Page 1

NXP Semiconductors

Document Number: WCT101XAV31AUG

User’s Guide

. 3.1

,

10

7

Rev

/201

WCT1011A/WCT1013A Automotive

MP-A9 V3.1 Wireless Charging

Application User’s Guide

1. Key Features

The Automotive MP-A9_Rev1.0

(MP-A9_Rev1_SCH-29323_B2,

MP-A9_Rev1_LAY-29323_B2) wireless

charging TX demo is used to transfer power

wirelessly to a charged device. A charged device

can be any electronic device equipped with a

dedicated Qi wireless charging receiver.

The main parameters of the wireless charging

transmitter (WCT) are as follows:

• The input voltage ranges from 9 V DC to

16 V DC (automotive bat range).

Contents

1. Key Features 1

2. Hardware Setup 2

3. Application Operation 6

4. Hardware Description 7

5. Application Monitoring and Contro l Through

FreeMASTER 15

6. Application Monitoring Through Console 21

7. Programming New Software and Cal ibration 23

• The input voltage can drop down to 6 V

DC level during the start-stop function.

• The nominal delivered power to the

receiver is 15 W (at the output of the

receiver) and can be compatible with 5W

receiver.

• Designed to meet the Qi 1.2.3

specification.

• Operation frequency: 125 kHz for Qi

devices.

© 2017 NXP B.V.

_______________________________________________________________________

8. Software Description 45

9. System Bring Up 50

10. Revision History 54

Page 2

2. Hardware Setup

2.1 Pack content

1. WCT Automotive MP-A9 (WCT-15WTXAUTO) demo board

2. Power supply connector

3. Power supply 12V/3A

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

2 NXP Semiconductors

Figure 1 Hardware pack contents

Page 3

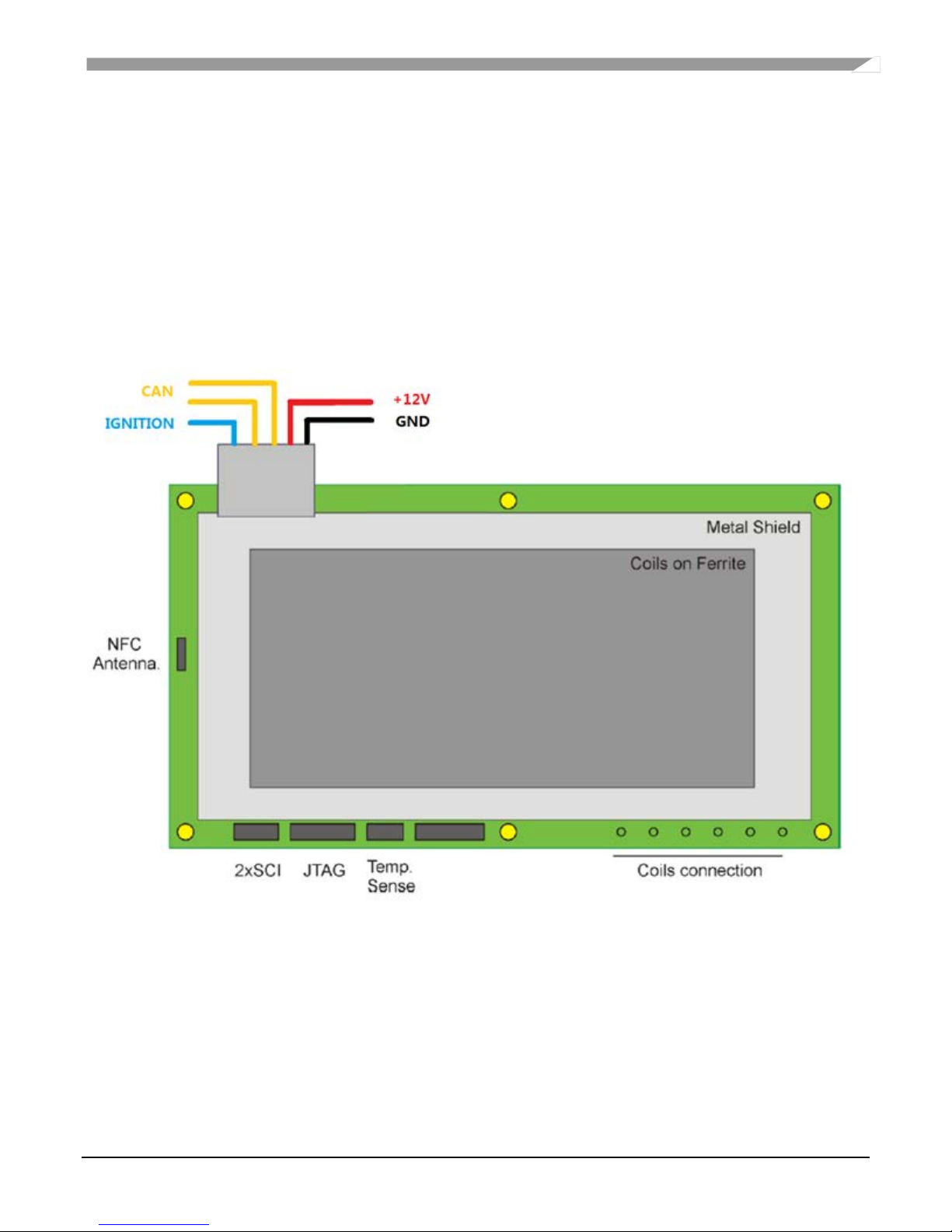

2.2 Board description

The WCT board is connected to the system by the main power connector. It comprises the automotive

battery connection (red wire = +12 V line, black wire = GND line), the CAN connection (yellow wires),

and the IGNITION (blue wire).

The connectors on the bottom edge of the board provide a JTAG connection for programming and

debugging, 2xSCI for the FreeMASTER tool connection for the debug option and the console connection,

and the temperature connector and backup touch sense connector are placed on the edge of the board. The

thermal resistor circuits can be used to develop the temperature sensing and protection.

The circuitry on the board is covered by the metal shield to lower the EMI and provides a f ixed position for

the coils. Figure 2 shows the device.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 3

Figure 2 Device

Page 4

2.3 Powering on a board

To power on a board, perform the following steps:

1. Plug power supply 12 V to the socket.

2. Plug the power supply connector into the board.

3. Connect power supply 12 V and power supply connector.

Figure 3 Power supply components

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

4 NXP Semiconductors

Page 5

2.4 Hardware setup for FreeMASTER and Console communication

Console FreeMaster

R47

10.0K

V3.3

RXD0

RXD1

TXD 1

R210

10.0K

TXD 0

J2

HDR_2X4_RA

1 2

3

4

6

5

7 8

To set up the hardware for FreeMASTER and Console communication, perform the following steps:

1. Find two UART-to-USB adaptor boards, and successfully install this UA RT-to-USB device driver

on the computer. The virtual serial port on the computer should work well.

2. Plug the USB-UART converting board to SCI connector J2 according to the SCH signal pin

position. The two channels of UART are for different purposes: FreeMASTER and Console.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 5

Figure 4 SCIs and JTAG connectors

Page 6

3. Application Operation

Connect the demo to the supply voltage +12 V DC. The WCT starts to send pe riodically the power ping to

check whether the compatible device wireless charging receiver (WCR) is placed on the charging surface.

When the Qi-compliant device is placed on the top of the TX coils area, the WCT starts the charging

process. If there is no correct Qi answer from the WCR side, the TX does not start the Qi charging process.

If the WCR answers properly, the power transfer starts. The actual level of the transferred power is

controlled by the WCT in accordance with WCR requirements. The receiver sends messages to the WCT

through ASK on the coil resonance power signal, and the transmitter sends the information to the receiver

by FSK according to the Qi specif ication. The power transfer is terminated if the receiver is removed from

the WCT magnetic field.

The system supports all Qi WCR devices: Qi_Ver-1.0 compliance and Qi_Ver-1.1 compliance, and the Qi

EPP 15 W receiver. The sy stem supports all the FOD features for different receivers. For the low-power 5

W receiver, the power loss FOD is supported. For the EPP 15 W receiver, both Q-value method and power

loss FOD method are supported.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

6 NXP Semiconductors

Page 7

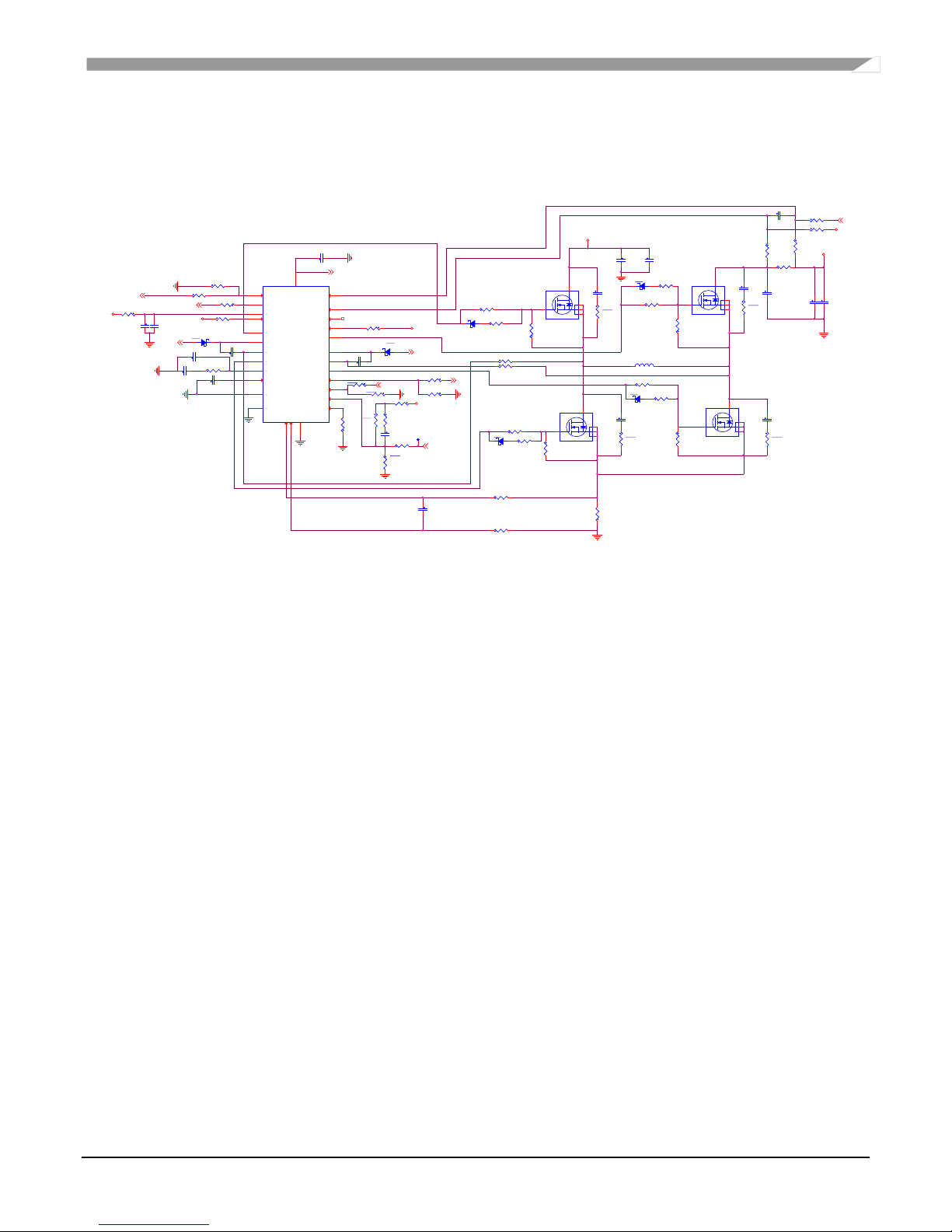

4. Hardware Description

BCM

Coil Selection

Full Bridge

Rail

Voltage

C

o

i

l

0

400nF

C

o

i

l

1

C

o

i

l

2

DDM

RC circuits

pack5

Q fator

detection

Input Voltage

Temperature

Sampling Circuit

Buck-boost

Digital /

analog

control

MOS DRIVER

WCT1011/3A

NFC

CAN

CONSOLE

FreeMaster

VIN

DCDC

VOUT

CAR battery

VIN

LDO

VOUT

Coil current

Q-voltage

WPC DDM

Q-resonance

Resonant Circuits

5V/0.3A

3.3V/0.2A

Inverter Current/

voltage

FB Inverter

Coil Switched

Digital buck-boost

Input Current

Input EMI filter

Can and Lin

NFC NCF3340

WCT1011/3A

UART&JTAG

Q-value detection

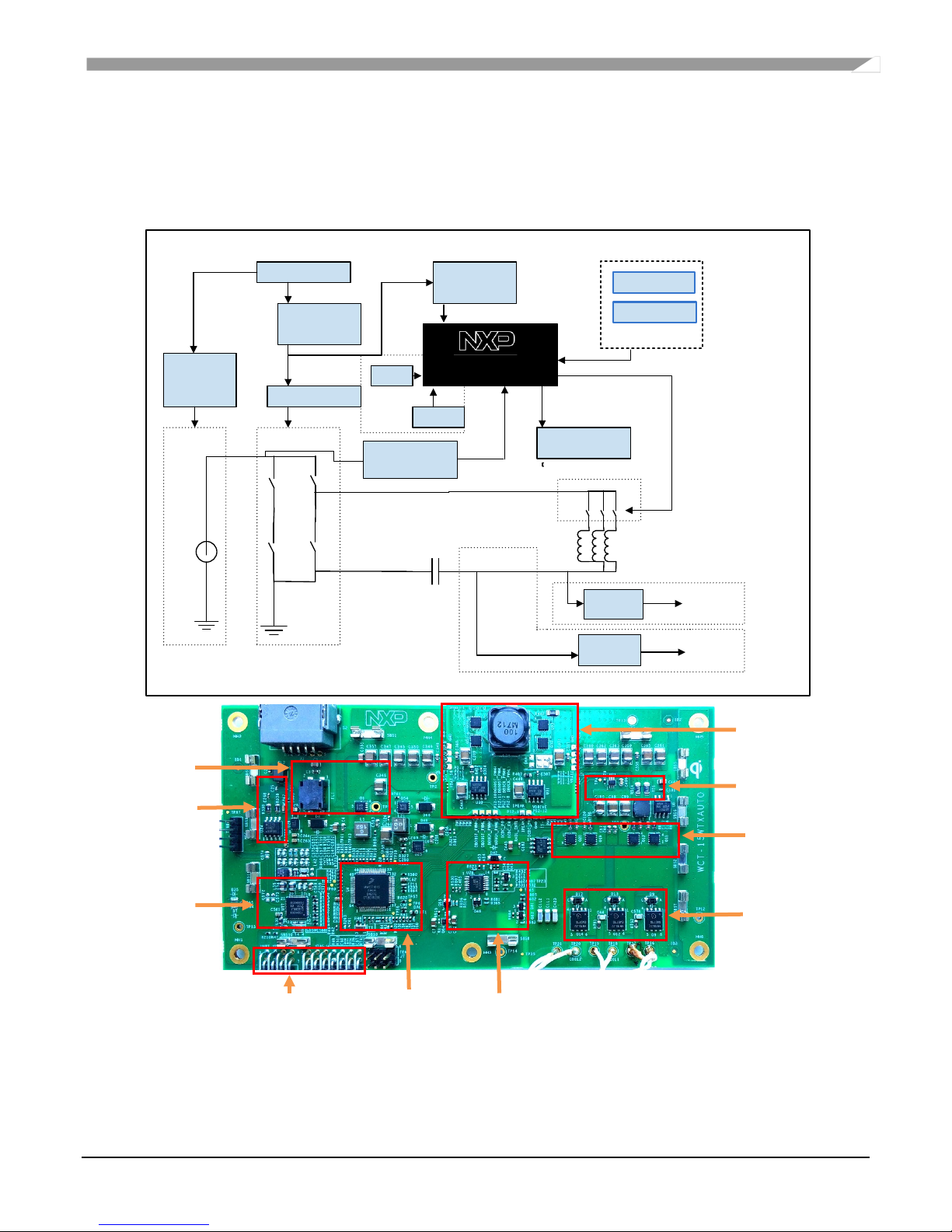

Figure 5 shows the block diagram of the automotive wireless charger MP-A9.

Go to the NXP website to obtain the latest Hardware Design files.

The whole design consists of several blocks, which are described in the following sections.

Figure 5 Block diagram of the automotive wireless charger MP-A9

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 7

Page 8

4.1 I nput EMI filter

C371

10uF

C311

0.1uF

50V

VRAIL_2

D84

PMEG060V050EPD

DNP

1

2

3

GND2

C496

47pF

C368

0.1uF

50V

Ipeak_S2

8

R442

0.015

C449 10uF

C448 10uF

GND2

GND2

GND2

GND2

GND2

GND2

Small board 2

D56

1PS76SB10

A C

D57

1PS76SB10

A

C

R400

10.0K

VDrive_S2

R401

10.0K

C305 0.1uF

C304 0.1uF

R402

10

R403 10

DBUCK_PWML_S2

8

DBUCK_PWMH_S2

8

R404 10

AUIRS2301S

U30

VCC

1

HIN

2

LIN

3

COM

4

LO

5

VS

6

HO

7

VB

8

Q51

NVTFS5820NLTAG

1

4

3

2

5

Q50

NVTFS5820NLTAG

1

4

3

2

5

Q52

NVTFS5820NLTAG

1

4

3

2

5

Q53

NVTFS5820NLTAG

1

4

3

2

5

R405

10.0K

R406

10.0K

VDrive_S2

C308 0.1uF

R408 10

C307 0.1uF

R407

10

DBOOST_PWML_S2

8

DBOOST_PWMH_S2

8

R409 10

L24

10UH

1

2

AUIRS2301S

U31

VCC

1

HIN

2

LIN

3

COM4LO

5

VS

6

HO

7

VB

8

VBAT_SW_2

C369

10uF

R411

3.32

C319

1000pF

C343

1000pF

C344

1000pF

C318

1000pF

R466

3.32

R410

3.32

R467

3.32

The input connector J1 provides the whole connection to the car wiring. It connects the battery voltage to

the WCT and CAN communication interface.

The input filter consists of the Common Mode Filter FL1 and the filter capacitors C1, C3, C4, C14, and

L1.

The main battery voltage switch is equipped with MOSFET Q1. This stage is controlled by the main

controller WCT1011A/WCT1013A and the IGNITION signal. The hardware overvoltage protection

(more than 20 V DC) is also implemented by D1 and Q2 to this switch.

4.2 System voltage DCDC and LDO

The 12 V Car Battery input is connected to a buck converter U25 (MPQ4558). Its output is 5 V and

supplies LDO U26 (MPQ8904), MOSFET Driver, and CAN Transceiver. The 3.3 V output of LDO is

mainly for WCT1011A/WCT1013A and other 3.3 V powered components.

Generally, the DCDC works at the light-load conditions. High efficiency in light-load is very important

for this auxiliary buck converter.

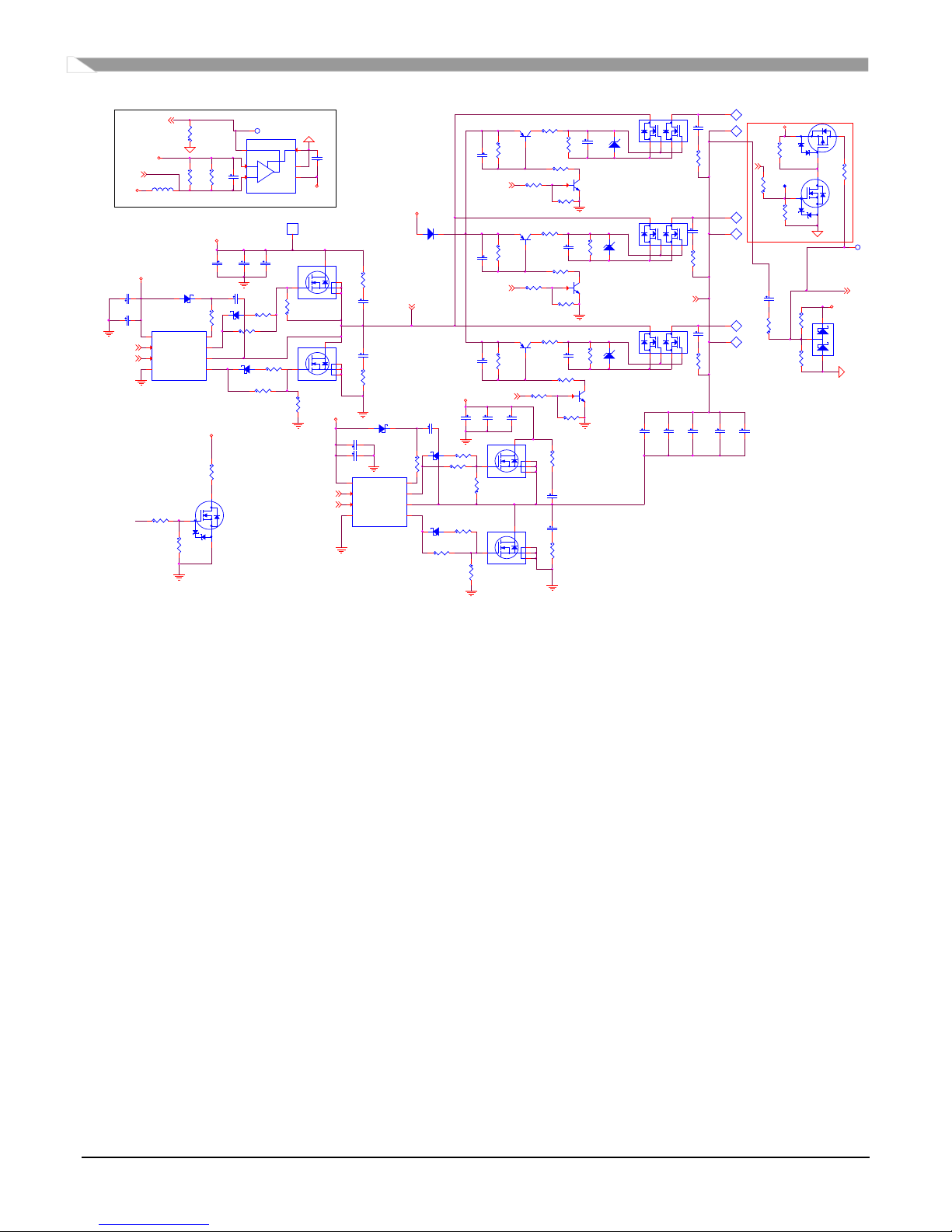

4.3 Rail voltage generated by digital buck-boost or analog buck-boost chip

The Qi specification for the MP-A9 topology requires the DC voltage control to control the power

transferred to the receiver. The buck-boost converter is selected to obtain the regulated DC voltage in the

range from 1 V DC to 24 V DC for the full-bridge inverter power supply. The buck-boost can be digitally

controlled by the WCT chip or the individual analog buck-boost converter and the WCT chip just controls

the output voltage feedback.

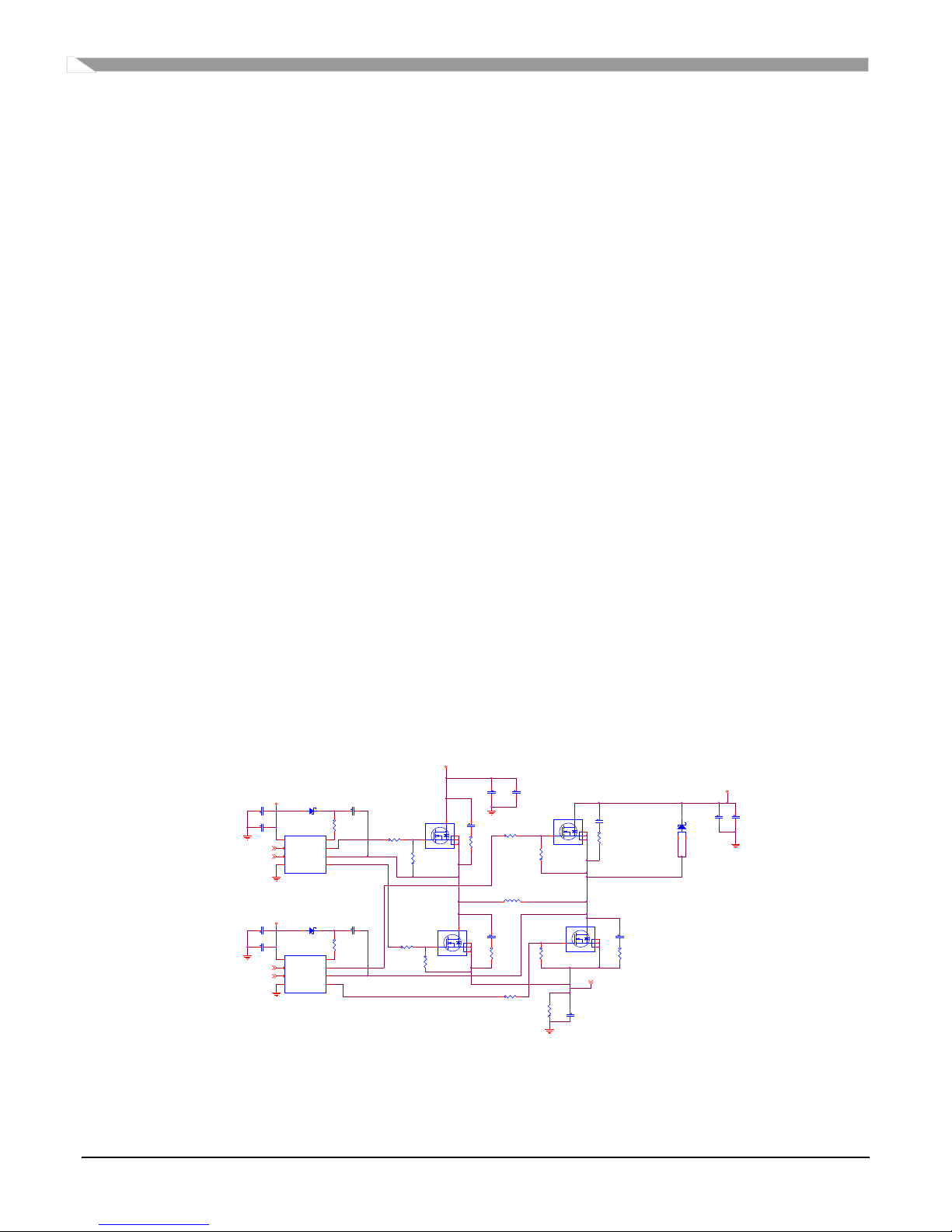

Digital buck-boost module includes the drivers, the full-bridge converter, and the output voltage feedback.

The DCDC converter’s control loop is implemented by the firmware, and the control parameters can be

optimized with different main circuit parameters, such as the inductor and output capacitor.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

8 NXP Semiconductors

Figure 6 Digital buck-boost main circuits

Page 9

For the analog buck-boost module, the LTC3789 is selected to generate the rail voltage. The WCT chip

C524 0.01uF

GND6

R664

1K

R665

1K

R666 68K

C525 1000pF

C526 3300pF

R6670

R6680

DNP

R669

120K

R671 0

R672 0

DNP

C527

10uF

R676

0.015

GND6

GND6

C529 0.22uF

INTVCC

9

C530 4.7uF

GND6

C531 0.22uF

GND6

VBAT_SW_6

R6790

GND6

INTVCC

9

INTVCC

9

GND6

R646

2.00k

R687

2.00k

LTC3789IGN

U75

VFB

1

SS

2

SENSE+3SENSE-

4

ITH

5

SGND

6

MODE/PLLIN

7

FREQ

8

RUN

9

VINSNS

10

VOUTSNS

11

ILIM

12

IOSENSE+

13

IOSENSE-

14

TRIM

15

SW2

16

TG2

17

BOOST2

18

BG2

19

EXTVCC

20

INTVCC

21

VIN

22

BG1

23

PGND

24

BOOST1

25

TG1

26

SW1

27

PGOOD

28

GND6

R6570

DCDC_PG_6

9

GND6

R6700

VRAIL_6

R625

1.6K

C502

10uF

GND6

C503

10uF

GND6

C504

10uF

GND6

R680 0

VBAT_SW_6

C513

47pF

VRAIL_6

TP64

DNP

Differential Wire

Small board 6

DCDC_EN_6

9

GND6

R634 10

R635 10

D90 1PS76SB10

A

C

R637 10

R636 10

R639 0

R638 0

D91

1PS76SB10

AC

R641 0

R640 0

R642 0

R643

0

C515

0.1uF

50V

R6450

D85

PMEG2005AEA

AC

D86

PMEG2005AEA

AC

D87

PMEG2005AEA

AC

D88

PMEG2005AEA

A

C

C518

0.1uF

50V

R651

0.015

R652

10.0K

R653

10.0K

Q76

NVTFS5820NLTAG

1

4

3

2

5

Q77

NVTFS5820NLTAG

1

4

3

2

5

R654

10.0K

Q78

NVTFS5820NLTAG

1

4

3

2

5

R655

10.0K

Q79

NVTFS5820NLTAG

1

4

3

2

5

L32

10UH

1

2

VBAT_SW_6

C521

0.1uF

50V

VRAIL_6

INTVCC

9

R662

200

C523

4700pF

RAIL_CNTL_6

9

INTVCC

9

R663

39K

R661 4.3K

GND6

R629 100

DNP

R628 100

DNP

VRAILB_S6

C514 1.0uF

IS-_S6

9

R677

100

R678

100

C517

2700pF

C520

2700pF

C519

2700pF

C516

2700pF

R648

3.32

R647

3.32

R650

3.32

R649

3.32

controls the rail voltage by one analog signal. This analog signal affects the analog buck-boost converter

feedback, and then the system can get the rail voltage as the system expects.

The digital buck-boost is recommended for use on this wireless charging solution due to its lower cost,

simpler hardware circuits, and easier to be controlled.

4.4 Full-bridge and resonant circuits

The full-bridge power stage consists of two MOSFET Drivers, U8 and U9, as well as four power

MOSFETs, Q13, Q15, Q19, and Q20. The MOSFET Drivers are powered by the stable voltage level 5 V

DC that decreases the power losses in the drivers and MOSFETs. The full-bridge power stage converts the

variable DC voltage VRAIL to the square wave 50% duty-cycle voltage with 125 kHz frequency. The

range of the used frequency (120 kHz to 130 kHz) is defined in the Qi specification for the MP-A9

topology.

The resonant circuits consist of C111, C112, C423, C580, and coils, all of which are fixed values defined

in the Qi specification for the MP-A9 topology. The snubber RC pairs connected in parallel to power

MOSFETs are used to lower the high frequency EMI products. The Vrail discharge circuit Q46, R376, is

switched ON while the system is terminated.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 9

Figure 7 Analog buck-boost main circuits

Page 10

C364

22uF

C578

1000PF

R752

51

R751

51

C44

1000PF

R753

51

C579

1000PF

COIL2

Q81

2N7002BKW

1

2 3

Q82

BSS84W

1

2 3

R683

6.8K

C423

0.1uF

R682

100K

R684

100K

C112

0.1uF

C111

0.1uF

C580

0.1uF

C582

0.1uF

DNP

R805

2.00k

D9

BZT52H-C16

A C

D17

BZT52H-C16

A C

D13

BZT52H-C16

A C

R573 1.5K

R575 1.5K

R574 1.5K

COIL1

COIL0

FOD

AC Coil Current

VBAT_SW

R80 5.11K

D14

BAT54SW

1 2

3

R98 5.11K

R88 5.11K

R116

5.11K

R81

33.2K

COILS

R90

33.2K

COIL0_EN

3

TP16

DNP

TP18

DNP

TP17

DNP

TP19

DNP

COIL1_EN

3

SW_GATE0

Q9

IPG20N10S4L-22

241

3

6

5

SW_GATE1

Q12

IPG20N10S4L-22

241

3

6

5

COIL2_EN

3

R101 33.2K

TP20

DNP

TP21

DNP

SW_GATE2

COILS

6

R95

7.5K

Q16

IPG20N10S4L-22

241

3

6

5

R74

7.5K

R84

7.5K

C101

0.022uF

C105

0.022uF

C439

4700pF

C109

0.022uF

C440

4700pF

C441

4700pF

V3.3A

DDM

AC_COIL_CURRENT_OP

3

GAIN_SWITCH

3

TP65

DNP

V3.3A

R118

3.9K

R224

51K

D42

BAS16H

A C

Q14

PMBT4401

2 3

1

Q10

PMBT4401

2 3

1

Q18

PMBT4401

2 3

1

Q8

PMBTA92

1

2 3

R73

5.11K

Q11

PMBTA92

1

2 3

Q17

PMBTA92

1

2 3

TP35

DNP

C210

4700pF

100V

R83

5.11K

R94

5.11K

C499

1.0uF

IS-

8

L7

2.9OHM

1 2

TP49

DNP

+

-

OUT

IN+

IN-

V+

GND

REF

U21

INA214AQDC KRQ1

1

2

3

4

5

6

R514

0.015

VRAIL

VRAILA

R76

0.015

C94

0.1uF

R79

10.0K

INPUT_CURRENT

3,5

FOD

Inverter Input Current

V3.3A

R376

100

R278

10.0K

VDriv e

R279

10.0K

R201 0

R426

0

HB1A

6

C108

1000pF

C107

1000pF

R89 4.7

R91 4.7

C104 0.1uF

R87

3.32

C181 0.1uF

R85

10

HB1A

R92

3.32

Q13

NVTFS5820NLTAG

1

4

3

2

5

TP7

DNP

1

D12

1PS76SB10

A C

VRAILA

Q15

NVTFS5820NLTAG

1

4

3

2

5

D59

PMEG2005AEA

AC

D25

PMEG2005AEA

AC

C96

0.1uF

50V

C97

0.1uF

50V

C444 4.7uF

AUIRS2301S

U8

VCC

1

HIN

2

LIN

3

COM

4

LO

5

VS

6

HO

7

VB

8

COIL_PWM_HL

3

COIL_PWM_HH

3

VDriv e

R281

10.0K

R280

10.0K

R428 0

C120

1000pF

R427 0

R105 4.7

C121

1000pF

R102 4.7

C118 0.1uF

HB1B

R99

10

C183 0.1uF

R106

3.32

R100

3.32

D18

1PS76SB10

A C

VRAILA

COIL_PWM_LH

3

COIL_PWM_LL

3

Q20

NVTFS5820NLTAG

1

4

3

2

5

Q19

NVTFS5820NLTAG

1

4

3

2

5

D61

PMEG2005AEA

A

C

D60

PMEG2005AEA

AC

AUIRS2301S

U9

VCC

1

HIN

2

LIN

3

COM

4

LO

5

VS

6

HO

7

VB

8

C445 4.7uF

R365

100k

R681

2.00k

Q46

2N7002BKW

1

2 3

VRAILA

C98

22uF

R77 20K

R86 20K

C99

22uF

R97 20K

C100

22uF

Figure 8 Full bridge circuits and coil selection circuits

4.5 Communication

There is bi-way communication between the medium power transceiver and receiver. Communication

from RX to TX: The receiver measures the received power and sends back to transmitter the information

about the re quired power level. This message is amplitude modulated (AM) on the coil current and sensed

by TX.

The RC circuits (C210, R116, R118, R224), known as DDM, sample the signals from the coil, compress

the signal amplitude, and feed to ADC B-channel of WCT1011A/WCT1013A. The information about the

current amplitude and modulated data are processed by the embedded software routine.

Communication from TX to RX: TX shall negotiate with RX in the negotiation phase if requested by RX.

TX uses FSK Modulation to communicate with RX, and the communication frequency is about 512 times

operating frequency.

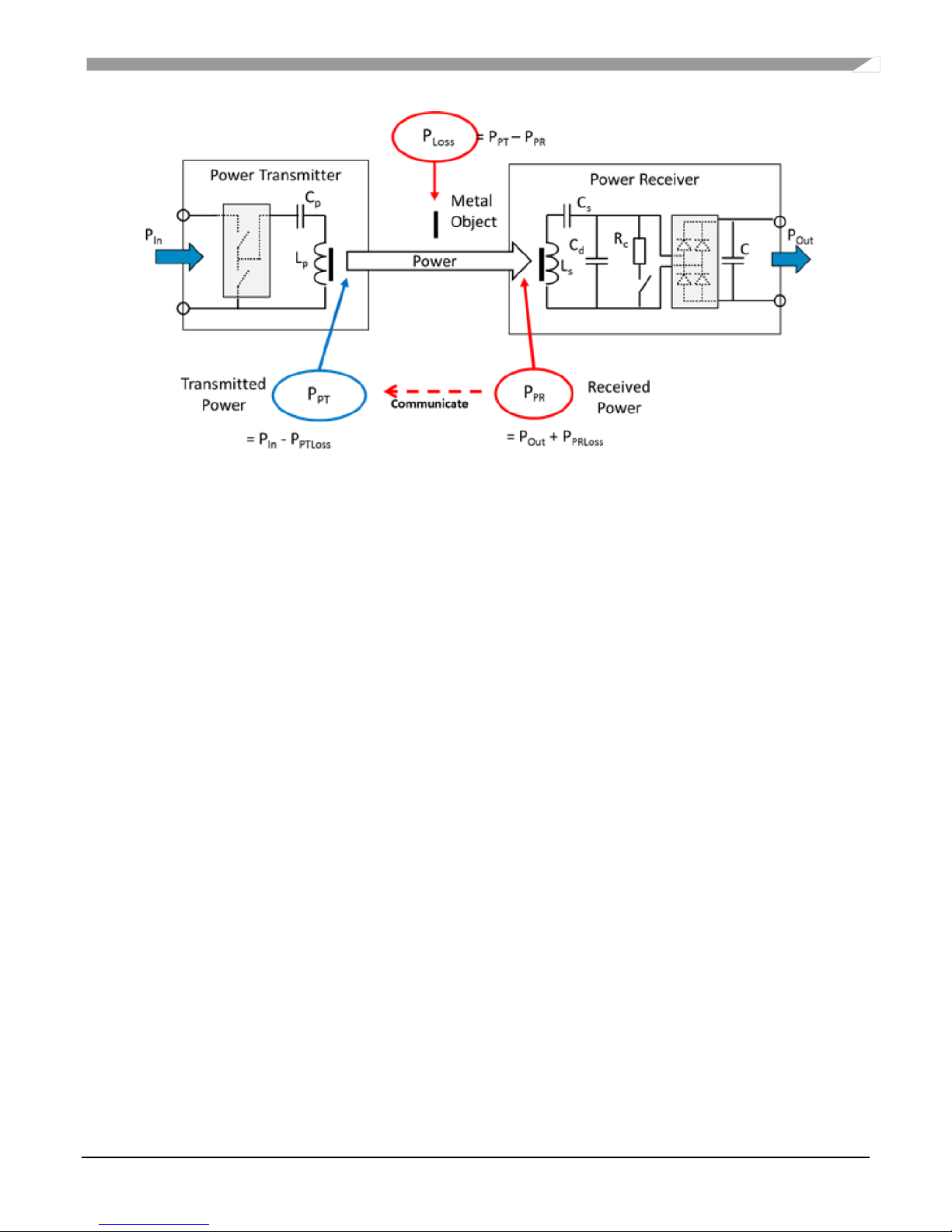

4.6 FOD based on power loss

The power loss

Received Power , i.e.

in Figure 9.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

10 NXP Semiconductors

, which is defined as the difference between the Transmitted Power and the

=

, provides the power absorption in Foreign Objects, as shown

Page 11

Figure 9 Power loss illustrated

When the FO is implemented in the power transfer, the power loss will increase accordingly, and the FO

can be detected based on the power loss method.

Power loss FOD method is divided into two types: FOD for baseline power profile (TX and RX can

transfer no more than 5 W of power) and extensions power profile (TX and RX can transfer power above

5 W).

4.6.1 Power loss FOD baseline

The equation for power loss FOD baseline is

The Transmitted Power represents the amount of power that leaves the TX due to the magnetic field

of the TX, and

=

, where represents the input power of the TX and

power dissipated inside the TX. could be measured by sampling input voltage and input current, and

could be estimated through the coil current.

The Received Power represents the amount of power that is dissipated within the RX due to the

magnetic field of the TX, and

is the power lost inside the RX.

=

+

When NXP WCT-15WTXAUTO charges the RX baseline, the power loss baseline is applied. The TX

continuously monitors

, and if it exceeds the threshold several times, the TX terminates power

transfer.

=

. The power

.

is provided at the RX’s output and

is the

4.6.2 Power loss FOD extensions

Typically, a RX estimates the power loss inside itself to determine its Received Power. Similarly, the TX

estimates the power loss inside itself to determine its Transmitted Power. A systematic bias in these

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 11

Page 12

estimates results in a difference between the Transmitted Power and the Received Power, even if there is

no Foreign Object present on the Interface Surface. To increase the effectiveness of the power loss

method, the TX can remove the bias in the calculated power loss by calibration. For this purpose, the TX

and Power RX execute the calibration phase before the power transfer phase starts. The TX needs to verify

that there is no FO present on its interface surface before the calibration phase and FOD based on Q factor

could work.

As the bias in the estimates can be dependent on the power level, the TX and RX determine their

Transmitted Power and Received Power at two load conditions — a “light” load and a “connected” load.

The “light” load is close to the minimum expected output power, and the “connected” load is close to the

maximum expected output power. Based on the two load conditions, the Power Transmitter can calibrate

its Transmitted Power using linear interpolation. Alternatively, the Power Transmitter can calibrate the

reported Received Power.

Take calibrated Transmitted Power as an example:

b =

()

a =

=

()

()

()

()

+

()

()

(

()

)

()

Therefore, the TX uses the calibrated Transmitted Power to determine the power loss as follows:

=

When a RX baseline is charged by NXP WCT-15WTXAUTO, only the power loss FOD baseline works.

If a RX extension is placed on NXP WCT-15WTXAUTO, the Q factor would be measured at first to

detect if there is a FO presents. If yes , the TX would stop charging; otherwise, the TX can proceed to

calibration phase and power transfer phase, and power loss FOD extension works to detect if a FO is

inserted during power transfer phase.

For details of FOD, see the WCT1011A /WCT1013A Automotive MP-A9 Run-Time Debug User’s Guide

(WCT101XARTDUG).

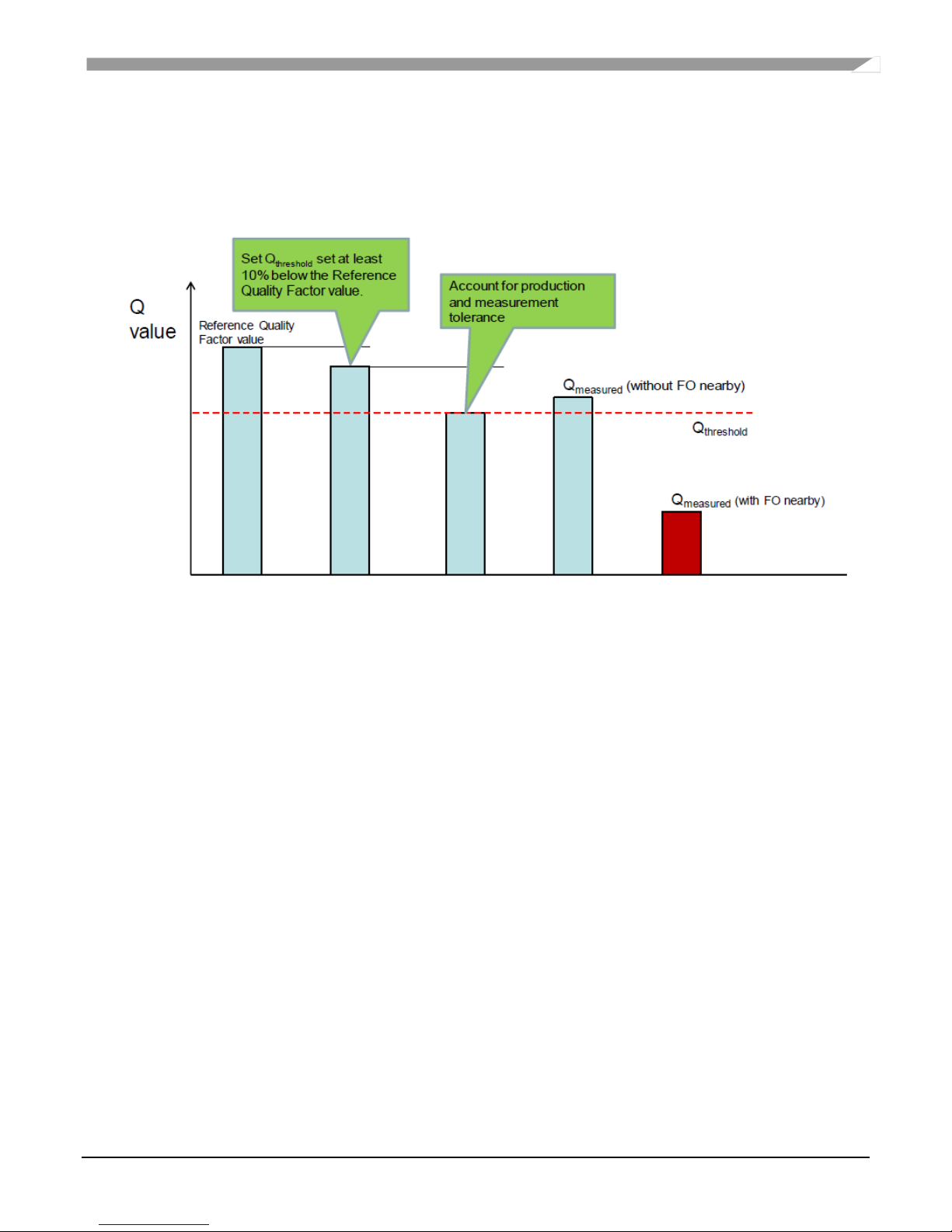

4.7 FOD based on Q factor change

A change in the environment of the TX coil typically causes its inductance to decrease or its equivalent

series resistance to increase. Both effects lead to a decrease of the TX coil’s Q factor. The RX sends a

packet including the reference Q factor for TX to compare and determine if FO exists, as shown in

Figure 10.

The reference Q factor is defined as the Q factor of Test Power Transmitter #MP1’s Primary Coil at an

operating frequency of 100 kHz with RX positioned on the interf ace surface and no FO nearby. Due to the

differences between its design and that of Test Power Transmitter #MP1, the difference between the

frequency it uses to determine its Q factor and 100 kHz, the TX needs to convert the Q factor it measured

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

12 NXP Semiconductors

Page 13

to that of Test Power Transmitter #MP1. NXP provides the conversion method and needs to get the

parameters on board at first. The TX would do auto-calibration and get parameters at the first time

powering up after flashed new image, and then these parameters are written to flash. Therefore, it is

necessary to make sure there is no object on the TX surface at the first time powering up after flashed new

image.

Figure 10 Quality factor threshold example

4.7.1 Free Resonance Q factor

The free resonance Q factor detection is to detect the decay rate of the resonance signal, as shown in

Figure 11. With the system’s high Q, driving just a few pulses near resonant frequency are sufficient to

serve as impulses and start the sy stem ringing. Collec t ADC data of tank voltage ( or coil current), and then

get the decay rate of the signal.

Q=/(-ln(Rate))

Rate is the value of decay rate of resonance signal.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 13

Page 14

TP23

DNP

C407

330pF

C406

330pF

D53

BAT54SW

1 2

3

R371

221K

R372

221K

V3.3A_Q

COILS

5

Q_RESONANCE_VOLT

3

V3.3A_Q

R531

100

R532

100

-

+

U28C

LMV824-N-Q1

10

9

8

C271

27PF

Figure 11 Resonance signal

The circuit for free resonance Q measurement is as shown in the following figure, which samples the

signal on resonance capacitors.

Figure 12 Free resonance Q measurement circuit

4.8 Coil selection

The Qi specification defines the MP-A9 as the more-than-one coil topology with one coil energized at a

time to realize the free position charging.

The coil selection topology connects only one coil to the full-bridge inverter at a time. The coil is equipped

with the dual N-MOSFETs, Q9, Q12, or Q16, controlled by the WCT1011A/WCT1013A controller

through the control interface based on the low power bipolar transistors.

4.9 Analog sensing

Some ports of the ADC A-channel of WCT1011A/WCT1013A are used for sensing analog signals, such

as temperature, full-bridge input current, input voltage, and rail voltage.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

14 NXP Semiconductors

Page 15

5. Application Monitoring and Control Through FreeMASTER

FreeMASTER is a user-friendly real-time debug monitor and data visualization tool for application

development and information management. Supporting nonintrusive variable monitoring on a running

system, FreeMASTER allows the data from multiple variables to be viewed in an evolving

oscilloscope-like display or in a common text for mat. The application can also be monitored and operated

from the web-page-like control panel.

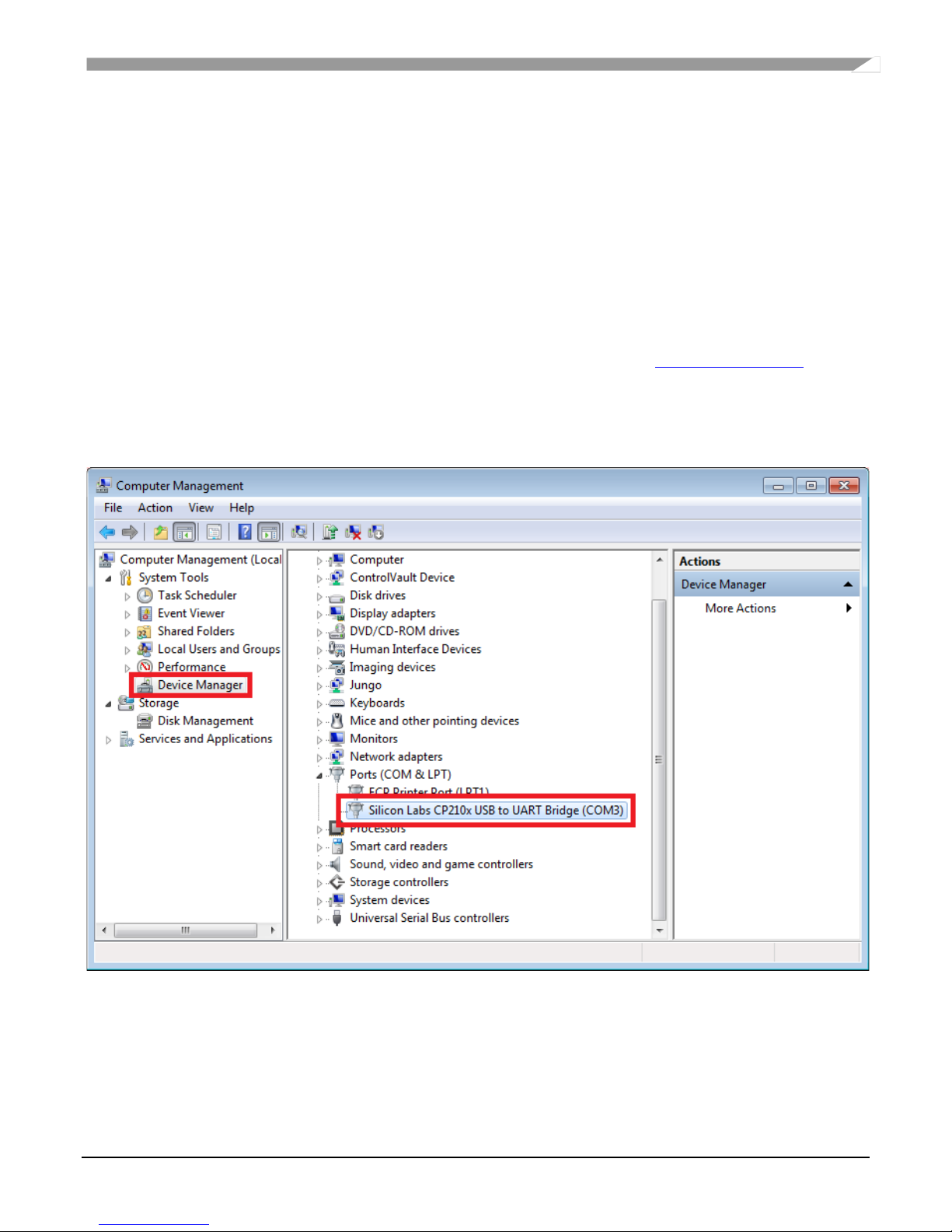

5.1 Software setup

To set up the software, perform the following steps:

1. Install FreeMASTER V2.0.2 or later version from the NXP website: nxp.com/freemaster

2. Plug the USB-UART converting board to SCI connector J2, and connect the FreeMASTER

MicroUSB port to your computer.

3. Open the Device Manager, and check the number of the COM port.

4. Unpack the embedded source code to your local disk.

5. Start the FreeMASTER application by opening:

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 15

Figure 13 Device manager

Page 16

• MWCT1013A

<unpacked_files_location>/15W_MP/example/wct1013a/ wct1013A.pmp

• MWCT1011A

<unpacked_files_location>/15W_MP/example/wct1011a/ wct1011A.pmp

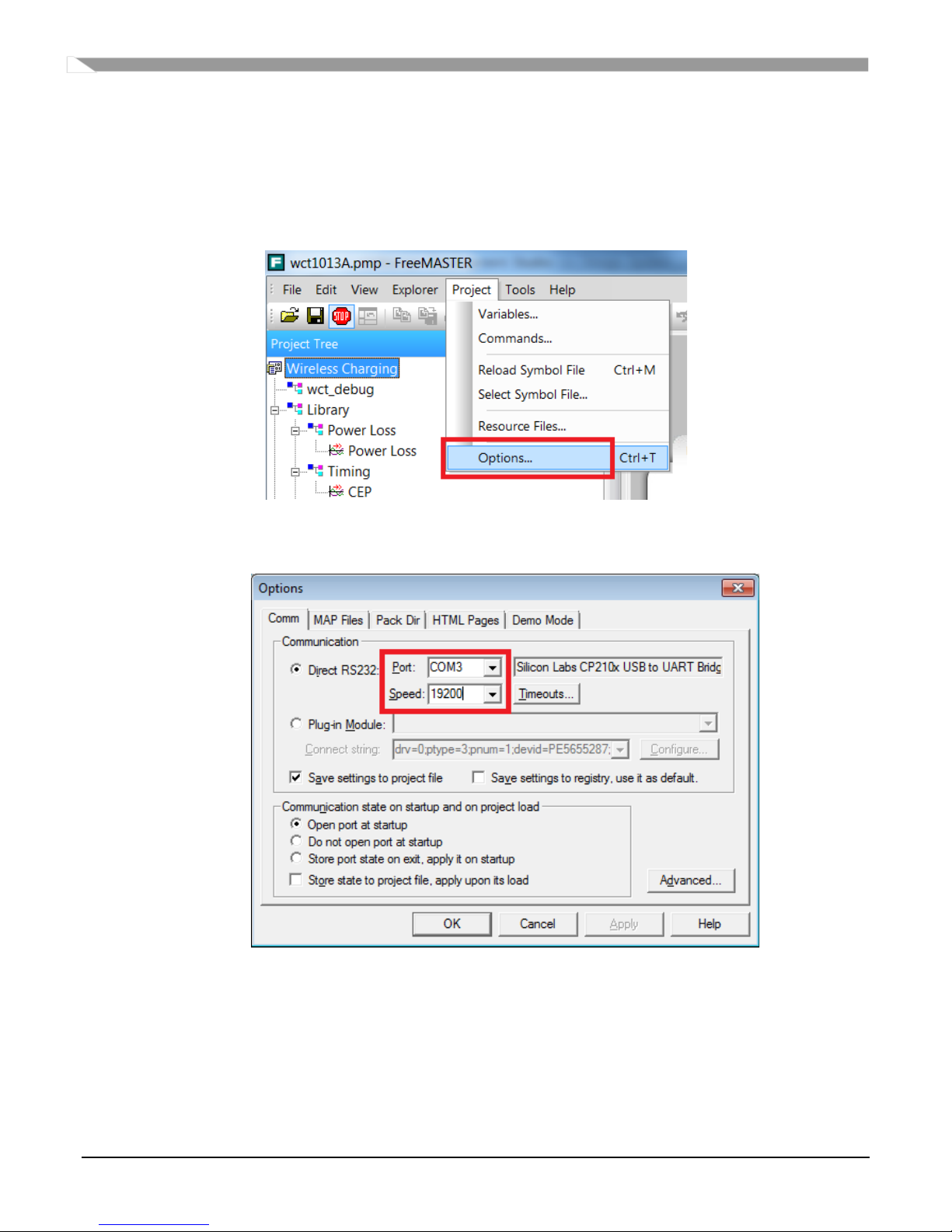

6. Choose Project –> Options.

Figure 14 Choosing Options

7. Ensure that the correct virtual Port (according to Step 3) and Speed are selected.

Figure 15 Setting Port and Spe ed

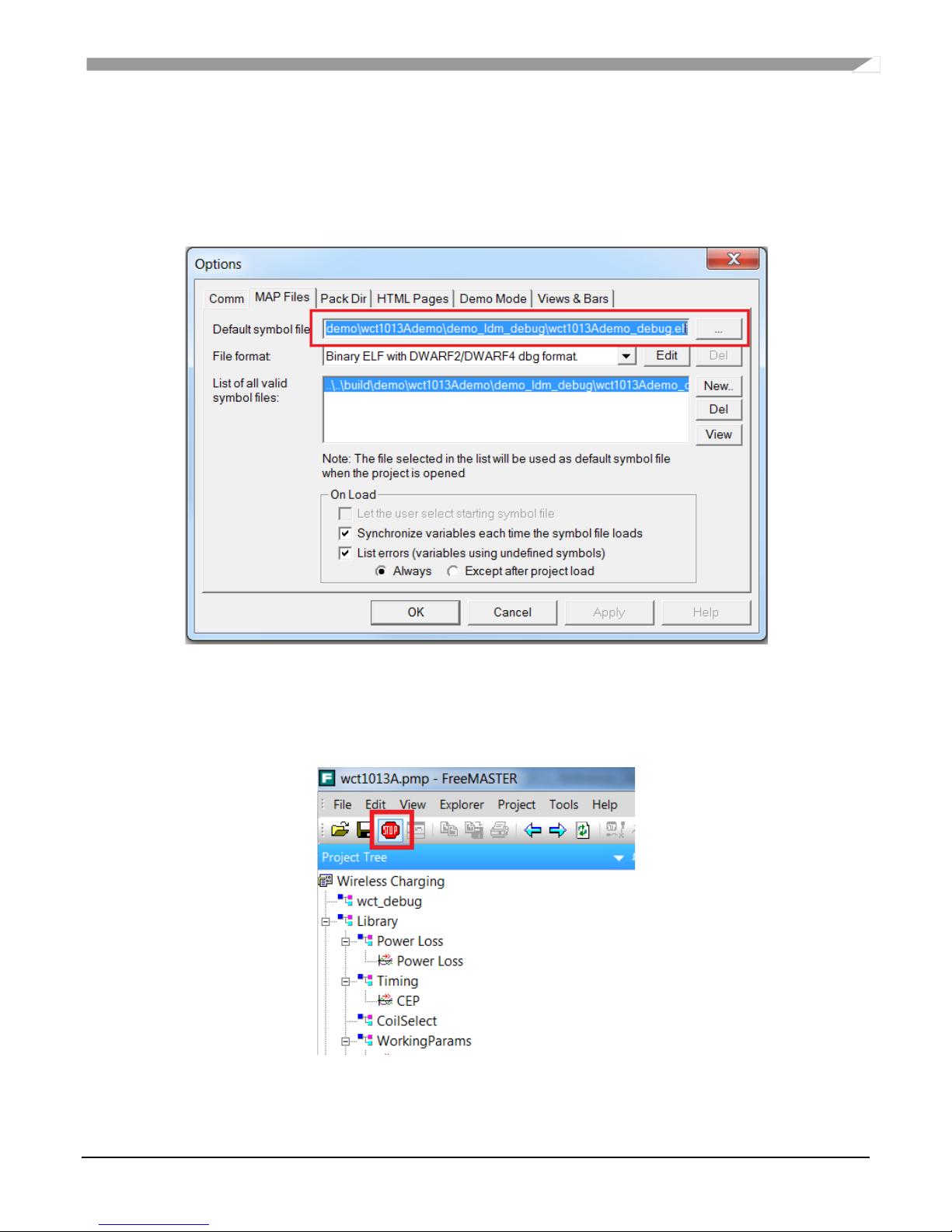

8. Ensure that the MAP file is correct. The default directories are as follows:

• MWCT1013A

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

16 NXP Semiconductors

Page 17

<unpacked_files_location>/15W_MP/build/demo/wct1013Ademo/demo_ldm_debug/wct1013A

demo_debug.elf

• MWCT1011A

<unpacked_files_location>/15W_MP/build/demo/wct1011Ademo/demo_sdm_debug/wct1011A

demo_debug.elf

Figure 16 Setting the MAP file

9. Connect FreeMASTER.

Power on MP-A9, and then start the communication by clicking the STOP button on the FreeMASTER

GUI.

Figure 17 Stop button

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 17

Page 18

5.2 Real-t ime application variables monitoring

FreeMASTER enables monitoring and updating all the application global variables. In this application,

several key variables are displayed in the scope windows. These variables are divided into differ ent blocks

as shown in the following figure.

Figure 18 Real-time application variables

• wct_debug

This block shows the variables used for the GUI command.

• Library

This block contains power loss variables, timing variables, coil selection variables, working

parameters, system status, DDM variables, and RX information.

• HAL

This block contains ADC raw data and DDM buffer values.

• NVM

This block lists all NVM parameters. Q factor sub-block shows the Q factor calibration constants.

RRQD sub-block shows the quick removal calibration constants. FOD sub-block shows the FOD

characterization calibration constants. Normalization sub-block shows the FOD normalization

constants. Analog sub-block shows the rail voltage calibration constants.

• LIB PARAMS

This block lists all parameters used for the WCT library.

• Command

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

18 NXP Semiconductors

Page 19

The command variable is used to stop WCT, start WCT, and do auto-calibration.

• QFactor

This block contains the variables for Q factor detection.

• Test

This block contains some variables for debugging.

• Protection

This block contains protection variables, such as input voltage protection, input current protection, and

temperature protection.

• KeyFOB

This block contains the variables used for KeyFob.

NOTE

Besides the variables above, all the global variables can be added to

FreeMASTER. The procedure to generate and add variables to watch

window is described in the FreeMASTER user manual.

5.3 Appl ic ation parameters modification

The application parameters (NVM parameters) can be easily viewed and changed on the control panel.

The control panel contains the web page elements (buttons, check boxes, and text fields) that enable a

user-friendly way to visualize and change the application control parameters.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 19

Page 20

Figure 19 Application variables

The application variables are divided into three tabs:

• System Params – group of general system parameters.

• Coil Params – enables access to the variables related to the coils control

• Calibration – group of parameters for calibration of the input current, input voltage, and foreign

objects detector

The meaning of each parameter is described next to the text field.

NOTE

• Some parameters of System Params and Coil Params are not used

for MP-A9. The used parameters are described in

WCT1011A/WCT1013A Automotive MP-A9 Run-Time User’s

Guide.

• The parameters of Calibration can be changed at run-time. But the

parameters of System Params and Coil Params cannot take effect

immediately. These parameters should be saved to project, rebuild

project, and re-flash the board.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

20 NXP Semiconductors

Page 21

6. Application Monitoring Through Console

The application sends some information and error states through SCI to the console. The information is

sent when the board is turned on, when the device is charging, or in case of some error state.

For digital buck-boost platform, only one SCI port (SCI0) is available. SCI0 is used for FreeMASTER by

default. Users select an alternative method to enable the debug console.

1. Disable FreeMASTER and configure SCI0 as the debug console.

a) #define DEBUG_CONSOLE_SUPPORTED (TRUE)

#define FREEMASTER_SUPPORTED (FASLE)

The macros are defined in example->wct101xa–>configure-> appcfg.h.

b) #define QSCI_CONSOLE_INDEX 0

#define QSCI_FREEMASTER_INDEX 1

The macros are defined in example->wct101xa->driver->qsci.h

c) gWCT_Params.tDebugConfig.bGeneralDbg = 1;

This variable is in wct_LibPar am s. c.

2. Change FreeMASTER communication interface to JTAG and configure SCI0 as the debug console.

a) #define DEBUG_CONSOLE_SUPPORTED (TRUE)

#define FREEMASTER_SUPPORTED (TRUE)

The macros are defined in example->wct101xa–>configure-> appcfg.h.

b) #define QSCI_CONSOLE_INDEX 0

#define QSCI_FREEMASTER_INDEX 1

The macros are defined in example->wct101xa->driver->qsci.h

c) #define FMSTR_USE_SCI 0 /* To select SCI communication interface */

#define FMSTR_USE_JTAG 1 /* 56F8xxx: use JTAG interface */

The macros are defined in example->wct101xa–>configure-> freemaster_cfg.h.

d) gWCT_Params.tDebugConfig.bGeneralDbg = 1;

This variable is in wct_LibPar am s. c.

6.1 Software setup

1. Plug the USB-UART converting board to SCI connector J2, and connect the console MicroUSB

port to the computer.

2. Open Device Manager, and check the number of the COM port.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 21

Page 22

Figure 20 Device Manager

3. Run the communication program supporting console, such as HyperTerminal or RealTerm.

4. The following table shows the communication setup.

Table 1 Port configurations

Port number Serial port from Device Manager

Baud 19200

Data Bits 8

Stop Bits 1

Parity None

Hardware Flow Control None

Display As ASCII

5. Open the port or start communication, which depends on the used Terminal.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

22 NXP Semiconductors

Page 23

7. Programming New Software and Calibration

Users are provided with a software package, which includes a WCT1011A/WCT1013A project and a Bin

file (.elf or .S). Users can flash alternative to the board. After flashing new software, board calibration

must be carried out.

7.1 I nst all CodeWarrior 10.7

1. Download installation files.

For proper installation of CodeWarrior 10.7, install both CodeWarrior for Microcontrollers

10.7 and CodeWarrior for MCUs v10.7 service pack.

Access the following webpage and log in:

https://www.nxp.com/products/developer-resources/software-development-tools/codewarrior-de

velopment-tools/codewarrior-development-suites/codewarrior-development-suite-special:CW-S

UITE-SPECIAL?tab=Design_Tools_Tab

Click Download for CodeWarrior Special Edition (offline or online).

Figure 21 Clicking Download for CodeWarrior Special Edition

Download CodeWarrior for Microcontrollers 10.7 service pack from the following link.

https://www.nxp.com/products/power-management/wireless-charging-ics/15-watt-wireless-charg

ing-transmitter-ics-for-automotive-applications:MWCT1x1xA?tab=Design_Tools_Tab

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 23

Page 24

Figure 22 Downloading CodeWarrior for MCU v10.7 service pack

2. Double-click CW_MCU_v10.7_b160721_SE.exe after downloading.

Figure 23 Setup file

3. Make sure that DSC is selected.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

24 NXP Semiconductors

Figure 24 DSC installed

Page 25

4. Launch CodeWarrior, create a folder workspace, and select it as the default workspace.

Figure 25 Workspace Launcher dialog box

5. Choose Help –> Install New Software.

Figure 26 Install New Software

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 25

Page 26

6. Click Add and Archive, and then select the

mcu10_7.Wireless_Charging_MWCT101x.win.sp.v1.0.1.zip file.

Figure 27 Selecting the update pack

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

26 NXP Semiconductors

Page 27

7. Select MCU v10.7 DSC Service Packs, and then click Next.

Figure 28 Selecting service packs

8. Review the license terms. If you agree with the license terms, select I accept the terms of the

license agreement, and then click Finish.

Figure 29 Installation finished

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 27

Page 28

7.2 Boar d and programmer connection

Connect the 14-pin debug cable to J4 of the board (notice pin-1 position of cable).

Figure 30 Connecting the debug cable to th e board

7.3 Program the project files

1. Import a project.

Right-click in the CodeWarri or Pro je cts window and choose Import to import an existing

project, as shown in the following figures. If the CodeWarrior Projects window is not displayed,

open it through Window -> Show View -> CodeWarrior Projects.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

28 NXP Semiconductors

Figure 31 Importing a project (1)

Page 29

Figure 32 Importing a project (2)

Select the project directory, as show in this figure.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 29

Figure 33 Importing a project (3)

Page 30

Select WCT1013A project.

Figure 34 Importing a project (4)

2. Build a project.

Select build configurations by clicking the project name in the project window shown in the

following figure. The demo_ldm_debug build contains debug information. The

demo_ldm_release is same with demo_ldm_debug except debug information.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

30 NXP Semiconductors

Page 31

Figure 35 Building a project (1)

Right-click wct1013Ademo, and then choose Clean Project and Build Project.

3. Download the project.

Download the project from the Debug drop-down list or form Run -> Debug. In Download

Configurations, select a download configuration according to your build configurations and

debugger type, USB TAP, PnE Multilink, or OSJTAG.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 31

Figure 36 Clean Project and Build Project

Page 32

Figure 37 Downloading the project

After the project is downloaded, the MCU stops at the startup code. Press the Run button or F8 to

let MCU run. Make sure that there is no object on the TX surface before making MCU run. Due to

the auto-calibration for rail voltage, Q-factor, and quick removal will be done at the first-time the

TX runs after flashed image.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

32 NXP Semiconductors

Figure 38 Project Downloaded

Page 33

7.4 Program the Bin file (.elf or .S)

1. Choose Flash Programmer –> Flash File to Target.

Figure 39 Choosing Flash File to Target

2. Click New to create a new connection.

Figure 40 Creating a new connection

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 33

Page 34

3. In the Name text box, enter a connection name (any name is OK), and click New to create a target.

Figure 41 Entering a connection name

4. In the Name text box, enter a target name (any name is OK but cannot be same with the connection

name), and choose dsc.MWCT101x -> MWCT1013A from the Target Type drop-down list.

Figure 42 Choosing MWCT1013A

5. Select Execute reset and Initialize target, set the initialization target file path to the CW

installation folder, and then select MWCT1013A.tcl.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

34 NXP Semiconductors

Page 35

Figure 43 Executing reset and initia lizing target

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 35

Page 36

6. Click the Memory tab. Select Memory configuration, set the memory configuration file path to

the CW installation folder, and then select MWCT1013A.mem. Click Finish.

Figure 44 Memory configuration

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

36 NXP Semiconductors

Page 37

7. Select USB TAP for the Connection type, and then click Finish.

Figure 45 Setting the connection type

8. Set the Bin file path to be File to Flash. Select Save the Target Task for future programming.

Power on MP-A9 and click Erase and Program.

9. Select the task path to save the task.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 37

Figure 46 Erase and Program

Page 38

Figure 47 Selecting the task path

10. When program is finished, the Console window displays the following log.

Figure 48 Programming finished log

11. For future programming, just select FLASH MPA9 and wait until the programming is finished.

Figure 49 Future programming

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

38 NXP Semiconductors

Page 39

7.5 Pro gram by boot loader

Boot loader is completely independent of the application codes, and it can reside in flash forever after

downloading an application code. When a system is reset, the boot loader starts to run. After a boot delay

in seconds, the boot loader jumps to the programmed application code, even without receiving the

application S-record file. When receiving the application S-record file, the boot loader programs the

application code to the on-chip flash. After completion, the boot loader jumps to the application startup

code.

1. The boot loader code is not flashed to the board by default. Download the boot loader code. Import

the boot loader project and follow the steps described in Section 7.3 to download the project.

Figure 50 Boot loader project

2. Generate an application S-record fil e.

Enable the boot loader function. Set the following macro to TRUE in appcfg.h.

#define BOOTLOADER_USED (TRUE)

Follow the figure below to configure the application project settings. Select the option Sort by

Address. Set Max S-Record Length to a value that does not exceed 255. Select DOS (\\r\\n) for

S-Record EOL Character.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 39

Page 40

Figure 51 Configure project settings

Recompile the project after completing the configuration above. The generated S-record file is in

<unpacked_files>\15W_MP\build\demo\wct1013Ademo\demo_ldm_debug for the WCT1013A

chip or <unpacked_files>\15W_MP\build\demo\wct1011Ademo\demo_sdm_debug for the

WCT1011A chip. The S-record file is the combined p and x S-record file without “.p” or “.x” in

the extension name (.s).

3. Download the application code by the boot loader.

Most serial terminal programs can be used to send an S-Record file from a host to the

WCT1011A/WCT1013A board through the boot loader. For example, Tera Term can be used in

the Windows platform.

SCI0 is used for communication. Plug the USB-UART convertor to the SCI connector J2 and the

computer. Open Tera Term, and then select Serial and Port. Check the COM port in the Device

Manager.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

40 NXP Semiconductors

Page 41

Figure 52 Tera Term connection

Choose Setup -> Serial port to configure the COM properties as shown in Figure 54.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 41

Figure 53 Serial port

Page 42

Figure 54 Serial port setup

Choose File -> Send file.

Figure 55 Send file

Select the application S-Record file and click Open.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

42 NXP Semiconductors

Page 43

Figure 56 Send application S-Record file

The downloading progress is displayed in the Tera Term window. After downloading is

completed, the application code starts.

Figure 57 Download application S-Record file

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 43

Page 44

7.6 Board calibration

NXP provides the FreeMASTER GUI tool for calibration and parameters tuning. For board calibration,

see the WCT1011A/WCT1013A Automotive MP-A9 V3.1 Run-Time Debugging User’s Guide

(WCT101XAV31RTDUG).

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

44 NXP Semiconductors

Page 45

8. Software Description

8.1 Sof tware overview

8.1.1 Directory Structure

The following figure shows an example of the directory structure of the whole WCT1013A_MP-A9

distribution.

Figure 58 Directory structure of the whole WCT1013A_MP-A9 distribution

8.1.2 CodeWarrior Projects

There are four CodeWarrior projects in the package. The following figure shows all the four projects in

CodeWarrior GUI when all of them are imported.

Figure 59 CW projects

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 45

Page 46

Combined with different program models and different user cases, multiple build configurations are

predefined in respective projects.

There are two program models provided for WCT parts.

• Small Program Model: The compiler generates a more efficient switch table, when the code is in

the range 0x0-0xFFFF. This model is more efficient, but the code size is limited to 64 KB words.

• Larger Program Model: Extends DSP56800E addressing range by providing 24-bit address

capability to instructions. That allows user accesses beyond the 64 KB word boundary of 16-bit

addressing.

For WCT1011A, there are two build configurations:

• demo_sdm_debug: Small Program Model, including code for debugging.

• demo_sdm_release: Small Program Model, excluding debugging code to save memory size.

Figure 60 WCT1011A build configur ation

For WCT1013A, there are three build configurations:

• demo_ldm_debug: Large Program Model, including code for debugging.

• demo_ldm_release: Large Program Model, excluding debugging code to save memory size.

• nfc_demo_ldm_debug: NFC dedicated build configuration. Large Program Model, including code

for debugging.

NOTE

The full-featured NFC stack will be released in next version. The slim NFC

stack is ready. Contact NXP for the firmware with the NFC feature.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

46 NXP Semiconductors

Page 47

Figure 61 WCT1013A build configuration

8.2 Func t ional description

NXP provides full-featured wireless charging functions on the reference board. If a certain function is not

needed, disable it by the definitions in the header file.

8.2.1 FreeMASTER

• FreeMASTER is supported. The following configuration is used to enable or disable it.

Configurations Default value Location Description

FREEMASTER_SUPPORTED TRUE appcfg.h Enables or disables the function. Set

• FreeMASTER communication interface configuration is in freemaster_cfg.h. SCI interface is

enabled and JTAG interface is disabled by default. Only one interface can be set at a time.

#define FMSTR_USE_SCI 1 /* To select SCI communication interface */

#define FMSTR_USE_JTAG 0 /* 56F8xxx: use JTAG interface */

• FreeMASTER SCI port is SCI0 by default.

1) #define FMSTR_SCI_BASE 0xE080 /* base address of SCI_0 */

The macro is in freemaster_cfg.h.

2) #define QSCI_FREEMASTER_INDEX 0 //QSCI0

The macro is in qsci.h.

Table 2 FreeMASTER configurations

TRUE to enable it. Set FALSE to

disable it.

8.2.2 Low power mode

Low power mode is supported. In the analog ping interval, the MCU enters LPSTOP mode and DCDC

module is closed. The following configuration is used to enable or disable it.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 47

Page 48

Table 3 Low power mode configurations

Configurations Default value Location Description

LOW_POWER_MODE_ENABLE FALSE appcfg.h Enables or disables the function.

Set TRUE to enable it. Set FA LSE

to disable it.

8.2.3 Debug console

Debug console is supported. The following configuration is used to enable or disable it.

Table 4 Debug console configurations

Configurations Default value Location Description

DEBUG_CONSOLE_SUPPORTED FALSE appcfg.h Enables or disables the function.

Set TRUE to enable it. Set FA LSE

to disable it.

For WCT1011A/WCT1013A digital buck-boost platform, only one SCI port is available. This port is

default used for FreeMASTER. If debug console is used, disable FreeMASTER or change FreeMASTER

communication interface to JTAG. The configurations are described in Chapter 6.

8.2.4 Bootloader

Bootloader is supported. The following configuration is used to enable or disable it.

Table 5 Bootloader configurations

Configurations Default value Location Description

BOOTLOADER_USED FALSE appcfg.h Enables or disables the function. Set

TRUE to enable it. Set FALSE to

disable it.

If bootloader is used, download the bootloader project to the board. Then change BOOTLOADER_USED

to TRUE, rebuild application project, and download application .S file by bootloader.

8.2.5 DCDC control type

NXP provides two DCDC control types: digital buck-boost and analog buck-boost. The default one is

digital buck-boost. The following configuration is used to switch the DCDC control type.

Table 6 DCDC control type configurations

Configurations Default value Location Description

DIGITAL_BUCKBOOST TRUE appcfg.h Switch DCDC control type. Set TRU E to

enable digital buck-boost. Set FALSE to

enable analog buck-boost.

8.3 Pro t ection mechanisms

The following table lists the protections that can be implemented.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

48 NXP Semiconductors

Page 49

Table 7 Protection mechanisms

Protection Default limits Variables Description

Rail voltage 23000 mV gPROT_Params.wMaxRailVol Application implemented. If the rail voltage

exceeds the limit, charging is turned off. The

limit value can be changed in PROT_Init().

Battery voltage Min: 8000 mV

Max: 18000

mV

Hysteresis:

1000 mV

Input current 4000 mA gPROT_Params.wMaxInputCurrent Application implemented. If the input current

Coil current 5000 mA gPROT_Params.wMaxCoilCurrent Application implemented. If the coil current

Input power Non power

transfer: 3000

mW

Power transfer:

240%

gPROT_Params.wMinBatteryVol

gPROT_Params.wMaxBatteryVol

gPROT_Params.wBatteryHystVol

gPROT_Params.wMaxInputPowerDuri

ngNonXfer

gPROT_Params.wMaxInputPowerMult

iPercent

Application implemented. If the battery

voltage exceeds the maximum, the WCT

library stops. When the battery voltage is

lower than the difference between maximum

and hysteresis, WCT library starts. When the

battery voltage is lower than the minimum,

the WCT library stops. When the battery

voltage is higher than the sum of the

minimum and hysteresis, the WCT library

starts.

The limit value can be changed in

PROT_Init().

exceeds the limit, charging is turned off. The

limit value can be changed in PROT_Init().

exceeds the limit, charging is turned off. The

limit value can be changed in PROT_Init().

Application implemented. When the TX is in

the PING phase, the maximum limit is 3000

mW by default. When the TX is in online

calibration (EPP RX), power transfer or

renegotiation phase, the maximum li mit is

240% of the RX maximum power. For BPP

RX, the maximum is 12 W. For EPP, the

maximum is 36 W. The limit value can be

changed in PROT_Init().

Temperature Max: 60℃

Hysteresis:

10℃

Safe digital ping 200 mA gPROT_Params.wSafeDigitalPingInpu

FOD BPP RX: 600

mW

EPP RX:

1000 mW

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 49

gPROT_Params.swTemperatureThres

hold

gPROT_Params.wTemperatureHyst

tCurrentThreshold

lFodParams.dwPowerLossLimit Library implemented. If the power loss

Application implemented. If the temperature

exceeds the maximum, the WCT library

stops. When the temperature is lower than

the difference between the maximum and

hysteresis, the WCT library starts. The limit

value can be changed in PROT_Init().

Library implemented. If the input current

sampled at the beginning of the digital ping

exceeds the limit, digital ping stops. The limit

value can be changed in PROT_Init().

exceeds the limit, charging is turned off for 5

minutes. The limit value can be changed in

WCT_GetFODParams().

Page 50

9. System Bring Up

9.1 Ping sequences

When low power mode is disabled and no receiver is placed on the charging surface, the ping sequence is

as follows:

Digital ping appears at about every 5 seconds and the analog ping appears at about every 400 ms. There

are 12 to 13 analog ping between two digital pings.

The following figures show the PWM waveforms of the ping sequence and ping patterns.

Figure 62 Digital ping interval

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

50 NXP Semiconductors

Page 51

Figure 63 Analog ping interval

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 51

Figure 64 Digital ping pattern

Page 52

Figure 65 Analog ping pattern

9.2 LED indicat ion

The default LED display modes for different TX working states are shown in the following table.

Table 8 LED display modes

LED No.

LED 1 (Red) Off Blink Off On On On

LED 2 (Green) Blink On On Off Off Off

Standby Charging Charging

LED operational status

FOD fault TX fault RX fault

complete

The display pattern can be changed in WCT_UpdateDevUsrIndication().

9.3 Debug messages

The system is able to print messa ges from a specified SCI por t to inform users about what ha ppened in the

system. That may be helpful for users to understand the system working procedure and debug issues.

Message: ID, T/O

Print information when identification packet times out.

Message: EXT ID, T/O

Prints information when extended identification packet times out.

Message: CFG, HOLDOFF Invalid

Prints information when hold off time is out of range.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

52 NXP Semiconductors

Page 53

Message: CFG, Incorrect Count, Count1 (Count2)

Prints information when the amount of optional configuration packets received does not match the number

in the configuration packet.

• Count 1: the number in configuration packet

• Count 2: TX received optional configuration packets amount

Message: CFG, Over CP

Prints information when the RX power is beyond capability.

Message: CFG, Rcvd 0xXX

Prints the packet type that should not be received in the configuration phase.

Message: CFG, T/O

Prints information when the configuration packet times out.

Message: XFER, INCOMP

Prints information when the RX version is not compatible.

Message: XFER, RCVPWR T/O

Prints information when receive power packet times out.

Message: XFER, PLoss T/O

Prints information when FOD happens.

Message: PROP, <Packet type>

Prints the proprietary packet header.

Message: XFER, Rcvd 0xXX Reset

Prints the packet type that should not be received in power transfer phase. Charging is reset.

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

NXP Semiconductors 53

Page 54

Message: XFER, Rcvd 0xXX

Revision number

Date

Substantive changes

0

10/2017

Initial release

Prints the packet type that is not defined in WPC specification.

10. Revision History

The following table provides the revision history.

Table 6 Revision history

WCT1011A/WCT1013A Automotive MP-A9 Wireless Charging Application User’s Guide, Rev. 0, 10/2017

54 NXP Semiconductors

Page 55

nxp.com

nxp.com/support

Information in this document is provided solely to enable system and software

implementers to use NXP products. There are no express or implied copyright licenses

granted hereunder to design or fabricate any integrated circuits based on the information

in this document. NXP reserves the right to make changes without further notice to any

products herein.

NXP makes no warranty, representation, or guarantee regarding the suitability of its

products for any particular purpose, nor does NX

application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation consequential or incidental damages. “Typical” parameters

that may be provided in NXP dat

different applications, and actual performance may vary over time. All operating

parameters, including “typicals,” must be validated for each customer application by

customer’s technical experts. NXP does n

nor the rights of others. NXP sells products pursuant to standard terms and conditions of

sale, which can be found at the following address:

NXP, the NXP logo, Freescale, the Freescale logo are trademarks of NXP B.V. All other

product or service names are the property of their respective owners.

© 2017 NXP

How to Reach Us:

Home Page:

Web Support:

P assume any liability arising out of the

a sheets and/or specifications can and do vary in

ot convey any license under its patent rights

nxp.com/SalesTermsandConditions.

B.V.

Document Number: WCT101XAV31AUG

Rev. 3.1

10/2017

Loading...

Loading...