OBL MB.31, MB.37, MB.50, MB.35, MB.49 Operating Manual

...

SERIE

MB

MC

>

OPERATING MANUAL

JOB N°

PUMP TYPE

SHEET

ELECTRIC ACTUATOR TYPE

OVERALL DRAWING

16

MB/MC 16

MB/MC Z-Z9 17

MECHANISM SECTIONAL DRAWINGS

18

PUMPHEAD SECTIONAL DRAWING

18

ENCLOSED

ITEM

SERIAL/No

GB

SERIES

MECHANICAL DIAPHRAGM

METERING PUMPS

SPRING RETURN

ENGLISH

:: M_

MB/MC

_GB_12.04 ::

1

2

3

4

5

6

PUMP CLEANING 1

TECHNICAL CHARACTERISTICS 2

MODEL NUMBER 3

1.1 - DESCRIPTION OF THE PUMP 4

1.2 - FLOW RATE 4

1.3 - MANUAL ADJUSTMENT 5

1.4 - MOTOR CHARACTERISTICS 5

1.5 - DIAPHRAGM STRUCTURE 5

2.1 - CORRECT INSTALLATION OF THE PUMP

6

2.2 - SUCTION LINE 6

2.3 - SUCTION SIDE FILTER 7

2.4 - SUCTION PIPING FOR VISCOUS LIQUIDS 8

2.5 - DISCHARGE LINE 8

2.6 - RELIEF VALVE 9

2.7 - INSTALLATION OF THE PULSATION DAMPER 9

2.8 - INSTALLATION OF THE PRESSURE GAUGE 10

2.9 - STANDARD PLANT ARRANGEMENT 10

2.10 -CASING OIL FILLING UP 10

3.1 - BEFORE STARTUP 11

3.2 - PUMP STARTUP 11

3.3 - POSSIBLE TROUBLES DURING STARTUP

12

4.1 - ROUTINE MAINTENANCE 13

4.2 - PREVENTIVE MAINTENANCE 14

4.3 - DISMANTLING (AND REASSEMBLY) 14

4.4 - OPERATING TROUBLES 15

5.1 - MB/5.2 -MC OVERALL DRAWINGS 16

5.3 - MB/MC Z-Z9 OVERALL DRAWINGS 17

MB/MC MECHANISM AND PUMPHEAD

SECTIONAL DRAWING 18

GENERAL SAFETY NORMS 20

DECLARATION OF CONFORMITY 21

GENERAL CHARACTERISTICS

INSTALLATION

STARTUP

MAINTENANCE

OVERALL DRAWINGS

SECTIONAL DRAWINGS

THE MACHINE DIRECTIVE

DECLARATION OF CONFORMITY

INDEX

1

1

2

4

3

A

B

SUCTION SIDE

Please be reminded to collect cleaning water in

specific containers. Containers to be collected

by authorised companies for the disposal of

waste waters.

- Pump to be

packed into palletised crate; pump to

be nailed to the

base in the vertical

position.

-

The cleaning procedure must be repeated for at

least 5 minutes.

-

Continue cleaning through

discharge port, maintaining

the connections horizontal.

SUCTION SIDE

-

Flush with water through the pump suction port

(motor opposite side).

-

Operator to be at least 2 metres away from pump.

-

Place the pump on

the floor, in a suitable area for waste

water collection,

with the inlet and

outlet ports horizontal.

A - Close terminal box cover and seal cable entry with PG plugs.

B- If there are no PG plugs available, the terminal box must be sealed

with adhesive waterproof tape.

-Sostituire il “TAPPO CON FORO” con il “TAPPO CIECO” fornito in dotazione con la pompa.

Pumps to be sent with cleanness certificate, so free from

any chemical trace into liquid end and all wetted parts.

If not supplied, pump (s) will be rejected and

sent back at customer’s charges.

MANDATORY REQUIREMENT

Basic suggestion for pump cleaning

C A U T I O N !

OBL s.r.l. welcome pumps despatched to our premises for servicing.

INFORMATION FOR CUSTOMERS

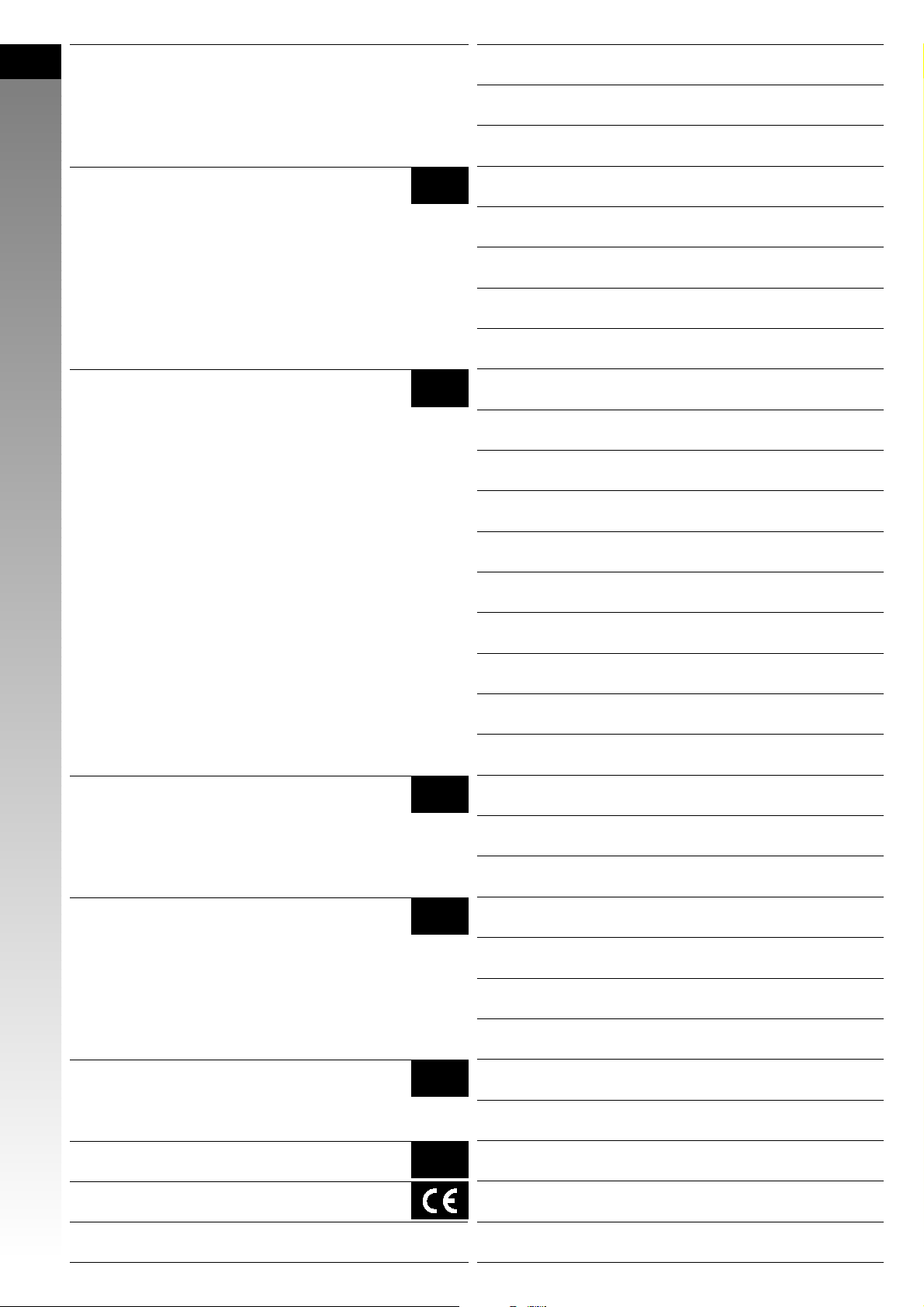

2

MB

MC

50 Hz

50 Hz

60 Hz

60 Hz

➜

➜

TYPE

STROKES/1’

MAX FLOW

RATE l/hØDIAPHRAGM

STROKE

MAX PRESS.

BAR

TYPE

STROKES/1’

MAX FLOW

RATE l/hØDIAPHRAGM

STROKE

MAX PRESS.

BAR

CONNECTIONS

THREADED FLANGED

PP A PP A

VA LV E

A P

TECHNICAL DATA

TECHNICAL DATA

CONNECTIONS

THREADED FLANGED

PP A PP A

VA LV E

A P

MECHANICAL DIAPHRAGM METERING PUMPS

MB.11 36 11 94 2 CML 5 VP 7 12

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.16 50 16 94 2 CML 5 VP 7 12

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.23 70 23 94 2 CM 7 VP 7 12

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.31 95 31 94 2 CM 7 VP 7 8

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.37 115 37 94 2 CM 7 VP 7 8

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.50 155 50 94 2 CM 7 VP 7 8

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.35 36 35 108 4 CM 8

VP 8,5

6

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.49 50 49 108 4 CM 8

VP 8,5

6

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.75 70 75 108 4 CM 8

VP 8,5

6

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.101 95 101 108 4 CM 8

VP 8,5

6

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.120 115 120 108 4 CM 9

VP 8,5

6

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.155 155 155 108 4 CM 9

VP 8,5

6

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.9 30 9 94 2 CML 5 VP 7 12

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.14 43 14 94 2 CML 5 VP 7 12

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.28 84 28 94 2 CM 7 VP 7 12

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.36 114 36 94 2 CM 7 VP 7 8

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.45 138 45 94 2 CM 7 VP 7 8

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.42 43 42 108 4 CM 8

VP 8,5

6

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.58 60 58 108 4 CM 8

VP 8,5

6

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.90 84 90 108 4 CM 8

VP 8,5

6

3/8” BSPF

DN15

1/2”ANSI 150#RF

MB.121 115 121 108 4 CM 9

VP 8,5

6

3/8” 1/2”

DN15

1/2”ANSI 150#RF

MB.145 138 145 108 4 CM 9

VP 8,5

6

3/8” 1/2”

DN15

1/2”ANSI 150#RF

MC.101 36 100 138 6

CM 13,5 VP 11 G73/4” BSPF

DN20

3/4”ANSI 150#RF

MC.131 50 132 138 6

CM 13,5 VP 11 G73/4” BSPF

DN20

3/4”ANSI 150#RF

MC.201 70 197 138 6

CM 13,5 VP 13,573/4” BSPF

DN20

3/4”ANSI 150#RF

MC.261 95 260 138 6

CM 13,5 VP 13,573/4” BSPF

DN20

3/4”ANSI 150#RF

MC.321 115 320 138 6

VM 16,5 VP 17

5

1”

BSPF

DN25

3/4”ANSI 150#RF

MC.421 155 420 138 6

VM 16,5 VP 17

5

1”

BSPF

DN25

3/4”ANSI 150#RF

MC.120 43 120 138 6

CM 13,5 VP 11 G73/4” BSPF

DN20

3/4”ANSI 150#RF

MC.158 60 158 138 6

CM 13,5 VP 13,573/4” BSPF

DN20

3/4”ANSI 150#RF

MC.236 84 236 138 6

CM 13,5 VP 13,573/4” BSPF

DN20

3/4”ANSI 150#RF

MC.312 114 312 138 6

VM 16,5 VP 17

5

1”

BSPF

DN25

1”ANSI 150#RF

MC.384 138 384 138 6

VM 16,5 VP 17

5

1”

BSPF

DN25

1”ANSI 150#RF

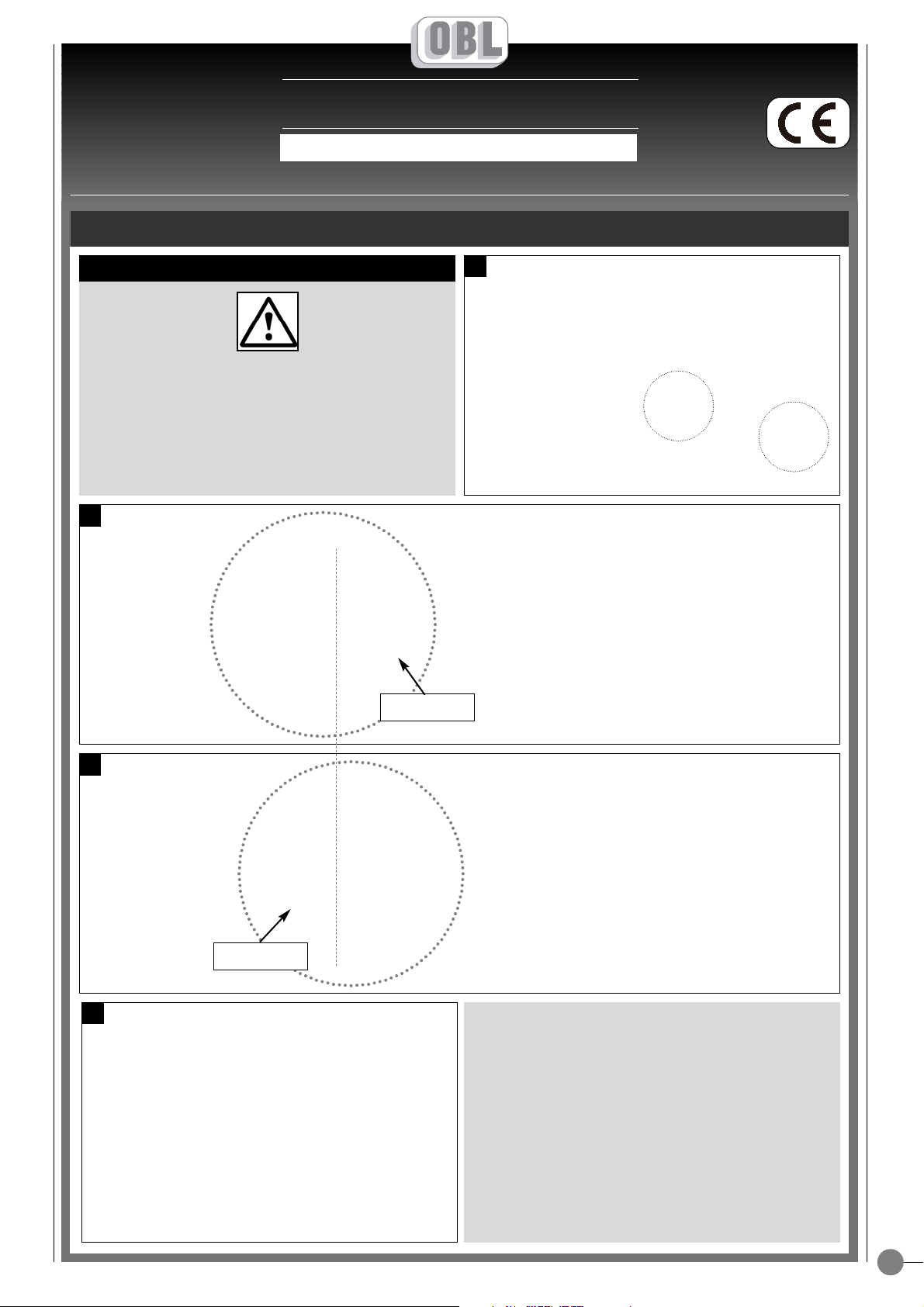

3

MB MC

PP PP11 PP32 A

➜

MB 37 PP F Z

➜

PARTS

MODEL NUMBERMATERIALS OF CONSTRUCTION

KEY TO SYMBOLS

PUPM TYPE

FLOW RATE l/h

PP PP CONSTRUCTION

A AISI-316L CONSTRUCTION

PP11 PP CONSTRUCTION+AISI-316L VALVE AND SEAT

PP32 PP CONSTRUCTION + HASTELLOY C VALVE - INCOLOY 825 SEAT

Z OBL ELECTRIC ACTUATOR

W 3÷15 PSI PNEUMATIC ACTUATOR

F UNI-DIN FLANGED CONNECTIONS

FA ANSI FLANGED CONNECTIONS

LIQUID END PP PP PP AISI 316L

VALVE GUIDE

POLYTHENE/PVC POLYTHENE/PVC POLYTHENE/PVC

AISI 316L

VALVE SEAT PVC AISI 316L

INCOLOY 825

AISI 316L

VA LV E PIREX AISI 316L

HASTELLOY C-276

AISI 316L

VALVE SEAL

VITON (FPM) VITON (FPM) VITON (FPM) VITON (FPM)

VALVE HOUSING PP PP PP AISI 316L

DIAPHRAGM

TEFLON (PTFE) TEFLON (PTFE) TEFLON (PTFE) TEFLON (PTFE)

1.1

1

4

1

0° 180° 360°

1.2

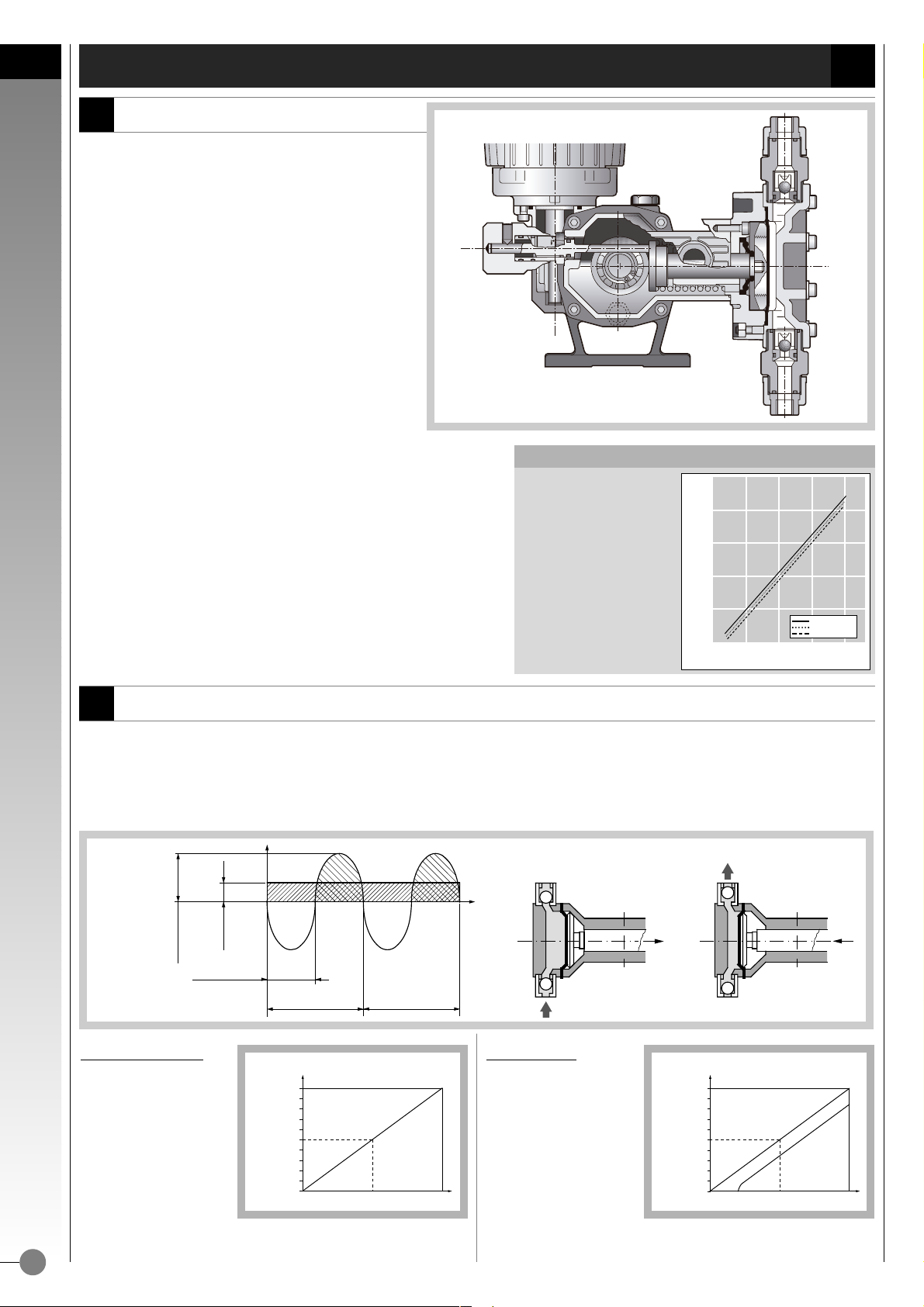

Fig. 2

Theor

etical flow rate

The theoretical flow rate

corresponds exactly to

the volume displaced by

the diaphragm during

its motion. Its graphic

representation is a diagonal straight line

whose progression is

determined by the

diaphragm stroke increasing (fig.3).

Actual flow rate

The actual flow rate is inevitably less than the theoretical flow rate because of the

losses due to the reaction

time of the valves. The ratio

between these two flow

rates determines the volumetric efficiency of the

pump. The efficiency

depends on pump size, pump head type (plunger or diaphragm), liquid

to be pumped, viscosity of the liquid, working

pressure, etc.

(fig. 4).

0° 50° 100°

10

5

0° 50° 100°

10

5

FLOW RATE

A

C

FLO

W

R

A

TE

TH

.FO

LW

R

A

TE

TH

.FO

LW

R

A

TE

FLOW RATE

CLOSED

OPEN

OPEN

CLOSED

DISCHARGE STAGESUCTION STAGE

2°COMPLETE CYCLE

1° COMPLETE CYCLE

SUCTION

FLOW RATE

PER HOUR

SNAPSHOT

FLOW RATE

• The reciprocating motion of the diaphragm determines the flow thanks to the inlet and outlet check valves of the pump head

(fig. 2).

During the suction stage the inlet valve opens because of the depression created by the diaphragm while the outlet valve remains closed. The product enters the pump head and goes out throught the outlet valve when pushed by the diaphragm during the discharge

stage.

FLOW RATE

THE FLOW RATE LINEARITY

The operating of an OBL mechanical diaphragm reflects the flow

rate linearity of a plunger pump.

This is proved by the graph here

on the left that evidences the

linear proportionality between

flow rate and adjustment percentage.

200

150

100

50

0

25% 50% 75% 100%

Adjustment %

Flow rate l/h

Table A

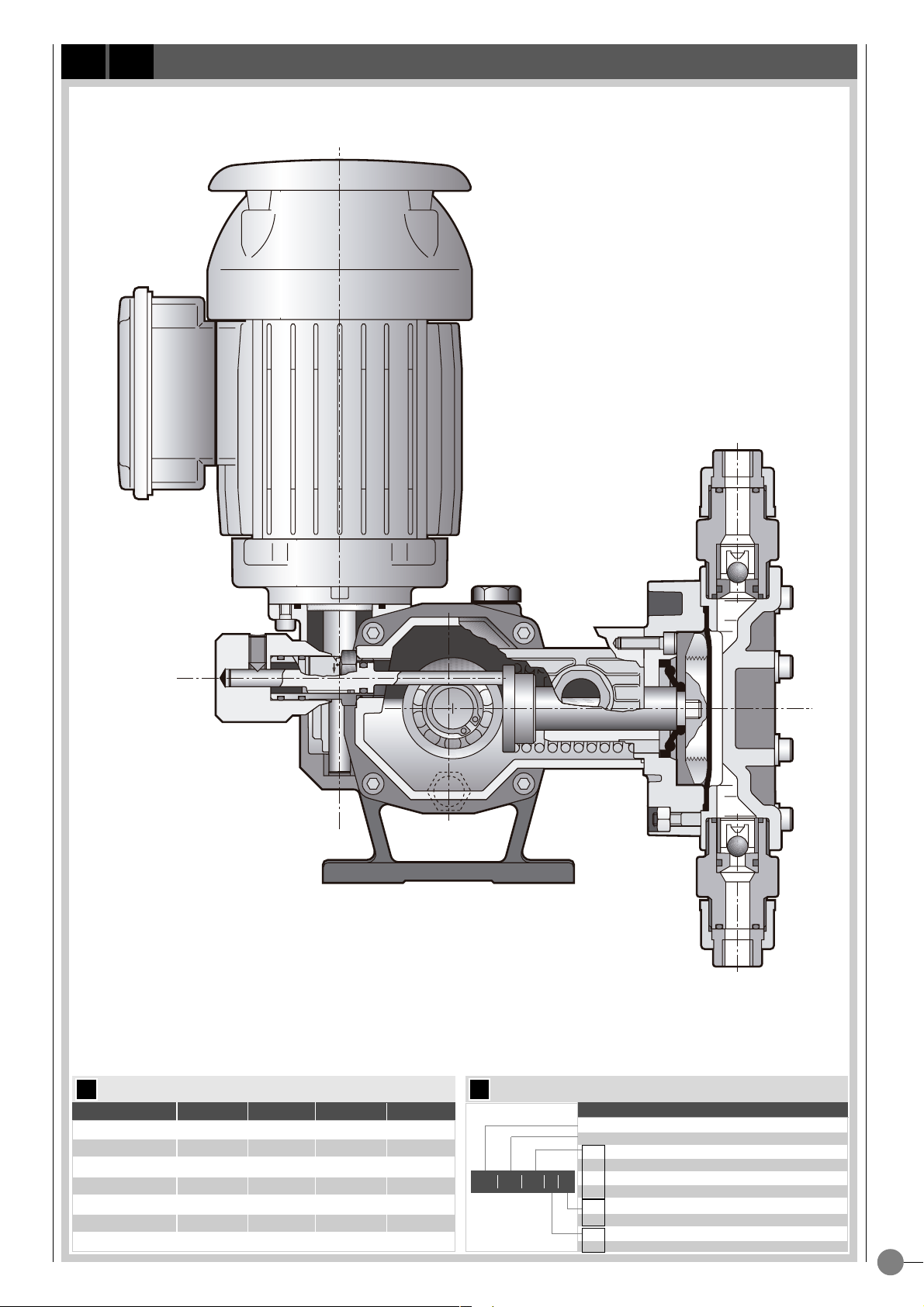

• The OBL’s metering pumps “MB/MC” series are con-

trolled-volume reciprocating pumps.

The crank gear is driven by an electric motor and the

strokes per minute of the diaphragm are given by an

integral, oil-splash-lubricated , endless

screw/wormwheel reduction gear (fig.1).

In MB/MC’s mechanical diaphragm metering pumps,

suction stage (diaphragm backward stroke) is by spring

return.

The MB/MC series metering pumps are characterised by

a so called mechanical diaphragm, where the reciprocating movement is transmitted directly by the crank gear.

The mechanical diaphragm works, both giving the swept

volume, acting basically as plunger, and as separator between crank

gear and the handled fluid.

• The MB/MC mechanical diaphragm metering pumps give a double

advantage:

- Leak-free head.

- No plunger packing and related wearing problems.

These results are achieved thanks to the unique structure of the diaphragm (patented), which bears the whole thrust of the handled liquid,

and, like a plunger pump, guarantees a linear flow rate (table A).

DESCRIPTION OF THE PUMP

GENERAL CHARACTERISTICS

GENERAL CHARACTERISTICS

Fig. 1

1

5

1.3

1.4

1.5

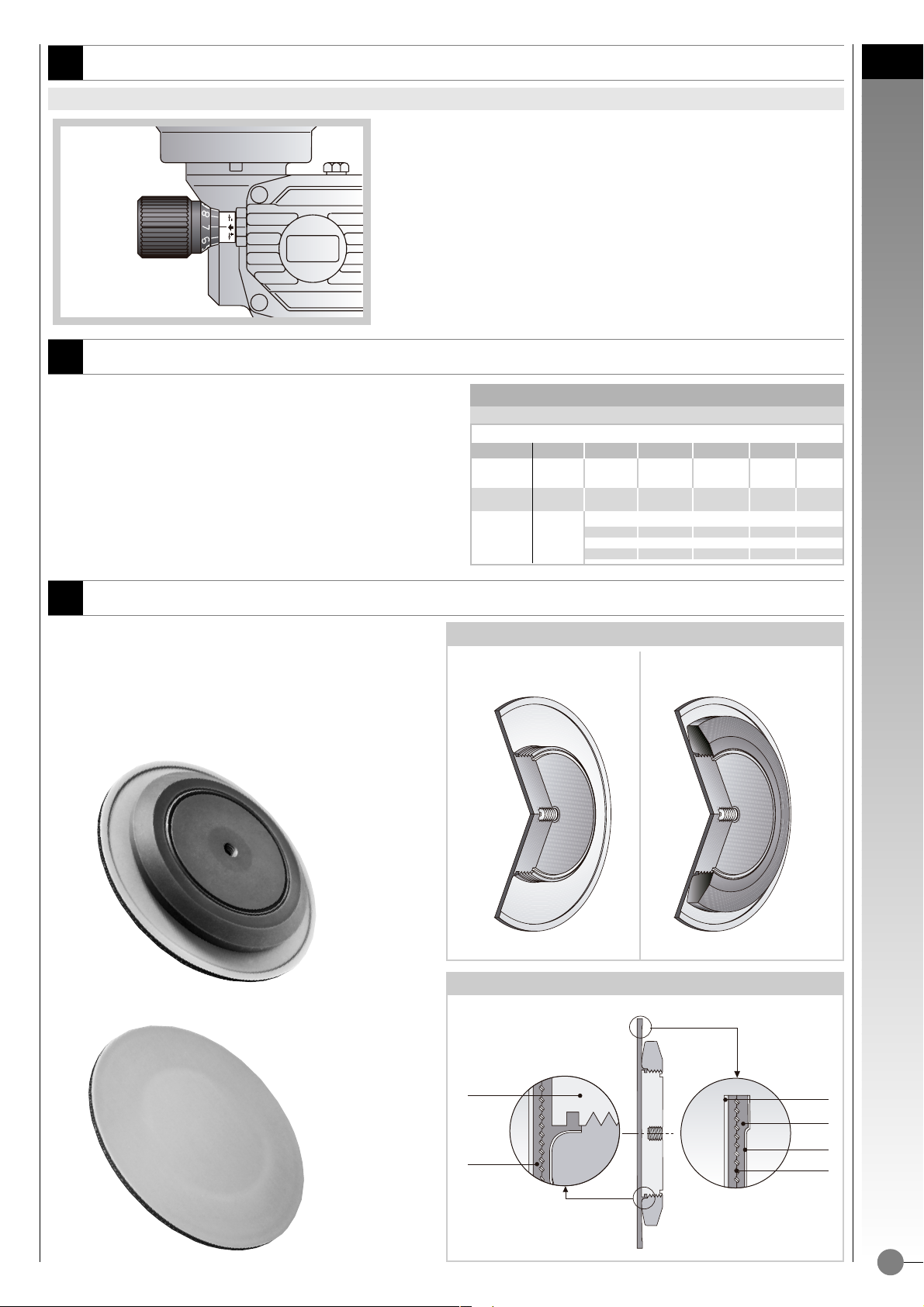

STANDARD

Fig. 5

DETAIL OF THE BONDING BETWEEN DIAPHRAGM AND METALLIC SUPPORT

DIAPHRAGM SECTIONAL VIEW

RUBBER

METALLIC

SUPPORT

PFTE

RUBBER

PFTE

NYLON NET

Sectional view without

plastic support ring.

Complete sectional view with

plastic support ring.

GAMAR MOTOR SPECIAL FLANGE AND SHAFT

PUMP TYPE PHASES kW POLES

SIZE

VOLT Hz

MB THREEPH 0,20 4 63

230

50/60

400

MC THREEPH 0,30 4 63

230

50/60

400

0,24/037 4 63/71 230 50

MB

SINGLEPH

0,24/037 4 63/71 230 60

MC 0,24/037 4 63/71 110 50

0,24/037 4 63/71 110 60

Table B

• The OBL's unique (patented) mechanical diaphragm

design ensures controlled volumetric displacement, giving

plunger-like performances.

Thus the flow rate is virtually unaffected by the working

pressure variations.

DIAPHRAGM STRUCTURE

• In table B are described motors installed on MB/MC pumps.

Endless screw is directly keyed on extended motor shaft.

MOTOR CHARACTERISTICS ACCORDING TO THE PUMP SIZE

• The adjustment of the diaphragm stroke is stepless and regular, and can be

carried out any time, i.e. when the pump stands still or is running (fig.5).

FLOW RATE MANUAL BY MICROMETER

GENERAL CHARACTERISTICS

MANUAL ADJUSTMENT

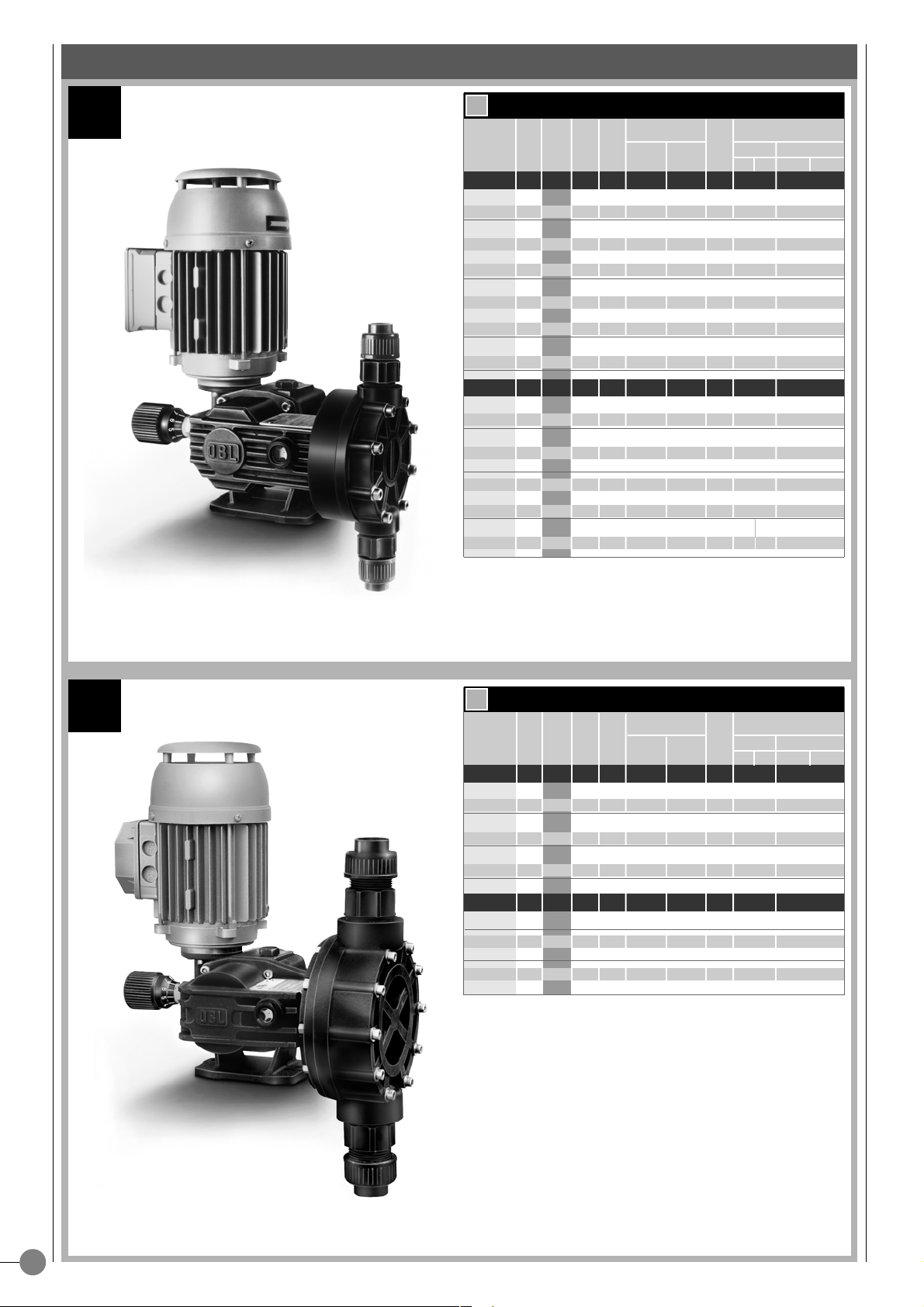

2

6

2.1

2.2

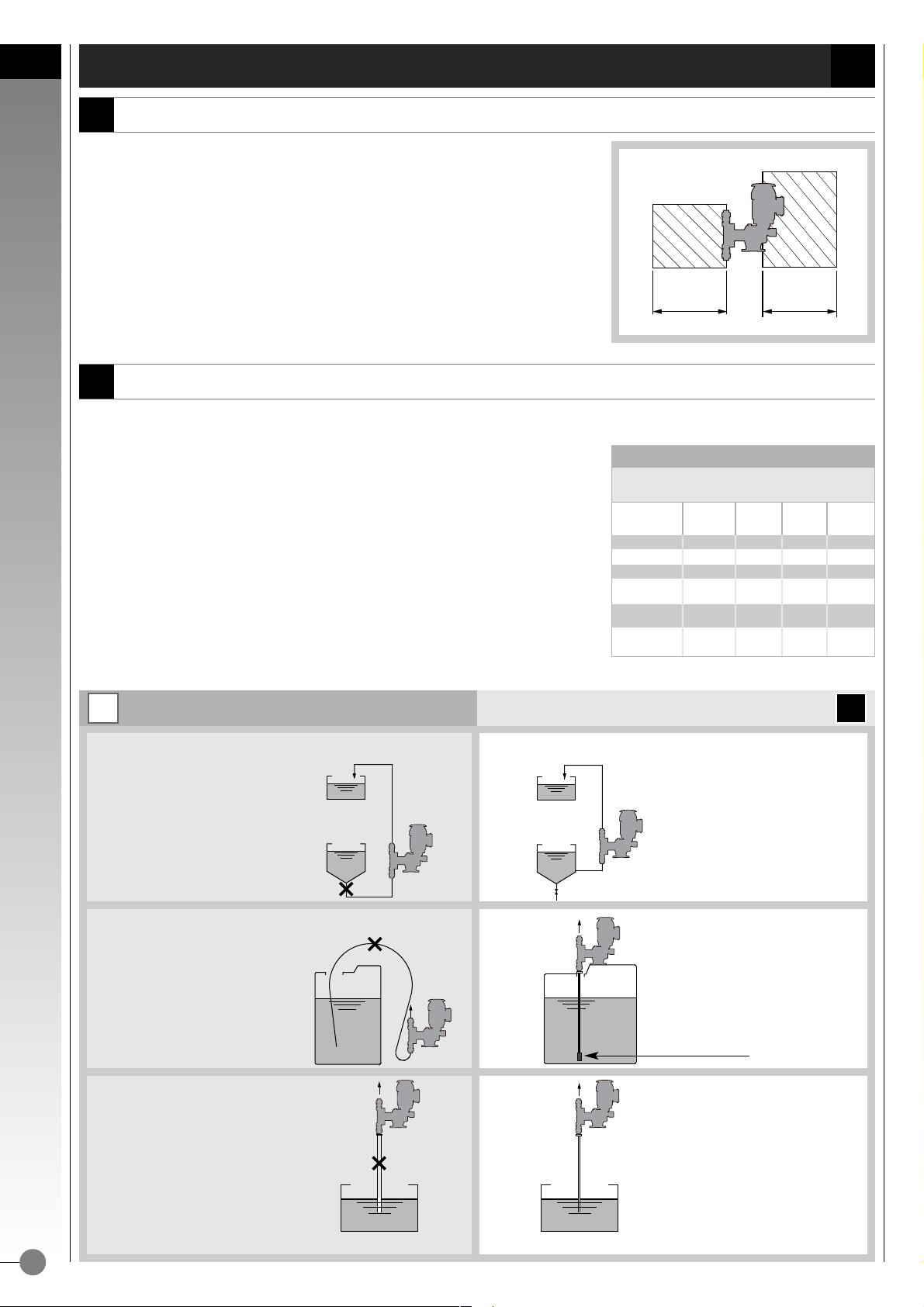

80 cm. 70 cm.

0÷15 4x6 - - 0÷30 6x10 - 1/4"-

0÷125 -

DN 10

3/8" Ø16

0÷155 -

DN 15

1/2" Ø20

1/2" ANSI

0÷260 -

DN 20

3/4" Ø25

3/4" ANSI

0÷420 -

DN 25

1" Ø32

1" ANSI

➜

➜

2

Fig. 7/A

Fig. 6

RIGHTWRONG

FILTER FOOT VALVE

Right

Right

Right

Pipe size according

with table C

Wrong

Risk of clogging of pump valves

Wrong

In the highest point of the piping

the fluid vein breaks

Wrong

Pipe size not according

with table C

• A proper installation and sizing of the suction line are of particular importance for a correct operation of the pump, the following

factors shall be taken into account

:

A) Pipe inner diameter

The pipe internal diameter will be chosen according to the pump flow rate (see table C)

.

The pump connections are oversized, in order to cover all applications.

B) Length of the piping

Suction piping is to be as short as possible, following the indications of table C

it is suggested:

- Max suction lift 1,5 metres

- Total length 2,5 metres (upright plus horizontal)

C) Arrangement of the suction line

For the arrangement of the suction line see Fig. 7/A and 7/B.

Table C

Relationship between flow rate and pipe size

FLOW RATE L/h

PIPE WITH

FITTINGS

FLANGED

PIPE

THREADED

PIPE

PVC GLUED

PIPE

SUCTION LINE

ADJUSTMENT SIDE

HYDRAULIC SIDE

ASSEMBLING AREA

• Provide with adequate clearance areas and safe access for operation and mainte-

nance, in particular in front of the hydraulic side and of the adjustment knob (fig. 6).

• If the pump is installed outdoors, a shelter is recommend, specially when the pump is

equipped with electric actuators or other delicate devices.

• PP pump heads can work properly only at ambient temperature and metered liquid

temperatures below 40°C.

• If necessary, provide suitable protection from sun rays and check the temperature of

the metered liquid.

INSTRUCTIONS FOR A PROPER INSTALLATION

INSTALLATION

INSTALLATION

Loading...

Loading...