OARTEC DX User Manual

USER MANUAL

DYNAMIC ROWING MACHINE

Introduction

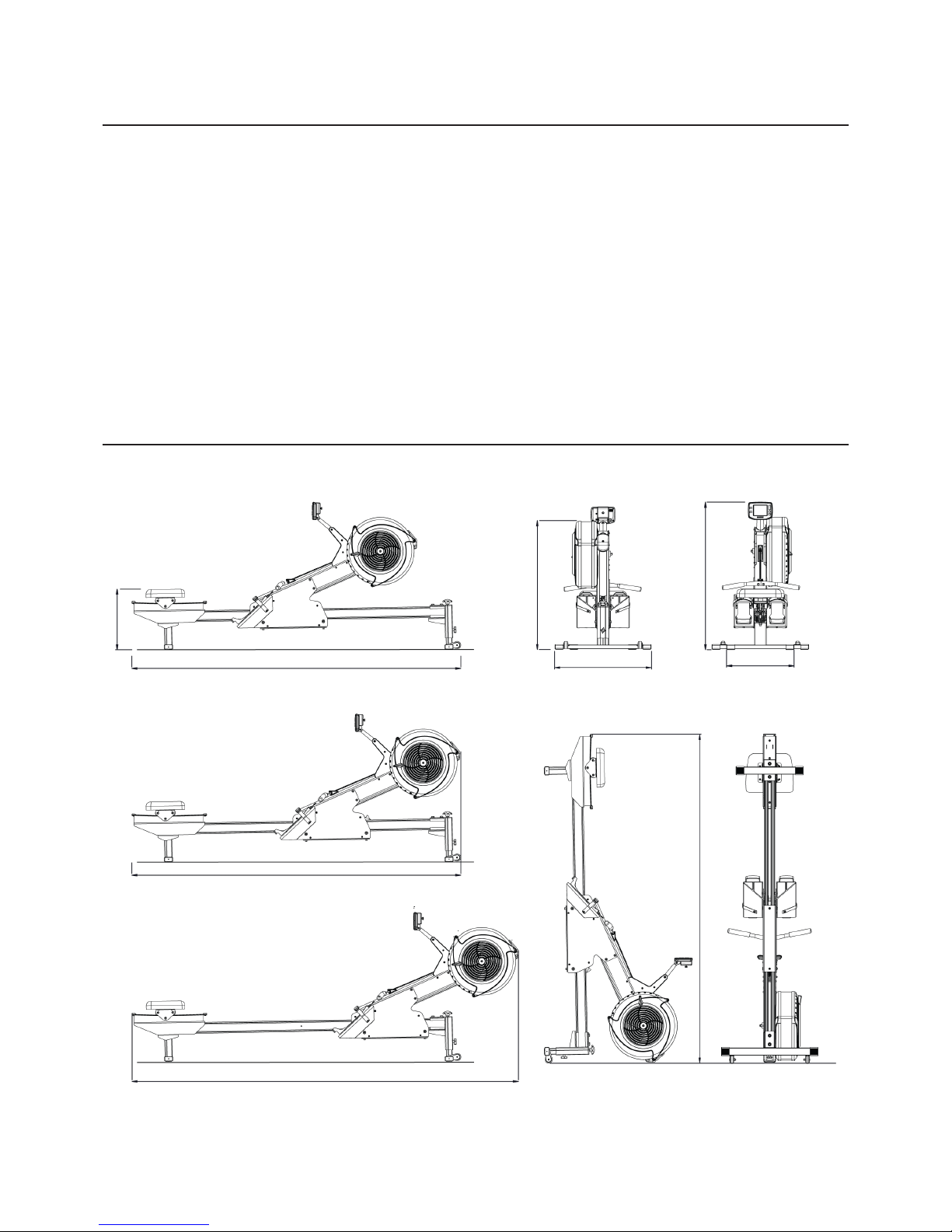

Base length

2.23m/7’4”

Seat height

41cm/16”

Front leg width

66cm/26”

Flywheel height

90cm/35”

Thankyou for purchasing the Oartec DX.

Indoor rowing is one of the best overall fitness exercises for the body.

Dynamic indoor rowing makes it even better because you are achieving the

same workout but without the wear and tear on the body, lower back and joints.

We are proud to be helping you achieve your fitness goals.

Please read the DX user manual carefully, following the procedures to assemble,

set up and maintain you DX in optimal working condition.

Enjoy your rowing!

Rear leg width

45cm/18”

Overall height

101cm/40”

Length locked

2.23m/7’4”

Maximum overall length

2.62m/8’7”

Length upright

2.23m/7’4”

Dimensions

Table of Contents

1. Assembly 3

Unpacking the box 3

Box contents 3

Step 1: Attaching rear leg, seat base to rail assembly 4

Step 2: Building front leg assembly 5

Step 3: Front assembly to rail assembly 6

Step 4: Front leg to rail assembly 7

Step 5: Seat to seat base 7

2. Getting Started 8

Adjusting the bottom roller wheels 8

Setting the front leg height 9

Locking the rolling frame 10

Storing the DX upright 10

Adjusting the feet height 11

Adjusting the footstraps 12

Storing the handle 12

Adjusting the resistance 13

Ready to row 13

3. Oartec Training Monitor OTM-2 14

Installing the batteries 14

Setting the date and time 14

Quick start guide 15

Setting workouts 16

Memory/Rerow 16

4. Maintenance 17

Cleaning the rails 17

Cleaning the seat track and wheels 17

Oiling the chain 17

Adjusting the bottom roller wheels 18/19

Cleaning the flywheel and flywheel housing 20

5. Troubleshooting 21

6. Warranty 22

2

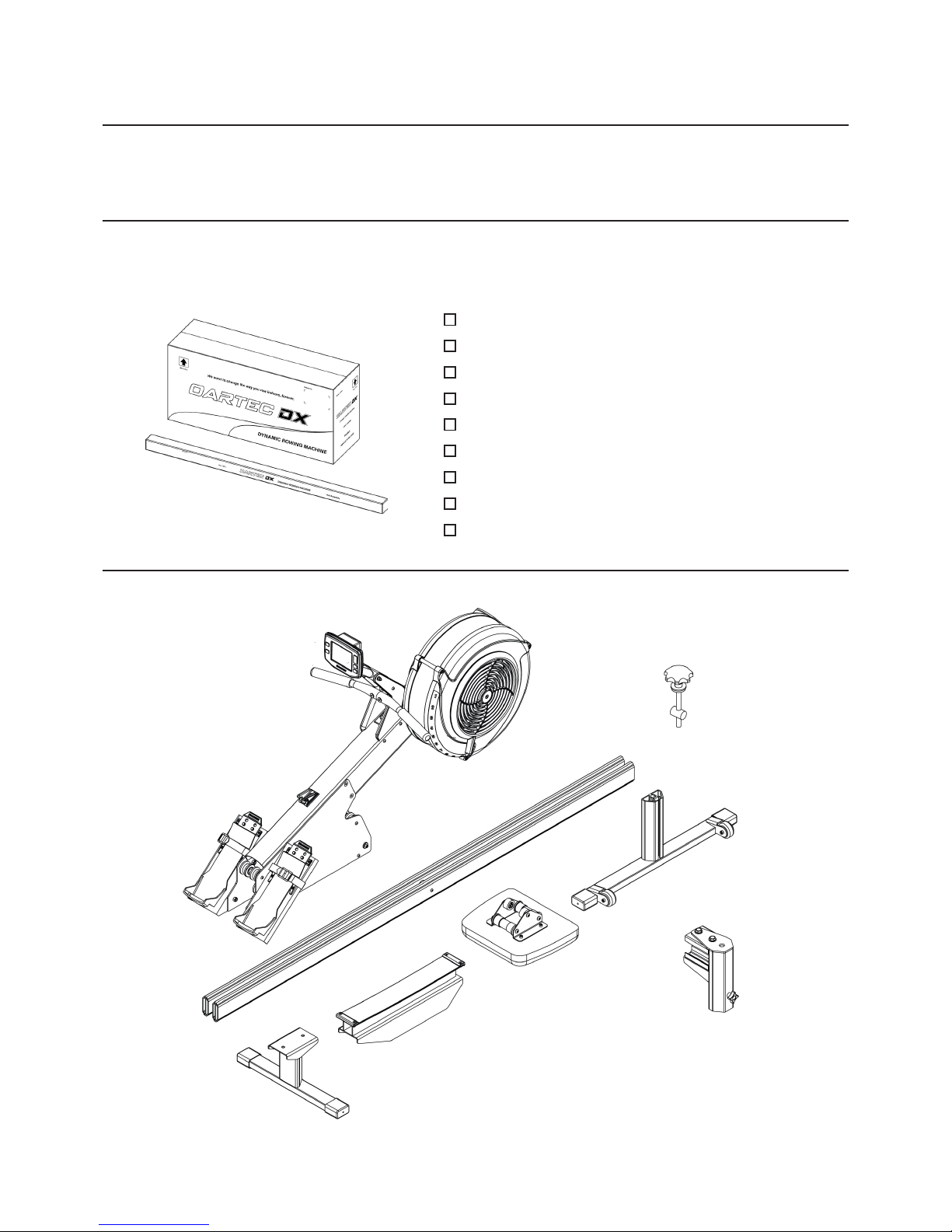

Box Contents

Unpacking the Box

1. ASSEMBLY

Please follow the assembly procedures below.

Assembly should take approximately 20 minutes and if possible get the help of a second person for the lifting.

Carefully unpack the box contents and lay out on the floor. With the help of a second person remove the front

assembly first. If assembling on a hard surface, use a drop sheet or blanket to protect the parts from damage

during assemblly. Check the contents of the box against the checklist below.

Front assembly

Seat assembly

Rail assembly

Front leg inner

Front leg outer

Rear leg

Seat base

Height adjuster assembly

Too l s

3

Front assembly

Rail assembly

Rear Leg

Seat Base

Seat assembly

Front leg inner

Front leg outer

Height adjuster

assembly

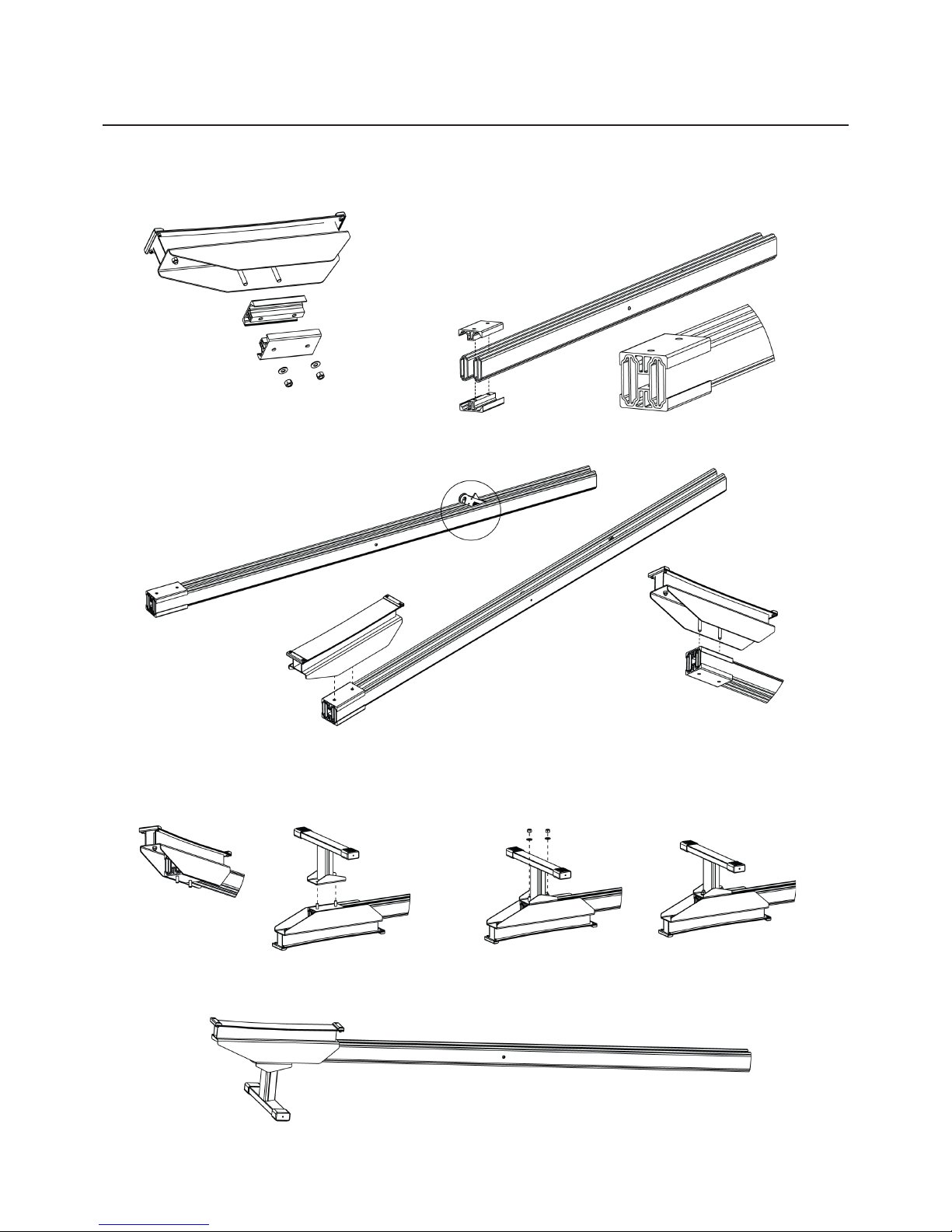

Step 1: Rear Leg and Seat Base to Rails

Tools required: 17mm wrench

4

1. Remove the rear extrusion mounts from the seat

base bolts.

5. Carefully roll the assembly over and rest on floor.

Attach the rear leg to the seat base bolts.

7. Turn assembly over and rest on floor.

4. Insert the seat base bolts

through the top extrusion mount.

IMPORTANT

3. Check that the locking latch opens on the top

rail edge. If it opens to the bottom, simply roll the rail

assembly over to orientate correctly.

2. Attach the extrusion mounts to the top and bottom

of the rear of the rail assembly, with the latch at the

front.

6. Add washers and nuts and firmly tighten with

17mm wrench but do not ovetighten.

Rear

Top

Front

Bottom

Tools required: 17mm wrench

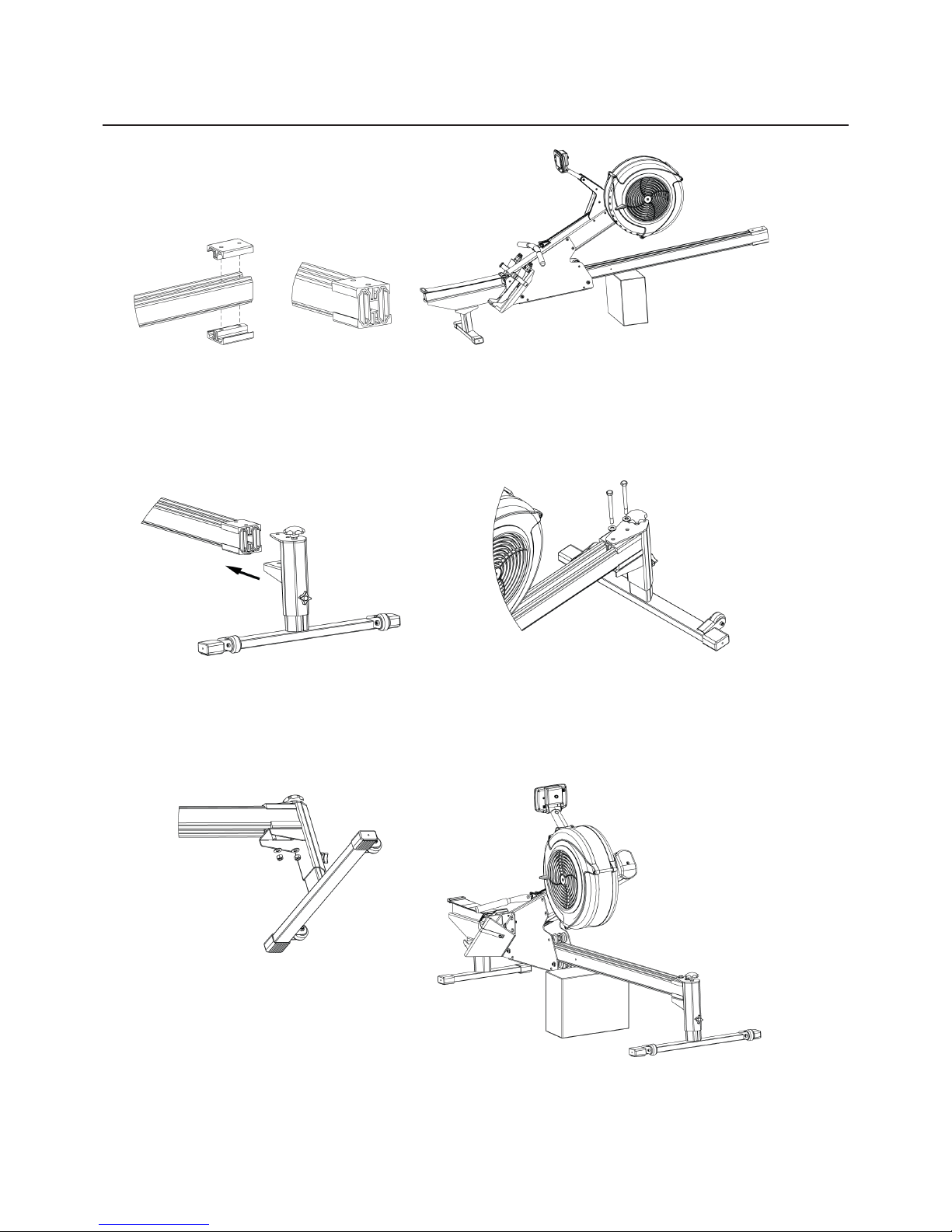

Step 2: Assemble Front Leg

5

1. Remove all parts from height adjuster threaded

axle assembly.

2. Insert the 20mm pin into the inner front leg hole

with the thread aligned vertically.

3. Screw the threaded flange into and

through the threaded pin by about 25mm/1”.

Add M16 washer.

4. Loosen the clamping knob.

Align the clamping plate square in the

slot as the outer front leg slides over

the inner leg.

5. Slide the outer leg down until

the axle protrudes through the top

plate.

6. Thread the M10 half nut and

knob onto the top of the height

adjuster thread.

7. While holding the knob, tighten

the nut with the 17mm wrench up

against the knob to secure in position.

Step 3: Front Assembly to Base Rails

No tools required

6

2. Carefully lift the front assembly and align the rail

ends with the gap between the top and bottom rollers.

** If available, get the help of a second person.

Slide the front assembly onto the rails until the rails

protrude through the other side.

3. While continuing to support the weight

of the front assembly, slide the front assembly

down the rails until it meets the box.

4. Lift the front assembly and rails over the box so

the front assembly can continue to slide down the

rails and rest touching the seat base. Once clear of the

box underneath, place the front of the rails back down

onto the seat box.

5. Check again that the rails and front assembly are

balanced and stable before leaving.

1. Place the empty seat box on the floor. Rest the

rail on the top of the seat box about along the rail

length toward the front. Check that it is stable before

leaving.

Step 4: Front Leg to Base Rails

7

Tools required: 16mm and 17mm wrench

1. Align the front extrusion mounts to the top and

bottom of the rails. Push the mounts tight onto the rails

and level with the end of rails.

2. Slide the front leg bracket over the

extrusion mounts and align bracket holes with

the extrusion mount holes.

3. Place washers over the bracket holes and insert

bolts through washers and the top and bottom

extrusion mounts. Gently tap or shake the front leg to

help the bolts through the holes.

4. Add washers and nuts to the underside

bolts and tighten with the 16mm and 17mm

spanners.

5. Remove the seat box from underneath the

rails and place front leg on floor.

Loading...

Loading...