print job to enable

borderless printing.

Hold down the Stop button for a

1.

second or more to cancel printing.

In the printer driver, change the

2.

settings to a paper size compatible

with borderless printing, and then

try printing again.

(→CD "Borderless Printing of

Photos and Images")

Check paper size setting in

driver.

The paper size as specied

on the printer does not match

the size specied in the printer

driver.

Press the Online button to resume

printing.

However, this may cause a paper

jam or printing problem.

Load paper of the same size as you

have specied in the printer driver.

(→P.8)

(→P.12)

Follow the steps below to ensure

the paper size matches on the

printer and in the printer driver.

Hold down the Stop button for a

1.

second or more to cancel printing.

Change the paper type in the

2.

printer driver and try printing again.

Press the Online button to resume

printing.

However, this may cause a paper

jam or printing problem.

30

Page 31

Responding to Messages

Error Messages Cause Corrective Action

Borderless print not

possible. Check paper

position.

The paper is not loaded

correctly.

Load a roll of the correct size.

(→CD "Paper Sizes")

Reload the roll in the printer.

(→P.8)

Paper loaded askew.

Straighten paper and

reload.

The printer has received a print

job that cannot be printed using

borderless printing because of

the paper width.

Paper is loaded askew.

Check the size of paper loaded in

the printer.

Follow the steps below to change

the setting of the print job to a width

compatible with borderless printing.

Hold down the Stop button for a

1.

second or more to cancel printing.

In the printer driver, change the

2.

Roll Paper Width setting to a

width compatible with borderless

printing, and try printing again.

Follow the steps below to reload the

roll.

Open the Top Cover.

1.

Push the Release Lever back.2.

Align the right edge of the roll

3.

paper parallel to the Paper

Alignment Line.

Pull the Release Lever forward.4.

Close the Top Cover.

5.

Select the paper type.6.

(→CD "Selecting the Paper Type

(Roll)")

Follow the steps below to reload the

sheet.

Open the Top Cover.

1.

Push the Release Lever back.2.

Align the right edge of the

3.

sheet parallel to the right Paper

Alignment Line and the far

edge parallel to the inner paper

alignment line.

Pull the Release Lever forward.4.

Close the Top Cover.5.

31

Page 32

Responding to Messages

Error Messages Cause Corrective Action

Wrong paper size. The paper size as specied

on the printer does not match

the size specied in the printer

driver.

If you have set Ignore Mismatch to

Yes, printing resumes at this point.

Load paper of the same size as you

have specied in the printer driver.

Follow the steps below to ensure the

paper size matches on the printer

and in the printer driver.

Hold down the Stop button for a

1.

second or more to cancel printing.

Change the paper size in the

2.

printer driver and try printing again.

Press the Online button to resume

printing.

However, this may cause a paper

jam or printing problem.

Paper size not detected.

Paper Type Wrong

Paper size not detected.

Paper has been loaded askew,

or warped paper has been

loaded.

The paper type as specied

on the printer does not match

the type specied in the printer

driver.

Paper has been loaded askew,

or warped paper has been

loaded.

Reload paper straight, in the correct

position.

(→P.8)

(→P.12)

Make sure the same type of paper

is specied on the printer as in the

printer driver.

(→P.8)

(→P.12)

Follow the steps below to ensure the

paper type matches on the printer

and in the printer driver.

Hold down the Stop button for a

1.

second or more to cancel printing.

Change the paper type in the

2.

printer driver and try printing again.

Press the Online button to resume

printing.

However, this may cause a paper

jam or printing problem.

Reload paper straight, in the correct

position.

(→P.8)

(→P.12)

32

Page 33

Responding to Messages

Error Messages Cause Corrective Action

Auto paper cutting is not

possible.

Roll paper cannot be cut using

the Cutter Unit.

Cut the roll paper manually.

(→CD "Cutting Roll Paper Manually")

There is a paper jam.

Cannot feed paper. The sheet cannot be fed

correctly.

Roll printing is selected, but

sheets are loaded.

No roll is loaded. No roll is loaded. Follow the steps below to load the

The roll is empty. There is no more paper left on

A print job for rolls was sent

when a sheet is loaded.

the roll.

Remove the jammed paper.

(→CD "Clearing Jammed Roll

Paper")

Reload the sheet straight, in the

correct position.

(→P.12)

Remove the sheet.

(→CD "Removing the Sheet")

Hold down the Stop button for a

second or more to cancel printing.

type and size of roll specied in the

printer driver.

Load the roll.1.

If no barcode was printed on the

2.

roll, specify the paper type.

If no barcode was printed on the

3.

roll, specify the paper length.

Hold down the Stop button for a

second or more to cancel printing.

Follow the steps below to replace

the used roll with a new roll of the

same type and size.

Remove the roll.1.

Load the new roll.2.

If no barcode was printed on the

3.

roll, specify the paper type.

If no barcode was printed on the

4.

roll, specify the paper length.

Messages regarding ink

Phenomenon Cause Corrective Action

Ink tank is empty. There is no ink left. Open the Ink Tank Cover and

Low ink. Press OK and

replace ink tank.

Ink Level: Check Not much ink is left. Prepare a new Ink Tank.

The ink level is low, so

you cannot print, clean

the Printhead, or do other

operations that require ink.

33

replace the Ink Tank for which the

Ink Lamp is ashing.

(→P.16)

Replace the Ink Tank that is low with

a new Ink Tank.

(→P.16)

We recommend replacing the Ink

Tank with a new Ink Tank at this

point if you plan to print banners or

high-quantity jobs.

Page 34

Responding to Messages

Phenomenon

Ink tank: No XX ink

loaded.(Here, XX is an ink

color)

Other messages

Phenomenon Cause

GARO WXXXX (X represents

a number)

Check printed documents. The document may have been

Cannot print as specied.

Load paper A3/Ledger or

larger.

Cannot print as specied.

Load paper A4/LTR or larger.

Cause

There is no Ink Tank of the

indicated color in the printer.

There is a problem with the Ink

Tank.

Corrective Action

Load or reload the Ink Tank.

(→P.16)

Replace it with a new Ink Tank.

(→P.16)

Corrective Action

There is a problem with the

print job.

printed faint.

The loaded paper is too small. Load paper A3/Ledger-sized or

The loaded paper is too small. Load paper A4/Letter-sized or larger.

Try printing again, using the correct

printer driver.

It is also possible to continue printing

in this state.

If printing is faint, clean the

Printhead.

(→P.16)

larger.

Cannot adjust band. The Printhead nozzles are

clogged.

The Printhead and feed

amount cannot be adjusted

when highly transparent lm is

loaded.

Follow the steps below to check the

nozzles.

Print a test pattern to check the

1.

nozzles.

(→P.25)

Clean the Printhead if the nozzles

2.

are clogged.

(→P.26)

We recommend loading a type of

paper that you often use, other than

lm, before adjusting the Printhead.

(→CD "Borderless Printing of Photos

and Images")

(→P.27)

Adjust the feed amount manually.

(→CD "Adjusting the Feed Amount

Manually")

34

Page 35

Responding to Messages

Phenomenon Cause Corrective Action

Cannot update rmware. You have uploaded rmware for

Replace part soon. It is almost time to replace

a different model.

consumables for which service

is required.

Check the rmware version.

(→CD "Updating the Firmware")

You can continue to use the printer

for some time until Past part

replacement. is displayed.

Contact your Océ dealer for

assistance.

Past part replacement. It is past the recommended

time to replace consumables for

which service is required.

Printhead error An incompatible Printhead has

been installed.

There is a problem with the

Printhead.

P Head lock cover is open. The Printhead Fixer Cover is

open.

PHead needs cleaning. The Printhead must be

cleaned.

Cannot adjust printhead. The Printhead nozzles are

clogged.

Contact your Océ dealer for

assistance.

Install a Printhead specied for use

with the printer.

(→CD "Replacing the Printhead")

Open the Top Cover. If the Carriage

is visible, replace the Printhead with

a new one.

(→CD "Replacing the Printhead")

If, after opening the Top Cover, you

see that the Carriage is not visible,

follow the steps below.

Close the Top Cover and press

1.

the Online button.

Replace the Printhead.2.

(→CD "Replacing the Printhead")

Close the Printhead Fixer Cover.

(→CD "Replacing the Printhead")

Specify Printhead cleaning options.

(→P.26)

Follow the steps below to check the

nozzles.

Print a test pattern to check the

1.

nozzles.

(→P.25)

Clean the Printhead if the nozzles

2.

are clogged.

(→P.26)

The Printhead and feed

amount cannot be adjusted

when highly transparent lm is

loaded.

35

We recommend loading a type of

paper that you often use, other than

lm, before adjusting the Printhead.

(→P.27)

Adjust the feed amount manually.

(→CD "Adjusting the Feed Amount

Manually")

Page 36

Responding to Messages

Phenomenon Cause Corrective Action

Multisensor error. Direct sunlight or strong lighting

may be shining on the printer

and causing the sensor to

malfunction.

Take steps to ensure the printer is

not used when exposed to direct

sunlight or strong lighting.

Maint cartridge problem. An incompatible or used

Maintenance Cartridge has

been installed.

Maint cart full. The Maintenance Cartridge is

full.

No maint cartridge The Maintenance Cartridge is

not installed.

No Maintenance Cartridge

capacity.

Check maint cartridge

capacity.

The Maintenance Cartridge

cannot absorb enough ink for

Printhead cleaning.

The Maintenance Cartridge is

almost full.

Install a Maintenance Cartridge

specied for use with the printer.

(→CD "Replacing the Maintenance

Cartridge")

After conrming that the printer

has stopped operating, replace the

Maintenance Cartridge.

(→CD "Replacing the Maintenance

Cartridge")

Install the Maintenance Cartridge.

(→CD "Replacing the Maintenance

Cartridge")

After conrming that the printer

has stopped operating, replace the

Maintenance Cartridge.

(→CD "Replacing the Maintenance

Cartridge")

You can continue printing. However,

prepare a new Maintenance

Cartridge.

36

Page 37

Troubleshooting if You Cannot Print

Printing does not start

Phenomenon Cause Corrective Action

The Display Screen

of the Control

Panel is blank.

The printer is not

selected in the printer

driver.

The print job is paused. In Windows, restart the print job as follows.

In Windows, select the printer by clicking Select

Printer or Printer in the printing dialog box and try

printing again.

Select the printer icon in the Printers and Faxes (or

1.

Printers) window.

Clear Pause Printing in the File menu to restart the

2.

print job.

37

Page 38

Troubleshooting if You Cannot Print

Phenomenon

An error message

appears on the

Display Screen of

the Control Panel.

Cause

There is a paper jam. Remove the jammed paper.

The printer is ofine. If an error message appears on the Display Screen

The printer is ofine. Check the error message shown on the printer Display

No paper is loaded. Load paper in the printer.

The paper type is not

specied for the paper

source.

Corrective Action

(→CD "Clearing Paper Jams")

of the Control Panel, check the message to solve the

error, and then press the Online button on the Control

Panel to bring the printer online.

(→P.29)

If Ofine appears on the Display Screen of the

Control Panel, press the Online button to bring the

printer online.

Screen of the Control Panel, Status Monitor

(Windows)

(→P.29)

On the printer Control Panel, specify the type of paper

in the paper source.

For details on types of paper, see the Media Guide.

(→CD "Paper Sizes")

If the wrong paper is specied, stop the print job and

specify the correct paper type before attempting to print

again.

(→P.14)

If a message appears on the Display Screen of the

Control Panel prompting you to replace the ink,

replace the indicated ink tank.

(→P.16)

Wait until the system has been lled with ink. This

process may take about ten minutes.

Ink unexpectedly

starts lling the

system.

Ink tank is empty.

When the printer

was turned off

previously, some

cleaning operation was

terminated.

Troubleshooting if the printer stops during a print job

Phenomenon Status Corrective Action

An error message is

shown on the Display

Screen.

An error message is displayed

during printing.

The last portion of roll paper

was used during a print job, and

paper could not be advanced

because the trailing edge is

taped to the roll.

Check the error message and take

action as necessary.

(→CD "Error Messages")

Remove the used roll and insert a new

roll.

(→CD "Removing the Roll")

(→P.8)

38

Page 39

Troubleshooting if You Cannot Print

Phenomenon

The printer ejects blank,

unprinted paper.

Status

The leading edge of the roll

paper was cut to straighten it.

The Printhead nozzles are

clogged.

There is little ink left. Check the ink level and replace the Ink

The printer is damaged. Contact your Océ dealer for

Corrective Action

This operation is normal.

When Forced is selected under Trim

Edge First in the printer menu, the

leading edge of a roll is cut after you

load the roll to ensure the edge is

straight and eliminate any scraps of

paper. The printer is ready to print after

this initial preparation.

When No Cutting is selected under

Trim Edge First, the edge is not cut

and scraps are not removed.

Print a test pattern to check the nozzles

and make sure the Printhead is in

good condition for printing.

(→P.25)

Clean the Printhead if the nozzles are

clogged.

(→P.26)

Tank that is low.

(→P.16)

assistance.

39

Page 40

Cannot print over a network

Phenomenon Cause Corrective Action

Cannot print over a

network.

The Ethernet cable is

not connected correctly

to the printer's Ethernet

port.

Troubleshooting if You Cannot Print

Make sure the printer is connected to the network

1.

with the correct Ethernet cable, and then turn the

printer on. For instructions on connecting the cable,

refer to the Quick Start Guide.

Make sure the Link indicator is lit.2.

The Link indicator is green if the printer is connected

via 100 Base-TX and amber if connected via

10Base-T.

If the Link indicator is not lit, check the following

points.

Make sure the hub is on.

•

Make sure the end of the Ethernet cable is

•

connected correctly.

Insert the Ethernet cable until it clicks and locks in

place.

Make sure there is no problem with the Ethernet

•

cable.

If there is any problem, replace the Ethernet cable.

Check the communication mode with the hub.•

Although the printer normally detects the hub

communication mode and transmission rate

automatically (in auto negotiation mode), sometimes

the hub settings cannot be detected. In this

case, congure the connection method manually,

specifying the communication mode in use.

(→CD "Conguring the Communication Mode

Manually")

Cannot print over a

TCP/IP network.

The printer's IP

address is not

congured correctly.

The printer's TCP/IP

network settings

are not congured

correctly.

The computer you

are trying to print

from is not congured

correctly.

Make sure the printer's IP address is congured

correctly.

(→CD "Conguring the IP Address Using GARO

Device Setup Utility")

(→CD "Conguring the IP Address Using the Printer

Control Panel")

Make sure the printer's TCP/IP network settings are

congured correctly.

(→CD "Conguring the Printer's TCP/IP Network

Settings")

Make sure the computer's TCP/IP network settings are

congured correctly.

(→CD "Conguring the Printer Driver Destination

(Windows)")

40

Page 41

Troubleshooting if You Cannot Print

Phenomenon

Cannot print over

AppleTalk or Bonjour

networks.

Cannot print over a

NetWare network.

Cause

The AppleTalk protocol

is not enabled on the

printer.

The computer you

are trying to print

from is not congured

correctly.

The computer and

printer are not on the

same network.

The printer's NetWare

settings are not

congured correctly.

The computer you

are trying to print

from is not congured

correctly.

The NetWare server

and services are not

congured correctly.

Corrective Action

Activate AppleTalk on the printer.

(→CD "Conguring the Printer's AppleTalk Network

Settings")

Make sure the computer's AppleTalk settings are

congured correctly.

(→CD "Conguring the Destination for Apple Talk

Network (Macintosh)")

(→CD "Conguring the Destination forBonjour Network

(Macintosh)")

Due to the nature of Bonjour, you cannot print if the

printer is on another network behind a router. Make

sure the computer and printer are on the same

network. For information about network settings, ask

your network administrator.

Make sure the printer's NetWare settings are

congured correctly. In particular, make sure a valid

frame type is selected.

(→CD "Conguring the Printer's NetWare Network

Settings")

Make sure the computer's NetWare settings are

congured correctly. For more information,

(→CD "Conguring NetWare Network Settings")

Check the following points.

Make sure the NetWare le server is running.

1.

Make sure there is enough free disk space on the

2.

NetWare le server. Insufcient disk space may

prevent you from processing large print jobs.

Start NWADMIN or PCONSOLE and conrm that

3.

the print service is congured correctly and the print

queue is available.

If data transmission to a printer on another subnet

4.

fails, deactivate NCP burst mode in that printer's

network protocol settings.

If the printer is used in queue server mode, specify

5.

Other/Unknown as the printer type.

41

Page 42

Troubleshooting If You Cannot Print as Expected

Problems with the Printing Quality

Phenomenon

Printing is faint. You may be printing on the

Cause

wrong side of the paper.

The Printhead nozzles are

clogged.

Other printed documents are still

stacked on the Output Stacker.

Ink has adhered to the needles

that supply ink, which have

become clogged.

Paper is jammed inside the Top

Cover.

Corrective Action

Print on the printing surface.

Print a test pattern to check the nozzles

and see if they are clogged.

(→P.25)

The Output Stacker can hold one

sheet.

Remove any printouts from the Output

Stacker before printing the next print

job.

After the Ink Tank has been installed

for at least 24 hours, run Head

Cleaning B.

(→P.26)

Follow the steps below to remove

jammed scraps of paper inside the Top

Cover.

Press the Online button to bring the

1.

printer ofine.

Open the Top Cover and move the

2.

Carriage to the right side.

Remove any scraps of paper inside

3.

the Top Cover.

Close the Top Cover.4.

For tips on clearing paper jams, refer to

the following topics.

(→P.48)

(→P.51)

During borderless printing, the

ink was not dry enough before

cutting.

42

In the printer menu, specify a longer

time in Roll Drying Time in Paper

Details.

(→CD "Main Menu Settings")

Page 43

Troubleshooting If You Cannot Print as Expected

Phenomenon

Paper rubs against the

Printhead.

Cause

The paper type as specied

on the printer does not match

the type specied in the printer

driver.

Paper has been loaded

incorrectly, causing it to wrinkle.

The Printhead is set too low.

You are printing on heavyweight

paper or paper that curls or

wrinkles easily after absorbing

ink.

Corrective Action

Make sure the same type of paper is

specied on the printer as in the printer

driver.

(→CD "Selecting the Paper Type

(Roll)")

(→CD "Selecting the Paper Type

(Sheet)")

Make sure the same paper type is

specied in the printer driver as on the

printer.

Hold down the Stop button for a

1.

second or more to cancel printing.

Change the paper type in the printer

2.

driver and try printing again.

Reload the paper.

(→P.8)

(→P.12)

In Head Height, choose Automatic.

(→CD "Adjusting the Printhead

Height")

When printing on Heavyweight Coated

Paper or other paper-based media,

choose a VacuumStrngth setting of

Strong or Strongest. If paper still rubs

against the printhead, try raising the

Printhead higher in Head Height, one

level at a time.

(→CD "Adjusting the Vacuum

Strength")

(→CD "Adjusting the Printhead Height")

43

Page 44

Troubleshooting If You Cannot Print as Expected

Phenomenon

The edges of the paper

are dirty.

Cause

The Platen has become dirty

after borderless printing or

printing on small paper.

The paper type as specied

on the printer does not match

the type specied in the printer

driver.

The paper is wrinkled or warped.

You are printing on heavyweight

paper or paper that curls or

wrinkles easily after absorbing

ink.

Corrective Action

Open the Top Cover and clean the

Platen.

(→P.21)

Make sure the same type of paper is

specied on the printer as in the printer

driver.

(→CD "Selecting the Paper Type

(Roll)")

(→CD "Selecting the Paper Type

(Sheet)")

Make sure the same paper type is

specied in the printer driver as on the

printer.

Hold down the Stop button for a

1.

second or more to cancel printing.

Change the paper type in the printer

2.

driver and try printing again.

Straighten out the wrinkles or curls and

reload the paper. Do not use paper that

has been printed on previously.

(→P.8)

(→P.12)

If this function is not needed, deactivate

CutDustReduct. in the printer menu.

(→CD "Main Menu Settings")

When printing on Heavyweight Coated

Paper or other paper-based media,

choose a VacuumStrngth setting of

Strong or Strongest. If paper still rubs

against the printhead, try raising the

Printhead higher in Head Height, one

level at a time.

(→CD "Adjusting the Vacuum

Strength")

(→CD "Adjusting the Printhead Height")

In Head Height, choose Automatic.The Printhead is set too low.

(→CD "Adjusting the Printhead Height")

44

Page 45

Troubleshooting If You Cannot Print as Expected

Phenomenon

The surface of the paper

is dirty.

The back side of the paper

is dirty.

There are black or white

streaks.

Colors in printed images

are uneven.

Cause

The Paper Retainer is soiled.

The Platen has become dirty

after borderless printing or

printing on small paper.

Paper width detection is

deactivated when printing.

The Paper Retainer is soiled. Clean the Paper Retainer.

The paper feed amount is out of

adjustment.

Printing does not proceed

smoothly because print jobs are

interrupted during transmission.

In the printer menu, Feed

Priority is set to Print Length.

While printing images in many

solid colors, Line Drawing/Text

is chosen.

Corrective Action

Clean the Paper Retainer.

(→P.21)

Open the Top Cover and clean the

Platen.

(→P.21)

Open the Top Cover and clean the

Platen.

(→P.21)

(→P.21)

Adjust the feed amount.

Exit other applications and cancel other

print jobs.

Adjust the feed amount by specifying

Band Joint in Feed Priority in the

printer menu.

Specify Image in the printer driver.

45

Page 46

Problems with printed images

Troubleshooting If You Cannot Print as Expected

Phenomenon

Lines are misaligned. The Printhead is out of

Corrupted characters are

printed.

The length of printed

images is inaccurate.

Cause

alignment.

The printer has received an

invalid print job.

The print job was sent from

an incompatible printer

driver, a driver other than the

iOcé Printer Driver.

In the printer menu, Feed

Priority is set to Band Joint.

Corrective Action

Adjust the Printhead alignment.

(→P.27)

(→CD "Adjusting the Printhead

Alignment Manually")

If the previous corrective actions do not

improve printing, adjust the angle of the

printhead.

(→CD "Adjusting the Printhead

Orientation")

Turn the printer and computer off and

on, and then try printing again.

Try printing again from the

Printer Driver.

To ensure the feed amount matches

the paper size, select Print Length in

Feed Priority in the printer menu and

enter the amount for adjustment. In

Adjust Length, enter the adjustment

amount in Adj.Setting. You can adjust

the feed amount in 0.02% increments.

(→CD "Main Menu Settings")

Documents are printed in

monochrome.

Printed colors are

inaccurate.

Image edges are blurred. The Platen vacuum strength is

In the Advanced Settings of

the printer driver, Monochrome

or Monochrome (BK ink) is

specied in Color Mode.

The Printhead nozzles are

clogged.

Color adjustment has not been

activated in the Advanced

Settings of the printer driver.

Colors have not been calibrated

on the computer or monitor.

The Printhead nozzles are

clogged.

In the printer driver, Application

Color Matching Priority is not

selected.

too strong.

The Printhead is set too high. Lower the Printhead.

In the Advanced Settings of the

printer driver, choose Color in Color

Mode for printing.

Print a test pattern to check the nozzles

and see if they are clogged.

(→P.25)

In the Advanced Settings of the

printer driver, choose Color Settings

in Color Mode to adjust the colors.

Refer to the computer and monitor

documentation to adjust the colors.

Adjust the settings of the color

management software, referring to the

software documentation as needed.

Print a test pattern to check the nozzles

and see if they are clogged.

(→P.25)

Select the Application Color

Matching Priority check box in the

printer driver.

Set VacuumStrngth to Weak.

(→CD "Adjusting the Vacuum

Strength")

(→CD "Adjusting the Printhead Height")

46

Page 47

Troubleshooting If You Cannot Print as Expected

Other problems

Phenomenon

The printer consumes a lot

of ink.

Check maint cartridge

capacity. is not cleared

after you replace the

Maintenance Cartridge.

Cause

Many full-page color images

have been printed.

Head Cleaning B is performed

often.

You have just nished initial

installation.

The printer has not detected the

new Maintenance Cartridge.

Corrective Action

In print jobs such as photos, images

are lled with color, which consumes

a lot of ink. This does not indicate a

problem with the printer.

Head Cleaning B consumes a lot of

ink. This does not indicate a problem

with the printer. Unless the printer

has been moved or stored for a long

period or for the troubleshooting

Printhead problems, we recommend

not performing Head Cleaning B

unnecessarily.

After initial installation or when the

printer is rst used after relocation, ink

ows into the system between the Ink

Tank and Printhead, which may cause

the ink level indicators to drop to 80%

immediately. This does not indicate a

problem with the printer.

After replacing the Maintenance

Cartridge, press the Information

button.

After replacing the Maintenance

Cartridge, print, or clean the

Printhead.

Paper is not cut straight. Paper rises by the ends of the

cut position before it is cut.

The printer does not go

on.

Roll paper cannot be

inserted into the Paper

Feed Slot

The printer is unplugged. Plug the power cord into the outlet, and

The specied voltage is not

supplied.

The roll paper is warped. Straighten out curls and reload the roll.

Reload the paper correctly.

then turn on the printer.

Check the voltage of the outlet and

breaker. For information on the

specied voltage,

(→CD "Specications")

47

Page 48

Clearing Jammed Roll Paper

If roll paper jams, follow the steps below to remove jams.

Caution

Remove any jammed paper promptly.

•

1

2

3

Turn the printer off.

Open the Top Cover.

If the Carriage is out, move the Carriage to separate it from the paper.

48

Page 49

Clearing Jamme d Roll Paper

Important

If you push the Carriage to the left edge, the blade of the Cut

•

lowered in preparation to cut the paper. Be careful not to pinch your ngers between

the Carriage and Platen if you have pushed the Carriage totheleftedgeorifa

paper jam occurs during cutting.

Do not touch the linear scale (a) or Carriage Shaft (b).

•

ter Unit will be

4

5

Push the Release Lever back.

Holding the paper on both sides, pull the jammed portion out toward the front. Use a

scissors to cut away the printed or wrinkled portion.

Caution

When cutting paper, be careful to avoid scratching the printer.

•

49

Page 50

Clearing Jammed Roll Paper

6

7

If the Carriage is on the left, move the

Carriage to the right until it stops.

Important

Always move the Carriage to the right side. If the Carriage is on the left, a

•

Carriage error may occur when you turn on the printer.

Pull the roll edge gently and align it with the Paper Alignment Line (a). Lower the

Release Lever toward the front.

Important

Do not force the roll paper into alignment with the Paper Alignment Line (a). This

•

may prevent the paper from being advanced straight.

If you pull out too much of the roll, an excessive amount will be cut away from

•

the edge.

50

Page 51

Clearing Jamme d Roll Paper

8

9

Close the Top Cover.

Turn the printer on.

The roll is now advanced. After it is nished being advanced, you can resume

printing.

51

Page 52

Clearing a Jammed Sheet

If a sheet jams, follow the steps below to remove it.

Caution

Remove any jammed paper promptly.

•

1

2

3

Turn the printer off.

Open the Top Cover.

If the Carriage is out, move the Carriage to separate it from the paper.

Important

Do not touch the linear scale (a) or Carriage Shaft (b).

•

52

Page 53

Clearing a Jammed Sheet

4

5

Push the Release Lever back.

If the paper is visible, grasp the paper and pull it forward.

6

7

If you cannot see the paper, remove the scrap from behind the printer.

After removing the paper, make sure there are no other scraps of paper in the printer.

If the Carriage is on the left, move the Carriage to the right until it stops.

Important

Always move the Carriage to the right side. If the Carriage is on the left, a

•

Carriage error may occur when you turn on the printer.

8

Turn the printer on.

53

Page 54

Consumables

Supported paper

Printhead

A replacement Printhead.

54

Ink tank

Ink Tankpart numbers.

29952265, IJC236 BK Dye Black

29952264, IJC236 MBK Pigment Black.

29952266, IJC236 C Cyan.

29952267, IJC236 M Magenta.

29952268, IJC236 Y Yellow.

Océ Draft Paper

Océ Standard Paper

Océ Premium Paper

Océ SmartMatt Paper

Océ Top Photo Plus Paper

Océ Smart Dry Photo Paper

Océ Double Matt, Film

Océ Transparent Paper

Océ Check Plot Bond

Océ Deluxe Bond

Océ Inkjet Premium Color Bond

Océ Matte Photopaper

Océ PhotoPerfectPlus Photopaper

Océ Instant Dry Photopaper

Océ Ink Jet Film

Océ Mono Vellum

Page 55

Consumables

Printhead

•

Maintenance cartridge

A replacement Maintenance Cartridge. Maintenance Cartridge includes a Shaft

Cleaner.

Maintenance Cartridge CS2136 29952288

•

Cutter unit

A reaplacement Cutter Unit.

Cutter Unit CS2136: 29801292

•

55

Page 56

Index

a

Adjusting the printhead . . . ... . . . ... . . . ... . . . ... . . ..27

b

Borderless Printing Ink Grooves . . . .. .. . . . .. .. . . . ..24

c

Canceling print jobs . . . . ... . . . ... . . . ... . . .. .. . . . .. ..14

Cleaning. . . . ... . . . ... . . .. ... . . .. ... . . .. ... . . .. .. . . . .21

Consumables . . . .. .. . . . ... . . . ... . . . ... . . .. ... . . .. .. .54

Cutter Unit . ... . . . ... . . .. .. . . . .. .. . . . .. .. . . . .. .. . . . .55

d

Data lamp . ... . . .. ... . . .. .. . . . .. .. . . . ... . . . ... . . .. ..15

e

Ejection Guide . . .. ... . . .. .. . . . .. .. . . . ... . . . ... . . . ..24

Error messages . . .. .. . . . ... . . . ... . . . ... . . . ... . . .. .. .29

f

Feed amount. ... . . .. ... . . .. ... . . .. .. . . . ... . . . ... . . . .27

g

Status Monitor . ... . . . .. .... . . . ... . . . ... . . . ... . . .. ..15

h

Holder Stopper . . .. .. . . . ... . . . ... . . . ... . . . ... . . .. .. . . 8

i

Ink Lamp .. .. . . . .. .. . . . ... . . . ... . . . ... . . .. ... . . .. ...20

Ink Tank. .. . . . ... . . . ... . . .. ... . . .. ... . . .. ... . . .. 16, 54

Ink Tank Cover.. . . .. ... . . .. ... . . .. .. . . . .. .. . . . ... . .18

Ink Tank Lock Lever .. . . . ... . . . ... . . .. ... . . .. ... . . .18

j

Jammed roll paper . . .. ... . . .. ... . . .. .. . . . .. .. . . . ... .58

Jammed sheets . . .. ... . . .. .. . . . .. .. . . . ... . . . ... . . . ..52

m

Maintenance Cartridge . .. . . . .. .. . . . ... . . . ... . . . ... .60

n

Nozzle Checking . . .. .. . . . ... . . . ... . . . ... . . . ... . . .. .25

o

Online lamp . . ... . . . ... . . .. ... . . .. ... . . .. ... . . .. .. . . . 6

Other problems . ... . . . ... . . .. ... . . .. .. . . . .. .. . . . ... .47

p

Paper Alignment Line . . . . ... . . . ... . . . ... . . . ... . . .. .13

Paper Retainer . . . .. .. . . . ... . . . ... . . . ... . . . ... . . .. .. .24

Platen. .. .. . . . ... . . . ... . . .. ... . . .. ... . . .. ... . . .. .. . . .24

Power button . . ... . . . ... . . .. ... . . .. ... . . .. ... . . .. 6, 18

Print Center . . ... . . . ... . . . ... . . . ... . . .. ... . . .. .. . . . .16

Printhead . . . ... . . . ... . . .. .. . . . .. .. . . . ... . . . ... . .26, 54

Printhead Cleaning . . .. ... . . .. ... . . .. .. . . . .. .. . . . ...26

Printing. . . . ... . . .. ... . . .. ... . . .. ... . . .. ... . . .. .. . . . .14

Printing is not possible . ... . . . ... . . .. ... . . .. ... . . .. .37

Problems with printed images . . . ... . . .. ... . . .. ... . .45

Problems with the printing quality . ... . . . ... . . . ... .42

r

Replacing ink tanks . . ... . . .. ... . . .. .. . . . .. ... . . .. ..16

s

Stop button . . . . ... . . . ... . . . ... . . . ... . . .. ... . . .. ... . . 15

Storing an ink tank . .. . . . ... . . . ... . . . ... . . . ... . . .. ..19

t

Top Cover .. ... . . .. ... . . .. ... . . .. .. . . . .. .. . . . ... . . ..22

Turning the printer off. . . . .. .. . . . ... . . .. ... . . .. ... . . .7

Turning the printer on . . . ... . . . ... . . .. ... . . .. .. . . . .. .6

Types of paper. . ... . . . ... . . . ... . . .. .. . . . .. ... . . .. ...54

u

User Software CD-ROM . . .. .. . . . ... . . . ... . . . ... . . .54

v

Vacuum Strength ... . . .. .. . . . .. .. . . . ... . . . ... . . . ... .10

w

Windows . . . ... . . . ... . . .. ... . . .. .. . . . .. .. . . . .. .. . . . .14

56

Page 57

FCC Regulations (U.S.A)

Océ wide format printer CS2136

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Use of shielded cable is required to comply with Class B limits in Subpart B of Part 15 of FCC Rules.

Do not make any changes or modifications to the equipment unless otherwise specified in the manual.

If such changes or modifications should be made, you could be required to stop operation of the equipment.

Océ North America Inc.

5450 North Cumberland Avenue

Chicago, IL 60656

USA

http://www.oceusa.com/

57

Loading...

Loading...