Oce Arizona 200 GT, Arizona 250 GT, Arizona 300 GT, Arizona 350 GT, Arizona 350 XT User Manual

Océ Arizona 200/250/300/350 GT

User Manual, Version 3.3 Revision A

Océ User Manual

Copyright

© 2009 Océ

All rights reserved. No part of this work may be reproduced, copied, adapted, or transmitted

in any form or by any means without written permission from Océ.

Océ makes no representation or warranties with respect to the contents hereof and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose.

Further, Océ reserves the right to revise this publication and to make changes from time

to time in the content hereof without obligation to notify any person of such revision or

changes.

Edition: 2010 #3010109680

Contents

Chapter 1

Introduction.........................................................................................................7

Preface.........................................................................................................8

Product Compliance.................................................................................11

Chapter 2

Product Overview.............................................................................................21

Printer Specifications...............................................................................22

Chapter 3

Safety Information............................................................................................27

Safety Guidelines for Ink Materials.........................................................28

UV Curing System Safety .......................................................................32

Interlock Safety System...........................................................................34

Océ Arizona 200/250/300/350 GT Safety Labels.....................................36

Safety Awareness.....................................................................................40

Roll Media Safety Awareness.................................................................51

Chapter 4

How to Navigate the User Interface...............................................................53

Operator Interface Hardware...................................................................54

Printer Interface Software........................................................................60

Print Job Control Module........................................................................62

Counters Module......................................................................................71

Settings Module.......................................................................................72

Tools and Utilities Module......................................................................77

Installation and Upgrade Module...........................................................81

Chapter 5

How to Operate the Océ Arizona 200/250/300/350 GT................................83

Training Requirements............................................................................84

How to Power the Printer On and Off.....................................................85

How to Install the Onyx Printer Driver....................................................90

How to Manage Print Jobs......................................................................93

Daily Start-up and Shut-down...........................................................93

How to Set Up a Print Job.................................................................94

How to Manage the Media Vacuum.......................................................98

The Media Vacuum System...............................................................98

How to Handle Media.......................................................................101

How to Create Custom Vacuum Zones...........................................104

How to Manage Media...........................................................................110

3

Contents

How to Handle Media.......................................................................110

Underlay Board to Reduce Artifacts.....................................................113

Chapter 6

How to Operate the Océ Arizona 350 XT.....................................................115

Océ Arizona 350 XT Specifications and Features................................116

How to Use the Océ Arizona 350 XT Vacuum System........................120

How to Print With Dual Origins.............................................................124

Chapter 7

How to Operate the Roll Media Option........................................................127

Roll Media Option Hardware.................................................................128

Roll Media Option Specifications..........................................................131

Roll Media Theory of Operations..........................................................133

Foot Pedal Switch Functions.................................................................136

Roll Media Manager...............................................................................137

How to Load Media................................................................................139

Settings Module.....................................................................................147

How to Unload and Cut Media..............................................................152

How to Set Up a Roll Media Job in ProductionHouse........................154

How to Print on Roll Media ..................................................................156

How to Determine Media Advance Correction....................................160

How to Use Media Edge Protectors......................................................163

Chapter 8

How to Use the Static Suppression Upgrade Kit........................................167

Reduce Static with a Static Suppression Kit .......................................168

Chapter 9

How to Work With White Ink.........................................................................171

Operator Guidelines for White Ink........................................................172

White Ink Workflow Overview...............................................................173

How to Configure ProductionHouse for White Ink..............................176

QuickStart................................................................................................178

How to Prepare White Ink Print Jobs....................................................180

How to Create a White Flood Fill Layer..........................................180

How to Create Spot Data with the Spot Layer Tool.......................182

How to Create White Spot Data in Photoshop...............................186

How to Create White Spot Data in Illustrator.................................191

How to Print With White Ink..................................................................203

How to Use Media Models..............................................................203

How to Create a Media for White Ink Print Jobs............................212

How to Create and Use Quick Sets.................................................225

Chapter 10

Ink System Management...............................................................................229

Arizona Printer Inks................................................................................230

4

Contents

How to Change Ink Bags........................................................................234

Chapter 11

Error Handling and Troubleshooting............................................................237

Troubleshooting Overview....................................................................238

How To Improve Quality When Banding Occurs.................................240

Chapter 12

Printer Maintenance.......................................................................................241

Maintenance Guidelines........................................................................242

Maintenance Procedures.......................................................................244

Clean Carriage Underside................................................................244

Printhead Maintenance....................................................................247

Swab Printheads...............................................................................254

Clean UV Lamp Filters......................................................................258

How to Remove Ink..........................................................................259

Empty the Ink Waste Tray................................................................261

Fill the Coolant Reservoir ................................................................263

Replace the Spit Catcher Foam Pad................................................266

Clean Gantry Rails............................................................................268

How to Change Ink Filters................................................................270

How to Change a UV Lamp Bulb.....................................................274

How to Maintain White Ink..............................................................282

Roll Media Option Maintenance...........................................................284

RMO Maintenance Guidelines.........................................................284

How to Clean the Rubber Capstan..................................................285

Appendix A

Application Information.................................................................................291

Application Resources on the Web Site...............................................292

5

Contents

6

Contents

Chapter 1

Introduction

Preface

Introduction

This manual provides the operator with information about the following Océ UV flatbed

inkjet printers:

■

Océ Arizona® 200 GT

■

Océ Arizona® 250 GT

■

Océ Arizona® 300 GT

■

Océ Arizona® 350 GT

■

Océ Arizona® 350 XT

The operational features of these printer models are similar with the following exceptions:

the 200 GT and 300 GT have four sets of printheads; the 250 GT has eight sets, the 350

GT and 350 XT have ten sets (with the white ink option). The main difference in function

is the actual speed (Refer to Printer Specifications in Chapter 2 for details). In term of

image quality and all other functions, the 200 GT and 250 GT models are the same,

while the 300 GT, 350 GT and 350 XT models have improved speed. The 350 XT has

a larger table than the other models. The manual uses the terms Océ Arizona

200/250/300/350 GT or Océ Arizona 350 XT to refer to these printers. The manual

orients you to the many features and procedures that allow you to print professional

quality images on various media with these printers. This version of the user manual

provides support for printer software up to Revision 3.3.

Multi-Language Support

The printer's user interface software supports multiple languages. To select your preferred

language and other setup information, refer to the Settings Module in Chapter 4.

This manual is also available in other languages. Printers are shipped with a printed copy

of the US English version. You can download a PDF file of the manual in all of the languages that we support from the Customer Support web site:

http://www.dgs.oce.com/PrinterSupport/PrinterSupportUser_index.htm

Supported languages:

■

English

■

Dutch

■

German

■

French

■

Spanish

■

Italian

■

Japanese

Chapter 1 - Introduction8

Preface

Océ DGS on the Internet

For further information on documentation and support for your printer or for information

on other Océ Display Graphics Systems products, please visit our web site:

http://www.dgs.oce.com

To provide feedback and report errors in this document: DGSTechnical.Writer@oce.com

Safety Information

This manual has three sections that contain details on safety when handling ink and using

the printer. Also, where applicable, cautions and warnings are used throughout this

manual to draw your attention to safety precautions.

■

"Safety Guidelines for Ink Materials" offers advice in the proper handling of UV inks;

■

"Interlock Safety System" explains the safety features built in to the printer that prevent

and minimize access to Mechanical, Electrical, Thermal and UV hazards; and

■

"UV Curing System Safety" presents warning about the dangers of exposure to UV

light. Some of the material from that section are duplicated here.

Customer Service

If your printer malfunctions and you are unable to resolve the problem, field service

technicians can be dispatched to your site to conduct repairs. Service visits are paid for

by the customer, either under a maintenance agreement, by purchase order or prepayment.

Time and material rates are charged for any service not covered under a maintenance

agreement. Before calling to report a problem, gather as much information about the

problem as possible and have it ready to provide to your customer care center. The more

information you can provide initially, the more quickly the problem can be corrected.

Statement of Foreseen Use

The Océ Arizona flatbed inkjet printers are intended for use in a commercial printshop

environment. Factory-authorized training is made available for operators at the time of

installation. The printers use piezo printing technology and UV curable inks to produce

outdoor-durable output. They can print directly onto rigid and flexible media of up to

48 mm (1.89 inch) thickness. The printer holds the media stationary while the printhead

assembly moves across to create the print, eliminating image skew problems often associated with rigid stock feed systems. With the Roll Media Option installed the printers can

also print on various roll media. See your local representative or visit http://mediaguide.oce.com/ for more details on recommended media.

Responsibilities of the Operator

The printer operator must be properly trained. Océ provides training for the operator in

the use of the printer hardware and software at the time of installation. It is the customer's

responsibility to ensure that only properly trained personnel operate the printer. Operators

must be fully versed in the operation of ONYX ProductionHouse® . For any operator

Chapter 1 - Introduction 9

Preface

unfamiliar with its operation, ONYX ProductionHouse® training is required. Training

courses are available; contact your local Océ representative.

The operator or other trained personnel are expected to handle all user maintenance as

detailed in the User Manual, and also replacement of consumable parts (except print

heads). If your site has a technician in charge of printer maintenance, that person is the

optimal candidate. While any trained operator may perform routine maintenance, the

best maintenance results from familiarity with the printer's internal operation and history.

The printer requires daily printhead maintenance to ensure the highest print quality and

longer life for the printheads. The printer design provides you easy access to perform this

simple task and it is essential that printhead maintenance is performed at least once a day,

and more frequently if needed. Periodic cleaning must be scheduled for some components

on a regular basis. A few minutes spent cleaning also helps to ensure optimal printer

function and the highest quality prints.

It is the responsibility of the operator to try to eliminate simple problems before calling

a service representative. But knowing when to call for service is also important. An untrained operator must not attempt to service the printer as this may cause further damage.

When you have determined that a service call is required, call as soon as possible. See the

Maintenance section for more details.

Responsibilities of the Service Technician

Field service technicians must have Océ Display Graphics Systems service training. The

service technician is responsible for all repairs, upgrading and modification requested by

the customer or mandated by the Océ Display Graphics Systems Service and Support

Group. The service technician who installs the printer will also provide training for the

operator that covers all of the basic skills required to operate the printer. Service personnel

are furnished with proper tools for the installation and maintenance of the printer. In

addition to the tools and custom kits, each engineer will have basic tools for proper

maintenance and servicing.

Chapter 1 - Introduction10

Preface

Product Compliance

Introduction

This section provides the EMC FCC compliance information and points to the DGS

web site for access to the official documents for all agency compliance standards that the

Océ Arizona 200/250/300/350 GT and Océ Arizona 350 XT conform to. It also provides

printer manufacturing and contact information and a list of any toxic or hazardous material in the printer.

Electromagnetic Compliance (EMC)

FCC Statement for Class A Device:

This equipment generates, uses and radiates radio frequency energy and if not installed

and used as designed or intended, may cause interference to radio communications. This

equipment has been tested and found to comply with the limits for a Class A computing

device. This equipment has been designed to provide reasonable protection against such

interference when operated in residential and commercial environments. Operation of

this equipment in a residential area may cause interference, in which case the user, at his

own expense, is required to take whatever measures are required to correct the interference.

FCC Notice: This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1) This device may not cause harmful interference, and

2) This device must accept any interference received, including interference that may

cause undesired operation.

Any change or modification not expressly approved by the manufacturer

could void the user's authority to operate the equipment.

This device contains an intentional radiator (RFID)

Radio Certificate Number: IC:6497A-3010105668

FCC Identifier: U2P-3010105668

Product Safety

The CE Declaration documents are provided here for your convenience. These documents

and all other applicable compliance certificates are available for download from the Arizona

Customer Support section of our web site: see http://www.dgs.oce.com/PrinterSupport/PrinterSupportUser_index.htm.

Chapter 1 - Introduction 11

Product Compliance

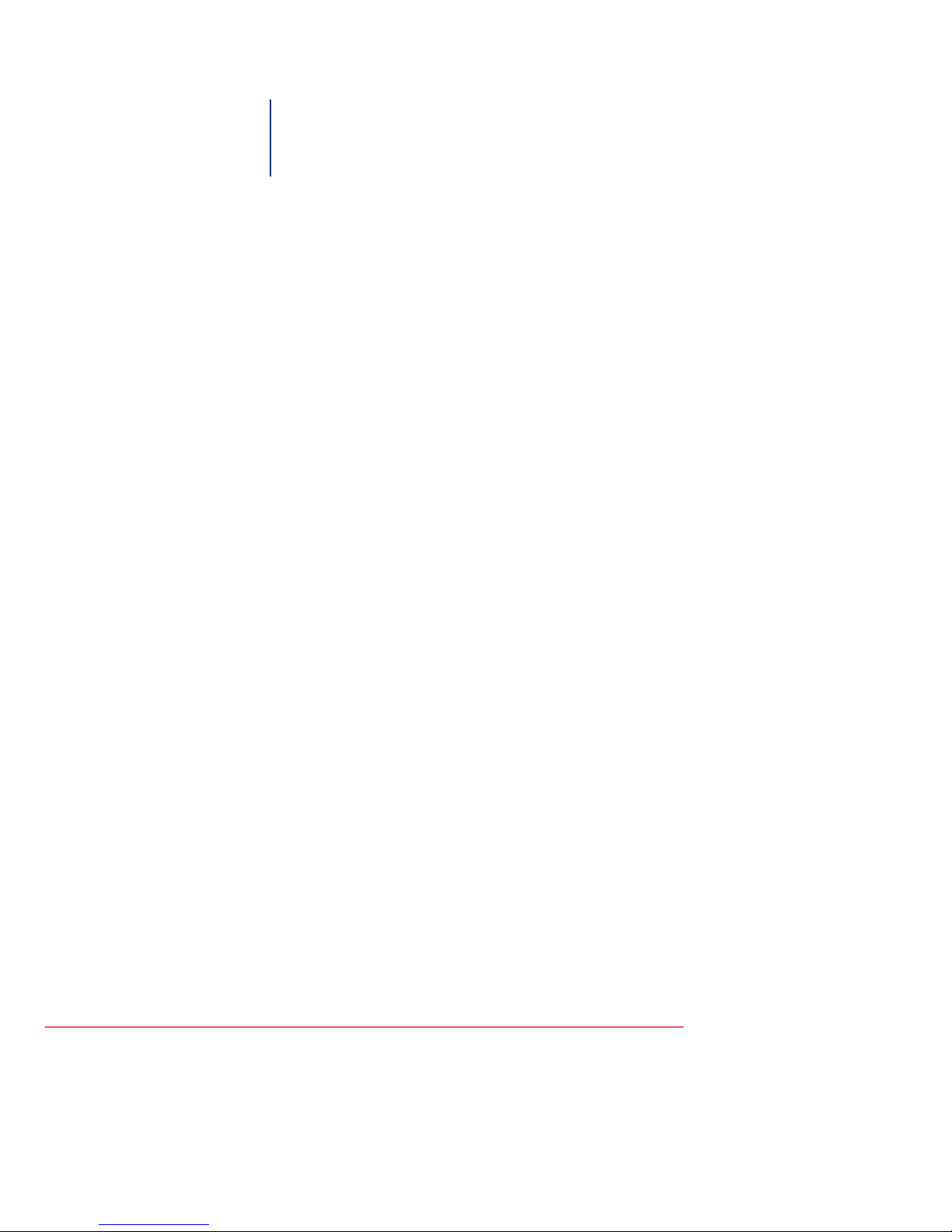

[1] CE Declaration 200GT & 250GT

Chapter 1 - Introduction12

Product Compliance

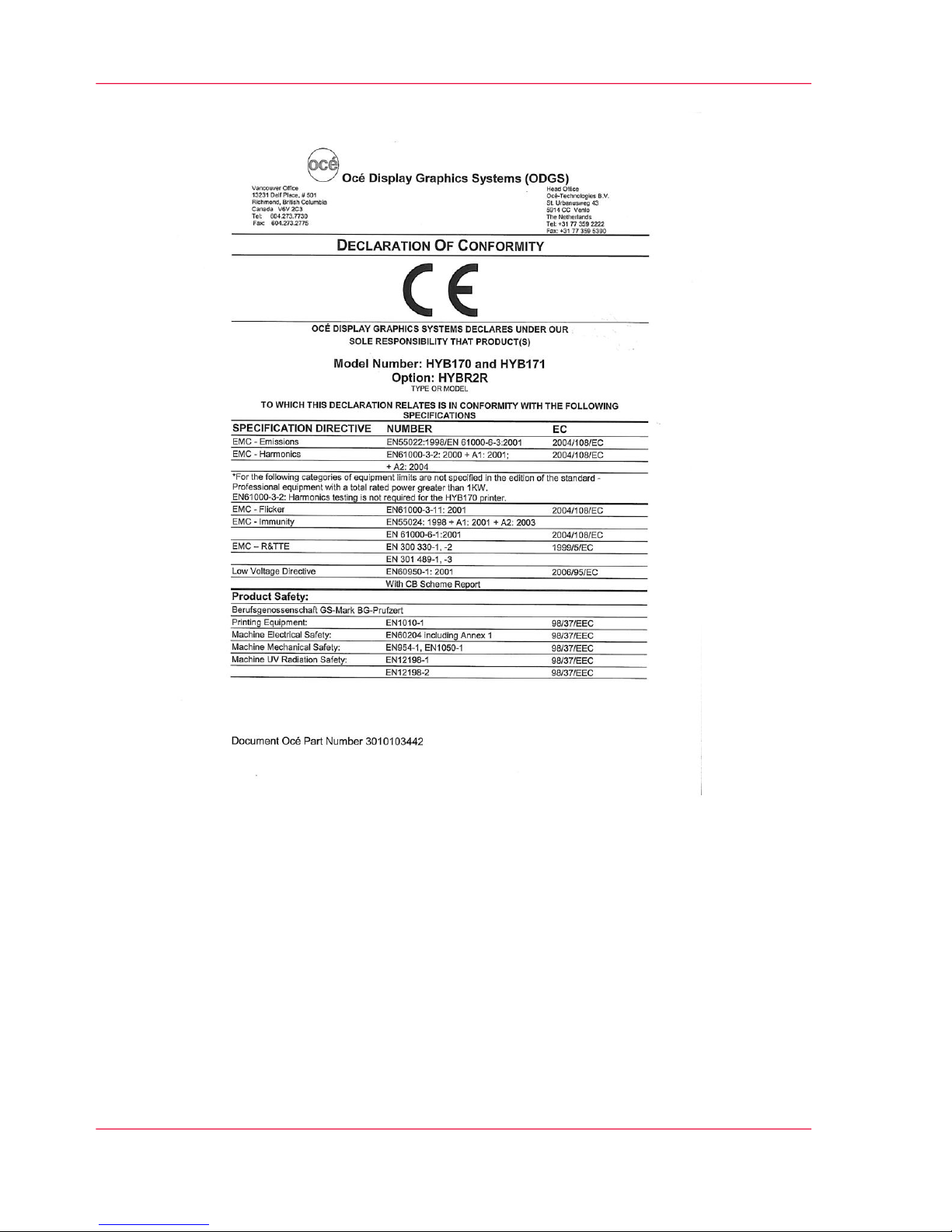

[2] CE Declaration 200GT & 250GT Page 2

Chapter 1 - Introduction 13

Product Compliance

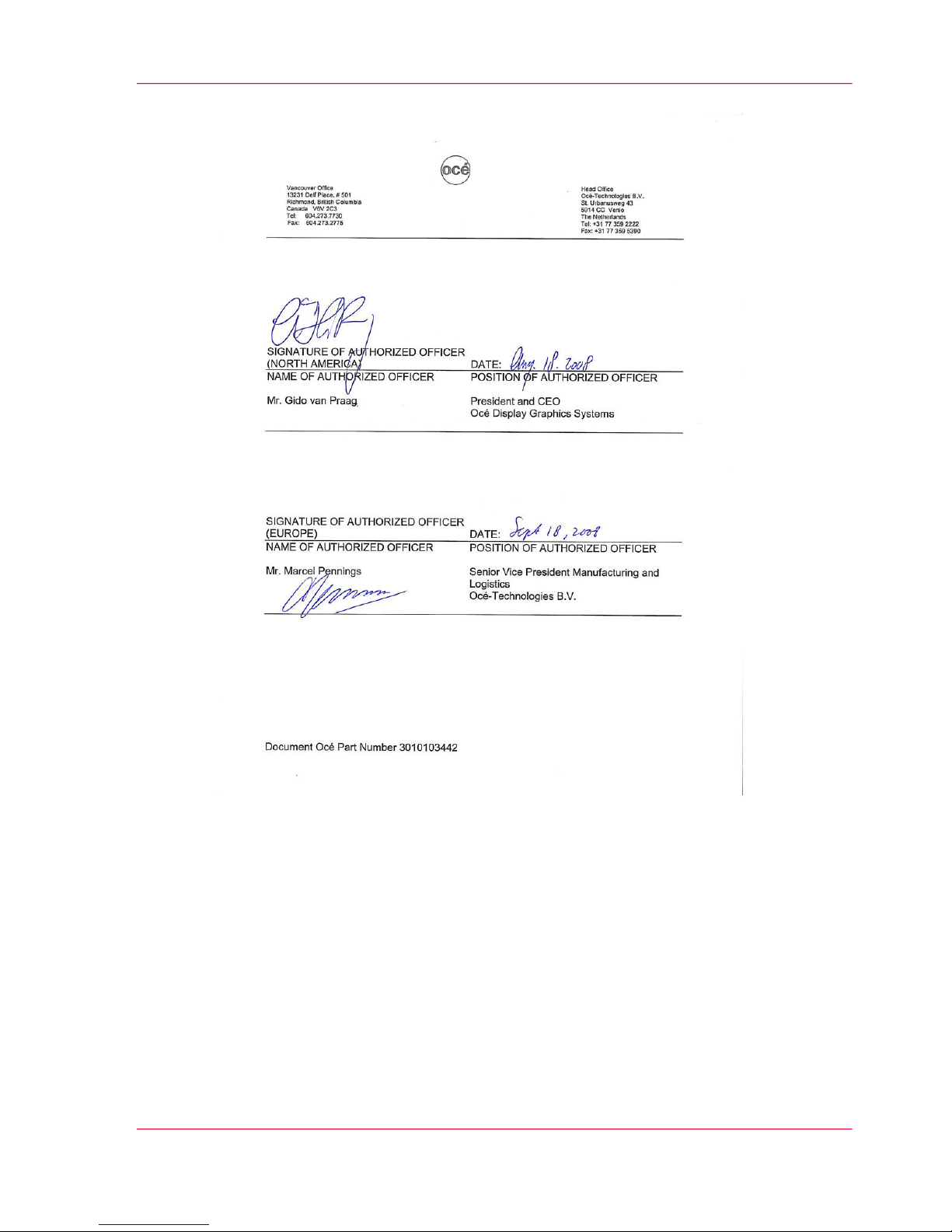

[3] CE Declaration 300GT & 350GT Page 1

Chapter 1 - Introduction14

Product Compliance

[4] CE Declaration 300GT & 350GT Page 2

Chapter 1 - Introduction 15

Product Compliance

[5] CE Declaration 350XT Page 1

Chapter 1 - Introduction16

Product Compliance

[6] CE Declaration 350XT Page 2

Noise Measurement Test Summary

Tested according to EN13023:2003, EN11204, ISO3744:1994(E)/ISO3746:1995(E)

and declared according to ISO4871:1984(E)

Measurements taken at the sample in 5 different locations, Printer in normal operation

with Vacuum Pump, does not exceed 75dB (maximum measured value: 66dB). For all

locations, provide noise protection enclosure or remove pump from location.

Chapter 1 - Introduction 17

Product Compliance

Manufacturer:

Océ Display Graphics Systems (ODGS)

13231 Delf Place - Building #501

Richmond, British Columbia

Canada V6V 2C3

http://www.dgs.oce.com/ Telephone (604) 273-7730 - Fax (604) 273-2775

Representatives Marketing the Océ Arizona 200/250/300/350 GT in Europe:

Océ Technologies B.V.

St. Urbanusweg 43,

Venlo, The Netherlands P.O. Box 101, 5900 MA Venlo

Telephone: (31) 77 359 2222

Fax: (31) 77 354 4700

E-mail: info@oce.com

Océ-Deutschland GmbH

Solinger Straße 5-7

45481 Mülheim/Ruhr Germany

Telephone: (49) 2084 8450 - Fax: (49) 2084 80950

E-mail: ves@oce.de - Web site: http://www.oce.de/

Océ (UK) Ltd.

Langston Road Loughton,

Essex IG10 3SL United Kingdom

Telephone: (44) 870 600 5544 - Fax: (44) 870 600 1113

E-mail: salesinformation@oce.co.uk - Web site: www.oce.co.uk

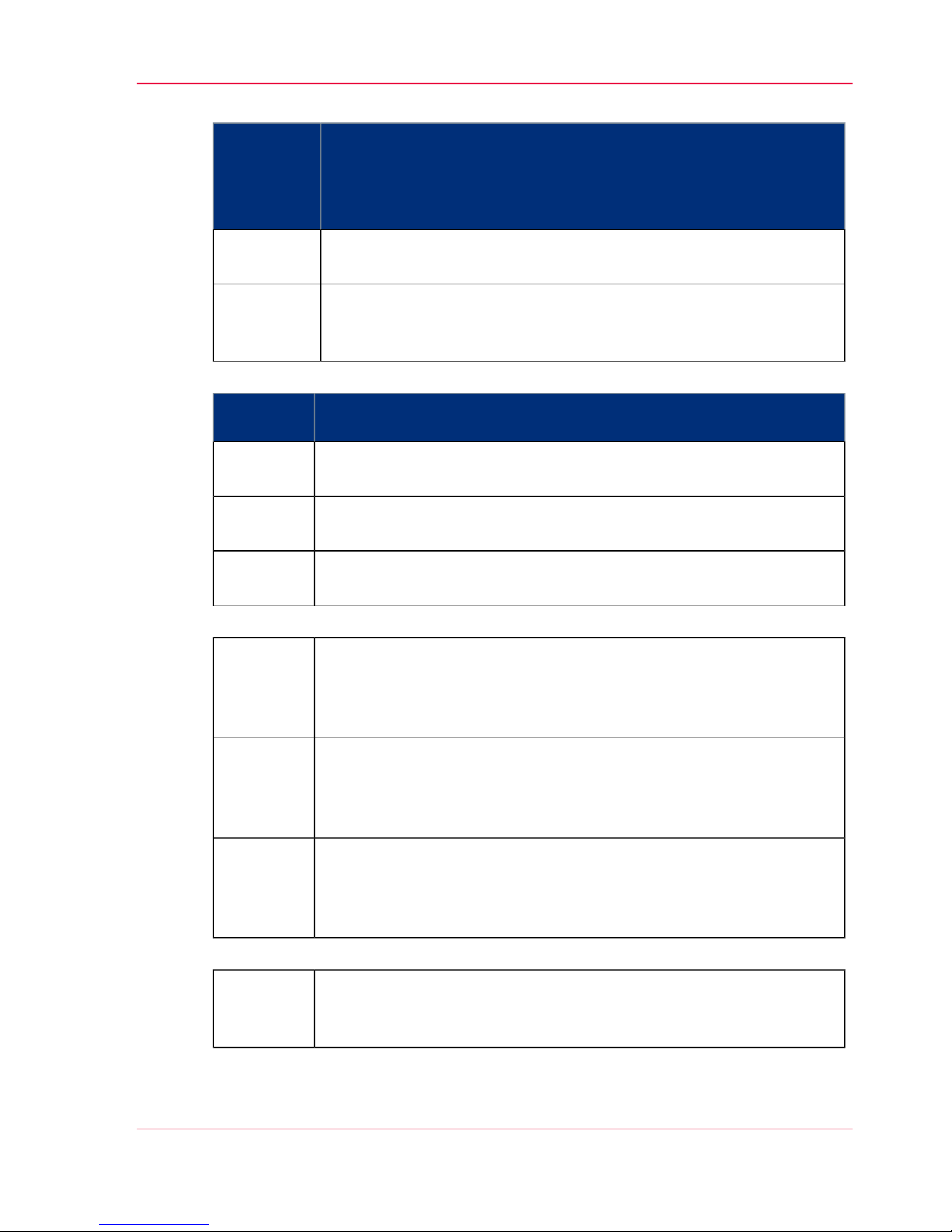

Toxic and Hazardous Substances or Elements in the Product

#

Polybrominated

dipenylether

(PBDE)

Polybromiated

biphenyls

(PBB)

Hexavalent

(CrVI)

Cadmium (Cd)

Mercury

(Hg)

Lead

(pb)

Part

Name

0000X0UV Curing

Lamps

0000X0VGA

Monitor

00000XVacuum

Guage

Indicator

Chapter 1 - Introduction18

Product Compliance

Polybrominated

dipenylether

(PBDE)

Polybromiated

biphenyls

(PBB)

Hexavalent

(CrVI)

Cadmium (Cd)

Mercury

(Hg)

Lead

(pb)

Part

Name

00000XLinear

Encoder

Readheads

00000XPrintheads

Chapter 1 - Introduction 19

Product Compliance

Chapter 1 - Introduction20

Product Compliance

Chapter 2

Product Overview

Printer Specifications

Introduction

The Océ Arizona 200/250/300/350 GT and Océ Arizona 350 XT are four or five color

flatbed inkjet printers capable of producing large format images on various rigid and

flexible media (the 200 GT and 250 GT models are CMYK only, while the 300 GT,

350 GT and 350 XT can include white with the white ink option). The printers consists

of a flatbed vacuum table and moving gantry. The material is held flat and stationary on

the vacuum table during printing. The gantry contains a carriage that sweeps across the

table as the gantry moves in steps along the length of the table to print an image on the

media. In addition to the benefits of stationary positioning, the use of UV ink technology

on rigid material eliminates finishing processes such as mounting and lamination. A Roll

Media Option is available for all printer models.

Note:

The printers must be operated in accordance with the environmental conditions specified

in the Océ Arizona 200/250/350GT & 350XT Site Preparation Guide and also the

safety requirements noted in this document.

Illustration

[7] Arizona 350 GT Printer

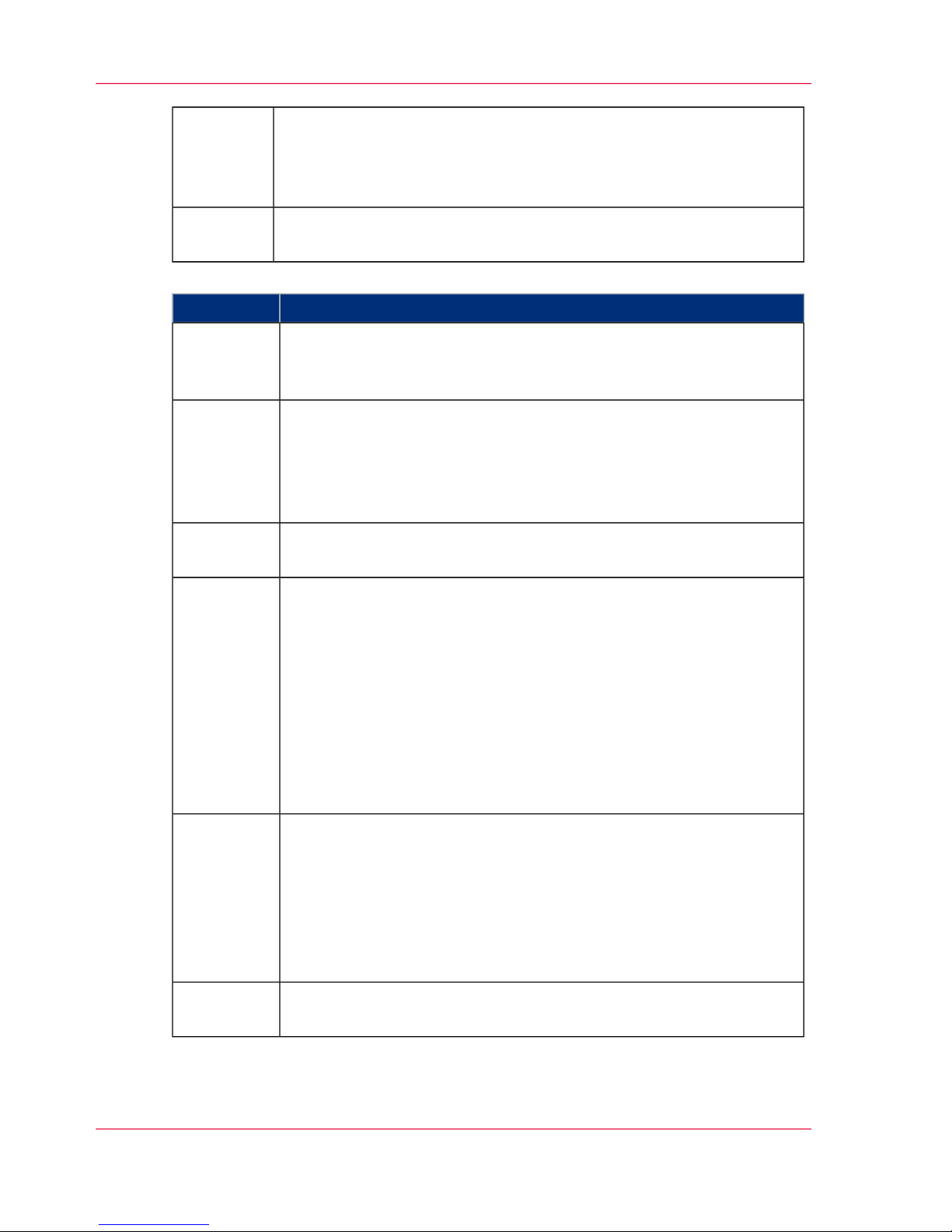

Océ Arizona 200/250/300/350 GT Specifications

The Océ Arizona 200/250/300/350 GT and Océ Arizona 350 XT are part of a complete

printing solution that includes: ONYX® workflow software (ONYX ProductionHouse™

Chapter 2 - Product Overview22

Printer Specifications

recommended), optional Roll Media Option for flexible media printing, Océ ProCut

flatbed cutter, Océ inks and other consumables, Océ media and Océ Professional Services.

The specifications for the Océ Arizona 200/250/300/350 GT models are listed below.

See Chapter 6 for Océ Arizona 350 XT specifications and features that are unique to that

model. See Chapter 7 for Roll Media Option specifications.

Note:

All specifications in this document are subject to change without notice.

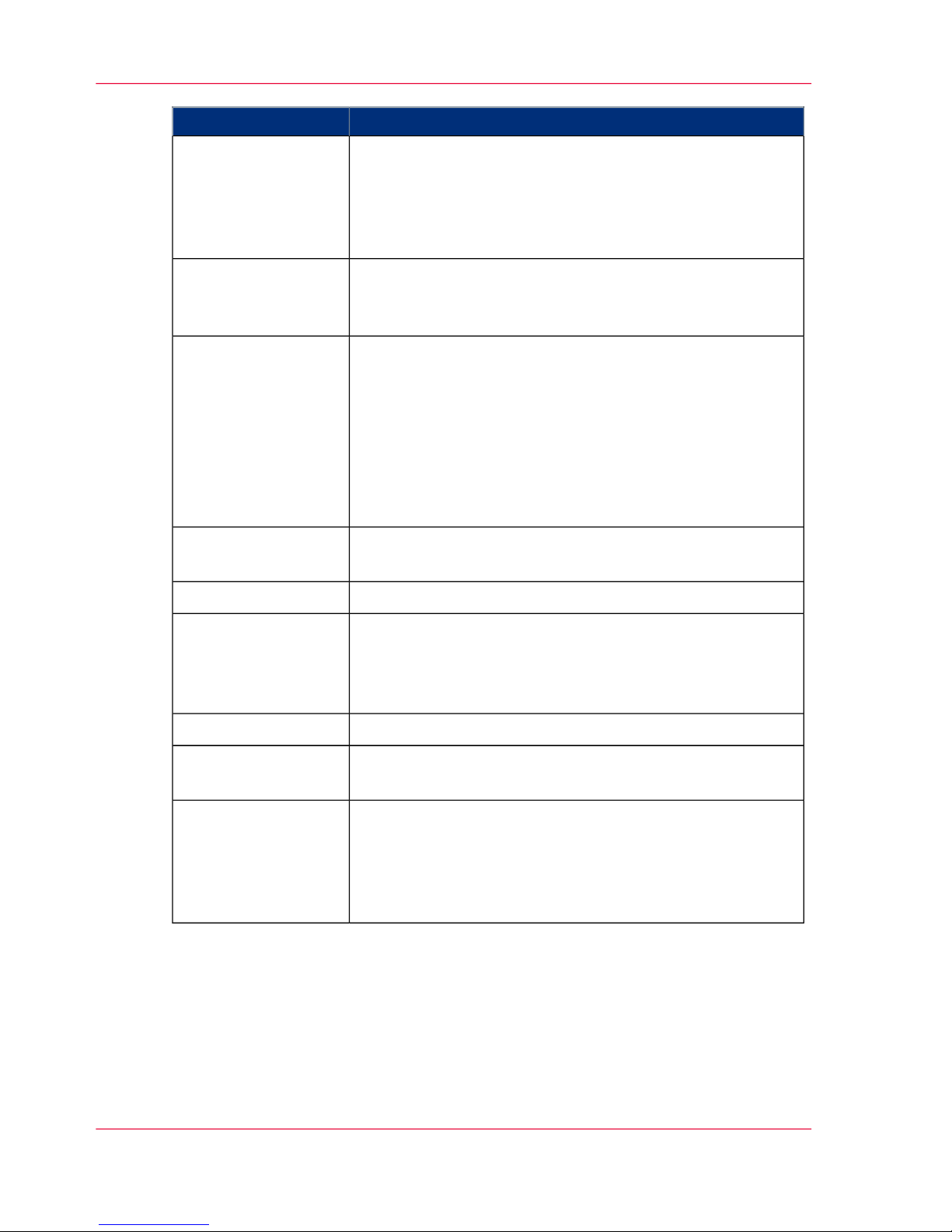

Specifications#

SpecificationFeature

Piezoelectric inkjet using Océ VariaDot™ technology:

The Arizona 350 GT and 350 XT have two variable dot

printheads per color, 10 in total (with the white ink option);

The Arizona 300 GT has one variable dot printheads per

color, 5 in total (with the white ink option);

The Arizona 250 GT has two variable dot printheads per

color, 8 in total;

The Arizona 200 GT has one variable dot printheads per

color, 4 in total.

Printing Technology

True flatbed printer for rigid media with Roll Media Option

for flexible media

Format

Océ IJC255 and Océ IJC256 UV-curable inks available in

Black, Cyan, Magenta, Yellow, and white (if installed).

Packaged in quick-change, 2 liter ink bags.

Ink System

2.5m (98.4") x 1.25m (49.2") or 3.050m (120.1") length

for the XT model.

Maximum Media Size

Maximum: 48mm (1.890")Media Thickness

2.51m (98.8") x 1.26m (49.6")

2.51m (98.8") x 3.06m (120.5") for the 350 XT

Maximum Print Size

Maximum: 34 kg/sq.m (7 lbs/sq.ft)Media Weight

The ability to vary the drop size to as little as 6 picolitres

produces sharp images with smoother gradients and quartertones. The ability to jet larger droplets up to 42 picolitres

produces dense, solid colors. The result is near-photographic

image quality. Text as small as 6 pt. is perfectly legible.

Nozzle Drop Volume:

Variable droplet sizes

from 6 to 42 picolitres

Production: 9.34 sq.metres/hr. (101 sq.ft./hr.)

Quality: 6.43 sq.metres/hr. ( 69 sq.ft./hr.)

Fine Art: 4.82 sq.metres/hr. (52 sq.ft./hr.)

Print Modes / speeds

(flatbed only) for Océ

Arizona 200 GT

Chapter 2 - Product Overview 23

Printer Specifications

SpecificationFeature

Production: 16.8 sq.metres/hr. (180 sq.ft./hr.)

Quality: 11.5 sq.metres/hr.) 124 sq.ft./hr.)

Quality-Matte: 8.3 sq. metres/hr. (89 sq. ft./hr.)

Quality-Density: 6.5 sq. metres/hr. (70 sq. ft./hr.)

Fine Art: 9.3 sq.metres/hr. (101 sq.ft./hr.)

Print Modes / speeds

(flatbed only) for Océ

Arizona 250 GT

Production: 12.3 sq.metres/hr. (133 sq.ft./hr.)

Quality: 8.5 sq.metres/hr. (91 sq.ft./hr.)

Fine Art: 6.4 sq.metres/hr. (68 sq.ft./hr.)

Print Modes / speeds

(flatbed only) for Océ

Arizona 300 GT

Production: 22.2 sq.metres/hr. (239 sq.ft./hr.)

Quality: 15.2 sq.metres/hr.) 164 sq.ft./hr.)

Quality-Matte: 10.9sq. metres/hr. (117 sq. ft./hr.)

Quality-Density: 8.5 sq. metres/hr. (91 sq. ft./hr.)

Fine Art: 12.3 sq.metres/hr. (133 sq.ft./hr.)

White Ink Option

Quality 3 Layer: 5.1 sq.metres/hr.) 55 sq.ft./hr.)

Quality 2 Layer: 7.6 sq.metres/hr. ) 82 sq.ft./hr.)

Print Modes / speeds

(flatbed only) for Océ

Arizona 350 GT

LCD flat-panel monitor and mouse on a user-positioned

podium.

User Interface

UV curing lampCuring System

208 through 240VAC ±10% 60Hz Single Phase

200 through 240VAC ±10% 50Hz Single Phase

Recommended Circuit Breaker:

North America 20A, European Union 16A.

Power Requirements

Voltage:

(Rated Current: 16A)

10,000 BTU (2950 watts) under continuous operation.BTU Output

USB, Ethernet TCP/IP, 100 base-T (or Gigabyte, if supported by the local network).

Hardware Interface

ONYX® ProductionHouse Océ Edition version 7 or greater

(ONYX® PosterShop is available but not recommended).

The drivers for the Océ Arizona 200/250/300/350 GT is

included in the ProductionHouse Océ edition, but is not in

the PosterShop Océ edition.

Image Processing

Software

Océ VariaDot™ Variable Droplet Imaging Technology

The Océ Océ Arizona 200/250/300/350 GT offers superior print quality and ink economy

through the use of Océ VariaDot imaging technology, the next evolution in piezoelectric

inkjet technology that enables a print head to produce droplets of varying volume. This

differs from the current piezoelectric print head technology that is restricted to the use

Chapter 2 - Product Overview24

Printer Specifications

of fixed droplets. The use of variable sized droplets results in dots on the media of varying

size (area) and density which in turn allows the use of four-color (CMYK) printing for

all image features. Using Océ VariaDot imaging technology results in excellent print

quality and a superior ink economy over 6-color printing systems.

Océ VariaDot imaging technology allows piezoelectric print heads to produce droplets

of varying volume on demand. This allows the ONYX™ ProductionHouse software to

specify the appropriate droplet size for each specific image feature. When imaging fine

detail such as small type or fine lines, very small droplets can be used, when imaging areas

of tonal transition or quarter-tone values such as skin tones drops of medium volume can

be used and when printing areas of high density such as solid colors, large droplets can

be used.

Océ VariaDot™ for Improved Image Quality

Océ VariaDot imaging technology can be compared to painting a room in your house.

You use a large brush size for quick coverage over large areas and a much smaller, finer

brush for detailed areas. Trying to paint a large wall with a tiny brush would result in

many artefacts and trying to paint a fine fresco trim with a large brush would be very

frustrating. In the same way, Océ VariaDot uses the appropriate size droplet for each

specific image feature resulting in the best possible image quality in every part of the

printed image.

Océ VariaDot™ for Reduced Ink Consumption

A significant benefit of Océ VariaDot imaging technology is that it allows the use of only

four inks (CMYK) for all areas of the printed image. This is very significant to the user

in terms of ink consumption per square meter because the current "de facto standard" in

the industry is six-color piezoelectric printing. This older technology uses lighter versions

of Cyan and Magenta inks, often referred to commercially as "Light Cyan" and "Light

Magenta" to overcome the image quality problem previously associated with four-color

(CMYK only) printing.

Chapter 2 - Product Overview 25

Printer Specifications

Chapter 2 - Product Overview26

Printer Specifications

Chapter 3

Safety Information

Safety Guidelines for Ink Materials

Introduction

This section outlines the safety concerns involved with the handling and use of the UV

ink and Flush for the Océ Arizona 200/250/300/350 GT printer. Read all of the material

in this section and also review the Material Safety Data Sheet (MSDS) documents before

handling any UV ink or using the printer. Always ensure that visitors are escorted and

warned of the possible hazards from ink contamination.

Note:

The full text of the MSDS for all UV inks and Flush is found in the Customer Support

section of the ODGS web site:

http://www.dgs.oce.com/PrinterSupport/PrinterSupportUser_index.htm

Caution:

Both UV inks and the curing lamps can be harmful if not properly handled. Follow these

guidelines carefully in order to ensure maximum safety.

Personal Safety

The operator should wear nitrile gloves, a protective apron, and safety glasses with side

shields when handling inks.

Note:

Warning for Seated Individuals- The UV Curing System on the Océ Arizona

200/250/300/350 GT generates hazardous levels of thermal, electrical and UV energies.

UV light exposure is at it's worst for individuals in a seated position (Table Height of

90cm). Do not sit within 5 metres of the printer and do not look at the UV lamps if

your eyes are positioned below the level of the printer table.

Ventilation and Room Volume

The printer should operate in an area where a good standard of general ventilation is

available at 5 to 10 air changes per hour. Mechanical Ventilation must be added where

the air changes are less than 5 per hour.

Handling UV Inks

Read and practice safety guidelines as outlined in the MSDS for each ink. Post these

documents in the work area as required by prevailing law. MSDS for all inks are provided

when you purchase inks. The following is a summary of the important safety aspects of

the MSDS that are common to all UV inks.

Chapter 3 - Safety Information28

Safety Guidelines for Ink Materials

Hazards Identification#

Irritating to skin. Risk of serious damage to eyes.

May cause sensitization by skin contact.

Possible risk of impaired fertility.

Harmful to aquatic organisms, may cause long-term adverse effects

in the aquatic environment

Dangers for

people and

environment

Inks are not suitable for food-related or children-related applications.

Avoid contact with uncured ink.

Avoid exposure

Set the lamp power as high as possible for each media to ensure that

the ink cures properly. This will minimize the risk of irritation and

sensitization of the skin from uncured ink.

Proper Curing

First-aid Measures#

Never make an unconscious person vomit or drink fluids. Immediately remove any clothing soiled by the product.

General information

Supply fresh air; consult doctor in case of complaintsAfter in-

halation

Immediately wash with water and soap and rinse thoroughly. If skin

irritation continues, consult a doctor.

After skin

contact

Rinse opened eye for several minutes under running water. Then consult

a doctor.

After eye

contact

Accidental Release Measures - Dealing With Spilled Ink#

Wear protective eyeglasses with side shields and use nitrile gloves. Keep

unprotected persons away. Ensure adequate ventilation.

Personal

Precautions and

Equipment

Do not allow product to reach sewage system or any water course. Inform respective authorities in case of seepage into water course or sewage

system. Do not allow to enter sewers/ surface or ground water.

Measures

for environmental protection

Absorb with liquid-binding material (sand, diatomite, acid binders,

universal binders, sawdust). Dispose contaminated material as indicated

in table Disposial Considerations (see below).

Measures

for cleaning/collecting

Handling & Storage#

Information for safe handling: Store in cool, dry place in tightly closed

receptacles. Keep away from heat and direct sunlight. Ensure good

ventilation/exhaustion at the workplace.

Handling

Chapter 3 - Safety Information 29

Safety Guidelines for Ink Materials

Store in accordance with current national regulations

Requirements to be met by storerooms and receptacles: Store between

5 - 30°C.

Protect from heat and direct sunlight.

Storage

Conditions

Do not store together with oxidizing and acidic materials. Do not store

together with alkalis (caustic solutions)

Storage Facility

Personal Protection#

StrategyArea

The instructions and information provided by the manufacturer of

the personal protective equipment on use, storage, maintenance and

replacement must always be followed.

Personal

Protection

Keep away from foodstuffs, beverages and feed. Immediately remove

all soiled and contaminated clothing

Wash hands before breaks and at the end of work.

Avoid contact with the eyes and skin.

Store protective clothing separately.

General

protective

and hygienic measures

Not necessary if room is well-ventilated.Breathing

equipment

There is no one glove material or combination of materials that will

give unlimited resistance to any individual or combination of chemicals.

The selection of single or multi-use gloves is dependent upon the level

of exposure (nitrile/neoprene gloves will last longer than latex/rubber).

The performance or effectiveness of the glove may be reduced by

physical/ chemical damage and poor maintenance. Always ensure that

gloves are free from defects and that they are stored and used correctly.

Gloves should be replaced regularly and if there is any sign of damage

to the glove material. Hands should be inspected on a regular basis for

any signs of skin damage or inflammation.

Protection

of hands

Penetration time of glove material: The exact break through time has

to be found out by the manufacturer of the protective gloves and has

to be observed.

In general, with the recommended nitrile gloves, replace the glove

within a few minutes if it is contaminated with ink.

Do not reuse single-use gloves

Do not handle prints without gloves if ink is not properly cured.

Gloves

Wear tightly sealed gogglesEye protec-

tion

Chapter 3 - Safety Information30

Safety Guidelines for Ink Materials

Loading...

Loading...