Page 1

o

More Power When

Printing

Océ

ColorStream

User Manual

Continuous Printing

System

Page 2

Copyright

Copyright © Océ 2008–2009

All rights reserved. This documentation may not be reproduced, copied, changed or transmitted in any form, either in whole or in part, without written authorization from Océ.

Océ does not assume any responsibility or offer any guarantee regarding the information

contained in this document and excludes in particular any implied warranty claims regarding

the market capability or usability for a certain purpose. Océ also reserves the right to revise

this documentation from time to time and amend the content without announcing these

changes.

The designations Océ ColorStream®, Océ VarioStream®, Océ JetStream®, Océ VarioPrint®,

Océ Web Buffer®, Océ PRISMA®production, Océ CustomTone®, Océ FlexiDark®, Océ

TonerSafe™ and Océ InkSafe™ are protected by trademark.

All hardware and software names used are trademarks of their respective owners.

We also offer courses in our Training Center for Océ ColorStream.

Information:

Phone +49 (0)8121 72 3940

Fax +49 (0)8121 72 3950

Océ Printing Systems GmbH

ITC

Postfach 1260

85581 Poing

Germany

Edition: A29246-X31-X-1- 80/2009-1176

Page 3

Contents

Chapter 1

Notes on the Printing System Documentation..............................................11

Notes on the Printing System Documentation — Overview................12

Guide through the Documentation.........................................................13

Notes on Help...........................................................................................15

Notes on the Help - Overview...........................................................15

Opening Help......................................................................................16

Navigating in Help..............................................................................18

Contents........................................................................................18

Index..............................................................................................19

Search............................................................................................20

Opening Direct Help...........................................................................21

Symbol Conventions................................................................................24

Symbols in the text............................................................................24

Symbols in figures.............................................................................25

Other Documents.....................................................................................27

Manufacturer of the printing system......................................................28

Statutory requirements............................................................................29

Chapter 2

Safety.................................................................................................................31

Safety — Overview...................................................................................32

Intended Purpose ....................................................................................33

Flagging of safety directives ..................................................................34

Warning and information signs..............................................................35

Accident and Damage Prevention..........................................................37

Accident and damage prevention - overview..................................37

Personal Representations..................................................................38

Operation............................................................................................39

Transportation, assembly and installation, repair...........................42

Fire, disposal.......................................................................................44

Safety Regulations and Standards.........................................................45

Safety regulations and standards — overview................................45

CE Mark...............................................................................................48

Accident prevention regulation for replacement carts (option).....49

Chapter 3

Description of the Printing System.................................................................51

Description of the Printing System — Overview...................................52

Main Modules...........................................................................................53

3

Contents

Page 4

Doors and Covers.....................................................................................54

Internal View.............................................................................................56

Internal View — Overview.................................................................56

Photoconductor unit...........................................................................58

Transfer unit........................................................................................60

Filter module.......................................................................................61

Console................................................................................................62

Printing method........................................................................................64

Operating Elements.................................................................................67

Operating Elements - Overview........................................................67

On key..................................................................................................69

Additional Operator Panels...............................................................70

Operator Attention Light....................................................................72

Operator Attention Light (OPAL) — Overview...........................72

Operator Attention Light (OPAL)/Bundle 11 Version.................73

Operator Attention Light (OPAL)/Bundle 10 Version.................75

Operating elements in the printing system......................................77

Paper specifications.................................................................................78

Chapter 4

Description of the Operator Panel...................................................................81

Description of the Operator Panel — Overview.....................................82

A tool bar...................................................................................................83

Toolbar — Overview..........................................................................83

Buttons and Displays in the Left Area..............................................84

Buttons and Displays in the Center Area .........................................86

Frame toolbar.....................................................................................90

Menu Tree.................................................................................................91

Menu Tree — Overview.....................................................................91

'General' Menus.................................................................................93

'General' menus — overview......................................................93

'User management' menus.........................................................94

'User' menus.................................................................................95

'Security' menus...........................................................................96

'ColorStream' Menus.........................................................................97

'ColorStream' Menus — Overview..............................................97

'Displays' menus...........................................................................99

'Configuration' menus................................................................100

'Setup' menus.............................................................................101

'Replace consumables' menus..................................................102

Menu display..........................................................................................104

Chapter 5

Working with the Operator Panel.................................................................105

Working with the Operator Panel — Overview....................................106

4

Contents

Page 5

Managing User Settings (Key Operator)..............................................107

Managing User Settings (Key Operator) — Overview..................107

Extended password protection (option).........................................109

'Add user' .........................................................................................110

'Delete user' .....................................................................................111

Set Password / 'General' Tab..........................................................112

Releasing and blocking menus and elements/'User rights' tab....113

Setting language/'User profile' tab.................................................114

Managing User Settings (Operator).....................................................115

Managing User Settings (Operator) — Overview..........................115

Log on as user and request an access ticket..................................116

Change Password / 'Password' Tab................................................118

Changing language/'User profile' tab.............................................119

Log off as user..................................................................................120

Selecting settings and entering values................................................121

Applying or resetting settings...............................................................122

Working with Setups..............................................................................123

Working with Setups — Overview..................................................123

Creating a new setup or changing a setup.....................................124

Importing a Setup.............................................................................125

Exporting a Setup.............................................................................127

Managing Resources.............................................................................129

Managing Resources — Overview..................................................129

Installing Resources.........................................................................130

Deleting Resources...........................................................................132

Editing 'Replace consumables' menus on the operator panel...........133

Chapter 6

Operating the Printing System......................................................................137

Operating the Printing System — Overview........................................138

Powering on the Printing System.........................................................139

After printing has stopped, switch the printing system back to 'Ready'

.................................................................................................................142

Inserting the paper web.........................................................................143

Inserting the Paper Web..................................................................143

Adjusting the Pressure Rollers........................................................148

Synchronizing the Paper Path.........................................................150

Affixing the paper web..........................................................................152

Removing the paper web .....................................................................155

Opening or Closing the Doors on the Printing System.......................156

Opening or Closing the Doors on the Printing System —

Overview...........................................................................................156

Opening Right Doors........................................................................157

Closing Right Doors.........................................................................159

Opening Left Doors..........................................................................161

5

Contents

Page 6

Closing Left Doors............................................................................163

Replacing the Developer Station..........................................................165

Replacing the developer station — overview................................165

Preparing the replacement cart.......................................................169

Removing the Developer Station....................................................171

Removing the developer station...............................................171

Storing the Developer Station in the Developer Station Shelf.177

Putting the Developer Station on the Stacking Tray...............181

Installing the Developer Station......................................................183

Removing the Developer Station from the Developer Station

Shelf.............................................................................................183

Replacing the Developer Station from the Stacking Tray.......187

Installing the developer station.................................................189

Replacing the Light Protection Cover.............................................194

Removing the Light Protection Cover.......................................194

Installing the Light Protection Cover.........................................197

Completing developer station replacement...................................198

Checking the print image ......................................................................199

Printing Test Print Jobs.........................................................................200

Printing Test Print Jobs — Overview..............................................200

'5C_PrintQualityInspection.600' Test Print Job..............................202

Test Print Job "ColorProof.ipds".....................................................207

Test Print Job 'ColorProof.ipds' — Overview...........................207

Test Print Job 'ColorProof.ipds' — Page 1...............................208

Test Print Job 'ColorProof.ipds' — Page 2...............................211

Test Print Job 'ColorProof.ipds' — Page 3...............................213

Test Print Job 'ColorProof.ipds' — Page 4...............................214

Test Print Job 'ColorProof.ipds' — Page 5...............................215

Test Print Job 'ColorProof.ipds' — Page 6/7............................216

Test Print Job "ColorProof.ipds_pdf"..............................................218

Test Print Job 'ColorProof.ipds_pdf' — Overview...................218

Test Print Job 'ColorProof.ipds_pdf' — Page 8........................219

Test Print Job 'ColorProof.ipds_pdf' — Page 9........................222

Test Print Job 'ColorProof.ipds_pdf' — Page 10......................223

Test Print Job 'ColorProof.ipds_pdf' — Page 11/12.................225

Test Print Job "ColorProof.pcl"........................................................227

Test Print Job 'ColorProof.pcl' — Overview.............................227

Test Print Job 'ColorProof.pcl' — Page 1..................................228

Test Print Job 'ColorProof.pcl' — Page 2..................................230

Test Print Job 'ColorProof.pcl' — Page 3..................................231

Test Print Job 'ColorProof.pcl' — Pages 4-10...........................232

Test Print Job 'ColorProof.pcl' — Page 11................................234

Test Print Job 'ColorProof.pcl' — Page 12................................236

'SpotColorPalette.pcl' Test Print Job..............................................237

6

Contents

Page 7

Optimizing the Color Printing................................................................239

Optimizing the Color Printing — Overview....................................239

Performing a Color Test...................................................................242

Calibrating the Colors of the Printing System...............................244

Calibrating the Colors of the Printing System — Overview....244

Printing Test Pages for Color Calibration.................................246

Scanning Test Pages for Color Calibration...............................249

Analyzing Test Pages for Color Calibration..............................253

Correcting Color Separation Shifts.......................................................255

Calibrating the Data Integrity Mark Sensor..........................................257

Converting the Printing System............................................................261

Emptying Condensation Water.............................................................263

Switching off the Printing System........................................................264

Chapter 7

Cleaning the Printing System........................................................................267

Cleaning the Printing System — Overview..........................................268

Cleaning Agents and Cleaning Intervals..............................................270

Cleaning the Surface of the Developer Stations..................................273

Cleaning the Surface of the Developer Stations — Overview......273

Swiveling off Developer Stations....................................................274

Cleaning Developer Station Surface...............................................275

Swiveling on developer stations.....................................................282

Cleaning the Paper Input.......................................................................283

Cleaning the Paper Output....................................................................286

Cleaning the Paper Path........................................................................289

Checking the Paper Path........................................................................296

Cleaning the Toner Suction System.....................................................301

Cleaning the Paper Brake Dust Filter....................................................305

Cleaning the Surface of the Printing System.......................................307

Cleaning the replacement cart for developer stations (option)..........308

Cleaning the Developer Station Shelf (Optional)................................309

Chapter 8

Replacing Consumables.................................................................................311

Replacing Consumables — Overview..................................................312

Order Numbers and Packing Units.......................................................313

Toner.......................................................................................................314

Toner Bottle Identification with Océ TonerSafe.............................314

Toner Supply with Additional Colors.............................................317

Refilling Toner (Standard: 6 kg / 13.2 lb Toner Bottle)..................318

Refilling Toner (Option: 1 kg / 2.2 lb Toner Bottle)........................324

Replace waste toner box..................................................................331

Filling a Toner Box...........................................................................335

Developer................................................................................................336

7

Contents

Page 8

Replacing the Developer - Overview..............................................336

Draining the Developer Mixture......................................................337

Fill in Developer................................................................................340

Chapter 9

Replacing Expendables..................................................................................345

Replacing Expendables — Overview....................................................346

Order Numbers and Packaging Units for Expendables......................349

Replacing the Belt..................................................................................350

Replacing the Belt — Overview.......................................................350

Replacing the Photoconductor Belt in the Upper Print Unit.........352

Removing Photoconductor Belt in Upper Print Unit and Replacing

Photoconductor Blade................................................................352

Insert a photoconductor belt in the upper print unit...............358

Replacing the Photoconductor Belt in the Lower Print Unit.........364

Removing Photoconductor Belt in Lower Print Unit and Replacing

Photoconductor Blade. ..............................................................364

Inserting a Photoconductor Belt in the Lower Print Unit........370

Replacing the Transfer Belt in the Upper Print Unit......................376

Removing the Transfer Belt in the Upper Print Unit - Prepara-

tion...............................................................................................376

Removing Transfer Belt in the Upper Print Unit......................380

Insert the Transfer Belt in the Upper Print Unit.......................385

Insertion of a Transfer Belt in the Upper Print Unit (Comple-

tion)..............................................................................................392

Replacing the Transfer Belt in the Lower Print Unit......................395

Removing the Transfer Belt in the Lower Print Unit - Prepara-

tion...............................................................................................395

Removing the Transfer Belt in the Lower Print Unit ...............398

Inserting the Transfer Belt in the Lower Print Unit..................402

Inserting the Transfer Belt in the Lower Print Unit..................408

Running in a Belt..............................................................................411

Replacing Corotrons..............................................................................412

Replacing the corotron — overview...............................................412

Removing the cleaning corotron slide-in unit or charge corotron

slide-in unit of the photoconductor unit.........................................413

Installing the cleaning corotron slide-in unit or charge corotron slide-

in unit of the photoconductor unit .................................................416

Removing the cleaning corotron slide-in unit of the transfer unit.418

Installing the cleaning corotron slide-in unit of the transfer unit .420

Removing the reload corotron slide-in unit of the transfer unit....421

Installing the reload corotron slide-in unit of the transfer unit....423

Removing the recharge corotron slide-in unit of the transfer unit.425

Installing the recharge corotron slide-in unit of the transfer unit.427

Replacing corotron wire...................................................................428

8

Contents

Page 9

Replacing the Cleaning Brush...............................................................433

Replacing the cleaning brush — overview.....................................433

Removing the cleaning brush of the photoconductor unit...........434

Installing the cleaning brush of the photoconductor unit.............437

Removing the cleaning brush of the transfer unit.........................439

Installing the cleaning brush of the transfer unit...........................441

Replacing fine filter................................................................................443

Replacing the cleaning felt....................................................................448

Replacing the Smoothing Rollers.........................................................454

Replacing the smoothing rollers — overview................................454

Removing the smoothing rollers....................................................455

Installing smoothing rollers.............................................................461

Replacing Expendables in Expert Mode...............................................469

Chapter 10

Correcting Errors.............................................................................................473

Correcting Errors — Overview .............................................................474

Processing messages on the operator panel ......................................475

Remote Diagnosis..................................................................................479

Allowing Remote Access — Overview...........................................479

Permitting or Blocking Remote Diagnosis.....................................480

Activating or Deactivating Remote Support..................................481

Correcting Fusing Problems..................................................................483

Correcting Print Image Errors...............................................................484

Appendix A

Technical Data.................................................................................................491

Technical Data — Overview..................................................................492

Technology and Print Speed.................................................................493

Paper........................................................................................................496

Electrical Values and Power Input........................................................498

Mechanical Conditions..........................................................................500

Environmental Conditions.....................................................................502

Replacement cart for developer stations (option)...............................503

Ruler for Checking Paper Path Synchronization..................................504

Appendix B

Comments.......................................................................................................507

Your comments on this User Manual...................................................508

9

Contents

Page 10

10

Contents

Page 11

Chapter 1

Notes on the Printing

System Documentation

Page 12

Notes on the Printing System Documentation — Overview

Introduction

The purpose of this documentation is to ensure that all printing system-related work is

carried out safely and correctly. It contains safety directives that must be strictly observed.

Each section is divided into small, easy-to-understand subject areas. Overviews at the

beginning of the sections help you to find the precise information you are looking for

quickly.

Storage Tray for the User Guide

The user guide should always be kept near the console in the storage tray.

Overview

You will find information on the following topics:

■

‘Guide through the Documentation’ on page 13

■

‘Notes on the Help - Overview’ on page 15

■

‘Symbols in the text’ on page 24

■

‘Symbols in figures’ on page 25

■

‘Other Documents’ on page 27

■

‘Manufacturer of the printing system’ on page 28

■

‘Statutory requirements’ on page 29

Chapter 1 - Notes on the Printing System Documentation12

Notes on the Printing System Documentation — Overview

Page 13

Guide through the Documentation

Introduction

Documentation available to you on the Océ ColorStream includes a printed user guide

and help on the operator panel. This help is updated with every new version of the oper-

ator panel software.

Security

This section gives you all necessary information on how to safely and efficiently operate

the printing system.

Description of the printing system

This section shows the structure of the printing system, describes the operating elements

and explains the printing principle. You will also find information on paper types and

how to handle the paper.

Description of the Operator Panel

This section describes the individual areas of the operator panel with the most important

menus, buttons and icons.

Working with the operator panel

This section explains how you manage all user settings, how you select or enter parameters

on the operator panel, how you collect special settings for frequently recurring print jobs

using setups, how you manage resources for printing operation and how you replace

consumables and expendables using the operator panel.

Operating the printing system

This section describes how to power the printing system on and off and the procedure

for inserting, affixing and removing the paper web, and also contains all other information

that you will need to operate the printing system.

Cleaning the printing system

This section shows you how often to clean the different components and how to carry

out this cleaning.

Chapter 1 - Notes on the Printing System Documentation 13

Guide through the Documentation

Page 14

Replacing consumables

This section describes in detail all the steps required to replace consumables. It also provides

the order numbers and package units for all consumables.

Replacing expendables

This section describes in detail all the steps required to replace expendables. It also provides

the order numbers and package units for all expendables.

Correcting Errors

This section shows you how to locate and remedy errors using the messages displayed on

the operator panel. It also describes how you can enable remote access to allow remote

diagnosis by Service during print operation . You will also find information on how to

correct any fusing or print image errors.

Technical data

This section contains the most important technical data for the printing system.

You can use the ruler for controlling the paper path synchronization to assign the marks

on the paper input to certain form lengths.

Index

The fastest way to find particular topics is via the detailed index at the end of the user

guide.

Your comments on this user guide

We are interested in your opinion on this user guide for the Océ ColorStream. You can

help us improve this user guide by answering the questions in this section.

Chapter 1 - Notes on the Printing System Documentation14

Guide through the Documentation

Page 15

Notes on Help

Notes on the Help - Overview

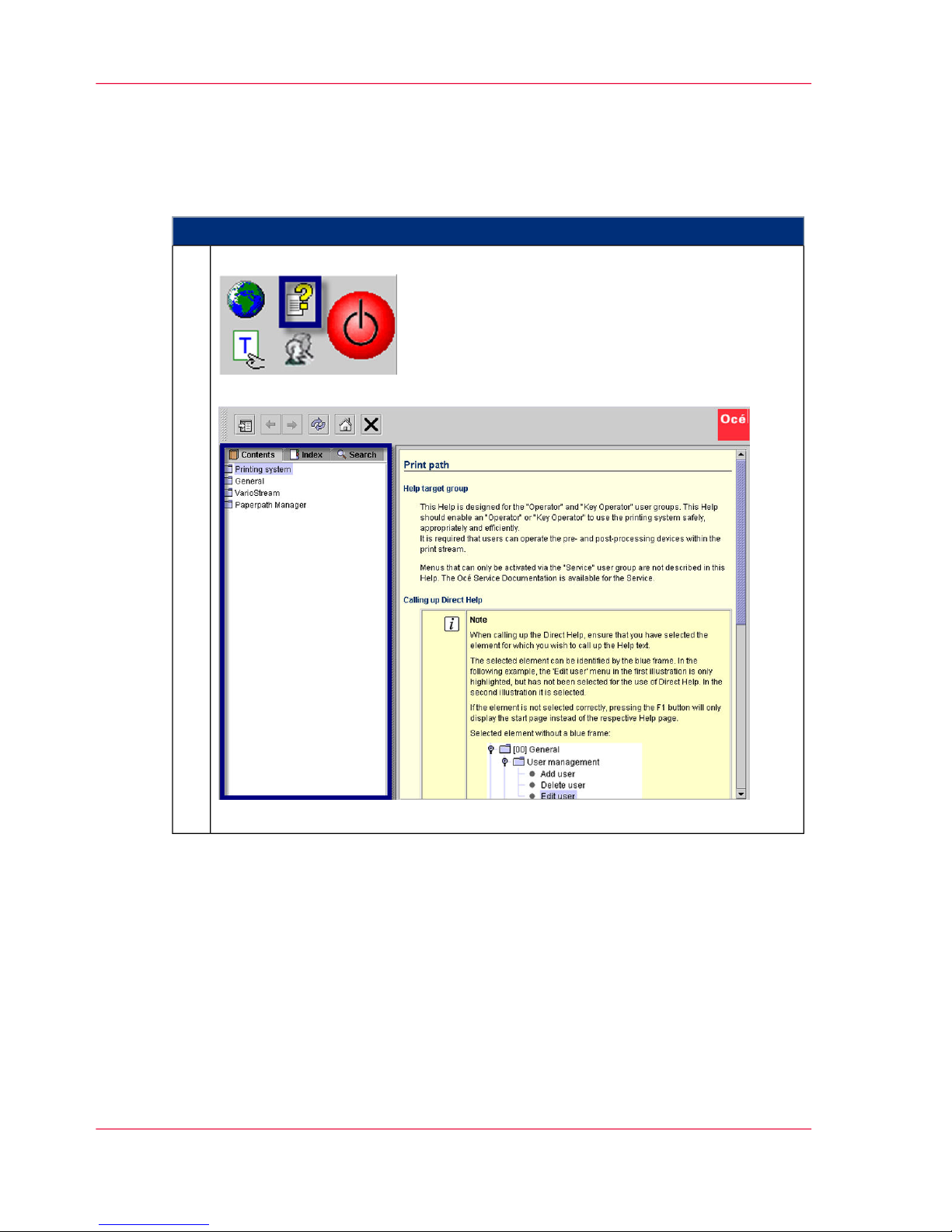

Help target group

This Help is designed for the "Operator" and "Key Operator" user groups. This Help

should enable an "Operator" or "Key Operator" to use the printing system safely, appro-

priately and efficiently.

Menus that are available to the Service group only are not displayed in this Help. The

Océ service documentation is available for Service.

Contents of Help

This Help describes the printing system and operator panel with the following main

groups:

■

'General'

■

'VarioStream' or 'ColorStream' or 'JetStream'

■

'Paperpath Manager'

■

With Océ VarioStream 9000 CustomTone or full-color printing systems and with

Océ ColorStream, also: 'Web Buffer'

Any connected pre- and post-processing devices are not covered in this Help. It is assumed

that the user is able to operate these devices properly and observes the safety instructions

in the relevant documentation sources for these pre- and post-processing devices.

Calling up Help

There are two ways you can access help topics:

■

Help button on the toolbar and subsequent navigation via contents, index or search:

‘Opening Help’ on page 16

‘Contents’ on page 18

‘Index’ on page 19

‘Search’ on page 20

■

Direct Help via the F1 key:

‘Opening Direct Help’ on page 21

Chapter 1 - Notes on the Printing System Documentation 15

Notes on the Help - Overview

Page 16

Opening Help

To open Help

#

Proceed as follows:

Click on the following button in the frame toolbar:

The Help window opens. The navigation area is displayed initially:

The width of the navigation area can be changed with the mouse.

1.

Chapter 1 - Notes on the Printing System Documentation16

Opening Help

Page 17

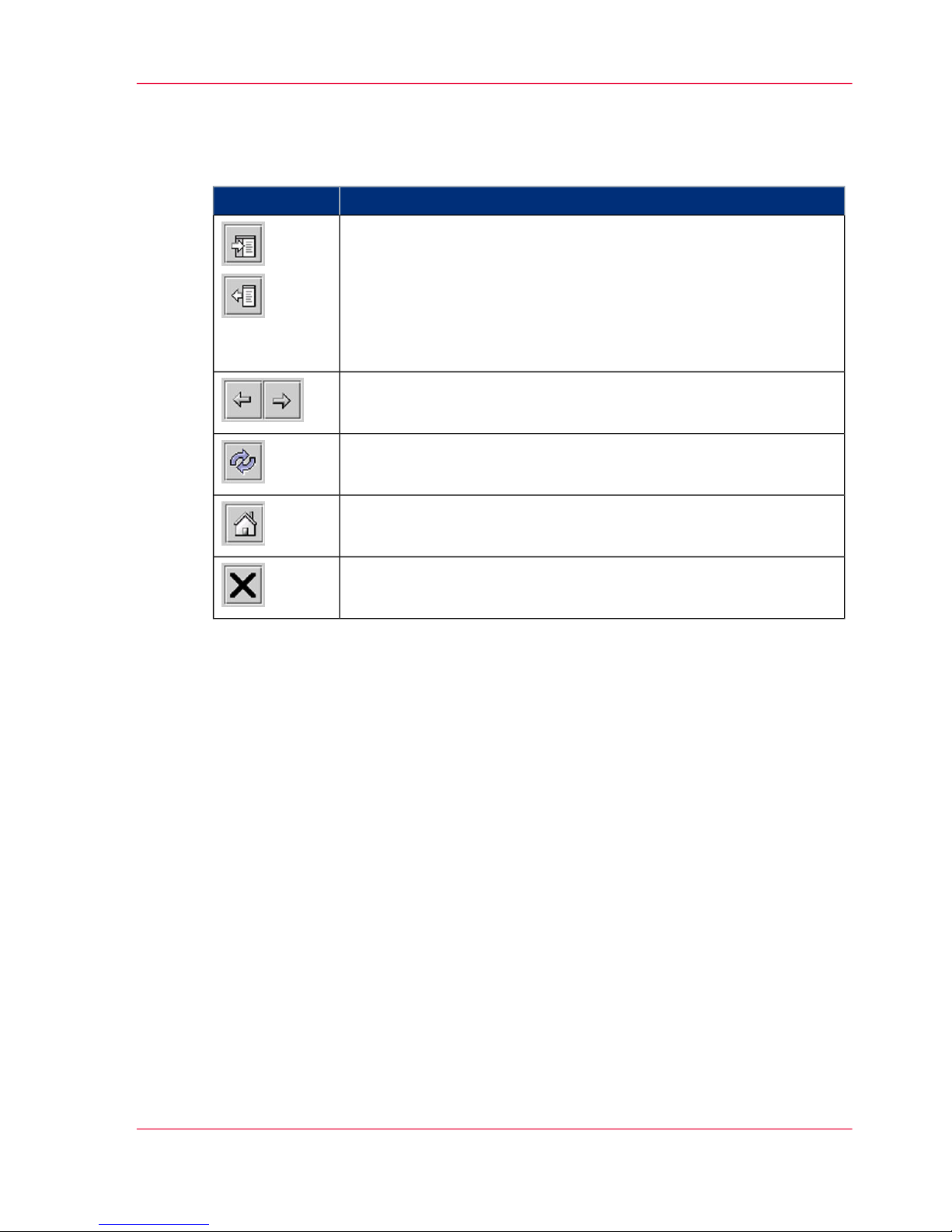

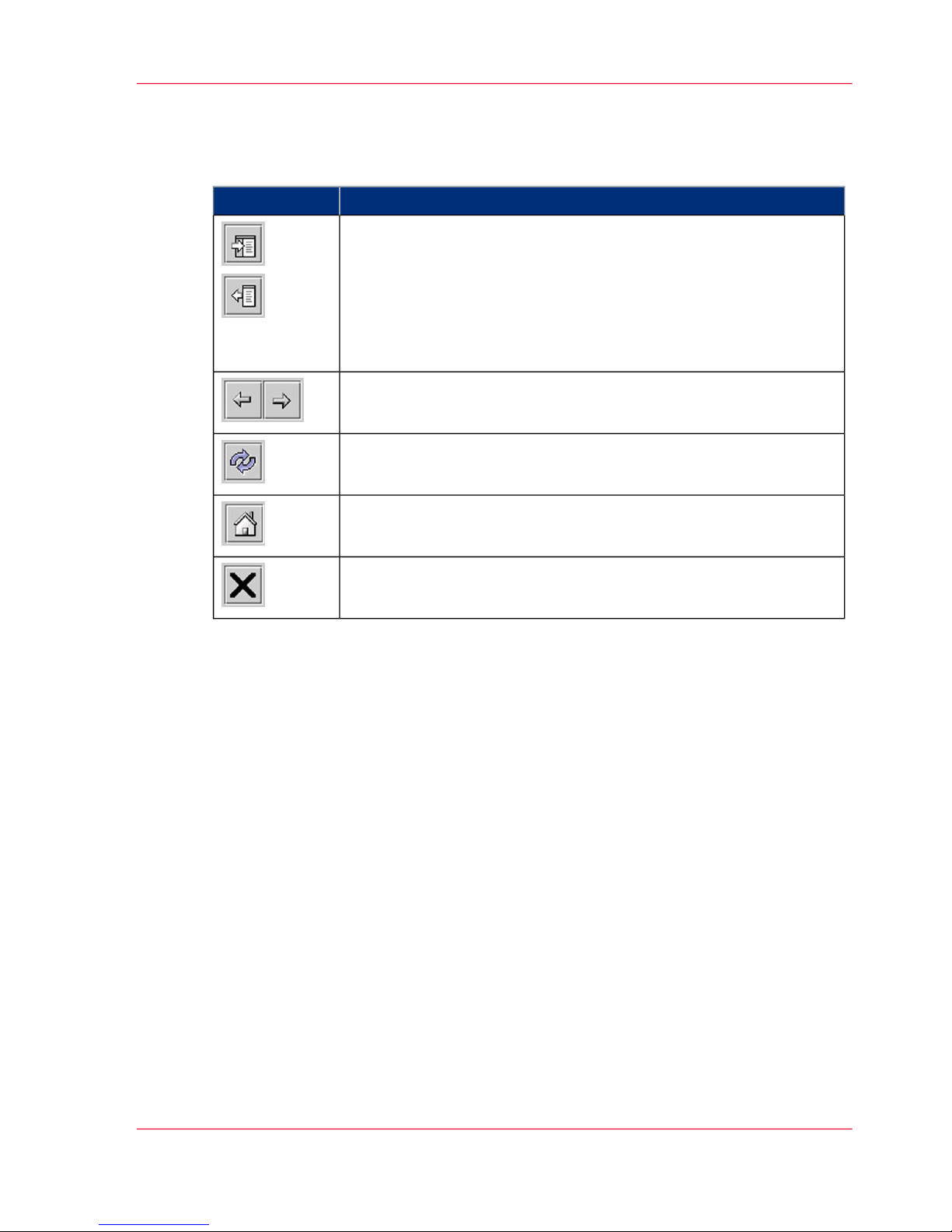

Function of the Buttons in the Help Window

#

FunctionButton

Hides or displays the navigation area with the following tabs:

■

‘Contents’ on page 18

■

‘Index’ on page 19

■

‘Search’ on page 20

When the navigation area is hidden, more space is available to view

the help topics.

Switches between the last help topics (backwards or forwards).

Reloads the displayed help topic, in case not all the necessary content

was loaded (e.g. graphics).

Switches from any help topic directly to the Help start page.

Closes Help.

Chapter 1 - Notes on the Printing System Documentation 17

Opening Help

Page 18

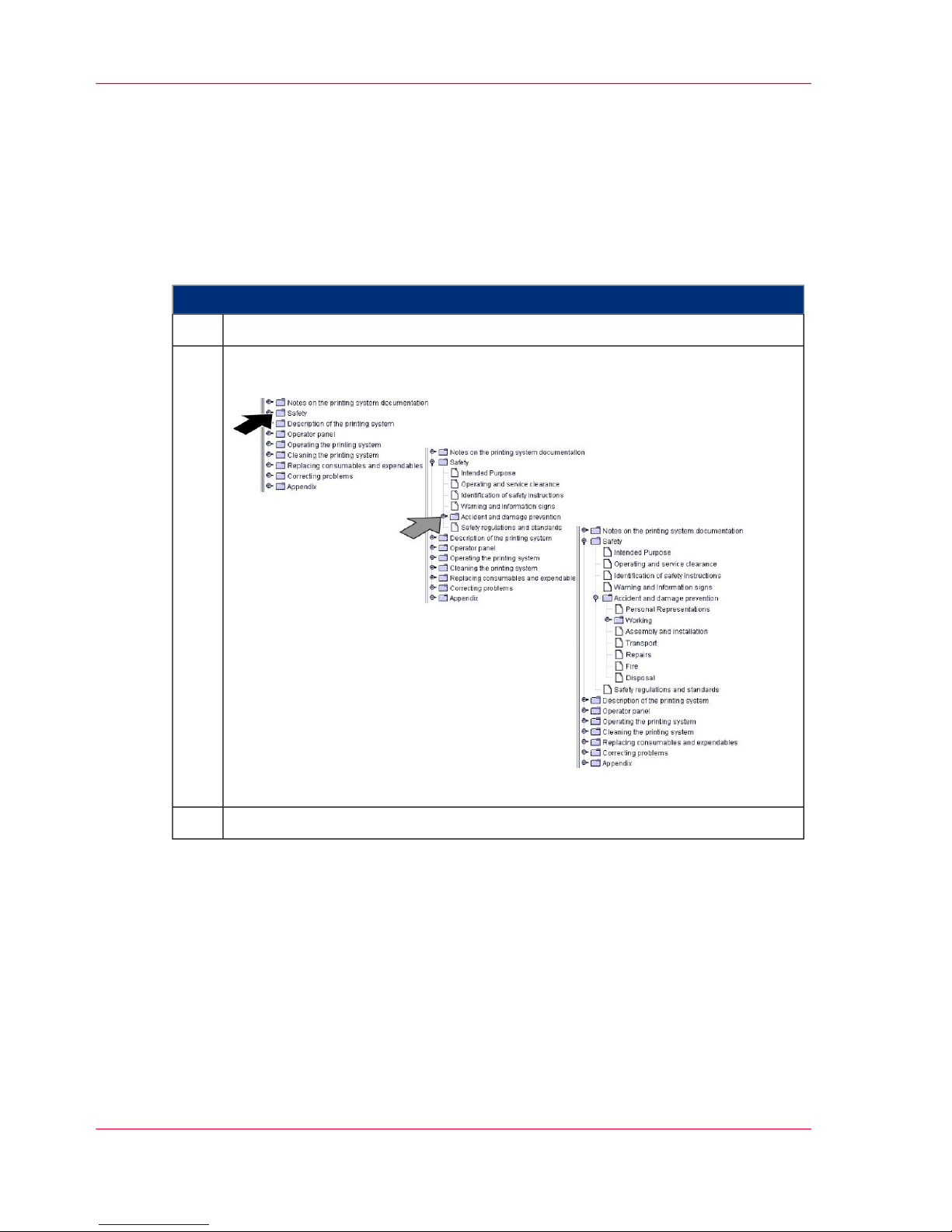

Navigating in Help

Contents

To call up Help topics via the contents

#

Proceed as follows:

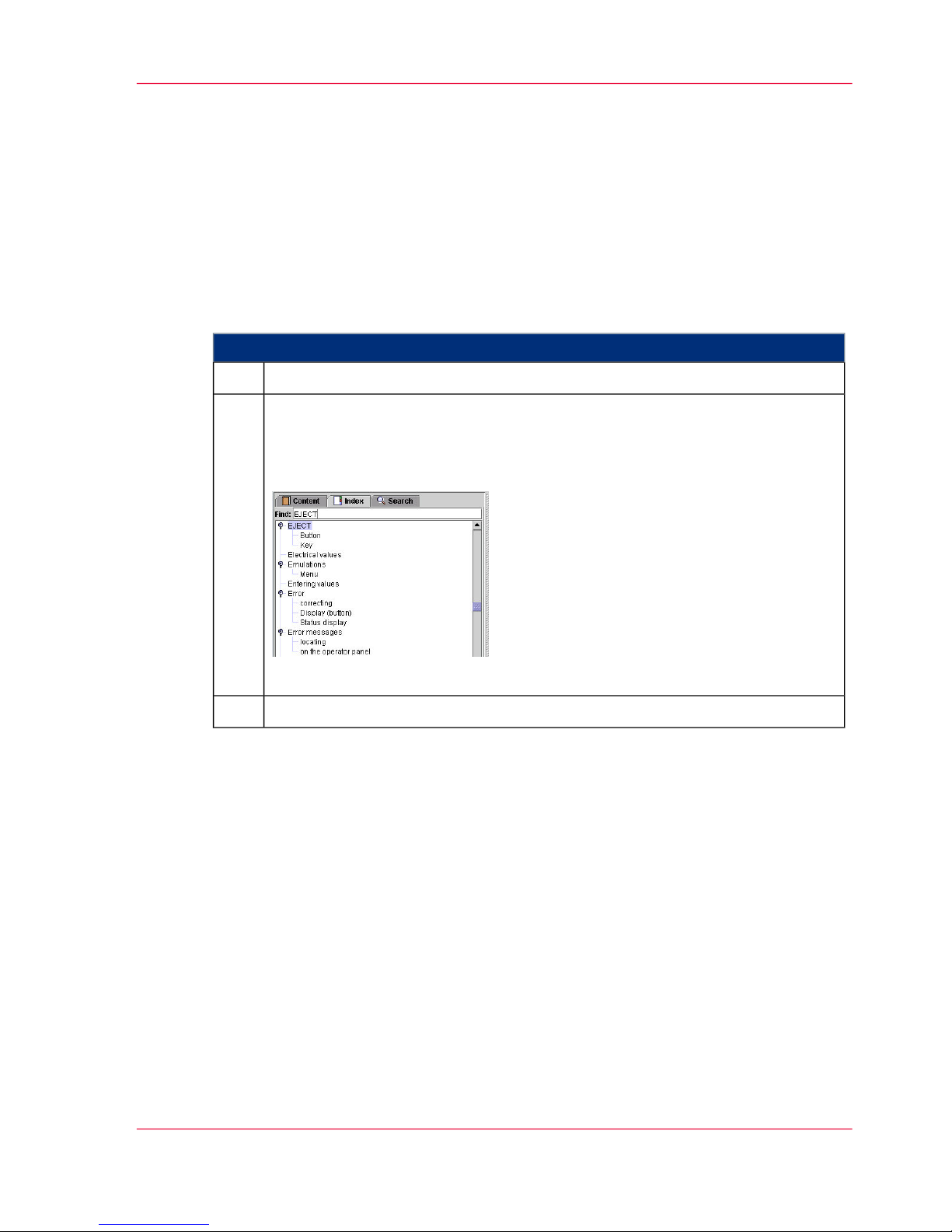

Click on the 'Contents' tab.1.

Click the buttons of the individual help levels to fade them in and out.

Example:

[13]

2.

Click on a help topic.3.

Chapter 1 - Notes on the Printing System Documentation18

Contents

Page 19

Index

Introduction

Entries on the 'Index' tab are sorted alphabetically. Any number of secondary keywords

can be attached to a primary keyword.

To select information via the Index

#

Proceed as follows:

Click on the "Index" tab.1.

Scroll through the index entries

or

enter text (including partial words) into the 'Search' field and press Enter.

Example:

[14]

2.

Click on a help topic3.

Chapter 1 - Notes on the Printing System Documentation 19

Index

Page 20

Search

Introduction

You can access the full text search function via the "Search" tab. The full text search is

used to find one or more specific words in the entire Help. Uppercase or lowercase is not

relevant for the search. Partial words cannot be found.

To call up information via the full text search

#

Proceed as follows:

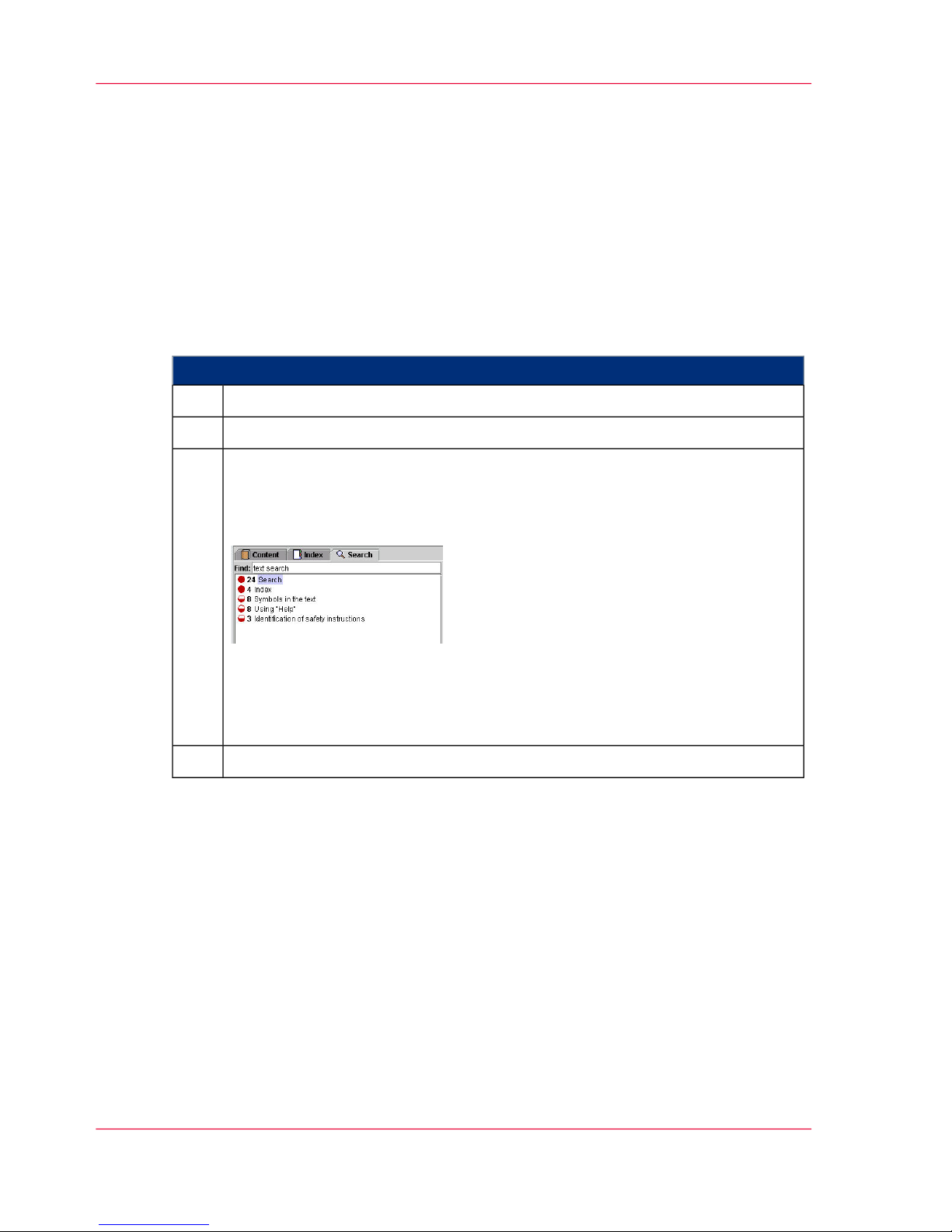

Click on the 'Search' tab.1.

Enter the text in the 'Search' input field.2.

Press Enter.

The search results are listed by the title of the corresponding help topic, and

are sorted by level of matches and the frequency in which the word appears in

the help topic. Example:

The circle in the first column indicates the level of matching. The more filled

the circle is, the better the result matches the text that was searched for.

The number in the second column of the search result indicates how often it

occurs in the Help topic.

3.

Click on a help topic4.

Chapter 1 - Notes on the Printing System Documentation20

Search

Page 21

Opening Direct Help

Introduction

Context-sensitive Direct Help provides detailed information on all:

■

Menus

■

Operating elements in menus

■

Errors and warnings

#

Note

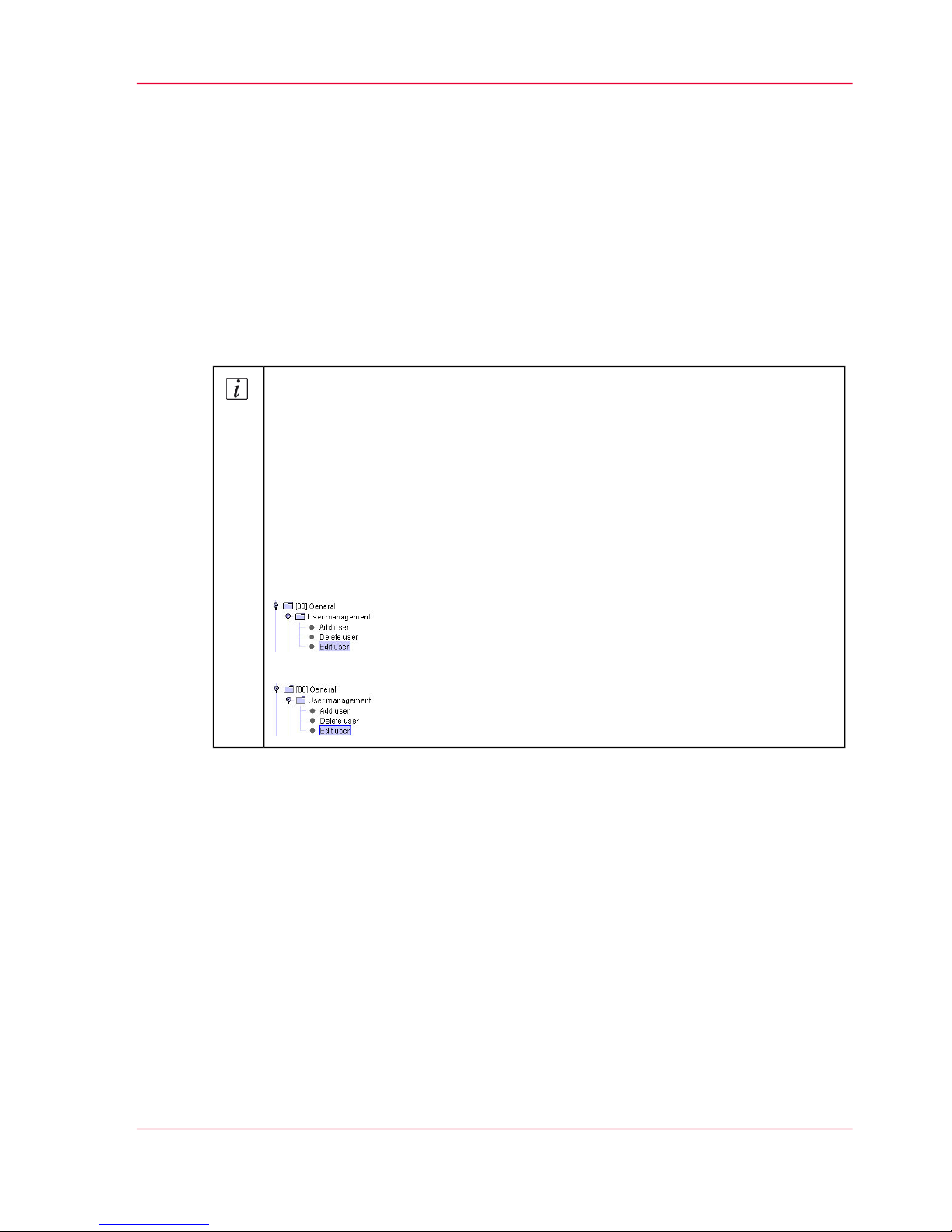

When calling up the Direct Help, ensure that you have selected the element

for which you wish to call up the Help text.

The selected element can be identified by the blue frame. In the following example, the 'Edit user' menu in the first illustration is only highlighted, but has

not been selected for the use of Direct Help. In the second illustration it is

selected.

If the element is not selected correctly, pressing the F1 button will only display

the start page instead of the respective Help page.

Selected element without a blue frame:

Selected element with a blue frame:

Chapter 1 - Notes on the Printing System Documentation 21

Opening Direct Help

Page 22

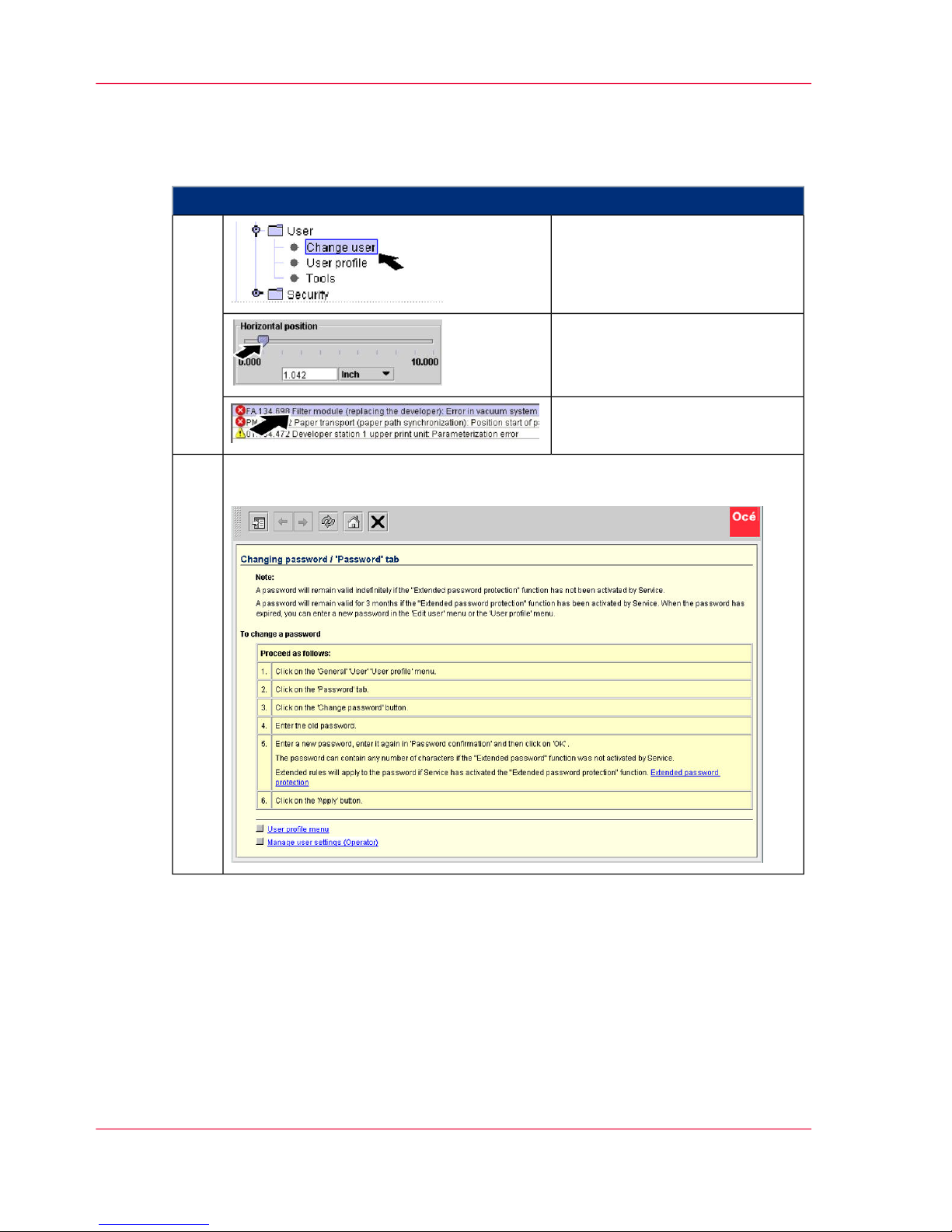

To call up the Direct Help

#

Proceed as follows:

Select menu

or

1.

select operating element

or

select message

Press F1.

The Help window opens. The navigation area is initially hidden, e. g.:

2.

Chapter 1 - Notes on the Printing System Documentation22

Opening Direct Help

Page 23

Function of the Buttons in the Help Window

#

FunctionButton

Hides or displays the navigation area with the following tabs:

■

‘Contents’ on page 18

■

‘Index’ on page 19

■

‘Search’ on page 20

When the navigation area is hidden, more space is available to view

the help topics.

Switches between the last help topics (backwards or forwards).

Reloads the displayed help topic, in case not all the necessary content

was loaded (e.g. graphics).

Switches from any help topic directly to the Help start page.

Closes Help.

Chapter 1 - Notes on the Printing System Documentation 23

Opening Direct Help

Page 24

Symbol Conventions

Symbols in the text

Display of operating elements on the operator panel

The operating element description is shown in inverted commas on the operator panel,

e.g.

'Configuration' menu.

Notes

Note:

This symbol indicates notes - tips for operating the Océ ColorStream.

Safety directives

Symbols are used for the safety directives, as well as different alert words depending on

the degree of danger: see ‘Flagging of safety directives ’ on page 34.

Chapter 1 - Notes on the Printing System Documentation24

Symbols in the text

Page 25

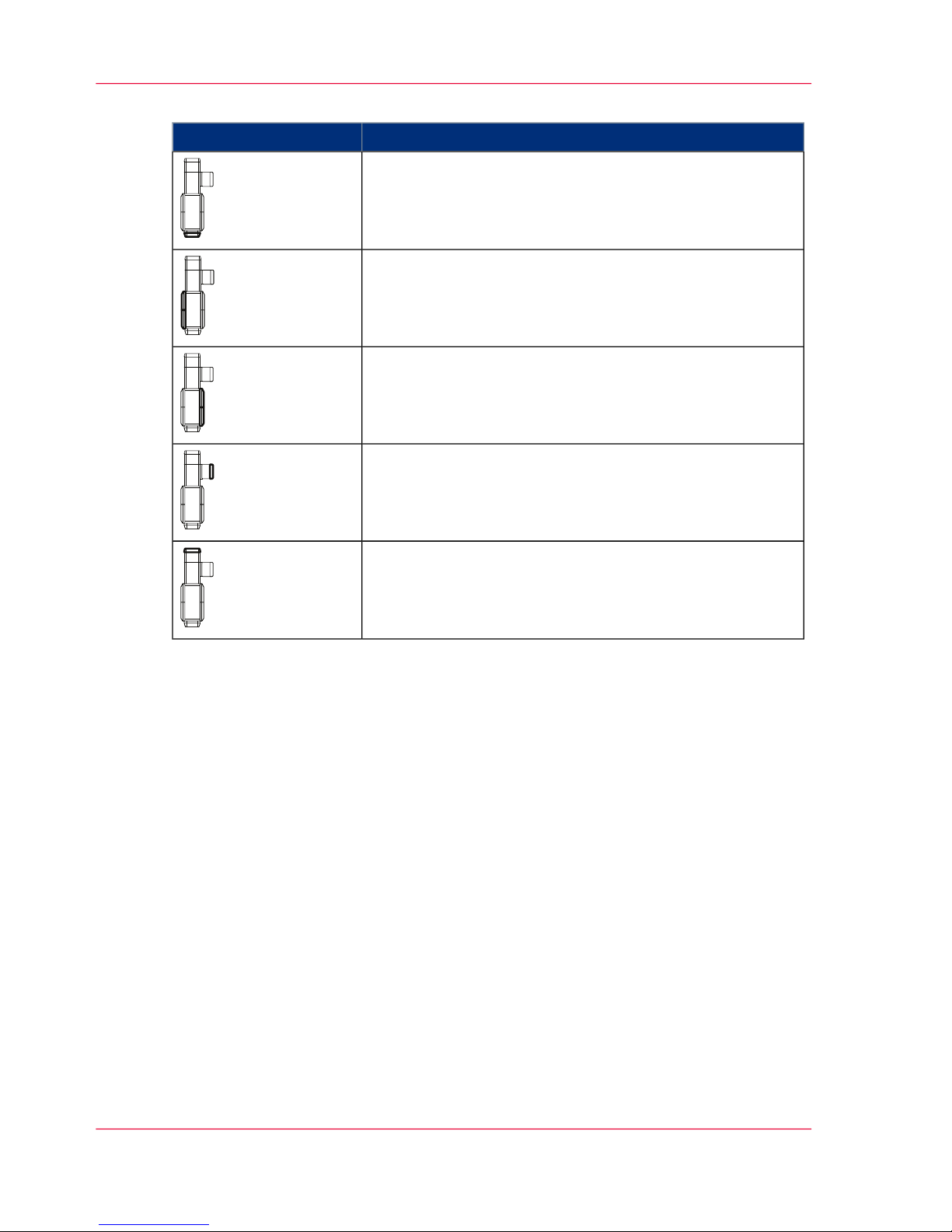

Symbols in figures

Introduction

If not indicated otherwise, diagrams and illustrations of actions depict the starting position

of the respective component for the described step.

To ease understanding, the illustrations depict the components that are directly relevant

to the immediate context in a larger line thickness.

Note:

As a result of the continuous technical further development, it may be that some of the

details on the images in the documentation are not always completely up-to-date with

the delivered printing system.

Arrows

Arrows denote the positions where you should perform an action or observe something

in particular. The colors of the arrows denote the type of actions and the sequence in

which they are performed:

#

MeaningArrow

Black arrow: Direction arrow

Perform this action first

Grey arrow: Direction arrow

Perform this action next

If further actions are depicted in an illustration, the numbers

on the arrows indicate the sequence of these further actions.

White arrow: Note arrow

An action should be performed in this area.

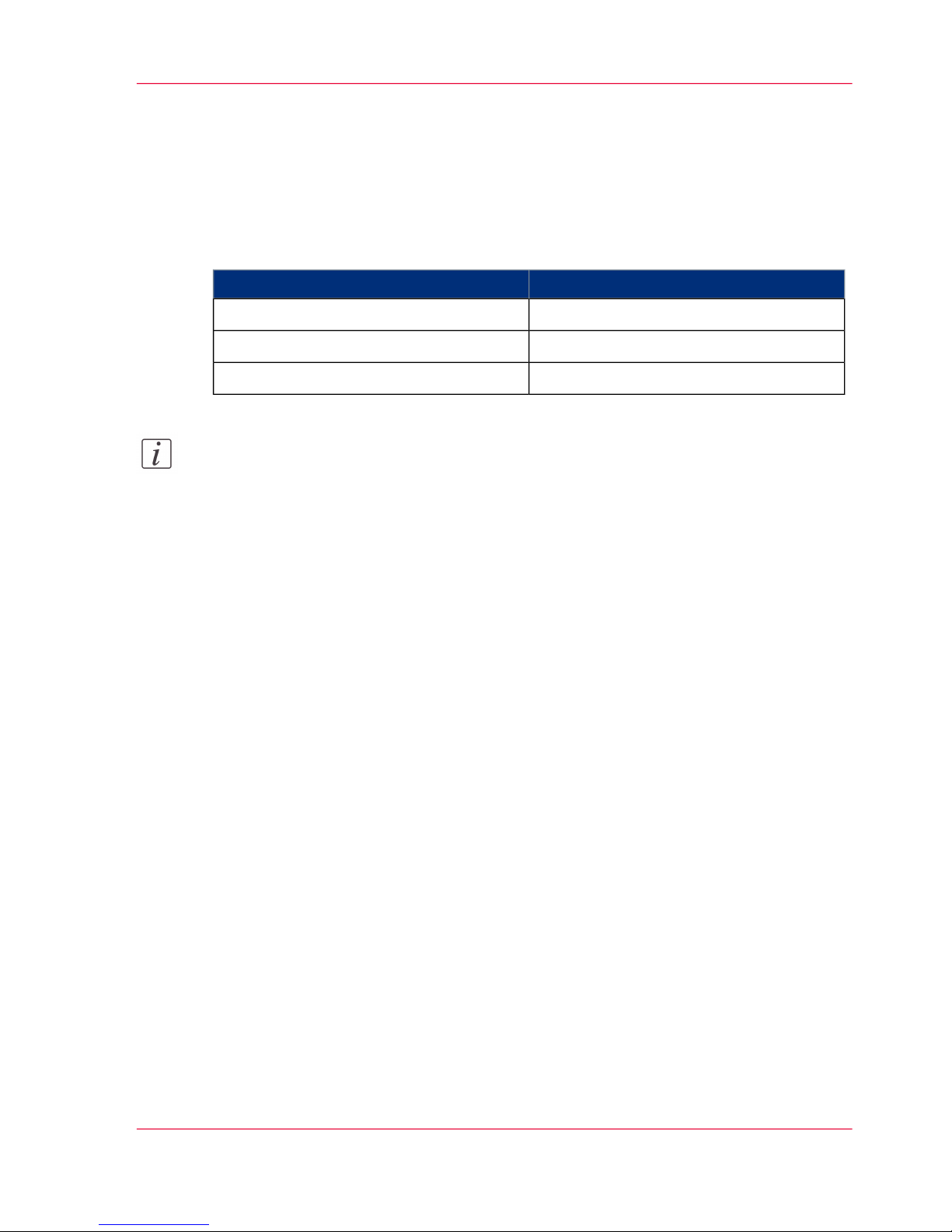

Overview Graphics

To provide a clear overview, the VarioStream 9000 and ColorStream printing systems

also indicate the side of the printing system where the action is to be performed.

Chapter 1 - Notes on the Printing System Documentation 25

Symbols in figures

Page 26

#

MeaningOverview graphic

Paper input

Left-hand side of printing system

Right-hand side of printing system

Filter module

Paper output

Chapter 1 - Notes on the Printing System Documentation26

Symbols in figures

Page 27

Other Documents

In Addition to the User Guide

The following documents are also provided for every printing system, in addition to the

user guide:

#

Order numberTitle

A29246-X34-X-n-79 (multi-lingual)Safety information

A29249-X5-X-n-mm59Paper specification

A29246-X27-X-n-mm80'Océ Web Buffer' User Guide

Note:

The respective edition of the document is indicated in the order number by the digit

"n", for example: Edition 3: n = 3. The letters "mm" stand for the language code of the

document:

■

German: mm = --

■

English: mm = 76

■

French: mm = 77

■

Italian: mm = 72

■

Spanish: mm = 78

■

Dutch: mm = 54

■

Japanese: mm = 5Z

■

Chinese: mm = 5D

Chapter 1 - Notes on the Printing System Documentation 27

Other Documents

Page 28

Manufacturer of the printing system

Océ ColorStream

The printing system Océ ColorStream was manufactured by:

Océ Printing Systems GmbH

Postfach 1260

85581 Poing

Germany

Chapter 1 - Notes on the Printing System Documentation28

Manufacturer of the printing system

Page 29

Statutory requirements

Technical changes

The information, data and instructions in this documentation were up-to-date at the

time of going to press. The right of technical modifications due to further development

of the printing system is reserved. For this reason, the information, illustrations and de-

scriptions in this documentation cannot give rise to any claims for modifications or addi-

tions to printing systems that have already been shipped and accepted.

Liability

No liability is accepted for damages resulting from:

■

Failure to comply with the documentation

■

Errors due to improper handling

■

Work performed incorrectly on the printing system

■

Use of non-original expendable parts, replacement parts and accessories

■

Use of non-original consumables

■

Unauthorized modification and retrofitting of the printing system by the agent or the

agent’s personnel.

Chapter 1 - Notes on the Printing System Documentation 29

Statutory requirements

Page 30

Chapter 1 - Notes on the Printing System Documentation30

Statutory requirements

Page 31

Chapter 2

Safety

Page 32

Safety — Overview

Security

This section gives you all necessary information on how to safely and efficiently operate

the printing system.

Safety Directives

In addition to the safety directives in section ‘Accident and damage prevention - overview’

on page 37, you must also observe the safety directives elsewhere in this documentation.

Please also observe the safety directives in the documentation for any pre-processing and

post-processing devices that may be connected.

Overview

You will find information on the following topics:

■

‘Intended Purpose ’ on page 33

■

‘Flagging of safety directives ’ on page 34

■

‘Warning and information signs’ on page 35

■

‘Accident and damage prevention - overview’ on page 37

■

‘Safety regulations and standards — overview’ on page 45

Chapter 2 - Safety32

Safety — Overview

Page 33

Intended Purpose

Océ ColorStream

The Océ ColorStream printing system shall only be considered as being used for its intended purpose if the notices and instructions in this documentation are strictly observed:

■

The printing system is intended solely for printing materials that comply with the

paper specification requirements (see ‘Other Documents’ on page 27).

■

The printing system must only be operated with the recommended consumables (see

‘Order Numbers and Packaging Units for Expendables’ on page 349).

■

The printing system must only be operated under the prescribed operating conditions

(see ‘Technical Data — Overview’ on page 492).

Any other use of the printing system can cause damage to the printing system or property

as well as injury to persons.

Chapter 2 - Safety 33

Intended Purpose

Page 34

Flagging of safety directives

Definition

The following notational conventions are used for the safety directives in the text of the

manual:

#

Alert word

Type or source of danger and consequences of failure to observe the

safety directives

Instructions on avoiding danger

Symbol

Different alert words are used for the safety directives, depending on the degree of danger.

Two classes of safety directives

Caution:

Warns against dangers that could lead to injuries.

Attention:

Warns against situations that could lead to damage to the printing system or disruptions

to operation.

Example of a safety directive

Attention:

Fluid can get inside the printing system. This could cause irreparable damage to the

electrical and mechanical components.

Do not place cleaning fluids on top of or in the immediate vicinity of the printing system.

Take care to prevent fluids from seeping into the printing system.

Chapter 2 - Safety34

Flagging of safety directives

Page 35

Warning and information signs

Identification of Danger Points

The following signs are affixed inside the printing system at potential danger points:

#

MeaningLabel

Warning: Live electric parts

There are live electric parts behind safety covers bearing this

sign. These safety covers may only be removed by authorized

Océ Service personnel.

Warning about rotating parts

In these areas, body parts (especially fingers), unprotected long

hair and loose hanging clothing (e.g. ties, jewelry, loose belts

etc.) can be pulled in by the rotating parts of the printing system, trapped and crushed.

Warning about hot components

In order to prevent burns, you must observe the cooling periods

and other directives specified in the documentation for all work

in these areas.

Observe documentation

For all work in this area, you must observe the relevant instructions in the documentation.

Disposal

This symbol means that separate, proper disposal of the components at the end of the product service life is obligatory in the

EU Member States. The black bar indicates that the regulation

became effective on August 13, 2005. Directive: 2002/96/EC.

The "Environmental Protection Use Period (EPUP)", applicable

in the People's Republic of China, amounts to 20 years for the

printing system.

This EPUP, which does not record consumables and expendables according to regulations, does not affect the liability for

defects and no special guarantee is given for the printing system.

Chapter 2 - Safety 35

Warning and information signs

Page 36

Additional warning and information signs on the Océ ColorStream

#

MeaningSign

Warning regarding laser beams

Components that produce laser beams are located behind protective covers bearing this sign. These protective covers may

only be removed by authorized Océ Service personnel.

Chapter 2 - Safety36

Warning and information signs

Page 37

Accident and Damage Prevention

Accident and damage prevention - overview

Overview

You will find information on the following topics:

■

‘Personal Representations’ on page 38

■

‘Operation’ on page 39

■

‘Transportation, assembly and installation, repair’ on page 42

■

‘Fire, disposal’ on page 44

Chapter 2 - Safety 37

Accident and damage prevention - overview

Page 38

Personal Representations

Agent

An agent is any individual or legal entity (corporate body) that uses or commissions the

use of the printing system.

Operator

The Operator

■

is trained directly on the printing system as to how to operate it and has been instructed

on the tasks assigned to them. They are familiar with the contents of the documentation.

■

is aware of the potential dangers of improper handling of the printing system.

■

has been informed about necessary safety installations, safety precautions and operating

conditions.

■

has been instructed or commissioned by the agent to operate the printing system.

■

can load defined setups.

Key Operator

The Key Operator

■

is an operator with a higher qualification assigned additional tasks by the agent (e.g.

assignment of user rights and passwords).

■

can also display or hide menus for the different operators and accordingly adapt the

menu structure to the respective requirements.

■

can compile defined printing system configurations to create setups.

Service

Service staff are specialized Océ personnel who carry out all work on and with the printing

system that operators may not (e.g., any work on the power circuits in the printing system).

Chapter 2 - Safety38

Personal Representations

Page 39

Operation

Introduction

Observe the following instructions when operating the printing system:

Service personnel

Only operators, key operators and Service personnel may operate the printing system.

The printing system must not be operated by persons under the influence of alcohol or

drugs, or by persons taking certain types of medication, such as psychotropic drugs.

Before operating the printing system, carefully read through the documentation. Please

ask if you do not understand anything in the documentation (e. g. regarding Service).

In cases of emergency, power off the printing system off immediately with the main

switch. In the event of damage to the casing, power cable or operating elements, or pen-

etration of fluids or foreign bodies, call the appropriate Service representative.

Do not wear any loose hanging clothing (e. g. ties, sleeves, scarves), necklaces and bracelets,

loose belts, rings and unprotected long hair. These can catch in the drive mechanisms or

moving parts of the printing system and cause injury.

Safety covers

Do not attempt to remove safety covers yourself; do not manipulate safety equipment

such as the switches monitoring the safety covers, fuses etc., and do not perform any work

not intended to be performed by operators. Such action can cause accidents and may also

damage the printing system.

Safe operation of the printing system is guaranteed only when the outer paneling is fully

mounted. Only properly and fully affixed casing ensures:

■

Protection from electrical shocks

■

Protection against injury from mechanical parts, e.g. cuts, drawing in, crushing

■

Protection against the spread of fire

■

Sufficient cooling of the printing system.

Keep all doors, trims, flaps and covers closed while the printing system is in operation.

This ensures that limit values for electromagnetic compatibility are not exceeded. Noise

emission is also minimized.

Chapter 2 - Safety 39

Operation

Page 40

Cleaning

Always use an industrial vacuum cleaner with a grounded suction tube, rubber nozzle

and filter set for fine dust. An explosion-proof industrial vacuum cleaner must be used

for large toner quantities because there can be a high build-up of static charge when

draining toner spill.

When cleaning the printing system, observe the instructions in the following sections:

■

‘Cleaning the Printing System — Overview’ on page 268

■

‘Cleaning Agents and Cleaning Intervals’ on page 270

Foreign bodies, noises

Make sure that no objects (e.g. jewelry chains, paper clips, coins etc.) or liquids get into

the interior of the printing system, since this may result in electric shocks or short circuits.

Do not place objects on the printing system, and especially do not place containers with

fluid, such as drinking bottles, glasses, cups or vases on top of or in the immediate vicinity of the printing system.

Should the printing system emit any unusual or noticeable noises or smells, power off

the printing system and contact your Service engineer.

Cooling, Heat, Emissions

Do not obstruct the cooling ducts, since this may result in overheating or combustion

while the device is in operation.

Make sure there is an adequate supply of fresh air and cooling air to the room in which

the printing system is located (see ‘Cooling air, fresh air, and air purity’ on page 502).

Do not obstruct the operating and maintenance areas of the Océ ColorStream printing

system with other devices or objects.

During operation, the inner area of the fuser module in the printing system becomes very

hot (greater than 500°C/932°F). Before doing any work on or around the fuser module,

always allow it to cool down for the specified length of time. Failure to observe the directives in this documentation could result in burns.

The ozone produced when the photoconductor and transfer belts are loaded is suctioned

off within the printing system and then transformed into oxygen through a catalytic filter

Chapter 2 - Safety40

Operation

Page 41

system. The life cycle of the filter system is designed so that it does not have to be replaced

during the lifetime of the printing system.

During printing, the ozone concentration is below the maximum allowable work place

concentration (MAC) of 0.1 ppm (0.2 mg/m3). With proper ventilation, harmful con-

centrations do not occur even if the filter system fails entirely. For ventilation, see ‘Cooling

air, fresh air, and air purity’ on page 502.

Consumables and Expendables

Observe the safety directives given in the manual for:

■

Toner

■

Developer

■

Fine filter

■

Photoconductor belt

■

Transfer belt

■

Cleaning agent

Keep all consumables for the printing system out of the reach of children. Store consum-

ables away from containers used for food and drink.

Optical wave guide

If your printing system has an optical wave guide connection:

Never look directly down a glass fiber cable or glass fiber cable connection. The laser

beams in fiber optic devices can injure your eyes.

Laser

If the printing system includes a laser:

Never look directly into a laser beam or laser optics. Never move a tool into the area of

the laser beam so that you do not unintentionally diffract the laser beam. The laser beams

in fiber optic devices can injure your eyes.

Remote control via LAN

If you operate the printing system from a remote operator panel:

The access ticket ensures that only one user at a time can access the printing system.

Warning and Information Signs

Observe all warning and information signs on and in the printing system (see ‘Warning

and information signs’ on page 35).

Chapter 2 - Safety 41

Operation

Page 42

Transportation, assembly and installation, repair

Transport

The printing system may only be transported by Service personnel or authorized transport

companies.

Assembly and installation

Observe the following instructions when assembling and installing the printing system:

■

The printing system may only be assembled and installed by Service personnel.

■

The printing system must have a dedicated electrical connection or type B plug connection (complying with VDE directives, EN 60950).

■

Do not route the lines and cables in such a way that they can be trodden on or tripped

over.

■

A fume hood should be installed over the fuser module (without a security detector).

In very seldom cases, paper that has been caught in the fuser module will be damaged

by the infrared fusing and will begin to smoke. However, even in this case there is no

danger of fire because the affected component is immediately isolated from the remaining printing system by sealed bulkheads. This bulkhead is part of a proven safety

concept and does not affect the availability of the printing system after the jammed

paper has been removed.

■

All printing system accessories and options must comply with statutory regulations

and directives for safety, electromagnetic compatibility, telecommunications terminal

devices as well as with the specifications published by Océ Printing Systems GmbH.

■

The installation of other accessories may constitute a violation of these requirements

and directives, and may also damage the printing system.

■

Consult Service personnel for details on which accessories and options are permitted

for the printing system.

■

With the exception of optical wave guide connections, all data, signaling, process,

measurement and control lines mapping the printing system with other devices must

be properly grounded.

■

Data transmission lines should neither be connected nor disconnected during electrical

storms.

Repairs

Repairs to the printing system must only be carried out by Service personnel. Access to

locked areas and areas which can only be opened with special tools is reserved for Service

personnel. Opening the device without authorization and improperly effected repairs

may put operators at considerable risk.

Chapter 2 - Safety42

Transportation, assembly and installation, repair

Page 43

The access ticket used by the Service technician ensures that the printing system cannot

be used via an LAN from a remote operator panel during repair work.

Chapter 2 - Safety 43

Transportation, assembly and installation, repair

Page 44

Fire, disposal

Fire

Observe the following instructions:

■

Poisonous gases can occur in any fire. They can also result from the printing system

Océ ColorStream.

■

Self-contained breathing apparatus must be worn when fighting fire or smoke emission.

Instructions to this effect should be deposited at the fire alarm center and with the

local fire-fighting force.

Disposal

Océ operates a system by which expendables and consumables can be returned for environmentally sound disposal.

Keep all used parts and consumables that are to be returned for disposal for collection by

Service or the contracted shipping company. These will be recycled or disposed of appropriately by Océ Printing Systems GmbH or a contracted disposal company.

Chapter 2 - Safety44

Fire, disposal

Page 45

Safety Regulations and Standards

Safety regulations and standards — overview

Introduction

The printing system Océ ColorStream complies with the relevant safety requirements for

information technology equipment. It meets the following national and international

safety regulations and standards:

Safety Standards

#

Fitting of high-voltage systems with electrical equipmentVDE 0160

Safety of information technology systems including electronic office machines

VDE 0805

Low voltage directive

EC directive for harmonization of the legal requirements

of member states regarding electrical equipment for use

within certain voltage limits (modified by EC Directive

93/68/EWG)

2006/95/EC

Safety of information technology equipment including

electrical business equipment

IEC 60950

Safety of information technology equipment, including

office devices, in connection with the CE mark

EN 60950-1 (Europe)

Safety of information technology equipment including

electrical business equipment

UL 60950-1 (USA)

Standard for safety of information technology equipment

including electrical business equipment

CAN-CSA Standard

CSA 60950-1 (Canada)

Certified Safety

General device safety is verified by:

■

VDE/GS

Chapter 2 - Safety 45

Safety regulations and standards — overview

Page 46

■

TÜV/GS

■

Or similar

Electromagnetic Compatibility

#

EMVDirective

EC Directive for harmonization of the legal requirements

of member states regarding Electromagnetic Compatibility

(modified by Directive 91/263/EEC, 92/31/EEC, and

Directive 93/68/EEC)

89/336/EWG

EuropeEN 55024

EN 55022 / Class A

USAFCC Part 15 Subpart B

Class A

CanadaC108.8-M1983 (Class

A)

Environmental Standards

#

Environmental Conditions - TestDIN / IEC 68

Environmental conditions for products

Permitted noise emissions from devices

EN 60721 - Part 3

RoHSDirective

EC directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment =

RoHS Directive (binding since 06/30/2006)

2002/95/EG

WEEDirective

EC directive on waste electrical and electronic equipment

= WEEE Directive (binding since 06/30/2006)

2002/96/EG

Recooler

The recooler complies with the following regulations and directives:

■

EMV-Directive 2004/108/EC

■

Low Voltage Directive 2006/95/EC

■

DIN EN 378 Refrigerating systems and heat pumps — safety and environmental requirements

Chapter 2 - Safety46

Safety regulations and standards — overview

Page 47

■

RoHS Directive

■

TÜV/GS

Overview

Here you will find additional information on the following topics:

■

‘CE Mark’ on page 48

■

‘Accident prevention regulation for replacement carts (option)’ on page 49

Chapter 2 - Safety 47

Safety regulations and standards — overview

Page 48

CE Mark

Océ ColorStream

The printing system Océ ColorStream fulfills the requirements of the EC directives

89/336/EWG, "Electromagnetic Compatibility" and 73/23/EWG "Low Voltage Directive".

The CE Mark indicates that the printing system complies with these EC directives.

The printing system is a Class A product (EN 55022). This product may cause radio interference in a domestic environment. In this case, the agent may be required to take appropriate measures to correct the interference at his or her own expense.

The printing system can cause the power supply to fluctuate if the power network is not

in order. According to EN 61000-3-11, the printing system should only be used on

premises that have a network with a continuous current-carrying capacity of 100 A per

phase or are supplied by a distribution network of 400/230 V.

The agent must ensure that the printing system is operated in a power supply network

that meets these requirements. If necessary, consult the power company to ensure that

the continuous current-carrying capacity of the power system at the connection point to

the public power grid is sufficient to connect the device.

Connected Devices

The optional "maintenance cart for developer stations" and "movable developer station

shelf" are also CE-certified.

All other devices that are connected to the printing system must also comply with the

requirements set forth in the relevant EC directives.

Chapter 2 - Safety48

CE Mark

Page 49

Accident prevention regulation for replacement carts (option)

Technical inspection

A technical inspection must be carried out annually by a technical expert as per BGV D8

"Winches, Lifting and Pulling Devices" or relevant country-specific regulations. The

technical inspection includes the following services:

■

Completeness, suitability and effectivity of the security mechanisms (e.g. rebound

guards, holdbacks, braking mechanisms, auxiliary brakes, winders, equipment for

locking the load shaft, overloading guards, emergency stopping equipment).

■

Condition of device, supports, castors, equipment and frame.

Records of the results of device inspections must be retained. The inspection can be

documented e.g. by entering the inspection results in an inspection log, by maintaining

a file or by affixing an inspection badge (with the date of inspection and the inspector in

each case).

Requirement for affixing the inspection badge: The device has no safety defects.

Chapter 2 - Safety 49

Accident prevention regulation for replacement carts (option)

Page 50

Chapter 2 - Safety50

Accident prevention regulation for replacement carts (option)

Page 51

Chapter 3

Description of the Printing

System

Page 52

Description of the Printing System — Overview

Description of the printing system

This section shows the structure of the printing system, describes the operating elements

and explains the printing principle. You will also find information on paper types and

how to handle the paper.

Overview

You will find information on the following topics:

■

‘Main Modules’ on page 53

■

‘Doors and Covers’ on page 54

■

‘Internal View — Overview’ on page 56

■

‘Printing method’ on page 64

■

‘Operating Elements - Overview’ on page 67

■

‘Paper specifications’ on page 78

Chapter 3 - Description of the Printing System52

Description of the Printing System — Overview

Page 53

Main Modules

Modular Design

The printing system has a modular structure consisting of the following main modules:

4

5

3 2 1

#

DesignationUnit

Paper Input Module1

Print Unit2

Fuser module3

Filter module4

Console5

#

Paper path direction

Chapter 3 - Description of the Printing System 53

Main Modules

Page 54

Doors and Covers

Introduction

Note:

Right-hand side means right in paper path direction.

Left-hand side means left in paper path direction.

Right-Hand Side of Printing System

Left-Hand Side of Printing System

Legend

#

MeaningColor

These doors may be opened during printing without causing

any adverse effects. There is no danger, even if a door is open

Chapter 3 - Description of the Printing System54

Doors and Covers

Page 55

MeaningColor

These doors and covers must not be opened during printing.

To avoid any danger, the entire printing system shuts down if

they are opened.

With the optional toner supply using 1 kg (2.2 lb) toner bottles,

this door can be opened during printer operation without having

to disconnect the printer from the mains.

However, if highest levels of print quality are to be maintained,

we recommend that this door be left closed during printer operation.

Option

Paper path direction

Note:

Detailed information on opening and closing the doors is provided in the following

sections:

■

‘Opening Right Doors’ on page 157

■

‘Closing Right Doors’ on page 159

■

‘Opening Left Doors’ on page 161

■

‘Closing Left Doors’ on page 163

Chapter 3 - Description of the Printing System 55

Doors and Covers

Page 56

Internal View

Internal View — Overview

The Most Important Components

Note:

The figure shows the maximum configuration of the Océ ColorStream printing system

with five developer stations in the upper and lower print unit.

11 9105612

1 2 3 4 5 6 7

7

8

#

FunctionComponent / Designation

In the paper cooling system, the printed paper web

is cooled down to such an extent that it can be

processed further without problems.

Paper cooling1

In the smoothing module, the toner is optimally

bonded to the hot paper web, using smoothing

rollers.

Smoothing module2

‘Filter module’ on page 61Filter module3

Chapter 3 - Description of the Printing System56

Internal View — Overview

Page 57

FunctionComponent / Designation

In the fuser module, the toner is fused on the front

and rear sides of the paper by means of an infrared

lamp.

Fuser module/Infrared

lamp

4

In the print unit, the front and rear sides of the

paper are printed at the same time via the upper

and lower print units.

Print unit

Upper print unit

Lower print unit

5

‘Photoconductor unit’ on page 58Upper photoconductor

unit

Lower photoconductor

unit

6

‘Transfer unit’ on page 60Upper transfer unit

Lower transfer unit

7

The paper web is fed into the print module from

the external paper feed via the paper input.

Paper input8

The rocker is unlocked and opened to insert the

paper web.

Rocker9

Together with an external recooler, the heat ex-

changer keeps the temperature of the developer

stations constant.

Heat exchanger10

The paper web is fed into the vacuum unit of the

web buffer via the paper output.

Paper output11

#

The developer stations are filled with toner using

toner bottles of 6 kg (13.2 lb) each (see ‘Console’ on

page 62) or bottles of 1 kg (2.2 lb) each (optional).

Toner Feed Unit12

#

Paper web

Chapter 3 - Description of the Printing System 57

Internal View — Overview

Page 58

Photoconductor unit

Important Components of the Photoconductor Unit

The illustration shows a cross section of the photoconductor unit in the upper print unit

with five developer stations.

1

2

3

4

5

6

7

8

9

#

FunctionComponent / Designation

Exposes the negatively charged photoconductor

belt and neutralizes the charge in areas where toner

is afterwards to be applied.

LED print head1

Negatively charges the photoconductor belt.Charge corotron2

Cleans away toner residue on the photoconductor

belt.

Photoconductor blade3

Brushes away toner particles not transferred to the

transfer belt.

Cleaning brush4

Removes any residual charge on the photoconductor belt.

Cleaning corotron5

Chapter 3 - Description of the Printing System58

Photoconductor unit

Page 59

FunctionComponent / Designation

Maintains a constant level of toner for the toner

feed.

Toner box6

Measures the quantity of toner for each color.Toner mark sensor7

Applies toner to areas on the photoconductor belt

exposed by the LED print head.

Developer stations8

Establishes an image pattern for each color, fol-

lowed by a toner image.

Photoconductor belt (=

OPC belt = Organic

Photo Conductor belt)

9

Chapter 3 - Description of the Printing System 59

Photoconductor unit

Page 60

Transfer unit

Important Components of the Transfer Unit

The illustration shows a cross section of the transfer unit in the upper print unit.

1

2

3

4

#

FunctionComponent / Designation

Establishes the required potential difference on

the transfer roller point between the transfer belt

and paper by reversing the polarity of the toner

particles from negative to positive.

Transfer corotron

(only in the upper print

unit)

1

Collects the colored image patterns for individual

colors with register accuracy and then transfers

these together to the paper web.

Transfer belt2

Reverses the polarity of residual toner particles on

the paper after the transfer process back to negative

in preparation for cleaning.

Cleaning corotron3

Brushes away toner particles not transferred onto

the paper.

Cleaning brush4

Chapter 3 - Description of the Printing System60

Transfer unit

Page 61

Filter module

Important components of the filter module

#

DescriptionComponent / Designation

The waste toner, which is drained from the print

unit, is collected in the waste toner box.

Waste toner box1

The exhaust air is cleaned with a fine filter and

sent out of the top of the filter module.

Fine filter2

Chapter 3 - Description of the Printing System 61

Filter module

Page 62

Console

Important Components of the Console

1

2

4

3 54

#

DescriptionComponent

Screen1

Keyboard and mouse2

Storage for the user guide3

Toner supply4

Toner hoses on the printing system5

Color Allocation in the Console

The developer stations for all colors are supplied by a toner suction system consisting of

toner bottles weighing 6 kg (13.2 lb) each. For full-color printing systems, the developer

station slots for CMYK are predefined. In order to keep the toner suction hoses as short

as possible, the slots in the console are also predefined:

Chapter 3 - Description of the Printing System62

Console

Page 63

#

ColorSlot

Yellow1

Magenta2

Cyan3

Black4

CustomTone or additional black, cyan, magenta or yellow

toner bottles.

5/6

Note:

In the case of CustomTone printing systems, the color allocation in the console can be

changed by Service.

Chapter 3 - Description of the Printing System 63

Console

Page 64

Printing method

Introduction

The print image is created through an electrophotographic printing process with LED

print heads and two-component developers.

With a full color printing system, the colors are generated using the subtractive color

mixing technique, using the color separations cyan, magenta and yellow:

To reduce the coverage and achieve a greater depth with dark colors, black is also used

as the fourth color.

Printing Process

#

DescriptionLevel

The rastered controller pages are written to the photoconductor belt

with the LED print head.

■

During bilevel printing, each dot can be assigned either 100% color

or 100% white (= LED in LED print head on or off).

■

During multilevel printing, the light intensity of each LED can range

between 16 brightness levels. This dot modulation allows continuous

runs.

1

The developer station inks the image pattern.2

The inked image pattern is transmitted from the photoconductor belt

to the transfer belt.

3

Chapter 3 - Description of the Printing System64

Printing method

Page 65

DescriptionLevel

The photoconductor belt is cleaned.4

Transfer is from the transfer belt to the paper web. In double-sided print

operation, the upper and the lower printed page are transferred at the

same time.

■

Single color printing: Black/White Printing System

For single color printing, the inked image pattern is transferred from

the transfer belt to the paper web. The transfer roller point remains

swiveled onto the paper web and paper transport is not stopped.

■

Color collection mode: Full-color or CustomTone printing system

The colored image patterns for the individual colors are first collected

on the transfer belt and then transferred together to the paper web.

During the collection process, the transfer roller point is swiveled off

from the paper web and paper transport is stopped (Start/Stop operation).

5

Example: Color collection mode in a full color printing system with

CustomTone as the fifth color

The transfer belt is cleaned.6

The inked paper is fused to the paper via infrared radiation in the fuser

module (simultaneously for single and double-sided printing).

7

Chapter 3 - Description of the Printing System 65

Printing method

Page 66

DescriptionLevel

The paper is cooled in the paper cooling unit for further processing in

the paper post-processing unit.

8

Chapter 3 - Description of the Printing System66

Printing method

Page 67

Operating Elements

Operating Elements - Overview