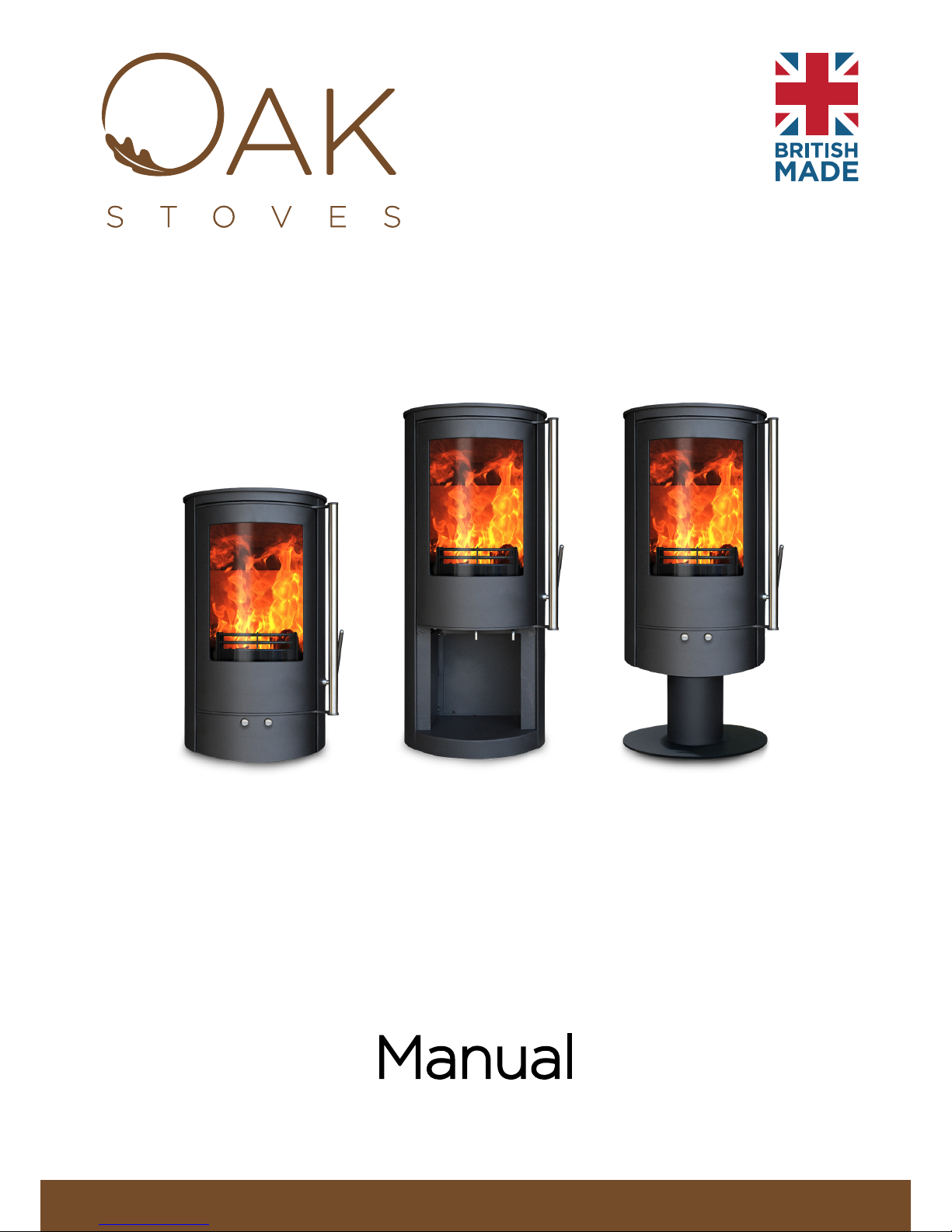

The Zeta 5 Window Series

ZETA5CW, ZETA5PW, ZETA5LW

Manual

Operation & Installation

sales@oakstoves.co.uk www.oakstoves.co.uk

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

2

IMPORTANT

READ BEFORE USE

We use Stove Bright® High Temperature Paint on all of our stoves and it is important that the paint

is cured properly during the rst burn of the stove. This is done to ensure the paint nish will be able

to withstand the high temperatures needed. Curing is done by following the instructions below. If this

process is not done properly during the rst burn of your stove, you may experience issues with the

paint peeling over time, especially when the stove is operated at a high heat.

Set / Cure the paint

For wood burning, follow these guidelines:

1. Build a small kindling re to start. The kindling re should be kept burning for 10 to 15

minutes.

2. Add fuel to build a medium size re to bring the stove surface temperature to about 450°F.

3. The medium size re should be kept burning for about 60 minutes.

4. For the nal stage of curing, add fuel to this re to make it a very hot re (surface temperature

above 600°F) and keep it at this level for about 60 minutes.

Once this initial process has been completed, the paint will be properly cured and you can operate

your stove normally according to the instructions provided in this manual. If any peeling of the paint

occurs on your stove this will only be as a result of improper curing or misuse of the stove such as

over fuelling or running the stove too hot. Therefore any peeling is not covered by your warranty.

NOTE: During the nal higher temperature burn phase there may be some visible smoke near the

stove surface. There may also be an unpleasant odour. To mitigate this effect, ventilate the room

with open windows and doors to provide airow.

HEALTH WARNING: The smoke from the curing process displaces oxygen. Small children, the

elderly and persons with existing breathing problems should vacate the area during the hot burn to

avoid the discomfort of lost oxygen. The smoke is primarily Carbon Dioxide, and therefore non-toxic

but uncomfortable.

Trouble Shooting: Paint Curing

Take care to build slowly to the medium temperature re. Building a hot re immediately will “shock”

the paint and cause it to release from the surface. The only remedy to this problem is to remove the

paint, prepare the surface for repainting, and repaint. To avoid problems during the curing process,

do not touch the surface with anything until the paint is fully cured.

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

3

Introduction

Thank you for purchasing an Oak Stove, we know that our stove will provide your home with many years of heat and

good service. We assure you that you have purchased a quality product that has been built to last, designed and

manufactured in the UK with an Eco-Cleanburn system to ensure a clean and efcient performance.

Please read the operation and installation guide carefully before commencing the installation and remember to keep this

manual safe for future reference.

Contents

EC Declaration Of Conformity 4

Technical Information 5

Operating Instructions

Recommended Fuels 6

Setting The Air Control Management 7

Lighting The Stove 8

Operating The Stove With The Door Open 9

Controlling The Stove 9

Refuelling 9

Cleaning & Maintenance 10

Ash Clearance 10

Throat, Bafe Plate & Flueway Cleaning 10

Chimney Sweeping 11

Combustion Air Supply 11

Seasonal Use 11

Troubleshooting 12

Placement & Fixing Advice 13

Installation Instructions

Health & Safety Precautions 15

Chimney 15

Hearth & Fire Surround 15

Flue Connection 16

Connecting The Flue 16

On Delivery Of The Stove 16

After Installation 16

Zeta 5W Dimensions 17

Zeta 5W Parts List 18

Maintenance 19

Warranty & Guarantee 20

DEFRA Requirements 22

WARNING!

The appliance will

become very hot.

During operation, the entire stove

unit becomes very hot and will cause

burn injuries if touched. Heat is also

radiated from the stove, especially

the glass, and high temperatures

will be emitted. Always take care

when near the re and that there

are no ammable materials closer

than the recommended distance

specied.

NOTE:

Ensure you report the installation

of your stove to your local

authority.

The owner of the property is

personally responsible for ensuring

compliance with all mandatory

safety requirements and that the

installation is carried out by an

approved and qualied installer.

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

4

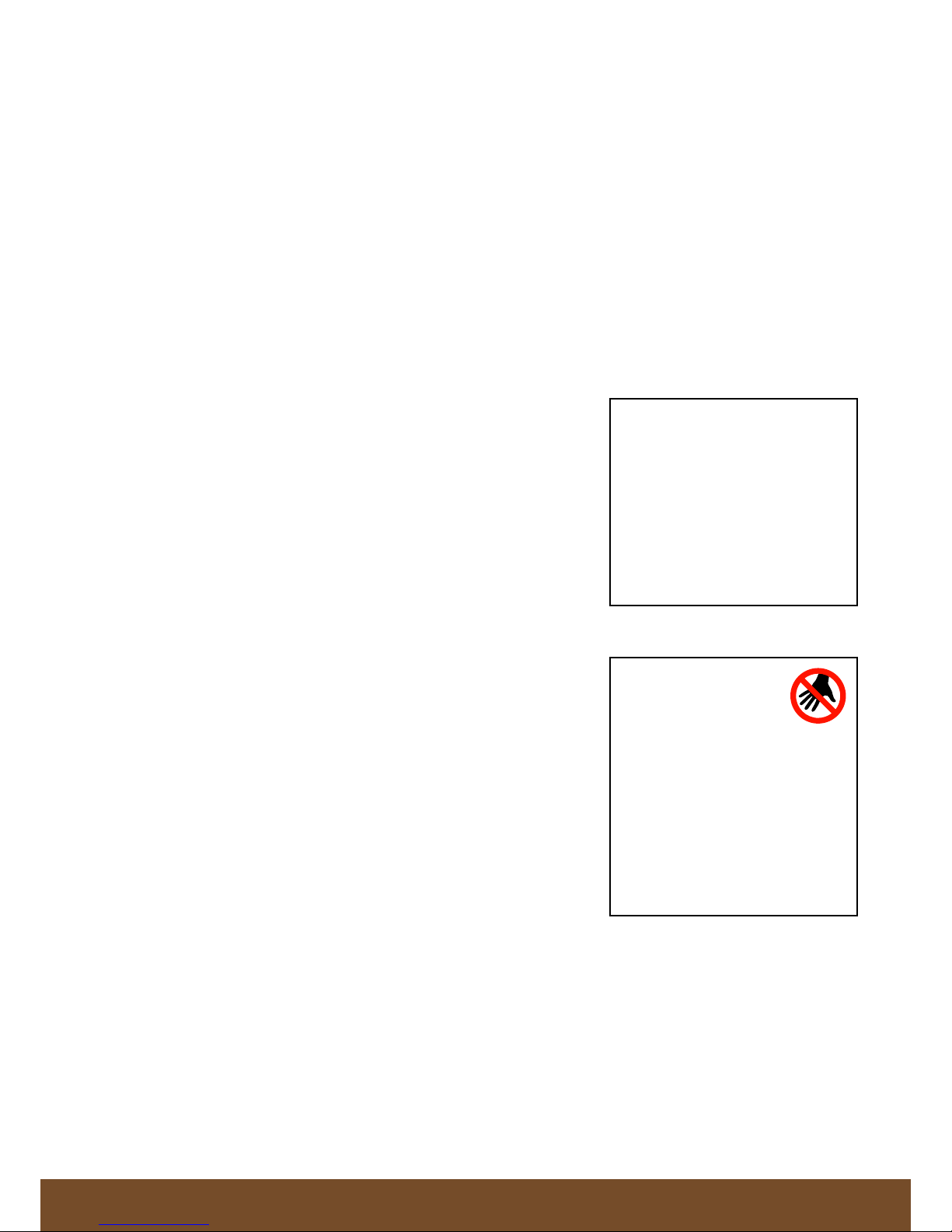

EC Declaration Of Conformity

MANUFACTURER

Name Oak Stoves

Address Unit 11, Village Farm Industrial Estate

Village Farm Road, Pyle

West Glamorgan, CF33 6BL

Telephone +44 (0)845 644 2815

Place Of Manufacture West Glamorgan, South Wales, United Kingdom

PRODUCT

Product Type Multi-Fuel Stoves red by solid fuel

Series Zeta 5W Series (Log Store, Pedestal & Compact)

Materials Used In Construction Plate Steel, Vermiculite Board, Ceramic Glass, Fire Rope.

Model Numbers

MODEL ZETA5LW ZETA5PW ZETA5CW

NAME Zeta 5 Log Store Zeta 5 Pedestal Zeta 5 Compact

CE Ref.

No.

ZETA5LW ZETA5PW ZETA5CW

Standard EN 13240 : 2001

Intended for use Heating of living accommodation

Fuels Wood logs & solid mineral fuel

Special conditions None

Date of issue 02/01/2018 - Version 2.8

WOOD

SOLID MINERAL

FUEL

NOMINAL OUTPUT 4.9kW 4.1kW

ENERGY EFFICIENCY (NET) 76.7% 77.7%

(Ancit)

CO EMISSION AT 13%

OXYGEN

0.47% 0.21%

CLEARANCE TO

COMBUSTIBLE MATERIAL

(MINIMUM)

75mm - REAR

500mm - SIDE

75mm - REAR

500mm - SIDE

AVERAGE FLUE GAS

TEMPERATURE

231

o

C 174oC

Manufacturer’s Declaration

The stove has been type tested by BSRIA Ltd. and fulls the applicable rules for EN-13240:2001 & CE

marking. Manufacture of the product has taken place in accordance with those specications. This forms

the relevant type approval certication and the required manufacturing processes and checks.

Richard Heatherill

Technical Director (Europe) - Oak Stoves

RECOMMENDED FUELS

WOOD LESS THAN 20%

MOISTURE

BRIQUETTED CLOSED FIRE

FUEL

THIS APPLIANCE IS CAPABLE

OF INTERMITTENT OPERATION

AND SHOULD ONLY BE USED

IN ACCORDANCE WITH THE

USER’S INSTRUCTIONS,

BURNING ONLY

RECOMMENDED FUELS.

THIS APPLIANCE IS NOT FOR

USE ON A SHARED FLUE

IMPORTANT

The CE plate can either be

found on the underside of

the door or log store.

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

5

Technical Information

All local regulations, including those referring to national and European Standards need to be complied with

when installing the appliance.

This manual is for the following models in the Zeta series:

MODEL ZETA5LW ZETA5PW ZETA5CW

NAME Zeta 5W Log Store Zeta 5W Pedestal Zeta 5W Compact

RANGE 4-6kW 4-6kW 4-6kW

EFFICIENCY 77.7% 77.7% 77.7%

MASS 140kg 130kg 130kg

THE MINIMUM FLUE DRAUGHT

FOR NOMINAL HEAT OUTPUT*

12pa (Pascals) 12pa (Pascals) 12pa (Pascals)

*where applicable, with open and closed redoors.

RECOMMENDED FUELS

WOOD LESS THAN 20% MOISTURE

BRIQUETTED CLOSED FIRE FUEL

THIS APPLIANCE IS CAPABLE OF INTERMITTENT OPERATION AND SHOULD ONLY BE USED IN

ACCORDANCE WITH THE USER’S INSTRUCTIONS, BURNING ONLY RECOMMENDED FUELS.

THIS APPLIANCE IS NOT FOR USE ON A SHARED FLUE

PLEASE COMPLETE ALL THE DETAILS BELOW AS THIS COULD AFFECT YOUR WARRANTY

SERIAL NUMBER DATE OF INSTALLATION

HETAS INSTALLER REGISTRATION NUMBER INSTALLER NAME

INSTALLER ADDRESS

Important To Remember

Installation By Authorised Technician

This manual contains instructions on how the stoves must be assembled, maintained and installed. To ensure the

function and safety of the stove, we recommend that the installation must be carried out by an authorised technician.

Contact one of our dealers to nd a suitable tter.

Structural Support

Check that the wood joists are strong enough to bear the weight of the stove and chimney. The stove and chimney can

usually be placed on a normal wooden joist in a single occupancy house, if the total weight does not exceed 400kg.

Building Permission

Before installing a stove or erecting a chimney, it is necessary for you to make an application for building permission to

your local authority. Ask your local authority for advice regarding building regulations and the application.

Hearth Plate

Due to the risk of embers falling out, a ammable oor must be protected by a hearth plate. It must extend 300mm in

front of the stove and 300mm on each side of the stove, or have a 200mm extension on each side of the opening. The

hearth plate can consist of natural stone, concrete, metal plate or glass.

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

6

Operating Instructions

NOTE: All multi-fuelled stoves must be installed by an approved installer, and all

necessary checks described in the Installation Instructions need to be carried out.

Only use the recommended fuels detailed below.

Recommended Fuels

The Zeta stoves are Multi-Fuel appliances, meaning they can burn a number of different

fuels, however you must ensure that you follow the instructions specic to your chosen type

of fuel and that your chimney is suitable for all the types of fuel you will use.

Wood

The wood you use to burn in this stove should only be dry and well seasoned. To prepare the

wood for burning ensure it is cut, split and then left to season in a dry, well ventilated area for

at least one year before burning. The ideal types of wood for this stove are hard woods such

as Ash, Beech or Oak. We recommend that all wood has a moisture content of less than 20%.

The rebox should have a bed of ash at the base for the wood to be placed on. The use of

unseasoned wood in this appliance can result in heavy tar deposits in the stove, on the glass

and within the chimney. Also unseasoned wood will produce lower outputs from the re.

Peat

Cut peat must be dried before using in the stove in order to reduce the amount of tar deposits

produced. You should burn Peat in the same way as wood fuel, on a bed of ash at the base

of the stove.

Smokeless Fuel (Solid Mineral Fuels)

A variety of smokeless fuels may be used in this stove, however you must check the necessary

precautions for each specic fuel to prevent damage. These fuels include:

• Ancit

• Anthracite Large Nuts

• Centurion

• Extracite

• Homere

• Maxibrite

• Phurnacite

Only smokeless fuels may be burnt in smoke control areas. Petroleum Coke and House Coal

is not suitable for use on this appliance, it’s use will void your warranty.

There are a few additional points to consider when lighting smokeless fuel res, please refer

to the ‘Burning solid mineral fuels’ section on the next page. Also when burning smokeless

fuels, the upper bafe vermiculite board (throat plate reboard) must be removed. Please

refer to page 19 for instructions on how to do this.

Operating Instructions

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

7

Operating Instructions

Setting The Air Control Management

The following is a recommendation only for maximum efciency.

When burning wood only or solid mineral fuels (smokeless fuels) the following settings are

recommendations only as it is all dependent on the moisture content of the material to be

burnt.

So if the moisture content is above 16 to 20% which is the recommended level in any of

these products you may well need to make adjustments to get the optimum burn efciency

out of this stove. So the following is a guide only to the position of the primary secondary and

tertiary air controls.

Please note that wood burns from the top of the re box down so more control is gained from

the secondary and tertiary slider control bar. This slider operates the clean glass air wash

system which assists in helping to prevent the glass blackening up. It also operates the EcoCleanburn at the rear of the re box which helps to insure that all of the gases given off from

the wood and solid mineral fuels are fully burnt prior to being exhausted up the chimney,

therefore giving maximum heat output and efciency to the stove.

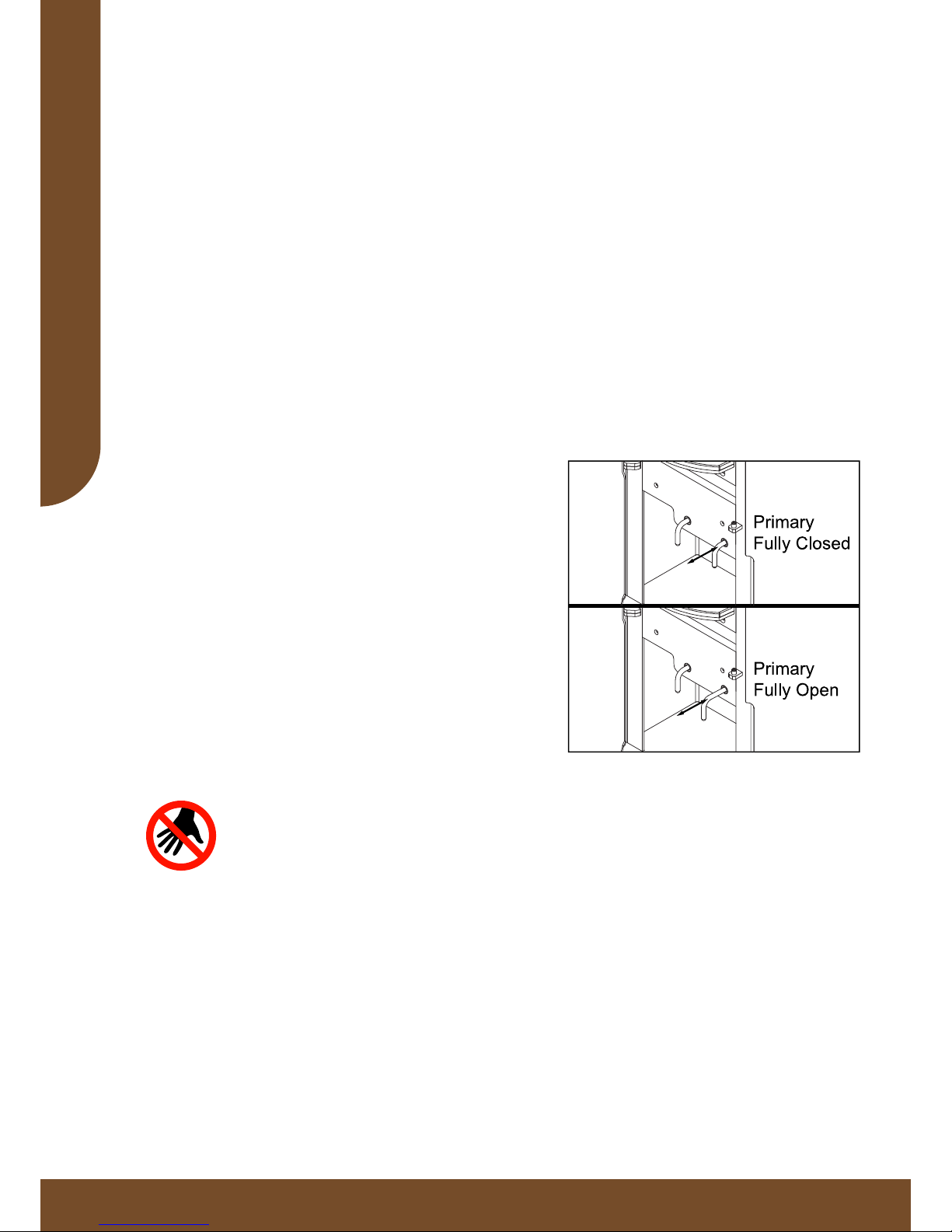

As you open and close the left hand slider (Fig. 2) for the clean glass air wash (secondary)

and the Eco-Cleanburn (tertiary) there is a balancing valve (which you never need to touch)

tted into the rear of the stove that automatically manages the volume of air being fed to each

of the outlet air controls so the optimum airow is delivered to the clean glass air wash down

the front of the glass and the Eco-Cleanburn afterburn at the rear of the re box.

However, solid mineral fuels burn from the bottom up so you require air ow from the right

hand slider (Fig. 1) and less from the secondary and tertiary control.

Please refer to the table below as a guide only to the position of the 2 air controllers. Also

note the required riddle grate position for each type of fuel. To change the riddle grate position

insert handle (see Fig. 4), then push backwards to close the grate or pull forward to open the

grate.

Burning wood only - (Rotating riddle should be in the closed position)

Position of air

management controls

Lighting the stove Once alight & burning

well

To shut the stove off

1

Primary slider

(right)

Fully open Push slider in to

approx 30% open

Close completely

2

Secondary slider

(left)

Pull slider out 75%

towards you

Push slider in to

approx 50% open

Push in fully to close

Burning solid mineral fuels - (Rotating riddle should be in the open position)

Position of air

management controls

Lighting the stove Once alight & burning

well

To shut the stove off

1

Primary slider

(right)

Fully open Push slider in to

approx 75% open

Close completely

2

Secondary slider

(left)

Pull slider out 75%

towards you

Push slider in

between 50% - 25%

Push in fully to close

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

8

Lighting The Stove

When lighting the stove for the rst time your appliance may give off an odour, this is caused

by the paint inside the stove reacting to the heat. This is completely normal and will cease

after a short time, however the room should be kept well ventilated while this is still occurring.

The stove door handle is located on the right hand side of the door, pull the handle out to

open the door and insert your fuel (Ensure riddle grate is in the appropriate position for your

fuel). When closing the door be careful not to slam it shut to avoid damage to the closing

mechanism or glass, also when opening the door be careful of any pieces of fuel or embers

that may be resting on the door. To begin you should only light a small re and allow it to burn

slowly for at least two hours. This initial re will evaporate any residual moisture contained

within the vermiculite bricks, allowing you to use the re as normal from then onwards.

When burning wood or peat ensure that there is a layer of ash at the base of the rebox

to prevent overheating and damage to the base. If there is no ash available when you rst

light the stove, you can add a layer of sand approximately 13mm (1/2 inch) thick to the base

instead.

Lighting the stove

To start the re you can use dry kindling wood with

either paper or re lighters. Place the paper or re

lighters along with the kindling on the base of the

rebox and cover with approximately 50mm of fuel.

Light the paper or re lighters to start the re, then

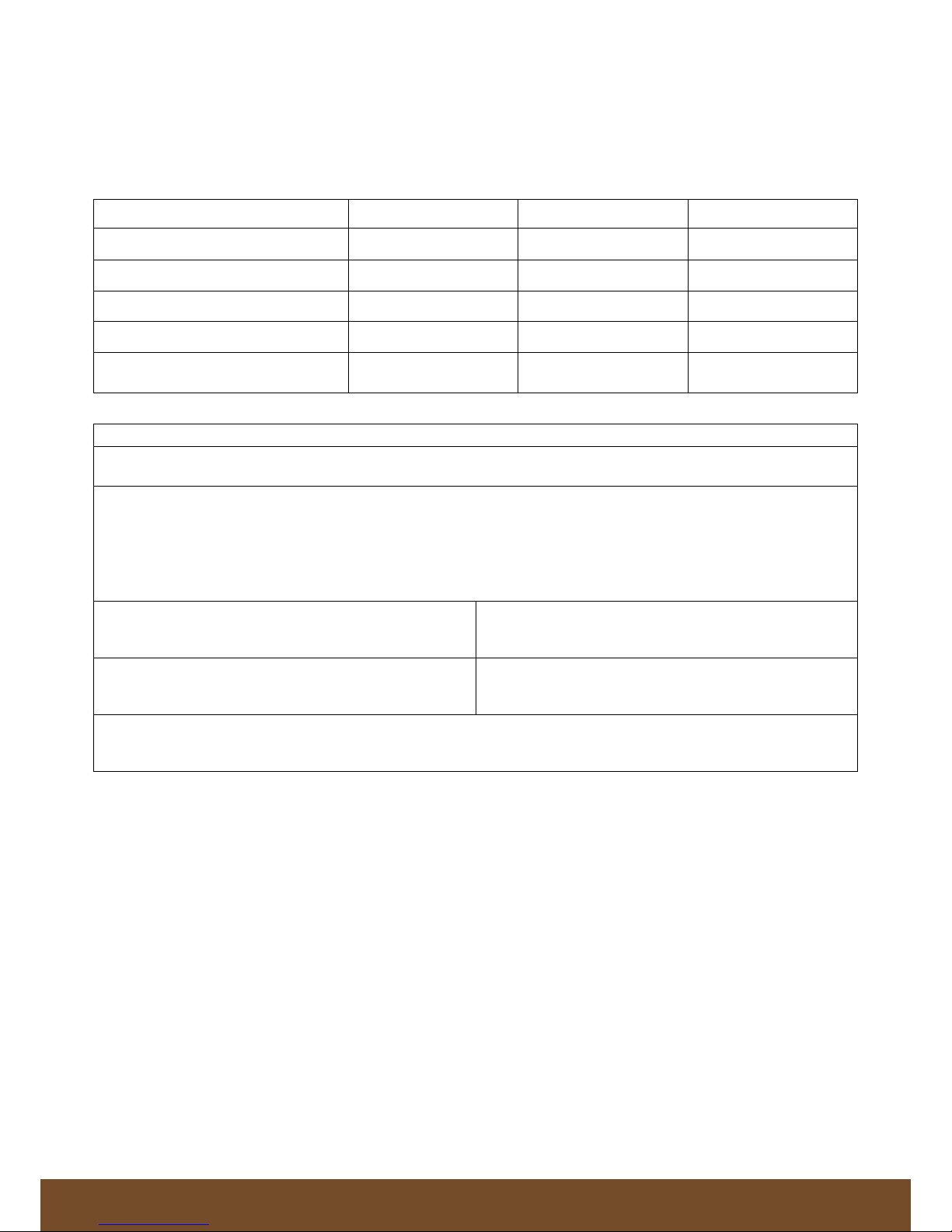

ensure the right hand primary air slider is open (See

Fig. 1) on the stove before closing the door, pull the

Air Wash control towards you to open the rear Air

Wash vent (see Fig. 2b). Allow the re to be fully

ignited before adjusting the air vents to the preferred

position, as detailed on page 7. Once fully lit, you

can partially close the primary slider.

Always take care when touching any part of the stove to prevent burning

yourself and we always advise using an appropriate glove when adjusting the

air vent, opening/closing the re door and when refuelling. Please note that

the stove can remain hot for long periods after the re has been extinguished.

When relighting the stove leave the ash from previous res on the base of the rebox, however

some may be removed if the build up starts to block the front grill. You should always ensure

there is enough ash at the bottom of the rebox to protect the stove’s base before lighting a

re.

Burning smokeless fuels

When loading the re with smokeless fuels it is advised not to put all the required fuel in at

once, load in two stages to ensure that the re will not be smothered and wait between each

stage for the ames to grow before adding the remaining fuel. Certain fuels may produce

more soot deposits than others, therefore it is essential for you to regularly clean the throat

plates to avoid build up. When relighting a smokeless fuel re ensure you have cleared the

grate and emptied the ashpan before starting a new re.

Fig. 1

Operating Instructions

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

9

Operating Instructions

Operating The Stove With The Door Open

This stove should not be operated with the door open, we do not recommend this. This stove

is designed to be operated with the door closed as this gives improved efciency and air

ows. Certain fuels such as wood and peat will burn better this way but it is vitally important

that you do not leave the re unattended with the door open at any time. Always keep

the door closed and the handle in the locked position.

Controlling The Stove

The right hand primary slider and the secondary

and tertiary slider bar below the door (see Fig.

2) control the rate of burning and in turn the

heat output. The clean air wash is known as the

secondary air control and the Eco-Cleanburn is

known as the tertiary. These are fully controlled

by the left slider bar. The primary air control slider

should only be left fully open when lighting or

when rapid burning is needed. If the slider is left

open for long periods then over-ring may occur.

Once lit we recommend the primary slider be left

slightly open, and adjust accordingly to control

the re.

The door handle, two control bars (air wash and primary) and riddle bar will heat

up when the re is lit and running. But when you need to touch them to adjust or

reload the re you must wear gloves. Therefore to avoid injury please wear

appropriate hand protection when touching any part of the stove as the body,

the glass and the primary air knob can get very hot.

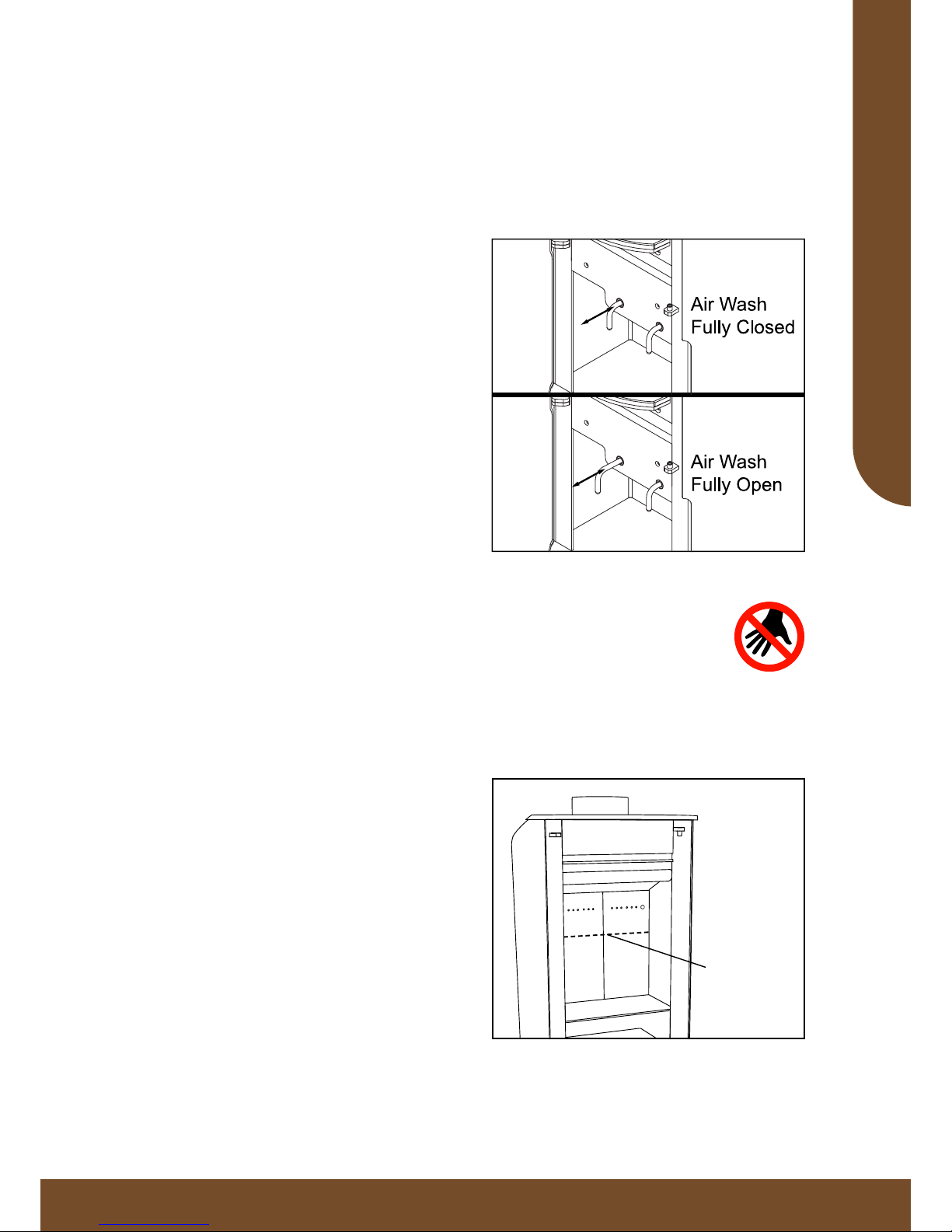

Refuelling

Keep the rebox well lled to maintain the re

but for safety reasons it is important not to overll

the stove, your fuel must not be spilling over the

top of the front grill or touching the door or glass

panel. Doing this could cause the re to spill out

when opening the door. Overlling can also cause

the glass to black up. Do not ll past the ll line,

which is 50mm below the tertiary holes as this

may restrict airow to the Eco-Cleanburn bar.

(see Fig. 3).

When adding fuel ensure that the appropriate

protection is worn such as a heat resistant glove

and tools such as re poker, tong or shovel are

used.

Fig. 2

Fill Line

(50mm below

tertiary holes)

Fig. 3

A

B

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

10

Cleaning & Maintenance

Our stoves are nished with high temperature resistant paint which can withstand the

temperatures expected in normal use. You may clean the stove with a damp lint-free cloth,

but ensure the stove is completely cold throughout before doing so.

To clean the glass on the door, again use a damp lint-free cloth to clean and ensuring that

you wipe with a dry cloth afterwards. Do not use any chemicals to clean the glass, this will

cause permanent damage to the glass. You may get deposits on the glass after the re has

run, most of these will burn off if you run the re again at a fast rate for a few minutes. Do not

use abrasive cloths on the glass or paintwork as these can cause scratching and permanent

damage to the stove.

Ash Clearance

With wood or peat res you should allow some

build up of ash at the base of the rebox, however

it is necessary to remove some ash once the

build up gets too much. This will only be needed

when the build up starts to restrict the airow by

blocking the front grill. Burning smokeless fuels

will require the ashpan to be emptied regularly, it

is very important to do this as this ash must not be

allowed to overow over the grate.

This model has a Remote Riddle Plate Handle

located under the left side of the door, pulling

this bar will rotate the grills allowing excess ash

to drop through to the ashpan below the rebox

(see Fig. 4). Be sure not to completely empty

the base of ash.

It is very important that all ash is cool before attempting to remove it from either the base or

the ashpan. We advise emptying the cold ash into a bin liner and sealing it before disposing.

Throat, Baffle Plate & Flueway Cleaning

It is very important that the throat, bafe plates and the ueway are kept clean and obstruction

free, failure to do so could result in dangerous emissions not escaping correctly. These fumes

can pose a serious health risk to occupants therefore it is necessary to clean both the throat

and bafe plates and the ueways at least weekly, or more frequently if needed.

To clean the throat and bafe plates, rst remove the side bricks to enable you to easily

remove the throat plate. To access the ueway, remove the two saddle clips to release the

upper bre board that covers the ueway. Any build up of soot should then be swept off the

plate down onto the re. Ret parts in reverse order when cleaning is nished, for more detail

please refer to page 19.

Fig. 4

Operating Instructions

Rotating

Riddle

Handle

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

11

Operating Instructions

Chimney Sweeping

Your chimney should ideally be swept at least twice a year. Depending on your installation

you may be able to sweep your chimney through your appliance, if not your installer would

have inserted a soot door to access the chimney once the stove has been moved clear. When

sweeping through your appliance you will rst need to remove the throat plate, upper bre

board and front grill from the stove.

Your installer will advise on what tools you will need to sweep your chimney. After sweeping

you must ensure that all ueways are clear and no soot deposits have collected to form a

blockage particularly on any horizontal surfaces.

Combustion Air Supply

In order for the stove to work efciently and safely there needs to be an adequate supply of

combustion air in the room where the stove is installed. This is necessary where the room

is double glazed or where a ue draught stabiliser is operating in the room where the stove

has been installed. Provision of air to the stove must be in accordance with current Building

Regulations Approved Document J. An open window is not appropriate. Any air inlets must

be positioned in such a way as they cannot be blocked.

Seasonal Use

If the stove is not used for a long period of time (e.g. Summer) then it must be thoroughly

cleaned with ash and unburned fuel being removed. It is important to leave air controls fully

open when the stove is not being used, this will prevent build-up of condensation / corrosion.

It is important that the ue connections, any bafes, throat plate and chimney are swept clean

prior to lighting again.

Adverse Weather Conditions

If, due to adverse weather conditions, your stove does not operate properly and smoke is

emitted into the room, DO NOT treat this as a minor problem. Smoke indicates that Carbon

Monoxide (CO) is entering the room. Should this happen, turn your stove controls to their

minimum setting (still allowing the re to burn) open windows to ventilate the room. DO NOT

close the windows before the re has burned out.

The smoke entering the room is probably due to a poor draught or a blocked ue. It is advisable

to have the ue pressure checked. The minimum operating pressure for a ue is 12 Pascals.

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

12

Troubleshooting

Fire will not burn

Check that:

• the air inlets are obstruction free

• chimneys and ueways are clear.

• you are using a suitable fuel.

• an adequate air supply is entering the room.

• an extractor fan is not tted in the same room as the stove.

• the chimney has a sufcient draw. A draught reading of at least 2.5mm water gauge

should be seen (once the chimney is warm).

Door glass blacks up

Because chimneys differ greatly the best draught settings will take a few trials to gure out,

but the following tips should help:

• When re-fuelling place the fuel towards the back of the rebox, keeping it as possible

from the front grill and avoid over lling.

• The primary air vent on the door may be kept slightly open to assist in keeping the

glass clean or open up the secondary and tertiary slider bar further.

• Unseasoned wood will cause more deposits on the glass if the moisture level is more

than 20%.

Bear in mind it tends to be more difcult to keep the glass panel clean if you’re running the

stove very slowly for a long period of time. If blackening of the glass still occurs ensure that

all ue connections are well sealed with re cement, as this can decay over a long period of

time and may need resealing. Also the chimney draw needs to be sufcient and not affected

by down-draught.

When certain smokeless fuels you may notice some blackening of the glass below the

grill level, this is to be expected and shouldn’t obscure your view of the re or affect the

performance of the stove.

Fume emission

IMPORTANT: If this appliance is properly installed and operated it will not emit fumes.

Occasional fumes when de-ashing or re-fuelling are to be expected, but fumes during normal

use are NOT usual. Persistent fume emission can be very dangerous and should NOT be

ignored. If you notice persistent fume emission you should immediately:

• Open all doors and windows in order to ventilate the room.

• Let the re go out and safely dispose of the remaining fuel from the appliance.

• Check for any blockage to the ue or chimney and clean if required.

• DO NOT attempt to re-light the re until the cause of the fumes has been identied

and resolved. Seek professional advice if necessary.

The most likely cause of fume emission would be due to ue or chimney blockages. For your

own safety it is vital that you regularly check and clean your ue and chimney.

Operating Instructions

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

13

Operating Instructions

Free Standing External Air Supply

Fire blazing out of control

Check that:

• the door is tightly closed, the handle is locked and the seal is intact.

• the air vents are closed fully (primary, secondary and tertiary).

• a suitable and well prepared fuel is being used.

Chimney res

If your chimney is properly installed and regularly swept, chimney res should not occur.

However, if a chimney re does occur the rst step would be to ensure the door is tightly

closed and the air vents are fully shut (primary, secondary and tertiary), doing this should

cause the chimney re to extinguish itself. After this you must keep the door and air vents

closed until the stove’s re has gone out completely to prevent the chimney re reigniting.

Once this has happened and the stove has cooled you must then clean the chimney and

ueways to prevent the chimney re from reoccurring next time you light the stove.

If the chimney re does not extinguish after closing all the vents and door then you must

contact the re brigade immediately, do not attempt to ght the re yourself. After any chimney

re your chimney should be carefully examined for damage before you attempt to relight your

stove, contact a professional for advice if necessary.

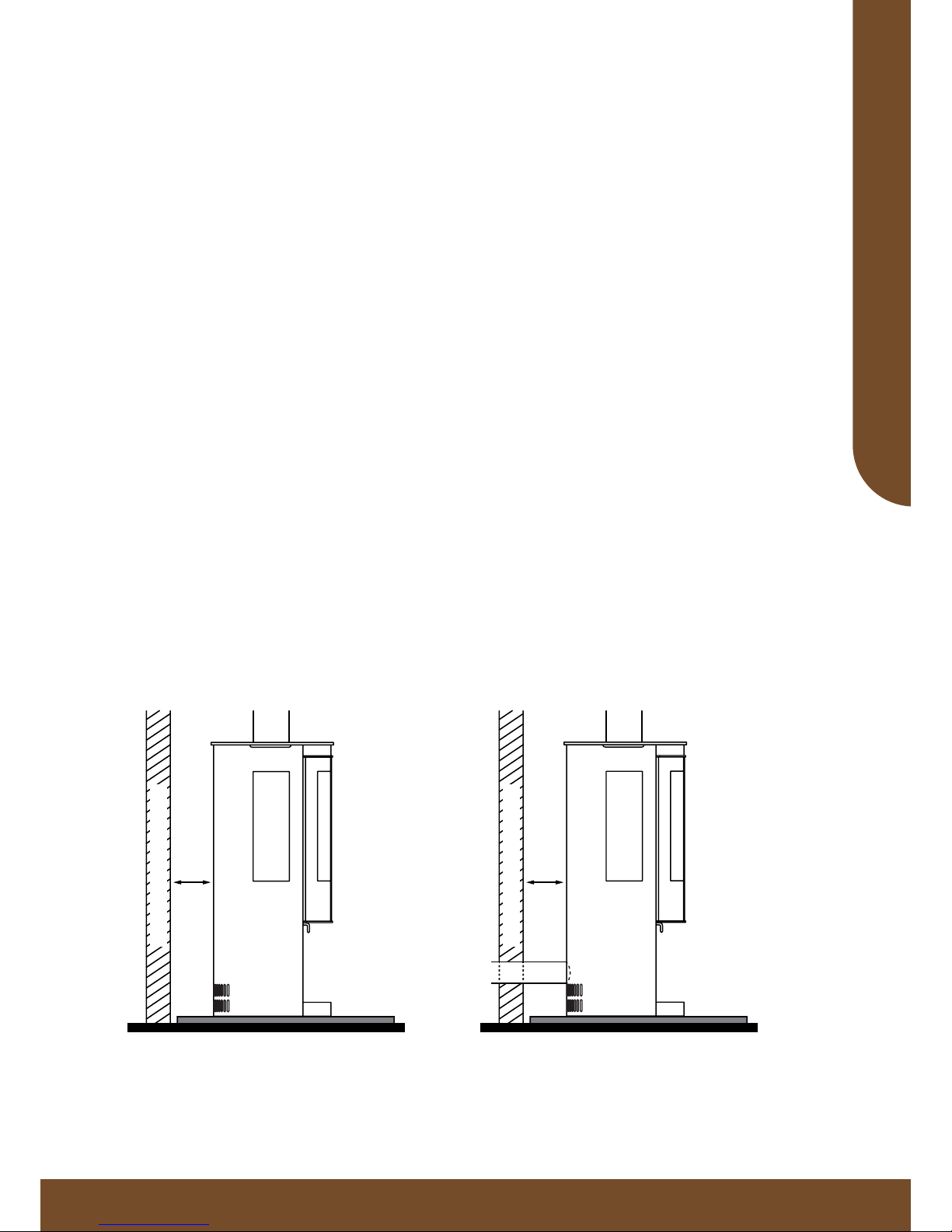

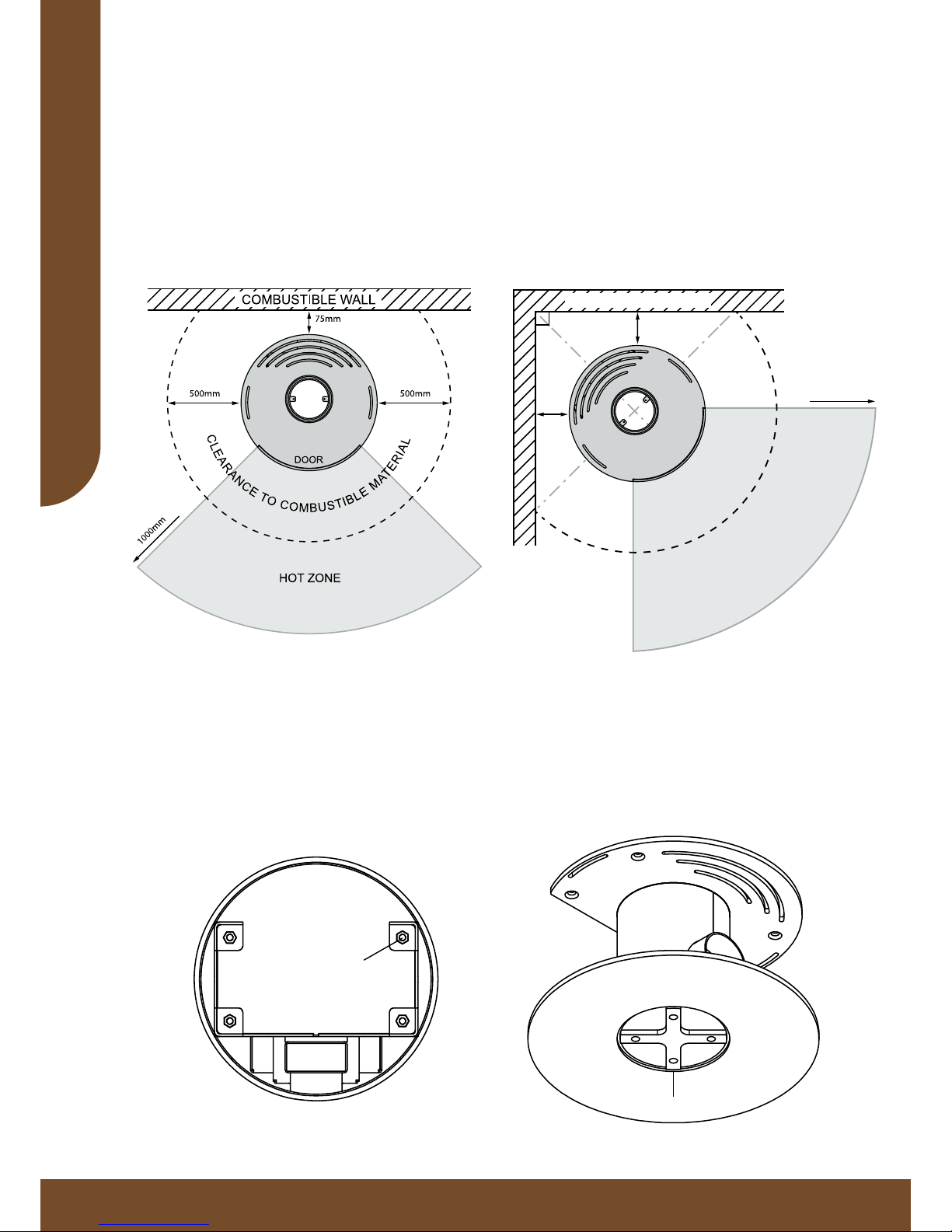

Placement & Fixing Advice

The placement of the stove is very important not only for safety reasons, but also to get the

best performance out of your appliance. Connecting the rear air supply to an external source

of cold air can improve the efciency of your stove, but it is not essential to do this for the

stove to perform normally. The below diagrams show examples of free standing and external

air supply installations. For more information see the Hearth & Fire Surround section.

75mm

COMBUSTIBLE WALL

75mm

COMBUSTIBLE WALL

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

14

The minimum distance from the rear of the stove to a wall is 75mm, and 500mm to either side

of the appliance. No combustible material should be within this area (see below, left).

There is however an exception made when the stove is placed in a corner, the closest point

of the stove to both walls should be at least 100mm (see below, right). We also recommend

at least 1000mm clearance around the stove to glass (excluding hearths).

Please note the Hot Zone to the front of the stove extends 1000mm from the window and

ends in line with each side of the door edge. This area can be 90oC, so we do not recommend

any combustibles in this area.

Fixing Points

If you would like to x the stove to the ground, you can do this using the xing points shown

below. For anchoring the Pedestal model to your hearth you will need x4 M12 bolts and x4

M12 nuts (not supplied).The Log Store model has M12 nuts built into the base, therefore you

will only require x4 M12 bolts (not supplied) for this model.

Log Store Model Pedestal Model

x4 M12 Nuts

x4 14mm Holes

Views from underneath of the stoves

Operating Instructions

HOT ZONE

100mm

100mm

C

L

E

A

R

A

N

C

E

T

O

C

O

M

B

U

S

T

I

B

L

E

M

A

T

E

R

I

A

L

COMBUSTIBLE WALL

DOOR

1000mm

90

o

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

15

Installation Instructions

Health & Safety Precautions

Before you begin the installation process there are a number of things to consider:

• We recommend you avoid tting the stove in the same room as an extractor fan.

However, if this is unaviodable, seek specialist advice to ensure safe installation and

operation of the stove.

• If work needs to be carried out that could potentially disturb any asbestos in your

home then ensure appropriate protection is worn before commencing work.

• The room you are tting the stove in needs to have an adequate air supply, especially

if the room has double glazed windows. We recommend you check this with your

local building control ofcer and adhere to the building regulations requirements for

providing oxygen into the room (your installer will conrm this with you).

• The requirements of both the BS 8303 and BS EN 15287-1:2007+A1:2010 standards

must be fullled.

• We recommend you only use a HETAS Approved Installer

to carry out the stove installation. See hetas.co.uk.

• All local authority laws and building regulations must be

adhered to before installation and the required permission

to install must be obtained.

• Ensure you have a carbon monoxide and smoke alarm tted in the same room as

the appliance.

Chimney

For the stove to perform correctly and safely your chimney height must not be less than

4 metres high, this height is taken from the outlet of the stove body to the very top of the

chimney. The outlet on our stove is 5 inches in diameter, therefore your chimney must have

a minimum width of 5 inches but preferably be 7-8 inches wide. Your chimney can be either

square or circular, as long as it meets the minimum width specications.

If installing a stove into an existing replace, it must be swept and inspected to ensure that it is

in good condition and suitable for the type of stove you are installing. If any cracks, blockages

or excessive cross sections are found then you should consult a professional regarding

getting your chimney lined. The type of fuel you wish to burn needs to be considered before

getting your chimney lined so that a suitable lining is used.

If there is an excessive draw with the chimney then we recommend a draught stabilizer

be tted. Alternatively if there is too little draw or down-draught then you must consult a

professional before lighting your stove. You should have a minimum draw of 2.5mm water

gauge.

Hearth & Fire Surround

The stove must be installed on a at reproof hearth for stability and the area in front and

around the re must be clear of any combustible materials. The stove should not be at

Installation Instructions

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

16

against a wall, we recommend a minimum clearance of 75mm to prevent restricting airow.

Building regulations regarding these appliances govern that the hearth must extend at least

300mm out in front of the stove and 250mm to each side. For safety we recommend that you

ensure there is a minimum of 300mm clearance around the entire appliance. This appliance

needs a good amount of air circulation around it, however if you are installing the stove in a

replace ensure that there is at least 250mm gap to each side and at least 300mm above the

top of the stove in order to prevent overheating and allow for good heat output.

You may wish to connect the rear Air Wash vent up to an external supply of air, this can be done

provided the connection is secure and doesn’t prevent the Air Wash Control from opening

and closing fully. A rear clearance of 75mm is still recommended in these circumstances. Also

you will need to consider how close your mantelpiece or any other objects directly above the

replace are, to prevent damage due to high temperatures.

Flue Connection

The Zeta Series has a top output connection, the type of installation that is best for your home

will depend on the chosen location for the stove. You must ensure that all building and health

and safety regulations that apply to your chosen type of installation are conformed to before

you begin to use the stove.

Your stove will normally be delivered assembled ready for connection.

Connecting The Flue

The ue collar must be sealed with re cement and all ue connections must be well sealed.

Any horizontal sections of ue must not be longer than 150mm.

With most ue connections your installer should t a soot door in your chimney to allow

access to sweep it, alternatively this chimney can be swept through the stove (see Chimney

Sweeping section).

On Delivery Of The Stove

Please ensure that the vermiculite bricks, throat plate and bafe plate have not moved in

transit (see page 19) and that the glass window is intact. Also check that you have all the

required parts (see back page) before installation.

After Installation

Upon completion of the installation you should allow time for the re cement and mortar to

dry out and set properly. Once dry you may begin preparing the re for its rst re. Ensure

that the throat plate, bafe plate and front grill are in place and that the door and vents close

properly before lighting.

When you’re ready to start the re, follow the instructions detailed in the Lighting section

relevant to your type of fuel. Once alight, check that the fumes and smoke are being drawn

up through the chimney correctly and that all joints and seals are not emitting fumes.

Your installer should advise on the operation and maintenance of your stove and chimney

and retain this manual for future reference.

Installation Instructions

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

17

Installation Instructions

Zeta 5W Dimensions

All dimensions shown are in mm

The Zeta Log Store

5kW

Model ZETA5LW

A 1050mm

B 125mm

C 300mm

D 675mm

E 420mm

F 470mm

G 150mm

H 420mm

The Zeta Pedestal

5kW

Model ZETA5PW

A 1050mm

B 125mm

C 300mm

D 800mm

E 500mm

F 420mm

G 470mm

H 195mm

I 240mm

J 150mm

K 420mm

Front View Side View

Front View Side View

The Zeta Compact

5kW

Model ZETA5CW

A 850mm

B 125mm

C 300mm

D 675mm

E 460mm

F 420mm

G 470mm

H 420mm

I 150mm

Front View Side View

F

G

H

I

B

E

D

C

A

F

G

I

H

K

J

B

E

D

C

A

E

F

F

G

H

B

D

C

A

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

18

Zeta Parts List

Installation Instructions

Item Qty Part No. Description Warranty

1 1 Z501 Secondary Slider Y

2 1 Z502 Grate Support Y

3 1 Z503 Door Handle Y

4 1 Z504 Primary Slider Y

5 1 Z505 Rotating Riddle Plate N

6 1 Z506 Throat Plate Fireboard N

7 1 Z507 Rear Fireboard (2 parts) N

8a 1 Z508a Left Side Fireboard N

8b 1 Z508b Right Side Fireboard N

9 1 Z509 Top Plate (3 parts) N

10 1 Z510 Bafe Deector Fireboard N

11 1 Z511 Side Panel Y

12 1 Z512 Regulator Cover Plate Y

13 1 Z513 Pneumatic Door Closer N

14 1 Z514 Ash Pan N

Item Qty Part No. Description Warranty

15 1 Z515 Zeta 5 Curved Glass N

16 1 Z516 Ash Pan Handle N

17 1 Z517 Stove Body Y

18 1 Z518 Stove Door Y

19 1 Z519 CE Plate Y

20 1 Z520 Grate Shelf N

21 1 Z521 Fire Grate Retainer Bars N

22a 1 Z522a Left Outer Side Window N

22b 1 Z522b Right Outer Side Window N

23 1 Z523 Rotating Riddle Handle N

24a 1 Z524a Left Flat Inner Side Window N

24b 1 Z524b Right Flat Inner Side Window N

25 2 Z525 Side Grate Retainer Bars N

26 1 Z526 Air Inlet Assembly N

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

19

Maintenance

Fig. 6

Fire Brick Removal

1. Remove the two screws holding the rear

boards in place, the two rear reboards can be

removed by pulling out from the middle.

2. Remove both Side Bolts from inside the

rebox to free the top of the Side Fireboards,

remove these carefully as they are very fragile.

3. Lift the Top Fireboard up to slide it off its

retainers and remove.

4. Remove the Retaining Plate by pulling

towards you to get it off the retainers each side.

You can now slide the Throat Plate Fireboard

backwards, then forward to allow it to drop out.

5. Firebox is now ready to clean.

NOTE: All screws removed at this time must be

renewed.

Side Fireboard

Retainer

Throat Plate

Fireboard

Rear Fireboards

Fire Brick Assembly

1. Place Throat Plate Fireboard against the roof of the rebox and slide forward over the

location pins then x in position by slotting the Retaining Plate under it with the lip facing

down.

2. Place Top Fireboard in position on its retainers.

3. Put the two Rear Fireboards back into position before retting the screws.

4. Lastly reposition the Side Fireboards one at a time using the Side Bolts to keep them in

place.

Recommended Periodic Checks

Check The Following If Fault Found Recommended

Frequency For Checks

Chimney is sweeped Arrange a sweep Every 6 months

Check the glass is not cracked Replace Before every use

Check re bricks have not deteriorated Replace Weekly

Check bafe plate and throat plate are clean and clear Unblock / Clean Weekly

Check none of the door seal re ropes have worn excessively Replace Weekly

Check the riddle grate is not blocked Unblock Weekly

Check ue pipe for blockages Unblock Monthly

Check all chimney / ue joint seal cement hasn’t deteriorated

or is leaking

Reseal Monthly

If you discover any issues or require replacement parts, please call your retailer / installer.

Installation Instructions

Retaining Plate

Top Fireboard

Side Bolts

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

20

Installation Instructions

Warranty & Guarantee

Multi-Fuel – 10 Year Extended Warranty

It’s important to know what requirements need to be met in order to qualify for our extended

10 year warranty, as well as being aware of exactly what it covers. This warranty only applies

to Multi-fuel stoves.

If you have purchased your stove from an authorised stockist within our Premium Retailer

Network, then automatically your product will carry a standard 2 year warranty. The 2 year

warranty can be further extended to a total warranty period of 10 years by registering your

Oak Stove within 60 days of the purchase date or installation date which ever is shortest.

Accordingly, the start date for the warranty period is the date of purchase. During the

registration process, the Premium Retailer details will be required for your Extended Warranty

to be activated. Any product purchased outside of our Premium Retailer Network will carry a

standard 12 month, non-extendable warranty.

Once you have purchased your Oak Stoves you can only register your purchase online. It

is a condition of the Extended Warranty that the installation complies with relevant Building

Regulations and the rules in force, and is carried out by a suitably trained and qualied

individual HETAS registered in the United Kingdom (or equivalent in other countries) with a

certicate of installation and the appropriate commissioning report completed and retained

by the end-user.

It is also a condition of the Extended Warranty that your Oak Stoves is regularly serviced

(every 12 months) by a suitably trained and qualied individual (HETAS registered) in the

United Kingdom (or equivalent in other countries). Records and receipts of annual services

will be required in the event of a warranty claim during the period of the extended warranty.

This warranty is not transferable and is extended only to, and solely for, the benet of the

original purchaser of the stove. Please retain your dated sales receipt as a proof of purchase.

During your extended warranty period, only genuine Oak spare parts must be used in the

servicing and maintenance of your stove, these spare parts can be ordered via the Premium

Retailer directly.

Consumable items such as glass, paint, grate parts, log retainers, bafes, ash pans, internal

re brick linings, and rope seals which are either subject to normal wear and tear or parts that

require replacement in connection with normal maintenance are not covered, either by the

original or the Extended Warranty.

Should you experience problems with your stove, any claim must be submitted rst to the

Premium Retailer from where the stove was purchased. Your Premium Retailer will either be

able to offer immediate assistance or make contact with Oak Stoves on your behalf.

Warranty Exclusions and Limitations

No Warranty is extended to consumable service parts. Repair or replacement of parts which

are subject to normal wear and tear during the warranty period or parts that will require

replacement in connection with normal maintenance. Such parts include but are not limited

to glass, paint, rope seals, rebricks, grate parts, log retainers, bafes and ash pans.

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

21

Installation Instructions

The Oak Stoves Extended Warranty does not cover:

a) In normal usage the paint nish of your Oak Stove may change colour slightly. As these circumstances

are considered normal, they are not covered by the warranty.

b) Enamelled components where these parts are subjected to abnormally high temperatures, chemical

abrasion or thermal shocks, resulting in chipping, cracking, bubbling or discolouration and crazing of

the enamelled nish.

c) Damage resulting from installation and usage where the appliance has not been installed or used

in accordance with the Oak Stoves installation and operation instructions, or if the installation does

not conform to local building, re and safety regulations.

d) Defects or faults caused by specic local conditions such as draught problems, water damage,

condensation and chimney defects.

e) The Extended Warranty does not cover damage caused by over-ring of the appliance. (Please

see your Installation and Operating Instructions for further information)

f) Damage or premature wear caused by burning inappropriate fuels such as Bituminous coal, “PetroCoke” or any other Petroleum based coals, only smokeless approved fuels must be used. Please

visit the HETAS website, www.hetas.co.uk, for a full list of approved fuels which are covered by the

warranty. Fuels outside of this list are not covered by the warranty.

g) Damage caused by burning material with high creosote content or any other painted/treated timber.

h) Damage caused by unauthorised modications, use or repair.

i) Damage or defects caused by the product being stored in a damp, unheated environment.

j) Consequential loss (to the extent permitted by law) relating to other associated products that have

not been supplied by Oak Stoves.

k) Consequential loss (to the extent permitted by law) related to decorations, furnishings or other

household assets.

l) Delivery to/or return transport costs. Removal and re-installation costs or any labour cost to t parts.

Repaired or replaced products are covered only for the remainder of the original warranty

period. If you should ever wish to make a warranty claim because of a product fault or defect,

you must inform your retailer within a reasonable amount of time, this is within 14 days from

the date on which the fault or defect rst became apparent. If the product fault or defect is

notied after 14 days from the date on which the fault or defect became apparent, Oak Stoves

cannot accept any liability for events or issues which arise after the 14 day period or which

are caused or increased by the lack of notication which therefore prevented action being

taken to restrict or eliminate any consequences arising from the fault or defect at an earlier

date.

In the event of a product fault occurring during the warranty period, Oak Stoves will send the

appropriate component or goods necessary to rectify the fault, free of charge. but does not

cover any labour cost to t them. Nothing in the Extended Warranty shall make Oak Stoves

liable for any or special, incidental or consequential damages, injury to persons or property,

or any other consequential loss beyond the consumer’s statutory rights. The liability on these

issues is covered by Oak Stoves Terms and Conditions of Sale.

Oak Stoves’ total liability extends only to the purchase price paid for the goods by the Premium

Retailer, except where such a limitation is prohibited by statute. Oak Stoves, in the event of

a warranty claim, reserve the right to either replace the goods in question or to refund the

purchase price of the goods as paid by the Premium Retailer.

The Oak Stoves Extended Warranty does not affect your statutory rights. The above warranty

terms and conditions came into effect on 1st January 2013 and are applicable for all relevant

products purchased after this date.

Please note: This warranty is applicable for purchases within the United Kingdom and the

Republic of Ireland.

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

22

DEFRA Requirements

DEFRA Requirements – using this stove in Designated Smoke Control Areas

The Zeta 5Kw range are DEFRA exempt so they can be used to burn well seasoned wood in a smoke free zone

(designated smoke control area).

The Zeta 5 range is also a multi-fuel stove so smoke fuel mineral fuels can also be burn on the stove in

designated smoke free zone (designated smoke control area).

The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole or part of the district of the authority to be a

smoke control area. It is an offence to emit smoke from a chimney of a building, from a furnace or from any xed

boiler if located in a designated smoke control area. It is also an offence to acquire an “unauthorised fuel” for

use within a smoke control area unless it is used in an “exempt” appliance (“exempted” from the controls which

generally apply in the smoke control area.

The Secretary of State for Environment, Food and Rural Affairs has powers under the Act to authorise smokeless

fuels or exempt appliances for use in smoke control areas in England. In Scotland and Wales this power rests

with Ministers in the devolved administrations for those countries. Separate legislation, the Clean Air (Northern

Ireland) Order 1981, applies in Northern Ireland.

Therefore it is a requirement that fuels burnt or obtained for use in smoke control areas have been “authorised” in

Regulations and that appliances used to burn solid fuel in those areas (other than “authorised” fuels) have been

exempted by an Order made and signed by the Secretary of State or Minister in the devolved administrations.

Further information on the requirements of the Clean Air Act can be found at:

http://smokecontrol.defra.gov.uk/

Your local authority is responsible for implementing the Clean Air Act 1993 including designation and supervision

of smoke control areas and you can contact them for details of Clean Air Act requirements

Recommend Fuels for use in a Designated Smoke Control Areas

The Zeta 5 multi-fuel stove appliance has been recommended as suitable for use in smoke control areas when

burning:

• Well seasoned woods with a moisture content less than 20%. (If you are unsure of the moisture content in the

wood you can buy a moisture tester from you local stove retailer these on average cost less than £20)

• Smokeless Mineral Fuels. Such as ANCIT. When purchasing these products it will state on the packaging that

it is suitable for use in a designated smoke control areas

Please refer to page 6 for more details.

Refuelling on to a low re bed

If there is insufcient burning material in the re-bed to light a new fuel charge, excessive smoke emission can

occur. Refuelling must be carried out onto a sufcient quantity of glowing embers and ash that the new fuel

charge will ignite in a reasonable period. If there are too few embers in the re bed, add suitable kindling to

prevent excessive smoke

Fuel overloading

The maximum amount of fuel specied in this manual should not be exceeded, overloading can cause excess

smoke. Please refer to page 9.

Do Not Operate this appliance with door left open. Operation with the door open can cause excess smoke. The

appliance must not be operated with the appliance door left open.

Air controls (primary, secondary and tertiary air controls)

The air controls must be used in accordance with this manual as detailed on pages 8 to 11.

Installation Instructions

Zeta 5W Series Manual - V2.8 © Oak Stoves 2018

23

What comes with your stove?

Manual

Stove body with door and handle tted

Ash pan

Ash pan handle

Protective gloves

Flue collar

Fire grate retainer bars

Riddle grate handle bar

Oak Stoves, Unit 11, Village Farm Industrial Estate, Village Farm Road, Pyle, Bridgend, CF33 6BL

t: +44 (0)845 644 2815 e: sales@oakstoves.co.uk w: www.oakstoves.co.uk

1 Supplier name or trademark Oak Stoves

2 Model identier Zeta Log Store Clean

Burn Stove

3 Energy class A+

4 Direct heat output 4.9kW

5 Indirect heat output N/A

6 Energy efciency index 102.2%

7 Energy efciency at nominal heat output 76.7%

8 Specic precautions See Manual

1 Supplier name or trademark Oak Stoves

2 Model identier Zeta Pedestal Clean

Burn Stove

3 Energy class A+

4 Direct heat output 4.9kW

5 Indirect heat output N/A

6 Energy efciency index 102.2%

7 Energy efciency at nominal heat output 76.7%

8 Specic precautions See Manual

1 Supplier name or trademark Oak Stoves

2 Model identier Zeta Compact Clean

Burn Stove

3 Energy class A+

4 Direct heat output 4.9kW

5 Indirect heat output N/A

6 Energy efciency index 102.2%

7 Energy efciency at nominal heat output 76.7%

8 Specic precautions See Manual

Loading...

Loading...