Oce Arizona T220 User Manual

Océ | Arizona T220

User Guide

Revision A • March, 2003

Océ Display Graphics Systems

© 2002 All Rights Reserved

Table of Contents

Preface

Copyright .................................................................iii

Current Document Version ......................................iii

Product Support, Documentation and Service ........iii

Product Compliance and Standards........................ v

1 T220 Product Overview

General Description................................................. 1

Safety Information ................................................... 4

Electromagnetic Compatibility .................................. v

Electrical Safety:....................................................... v

Product Safety:......................................................... v

Specifications ...........................................................1

Printer Power Requirements ....................................2

Vacuum Pump Power Requirements ....................... 3

Safety Labels............................................................6

2 Ink System Management

Océ Ink .................................................................... 9

Solvent..................................................................... 9

Changing an Ink Bottle .......................................... 10

Refilling the Solvent Bottle ..................................... 12

Emptying the Waste Bottle .....................................13

The Capping Station...............................................14

The Blotting Station ................................................15

Changing the Blotting cloth .................................... 15

The Pre-Fire Stripe.................................................17

Pre-Fire Stripe Catcher ..........................................17

Adjusting the Pre-Fire Stripe Catcher.....................17

3Media

Handling Media...................................................... 19

Recovering From a Carriage Crash ....................... 19

Thermal Expansion of Media..................................19

Media Holder Strips................................................20

3/10/03 i

Océ |

4 User Interface

Control Panel......................................................... 23

Key Pad, Display Screen and Status LEDs........... 24

Key Pad.................................................................. 24

Status Lights........................................................... 25

Online Screen......................................................... 25

Menu Structure ...................................................... 26

Print Queue Menu .................................................. 26

Operator Menu .......................................................26

Configure I/O Menu ................................................36

5 Operating the Arizona T220

Powering On and Off ............................................. 39

Printer Warm-Up.................................................... 40

Printing a Job......................................................... 41

Print Job Parameter Options .................................. 42

Print Job Settings ...................................................44

Using the Media Vacuum System ......................... 47

Maintaining Print Quality........................................ 48

Gradual Degradation in Print Quality......................48

Start of Day (Post-Maintenance) ............................ 48

Printing with High Heat...........................................48

Ineffective Drying at Start of Image ......................48

Banding ..................................................................49

Other Recommendations ....................................... 49

Evaluating the Diagnostic Stripe ............................ 50

Flushing the Heads ................................................54

6 Printer Maintenance

Maintenance Guidelines ........................................ 57

Who Should Do Maintenance?...............................57

Operator Maintenance Schedule............................57

Print Head Maintenance and Nozzle Recovery......58

Cleaning Solution Usage........................................58

Recommended Maintenance Frequencies............. 58

Daily Maintenance ................................................. 59

ii 3010100686

Weekly Maintenance .............................................63

Monthly Maintenance ............................................. 65

Bi-Yearly Maintenance ..........................................66

List of Figures

Arizona T220 Printer ........................................................1

Ink Station showing Ink Bottles ......................................10

Ink Station tray showing Solvent Bottle..........................12

Gantry Doors Open Showing Waste Bottle ....................13

Capping Station.............................................................. 14

Blotting Station ............................................................... 15

Mounting the Old Cardboard Core ................................. 16

Changing Blotting Paper ................................................ 16

Spit Catcher Adjustment ................................................ 18

Sheet of Foam Cor with 3 Media Hold-Down Strips.......20

Sharp edge of the strip butts up against the media.......21

Arizona T220 Control Panel ...........................................23

Key Pad, Display Screen, and Status LEDs ..................24

Maintenance Menu Tree ................................................ 27

Sample Nozzle Print....................................................... 30

Print Parameters Menu .................................................. 32

Units Menu ..................................................................... 33

Set Clock Menu.............................................................. 34

About Printer Menu ........................................................35

Configure IO Menu.........................................................36

AC Power Circuit Breaker Switch...................................39

T220 Printing Direction................................................... 46

Location of Vacuum Zones ............................................ 47

Detail From Diagnostic Stripe ........................................ 50

One Nozzle Not Firing Properly .....................................51

Five Adjacent Nozzles Not Firing ...................................51

Black Head Poorly Positioned........................................52

Poorly Operating Magenta Head....................................53

Removing Carriage Cover..............................................54

Syringing the Heads.......................................................55

3/10/03 iii

Océ |

iv 3010100686

Preface

0.1Copyright

© 2002 Océ Display Graphics Systems. All rights reserved.

This document contains information proprietary to Océ, to its subsidiaries, or to third

parties to which Océ may have a legal obligation to protect such information from

unauthorized disclosure, use or duplication. Any disclosure, use, or duplication of this

document or of any of the information contained herein for other than the specific purpose

for which it was disclosed is expressly prohibited, except as Océ may otherwise agree to in

writing. Due to continuing research and product improvements, features or product

specifications may change at any time without notice.

0.2Current Document Version

Copyright |

Date Doc. Number Revision Summary

03/05/03 3010100686 A Section to show electrical compliance.

Includes new pre-fire stripe catcher.

Revised maintenance section.

0.3Product Support, Documentation and Service

For further information on documentation and support for your Arizona T220 or for

information on other Océ Display Graphics Systems products, please contact:

Océ Display Graphics Systems

13231 Delf Place, #501

Richmond, British Columbia, Canada V6V 2C3

Phone: (604) 273-7730 Fax: (604) 273-2775

Web: http://www.dgs.Océ.com

FTP Site: http://www.cymbolic.com/ftp.html

Comments on this manual?

Please forward to the above address, marked Attention: Technical Writer.

Océ maintains a comprehensive support structure for its Arizona T220

customers. Upon

installation of your printer, you will be provided with the name of the sales and service office

responsible for your account. Record this information, along with the serial number of your

Arizona T220. Always report service problems to the office assigned to your account at

installation. Contacting the factory directly may cause unnecessary delays in resolving your

service issue.

3/10/03 -iii-

Océ |

US and Canadian Customers:

Océ Display Graphics Systems Service: 1-800-456-3473

13231 Delf Place, Building #501 Fax: 604-232-3154

Richmond, British Columbia, Canada Spares Orders: 1-800-295-6433 ext. 4

V6V 2C3

European Customers:

Océ Display Graphics Systems Service: 44 (0) 1628-519720

6 Waltham Park Service Fax: 44 (0) 1628-519589

Waltham Road Spares Enquiries: 44 (0) 1628-519736

White Waltham Spares Orders Fax: 44 (0) 1628-519751

Berkshire SL6 3TN

England

Asia Pacific Customers:

Océ Display Graphics Systems Service: 81-3-5472-3066

Grand Palace Tamachi 601 Fax: 81-3-5484-2071

4-9-18 Shibaura, Minato-ku

Tokyo, Japan 108-0023

Other:

Your regional distributor.

Customer Service Procedure:

When you call one of our customer service numbers you will be provided with telephone

technical support. Outside of office hours, you can leave a message and your call will be

returned the next working day. When you call, identify yourself as an Arizona T220

customer and provide the following information:

• The serial number of your Arizona T220

• Your company name and your name

• Your telephone number

• Nature of the problem

If we are unable to resolve your problem over the telephone, field engineers can be

dispatched to your site to conduct repairs. Service visits are paid for by the customer, either

under a maintenance agreement, by purchase order or prepayment. Time and material rates

are charged for any service not covered under a maintenance agreement. Before calling to

report a problem, gather as much information about the problem as possible and have it

ready to provide to the customer care center engineer. The more information you can

provide initially, the more quickly the problem can be corrected.

-iv- 3010100686-A

Product Compliance and Standards |

0.4Product Compliance and Standards

0.4.1Electromagnetic Compatibility

This equipment generates, uses and radiates radio frequency energy and if not installed and

used as designed or intended, may cause interference to radio communications. This

equipment has been tested and found to comply with the limits for a Class A computing

device. This equipment has been designed to provide reasonable protection against such

interference when operated in residential and commercial environments. Operation of this

equipment in a residential area may cause interference, in which case the user, at his own

expense, is required to take whatever measures are required to correct the interference

0.4.2Electrical Safety:

North America:

CSA 60950-00 and UL 60950-2000 )

European Community:

EN60950

EN60204-1 Low Voltage Directive 73/23/EEC

0.4.3Product Safety:

TUV EN 292-2:1996+A1

EN60950:1992+A1+A2+A3+A4+A11 Low Voltage Directive 73/23/EEC

EMC:

This device complies with Class A emission limits in accordance with:

EMC Directive 89/336/EEC

EN61000-6-2:2000

EN61000-6-4:2000

FCC Part 15:2001

3/10/03 -v-

Océ |

-vi- 3010100686-A

1 T220 Product Overview

1.1General Description

The Arizona T220 is a six color digital inkjet printer capable of producing large format

images on various rigid and flexible stock materials. The printer consists of a large

vacuum table and moving gantry. The material is held flat and stationary on the

vacuum table during printing. Printing occurs as the gantry moves from one end of the

table to the other. The printer uses solvent-based inks. An infrared heater attached to

the gantry provides curing of the ink on the media. The Arizona T220 must be operated

in accordance with certain environmental and safety reqirements noted in this

document.

1.1.1Specifications

Printhead Technology: .................Piezoelectric (504 nozzles per color)

Colors: .........................................Black, Cyan, Light Cyan, Magenta, Light

Ink: ...............................................Océ Display Graphic Systems 2200

Resolution: ...................................309 dpi

3/10/03 1-1

Figure 1 Arizona T220 Printer

Magenta, Yellow

solvent-based pigment Ink

Océ | T220 Product Overview

Throughput: ................................. 4 Pass Mode - Up to 165 sq. feet (15.33 sq.

meters) per hour

8 Pass Mode – Up to 90 sq. feet (8.36 sq.

meters) per hour

Max. Media Size: ......................... 62” wide x 120” long x 2” thick

Max. Print Size: ........................... 62.5” wide x 120.5” long

Printer Dimensions: ..................... Table – 70.5” x 168”

Gantry – 36” x 120”

Weight: ........................................ 1700 lbs

Air Requirement: Pressure: ......... 80 to 100 psi min.

Flow: 1cfm min.

Air supplied to the printer must pass through an Air Preparation Unit that contains the

following:

Air Filter – 5 micron element c/w auto drain;

Coalescing Filter – 99.97% efficiency c/w auto drain; and

Regulator c/w gauge.

1.1.2Printer Power Requirements

The printer operates in the following two configurations.

Delta (USA) Configuration:

Voltage:......................230VAC +/-10%, 3 Phase

Frequency:.................47 to 63 Hz

Current:......................24AMPS maximum steady state

Power: ....................... 15kW max.

Circuit Breaker...........30 Amps

Wye (European) Configuration:

Voltage:......................400VAC +/-10%, 3 Phase

Frequency:.................47 to 63 Hz

Current:......................24AMPS maximum steady state

Power: ....................... 15kW max.

Circuit Breaker...........30 Amps

1-2 3010100686-A

General Description |

1.1.3Vacuum Pump Power Requirements

The vacuum pump operates over the following range of voltages and frequencies:.

230 Volts @ 60HZ

Voltage:......................230 VAC +/-10%, 3 Phase

Current:......................14 AMPS maximum steady state

Power: .......................7kW max.

Circuit Breaker...........20 Amps

400 Volts @ 60Hz

Voltage:......................400 VAC +/-10%, 3 Phase

Current:......................7 AMPS maximum steady state

Power: .......................7kW max.

Circuit Breaker...........15 Amps

190 Volts @ 50 Hz

Voltage:......................190 VAC +/-10%, 3 Phase

Current:......................16.5 AMPS maximum steady state

Power: .......................7kW max.

Circuit Breaker...........20 Amps

380 Volts @ 50 Hz

Voltage:......................380 VAC +/-10%, 3 Phase

Current:......................8 AMPS maximum steady state

Power: .......................7kW max.

Circuit Breaker...........15 Amps

ODGS recommends that the AC power outlet for the vacuum pump be located within 8

feet of the power inlet on the pump.

Important: Unplugging the power cord from the wall socket is the only way to

isolate the entire machine.

3/10/03 1-3

Océ | T220 Product Overview

1.2Safety Information

MSDS

Read and practice safety guidelines as outlined in the Material Safety Data Sheet

(MSDS) for each ink. Post the document in the work area as required by prevailing law.

MSDS for all six inks and the CGS80 solvent are available via the Internet.

1. Go to www.3m.com

2. Click on Search, MSDS

3. Select 3M ID Number

4. Enter one of the following 11 digit numbers:

• 75-3470-3042-3 T2295 Black

• 75-3470-3043-1 T2296 Cyan

• 75-3470-3039-9 T2286 Light Cyan

• 75-3470-3040-7 T2291 Magenta

• 75-3470-3038-1 T2281 Light Magenta

• 75-3470-3041-5 T2292 Yellow

• 75-3465-0408-9 CGS80 Solvent

Note: These numbers are printed on the cardboard box for the ink and on the ink

bottles themselves.

Personal Safety

The operator should wear butyl rubber gloves, a protective apron, an NIOSH-approved

respirator (half-mask organic vapor respirator), and Safety glasses with side shields

when handling inks.

Risks Associated with Handling Inks

The Arizona T220 uses solvent-based inks; the liquid and the fumes are combustible.

The inks may cause eye irritation or skin irritation upon prolonged or repeated contact.

The inks may be absorbed through the skin, and may cause respiratory system irritation

and nervous system impairment.

1-4 3010100686-A

What to do with Ink Spills on Surfaces

Observe precautions as noted above, then:

a) Ventilate the area;

b) Contain the spill;

c) Cover with absorbent material;

d) Collect spilled absorbent material;

e) Place in a closed container;

f) Clean up residue with water (do not release to waterways or sewer);

g) Incinerate in a permitted hazardous waste incinerator.

What to do with Ink Spills on Persons

Safety Information |

• Eye contact: immediately flush eyes with large amounts of water. Get

immediate medical attention.

• Skin contact: flush skin with large amounts of water. If irritation persists,

get medical attention.

• Inhalation: remove person to fresh air. If not breathing, get immediate

medical attention and give artificial respiration. If breathing is difficult, get

immediate medical attention.

• If swallowed: call a physician immediately. Only induce vomiting at the

instructions of a physician. Never give anything by mouth to an

unconscious person.

IR Heater

Two infared heaters mounted on the gantry are used to dry the ink during printing. Each

heater has two 3kw elements. The printer uses 3 of the 4 possible elements thus

providing a maximum of 9kw of heat. The carriage passes under the heater and has a

protective cover that reflects heat. The heater operates automatically and does not

require operator intervention.

Caution:

Keep hands clear of the heater assembly. This area will be hot during

and right after printing.

3/10/03 1-5

Océ | T220 Product Overview

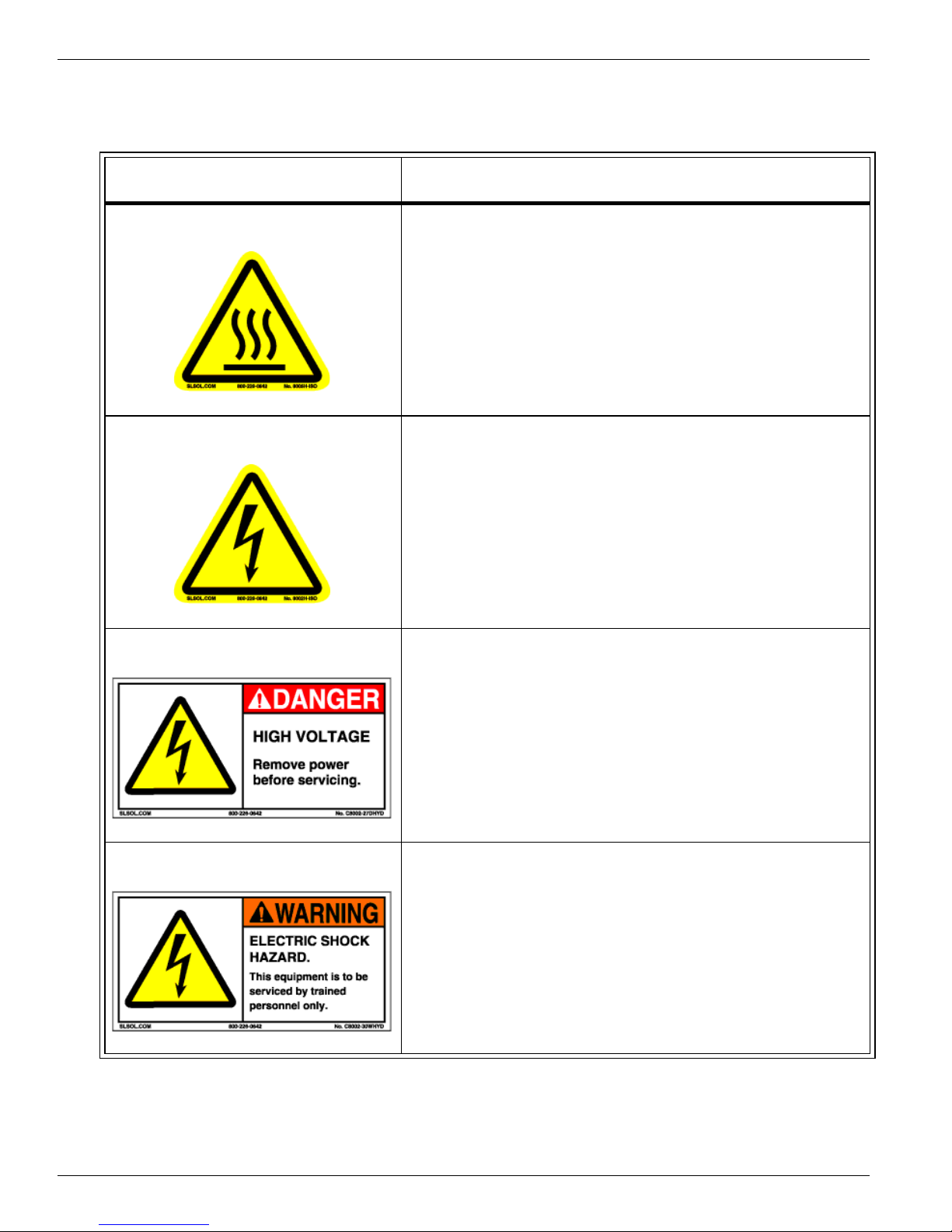

1.2.1Safety Labels

Table 1 Safety Labels

Label Description

Burn Hazard

Shock Hazard

Located on the heater assembly at the Home

end of the gantry. Entire gantry area is hot

during and after printing.

Located on the heater assembly at the Home

end of the gantry. Area is heated by electricity

and is a potential shock hazard.

DANGER High Voltage Remove power before servicing

Located inside the electronics enclosure. AC

power cable should be disconnected before

servicing any electrical components.

Electric Shock Hazard This equipment is to be serviced by

trained personnel only

Located on the door to the electronics

enclosure. This door must be kept locked and

only opened by a trained technician.

1-6 3010100686-A

Safety Information |

Table 1 Safety Labels

Label Description

Voltage Warning Before connecting Power Supply Cord to the unit,

Befor e connecting Power

Supply Cord to the unit, refer

to the installation instruction

to determine proper In put

!

Voltage Configuration.

refer to the installation instruction to determine

proper Input Voltage Configuration.

See Technical Service Manual Part 2

“Installation and Setup”.

Grounding Warning WARNING HIGH LEAKAGE CURRENT EARTH

CONNECTION ESSENTIAL BEFORE

WARNING

CONNECTING SUPPLY.

!

Pinch Point

Crush Hazard

Located above the AC power cable.

Located on the bracket endplate and the plateend cap.

Located on the gantry end covers.

3/10/03 1-7

Océ | T220 Product Overview

Table 1 Safety Labels

Label Description

Danger Crush Hazard Keep hands clear while operating.

Warning Moving Gantry German Translation:

Lock out power before servicing.

Located on the endplate of the gantry where

the carriage rests on the capping station.

WARNUNG

BEWEGLICHE MASCHINENTEILE

Located on the table to identify the risk

involved with the gantry moving during

printing.

1-8 3010100686-A

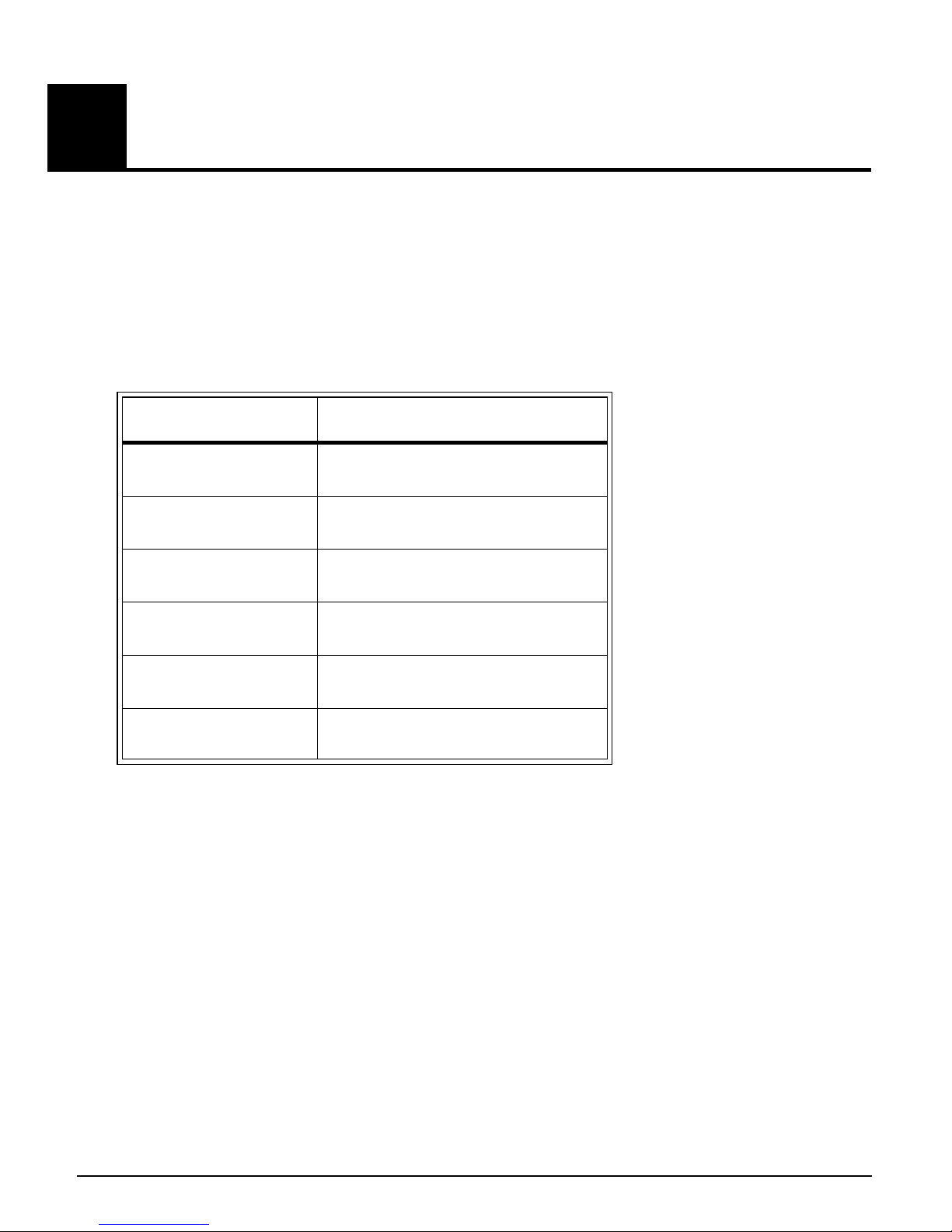

2 Ink System Management

2.1Océ Ink

The Arizona T220 uses solvent-based pigmented inks including Cyan (C), Magenta

(M), Yellow (Y), Black (K), Light Magenta (LM), and Light Cyan (LC). The ink is

supplied in 0.95 liter (32 ounce) bottles. The Océ ink part numbers, which are

necessary for ordering more ink, are provided in the following table:

Table 2

Ink Océ Part #

Black

Cyan

Magenta

Yellow

Light Cyan

Light Magenta

2.2Solvent

3012000180

3012000181

3012000182

3012000183

3012000184

3012000185

The T220 use CGS 80 (part #3000-0057) solvent as a maintenance solution.

Important: See “Safety Information” on page 4 before handling solvent or ink.

3/10/03 2-9

Océ | Ink System Management

2.3Changing an Ink Bottle

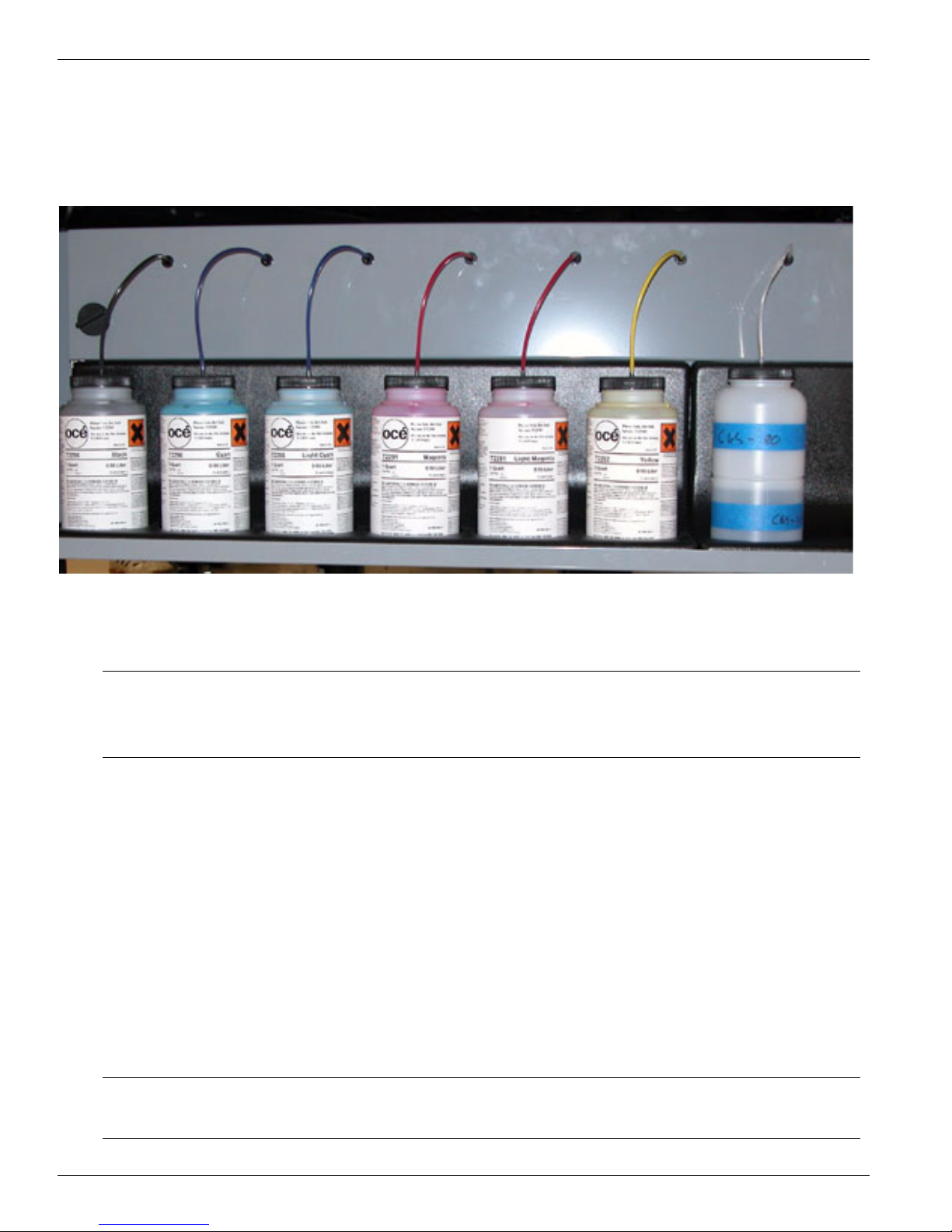

The ink bottles are located on the Ink Station tray. Ink levels for each bottle are

monitored by sensors. Low ink levels are indicated on the control panel.

Figure 2 Ink Station showing Ink Bottles

Important: To reduce the chance of poor image quality, do not shake the ink supply

bottles before installation or during printing. This may introduce air

bubbles into the ink supply system.

When the control panel displays an “XXX ink low” message, that particular ink should

be replaced. Ink can be replaced at any time, with one exception — Do NOT replace inks

immediately after a purge since the ink pumps may be activated at that time. To replace

an ink bottle:

1. Unscrew the lid on a new ink bottle and remove the silver sealing foil;

2. Unscrew the lid on the empty ink bottle and unplug the coupler. Note that the lid

stays attached to the ink line and coupler. Put the old bottle aside and immediately

place the coupler into the new ink bottle by pushing the flange all the way into the

ink pick-up insert;

Important: Ensure that the coupler is fully inserted into the ink pick-up insert to

prevent air being drawn into the ink line when the pump is on.

2-10 3010100686-A

Changing an Ink Bottle |

3. Place the attached lid on the new ink bottle and screw it on tightly;

Caution:

Do not use the residual ink to top up the ink in another bottle as this

will introduce contaminants that collect at the bottom of the bottle.

4. Dispose of the used ink in an environmentally friendly manner.

Warning:

Océ Display Graphics Systems accepts no liability when non-Océ ink

is used. Customers using non-Océ ink assume all risk of damage that

might result. Customer agrees to waive any claims or rights they may

otherwise have against Océ Display Graphics Systems or its agents for

damage and/or loss of business resulting from use of non-Océ ink.

5. Press ACCEPT on the control panel to enter the type of color and begin printing.

3/10/03 2-11

Océ | Ink System Management

2.3.1Refilling the Solvent Bottle

Solvent is used to maintain the capping station. The solvent supply bottle is located on

the end of the ink station tray, to the right of the ink bottles. A sensor monitors the

solvent level in the bottle. A low solvent level causes a message to display on the control

panel.

Figure 3 Ink Station tray showing Solvent Bottle

Refill the solvent bottle when the control panel indicates the solvent is low. Top up the

solvent bottle if the printer is to be left unattended longer than overnight. To refill the

solvent bottle:

1. Unscrew the lid and remove the coupler. Remove the solvent bottle from the Ink

Station Tray before filling. This prevents spilling of solvent on the painted metal

surfaces or the solvent level sensor;

Note: Tapping the sides of the lid on a new 1 gallon solvent container will ease the

removal of the lid.

2. Place the funnel (Part #3010100404) into the off-center hole in the ink pick-up

insert inside the solvent bottle and fill the solvent to the level of the shoulder on the

bottle.

3. Set the bottle on the tray and replace the coupler by inserting it fully into the hole in

the lid. Screw the lid back on securely.

2-12 3010100686-A

Changing an Ink Bottle |

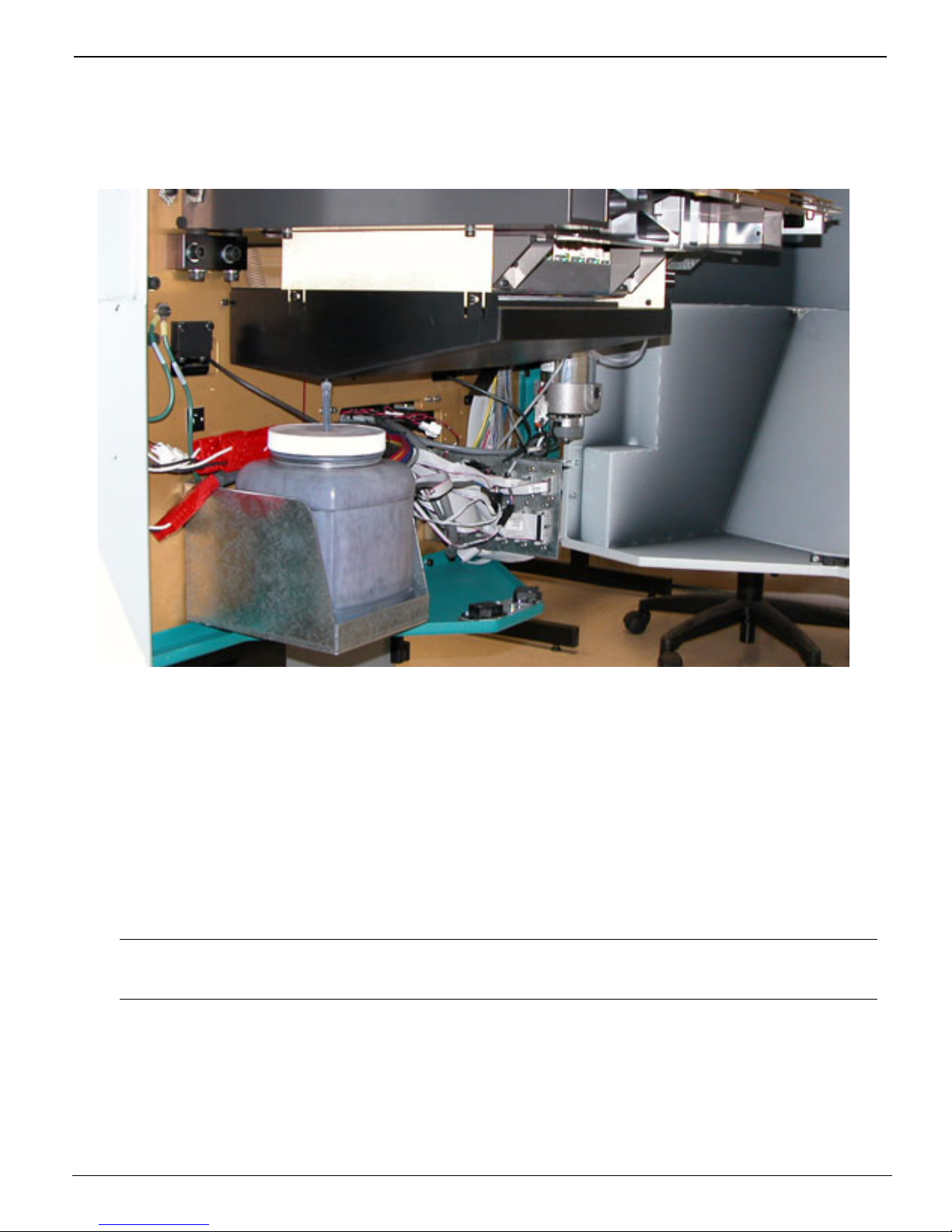

2.3.2Emptying the Waste Bottle

The printer accumulates waste that is made up of ink and solvent. The waste bottle is

located in the right side of the gantry beneath the capping station. A sensor monitors the

waste level in the bottle, and a high level is reported on the control panel.

Figure 4 Gantry Doors Open Showing Waste Bottle

The waste bottle should be emptied when the control panel indicates that the waste bottle

is almost full. To empty the waste bottle:

1. Remove the drainage tube from the lid of the waste bottle;

2. Remove the waste bottle from the bracket and pour the waste into a suitable

container for disposal. Dispose of waste in accordance with local laws or as directed

in the MSDS sheets — See “Safety Information” on page 4.

Note: If you need to replace the waste bottle container with a new one, or if you

require a spare bottle, order part # 3010100266.

3. Replace the empty container by fitting it into the bracket;

4. Ensure that the lid is securely screwed on to the waste bottle and finally re-insert the

drainage tube.

3/10/03 2-13

Océ | Ink System Management

2.3.3The Capping Station

The capping station is located in the right end of the gantry. The function of the capping

station is to prevent the printheads from drying out when not in use. The capping station

is essentially a tray supporting 24 solvent saturated foam pads, one for each printhead.

The tray also provides drainage for excess ink and solvent. Excess ink and solvent are

collected under the capping tray and funneled into the waste bottle. While capped, each

printhead’s nozzle plate comes in contact with a solvent-saturated foam pad. Solvent is

automatically pumped up to the tray at regular intervals to ensure all the pads are suitably

soaked.

Figure 5 Capping Station

2-14 3010100686-A

Loading...

Loading...