Oberheim Prommer Service Manual

Oberheim Prommer

Digital MIDI Sampler / PROM Programmer

SERVICE MANUAL

Paul J. White

© 1986 Oberheim – A Division Of ECC Development Corporation

11650 West Olympic Boulevard, Los Angeles, California 90064

Oberheim, the Oberheim logo and Prommer are trademarks of ECC

Development Corporation.

Prommer Service Manual 1

Table of Contents

Introduction .......................................................................................................... 3

Power Supply Adjustment.................................................................................... 3

Initialization .......................................................................................................... 3

Test Programs...................................................................................................... 4

Display Intensity................................................................................................ 4

Memory Test..................................................................................................... 4

Display test.......................................................................................................5

Sine wave test .................................................................................................. 5

VCC Supply test ............................................................................................... 5

VPP Power supply test..................................................................................... 6

Relay Test ........................................................................................................ 6

PROM data test................................................................................................6

Battery replacement............................................................................................. 7

Circuit description................................................................................................. 7

Power supply....................................................................................................7

Programmable power supplies ......................................................................... 8

Battery backup.................................................................................................. 8

RESET circuitry ................................................................................................ 8

Microprocessor and memory ............................................................................ 8

Clock and timing circuitry.................................................................................. 9

MIDI interface ................................................................................................... 9

Audio input...................................................................................................... 10

Analog to digital converter.............................................................................. 10

Digital to Analog conversion (Playback) ......................................................... 11

Reference voltage generation......................................................................... 11

Vacuum Fluorescent Display..........................................................................12

EPROM Programming circuitry....................................................................... 12

Switch Matrix .................................................................................................. 13

LED audio level meter .................................................................................... 13

External Trigger Input..................................................................................... 13

Prommer 6809 Programming Reference............................................................ 14

Interrupts ........................................................................................................ 14

Memory........................................................................................................... 15

Memory Map of the Prommer...................................................................... 15

Programming considerations..........................................................................19

Prommer Service Manual 2

Introduction

This manual is divided into two sections. The first section is designed to assist

the service technician in testing and troubleshooting the Oberheim Prommer

MIDI Audio sampler / PROM programmer. The second section is a programming

reference for the Prommer for those who wish to write application programs for

the Prommer.

The reader should have a basic knowledge of electronics and microprocessor

systems, and be familiar with standard repair techniques.

Power Supply Adjustment

The first step in testing is the calibration of the +5 volt power supply. This is the

only adjustment necessary for correct operation. Open the unit by removing the

two screws under the front edge and lifting the front panel open. With AC power

ON, connect the common lead of a DC voltmeter to ground and probe the +5 volt

test point (the lower end of resistors R81 and R82). Now, adjust the trimmer VR1

(near the upper right corner of the processor board) until the measured voltage is

5.00 volts +/- 10 millivolts.

You may verify the correct operation of the other power supply voltages on the

processor board now. There are no adjustments for the other supplies, but they

should be within the specified ranges.

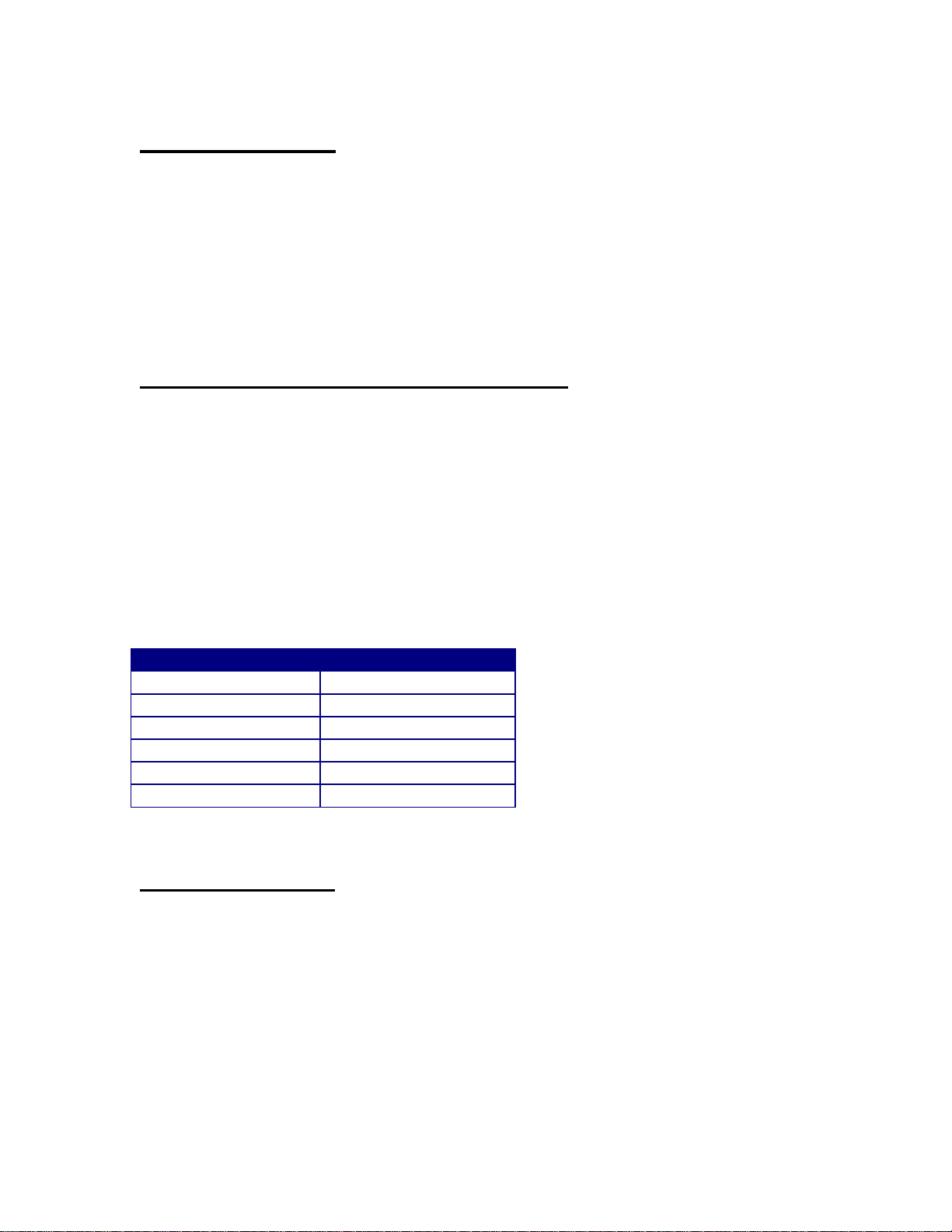

Voltage Test point location

+12v +/- 600mv Pin 4, U18 (TL084)

-12v +/- 600mv Pin 11, U18 (TL084)

-5.1v +/- 500mv Pin 7, U14 (4051)

-35v +/- 5 volts D7 anode

+35 volts +/- 5 volts Q1 collector

-4.1v +/- 100mv Pin 1, U9 (TL082)

Initialization

The first time the unit is powered up, the RAM will contain random data. The

display will read CHECK BATTERY if the unit has never been initialized or if a

memory loss has occurred. To clear the CHECK BATTERY message, initialize

all system and block variables and erase all sound storage RAM, turn the unit off,

press and hold the CLEAR key, and turn the power back on. Continue holding

the CLEAR button until the display lights.

Prommer Service Manual 3

Test Programs

There are eight test programs built into the Prommer. To access the test

programs, hold down the PLAY and RECORD switches while turning on the AC

power. The display should read “TEST PROGRAMS” until the switches are

released, and then will display the first test. To skip over any test in the

sequence, just press the STOP switch.

Display Intensity

Display reads: DISPLAY INTENS. . . The arrow buttons are used to increase or

decrease the brightness of the display. After the display intensity is at an

acceptable level, press the STOP switch to access the next test. The brightness

will remain set at this level until an ERASE ALL, or power-on erase command

resets all memory.

Memory Test

Display reads: MEMORY TEST *. Press EXECUTE to start this non-destructive

RAM test. The display should read BUSY for about 15 seconds and then if there

are no errors in the 64K of data storage memory, the display will read OK. If a

memory error occurs, the address of the first bad location will be displayed. To

locate a bad RAM chip use the following table.

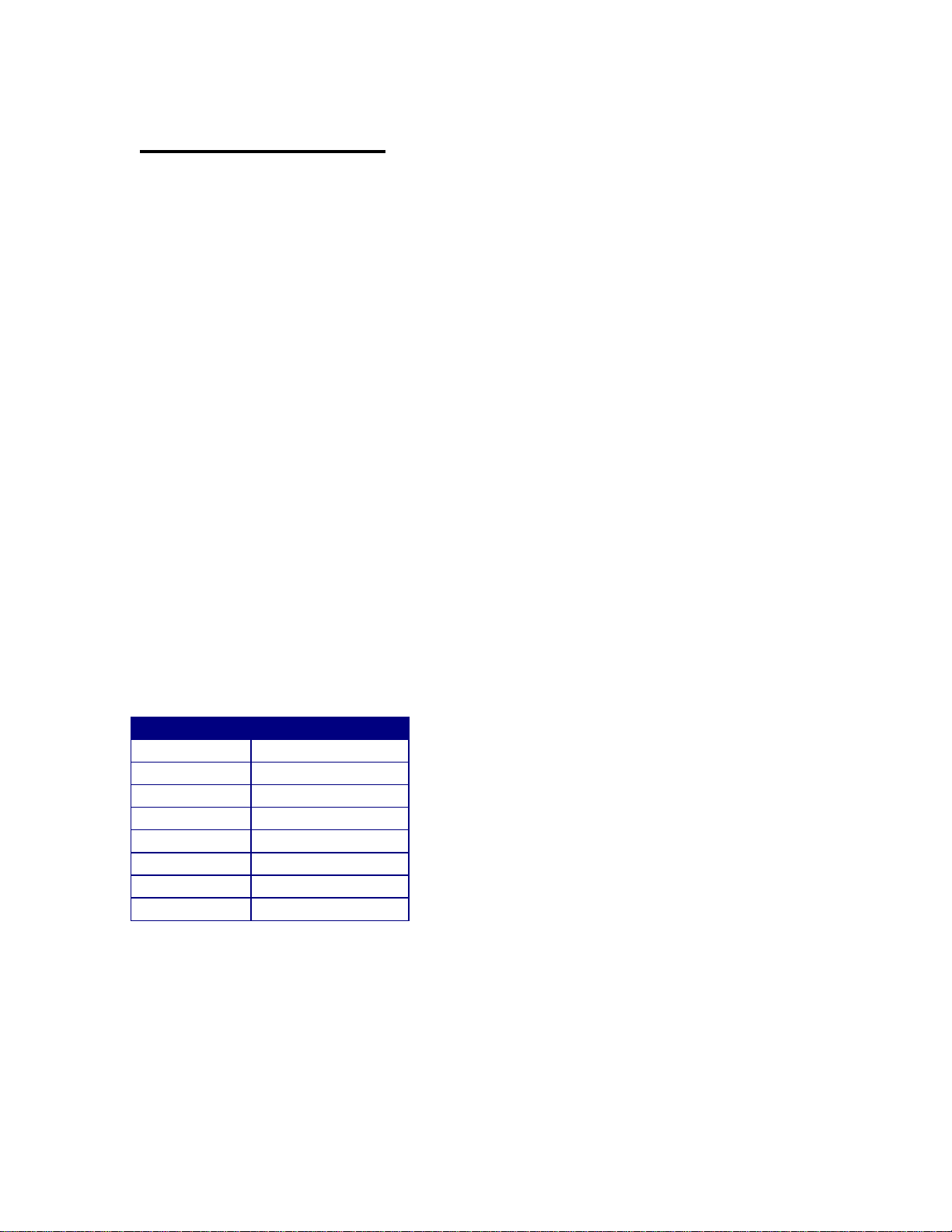

IC number Address range

U46 0 – 8192

U47 8192 – 16383

U48 16384 – 24575

U49 24576 – 32767

U53 32768 – 40959

U54 40960 – 49151

U55 49152 – 57343

U56 57344 – 65535

Press STOP after the memory test is complete to go to next test.

Prommer Service Manual 4

Display test

Display reads: DISPLAY TEST *. Press EXECUTE to start the display test. The

letters A through Z will be displayed in all sixteen character positions in repeating

sequence until the STOP key is pressed. Press STOP to end the display test.

Sine wave test

Display reads: 440HZ SINE WAVE *. Press EXECUTE to start the sine wave

test. A 440HZ sine wave will be generated using the Prommer digital to analog

circuitry. An amplifier and speaker connected to the Line Output can be used to

monitor the output for distortion or an oscilloscope may be used to check the

waveshape. The amplitude of the wave at the output should be about 7 volts

peak-to-peak. If the frequency of the wave is not 440.0Hz, there may be a

problem with the sample rate generator, or the master clock oscillator. Press

STOP to access the next test.

VCC Supply test

Display reads: VCC SUPPLY TEST *. This test and the next one are used to

verify the operation of the programmable power supplies used for EPROM

programming. Make sure the EPROM socket is empty before continuing. Press

EXECUTE to start the test. Connect a DC voltmeter to pin 14 (ground) and

probe pin 28 of the EPROM socket on the front panel. (Note: pin 14 is located at

the lower left corner of the socket, pin 28 is at the diagonally opposite corner and

pin 1 is at the top left corner.) Now, the measured voltage should be within about

five percent of the voltage displayed on the Prommer front panel (see the table).

Use the arrow switches to make the voltage (displayed in millivolts) go up or

down. You may press the “9” switch to set the voltage to its maximum value, or

press the CLEAR switch to reset the voltage to zero.

The VCC supply should be test at several points including zero volts, five volts

(4992 millivolts) and six volts (6016 millivolts). Press STOP to go to the next test.

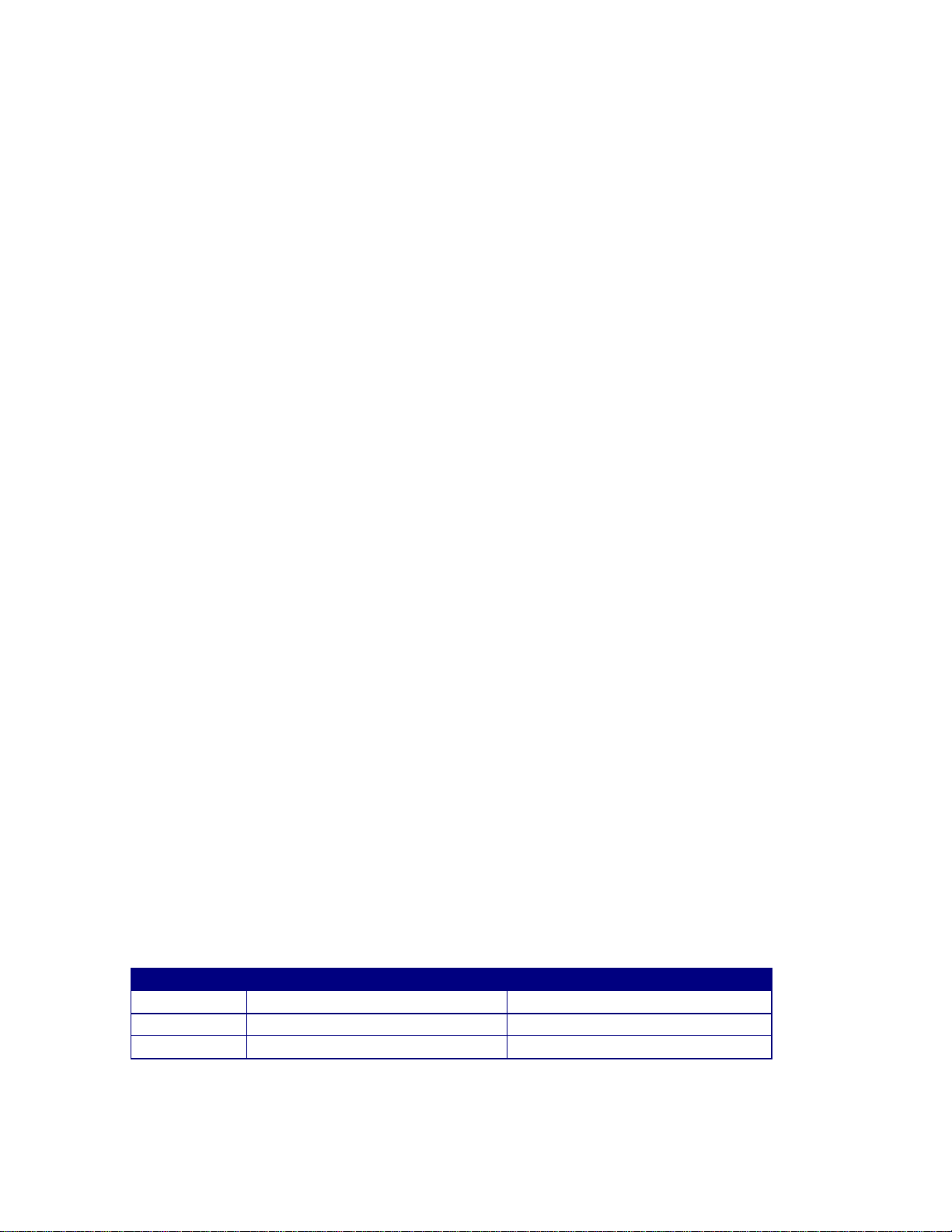

VCC test voltages (pin 28)

Displayed Minimum Voltage Reading Maximum Voltage Reading

0 -0.05 +0.05

4992 4.75 5.25

6016 5.70 6.30

Prommer Service Manual 5

VPP Power supply test

Display reads: VPP SUPPLY TEST *. Press EXECUTE to test the high voltage

programmable power suplly. Connect a DC voltmeter to pin 14 (ground) and

probe pin 1 of the EPROM socket on the front panel. Use the arrow switches to

change the voltage. Voltages should be within about five percent of the

displayed value. Test the VPP supply voltage at zero volts, twelve volts

(11978mv), and twenty-five volts (25016mv). Press STOP to go on to the next

test.

VPP test voltages (pin1)

Displayed Minimum Voltage Reading Maximum Voltage Reading

0 -0.05 +0.05

11978 11.5 12.5

25016 24.0 26.0

If an oscilloscope is available, check the rise and fall time of both power supplies

as you toggle between zero and the maximum voltage. The rise and fall times

should be less than 100 microseconds and there should be no more than 0.5

volts of overshoot. Also check the waveforms for ripple or oscillation. There

should be no more than 100mv of ripple on either power supply at any setting.

Relay Test

Display reads: RELAY TEST *. Press EXECUTE to turn all relays in the

EPROM programming circuitry on and off repeatedly. You should be able to

hear the three relays clicking on and off in a steady rhythm. Press STOP to end

the relay test. You may need to hold the STOP switch for a second before the

Prommer will respond. If the display still reads RELAY TEST, press STOP again

to go to the next test.

PROM data test

Display reads: PROM DATA TEST *. Press EXECUTE to start the test. Display

will then read BUSY…. The PROM data test toggles all address and data lines

connected to the EPROM socket on the front panel. An oscilloscope or signature

analyzer is required to complete this test. Pressing STOP will now return control

to then normal Prommer power-on sequence.

Prommer Service Manual 6

Loading...

Loading...