OASIS-4i Installation Guide

Warning!

This board contains static sensitive components. Please take the

necessary precautions when handling and installing the board, to

prevent damage or malfunction.

Contents

Introduction...........................................................................................1

Installation Requirements .....................................................................2

Installation Process...............................................................................2

Connector Identification........................................................................3

Hardware Installation Procedure...........................................................3

Driver Installation Procedure for Windows

Driver Installation Procedure for Windows 98/Me................................5

Driver Installation Procedure for Windows NT.....................................6

Configuring the OASIS-4i controller......................................................6

OASIS Configuration Wizard.............................................................6

2000/XP.............................5

OASIS Flash Memory Configuration Utility........................................7

What Next?...........................................................................................9

If You Need Help ..................................................................................9

Troubleshooting Guide..........................................................................9

Introduction

Thank you for purchasing the OASIS-4i four axis stepper controller for

the PCI bus! The OASIS-4i is an advanced, high-performance

controller designed for the most demanding imaging and microscopy

applications. The compact PCI form factor ensures a highly integrated

solution for automation control.

This guide provides an overview of how to physically install the OASIS4i card into your system, install the required driver software, and

configure the controller for your particular setup.

Note that your OASIS-4i may have been provided as part of an

integrated automation system. There may be aspects of your system

configuration that are specialized for your application. In these

situations, please contact your system vendor for details regarding

your configuration before proceeding.

Installation Requirements

In order to install the OASIS-4i card into your system, you will need the

following:

• PC with one three-quarter length PCI slot available

•

Windows® XP, Windows® 2000, Windows® 95/98/Me, or

Windows® NT4.0 operating system

•

CD-ROM drive

One free (hard disk style), power connector, with 2A at 12V

•

available

•

Cross-head screwdriver

•

OASIS-4i Installation CD

Installation Process

The OASIS-4i installation process consists of three distinct steps:

1. Hardware Installation. In this step, you will physically place

the OASIS-4i card inside your computer.

2. Driver Installation. After installing the hardware, you need to

install the driver software so that Windows recognizes the card

and application software can use it.

3. Configuration. You will need to configure the OASIS-4i card to

match your particular system setup.

Once these steps are complete, the OASIS-4i card is generally ready

for use. However, if you are using a 3

need to install additional software so that your application package can

use the OASIS-4i controller to drive the motorized components of your

system. Refer to your application / system documentation for further

details on how to configure the application for use with OASIS-4i.

rd

party application, you may

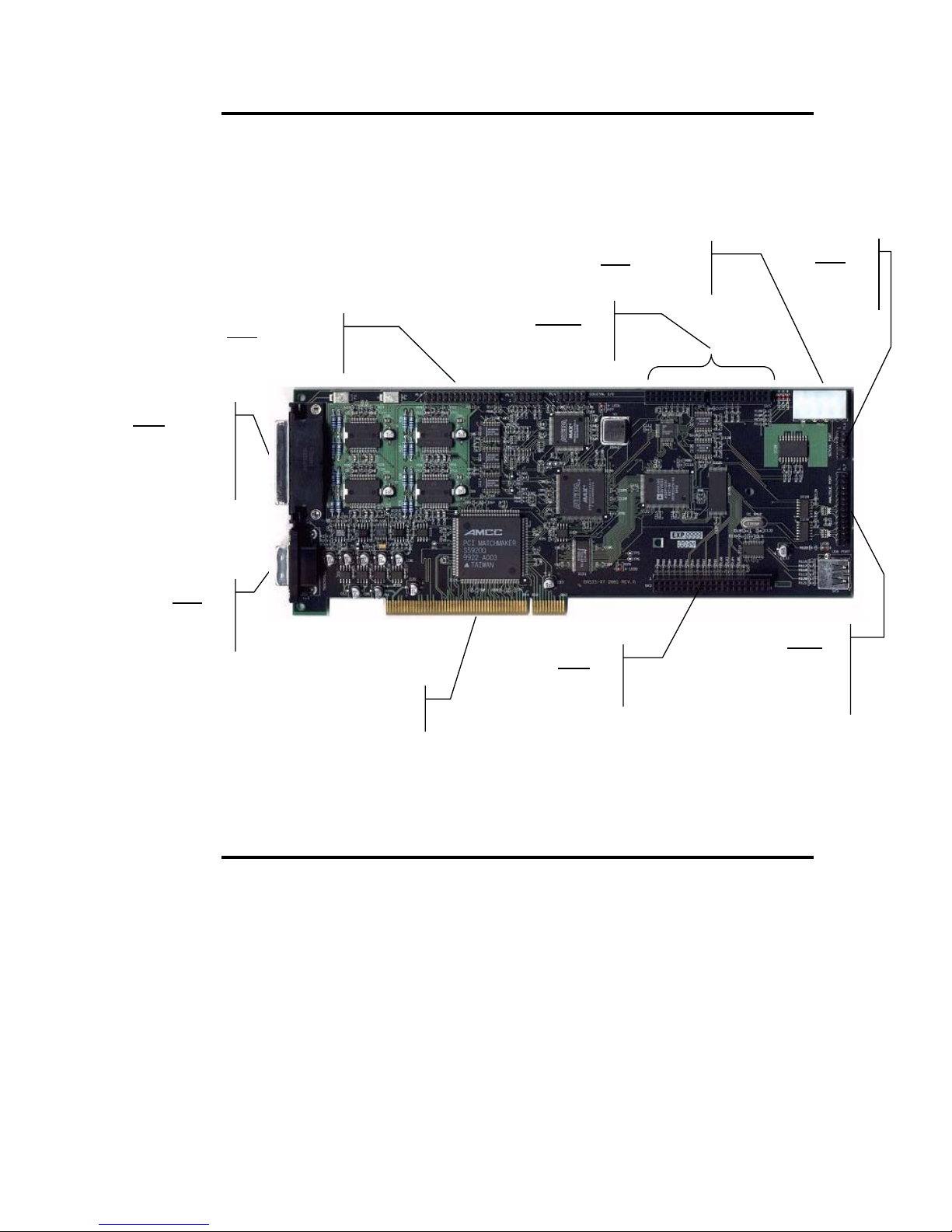

Connector Identification

–

r

–

r

–

–

A

r

–

Refer to the following diagram for information regarding the various

connectors available on the OASIS-4i card.

SK1 – XYZ

output, video

I/O, general

logic output

PL1

Trackball

serial port

PL2 – Fourth

axis output

PCI Connecto

SK3,4

Option card

SK2

Option card

PL5 –Motor

powe

PL7

nalogue port

for Joystick o

OI-SNP

PL6

Serial

port

Hardware Installation Procedure

Preparing the

PC case

1) Switch off the PC and unplug from the mains to disable any

standby power.

2) Remove the system unit cover or side panel.

3) Select a suitable PCI slot with no obstructions (preferably one with

adequate air-flow from the auxiliary fan), and remove blanking

panel as necessary.

Figure 1. OASIS-4i Connectors

Fitting the

card

4) Ground yourself to an antistatic mat or other grounded source to

discharge static electricity before handling the board.

5) Pick up the board (still in its anti-static sleeve), by grasping the

metal edge bracket with one hand, and remove the sleeve.

6) Taking care to hold the edges of the board, avoiding contact with

the electronic components, position it over the PCI slot and locate

the tip of the metal bracket in the slot of the PC chassis, before

pushing the board firmly but gently home with a slight rocking

action.

7) Secure the bracket with a retaining screw.

Connecting

power and

options

8a) If intending to use the 4th axis, you will need to fit an adapter

plate to another spare slot and the interconnecting cable to PL2 the

4th axis output. Be careful to attach pin 1 of the ribbon cable (with

the red stripe), to pin 1 of PL2, which is marked on the board

(towards metal bracket).

8b) If fitting a joystick or OI-SNP (Leica SmartMove interface), you will

need to fit an adapter plate to another spare slot and the

interconnection cable to PL7, the Analogue Port. Be careful to

attach pin 1 of the ribbon cable (with the red stripe), to pin 1 of

PL7, which is marked on the board (towards the power connector).

8c) If intending to use the OASIS-XA1 5th axis module, please refer to

the OASIS-XA1 documentation for connection details.

8d) If intending to use the OASIS-DC1 module, please refer to the

OASIS-DC1 documentation for connection details.

9) Connect a spare power connector from the PC power supply to

PL5 at the rear of the board. Preferably the OASIS-4i should be the

only device drawing power from this lead. The on board motor

drive components get their power via the +12V from this connector.

Making

external

connections

10) Replace PC system cover or side panel.

11) If using a Kensington Expert Mouse 5.0 trackball or other serial

control device, connect it to PL1, the 9-pin trackball serial port

below the 44-way main connector.

12) Connect the appropriate cable from SK1, the 44-way XYZ and

video in/out connector, to your desired XY stage, focus adapter(Z)

and video source as required. Notice that this 44 way connector is

keyed to prevent insertion of an incorrect cable.

13) You are now ready to switch on the PC and proceed with the

driver installation for your operating system.

Warning: Do not connect or disconnect motor cables while the PC is

powered on. The OASIS-4i card may be applying power to the motors,

in which case a connection or disconnection could damage the OASIS4i card.

Driver Installation Procedure for Windows

2000/XP

1) Switch on PC and boot into Window.

2) The 'Add New Hardware Wizard' should appear.

3) Select 'Search for best driver for your device' and press next.

4) Insert OASIS-4i installation CD into your CD-Rom drive and select

'Specify a Location' with 'D:' as the source for the driver. (Where D:

is the CD-Rom drive letter).

5) Windows should find 'OASIS-4i : 4-axis PCI Stage Controller'.

Press next.

6) After drivers and dll's have been copied to the relevant directories,

press 'Finish'.

7) Re-boot the PC before operation of the board and/or installation of

the SDK or other software.

8) A 'WinDriver Virtual Device' may be found after a re-boot. If so, a

suitable driver is included in the 'Drivers' folder of the OASIS-4i

installation CD.

Driver Installation Procedure for Windows 98/Me

1) Switch on PC and boot into Window.

2) The 'Add New Hardware Wizard' should appear.

3) Select 'Search for best driver for your device' and press next.

4) Insert OASIS-4i installation CD into your CD-Rom drive and select

'Specify a Location' with 'D:' as the source for the driver. (Where D:

is the CD-Rom drive letter).

5) Windows 98 should find 'OASIS-4i : 4-axis PCI Stage Controller'.

Press next.

6) After drivers and dll's have been copied to the relevant directories,

press 'Finish'.

7) Re-boot the PC before operation of the board and/or installation of

the SDK or other software.

Driver Installation Procedure for Windows NT

1) Boot into Windows.

2) Run the program called 'Oasis4i_Setup.exe', which is located in the

root directory of the CD. This will install, register and start the

driver.

3) It will be necessary to re-boot before using the board or installing

the SDK or other software.

Configuring the OASIS-4i controller

The OASIS-4i controller is designed to work with a wide range of

different types of automation hardware. For instance, there are a

number of manufacturers of XY motorized stages for microscopes, and

each manufacturer uses different styles of connectors, wirings for limit

switch logic, and other features specific to their make and model of

stage.

In order to drive these different types of hardware, the OASIS-4i

controller must be configured accordingly. Most of these configuration

settings are stored in the onboard flash memory of the OASIS-4i card,

permitting the correct startup conditions when the card is powered up

and initialised.

OASIS Configuration Wizard

The easiest way to configure the card is to run the OASIS

Configuration Wizard (Figure 2). The wizard provides step-by-step

instructions for defining the settings most appropriate for your

particular system.

Figure 2. OASIS Configuration Wizard.

The wizard includes a listing of the various makes and models of XY

stage, focus drives, and filter wheels, and can setup the card based on

known default values for the particular device. The wizard can also

auto-detect the settings of your particular systems—such as limit

switch polarity, axis and limit directions, and encoder settings (if

fitted)—by performing various movements to test and measure your

system’s characteristics.

OASIS Flash Memory Configuration Utility

Individual flash memory settings may be modified using the OASIS

Flash Memory Configuration Utility (Figure 3).

Figure 3. OASIS Flash Memory Configuration Utility.

The flash configuration utility provides a means to adjust the following

settings for each axis:

• Maximum motor current

• Standby motor current

• Backlash correction distance

• Standby power timer interval

• Power-on cruise speed

• Power-on ramp profile

• Axis direction (clockwise or counter clockwise)

• Limit switch direction

• Limit switch polarity

• Trackball sense (direction)

• Joystick sense (direction)

• Joystick sensitivity

• Axis Type

• Maximum acceptable move command distance

• Microstepping setup

• Encoder setup

• Calibration leadscrew pitch

Also, advanced settings such as autofocus settings, acceleration ramp

tables, motor drive tables, and joystick deflection tables are defined in

the OASIS-4i flash memory.

What Next?

Once the OASIS-4i card has been installed and configured, the next

step depends on your situation.

If you are the user of a 3

need to perform any further installation required to support the OASIS4i card within you application. Please refer to your imaging

application’s documentation for further instructions.

If you are a developer of applications that will use the OASIS-4i

controller, you should next install the OASIS-4i SDK from the OASIS

CD. This will copy the full OASIS software utilities, libraries and

include files, and support documentation to your development system.

Please refer to the OASIS-4i SDK DLL manual for further details

regarding integration of the OASIS-4i into your system software.

rd

party imaging application, you would next

If You Need Help

As mentioned in the Introduction, if your OASIS-4i controller was

provided as part of an integrated solution, your first contact should by

to your system vendor. They will be most familiar with your overall

system and any specialized configuration details.

To contact Objective Imaging directly, please visit

www.objectiveimaging.com for contact details for your area.

Troubleshooting Guide

Problem Possible Causes Solution

OASIS-4i card not

detected by Windows;

Plug-and-Play does not

find OASIS-4i card

• Card not fully seated

into PCI slot

Ensure card is fully seated

into PCI slot along entire

length

• Conflict with another

card on PCI bus

Move OASIS-4i card to

another free PCI slot

Problem Possible Causes Solution

OASIS-4i card is listed as

an unknown PCI device in

Windows Device Manager

My 3rd party application

software cannot recognize

OASIS-4i card

My 3rd party application

recognizes the OASIS-4i

card, but the motors are

not working

• OASIS-4i driver not

installed

• OASIS-4i driver not

installed

• Application’s support

library for OASIS-4i

card not installed

• Motor power not

connected

• Motor cable

connectors

disengaged or faulty

Perform driver installation

procedure

Perform driver installation

procedure

Run application’s

motorized controller

installation procedure;

refer to the application

documentation for further

details

Ensure OASIS-4i motor

power connector (PL5) is

fitted with a power supply

plug

Ensure motors are

connected fully fitted at

OASIS-4i connector SK1

and at motor end of cables

The system is stalling

when making movements

• OASIS-4i is not

properly configured for

the type of automation

hardware fitted

• Axis positions are

outside the limits of

travel

• Insufficient power to

motor drives

• Insufficient power to

motor drives

Run OASIS configuration

wizard to setup the card

for your system

Run OASIS configuration

wizard or 3

rd

party

application options to

initialize the axis

coordinate system

Adjust maximum motor

current using the OASIS

Flash Memory

Configuration utility

Use parallel motor

windings to increase

current in motor phases

Problem Possible Causes Solution

The XY stage does not

halt when a physical limit

is reached

An axis is not moving the

correct distance when

attempting to step a

known amount

• Insufficient power to

motor drives

• The drive leadscrew is

damaged

• Limit switch direction

is incorrect for stage

type

• Axis calibration

incorrect

• The axis is stalling

• Encoder, if fitted, is

configured incorrectly

Increase motor drive

voltage using external 24V

power supply

Contact automation

mechanics manufacturer

for service details

Run OASIS configuration

wizard to auto-detect limit

switch direction and

polarity

Set axis pitch or step size

using OASIS or 3

rd

party

application software

See troubleshooting

section for stalling during

movement

Run OASIS configuration

wizard for encoders or

define encoder settings

using OASIS Flash

Memory Configuration

utility

The Joystick is not

working

• Internal cable

connection error

Verify internal connection

from joystick cable

connector plate to PL7 on

back end of OASIS-4i

card; ensure red stripe on

ribbon cable is aligned to

Pin 1 on connector PL7

Loading...

Loading...