Page 1

© 2019 NXP B.V.

WCT1012VLF/WCT1013VLH Consumer MPA11 (WCT-15W1CFFPD) V1.0 Wireless

Charging Application User’s Guide

1. Key features

The WCT1012VLF/WCT1013VLH Consumer MPA11_Rev1.0 (MP-A11_Rev1_SCH-32212_B, MPA11_Rev1_LAY-32212_B) wireless charging TX demo

(WCT-15W1CFFPD) is used to wirelessly transfer power

to a charged device. The charged device can be any

electronic device equipped with a dedicated Qi wireless

charging receiver.

The main parameters of the Wireless Charging

Transmitter (WCT) are:

• Support for QC 3.0 and USB PD 2.0/3.0 input.

The input voltage ranges from 5 to 19 V DC.

• The input voltage can drop down to 5 V DC

during the start-stop function.

• The nominal power delivered to the receiver is

15 W, up to 22 W (at the output of the receiver)

and compatible with a 5 W receiver.

• Designed to meet the Qi 1.2.4 specification.

• Operation frequency: 120 kHz ~ 130 kHz (the

default is 127.772 kHz) for Qi devices.

NXP Semiconductors

Document Number: WCT101XV10AUG

User’s Guide

Rev. 1

05/2019

1. Key features ....................................................................... 1

2. Hardware setup .................................................................. 2

3. Application operation ........................................................ 6

4. Hardware description ......................................................... 6

5. Application monitoring and control using FreeMASTER 15

6. Application monitoring using console ..............................20

7. Programming new software and calibration .....................22

8. Software description .........................................................46

9. System bring up ................................................................52

10. Revision history ................................................................ 56

Contents

Page 2

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

2 NXP Semiconductors

2. Hardware setup

2.1.

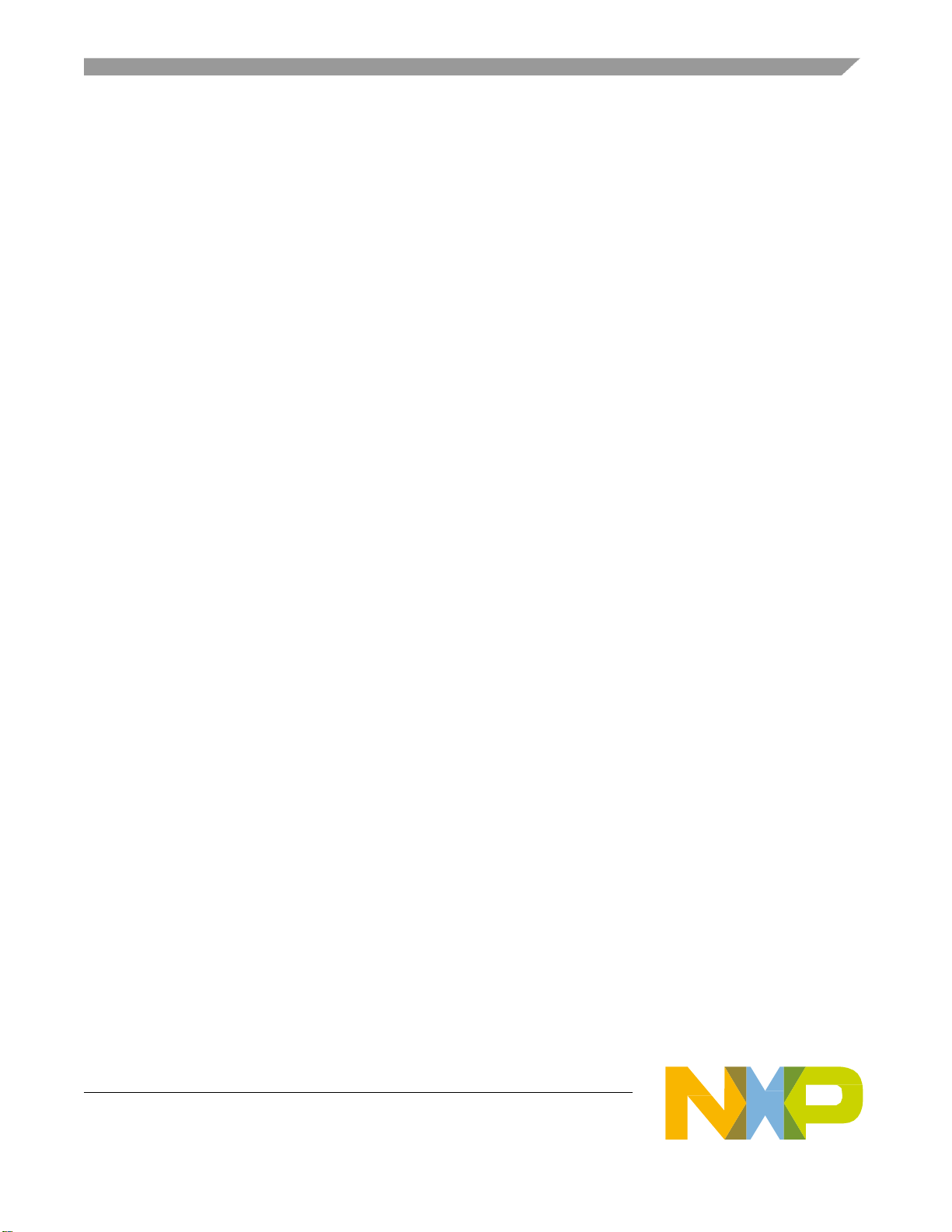

Package contents

1. WCT Consumer MP-A11 (WCT-15W1CFFPD) demo board.

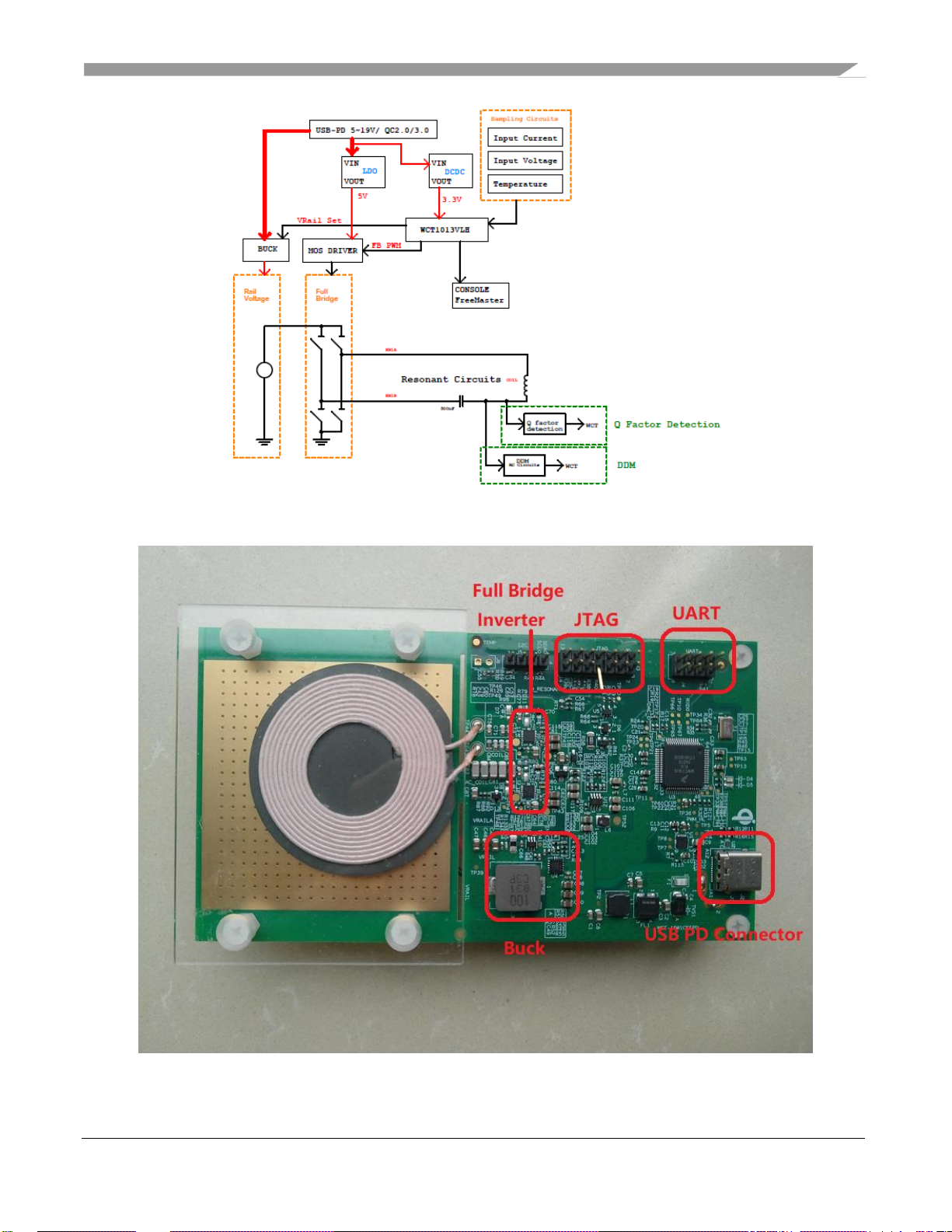

Figure 1. MP-A11 (WCT-15W1CFFPD) demo board

Page 3

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 3

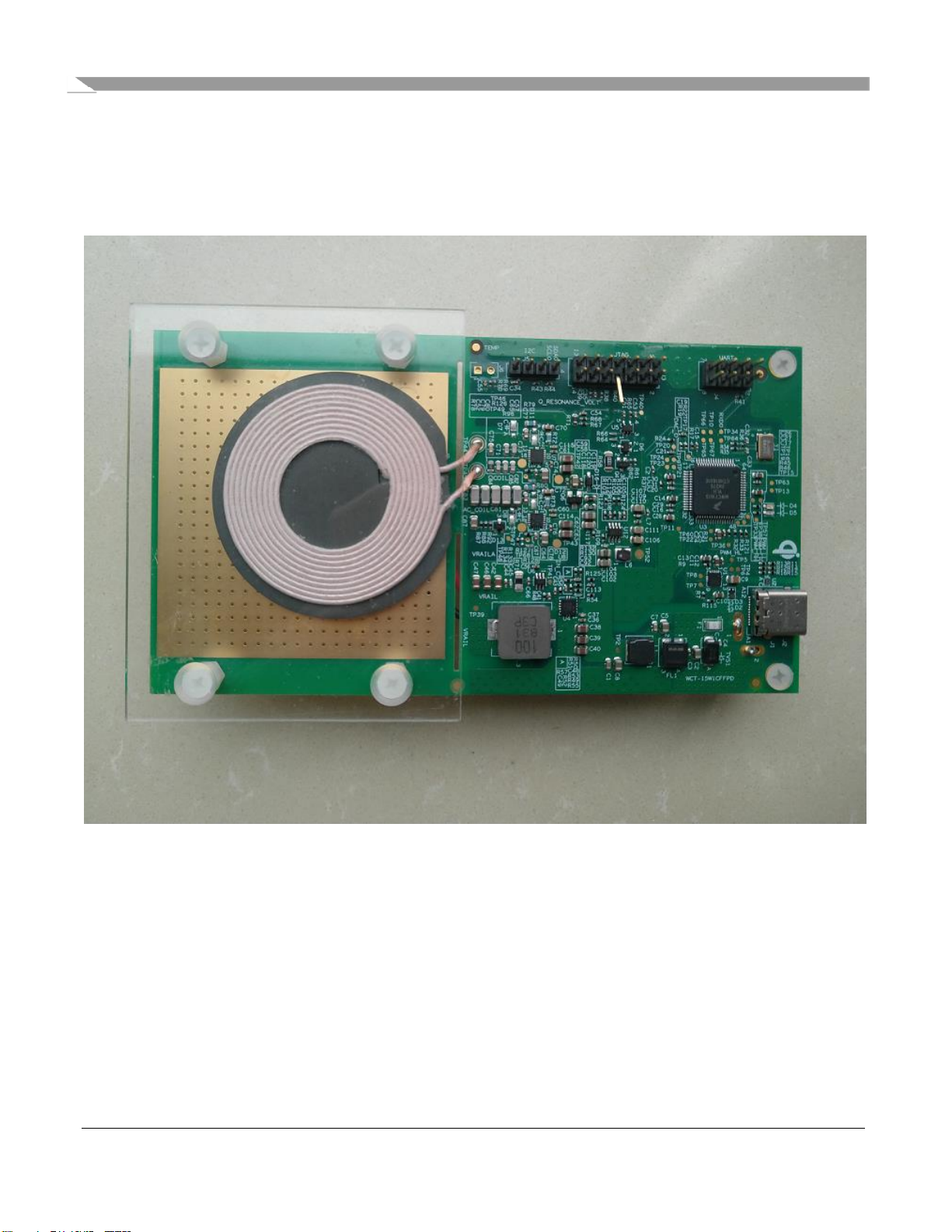

2.2.

Board description

The WCT board is powered through the on-board power connector.

The connectors on the upper-middle part of the board provides the JTAG connection for programming

and debugging and 1xUART for the FreeMASTER tool connection for the debug option and console

connection. The I2C connector is placed on the upper left-hand side of the board.

Figure 2 shows the device.

Coil

I2C

UARTJTAG

DSC

USB PD

Buck

FB

Invertor

Power

Figure 2. Device overview

2.3.

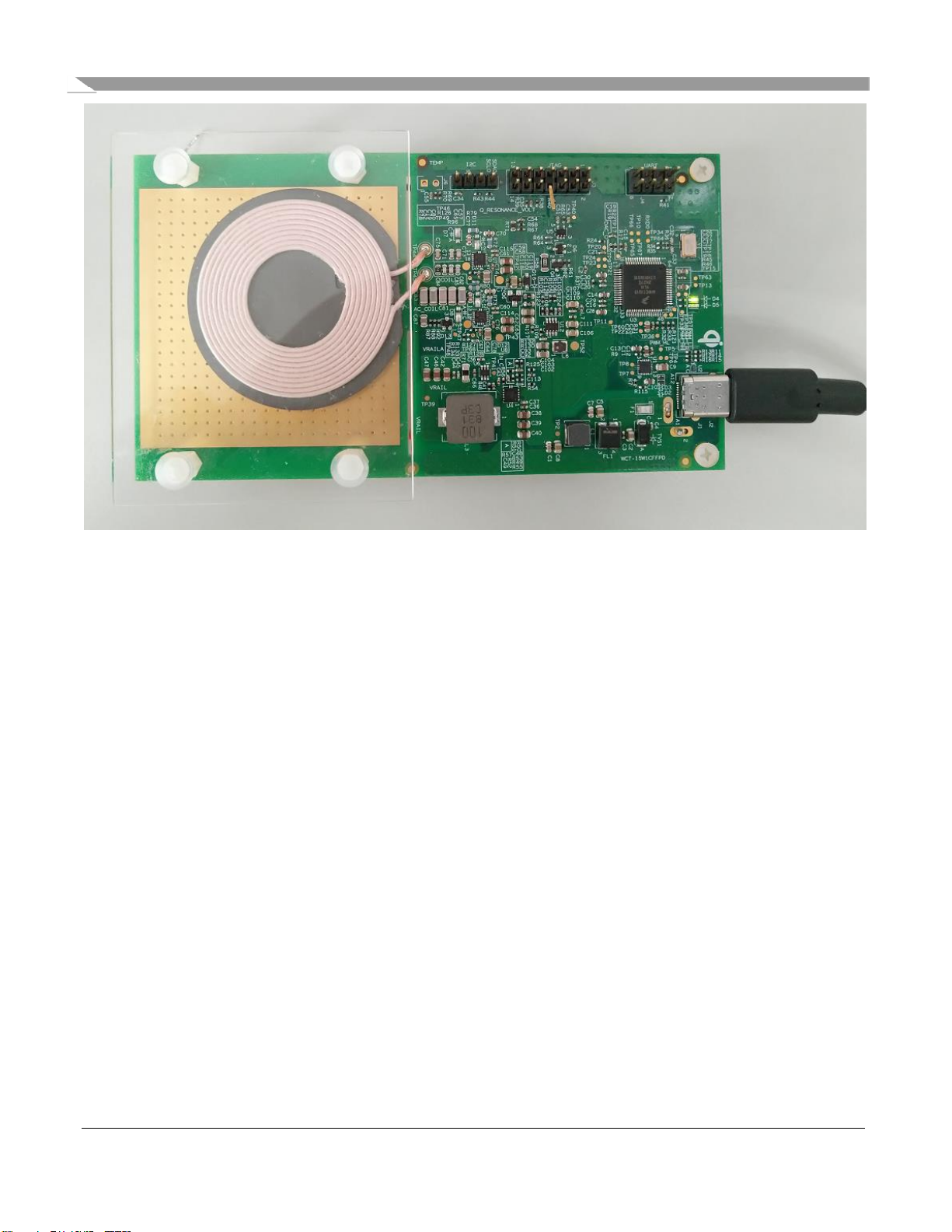

Powering the board on

To power the board on, perform these steps:

1. Plug the USB PD or QC adaptor.

2. Connect the board with the USB PD or QC adaptor by an USB type-C cable.

Page 4

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

4 NXP Semiconductors

Figure 3. Power supply components

2.4.

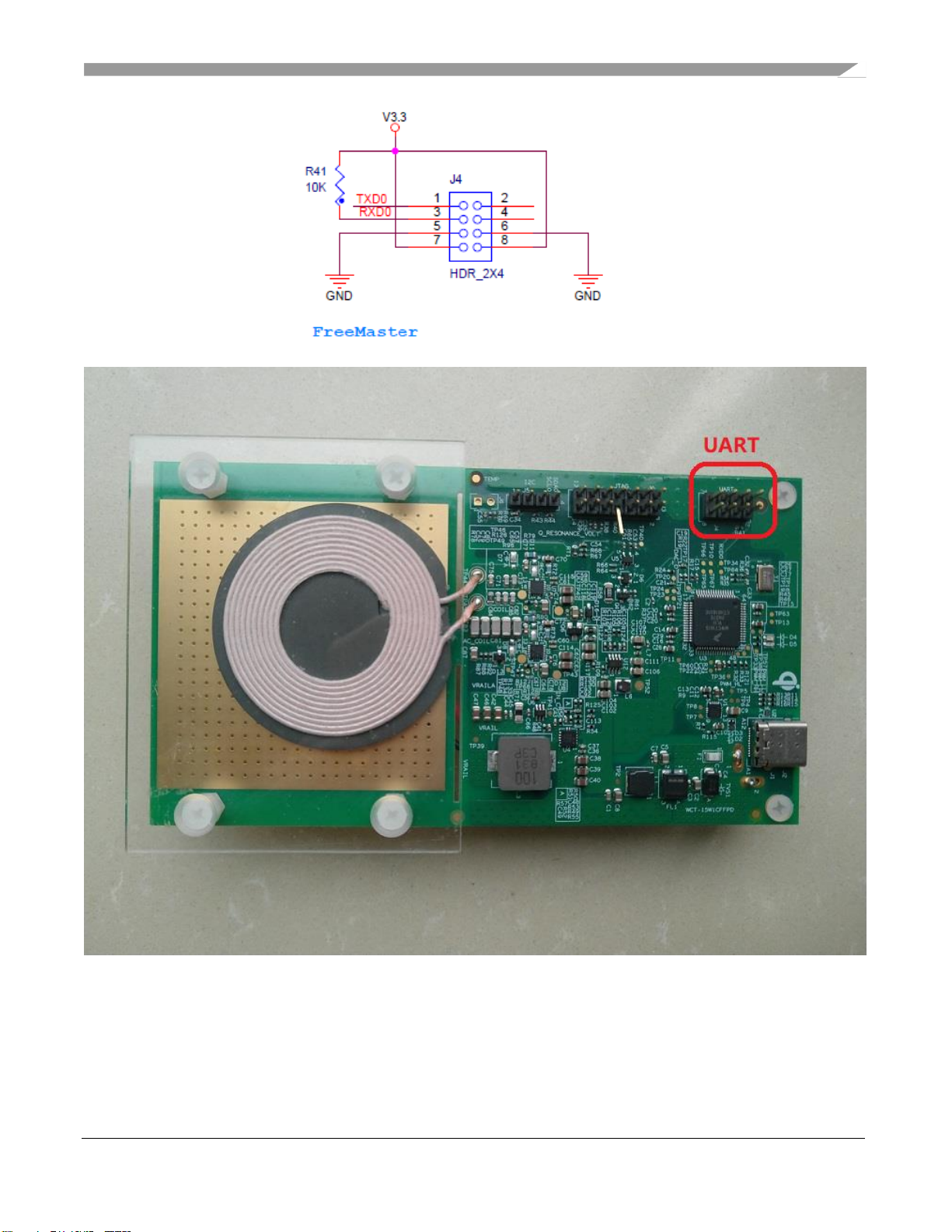

Hardware setup for FreeMASTER and console communication

To set up the hardware for the FreeMASTER and console communication, perform these steps:

1. Find the UART-to-USB adapter on the board and install the UART-to-USB device driver on the

computer. The virtual serial port on the computer should work well.

2. Plug the USB-UART converting board to the SCI connector according to the SCH signal pin

position.

Page 5

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 5

Figure 4. UART and JTAG connectors

Page 6

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

6 NXP Semiconductors

3. Application operation

Connect the demo to the USB PD or QC adaptor using a cable. The WCT starts to periodically send the

power ping to check whether a compatible Wireless Charging Receiver (WCR) is placed on the charging

surface.

When a Qi-compliant receiver is placed on the top of the TX coil area, the WCT starts the charging

process. If there is no correct Qi answer from the WCR side, the TX does not start the Qi charging

process.

If the WCR answers properly, the power transfer starts. The actual level of the transferred power is

controlled by the WCT in accordance with the WCR requirements. The receiver sends messages to the

WCT through the ASK on the coil resonance power signal and the transmitter sends the information to

the receiver using FSK, as per the Qi specification. The power transfer is terminated when the receiver is

removed from the WCT magnetic field.

The system supports all Qi WCR devices: Qi_Ver-1.0 compliance, Qi_Ver-1.1 compliance, and the Qi

EPP receiver. The system supports all the FOD features for different receivers. For the BPP receiver, the

power loss FOD is supported. For the EPP receiver, both the Q-value FOD method and the power loss

FOD method are supported.

4. Hardware description

Figure 5 shows the block diagram of the consumer wireless charger MP-A11 (WCT-15W1CFFPD).

Visit www.nxp.com to get the latest hardware design files.

The whole design consists of several blocks, which are described in the following sections.

Page 7

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 7

Figure 5. Block diagram of the consumer wireless charger MP-A11 (WCT-15W1CFFPD)

Page 8

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

8 NXP Semiconductors

4.1.

Input EMI filter

The input filter consists of the common-mode filter FL1 and filter capacitors C2, C3, C5, C7, and L1.

4.2.

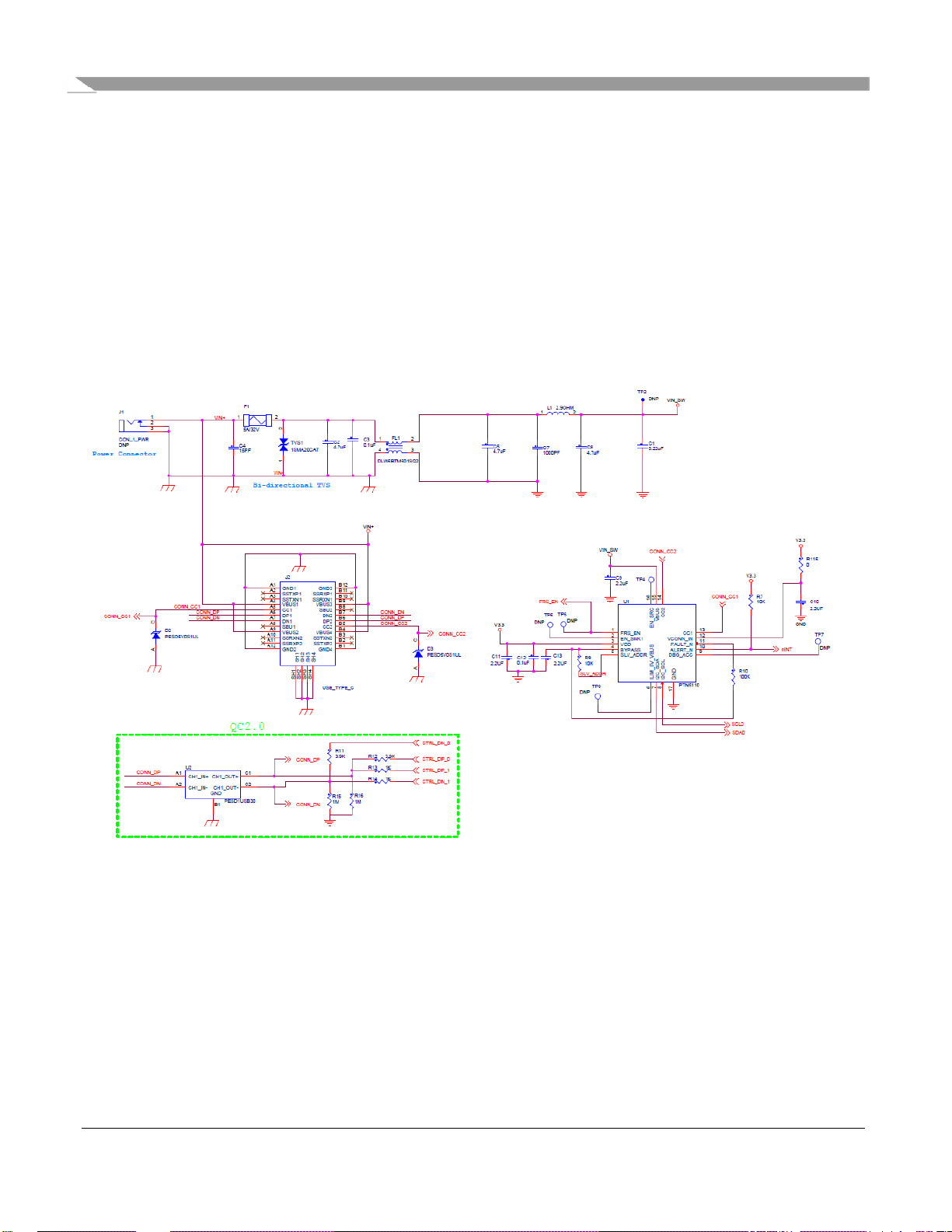

USB power supply

A USB type-C cable can be plugged to the USB type-C connector J2. The PTN5110 USB PD PCTC

PHY is selected to support the type-C Configuration Channel (CC) interface and the USB PD physical

layer functions.

The MPA-11 design also supports the Qualcomm Quick Charge 2.0/3.0 technology. The WCT

controller manages the Qualcomm QC 2.0/3.0 protocol through the GPIOs and resistors connected to the

D+/D- data line.

Figure 6. USB PD power supply and QC circuits

4.3.

System voltage DCDC

The USB PD or QC adaptor input is connected to buck converter U12 (MP2314). Its output is 3.3 V.

This 3.3 V output is mainly for the WCT1012VLF/WCT1013VLH and other 3.3 V-powered

components. Generally, the DCDC load current is low. It is preferable to select a DCDC with a high

efficiency in the light-load condition.

The MP-A11 design can also support other customized-propriety power protocols.

Page 9

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 9

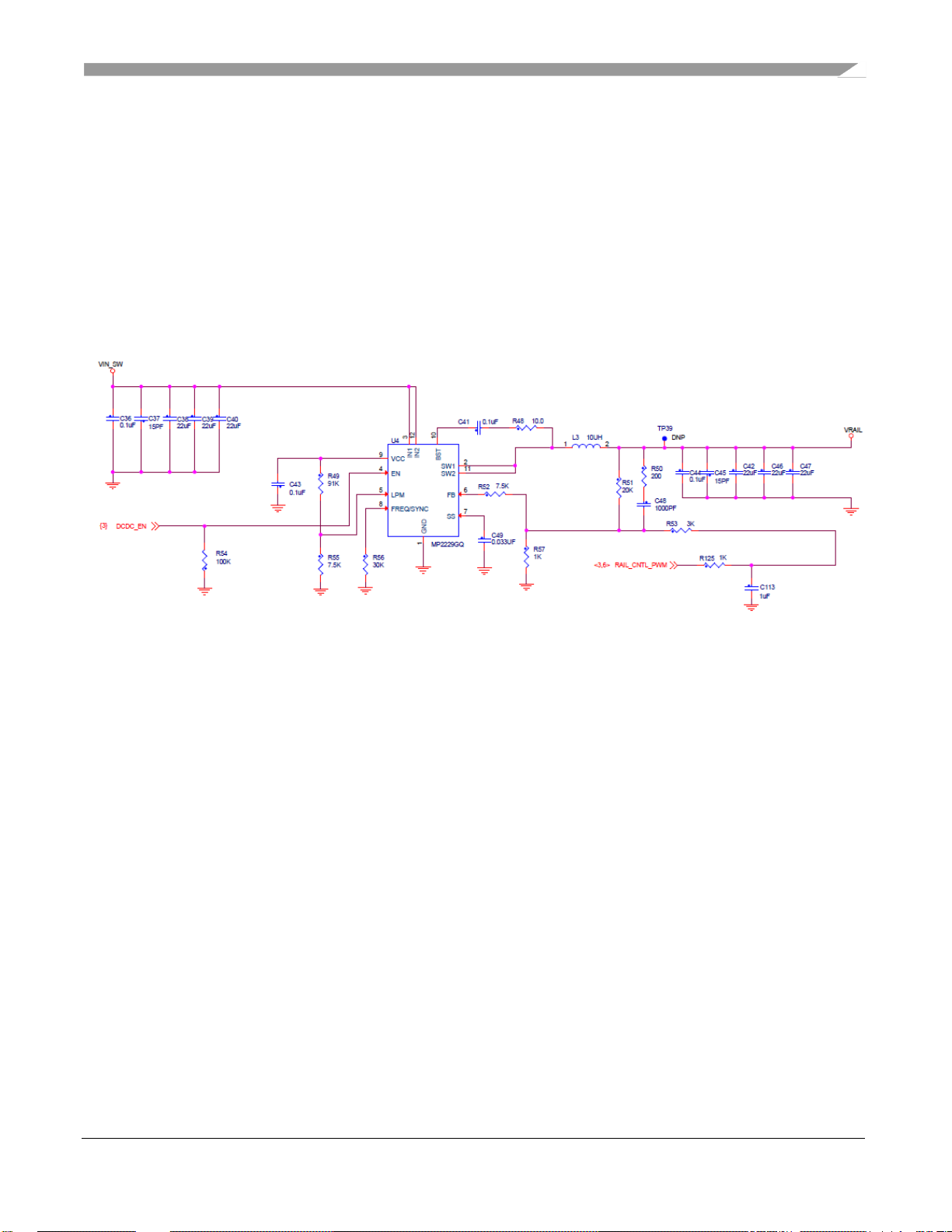

4.4.

Rail voltage generated by analog buck chip

The Qi specification for the MP-A11 topology requires the DC voltage control to control the power

transferred to the receiver. The buck converter is selected to get the regulated DC voltage ranging from

3 V DC to 18 V DC for the full-bridge inverter power supply. The buck is controlled by the individual

analog buck converter and the WCT chip only controls the output voltage feedback.

For the analog buck module, MP2229 (or a similar IC like SY8286) is selected to generate the rail

voltage. The WCT chip generates one analog signal from the PWM and controls the rail voltage using

this signal. This analog signal adjusts the analog buck converter feedback, and the system can get the

rail voltage as the system expects.

Figure 7. Analog buck-boost main circuits

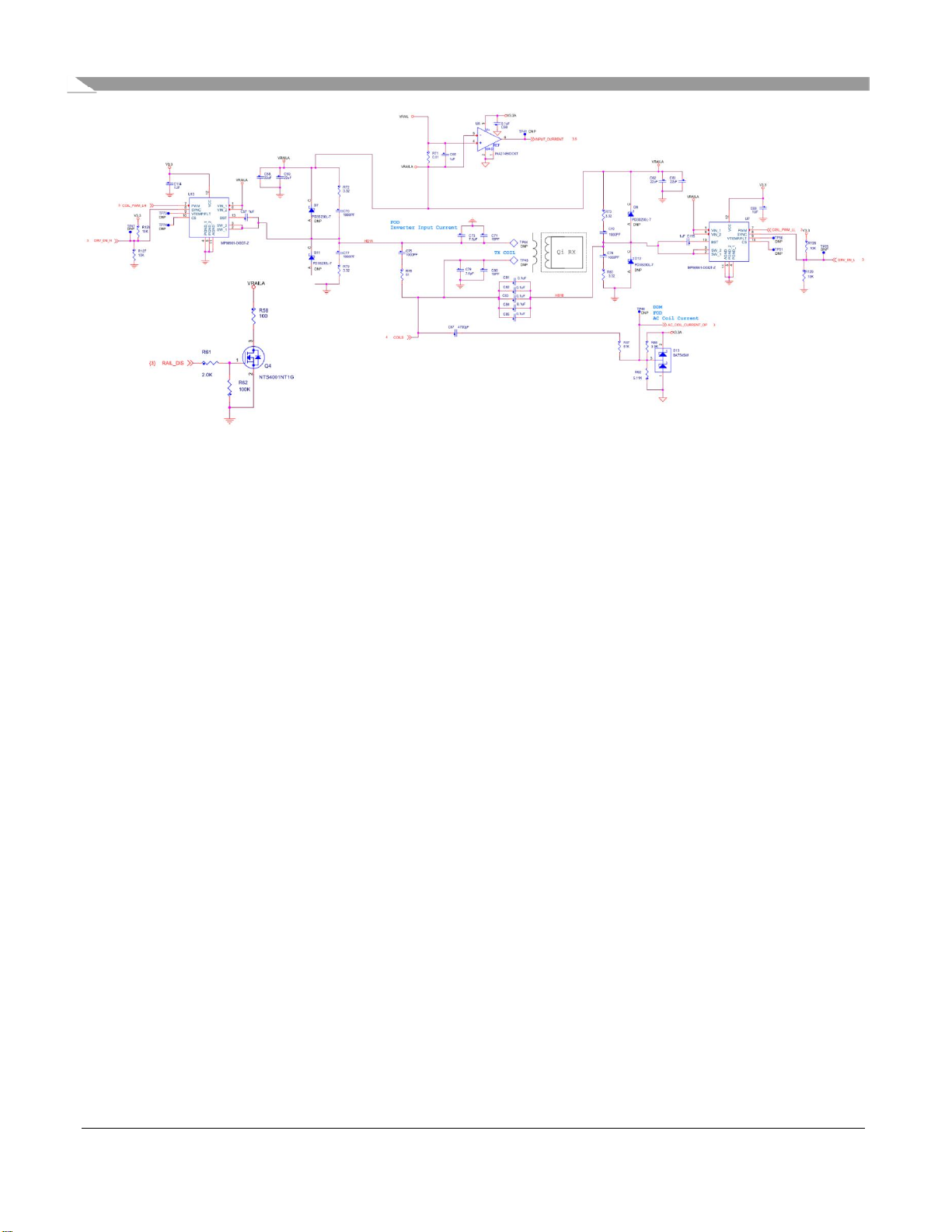

4.5.

Full-bridge and resonant circuits

The full-bridge power stage consists of integrated power stage unit (U7 and U8). The MOSFETs and

their driver are integrated inside the power stage unit. The full-bridge power stage converts the variable

DC voltage VRAIL to the square-wave 50 % duty-cycle voltage with a default frequency of 127.772

kHz. The range of the frequency used (from 120 kHz to 130 kHz) is defined in the Qi specification for

the MP-A11 topology.

The resonant circuits consist of C81, C82, C83, C84, C85, and coils, all of which are fixed values

defined in the Qi specification for the MP-A11 topology. The snubber RC pairs connected in parallel to

the integrated power stages are used to lower the high frequency of the EMI products. The Vrail

discharge circuit (Q4 and R58) is switched ON while the system is terminated.

Page 10

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

10 NXP Semiconductors

Figure 8. Full bridge circuits

4.6.

Communication

There is bi-way communication between the EPP power transceiver and receiver. Communication from

RX to TX: The RX measures the received power and sends the information about the required power

level back to the transmitter. This message is Amplitude Modulated (AM) on the coil current and sensed

by the TX.

The RC circuits C87, R87, R88, and R92 (known as DDM) sample the signal from the coil, compress

the signal amplitude, and feed it to the ADC B-channel of the WCT1012VLF/WCT1013VLH. The

information about the current amplitude and modulated data are processed by the embedded software

routine.

Communication from TX to RX: The TX shall negotiate with the RX in the negotiation phase (if requested

by the RX). The TX uses the FSK modulation to communicate with the RX, and the communication

frequency is about 512 times the operating frequency.

4.7.

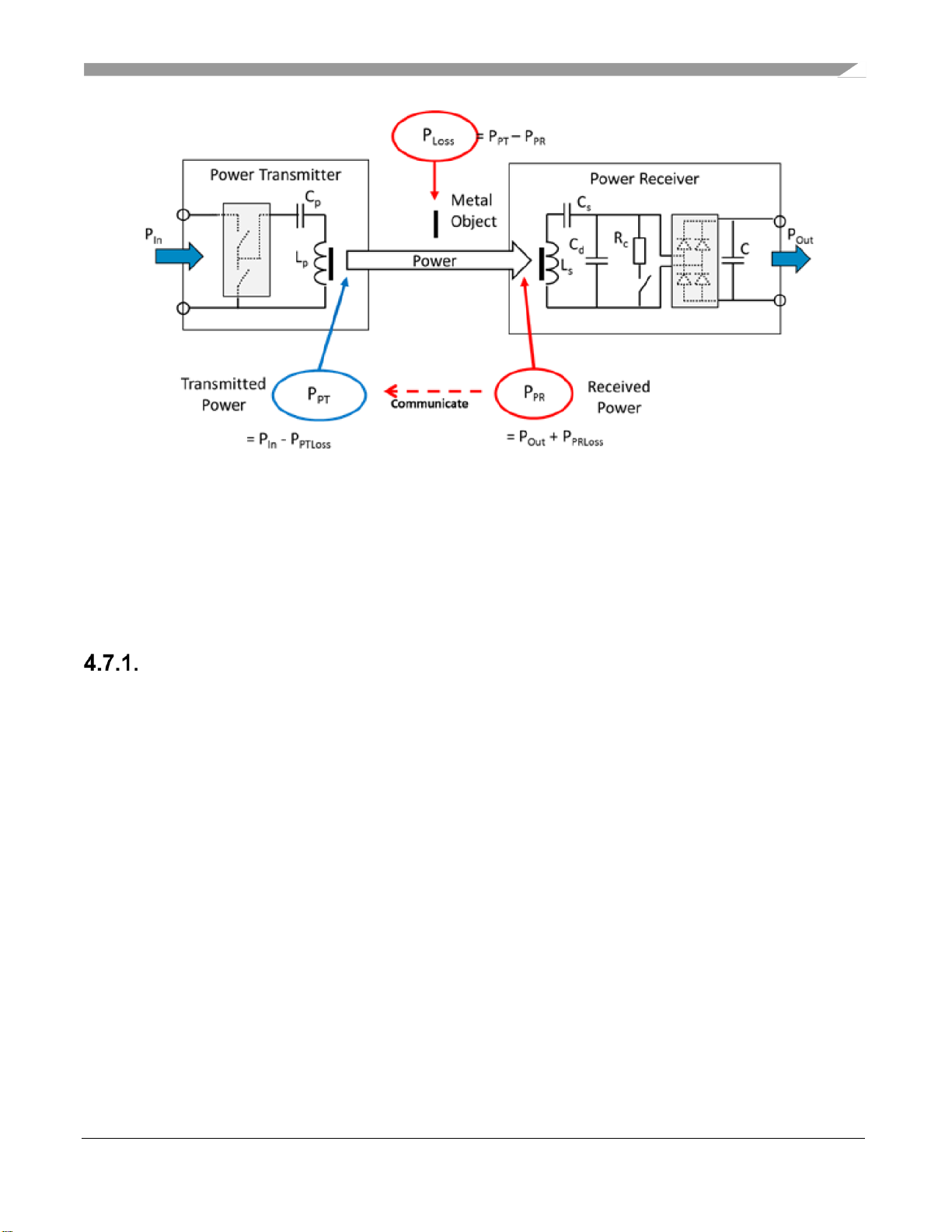

FOD based on power loss

The power loss

, which is defined as the difference between the Transmitted Power and the

Received Power , i.e.

, provides the power absorption in foreign objects, as shown

in Figure 9.

Page 11

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 11

Figure 9. Power loss illustrated

When the FO is implemented in the power transfer, the power loss increases accordingly, and the FO

can be detected based on the power loss method.

The power loss FOD method is divided into two types: FOD for the baseline power profile (TX and RX

can transfer no more than 5 W of power) and extensions power profile (TX and RX can transfer power

above 5 W).

Power-loss FOD baseline

The equation for the power-loss FOD baseline is

.

The Transmitted Power represents the amount of power that leaves the TX due to the magnetic field

of the TX, and

, where represents the input power of the TX and

is the

power dissipated inside the TX. can be measured by sampling the input voltage and input current,

and

can be estimated using the coil current.

The Received Power represents the amount of power that is dissipated within the RX due to the

magnetic field of the TX, and

. The power

is provided at the RX output and

is the power lost inside the RX.

When the NXP MP-A11 transmitter charges the baseline profile RX, the power-loss baseline is applied.

The TX continuously monitors

, and if it exceeds the threshold several times, the TX terminates

the power transfer.

Page 12

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

12 NXP Semiconductors

Power loss FOD extensions

Typically, the RX estimates the power loss inside itself to determine its received power. Similarly, the

TX estimates the power loss inside itself to determine its transmitted power. A systematic bias in these

estimates results in a difference between the transmitted power and the received power, even if there is

no Foreign Object (FO) present on the interface surface. To increase the effectiveness of the power-loss

method, the TX can remove the bias in the calculated power loss by calibration. For this purpose, the TX

and the power RX execute the calibration phase before the power transfer phase starts. The TX must

verify that there is no FO present on its interface surface before the calibration phase and FOD based on

the Q factor can work.

Because the bias in the estimates may depend on the power level, the TX and RX determine their

Transmitted Power and Received Power at two load conditions—a “light” load and a “connected” load.

The “light” load is close to the minimum expected output power, and the “connected” load is close to

the maximum expected output power. Based on the two load conditions, the power transmitter can

calibrate its transmitted power using linear interpolation. Alternatively, the power transmitter can

calibrate the reported received power.

Take the calibrated transmitted power as an example:

Therefore, the TX uses the calibrated transmitted power to determine the power loss as follows:

When the MP-A11 transmitter charges an RX baseline, only the power-loss FOD baseline works. If an

RX extension is placed on the MP-A11 transmitter, the Q factor is measured first to detect if there is an

FO present. If yes, the TX stops charging; otherwise, the TX can proceed to the calibration phase and

the power transfer phase, and the power-loss FOD extension works to detect if an FO is inserted during

the power transfer phase.

For more details about the FOD, see the WCT1012VLF /WCT1013VLH Consumer MP-A11 Run-Time

Debug User’s Guide (document WCT101XRTDUG).

4.8.

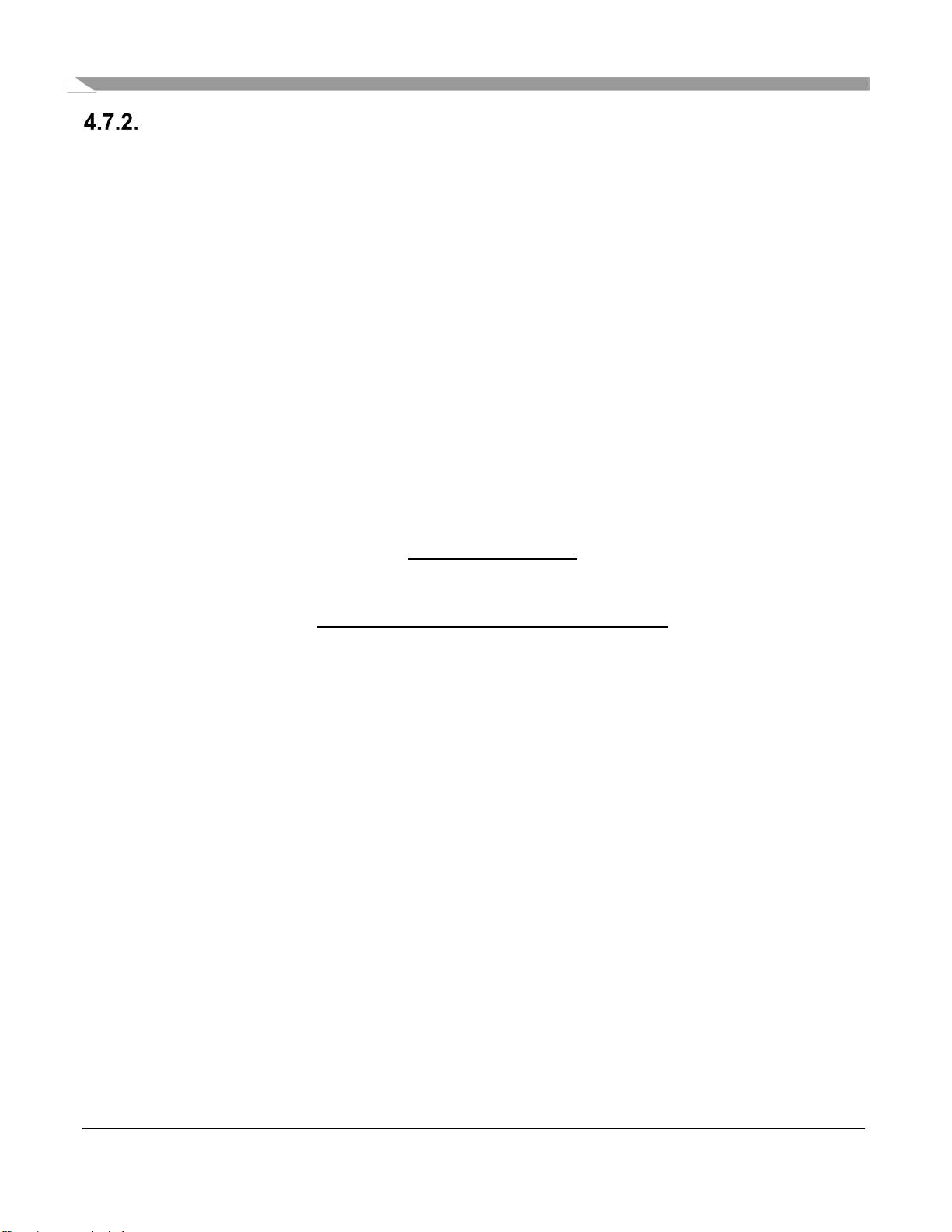

FOD based on Q factor change

A change in the environment of the TX coil typically causes its inductance to decrease or its equivalent

series resistance to increase. Both effects lead to a decrease of the TX coil’s Q factor. The RX sends a

packet including the reference Q factor for the TX to compare and determine if the FO exists, as shown

in Figure 10.

Page 13

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 13

The reference Q factor is defined as the Q factor of the test power transmitter #MP1’s primary coil at the

operating frequency of 100 kHz with RX positioned on the interface surface and no FO nearby. Due to

the differences between its design and that of the test power transmitter #MP1, the TX needs to convert

the Q factor it measured to that of the test power transmitter #MP1. NXP provides the conversion

method and must get the on-board parameters first. The TX performs the automatic calibration and gets

the parameters at the first powerup after a new image is flashed. These parameters are then written to the

flash memory. Therefore, it is necessary to ensure that there is no object on the TX surface during the

first powerup after flashing a new image.

Figure 10. Q factor threshold example

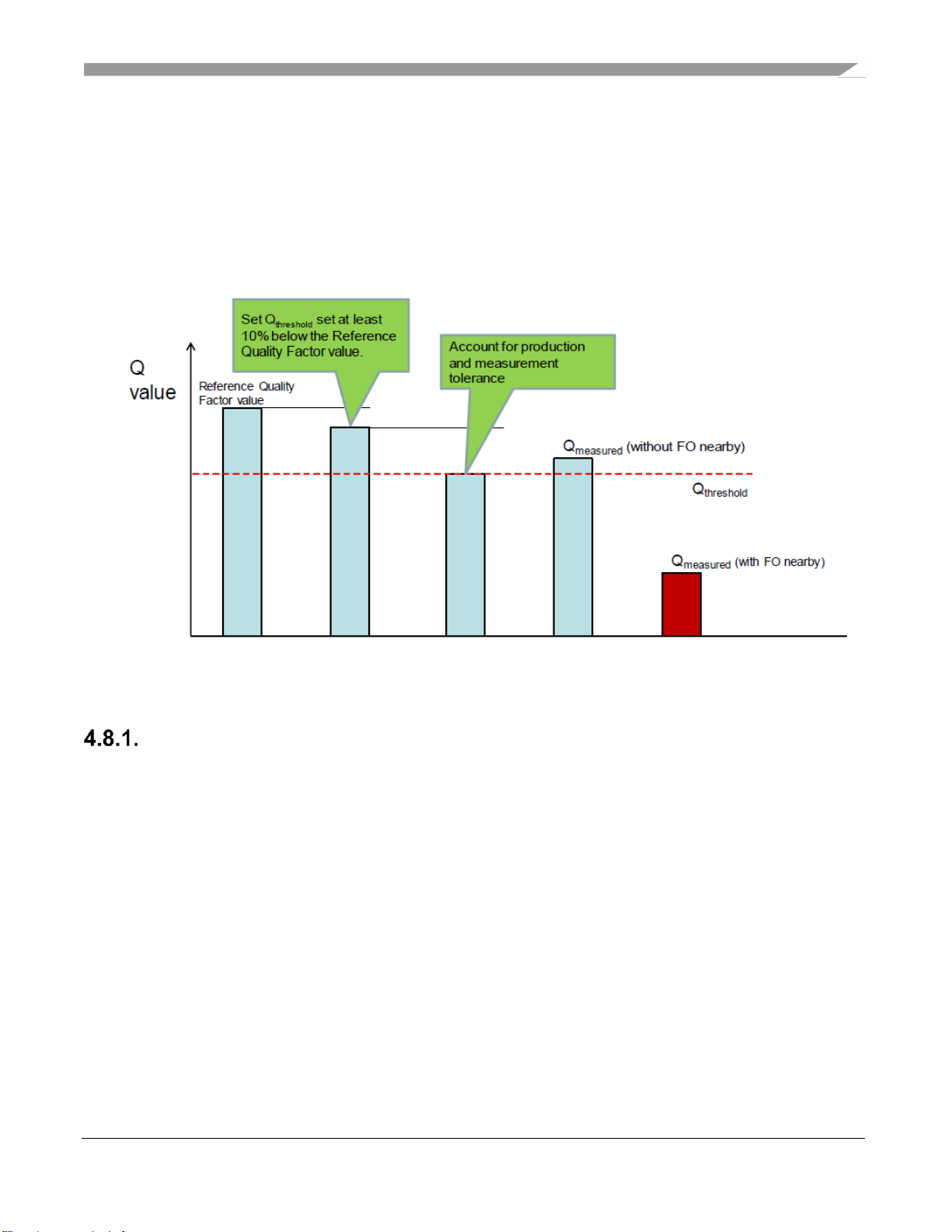

Free-resonance Q factor

The free-resonance Q factor detection detects the decay rate of the resonance signal, as shown in Figure

11. With the system’s high Q, just a few pulses near the resonant frequency are sufficient to serve as

impulses and start the system ringing. Collect the ADC data of the tank voltage (or coil current), and get

the decay rate of the signal.

Q=/(-ln(Rate))

Rate is the value of the decay rate of the resonance signal.

Page 14

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

14 NXP Semiconductors

Figure 11. Resonance signal

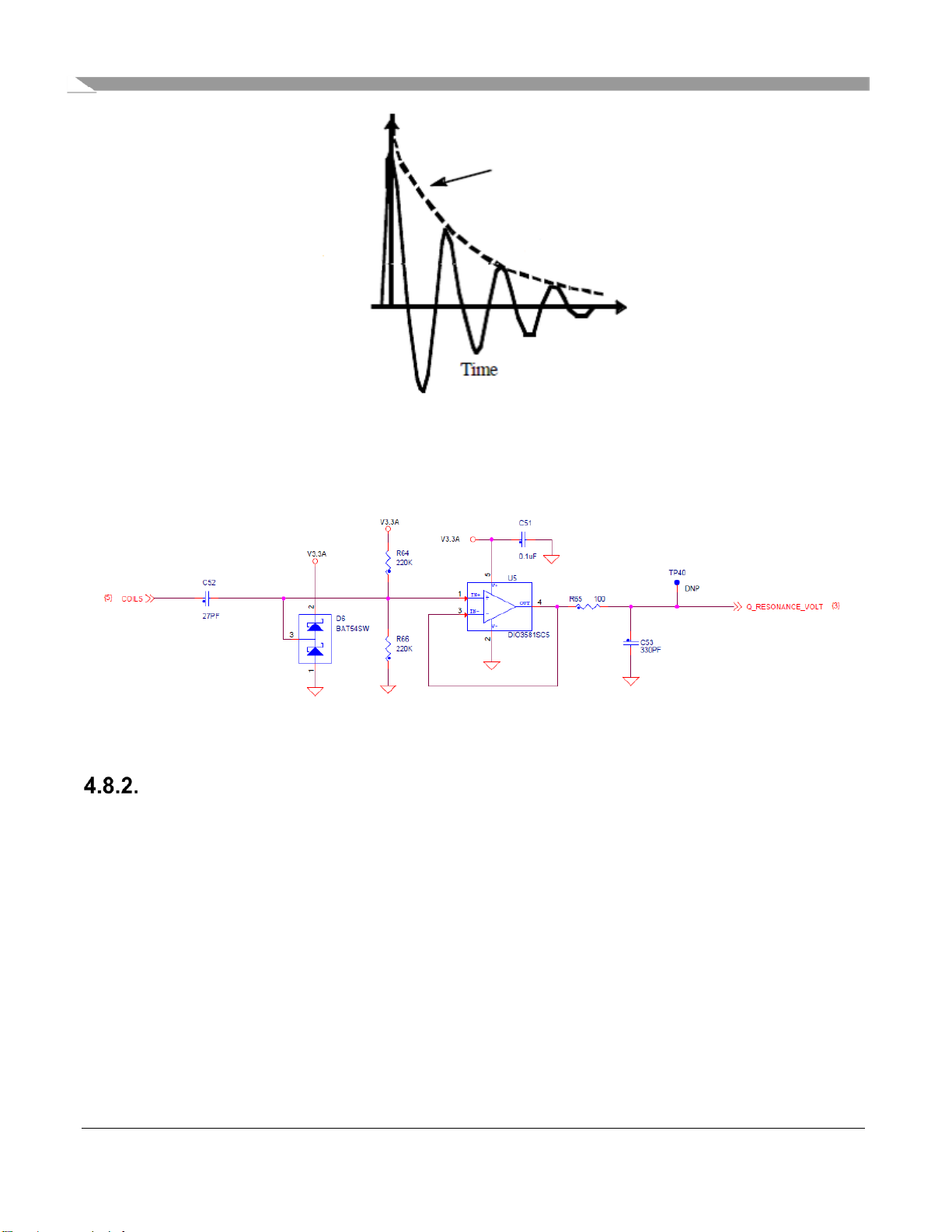

The circuit for the free-resonance Q measurement is as shown in the following figure, which samples the

signal on resonance capacitors.

Figure 12. Free-resonance Q measurement circuit

Pre-FOD based on the Q factor

The pre-FOD serves to detect foreign objects without an RX. The TX uses analog ping to detect objects.

If an object is detected, a digital ping is initiated to decide if it is an RX. If the object is a metal FO, it is

heated by a digital ping. The TX provides a pre-FOD method based on the Q factor to detect the foreign

object and prevent it from being heated before the transfer is initiated.

4.9.

Analog sensing

Some ports of the ADC A-channel of the WCT1012VLF/WCT1013VLH are used to sense analog

signals, such as the temperature, full-bridge input current, input voltage, and rail voltage.

Page 15

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 15

5. Application monitoring and control using FreeMASTER

FreeMASTER is a user-friendly real-time debug monitor and data visualization tool for application

development and information management. Supporting non-intrusive variable monitoring on a running

system, FreeMASTER allows the data from multiple variables to be viewed in an evolving

oscilloscope-like display or in a plain-text format. The application can also be monitored and operated

from the web-page-like control panel.

5.1.

Software setup

To set up the software, perform these steps:

1. Install FreeMASTER version 2.0.2 (or later) from the NXP website: www.nxp.com/freemaster.

2. Plug the USB-UART converting board to the SCI connector J4, and connect the FreeMASTER

Micro-USB port to your computer.

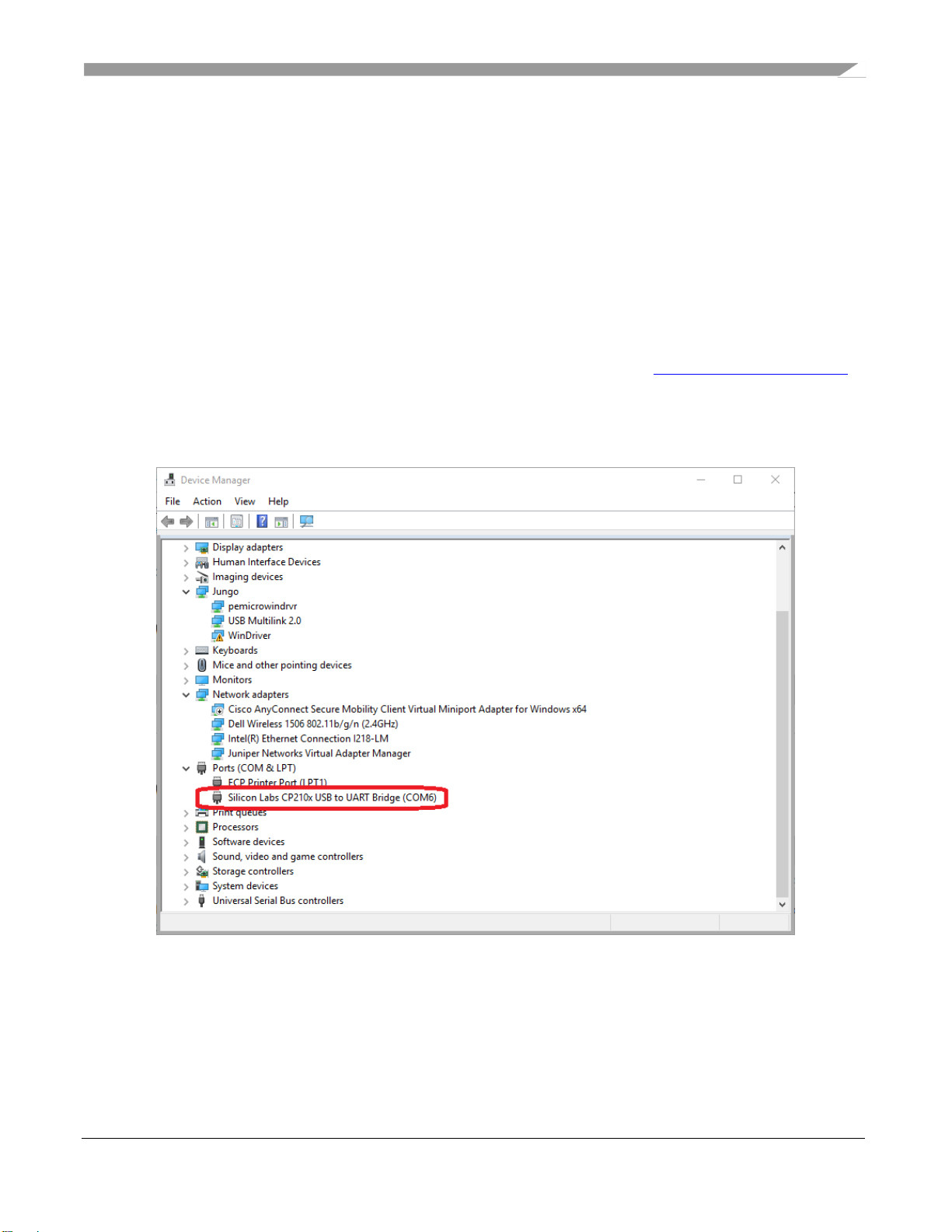

3. Open the Device Manager, and check the number of the COM port.

Figure 13. Device Manager

4. Unpack the embedded source code to your local disk.

5. Start the FreeMASTER application by opening:

• MWCT1013

<unpacked_files_location>/15W_MP/example/wct1013PD/ wct1013pd.pmp

Page 16

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

16 NXP Semiconductors

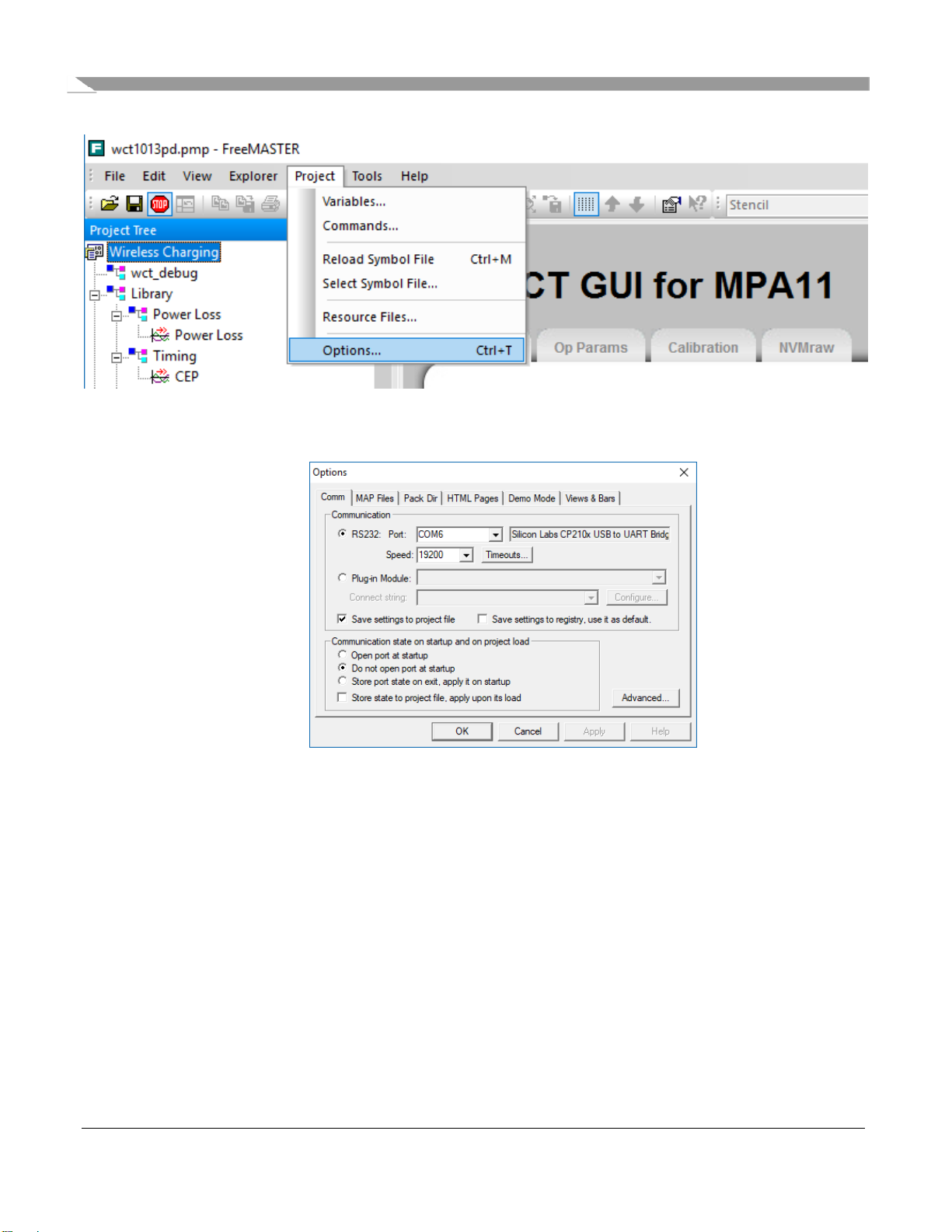

6. Choose “Project” –> “Options”.

Figure 14. Choosing “Options”

7. Ensure that the correct virtual port (according to Step 3) and speed are selected.

Figure 15. Setting port and speed

8. Ensure that the MAP file is correct. The default directories are:

• MWCT1013

<unpacked_files_location>/15W_MP/build/demo/wct1013PDdemo/demo_ldm_debug/wct1013P

Ddemo_debug.elf

Page 17

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 17

Figure 16. Setting the MAP file

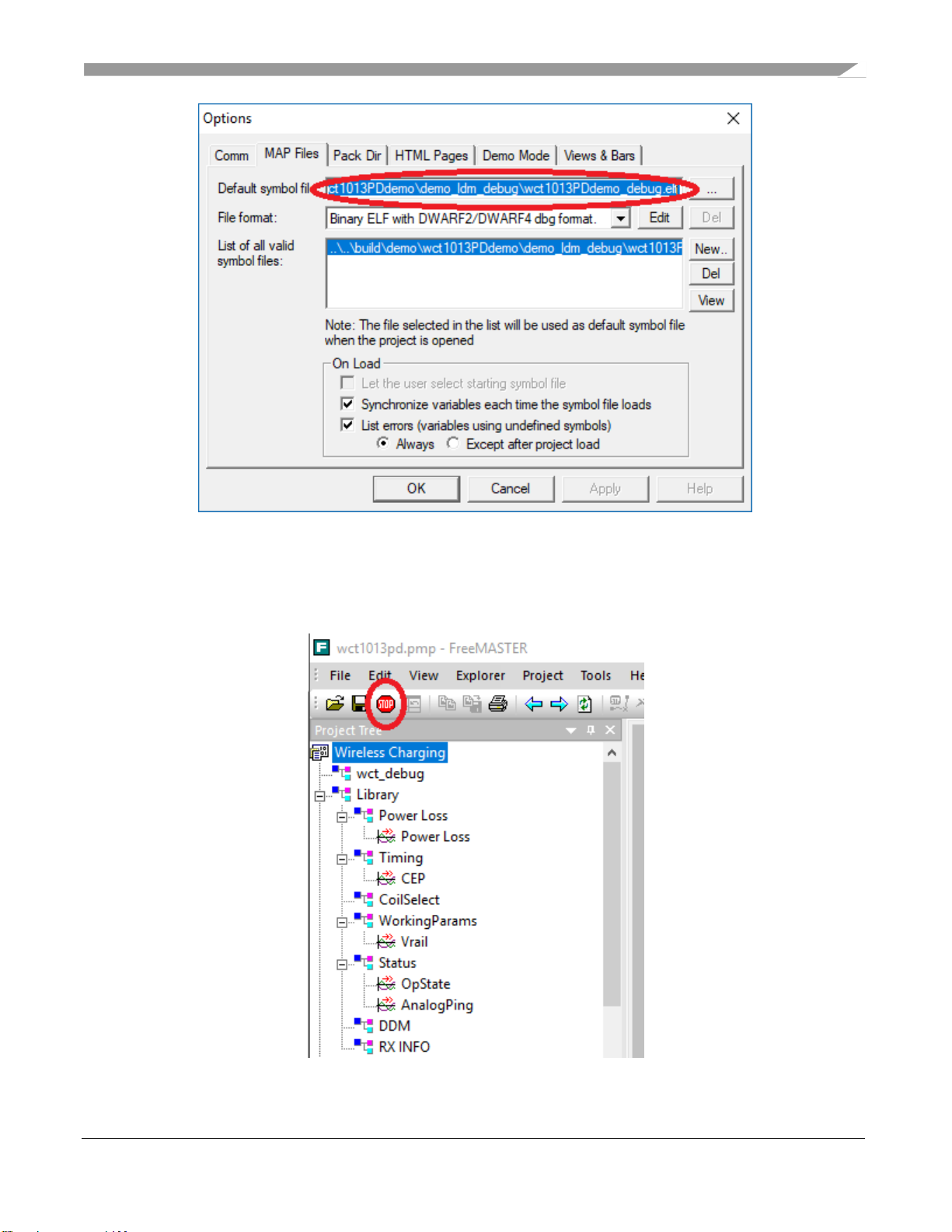

9. Connect FreeMASTER.

Power the MP-A11 on and start the communication by clicking the “STOP” button in the

FreeMASTER GUI.

Figure 17. “STOP” button

Page 18

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

18 NXP Semiconductors

5.2.

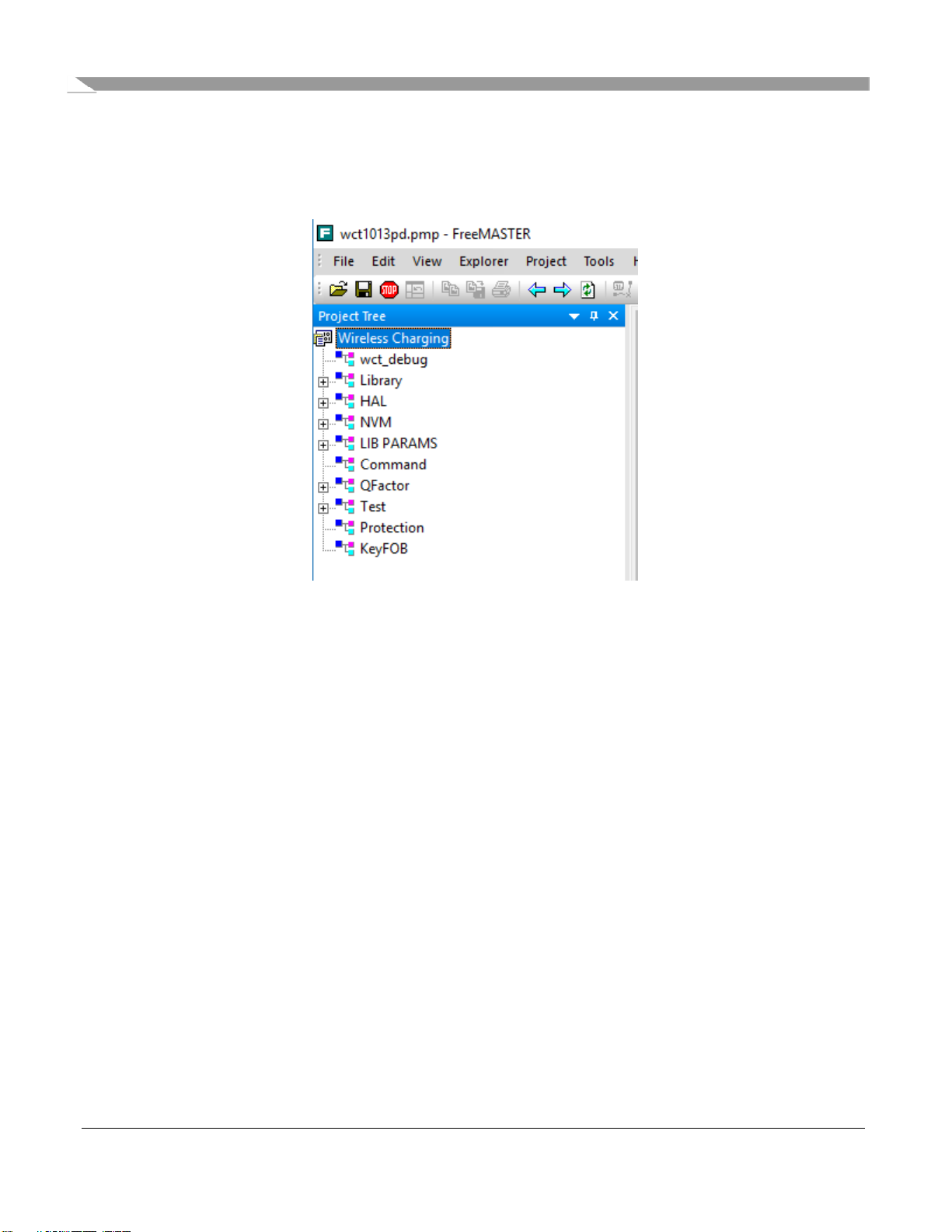

Real-time application variables monitoring

FreeMASTER enables the monitoring and updating of all the application global variables. In this

application, several key variables are displayed in the scope windows. These variables are divided into

different blocks, as shown in the following figure.

Figure 18. Real-time application variables

• wct_debug

This block shows the variables used for the GUI command.

• Library

This block contains the power loss variables, timing variables, coil selection variables, working

parameters, system status, DDM variables, and RX information.

• HAL

This block contains the ADC raw data and DDM buffer values.

• NVM

This block lists all NVM parameters. The Q factor sub-block shows the Q factor calibration

constants. The RRQD sub-block shows the quick-removal calibration constants. The FOD

sub-block shows the FOD characterization calibration constants. The normalization sub-block

shows the FOD normalization constants. The analog sub-block shows the rail voltage calibration

constants.

• LIB PARAMS

This block lists all the parameters used for the WCT library.

• Command

The command variable is used to stop the WCT, start the WCT, and perform automatic

calibration.

Page 19

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 19

• QFactor

This block contains the variables for the Q factor detection.

• Test

This block contains some variables for debugging.

• Protection

This block contains protection variables, such as the input voltage protection, input current

protection, and temperature protection.

NOTE

Besides the above variables, all the global variables can be added to

FreeMASTER. The procedure to generate and add variables to the watch

window is described in the FreeMASTER user manual.

5.3.

Application parameters modification

The application parameters (NVM parameters) can be easily viewed and changed in the control panel.

The control panel contains the web page elements (buttons, check boxes, and text fields) that enable a

user-friendly way to visualize and change the application control parameters.

Figure 19. Application variables

The application variables are divided into these tabs:

• “Op Params”—enables access to variables related to the operation control.

Page 20

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

20 NXP Semiconductors

• “Calibration”—a group of parameters for calibration of the input current, input voltage, and

foreign objects detector.

The meaning of each parameter is described next to the text field.

NOTE

The parameters of the “Calibration” tab can be changed at

run-time, but the parameters of the “Op Params” tab cannot take

effect immediately. To modify the parameters in the “Op Params”

page: enter the debug mode, modify the parameters, and exit the

debug mode. The parameters can then take effect.

6. Application monitoring using console

The application sends some information and error states through the SCI to the console. The information

is sent when the board is turned on, when the device is charging, or in case of an error state.

On the MP-A11 design, only one SCI port (SCI0) is available on the J4 connector. SCI0 is used for

FreeMASTER by default. Select an alternative method to enable the debug console.

1. Disable FreeMASTER and configure the SCI0 as the debug console.

a) #define DEBUG_CONSOLE_SUPPORTED (TRUE)

#define FREEMASTER_SUPPORTED (FASLE)

The macros are defined in example->wct101xa–>configure-> appcfg.h.

b) #define QSCI_CONSOLE_INDEX 0

#define QSCI_FREEMASTER_INDEX 1

The macros are defined in example->wct101xa->driver->qsci.h.

c) gWCT_Params.tDebugConfig.bGeneralDbg = 1;

This variable is in wct_LibParams.c.

2. Change the FreeMASTER communication interface to JTAG and configure the SCI0 as the debug

console.

a) #define DEBUG_CONSOLE_SUPPORTED (TRUE)

#define FREEMASTER_SUPPORTED (TRUE)

The macros are defined in example->wct101xa–>configure-> appcfg.h.

b) #define QSCI_CONSOLE_INDEX 0

#define QSCI_FREEMASTER_INDEX 1

The macros are defined in example->wct101xa->driver->qsci.h.

c) #define FMSTR_USE_SCI 0 /* To select SCI communication interface */

#define FMSTR_USE_JTAG 1 /* 56F8xxx: use JTAG interface */

Page 21

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 21

The macros are defined in example->wct101xa–>configure-> freemaster_cfg.h.

d) gWCT_Params.tDebugConfig.bGeneralDbg = 1;

This variable is in wct_LibParams.c.

6.1.

Software setup

1. Plug the USB-UART converting board to SCI connector J4 and connect the console Micro-USB

port to the computer.

2. Open the Device Manager and check the number of the COM port.

Figure 20. Device Manager

3. Run the communication program supporting console, such as HyperTerminal or RealTerm.

4. The following table shows the communication setup.

Table 1. Port configurations

Port number

Serial port from Device Manager

Baud

19200

Data Bits

8

Stop Bits

1

Parity

None

Hardware Flow Control

None

Display As

ASCII

5. Open the port or start the communication, depending on the terminal used.

Page 22

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

22 NXP Semiconductors

7. Programming new software and calibration

The provided software package includes a WCT1013 project and a binary file (.elf or .S). You can flash

the alternative to the board. After flashing a new software, carry out the board calibration.

7.1.

Installing the latest CodeWarrior IDE

NOTE

The following steps demonstrate the installation of the CodeWarrior for

Microcontrollers v10.7 IDE as an example. You can also select a later

version.

1. Download installation files.

For a proper installation of CodeWarrior 10.7, install both the CodeWarrior for Microcontrollers

10.7 IDE and the CodeWarrior for MCUs v10.7 service pack.

Access the following webpage and log in:

www.nxp.com/products/developer-resources/software-development-tools/codewarriordevelopment-tools/codewarrior-development-suites/codewarrior-development-suite-special:CWSUITE-SPECIAL?tab=Design_Tools_Tab

Click the “Download” button for the CodeWarrior Special Edition (offline or online).

Figure 21. Clicking “Download” for CodeWarrior Special Edition

Download the CodeWarrior for Microcontrollers 10.7 service pack at this link:

www.nxp.com/products/power-management/wireless-charging-ics/15-watt-wireless-chargingtransmitter-ics-for-automotive-applications:MWCT1x1xA?tab=Design_Tools_Tab

Page 23

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 23

Figure 22. Downloading CodeWarrior for MCU v10.7 service pack

2. Double-click the CW_MCU_v10.7_b160721_SE.exe file after downloading.

Figure 23. Setup file

3. Make sure that the “DSC” option is selected.

Figure 24. DSC installed

Page 24

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

24 NXP Semiconductors

4. Launch CodeWarrior, create a folder workspace, and select it as the default workspace.

Figure 25. Workspace Launcher dialog box

5. Select “Help” –> “Install New Software”.

Figure 26. Install New Software

Page 25

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 25

6. Click the “Add”, “Archive”, and then select the

mcu10_7.Wireless_Charging_MWCT101x.win.sp.v1.0.1.zip file.

Figure 27. Selecting the update pack

7. Select the “MCU v10.7 DSC Service Packs” option, and then click “Next”.

Figure 28. Selecting service packs

8. Review the license terms. If you agree with the license terms, select “I accept the terms of the

license agreement” and then click “Finish”.

Page 26

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

26 NXP Semiconductors

Figure 29. Installation finished

7.2.

Board and programmer connection

Connect the 14-pin debug cable to J3 on the board (notice the pin-1 position of the cable).

Page 27

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 27

Figure 30. Connecting the debug cable to the board

7.3.

Programming project files

1. Import a project.

2. Select the “File” tab and then click the “Import” button to import an existing project, as shown in

the following figures.

Page 28

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

28 NXP Semiconductors

Figure 31. Importing a project (1)

Figure 32. Importing a project (2)

Page 29

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 29

3. Select the project directory, as shown in the following figure.

Figure 33. Importing a project (3)

4. Select the WCT1013 project.

Page 30

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

30 NXP Semiconductors

Figure 34. Importing a project (4)

5. Build a project.

Select the build configurations by clicking the project name in the project window, as shown in

the following figure. The “demo_ldm_debug” build contains debug information. The

“demo_ldm_release” is the same as the “demo_ldm_debug”, except for debug information.

Figure 35. Building a project (1)

Page 31

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 31

6. Right-click “wct1013demo” and select the “Clean Project” and “Build Project” options.

Figure 36. Clean Project and Build Project options

7. Download the project.

Download the project from the “Debug” drop-down list or from “Run” -> “Debug”. In

“Download Configurations”, select a download configuration according to your build

configurations and debugger type: USB TAP, PnE Multilink, or OSJTAG.

Figure 37. Downloading the project

Page 32

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

32 NXP Semiconductors

After the project is downloaded, the MCU stops at the startup code. Click the “Run” button or

press the “F8” key to run the MCU. Make sure that there is no object on the TX surface before

running the MCU. Due to the automatic calibration of the rail voltage, the Q-factor and quick

removal is done the first time the TX runs after flashing a new image.

Figure 38. Project downloaded

Page 33

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 33

7.4.

Programming the binary file (.elf or .S)

1. Select “Flash Programmer” –> “Flash File to Target”.

Figure 39. Choosing Flash File to Target

2. Click the “New” button to create a new connection.

Page 34

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

34 NXP Semiconductors

Figure 40. Creating a new connection

3. In the “New Connection” text box, select “Hardware or Simulator Connection” and click “Next”.

Figure 41. Entering a connection name

Page 35

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 35

4. In the “Name” text box, enter a connection name (any name is OK), and click “New” to create a

target.

Figure 42. Entering a connection name

5. In the “Name” text box, enter a target name (any name is OK, but it cannot be the same as the

connection name) and choose “dsc.MWCT101x” -> “MWCT1013A” from the “Target Type”

drop-down menu.

Page 36

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

36 NXP Semiconductors

Figure 43. Choosing MWCT1013A

6. Select “Execute reset” and “Initialize target”, set the initialization target file path to the

CodeWarrior IDE installation folder, and then select MWCT1013A.tcl.

Page 37

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 37

Figure 44. Executing reset and initializing target

7. Click the “Memory” tab.

8. Select “Memory configuration”, set the memory configuration file path to the CodeWarrior IDE

installation folder, and then select “MWCT1013A.mem”.

9. Click “Finish”.

Page 38

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

38 NXP Semiconductors

Figure 45. Memory configuration

10. Select “USB TAP” for the “Connection type”, and then click “Finish”.

Page 39

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 39

Figure 46. Setting the connection type

11. Set the binary file path to “File to Flash”. Select “Save the Target Task” for future programming.

Power the MP-A11 on and click “Erase and Program”.

Page 40

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

40 NXP Semiconductors

Figure 47. Erase and Program

12. Specify the task path and click “OK” to save the task.

Figure 48. Selecting the task path

13. When program is finished, the “Console” window displays the following log.

Figure 49. Programming finished log

Page 41

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 41

7.5.

Programming by bootloader

The bootloader is independent of the application codes and can reside in the flash forever after the

application code is downloaded. When a system is reset, the bootloader starts. After a boot delay (in

seconds), the bootloader jumps to the programmed application code without receiving the application

S-record file. When receiving the application S-record file, the bootloader programs the application code

to the on-chip flash. After completion, the bootloader jumps to the application startup code.

1. The bootloader code is not flashed to the board by default. Download the bootloader code.

Import the bootloader project and follow the steps described in Section 7.3 to download the

project.

Figure 50. Bootloader project

2. Generate an application S-record file.

Enable the bootloader function. Set the following macro to TRUE in appcfg.h.

#define BOOTLOADER_USED (TRUE)

See the figure below to configure the application project settings. Select the “Sort by Address”

option. Set “Max S-Record Length” to a value that does not exceed 255. Select “DOS (\\r\\n)”

for the “S-Record EOL Character”.

Page 42

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

42 NXP Semiconductors

Figure 51. Configure project settings

Recompile the project after completing the configuration above. The generated S-record file is in

the <unpacked_files>\15W_MP\build\demo\wct1013PDdemo\demo_ldm_debug folder for the

WCT1013 chip. The S-record file is the combined p and x S-record file without “.p” or “.x” in

the extension name (.s).

3. Download the application code using the bootloader.

Most serial terminal programs can be used to send the S-Record file from the host to the

WCT1013 board using the bootloader. For example, Tera Term can be used in the Windows OS

platform.

Page 43

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 43

SCI0 is used for communication. Plug the USB-UART converter to the SCI connector J2 and the

computer. Open Tera Term, and select “Serial” and “Port”. Check the COM port in the Device

Manager.

Figure 52. Tera Term connection

4. Choose “Setup” -> “Serial port” to configure the COM properties, as shown in the following

figure.

Figure 53. Serial port

Page 44

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

44 NXP Semiconductors

Figure 54. Serial port setup

5. Choose “File” -> “Send file”.

Figure 55. Send file

6. Select the application S-Record file and click “Open”.

Page 45

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 45

Figure 56. Send application S-Record file

The download progress is displayed in the Tera Term window. After the download completes,

the application code starts.

Figure 57. S-Record file download complete

Page 46

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

46 NXP Semiconductors

7.6.

Board calibration

NXP provides the FreeMASTER GUI tool for calibration and parameters tuning. For board calibration,

see the WCT1012VLF/WCT1013VLH Consumer MP-A11 V1.0 Run-Time Debugging User’s Guide

(document WCT101XV10RTDUG).

8. Software description

8.1.

Software overview

Directory structure

The following figure shows an example of the directory structure of the whole WCT1013_MP-A11

distribution.

Figure 58. Directory structure of the whole WCT1013_MP-A11 distribution

Page 47

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 47

8.2.

CodeWarrior projects

There are four CodeWarrior projects in the package. The following figure shows all four projects in the

CodeWarrior GUI when all of them are imported.

Figure 59. CodeWarrior projects

Combined with different program models and different user cases, multiple build configurations are

predefined in the respective projects.

There are two program models provided for the WCT parts.

• Small program model: The compiler generates a more efficient switch table when the code is in

the range of 0x0-0xFFFF. This model is more efficient, but the code size is limited to 64-KB

words.

• Larger program model: Extends the DSP56800E addressing range by providing 24-bit address

capability to the instructions. This enables the user accesses beyond the 64-KB word boundary of

16-bit addressing.

For the WCT1013 of the MP-A11 design, only the larger program model is provided.

For WCT1013, there are two build configurations:

• “demo_ldm_debug”: larger program model, including the code for debugging.

• “demo_ldm_release”: larger program model, excluding the debugging code to save memory size.

Page 48

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

48 NXP Semiconductors

Figure 60. WCT1013 build configuration

8.3.

Functional description

NXP provides full-featured wireless charging functions on the reference board. If a certain function is

not needed, disable it by the definitions in the header file.

FreeMASTER

• FreeMASTER is supported. The following configuration is used to enable or disable it.

Table 2. FreeMASTER configurations

Configurations

Default value

Location

Description

FREEMASTER_SUPPORTED

TRUE

appcfg.h

Enables or disables the function. Set

TRUE to enable it. Set FALSE to

disable it.

• FreeMASTER communication interface configuration is in freemaster_cfg.h. The SCI

interface is enabled and the JTAG interface is disabled by default. Only one interface can be

set at a time.

#define FMSTR_USE_SCI 1 /* To select SCI communication interface */

#define FMSTR_USE_JTAG 0 /* 56F8xxx: use JTAG interface */

• The FreeMASTER SCI port is SCI0 by default.

1) #define FMSTR_SCI_BASE 0xE080 /* base address of SCI_0 */

The macro is in freemaster_cfg.h.

2) #define QSCI_FREEMASTER_INDEX 0 //QSCI0

The macro is in qsci.h.

Page 49

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 49

Low-power mode

The low-power mode is supported. In the analog ping interval, the MCU enters the LPSTOP mode and

the DCDC module is closed. The following configuration is used to enable or disable it.

Table 3. Low power mode configurations

Configurations

Default value

Location

Description

LOW_POWER_MODE_ENABLE

FALSE

appcfg.h

Enables or disables the function.

Set TRUE to enable it. Set

FALSE to disable it.

Debug console

The debug console is supported. The following configuration is used to enable or disable it.

Table 4. Debug console configurations

Configurations

Default value

Location

Description

DEBUG_CONSOLE_SUPPORTED

FALSE

appcfg.h

Enables or disables the

function. Set TRUE to enable it.

Set FALSE to disable it.

For the WCT1011A/WCT1013A digital buck-boost platform, only one SCI port is available. This port is

used for FreeMASTER by default. If the debug console is used, disable the FreeMASTER or change the

FreeMASTER communication interface to JTAG. The configurations are described in Chapter 6.

Bootloader

Bootloader is supported. The following configuration is used to enable or disable it.

Table 5. Bootloader configurations

Configurations

Default value

Location

Description

BOOTLOADER_USED

FALSE

appcfg.h

Enables or disables the function. Set

TRUE to enable it. Set FALSE to

disable it.

If the bootloader is used, download the bootloader project to the board. Then change

BOOTLOADER_USED to TRUE, rebuild the application project, and download the application .s file

using the bootloader.

DCDC control type

NXP provides two DCDC control types: digital buck-boost and analog buck-boost. Because the MPA11

design doesn’t use the buck-boost circuit, the default one shall be FALSE.

Table 6. DCDC control type configurations

Configurations

Default value

Location

Description

DIGITAL_BUCKBOOST

FALSE

appcfg.h

Switch the DCDC control type. Set

TRUE to enable the digital

buck-boost. Set FALSE to enable the

analog buck-boost.

Page 50

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

50 NXP Semiconductors

Library functions

Some key functions are implemented in the WPC library and can be enabled or disabled in the

application. The following configurations are used to enable or disable them.

Table 7. Library functions configurations

Function

Function description

Variables

Default

value

Description

FOD

Foreign object detection

based on power loss

during power transfer

state

gWCT_Params.uCtrlBit.bFODEnable

1

FOD feature enable

or disable. 1:

enable, 0: disable.

RX removal

quick

detection

RX removal quick

detection based on

current and voltage (~350

ms) instead of

communication timeout

(1.5 s)

gWCT_Params.uCtrlBit.bRRQDEnable

1

RX removal quick

detection enable or

disable. 1: enable, 0:

disable.

Safe digital

ping

Digital ping with lower

coupling to avoid large

current damage of a large

metal

gWCT_Params.uCtrlBit.bSafeDPEnabl

e

1

Safe digital ping

enable or disable. 1:

enable, 0: disable.

Maximum

voltage limit

Refer to MVL in the WPC

Qi specification

gWCT_Params.uCtrlBit.bMVLEnable

1

Maximum voltage

limit enable or

disable. 1: enable, 0:

disable.

Fast charging

Enable fast charging for

some types of phones,

contact NXP for details

gWCT_Params.uCtrlBit.bFastCharging

Enable

1

Fast charging

enable or disable. 1:

enable, 0: disable.

Analog ping

Use several power pulses

to detect object before

digital ping

gWCT_Params.uCtrlBit.bAnalogPingDi

sable

0

Analog ping enable

or disable. 0:

enable, 1: disable.

Q factor

recharge retry

Foreign object removal

detection based on Q

factor method during

recharge retry state

gWCT_Params.uCtrlBit.bQfactorRetry

1

Using Q factor

method for recharge

retry state. 1:

enable, 0: disable.

Maximum

power limit

TX maximum output

power limit

gWCT_Params.uCtrlBit.bMPLEnable

1

Maximum power

limit enable or

disable. 1: enable, 0:

disable.

Active power

protection

Refer to overvoltage

protection in the WPC Qi

specification

gWCT_Params.uCtrlBit.bActivePower

ProtectionEnable

1

Active power

protection enable or

disable. 1: enable, 0:

disable

Low-power

mode for

recharge retry

state

Low-power mode enable

or disable when TX is

under the recharge retry

state

gWCT_Params.uCtrlBit.bRechargeRet

ryLowPowerEnable

0

Low power mode

enable or disable

under recharge retry

state. 1: enable, 0:

disable

Page 51

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 51

Power down

for maximum

rail voltage

Power down or keep the

maximum rail voltage

when rail voltage exceeds

the maximum

gWCT_Params.uCtrlBit.bPowerDownF

orMaxVrail

1

Power down or not

when rail voltage

exceed maximum

value. 1: power

down,

0: keep maximum

“Not Res

Sens” bit for

TX capability

packet

Set “Not Res Sens” bit for

TX capability packet

gWCT_Params.uCtrlBit.bNotResSens

1

Set the value of Not

Res Sens bit for TX

capability packet, 0:

set this bit to 0, 1:

set this bit to 1

Pre-FOD

FOD protection when TX

is in standby state

gWCT_Params.uCtrlBit.bPreFODEnab

le

1

Pre-FOD enable or

disable during

standby state,

1:enable, 0:disable

Duty cycle

control

Duty cycle control when

TX rail voltage is down to

minimum value

gWCT_Params.uCtrlBit.bEnableDutyC

ycleControlForMinRailVol

0

Duty cycle control

enable or disable,

1:enable, 0:disable

BPP

transmitter

TX behaves as BPP

transmitter

gWCT_Params.uCtrlBit.bBPPOnly

0

Only BPP mode

enable or disable. 1:

BPP mode, 0: EPP

mode

8.4.

Protection mechanisms

The following table lists the protection that can be implemented.

Table 8. Protection mechanisms

Protection

Default limits

Variables

Description

Rail voltage

17000 mV

gPROT_Params.wMaxRailVol

Application implemented. If the rail voltage

exceeds the limit, charging is turned off. The

limit value can be changed by

FreesMASTER GUI.

Battery voltage

Min: 8000 mV

Max: 22000

mV

Hysteresis:

1000 mV

gPROT_Params.wMinBatteryVol

gPROT_Params.wMaxBatteryVol

gPROT_Params.wBatteryHystVol

Application implemented. If the battery

voltage exceeds the maximum, the WCT

library stops. When the battery voltage is

lower than the difference between the

maximum and hysteresis, the WCT library

starts. When the battery voltage is lower

than the minimum, the WCT library stops.

When the battery voltage is higher than the

sum of the minimum and hysteresis, the

WCT library starts.

The minimum and maximum limits can be

changed by the FreeMASTER GUI. The

hysteresis value can be changed in

PROT_Init().

Input current

5000 mA

gPROT_Params.wMaxInputCurrent

Application implemented. If the input current

exceeds the limit, charging is turned off. The

limit value can be changed by the

FreeMASTER GUI.

Page 52

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

52 NXP Semiconductors

Coil current

8000 mA

gPROT_Params.wMaxCoilCurrent

Application implemented. If the coil current

exceeds the limit, charging is turned off. The

limit value can be changed by the

FreeMASTER GUI.

Temperature

Max: 60

Hysteresis:

10

gPROT_Params.swTemperatureThres

hold

gPROT_Params.wTemperatureHyst

Application implemented. If the temperature

exceeds the maximum, the WCT library

stops. When the temperature is lower than

the difference between the maximum and

hysteresis, the WCT library starts. The

maximum limit can be changed by the

FreeMASTER GUI. The hysteresis value can

be changed in PROT_Init().

Safe digital ping

200 mA

gPROT_Params.wSafeDigitalPingInpu

tCurrentThreshold

Library implemented. If the input current

sampled at the beginning of the digital ping

exceeds the limit, digital ping stops. The limit

value can be changed in PROT_Init().

FOD

BPP RX:

400 mW

EPP RX:

800 mW

EPP5W RX:

450 mW

gWCT_Params.wBPPLPPowerLossTh

resholdInOperationMode

gWCT_Params.wEPPMPPowerLossT

hresholdInOperationMode

gWCT_Params.wEPPLPPowerLossTh

resholdInOperationMode

Library implemented. If the power loss

exceeds the limit, charging is turned off for 5

minutes. The limit value can be changed by

the FreeMASTER GUI.

9. System bring up

9.1.

Ping sequences

When the low-power mode is disabled and no receiver is placed on the charging surface, the ping

sequence is as follows:

The digital ping appears about every 5 seconds and the analog ping appears about every 400 ms. There

are 12 to 13 analog pings between two digital pings.

The following figures show the PWM waveforms of the ping sequence and ping patterns.

Page 53

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 53

Figure 61. Digital ping interval

Figure 62. Analog ping interval

Page 54

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

54 NXP Semiconductors

Figure 63. Digital ping pattern

Figure 64. Analog ping pattern

9.2.

LED indication

The default LED display modes for different TX working states are shown in the following table.

Page 55

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

NXP Semiconductors 55

Table 9. LED display modes

LED number

LED operational status

Standby

Charging

Charging

complete

D fault

TX fault

RX fault

LED 1 (Red)

Off

Blink

Off

On

On

On

LED 2 (Green)

Blink

On

On

Off

Off

Off

The display pattern can be changed in WCT_UpdateDevUsrIndication().

9.3.

Debug messages

The system can print messages from a specified SCI port to inform you what happened in the system.

The messages help you to understand the system working procedure and debug the issues.

Message: ID, T/O

Prints information when the identification packet times out.

Message: EXT ID, T/O

Prints information when the extended identification packet times out.

Message: CFG, HOLDOFF Invalid

Prints information when the hold off time is out of range.

Message: CFG, Incorrect Count, Count1 (Count2)

Prints information when the amount of optional configuration packets received does not match the

number in the configuration packet.

• Count 1: the number in the configuration packet.

• Count 2: The amount of TX optional configuration packets received.

Message: CFG, Over CP

Prints information when the RX power is beyond capability.

Message: CFG, Rcvd 0xXX

Prints the packet type that should not be received in the configuration phase.

Page 56

WCT1012VLF/WCT1013VLH Consumer MP-A11 (WCT-15W1CFFPD) V1.0 Wireless Charging Application User’s

Guide, Rev. 1, 05/2019

56 NXP Semiconductors

Message: CFG, T/O

Prints information when the configuration packet times out.

Message: XFER, INCOMP

Prints information when the RX version is not compatible.

Message: XFER, RCVPWR T/O

Prints information when the receive power packet times out.

Message: XFER, PLoss T/O

Prints information when the FOD happens.

Message: PROP, <Packet type>

Prints the proprietary packet header.

Message: XFER, Rcvd 0xXX Reset

Prints the packet type that is not received in the power-transfer phase. Charging is reset.

Message: XFER, Rcvd 0xXX

Prints the packet type that is not defined in the WPC specification.

10. Revision history

Table 10 summarizes the changes done to this document since the initial release.

Table 10. Revision history

Revision number

Date

Substantive changes

0

04/2019

Initial release.

1

05/2019

Updated Section 1, “Key features” and

Section 4.5, “Full-bridge and resonant

circuits”.

Updated Table 8.

Page 57

Document Number: WCT101XV10AUG

Rev. 1

05/2019

How to Reach Us:

Home Page:

www.nxp.com

Web Support:

www.nxp.com/support

Information in this document is provided solely to enable system and software

implementers to use NXP products. There are no express or implied copyright licenses

granted hereunder to design or fabricate any integrated circuits based on the

information in this document. NXP reserves the right to make changes without further

notice to any products herein.

NXP makes no warranty, representation, or guarantee regarding the suitability of its

products for any particular purpose, nor does NXP assume any liability arising out of

the application or use of any product or circuit, and specifically disclaims any and all

liability, including without limitation consequential or incidental damages. “Typical”

parameters that may be provided in NXP data sheets and/or specifications can and do

vary in different applications, and actual performance may vary over time. All operating

parameters, including “typicals,” must be validated for each customer application by

customer’s technical experts. NXP does not convey any license under its patent rights

nor the rights of others. NXP sells products pursuant to standard terms and conditions

of sale, which can be found at the following address:

www.nxp.com/SalesTermsandConditions.

While NXP has implemented advanced security features, all products may be subject to

unidentified vulnerabilities. Customers are responsible for the design and operation of

their applications and products to reduce the effect of these vulnerabilities on

customer’s applications and products, and NXP accepts no liability for any vulnerability

that is discovered. Customers should implement appropriate design and operating

safeguards to minimize the risks associated with their applications and products.

NXP, the NXP logo, NXP SECURE CONNECTIONS FOR A SMARTER WORLD,

COOLFLUX, EMBRACE, GREENCHIP, HITAG, I2C BUS, ICODE, JCOP, LIFE VIBES,

MIFARE, MIFARE CLASSIC, MIFARE DESFire, MIFARE PLUS, MIFARE FLEX,

MANTIS, MIFARE ULTRALIGHT, MIFARE4MOBILE, MIGLO, NTAG, ROADLINK,

SMARTLX, SMARTMX, STARPLUG, TOPFET, TRENCHMOS, UCODE, Freescale, the

Freescale logo, AltiVec, C5, CodeTEST, CodeWarrior, ColdFire, ColdFire+, CWare,

the Energy Efficient Solutions logo, Kinetis, Layerscape, MagniV, mobileGT, PEG,

PowerQUICC, Processor Expert, QorIQ, QorIQ Qonverge, Ready Play, SafeAssure, the

SafeAssure logo, StarCore, Symphony, VortiQa, Vybrid, Airfast, BeeKit, BeeStack,

CoreNet, Flexis, MXC, Platform in a Package, QUICC Engine, SMARTMOS, Tower,

TurboLink, and UMEMS are trademarks of NXP B.V. All other product or service names

are the property of their respective owners. AMBA, Arm, Arm7, Arm7TDMI, Arm9,

Arm11, Artisan, big.LITTLE, Cordio, CoreLink, CoreSight, Cortex, DesignStart,

DynamIQ, Jazelle, Keil, Mali, Mbed, Mbed Enabled, NEON, POP, RealView,

SecurCore, Socrates, Thumb, TrustZone, ULINK, ULINK2, ULINK-ME, ULINK-PLUS,

ULINKpro, µVision, Versatile are trademarks or registered trademarks of Arm Limited

(or its subsidiaries) in the US and/or elsewhere. The related technology may be

protected by any or all of patents, copyrights, designs and trade secrets. All rights

reserved. Oracle and Java are registered trademarks of Oracle and/or its affiliates. The

Power Architecture and Power.org word marks and the Power and Power.org logos and

related marks are trademarks and service marks licensed by Power.org.

© 2019 NXP B.V.

Loading...

Loading...