OASIS® VERSACOOLER®II MODELS PAC, PGAC, PFAC, P8AC, PG8AC, PF8AC, P8ACEE, PF8ACEE, PV8AC

SUNROC MODELS ADAAC, ADAFAC, ADA8AC, ADAF8AC, ADA8ACHF, ADAF8ACHF

A. INSPECTION

Inspect the carton and water cooler for evidence of rough handling and concealed damage. Damage claims should be filed with the carrier.

B. TO PUT WATER COOLER INTO SERVICE

1. Note: The following states require a licensed plumber to install cooler; AR, GA, MA, MI, OK, RI, SC, SD, TX, VT and WI. CA, KS, MN, NM and OR allow for a state-

registered installer or contractor as well. State and loc al plum bing code s ma y prohibit the use of saddle tapping valve s for wa ter line c onnection in som e applic ations. All

connections must conform to applicable plum bing code s.

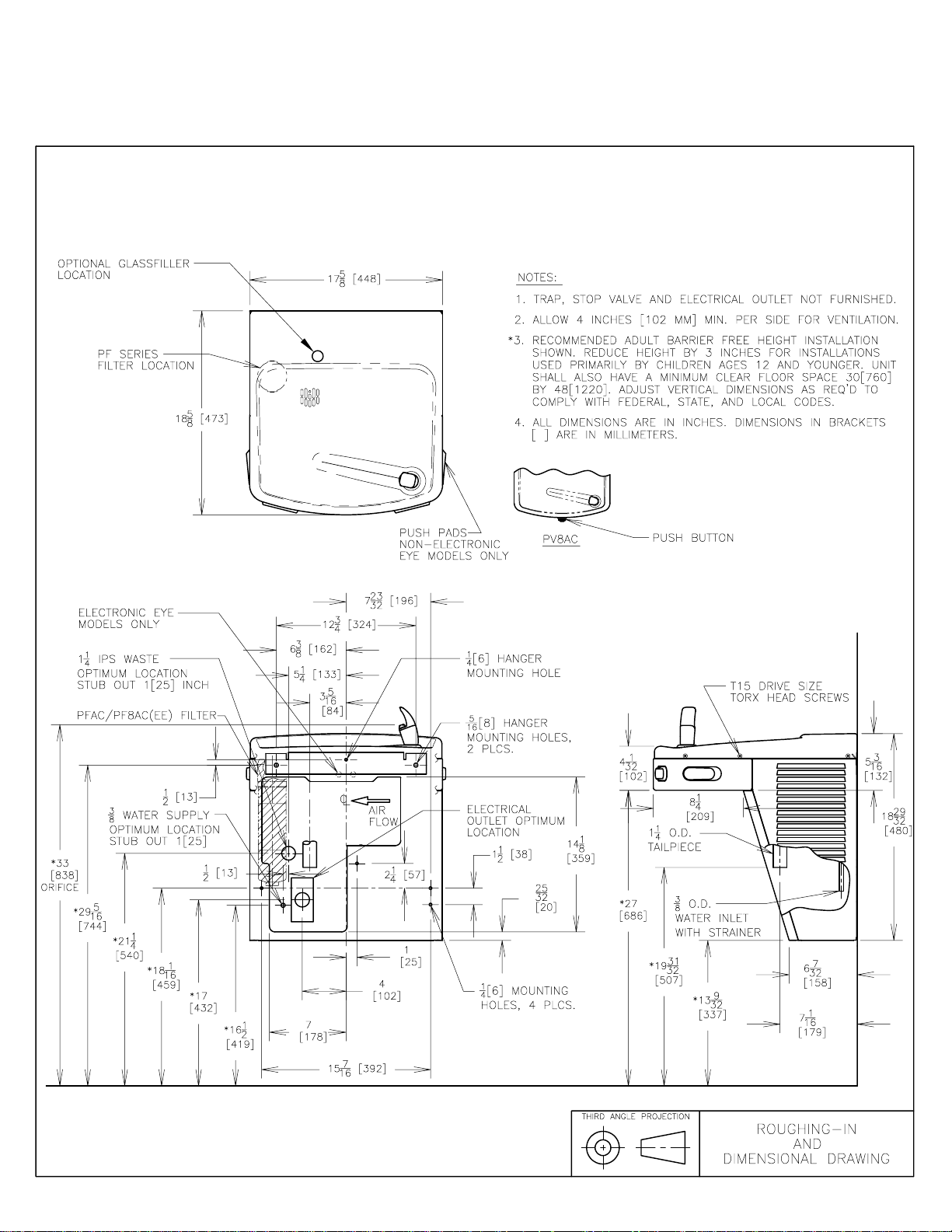

2. Locate and install plumbing and electrical service, if required, in accordance with the Roughing-in Drawing. Filter units have additional instructions on a label inside the access

panel. Read these before installing unit.

3. FLUSH BUILDING WATER SUPPLY LINE BEFORE INSTALLING UNIT.

4. Install unit on the wall hanger. Wall hanger is shipped fastened to the back of the unit.

5. Install a trap in the waste line and a shut off valve in the water supply line. An in-line strainer is furnished in the “Wa ter Supply ” tube. Connec t the “Wa ter Supply ” tube to

the shut off valve. This connection should not be a solder joint or flare connection to allow access to the strainer for service. To ease removal of the strainer, a sheet metal screw

may be lightly threaded into the open end. Whe n the unit has a n interna l waste trap, the trap should be w rapped w ith insulatin g tape to pre vent swe ating. U se of the 1-3/4 diam ete r

knockout for a waste line is not recommended because of a potential conflict with ADA* toe space clearance requirements. Check your local building code inspector for approval.

6. Rotate the fan blade by hand to see that it is free of obstructions.

7. Check the available power supply against the wate r cooler da ta pla te to assure corre ct el ectric al se rvice. Plug power supply cord into wall outlet. The rear most 1-3/8 diameter

knockout in the frame bottom is for an externally loc ate d elec trica l supply. Ma ke sure the knockout hole edge is smooth a nd fre e of any burrs. Use of a H eyc o bushing #2184 in the

knocked out hole is recommended in order to pre vent dam age to the se rvice cord and to c lose up e xcess ope ning around the cord. Route the cord so it does not interfere with

ADA* space requirements.

8. To fill the cold water tank on water cooler versions, open the wa ter supply line shut-off and push a ny one of the front or side pushbuttons to allow wate r to flow to the bubble r. On

the EE or HF model, actuate the solenoid by holding one hand approxim ate ly 3” from the infra red sensor. Run wa ter until strea m is free of bubbles.

9. To Adjust Bubbler Stream:

a) All Pushbutton models are equipped with a Cartridge Regulator. The P8AC, PAC, PG8AC, PGAC, PF8AC, PFAC, ADAAC, ADAFAC, ADA8AC and ADAF8AC ha ve a

slot in the shelf below the Pushbuttons. Insert a screwdriver in this slot to adjust regulator. Turn adjustm ent c lockwise to increase stream height. To access the PV8AC

adjustment, remove the Bezel and Button from the front of the cooler.

b) El ectric Ey e (EE or HF) mode ls have a Re gulator built into the B ubbler. If a djustme nt is nee ded, inse rt a 5/64 hex wre nch appr oxim ate ly 1-1/8” into the bubbler noz zle

opening until it bottoms out and is seated in an adjust screw. Turn the adjust screw clockwise to reduce the stre am height or countercloc kwise to inc rea se the height. N ote,

less than one turn is required to go from a closed to a wide open flow. Do not over tighten the adjuster in the close d position as stripping the hex impression in the adjust

screw may result. Turn the adjuster 1/16 of a turn at a time .

10. On electric eye equipped models, place and then hold hand approximately 3” from the sensor to actuate the solenoid valve. After approximately 30 seconds run time, the sensor

will automatically shut off the solenoid valve. To reactivate, move hand away for an instant and then again place it in front of the sensor.

11. To adjust the bea m ra nge of the sensor (EE and HF m odels only ):

a) Shut off the water and power supplies.

b) R em ove the four sc rew s from the top front.

c) Remove the eight screws from the bottom of the nose that holds the nose to the she lf.

d) Rem ove the nose to gain access to the sensor adjusting screw located between the two lenses.

e) The screw can be turned a ma xim um of ¾ turns. T urn scre w counte rcloc kwise to de crea se ra nge. T he sensor ha s an a djustable ra nge of 24” to 48”. It is fa ctory set a t 27”.

There is a non-adjustable on-time delay of 0. 75 sec onds to prevent nuisa nce a ctua tion of the sole noid valve should som eone wa lk by. After drinking, the wate r will shut off

immediately after walking aw ay. Maxim um run tim e is 30 se conds should som eone tam per with the sensor. N OTE: Wa lls with a re flective finish, i.e., ce ramic tile, ac ross

from the sensor may cause false actuation no matter what the sensor adjustment is for distance. Therefore, do not install the unit in such an area or dull the surface of the wall

so it will not reflect light.

C. MAINTENANCE

The only maintenance operation require d is the re mova l of dirt and lint from the c ondense r where used. Inspe ction should be m ade at 3-m onth interva ls. Disc onnec t the powe r supply

cord, then clean the condenser with a sm all stiff non-wire or vacuum c leane r atta chm ent brush whe n required. Observa nce of this procedure will insure ade quate air ci rculation through

the condenser so operation is efficient and econom ica l.

D. OVERLOAD PROTECTION

The compressor motor, where used, is equipped with a n autom atic re set protec tor which will disc onnect the m otor from the line in c ase of an ove rload.

E. LUBRICATION

This unit is equipped with a hermetically sea led com pressor a nd require s no additional lubric ation. T he fan m otor, w here use d, on this unit seldom needs oiling, but if require d, a fe w

drops of SAE 10 oil should be used.

F. TO DISCONTINUE USE OF WATER COOLER

1. Close water shut-off valve.

2. Provide container to catch water to be draine d.

3. On the push button model, disconnect the water supply line a t the shut off valve and re move the ta nk drain plug. A ctuat e and hold in the pushbutton to open the solenoid valve

and completely drain the cooler. Disc onnec t the powe r supply c ord.

4. On the EE model, disconnect the wa ter supply line at the shut off valve a nd rem ove the tank dra in plug. Ac tuate the solenoid, a s explaine d in Step B7 to c omple tely drain the

cooler. Disconnect the power supply cord.

5. Replace plug when draining is complete.

6. ALWAYS DRAIN ALL WATER WHEN FREEZING TEMPERATURES ARE ANTICIPATED AND BEFORE SHIPPING THE WATER COOLER.

*Americans With Disabilities Act

The warranty and the Underwriters' Labora tory Li sting for this m a chine a re a utom atic a lly voide d if this m a chine is alte red, modified, or combined with any other machine or device.

Alteration or modification of this machine may cause serious flooding and/or hazardous electrical shock or fire.

EXCEPT AS SET FORTH HEREIN, THE MANUFACTURER MAKES NO OTHER WARRANTY, GUARANTEE OR AGREEMENT EXPRESSED, IMPLIED OR STATUTORY,

INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

WARNING

222 East Campus View Blvd. • Columbus, OH 43235 U.S.A.

1-800-950-3226

www.oasiscoolers.com

is a trademark of Oasis International © 2009 Oasis International

®

OASIS

is a registered trademark of Oasis International 030099-267 Rev C

OASIS® VERSACOOLER®II MODELS

P AC, PGAC, PF AC, P8AC, PG 8AC, PF8AC, P8ACEE, PF8A CEE, PV8AC

SUNR OC MODELS AD AAC, ADAFAC, ADA8AC, ADAF8AC, AD A8ACHF, ADAF8ACH F

Loading...

Loading...