Oase FiltoMatic CWS 7000, FiltoMatic CWS 14000, FiltoMatic CWS 25000 Operating Instructions Manual

Page 1

FiltoMatic CWS 7000/14000 /25000

Page 2

2

Page 3

3

Page 4

4

Page 5

5

Page 6

6

Page 7

- GB -

- GB -

Foreword

Welcome to OASE Living Water. You made a good choice with the purchase of this productFiltoMatic

CWS .

Prior to commissioning the unit, please read the instructions of use carefully and fully familiarise yourself

with the unit. Ensure that all work on and with this unit is only carried out in accordance with these

instructions.

Adhere to the safety information for the correct and safe use of the unit.

Keep these instructions in a safe place! Please also hand over the instructions when passing the unit on

to a new owner.

Table of Contents

1 Scope of delivery.............................................................................................................................. 23

2 Overview .......................................................................................................................................... 23

3 Legal conditions ............................................................................................................................... 23

4 Safety information ............................................................................................................................ 24

5 Installation ........................................................................................................................................ 25

6 Installation ........................................................................................................................................ 26

7 Start-up............................................................................................................................................. 27

8 Operation.......................................................................................................................................... 28

9 Remedy of faults .............................................................................................................................. 31

10 Maintenance and cleaning ............................................................................................................... 32

11 Wear parts........................................................................................................................................ 36

12 Storage/Over-wintering .................................................................................................................... 36

13 Disposal............................................................................................................................................ 36

Technical data ........................................................................................................................................ 337

Symbols on the unit................................................................................................................................ 341

Spare parts ............................................................................................................................................. 342

3.1 Intended use ............................................................................................................................ 23

3.2 Extended guarantee conditions for the OASE ClearWaterSystem.......................................... 23

4.1 Hazards encountered by the combination of water and electricity .......................................... 24

4.2 Correct electrical installation .................................................................................................... 24

4.3 Safe operation.......................................................................................................................... 24

8.1 Controller overview .................................................................................................................. 28

8.2 Setting the dirty water pump ....................................................................................................29

8.3 Setting the UVC clarifying unit .................................................................................................30

10.1 Cleaning foam filters ................................................................................................................ 32

10.2 Remove and separate the cleaning components from each other .......................................... 32

10.3 Cleaning the dirty water pump ................................................................................................. 33

10.4 Changing the UVC lamp in the UVC clarifying unit.................................................................. 33

10.5 Checking the cleaning rotor .....................................................................................................34

10.6 Changing the foam filters ......................................................................................................... 34

10.7 Thorough cleaning of the unit .................................................................................................. 35

22

Page 8

1 Scope of delivery

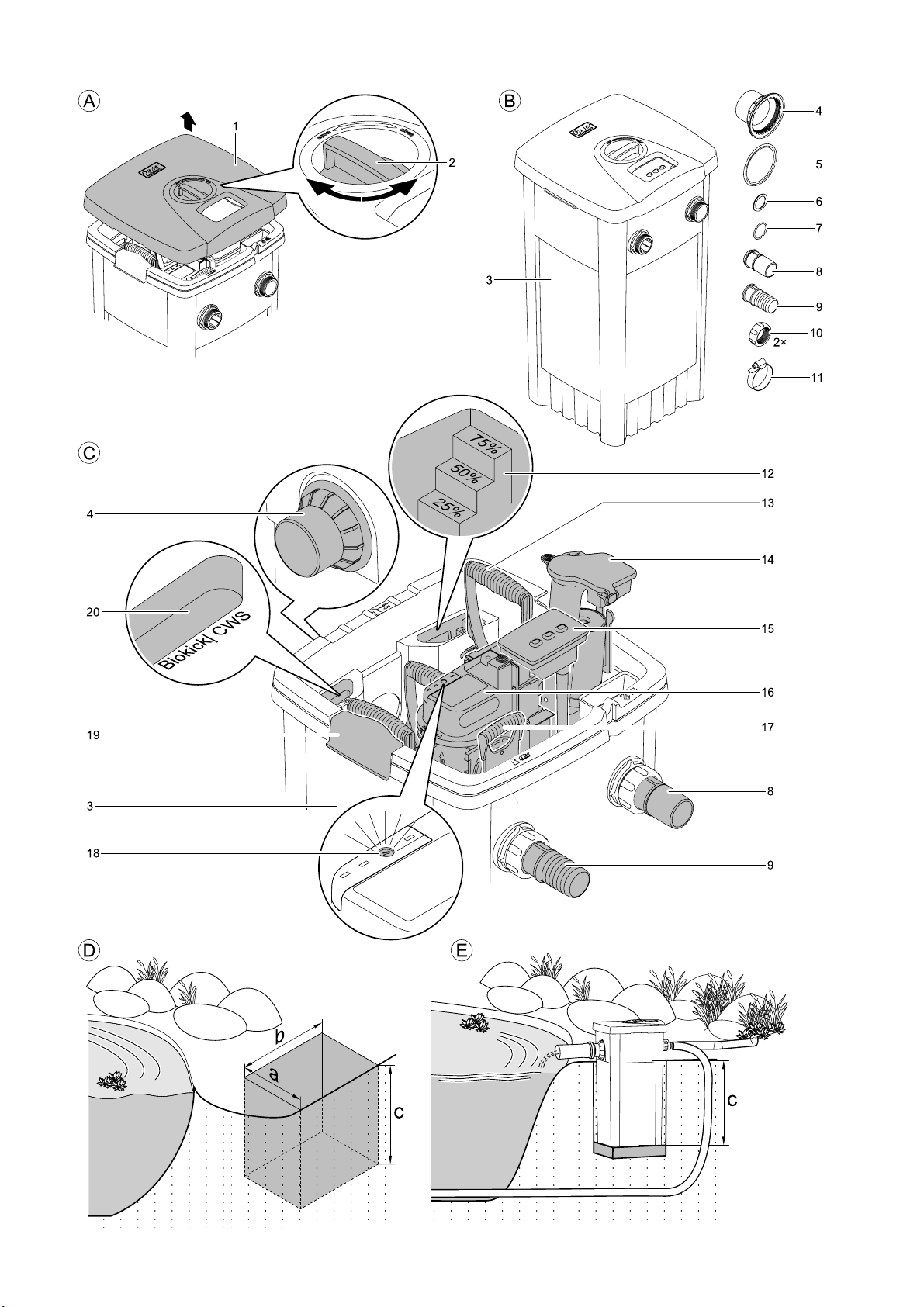

► Open the lid (1) using the rotary handle (2) to remove the assembly components (Figure A).

Figure B Number Description

3 1 Container FiltoMatic CWS

4 1 Outlet DN70

5 1 Flat sealing DN70

6 1 Flat sealing 1 ½“

7 1 O ring DN40

8 1 Outlet sheath DN40

9 1 Inlet sheath 1 ½“

10 2 Union nut

11 1 Hose clip

1 Instructions for use

1 Fast assembly instruction manual

1 Guarantee brochure

1 Clear water guarantee card

1 Guarantee extension card 2+1

2 Overview

Figure C Designation For a description, please refer to Chapter …

3 Container Assembly, cleaning and maintenance

4 Outlet DN70 Installation

8 Dirty water outlet DN40 Installation

9 Inlet 1 ½“ Installation

12 Soiling indicator Maintenance and cleaning

13 Foam holder Maintenance and cleaning

14 Dirty water pump Maintenance and cleaning

15 Controller Operation

16 UVC clarifying unit Maintenance and cleaning

17 Stop valve for inlet Starting up, cleaning and maintenance

18 UVC lamp control window Maintenance and cleaning

19 Engagement hooks Maintenance and cleaning

20 Biokick CWS infill opening Start-up

- GB -

3 Legal conditions

3.1 Intended use

The FiltoMatic CWS is intended as a filter system for the mechanical and biological cleaning of garden

ponds having a water temperature of between +4 °C and +35 °C. The unit is exclusively suited for

private use and may only be employed for cleaning garden ponds with or without fish population.

3.2 Extended guarantee conditions for the OASE ClearWaterSystem

Guarantee claims can only be brought forward to us, OASE GmbH, Tecklenburger Straße 161 in

D-48477 Hörstel, by returning to us the unit or part of the unit subject to complaint, freight free, at your

own risk, accompanied by the original purchase receipt from the OASE specialist dealer, this guarantee

document and written information of the fault encountered. Should the dirty water pump, UVC clarifying

unit or controller be defective, only return the individual defective component (dirty water pump, UVC

clarifying unit, controller), not the complete unit.

23

Page 9

- GB -

4 Safety information

Hazards to persons and assets may emanate from this unit if it is used in an improper manner or not in

accordance with its intended use, or if the safety instructions are ignored.

This unit can be used by children from the age of 8 and by persons with physical,

sensory or mental impairments or lack of experience and knowledge, as long as they

are supervised or instructed on how to use the unit safely and are able to understand

the potential hazards. Do not allow children to play with the unit. Do not allow children

to clean or maintain the unit without close supervision.

4.1 Hazards encountered by the combination of water and electricity

► The combination of water and electricity can lead to death or severe injury from electrocution, if the

unit is incorrectly connected or misused.

► Prior to reaching into the water, always switch off the mains voltage to all units used in the water.

4.2 Correct electrical installation

► For your own safety, consult a qualified electrician when you have questions or encounter problems.

► Electrical installations at garden ponds must meet the international and national regulations valid for

installers. Especially adhere to DIN VDE 0100 and DIN VDE 0702.

► Compare the electrical data of the power supply with those indicated on the type plate on the UVC

clarifying unit.

► Only operate the FiltoMatic CWS when plugged into a correctly fitted socket.

► Please note that the power supply must be fused via a fault current protection system with a

maximum reference fault current of 30 mA.

► Install the FiltoMatic CWS such that any risk of injury to persons is excluded.

► Only use cables that are uncoiled.

► Extension cables must be approved for outdoor use and meet DIN VDE 0620 standards.

► Route the connection cable so that damage is excluded.

► Keep all connection points dry. Risk of electrocution.

4.3 Safe operation

► Only operate the FiltoMatic CWS if no persons are in the water.

► Never carry or pull the UVC clarifying unit and the dirty water pump of the FiltoMatic CWS by holding

on the connection cables.

► Do not operate defective units. Do not operate the FiltoMatic CWS if the electrical connection cables

are defective. Pull the power plug immediately. The connection cables of the UVC clarifying unit and

of the dirty water pump cannot be repaired. Replace the components. Dispose of the defective

components in compliance with the environmental regulations.

► Never open the housing of the UVC clarifying unit, dirty water pump, control system or their

attendant components, unless this is explicitly mentioned in these instructions of use.

► Only use original spare parts and accessories.

► Never use the system for filtering fluids other than water.

► The radiation of the UVC lamp, even in small doses, is dangerous for eyes and skin. Never operate

the UVC lamp in a defective housing or outside of the housing.

► Never operate the UVC lamp without cleaning rotor, as this also acts as an eye protection against

UVC radiation.

► Overvoltage in the mains could lead to operating malfunctions of the unit. For information, please

refer to chapter "Remedy of faults".

24

Page 10

5 Installation

We recommend to thoroughly clean the garden pond to ensure almost maintenance-free operation of

the FiltoMatic CWS from the very beginning. OASE's recommendation for this cleaning work is the use

of the pond sludge suction unit Pondovac. In general, cleaning work can be omitted when the FiltoMatic

CWS is used in a newly installed garden pond.

Installing the FiltoMatic CWS (Figure D,E)

Plan the installation of the FiltoMatic CWS. Careful planning and taking the environmental conditions

into account will lead to optimum operating conditions for the FiltoMatic CWS. The following points can

help you with your planning.

► A water course guarantees optimum water return from the FiltoMatic CWS to the garden pond. In

this manner, the filtered pond water is enriched with oxygen prior to returning to the pond. Should

the local situation not allow the installation of a water course, extend the outlet using a DN70 pipe for

the filtered water to return to the pond via the pipe. Please refer to the Installation chapter for the

installation of a DN70 pipe.

► Horizontal alignment of the FiltoMatic CWS is crucial to prevent drainage of the pond in the event of

an overflow. Carry out the alignment using a spirit level.

► Take the large volume of the FiltoMatic CWS as well as the resulting weight when filled into account.

Select a suitable ground or a bottom slab in the pit to prevent the FiltoMatic CWS from sagging.

► Plan sufficient space for movement to be able to carry out cleaning and maintenance work.

► Dig a suitably dimensioned pit for the installation of FiltoMatic CWS (Figure D). Take into

consideration that the FiltoMatic CWS can be buried up to the top recess (Figure E, height c).

Please use the following table as a basis for the pit dimensions:

Model a b c (+ bottom slab height)

FiltoMatic CWS 7000 approx. 50 cm approx. 50 cm approx. 30 cm

FiltoMatic CWS 14000 approx. 50 cm approx. 50 cm approx. 50 cm

FiltoMatic CWS 25000 approx. 50 cm approx. 70 cm approx. 50 cm

► Fill the container (3) with water prior to backfilling the soil to avoid compressing the container.

► Route the DN40 pipe end for the dirty water outlet at a distance from the pond that prevents the

pumped out dirty water from flowing back into the pond.

- GB -

25

Page 11

- GB -

6 Installation

Installation of the FiltoMatic CWS

The FiltoMatic CWS is delivered pre-assembled. Assembly is reduced to the outlet and the inlet and

dirty water outlet connections.

The outlet sheath (8) for the dirty water outlet is transparent. In this manner, the degree of soiling of the

outflowing water is visible during future cleaning. Pumping can be stopped as soon as visibly clean

water flows out of the dirt outlet. Cleaning is then completed.

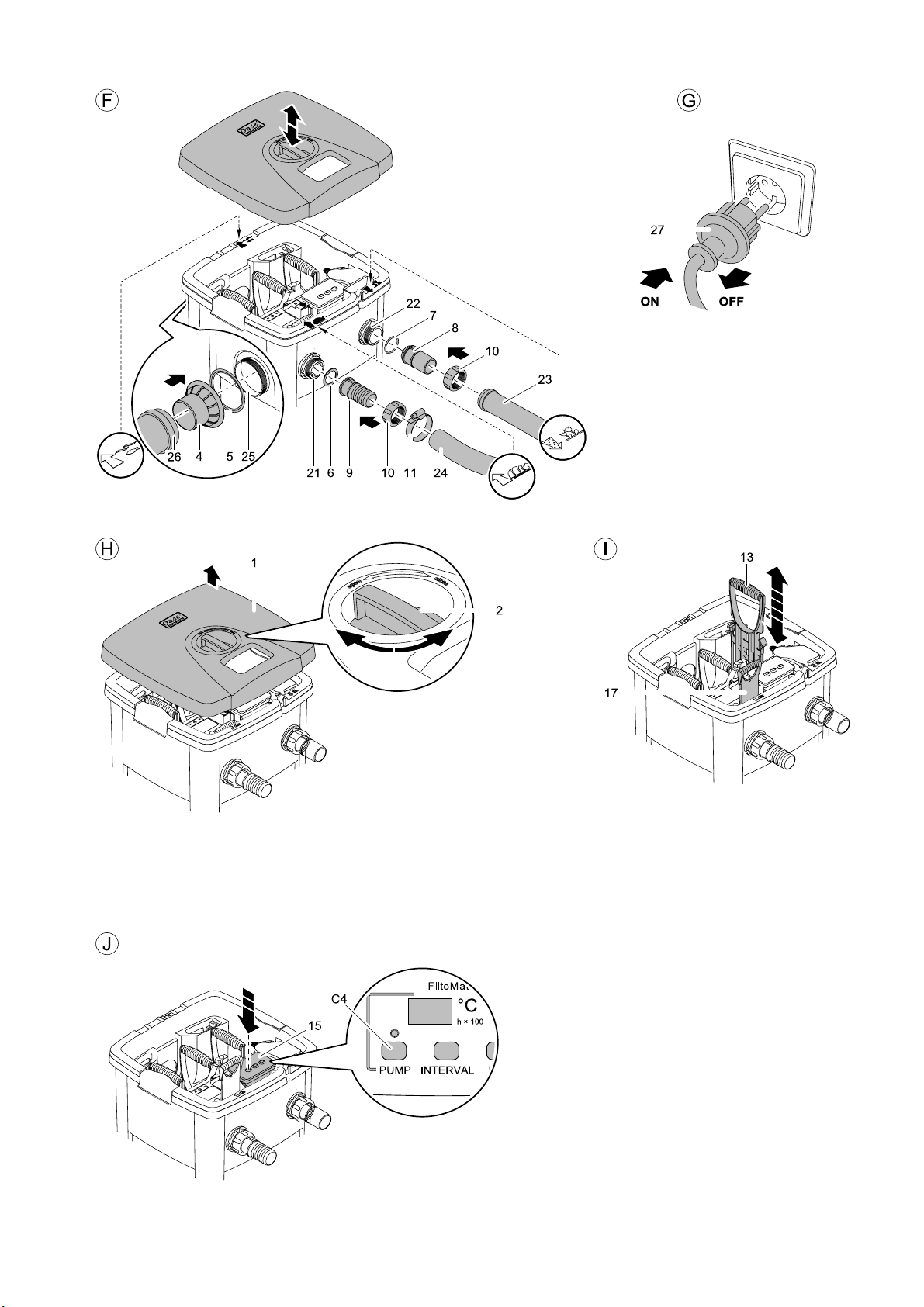

Installation of the outlet (Figure F)

1. Place the flat sealing (5) over the outlet screw (25) pre-fitted on the housing.

2. Screw the outlet (4) on the outlet screw (25).

3. If necessary, connect a DN70 pipe (26) to the outlet (4) as an extension to allow the filtered pond

water to return into the pond. Ensure a minimum incline of 1.5 % for the DN70 pipe.

As an extension for the outlet, OASE recommends the following:

− DN70 pipe, 480 mm, black (OASE Order No. 55034)

− DN70 pipe elbow, 45°, black (OASE Order No. 55044)

− DN70 pipe elbow, 87°, black (OASE Order No. 55045)

− DN70 pipe elbow, T, black (OASE Order No. 55046)

Installation of the inlet (Figure F)

1. Plug the inlet sheath (9) and the flat sealing (6) into the union nut (10) and tighten at the stop valve

thread (21).

2. Slide the hose clip (11) over the hose (24) arriving from the Aquamax. Push the hose on the inlet

sheath (9) and fasten with the hose clip.

Hose recommended by OASE: Spiral hose, green (OASE Order No. 52981)

Prior to the assembly, place the hose end in hot water for two minutes. It will then be easier to slide the

hose onto the inlet sheath (9).

Installation of the dirty water outlet (Figure F)

1. Fit the O ring (7) on the outlet sheath (8) and into the union nut (10). Then tighten to the thread of

the pre-assembled dirty water outlet (22).

2. Plug a DN40 pipe (23) onto the outlet sheath (8). Route the end of the DN40 pipe to a point where

the dirty water to be pumped out can trickle into the ground. Ensure a gravity of 1.5 % to 2 % for the

DN40 pipe.

As an extension for the dirty water outlet, OASE recommends the following:

− DN40 pipe, 480 mm, black (OASE Order No. 50307)

− DN40 pipe elbow, 45°, black (OASE Order No. 50308)

26

Page 12

7 Start-up

Attention! Sensitive electrical components.

Possible consequence: The unit will be destroyed.

Protective measure:

► Do not connect the unit to a dimmable power supply.

► Do not operate the unit with a timer.

Attention! Dangerous electrical voltage.

Possible consequences: Death or severe injury.

Protective measures: Disconnect the power plug (Figure G) prior to reaching into the water and

commencing work.

Follow the safety information!

The FiltoMatic CWS switches on automatically when the power connection is established.

Switching on (Fig. G): Plug the power plug (27) into the socket.

Switching off (Fig. G): Disconnect the power plug (27).

Fill the container with water (Figure C)

► Switch the Aquamax pump on prior to commissioning the FiltoMatic CWS. Container (3) has to be

filled with water.

- GB -

Stop valve (17) needs to be open to enable the container to be filled. For this purpose, press the stop

valve (17) down against the stop.

As soon as the water level in the container (3) reaches the outlet (4), the filtered pond water returns into

the pond via the outlet (4).

For further settings of the FiltoMatic CWS, please read the following Chapter Operation.

Filling with biological filter starter (Figure C)

We recommend the OASE filter starter Biokick CWS (OASE Order No. 50295) for a fast growth of

bacteria populations. Micro-organisms colonise the filter system, multiply and ensure an enhanced

quality of the pond water by the decomposition of excess nutrients.

► Fill the quantity of Biokick CWS sufficient for the volume of your pond into the infill opening (20).

27

Page 13

- GB -

8 Operation

8.1 Controller overview

Displays on the controller

The display (C1) shows

− the water temperature as standard.

− automatically the water temperature again 2 seconds after the last key operation.

− the cleaning programs if selected accordingly.

− the saved settings when pressing a key.

− the remaining operating life (h × 100) of the UVC lamp.

Displayed messages (C1)

− "LA" flashes in an 8 sec. interval 1×: The UVC lamp was active for 7500 operating hours; remaining operating life: 500

operating hours

− "LA" flashes in an 8 sec. interval 2×: The UVC lamp has operated for 8000 hours and should be replaced.

− "PS" lights up in a 4 sec. interval: The dirty water pump has reached its max. running time and is blocked for 1.5 hours.

LED for dirty water pump (C2)

− LED flashes green: Partial container drainage.

− LED is lit green: complete container drainage.

− LED is lit red: Pump blocked.

− LED off: Pump not active.

LED for UVC clarifying unit (C3)

− LED is lit blue: UVC clarifying unit is switched on.

− The LED flashes in an 8 sec. interval blue: The UVC clarifying unit is integrated in the Automatic (AU) operating program.

− LED off: UVC clarifying unit is switched off.

Note:

The integrated thermometer permanently measures the water temperature, thereby forming the reference value for the operating

programs.

The silicone cover protects the controller from soiling; it impairs neither the display reading nor the functionality of the keys. The

controller is water tight and can also be operated without the silicone cover.

C1 Display

C2 LED displaying the dirty water

pump function

C3 LED displaying the UVC

function

C4 Key for manual dirty water

pump operation

C5 Key for setting a cleaning

program for the dirty water

pump

C6 Key for setting an operating

program for the UVC clarifying

unit

28

Page 14

8.2 Setting the dirty water pump

In addition to the water temperature, the degree of soiling of the pond water greatly depends on the fish

population. The dirty water pump pumps out the dirt from the container bottom in intervals. The four

different cleaning programs allow individual adaptation of the interval for pumping off the dirty water

according to the degree of soiling. One cleaning cycle takes approx. 9 sec. and requires approx. 4 litres

of water. The table shows the cleaning program selection options. The cleaning program INTERVAL 1

includes the majority of cleaning intervals, INTERVAL 4 the smallest number of intervals. Select a

program that is best suited for the degree of soiling of the pond water. When delivered, cleaning

program INTERVAL 2 is set as a default.

Water temperature

INTERVAL 1 INTERVAL 2 INTERVAL 3 INTERVAL 4 OFF

< 5 °C

< 8 °C

8 °C - 14 °C 2 × per day 1 × per day every 2 days every 3 days off

15 °C - 21 °C 4 × per day 2 × per day 1 × per day every 2 days off

≥ 22 °C

off off off off off

1 × per day every 2 days every 3 days every 3 days off

8 × per day 4 × per day 2 × per day 1 × per day off

The cleaning programs are inactive at water temperatures between <0 °C and >35 °C. The pump can

then only be actuated manually. For fully pumping out, keep the PUMP (C4) key permanently pressed.

Setting the cleaning program for the dirty water pump

1. Press the INTERVAL (C5) key. The cleaning program INTERVAL 2 appears in the display (C1).

2. Press the INTERVAL (C5) key until the desired cleaning program appears.

3. Release the INTERVAL (C5) key when the desired cleaning program is displayed.

− The setting is saved when the water temperature appears in the display (C1) after a period of

approx. 2 seconds.

Manual pumping out of the dirty water

The dirty water can also be removed by pumping manually.

► Press the PUMP (C4) key

− The LED (C2) flashes green. Soiling removal starts immediately.

+ Intervals

- GB -

Cleaning programs, dirty water pump

− Intervals

► Complete container emptying starts when you keep the PUMP (C4) key pressed for longer than 10

seconds. The green LED (C2) is lit. The dirty water pump runs for a maximum of 4 minutes. You can

stop the drainage cycle by pressing the PUMP (C4) key once.

► The maximum running time of the dirty water pump is limited to 12 minutes per 1.5 hours in order to

avoid damage resulting from overheating. With heavy soiling, the running time can also be limited to

8 minutes. Once the max. running time is reached; the pump can no longer be operated manually.

The display shows "PS". After 1.5 hours the dirty water pump is once again operational.

29

Page 15

- GB -

8.3 Setting the UVC clarifying unit

The degree of soiling of the pond water by the formation of algae is notably determined by the water

temperature. With its UV light, the UVC clarifying unit operating under water removes green algae, as

such forming a significant component for pond water cleaning. Depending on the water temperature, the

UVC lamp of the UVC clarifying unit is switched on and off in intervals with the AU operating program. In

this manner it can be individually adapted to the degree of soiling. The following table shows the

operating program AU (Automatic) of the UVC clarifying unit as well as the operating statuses ON and

OFF.

Water temperature

UVC lamp is switched

< 8 °C

8 °C - 14 °C 48 h 24 h

15 °C - 21 °C 72 h 24 h

≥ 22 °C

on

8 h 16 h

96 h 24 h

When delivered, the operating program AU is set as a default.

► With Power ON, the operating program AU starts with the OFF interval. The UVC lamp does not lit

up for a minimum of 16 hours. The use of Biokick CWS during start-up protects the bacteria cultures

in the Biokick CWS.

► The UVC clarifying unit starts with the ON interval when the AU operating program is manually

selected.

Setting the operating program for the UVC clarifying unit

1. Press the UVC (C6) key. The AU operating program appears on the display (C1).

2. Press the UVC (C6) key until the desired operating program is displayed.

3. Release the UVC (C6) key when the desired operating program is displayed.

− The setting is saved when the water temperature appears in the display (C1) after a period of

approx. 2 seconds.

Inquiry of the operating hour counter reading of the UVC clarifying unit

The operating life of a UVC lamp for the UVC clarifying unit is approx. 8000 hours. The integrated

operating hour counter counts down from this value.

► Keep the UVC (C6) key pressed for 5 seconds. A number appears in the display (C1).

− Multiply this number by 100 to calculate the remaining number of operating hours.

− Example: displayed value '45' × 100 = 4500 remaining operating hours.

Resetting the operating hour counter reading of the UVC clarifying unit

Reset the operating hour counter after changing a UVC lamp.

1. Keep the UVC (C6) key pressed for 12 seconds!

− The remaining operating life appears on the display (C1) after 5 seconds. Following this, the

display flashes. The operating hour counter is reset to 8000 hours, when the water temperature

appears in the display (C1).

2. Release the UVC (C6) key.

UVC clarifying unit operating programs

AU ON OFF

UVC lamp is switched

off

UVC lamp is

permanently switched

on

UVC lamp is

permanently switched

off

30

Page 16

- GB -

9 Remedy of faults

Malfunction Cause Remedy

The controller does not switch on

to the pond

Dirty water pump does not switch on

No mains voltage Check mains voltage

Check supply lines

Controller incorrectly positioned on the UVC

Check the controller seating

clarifying unit

Aquamax pump not switched on Switch on Aquamax pump Water from the DN70 outlet does not return

Stop valve closed with the lid open Open stop valve

Pump rotor blocked Clean pump rotor

Container already empty Fill container

Container partly emptied, dirty water pump

Fill container

cannot prime

The cleaning programs are inactive at water

temperatures between<0 °C and >35 °C

Now the dirty water pump can only be

operated manually.

− Keep the PUMP key pressed for complete

drainage.

The dirty water pump has reached its max.

running time. The display shows "PS".

Wait for 1.5 hours. Once this time has

elapsed, the dirty water pump is operational

again.

UVC lamp defective Changing the UVC lamp UVC lamp does not switch on

The safety system in the UVC clarifying unit

has tripped as a result of overvoltage in the

mains

Switch of the mains voltage and on again to

reset the safety system

− Check that the UVC lamp is lit in the

control window (blue light)

− To test, we suggest to switch on the UVC

lamp using the UVC key (operating status

ON)

31

Page 17

- GB -

10 Maintenance and cleaning

Attention! Dangerous electrical voltage.

Possible consequences: Death or severe injury.

Protective measures:

► Prior to reaching into the water, switch off the mains voltage to all units used in the water.

10.1 Cleaning foam filters

► Switch off the mains voltage prior to carrying out work on the unit.

Cleaning intervals depend on the degree of soiling of the foam filters. A higher water level in the soiling

indicator (Figure C, 12) in the inner cover signals that the foam filter cleaning capacity has decreased.

Cleaning is due from a degree of soiling of 75 % or in the event of an overflow at the latest.

How to clean the foam filters (Fig. H, I, J)

1. Open lid (1) with the rotary handle (2) and remove lid from the container (3).

2. Close the stop valve (17) by pulling it up.

− Pond water no longer flows into the container.

− Note: Water will spurt out of the air intake socket when closing the stop valve (17).

3. Pull foam filters (13) up several times.

− The foam filters will be compressed. The soiling will be washed out.

4. Press the PUMP key (C4) on the controller (15) for longer than 10 seconds.

− The LED (C2) is lit green. All of the dirty water in the container will be pumped out.

5. Open the stop valve (17) by pressing it down.

− The container fills up with pond water again.

Repeat the cleaning cycle if the foam filters are heavily soiled.

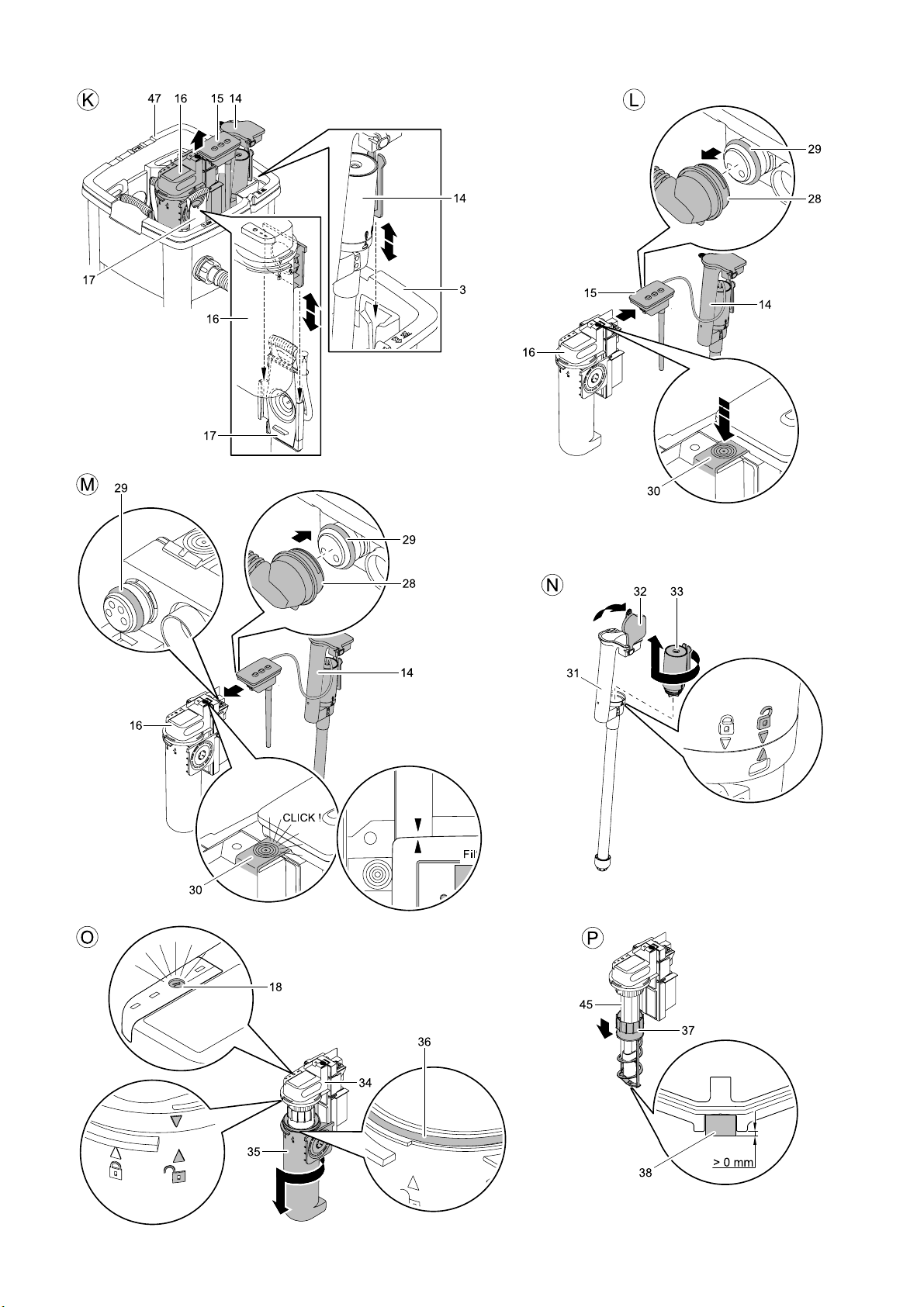

10.2 Remove and separate the cleaning components from each other

For cleaning and maintenance of the cleaning components of the dirty water pump (14) and the UVC

clarifying unit (16) it is necessary to take both out of the container. The controller (15) is fitted to the UVC

clarifying unit. The cleaning components are not permanently connected to the inner cover (47) but rest

in the guides of the inner cover (47) or of the stop valve (17) respectively.

This is how to remove the cleaning components (Figure K)

1. Open lid (1) with the rotary handle (2) and remove lid from the container (3) (Figure H).

2. Close the stop valve (17) by pulling it up.

− Pond water no longer flows into the container.

− Note: Water will spurt out of the air intake socket when closing the stop valve.

3. Lift the cleaning components of the dirty water pump (14) and of the UVC clarifying unit (16) out of

the inner cover (47) as one unit.

This is now the cleaning components and the controller are separated from one another (Figure

L)

1. Keep the engagement hook (30) on the UVC clarifying unit (16) pressed.

2. Remove the controller (15) from the UVC clarifying unit by applying force.

3. Pull the connection cable (28) of the dirty water pump off the controller (15) by applying force.

4. Plug in the silicone caps to protect the open sockets.

5. Reassemble the cleaning components and the controller in the reverse order (Figure M).

− When assembling the controller and the UVC clarifying unit, ensure that the arrows on both

components point to one another.

During assembly, check the seating of the O rings (29) at the connection points of the controller and of

the UVC clarifying unit! Clean the O rings (29) as required. The electrical contacts will corrode if the O

rings are missing or incorrectly seated. This will lead to irreparable damage to the components!

32

Page 18

10.3 Cleaning the dirty water pump

Cleaning of the dirty water pump becomes due when the rotor of the pump motor (33) is heavily soiled

or blocked. This can happen as a result of larger soiling, such as, e.g. stones. The LED indicator (C2) on

the controller (15)

How to clean the dirty water pump (Fig. N)

1. Turn the motor housing (33) until the symbol showing " Lock open" points to the arrow on the top

pipe (31).

2. Remove and clean the motor housing (33).

3. Reassemble in the reverse order.

− Important: The motor housing (33) is only arrested when the "Lock closed" symbol points to the

arrow on the top pipe (31) (Figure N).

4. Press the PUMP button (C4) once.

− The LED (C2) changes from red to green. The dirty water pump (14) starts up. Otherwise, the dirty

water pump (14) will not start up because of a malfunction. In this context, please refer to Chapter

Remedy of faults.

5. If necessary, clean the overflow on the top pipe (31). To this effect, open the soiling pipe cover (32).

10.4 Changing the UVC lamp in the UVC clarifying unit

Attention! Dangerous ultra-violet radiation.

Possible consequences: Severe injury to the eyes and the skin.

Protective measures: Only switch the unit on with the housing fitted.

The controller (15) does not show when the UVC lamp is defective. Check the function of the UVC lamp

by looking into the control window (18) at regular intervals (Figure O).

The operating life of the UVC lamp being limited, it has to be replaced once its useful life has elapsed

(please also refer to Chapter Checking the reading of the UVC clarifying unit operating counter).

1. Turn the water housing (35) until the symbol showing " Lock open" points to the arrow at the UVC top

pipe (34) (Figure O).

2. Pull off the water housing (35) (Figure O).

3. Remove the cleaning rotor (37) from the quartz glass tube (45) (Figure P).

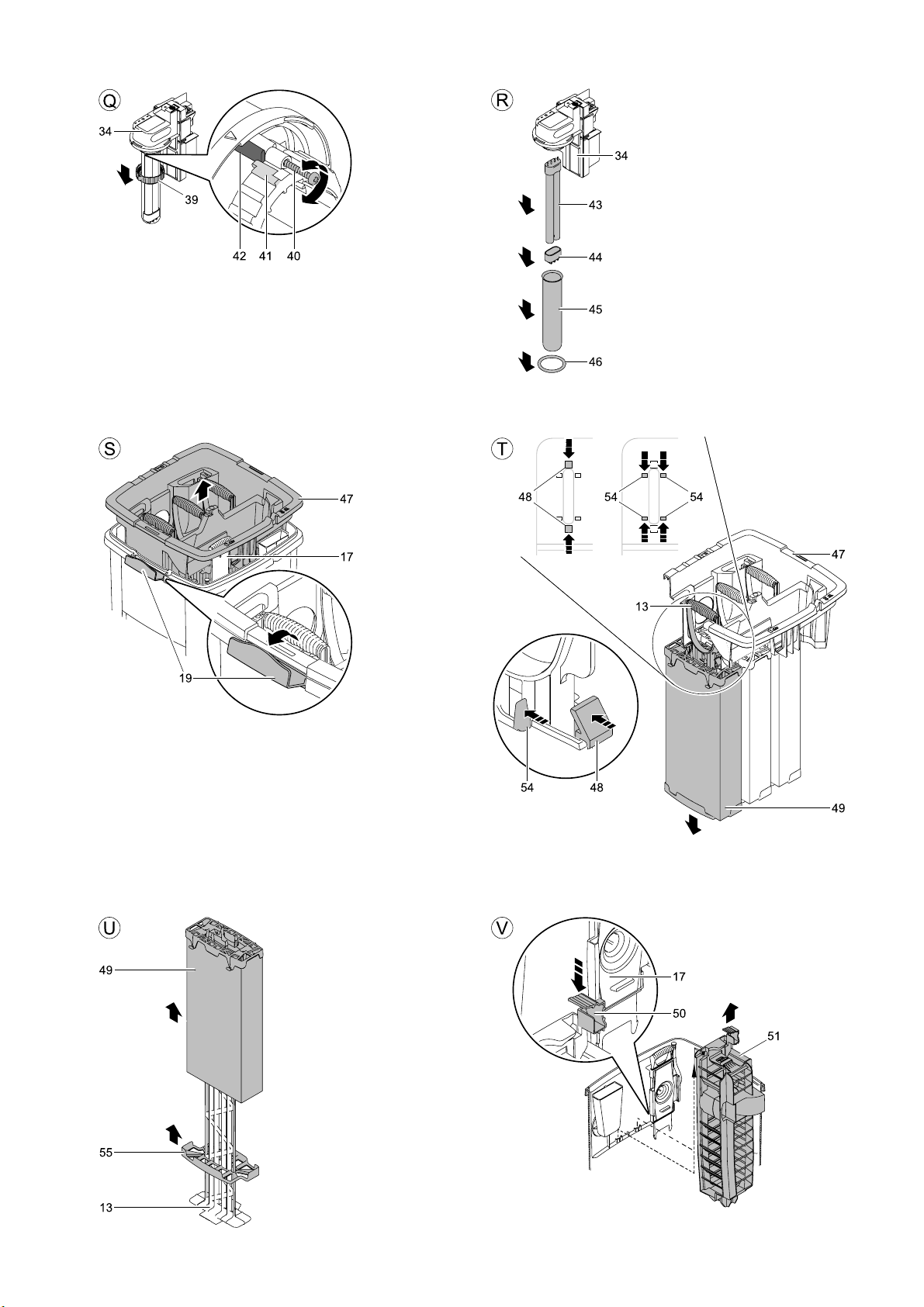

4. Loosen the screw (40) from the union nut (39), then unscrew the union nut (39) (Figure Q).

5. Pull off the quartz glass tube (45) including the O ring (46) by a rotary movement (Figure R).

6. Pull off the UVC lamp protection (44) (Figure R).

7. Pull the UVC lamp (43) out of its position in the UVC top section (34) and replace (Figure R).

8. Reassemble the UVC clarifying unit in the reverse order.

− Important: The water housing (35) is only closed when the "Lock closed" symbol points to the

arrow on the UVC top section (34) (Figure O).

- GB -

► During assembly ensure that the stop (41) of the union nut (39) butts against the stop (42) on the

UVC top section (34). Only then can the screw (40) be turned in (Figure Q).

► The O ring (36) on the water housing closure (35) is firmly clamped on. Only remove the O ring (36)

if it needs replacing, e.g. has become brittle (Figure O).

► Condensate forms in the quartz glass tube (45). This condensate cannot be avoided, however, it

does not impair function and safety.

► The quartz glass tube (45) can become scratched or blind over time. In this case, sufficient cleaning

performance of the UVC lamp (43) is no longer guaranteed. The quartz glass tube (45) must be

replaced.

33

Page 19

- GB -

10.5 Checking the cleaning rotor

The cleaning rotor (37) cleans the quartz glass tube (45). The rotor is driven by the water flow in the

water housing (Figure P).

The constant rotational movement of the cleaning rotor (37) causes wear of the bearing bush (38). In

this case, the cleaning rotor (37) needs replacing (Figure P).

1. Turn the water housing (35) until the symbol showing " Lock open" points to the arrow at the UVC top

pipe (34) (Figure O).

2. Pull off the water housing (35) (Figure O).

3. Check the wearing condition of the bearing bush (38).

− When the bearing bush (38) has worn down to 0 mm, the cleaning rotor (37) needs to be

replaced (Figure P).

4. Reassemble the UVC clarifying unit in the reverse order.

− Important: The water housing (35) is only closed when the "Lock closed" symbol points to the

arrow on the UVC top section (34) (Figure O).

10.6 Changing the foam filters

We recommend to change the foam filters (49) once per year.

How to change the foam filters:

1. Open lid (1) with the rotary handle (2) and remove lid from the container (3) (Figure H).

2. Close stop valve (17) by pulling it up (Figure S).

− Pond water no longer flows into the container.

− Note: Water will spurt out of the air intake socket when closing the stop valve (17).

3. Pull up the foam holder (13) in the inner cover (47) several times. The water in the foam filters (49) is

pressed out (Figure I).

4. Press the PUMP key (C4) on the controller (15) for longer than 10 seconds (Figure J).

− The LED (C2) is lit green. The dirty water in the container will be pumped out.

5. Lift the cleaning components of the dirty water pump (14) and of the UVC clarifying unit (16) out of

the inner cover (47)(Figure K).

6. Release the blue engagement hooks (19) on both sides, and then remove the inner cover (47)

including the foam holders (13) out of the container (Figure S).

7. Slightly lift the foam holder (13), press together the two blue engagement hooks (48) at the foam

holders (13), then push the foam holders downward and out of the inner cover (47) (Fig. T).

8. Press in the four black engagement hooks (54) at the upper part of the foam and take out the foam

holder (13) downward including the filter cartridge (49) (Fig. T).

− Note: Press together the engagement hooks (54) arranged opposite of each other one after

another and push the hooks downward and out of the inner cover (47).

9. Remove the used filter cartridge (49) as well as the bottom part of the foam (55) from the foam

holder (13) (Fig. U).

− Dispose of the filter cartridge in accordance with the regulations.

10. Start by placing a new bottom foam part (55), on the foam holder (13), followed by a new filter

cartridge (49) (Fig. U).

− Ensure that the filter cartridge (49) fits exactly into the bottom foam part (55).

11. Insert the new foam holder (13) together with the new filter cartridge (49) into the inner cover from

below. While inserting, pull up the foam holder until the two blue engagement hooks (48) and the

four black engagement hooks (54) engage in the inner cover (Fig. T).

− Important: Perfect seating of the filter cartridge (49) is not guaranteed unless all four black

engagement hooks (54) are engaged.

34

Page 20

10.7 Thorough cleaning of the unit

Light-weight suspended matter is mechanically filtered by the foam filters and, if necessary, biologically

broken down. Suspended matter heavier than water will sediment out and soil the container bottom.

Thoroughly clean the unit once per year, preferably when you prepare the FiltoMatic CWS for the winter.

Fully drain the container

Full drainage takes a maximum of 4 minutes.

1. Switch off the Aquamax pump.

2. Open lid (1) with the rotary handle (2) and remove lid from the container (3) (Figure H).

3. Pull up the foam holder (13) three times (Figure J).

− The foam filters will be compressed. The soiling will be washed out.

4. Press the PUMP (C4) key for longer than 10 seconds.

− The LED (C2) is lit green. The container is emptied.

− You can stop the drainage cycle by pressing the PUMP (C4) key once. Once the container if fully

drained, when the dirty water pump switches off no water flows through the transparent outlet

sheath (6).

Cleaning the unit

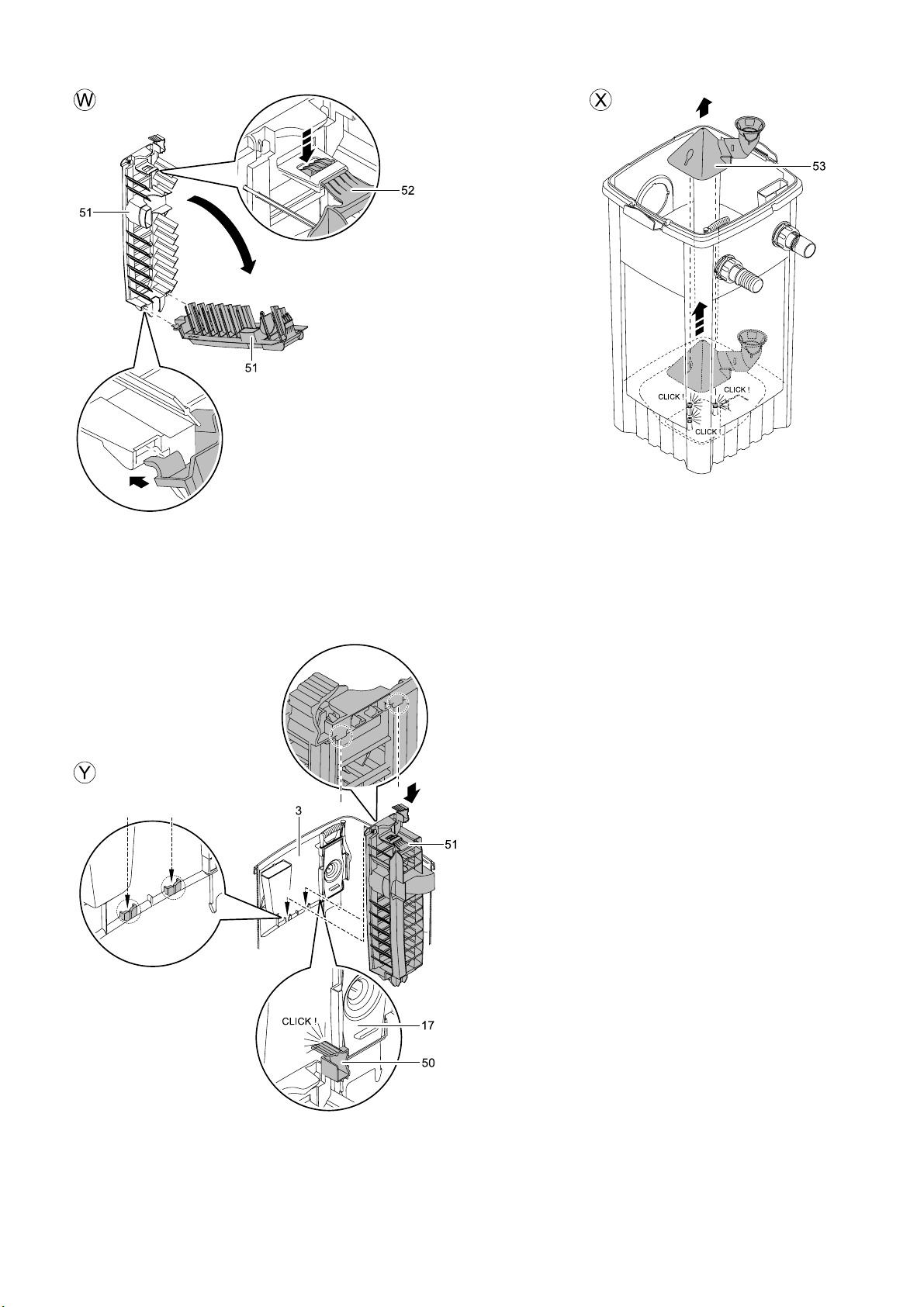

For this purpose, remove the lamella separator (51) and the dirt pyramide (52). To this effect, completely

empty the container and remove the inner cover (47). Please refer to the chapters above.

How to remove and clean the lamella separator

1. Press down the engagement hook (50) and pull the lamella separator (51) upward and out of the the

guide on the container (3) (Figure V).

2. Press in the engagement hook (52) at the lamella separator top (51) and fold out both sections of

the lamella separator (51) (Figure W).

3. Clean both parts using clean water and a soft brush.

4. Reassemble the lamella separator (51) in the reverse order

5. Insert the lamella separator (51) in the container (3) (Figure Y).

− Ensure that the engagement hook (50) engages at the stop valve (17).

How to remove and clean the dirt pyramid (Figure X)

Only remove the dirt pyramid (53) if necessary. A great deal of force is required for disassembly and reassembly.

1. Reach beneath the dirt pyramid (53) and detach the pyramid from the three holders at the container

bottom by vigorously pulling up.

2. Clean the dirt pyramid (53) using water and a soft brush.

3. Wash out the container bottom.

4. Plug the dirt pyramid (53) onto the holders by applying a large amount of pressure.

− The engagement in the holders is audible by a click.

- GB -

An approx. 8 mm spacing is provided between the dirt pyramid (53) and the container bottom. This gap

allows the dirty water pump to pump off the dirt gathered at the container bottom. Take this spacing into

account during assembly. Do not attempt to press the dirt pyramid (53) fully down to the container

bottom by applying excessive force!

35

Page 21

- GB -

11 Wear parts

Wear part Model Ident No.

UVC CWS lamp

Quartz glass tube

Cleaning rotor

Filter cartridges

FiltoMatic CWS 7000 56112

FiltoMatic CWS 14000 56237

FiltoMatic CWS 25000 56237

FiltoMatic CWS 7000 13312

FiltoMatic CWS 14000 13332

FiltoMatic CWS 25000 13332

FiltoMatic CWS 7000 12703

FiltoMatic CWS 14000 12705

FiltoMatic CWS 25000 12705

FiltoMatic CWS 7000 50901 (1×)

FiltoMatic CWS 14000 50904 (1×)

FiltoMatic CWS 25000 50904 (2×)

12 Storage/Over-wintering

Prior to the period of frost starting, store the cleaning units dirty water pump (14), controller (15) and

UVC clarifying unit (16) in a frost-free place.

1. Thoroughly clean all components (see chapter Carry out complete cleaning) and check all

components for damage.

− The container (3) and the foam filters (49) need not be stored frost-free. However, completely

empty the container (3) prior to storing using the pump.

2. Cover the container (3) to prevent the ingress of water.

− The lid (1) being closed is not sufficient, as water can enter the container through the recess

provided for the controller.

OASE recommends the following cover:

− FiltoMatic Cap, size L, for FiltoMatic 7000 CWS and 14000 CWS (OASE Order No. 50268)

− FiltoMatic Cap, size XL, for FiltoMatic 25000 CWS (OASE Order No. 50269)

13 Disposal

Dispose of the unit in accordance with the national legal regulations.

36

Page 22

DE Technische

Daten

Anschlussspannung Leistungsaufnahme UVC-

Vorklärer

GB Technical data Connection voltage Power consumption UVC

clarifying unit

FR Caractéristiques

techniques

NL Technische

gegevens

Tension de

raccordement

Consommation Appareil

de préclarification à UVC

Aansluitspanning Stroomverbruik UVC-

voorzuiveringsapparaat

ES Datos técnicos Tensión de conexión Consumo de potencia

Preclarificador UVC

PT Dados técnicos Tensão eléctrica Consumo de energia

Aparelho de pré-

tratamento UVC

IT Caratteristiche

tecniche

Tensione di attacco Potenza assorbita

Predepuratore UVC

Pompa dell'acqua sporca

DK Tekniske data Tilslutningsspænding Strømforbrug

UVC-forrenseenhed

NO Tekniske data Nettspenning Inngangseffekt

UV-forrenser

SE Tekniska data Anslutningsspänning Effekt

UVC-förrening

FI Tekniset tiedot Liitäntä-jännite Ottoteho

UVC-esipuhdistaja

HU Műszaki adatok Csatlakoztatási

feszültség

PL Dane techniczne Napięcie

przyłączeniowe

Teljesítményfelvétel

UVC előtisztító

Pobór mocy

Osadnik wstępny z lampą

UV

CZ Technické údaje Připojovací napětí Příkon

Předčišťovač UVC

SK Technické údaje Napájacie napätie Príkon

UVBC-odkalovač

SI Tehnični

podatki

Priključna napetost Nazivna moč

UVC predčistilna naprava

HR Tehnički podaci Priključni napon Prijemna snaga

UVC-razbistrivač

RO Date tehnice Tensiune de

conexiune

Putere consumatã

Dispozitivul de pre-

limpezire cu raze

ultraviolete

BG Технически

данни

UA Технічні

характеристики

Напрежение в

точката на

свързване

Напруга мережі

живлення

Потребявана мощност

UVC-устройство за

предварителна очистка

Споживана потужність

Ультрафіолетовий

очисний пристрій

Leistungsaufnahme

Schmutzwasserpumpe

Power consumption

Dirty water pump

Consommation

Pompe à eau sale

Stroomverbruik

Afvalwaterpomp

Consumo de potencia

Bomba de agua sucia

Consumo de energia

Bomba de água suja

Potenza assorbita

Strømforbrug

Spildevandspumpe

Inngangseffekt

Spillvannspumpe

Effekt

Smutsvattenpump

Ottoteho

Likavesipumppu

Teljesítményfelvétel

Szennyvíz szivattyú

Pobór mocy

Pompa brudnej wody

Příkon

Kalové čerpadlo

Príkon

Čerpadlo znečistenej

vody

Nazivna moč

Črpalka za onesnaženo

vodo

Prijemna snaga

Crpka za prljavu vodu

Putere consumatã

Pompa de apă murdară

Потребявана мощност

Помпа за мръсна вода

Споживана потужність

Очисний насос

Leistungsaufnahme

Wassertemperatur Gewicht Länge Anschlussleitung

Steuerung

Control system power

Water temperature Weight Length of connection cable

consumption

Puissance absorbée,

commande

Vermogensopname

Température de l’eau Poids Conduite de raccordement

longue

Watertemperatuur Gewicht Lengte aansluitleiding

besturing

Consumo de potencia

del control

Consumo de energia

sistema de controlo

Potenza assorbita

comando

Strømforbrug af

styring

Temperatura del agua Peso Longitud del cable de

conexión

Temperatura de água Peso Comprimento do cabo de

alimentação

Temperatura

dell'acqua

Peso Lunghezza cavo di

collegamento

Vandtemperatur Vægt Længde på tilslutnings-

ledning

Inngangseffekt styring Vanntemperatur Vekt Lengde stikkledninger

Effektförbrukning

Vattentemperatur Vikt Längd anslutningsledning

styrning

Ottoteho ohjaus Veden lämpötila Paino Liitäntäjohdonpituus

Vezérlő

Vízhõmérséklet Súly Csatlakozóvezeték hossza

teljesítményfelvétel

Pobór mocy

sterowania

Temperatura wody Masa Długość przewodu

przyłączeniowego

Řízení příkonu Teplota vody Hmotnost Délka připojovacího vedení

Príkon riadenia Teplota vody Hmotnost’ Dĺžka prípojného vedenia

Moč krmilnega

Temperatura vode Teža Dolžina priključne vrvice

sistema

Potrošnja energije

Temperatura vode Težina Duljina priključne cijevi

upravljača

Puterea consumată de

sistemul de comandă

Консумация на

мощност управление

Споживана

Temperatura apei Greutate Lungimea cablului de

conexiune

Температурата на

водата

Тегло Дължина свързващ

проводник

Температура води Вага Довжина злучного проводу

потужність

управління

337

Page 23

RU Технические

中文 技术数据 连接电压 紫外线预净化器的消耗功

FiltoMatic

CWS 7000

FiltoMatic

CWS 14000

FiltoMatic

CWS 25000

данные

AC 230 V / 50 Hz

AC 230 V / 50 Hz

AC 230 V / 50 Hz

Напряжение

питающей сети

AC 12 V / 30 VA

AC 12 V / 30 VA

AC 12 V / 30 VA

Потребляемая

мощность

УФ-блок

предварительной

очистки

率

11 W 27 W 2.8 W +4 … +35 °C 9.2 kg 10 m

24 W 27 W 2.8 W +4 … +35 °C 10.3 kg 10 m

24 W 27 W 2.8 W +4 … +35 °C 13.4 kg 10 m

Потребляемая

мощность

Насос для откачки

грязной воды

污水泵的消耗功率 控制器的消耗功率 水温 重量 连接导线长度

Потребляемая

мощность системы

управления

Температура воды Вес Длина

подсоединительного

провода

338

Page 24

DE Technische

Daten

GB Technical

data

FR Caractéristiqu

es techniques

NL Technische

gegevens

ES Datos

técnicos

PT Dados

técnicos

IT Caratteristich

e tecniche

DK Tekniske data Dimensioner Temperatursensors

NO Tekniske data Dimensjoner Målepresisjon

SE Tekniska data Mått Mätprecision

FI Tekniset

tiedot

HU Műszaki

adatok

PL Dane

techniczne

CZ Technické

údaje

SK Technické

údaje

SI Tehnični

podatki

HR Tehnički

podaci

RO Date tehnice Dimensiuni Precizia de măsurre a

Abmessungen Messgenauigkeit

Temperaturfühler

Dimensions Measuring accuracy

of the temperature

sensor

Dimensions Précision de mesure

du thermostat

Afmetingen Meetnauwkeurigheid

temperatuursensor

Dimensiones Exactitud de medición

sensor de

temperatura

Dimensões Precisão de medição

do sensor de

temperatura

Dimensioni Precisione di

misurazione sonda

termica

målenøjagtighed

Temperaturføler

temperaturgivare

Mitoitus Mittaustarkkuus

lämpötilatunnistin

Méretek Hőmérsékletérzékelő

mérési pontossága

Wymiary Dokładność

pomiarowa czujnika

temperatury

Rozměry Přesnost měření

snímače teploty

Rozmery Presnosť merania

snímača teploty

Velikosti Merilna natančnost

temperaturnega tipala

Dimenzije Točnost mjerenja

pipka za temperaturu

senzorului de

temperatură

ohne Fischbesatz

Pond volume w/o

zonder visbestand

Damstørrelse uten

Dammvolym utan

ilman kalajoukkoa

halállomány nélkül

Pojemność stawu

Prostornina ribnika

Teichvolumen

fish population

Volume de

bassin/de l'étang

sans poissons

Vijvervolume

Volumen del

estanque sin

peces

Volume do lago

sem peixes

Volume laghetto

senza patrimonio

ittico

Dammens

volumen, uden

fiskebestand

fiskebestand

fisk

Lammen tilavuus

Tótérfogat

bez zarybienia

Objem jezírka

bez rybí obsádky

Objem záhradnej

nádrže bez

zarybnenia

brez ribjega

staleža

Obujam jezerca

bez oribljenosti

Volumul iazului

fără populaţie

piscicole

Teichvolumen

mittlerer Fischbesatz

Pond volume,

medium fish

population

Volume de bassin/de

l'étang avec quantité

moyenne de poissons

Vijvervolume

gemiddeld visbestand

Volumen del

estanque con

algunos peces

Volume do lago,

número médio de

peixes

Volume laghetto

patrimonio ittico

medio

Dammens volumen,

mellem fiskebestand

Damstørrelse middels

fiskebestand

Dammvolym med

medelstor mängd fisk

Lammen tilavuus

keski-kalajoukolla

Tótérfogat közepes

halállománnyal

Pojemność stawu ze

średnim zarybieniem

Objem jezírka

se střední velká rybí

sádkou

Objem záhradnej

nádrže s priemerným

zarybnením

Prostornina ribnika s

srednje velikim ribjim

staležem

Obujam jezerca s

osrednjom oribljenosti

Volumul iazului cu

populaţie piscicolă

medie

Teichvolumen hoher

Fischbesatz

Pond volume, high

fish population

Volume de bassin/de

l'étang avec quantité

importante de

poissons

Vijvervolume hoog

visbestand

Volumen del

estanque con muchos

peces

Volume do lago, alto

número de peixes

Volume laghetto

notevole patrimonio

ittico

Dammens volumen,

stor fiskebestand

Damstørrelse tett

fiskebestand

Dammvolym med stor

mängd fisk

Lammen tilavuus

korkealla kalajoukolla

Tótérfogat magas

halállománnyal

Pojemność stawu z

wysokim zarybieniem

Objem jezírka

s velkou rybí sádkou

Objem záhradnej

nádrže s vysokým

zarybnením

Prostornina ribnika z

velikim ribjim

staležem

Obujam jezerca s

velikom oribljenosti

Volumul iazului cu

populaţie piscicolă

ridicată

Wasseraufnahme

Behälter

Container water

volume

Volume du

récipient

Wateropname

bak

Volumen de agua

del recipiente

Capacidade do

depósito

Capacità

recipiente

Beholders

vandoptagelse

Tømme beholder Driftstrykk maks. gjenn

Vattenvolym i

behållare

Vedenotto säiliö Käyttöpaine Maks.

Tartály vízfelvétel Üzemi nyomás max.

Pobór wody

zbiornika

Napouštění

nádrže

Zásobník prítoku Prevádzkový

Posoda za vodo Delovni tlak Maks. pretok Min. pretok

Potrošnja vode u

spremniku

Capacitatea

vasului de apă

Betriebsdruck Max.

Operating

pressure

Pression de

service

Bedrijfsdruk max.

Presión de

servicio

Pressão de

serviço

Pressione

d'esercizio

Driftstryk maks.

Drifttryck Max. flöde Min. flöde

Ciśnienie

robocze

Prevádzkový

tlak

tlak

Radni tlak maks.

Presiune de

funcţionare

Durchfluss

Max. flow Min. flow

Débit

maximal

doorstroming

Paso máx. Paso mín.

Caudal

máximo

Portata max. Portata min.

gennemløb

omstrømmin

g

läpivirtaus

átáramlás

maks. natęż

enie

przepływu

max. průtok min. průtok

max. prietok min. prietok

protjecanje

Debitul max. Debitul min.

Min.

Durchfluss

Débit minimal

min.

doorstroming

Caudal

mínimo

min.

gennemløb

min. gjennom

strømming

Min.

läpivirtaus

min.

átáramlás

min. natężeni

e przepływu

min.

protjecanje

339

Page 25

BG Технически

UA Технічні

RU Технические

中文 技术数据 尺寸 温度传感器测量精度 没有鱼时的池塘容量 有中等鱼量时的池塘

FiltoMatic

CWS 7000

FiltoMatic

CWS 14000

FiltoMatic

CWS 25000

данни

характеристи

ки

данные

380 × 380

380 × 380

380 × 580

Размери Измервателна

точност

температурен

датчик

Виміри Точність виміру

датчика

температури

Измерения Точность измерения

датчика

температуры

±2 °C (+4 … +35 °C) 6 m3 3 m3 1.5 m3 20 l max. 0.6 bar 3500 l/h 2500 l/h

× 520 mm

±2 °C (+4 … +35 °C) 12 m3 6 m3 3 m3 35 l max. 0.6 bar 5000 l/h 3500 l/h

× 720 mm

±2 °C (+4 … +35 °C) 24 m3 12 m3 6 m3 65 l max. 0.6 bar 6000 l/h 5000 l/h

× 720 mm

Обем на езерото

без риби

Об'єми ставка без

риби

Объем пруда без

рыбопосадки

Обем на езерото

средно количество

риба

Об'єми ставка із

середньою кількістю

риби

Объем пруда со

средней

рыбопосадкой

容量

Обем на езерото

голямо количество

риба

Об'єми ставка з

великою кількістю

риби

Объем пруда с

большой

рыбопосадкой

有大量鱼时的池塘容

量

Консумация на

вода резервоар

Водопоглинення

резервуара

Емкость

резервуара для

воды

箱体容量 运行压力 最大流量 最小流量

Работно

налягане

Робочий тиск Максимальн

Рабочее

давление

Макс.

разход

е протікання

макс. расход мин. расход

Мин. разход

Мінімальне

протікання

340

Page 26

DE Staubdicht. Wasserdicht bis 2 m

GB Dust tight. Submersible to 2 m

FR Imperméable aux poussières.

NL Stofdicht. Waterdicht tot een diepte

ES A prueba de polvo. Impermeable al

PT À prova de pó. À prova de água até

IT A tenuta di polvere. Impermeabile

DK Støvtæt. Vandtæt ned til 2 m

NO Støvtett. Vanntett ned til

SE Dammtät. Vattentät till

FI Pölytiivis. Vesitiivis 2 m syvyyteen

HU Portömített. Vízálló 2 m-es

PL Pyłoszczelny. Wodoszczelny do

CZ Prachotěsný. Vodotěsný do

SK Prachotesný. Vodotesný do hĺbky

SI Ne prepušča prahu. Ne prepušča

HR Ne propušta prašinu. Ne propušta

RO Etanş la praf. Etanş la apă, până la

BG Защитено от прах. Водоустойчив

UA Пилонепроникний.

RU Пыленепрониц. Водонепрониц.

CN

Tiefe.

depth.

Etanche à l'eau jusqu'à une

profondeur de 2 m.

van 2 m.

agua hasta 2 m de profundidad.

2 m de profundidade.

all'acqua fino a 2 m di profondità.

dybde.

2 m dyp.

2 m djup.

asti

mélységig.

2 m głębokości.

hloubky 2 m.

2 m.

vode do globinen 2 m.

vodu do 2 m dubine.

o adâncime de 2 m.

до дълбочина 2 м.

Водонепроникний до 2 м.

на глубине до 2 м.

防尘。至 2 米深防水。 注意!

Achtung!

Gefährliche UVC-Strahlung!

Attention!

Dangerous UVC radiation!

Attention !

Rayonnement UVC dangereux !

Let op!

Gevaarlijke UVC-straling!

¡Atención!

Radiación UVC peligrosa.

Atenção!

Radiação UVC perigosa!

Attenzione!

Pericolosa radiazione UVC!

Fare!

Farlig UVC-stråling!

NB!

Farlig UV-stråling!

Varning!

Farlig UVC-strålning!

Huomio!

Vaarallinen UVC-säteily!

Figyelem!

Veszélyes UVC-sugárzás!

Uwaga!

Niebezpieczne promieniowanie

ultrafioletowe!

Pozor!

Nebezpečné ultrafialové záření.

Pozor!

Nebezpečné ultrafialové žiarenie.

Pozor!

Nevarno UVC-sevanje!

Pažnja!

Opasno UVC zračenje!

Atenţie!

Radiaţii ultraviolete periculoase!

Внимание!

Опасно ултравиолетово лъчение!

Увага!

Небезпечне ультрафіолетове

випромінювання!

Внимание!

Опасное коротковолновое

УФ-излучение!

危险的紫外线照射!

Vor direkter Sonneneinstrahlung

schützen

Protect from direct sun radiation. Remove the unit at temperatures

Protéger contre les rayons directs

du soleil.

Beschermen tegen direct zonlicht. Bij vorst moet het apparaat

Protéjase contra la radiación

directa del sol.

Proteger contra radiação solar

directa.

Proteggere contro i raggi solari

diretti.

Beskyt mod direkte sollys. Afinstaller enheden ved frostvejr! Må ikke bortskaffes med det

Beskytt mot direkte sollys. Demonter apparatet ved frost! Ikke kast i alminnelig

Skydda mot direkt solstrålning. Demontera apparaten innan första

Suojattava suoralta

auringonvalolta.

Óvja közvetlen napsugárzástól. Fagy esetén a készüléket szerelje

Chronić przed bezpośrednim

nasłonecznieniem.

Chránit před přímým slunečním

zářením.

Chránit’ pred priamym slnečným

žiarením.

Zaščitite pred neposrednimi

sončnimi žarki.

Zaštitite od izravnog sunčevog

zračenja.

Protejaţi împotriva razelor directe

ale soarelui.

Да се пази от слънчеви лъчи. При опасност от измръзване

Пристрій повинен бути

захищений від прямого

сонячного випромінювання.

Защищать от прямого

воздействия солнечных лучей.

防止阳光直射。

Bei Frost das Gerät deinstallieren! Nicht mit normalem Hausmüll

below zero (centigrade)!.

Retirer l’appareil en cas de gel ! Ne pas recycler dans les ordures

gedeïnstalleerd worden!

Desinstale el equipo en caso de

heladas.

Em caso de geada, desinstalar o

aparelho!

In caso di gelo disinstallare

l'apparecchio!

frosten!

Laite on purettava ennen pakkasta. Älä hävitä laitetta tavallisen

le!

W razie mrozu zdeinstalować

urządzenie!

Při mrazu přístroj odinstalovat! Nelikvidovat v normálním

Pri mraze prístroj odinštalovať! Nelikvidovať v normálnom

Ob zmrzali demontirajte aparat! Ne zavrzite skupaj z

U slučaju mraza deinstalirajte

uređaj!

La îngheţ dezinstalaţi aparatul ! Nu aruncaţi în gunoiul menajer ! Atenţie !

деинсталирайте уреда!

Перед морозами пристрій

необхідно демонтувати

При наступлении морозов прибор

демонтировать!

在霜冻时

拆卸设备!

entsorgen!

Do not dispose of together with

household waste!

ménagères !

Niet bij het normale huisvuil doen! Let op!

¡No deseche el equipo en la

basura doméstica!

Não deitar ao lixo doméstico! Atenção!

Non smaltire con normali rifiuti

domestici!

almindelige husholdningsaffald.

husholdningsavfall!

Får inte kastas i hushållssoporna! Varning!

talousjätteen kanssa!

A készüléket nem a normál

háztartási szeméttel együtt kell

megsemmisíteni!

Nie wyrzucać wraz ze śmieciami

domowymi!

komunálním odpadu!

komunálnom odpade!

gospodinjskimi odpadki!

Nemojte ga bacati u običan kućni

otpad!

Не изхвърляйте заедно с

обикновения домакински боклук!

Не викидайте разом із

побутовим сміттям!

Не утилизировать вместе с

домашним мусором!

不要与普通的家庭垃圾一起丢弃! 注意!

Achtung!

Lesen Sie die Gebrauchsanleitung

Attention!

Read the operating instructions

Attention !

Lire la notice d'emploi

Lees de gebruiksaanwijzing

¡Atención!

Lea las instrucciones de uso

Leia as instruções de utilização

Attenzione!

Leggete le istruzioni d'uso!

OBS!

Læs brugsanvisningen

NB!

Les bruksanvisningen

Läs igenom bruksanvisningen

Huomio!

Lue käyttöohje

Figyelem!

Olvassa el a használati útmutatót

Uwaga!

Przeczytać instrukcję użytkowania!

Pozor!

Přečtěte Návod k použití!

Pozor!

Prečítajte si Návod na použitie

Pozor!

Preberite navodila za uporabo!

Pažnja!

Pročitajte upute za upotrebu!

Citiţi instrucţiunile de utilizare !

Внимание!

Прочетете упътването

Увага!

Читайте інструкцію.

Внимание!

Прочитайте инструкцию по

использованию

请阅读使用说明书。

341

Page 27

342

Page 28

343

Page 29

344

Page 30

OASE GmbH · www.oase-livingwater.com

Tecklenburger Straße 161 · 48477 Hörstel · Germany

17901/02-14

Loading...

Loading...