Page 1

ENMET Corporation

PO Box 979

Ann Arbor, MI 48106-0979

Operation & Maintenance Manual

TARGET Series

Portable Gas Detector

Manual Part Number

80012-014

MCN-380, 11/07/07

Page 2

Table of Contents

1.0 Introduction.................................................................................................................................................. 1

1.1 Warnings and Cautions...............................................................................................................................................1

1.2 Unpack.......................................................................................................................................................................1

1.3 Check Order...............................................................................................................................................................2

1.4 Serial Numbers...........................................................................................................................................................2

2.0 TARGET Features.......................................................................................................................................... 2

2.1 Sensors.......................................................................................................................................................................2

2.2 Other features include:................................................................................................................................................2

2.4 Locations and Data logging.........................................................................................................................................4

3.0 Instrument Operation................................................................................................................................... 4

3.1 Turning the Instrument On and Off.............................................................................................................................4

3.1.1Turning the TARGET On .......................................................................................................................................4

3.1.2 Turning the TARGET Off ......................................................................................................................................4

3.2 Charging the Battery...................................................................................................................................................5

3.3 Display Backlight.......................................................................................................................................................6

3.4 Alarms .......................................................................................................................................................................6

3.4.1 Instantaneous Gas Alarm.....................................................................................................................................6

3.4.2 STEL/TWA Alarms...............................................................................................................................................6

3.4.3 Over-range and Under-range Alarms...................................................................................................................7

3.4.4 Low Battery.........................................................................................................................................................7

3.4.5 Fault....................................................................................................................................................................7

3.5 Pop-Up Menu.............................................................................................................................................................7

3.5.1 Auto-Zero ............................................................................................................................................................7

3.5.2 Calibration Status................................................................................................................................................8

3.5.3 Combustible Gas Display.....................................................................................................................................8

3.5.4 Locations.............................................................................................................................................................8

3.5.5 Internal Sampling Pump.......................................................................................................................................9

4.0 Basic User Operation................................................................................................................................. 10

4.1 Date/Time/Battery Information.................................................................................................................................10

4.2 Alarms Values..........................................................................................................................................................10

5.0 Advanced User Operation ......................................................................................................................... 11

5.1 Date/Time/Battery Information.................................................................................................................................11

5.2 Alarms Values..........................................................................................................................................................11

5.3 Min/Max Values.......................................................................................................................................................11

5.4 TWA Values ............................................................................................................................................................11

5.5 STEL Values............................................................................................................................................................11

6.0 Maintenance Operations............................................................................................................................ 12

6.1 Recommendations....................................................................................................................................................12

6.2 Standard Maintenance Menu.....................................................................................................................................12

6.3 Calibration ...............................................................................................................................................................12

6.3.1 Calibration Menu...............................................................................................................................................12

6.3.2 Zero Adjust........................................................................................................................................................13

6.3.3 Applying Span Gas.............................................................................................................................................13

6.4 Advanced Maintenance Menu, Software 4.94 version................................................................................................15

6.4.1 Calibration........................................................................................................................................................15

6.4.2 Setting Instantaneous Alarms .............................................................................................................................15

6.4.3 Enable Sensors...................................................................................................................................................16

6.4.4 Set Clock/Chirp..................................................................................................................................................16

6.4.5 Set Password......................................................................................................................................................16

6.4.6 Set Battery Type.................................................................................................................................................17

6.4.7 Set Operation Menu...........................................................................................................................................17

6.4.8 Internal Pump Calibration .................................................................................................................................17

6.4a Advanced Maintenance Menu, Software 6.0 version................................................................................................18

6.4a.1 Calibration ......................................................................................................................................................18

6.4a.2 Setting Instantaneous Alarms ...........................................................................................................................18

6.4a.3 Enable Sensors.................................................................................................................................................19

6.4a.4 Internal Pump Calibration ...............................................................................................................................19

Page 3

6.5 Replacing Battery Pack.............................................................................................................................................20

6.6 Replacing Internal Pump...........................................................................................................................................20

6.7 Replacing Sensors ....................................................................................................................................................21

7.0 Instrument Information.............................................................................................................................. 22

7.1 Replacement Parts List.............................................................................................................................................22

7.2 Target Specifications ................................................................................................................................................23

8.0 Default Alarm and Configurations............................................................................................................. 24

9.0 Flow Diagrams........................................................................................................................................... 25

9.1 Basic Operation Menu..............................................................................................................................................25

9.2 Standard Maintenance Menu.....................................................................................................................................26

9.3 Advanced Operation Menu .......................................................................................................................................27

9.4 Advanced Maintenance Menu, Software 4.94 version................................................................................................28

9.4 Advanced Maintenance Menu, Software 6.0 version..................................................................................................29

10.0 Troubleshooting....................................................................................................................................... 30

11.0 WARRANTY.............................................................................................................................................. 31

List of Figures and Tables

F

IGURE

1: F

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

T

ABLE

T

ABLE

F

IGURE 8A

F

IGURE

F

IGURE

F

IGURE 9A

F

IGURE

F

IGURE

T

ABLE

T

ABLE

T

ABLE

RONT VIEW

2: S

ENSOR VIEW

3: T

OP VIEW

4: B

OTTOM VIEW

5: M

AIN GAS DISPLAY

6: I

NSERT CHARGE JACK

7: R

EMOVE CHARGE JACK

1: B

ATTERY LIFE

2: P

ROGRAMMED FLAMMABLE GAS COEFFICIENTS

: C

ALIBRATION SHIELD ATTACHMENT

8: V

ARIOUS CALIBRATION ADAPTER ATTACHMENTS

9: R

EPLACING BATTERY PACK AND INTERNAL PUMP

: R

EPLACING INTERNAL PUMP FOR INSTRUMENTS WITH S/N

10: R

EMOVE SHORTING CLIP

11: R

EPLACING SENSORS

3: D

EFAULT ALARM

4: D

EFAULT CONFIGURATION

5: T

ARGET MENU QUICK REFERENCE

.........................................................................................................................................................3

.......................................................................................................................................................3

............................................................................................................................................................3

......................................................................................................................................................3

..............................................................................................................................................3

...........................................................................................................................................5

.........................................................................................................................................5

.......................................................................................................................................................6

.....................................................................................................8

.................................................................................................................13

...............................................................................................14

..............................................................................................20

0699

AND BELOW

.......................................................20

...................................................................................................................................21

.......................................................................................................................................21

.................................................................................................................................................24

...................................................................................................................................24

.......................................................................................................................25

Reference Information:

N

OTE

: [important information about use of the instrument.]

C

W

ARNING

AUTION

: [affects equipment – if not followed may cause damage to instrument, sensor etc…]

:

[affects personnel safety – if not followed may cause bodily injury or death.]

Page 4

TARGET Series ENMET Corporation

1.0 Introduction

1.1 Warnings and Cautions

The TARGET Series gas detectors are designed to detect hazardous atmospheric conditions. An indication of life

threatening hazards should be taken very seriously. NEVER ignore an alarm condition.

W

ARNINGS

C

N

OTE

1.2 Unpack

:

• Any rapid upscale combustible gas reading followed by a declining or erratic reading may indicate a gas

concentration beyond the upper-scale limit. This may indicate a flammable concentration.

• Off-scale readings may indicate a flammable concentration.

• Electromagnetic interference (EMI) signals may cause incorrect operation.

• CSA requirement: Before each day’s usage, instrument sensitivity must be tested on a known concentration of

methane between 25-50% LEL. Accuracy must be within –0 to +20% of the actual concentration applied.

Accuracy may be corrected, if necessary, by performing sensor calibration.

• Oxygen deficient conditions can cause lower combustible gas readings than actual concentrations.

• Oxygen enriched conditions can cause higher combustible gas readings than actual concentrations.

• The instrument batteries should only be charged in a non-hazardous location.

• The instrument should only be connected to a computer in a non-hazardous location.

AUTIONS

Any sensor that fails calibration procedures should be replaced and recalibrated immediately.

The combustible portion of this instrument has been assessed by CSA for performance. Users may refer to ANSI/ISA

RP12.13 or an equivalent international recommended practice for guidance in the use of combustible gas detection

equipment.

TARGET instruments with a CSA logo on the serial number label are approved for Intrinsic Safety when used in Class

1, Division 1, Group A, B, C, D Hazardous Location environments.

:

• In case of an atmospheric alarm condition, follow your organization’s established procedures for such a situation.

Evacuating the affected area is usually the first course of action, followed by ventilation and re-testing of the

environment prior to re-entry.

• Silicone compound vapors may adversely affect the TARGET instrument’s standard combustible sensor causing

lower readings than actual concentrations. If the instrument has been exposed to silicone vapors it is strongly

recommended that the instrument be recalibrated prior to its next use. Repeated exposure to silicone compounds

will prematurely destroy the standard combustible sensor.

NOTE: The optional MOS combustible sensor is much less susceptible to silicone poisoning, but instrument

calibration should take place on a more frequent schedule.

• The sensor sampling area must be kept clean. Contamination of this area can prevent proper operation of the

sensors.

: Any specifications stated in this manual may change without notice.

Unpack the TARGET Series instrument and examine it for shipping damage. If such damage is observed, notify both

ENMET customer service personnel and the commercial carrier involved immediately.

Regarding Damaged Shipments

N

OTE

: It is your responsibility to follow these instructions. If they are not followed, the carrier will

not honor any claims for damage.

This shipment was carefully inspected, verified and properly packaged at our company and delivered to the

carrier in good condition.

When it was picked up by the carrier at ENMET, it legally became your company’s property.

If your shipment arrives damaged:

• Keep the items, packing material, and carton “As Is.” Within 5 days of receipt, notify the carrier’s local office

and request immediate inspection of the carton and the contents.

• After the inspection and after you have received written acknowledgment of the damage from the carrier,

contact ENMET Customer Service for return authorization and further instructions. Have your Purchase Order

and Sales Order numbers available.

1

Page 5

TARGET Series ENMET Corporation

ENMET either repairs or replaces damaged equipment and invoices the carrier to the extent of the liability

coverage, usually $100.00. Repair or replacement charges above that value are your company’s responsibility.

The shipping company may offer optional insurance coverage. ENMET only insures shipments with the

shipping company when asked to do so in writing by our customer. If you need your shipments insured, please

forward a written request to ENMET Customer Service.

Regarding Shortages

If there are any shortages or questions regarding this shipment, please notify ENMET Customer Service within 5 days

of receipt at the following address:

ENMET Corporation

680 Fairfield Court

Ann Arbor, MI 48108

734-761-1270 734-761-3220 Fax

1.3 Check Order

Check, the contents of the shipment against the purchase order. Verify that the TARGET Series instrument is received

as ordered. Follow the procedure outlined in paragraph 2.0 to determine your instrument configuration. If there are

accessories on the order, ascertain that they are present. Check the contents of calibration kits. Notify ENMET

customer service personnel of any discrepancy immediately.

1.4 Serial Numbers

Each TARGET Series instrument is serialized. These numbers are on tags on the equipment and are on record in an

ENMET database.

2.0

TARGET

Features

2.1 Sensors

The TARGET Series by ENMET Corporation is a multi-gas portable instrument that may be configured with one to six

sensors. Sensors include:

• Oxygen

• Flammable

• Broad Range Hydrocarbon Toxic MOS (Metallic Oxide Semiconductor) Sensor

• Carbon monoxide

• Hydrogen sulfide

• Ammonia, Sulfur dioxide, Chlorine and many more will be available soon.

2.2 Other features include:

• Metal enclosure for improved durability

• RFI resistant design

• Four line display with backlight

• Push-button calibration procedure

• Programmable combustible sensor

• Optional internal sampling pump

• Audible alarms

• Visual alarm for each sensor

• Dual alarm levels for Toxic and Combustible gases

• Oxygen deficiency and enrichment alarms

• Maximum and Minimum tracking of gas readings

• Peak hold

• Latching alarms

• STEL and TWA alarms

• Datalogging

• Calibration reminder

• Intrinsically safe by design. CSA approved.

• CE approval pending

2

Page 6

TARGET Series ENMET Corporation

BRH

Menu

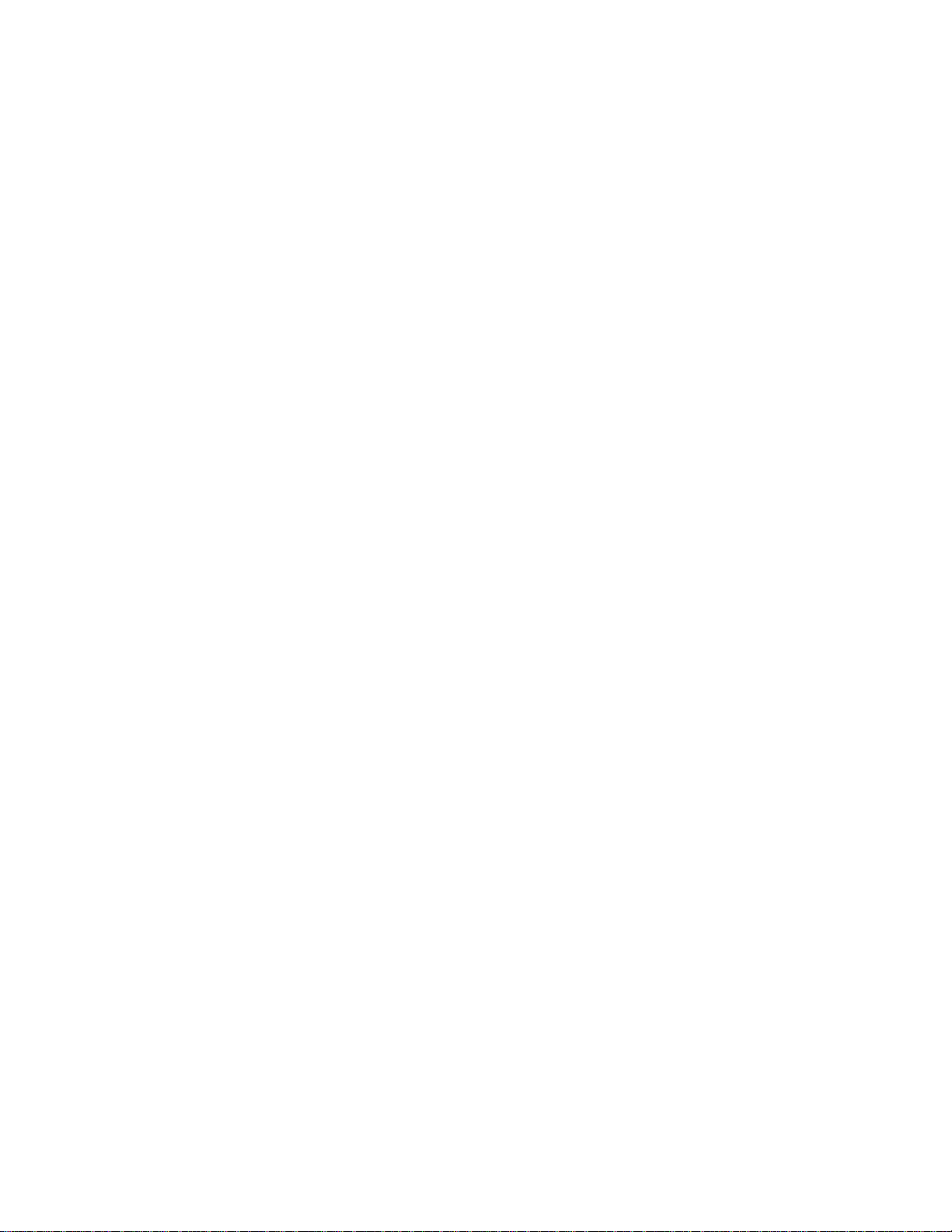

See Figures 1 and 2

Visual Alarms There are visual alarms for each of the gas sensors installed.

Display 4 line by 20 character dot-matrix LCD with on-demand back light.

I/O and Charging Port Connector for battery charger, computer cable, remote annunciator cable, and earphone.

Visual alarms

Display

Display

See Figures 3 and 4

Horn Audio Alarm

ON/OFF Button Power button and back light

SELECT Button SELECT button and audio defeat

MENU Button MENU button

Gasket For sealing instrument enclosure

Oxygen

Combustible

Tox 2

I/O and Charging Port

Figure 1: Front View Figure 2: Sensor View

Tox 1

Gasket

Gasket

On/Off

Button

Horn

Select

Button

Button

Dust Cap

Figure 3: Top View Figure 4: Bottom View

02 20.9%

CO 0ppm H2S 0ppm

Mth0%LEL BRH 0ppm

Status Line

Figure 5: Main Gas Display

Belt Clip

3

Page 7

TARGET Series ENMET Corporation

2.4 Locations and Data logging

The TARGET instrument has the ability to store users or location information and log exposure information. TARGET

Trakker software is required for these operations. Further details on its operation and interaction with the instrument is

provided in software manual. If desired, contact ENMET or your local distributor.

3.0 Instrument Operation

3.1 Turning the Instrument On and Off

3.1.1Turning the TARGET On

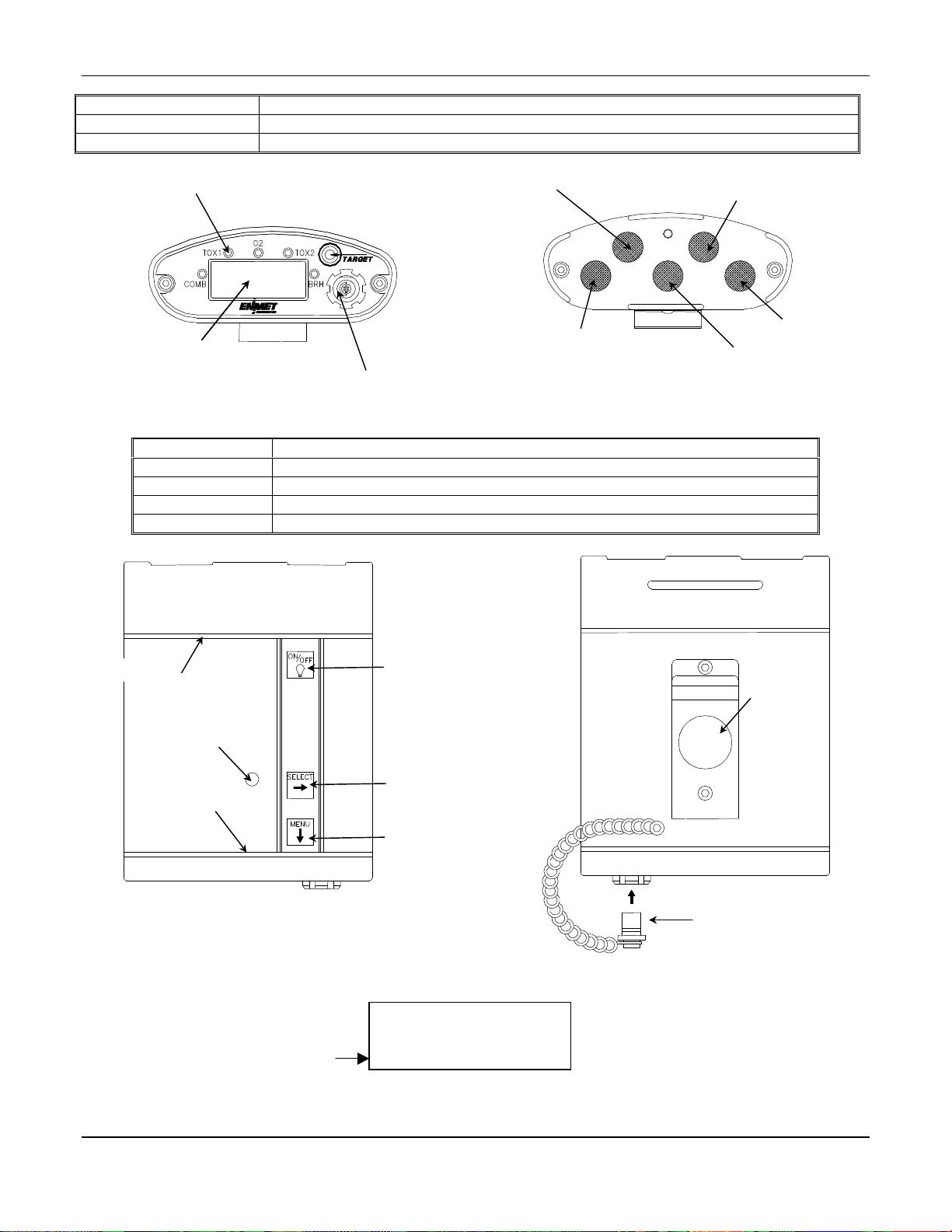

Press and hold the ON/OFF button. The audio alarm may squeal slightly while holding the ON/OFF button. This is

normal. When the instrument turns on, it beeps once and all of the alarm LEDs light up. The TARGET performs a one

minute warm-up procedure which includes a self test, checking sensor signals and instrument electronics. At the end

of the one minute warm-up procedure, the instrument will beep several times before giving the user the option to

perform an auto zero function, or other functions that appear in the Pop-Up menu. See section 3.5 for further

information.

ENMET CORP

TARGET Series

GAS MONITOR

Rev:3.0-3.1

02 20.9%

CO 0ppm H2S 0ppm

Mth0%LEL BRH 0ppm

Warming up...30

Example: Warm-up Displays

3.1.2 Turning the TARGET Off

Press and hold the ON/OFF button for approximately three seconds. The instrument shows a three second count

down and beeps just before shutting down. To protect the user from accidental shut down, the ON/OFF button must

be held for the duration of the three second count down. The audio alarm beeps once to indicate instrument shut

down.

POWER DOWN SEQUENCE

Press and hold power

switch for 3sec

2

Example: Power Down Display

4

Page 8

TARGET Series ENMET Corporation

♦

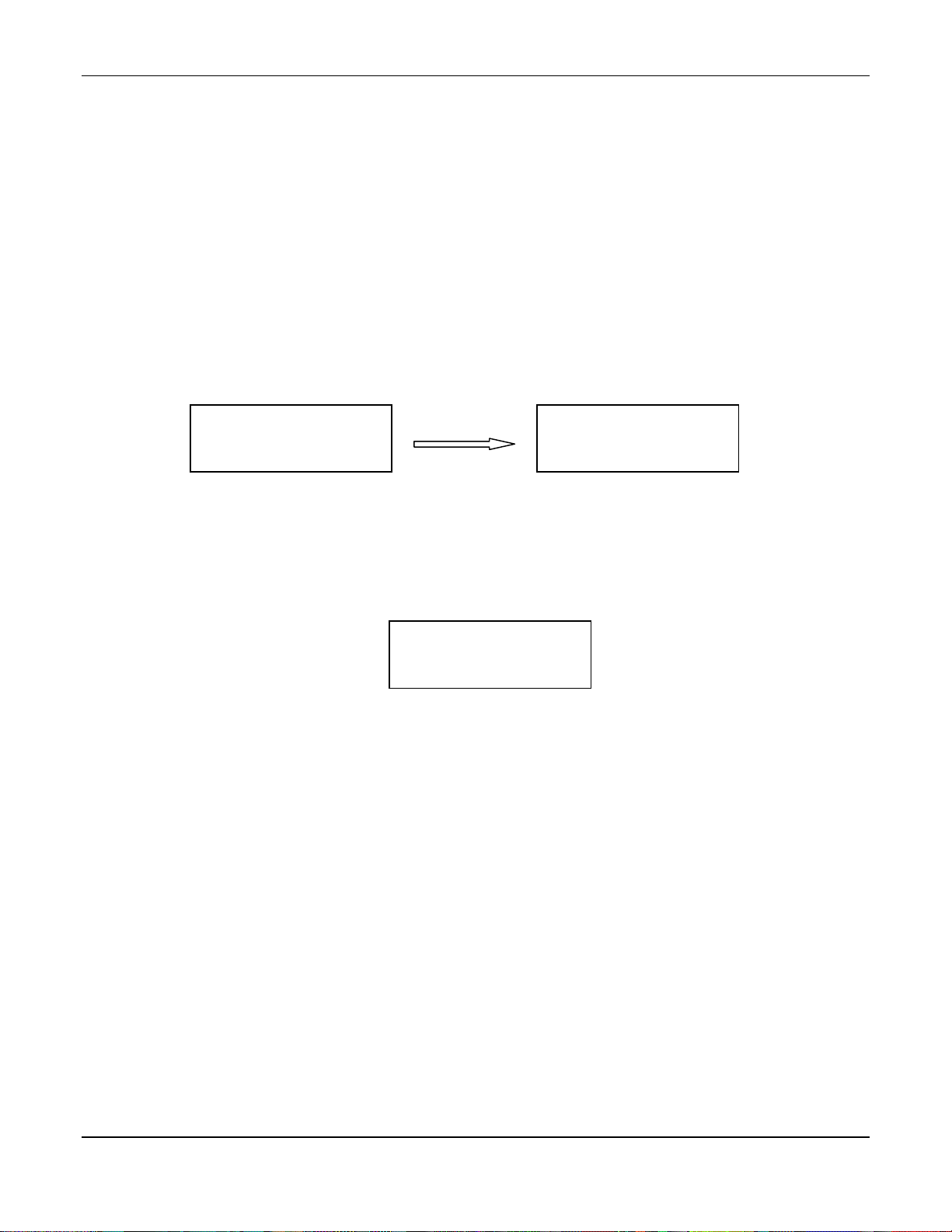

3.2 Charging the Battery

W

ARNING

:

Never charge the TARGET instrument in a hazardous location

The TARGET instrument has a 4.8 volt, nickel metal hydride (NiMH) battery pack. The supplied battery charger charges

the instrument batteries usually in three to four hours. The charger is supplied with a power cord for connection to 110

VAC wall outlet. The batteries may also be charged in the same time frame with a 12 VDC vehicle accessory adapter.

Instrument electronics protect alkaline battery packs from being charged by the TARGET battery charger.

N

OTE

: The connector is keyed and will only go in one way.

Grasp by ridged portion of

connector

♦ If cable is pulled connector

may be damaged

Figure 6: Insert Charge Jack Figure 7: Remove Charge Jack

Plug the battery charger into the wall and then plug

the charger connector in to the I/O and charging

port on the front of the TARGET instrument. See

figures 6 and 7.

Once inserted, the instrument’s display activates

and shows the charge status:

When the batteries are fully charged, the following

is displayed providing information on charge time,

capacity and status:

Example: Display, Battery Charging

BATTERIES CHARGING

Charge started:

May 15 1999 5:29:00 pm

Chrg:25% Time: 0:01

CHARGING DONE

Charge started:

May 15 1999 5:29:00 pm

Chrg:100% Time: 3:15

Example: Display, Charging Complete

N

OTE

: While charging the batteries, the instrument enclosure becomes warm to the touch. The instrument electronics

detect peak battery charge and stop charging at the appropriate time. Once charging is complete, the enclosure will

cool to room temperature.

The instrument may be left indefinitely on the charger. It is recommended to do so, to keep the battery pack at full

charge.

C

AUTION

: When removing the charge jack be sure to grab onto only the ribbed portion of the connector, otherwise the

connector will not release. See Figure 7.

5

Page 9

TARGET Series ENMET Corporation

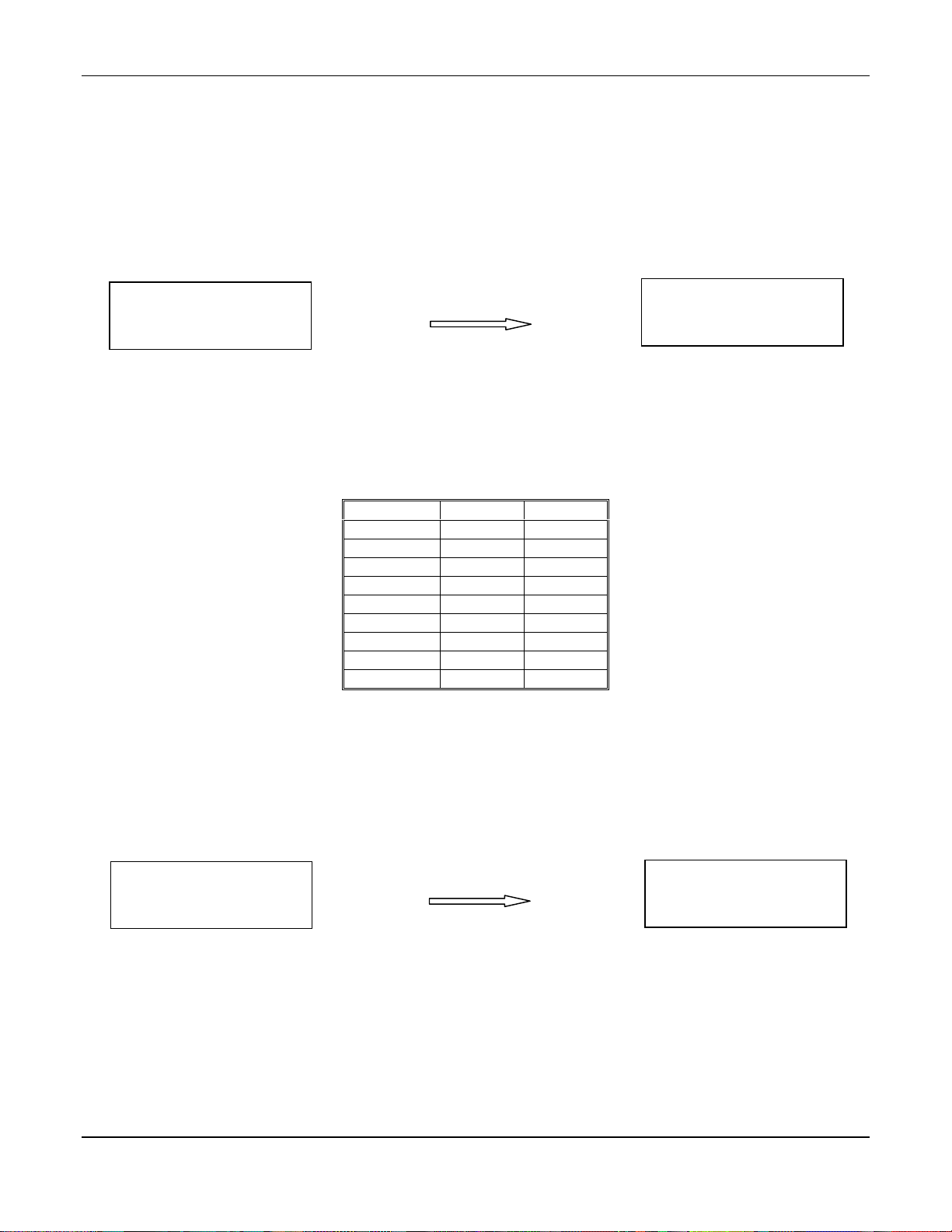

Table 1: Battery Life

Normal operation with standard sensors

Normal operation with BRH toxic sensor installed

Or while using the optional internal pump.

Normal operation with the BRH sensor and optional

internal pump.

A fully charged NiMH battery pack may provide up to 18 hours

of operation. It may take several charge and discharge cycles to

achieve optimal battery performance.

If the BRH toxic gas sensor is installed or the internal motorized

sample pump is used continuously, instrument operation time is

reduced.

Typical operation time with the BRH sensor or the activated

internal pump is 11 hours.

Operation time with both the BRH sensor and pump activated is

approximately 8 hours.

3.3 Display Backlight

The TARGET display backlight automatically activates during an alarm condition. To manually activate the backlight,

quickly press and release the ON/OFF button. The backlight remains on for approximately 30 seconds.

3.4 Alarms

Never ignore an alarm condition!

procedures for such a situation. If the cause of the alarm is an atmospheric condition, evacuating the affected area is

usually the first course of action, followed by ventilation and re-testing of the environment prior to re-entry.

If an alarm for any sensor is acknowledged (silenced), the audio alarm reactivates in case of an additional alarm

condition for that sensor or any others occur.

In case of an alarm condition, follow your organization’s established

3.4.1 Instantaneous Gas Alarm

The TARGET Series instrument has two levels of instantaneous alarm for each installed sensor. For the oxygen

channel, the alarms are for oxygen deficiency and enrichment. For the toxic and combustible sensors, there are low

and high alarms. Default alarm values are shown in Section 9. Values in the instrument may be viewed by entering

the Operational Menu. See Section 4.2 or 5.2. All instantaneous alarms are latching and continue to activate audio

and visual indicators until they are acknowledged by pressing the SELECT button. If an alarm is acknowledged,

visual indication continues until the condition clears.

The low level alarm for toxic and combustible gases is identified by a flashing LED and a pulsed audio tone. The

audio alarm may be acknowledged and silenced by pressing the SELECT button. If the alarm condition doesn’t clear,

the audio alarm will reactivate in 10 minutes.

The high level alarms for toxic and combustible gases is identified by a steady LED and a continuous audio tone. The

oxygen alarms act in this same manner. The audio alarm may be acknowledged and silenced by pressing the

SELECT button. If the alarm condition doesn’t clear, the audio alarm will reactivate in 5 minutes.

During either instantaneous alarm condition, the display automatically peak holds the highest concentration of the

affected sensor until the alarm is acknowledged. If a low level “pulsed” alarm occurs, and is acknowledged, the audio

alarm reactivates as a steady tone if the high level alarm level is exceeded.

3.4.2 STEL/TWA Alarms

The STEL and TWA alarms are present for the TOX1 and TOX2 sensors. Default alarm values are shown in Section

9. Values in the instrument may be viewed by entering the Operational Menu. See Section 4.2 or 5.2.

A STEL or TWA alarm is identified by a steady LED and continuous audio tone. The status line of the LCD shows

the type of alarm. The audio alarm may be acknowledged and silenced by pressing the SELECT button. If the alarm

condition doesn’t clear, the audio alarm will reactivate in 5 minutes.

6

Page 10

TARGET Series ENMET Corporation

3.4.3 Over-range and Under-range Alarms

The over-range alarm activates audio and visual alarms. It can occur if the instrument is exposed to a gas

concentration higher than its display range. Over-range alarms cannot be acknowledged. An alarm for the Toxic or

Oxygen sensors clears once the over-range condition clears. The over-range alarm for the combustible sensor is

latching and will not clear until the instrument has been removed from the affected area, turned off and turned on in an

environment less than 100 %LEL. Under range conditions can occur if an instrument is auto-zeroed or calibrated in an

area with background levels of gas. Under range alarms can be cleared by performing an auto-zero function as

described in Section 3.5.1.

The over-range condition is indicated by OVERNG shown in the affected sensor location on the display. Under-range

is indicated by UNDRNG.

3.4.4 Low Battery

The TARGET Series instrument has a low battery alarm to provide the user with adequate warning of a low battery

condition. The instrument provides a steady tone audio alarm when there is approximately 15 to 30 minutes of battery

life left. A low battery warning message is displayed on the status line of the instrument LCD. The audio alarm can

be acknowledged by pressing the SELECT button. The audio alarm and backlight reactivate after approximately five

minutes. See section 3.2 for battery charging procedure.

3.4.5 Fault

Fault alarms have a steady audio alarm and are displayed on the status line of the LCD. The status line describes the

fault condition and appropriate action should be take to resolve the issue. See section 11 for troubleshooting

information.

3.5 Pop-Up Menu

The Pop-Up menu is displayed after the one minute instrument warm-up procedure. The instrument beeps several

times prior to showing this display. The Pop-Up menu provides the user the ability to perform an auto-zero, check the

last date of calibration, change the combustible gas display, set user locations and activate/deactivate the optional

internal pump, if installed.

POP-UP MENU

*Auto-Zero Comb disp

Cal Stat Location

Set Pump ON

Example: Pop-Up Menu

N

OTE

: The Pop-Up menu can be accessed at any time during normal instrument operation by pressing and holding the

MENU button for approximately two seconds while the instrument is at the Main Gas display.

3.5.1 Auto-Zero

To compensate for sensor aging and drift, the TARGET instrument has an Auto-Zero function. Zeroing the instrument

sets all gas readings to zero and sets the oxygen to 20.9%.

environment

.

To perform an Auto-Zero, press and hold the Menu button to enter the Pop-Up menu. Note the asterisk next to Auto-

Zero. Press the SELECT button. The instrument electronically compensates all sensor readings. OK is displayed

next to all sensors where valid adjustments are made. The sensor readings must be within an acceptable range when

the Auto-Zero function is initiated, otherwise FAIL or ERR is displayed next to the affected sensor.

POP-UP MENU

*Auto-Zero Comb disp

Cal Stat Location

SELECT

This function must be performed in a fresh air

O2 : OK

CO : OK

H2S: OK

Mth: OK BRH: OK

Example: Display, Auto-Zero from Pop-Up Menu

7

Page 11

TARGET Series ENMET Corporation

3.5.2 Calibration Status

The TARGET instrument keeps track of the date of last calibration for each sensor. To view the last calibration date,

press and hold the Menu button to enter the Pop-Up menu. Press the MENU button two times to move the asterisk to

the Cal Status position, then the SELECT button once to select the Calibration Status screen. The display shows

the status of up to three sensors. Press the SELECT button to view the remaining sensors. If any of the sensors are

overdue for calibration, Calibration due is displayed next to it. If a sensor has failed a calibration, Cal error is

displayed next to appropriate sensor.

N

OTE

:

OK appears next to each sensor that has been calibrated within the last 90 days.

Field tests must still be

performed to confirm the performance status of each sensor.

Auto-Zero Comb disp

POP-UP MENU

*Cal Stat Location

SELECT

SENSOR CAL STATUS

O2 OK May 15 1999

CO Calibration due

H2S OK May 15 1999

Example: Display of Calibration Status

3.5.3 Combustible Gas Display

Combustible gases vary considerably with respect to their flammable nature. Some gases are flammable at lower

concentrations than others. The TARGET instrument has ten flammable gases response characteristics programmed in

memory. Each gas has a different coefficient (K) that is used to compensate the instrument display:

Table 2: Programmed Flammable Gas Coefficients

Methane Mth K=1.00

Propane Prp K=1.88

Butane Btn K=2.04

Pentane Pnt K=2.30

Hexane Hxn K=2.35

Hydrogen H2 K=1.24

Ethane Eth K=1.54

Benzene Bnz K=2.51

Toluene Tln K=2.47

Xylene Xyl K=2.99

The combustible sensor cannot determine which gas is present. When the combustible gas is unknown, it is

recommended to change the display to higher K (coefficient) value gas. Hexane or Xylene may not be the gases

present, but using their K value substantially increase, the instrument’s sensitivity to flammable gases.

To select a different combustible gas display, press and hold the Menu button to enter the Pop-Up menu. Press the

MENU button three times to move the asterisk to the Comb disp position. Press the SELECT button once to choose

this screen. Press the MENU button to sequence through the list shown in Table 2. The instrument automatically

changes the combustible display to the last one displayed.

Auto-Zero *Comb disp

POP-UP MENU

Cal Stat Location

SELECT

SET COMB GAS DISPLAY

Select type:

MTH(K=1.00)

Example: Display, Combustible Gas

3.5.4 Locations

The TARGET instrument has the ability to store user name or locations. They are entered into the instrument using the

TARGET Trakker software package, see section 7.0 for part number information. Set in accordance with software

manual.

8

Page 12

TARGET Series ENMET Corporation

3.5.5 Internal Sampling Pump

If the TARGET instrument has the optional internal sampling pump installed, the Pop-Up menu provides the ability to

turn the pump on and off.

C

AUTION

: Some gases require that the pump be on for proper detection and calibration.

See Section 8.0, Tables 3 and 4.

To turn the pump on or off:

Press and hold the Menu buttons to enter the Pop-Up menu.

Press the MENU button five times to move the asterisk to the Pump position.

Press the SELECT button once to choose this screen.

Press the SELECT button to turn the pump on

Press the MENU button to turn the pump off.

POP-UP MENU

Auto-Zero Comb disp

Cal Stat Location

*Set Pump ON

SELECT

SAMPLING PUMP

SELECT=ON MENU=OFF

Current state: OFF

Example: Display, Internal Pump Status

If the pump is off, the bottom line of the display says “Set Pump ON”.

If the pump is on, the bottom line of the display says “Set Pump Off”.

N

OTE

:

The Pump feature is only displayed in the Pop-Up menu if the instrument is supplied with the optional internal

sampling pump.

Attach the sampling shield supplied with the instrument, to the bottom of the instrument in the same manner as the

calibration shield, see Figure 8. The calibration shield has a orange label. The sampling shield has an yellow label.

Attach the supplied 20 foot sampling hose or the optional 2 foot sampling wand to the hydrophobic filter on the back

of the shield.

Sensor response time, if the tubing is 20 feet long, allow at least 10 seconds for the test sample to make it through the

tubing. The sensor response time is typically 30 – 60 seconds to achieve 90% of the final reading, depending on the

specific sensor and the gas being detected. Therefore, the total 'system' response time for an instrument using the

internal sampling pump and 20 feet of hose is approximately 40-70 seconds to achieve 90% of the final reading.

N

OTE

:

The sampling shield and sampling hose or wand must be firmly and correctly attached to the TARGET

instrument for proper remote sampling operation.

The instrument monitors the sample pump operation and provides an audible alarm and visual indication on the status

line of the display, in the event of a low flow condition.

N

OTE

:

The sampling shield and sampling hose or wand must be removed from the TARGET instrument for diffusion

operation.

For instruments with internal sampling pumps, a calibration procedure is required whenever a pump is replaced or

when calibration is performed on the instrument sensors.

It is also recommended to perform pump calibration if any abnormal pump operation is observed. Pump calibration is

performed in the Advanced Maintenance Menu. See section 6.4.8 for pump calibration instructions.

9

Page 13

TARGET Series ENMET Corporation

4.0 Basic User Operation

The TARGET instrument has two operation levels, BASIC and ADVANCED. The BASIC mode is intended to

simplify instrument operation and discussed here. The ADVANCED menu provides additional information and is

discussed in section 5. The instrument may be changed to the ADVANCED menu by following the procedure

outlined in sections 6.3 and 6.3.7.

The TARGET operational menu is used to access various information stored in the instrument electronics. The MENU

button is pressed to display the operational menu and an asterisk is displayed next to a function or sub-menu. Pressing

the MENU button repeatedly, advances the asterisk once for each press. To display a sub-menu or listed function,

press the SELECT button when the asterisk is next to desired function or sub-menu. See section 9.1 for a flow

diagram of Basic Operation Menu.

4.1 Date/Time/Battery Information

From the main gas display, press the MENU button once to put the asterisk next to the Date/Time/Batt line. Press the

SELECT button to enter the Date/Time/Batt line screen. The ON: value is the elapsed time that the instrument has

been on. The battery gauge is a vertical bar graph on the bottom line of the display that provides relative information

on amount of battery life left. The temperature figure in the upper right hand corner of the display is the internal

enclosure temperature and is used for temperature compensation of the gas sensors. Press the MENU button to return

to the Operation menu.

*Date/Time/Batt

Alarm Values

Maintenance Menu

Return to Main displ

SELECT

May 21 1999 72°F

05:19:00pm On:10:05

Bat Gauge 4.80V

25%: |||||

Example: Display of Date, Time, Battery Level

4.2 Alarms Values

From the main display, press the MENU button once to access the Operation menu. Press the MENU button again to

move the asterisk next to the Alarm values line. Press the SELECT button to enter the View Alarms menu. The Low

level instantaneous alarms are displayed. Press the MENU button to return to the Operation menu.

Date/Time/Batt

*Alarm Values

Maintenance Menu

Return to Main displ

SELECT

CO 35ppm H2S 10ppm

Mth10%LEL BRH100ppm

02 19.5

ALARM VALUES

Example: Display of Alarm Values

10

Page 14

TARGET Series ENMET Corporation

5.0 Advanced User Operation

The TARGET instrument has two operation levels, BASIC and ADVANCED. The BASIC mode is intended to

simplify instrument operation and is discussed in Section 4. The ADVANCED menu provides additional information

and is discussed here.

The TARGET operational menu is used to access various information stored in the instrument electronics. Press the

MENU button to display the operational menu and an asterisk next to a function or sub-menu. Pressing the MENU

button repeatedly, to advance the asterisk once for each press. To display a sub-menu or listed function, press the

SELECT button when the asterisk is next to the desired function or sub-menu. See section 9.3 for the flow diagram of

the Advanced Operation Menu.

5.1 Date/Time/Battery Information

From the main gas display, press the MENU button once to put the asterisk next to the Date/Time/Batt line. Press the

SELECT button to enter the Date/Time/Batt line screen. The ON: value is the elapsed time that the instrument has

been on. The battery gauge is a vertical bar graph on the bottom line of the display that provides relative information

on amount of battery life left. The temperature figure in the upper right hand corner of the display is the internal

enclosure temperature and is used for temperature compensation of the gas sensors. Press the MENU button to return

to the Operation menu. Same as in section 4.1.

5.2 Alarms Values

From the main display, press the MENU button once to access the Operation menu. Press the MENU button again to

move the asterisk next to the View Alarms line. Press the SELECT button to enter the View Alarms menu. The Low

level instantaneous alarms are displayed. Press the SELECT button again to view the High level alarms. Press again

to view the STEL alarms. Press again to view TWA alarm points. Press the MENU button to return to the

Operation menu. Same as in section 4.2.

5.3 Min/Max Values

From the main display, press the MENU button once to access the Operation menu. Press the MENU button two

more times to move the asterisk next to the Min / Max Values line. Press the SELECT button to enter the Min / Max

Values menu. The Min Values are displayed. Press the SELECT button again to view at the Max Values. Press the

MENU button to return to the Operation menu.

SELECT

Date/Time/Batt

Alarm Values

*Min / Max Values

TWA Values

Example: Display Minimum and

Maximum Values

CO 0ppm H2S 0ppm

Mth0%LEL BRH 0ppm

02 20.3%

MINIMUM VALUES

5.4 TWA Values

From the main display, press the MENU button once to access the Operation menu. Press the MENU button three

more times to move the asterisk next to the TWA Values line. Press the SELECT button to enter the TWA Values

menu. The TWA current calculations are displayed. Press the MENU button to return to the Operation menu.

SELECT

Date/Time/Batt

Alarm Values

Min / Max Values

*TWA Values

Example: Display of TWA Values

CO 1ppm H2S 0ppm

TWA MEASURE

5.5 STEL Values

From the main display, press the MENU button once to access the Operation menu. Press the MENU button four

more times to move the asterisk next to the STEL Values line. Press the SELECT button to enter the STEL Values

menu. The STEL current calculations are displayed. Press the MENU button to return to the Operation menu.

SELECT

*STEL Values

Maintenance Menu

Back to main disply

Example: Display of STEL Values

CO 2ppm H2S 0ppm

STEL MEASURE

11

Page 15

TARGET Series ENMET Corporation

6.0 Maintenance Operations

6.1 Recommendations

Instrument calibration should be performed at least once every three months.

Field tests using gas concentrations above alarm level should be performed at least monthly or prior to each use for

seldom used instruments. For frequently used instruments, field tests should be performed bimonthly to weekly. A

field test consists of applying field test or calibration gas and confirming appropriate gas sensor response.

Instruments with sensors installed in the BRH location should remain on charge when not in use to stabilize sensor

response.

6.2 Standard Maintenance Menu

The Standard Maintenance menu provides the quickest and simplest access to the most common maintenance

procedure, instrument calibration.

To enter the Standard Maintenance menu, press the MENU button repeatedly from the main gas display or

Operation menu. Move the asterisk until it is next to the Maintenance Menu line. Press the SELECT button to

move to the password entry screen. The password is set to 1270 from the factory. Note the cursor under the first

digit. Use the MENU button to increment the digit and the SELECT key to move the cursor to the next digit. Press

SELECT when the password has been entered. If proper password is not entered, INVALID PASSWORD is

displayed and the instrument returns to Operation menu.

SELECT

Date/Time/Batt

Alarm Values

*Maintenance Menu

Return to Main displ

Example: Display, Password to

Enter Maintenance Menu

Enter Password

to access

STD MAINTENANCE MENU

1270

Once in the Standard Maintenance menu, the options are to enter the Calibration menu or exit. Press the SELECT

button to enter the Calibration Menu.

*Calibrate

Exit

Example: Display of Maintenance Menu

6.3 Calibration

6.3.1 Calibration Menu

Calibration is the process of aligning the instrument electronics to the installed sensors, making the instrument read

accurately. It consists of a zero reading which tells the instrument what it should read in fresh air, and a span reading

which tells the instrument what it should read in the presence of its target gas.

Instruments configured for the combination of gases CO/H2S/O2/Mth, sensors may be calibrated all at once with

multi-component gas. All other configurations, calibration must be performed for each sensor individually. See

section 7.0 for ENMET part numbers of available calibration gas.

To initiate a calibration procedure, move the asterisk to the appropriate location using the MENU button. Press the

SELECT button to choose the calibration procedure. If N/A appears next to a sensor then that sensor is not installed

in the instrument and calibration is not possible.

N

OTE

: The calibration procedure may be aborted by pressing the MENU button anytime during the process.

N

OTE

: If a sensor is installed in the BRH location, the instrument display may show BRH, HS+, CO+, Tol, or similar.

It will always appear above the O2/CO/H2S/Mth combination calibration. The instrument must be on charge

over night prior to calibration or field test.

CALIBRATION MENU

BRH

*O2/CO/H2S/Mth

Individual Sensors

SELECT

Example: Display of Calibration Menu

12

CAL: O2/CO/H2S/Mth

Apply CLEAN AIR

SEL: frwd MENU:Exit

Page 16

TARGET Series ENMET Corporation

End Cap

Groove

Calibration Shield

with Calibration

Thumb screw

End Cap

Flap of Shield

Calibration Shield

Thumb screw

6.3.2 Zero Adjust

The calibration zero procedure is activated by pressing the SELECT button again. This starts a 30 second count down

timer, at the end of which, the zero reading is stored in memory. The next screen displays the span gas concentration.

CAL: O2/CO/H2S/Mth

Sampling CLEAN AIR

MENU:Exit

Sample in 30 sec.

N

OTE

: The oxygen sensor requires only the initial 30 second clean air procedure.

Example:

Display of Calibration Count Down

CAL: O2/CO/H2S/Mth

Apply Multi-Blend

SEL: frwd MENU:Exit

6.3.3 Applying Span Gas

Attach the calibration adapter to the cylinder of span gas and calibration shield. See figure 8.

C

AUTION

: Some gas require that the Target Sampling Shield and flow demand regulator be used for calibration. See

Section 8.0, Table 3 and 4.

I

F A SENSOR IS INSTALLED IN

BRH L

OCATION

:

Place instrument on charge over night.

The BRH sensor should be calibrated before any others. If the BRH sensor is installed in the TARGET, it will

become contaminated if exposed to the combination or test gas and must be calibrated separately.

If the BRH sensor is being calibrated with the 04834-002 calibration fixture, fill the humidifier bowl approximately

1/3 full with clean, tap water. The tube should NOT go under the water line. No bubbles should be visible when

gas is flowing. See figure 8.

N

OTE

: The arrow on the humidifier bowl points in the opposite direction of airflow.

If the BRH sensor is being calibrated with the 04834-005 calibration fixture, fill the humidifier bowl to level

indicated. Use the storage case to support the humidifier while in use. See figure 8.

N

OTE

: The arrow on the humidifier bowl points in the same direction of airflow. 04834-005 calibration fixture

supplied starting November 2002.

Failure to follow both of the BRH steps will cause an inaccurate calibration.

F

OR ALL OTHER SENSORS INSTALLED

:

Use the reactive gases calibration adapter which does not have a humidifier bowl. For CO, O2, Methane sensor

calibration these sensors may be calibrated simultaneously or individually using the combination calibration gas and

reactive gases calibration adapter. See figure 8.

N

OTE

: When calibrating CO, O2 and CH4, with individual gas cylinders, the BRH calibration adapter should be used.

Failure to do so will cause an inaccurate calibration.

SPAN gas concentrations are not adjustable in this calibration procedure. SPAN gas concentrations are, by

design, the concentrations available with ENMET calibration kits. See Section 8.0 for the default

concentrations. If other concentrations are to be used for calibration, the calibration procedure in the

Advanced Maintenance menu must be followed.

N

OTE

: If the span gas value has been previously changed in the Advanced Maintenance menu, that change is

carried over to this procedure.

Threaded hole

for thumb screw

Sensor

Attach the calibration shield to the sensor end cap of the instrument. See Figure 8A. Guide the flap of the shield into

the groove on the bottom of the end cap and bring the top of the shield towards the top of the end cap. Tighten the

thumb screw into the threaded hole in the sensor end cap.

TOP

Sensor

Sensor End Cap

BOTTOM

Shield attached

Figure 8a: Calibration Shield Attachment

13

Page 17

TARGET Series ENMET Corporation

Calibration Adapter, BRH

§

←

Sensor end cap w/cal shield

Regulator

Humidifier Bowl

Cylinder,

Calibration Gas

Example of Storage

Calibration Adapter, BRH 04834-005

Case used as Support

for Humidifier

Sensor end cap w/cal shield

Sensor end cap

w/cal shield

Humidifier Bowl

Top View of Humidifier Bowl

To Sensor

Cylinder, Calibration Gas

04834-002

Apply the span gas and press the SELECT button to initiate the sample count down timer. Count down is shown on

the lowest line of the display, at the end of the count down the span reading is stored in memory. Remove the span gas

and the calibration shield. Calibration of this sensor is complete.

If the sensor is within acceptable sensitivity parameters, OK is displayed next to the gas momentarily before the

display returns to the Calibration menu.

If there is a problem, Cal error is displayed next to the appropriate channel. See section 10.0 for troubleshooting.

CAL: O2/CO/H2S/Mth

Sampling MULTI-BLEND

MENU:Abort

Sample in 120 sec.

Regulator

To Regulator

Cylinder, Calibration Gas

Calibration Adapter, Reactive Gases

Figure 8: Various Calibration Adapter Attachments

Example:

Display during and after Calibration

Regulator

O2: OK

CO: Cal error

H2S: OK

Mth: OK

Repeat the above procedure for each individual sensor as required. If a calibration error occurs it will also be

displayed as a general condition on the Status Line of the Main Gas Display and can be viewed in the Cal Status

screen of the Pop-Up menu.

Exit the Calibration menu when completed. Remove span gas and calibration shield. Then exit the Standard

Maintenance menu.

14

Page 18

TARGET Series ENMET Corporation

Enter Password

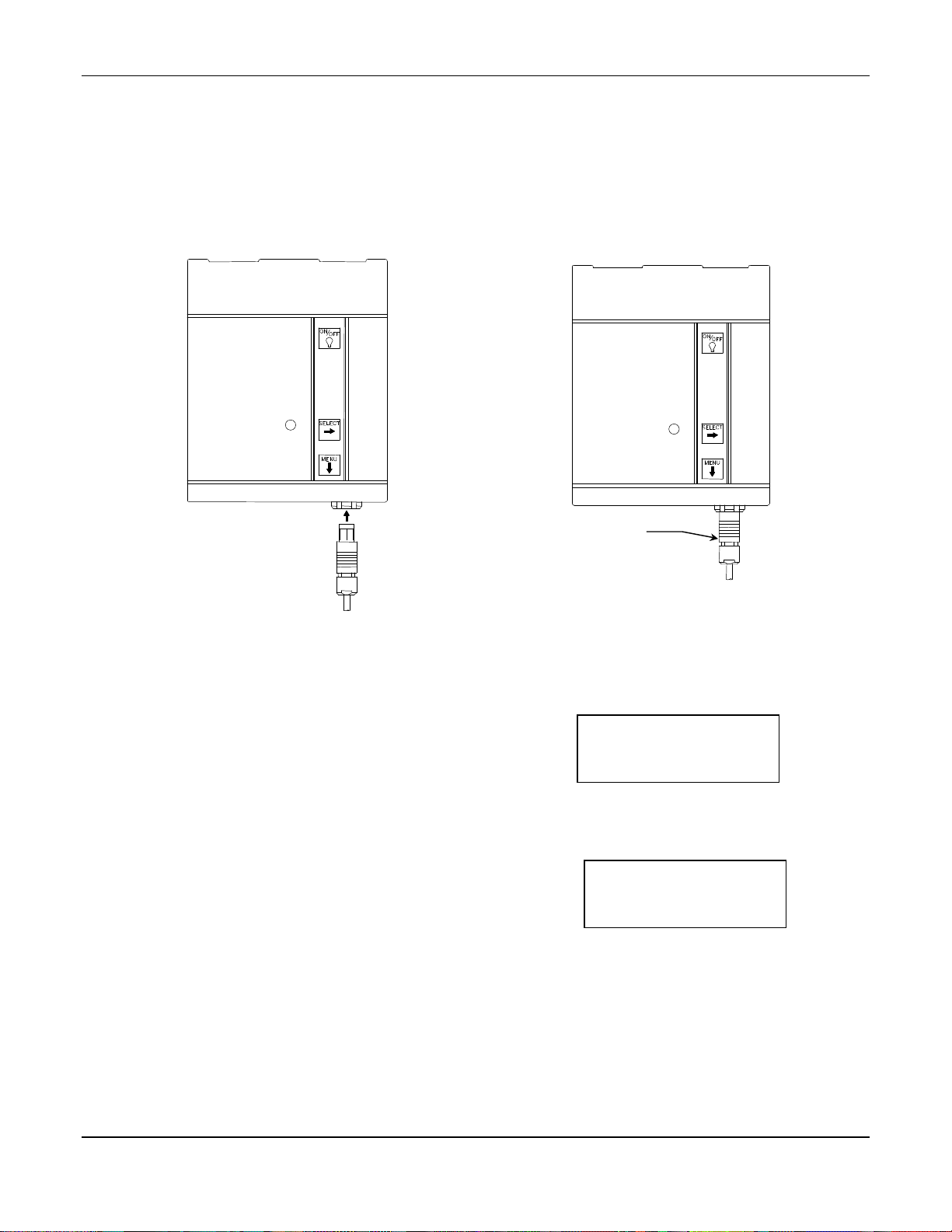

6.4 Advanced Maintenance Menu, Software 4.94 version

The Advanced Maintenance menu provides access to enhanced programming features of the TARGET instrument.

To enter the Advanced Maintenance menu, press the MENU button repeatedly from the main gas display or

Operation menu. Move the asterisk until it is next to the Maintenance menu line. Press the SELECT button to move

to the password entry screen. The password is set to 1270 from the factory. Press and hold the MENU button for

about two seconds. Note that the third line changes from STD Maintenance Menu to ADV Maintenance Menu.

Use the MENU button to increment the first digit and the SELECT button to move the cursor to the next digit. Press

SELECT when the proper password has been entered. If proper password is not entered, INVALID PASSWORD is

displayed and the instrument returns to Operation menu.

Enter Password

to access

ADV MAINTENANCE MENU

1270

*Set Password

Set Battery

Set Op. Menu Type

Pump Cal Exit

STD MAINTENANCE MENU

to access

1270

*Calibrate

Set Alarms

Enable Sensors

Set Clock/Chirp

Press and hold MENU

MENU

Example: Display of Advanced Maintenance Menu

6.4.1 Calibration

The calibration procedure in the Advanced Maintenance menu is very similar to the procedure in the Standard

Maintenance menu, section 6.3. The difference is that in the Advanced Maintenance menu version, the span values

can be modified and the zero and span settings must be acknowledged by pressing the SELECT button.

*Calibrate

Set Alarms

Enable Sensors

Set Clock/Chirp

SELECT

ADV CALIBRATION MENU

*BRH

O2/CO/H2S/Mth

Individual Sensors

Example: Display of Advanced Calibration Menu

If the BRH sensor is installed, see section 6.3.3 for applying span gas.

Expose the instrument to fresh air. When the mV reading on the bottom line is stable, press the SELECT button to set

the ZERO reading.

6.4.2 Setting Instantaneous Alarms

CAL: BRH

*ZERO: 0 ppm

SPAN: 100 ppm

BRH: 196 mV

SELECT

CAL: BRH

ZERO: 0 ppm

*SPAN: 100 ppm

BRH: 1504 mV

Example: Display of BRH Calibration

The asterisk now highlights the SPAN gas concentration. Default values for each sensor are listed in Section 8.0.

To modify the span value, use the Menu key to initiate the change and then increment the digits. The SELECT

button is used to select the digit. SELECT the last digit only after span gas has been applied and the mV reading is

stable.

If no modification is necessary, apply calibration gas and press the SELECT button when the mV reading is stable.

Repeat the procedure for each sensor as necessary.

From the Advanced Maintenance menu, press the MENU button once to put the asterisk next to the Set Alarms line.

Press the SELECT button to enter the Set Alarms screen. Use the MENU button to move the asterisk next to the

desired gas for alarm to be changed. Press the SELECT button to move the cursor to the first digit. The MENU

button is used to increment the digit and the SELECT button to move the cursor to the next digit. Press the SELECT

15

Page 19

TARGET Series ENMET Corporation

button at the Exit line to go back to the Maintenance menu. STEL and TWA alarms are preset at the factory and can

only be changed using the TARGET Trakker software package.

Calibrate

*Set Alarms

Enable Sensors

Set Clock/Chirp

SELECT

SET ALARMS

*O2 19.5 / 23.5 %

CO 35 ppm

H2S 10 ppm

Example: Display of Set Alarm Menu

6.4.3 Enable Sensors

From the Advanced Maintenance menu, press the MENU button twice once to put the asterisk next to the Enable

Sensors line. Press the SELECT button to enter the Enable Sensors screen. Use the MENU button to move the

asterisk next to the gas whose alarm needs to be changed. Press the SELECT button to toggle the sensor ON or OFF.

Press SELECT at the Exit line to go back to the Maintenance menu.

Calibrate

Set Alarms

*Enable Sensors

Set Clock/Chirp

6.4.4 Set Clock/Chirp

From the Advanced Maintenance menu, press the MENU button three times to put the asterisk next to the Set

Clock/Chirp line. Press the SELECT button to enter the Set Clock/Chirp screen. Use the MENU button to move

the asterisk next to the value that needs to be changed. Press the SELECT button to move a cursor to the first digit.

The MENU button is used to increment the digit and the SELECT button to move to the next digit.

Time must be entered in a 24 hour format (i.e. 4:30 pm is entered as 16:30). The confidence chirp sounds at interval

entered in this screen. Factory default value is 120 seconds.

Press the SELECT button at the Exit line to go back to the Maintenance menu.

SELECT

ENABLE SENSORS

*O2 ON

CO ON

H2S ON

Calibrate

Set Alarms

Enable Sensors

*Set Clock/Chirp

SELECT

*M/D/Y: 05/22/99

Time (24Hr): 18:53

Chirp (sec): 120

Exit

Example: Display while Setting Clock and Chirp interval

6.4.5 Set Password

From the Advanced Maintenance menu, press the MENU button four times to put the asterisk next to the Set

Password line. Press the SELECT button to enter the Set Password screen. Use the MENU button to increment the

digit and the SELECT button to move to the next digit. Any four digit password from 0000 to 9999 may be entered

by this operation.

*Set Password

Set Battery

Set Op. Menu Type

Exit

SELECT

CHANGE PASSWORD

Enter new value:

1270

Example: Display Changing Password

16

Page 20

TARGET Series ENMET Corporation

6.4.6 Set Battery Type

From the Advanced Maintenance menu, press the MENU button five times to put the asterisk next to the Set Battery

line. Press the SELECT button to enter the Set Battery screen. Use the MENU button alternate between NiMH

(rechargeable) and Alkaline. Press the SELECT button to choose the desired battery type. Setting the proper battery

type is important to achieve maximum life out of the battery pack.

W

ARNING

:

Substitution of batteries or other components may compromise the intrinsic safety of the instrument.

Set Password

*Set Battery

Set Op. Menu Type

Exit

SELECT

Set BATTERY TYPE

Select type:

NiMH

Example: Display Setting Battery Type

6.4.7 Set Operation Menu

From the Advanced Maintenance menu, press the MENU button six times to put the asterisk next to the Set Op. menu

type line. Press the SELECT button to enter the Set Op. menu type screen. Use the MENU button alternate

between Basic and Advanced. Press the SELECT button to choose the desired operational menu. The Basic menu

type is the default menu.

Set Password

Set Battery

*Set Op. Menu Type

Exit

SELECT

Set OP MENU TYPE

Select type:

Basic

Example: Display of Set Operation Menu

6.4.8 Internal Pump Calibration

For instruments with internal sampling pumps, a calibration procedure is required whenever a pump is replaced or

when calibration is performed on the instrument sensors. It is also recommended to perform pump calibration if any

abnormal pump operation is observed.

N

OTE

: The calibration or sampling shield should not be attached to the instrument during pump calibration.

Press the menu button to move the asterisk next to the Pump Calibration prompt.

Press the select button to initiate the procedure.

The pump will automatically come on. The instrument samples the pump signal for one minute. At the end of the

one minute, the instrument is ready for the blocked flow measurement.

Put your finger over one of the two sampling holes on the back of the sensor housing.

Press the select button. The instrument samples the blocked flow condition for 10 seconds and then stores the

reading. See figure 9, for location of sampling holes.

The low flow alarm is set automatically by the instrument based on the free flow and blocked flow readings. No

further adjustments are necessary.

Exit the Maintenance Menu when maintenance operations are complete.

17

Page 21

TARGET Series ENMET Corporation

Enter Password

6.4a Advanced Maintenance Menu, Software 6.0 version

The Advanced Maintenance menu provides access to enhanced programming features of the TARGET instrument.

To enter the Advanced Maintenance menu, press the MENU button repeatedly from the main gas display or

Operation menu. Move the asterisk until it is next to the Maintenance menu line. Press the SELECT button to move

to the password entry screen. The password is set to 1270 from the factory. Press and hold the MENU button for

about two seconds. Note that the third line changes from STD Maintenance Menu to ADV Maintenance Menu.

Use the MENU button to increment the first digit and the SELECT button to move the cursor to the next digit. Press

SELECT when the proper password has been entered. If proper password is not entered, INVALID PASSWORD is

displayed and the instrument returns to Operation menu.

Enter Password

to access

ADV MAINTENANCE MENU

1270

*Calibrate

Set Alarms

Enable Sensors

Pump Cal Exit

STD MAINTENANCE MENU

to access

1270

Enter Password

to access

ADV MAINTENANCE MENU

1270

Press and hold MENU

MENU

Example: Display of Advanced Maintenance Menu

6.4a.1 Calibration

The calibration procedure in the Advanced Maintenance menu is very similar to the procedure in the Standard

Maintenance menu, section 6.3. The difference is that in the Advanced Maintenance menu version, the span values

can be modified and the zero and span settings must be acknowledged by pressing the SELECT button.

*Calibrate

Set Alarms

Enable Sensors

Pump Cal Exit

SELECT

ADV CALIBRATION MENU

*BRH

O2/CO/H2S/Mth

Individual Sensors

Example: Display of Advanced Calibration Menu

If the BRH sensor is installed, see section 6.3.3 for applying span gas.

Expose the instrument to fresh air. When the mV reading on the bottom line is stable, press the SELECT button to set

the ZERO reading.

6.4a.2 Setting Instantaneous Alarms

CAL: BRH

*ZERO: 0 ppm

SPAN: 100 ppm

BRH: 196 mV

SELECT

CAL: BRH

ZERO: 0 ppm

*SPAN: 100 ppm

BRH: 1504 mV

Example: Display of BRH Calibration

The asterisk now highlights the SPAN gas concentration. Default values for each sensor are listed in Section 8.0.

To modify the span value, use the Menu key to initiate the change and then increment the digits. The SELECT

button is used to select the digit. SELECT the last digit only after span gas has been applied and the mV reading is

stable.

If no modification is necessary, apply calibration gas and press the SELECT button when the mV reading is stable.

Repeat the procedure for each sensor as necessary.

From the Advanced Maintenance menu, press the MENU button once to put the asterisk next to the Set Alarms line.

Press the SELECT button to enter the Set Alarms screen. Use the MENU button to move the asterisk next to the

desired gas for alarm to be changed. Press the SELECT button to move the cursor to the first digit. The MENU

button is used to increment the digit and the SELECT button to move the cursor to the next digit. Press the SELECT

18

Page 22

TARGET Series ENMET Corporation

button at the Exit line to go back to the Maintenance menu. STEL and TWA alarms are preset at the factory and can

only be changed using the TARGET Trakker software package.

Calibrate

*Set Alarms

Enable Sensors

Pump Cal Exit

SELECT

SET ALARMS

*O2 19.5 / 23.5 %

CO 35 ppm

H2S 10 ppm

Example: Display of Set Alarm Menu

6.4a.3 Enable Sensors

From the Advanced Maintenance menu, press the MENU button twice once to put the asterisk next to the Enable

Sensors line. Press the SELECT button to enter the Enable Sensors screen. Use the MENU button to move the

asterisk next to the gas whose alarm needs to be changed. Press the SELECT button to toggle the sensor ON or OFF.

Press SELECT at the Exit line to go back to the Maintenance menu.

Calibrate

Set Alarms

*Enable Sensors

Pump Cal Exit

6.4a.4 Internal Pump Calibration

For instruments with internal sampling pumps, a calibration procedure is required whenever a pump is replaced or

when calibration is performed on the instrument sensors. It is also recommended to perform pump calibration if any

abnormal pump operation is observed.

N

OTE

: The calibration or sampling shield should not be attached to the instrument during pump calibration.

Press the menu button to move the asterisk next to the Pump Calibration prompt.

Press the select button to initiate the procedure.

The pump will automatically come on. The instrument samples the pump signal for one minute. At the end of the

one minute, the instrument is ready for the blocked flow measurement.

Put your finger over one of the two sampling holes on the back of the sensor housing.

Press the select button. The instrument samples the blocked flow condition for 10 seconds and then stores the

reading. See figure 9, for location of sampling holes.

The low flow alarm is set automatically by the instrument based on the free flow and blocked flow readings. No

further adjustments are necessary.

SELECT

ENABLE SENSORS

*O2 ON

CO ON

H2S ON

Exit the Maintenance Menu when maintenance operations are complete.

19

Page 23

TARGET Series ENMET Corporation

Instrument

Battery

Pump

Internal Pump

Tubing to Pump from Sampling Holes

Internal Pump

6.5 Replacing Battery Pack

W

ARNING

C

Housing

:

Substitution of batteries or other components may compromise the intrinsic safety of the instrument.

Replacing the battery pack is accomplished by removing the two screws holding the sensor end-cap of the instrument

housing. A 2 mm allen key is required. Slide the battery pack out and disconnect it from the PCB connector.

AUTION

: the battery pack cable has a locking connector. The center tab must be pushed down before the connector can

be removed.

Connect the new battery pack to the PCB and slide the battery pack into the instrument housing. See figure 9.

Gasket

PCB Connector

(For instruments with s/n 0700 and above)

(Length shown for reference, they are about 1 ½”)

PCB

Sampling Hole, IN

Battery Pack

PCB Connector

Sensor End Cap

2mm Allen Screws

Figure 9: Replacing Battery Pack and Internal Pump

C

AUTION

: Be sure to properly install the gasket when re-assembling the instrument. The best technique is to thread the

screws most of the way in. Install the gasket, then tighten the screws.

C

AUTION

: Be sure that all wires and tubing will not be pinched or stressed when sensor end cap is replaced.

6.6 Replacing Internal Pump

Replacing the internal pump is accomplished by removing the two screws holding the sensor end-cap of the instrument

housing. A 2 mm allen key is required. Slide the internal pump out and disconnect it from the PCB connector and the

tubing from the pump.

C

AUTION

: the internal pump cable has a locking connector. The center tab must be pushed down before the connector

can be removed.

C

AUTION

: Be sure that all wires and tubing will not be pinched or stressed when sensor end cap is replaced.

For instruments with s/n 0700 and above:

Connect the new pump to the PCB and tubing. Pump IN port is indicated by arrow. See figure 9.

For instruments with s/n 0699 and below:

Connect the new pump to the PCB and tubing.

(For instruments with s/n 0699 and below)

Sampling Hole, IN

Pump IN port is indicated on the pump.

Attach pump to bracket. See figure 9a.

Bracket

Bracket

End View of Enclosure with Pump

Figure 9a: Replacing Internal Pump for instruments with s/n 0699 and below

20

Page 24

TARGET Series ENMET Corporation

Sensor

Bottom View

Sensor (PCB)

Bracket

6.7 Replacing Sensors

When sensors can no longer be calibrated, they must be replaced. Replacing them is accomplished by removing the

two screws holding the sensor end-cap of the instrument housing. A 2 mm allen key is required. Two #6-32 screws

hold a bracket over the sensor board. Remove the screws and bracket. Remove the 2 spacers beneath the bracket to

remove the sensor circuit board. Replace sensors as necessary and re-assemble. See figures 10 and 11.

C

AUTION

: New TOX1 and TOX2 sensors come with a shorting clip that must be removed for proper operation.

Figure 10: Remove shorting clip

Sensor End Cap

2mm, Allen Screws

Gasket

Sensors

Circuit Board

Spacers

2, #6-32 Screws

Figure 11: Replacing Sensors

N

OTE

:

Be sure to properly install the gasket when re-assembling the instrument. The best technique is to thread the

screws most of the way in. Install the gasket, then tighten the screws.

C

AUTION

: Be sure that all wires and tubing will not be pinched or stressed when sensor end cap is replaced.

If your TARGET instrument was ordered with less than five sensors installed, one or more sensor inserts have been

installed. These inserts are not operational and are installed to provide environmental and structure integrity of the

sensor housing. If activating any of these is desired, contact ENMET or your local distributor for upgrade

information.

21

Page 25

TARGET Series ENMET Corporation

7.0 Instrument Information

7.1 Replacement Parts List

Replacement Parts:

ENMET Part No. Description

04835-000 Sampling hose

04835-001 Sampling wand

04835-002 Hand aspirator, requires 04835-000 or 04835-001 or both

04833-000 Protective carrying case

04833-003 Alkaline battery holder

66014-003 Charger cable, 12 V

73083-007 Economy Black Transit Case with Lining

04832-000 Battery Charger, 100-240 VAC, req. cable 66018-000 or equiv.

66018-000 Power cable for charger, 110 VAC plug

67019-024 Battery Pack, NiMH

04833-002 Internal Pump, is round pump w/crimps & connector

for units with s/n 15-0699 and below

04833-004 Internal Pump, is square pump w/crimps & connector

for units with s/n 15-0700 and above

03620-017 Calibration/hand aspirator cover

04833-001 Computer Cable

04836-000 Sampling cover for internal sample pump

73089-068 Sampling filter

04833-005 Trakker software

80012-014 TARGET Series Operation and Maintenance Manual

DC

Calibration Gas and accessories:

ENMET Part No. Description

03388-000 Calibration Gas, 34 liter, 50% LEL CH4, 20ppm H2S, 100 ppm CO, 20.9% O

03286-100 Calibration Gas, 17 liter, 100ppm Toluene for BRH Sensor

03227-800 Calibration Gas, 17 liter, 800ppm Hydrogen, H

03220-050 Calibration Gas, 17 liter, 50% LEL Methane, CH

2

4

03219-100 Calibration Gas, 17 liter, 100ppm Carbon monoxide, CO

∆

03302-010

Calibration Gas, 34 liter, 10ppm Hydrogen chloride, HCL

03303-010 Calibration Gas, 34 liter, 10ppm Hydrogen cyanide, HCN

03314-020 Calibration Gas, 34 liter, 20ppm Hydrogen sulfide, H2S

03315-010 Calibration Gas, 17 liter, 10ppm Sulfur dioxide, SO

03318-025 Calibration Gas, 17 liter, 25ppm Ammonia, NH

∆

03331-005

∆

03332-005

Calibration Gas, 17 liter, 5ppm Chlorine, Cl

Calibration Gas, 34 liter, 5ppm

Ethylene oxide, ETO

2

3

2

03334-025 Calibration Gas, 34 liter, 25ppm Nitric oxide, NO

04834-001 Calibration Adapter, Reactive Gases

04834-005 Calibration Adapter, for BRH sensor

03620-017 Calibration Shield

*03510-002 Calibration Adapter, Flow Demand

2

*Required in use with ∆ calibration gases.

∆ These gases require the Sampling Shield p/n 04836-000 to be in place and pump activated for

accurate detection and calibration.

22

Page 26

TARGET Series ENMET Corporation

Replacement Sensors:

ENMET Part No. Description

03008-131

03008-012 Sensor, BRH012

03015-012 Sensor, HS+/CO+

03070-002 Sensor, Combustible (HW)