Oakton 35102-00 Instruction Manual

OPERATING INSTRUCTIONS

OAKTON Model 35102-00

1

⁄8 DIN pH 200

Controller

R1 6/02

MEAS

CAL

SETUP

pH °C mV

ENTER

MODE

ESCAPE

REL 1

REL 2

68X276102

Write the name and contact information of your Oakton

distributor below.

pH200cntrmnl 6/4/2002 9:59 AM Page 1

32

Table of Contents

1. Introduction..................................................................................4

2. Overview ..................................................................................5-11

2.1 Front panel .................................................................................5

2.2 Back panel...............................................................................6-7

2.3 Wiring......................................................................................8-9

2.4 Panel-mounting the controller.........................................10-11

3. Measurement Mode.................................................................12

4. Password....................................................................13

5. pH Calibration.......................................................14-15

6. ORP calibration..........................................................16

7. Temperature calibration............................................17

8. Setup Mode ..........................................................................18-29

8.1 Setup mode overview.......................................................18-19

P1.0: Set point 1 .......................................................................20-21

P1.1: Select relay set point value.............................................20

P1.2: Set relay as high or low set point..................................21

P1.3: Set hysteresis value..........................................................21

P2.0: Set point 2 .......................................................................22-23

P2.1: Select relay set point value.............................................22

P2.2: Set relay as high or low set point..................................23

P2.3: Set hysteresis value..........................................................23

P3.0: Configuration.................................................................24-25

P3.1: Select pH or ORP units ...................................................24

P3.2: Select symmetrical or asymmetrical input mode........25

P3.3: Select temperature compensation .................................25

P4.0: Viewing calibration points: pH or ORP.........................26

P5.0: Viewing pH electrode data...............................................27

P5.1: View electrode offset .......................................................27

P5.2: View electrode slope........................................................27

P5.3: View temperature probe offset ......................................27

P5.0: Viewing ORP electrode data............................................28

P5.1: View electrode offset .......................................................28

P5.2: View temperature probe offset ......................................28

P6.0: Controller reset....................................................................29

9. Specifications.............................................................................30

10. Transmitter function ...............................................30

11. Specifications...........................................................................31

12. Accessories.........................................................................32-33

Appendix 1. Symmetrical mode ...............................34-35

Appendix 2. External relays......................................................36

Appendix 3. Factory defaults...................................................37

13. Warranty...................................................................................38

14. Return of Goods.....................................................................38

pH200cntrmnl 6/4/2002 9:59 AM Page 2

4

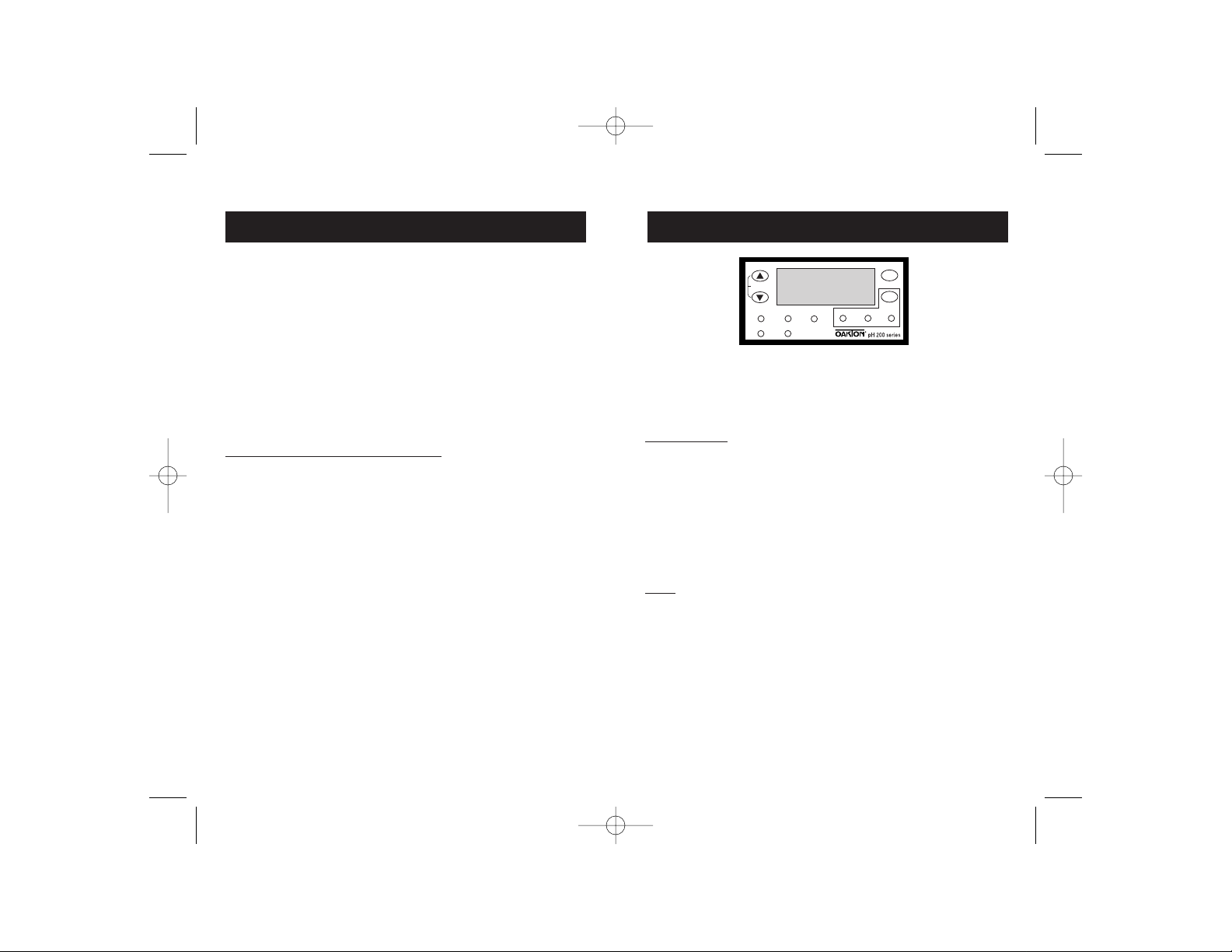

2. Overview

2.1 Front Panel

The front panel consists of a 4-digit LED display, 8 LED

annunciators and 4 keys. See diagram above.

Annunciators

MEAS Displayed in measurement mode

CAL Displayed in calibration mode

SETUP Displayed in setup mode

pH, °C, mV Units of the displayed parameter

REL 1 Displayed when Relay 1 is activated

REL 2 Displayed when Relay 2 is activated

Keys

▲ (Up/Increment) Use during calibration and setup modes

to increment

▼(Down/Decrement) Use during calibration and setup modes

to decrement

MODE Use to toggle between measurement modes

(pH/ORP and temperature)

ENTER Press to confirm changes or to enter into

further levels of the lower menu.

▲ + ▼ together Escape to Measurement mode.

MEAS

CAL

SETUP

pH °C mV

ENTER

MODE

ESCAPE

REL 1

REL 2

1. Introduction

Thank you for purchasing a pH 200 1⁄8 DIN pH/ORP Controller. This

controller is a member of the line of quality process controllers available from OAKTON Instruments. These sturdy, economical pH/ORP

controllers are designed with the features and reliability of a much

more expensive instrument.

Your controller includes:

• removable terminal blocks for easy connections

• two mounting brackets for easy panel mounting

• a preinstalled wire jumper to preset the instrument for two wire

Pt 100 operation.

When shipped, the controller is set to the pH mode. See Setup

program P3.1 on page 24 for directions on selecting ORP mode.

Some of the features of this controller are:

• Two set point, two SPDT relay operation

• Scrolling, 14-segment LED guides user easily through setup

functions

• Reliable power supply from 85 to 250 V AC/DC withstands

voltage fluctuations

• All-push button operation from the front panel

• Two-point pH calibration, offset temperature and ORP calibration

• Adjustable hysteresis band prevents rapid contact switching near

set-point

• Selectable automatic or manual temperature compensation

• Two level password protection

• Removable terminal strips for quick and easy connections

• Built-in memory backup retains setup even if power fails, and lets

you configure unit before installation

• 4-20 mA output for remote monitoring or hard copy recording

5

pH200cntrmnl 6/4/2002 9:59 AM Page 3

6

7

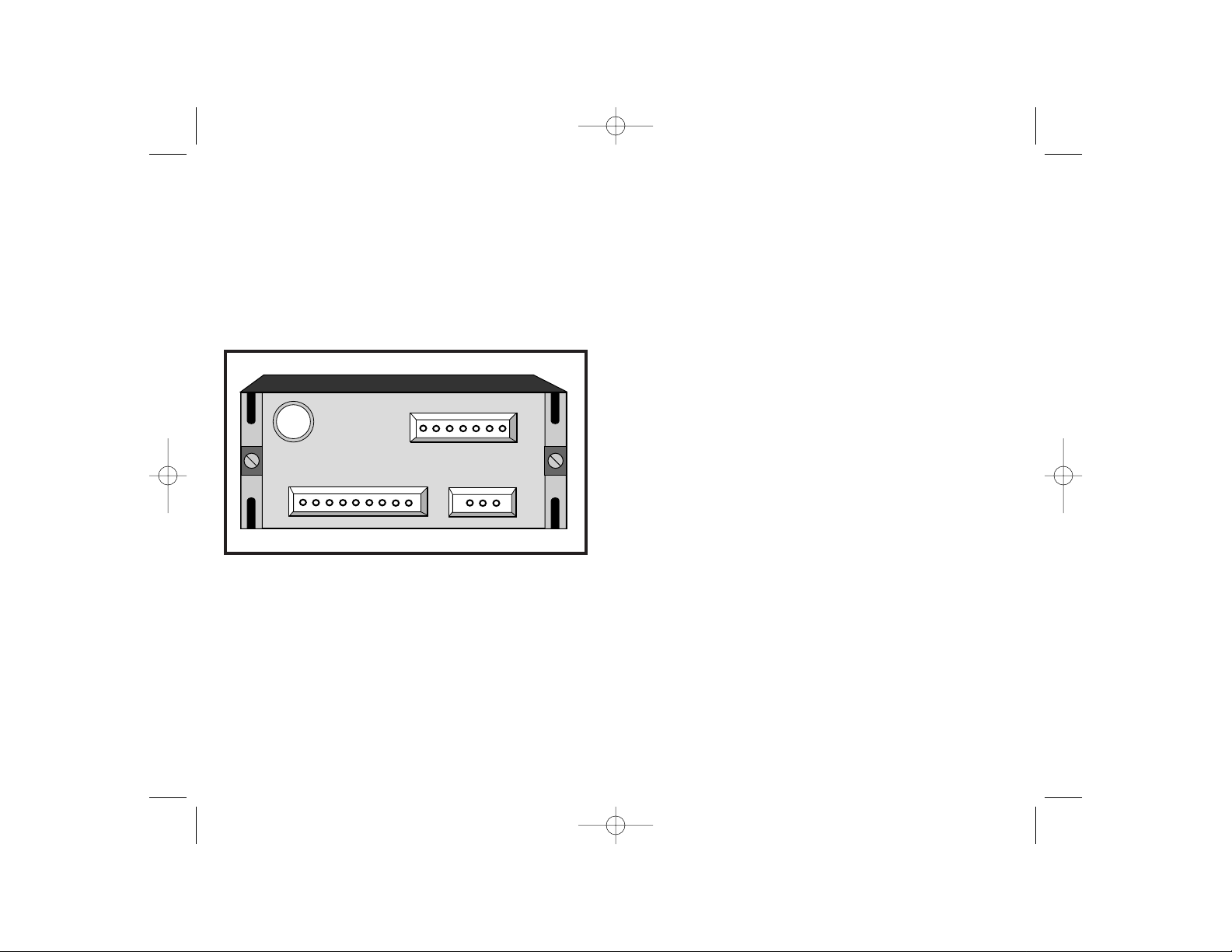

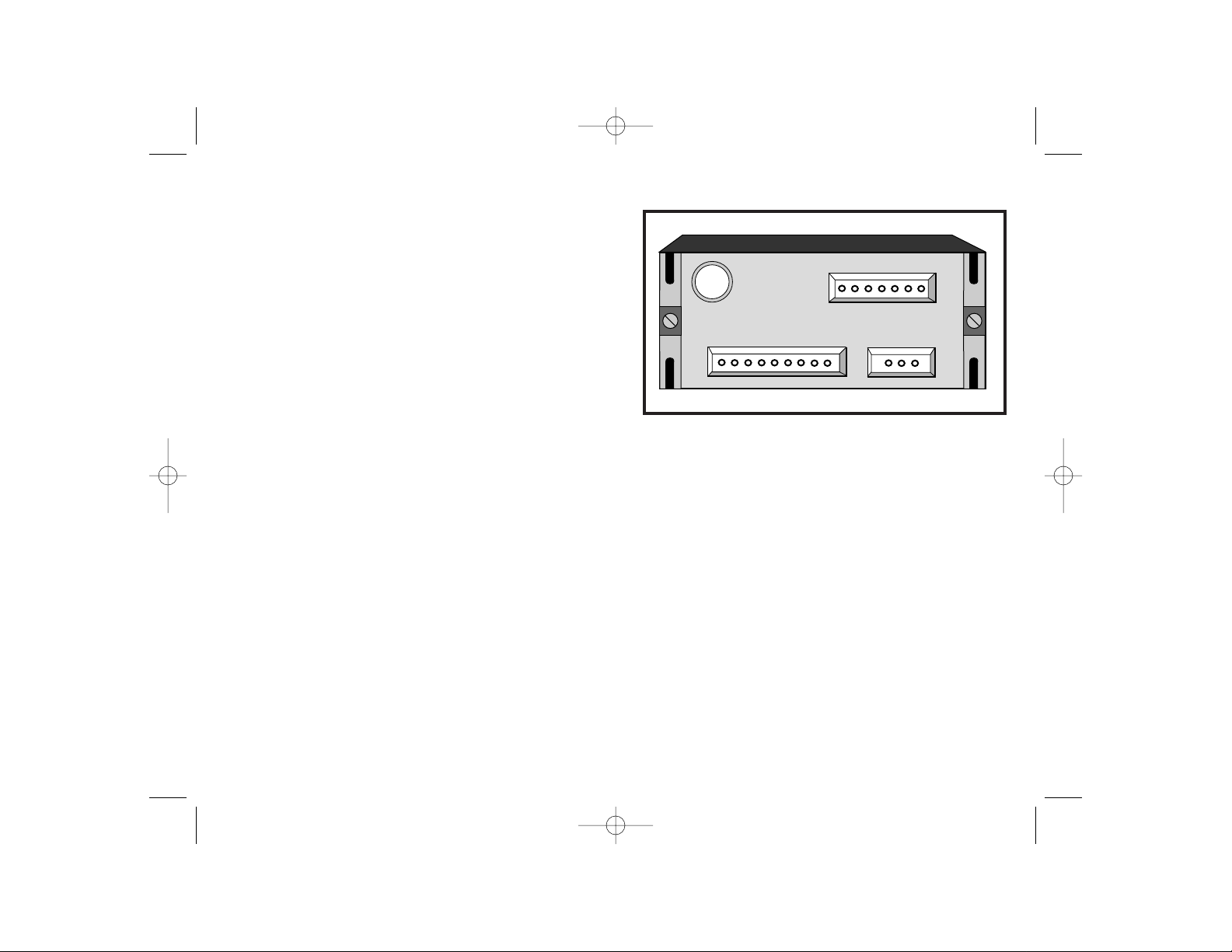

2.2 Back Panel

The back panel consists of four different connectors that can be used

with removable terminal blocks (included):

A. BNC connector (for pH or ORP electrode)

B. 7 pin connector (for temperature sensor)

C. 9 pin connector (for relays)

D. 3 pin connector (for power supply)

▲▲

!

CAUTION: Electrical shock hazard! Make sure to

remove AC power to the controller before wiring

input and output connections.

B. The connection for the 7-pin connector are (from the left to right):

1. unused

2. unused

3. unused

4. unused

5. Pt 100 connection: ground (red or white)*

6. Pt 100 connection: input (red or white)*

7. Pt 100 connection: sense (jumper to terminal 6 if using

2-wire RTD)

*If using an Oakton pH electrode with Pt 100 temperature element.

C. The connections for the 9-pin connector are (from left to right):,

1. 4-20 mA connection, positive

2. 4-20 mA connection, negative

3. Relay 1 activated position (normally open)

4. Relay 1 center pole

5. Relay 1 deactivated position (normally closed)

6. Relay 2 activated position (normally open)

7. Relay 2 center pole

8. Relay 2 deactivated position (normally closed)

9. Liquid ground

D. The connections for the 3-pin connector are (from left to right):,

1. VAC protective ground wire

2. VAC neutral wire

3. VAC live wire

A.

B.

C.

D.

pH200cntrmnl 6/4/2002 9:59 AM Page 4

1234

1234

567

567

1234

8

9

567

123

▲▲

8 9

!

CAUTION: Electrical shock hazard! Make sure to

remove AC power to the controller before wiring

input and output connections, and before opening the

controller housing.

2.3 Wiring

1. Connect the power supply to the three-pin terminal block (D):

• VAC protective ground wire = 1

• VAC neutral wire = 2

• VAC live wire = 3

This controller can accept voltages from 85 to 250 VAC/DC,

50/60 Hz.

2. Connect the Pt 100 leads to terminals 5 and 6 of the seven-pin

terminal block (B). Either wire can be connected to either terminal.

Terminals 6 and 7 must be shunted unless using a 3-wire RTD.

NOTE: pH 200 is factory set for manual temperature compensation.

To select ATC, see page 25.

3. Slide the BNC connector of the pH (ORP) probe to the BNC

connector on the back of the controller. Turn the notches of the

connector until they lock into place.

4. Power on the controller. The display automatically shows

the pH (ORP) reading, and the pH (ORP) annunciator lights.

NOTE: If the Pt 100 temperature probe is not connected or is broken

and automatic temperature compensation is turned on, the display

flashes to alert you.

A.

B.

C.

D.

pH200cntrmnl 6/4/2002 9:59 AM Page 5

1234

1234

567

567

1234

8

9

567

123

10 11

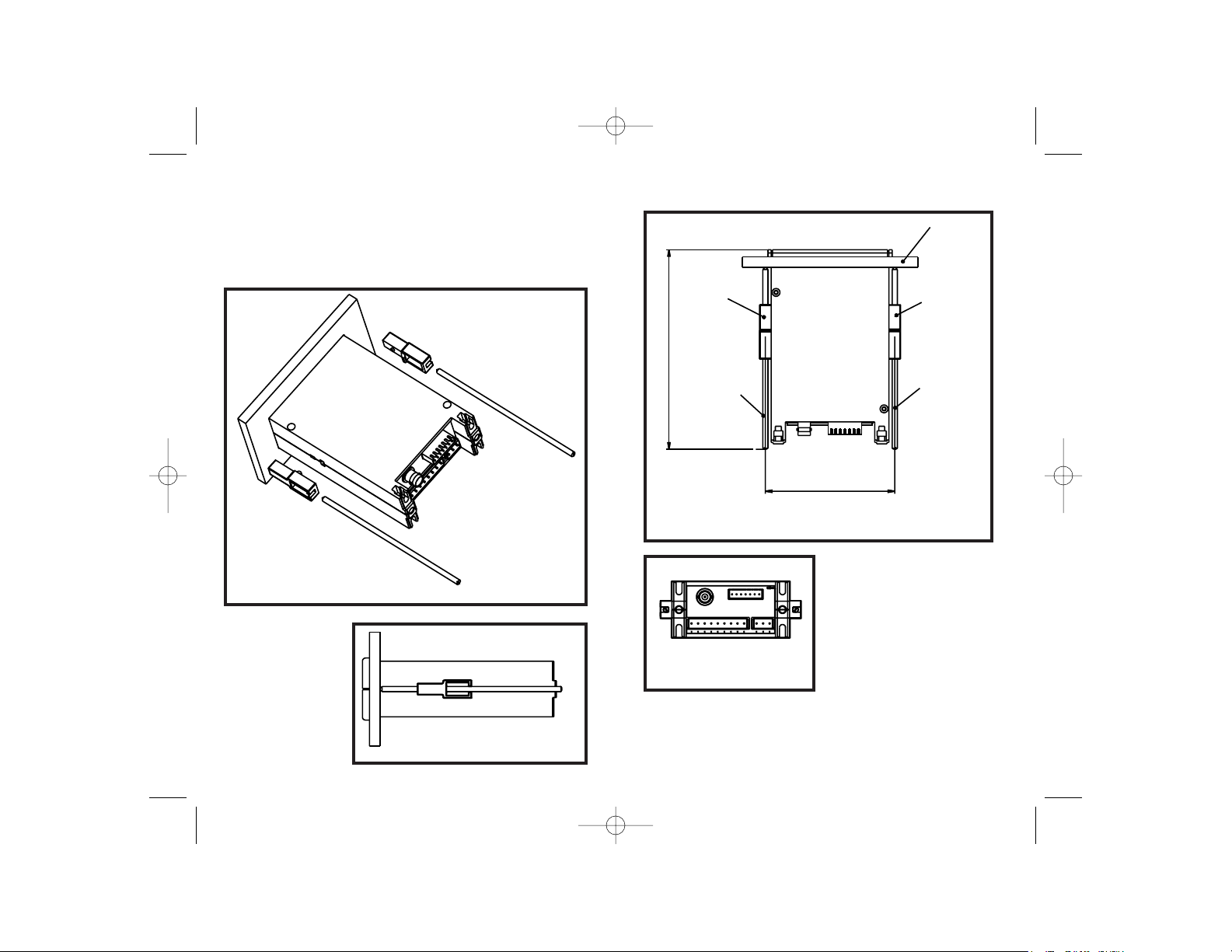

2.4 Panel-mounting the controller

The supplied mounting hardware allows surface mounting

to all panels and protective enclosures. Mounting cut-out size

is 91 x 45 mm.

pH200cntrmnl 6/4/2002 9:59 AM Page 6

Wall panel

3D VIEW

Catch

154.20

approx.

Threaded rod

BACK VIEW

approx.

100

TOP VIEW

Catch

Threaded rod

SIDE VIEW

Loading...

Loading...