Oce Arizona 640 GT, Arizona 640 XT, Arizona 660 GT, Arizona 660 XT User Manual

User Guide

Océ Arizona 600 Series

Océ Arizona 640/660 GT/XT, Revision 3010119679

Copyright

© 2015, Océ

All rights reserved. No part of this work may be reproduced, copied, adapted, or transmitted in

any form or by any means without written permission from Océ.

Océ makes no representation or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of merchantability or fitness for any particular purpose.

Furthermore, Océ reserves the right to revise this publication and to make changes from time to

time in the content hereof without obligation to notify any person of such revision or changes.

Edition #3010119679

US

Contents

Chapter 1

Introduction.........................................................................................................................7

Preface...............................................................................................................................................................8

Product Compliance....................................................................................................................................... 11

Chapter 2

Product Overview............................................................................................................. 15

Printer Specifications..................................................................................................................................... 16

Chapter 3

Safety Information............................................................................................................19

UV Ink and Flush.............................................................................................................................................20

UV Curing System ......................................................................................................................................... 22

Safety Interlock System................................................................................................................................. 23

Océ Arizona 600 Series Safety Labels.......................................................................................................... 24

Safety Awareness...........................................................................................................................................27

Roll Media Safety Awareness........................................................................................................................35

Chapter 4

How to Navigate the User Interface............................................................................... 37

Operator Interface Hardware.........................................................................................................................38

Printer Interface Software..............................................................................................................................40

Print Job Control Module.............................................................................................................................. 42

Periodic Maintenance.....................................................................................................................................50

Counters Module............................................................................................................................................ 52

Settings Module............................................................................................................................................. 53

Tools and Utilities Module.............................................................................................................................56

Installation and Upgrade Module................................................................................................................. 59

Chapter 5

How to Operate Your Océ Arizona Printer..................................................................... 61

Training Requirements.................................................................................................................................. 62

How to Power ON...........................................................................................................................................63

How to Power Off.....................................................................................................................................64

How to Prepare the Printer for Idle Periods........................................................................................... 65

How to Lock Out the Power Switch........................................................................................................ 66

How to Manage Print Jobs............................................................................................................................ 67

Daily Start-up and Shut-down - Start-up Procedure............................................................................. 67

Daily Start-up and Shut-down - Shut-down Procedure..................................................................67

How to Set Up a Print Job.......................................................................................................................68

How to Manage the Media Vacuum............................................................................................................. 71

The Table Vacuum System..................................................................................................................... 71

Using Vacuum Zones - Metric Zones..................................................................................................... 74

Print the Metric Zone Map................................................................................................................ 75

Imperial Vacuum Zones.................................................................................................................... 76

Print Imperial Zone Map................................................................................................................... 77

How to Manage Media...................................................................................................................................78

How to Handle Media.............................................................................................................................. 78

Contents

3

Océ Arizona 600 Series

Chapter 6

How to Operate the Océ Arizona 600 Series XT............................................................81

Océ Arizona 600 Series XT Features.............................................................................................................82

How to Use the Océ Arizona 600 Series XT Vacuum System.................................................................... 84

How to Print With Dual Origins..................................................................................................................... 86

Chapter 7

How to Operate the Roll Media Option.......................................................................... 89

Roll Media Option Hardware......................................................................................................................... 90

Roll Media Option Specifications..................................................................................................................92

Foot Pedal Switch Functions......................................................................................................................... 93

Roll Media Manager....................................................................................................................................... 94

How to Load Media........................................................................................................................................ 96

Loading the Media - Standard Method.................................................................................................. 98

Loading the Media - Alternate Method ............................................................................................... 101

How to Unload and Remove Media............................................................................................................103

How to Set Up a Roll Media Job................................................................................................................. 104

Set a Hold on a Roll Job........................................................................................................................ 104

How to Print on Roll Media .........................................................................................................................106

How to Determine the Media Advance Correction Factor........................................................................ 109

How to Use Media Edge Protectors............................................................................................................ 111

Chapter 8

How to Use the Static Suppression Option................................................................. 115

Reduce Static with the Static Suppression Option....................................................................................116

How to Change the Height of the Bar...................................................................................................117

Chapter 9

How to Work With White Ink and Varnish................................................................... 119

Operator Guidelines for White Ink and Varnish.........................................................................................120

White Ink Workflow Overview.....................................................................................................................121

Varnish Workflow Overview........................................................................................................................124

Configure ONYX Software for White Ink / Varnish....................................................................................126

White Ink and Varnish ONYX Media Profiles............................................................................................. 128

How to Prepare White Ink/Varnish Print Jobs............................................................................................130

Select the Best Workflow...................................................................................................................... 130

How to Setup a Printer Flood Fill..........................................................................................................131

How to Create Spot Data with the Spot Layer Tool............................................................................ 132

How to Access the Spot Layer Tool............................................................................................... 134

How to Create Spot Data in Photoshop............................................................................................... 136

How to Prepare Spot Data in Adobe Illustrator................................................................................... 139

How to Overprint Spot Data in Illustrator......................................................................................141

How to Place Raster Images in Illustrator .....................................................................................144

How to Create a Spot Channel Path in Illustrator......................................................................... 145

How to Set Up a File for Preflight's Spot Layer Tool....................................................................147

How to Name Your Spot Data in Illustrator...................................................................................148

White Ink QuickStart.....................................................................................................................................150

How to Print White Ink Jobs........................................................................................................................ 152

Varnish QuickStart........................................................................................................................................156

How to Print Varnish Jobs........................................................................................................................... 158

How to Get Good Results With Varnish..................................................................................................... 160

Chapter 10

Ink System Management............................................................................................... 165

Arizona Printer Inks as of 2015.................................................................................................................... 166

How to Change Ink Bags..............................................................................................................................170

Contents

4

Océ Arizona 600 Series

Chapter 11

Error Handling and Troubleshooting............................................................................ 173

Troubleshooting Overview.......................................................................................................................... 174

How To Improve Quality When Banding Occurs.......................................................................................176

Chapter 12

Printer Maintenance....................................................................................................... 177

Maintenance Guidelines.............................................................................................................................. 178

Maintenance Procedures............................................................................................................................. 180

Clean Carriage Underside..................................................................................................................... 180

How To Perform Printhead Maintenance.............................................................................................183

How to Print a Nozzle Check........................................................................................................... 187

How to Evaluate a Nozzle Check.................................................................................................... 188

Printhead Maintenance - How to Correct Nozzle Dropouts......................................................... 189

Printhead Maintenance - Maintenance for Select Printheads......................................................190

Swab Printheads.................................................................................................................................... 191

How to Clean the UV Lamp Filter......................................................................................................... 194

How to Remove Ink from the Table......................................................................................................196

Empty the Ink Waste Tray..................................................................................................................... 198

Fill the Coolant Reservoir ..................................................................................................................... 199

Replace the Spit Catcher Foam Pad..................................................................................................... 201

Clean Gantry Rails..................................................................................................................................203

How to Change Ink Filters..................................................................................................................... 205

How to Bleed an Ink Filter .................................................................................................................... 208

How to Change a UV Lamp Bulb.......................................................................................................... 211

How to Remove the UV Lamp Bulb .............................................................................................. 213

How to Replace the Lamp Bulb...................................................................................................... 215

How to Replace the Lamp Housing................................................................................................216

How to Maintain White Ink....................................................................................................................217

Roll Media Option Maintenance..................................................................................................................218

RMO Maintenance Guidelines.............................................................................................................. 218

How to Clean the Rubber Capstan........................................................................................................219

How to Remove Uncured Ink on the Capstan............................................................................... 220

How to Remove Stains (coffee, tea, soda pop, etc.)..................................................................... 223

Appendix A

Application Information................................................................................................. 225

Application Resources on the Web Site..................................................................................................... 226

Index.................................................................................................................................229

Contents

5

Océ Arizona 600 Series

Contents

6

Océ Arizona 600 Series

Chapter 1

Introduction

Preface

Introduction

This manual provides the operator with information about the following Océ Arizona 600 Series

UV flatbed inkjet printers:

• Océ Arizona® 640 GT/XT

• Océ Arizona® 660 GT/XT

The operational features of these printer models are similar. The XT models have a larger table

than the GT models. The main functional differences between models are based on the number

of printheads and therefore the available channels for ink and varnish. The table below provides

an indication of the possible ink and varnish output that each model is capable of supporting.

Océ Arizona 640 GT/XT

4 channel CMYK

Océ Arizona 660 GT/XT 6 channel CMYKWW

CMYKWV

CMYKCM

This manual uses the terms Océ Arizona 600 Series GT or Océ Arizona 600 Series XT to refer to

these printers generally. The specific model printer name will depend on the configuration

selected. Also, the 4 channel printer can be upgraded to 6 channels.

This manual orients you to the many features and procedures that allow you to print professional

quality images on various media with these printers.

Multi-Language Support

The printer's user interface software supports multiple languages. To select your preferred

language and other setup information, refer to the Settings Module in Chapter 4.

This manual is also available in other languages. Printers are shipped with a printed copy of the

US English version. You can download a PDF file of the manual in all of the languages that we

support from the Customer Support web site: http://dgs.oce.com/

Supported languages:

• English

• Dutch

• German

• French

• Spanish

• Italian

• Portuguese

• Japanese

• Chinese

Océ DGS on the Internet

For further information on documentation and support for your printer or for information on

other Océ Display Graphics Systems products, please visit our web site: http://www.dgs.oce.com

To provide feedback and report errors in this document: dgstechnical.writer@oce.com

Preface

8

Chapter 1 - Introduction

Océ Arizona 600 Series

Safety Information

This manual has three sections that contain details on safety when handling ink and using the

printer. Also, where applicable, cautions and warnings are used throughout this manual to draw

your attention to safety precautions.

• "Safety Guidelines for Ink Materials" offers advice in the proper handling of UV inks;

• "Interlock Safety System" explains the safety features built in to the printer that prevent and

minimize access to Mechanical, Electrical, Thermal and UV hazards; and

• "UV Curing System Safety" presents warning about the dangers of exposure to UV light. Some

of the material from that section are duplicated here.

Customer Service

If your printer malfunctions and you are unable to resolve the problem, field service technicians

can be dispatched to your site to conduct repairs. Service visits are paid for by the customer,

either under a maintenance agreement, by purchase order or prepayment. Time and material

rates are charged for any service not covered under a maintenance agreement. Before calling to

report a problem, gather as much information about the problem as possible and have it ready to

provide to your customer care center. The more information you can provide initially, the more

quickly the problem can be corrected.

Statement of Foreseen Use

The Océ Arizona flatbed inkjet printers are intended for use in a commercial print shop

environment. Factory-authorized training is made available for operators at the time of

installation. The printers use piezo printing technology and UV curable inks to produce outdoordurable output. They can print directly onto rigid and flexible media of up to 50.8mm (2.0 inch)

thickness. The printer holds the media stationary while the printhead assembly moves across to

create the print, eliminating image skew problems often associated with rigid stock feed systems.

With the Roll Media Option installed the printers can also print on various roll media. See your

local representative or visit the Océ Media Guide for more details on recommended media.

http://mediaguide.oce.com/

Responsibilities of the Operator

The printer operator must be properly trained. Océ provides training for the operator in the use of

the printer hardware and software at the time of installation. It is the customer's responsibility to

ensure that only properly trained personnel operate the printer. Operators must be fully versed in

the operation of ONYX Thrive® or ProductionHouse® . For any operator unfamiliar with these

applications, ONYX training is required. Training courses are available; contact your local Océ

representative.

The operator or other trained personnel are expected to handle all user maintenance as detailed

in the User Manual, and also replacement of consumable parts (except print heads). If your site

has a technician in charge of printer maintenance, that person is the optimal candidate. While any

trained operator may perform routine maintenance, the best maintenance results from familiarity

with the printer's internal operation and history.

The printer requires daily printhead maintenance to ensure the highest print quality and longer

life for the printheads. The printer design provides you easy access to perform this simple task

and it is essential that printhead maintenance is performed at least once a day, and more

frequently if needed. Periodic cleaning must be scheduled for some components on a regular

basis. A few minutes spent cleaning also helps to ensure optimal printer function and the highest

quality prints.

Preface

Chapter 1 - Introduction

9

Océ Arizona 600 Series

It is the responsibility of the operator to try to eliminate simple problems before calling a service

representative. But knowing when to call for service is also important. An untrained operator

must not attempt to service the printer as this may cause further damage. When you have

determined that a service call is required, call as soon as possible. See the Troubleshooting and

Maintenance sections for more details.

Responsibilities of the Service Technician

Field service technicians must have Océ Display Graphics Systems service training. The service

technician is responsible for all repairs, upgrading and modification requested by the customer or

mandated by the Océ Display Graphics Systems Service and Support Group. The service

technician who installs the printer will also provide training for the operator that covers all of the

basic skills required to operate the printer. Service personnel are furnished with proper tools for

the installation and maintenance of the printer. In addition to the tools and custom kits, each

engineer will have basic tools for proper maintenance and servicing.

Preface

10

Chapter 1 - Introduction

Océ Arizona 600 Series

Product Compliance

Introduction

This section provides important information about EMC and FCC compliance for the Océ Arizona

600 Series GT and Océ Arizona 600 Series XT. It also provides printer manufacturing and contact

information and a list of any toxic or hazardous material in the printer.

MSDS (Material Safety Data Sheets) and PSDS (Personal Safety Data Sheets) are provided for the

safety and convenience of all customers and anyone involved in use and handling of the printers,

inks and related materials. The MSDS and PSDS for current and recent Océ Arizona products are

available from the GEM website: http://global.oce.com/support/.

Electromagnetic Compliance (EMC)

FCC Statement for Class A Device:

This equipment generates, uses and radiates radio frequency energy and if not installed and used

as designed or intended, may cause interference to radio communications. This equipment has

been tested and found to comply with the limits for a Class A computing device. This equipment

has been designed to provide reasonable protection against such interference when operated in

residential and commercial environments. Operation of this equipment in a residential area may

cause interference, in which case the user, at his own expense, is required to take whatever

measures are required to correct the interference.

FCC Notice: This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1) This device may not cause harmful interference, and

2) This device must accept any interference received, including interference that may cause

undesired operation.

Any change or modification not expressly approved by the manufacturer could void the user's

authority to operate the equipment.

This device contains an intentional radiator (RFID)

Radio Certificate Number: IC:6497A-3010105668

FCC Identifier: U2P-3010105668

Product Safety

The CE Declaration of Conformity document is provided for your convenience.

[1] CE Declaration of Conformity

Product Compliance

Chapter 1 - Introduction

11

Océ Arizona 600 Series

Marking Declaration Table China Pollution Act

Toxic and Hazardous Substances or Elements in the Product

Part Name Lead (Pb) Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

(CrVI)

Polybromi‐

ated bi‐

phenyls

(PBB)

Polybromi‐

nated dipe‐

nylether

(PBDE)

Curing Lamp

UV

0 X 0 0 0 0

Inkjet Heads X 0 0 0 0 0

O: indicates that the content of the toxic and hazardous substance in all the homogeneous

materials of the part is below the concentration limit requirement as described in SJ/T11363-2006.

Product Compliance

12

Chapter 1 - Introduction

Océ Arizona 600 Series

X: indicates that the content of the toxic and hazardous substance in at least one homogeneous

material of the part exceeds the concentration limit requirement as described in SJ/T11363-2006.

Manufacturer:

Océ Display Graphics Systems

13251 Delf Place - Building #406

Richmond, British Columbia

Canada V6V 2A2

Telephone +1 604)273-7730 - Fax +1 604 273-2775

E-mail: dgsinfo@oce.com

Representative Marketing the Océ Arizona 600 Series in Europe:

Océ Technologies B.V.

St. Urbanusweg 43,

Venlo, The Netherlands, 5900 MA Venlo

Telephone: 31 77 359 2222

Fax: 31 77 354 4700

E-mail: info@oce.com

Product Compliance

Chapter 1 - Introduction

13

Océ Arizona 600 Series

Product Compliance

14

Chapter 1 - Introduction

Océ Arizona 600 Series

Chapter 2

Product Overview

Printer Specifications

Introduction

The Océ Arizona 600 Series GT and Océ Arizona 600 Series XT are flatbed inkjet printers capable

of producing large format images on various rigid and flexible media. The printers consist of a

flatbed vacuum table and moving gantry. Media is held flat and stationary on the vacuum table

during printing. The gantry contains a carriage that sweeps across the table as the gantry moves

in steps along the length of the table to print an image on the media. A Roll Media Option is

available to facilitate printing on roll media.

Illustration

[2] Arizona GT Printer with RMO

Printer Specifications

The printer must be operated in accordance with the environmental conditions specified in the

Océ Arizona Site Preparation Guide. Also note that there are many safety requirements and

precautions indicated in this document. Be sure to read all of the safety sections before using

your printer.

NOTE

All specifications in this document are subject to change without notice. While due caution has

been exercised in the production of this document, possible errors and omissions are

unintentional.

Specifications

Feature

Specification

Printing Technology Piezoelectric inkjet with Océ VariaDot™ technology

Maximum Media Size GT models: 2.5m (98.4") x 1.25m (49.2")

XT models: 2.5m (98.4") x 3.05m (120.1")

Media Thickness Maximum: 50.8 mm (2.0")

Maximum Print Size GT models: 2.51m (98.8") x 1.26m (49.6")

XT models: 2.51m (98.8") x 3.06m (120.5")

4

Printer Specifications

16

Chapter 2 - Product Overview

Océ Arizona 600 Series

Feature Specification

Media Weight Maximum: 34 kg/m² (7 lbs/ft²)

Nozzle Drop Volume: Variable droplet sizes: 6 to 42 picolitres

User Interface LCD flat-panel monitor and mouse on a user positioned podium.

Curing System UV curing lamps with variable power settings.

Power Requirements

Voltage:

(Rated Current: 16A)

208 through 240VAC ±10% 60Hz Single Phase

200 through 240VAC ±10% 50Hz Single Phase

Current: 2 AC lines -16A

Recommended Circuit Breaker:

North America 20A, European Union 16A.

BTU Output 10,000 BTU (2950 watts) under continuous operation.

Hardware Interface USB, Ethernet TCP/IP, 100 base-T (or Gigabyte, if supported by the

local network).

Image Processing Software THRIVE® (preferred) or ONYX® ProductionHouse Océ Edition ver-

sion X10.

Printer Specifications

Chapter 2 - Product Overview

17

Océ Arizona 600 Series

Printer Specifications

18

Chapter 2 - Product Overview

Océ Arizona 600 Series

Chapter 3

Safety Information

UV Ink and Flush

Introduction

The safety concerns involved with the handling and use of the UV ink and Flush are detailed in

the Material Safety Data Sheet (MSDS) documents. Review them before handling any UV ink or

flush.

NOTE

The MSDS for all UV inks and Flush are available from the corporate Océ website. For the latest

MSDS and PSDS, visit: http://global.oce.com/support/

CAUTION

UV inks can be harmful if not properly handled. Follow the MSDS guidelines carefully in order

to ensure maximum safety. The information below is a summary of the MSDS documents

published by the UV ink manufacturer.

UV Ink Personal Safety

The operator must wear nitrile gloves, a protective apron, and safety glasses with side shields

when handling inks. Read and practice safety guidelines as outlined in the MSDS for each ink.

Post these documents in the work area as required by prevailing law. MSDS are provided with all

inks and flush when you purchase them.

Chemicals in UV ink begin to permeate nitrile gloves in less than 10 minutes. While this action

may not be visible, changing contaminated gloves should occur every few minutes. These

penetrating chemicals have no pigment so they are not visible; therefore just because you don’t

have pigment on the glove or your skin doesn’t mean that exposure has not occurred.

Latex gloves may appear to be robust but provide no protection at all. They only temporarily stop

UV pigment penetration while allowing the invisible harmful chemicals to pass through, where

they are trapped next to the skin, improving contact and associated risk.

Océ recommends that only nitrile gloves, which have been checked for chemical resistance and

approved by the Océ Occupational Health and Safety department, are used. At present, this

includes only the Ansell Touch N Tuff gloves, 92-600 for smooth or 92-605 for textured. Use the

gloves one time only, and replace them immediately if they are punctured or degraded. Never reuse contaminated gloves once they are removed.

CAUTION

Always use Nitrile gloves when working with UV curing inks. If you get ink on your skin, wash

it off with mild soap and water. Never use alcohol to remove UV ink from your skin as this will

transport the chemicals more easily through your skin and into your body. Hands should be

inspected on a regular basis for any signs of skin damage or inflammation.

Disposal of UV Ink

All waste containing uncured or partly cured UV ink is hazardous and must be disposed of

separately according to local regulations. Do not mix ink waste with non-hazardous waste

(household, office, etc). Do not allow it to reach sewage systems or drinking water supplies. Ink

waste includes maintenance pads and cloths, gloves and any other material containing uncured

or partly cured UV ink. Disposal must be made according to official local regulations.

UV Ink and Flush

20

Chapter 3 - Safety Information

Océ Arizona 600 Series

UV Ink Misting - Carriage Height Warning

Always measure the thickness of the media in use and set the carriage height correctly for that

media. Avoid printing at a height greater than measured as this causes excessive emissions of

UV light and ink mist.

UV Ink and Flush

Chapter 3 - Safety Information

21

Océ Arizona 600 Series

UV Curing System

Introduction

UV-curable ink need a high energy level of UV light to cure. The UV curing system is made up of

two mercury arc lamps attached to the carriage.

How to Handle UV Lamp: UV lamps operate at high temperatures. Never touch a lamp in

operation. Let the lamps cool for a minimum of five minutes before attempting any maintenance.

Use extreme care in handling the UV lamp bulbs. The UV bulbs contain a small amount of

metallic mercury which is toxic when ingested, handled, or breathed. Therefore, if bulbs are

broken, care should be taken to clean up the spill immediately, and then disposed of according to

local regulations concerning Mercury disposal.

Bare skin contact with the UV lamp bulbs must be avoided. When heated, compounds from the

skin can form permanent etching on the surface of the UV bulb. A contaminated bulb may fail

prematurely.

Ozone: As a UV lamp warms up, it briefly passes through a section of the light spectrum which

excites oxygen molecules enough to create ozone. Once a UV lamp has completely warmed up,

only very minute amounts of ozone are present.

NOTE

A high concentration of ozone can cause irritation, headaches or nausea. Provide adequate

ventilation as indicated in the Site Preparation Guide.

CAUTION

Warning for Seated Individuals: UV emissions are highest at a height of 90 cm (35 inches) above

the floor. This can be an issue for individuals seated near the printer.Remove all chairs within 5

meters (16 feet) of the printer.

IMPORTANT

The UV Lamps contain Mercury. Dispose according to local environmental regulations.

Personal Safety

UV Light Emissions can be harmful:

Protective measures are essential in the workplace. Use the UV safety glasses with side shields

supplied with the printer. Wear appropriate clothing that protects the skin from UV light

exposure. Keep a distance of at least 1 m (3 ft) from UV lamps while printing.

NOTE

Wear Industrial Protective Eyewear with lenses that block both UVA and UVB. Gloves and longsleeved work clothes are essential to reduce the skin's exposure to UV emissions.

UV Curing System

22

Chapter 3 - Safety Information

Océ Arizona 600 Series

Safety Interlock System

Introduction

The printer has three Emergency-Stop buttons. The Maintenance Station drawer is part of the

safety interlock system. A beacon light indicates the status of the safety system and the printer.

Components of the Interlock System

Emergency Stop Buttons:

These are located on the Operator Control Station, and on each end of the Gantry. Activating an

Emergency-Stop button stops all printer motion and turns off the UV curing system.

To re-activate the printer after you press an Emergency Stop button, turn the button counterclockwise. Upon release of the button, no motion can be initiated without acknowledgment of the

Operator from the Control Station.

Maintenance Station Interlock Function:

The Maintenance Station is located under the carriage and provides access to perform Printhead

Maintenance and swab printheads. Carriage and Gantry motion motors are disabled and UV

lamps are turned off (if they were On), when the station drawer is open. The Interlock system is

automatically reset when the drawer is closed.

Beacon Light Status

A green beacon light is mounted to the top surface of the printer carriage. The purpose of this

light is to indicate basic printer status to the operator.

Beacon off: indicates the printer can be approached without caution. The machine cannot initiate

movement since the interlock Safety System has disabled all motion and hazardous hardware.

Beacon on: indicates the printer is powered up and ready to initiate motion. This tells an operator

to approach the machine with caution, because it can initiate motion at any moment.

Safety Interlock System

Chapter 3 - Safety Information

23

Océ Arizona 600 Series

Océ Arizona 600 Series Safety Labels

Introduction

The safety labels are placed at strategic locations on the printer to warn the operator of possible

dangers and hazards. It is important to be aware of the meaning of these labels to ensure safe

operation of the printer.

CAUTION

Read and understand all of the safety label descriptions in the table below before operating the

printer.

Safety Labels

Safety Labels

Description Label

Warning: UV Light Hazard.

Avoid looking directly at UV lamps.

Located on carriage cover to remind the operator that

looking at the UV light source is dangerous.

Wear protective eye-wear with side shields, gloves and

long sleeves when using this printer.

Ultraviolet Light Radiation Hazards Emission: Effective UVirradiance Emission Category according to 7.1 of

EN12198-1:2000 - - Special restrictions and protective

measures are essential when the machine is used in the

workplace.

Wear Safety Gloves

Located on the maintenance station as a reminder to always wear gloves when handling ink.

Risk of Eye Injury. Wear Eye Protection - Located on the

maintenance station as a reminder that the UV-curable ink

is harmful to the eyes and skin. Always wear glasses and

gloves when handling ink.

Machine lockout: a reminder to turn off and lock out the

AC power switch before servicing any electrical components.

Located on the mains power switch.

Warning: Electric Shock Hazard

Located on the door to the electronics enclosure, the UV

lamp power supply cover, the carriage cover, and the vacuum pump enclosure. This area can only be accessed by a

trained service technician.

4

Océ Arizona 600 Series Safety Labels

24

Chapter 3 - Safety Information

Océ Arizona 600 Series

Description Label

General Warning

Located on the AC enclosure cover. This area can only be

accessed by a trained service technician.

Pinch Point

A reminder that horizontal movement of the carriage can

create a pinch hazard as it moves along the gantry.

Located on both ends and the rear of the carriage.

Crush Hazard: Keep hands clear while operating.

A reminder that vertical movement of the carriage can be

a crush hazard if hands or objects are placed in these locations. Located on the maintenance station and both ends

of the gantry.

Thermal Hazard

Radiated heat from the UV lamps can cause burns.

Located on the carriage near the two UV lamps.

Caution: For Continued Protection Against Fire And Elec‐

tric Shock

Replace Only With Same Type and Ratings of Fuse

Caution: Disconnect Power Before Changing Fuse.

Refer to the section "How to Power the Printer On and Off"

[3] Disconnect Power

Electrical Shock Hazard Equipment

Powered by two power cords.

Turn off power switch or remove both power cords before

servicing

Refer to the section "How to Power the Printer On and Off"

[4] Electrical Shock Hazard

Warning: High Leakage Current Earth Connection Essen‐

tial Before Connecting Supply

Refer to the Arizona Printer Site Preparation Guide.

[5] High Leakage Current

Danger: High Voltage

Warning that High Voltage is present behind marked panel.

[6] High Voltage

4

Océ Arizona 600 Series Safety Labels

Chapter 3 - Safety Information

25

Océ Arizona 600 Series

Description Label

Warning: Isolate Power Before Servicing.

Refer to the section "How to Power the Printer On and Off"

and sub-section "How to Lock Out the Power Switch".

[7] Isolate Power

Warning: Line Voltage Always Present

Warning that High Voltage is present behind marked panel

at all times, even when machine is turned off

[8] Line Voltage Present

Warning: Moving Gantry

If the green beacon light on top of the carriage is on, the

gantry may start moving at any time.

[9] Moving Gantry

No Step

Do not step on the table strut. If pressure is put on the table strut it can bend and thus affect the level of the printer

table and therefore print quality.

[10] No Step on Strut

PE - K

GND Protective Earth Identification.

[11] PE-K

Océ Arizona 600 Series Safety Labels

26

Chapter 3 - Safety Information

Océ Arizona 600 Series

Safety Awareness

Introduction

This section contains two sets of principles that must be followed to assure maximum safety

when operating your Océ Arizona printer. The first set uses negative examples to show you

things to avoid in order to prevent injury to the operator. The second set of principles illustrates

some of the residual risks that are inherent in the operation of the printer. These are situations or

physical aspects of the printer that may present a potential danger to the operator, but would

compromise the capabilities of the printer if changed. Therefore, they are pointed out as a

precaution the operator must be aware of when using the printer.

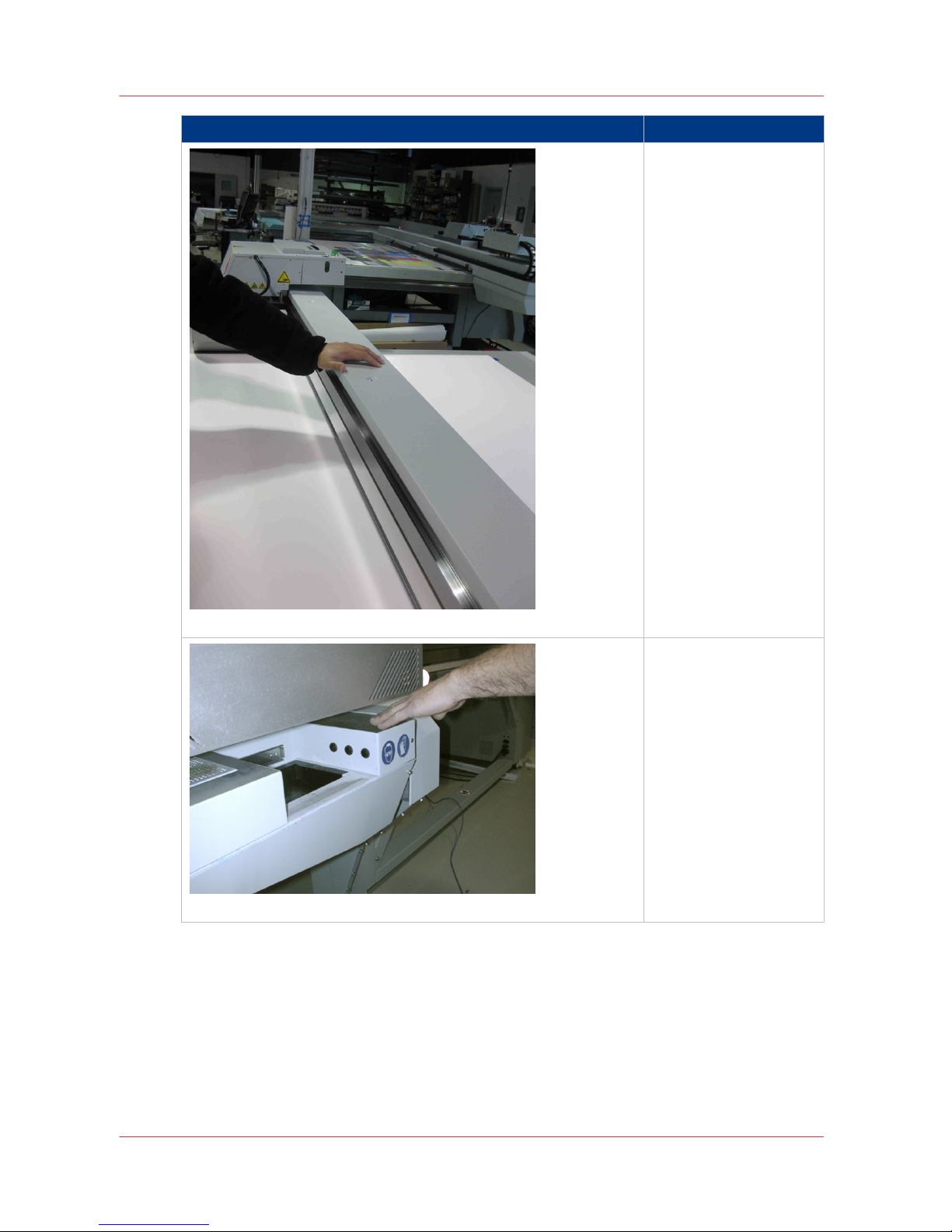

IMPORTANT

The photos in the following table illustrate situations that must be avoided when operating your

printer.

Situations and Actions to Avoid

How NOT to use the printer

Avoid these Situations For Your Personal Safety

[12] Keep the table clear

Do not place your hand

in the carriage pathway

when printer power is

on. Do not leave any objects on the table printing

surface, except for media

that you will print on. Also make sure the media

is 48 mm (1.89 inches) or

less in thickness.

[13] Avoid Carriage Movement

Do not push or force the

carriage to move manually if it is already in

motion. If you do move

the carriage, a Motion Error message will display

and you will have to use

the mouse to click Reset

on the user interface LCD

display.

4

Safety Awareness

Chapter 3 - Safety Information

27

Océ Arizona 600 Series

Avoid these Situations For Your Personal Safety

[14] Do not push gantry

Do not push or force the

gantry to move manually

if it is already in motion.

If you do move the gantry, a Motion Error message will display and you

will have to use the

mouse to click Reset on

the user interface LCD

display.

[15] Hot UV Lamps

When the Maintenance

Station is open to perform printhead maintenance, do not touch the

UV lamp assembly as it

can be hot. Also be

aware that the carriage

will move up or down

when the Raise Carriage

switch is pushed.

4

Safety Awareness

28

Chapter 3 - Safety Information

Océ Arizona 600 Series

Avoid these Situations For Your Personal Safety

[16] Carriage Crush Hazard

Movement of the carriage up and down may

be a crush hazard. Do not

rest your hands in this

area during daily printhead maintenance as this

process causes the carriage to move up and

down.

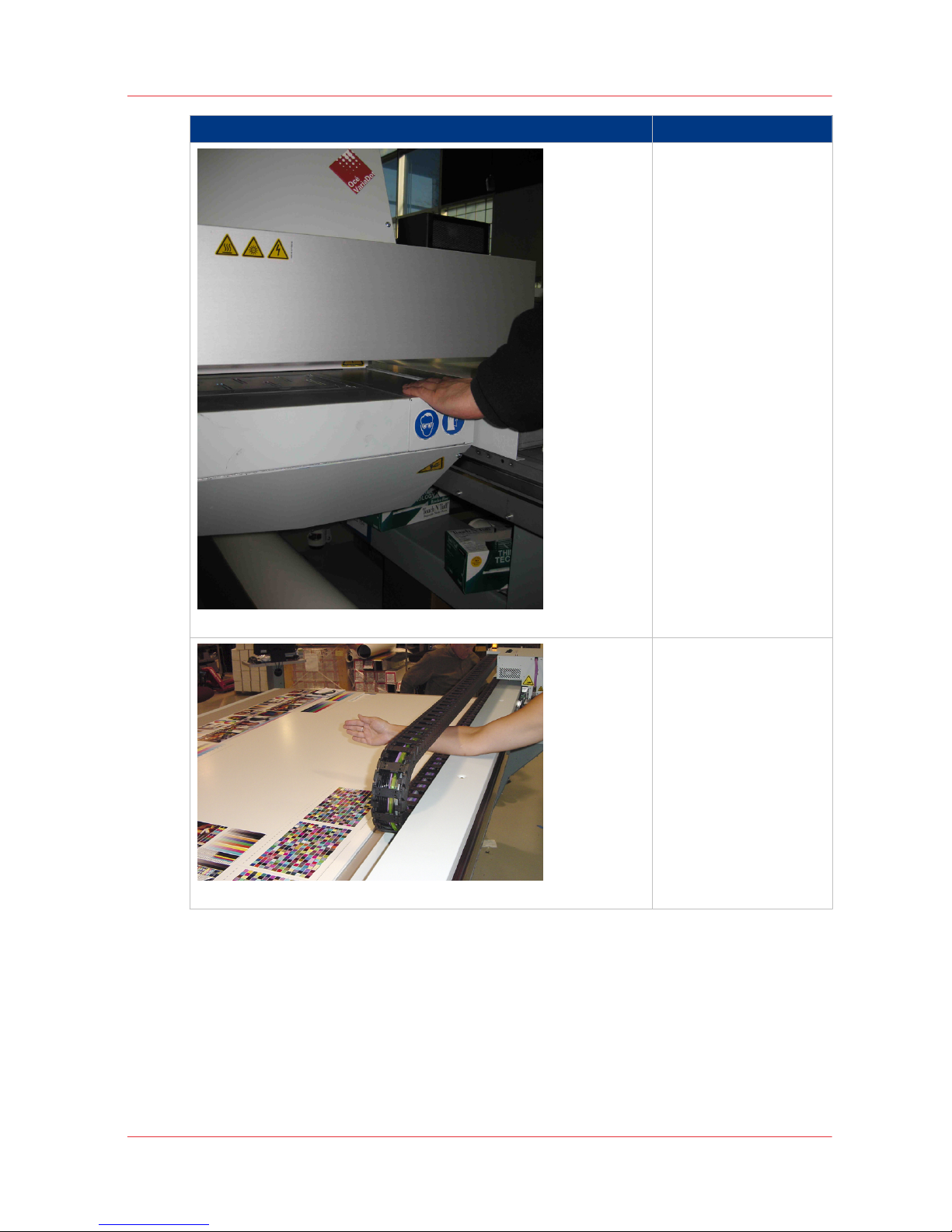

[17] IGUS Hazard

Avoid placing fingers,

hands or other objects in

the IGUS track unless

power is off and the

printer is locked out.

4

Safety Awareness

Chapter 3 - Safety Information

29

Océ Arizona 600 Series

Avoid these Situations For Your Personal Safety

[18] UV Lamp Hazard

Keep a distance of at

least 1 m (3 ft.) to the UV

light when printing.

Avoid looking at the UV

lamps, especially if you

are seated at the same

level as the carriage. Do

not sit within 5 meters

(17 feet) of the carriage

path.

Also do not touch the UV

lamp assembly or the

surrounding guard as

they will be hot and may

result in burns of the

skin.

Residual Safety Risks

Your Océ Arizona printer is engineered to minimize machine components and operating

procedures that may compromise operator safety. However, in order to maintain some machine

operations and functionality, certain compromises are required. The following table documents

some of these residual hazards. By making the operator aware of the potential risks, we hope to

ensure maximum safety in the operation of this printer.

Caution: there may be a time lag between when a print job is issued and when the gantry

movement actually begins as the UV lamps must warm up first. Movement can start many

minutes after a print job is sent.

Arizona Printer Residual Risks

Residual Risk Area Hazard

A high risk crushing hazard is created by the

movement of the carriage and gantry supports. Keep hands away

from this area unless the

printer power is off.

[19] Carriage guard and 45° guard on Gantry Supports

4

Safety Awareness

30

Chapter 3 - Safety Information

Océ Arizona 600 Series

Loading...

Loading...