Oasis C8b, H17b, C25b, C25Tb, C35T-Vb Installation Instructions Manual

...

SWIMMING POOL HEAT PUMP UNIT

Installation & Instruction Manual

CONTENTS

1. Preface

2. Specifications

2.1 Performance Data of Swimming Pool Heat Pump Unit

2.2 Dimensions for Swimming Pool Heat Pump Unit

3. Installation and Connection

3.1 Installation of System

3.2

3.3 How Close to You r P oo l?

3.4

3.5

3.6 Initial Start-up of the Unit

4. Usage and Operation

4.1

4.2

4.3

5. Maintenance and Inspection

5.1

5.2 Malfunction table

6.Appendix

Spa Heat Pumps Location

Spa Heat Pumps Plumbing

Spa Heat Pumps Electrical Wiring

Function of wire controller

The controller usage

Parameter table

Maintenance

6.4 Cable specification

6.1 Connection of PCB Illustration

6.2 Connections Explanation

6.3 Caution & Warning

6.5 Explosive view of the unit

1

2

2

4

6

6

7

7

8

9

9

10

10

12

19

20

20

21

22

22

22

23

24

25

1. PREFACE

The unit can only be repaired by qualified installer center personnel or an authorised

dealer.

Maintenance and operation must be carried out according to the recommended time and

frequency, as stated in this manual.

Use genuine standard spare parts only. Failure to comply with these recommendations

will invalidate the warranty.

SWIMMING POOL HEAT PUMP Unit heats the spa water and keeps the temperature

constant.

This type of pump has the fol lowing cha ra cteristic s:

1. Durable

Withstand prolonged exposure to corrosives such as chlorine. The heat exchanger is

made of pvc & titanium tube which can .

2. Install at ion flexib ility

The unit can be installed outside or inside of the Spa.

3. Quiet oper at ion

The unit comprises an efficient rotary/ scroll compressor and a low-noise fan motor,

which guarantees its quiet operation.

4. Advanced c on trolling

The unit includes micro-computer controlling, allowing all operation parameters to be set.

Operation status can be displayed on the wire controller.

1

In order to provide our customers with quality, reliability and versatility, this

product has been made to strict production standards. This manual

includes all the necessary information about installation, debugging,

discharging and maintenance. Please read this manual carefully before

you open or maintain the unit. The manufacturer of this product will not be

held responsible if someone is injured or the unit is damaged, as a result of

improper installation, debugging, or unnecessary maintenance. It is vital

that the instructions within this manual are adhered to at all times. The unit

must be installed by qualified personnel.

2

2.SPECIFICATION

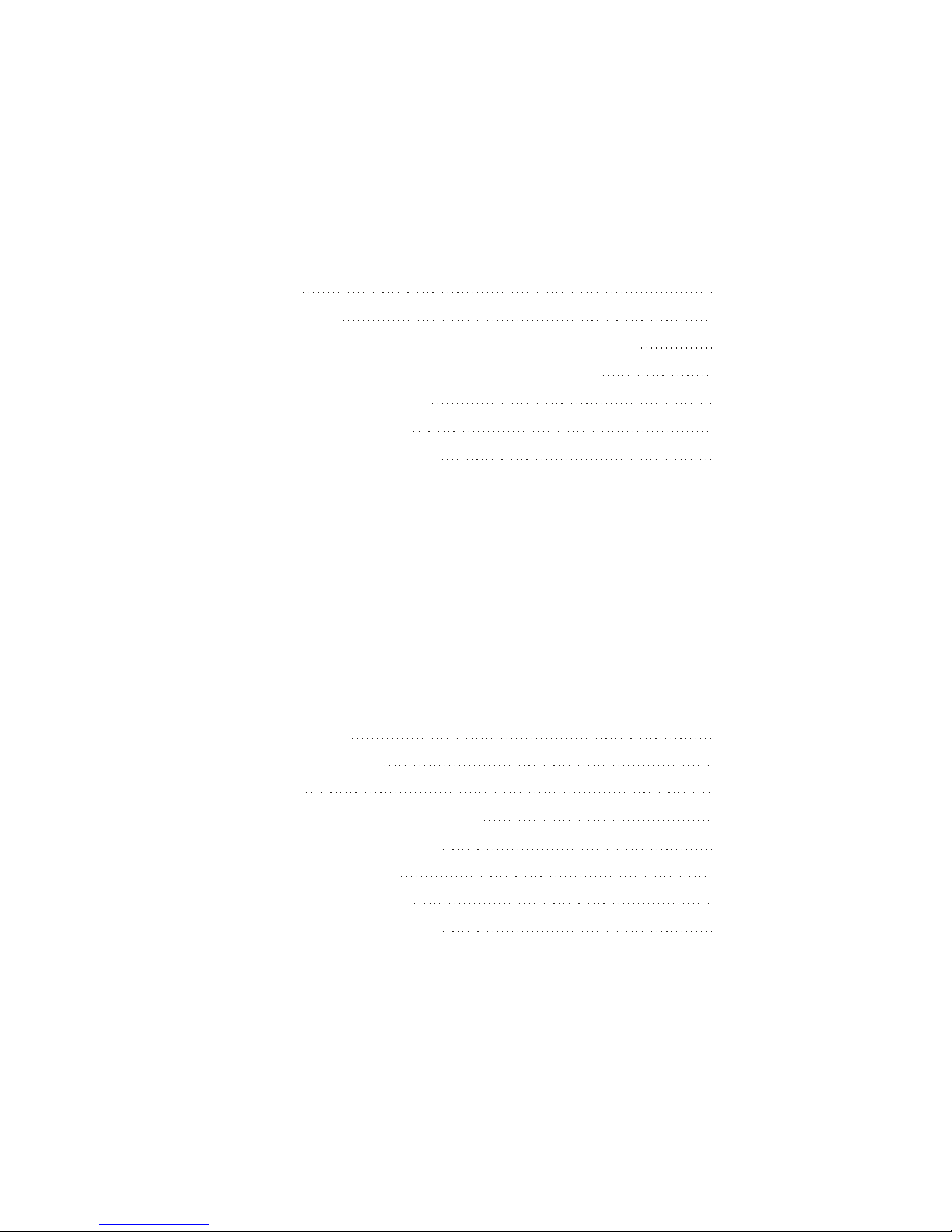

2.1 Performance data of Swimming Pool Heat Pump Unit

REFRIGERANT :R407C

Unit

Heating Capacity

Heating Power Input

Running Current

Power Supply

Compressor Quantity

Compressor

Fan Quantity

Fan Power Input

Fan Rotate Speed

Fan Direction

Noise

Water Conne ction

Water Flow Volume

Wat er Pres sure Dr op(ma x)

Unit Net Dimensions(L/W/H)

Unit Shipping Dimensions(L/W/H)

Net Weight

Shipping Weight

Model

kW

BTU/h

kW

A

W

RPM

dB(A)

inch

3

m/h

kPa

mm

mm

kg

kg

Oasis C13b

13.2

45000

2.6

11.8

230V~/50Hz

1

Rotary

1

120

850

Horizontal

54

1.5

4.5

10

1000 420 650

1060 440 710

65

72

REFRIGERANT :R407C

Unit

Heating Capacity

Heating Power Input

Running Current

Power Supply

Compressor Quantity

Compressor

Fan Quantity

Fan Power Input

Fan Rotate Speed

Fan Direction

Noise

Water Conne ction

Water Flow Volume

Wat er Pres sure Dr op(ma x)

Unit Net Dimensions(L/W/H)

Unit Shipping Dimensions(L/W/H)

Net Weight

Shipping Weight

Model

kW

BTU/h

kW

A

W

RPM

dB(A)

inch

3

m/h

kPa

mm

mm

kg

kg

Oasis C17b

17.5

60000

3.5

15.9

230V~/50Hz

1

Scroll

1

120

850

Horizontal

54

1.5

6.0

10

1120

470 850

1200

480 1010

100

108

Oasis C8b

8.8

30000

1.7

7.7

230V~/50Hz

1

rotary

1

120

850

horizontal

51

1.5

3.0

10

1000 420 650

1060 440 710

60

67

Oasis H13b

13.2

45000

2.6

11.8

230V~/50Hz

1

Rotary

1

120

850

Horizontal

54

1.5

4.5

10

1000 420 650

1060 440 710

65

72

Oasis H17b

17.5

60000

3.5

15.9

230V~/50Hz

1

Scroll

1

120

850

Horizontal

54

1.5

6.0

10

1120

470 850

1200

480 970

100

108

Oasis C25b

25

90000

5.0

22.7

230V~/50Hz

1

Scroll

2

120 2

850

Horizontal

56

1.5

9.0

12

1120

470 1240

1200

490 1380

132

145

3

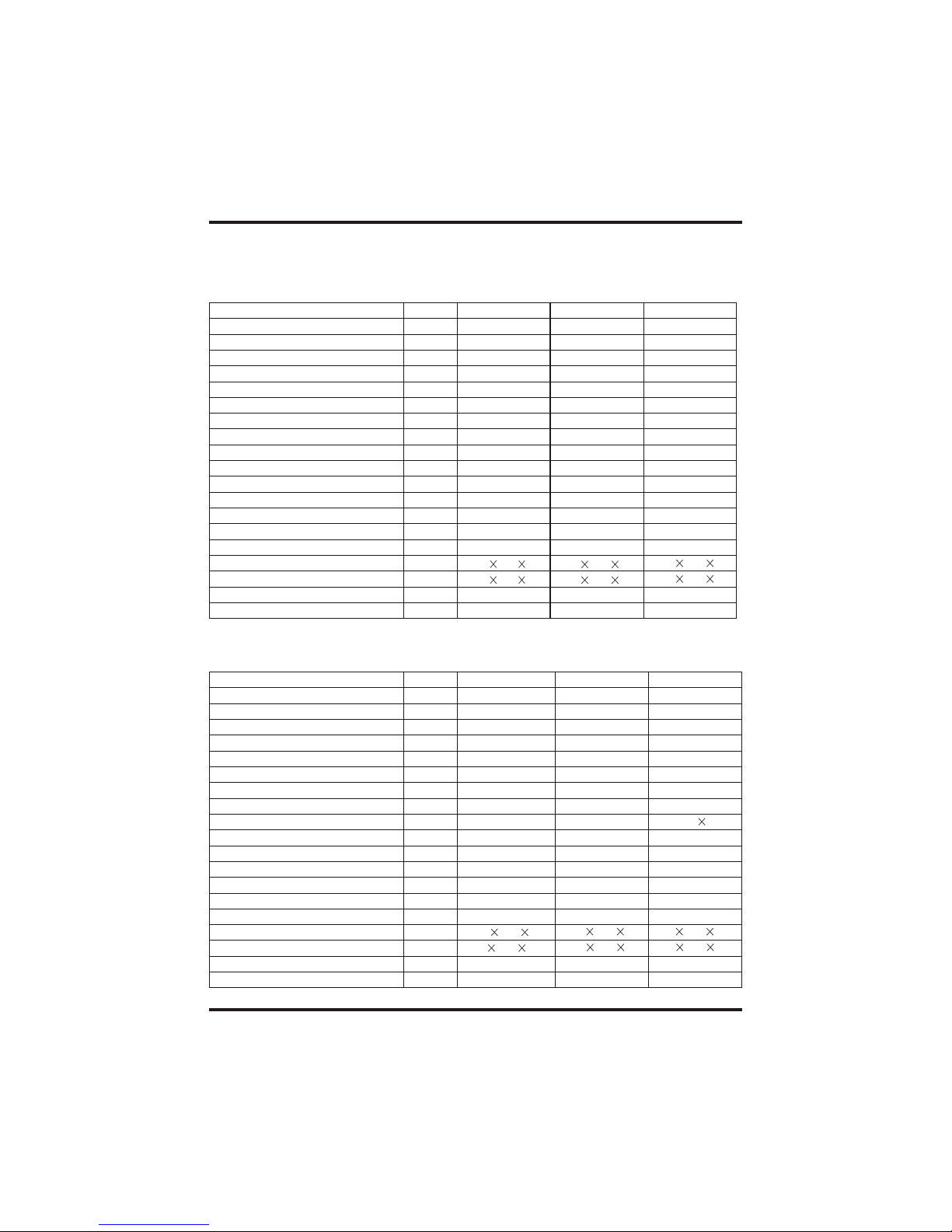

2.SPECIFICATION

2.1 Performance data of Swimming Pool Heat Pump Unit

REFRIGERANT :R407C

Unit

Heating Capacity

Heating Power Input

Running Current

Power Supply

Compressor Quantity

Compressor

Fan Quantity

Fan Power Input

Fan Rotate Speed

Fan Direction

Noise

Water Conne ction

Water Flow Volume

Water Press ure Drop(max)

Unit Net Dimensions(L/W/H)

Unit Shipping Dimensions(L/W/H)

Net Weight

Shipping Weight

Model

kW

BTU/h

kW

A

W

RPM

dB(A)

inch

3

m/h

kPa

mm

mm

kg

kg

Oasis C35T-Vb

35

120000

7.1

12.7

380V/3N~/50Hz

2

Scroll

2

200 2

850

Horizontal

61

2.0

12

15

1490 735 1130

1520 790 1340

244

284

Oasis C25Tb

25

90000

5.0

8.3

380V/3N~/50Hz

1

Scroll

2

120 2

850

Horizontal

56

1.5

9.0

12

1120

470 1240

1200

490 1380

130

140

REFRIGERANT :R410A

Unit

Heating Capacity

Heating Power Input

Running Current

Power Supply

Compressor Quantity

Compressor

Fan Quantity

Fan Power Input

Fan Rotate Speed

Fan Direction

Noise

Water Conne ction

Water Flow Volume

Water Press ure Drop(max)

Unit Net Dimensions(L/W/H)

Unit Shipping Dimensions(L/W/H)

Net Weight

Shipping Weight

Model

kW

BTU/h

kW

A

W

RPM

dB(A)

inch

3

m/h

kPa

mm

mm

kg

kg

Oasis C21b

22

75000

4.25

19.32

230V~/50Hz

1

Scroll

2

120 2

850

Horizontal

56

1.5

7.5

12

1120 470 1240

1200

490 1410

135

152

Oasis C50T-Vb

55

187000

11.6

20.7

380V/3N~/50Hz

2

Scroll

2

390 2

900

Horizontal

61

2.0

19.5

15

1490 735 1130

1520 790 1340

300

325

EH9b

9.2

31400

1.65

7.50

230V /50Hz

1

rotary

1

120

850

horizontal

51

1.5

3.0

10

1002 455 658

1130 470 695

61

71

4

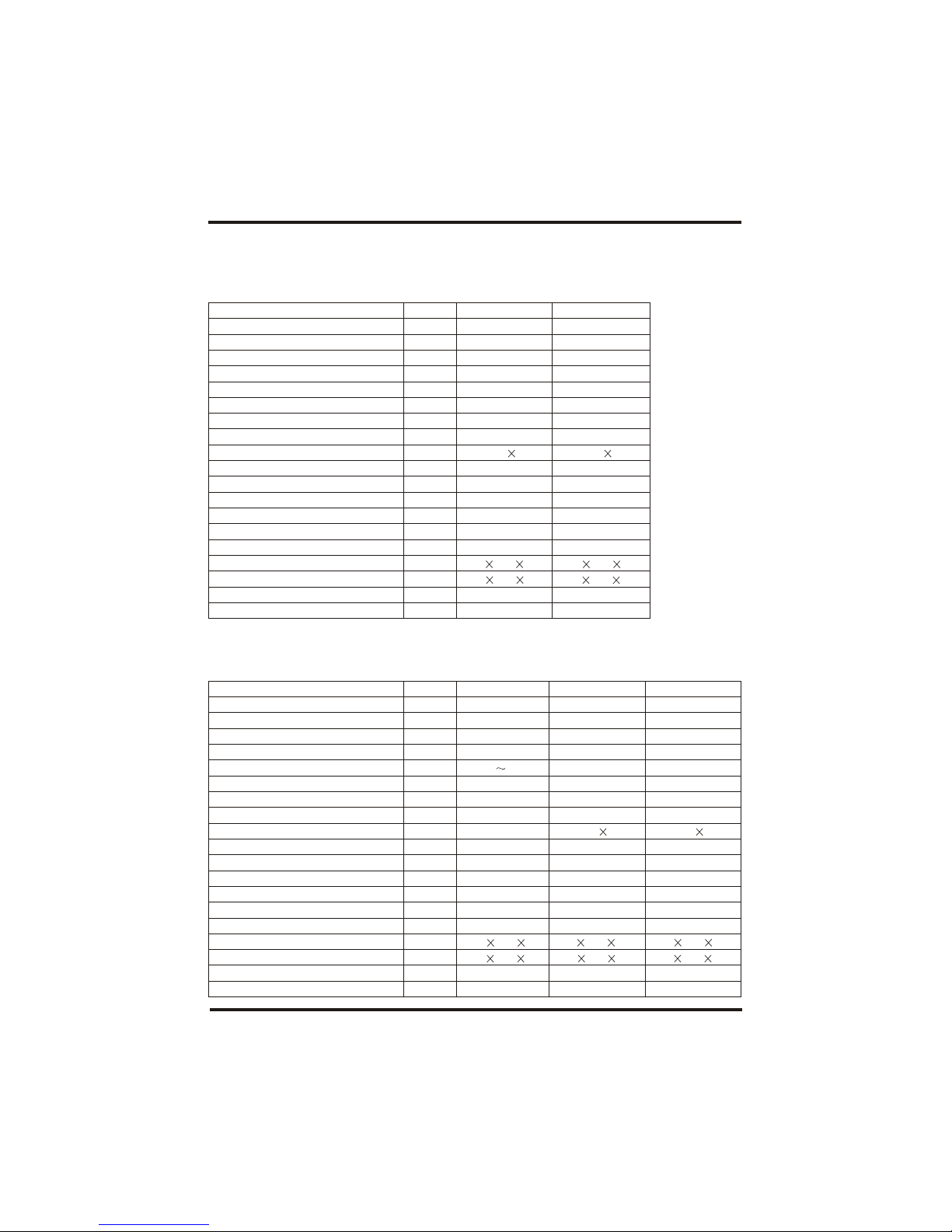

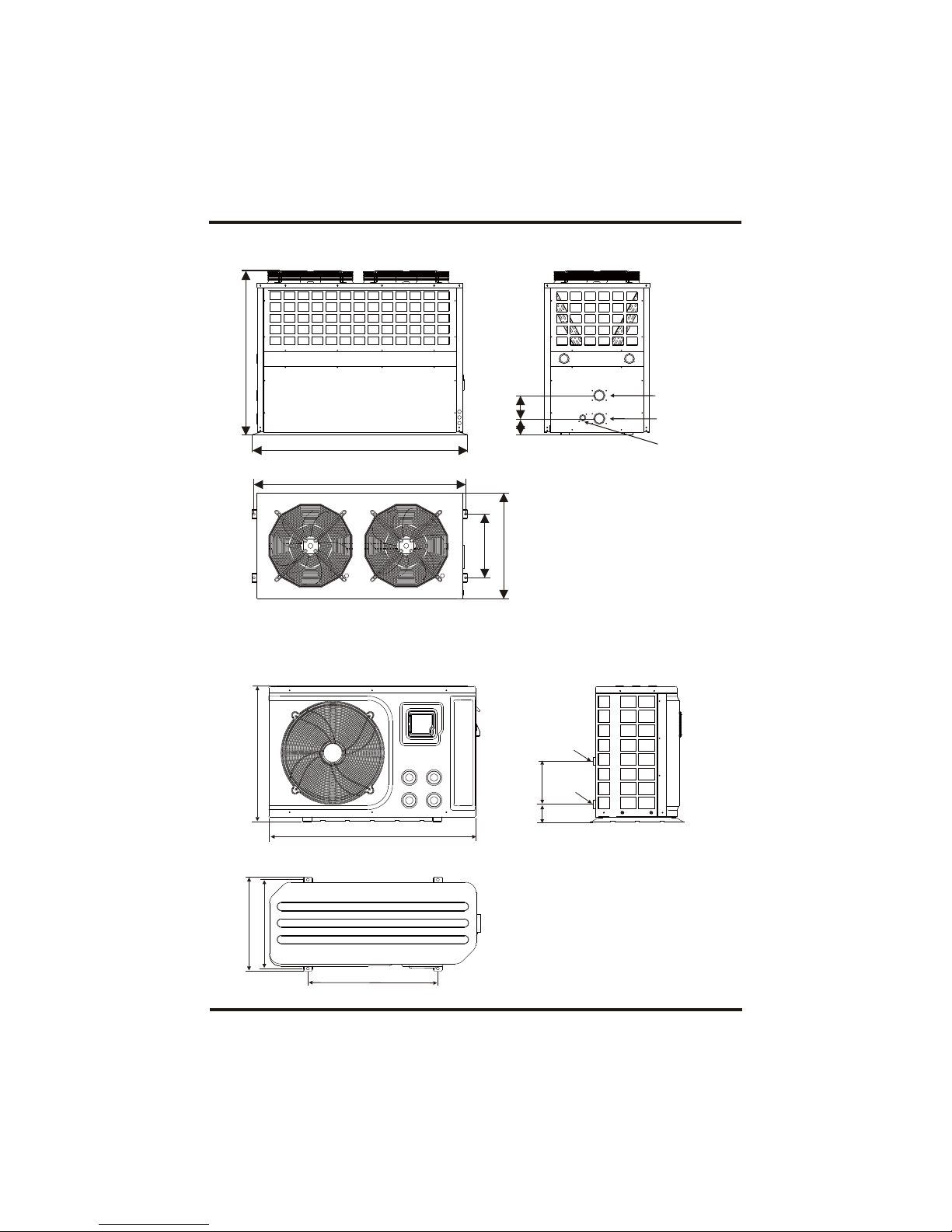

2.2 The dim ensions for Swi mming Pool He at Pump Unit

2.SPECIFICATION

Models: Oasis C8b/Oasis C13b/Oasis H13b/Oasis C17b/Oasis H17b

Models: Oasis C21b/Oasis C25b/Oasis C25Tb

Water In let

Water Ou tlet

A

E

D

C

B

TYPE

B

A

C

D

SIZE

E

unit mm

Oasis C8b/C13b/H13b

650

1000

700

420

400

255

101

Horizontal vision

Vert ical v ision

Oasis C17b/H17b

850

1120

720

470

440

400

97

TYPE

B

A

C

D

SIZE

1240

1120

720

470

440

475

95

E

Unit mm

Oasis C21b/C25b/C25Tb

A

E

D

C

B

Horizontal vision

Wat er In let

Water Outlet

Vertical visio n

FG

F

G

F

G

GF

5

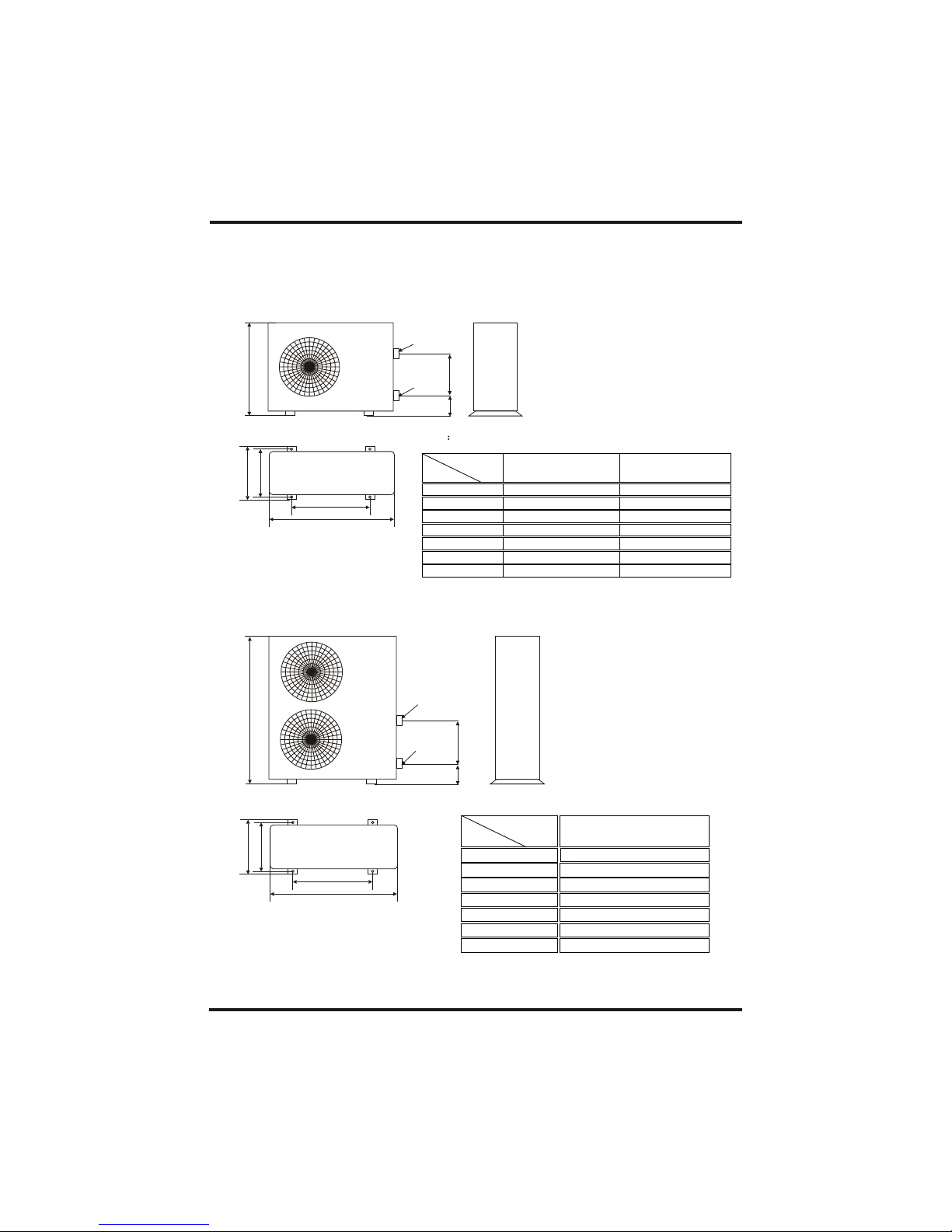

2.SPECIFICATION

Models:

Oasis C35T-Vb/Oasis C50T-Vb

Models:

EH9b

1002

658

430

455

630

Water In let

Water Ou tlet

Hor izont al visi on

Vertical vision

113 0

1490

1464

480

735

Water inlet

Water outlet

Drainage

Horizontal vision

Vertical vision

255102.5

88 120

6

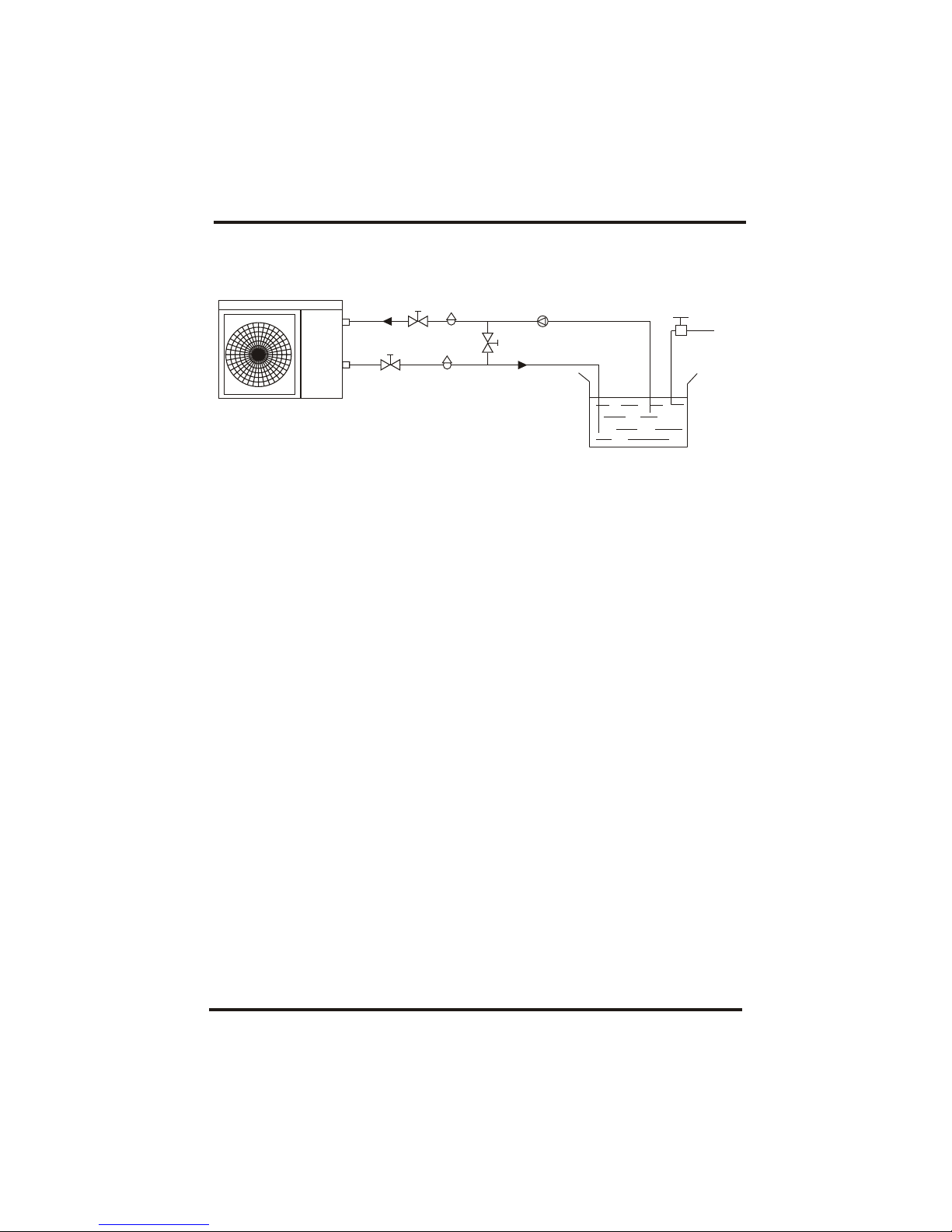

Installation items:

The factory only provides the heat pump unit; the other items in the illustration are

necessary spare parts for the water system ,provided by users or the installer.

3.1 Install at ion illustr ation

3.INSTALLATION AND CONNECTION

Chlorinator cell

Wat er outl et

Pool

Val ve

Wat er supp ly

Wat er inle t

Water pump

Sand fi lter

(or other type filter)

By-pass valve

Special Notes:

If the heat pump is used to heat the spa, then the parts will not strictly like what shown as

above, please make sure the water loop is clear and enough.

7

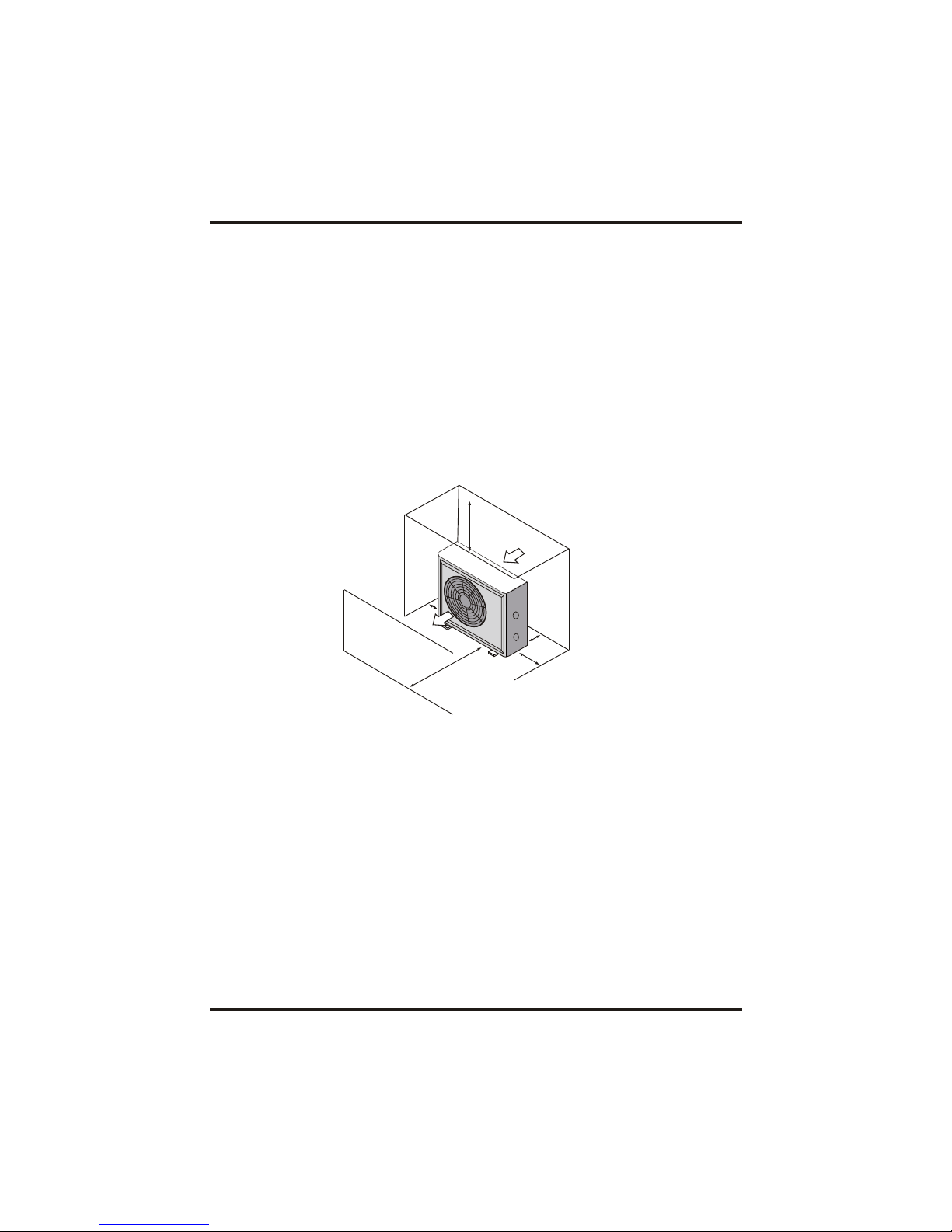

The uni t will pe rform well in an y outdo or loca tion pr ovide d that t he follo wing th ree fac tors ar e present .

1. Fresh Air - 2. El ectricity - 3. filter pipi ng

DO NOT place the unit in an enclosed area with a limited air volume, where the units

disch arge ai r wil l be re-c ircul ate d. DO NOT plac e the uni t to shrubs wh ich can b lock air inl et. These

locations deny the unit of a continuous source of fresh air which reduces it efficiency and

may prevent adequate heat delivery.

3.2 Spa Heat Pumps Location

3.3 How Close To Your spa?

3.INSTALLATION AND CONNECTION

Air inlet

Air outlet

2500mm

700mm

300mm

500mm

700mm

Norma lly, the longer th e distanc e from the spa, t he gre ater the h eat lo ss from th e pipi ng. I t

is rec ommen ded to ins tall t he hea t pu mp nea r the spa.

3.4 Spa Heat Pumps Plumbing

Locat ion: C onnec t the unit in the poo l pump disch arge (ret urn) l ine do wnstr eam o f all f ilter

and po ol pum ps, and up strea m of a ny chl orina tors, ozona tors or ch emica l pump s.

Stand ard mo del ha ve slip gl ue fit tings whi ch acc ept 40 mm NB PVC p ipe f or con necti on to

the po ol or spa f iltra tion p iping . By using a 50 NB to 40NB you ca n pl umb 50 NB PVC pip ing

strai ght in to the uni t.

Give s eriou s cons idera tion to ad ding a qui ck cou pler f ittin g at the un it inlet a nd out let t o allo w

easy d raini ng of unit for wi nteri zing and t o prov ide e asier acces s shou ld servic ing be

required.

Condensation: Since the Heat pump cools down the air about 4 -5 , water may condense on

the fins of the horseshoe shaped evaporator. If the relative humidity is very high, this could

be as much as several litres an hour. The water will run down the fins into the basepan and

drain out through the barbed plastic condensation drain fitting on the side of the basepan.

This fitting is designed to accept 3/4" clear vinyl tubing which can be pushed on by hand and

run to a suitable drain. It is easy to mistake the condensation for a water leak inside the unit.

NB: A quick way to verify that the water is condensation is to shut off the unit and keep the

pool pump running. If the water stops running out of the basepan, it is condensation. AN

EVEN QUICKER WAY IS to TEST THE DRAIN WATER FOR CHLORINE - if the is no chlorine

present, then it's condensation.

3.INSTALLATION AND CONNECTION

To Sp a

From pump

PVC COUPLER

RECOMMENDED(Provided)

The Spa Heat Pumps exclusive rated flow titanium heat exchanger requires no special

plumbing arrangements except bypass(please set the flow rate according to the nameplate).

The water pressure drop is less than 10kPa at max. Flow rate. Since there is no residual

heat or flame Temperatures, The unit does not need copper heat sink piping. PVC pipe can

be run straight into the unit.

8

Horizontal vision

9

3.5 Spa Heat Pu mps Electri ca l Wiring

NOTE: Although the unit heat exchanger is electrically isolated from the rest of the unit, it

simply prevents the flow of electricity to or from the pool water. Grounding the unit is still

required to protect you against short circuits inside the unit. Bonding is also required.

3.INSTALLATION AND CONNECTION

3.6 Initial startup of the Unit

NOTE- In order for the unit to heat the pool or spa, the filter pump must be running to

circulate water through the heat exchanger.

Start up Procedure - After installation is completed, you should follow these steps:

1. Turn on your filter pump. Check for water leaks and verify flow to and from the pool.

2. Turn on the electrical power supply to the unit, then press the key ON/OFF of wire

controller, It should start in several seconds.

3. After running a few minutes make sure the air leaving the top(side) of the unit is

cooler(Between 5-10 )

4. With the unit operating turn the filter pump off. The unit should also turn off automatically,

5. Allow the unit and pool pump to run 24 hours per day until desired pool water temperature

is reached. When the water-in temperature reach setting, The unit just

shuts off. The unit will now automatically restart (as long as your pool pump is running)when

the pool temperature drops more than 2 below set temperature.

Water Flow Switch - the unit is equipped with a flow switch that turns it on when the pool

pump is running and shuts it off when the pump shuts off. This switch is the same type used in

all gas pool heaters and is factory adjusted for normal pool installations. If the pool water

level is more than a few feet above or below the thermostat knob of the unit, your dealer may

need to adjust it at initial startup.

Time Delay- The unit is equipped with a 3 minute built-in solid state restart delay included to

protect control circuit components and to eliminate restart cycling and contactor chatter.

This time delay will automatically restart the unit approximately 3 minutes after each control

circuit interruption. Even a brief power interruption will activate the solid state 3 minute

restart delay and prevent the unit from starting until the 5 minute countdown is completed.

The unit has a separate molded-in junction box with a standard electrical conduit nipple

already in place. Just remove the screws and the front panel, feed your supply lines in

through the conduit nipple and wire-nut the electric supply wires to the three connections

already in the junction box (four connections if three phase). To complete electrical hookup,

connect Heat Pump by electrical conduit, UF cable or other suitable means as specified (as

permitted by local electrical authorities) to a dedicated AC power supply branch circuit

equipped with the proper circuit breaker, disconnect or time delay fuse protection.

Disconnect - A disconnect means (circuit breaker , fused or un-fused switch) should be

located within sight of and readily accessible from the uni, This is common practice on

commercial and residential air conditioners and heat pumps. It prevents remotely-energizing

unattended equipment and permits turning off power at the unit while the unit is being

serviced.

Disco nnect

Loading...

Loading...