Page 1

User manual

BLM 500 / Bookletmaker 50

Operating information

Page 2

Copyright

Copyright

2008 Océ

All rights reserved. No part of this work may be reproduced, copied, adapted, or

transmitted in any form or by any means without written permission from Océ.

Océ makes no representation or warranties with respect to the contents hereof and

specifically disclaims any implied warranties of merchantability or fitness for any

particular purpose.

Further, Océ reserves the right to revise this publication and to make changes from

time to time in the content hereof without obligation to notify any person of such

revision or changes.

Note: The contents of this document are subject to copyright

protection by third parties.

Edition 2008-08

US

Page 3

Table of Contents

Table of Contents

Chapter 1

Introduction to the Booklet maker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Description of the Booklet maker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Right-Hand Side of the Booklet maker. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

The Rear Panel of the Booklet maker . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2

How to run the Booklet maker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Turn ON the Booklet maker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Enter the Job Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Stacker adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Run the Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 3

The User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

The Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

The Job Mimic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

The BASIC Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

The LOAD & SAVE Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

The ADVANCED Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

The CONFIGURE Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

The MENU Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 4

Standard Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Load and Save the Job Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Adjust the Stitch Pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Open the Connecting Bridge Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Open and Close the Folder Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Lift and Lower the Clincher Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Open the Gathering Area Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Lift the Booklet maker Main Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Empty the Trim Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Open the Stitch Wire Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Adjust the Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Operate the Booklet maker offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3

Page 4

Table of Contents

Chapter 5

Error Conditions, Problems, and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Clear a Printer Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Clear a Booklet maker error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

General Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Book Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Clear Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Stitch Timeout Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Stitch Head Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Clear a Stitch Wire Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Clear a Stitch Head Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Calibrate the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Change the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Manually park the Shuttle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Chapter 6

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

About Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Booklet maker cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Clean the Static Elimination Bars. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Clean the Former Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Clean the Polyurethane Strips in the Form Clamp. . . . . . . . . . . . . . . . . . 96

Clean the Trimmings Removal Fingers . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Clean excess grease from the Stitch Head . . . . . . . . . . . . . . . . . . . . . . 101

Lubricate the Stitch Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Lubricate the Wire-feed Cam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Install New Stitch Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Appendix B

Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

4

Page 5

Chapter 1

Introduction to the Booklet

maker

5

Page 6

Introduction

Introduction

Introduction

Thank you for choosing the Booklet maker.

Your Manual

The User Manual for the Booklet maker describes how to perform these tasks:

■ Operate the Booklet maker

■ Find and correct error conditions

■ Perform normal maintenance tasks

Operator training is given when the Booklet maker is installed. To make sure you use

your Booklet maker correctly, read your manual.

The User Manual for the Booklet maker does not describe the operation of the

printer. If needed, refer to your printer user manual.

Safety Information

Safety information is included in the separate “Safety Information Manual.” Read

the safety information before you use your Booklet maker.

Caution: A CAUTION message tells you that a procedure or operation can

be dangerous. To prevent injury, you must follow the instructions.

Attention: An ATTENTION message tells you that a procedure or operation can

damage the machine or the product. To prevent damage, you must follow the

instructions.

Installation

Your Booklet maker must be installed by a service engineer. Special knowledge is

needed to install the machine.

Attention:

Connect the machine only to a power supply of the correct voltage with a good

ground connection. The correct machine voltage is shown on the label at the power

supply input on the rear of the machine. If the machine is connected to the wrong

supply, the warranty is voided.

6 Chapter 1 Introduction to the Booklet maker

Page 7

How to Get Help

If you have any questions or problems, refer to the problem-solving section in this

manual (see the chapter “Error Conditions, Problems, and Solutions”). Contact your

Booklet maker supplier for further help.

Introduction

7

Page 8

Description of the Booklet maker

Description of the Booklet maker

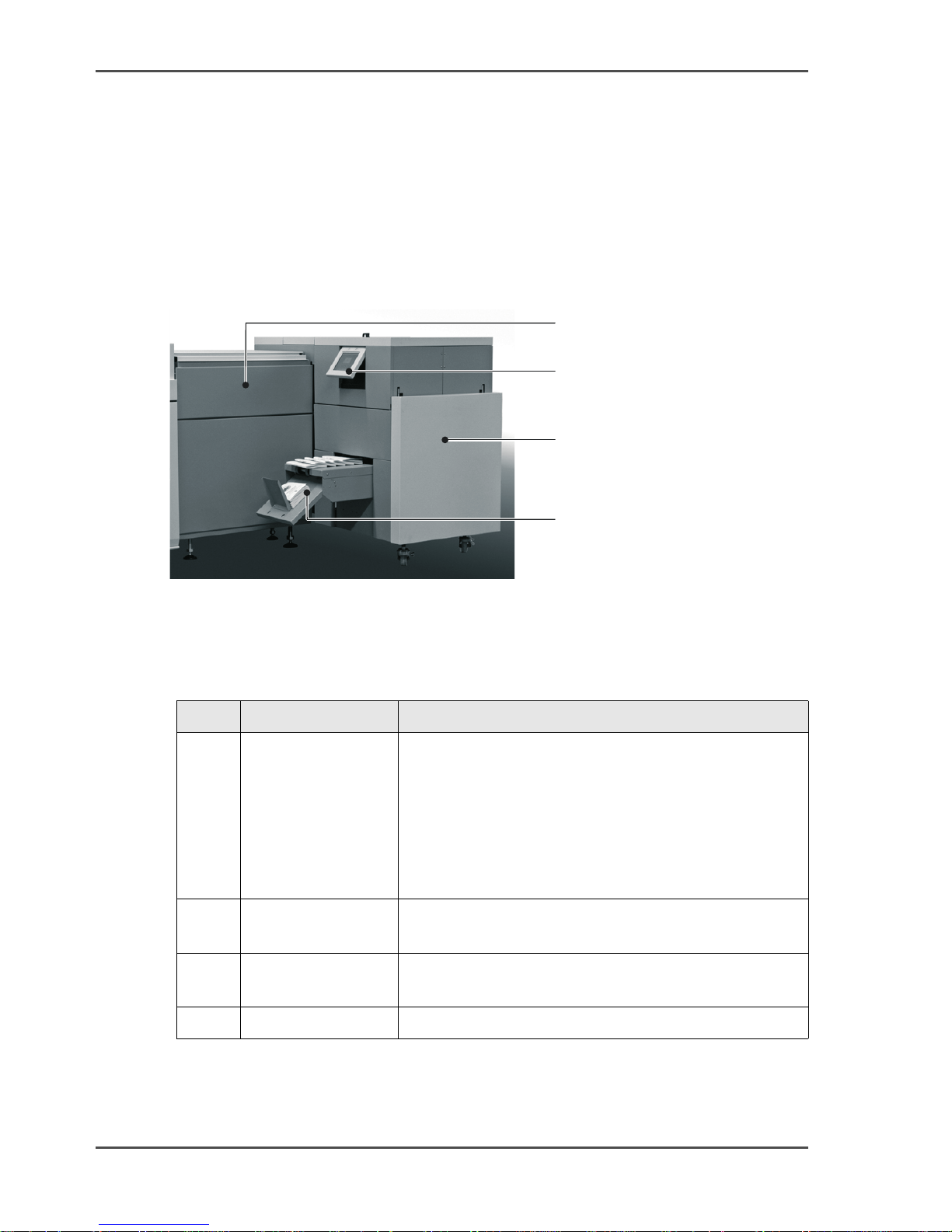

Introduction

The Booklet maker operates online with digital printers to process sets of printed

pages into stitched books. The main parts are shown below.

Illustration

[1]

A

B

C

[1] Operator Side of the Booklet maker

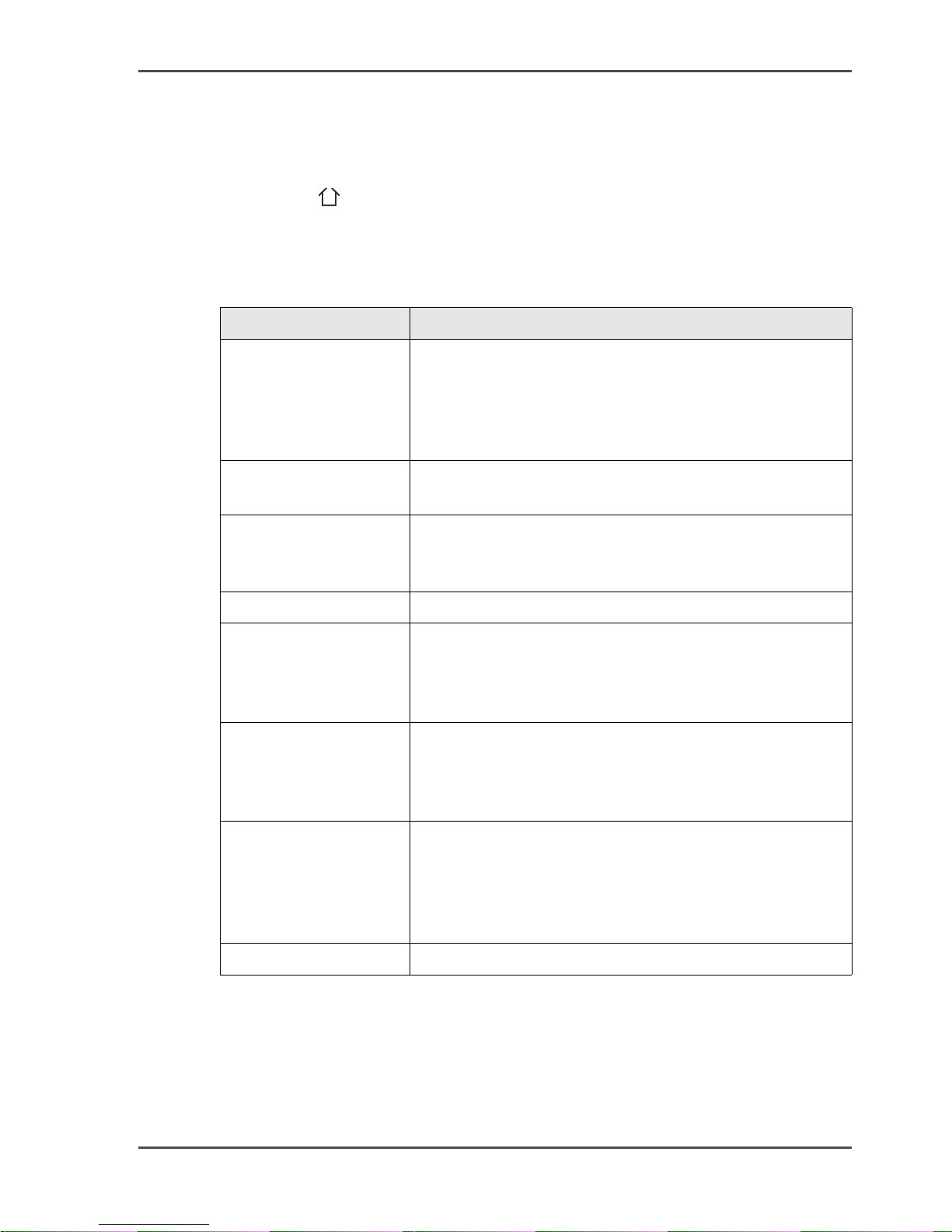

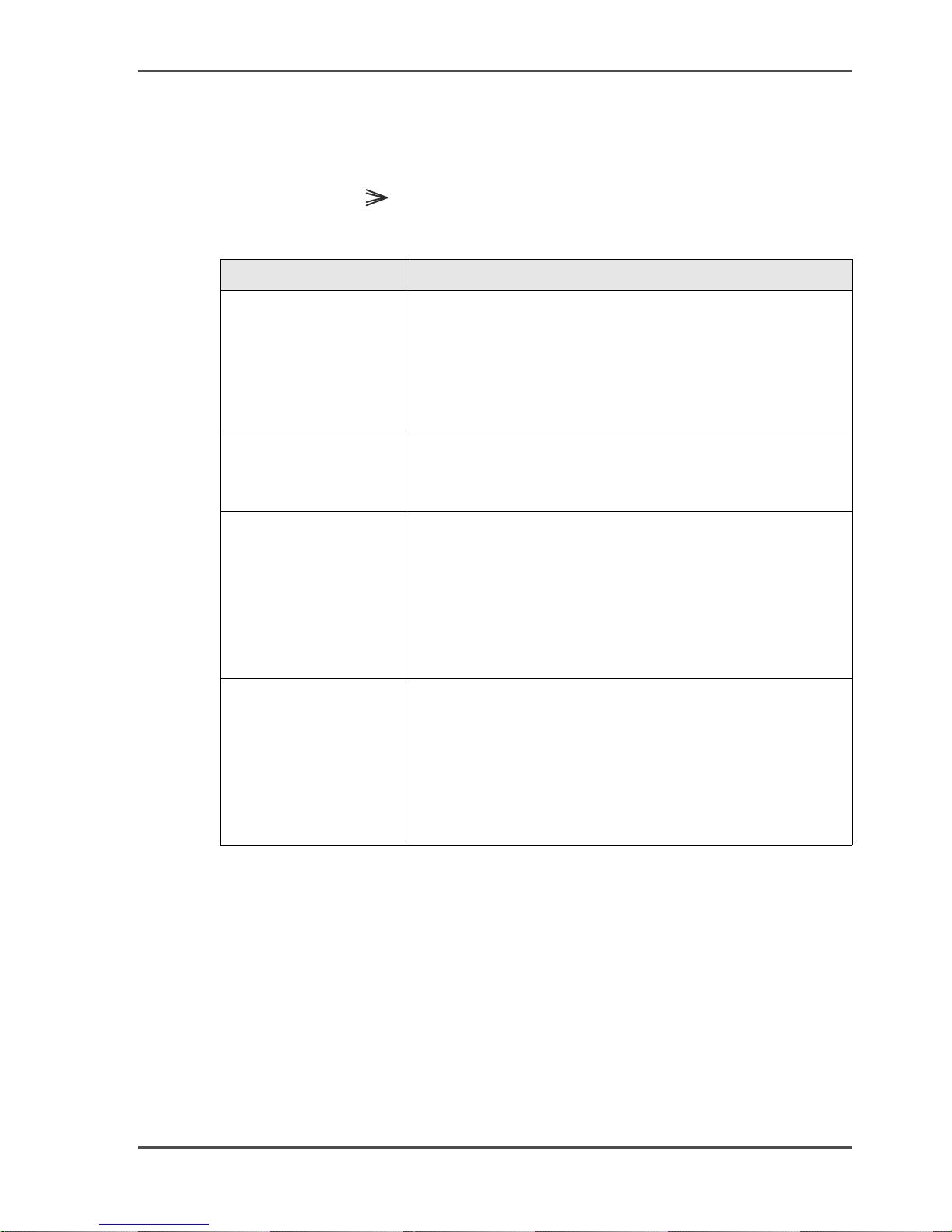

Component - function table

[1]

[1] Operator Side of the Booklet maker

Component Function

A The connecting

bridge

B The user interface The user interface has a color touch screen, a start

C The Booklet

maker

D

The connecting bridge moves the printed sheets from

the printer to the Booklet maker. If needed, the sheets

are rotated into the correct direction. Rotation lets the

printer operate at optimum print speed. Adjustment

for the size of the paper and sheet rotation is

automatic, according to the settings entered on the

touch screen.

button, and a stop button.

The Booklet maker stitches, folds, spine-forms, and

trims the sheets to make a finished book.

D The stacker The stacker collects the finished books.

8 Chapter 1 Introduction to the Booklet maker

Page 9

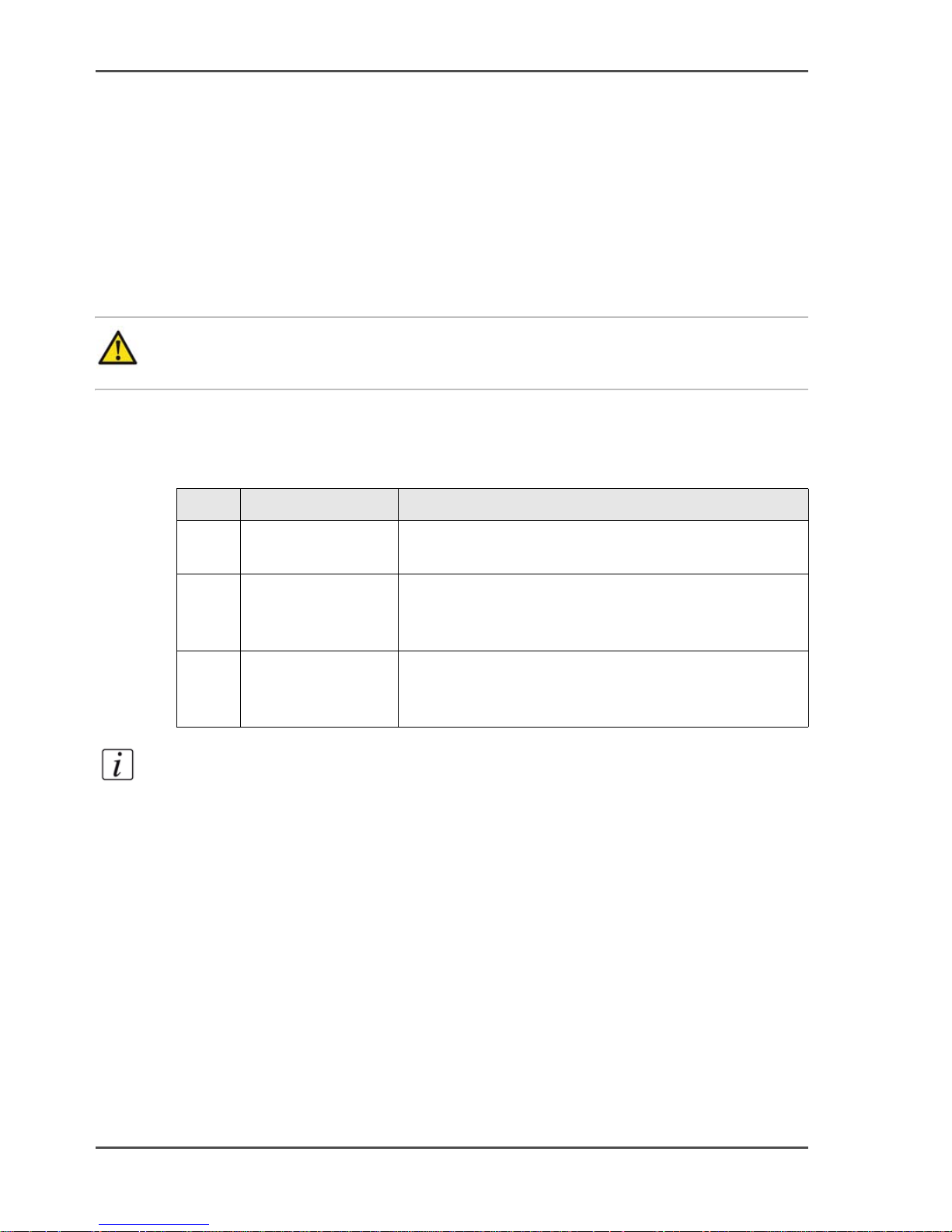

Right-Hand Side of the Booklet maker

Right-Hand Side of the Booklet maker

Illustration

[2]

A

B

[2] Right-hand side of the Booklet maker

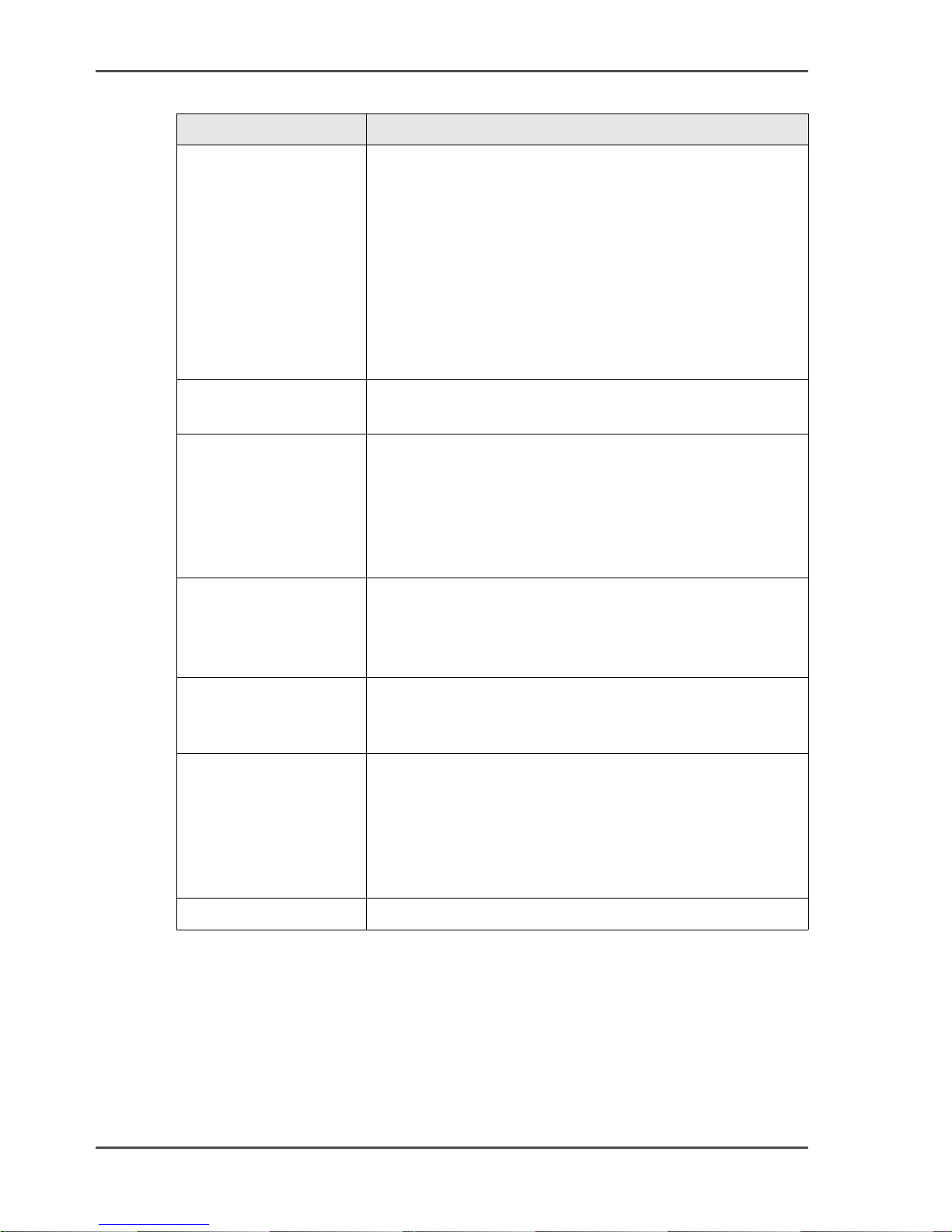

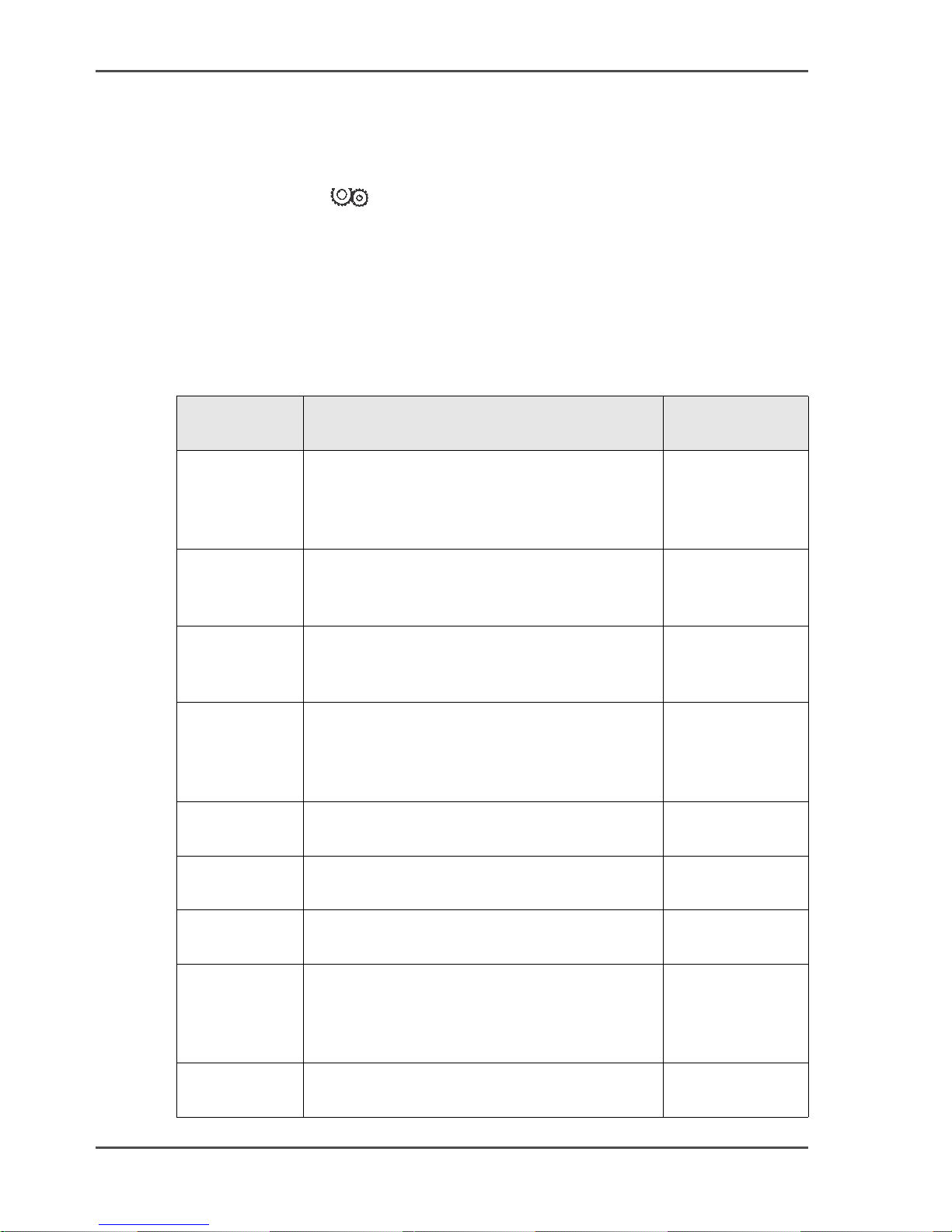

Component - function table

[2]

[2] Right-hand side of the Booklet maker

Component Function

A The stitch-wire

cabinet

B Trim Bin The trim bin collects the paper that is trimmed from

The stitch-wire cabinet holds the spool of

stitch-wire.

the edge of the book

9

Page 10

The Rear Panel of the Booklet maker

The Rear Panel of the Booklet maker

Illustration

[3]

[3] The Rear Panel of the Booklet maker

A

B

C

D

E

F

Component - function table

[3]

[3] The Rear Panel of the Booklet maker

Component Function

A Rating and serial

label

B Power ON/OFF

switch

C Voltage advisory

label

D Fuses The fuses make sure the operator and the machine

E Voltage label The voltage label is fitted to the Booklet maker

The rating label displays the type of machine, serial

number, power use, and fuse information.

The power ON/OFF switch turns the Booklet

maker ON or OFF. When you turn OFF the Booklet

maker, the current settings are stored.

The voltage advisory label tells the installer to refer

to the installation instructions before the Booklet

maker is connected to the electrical power supply.

The Booklet maker can be adjusted for one of

several different input voltages.

are protected if there is an electrical problem or

short circuit.

during the installation procedure. The voltage label

displays the selected voltage.

F Power input

connector

10 Chapter 1 Introduction to the Booklet maker

The power input connector is used to connect the

Booklet maker to the electrical power supply.

Page 11

Chapter 2

How to run the Booklet maker

This chapter gives information on how to run a job on the Booklet maker. For

information on how to operate the printer, refer to the printer documentation.

Information about the user interface is included in the chapter “The User Interface.”

Information about standard procedures, for example opening covers to clear a paper

jam, is included in the chapter “Standard Tasks.”

11

Page 12

Before You Begin

Before You Begin

Paper and Book Quality Instructions

■ The size of paper and the thickness of the set must be measured. These

measurements are entered via the touch screen before you begin a print job.

■ Measure the size of the printed paper. The paper dimension changes when the

paper is printed.

■ Measure the set thickness as accurately as possible. Use the measuring tool

supplied with the machine.

■ Enter accurate dimensions via the touch screen.

■ If the book is made from several different types of paper, make sure the different

paper types are all the same size.

See Book Quality on page 63 for further information.

12 Chapter 2 How to run the Booklet maker

Page 13

Turn ON the Booklet maker

Procedure

1. Connect the Booklet maker to the power supply.

2. Use the ON/OFF switch to turn ON the Booklet maker.

Result

The machine makes this sequence of beeps:

'beep__beep beep beep beep_____ beep beep'.

The touch screen illuminates and the machine is ready for use.

Turn ON the Booklet maker

13

Page 14

Enter the Job Settings

Enter the Job Settings

Introduction

Enter the settings for a new job in the BASIC window on the touch screen. See the

chapter “The User Interface” for more information.

The PAPER SIZE and PAGE DIRECTION settings are entered on the touch screen.

These dimensions refer to the format of the paper when it enters the Booklet maker.

Attention: Do not operate the touch screen with a sharp object or with too much

force. These actions can damage the touch screen.

Before You Begin

[4]

Step Action Information

1 Print a set to the

stacker.

2 Measure the sheet

size and the set

thickness.

Measure the set accurately. To make an accurate

book you must enter accurate paper dimensions via

the touch screen.

3Use these

dimensions for the

job setting.

Note: This set can be made into a book (see Operate the Booklet maker offline on

page 47).

14 Chapter 2 How to run the Booklet maker

Page 15

Procedure for a New Job

[5]

Step Action Information

1Touch BASIC

Enter the Job Settings

2 Enter the paper

size

3 Enter the page

direction

4 Enter the page

rotation setting

5 Enter the set

thickness.

6 Enter the number

of stitches.

Touch PAPER SIZE. Enter the dimensions of the

paper.

The job setting is easier if you first select a preset

paper size, then adjust the settings as necessary

Touch PAPER SIZE > PRESETS > A3 or A4. (USA:

11x17, 8.5x11 or 8.5x14)

Touch PAGE DIRECTION > LANDSCAPE or

PORTRAIT.

If the PAGE DIRECTION option is not available, the

PAGE DIRECTION cannot be changed.

For A4 paper size, the normal setting for ROTATE is

ON. Rotation lets the printer operate at optimum

speed.

Touch ROTATE to turn the sheet rotation ON or OFF.

Always select the page direction before you change

the rotate setting.

Touch SET THICKNESS. Enter the measured value.

Touch STITCHES and enter the number of stitches.

If needed, the stitch pitch can be changed. See

"STITCH PITCH," table 9 on page 25

7 Enter the spine

form setting

8 Enter the trim

setting.

9Touch CLOSE

If needed, save the

job settings to

memory.

Procedure for a Saved Job

1. Touch LOAD & SAVE

The spine form setting is automatic, according to the

SET THICKNESS setting. If needed, the setting can

be changed. See "FORM" in table 9 on page 25

The trim setting is automatic, according to the PAGE

SIZE and SET THICKNESS settings. To change the

setting, touch TRIM. See “TRIM” in table 10 on

page 27

If the same job settings are used frequently, then save

the job settings to memory.

See "Save a job."Load and Save the Job Settings on

page 34

15

Page 16

Enter the Job Settings

2. Touch the job name or use the Up arrow or the Down arrow to select the job.

3. Touch LOAD.

4. Wait until the Booklet maker is ready

16 Chapter 2 How to run the Booklet maker

Page 17

Stacker adjustment

Adjust the Stacker

Adjust the stacker according to the size and thickness of the finished bookAdjust the

Stacker on page 45.

Stacker adjustment

17

Page 18

Run the Job

Run the Job

1. Make sure the adjustments on the Booklet maker are complete before you release the

print job from the print queue.

2. Start the print job. The Booklet maker starts automatically.

3. Check the quality of the first book.

4. If the quality is not acceptable, make adjustments (see ‘Book Quality’ on page 63).

Result

During the job

■ Unload books from the stacker before the stacker is full. The Booklet maker stops

and displays a message if the stacker is full.

■ Empty the trim bin from time to time. The Booklet maker displays a message if

the trim bin is full (see ‘Empty the Trim Bin’ on page 43).

18 Chapter 2 How to run the Booklet maker

Page 19

Chapter 3

The User Interface

19

Page 20

The Touch Screen

The Touch Screen

Introduction

[4]

[4] The User Interface

[6]

ASTART Button

B STOP Button

A

B

C

CTouch Screen

The user interface includes a color touch screen and START/STOP buttons.

Operate the touch screen with your fingertip. You can touch the screen with a blunt

item, for example a palm-top 'wand' or the blunt end of a pen. Do not use too much

force. A light touch is all that is needed.

Power save

The touch screen has a power-save function. After several minutes without use, the

brightness of the touch screen decreases. After several hours, the touch screen turns

off. Touch the screen to restore the normal brightness. The touch screen takes two or

three minutes to reach full brightness.

If you hear a 'beep' when you operate the touch screen, the selected function is not

available. Some functions are not available when the machine is in operation.

Some functions and buttons are only available at certain access levels. See "ACCESS

LEVEL" The MENU Window on page 31.

Attention: Do not operate the touch screen with a sharp object or with too much

force. These actions can damage the touch screen.

20 Chapter 3 The User Interface

Page 21

Illustration

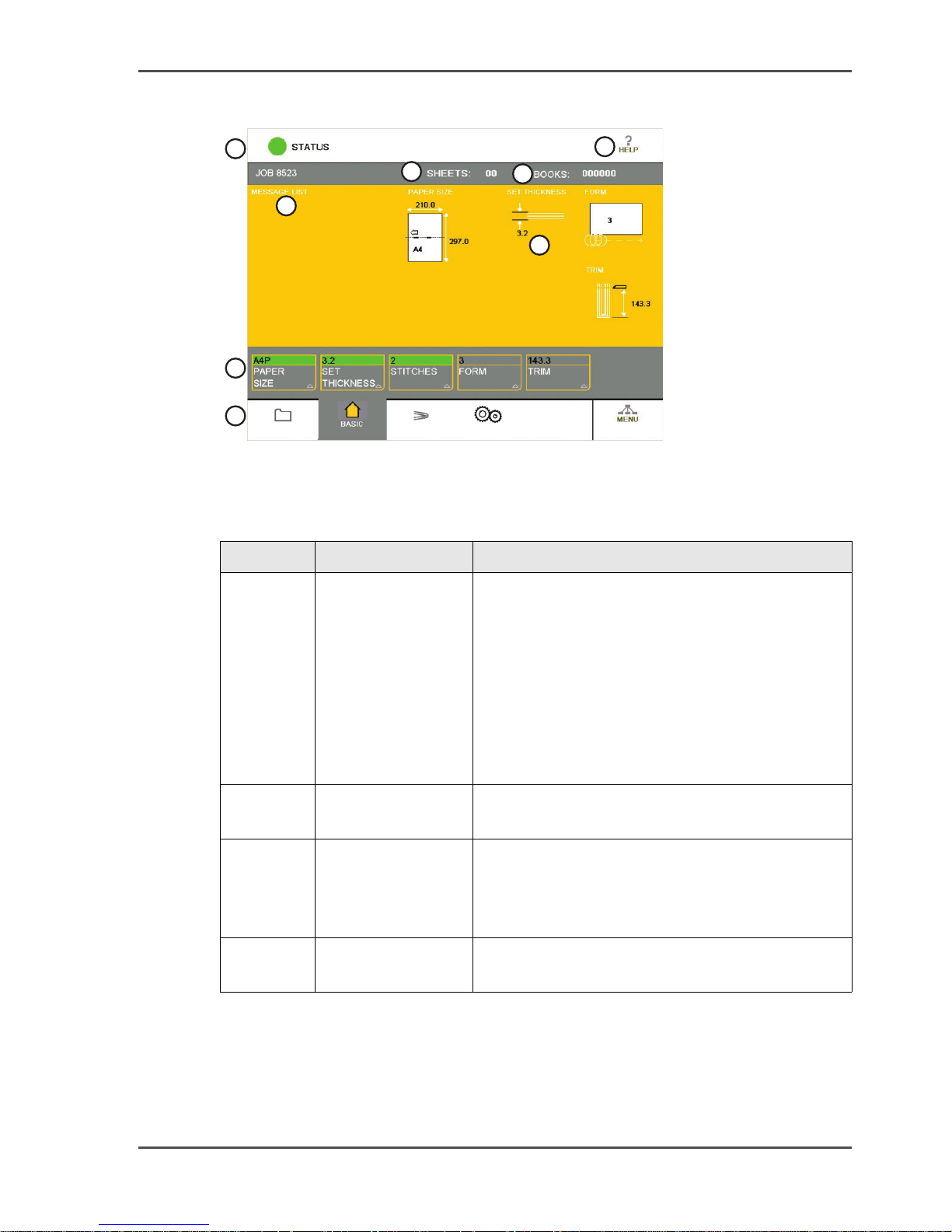

[5]

The Touch Screen

5

3

2

1

[5] The Touch Screen

Component - function table

[7]

No. Component Function

1 Window Tabs The touch screen buttons are divided into groups

6

7

8

4

that have related functions. Each group of

buttons has a separate window. Touch the correct

tab to select the window.

LOAD & SAVE

BASIC

ADVANCED

CONFIGURE

MENU

2 Window Buttons Each window contains a group of buttons. Touch

3 Message List Information and error messages are shown in the

4 Job Mimic The job mimic shows the current machine

the button to select the function.

MESSAGE LIST. To display the information

about a message, touch HELP then touch the

message list.

settings.

21

Page 22

The Touch Screen

No. Component Function

5 Status The STATUS line shows the machine status.

6 Help Help text is available on the touch screen.

- GREEN The Booklet maker is READY or RUNNING.

- ORANGE PLEASE WAIT - wait until the Booklet maker

is ready. ATTENTION - the Booklet maker

needs intervention by the operator.

- RED The Booklet maker is in an ERROR condition.

■ Touch HELP then touch any button or tab on

the screen. Information about that button or

tab is displayed.

■ Use the Up arrow and the Down arrow to

scroll up and down the screen.

■ Some text has more than one screen. Use the

right arrow and left arrow to see the other

screens.

To leave the help text, touch HELP or touch X.

7 Sheet Counter The sheet counter shows the number of sheets in

the gathering area. The counter starts again with

each book.

8 Book Counter The book counter shows the number of books

made. The counter is reset to zero when the

Booklet maker is turned off.

22 Chapter 3 The User Interface

Page 23

The Job Mimic

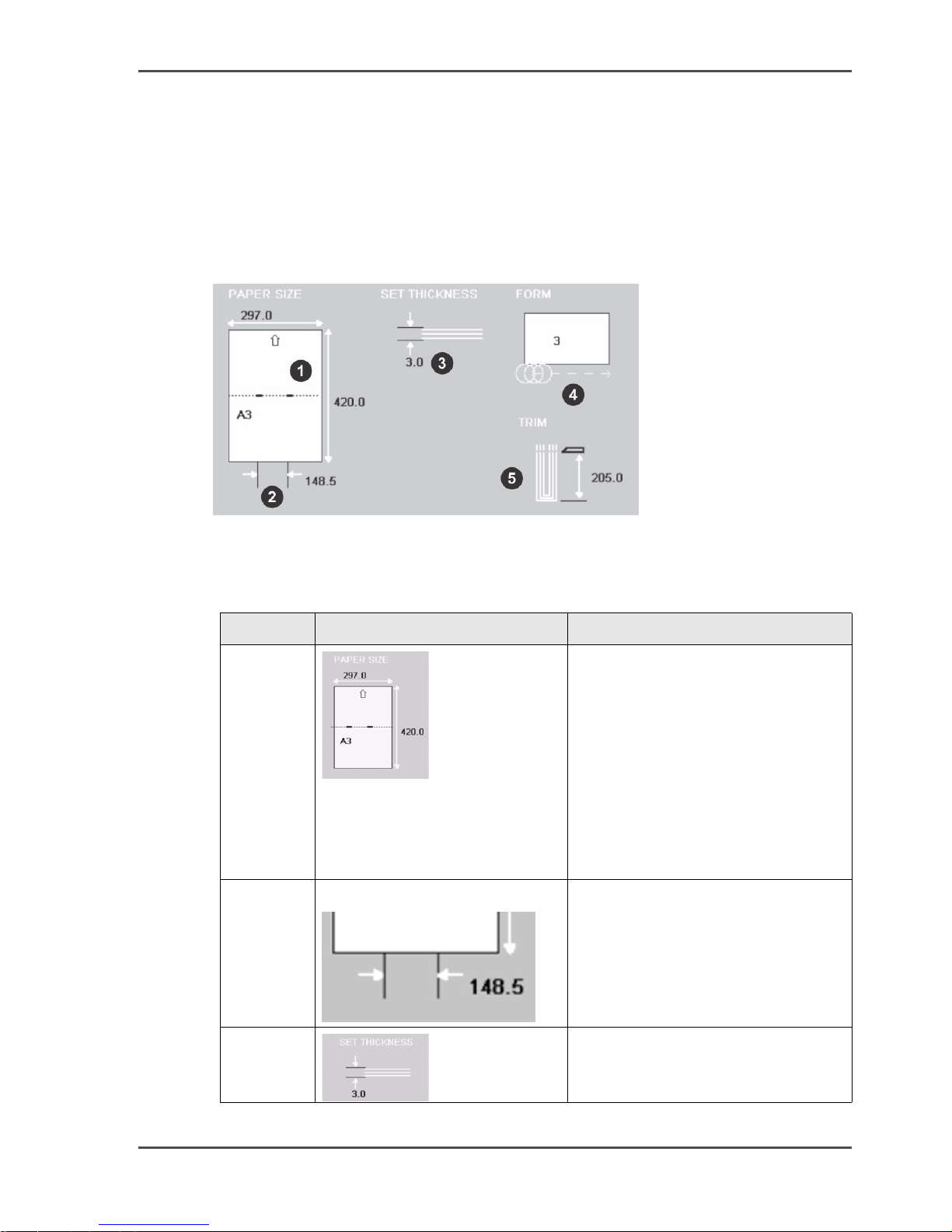

Introduction

The job mimic shows the current machine status.

Illustration

[6]

The Job Mimic

[6] The Job Mimic

Component - function table

[8]

No. Icon Information

1

[7]

2 Stitch Pitch

[8]

The following items are shown

■ the size of paper

■ the format of the paper in the

gathering area

■ the broken line shows the fold

line

■ the small thick lines show the

stitches

■ the arrow shows the original

feed edge in the printer

The stitch pitch is shown only when

a non-standard setting is selected.

3

[9]

The set thickness, in mm, is shown.

23

Page 24

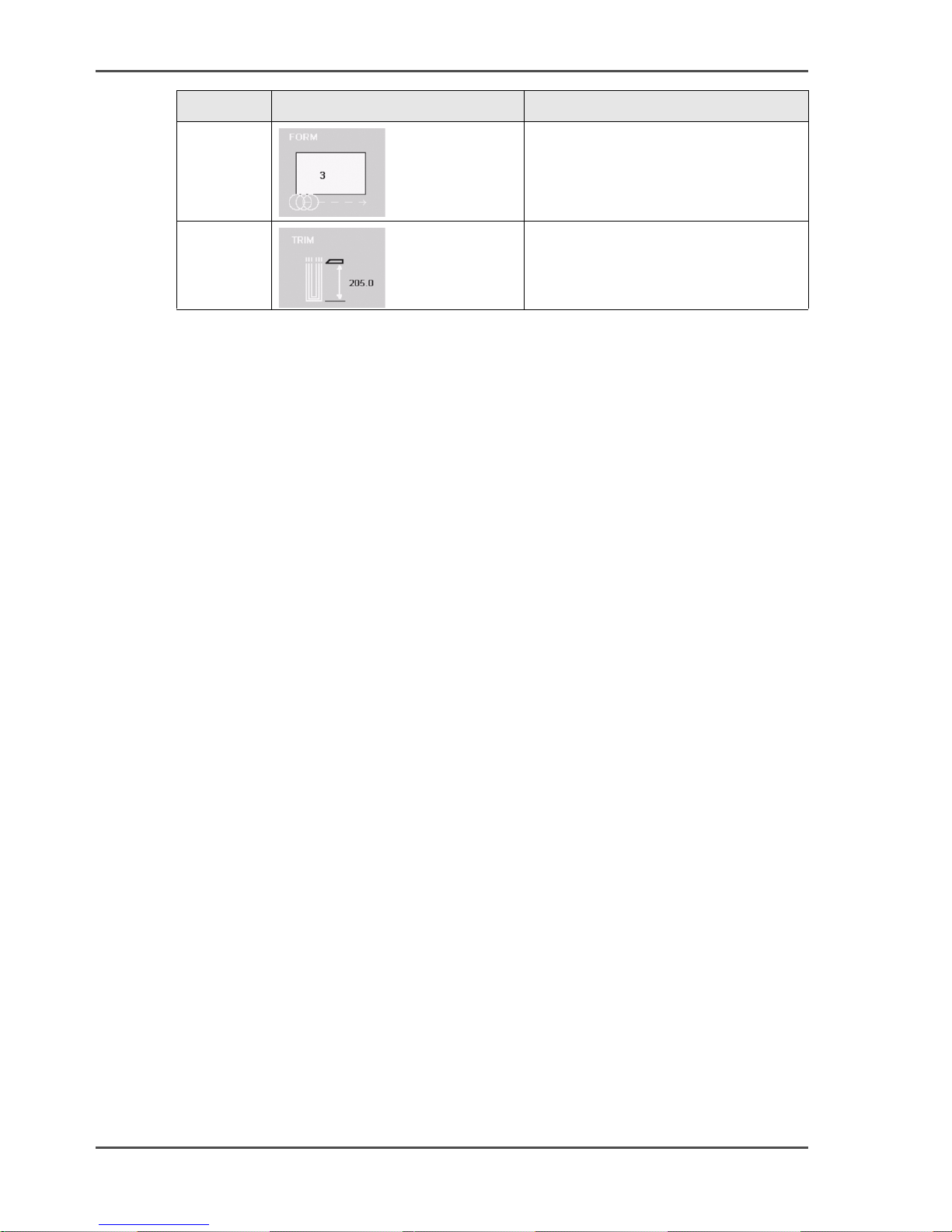

The Job Mimic

No. Icon Information

4

5

[10]

The number of forms is shown. If

the pressure is adjusted, the setting

is shown in brackets. A red X shows

that the form function is not active.

[11]

The trim setting is displayed. A red

X shows that the trim function is not

active.

24 Chapter 3 The User Interface

Page 25

The BASIC Window

Introduction

The BASIC window gives you access to frequently-changed machine settings.

Button overview

[9]

[9] The BASIC Window Buttons (1 – 2)

Button Information

PAPER SIZE Measure the accurate size of the paper before you make

- PAGE DIRECTION Touch PAGE DIRECTION to change the direction of

The BASIC Window

a book.

Touch PAPER SIZE to enter the paper size. When the

machine is in operation, you can adjust the PAPER

SIZE by a maximum of +/- 1 mm.

the paper to Landscape or Portrait.

- ROTATE Touch ROTATE to set the sheet rotation ON or OFF. If

you select A4 portrait (USA: 8.5x11), ROTATE is set to

ON automatically.

- PRESETS Touch PRESET to select a standard paper size.

SET THICKNESS Use the SET THICKNESS window to define the

thickness of the set.

Measure the thickness of the set before you make a book.

Touch SET THICKNESS and enter the value.

STITCHES Touch STITCHES to select the number of stitches.

Available options are 1 - 6. The machine automatically

calculates the position of the stitches according to the

size of the paper. Select 0 to turn off the stitch function.

- STITCH PITCH The stitch pitch is the space between the stitches. The

machine automatically calculates the stitch pitch

according to the size of the paper.

If a non-standard stitch pitch is needed, use STITCH

PITCH to make the adjustment.

- AUTO Touch AUTO to select the default stitch pitch.

25

Page 26

The BASIC Window

[9] The BASIC Window Buttons (2 – 2)

Button Information

FORM To make the square spine of the book, pressure is applied

- AUTO Touch AUTO to select the optimum amount of spine

- NUMBER Touch NUMBER to select how many times the form

to the spine. This process is called forming. Touch

FORM to specify the amount of spine form. To make a

good spine on different paper types, the amount of spine

form can be changed.

To change the amount of spine form

■ Touch NUMBER to change how many times the

spine is processed

■ Touch PRESSURE to change the pressure

form, according to the set thickness.

roller processes the spine. The available options are 1, 2,

3, or 4. The form function can be turned off. An increase

in NUMBER increases the time taken to form the spine

and can decrease the production rate for thin books.

Alternatively, increase the PRESSURE.

- PRESSURE Touch PRESSURE to increase or decrease the pressure

used to form the spine. Touch + to increase the amount of

spine form. Touch - to decrease the amount of spine form.

The range is -9 to +9. The default setting is 0.

- THRESHOLD The square spine is formed only on sets thicker than 0.8

mm. To change this value, touch THRESHOLD and

enter the value you need. The maximum value is 1.5 mm.

TRIM The trim dimension is calculated automatically

according to the PAPER SIZE and SET THICKNESS.

If needed, the trim dimension can be changed. Touch

TRIM to adjust the size of the finished book after the

fore-edge is trimmed. The maximum trim is 28 mm. The

trim function can be turned off.

- AUTO Touch AUTO to select the default trim position.

26 Chapter 3 The User Interface

Page 27

The LOAD & SAVE Window

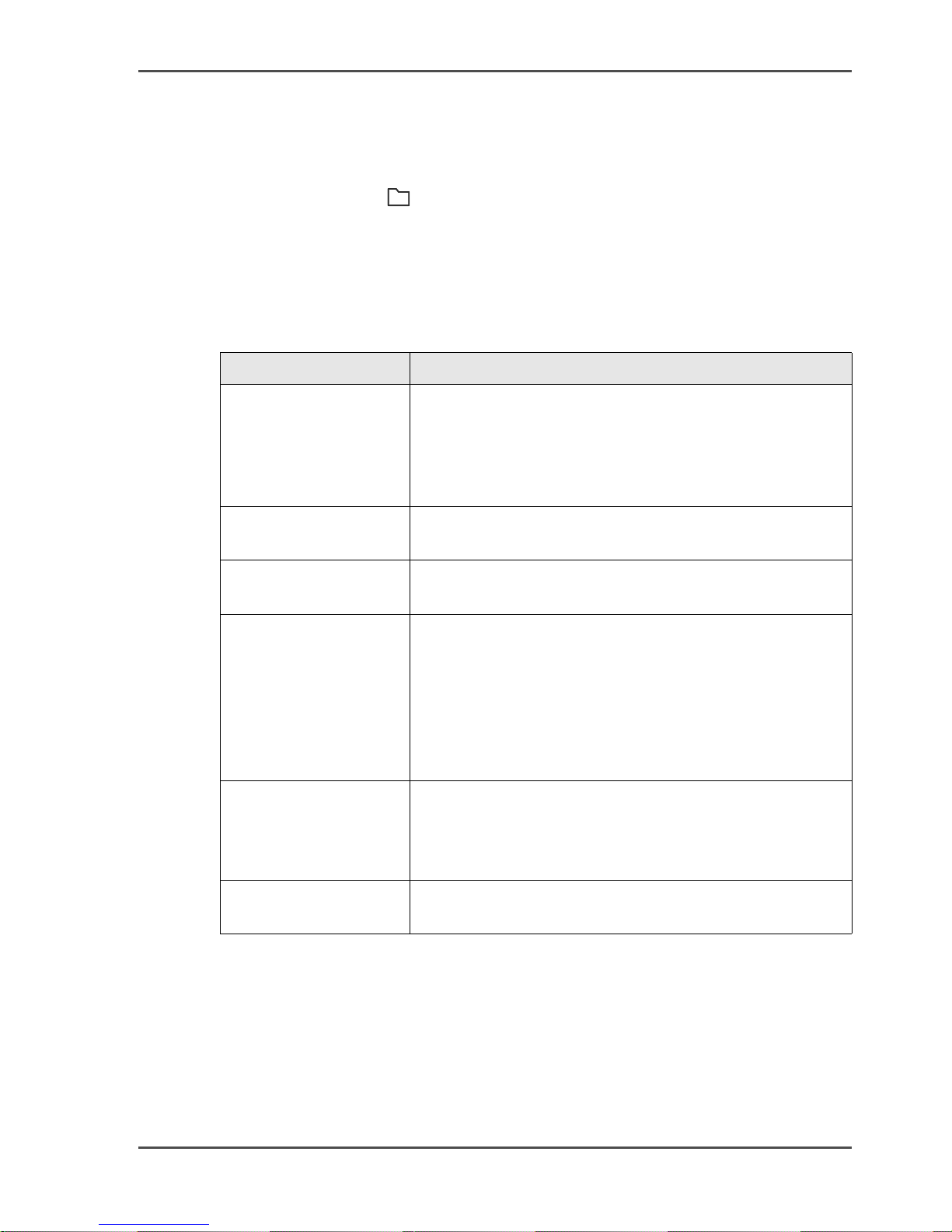

Introduction

The LOAD & SAVE window lets you save and reload job settings. Each job is

given a name. The jobs are displayed in a list on the screen. Touch the job name or

use the Up arrow or Down arrow to make the selection.

Button overview

[10]

[10] The LOAD & SAVE Window Buttons (1 – 2)

Button Information

SAVE Touch SAVE to save the current settings. An on-screen

keyboard is displayed. Enter the job name. Touch OK or

CLOSE. The new job appears in the list of saved jobs.

You can reload a saved job to decrease set-up time in the

future.

The LOAD & SAVE Window

- REPLACE If you change the settings of a saved job, touch

REPLACE to save the new settings.

- CANCEL Touch CANCEL if you do not need to save a job that you

have changed.

- SAVE NEW If you change the settings of a saved job, touch SAVE

NEW to save the new settings as a new job. An on-screen

keyboard is displayed. Enter the new job name. Touch

OK or CLOSE. The original job is not changed. If the

job name is not changed before OK or CLOSE is

touched, the job will be saved with the current name

followed by an asterisk *.

JOB DETAILS JOB DETAILS shows the settings for each saved job.

Select the job that you need to view from the job list.

Touch JOB DETAILS to see a summary of the job

settings.

LOAD Touch the job name or use the Up arrow or the Down

arrow to make the selection. Touch the LOAD button

27

Page 28

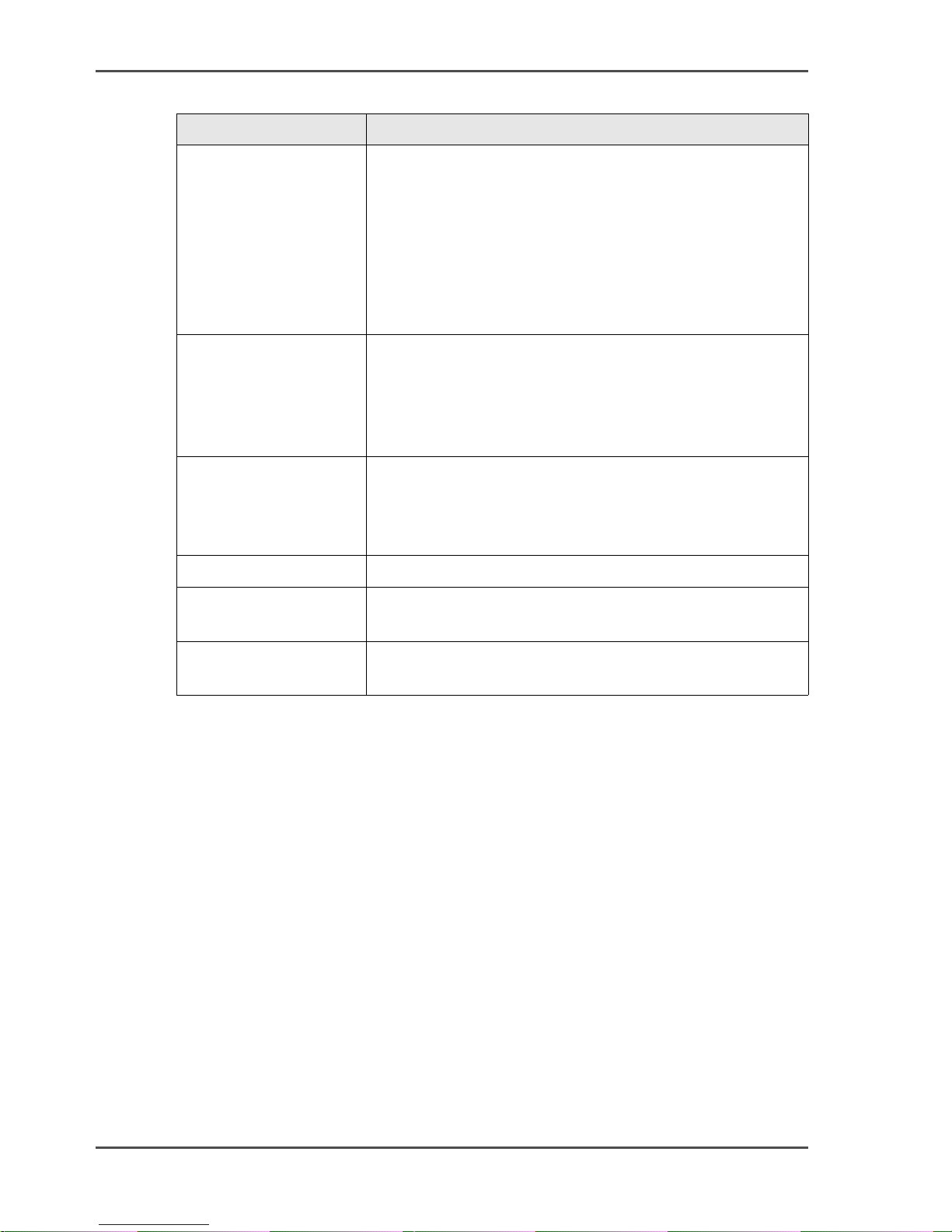

The LOAD & SAVE Window

[10] The LOAD & SAVE Window Buttons (2 – 2)

Button Information

PADLO CK

SYMBOL

The padlock symbol shows when a saved job is locked or

unlocked. There is a small padlock symbol next to each

locked job. To lock or unlock a job.

1. select the job from the job list

2. touch the large key symbol.

A padlock symbol displayed in light grey shows that a

job has been locked by a supervisor to prevent changes to

the settings

DELETE To delete a particular job it must be unlocked. Touch the

job name or use the Up arrow or Down arrow to make the

selection from the job list. Touch and hold DELETE. A

red line appears. The red line fills from left to right. Hold

DELETE until the red line reaches the right-hand side.

VIEW OF JOB LIST VIEW OF JOB LIST changes the order that saved jobs

are listed. There is a line between Factory Template jobs

and jobs saved by the operator. The Factory Template

jobs are at the top of the list

- A->Z Touch A->Z to list the jobs in alphabetical order.

- BY USE Touch BY USE to list jobs in the order they were last

used. The most recently-run job is at the top of the list.

- BY INDEX Touch BY INDEX to list jobs in numerical order. the

machine gives a number to all jobs that are saved.

28 Chapter 3 The User Interface

Page 29

The ADVANCED Window

Introduction

The ADVANCED window gives you access to special machine functions.

[11]

[11] Button overview

Button Information

RE-REF If the machine calibration appears incorrect or if an 'axis

moving' error message remains on the screen, touch

RE-REF to re-reference the adjustment axes. The

adjustment axes return to the current settings. At

intervals, the machine will re-reference the axes during

the set-up procedure.

STITCHER UP Touch STITCHER UP before you lubricate the stitch

head. This action moves the stitch head to the correct

position for lubrication.

The ADVANCED Window

PURGE SET When an error occurs, a set or part of a set can remain in

the gathering area. Touch START , then touch PURGE

SET to clear the set from the machine. The book is not

stitched or trimmed

According to the type of error that occurred, there can be

a pause of 7 seconds before the PURGE SET button will

operate.

- MAKE BOOK When an error occurs, a set or part of a set can remain in

the gathering area. Touch START then touch MAKE

BOOK to clear the set from the machine. The book is not

stitched or trimmed.

According to the type of error that occurred, there can be

a pause of 7 seconds before the MAKE BOOK button

will operate.

29

Page 30

The CONFIGURE Window

The CONFIGURE Window

Introduction

The CONFIGURE window lets you make changes to the configuration of the

machine.

Some functions and buttons are only available at certain access levels, see 'ACCESS

LEVEL' table 13 on page 31.

CONFIGURE Window Buttons

[12]

[12] Button overview

Button Information Supervisor

Access

MACHINE

OPTIONS

Touch MACHINE OPTIONS to view the

general machine setup. Some of the settings

can be changed, depending on the current

access level.

MEASUREM

Select 'mm' or 'inch' as the unit of

measurement.

ENT

- STITCH

SENSOR

There is a sensor that checks for stitches.

Touch STITCH SENSOR to turn the stitch

sensor on or off. The default setting is ON.

- PRESET

PAPER SIZES

The preset paper sizes can be either ISO A

sizes or US paper sizes. To select which preset

paper sizes are available, touch the relevant

button.

NETWORK

This button is used by the service engineer. No

SETTINGS

SHUTTLE Touch SHUTTLE to make adjustments to the

tamper.

Ye s

Ye s

Ye s

Ye s

Ye s

-TAMPER

This button is used by the service engineer. View only

DELAY

- TAMPER

TIME

TAMPER TIME adjusts the time that the

tamper touches the set.

An increase in TAMPER TIME causes a

decrease in the production rate for thin books.

FORM

This button is used by the service engineer. View only

SETUP

30 Chapter 3 The User Interface

Ye s

Page 31

The MENU Window

Introduction

MENU shows the settings that are not changed during day-to-day operation.

These settings include

■ Change the Access Level

■ Change the display language

■ Advanced machine settings that are accessed by a person who has the correct

access-code.

Button overview

[13]

[13] The MENU Window Buttons (1 – 2)

Button Information

ACCESS LEVEL The Touch Screen has five different access levels

The MENU Window

■ Operator

■ Supervisor

■ Service

■ Distributor

■ Factory

Touch ACCESS LEVEL and select the correct level

from the list. The last three levels are protected by access

codes. To protect job settings, the supervisor level allows

jobs to be locked.

CURRENT

Touch one of the flags to select the language you need.

LANGUAGE

AXES Touch AXES to re-reference individual axes. Supervisor

access level is needed for this function.

Other functions on this button are used by the service

engineer.

BRIDGE Touch BRIDGE to re-reference the bridge axes.

Supervisor access level is needed for this function.

Other functions on this button are used by the service

engineer.

SERVICE OPTIONS This button is used by the service engineer.

TEST This button is used by the service engineer.

31

Page 32

The MENU Window

[13] The MENU Window Buttons (2 – 2)

Button Information

COUNTERS The counters display the

-RESET Touch RESET to reset the book, sheet counter, and stitch

■ number of books that have been made

■ number of sheets that have been processed

■ number of stitches that have been used

counter.

Touch and hold RESET. A red line appears. The red line

fills from left to right. Hold RESET until the red line

reaches the right-hand side.

32 Chapter 3 The User Interface

Page 33

Chapter 4

Standard Tasks

This chapter describes the standard tasks that are needed in the day-to-day operation

of your Booklet maker.

33

Page 34

Load and Save the Job Settings

Load and Save the Job Settings

Introduction

The current job settings can be saved to memory and reloaded for use again at a later

date. Load the 'Default Job Template' to reset the Booklet maker to normal settings.

Save a job

1. Touch LOAD & SAVE > SAVE.

2. If these options appear, select one.

■ REPLACE to over-write the previous job with the current job settings.

■ SAVE NEW to save the current job with a new name.

■ CANCEL to cancel the job save.

3. Enter the name for the job on the keyboard

4. Touch OK or CLOSE.

Load a job

1. Touch LOAD & SAVE .

2. Touch the job name or use the Up arrow or the Down arrow to select the job.

3. Touch LOAD.

4. Wait until the Booklet maker has made the adjustments.

Reset the Booklet maker to default settings

1. Touch LOAD & SAVE .

2. Select the Default Job Template from the list of jobs.

3. Touch LOAD.

4. Touch YES.

34 Chapter 4 Standard Tasks

Page 35

Adjust the Stitch Pitch

Introduction

The stitch pitch is the space between the stitches. The machine automatically

calculates the stitch pitch according to the size of the paper and the number of

stitches. The stitches are inserted symmetrically on the spine of the book.

If a non-standard stitch pitch is needed, use STITCH PITCH to make the adjustment.

[12]

A = Stitch Pitch

AAB

[12] Stitch Pitch

Limitations:

■ The minimum stitch pitch 'A' is 25 mm.

■ The minimum distance from the center of the stitch to the edge of sheet 'B' is 15

mm.

Adjust the Stitch Pitch

When to do

If you need the Booklet maker to insert the stitches in a non-standard position. For

example, to keep the stitches away from the text on the spine of the book.

Select a non-standard stitch pitch

1. Touch BASIC > STITCHES

2. Touch AUTO. The STITCH PITCH value becomes green.

3. Change the stitch pitch value. Either use the "+" and "-" or touch the green stitch

pitch value to open a numeric keypad.

4. Touch STITCHES to close the window.

The stitch pitch value is displayed in the job mimic and on the STITCHES button.

Select a standard stitch pitch

1. Touch BASIC > STITCHES.

2. Touch AUTO to select ON.

3. Touch STITCHES to close the window.

The stitch pitch value is not displayed in the job mimic or on the STITCHES button.

35

Page 36

Open the Connecting Bridge Cover

Open the Connecting Bridge Cover

Introduction

The Booklet maker will not stop if you open the connecting bridge cover.

[13]

A

[13] Connecting Bridge Cover in the open position.

[14]

When to do

If a machine error occurs, or for maintenance.

■ To clear a paper jam

■ To clean the static elimination bar

Caution: Keep your hands, clothing and hair away from the belts.

Procedure

Lift the connecting bridge cover.

A Connecting Bridge Cover

36 Chapter 4 Standard Tasks

Page 37

Open and Close the Folder Cover

Introduction

If a machine error occurs, or for maintenance.

■ To access the stitch area

■ To access the folder area

Note: The folder cover has an interlock switch. The Booklet maker stops if you open

the folder cover.

[14]

Open and Close the Folder Cover

[14] Unlock and lock the Folder Cover.

Open the Folder Cover

1. Lift the black locking handle against the spring pressure.

2. Turn the handle through 90° to unlock.

3. Lift the folder cover carefully to the vertical position.

Close the Folder Cover

Caution: Check that the folder cover will not hit the clincher frame locking

handle when you close the folder cover. If necessary, lift and rotate the

clincher frame locking handle to a new position figure 16 on page 38.

1. Lower the folder cover.

2. Turn the handle through 90° to lock.

3. Close the locking handle to lock the folder cover.

37

Page 38

Lift and Lower the Clincher Frame

Lift and Lower the Clincher Frame

Introduction

[15]

[15] Folder Cover in the vertical position.

[15]

A Folder Cover

A

B

B Clincher Frame

[16]

A

B

C

[16] Clincher Frame Components

[16]

A Clincher

B Locking Handle

C Clincher Frame

When to do

If a machine error occurs, or for maintenance.

■ To clear a paper jam in the stitch area

■ To unlock the Booklet maker main deck

38 Chapter 4 Standard Tasks

Page 39

Lift the Clincher Frame

1. Open the folder cover.

2. Turn the locking handle to the left , until the thread is disengaged.

3. Lift the clincher frame to the vertical position.

Lower the Clincher Frame

Attention: You must hold the weight of the clincher frame. Do not let the

clincher frame fall on your hand.

1. Lower the clincher frame.

2. Turn the locking handle to the right , until the handle is tight.

3. Check that the locking handle will not be hit by the folder cover when you close the

folder cover. The locking handle should point towards the middle of the machine. If

necessary, lift and rotate the locking handle to a new position.

Lift and Lower the Clincher Frame

39

Page 40

Open the Gathering Area Cover

Open the Gathering Area Cover

Introduction

[17]

[17] Gathering Area Cover.

[17]

A Connecting Bridge Cover open

A

B

C

When to do

If a machine error occurs, or for maintenance.

■ To access the gathering area

■ To access the static elimination bar in the gathering area

The Booklet maker will stop if you open the gathering area cover.

Procedure

1. Open the connecting bridge cover.

2. Use the gathering area cover handle to lift the gathering area cover.

B Gathering Area Cover

C Gathering Area Cover Handle

40 Chapter 4 Standard Tasks

Page 41

Lift the Booklet maker Main Deck

Introduction

[18]

[18] Lift the Booklet maker Main Deck

[18]

A Folder Cover open

Lift the Booklet maker Main Deck

A

B

C

D

E

When to do

If a machine error occurs, or for maintenance.

■ To access the stitch head

■ To access the former area

■ To access the trim area

Procedure

Caution: Keep your hands and fingers clear when you lift the main deck.

B Connecting Bridge Cover open

C Clincher Frame lifted

D Gathering Area Cover

EMain Deck

41

Page 42

Lift the Booklet maker Main Deck

[19]

Step Action Information

1 Open the connecting bridge

cover.

(see ‘Open the Connecting Bridge

Cover’ on page 36)

2 Open the folder cover. (see ‘Open the Connecting Bridge

Cover’ on page 36)

3 Lift the clincher frame. (see ‘Lift the Clincher Frame’ on

page 39)

4 Open the gathering area cover. (see ‘Lower the Clincher Frame’

on page 39)

5 Lift the Booklet maker main

deck.

The main deck lifts to

approximately 60º. The weight of

the main deck is supported by a gas

strut. Let the gas strut control the

movement of the main deck.

42 Chapter 4 Standard Tasks

Page 43

Empty the Trim Bin

Introduction

[19]

Empty the Trim Bin

A

B

[19] Trim Bin Open.

[20]

Note: The Booklet maker operates with the trim bin removed for a short period of

time. The printer waits while the trim bin is removed, then continues when the trim

bin is replaced. To prevent lost production, you must remove, empty, and return the

trim bin to the Booklet maker as quickly as possible.

When to do

■ An error message is displayed on the touch screen when the trim bin is full.

■ You can empty the trim bin when you choose. For example, before you start a

Procedure

1. Use the handle to open the trim bin.

2. Use the side handles to lift and remove the trim bin.

3. Empty the trim bin

4. Fit the bottom of the trim bin over the mounting rail.

5. Push the trim bin closed at the top.

A Trim Bin Side Handle

B Trim Bin open

print job.

43

Page 44

Open the Stitch Wire Cabinet

Open the Stitch Wire Cabinet

Introduction

[20]

A

[20] Stitch Wire Cabinet.

[21]

When to do

■ To see if the stitch wire is jammed or finished. An error message is displayed on

■ To install a new stitch wire spool. (see ‘Install New Stitch Wire’ on page 107).

Procedure

Open the stitch wire cabinet cover. The cover is held closed by a magnetic catch.

A Stitch wire cabinet open

the touch screen when the stitch wire is jammed or finished.

44 Chapter 4 Standard Tasks

Page 45

Adjust the Stacker

Introduction

The collection table must be in the correct position for the stacker to operate. The

position of the collection table depends on the finished size of the job.

■ When you start a new job

■ If the books do not stack correctly

[21]

Adjust the Stacker

A

1

2

B

C

[21] The Stacker

[22]

A Catch tray adjustment

B Collection table

C Catch tray

[22]

A

[22] Collection table position

B

C

D

45

Page 46

Adjust the Stacker

[23]

A Book size in window

B Collection table

C Orange plastic hand screw

D Catch tray

Procedure

[24]

Step Action Information

1 Set the catch tray angle according

to the thickness of the book.

For books that are 1.5 mm thick or

less, use position 1.

For books that are 1.5 mm thick or

less, use position 2.

figure 21 on page 45

2 Set the collection table position

according to the size of the book.

Read the settings through the

window.

figure 22 on page 45

These settings are recommendations. The settings can change with the size,

thickness, and material of book. Make further adjustments if necessary.

46 Chapter 4 Standard Tasks

Page 47

Operate the Booklet maker offline

Introduction

You can hand feed sets into the Booklet maker if offline operation is needed. The

machine operates when you push the two buttons.

When to do

■ To check the settings are correct

■ To make a small number of books offline

Attention: Do not put your hands in the gathering area when the machine

operates. Use two hands to push the buttons. For safety reasons, this task is for a

single operator. Do not let another person help you.

Operate the Booklet maker offline

Procedure

1. Enter the correct settings on the touch screen, according to the size and thickness of

2. Touch START

3. Open the connecting bridge cover.

4. Open the gathering area cover.

5. Put the set in the gathering area with the middle pages of the book face up.

6. Press the two buttons and hold for 9 seconds, or until you hear the folder operate.

the job.

The time interval changes according to the number of stitches.

47

Page 48

Operate the Booklet maker offline

48 Chapter 4 Standard Tasks

Page 49

Chapter 5

Error Conditions, Problems,

and Solutions

This chapter describes how to correct problems that can occur with your Booklet maker.

If a problem persists, contact your service engineer.

49

Page 50

Clear a Printer Error

Clear a Printer Error

Introduction

If a paper jam or other error occurs in the printer, the printer and the Booklet maker

stop.

Procedure

1. Clear the printer error.

2. Follow the instructions on the printer. If the printer tells you to remove paper from

the Booklet maker, touch START to start the machine.

3. Then touch ADVANCED > PURGE SET > PURGE SET.

4. The partial book is delivered to the stacker.

5. Discard the book.

50 Chapter 5 Error Conditions, Problems, and Solutions

Page 51

Clear a Booklet maker error

Introduction

If a paper jam or other error occurs in the Booklet maker, the printer and the Booklet

maker stop. The type of error is displayed on the touch screen (see ‘Error Messages’

on page 54).

Procedure

1. Clear the error. The error message on the touch screen tells you about the error.

2. Remove all sheets from the Booklet maker.

3. Follow the instructions on the printer.

Clear a Booklet maker error

51

Page 52

General Problems

General Problems

[25]

Problem Cause Solution

The Booklet maker does

not start

The Booklet maker is not

turned on.

Turn ON the Booklet

maker (see ‘Turn ON the

Booklet maker’ on

page 13).

The printer has not sent a

job to the Booklet maker.

The Booklet maker is not

connected to the power

supply.

Correct the problem at the

printer.

Connect to the power

supply of the correct type

and voltage (see ‘Turn ON

the Booklet maker’ on

page 13)

A safety cover is open. Close all safety covers.

The trim bin is not

Install the trim bin.

installed or the trim bin is

not installed correctly.

The Booklet maker is not

connected to the printer

interface.

Check the interface

cables. Connect the

cables.

The START and STOP

buttons do not work

A fuse has blown on the

power input.

The stitch head is

jammed.

An error condition exists

on the Booklet maker.

The touch screen is in

power-save mode

Replace the fuse(s) as

needed (see ‘Change the

Fuses’ on page 85)

Clear the stitch head jam

and start the Booklet

maker again.Clear a

Stitch Head Jam on

page 80

Check the error message

on the touch screen.

Correct the fault (see

‘Error Messages’ on

page 54)

Touch the touch screen to

restore normal function

The Touch Screen on

page 20.

52 Chapter 5 Error Conditions, Problems, and Solutions

Page 53

Problem Cause Solution

General Problems

The operation of the

touch screen is incorrect

The touch screen is in

power-save mode

The touch screen

calibration is incorrect

Touch the touch screen to

restore normal function

The Touch Screen on

page 20.

Calibrate the touch screen

(see ‘Calibrate the Touch

Screen’ on page 84).

53

Page 54

Error Messages

Error Messages

[26]

Problem Cause Solution

AXES MOVING Some of the machine axes

are moving. This message

clears when the

adjustment is complete.

If the message does not

clear, touch ADVANCED

> RE REF

BOOK CYCLE TIME

TOO LONG

The printer has delivered

the sets faster than the

books can be made. To

decrease the book cycle

time, adjust the machine

settings:

■ decrease the number

of FORMS

■ decrease the number

of STITCHES

■ decrease the TAMPER

TIME

■ touch STOP to clear

the message from the

screen

Bridge axis moving The bridge axis is

moving. This message

clears when the

adjustment is complete.

If the message does not

clear, touch ADVANCED

> RE REF.

BRIDGE INFEED

COVER OPEN

54 Chapter 5 Error Conditions, Problems, and Solutions

The bridge infeed cover is

open.

The machine will not

operate until the cover is

closed.

(see ‘Clear Paper Jams’

on page 68)

Page 55

Problem Cause Solution

Error Messages

BRIDGE MOTOR

STALL

Check for a paper jam in

the connecting bridge.

■ Touch STOP to stop

the Booklet maker.

■ Clear the paper jam.

■ Touch STOP to clear

the message from the

screen.

■ Continue the print job.

CHECK THE TRIM BIN The trim bin is either open

or full. Check the trim

bin. Empty the trim bin if

necessary.

COVER OPEN A safety cover is open.

The machine will not

operate until the cover is

closed.

DRIVE MOTOR STALL There is a paper jam.

Check the machine and

correct the error.

Touch STOP to clear the

message from the screen.

(see ‘Clear Paper Jams’

on page 68)

Endlay axis moving The endlay axis (size

adjustment) is moving.

This message clears when

the adjustment is

complete.

If the message does not

clear, touch ADVANCED

> RE REF.

ERROR IN TRIM AREA There is an error at the

trimmer.

Check the trimmer for a

paper or book jam.

Touch STOP to clear the

message from the screen.

FLOW ERROR BRIDGE

There is an error at the

connecting bridge. Open

the connecting bridge

cover and check for a

paper jam.

(see ‘Clear Paper Jams’

on page 68)

55

Page 56

Error Messages

Problem Cause Solution

FLOW ERROR FORMER

FLOW ERROR OUTFEED

There is an error at the

former. Open the folder

cover and remove the

book(s). If necessary,

open the main deck to

remove the book(s).

If there is paper in the

gathering area, touch

START, then touch

ADVANCED > PURGE

SET > PURGE SET to

clear the set from the

machine.

There is an error at the

outfeed. Check the

outfeed. If necessary,

remove the trim bin and

open the trim stop guard

to remove the book(s).

Touch STOP to clear the

message from the screen.

If there is paper in the

gathering area, touch

START, then touch

ADVANCED > PURGE

SET > PURGE SET to

clear the set from the

machine.

Jam in the Folder or

Former Area on page 72

Jam in the Trim Area on

page 74

Fold blade axis moving The fold blade axis (book

FOLD BLADE NOT

PAR KE D

56 Chapter 5 Error Conditions, Problems, and Solutions

thickness adjustment) is

moving. This message

clears when the

adjustment is complete.

If the message does not

clear, touch ADVANCED

> RE REF

The fold blade is in the

wrong position. Touch

START to reset the

position. Follow the

instructions on the screen.

Page 57

Problem Cause Solution

Error Messages

FORM CLAMP

CLOSED

The form clamp is in the

wrong position. Touch

START to reset the

position. Follow the

instructions on the screen.

FORM ROLLER ERROR The form roller is

jammed. Clear the jam

and continue.

FORM ROLLER NOT

PAR KED

The form roller is in the

wrong position. Touch

START to reset the

position. Follow the

instructions on the screen.

GATHERING AREA

COVER OPEN

Close the gathering area

cover if you need to

operate the machine

online.

INVERTER ERROR Check for a paper jam and

clear if necessary.

Touch STOP to clear the

message from the screen.

If the problem continues,

contact your service

engineer.

(see ‘Jam in the Trim

Area’ on page 74)

JAM AT BRIDGE

INFEED

JAM AT FORM

ROLLER

JAM BEFORE

TRIMMER

JAM IN CONNECTING

BRIDGE

There is a paper jam at the

infeed to the connecting

bridge. Clear the jam and

continue.

The form roller is

jammed. Open the folder

cover and remove the jam.

There is a book jammed

before the trimmer. Clear

the jam and continue.

There is a paper jam in the

connecting bridge. Clear

the jam and continue.

(see ‘Clear Paper Jams’

on page 68)

(see ‘Jam in the Trim

Area’ on page 74).

(see ‘’ on page 73).

(see ‘Jam in the

Connecting Bridge’ on

page 70)

57

Page 58

Error Messages

Problem Cause Solution

JAM IN GATHERING

AREA

There is a paper jam in the

gathering area. Open the

connecting bridge cover,

lift the connecting bridge

and remove the paper

jam.

JAM IN STACKER

AREA

There is a paper jam at the

outfeed of the machine.

Remove the jammed

books and continue.

JAM IN STITCHER

AREA

There is a paper jam in the

stitch area. Open the

folder cover, remove the

paper jam and continue.

JAM IN STITCH HEAD There is a jam in the stitch

head.

JAM IN TRIMMER There is a book jammed

in the trimmer. Clear the

jam and continue.

(see ‘Jam in the

Gathering Area’ on

page 71)

(see ‘Jam in the Stitch

Area’ on page 72)

Clear a Stitch Head Jam

on page 80

(see ‘Jam in the Trim

Area’ on page 74)

MANUALLY PARK

SHUTTLE

The shuttle is not parked

correctly. Open the folder

cover and move the

shuttle to the park

position. Close the folder

cover. The shuttle will

reset. When the message

list is clear, continue

operation.

MISSING STITCHES The machine has detected

missed stitches. Check to

see whether the

stitch-wire is jammed or

whether the stitch-wire

spool is empty.

MOTOR CONTROLLER

NOT READY

The drive motor

controller is not ready. If

the problem continues,

contact your service

engineer.

Manually park the Shuttle

on page 86

(see ‘Clear a Stitch Wire

Jam’ on page 77)

(see ‘Install New Stitch

Wire’ on page 107)

58 Chapter 5 Error Conditions, Problems, and Solutions

Page 59

Problem Cause Solution

Error Messages

REMOVE SET FROM

FOLD AREA

REMOVE SET GATHERING AREA

Open the folder cover and

remove the set.

Open the gathering area

and remove the sheets.

Or touch START, then

touch ADVANCED >

PURGE SET > PURGE

SET to clear the set from

the machine.

Rotate axis moving The rotate axis is moving.

This message clears when

the adjustment is

complete.

If the message does not

clear, touch ADVANCED

> RE REF.

SET IN GATHERING

AREA

There is a set or partial set

in the gathering area.

If the print job has been

canceled, open the

gathering area and

remove the sheets. Or

touch START, then touch

ADVANCED > PURGE

SET > PURGE SET to

clear the set from the

machine.

Shuttle axis moving The shuttle axis is

SHUTTLE MOTOR

COMMS FAIL

moving. This message

clears when the

adjustment is complete.

If the message does not

clear, touchADVANCED

> RE REF.

Use the ON/OFF switch.

Turn the machine OFF,

then turn the machine

ON. If the problem

continues, call your

service engineer.

59

Page 60

Error Messages

Problem Cause Solution

SHUTTLE MOTOR

ERROR

Use the ON/OFF switch.

Turn the machine OFF,

then turn the machine

ON. If the problem

continues, call your

service engineer.

SHUTTLE NOT

PAR KE D

The shuttle is in the

wrong position. Touch

START to reset the

position.

Then touch STOP to clear

the message from the

screen.

Sidelay axis moving The sidelay axis (size

adjustment) is adjusting.

This message clears when

the adjustment is

complete.

If the message does not

clear, touchADVANCED

> RE REF.

STACKER FULL The stacker is full.

Unload the books from

the stacker.

Stitch axis moving The stitch axis is moving.

This message clears when

the adjustment is

complete.

If the message does not

clear, touchADVANCED

> RE REF.

Stitch position adjusting The stitch position is

adjusting. This message

clears when the

adjustment is complete.

If the message does not

clear, touchADVANCED

> RE REF.

60 Chapter 5 Error Conditions, Problems, and Solutions

Page 61

Problem Cause Solution

Error Messages

STITCH TIMEOUT There is an error at the

stitcher.

If the problem continues,

call your service engineer.

TOO MANY PAGES The printer has delivered

more than 55 sheets into

the gathering area.

Remove the incorrect set.

Correct the printer

setting.

Touch STOP to clear the

message from the screen.

TOUCH PAD ERROR There is a fault with the

START and STOP touch

pads. If the problem

continues, call your

service engineer.

Touch START to clear

machine

There may be some paper

in the machine. Touch

START to clear the

machine before you start

a new job.

Stitch Timeout Error on

page 75

(see ‘Open the Gathering

Area Cover’ on page 40)

Trim axis moving The trim axis (size

adjustment) is moving.

This message clears when

the adjustment is

complete.

If the message does not

clear, touchADVANCED

> RE REF.

TRIM BIN OPEN The trim bin is not

installed or is not in

contact with the safety

switch. Install the trim

bin.

61

Page 62

Error Messages

Problem Cause Solution

TRIM BLADE NOT

PAR KE D

The trim blade is in the

wrong position. Touch

START to reset the

position.

Follow the instructions on

the screen.

USER STOP The user has touched the

STOP button while the

machine is in operation.

Touch START to restart

the machine.

62 Chapter 5 Error Conditions, Problems, and Solutions

Page 63

Book Quality

Paper Size and Book Quality Instructions

■ Careful measurement of the paper size and set thickness is important.

■ To make an accurate book you must enter accurate paper dimensions into the

touch screen.

■ Measure the size of the printed paper. The paper dimension changes when the

paper is printed.

■ If the book is made from several different types of paper, make sure the different

paper types are all the same size. If the size of the paper is different, an accurate

book cannot be made.

■ The paper must be cut accurately. If the sheets are not cut squarely, an accurate

book cannot be made.

■ Adjustments to the FORM settings can be necessary for some types of paper.

Machine Adjustments

Book Quality

Machine adjustments can be made while the machine is in operation. The PA PER

SIZE adjustment is limited to a maximum of +/- 1 mm when the machine is in

operation.

63

Page 64

Book Quality

[27]

Book Quality

Problem

Cause Solution

The finished book

is not neat and tidy

The sheets are not

aligned

The wrong paper size was

entered on the touch screen.

The book is made from

paper that is different sizes.

The Booklet maker

adjustment system is not

calibrated correctly.

The static elimination bars

are dirty.

Incorrect function of the

static elimination bars.

Measure the paper and enter

the correct dimensions (see

‘Enter the Job Settings’ on

page 14).

Only use paper of the same

size (see ‘Paper Size and Book

Quality Instructions’ on

page 63).

Touch RE-REF in the

ADVANCED window to

calibrate the Booklet maker

adjustment axes. (see table 11

on page 29)

Clean the static elimination

bars (see ‘Clean the Static

Elimination Bars’ on

page 92).

Call your service engineer.

The spine is not

formed correctly

The book is not

trimmed

The book is not

trimmed square

The trimmed edge

is of bad quality

Incorrect settings. (see ‘Spine Form Problems’

on page 66)

The TRIM function is not

selected.

Turn on the TRIM function.

See "TRIM" in table 9 on

page 25

The trim position is set

larger than the book.

Reset the trim position. See

"TRIM" in (see table 9 on

page 25)

Trimmed paper has

collected on the trim stop.

Clear the trimmed paper from

the trim stop. (see ‘Jam in the

Trim Area’ on page 74)

The trimmer blade is blunt

Call your service engineer.

or damaged.

64 Chapter 5 Error Conditions, Problems, and Solutions

Page 65

Book Quality

Book Quality

Problem

The stitch is not on

the center-line of

the spine

The books do not

stack on the

stacker

The book cover is

dirty or marked

Cause Solution

The wrong paper size was

entered on the touch screen.

The Booklet maker

adjustment system is not

calibrated correctly.

Measure the paper and enter

the correct dimensions.

Touc h RE-REF in the

ADVANCED window to

calibrate the Booklet maker

adjustment axes. (see table 11

on page 29)

The collection table is in the

wrong position.

Adjust the position of the

collection table to fit the size

of the finished book. Adjust

the Stacker on page 45

The former roller is dirty. Clean the former roller (see

‘Clean the Former Roller’ on

page 94).

[23]

Marks on the spine

The former clamp is dirty. Clean the Polyurethane Strips

in the Form Clamp on page 96

[24]

Marks beside the spine

65

Page 66

Book Quality

Book Quality

Problem

The book cover is

dirty or marked

Cause Solution

The trimmings-removal

fingers are dirty.

[25]

Clean the Trimmings Removal

Fingers on page 98

Curved marks on the book

There are grease marks

around the stitches.

[26]

Clean excess grease from the

Stitch Head on page 101

Grease marks near the stitches

Spine Form Problems

To make the square spine of the book, pressure is applied to the spine. This process

is called forming. The Booklet maker automatically applies the optimum amount of

form according to the book thickness.

Some types of paper may need further adjustment.

[28]

Spine Form Condition

[27]

Correct

The spine is square at each end and the paper is not

damaged.

The Booklet maker setting is correct. Adjustment is

not needed.

66 Chapter 5 Error Conditions, Problems, and Solutions

Page 67

Spine Form Condition

[28]

Incorrect - The spine needs more form.

Check these settings:

Book Quality

The SET THICKNESS

setting is incorrect

Measure the set thickness

and enter the correct

dimension. Enter the Job

Settings on page 14

The folder cover is not

securely closed?

Close the folder

cover.Close the Folder

Cover on page 37

The FORM function is

not turned on?

Turn on the FORM

function. See "FORM" in

table 9 on page 25

The THRESHOLD

value is less than the SET

THICKNESS?

Decrease the

THRESHOLD value.

See THRESHOLD

table 9 on page 25

Does the spine need more

form at one end?

Change NUMBER to 2

or 4. See "FORM" in

table 9 on page 25

Does the spine need more

form at each end?

Increase PRESSURE.

Then, if the spine still

needs more form,

increase NUMBER. See

"FORM" in table 9 on

page 25

[29]

Incorrect - The spine is damaged or there are

creases near the spine.

Check these settings:

The SET THICKNESS

setting is incorrect?

The spine of the book

needs less forming.

Measure the set thickness

and enter the correct

dimension. Enter the Job

Settings on page 14

Decrease PRESSURE.

Then, if the spine is still

over formed, decrease

NUMBER. See "FORM"

in table 9 on page 25

67

Page 68

Clear Paper Jams

Clear Paper Jams

Introduction

[30]

A

B

C

D

E

[30] Paper Jam Locations

[29]

A Connecting Bridge

B Gathering Area

C Stitch Area

D Fold and Forming Areas

ETrim Area

[31]

A

[31] Paper Jam Location - Bridge Infeed

68 Chapter 5 Error Conditions, Problems, and Solutions

Page 69

Clear Paper Jams

[30]

A Bridge Infeed Cover

[32]

A

B

[32] Trimmer Infeed Conveyor viewed from above.

Jam before the Trimmer on page 72

[31]

A Trimmer Infeed Conveyor

B Former-clamp mechanism

[33]

A

B

C

[33] Trim Stop Assembly

Jam in the Trim Area on page 74

69

Page 70

Clear Paper Jams

[32]

A Orange Plastic Hand Screw

B Locking Plate

CTrim Stop Guard

[34]

[34] Gathering Area Belt Positions

Jam in the Bridge Infeed

1. Open the bridge infeed cover.

2. Remove the jammed paper.

3. Close the bridge infeed cover.

4. Touch STOP to clear the message from the screen.

5. If there is paper in the gathering area, touch START , then touch ADVANCED

> PURGE SET > PURGE SET to clear the set from the machine.

6. Continue the print job.

Jam in the Connecting Bridge

1. Open the connecting bridge cover.

2. Remove the jammed paper. Do not damage or move the belts.

3. Close the connecting bridge cover.

4. Touch STOP to clear the message from the screen.

70 Chapter 5 Error Conditions, Problems, and Solutions

Page 71

5. If there is paper in the gathering area, touch START , then touch ADVANCED

> PURGE SET > PURGE SET to clear the set from the machine.

6. Continue the print job.

Jam in the Gathering Area

1. Open the connecting bridge cover.

2. Lift the gathering area cover.

3. Remove the jammed paper.

4. Check the belts are in the correct position. Adjust the position of the belts if

necessary. figure 34 on page 70

5. Close the gathering area cover.

6. Close the connecting bridge cover.

7. Touch STOP to clear the message from the screen.

8. Continue the print job.

Clear Paper Jams

71

Page 72

Clear Paper Jams

Jam in the Stitch Area

[33]

Step Action Information

1 Open the folder cover. (see ‘Open and Close the Folder

2 Lift the clincher frame. (see ‘Lift and Lower the Clincher

3 Remove the jammed paper.

4 Check for broken or damaged

5 Lower the clincher frame. (see ‘Lift and Lower the Clincher

stitches in the clincher area.

Manually operate the clincher

to clear any stitches that are

jammed.

Cover’ on page 37)

Frame’ on page 38).

[35]

A

Press to manually operate the

clincher.

Frame’ on page 38)

6 Close the folder cover.

7 If there is paper in the

gathering area, touch START,

then touch ADVANCED >

PURGE SET > PURGE

SET.

8 Continue the print job.

Jam in the Folder or Former Area

1. Open the folder cover.

2. Remove the jammed paper. If you cannot see the paper in the former area. (see ‘Jam

in the Trim Area’ on page 74)

3. Close the folder cover.

4. If there is paper in the gathering area, touch START , then touch ADVANCED >

PURGE SET > PURGE SET to clear the set from the machine.

5. Continue the print job.

Jam before the Trimmer

This action clears paper from the

BLM 500 / Bookletmaker 50.

The error message JAM BEFORE TRIMMER is displayed. This error can be

1. a book jammed before the trimmer

2. a piece of paper trimming has covered the jam sensor

72 Chapter 5 Error Conditions, Problems, and Solutions

Page 73

[34]

Step Action Information

1 Open the Booklet maker main

deck

2 Remove the trim bin.

Clear Paper Jams

3 Loosen the trimmer infeed

conveyor.

4 Remove the book, if one is

found.

The procedure can be seen from

the top of the machine. Access to

the parts is through the

former-clamp mechanism. Hold

the shaft and push to the right,

against the spring pressure.

Hold the shaft and push to the

right, against the spring pressure to

disengage the shaft from the drive

pin.

[36]

Lift the left-hand end clear.

5 Remove any paper offcuts

from the trimmer infeed

conveyor.

6 Install the trimmer infeed

conveyor.

7 Install the trim bin.

8 Close the Booklet maker main

deck and covers.

9 If there is paper in the

gathering area, touch START,

then touch ADVANCED >

PURGE SET > PURGE

SET.

10 Continue the print job.

A small piece of paper can cover

the jam sensor and cause an error

message.

Insert the right-hand end of the

shaft into the bearing, against the

spring pressure. Insert the

left-hand end.

This action clears paper from the

Booklet maker.

73

Page 74

Clear Paper Jams

Jam in the Trim Area

[35]

Step Action Information

1 Remove the trim bin.

2 Loosen the 2 orange plastic

hand screws to release the

The locking plates can rotate to

release the trim stop guard.

locking plates.

3 Pull the trim stop guard

towards you.

4 Remove the jammed book. Check the trim stop and remove

any pieces of trimmed paper.

5 Push the trim stop guard into

position.

6 Hold the locking plates in

position and tighten the orange

hand screws.

7 Attach the trim bin.

8 Touch START, then touch

ADVANCED > PURGE SET

This action clears any other paper

from the Booklet maker.

> PURGE SET.

9 Continue the print job.

74 Chapter 5 Error Conditions, Problems, and Solutions

Page 75

Stitch Timeout Error

Introduction

[36]

Step Action Information

1 Open the folder cover. Open and Close the Folder Cover

2 Lift the clincher frame. Lift and Lower the Clincher Frame

3 Remove the paper.

4 Lower the clincher frame. Lift and Lower the Clincher Frame

5 Close the folder cover.

Stitch Timeout Error

on page 37

on page 38

on page 38

6 If the error message

SHUTTLE NOT PARKED is

displayed, touch START

7 Touch STOP and then

continue the print job.

This action moves the shuttle to the

correct position.

75

Page 76

Stitch Head Problems

Stitch Head Problems

[37]

Problem Cause Solution

The stitch head does not

operate

The STITCH function is

not selected.

The stitch wire is

finished.

The stitch wire is

jammed.

The stitches are broken There is stitch wire

jammed in the stitch head.

The stitch wire is jammed

on the spool

The stitch wire spool is

not installed correctly.

Make sure STITCH is set

to 1 or more (see ‘The

BASIC Window’ on

page 25).

Load a new spool of

stitch-wire (see ‘Install

New Stitch Wire’ on

page 107).

Clear the jammed stitch

wire (see ‘Clear a Stitch

Wire Jam’ on page 77).

Inspect and remove the

jammed stitch wire (see

‘Clear a Stitch Wire Jam’

on page 77).

Check and correct (see

‘Fit a New Stitch Wire

Spool’ on page 108).

76 Chapter 5 Error Conditions, Problems, and Solutions

Page 77

Clear a Stitch Wire Jam

Introduction

Before you begin:

Lift the Booklet maker main deck. See Lift the Booklet maker Main Deck on page 41

[37]

Clear a Stitch Wire Jam

A

B

C

[37] Stitch Head.

D

77

Page 78

Clear a Stitch Wire Jam

[38]

A Top location of Middle Wire Tube

BMiddle Wire Tube

CMetal Spring Clip

DFeed Gears

Before You Begin

[39]

Step Action Information

1 Turn off the Booklet maker Use the ON/OFF switch.

2 Disconnect the Booklet maker

from the power supply.

3 Lift the Booklet maker main

Clear the Jammed Wire

[40]

Step Action Information

1 Cut the stitch wire at position

'A' approximately 50mm (2

inches) from where the stitch

wire leaves the stitch wire

guide.

2 Cut the stitch wire at position

'B' between the feed gears

and the middle wire tube.

deck

(see ‘Lift the Booklet maker Main

Deck’ on page 41)

[38]

A

Detail A: Cut stitch wire here.

[39]

3 Pull the stitch wire from the

stitch wire guide block.

78 Chapter 5 Error Conditions, Problems, and Solutions

B

Detail B: Cut stitch wire here.

[40]

Pull stitch wire in direction of arrow

Page 79

Step Action Information

Clear a Stitch Wire Jam

Remove the middle wire

tube.

Pull the wire from the stitch

head.

5 Install the stitch wire into the

stitch head.

figure 37 on page 77

(see ‘Install the Stitch Wire into the

Stitch Head’ on page 110)

79

Page 80

Clear a Stitch Head Jam

Clear a Stitch Head Jam

Introduction

The error message JAM IN STITCH HEAD is displayed.

This may be caused by

■ the SET THICKNESS setting is incorrect

■ the stitch head is jammed by broken wire

■ the stitch head needs lubrication

Do Procedure 1. If the error message continues, do Procedure 2.

80 Chapter 5 Error Conditions, Problems, and Solutions

Page 81

Procedure 1

[41]

Step Action Information