Page 1

INSTALLATION / OPERATION MANUAL

FSTB-A SERIES BREWERS

FSTB-A60

*FSTB-A60C

Length 20-1/2

Height 16-7/8

Width 9-7/8

1430 Watts

12 Amps

120 Volts

*Model includes carafe

P. O. Box 3150•Columbus, OH 43213-0150

OASIS CORPORATION

265 N. Hamilton Road

1-800-64-OASIS (1-800-646-2747)

www.OasisWaterCoolers.com

FSTB-A80

Length 20-1/2

Height 21-1/2

Width 10-1/4

1430 Watts

12 Amps

120 Volts

Manual PN 30099-256

Page 2

CAUTION: READ INSTALLATION / OPERATION INSTRUCTIONS PRIOR TO

INSTALLATION INSTRUCTIONS

A. INSPECTION

Brewer comes complete with brew basket, detachable power cord and installation/operation manual (carafe may be

included, but is sold separately).

1. Inspect the carton and brewer for evidence of rough handling and concealed damage. Damage claims should be

filed with the carrier.

2. Remove top cover.

3. Remove float cap assembly from the feed reservoir. Inspect float arms to ensure they are moving freely (shipping

may cause floats to catch against the side of the float cap). If float arm is caught, pull arm down and ensure it is

moving freely.

4. Replace float cap assembly to the feed reservoir.

5. Check that the spray head tube from the solenoid valve to the spray head is securely connected (see Figure 8).

6. Replace top cover.

B. CONNECTING WATER SUPPLY TO BREWER

IMPORTANT: Unit must be installed on a water line with water pressure between 20 PSI and 90

PSI. If water pressure exceeds 90 PSI or has the ability to spike beyond 90PSI a

pressure regulator should be installed.

1. Place brewer on a level surface.

2. Insert water supply tube into external fitting (see figure 1). Brewer is equipped with an external fitting (located at

rear) capable of accepting a 3/8” tube.

NOTE: Brewers are shipped with a plug in the external fitting. Plug must be removed before installin g the water

supply tube.

PLASTIC TUBING

• Cut tube ends square and straight. Do not deform the tube (i.e., cause tube to compress its diameter so it is

• Make sure the outer surface of the tube is clear of marks or scratches for a length equal to twice the tube

• Avoid sharp changes in direction when routing the tubing. Sharp turns cause the tubing to flex and deform

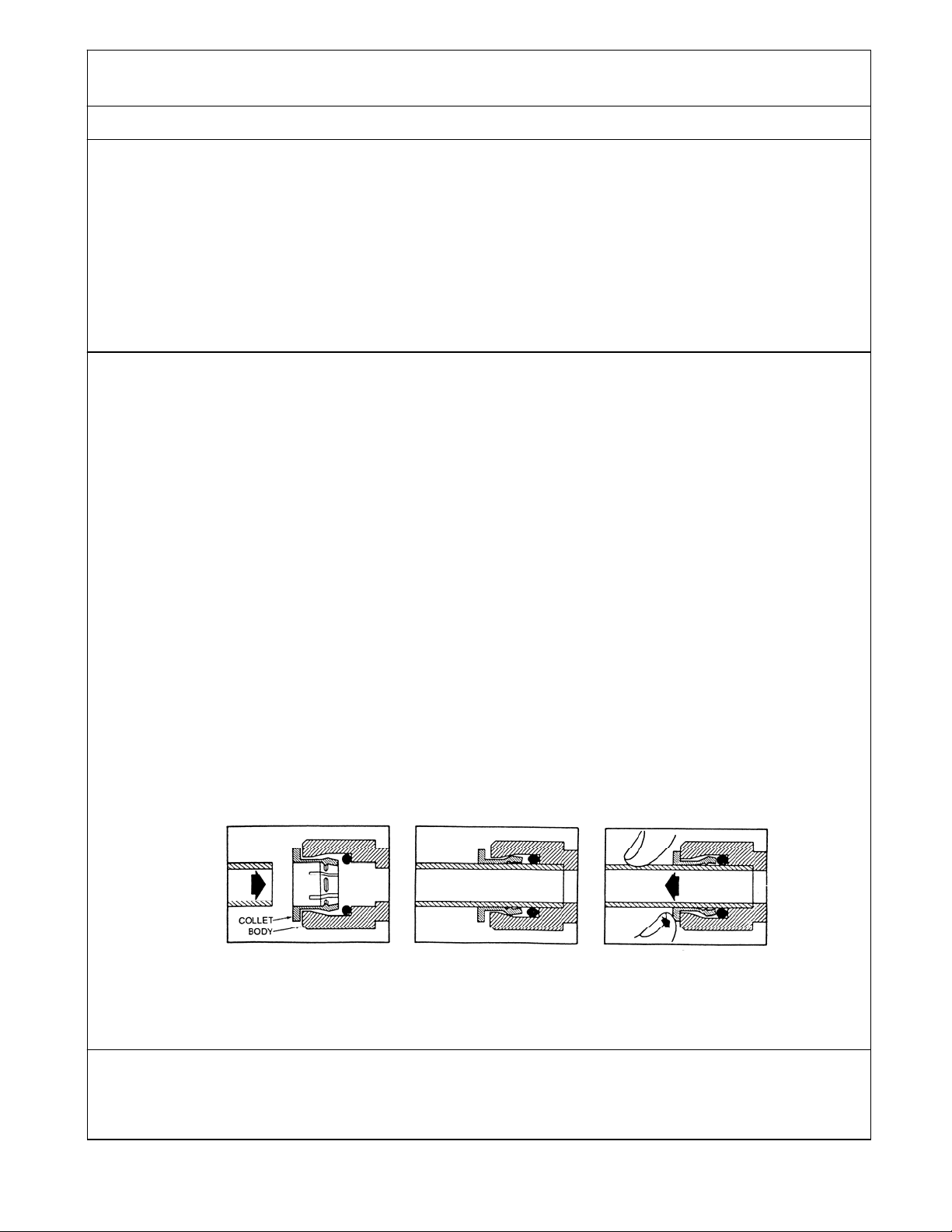

QUICK-CONNECT FITTINGS

• Fittings consist of two parts: a body and a collet (See Figure 1).

• To install a tube, push it through the collet until it seats firmly at the bottom of the fitting.

•

C. ELECTRICAL CONNECTION

Figure1

How to Use Quick-

Connect Fittings

3. Open water supply. The tank will immediately begin to fill. Tank fill time is approximately 3-5 minutes and is

complete when the sound of flowing water has stopped.

1. When tank has completed the water fill cycle, insert the IEC side of the electrical cord into the receptacle at the

rear of the brewer.

2.

Plug the three prong electrical cord in 120 Volts outlet capable of carrying 15 AMPS – 1600 Watts.

INSTALLING AND OPERATING THE FRESHSTART BREWER

Flush water line prior to installing brewer. Brewer should be connected to a COLD

WATER LINE.

no longer round).

diameter. This allows the “O” ring to seat properly against the tube (See Figure 1).

which reduces its flow capacity.

To remove a tube, push and hold the collet against the body while pulling the tube out.

Push tube through Collet into Body

Tube must seat firmly at bottom of fitting

Push Collet against Body to

release tube

Page 3

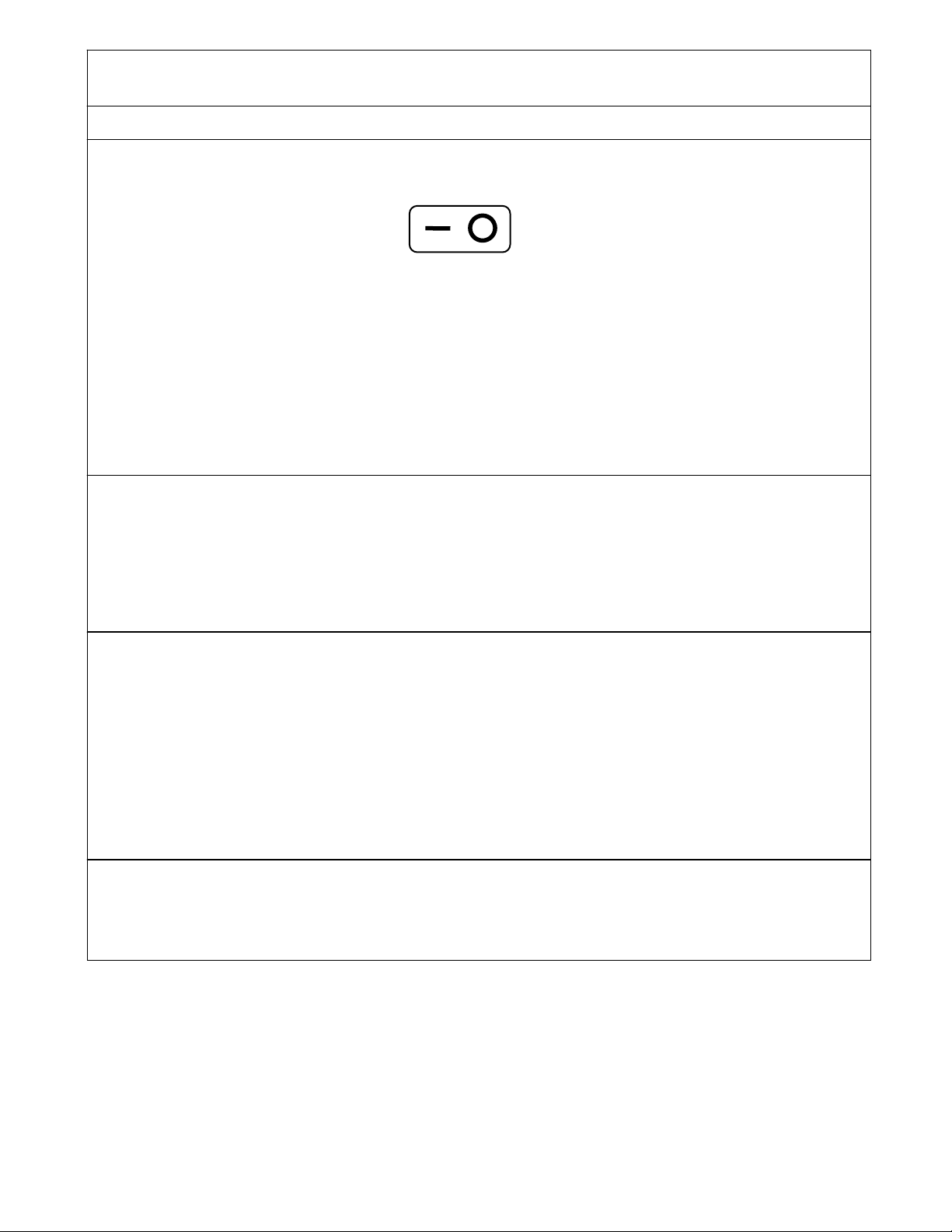

WARNING: WATER TANK MUST BE FILLED BEFORE PLUGGING MACHINE INTO

V

OLUME PROGRAM PROCEDURE

A. ENERGIZE BREWER / HOT TANK HEAT UP

1. To power up brewer and start the hot tank, push the ON/OFF MAIN POWER switch, at rear of the brewer, to the

ON position (See Figure 2).

2. Turn the front control panel on by pressing the ON/OFF BREW CANCEL button. The red light above this button

will illuminate indicating that the front control panel in on.

3. Hot tank must reach full temperature. From a cold start, final temperature will be reached in 10-15 minutes and is

indicated when the green OPTIMUM WATER TEMPERATURE light is illuminated.

4. Once hot tank has reached final temperature, the expanded water must be released. To do so, place the

appropriate empty carafe into position under brew basket, start a brew cycle by pressing the BREW (FULL POT)

button and let it run for about (20 seconds). To stop the brew cycle, press the ON/OFF BREW CANCEL button.

NOTE: Brewer is pre-programmed at the factory for a (6 oz.) brew cycle. Program procedure must be

B. INITCIATE VOLUME PROGRAM PROCEDURE

1. Make sure power is shut off to the brewer by pushing the ON/OFF MAIN POWER switch to the OFF position.

2. Press and hold down the BREW (FULL POT) button on the front control panel.

3. While holding down the BREW (FULL POT) button, push the ON/OFF MAIN POWER switch at the rear of the unit

to the ON position.

4. Once the ON/OFF MAIN POWER switch has been pushed to the ON position, the BREW (FULL POT) button can

be released.

The brewer is now in the volume set up mode and is indicated by a flashing red light ab ove the BREW (FULL POT)

button.

C. PROGRAM POT SIZE

1. Remove brew basket.

2. Place measuring pitcher on base under the spray head (spray head must be attached for accurate volume).

3. Press the BREW (FULL POT) button to start water flow (red light will continue to blink).

4. Allow measuring pitcher to fill to the required volume.

5. Press the BREW (FULL POT) button to stop water flow when it has reached the required volume.

6. Press the BREW (FULL POT) button again to lock the volume into memory.

NOTE: Programmed volume will remain in memory even with lose of power or if unplugged, until the volume

Half pot function is automatically calculated and set to exactly half of the programmed volume.

CAUTION: THE FILTER LOCATED ON THE FLOAT CAP MUST REMAIN

ELECTICAL OUTLET

ON OFF

ON/OFF MAIN POWER switch illustration (switch

completed to set required pot volume.

program procedure is initiated and volume is reprogrammed.

COMPLETELY DRY AT ALL TIMES. TAKE SPECIAL CARE IN

TRANSPORTING A BREWER WITH A FULL UPPER RESERVOIR AS IT

MAY CAUSE THE FILTER TO GET WET.

Figure 2

located at rear of brewer)

Page 4

OPERATION INSTRUCTIONS

A. BREWING COFFEE

1. Remove brew basket from brewer.

2. Place one (1) standard commercial filter (9.5 inch

B. CANCELLING A BREW CYCLE

C. CUP DRAW FROM SAFTEY FAUCET

diameter) into brew basket.

3. Put required amount of coffee grounds into filter and

shake brew basket to level off coffee grounds.

4. Return brew basket to brewer.

NOTE: Brew basket is designed to click into

place when properly installed. This action

secures the brew basket to the cabinet.

5. Place appropriate EMPTY thermal carafe into position

below the brew basket.

6. Press the BREW (FULL POT) button for full pot volume

or the BREW (HALF POT) button for half pot volume.

NOTE: The corresponding light above the chosen

BREW button will blink for the duration of

the brew cycle. When light has stopped

blinking, the brew cycle is complete and it

is safe to remove the carafe.

7. After brewing is complete, remove brew basket and

discard used coffee grounds and filter.

8. Rinse brew basket and return to brewer.

To cancel a brew cycle that is in process, press the ON/OFF BREW CANCEL button located on the front control

panel. When canceling a brew cycle, water is shut off to the spray head, but the brew basket will continue to drain

until depleted.

CAUTION: WATER FROM SAFETY FAUCET IS HOT

To draw a cup of hot water from the safety hot faucet (red button

located on the front panel of the brewer):

1. Place an empty cup directly under the non-textured bump

2. Push the red button down and forward to start the flow of

3. When finished, release button. Button will return to original

out located directly under the CAUTION HOT WATER label

(see figure 4).

hot water.

position and hot water will stop flowing.

Filter/Coffee

Placement

Brew Basket

Figure 3

Brew Basket Illustration

Figure 4

Safety Faucet Illustration

Page 5

SERVICE INSTRUCTIONS

r

A. ADJUSTING HOT TANK THERMOSTAT

Whenever thermostat adjustment becomes

necessary, complete the following procedure:

1. Disconnect power cord from electrical

outlet.

2. Remove (2) screws and rear panel (see

figure 5).

3. Use a bladed screwdriver to adjust the

thermostat knob (see figure 5). Turn

clockwise for hotter water temperature

and counter clockwise for cooler water

temperature.

4. Replace rear panel and (2) screws.

5. Plug power cord into electrical outlet and

follow steps 1-3 in ENERGIZE

BREWER/HOT TANK HEAT UP

B. CLEANING THE SPRAYHEAD

Over time mineral build up may develop around the

(6) spray holes on the spray head which may lead to

pot volume variances. Periodic inspection and

cleaning of the spray head is recommended.

1. Turn spray head counter clockwise a quarter

turn until it stops (see figure 6).

2. The spray head and the brew basket rail will

drop straight down to remove.

3. Remove gasket from spray head when cleaning.

4. Reassemble spray head and brew basket rail

using reverse procedure. Make sure spray

head detents (clicks) into place when

reassembling.

C. REMOVING HOT TANK ASSEMBLY FROM CABINET ASSEMBLY

1. Turn the main water supply to brewer OFF.

2. Disconnect the power cord from both the electrical outlet

and the IEC plug located at the rear of the brewer (see

figure 5).

3. Disconnect 3/8 inch supply tube from quick tube connect

(see Figure 5).

NOTE: If hot tank is full, water will dribble from the

4. Remove cover from cabinet assembly.

5. Remove (2) screws and rear panel (see figure 5).

6. Pull drain tube out rear access opening.

7. Remove plug from end of drain tube.

CAUTION: HOT WATER WILL IMIDIATLY FLOW

8. Remove ribbon cable for circuit board.

9. Let tank completely drain of water.

10. When finished draining tank, replace the drain tube plug.

11. Remove silicone tube from hot water faucet fitting.

12. Remove molded silicone tube from spray head top.

13. Remove (2) screws from rear switch plate (see figure 5).

14. Remove hot tank assembly from cabinet by lifting from

external tube fitting. It is recommended that

the fitting be plugged with the provided 3/8

inch plug.

FROM DRAIN TUBE.

the upper plastic reservoir (see figure 7).

3/8” Quick Tube

Connect

Thermostat

Adjustment Knob

Brew Basket Rails

Spray Head Gasket

Spray Head

Assembly

Assembly

Cove

Hot Tank

Cabinet

Rear Switch Plate

Screws (2)

Figure 5

Figure 5

Thermostat Adjustment Illustration

Thermostat Adjustment Illustration

Figure 6

Spray head removal Illustration

Figure 7

Hot Tank / Cabinet Assembly

On/Off main

power switch

IEC Cord

Receptacle

Rear Panel

Hot Water

Faucet Outlet

Opening

Page 6

D. SERVICING THE MECHANICAL FLOATS

Anti

r

r

A

r

Resetting the Safety Float

1. Remove cover from cabinet.

2. Press down on the safety float

re-set button (see figure 8).

Float arm inspection

1. Remove float cap from top

reservoir.

2. Float arms should move up and

down freely and should not bind

or catch (see figure 9).

E. INSPECT AND REPLACE CIRCUIT BOARD FUSE

1. Disconnect power cord from electrical outlet.

2. Remove cover from cabinet.

3. Locate fuse at the lower right side of the circuit board (see

figure 8) and inspect the fuse filament for breakage.

4. If fuse appears to have blown, carefully remove it from the

circuit board and check it for continuity.

5. If fuse is blown, replace it with a 25 volt, 5 AMP, slow blow

fuse.

F. INSPECT AND REPLACE DUMP SOLENOID VALVE

1. Disconnect power cord from electrical outlet.

2. Remove cover from cabinet.

3. Locate dump solenoid (see figure 8) and visually inspect clear

solenoid valve body for mineral build up or debris.

4. If build up or obstruction has occurred, remove the hot tank assembly

from the outer cabinet (see section C).

5. Remove both sets of wires from the solenoid valve.

6. Remove from the solenoid valve both the silicone tube from the hot

tank and the angled silicone tube going to the spray head.

7. Remove the dump solenoid by loosening the two screws that hold it to

the bracket assembly. Once the screws have been loosened, the

solenoid valve can be removed from the bracket slots (see figure 10).

8. If replacement is required, assemble a new or refurbished dump

solenoid valve in the reverse order.

Air filte

Safety float

re-set button

Circuit Board

Open Cover

G. THERMOSTAT REPLACEMENT

Primary Thermostat (see figure11)

1. Disconnect the power cord from both the electrical outlet

and the IEC plug located at the rear of the brewer (see

figure 5).

2. Remove the hot tank assembly from the outer cabinet (see

section C).

3. Remove both wires from the anti boil thermostat.

4. Loosen tie wire and remove the rear half of the insulation

from the hot tank.

5. Using an 11/32

threaded weld stud. Nut secures thermostat and cover.

6. Remove thermostat cover.

7. Remove thermostat from threaded weld stud.

8. Remove both wires from thermostat.

9. Replace using the reverse order as above.

NOTE: When threading the nut back to the weld stud (the

reverse of step 5) a torque value of 18 inch pounds must be

applied for proper assembly.

-Boil Thermostat (see figure 11)

1. Follow steps (1-4) from Primary Thermostat.

2. Using a ¼ inch nut driver remove both screws from bracket.

3. Replace using the reverse order.

inch nut driver, remove nut from thermostat

Figure 8

Solenoid

Valve

Spray Head

Tube

Loosen Solenoid

Screws (2)

Primary

Thermostat

Primary Thermostat

Cove

Mechanical Float Cap Assembly

Figure 10

Dump Solenoid Valve

Limite

Control

Figure 11

Thermostat Locations

Figure 9

nti-Boil

Thermostat

Page 7

G. THERMOST AT REPL ACEMENT (CONTINUED)

Limiter Control (see figure 11)

1. Follow steps 1 and 2 from Primary Thermostat.

2. Remove tank feed and vent silicone tubing from

H. INSPECT AND REPLACE HOT FAUCET

reservoir bottom.

3. Remove upper reservoir by releasing the (3) clips.

4. Remove both wires from limiter thermostat.

5. Using a ¼ inch nut driver remove both screws from

bracket.

6. Replace limiter control using the reverse order.

Mineral build up may occur over time causing a

slower than normal flow rate from hot faucet.

Periodically inspect the faucet outlet (see figure

6) for mineral build up. Also check for mineral

build up, obstruction or kinking of the silicone

tube from the hot tank to the hot faucet. If build

up is abundant, the hot faucet may need to be

replaced. For replacement see instructions

below.

1. Drain hot tank (see Section C steps 1-8)

2. Remove silicone tube from hot faucet.

3. Remove (4) front panel assembly screws

from inside cabinet.

4. Remove (2) faucet bracket screws from

front panel assembly.

5. Loosen hot faucet nut and remove faucet

from bracket.

6. Replace hot faucet using the reverse

order.

NOTE: If dripping from hot faucet occ urs, the

bonnet (see Figure13) may be too

loose. To tighten, turn bonnet one

quarter turn clockwise.

Remove (4)

Screws

Remove (2)

Screws

Hot Faucet Assembly

Figure12

Hot Faucet

Bonnet

Figure 13

Hot Faucet

I. FLOAT CAP AIR FILTER (see fig ure 8)

NOTE: If brewer is moved while filled with water, splashing from the upper reservoir may cause the air filter on

NOTE: Make sure the air filter is completely dry of before setting the pot volume.

If the filter media inside the air filter is wet during the programming of a pot volume, it may cause variances in pot

volumes for subsequent brew cycles. Make sure the air filter is completely dry of before setting the pot volume.

If the filter media inside the air filter gets wet anytime after the programming of pot volume, it may cause erratic

pot volumes.

the float cap to get wet. When moving or transporting brewers, make sure the tank is drained enough

that the upper feed reservoir is not holding any water.

J. HOT TANK MAINTENANCE

NOTE: Over time the hot tank and hot water ways may develop mineral build up which can narrow waterways

affecting pot volumes and hot faucet draws. Mineral build up may occur sooner or later depending on

the TDS level of the supply water to the brewer.

Page 8

TROUBLE SHOOTING GUIDE

•

•

•

•

•

•

•

Brew Cycle Will Not Start

PROBLEM RESOLUTION

No Hot Water or Not Hot Enough Hot Water

Check that the power cord is properly plugged into the

IEC receptacle located at the back of the brewer (see

Figure 5).

• Check that the power cord is plugged into a proper

electrical outlet (see Service Instructions Section C).

• Check that the power switch is in the “on” position (see

figure 2).

• Check that the water supply line to the brewer is

connected properly and turned on (see Service

Instructions Section B).

• Check/ replace fuse on circuit board (see Service

Instructions Section E).

• Re-set safety float (see Service Instructions Section D).

• Check for mineral build up, clogs or kinks to water lines

and fittings.

• Clean spray head (see Service Instructions Section B).

• Check solenoid valve for mineral build up or blockage

(see Service Instructions Section F).

• Replace solenoid valve (see Service Instructions Section

G).

• Verify that the volume program procedure was completed

correctly according to the manual (see Volume Program

Procedure).

Check that brewer is getting power

• Adjust thermostat (see Service Instructions Section A).

• Replace primary thermostat (see Service Instructions

Section G).

• Replace heating element.

Carafe Overflows

Weak Coffee

Hot Faucet Dripping

Slow Flow Rate from Hot Faucet

Verify carafe is empty before brewing fresh pot.

• Verify supply line pressure – if needed add a pressure

regulator.

• Check that float arms are moving up and down freely and

are not binding (see Service Instructions Section D).

• Check for mineral buildup, clogs or kinks to water lines

and fittings.

• Remove and dry (air) filter (see Service Instructions

Section I).

• Check hot tank for mineral build up (see Service

Instructions Section J).

• Re-set pot size (see Volume Program Procedure).

Adjust thermostat to provide hotter water (see Service

Instructions Section B).

• Clean spray head (see Service Instructions Section B).

• Modify coffee roast, blend, grind or filter.

Tighten hot faucet bonnet one quarter turn (see Service

Instructions Section H).

• Replace hot faucet (see Service Instructions Section H).

Check for mineral build up at the faucet outlet (see

Service Instructions Section H).

• Check for mineral build up, obstructions or kinks to

silicone tube from hot tank outlet to hot faucet (see

Service Instructions Section H).

Dry Coffee Remaining in Brew Basket

Clean spray head (see service instructions section B).

• Sift grounds flat to set filter (see operation instructions

section A).

• Check for mineral build up, clogs or kinks to water lines

and fittings.

Loading...

Loading...