OAV P305 Instruction Manuals

12” PANEL SAW

INSTRUCTION MANUALS

Table of Contents

2

3

3

4

6

7

7

7

7

8

8

8

8

10

10

11

12

13

14

16

16

17

17

18

18

18

19

19

20

22

24

24

25

25

26

27

27

General Information .......................................................................................................................................

Safety Rules ...................................................................................................................................................

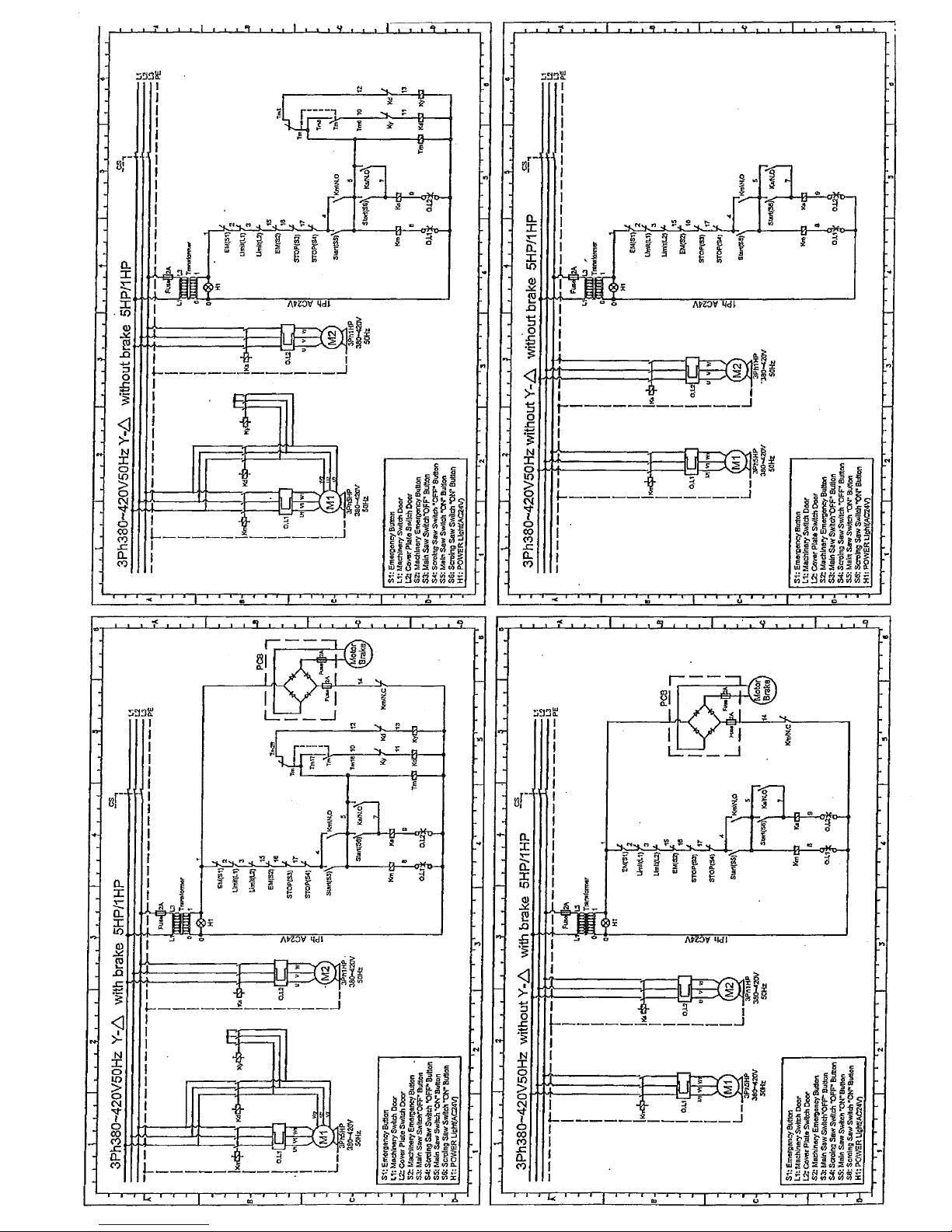

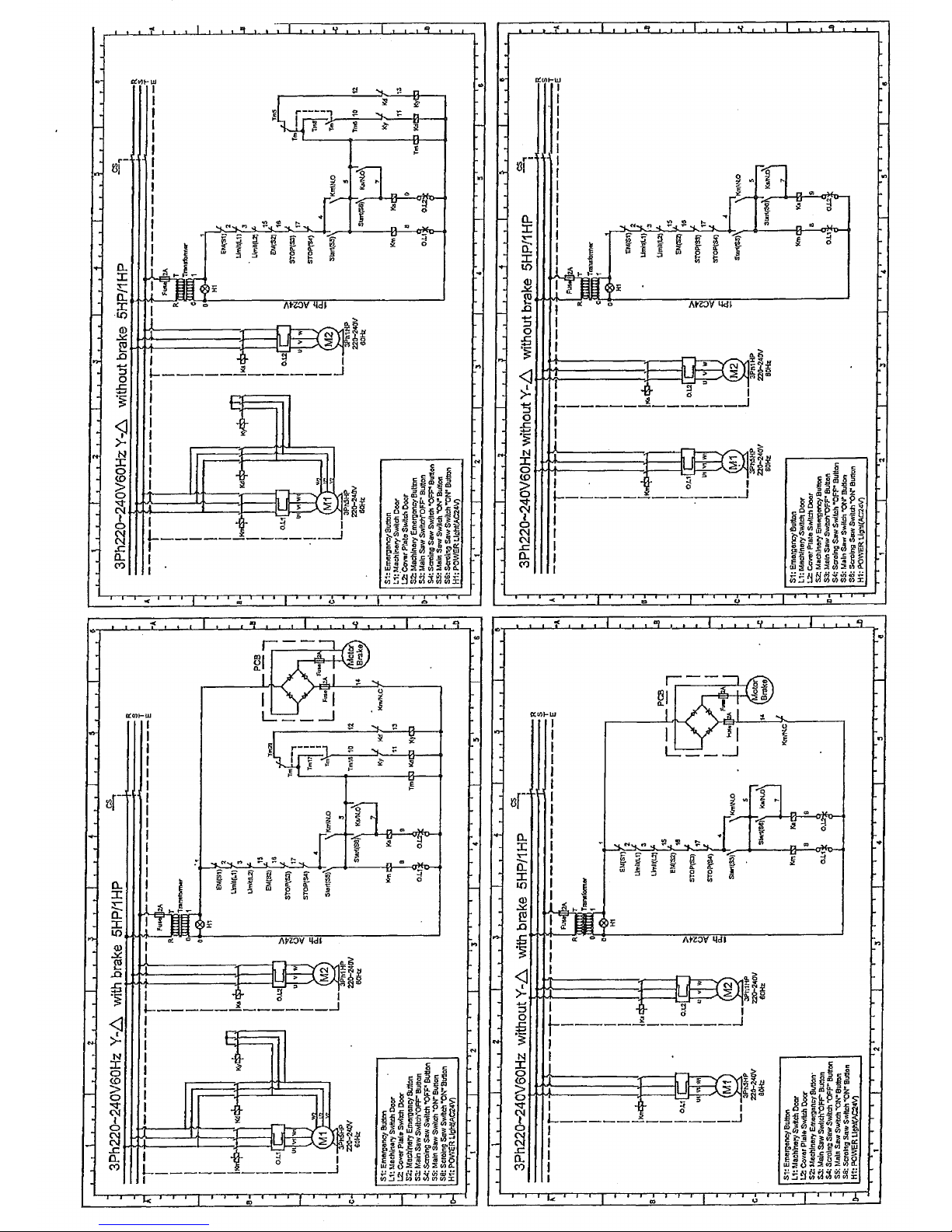

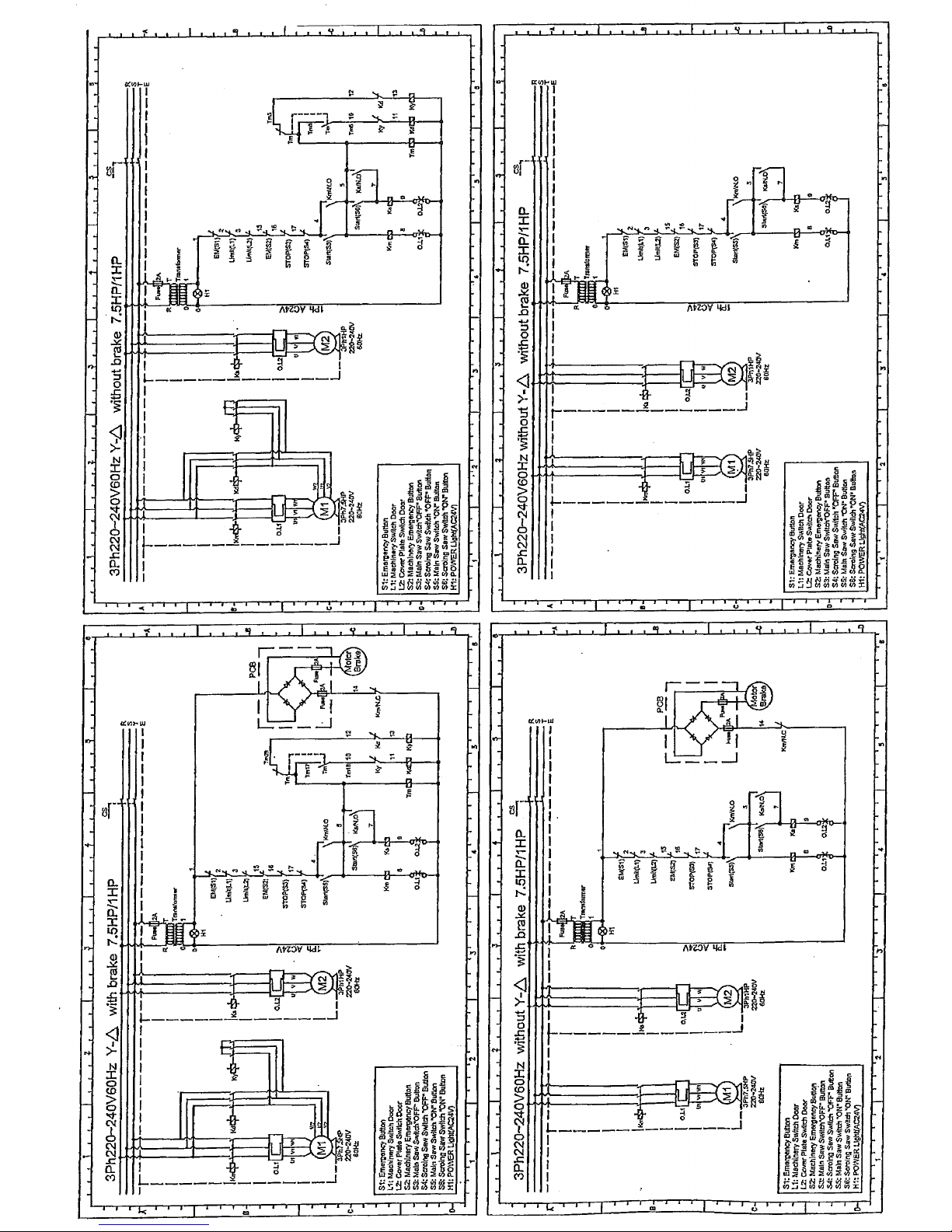

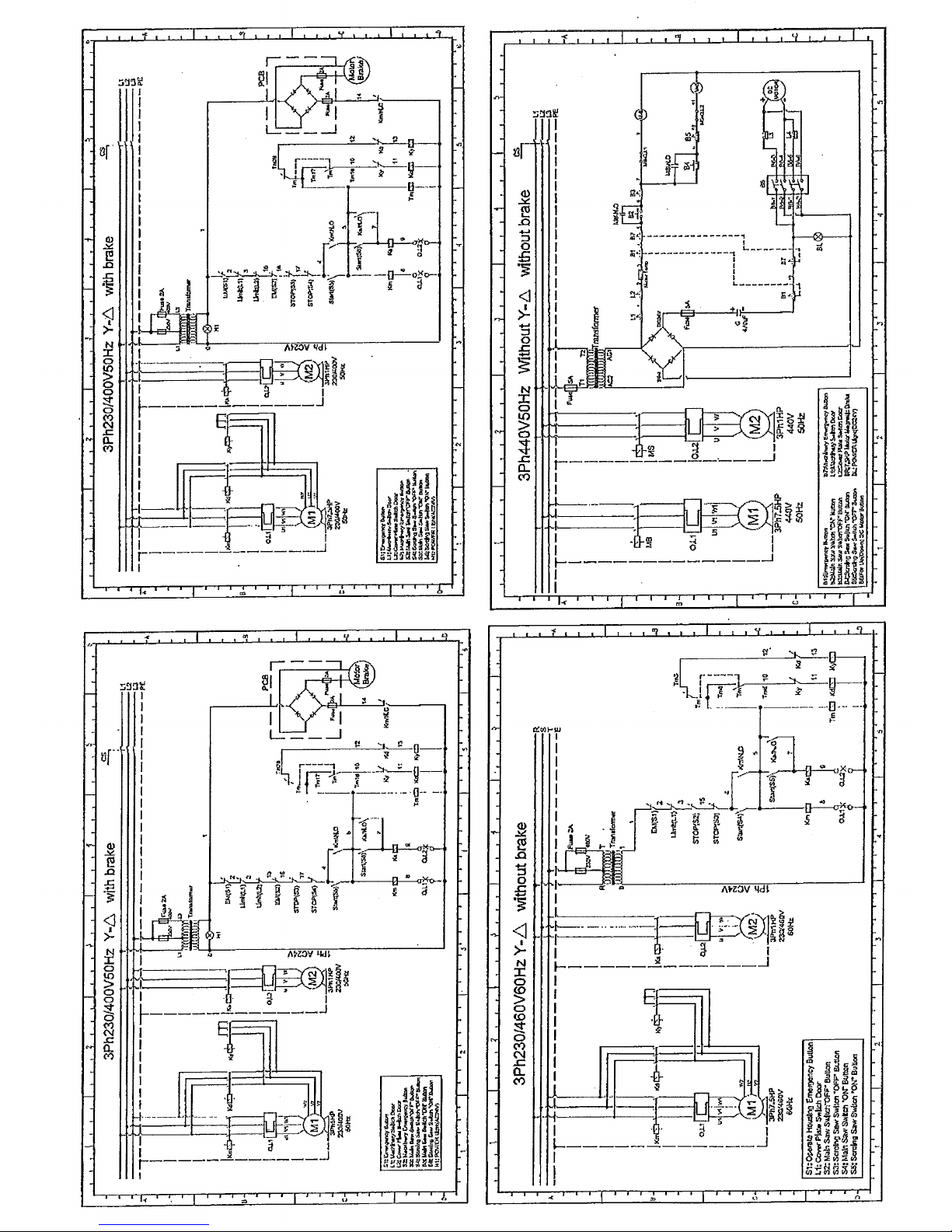

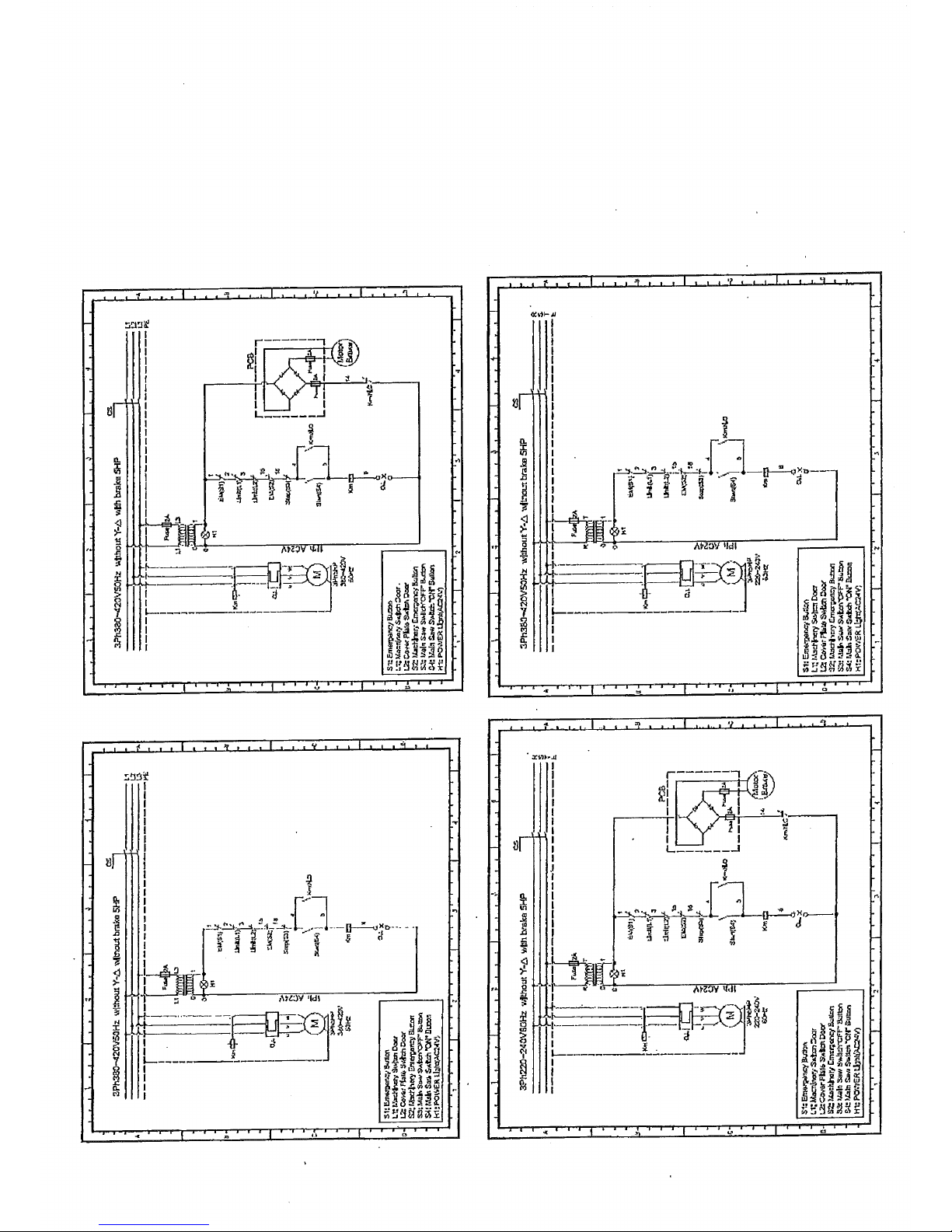

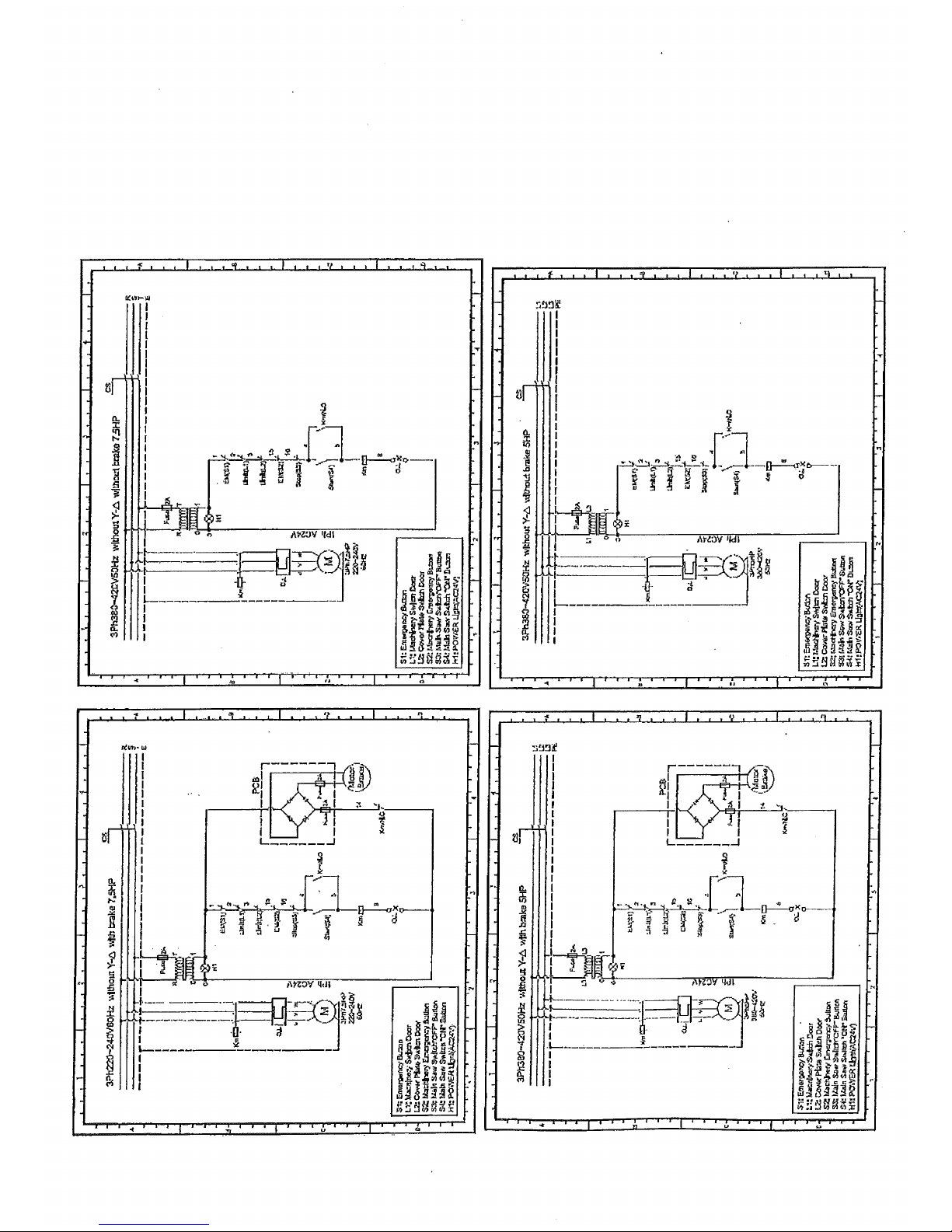

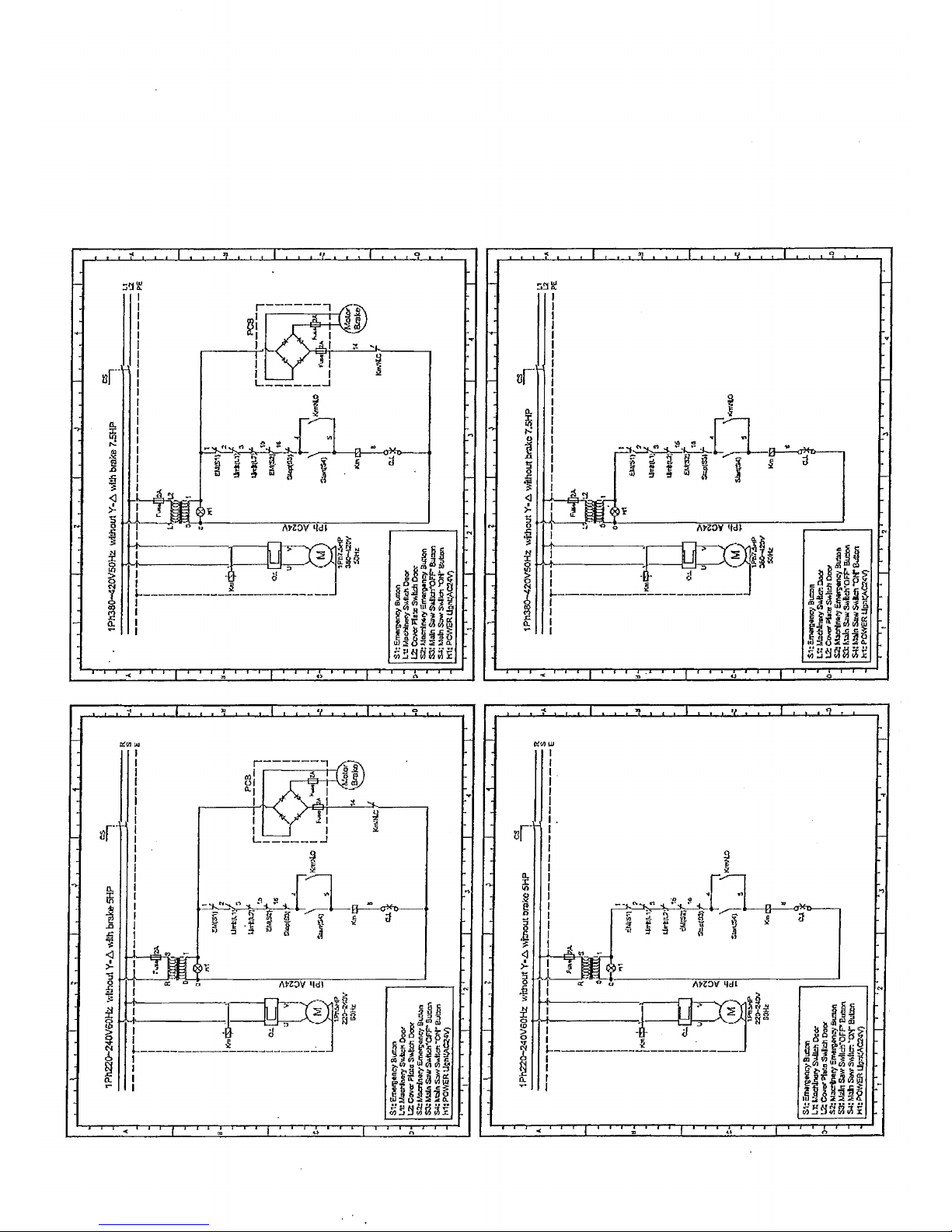

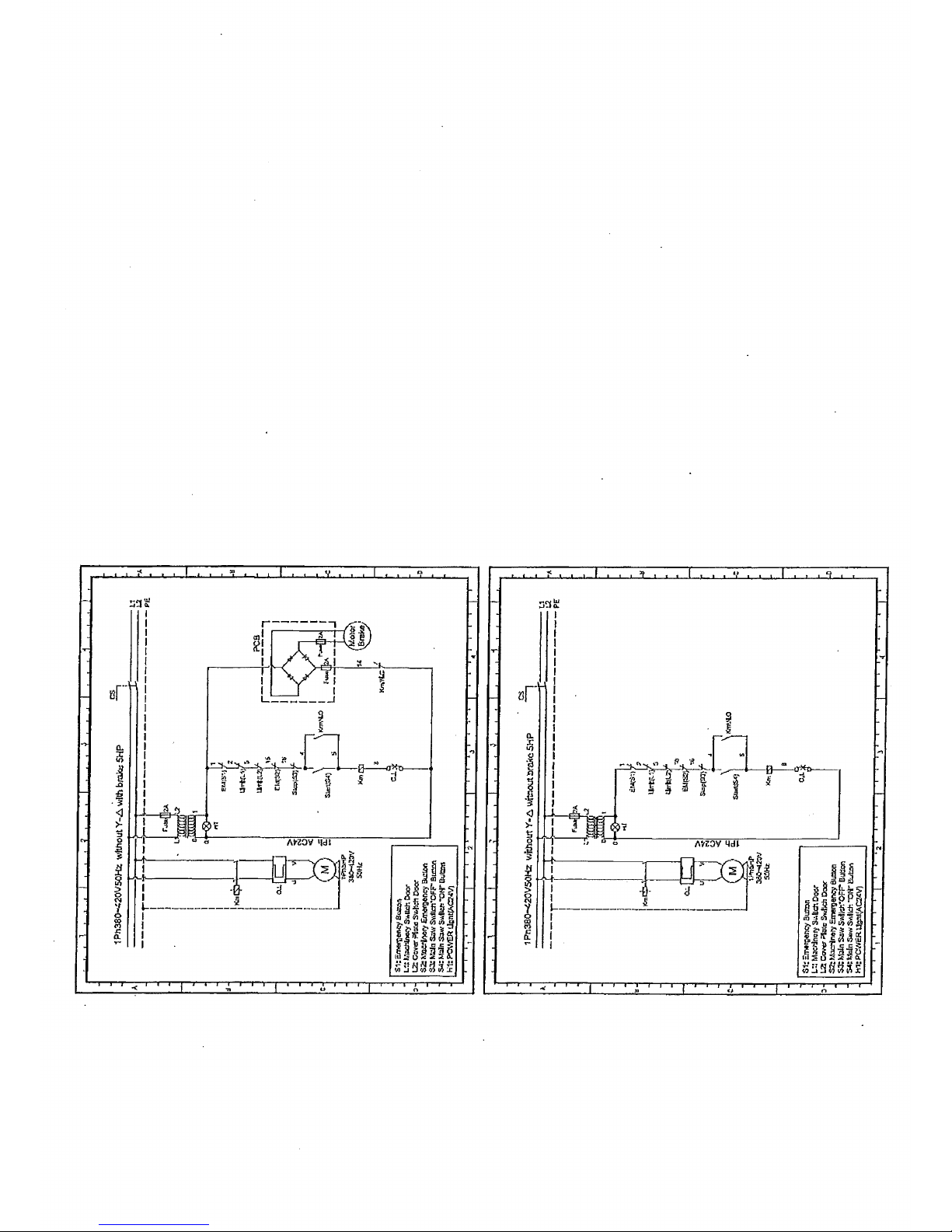

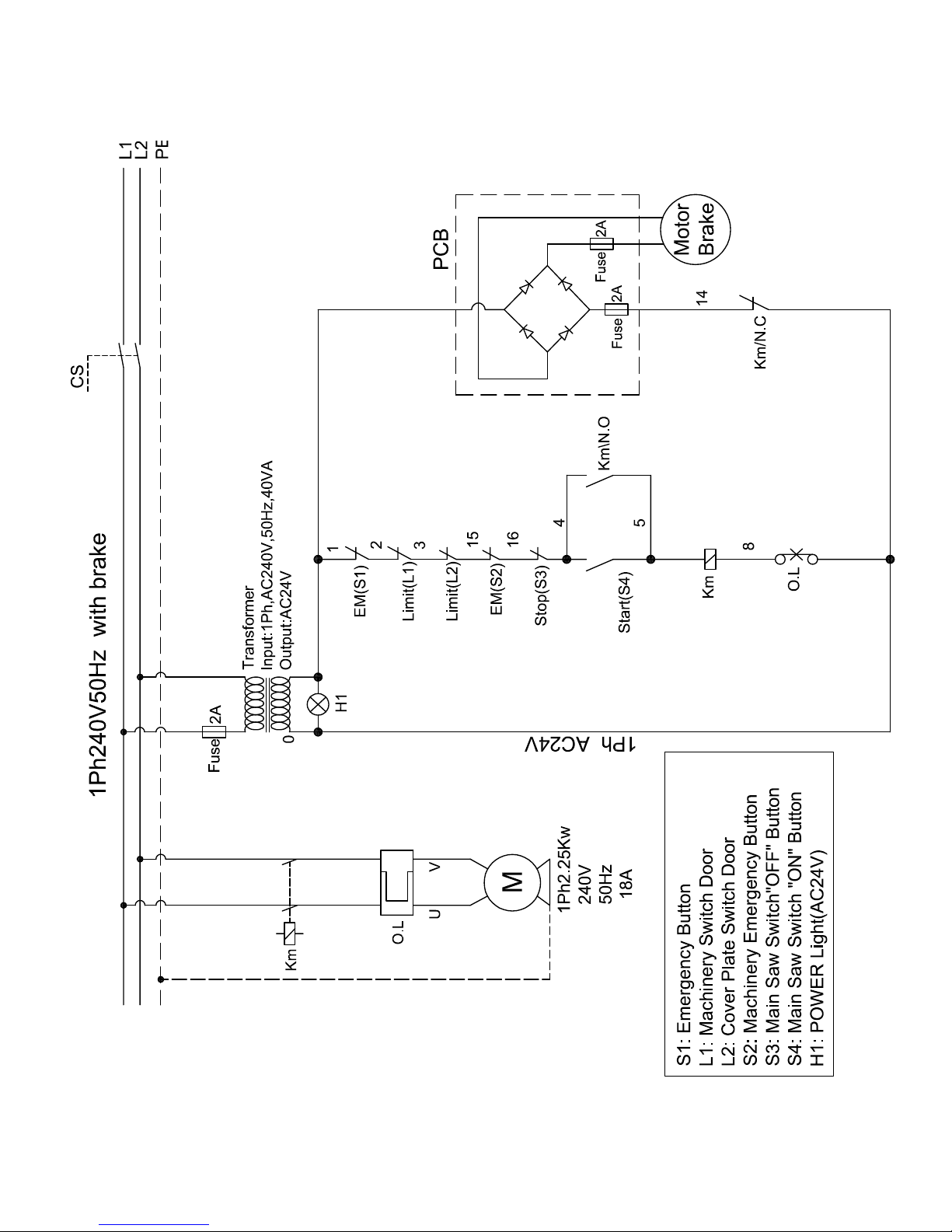

Wiring diagram ...............................................................................................................................................

Specification Sheet ........................................................................................................................................

Main Features ................................................................................................................................................

Assembly And Set Up ....................................................................................................................................

(1). Control Panel ....................................................................................................................................

(2). Rip Fence ........................................................................................................................................

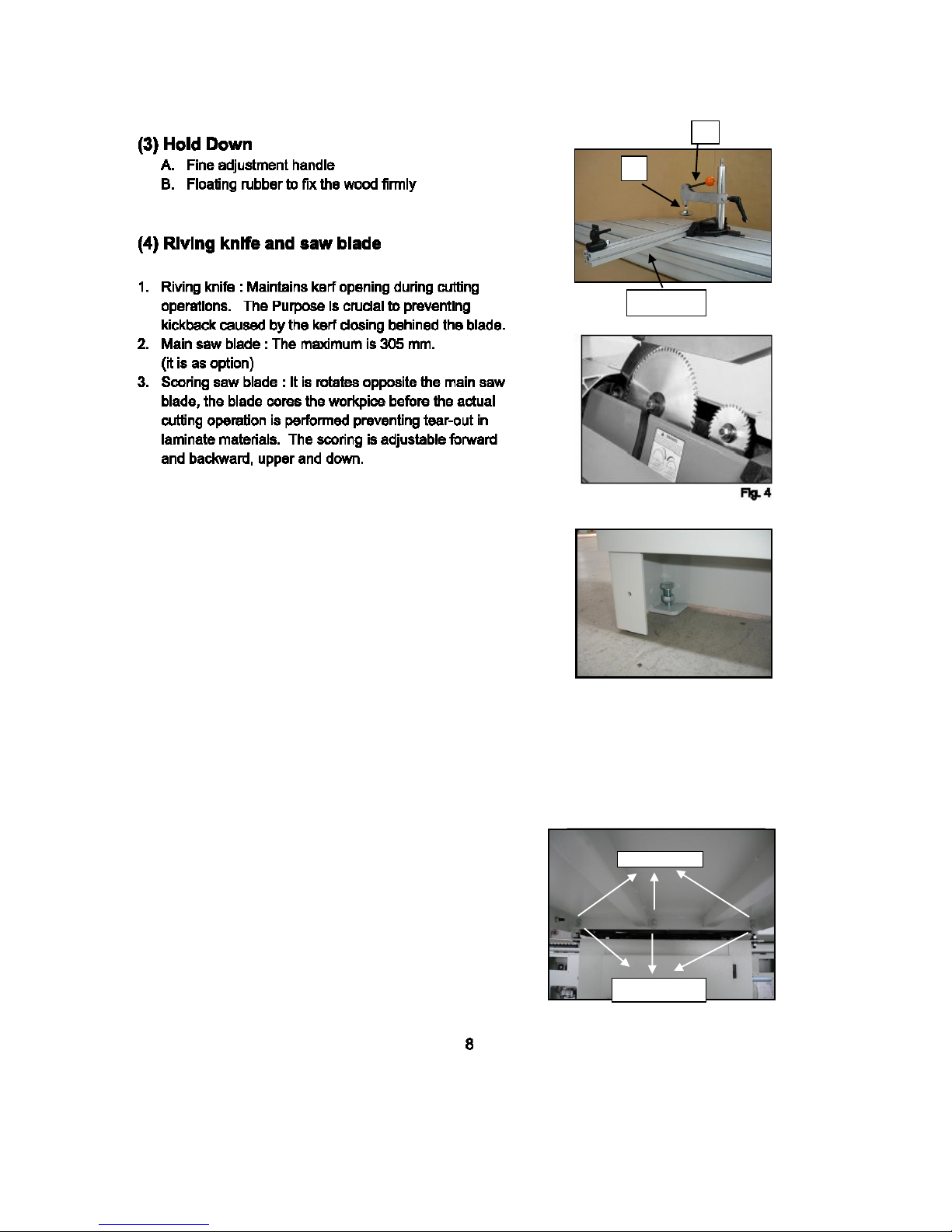

(3). Hold Down .......................................................................................................................................

(4). Riving Knife & Saw Blade ................................................................................................................

(5). Moving & Fixed The Base Unit ........................................................................................................

(6). Extension Table (large & Small) .......................................................................................................

(7). Scale Adjustment ..............................................................................................................................

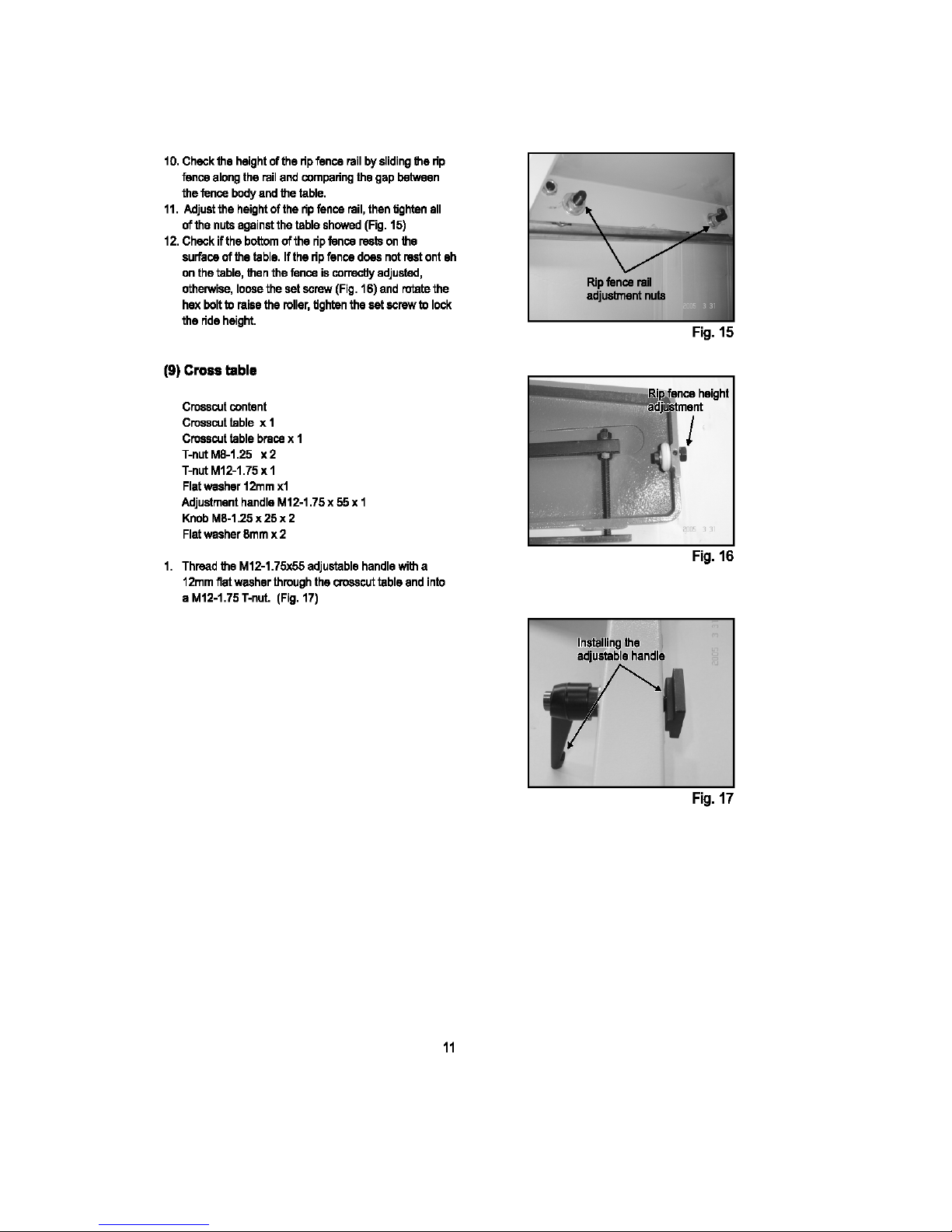

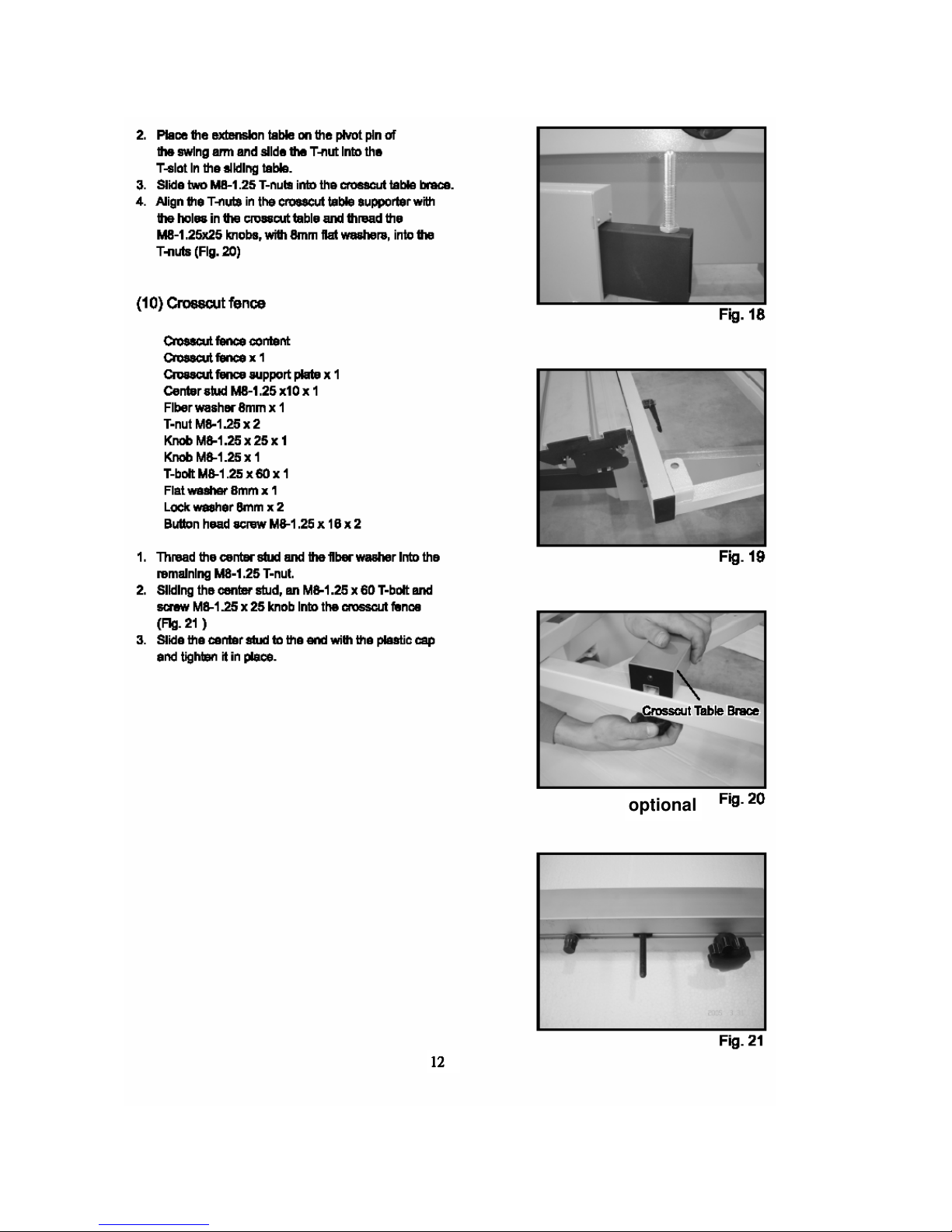

(8). Rip Fence ........................................................................................................................................

(9). Cross Table ......................................................................................................................................

(10). Cross Fence .....................................................................................................................................

(11). Sliding Table .....................................................................................................................................

(12). Main Blade ......................................................................................................................................

(13). Scoring Blade ..................................................................................................................................

(14). Fence Scale Alignment ....................................................................................................................

(15). Dust Collection .................................................................................................................................

(16). Power Cord ......................................................................................................................................

(17). Test Run ...........................................................................................................................................

Operation .......................................................................................................................................................

(1) Change Main Blade ............................................................................................................................

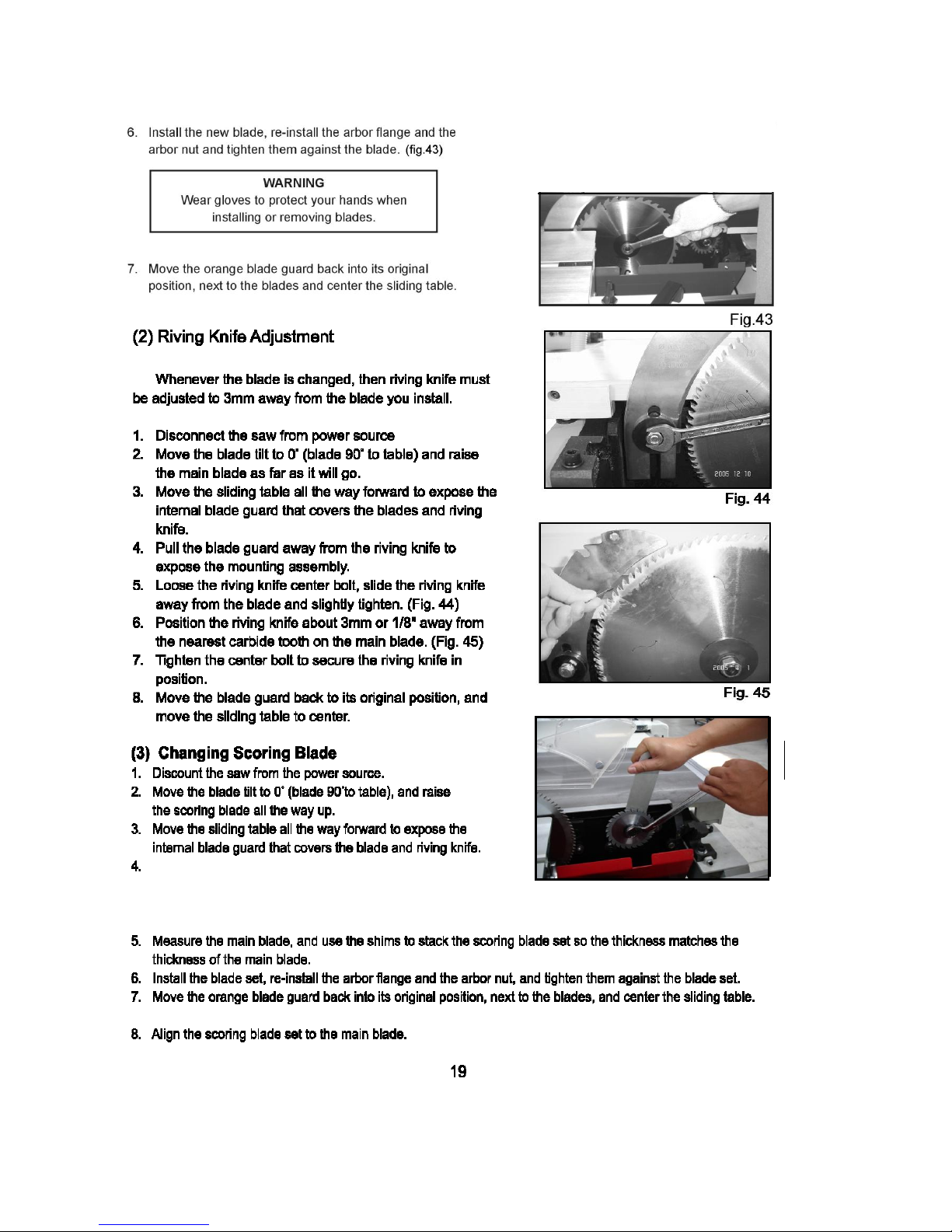

(2) Riving Knife Adjustment ......................................................................................................................

(3) Change Scoring Blade ........................................................................................................................

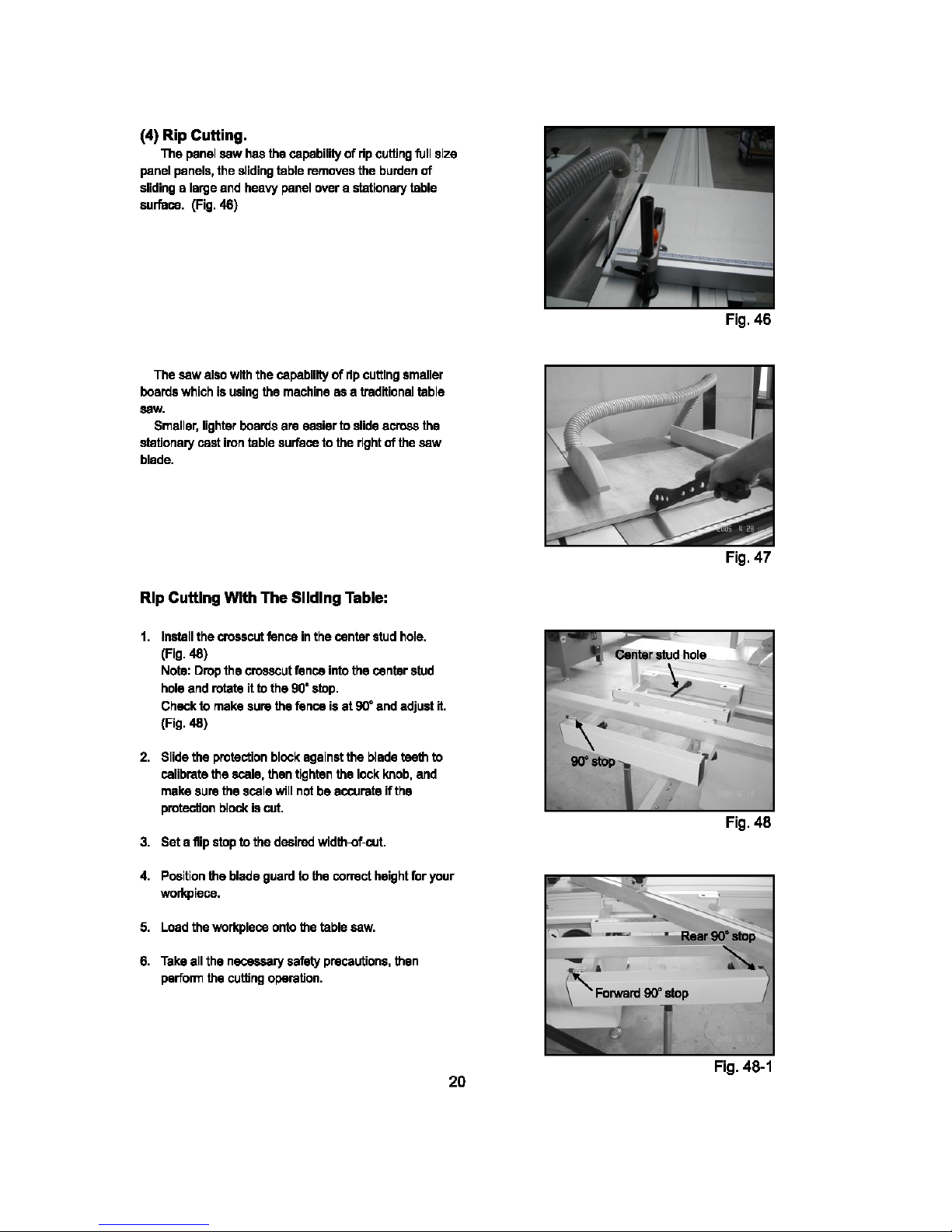

(4) Rip Cutting ..........................................................................................................................................

(5) Crosscutting ........................................................................................................................................

(6) Miter Cutting .......................................................................................................................................

(7) Lubrication ..........................................................................................................................................

(8) Replace Belts .....................................................................................................................................

(9) Blade Tilt .............................................................................................................................................

(10) Sliding Table Parallel Adjustment ........................................................................................................

(11) Squaring Crosscut Fence To Blade .....................................................................................................

(12) Trouble Shooting .................................................................................................................................

General Information

Safety Rules

OAV

For your own safety read instruction manual before operating

equipment & tools, inc. is specialized to supply full series of panel saw from 1600, 2300, 2500 to 3200mm.

The outlook design of this machine is so unique, complete cast iron trunnion bracket instead of sheet metal,

enlarged outtirgger and carriage, direct dust collection outlet. term its overall condition. The table saw is also an

important products after our band saw series, please enjoy your operation on this machine and If you have any

comment to improve this saw, please don't hesitate to contact us through your agent.

1. To avoid dangerous working environments, do not use stationary machine tools in wet or damp locations, keep

area as clean and well-lit.

2. Wear proper apparel, no loose clothing or jewery which can get caught in moving parts.

3. Never leave when machine is running.

4. Disconnect electrical power before tools are serviced.

5. Remove adjusting keys and wrenches before turning machine on.

6. Be sure that the keys and adjusting wrenches have been removed and all the nuts and bolts are secured.

7. Keep guards in place and in working order.

8. Keep children and visitors away, they should be kept at a safe distance from the work area. Never leave the

machine with power on.

9. Keep hands well away from blades and all moving parts. Do not clear chips and sawdust away with hands.

work

3

Specification Sheet

Model

P305 (one motor)

P305 (two motors)

Cast iron fixed table

dimension

548x896mm

Sliding table dimension

3,200x360mm

Main saw blade

305mm (Max. 355mm)

Main saw bore

30mm

Max. cutting height with

blade at 90°

90mm (25-115mm)

Max. cutting height with

blade at 45°

64mm

Main motor power(3ph)

5HP(3Kw)

Main blade speed

4,000rpm

Scoring saw blade

120mm

Scoring saw blade bore

20mm

Scoring blade motor

power(optional)

3/4HP(0.56Kw)

Scoring blade speed

8,000rpm

Cutting width

1,300mm

Blade tilting adjustment

Manual(0~45°)

Main saw height

adjustment

Manual

Dust collection system

120mm/60mm

N.W./G.W./MEAS.

(Machine)

500/600KGS

2,100*1,100*1,120mm

520/620KGS

2,100*1,100*1,120mm

N.W./G.W./MEAS.

(Sliding table)

80/103KGS

3,300*430*220mm

80/103KGS

3,300*430*220mm

Ctn. Q’ty.

8/19 sets

Due to need of continuous improvement, specifications are subjected to change

without prior notice.

6

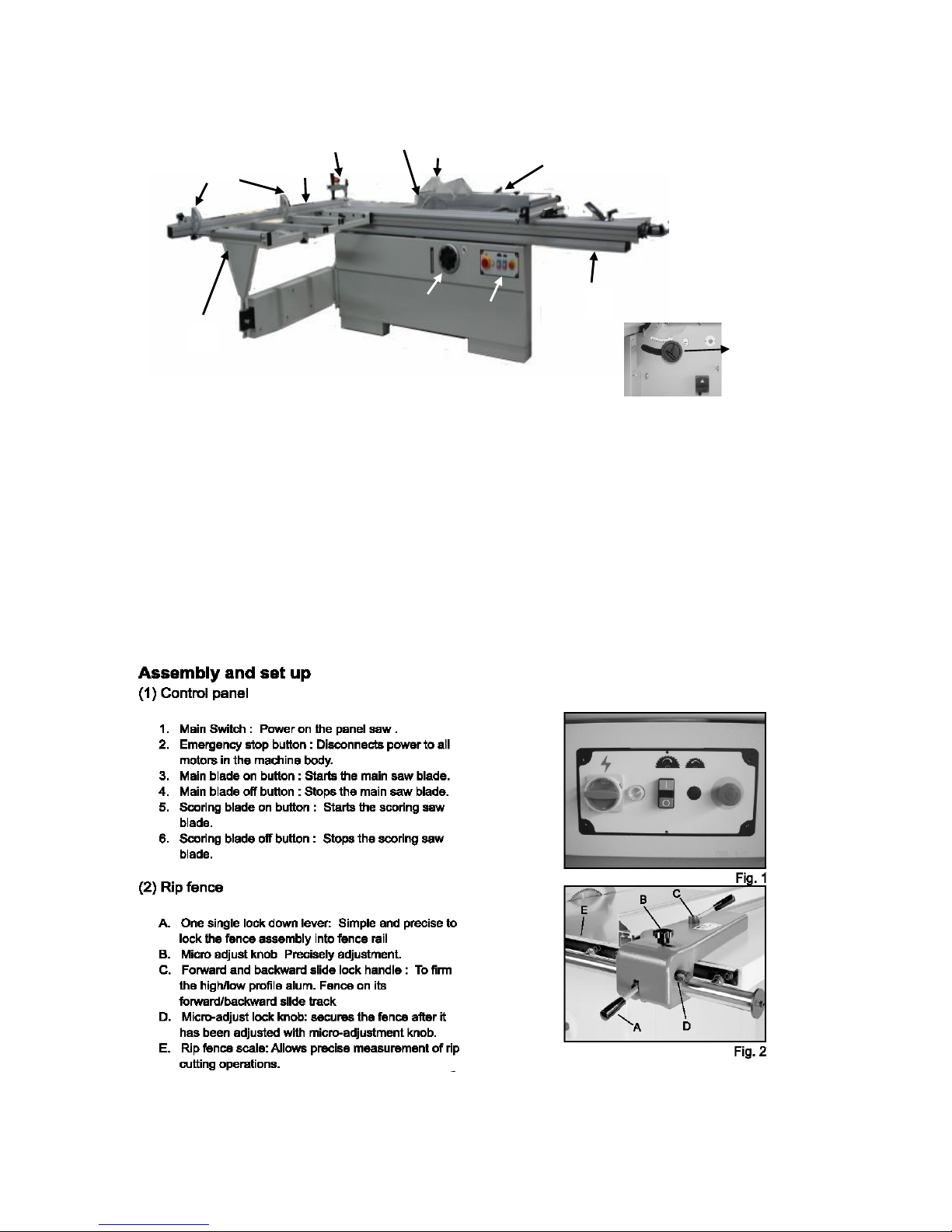

Main Feature

1. Flip Stopper-Large stopper for accurate measurements

2. Crosscut Fence-90° and 45° quick position design for a precise crosscutting operation

3. Hold Down : Strong design with fine adjustment and floating rubber pad.

4. Saw Blade Guard : Fully adjustable blade maintains maximum protection around the saw blades.

5. Cast Iron Rip Fence : Micro adjustment for smooth and pricise cutting

6. Sliding table : Double roller carriage with steel bar guidance for smoothly cutting, precise

sliding guides the workpiece through the blade.

7. Control Panel : Simple push button controls for operation

8. Blade Angle Adjusting Handwheel : Manual adjusts the angle of saw blade

9. Blade Height Adjusting Handwheel : Manual adjusts the height of saw blade

10. Cross table : Stronger table and stable to support large size panel during crosscutting operation.

11. Riving Knife : It is prevent kick back caused by the knife closing behind the blade.

1

2

3

4

5

6

7

8

10

11

9

7

(5) Moving & fixing the base unit

Place a level on the saw table and djusting foot stands,

so the saw table is level from left to right and from front to

back. Lock the foot studs in position by tightening their

jam bolts against the machine body. (fig.5)

*Remind firstly to remove the wood ad supporting of motor

before starting the table saw.

A

B

Optional

Fig. 5

Upper lock

Lower adjust

(6) Extension Tables content

How to install the extension tables

1. Thread the set screws into the suitable holes from the

inside of both extension tables.

2. Before the tables are leveleed, please don't completely tighten

the bolts in follw steps.

3. Attach the large extension table with three cap screws, lock

washers and flat washers (Fig. 6)

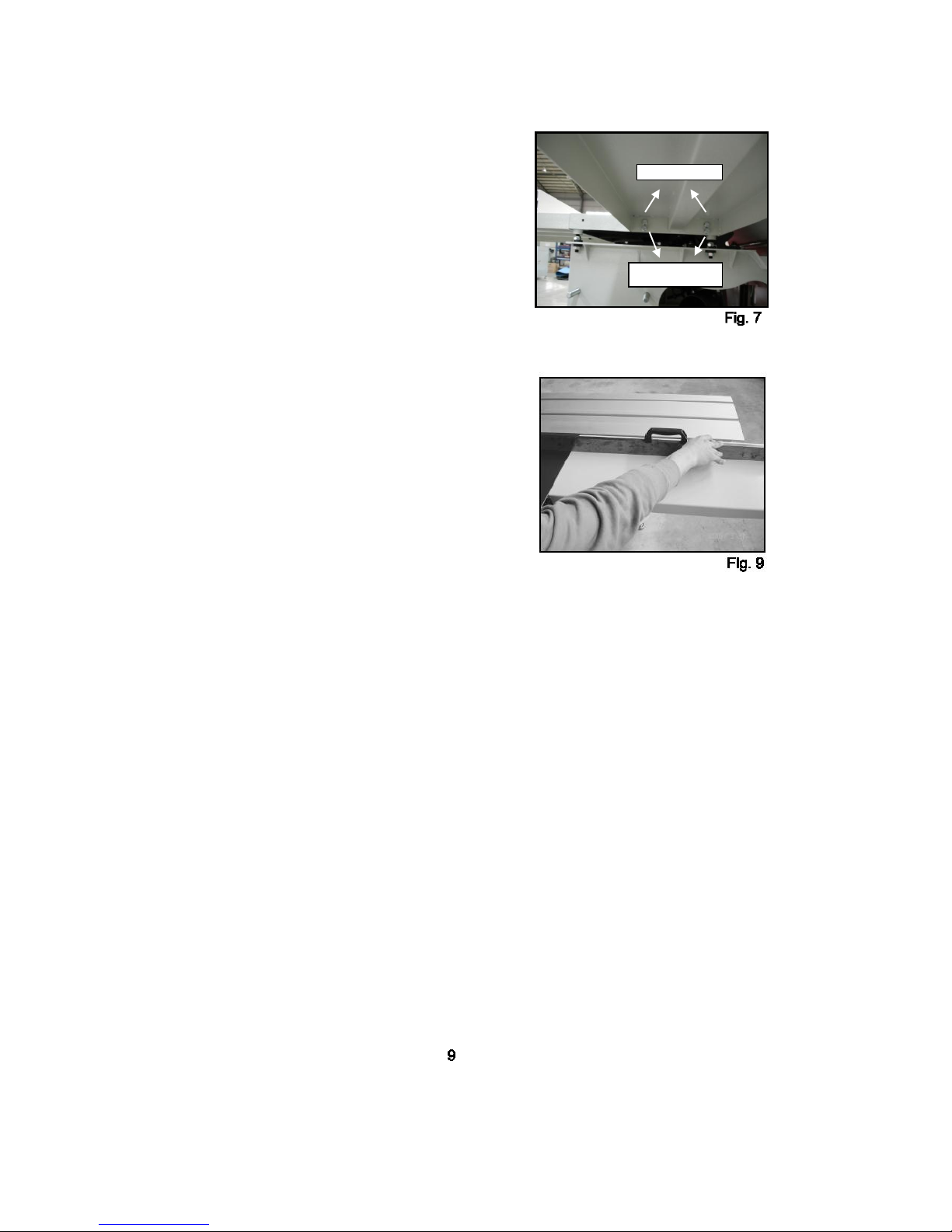

4. Attach the small extension table with cap screws, lock

washer and flat washers(Fig. 7)

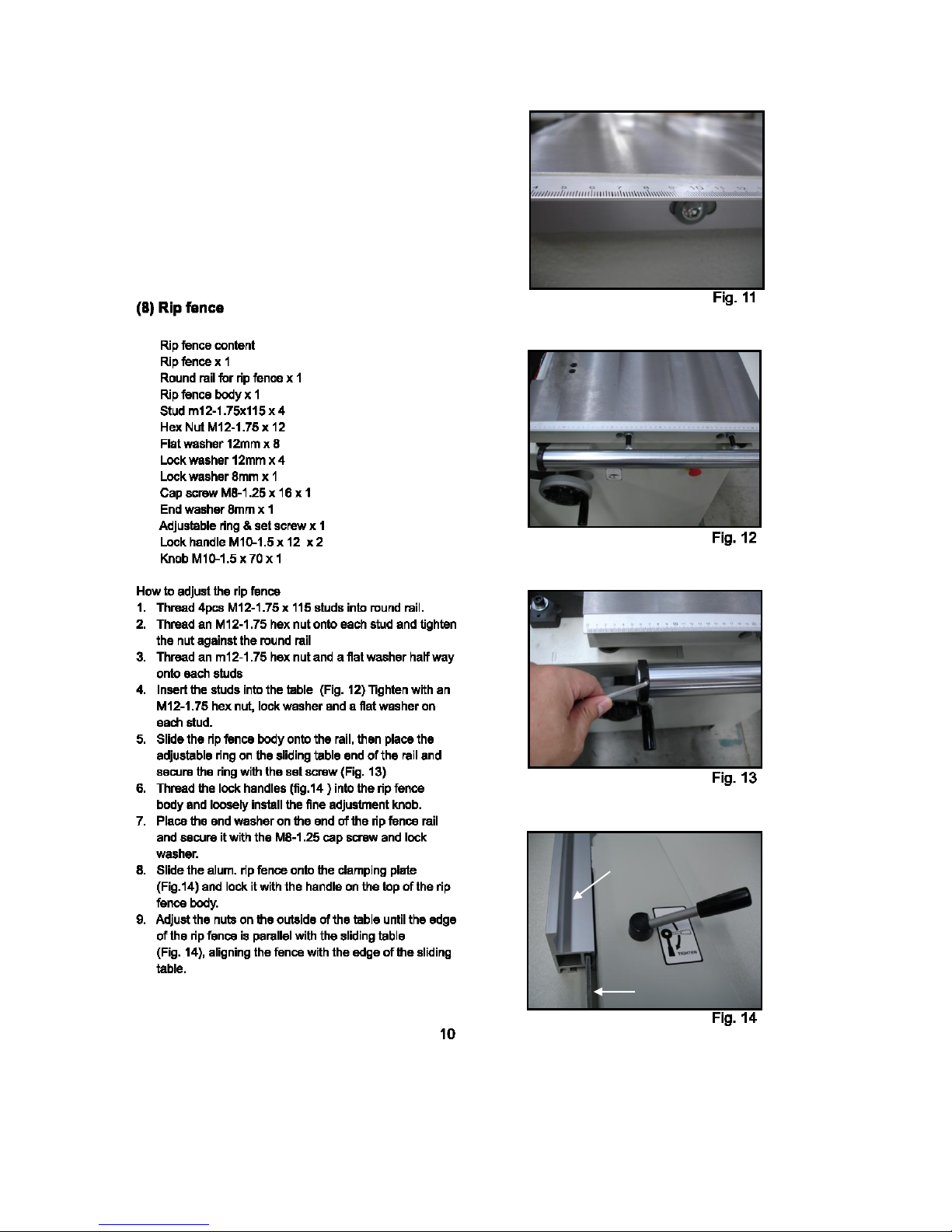

5. Check the surfaces 0 degree the table with a

straightedge(Fig. 8)

6. Assemble the supportbracket into the extension table(we

have rest holes for fixing), then adjust the levelling screw of

foot struds in order to make left ext. Table is parallel with saw

table.

Upper lock

Lower adjust

(7) Scale adjustment

1. Tight the cap screws to the extension table and

adjust to be with the top of the table.

Rip fence

Clamping plate

12

1212

12

optional

13

14

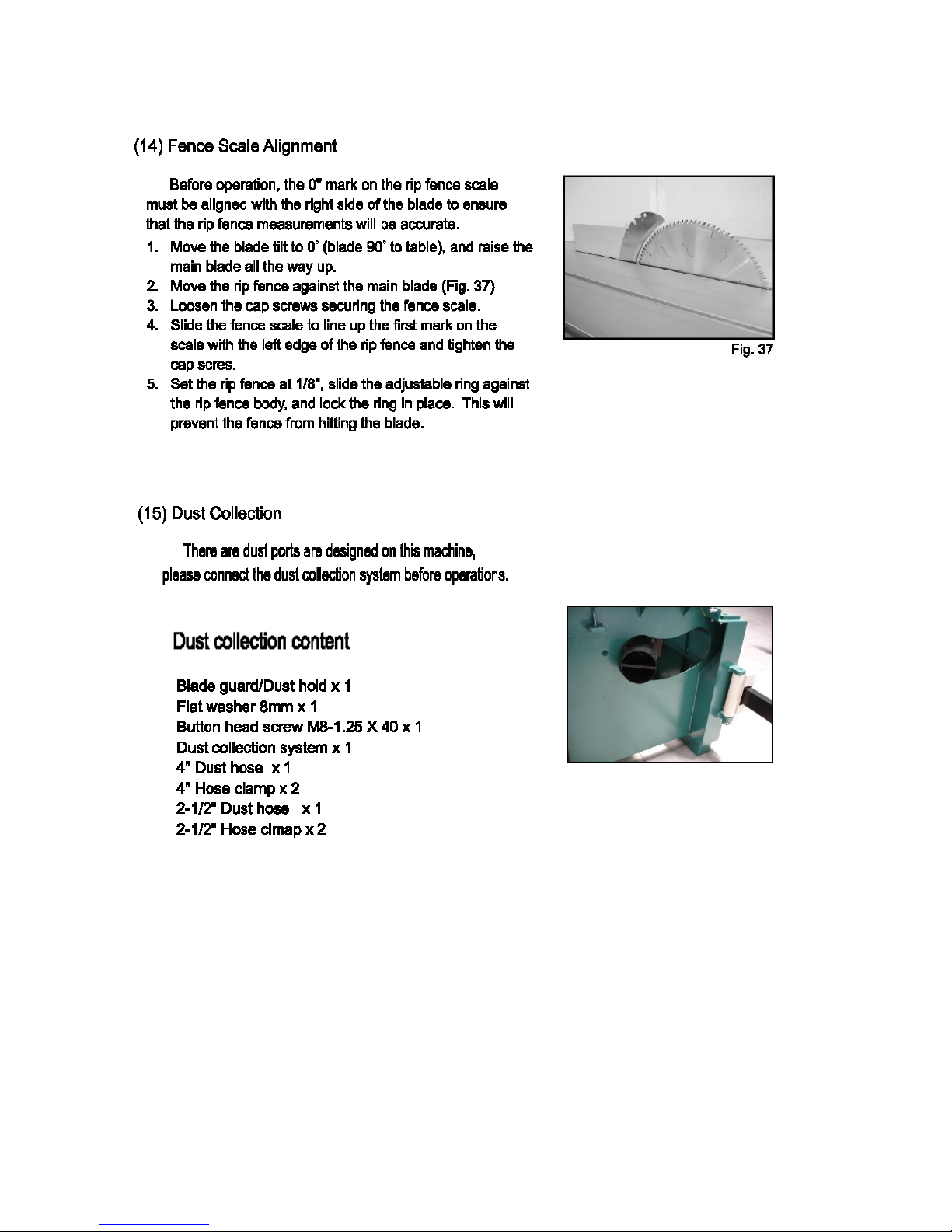

fig.30

(fig.31)

15

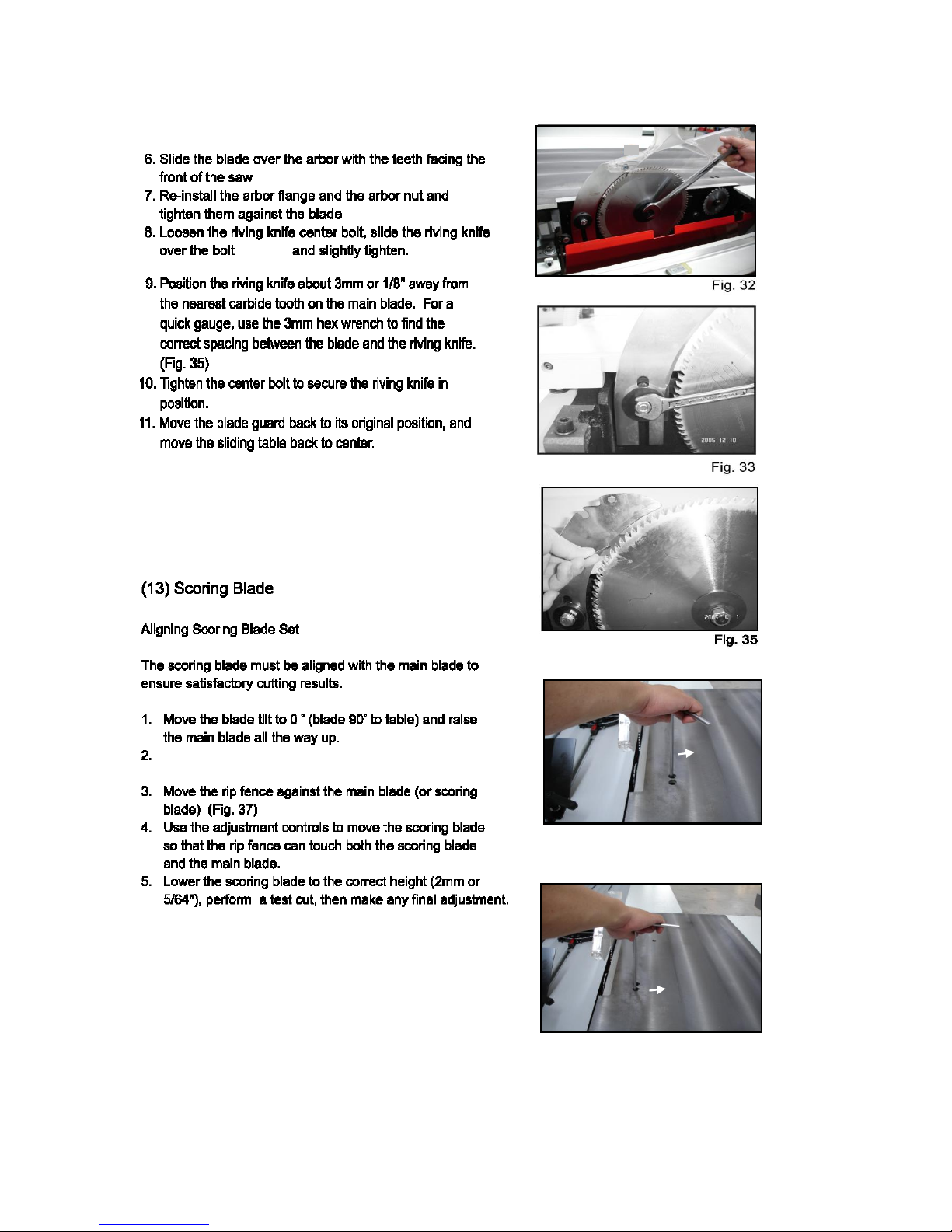

(fig.32)

(fig.32)

(fig.33)

Adjusting

scoring

rise/fall

Use T tool to adjust scoring blade (Fig. 36-1/-2)

Adjusting

scoring

forwader/back

Fig. 36-1

Fig. 36-2

Adjusting

scoring rise/fall

16

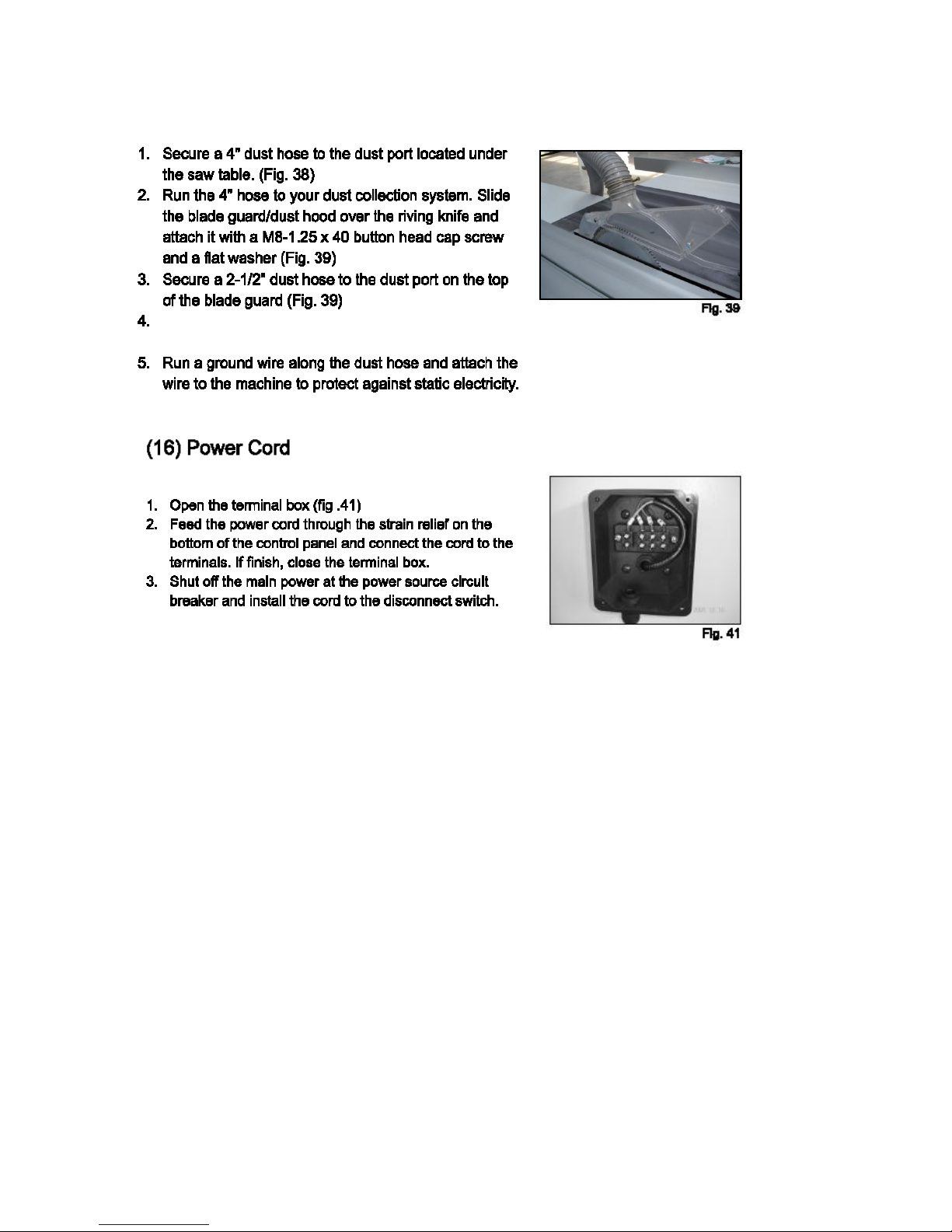

fig.38

17

Run the hose over and aconnect it to the dust

collection system.

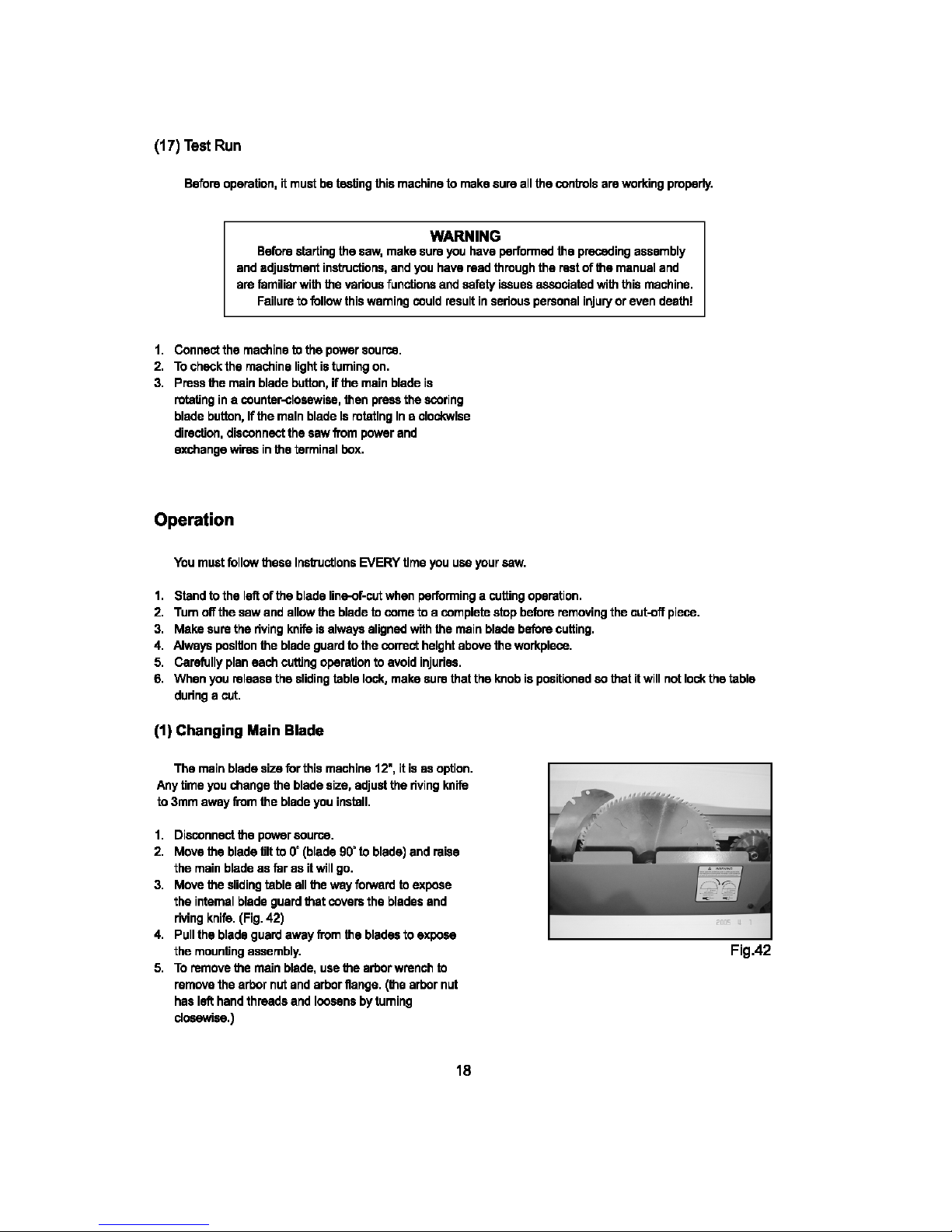

Fig.45-1

To fix the scoring by offered U Tool and using the

arbor wrench to remove the nut. (The arbor nut has

right hand threads and loosens by turning

counterclockwise.(fig.45-1)

Loading...

Loading...