Page 1

HCS08

Microcontrollers

freescale.com

MC9S08LG32

MC9S08LG16

Reference Manual

THIS DOCUMENT CONTAINS INFORMATION ON A NEW PRODUCT UNDER DEVELOPMENT. FREESCALE RESERVES THE RIGHT TO CHANGE OR

DISCONTINUE THIS PRODUCT WITHOUT NOTICE.

MC9S08LG32RM

Rev. 5

8/2009

Page 2

Page 3

MC9S08LG32 Series Features

8-Bit HCS08 Central Processor Unit (CPU)

• Up to 40 MHz CPU at 5.5 V to 2.7 V across temperature

range of –40 °C to 85 °C and –40 °C to 105 °C

• HCS08 instruction set with added BGND instruction

• Support for up to 32 interrupt/reset sources

On-Chip Memory

• 32 KB or 18 KB dual array flash; read/program/erase

over full operating voltage and temperature

• 1984 byte random access memory (RAM)

• Security circuitry to prevent unauthorized access to

RAM and flash contents

Power-Saving Modes

• Two low-power stop modes (stop2 and stop3)

• Reduced-power wait mode

• Peripheral clock gating register can disable clocks to

unused modules, thereby reducing currents

• Low power on-chip crystal oscillator (XOSC) that can be

used in low-power modes to provide accurate clock

source to real time counter and LCD controller

• 100 μs typical wakeup time from stop3 mode

Clock Source Options

• Oscillator (XOSC) — Loop-control Pierce oscillator;

crystal or ceramic resonator range of 31.25 kHz to

38.4 kHz or 1 MHz to 16 MHz

• Internal Clock Source (ICS) — Internal clock source

module containing a frequency-locked-loop (FLL)

controlled by internal or external reference; precision

trimming of internal reference allows 0.2% resolution

and 2% deviation over temperature and voltage; supports

bus frequencies from 1 MHz to 20 MHz

System Protection

• On-chip in-circuit emulator (ICE) debug module

containing three comparators and nine trigger modes;

eight deep FIFO for storing change-of-flow addresses

and event-only data; debug module supports both tag and

force breakpoints

Peripherals

• LCD — Up to 4 x 41 or 8 x 37 LCD driver with internal

charge pump

• ADC — Up to 16-channel, 12-bit resolution; 2.5 μs

conversion time; automatic compare function;

temperature sensor; internal bandgap reference channel;

runs in stop3 and can wake up the system; fully

functional from 5.5 V to 2.7 V

• SCI — Full duplex non-return to zero (NRZ); LIN

master extended break generation; LIN slave extended

break detection; wakeup on active edge

• SPI— Full-duplex or single-wire bidirectional;

double-buffered transmit and receive; master or slave

mode; MSB-first or LSB-first shifting

• IIC — With up to 100 kbps with maximum bus loading;

multi-master operation; programmable slave address;

interrupt driven byte-by-byte data transfer; supports

broadcast mode and 10-bit addressing

• TPMx — One 6 channel and one 2 channel; selectable

input capture, output compare, or buffered edge or

center-aligned PWM on each channel

• MTIM — 8-bit counter with match register; four clock

sources with prescaler dividers; can be used for periodic

wakeup

• RTC — 8-bit modulus counter with binary or decimal

based prescaler; three clock sources including one

external source; can be used for time base, calendar, or

task scheduling functions

• KBI — One keyboard control module capable of

supporting 8x8 keyboard matrix

• IRQ — External pin for wakeup from low-power modes

• COP reset with option to run from dedicated 1 kHz

internal clock or bus clock

• Low-voltage warning with interrupt

• Low-voltage detection with reset

• Illegal opcode detection with reset

• Illegal address detection with reset

• Flash and RAM protection

Development Support

• Single-wire background debug interface

• Breakpoint capability to allow single breakpoint setting

during in-circuit debugging (plus two more breakpoints

in on-chip debug module)

Input/Output

• 39, 53, or 69 GPIOs

• 8 KBI and 1 IRQ interrupt with selectable polarity

• Hysteresis and configurable pullup device on all input

pins; configurable slew rate and drive strength on all

output pins

Package Options

• 48-pin LQFP, 64-pin LQFP, and 80-pin LQFP

Page 4

Page 5

MC9S08LG32 Reference Manual

Covers MC9S08LG32

MC9S08LG16

HIS DOCUMENT CONTAINS INFORMATION ON A NEW PRODUCT UNDER DEVELOPMENT. FREESCALE RESERVES THE RIGHT TO CHANGE OR

T

DISCONTINUE THIS PRODUCT WITHOUT NOTICE.

Related Documentation:

• MC9S08LG32PB (Product Brief)

Contains descriptive feature set, example application

information, and developer environment details

• MC9S08LG32 Data Sheet

Contains package information, pinouts,

electricals/characterization data, and mechanical

drawings

Find the most current versions of all documents at:

http://www.freescale.com

Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc.

© Freescale Semiconductor, Inc., 2009. All rights reserved.

MC9S08LG32RM

Rev. 5

8/2009

Page 6

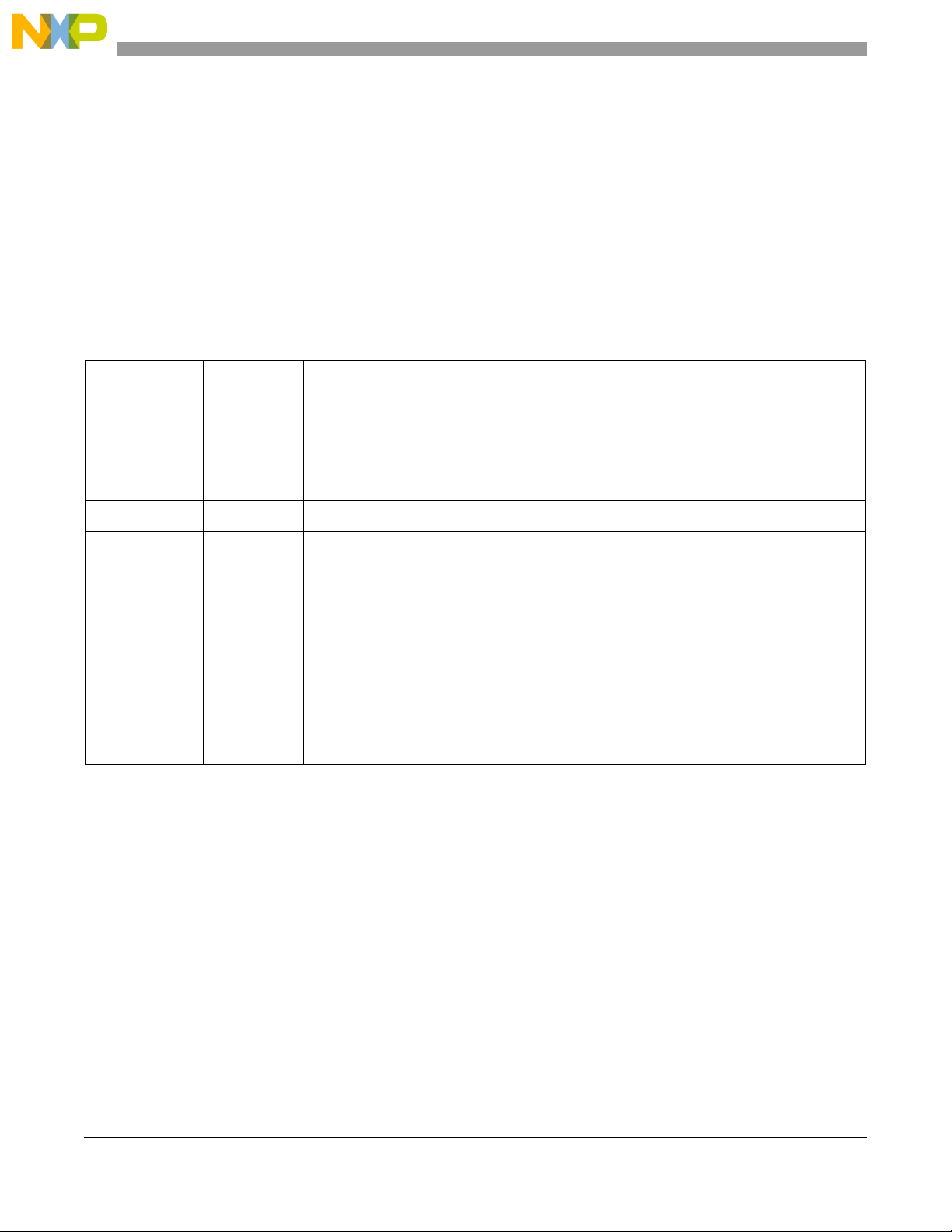

Revision History

To provide the most up-to-date information, the revision of our documents on the World Wide Web will be

the most current. Your printed copy may be an earlier revision. To verify you have the latest information

available, refer to:

http://www.freescale.com

The following revision history table summarizes changes contained in this document.

Revision

Number

Rev. 1 9/2008 First Initial Release.

Rev. 2 9/2008 Second Initial Release.

Rev. 3 11/2008 Alpha Customer Release.

Rev. 4 2/2009 Launch Release.

Rev. 5 8/2009

Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc.

© Freescale Semiconductor, Inc., 2009. All rights reserved.

Revision

Date

Description of Changes

•In Chapter 3, “Modes of Operation,” added On-Chip Peripheral Modules in

Stop Modes section in Chapter 3.

•In Ta bl e 5 -2 , corrected addresses for vector number from 23 to 18.

•In Ta bl e 7 -1 , updated KBI pins order as per PINPS1 register.

• Changed TCLK, T1CH0, T1CH1, T2CH0, T2CH1, T2CH2, T2CH3, T2CH4,

T2CH5 to TPMCLK, TPM1CH0, TPM1CH1, TPM2CH0, TPM2CH1,

TPM2CH2, TPM2CH3, TPM2CH4, TPM2CH5.

• Changed ‘LCDCPEN” to “LCDPEN” and “LCDFWF” to “LCDWF.”

•In Chapter 12, “Inter-Integrated Circuit (S08IICV2),” a note is added in the

introduction mentioning that MC9S08LG32 series of MCUs include only one

IIC module.

MC9S08LG32 MCU Series, Rev. 5

6 Freescale Semiconductor

Page 7

List of Chapters

Chapter Title Page

Chapter 1 Device Overview ....................................................................................... 21

Chapter 2 Pins and Connections .............................................................................. 27

Chapter 3 Modes of Operation .................................................................................. 41

Chapter 4 Memory ...................................................................................................... 49

Chapter 5 Resets, Interrupts, and General System Control ................................... 73

Chapter 6 Parallel Input/Output Control ...................................................................97

Chapter 7 Keyboard Interrupt (S08KBIV2) ............................................................. 128

Chapter 8 Central Processor Unit (S08CPUV5) ..................................................... 135

Chapter 9 LCD Module (S08LCDLPV1)................................................................... 158

Chapter 10 Analog-to-Digital Converter (S08ADC12V1) ....................................... 200

Chapter 11 Internal Clock Source (S08ICSV3)....................................................... 226

Chapter 12 Inter-Integrated Circuit (S08IICV2) ...................................................... 241

Chapter 13 Serial Communications Interface (S08SCIV4).................................... 259

Chapter 14 Serial Peripheral Interface (S08SPIV4)................................................ 278

Chapter 15 Real-Time Counter (S08RTCV1) .......................................................... 297

Chapter 16 Timer/Pulse-Width Modulator (S08TPMV3) ........................................ 306

Chapter 17 Modulo Timer (S08MTIMV1) ................................................................. 327

Chapter 18 Development Support........................................................................... 337

Chapter 19 Debug Module (DBG) (64K).................................................................. 350

MC9S08LG32 MCU Series, Rev. 5

Freescale Semiconductor 7

Page 8

Page 9

Contents

Section Number Title Page

Chapter 1

Device Overview

1.1 Devices in the MC9S08LG32 Series ...............................................................................................21

1.2 MCU Block Diagram .......................................................................................................................22

1.3 System Clock Distribution ...............................................................................................................24

Chapter 2

Pins and Connections

2.1 Introduction ......................................................................................................................................27

2.2 Device Pin Assignment ....................................................................................................................27

2.3 Recommended System Connections ................................................................................................31

2.3.1 Power ................................................................................................................................33

2.3.2 Oscillator ...........................................................................................................................33

2.3.3 RESET ..............................................................................................................................34

2.3.4 Background / Mode Select (BKGD/MS) ..........................................................................34

2.3.5 IRQ ....................................................................................................................................35

2.3.6 LCD Pins ...........................................................................................................................35

2.3.7 General-Purpose I/O (GPIO) and Peripheral Ports ...........................................................36

Chapter 3

Modes of Operation

3.1 Introduction ......................................................................................................................................41

3.2 Features ............................................................................................................................................41

3.3 Run Mode.........................................................................................................................................41

3.4 Active Background Mode ................................................................................................................41

3.5 Wait Mode ........................................................................................................................................42

3.6 Stop Modes.......................................................................................................................................43

3.6.1 Stop2 Mode .......................................................................................................................43

3.6.2 Stop3 Mode .......................................................................................................................44

3.6.3 Active BDM Enabled in Stop Mode .................................................................................45

3.6.4 LVD Enabled in Stop Mode ..............................................................................................45

3.7 Mode Selection.................................................................................................................................45

3.7.1 On-Chip Peripheral Modules in Stop Modes ....................................................................48

Chapter 4

Memory

4.1 Introduction ......................................................................................................................................49

MC9S08LG32 MCU Series, Rev. 5

Freescale Semiconductor 9

Page 10

Section Number Title Page

4.2 MC9S08LG32 Series Memory Map ................................................................................................49

4.3 Reset and Interrupt Vector Assignments ..........................................................................................50

4.4 Register Addresses and Bit Assignments.........................................................................................52

4.4.1 Reserved Flash Locations .................................................................................................59

4.5 RAM.................................................................................................................................................60

4.6 Flash .................................................................................................................................................60

4.6.1 Features .............................................................................................................................61

4.6.2 Program and Erase Times .................................................................................................61

4.6.3 Program and Erase Command Execution .........................................................................62

4.6.4 Burst Program Execution ..................................................................................................63

4.6.5 Access Errors ....................................................................................................................65

4.6.6 Flash Block Protection ......................................................................................................65

4.6.7 Vector Redirection ............................................................................................................66

4.7 Security.............................................................................................................................................66

4.8 Flash Registers and Control Bits......................................................................................................67

4.8.1 Flash Clock Divider Register (FCDIV) ............................................................................68

4.8.2 Flash Options Register (FOPT and NVOPT) ....................................................................69

4.8.3 Flash Configuration Register (FCNFG) ...........................................................................70

4.8.4 Flash Protection Register (FPROT and NVPROT) ..........................................................70

4.8.5 Flash Status Register (FSTAT) ..........................................................................................71

4.8.6 Flash Command Register (FCMD) ...................................................................................72

Chapter 5

Resets, Interrupts, and General System Control

5.1 Introduction ......................................................................................................................................73

5.2 Features ............................................................................................................................................73

5.3 MCU Reset.......................................................................................................................................73

5.4 Computer Operating Properly (COP) Watchdog..............................................................................74

5.5 Interrupts ..........................................................................................................................................75

5.5.1 Interrupt Stack Frame .......................................................................................................76

5.5.2 External Interrupt Request (IRQ) Pin ...............................................................................76

5.5.3 Interrupt Vectors, Sources, and Local Masks ...................................................................77

5.6 Low-Voltage Detect (LVD) System .................................................................................................79

5.6.1 Power-On Reset Operation ...............................................................................................79

5.6.2 Low-Voltage Detection (LVD) Reset Operation ...............................................................79

5.6.3 Low-Voltage Warning (LVW) Interrupt Operation ...........................................................79

5.7 Peripheral Clock Gating ...................................................................................................................79

5.8 Reset, Interrupt, and System Control Registers and Control Bits....................................................80

5.8.1 Interrupt Pin Request Status and Control Register (IRQSC) ............................................80

5.8.2 System Reset Status Register (SRS) .................................................................................82

5.8.3 System Background Debug Force Reset Register (SBDFR) ............................................83

5.8.4 System Options Register 1 (SOPT1) ................................................................................84

MC9S08LG32 MCU Series, Rev. 5

10 Freescale Semiconductor

Page 11

Section Number Title Page

5.8.5 System Options Register 2 (SOPT2) ................................................................................85

5.8.6 System Device Identification Register (SDIDH, SDIDL) ................................................86

5.8.7 System Power Management Status and Control 1 Register (SPMSC1) ...........................87

5.8.8 System Power Management Status and Control 2 Register (SPMSC2) ...........................88

5.8.9 System Clock Gating Control 1Register (SCGC1) ...........................................................90

5.8.10 System Clock Gating Control 2 Register (SCGC2) ..........................................................91

5.8.11 Pin Position Control Register (PINPS1) ...........................................................................92

5.8.12 Pin Position Control Register (PINPS2) ...........................................................................93

5.8.13 Pin Position Control Register (PINPS3) ...........................................................................94

5.8.14 Pin Position Control Register (PINPS4) ...........................................................................95

Chapter 6

Parallel Input/Output Control

6.1 Introduction ......................................................................................................................................97

6.2 Pins Shared with LCD......................................................................................................................97

6.3 Port Data and Data Direction ...........................................................................................................97

6.4 Pullup, Slew Rate, and Drive Strength.............................................................................................98

6.4.1 Port Internal Pullup Enable ...............................................................................................98

6.4.2 Port Slew Rate Enable ......................................................................................................99

6.4.3 Port Drive Strength Select ................................................................................................99

6.5 Open Drain Operation ......................................................................................................................99

6.6 Pin Behavior in Stop Modes.............................................................................................................99

6.7 Parallel I/O and Pin Control Registers ...........................................................................................100

6.7.1 Port A Registers ..............................................................................................................100

6.7.2 Port B Registers ..............................................................................................................104

6.7.3 Port C Registers ..............................................................................................................107

6.7.4 Port D Registers ..............................................................................................................110

6.7.5 Port E Registers ..............................................................................................................113

6.7.6 Port F Registers ............................................................................................................... 116

6.7.7 Port G Registers ..............................................................................................................119

6.7.8 Port H Registers ..............................................................................................................122

6.7.9 Port I Registers ................................................................................................................125

Chapter 7

Keyboard Interrupt (S08KBIV2)

7.1 Introduction ....................................................................................................................................128

7.1.1 Module Configuration .....................................................................................................128

7.1.2 KBI Clock Gating ...........................................................................................................128

7.1.3 Features ...........................................................................................................................130

7.1.4 Modes of Operation ........................................................................................................130

7.1.5 Block Diagram ................................................................................................................130

7.2 External Signal Description ...........................................................................................................131

MC9S08LG32 MCU Series, Rev. 5

Freescale Semiconductor 11

Page 12

Section Number Title Page

7.3 Register Definition .........................................................................................................................131

7.3.1 KBI Status and Control Register (KBISC) .....................................................................131

7.3.2 KBI Pin Enable Register (KBIPE) ..................................................................................132

7.3.3 KBI Edge Select Register (KBIES) ................................................................................132

7.4 Functional Description ...................................................................................................................133

7.4.1 Edge Only Sensitivity .....................................................................................................133

7.4.2 Edge and Level Sensitivity .............................................................................................133

7.4.3 KBI Pullup/Pulldown Resistors ......................................................................................134

7.4.4 KBI Initialization ............................................................................................................134

Chapter 8

Central Processor Unit (S08CPUV5)

8.1 Introduction ....................................................................................................................................135

8.1.1 Features ...........................................................................................................................135

8.2 Programmer’s Model and CPU Registers ......................................................................................136

8.2.1 Accumulator (A) .............................................................................................................136

8.2.2 Index Register (H:X) ......................................................................................................136

8.2.3 Stack Pointer (SP) ...........................................................................................................137

8.2.4 Program Counter (PC) ....................................................................................................137

8.2.5 Condition Code Register (CCR) .....................................................................................137

8.3 Addressing Modes..........................................................................................................................139

8.3.1 Inherent Addressing Mode (INH) ...................................................................................139

8.3.2 Relative Addressing Mode (REL) ..................................................................................139

8.3.3 Immediate Addressing Mode (IMM) ..............................................................................139

8.3.4 Direct Addressing Mode (DIR) ......................................................................................139

8.3.5 Extended Addressing Mode (EXT) ................................................................................140

8.3.6 Indexed Addressing Mode ..............................................................................................140

8.4 Special Operations..........................................................................................................................141

8.4.1 Reset Sequence ...............................................................................................................141

8.4.2 Interrupt Sequence ..........................................................................................................141

8.4.3 Wait Mode Operation ......................................................................................................142

8.4.4 Stop Mode Operation ......................................................................................................142

8.4.5 BGND Instruction ...........................................................................................................143

8.5 HCS08 Instruction Set Summary ...................................................................................................144

Chapter 9

LCD Module (S08LCDLPV1)

9.1 Introduction ....................................................................................................................................158

9.1.1 LCD Clock Sources ........................................................................................................158

9.1.2 LCD Modes of Operation ...............................................................................................158

9.1.3 LCD Status after Stop2 Wakeup .....................................................................................158

9.1.4 LCD Clock Gating ..........................................................................................................158

MC9S08LG32 MCU Series, Rev. 5

12 Freescale Semiconductor

Page 13

Section Number Title Page

9.1.5 Features ...........................................................................................................................160

9.1.6 Modes of Operation ........................................................................................................161

9.1.7 Block Diagram ................................................................................................................161

9.2 External Signal Description ...........................................................................................................162

9.2.1 LCD[44:0] .......................................................................................................................163

9.2.2 V

9.2.3 V

9.3 Register Definition .........................................................................................................................163

9.3.1 LCD Control Register 0 (LCDC0) ..................................................................................163

9.3.2 LCD Control Register 1 (LCDC1) ..................................................................................164

9.3.3 LCD Voltage Supply Register (LCDSUPPLY) ...............................................................165

9.3.4 LCD Regulated Voltage Control Register (LCDRVC) ...................................................166

9.3.5 LCD Blink Control Register (LCDBCTL) .....................................................................167

9.3.6 LCD Status Register (LCDS) ..........................................................................................168

9.3.7 LCD Pin Enable Registers 0–5 (LCDPEN0–LCDPEN5) ..............................................168

9.3.8 Backplane Enable Registers 0–5 (BPEN0–BPEN5) ......................................................169

9.3.9 LCD Waveform Registers (LCDWF[44:0]) ...................................................................170

9.4 Functional Description ...................................................................................................................174

9.4.1 LCD Driver Description .................................................................................................175

9.4.2 LCDWF Registers ...........................................................................................................183

9.4.3 LCD Display Modes .......................................................................................................183

9.4.4 LCD Charge Pump, Voltage Divider, and Power Supply Operation ..............................185

9.4.5 Resets ..............................................................................................................................188

9.4.6 Interrupts .........................................................................................................................189

9.5 Initialization Section ......................................................................................................................189

9.5.1 Initialization Sequence ....................................................................................................189

9.5.2 Initialization Examples ...................................................................................................190

9.6 Application Information.................................................................................................................194

9.6.1 LCD Seven Segment Example Description ....................................................................195

9.6.2 LCD Contrast Control .....................................................................................................198

9.6.3 Stop Mode Recovery .......................................................................................................199

LL1

cap1

, V

, V

LL2

cap2

, V

...........................................................................................................163

LL3

.....................................................................................................................163

Chapter 10

Analog-to-Digital Converter (S08ADC12V1)

10.1 Introduction ....................................................................................................................................200

10.1.1 ADC shared with LCD ...................................................................................................200

10.1.2 ADC Reference and Supply Voltage ...............................................................................200

10.1.3 ADC Clock Gating ..........................................................................................................200

10.1.4 Module Configurations ...................................................................................................201

10.1.5 Features ...........................................................................................................................204

10.1.6 ADC Module Block Diagram .........................................................................................204

10.2 External Signal Description ...........................................................................................................205

MC9S08LG32 MCU Series, Rev. 5

Freescale Semiconductor 13

Page 14

Section Number Title Page

10.2.1 Analog Power (V

10.2.2 Analog Ground (V

10.2.3 Voltage Reference High (V

10.2.4 Voltage Reference Low (V

) ....................................................................................................206

DDA

) ...................................................................................................206

SSA

) ...................................................................................206

REFH

) ....................................................................................206

REFL

10.2.5 Analog Channel Inputs (ADx) ........................................................................................206

10.3 Register Definition .........................................................................................................................206

10.3.1 Status and Control Register 1 (ADCSC1) ......................................................................206

10.3.2 Status and Control Register 2 (ADCSC2) ......................................................................208

10.3.3 Data Result High Register (ADCRH) .............................................................................208

10.3.4 Data Result Low Register (ADCRL) ..............................................................................209

10.3.5 Compare Value High Register (ADCCVH) ....................................................................209

10.3.6 Compare Value Low Register (ADCCVL) .....................................................................210

10.3.7 Configuration Register (ADCCFG) ................................................................................210

10.3.8 Pin Control 1 Register (APCTL1) ..................................................................................211

10.3.9 Pin Control 2 Register (APCTL2) ..................................................................................212

10.3.10Pin Control 3 Register (APCTL3) ..................................................................................213

10.4 Functional Description ...................................................................................................................214

10.4.1 Clock Select and Divide Control ....................................................................................215

10.4.2 Input Select and Pin Control ...........................................................................................215

10.4.3 Hardware Trigger ............................................................................................................215

10.4.4 Conversion Control .........................................................................................................215

10.4.5 Automatic Compare Function .........................................................................................218

10.4.6 MCU Wait Mode Operation ............................................................................................218

10.4.7 MCU Stop3 Mode Operation ..........................................................................................219

10.4.8 MCU Stop2 Mode Operation ..........................................................................................219

10.5 Initialization Information ...............................................................................................................220

10.5.1 ADC Module Initialization Example ..............................................................................220

10.6 Application Information .................................................................................................................222

10.6.1 External Pins and Routing ..............................................................................................222

10.6.2 Sources of Error ..............................................................................................................223

Chapter 11

Internal Clock Source (S08ICSV3)

11.1 Introduction ....................................................................................................................................226

11.1.1 Features ...........................................................................................................................228

11.1.2 Block Diagram ................................................................................................................228

11.1.3 Modes of Operation ........................................................................................................229

11.2 External Signal Description ...........................................................................................................230

11.3 Register Definition .........................................................................................................................230

11.3.1 ICS Control Register 1 (ICSC1) .....................................................................................231

11.3.2 ICS Control Register 2 (ICSC2) .....................................................................................233

11.3.3 ICS Trim Register (ICSTRM) .........................................................................................233

MC9S08LG32 MCU Series, Rev. 5

14 Freescale Semiconductor

Page 15

Section Number Title Page

11.3.4 ICS Status and Control (ICSSC) .....................................................................................234

11.4 Functional Description ...................................................................................................................236

11.4.1 Operational Modes ..........................................................................................................236

11.4.2 Mode Switching ..............................................................................................................238

11.4.3 Bus Frequency Divider ...................................................................................................239

11.4.4 Low Power Bit Usage .....................................................................................................239

11.4.5 DCO Maximum Frequency with 32.768 kHz Oscillator ................................................239

11.4.6 Internal Reference Clock ................................................................................................239

11.4.7 External Reference Clock ...............................................................................................240

11.4.8 Fixed Frequency Clock ...................................................................................................240

11.4.9 Local Clock .....................................................................................................................240

Chapter 12

Inter-Integrated Circuit (S08IICV2)

12.1 Introduction ....................................................................................................................................241

12.1.1 Module Configuration .....................................................................................................241

12.1.2 IIC Clock Gating .............................................................................................................241

12.1.3 Features ...........................................................................................................................243

12.1.4 Modes of Operation ........................................................................................................243

12.1.5 Block Diagram ................................................................................................................243

12.2 External Signal Description ...........................................................................................................244

12.2.1 SCL — Serial Clock Line ...............................................................................................244

12.2.2 SDA — Serial Data Line ................................................................................................244

12.3 Register Definition .........................................................................................................................244

12.3.1 IIC Address Register (IICxA) .........................................................................................245

12.3.2 IIC Frequency Divider Register (IICxF) ........................................................................245

12.3.3 IIC Control Register (IICxC1) ........................................................................................248

12.3.4 IIC Status Register (IICxS) .............................................................................................248

12.3.5 IIC Data I/O Register (IICxD) ........................................................................................249

12.3.6 IIC Control Register 2 (IICxC2) .....................................................................................250

12.4 Functional Description ...................................................................................................................251

12.4.1 IIC Protocol .....................................................................................................................251

12.4.2 10-bit Address .................................................................................................................254

12.4.3 General Call Address ......................................................................................................255

12.5 Resets .............................................................................................................................................255

12.6 Interrupts ........................................................................................................................................255

12.6.1 Byte Transfer Interrupt ....................................................................................................255

12.6.2 Address Detect Interrupt .................................................................................................256

12.6.3 Arbitration Lost Interrupt ................................................................................................256

12.7 Initialization/Application Information ...........................................................................................257

MC9S08LG32 MCU Series, Rev. 5

Freescale Semiconductor 15

Page 16

Section Number Title Page

Chapter 13

Serial Communications Interface (S08SCIV4)

13.1 Introduction ....................................................................................................................................259

13.1.1 Module Instances ............................................................................................................259

13.1.2 Module Configuration .....................................................................................................259

13.1.3 SCI Clock Gating ............................................................................................................259

13.1.4 Features ...........................................................................................................................261

13.1.5 Modes of Operation ........................................................................................................261

13.1.6 Block Diagram ................................................................................................................262

13.2 Register Definition .........................................................................................................................264

13.2.1 SCI Baud Rate Registers (SCIxBDH, SCIxBDL) ..........................................................264

13.2.2 SCI Control Register 1 (SCIxC1) ...................................................................................265

13.2.3 SCI Control Register 2 (SCIxC2) ...................................................................................266

13.2.4 SCI Status Register 1 (SCIxS1) ......................................................................................267

13.2.5 SCI Status Register 2 (SCIxS2) ......................................................................................269

13.2.6 SCI Control Register 3 (SCIxC3) ...................................................................................270

13.2.7 SCI Data Register (SCIxD) .............................................................................................271

13.3 Functional Description ...................................................................................................................271

13.3.1 Baud Rate Generation .....................................................................................................271

13.3.2 Transmitter Functional Description ................................................................................272

13.3.3 Receiver Functional Description ....................................................................................273

13.3.4 Interrupts and Status Flags ..............................................................................................275

13.3.5 Additional SCI Functions ...............................................................................................276

Chapter 14

Serial Peripheral Interface (S08SPIV4)

14.1 Introduction ....................................................................................................................................278

14.1.1 Module Configuration .....................................................................................................278

14.1.2 SPI Clock Gating ............................................................................................................278

14.1.3 Features ...........................................................................................................................280

14.1.4 Block Diagrams ..............................................................................................................280

14.1.5 SPI Baud Rate Generation ..............................................................................................282

14.2 External Signal Description ...........................................................................................................283

14.2.1 SPSCK — SPI Serial Clock ............................................................................................283

14.2.2 MOSI — Master Data Out, Slave Data In ......................................................................283

14.2.3 MISO — Master Data In, Slave Data Out ......................................................................283

14.2.4 SS

14.3 Modes of Operation........................................................................................................................284

14.3.1 SPI in Stop Modes ..........................................................................................................284

14.4 Register Definition .........................................................................................................................284

14.4.1 SPI Control Register 1 (SPIxC1) ....................................................................................284

14.4.2 SPI Control Register 2 (SPIxC2) ....................................................................................285

— Slave Select ..........................................................................................................283

MC9S08LG32 MCU Series, Rev. 5

16 Freescale Semiconductor

Page 17

Section Number Title Page

14.4.3 SPI Baud Rate Register (SPIxBR) ..................................................................................286

14.4.4 SPI Status Register (SPIxS) ............................................................................................287

14.4.5 SPI Data Register (SPIxD) .............................................................................................288

14.5 Functional Description ...................................................................................................................289

14.5.1 Master Mode ...................................................................................................................289

14.5.2 Slave Mode .....................................................................................................................290

14.5.3 SPI Clock Formats ..........................................................................................................291

14.5.4 Special Features ..............................................................................................................293

14.5.5 SPI Interrupts ..................................................................................................................295

14.5.6 Mode Fault Detection .....................................................................................................295

Chapter 15

Real-Time Counter (S08RTCV1)

15.1 Introduction ....................................................................................................................................297

15.1.1 RTC Clock Gating ..........................................................................................................297

15.1.2 Features ...........................................................................................................................299

15.1.3 Modes of Operation ........................................................................................................299

15.1.4 Block Diagram ................................................................................................................300

15.2 External Signal Description ...........................................................................................................300

15.3 Register Definition .........................................................................................................................300

15.3.1 RTC Status and Control Register (RTCSC) ....................................................................301

15.3.2 RTC Counter Register (RTCCNT) ..................................................................................302

15.3.3 RTC Modulo Register (RTCMOD) ................................................................................302

15.4 Functional Description ...................................................................................................................302

15.4.1 RTC Operation Example .................................................................................................303

15.5 Initialization/Application Information ...........................................................................................304

Chapter 16

Timer/Pulse-Width Modulator (S08TPMV3)

16.1 Introduction ....................................................................................................................................306

16.1.1 TPM External Clock .......................................................................................................306

16.1.2 Module Instances ............................................................................................................306

16.1.3 Module Configuration .....................................................................................................306

16.1.4 TPM Clock Gating ..........................................................................................................307

16.1.5 Features ...........................................................................................................................308

16.1.6 Modes of Operation ........................................................................................................308

16.1.7 Block Diagram ................................................................................................................309

16.2 Signal Description ..........................................................................................................................311

16.2.1 Detailed Signal Descriptions ..........................................................................................311

16.3 Register Definition .........................................................................................................................314

16.3.1 TPM Status and Control Register (TPMxSC) ................................................................314

16.3.2 TPM-Counter Registers (TPMxCNTH:TPMxCNTL) ....................................................315

MC9S08LG32 MCU Series, Rev. 5

Freescale Semiconductor 17

Page 18

Section Number Title Page

16.3.3 TPM Counter Modulo Registers (TPMxMODH:TPMxMODL) ....................................316

16.3.4 TPM Channel n Status and Control Register (TPMxCnSC) ..........................................317

16.3.5 TPM Channel Value Registers (TPMxCnVH:TPMxCnVL) ..........................................318

16.4 Functional Description ...................................................................................................................319

16.4.1 Counter ............................................................................................................................320

16.4.2 Channel Mode Selection .................................................................................................321

16.5 Reset Overview ..............................................................................................................................324

16.5.1 General ............................................................................................................................324

16.5.2 Description of Reset Operation .......................................................................................324

16.6 Interrupts ........................................................................................................................................324

16.6.1 General ............................................................................................................................324

16.6.2 Description of Interrupt Operation .................................................................................325

Chapter 17

Modulo Timer (S08MTIMV1)

17.1 Introduction ....................................................................................................................................327

17.1.1 MTIM Clock Gating .......................................................................................................327

17.1.2 Features ...........................................................................................................................329

17.1.3 Modes of Operation ........................................................................................................329

17.1.4 Block Diagram ................................................................................................................330

17.2 External Signal Description ...........................................................................................................330

17.3 Memory Map and Register Definition ...........................................................................................331

17.3.1 Memory Map (Register Summary) .................................................................................331

17.3.2 Register Descriptions ......................................................................................................331

17.4 Functional Description ...................................................................................................................335

17.4.1 MTIM Operation Example .............................................................................................336

Chapter 18

Development Support

18.1 Introduction ....................................................................................................................................337

18.1.1 Forcing Active Background ............................................................................................337

18.1.2 Module Configuration .....................................................................................................337

18.1.3 Features ...........................................................................................................................338

18.2 Background Debug Controller (BDC) ...........................................................................................338

18.2.1 BKGD Pin Description ...................................................................................................339

18.2.2 Communication Details ..................................................................................................339

18.2.3 BDC Commands .............................................................................................................343

18.2.4 BDC Hardware Breakpoint .............................................................................................345

18.3 Register Definition .........................................................................................................................345

18.3.1 BDC Registers and Control Bits .....................................................................................346

18.3.2 System Background Debug Force Reset Register (SBDFR) ..........................................348

MC9S08LG32 MCU Series, Rev. 5

18 Freescale Semiconductor

Page 19

Section Number Title Page

Chapter 19

Debug Module (DBG) (64K)

19.1 Introduction ....................................................................................................................................350

19.1.1 Features ...........................................................................................................................350

19.1.2 Modes of Operation ........................................................................................................351

19.1.3 Block Diagram ................................................................................................................351

19.2 Signal Description ..........................................................................................................................352

19.3 Memory Map and Registers ...........................................................................................................352

19.3.1 Module Memory Map .....................................................................................................352

19.3.2 Register Descriptions ......................................................................................................354

19.4 Functional Description ...................................................................................................................365

19.4.1 Comparator .....................................................................................................................365

19.4.2 Breakpoints .....................................................................................................................365

19.4.3 Trigger Selection .............................................................................................................366

19.4.4 Trigger Break Control (TBC) .........................................................................................366

19.4.5 FIFO ................................................................................................................................370

19.4.6 Interrupt Priority .............................................................................................................371

19.5 Resets .............................................................................................................................................371

19.6 Interrupts ........................................................................................................................................371

MC9S08LG32 MCU Series, Rev. 5

Freescale Semiconductor 19

Page 20

Page 21

Chapter 1 Device Overview

The MC9S08LG32 and MC9S08LG16 are the members of the low-cost, low-power, and

high-performance HCS08 family of 8-bit microcontroller units (MCUs). All MCUs in the family use the

enhanced HCS08 core and are available with a variety of memory sizes and package types.

The MC9S08LG32 series MCUs are targeted to serve automotive, consumer and industrial markets.

Please check the ordering part numbers for different qualification tier products in Ordering Information

section of MC9S08LG32 Data Sheet.

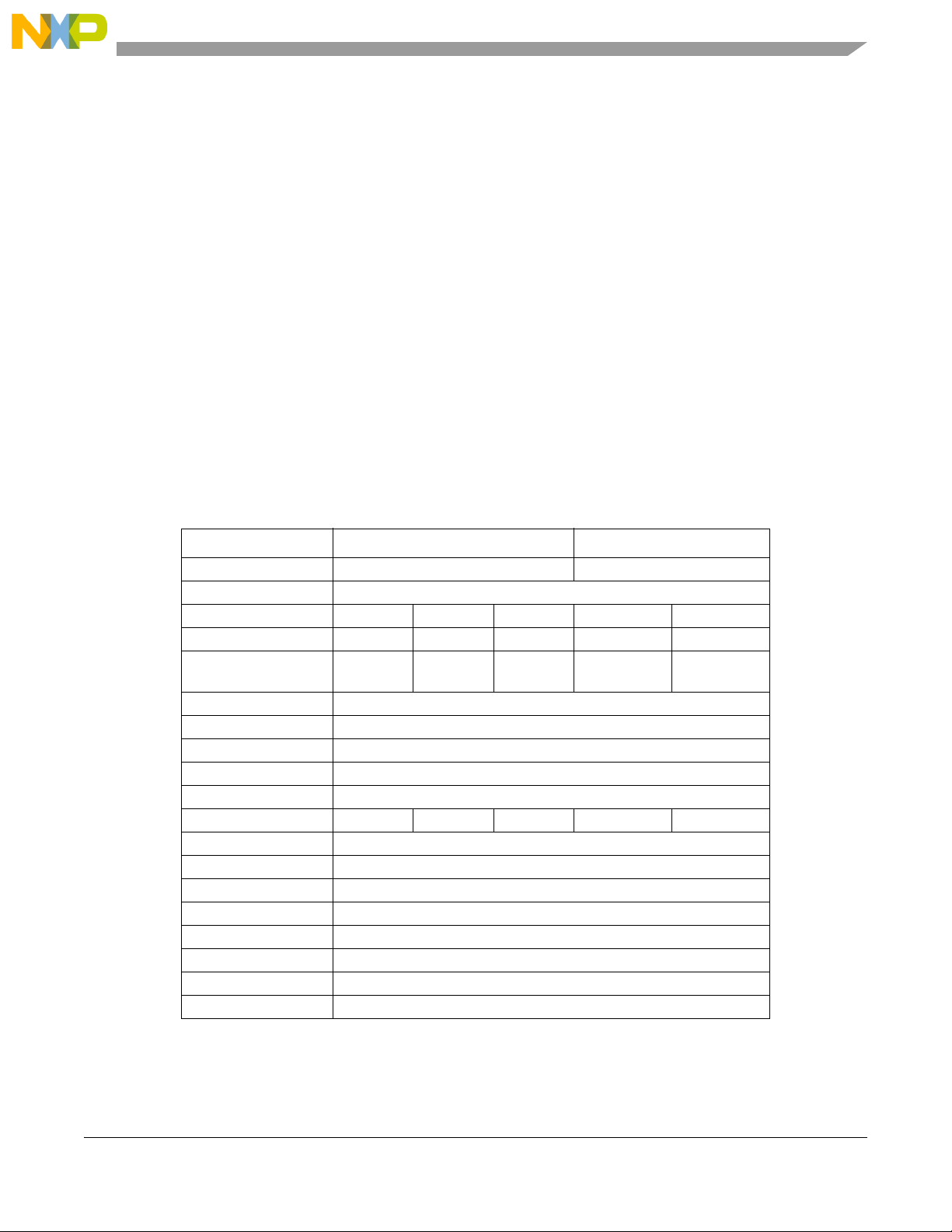

1.1 Devices in the MC9S08LG32 Series

Table 1-1 summarizes the feature set available in the MC9S08LG32 series of MCUs.

Table 1-1. MC9S08LG32 series Features by MCU and Package

Feature MC9S08LG32 MC9S08LG16

Flash size (bytes) 32,768 18,432

RAM size (bytes) 1984

Pin quantity 80 64 48 64 48

ADC 16 ch 12 ch 9 ch 12 ch 9 ch

LCD 8 x 37

4 x 41

ICE + DBG yes

ICS yes

IIC yes

IRQ yes

KBI 8 pin

GPIOs 695339 53 39

RTC yes

MTIM yes

SCI1 yes

SCI2 yes

SPI yes

TPM1 channels 2

TPM2 channels 6

XOSC yes

8 x 29

4 x 33

8 x 21

4 x 25

8 x 29

4 x 33

8 x 21

4 x 25

MC9S08LG32 MCU Series, Rev. 5

Freescale Semiconductor 21

Page 22

Chapter 1 Device Overview

8-BIT KEYBOARD

INTERRUPT (

KBI

)

IIC MODULE (

IIC

)

SERIAL PERIPHERAL

INTERFACE (

SPI

)

USER FLASH B

USER RAM

ON-CHIP ICE (

ICE

) and

DEBUG MODULE (

DBG

)

(LG32 = 16K BYTES)

HCS08 CORE

CPU

BKGD

INT

BKP

2-CHANNEL TIMER/PWM

(

TPM1

)

HCS08 SYSTEM CONTROL

RESETS AND INTERRUPTS

MODES OF OPERATION

POWER MANAGEMENT

IRQ LVD

LOW-POWER OSCILLATOR

INTERNAL CLOCK

Source (

ICS

)

SERIAL COMMUNICATIONS

6-CHANNEL TIMER/PWM

(

TPM2

)

V

LL1

(LCD)

V

LL2

V

LL3

V

CAP1

V

CAP2

LCD[44:0]

V

SS

V

DD

VO LTAGE

REGULATOR

USER FLASH A

(LG16 = 2K BYTES)

LCD28/ADC5/TPMCLK

/PTA7

LCD27/ADC4/TPM2CH1/KBI7/

PTA6

LCD25/ADC2/RX2/KBI5/

PTA4

INTERFACE (

SCI1

)

TxD1

RxD1

SS

SPSCK

SCL

SDA

MOSI

MISO

V

SSA/VREFL

V

DDA/VREFH

XTAL

EXTAL

IRQ

KBI[7:0]

PORT A

RESET

LIQUID CRYSTAL

DISPLAY DRIVER

ANALOG-TO-DIGITAL

CONVERTER (

ADC

)

12-BIT

AD[15:0]

TPM2CH[5:0]

TPMCLK

TPMCLK

LCD24/ADC1/TX2/KBI4/

PTA3

LCD23/ADC0/SDA/

PTA2

LCD22/SCL/

PTA1

LCD21/

PTA0

(LG32 = 16K BYTES)

(LG16 = 16K BYTES)

LCD26/ADC3/TPM2CH0/KBI6/

PTA5

BKGD/MS

TPM1CH[1:0]

COP

Real Time Counter

(

RTC

)

TMRCLK

SERIAL COMMUNICATIONS

INTERFACE (

SCI2

)

TxD2

RxD2

PORT C

EXTAL/

PTF7

XTAL/

PTF6

TPM2CH4/KBI1/MISO

/

PTF4

PORT F

TPM2CH5/KBI0/SS/

PTF3

ADC14/IRQ/TPM1CH1/SPSCK/

PTF2

ADC13/TPM1CH0/RX1/

PTF1

ADC12/TPM2CH2/KBI3/TX1/

PTF0

TPM2CH3/KBI2/MOSI/

PTF5

SPSCK/SDA/TPM2CH1/

PTI4

PORT I

MOSI/TPM2CH2/

PTI3

MISO/TPM2CH3/

PTI2

TX2/TMRCLK/

PTI1

RX2

/PTI0

SS/SCL/TPM2CH0/

PTI5

PORT D

PORT E

LCD[40:37]

/PTB[7:4]

LCD[32:29]

/PTB[3:0]

LCD[7:0]

/PTD[7:0]

PORT B

LCD[15:8]/

PTE[7:0]

LCD[44:41]/

PTG[7:4]

LCD[36:33]

/PTG[3:0]

PORT G

ADC11/TPM1CH0/KBI3/TX1/

PTH5

ADC10/TPM1CH1/KBI2/RX1/

PTH4

ADC[9:6]/KBI[7:4]/

PTH[3:0]

TPM2CH4/KBI1/

PTH7

ADC15/KBI0/TPM2CH5/

PTH6

PORT H

V

SS2

V

LL3_2

Available only on 80-pin package

Available only on 64-pin and 80-pin package

*/

Default function out of reset

/*

BKGD/MS

/PTC5

RESET

/PTC6

Modulo Timer

(

MTIM

)

1984 BYTES

LCD[20:16]/

PTC[4:0]

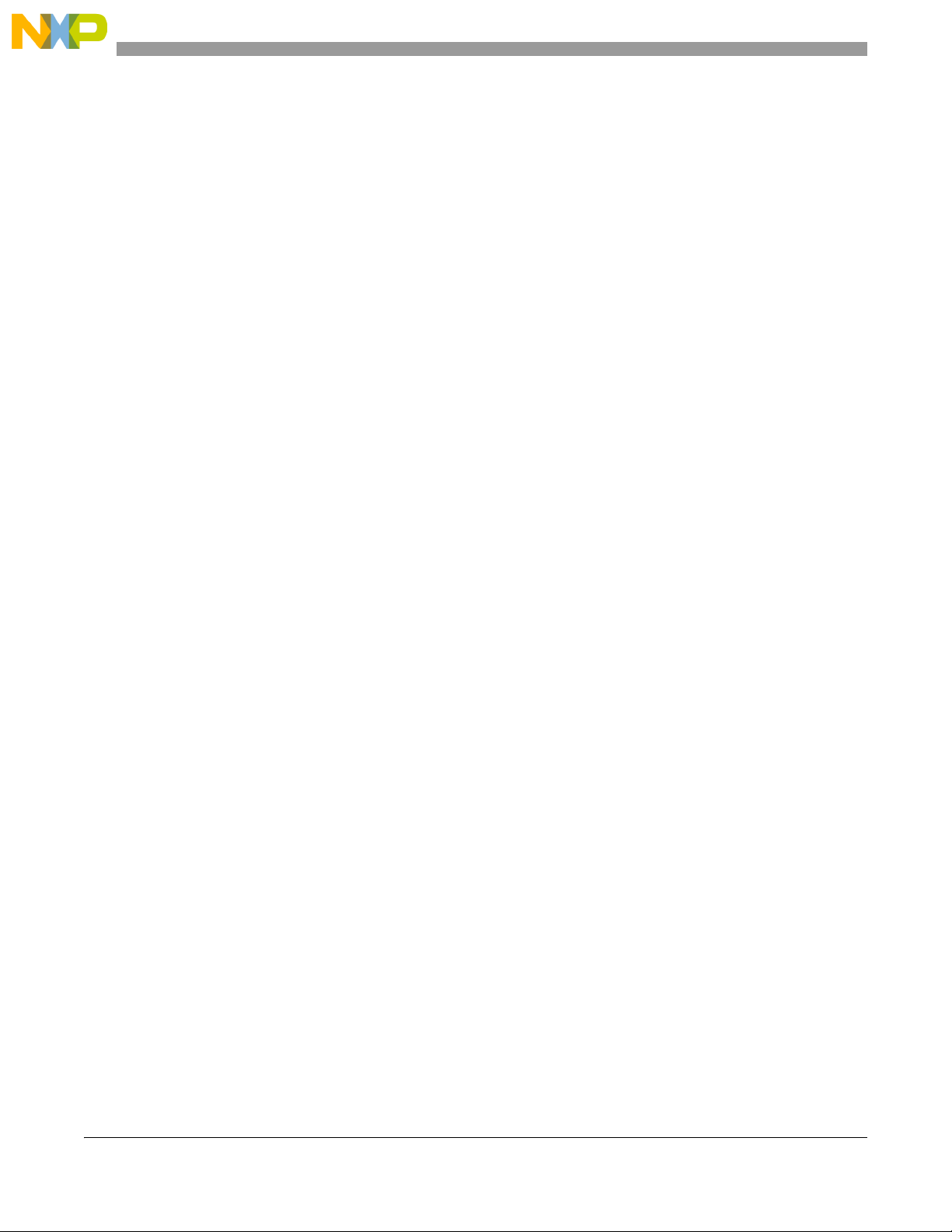

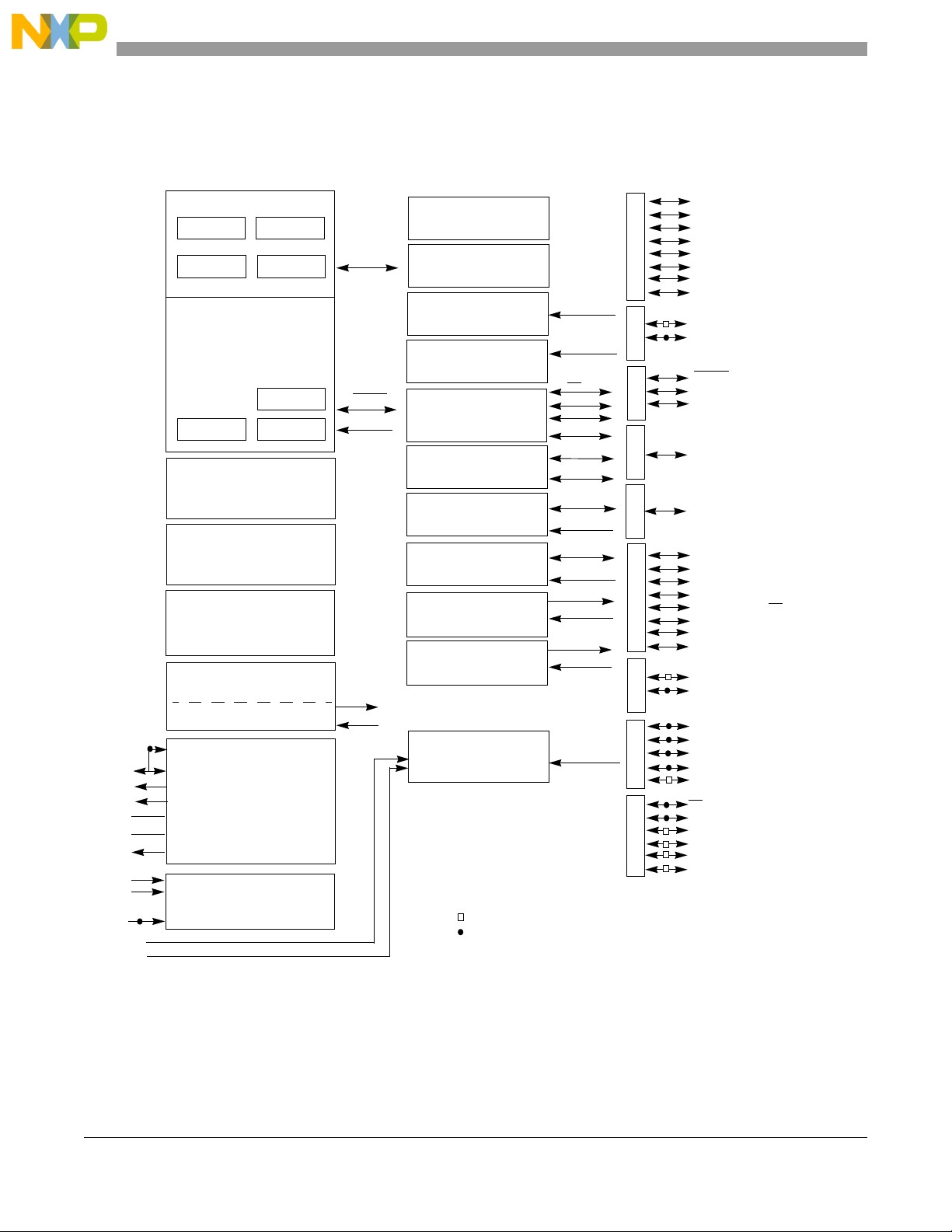

1.2 MCU Block Diagram

The block diagram in Figure 1-1 shows the structure of the MC9S08LG32 series MCU.

22 Freescale Semiconductor

Figure 1-1. MC9S08LG32 Series Block Diagram

MC9S08LG32 MCU Series, Rev. 5

Page 23

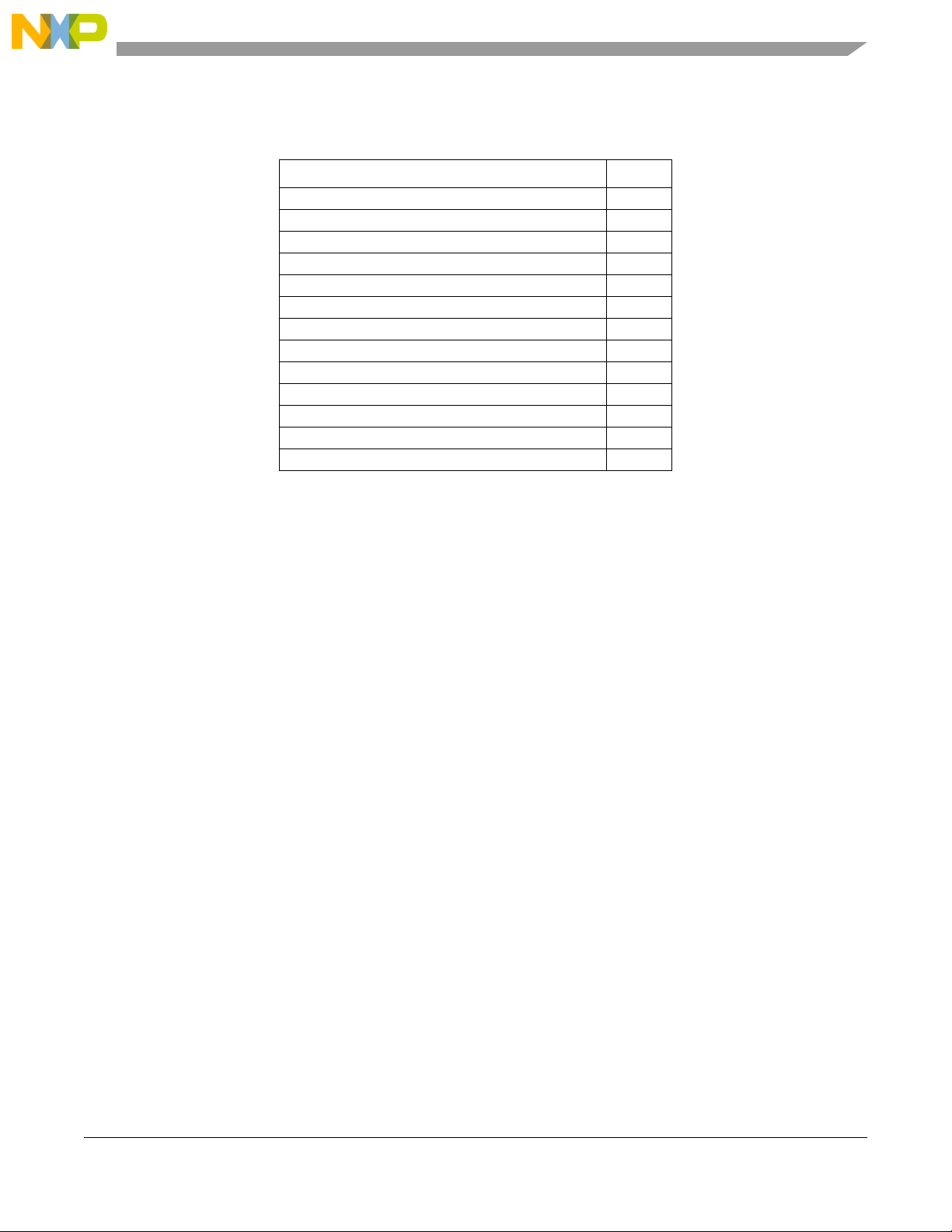

Table 1-2 provides the functional version of the on-chip modules.

Table 1-2. Module Versions

Module Version

Analog-to-Digital Converter (ADC12) 1

Central Processor Unit (CPU) 5

Inter-Integrated Circuit (IIC) 2

Internal Clock Source (ICS) 3

Keyboard Interrupt (KBI) 2

Liquid Crystal Display Module (LCD) 1

Low Power Oscillator (XOSC) 1

Modulo Timer (MTIM) 1

On-Chip In-Circuit Debug/Emulator (DBG) 3

Real Time Counter (RTC) 1

Serial Communications Interface (SCI) 4

Serial Peripheral Interface (SPI) 4

Timer Pulse Width Modulator (TPM) 3

Chapter 1 Device Overview

MC9S08LG32 MCU Series, Rev. 5

Freescale Semiconductor 23

Page 24

Chapter 1 Device Overview

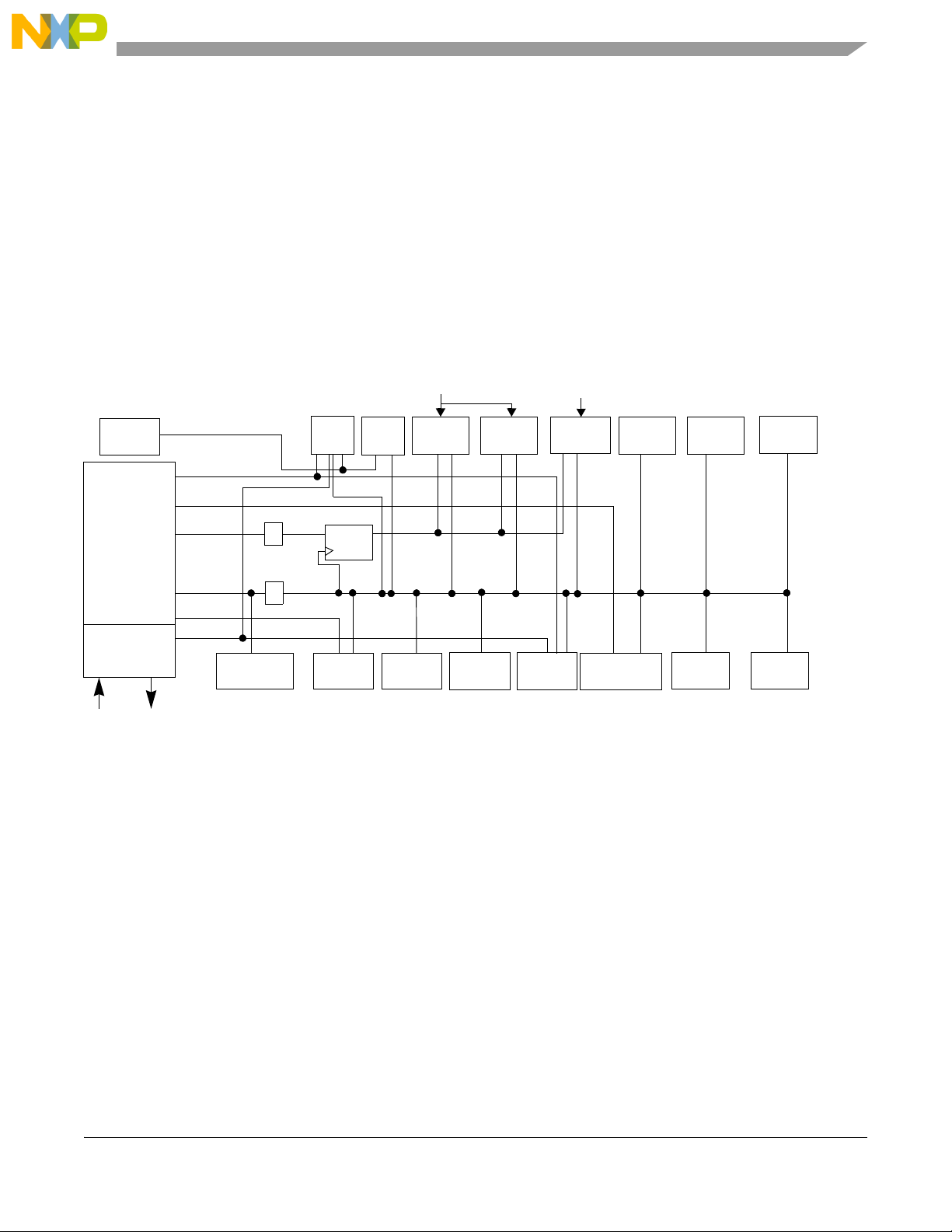

1.3 System Clock Distribution

Figure 1-2 shows a simplified clock connection diagram of the ICS. Some modules in the MCU have

selectable clock inputs as shown. The clock inputs to the modules indicate the clock(s) that are used to

drive the module function. All memory-mapped registers associated with the modules are clocked with

BUSCLK. The ICS supplies the following clock sources:

• ICSOUT — This clock source is used as the CPU clock and is divided by 2 to generate the

peripheral bus clock, BUSCLK. Control bits in the ICS control registers determine which of the

three clock sources is connected:

— Internal reference clock

— External reference clock

— Frequency-locked loop (FLL) output

For more information on configuring the ICSOUT clock, see Chapter 11, “Internal Clock Source

(S08ICSV3).”

• ICSLCLK — This clock source is derived from the digitally controlled oscillator (DCO) of the ICS

when the ICS is configured to run off the internal or external reference clock. The development

tools can select this internal self-clocked source (~ 8 MHz) to speed up the BDC communications

in systems where the bus clock is slow.

• ICSERCLK — This is an external reference clock and can be selected as the alternate clock for

ADC. The “Optional External Reference Clock” section in Chapter 11, “Internal Clock Source

(S08ICSV3),” explains the ICSERCLK in more detail. For more information regarding the use of

ICSERCLK with this module, see Chapter 10, “Analog-to-Digital Converter (S08ADC12V1).”

• ICSIRCLK — This is an internal reference clock and can be selected as the RTC clock source, or

as ALTCLK source for the LCD. Chapter 11, “Internal Clock Source (S08ICSV3)” explains the

ICSIRCLK in more detail. For more information regarding use of ICSIRCLK with these modules,

see Chapter 15, “Real-Time Counter (S08RTCV1),” and Chapter 9, “LCD Module

(S08LCDLPV1).”

• ICSFFCLK — This fixed frequency clock (FFCLK) is generated after it is synchronized with the

bus clock. The frequency of the ICSFFCLK is determined by the settings of the ICS. For more

information, see the “Fixed Frequency Clock” section in Chapter 11, “Internal Clock Source

(S08ICSV3).” It can be selected as a clock source for the MTIM and TPM modules. For

information regarding use of ICSFFCLK with these modules, see Chapter 16, “Timer/Pulse-Width

Modulator (S08TPMV3),” and Chapter 17, “Modulo Timer (S08MTIMV1).”

• LPOCLK — This clock is generated from an internal low power oscillator (LPO) that is

completely independent of the ICS module. The LPOCLK can be selected as the clock source to

the COP and RTC module. See Section 5.4, “Computer Operating Properly (COP) Watchdog,” and

Chapter 15, “Real-Time Counter (S08RTCV1),” for details on using the LPOCLK with these

modules.

• OSCOUT — This is the output of the XOSC module and can be selected as the LCD and RTC

clock source. This clock source can be used for LCD and RTC in stop2 mode. For more information

regarding use of OSCOUT with these modules, see Chapter 15, “Real-Time Counter

(S08RTCV1),” and Chapter 9, “LCD Module (S08LCDLPV1).”

MC9S08LG32 MCU Series, Rev. 5

24 Freescale Semiconductor

Page 25

Chapter 1 Device Overview

TPM1 TPM2

SCI1 SCI2

BDC

CPU

ADC

FLASH

ICS

ICSOUT

÷2

BUSCLK

ICSLCLK

ICSIRCLK

COP

* The fixed frequency clock (FFCLK) is internally

synchronized to the bus clock and must not

exceed one half of the bus clock frequency.

Flash has frequency

requirements for program

and erase operation. See the

electricals appendix for

details.

ADC has min and max

frequency requirements.

See the ADC chapter and

electricals appendix for

details.

XOSC

EXTAL XTAL

FFCLK*

ICSFFCLK

1 kHz

LPO

ICSERCLK

÷2

IIC

DBG

SYNC*

LPOCLK

OSCOUT

LCD

TPMCLK

MTIM

TMRCLK

SPI

KBI

RTC

• TPMCLK — The TPMCLK is an optional external clock source for the TPM modules. The

TPMCLK must be limited to 1/4th of the frequency of the bus clock for synchronization. For more

information, see the “External TPM Clock Sources” section in Chapter 16, “Timer/Pulse-Width

Modulator (S08TPMV3).”

• TMRCLK — The TMRCLK is an optional external clock source for the MTIM module. For more

information, see Chapter 17, “Modulo Timer (S08MTIMV1).”

NOTE

ICSERCLK is a gated version of OSCOUT. ICSERCLK is not available in

STOP modes while OSCOUT is available if ERCLKEN and EREFSTEN

are set.

Figure 1-2. System Clock Distribution Diagram

Freescale Semiconductor 25

MC9S08LG32 MCU Series, Rev. 5

Page 26

Chapter 1 Device Overview

MC9S08LG32 MCU Series, Rev. 5

26 Freescale Semiconductor

Page 27

Chapter 2 Pins and Connections

2.1 Introduction

This section describes signals that connect to the package pins. It includes pinout diagrams, recommended

system connections, and detailed discussions of signals.

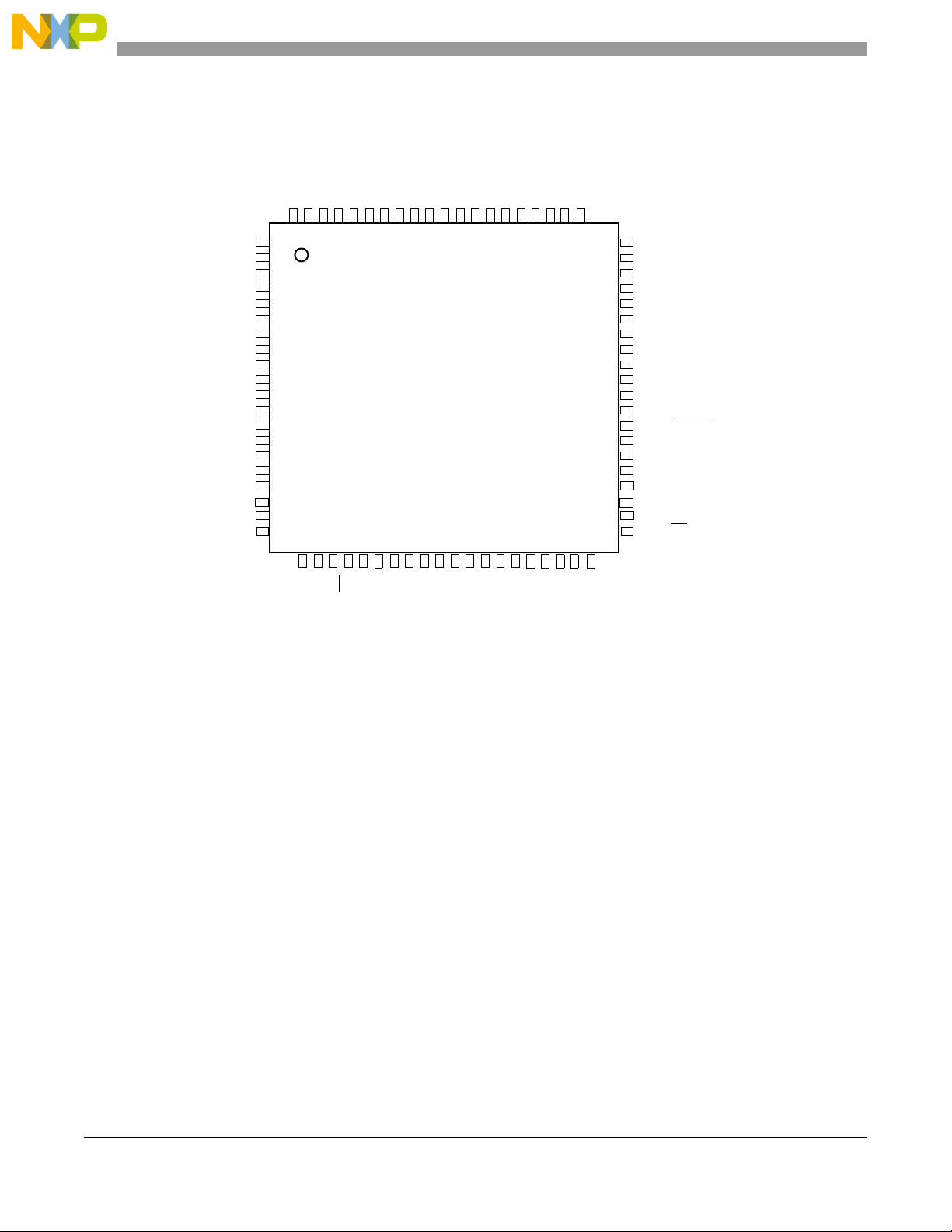

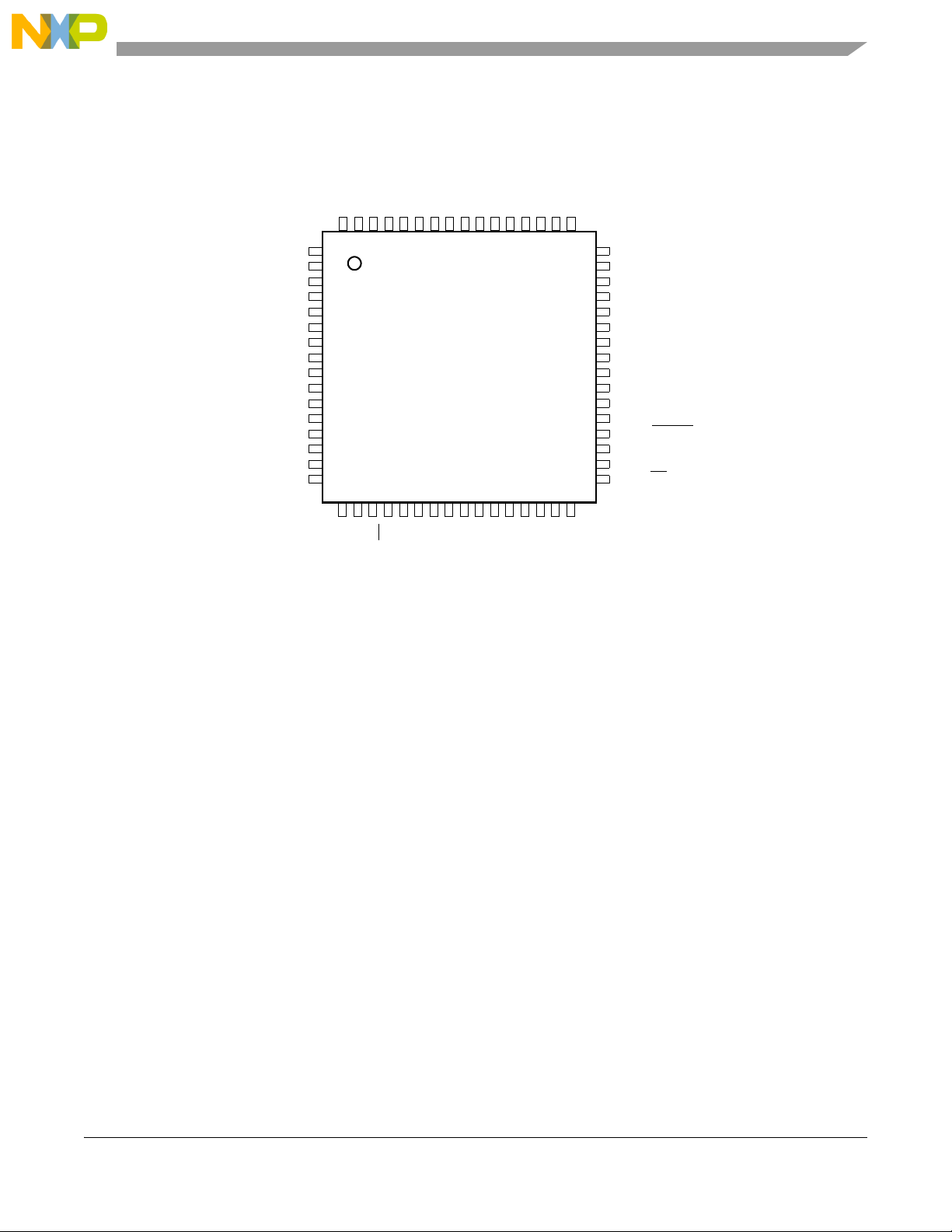

2.2 Device Pin Assignment

This section shows the pin assignments for MC9S08LG32 series. The priority of functions on a pin is in

ascending order from left to right and bottom to top. Another view of pinouts and function priority is given

in Table 2-1.

MC9S08LG32 MCU Series, Rev. 5

Freescale Semiconductor 27

Page 28

Chapter 2 Pins and Connections

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21222324252627282930313233343536373839

40

80-Pin LQFP

PTE0/LCD8

PTE1/LCD9

PTE2/LCD10

PTE3/LCD11

PTE4/LCD12

PTE5/LCD13

PTG0/LCD33

PTG1/LCD34

PTG4/LCD41

PTG5/LCD42

PTG6/LCD43

PTG7/LCD44

V

LL3_2VSS2

PTE6/LCD14

PTE7/LCD15

PTC0/LCD16

PTC1/LCD17

PTC2/LCD18

PTC3/LCD19

PTD7/LCD7

PTD6/LCD6

PTD5/LCD5

PTD4/LCD4

PTD3/LCD3

PTD2/LCD2

PTB3/LCD32

PTB2/LCD31

PTB7/LCD40

PTB6/LCD39

PTB5/LCD38

PTB4/LCD37

PTB1/LCD30

PTB0/LCD29

PTD1/LCD1

PTD0/LCD0

V

CAP1

V

CAP2

V

LL1

V

LL2

V

LL3

PTF5/MOSI/KBI2/TPM2CH3

PTF4/MISO/KBI1/TPM2CH4

PTI5/TPM2CH0/SCL/SS

PTI4/TPM2CH1/SDA/SPSCK

PTI3/TPM2CH2/MOSI

PTI2/TPM2CH3/MISO

PTI1/TMRCLK/TX2

PTI0/RX2

PTH7/KBI1/TPM2CH4

V

SS

V

DD

PTF7/EXTAL

PTF6/XTAL

V

DDA

/V

REFH

V

SSA

/V

REFL

PTH6/TPM2CH5/KBI0/ADC15

PTF2/SPSCK/TPM1CH1/IRQ/ADC14

PTF1/RX1/TPM1CH0/ADC13

PTF0/TX1/KBI3/TPM2CH2/ADC12

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

PTC4/LCD20

PTA0/LCD21

PTG2/LCD35

PTG3/LCD36

PTA1/SCL/LCD22

PTA2/SDA/ADC0/LCD23

PTA3/KBI4/TX2/ADC1/LCD24

PTA4/KBI5/RX2/ADC2/LCD25

PTA5/KBI6/TPM2CH0/ADC3/LCD26

PTA6/KBI7/TPM2CH1/ADC4/LCD27

PTA7/TPMCLK/ADC5/LCD28

PTC5/BKGD/MS

PTC6/RESET

PTH0/KBI4/ADC6

PTH1/KBI5/ADC7

PTH2KBI6/ADC8

PTH3/KBI7/ADC9

PTH4/RX1/KBI2/TPM1CH1/ADC10

PTH5/TX1/KBI3/TPM1CH0/ADC11

PTF3/SS

/KBI0/TPM2CH5

80797877767574737271706968676665646362

61

V

REFH/VREFL

are internally connected to V

Figure 2-1. 80-Pin LDFP

NOTE

DDA/VSSA

.

28 Freescale Semiconductor

MC9S08LG32 MCU Series, Rev. 5

Page 29

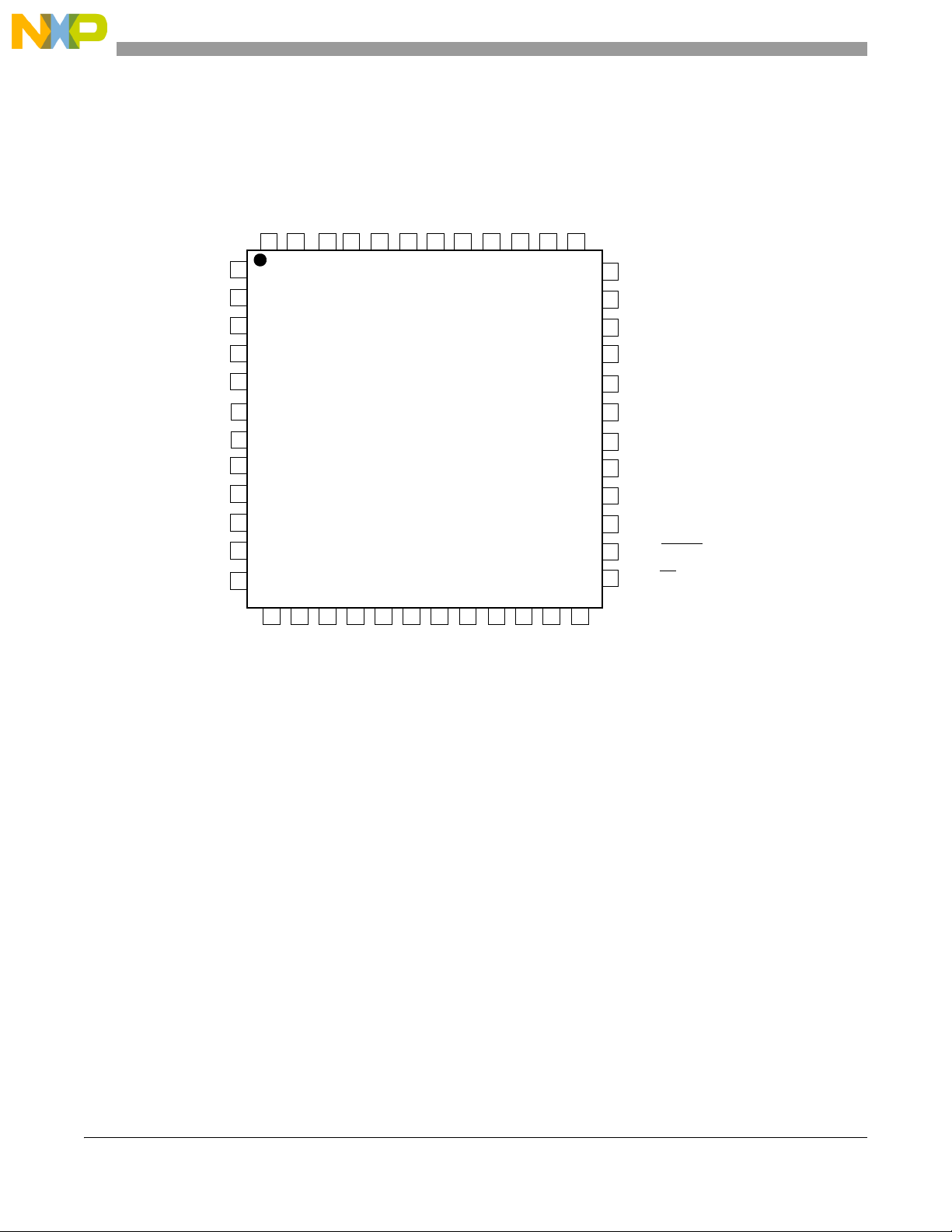

Chapter 2 Pins and Connections

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

171819202122232425262728293031

32

64-Pin LQFP

PTE0/LCD8

PTE1/LCD9

PTE2/LCD10

PTE3/LCD11

PTE4/LCD12

PTE5/LCD13

PTG0/LCD33

PTG1/LCD34

V

LL3_2VSS2

PTE6/LCD14

PTE7/LCD15

PTC0/LCD16

PTC1/LCD17

PTC2/LCD18

PTC3/LCD19

PTD7/LCD7

PTD6/LCD6

PTD5/LCD5

PTD4/LCD4

PTD3/LCD3

PTD2/LCD2

PTB3/LCD32

PTB2/LCD31

PTB1/LCD30

PTB0/LCD29

PTD1/LCD1

PTD0/LCD0

V

CAP1

V

CAP2

V

LL1

V

LL2

V

LL3

PTF5/MOSI/KBI2/TPM2CH3

PTF4/MISO/KBI1/TPM2CH4

PTI5/TPM2CH0/SCL/SS

PTI4/TPM2CH1/SDA/SPSCK

PTH7/KBI1/TPM2CH4

V

SS

V

DD

PTF7/EXTAL

PTF6/XTAL

V

DDA

/V

REFH

V

SSA

/V

REFL

PTH6/TPM2CH5/KBI0/ADC15

PTF2/SPSCK/TPM1CH1/IRQ/ADC14

PTF1/RX1/TPM1CH0/ADC13

PTF0/TX1/KBI3/TPM2CH2/ADC12

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

646362616059585756555453525150

49

PTC4/LCD20

PTA0/LCD21

PTG2/LCD35

PTG3/LCD36

PTA1/SCL/LCD22

PTA2/SDA/ADC0/LCD23

PTA3/KBI4/TX2/ADC1/LCD24