Page 1

MC92602

Reduced Interface SerDes

Design Verification Board

User’s Guide

MC92602DVBUG

Rev. 3, 06/2005

Page 2

Page 3

Contents

Paragraph Page

Number Title Number

Chapter 1

General Information

1.1 Introduction...................................................................................................................... 1-1

1.2 Design Verification Board Features ................................................................................. 1-1

1.3 Specifications................................................................................................................... 1-2

1.4 Abbreviation List ............................................................................................................. 1-2

1.5 Related Documentation.................................................................................................... 1-3

1.6 Block Diagram................................................................................................................. 1-3

1.7 Board Components .......................................................................................................... 1-3

1.8 Contact Information......................................................................................................... 1-3

Chapter 2

Hardware Preparation and Installation

2.1 Unpacking Instructions .................................................................................................... 2-1

2.2 MC92602DVB Package Contents ................................................................................... 2-1

2.3 Hardware Preparation ...................................................................................................... 2-1

2.3.1 Setting the Power Supply and Voltage Regulators ...................................................... 2-1

2.3.2 Setting the Voltage Regulators..................................................................................... 2-2

2.3.3 HSTL Voltage Reference Regulator ............................................................................ 2-3

2.4 Reference Clock Source................................................................................................... 2-3

2.4.1 Using the Onboard Oscillator ...................................................................................... 2-4

2.4.2 External Reference Clock Source................................................................................ 2-4

2.4.3 Supplying a Clock to the MC92602 ............................................................................ 2-4

2.4.4 3.3V_CLK_OUTn SMA Connectors .......................................................................... 2-5

2.4.5 Clock Frequency Selection .......................................................................................... 2-5

2.5 Interface Components ...................................................................................................... 2-6

2.5.1 Parallel Inputs and Outputs.......................................................................................... 2-6

2.5.1.1 Parallel Inputs .......................................................................................................... 2-6

2.5.1.2 Parallel Outputs ....................................................................................................... 2-7

2.5.2 +V

2.5.3 Serial Inputs and Outputs............................................................................................. 2-7

2.6 Special Test Connection................................................................................................... 2-7

2.7 Test Traces ....................................................................................................................... 2-8

and Ground (GND) Access Connections........................................................ 2-7

DDQ

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor iii

Page 4

Paragraph Page

Number Title Number

Chapter 3

Laboratory Equipment and Quick Setup Evaluation

3.1 Recommended Laboratory Equipment ............................................................................ 3-1

3.2 Quick Setup Data-Eye Diagram ...................................................................................... 3-2

3.2.1 Quick Setup Data-Eye Generation and Observation ................................................... 3-3

3.2.1.1 Equipment Setup...................................................................................................... 3-3

3.2.1.2 Parallel Input Connections....................................................................................... 3-4

3.2.2 Basic Eye Observation—Test Procedure..................................................................... 3-5

3.2.3 Quick Setup Bit Error Rate Checking.......................................................................... 3-6

3.2.3.1 Equipment Setup...................................................................................................... 3-6

3.2.3.2 Parallel I/O Connections.......................................................................................... 3-7

3.2.3.3 Quick Setup BERC Test Procedure ......................................................................... 3-7

Chapter 4

Test Setups

4.1 Serial Link Verification Using a Serial Bit Error Rate Tester (BERT) ............................ 4-1

4.1.1 Test Setup for Full-Speed Mode .................................................................................. 4-2

4.1.2 Test Setup for Half-Speed Mode ................................................................................. 4-2

4.2 Jitter Testing..................................................................................................................... 4-3

4.2.1 Jitter Test System Calibration ...................................................................................... 4-3

4.2.2 Reference Clock Jitter Transfer Test............................................................................ 4-4

4.2.3 Reference Clock Jitter Tolerance Test ......................................................................... 4-5

4.2.4 Data Jitter Tolerance Test............................................................................................. 4-6

Appendix A

Connector Signals

A.1 Input: 2 × 10 (0.100") Connectors.................................................................................... A-1

A.1.1 Control Signal Input Connectors ................................................................................ A-1

A.1.2 Transmitter Parallel Data Input Connectors ............................................................... A-3

A.2 Output: 2 × 20 (0.100") Connectors................................................................................. A-4

A.3 TEST_0 Connector ......................................................................................................... A-5

Appendix B

Parts List

B.1 Design Verification Board Parts List ...............................................................................B-1

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

iv Freescale Semiconductor

Page 5

Paragraph Page

Number Title Number

Appendix C

Prescaler for Jitter Measurement

C.1 Divide-by-xx Prescaler Description.................................................................................C-1

C.2 Prescaler Components......................................................................................................C-2

Appendix D

Revision History

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor v

Page 6

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

vi Freescale Semiconductor

Page 7

Chapter 1

General Information

1.1 Introduction

This user’s guide describes the MC92602 design verification board, Rev. B and higher. The design

verification board (DVB) facilitates the full evaluation of the MC92602 Quad Reduced Interface SerDes.

It should be read in conjunction with the MC92602 Quad 1.25 Gbaud Reduced Interface SerDes Reference

Guide. This design verification board is intended for evaluation and testing purposes only. Freescale does

not guarantee its performance in a production environment.

This board was designed to be used with laboratory equipment (pattern generators, data analyzers, BERT,

scopes, etc.) or connected to other evaluation boards. Access to the MC92602 device (verification chip) is

through connectors to each pin, to allow complete in-depth ‘design verification’ testing of the chip design.

This allows the user to check any or all features/functions of the MC92602 device.

The four parallel data input ports and all configuration/control signal pins, are accessed through common

2 × 10, 0.100" male connectors (headers). The parallel data output ports are accessed through 2 × 20, 0.100"

connectors. Device JTAG port signals are also accessed with a separate connector.

The MC92602 high-speed serial receivers and transmitters are accessed via SMA coaxial connectors for

signal integrity measurements.

A single 5.0-V power source is required for the DVB operation. All necessary voltages are generated by

regulators onboard. The reference clock for the MC92602 chip may be provided using either an external

clock or the onboard crystal oscillator. Clock drivers on the DVB provide additional clock signals for

triggering analyzer instrumentation and scopes.

1.2 Design Verification Board Features

The functional, physical, and performance features of the MC92602DVB are as follows:

• A single external 5.0-V to onboard regulators supply power to all onboard circuitry.

• Reference clock source is a 250-MHz crystal oscillator or an external clock source.

• Parallel data and control interfaces accessible through standard 0.100", 2 row connectors for data

generators and analyzers.

• The full-duplex differential data links accessible through SMA connectors.

• Two pairs of 50-Ω test traces with SMA connections facilitate TDR measurements of the

characteristic impedance of representative board traces.

• Connector provided for JTAG test access port

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 1-1

Page 8

General Information

1.3 Specifications

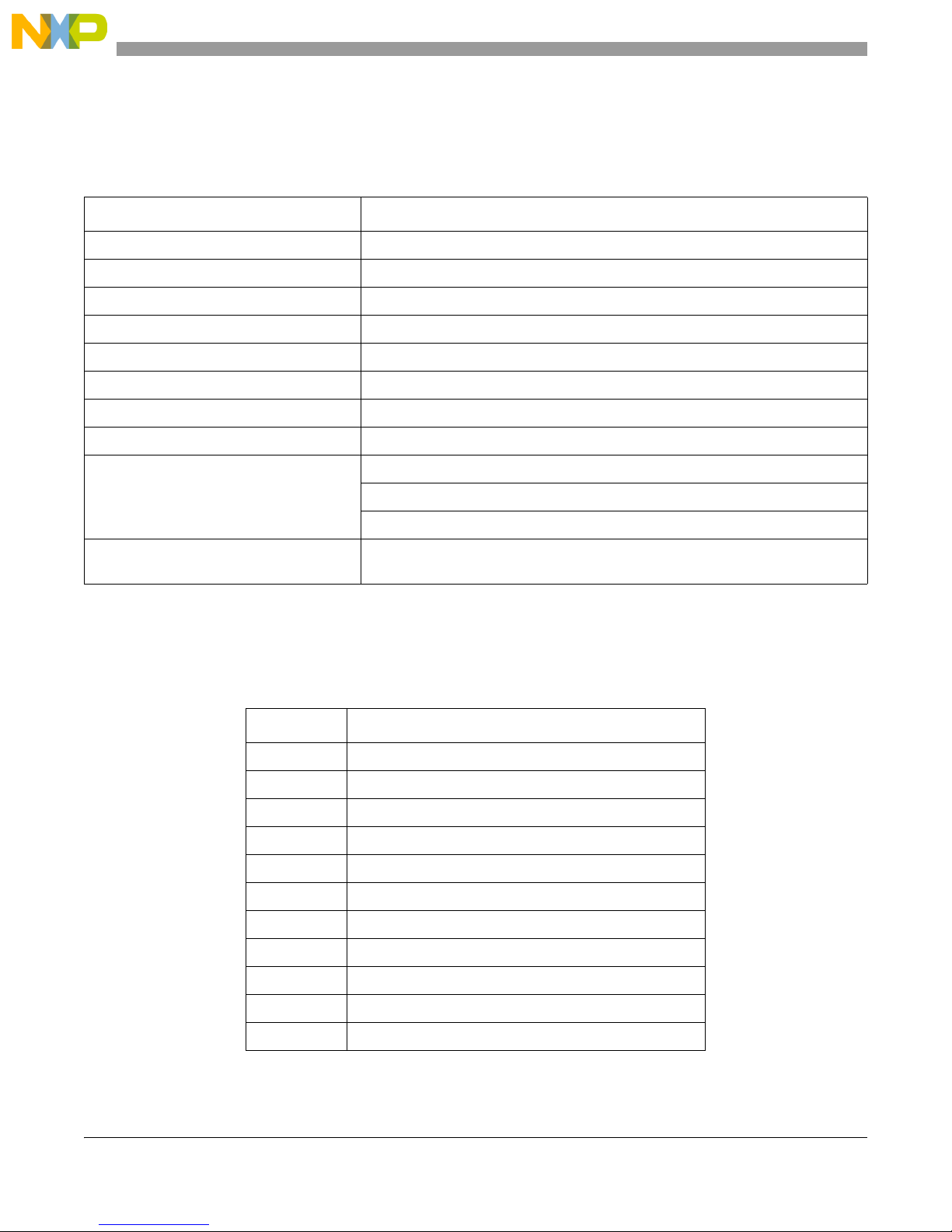

The MC92602DVB design verification board specifications are provided in Table 1-1.

Tabl e 1-1. MC92602DVB Design Verification Board Specifications

Characteristics Specifications

Board revision Rev. B and higher

External power supply +5 V DC ± 0.5 V DC < 2.0 A typical

Support circuit regulator 3.3 V ± 0.3 V DC

MC92602 core and link I/O regulator 1.8 V ± 0.15 V DC

Interface I/O (V

MC92602 package 196 MAPBGA

Operating temperature 0°−30°C

Material FR-4

Dimensions Height 14.8", 377 mm

Conducting layers Four ground planes, one split power plane, three signal routing layers, top and

) regulator 2.5 V ± 0.2 or 3.3 V ± 0.3 V DC

DDQ

Width 12.3", 312 mm

Thickness 0.1", 2.4 mm

bottom component layers with some additional signal routing.

1.4 Abbreviation List

Table 1-2 contains abbreviations used in this document.

Tabl e 1-2. Acronyms and Abbreviated Terms

Term Meaning

‘1’ High logic level (nominally 1.5 or 3.3 V)

‘0’ Low logic level (nominally 0.0 V)

BIST Built-in self-test

DVB Design verification board

I/F Interface

N/C No connection

PN Pseudo-noise

PRBS Pseudo random bit sequence

TA P Test access port

TDR Time delay reflectometry

UIp-p Peak-to-peak unit interval

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

1-2 Freescale Semiconductor

Page 9

General Information

1.5 Related Documentation

Related documentation includes the following:

• MC92602 Quad 1.25 Gbaud Reduced Interface SerDes Reference Guide (MC92602RM)

• MC92602DVB schematics

• MC100ES6222 data sheet

• MC100ES8111 data sheet

• MPC9456 data sheet

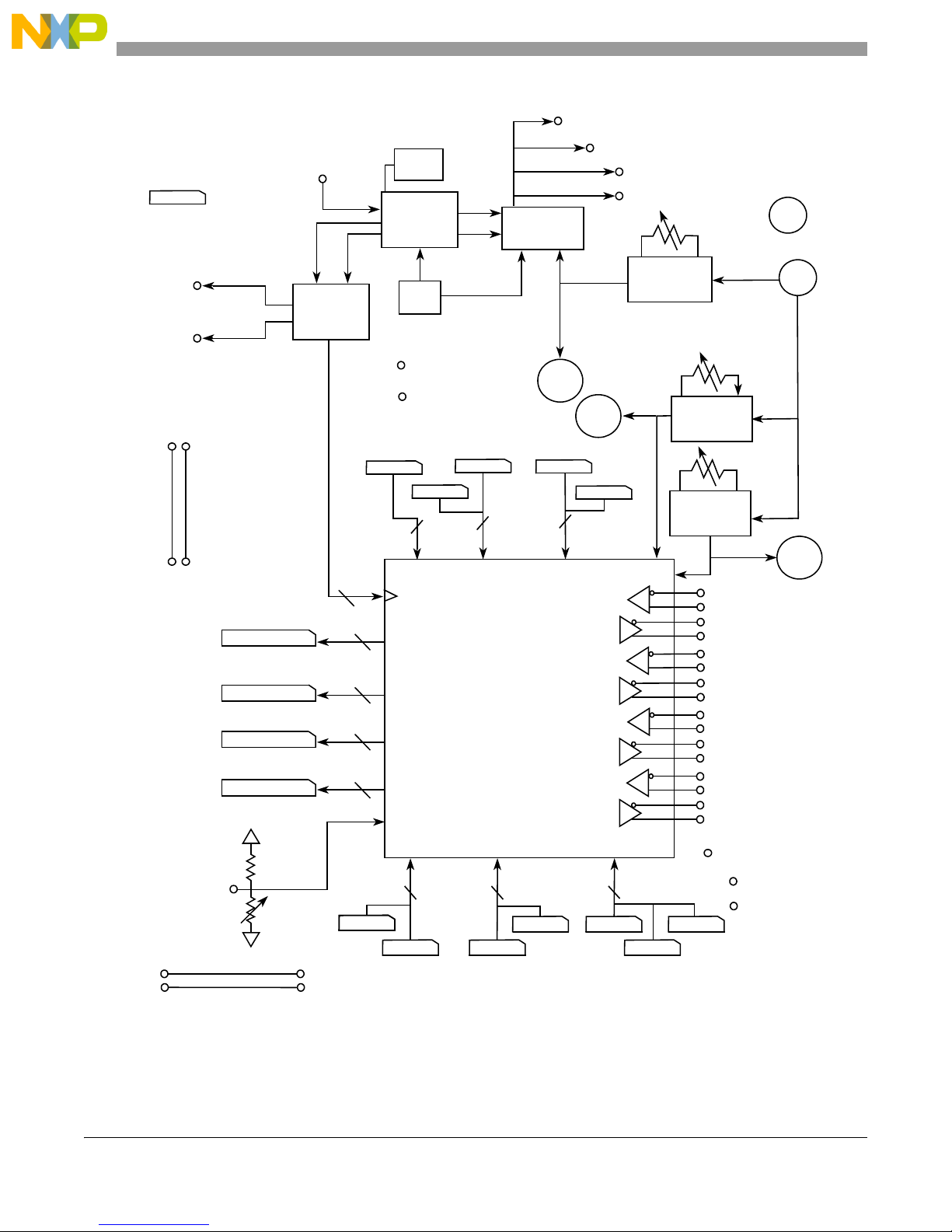

1.6 Block Diagram

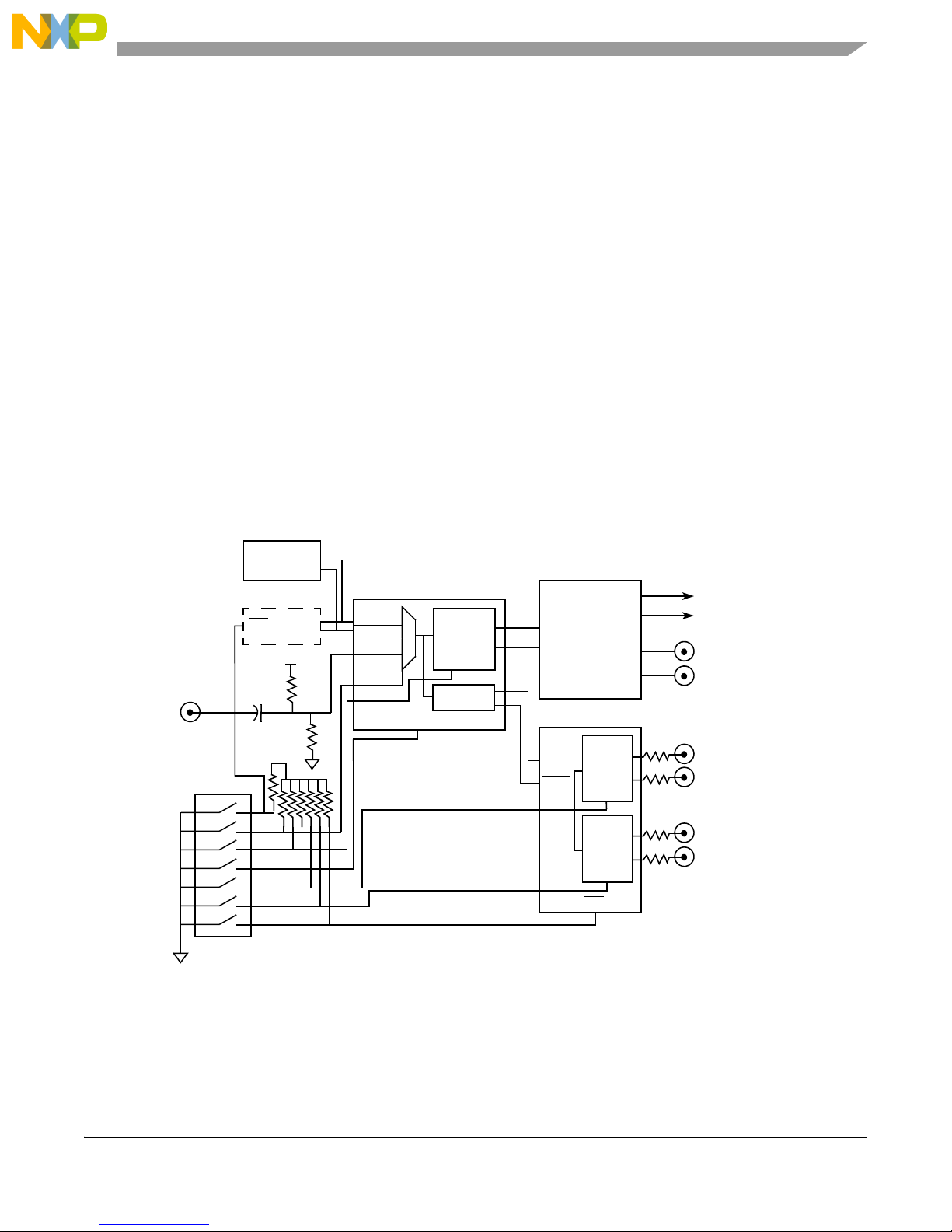

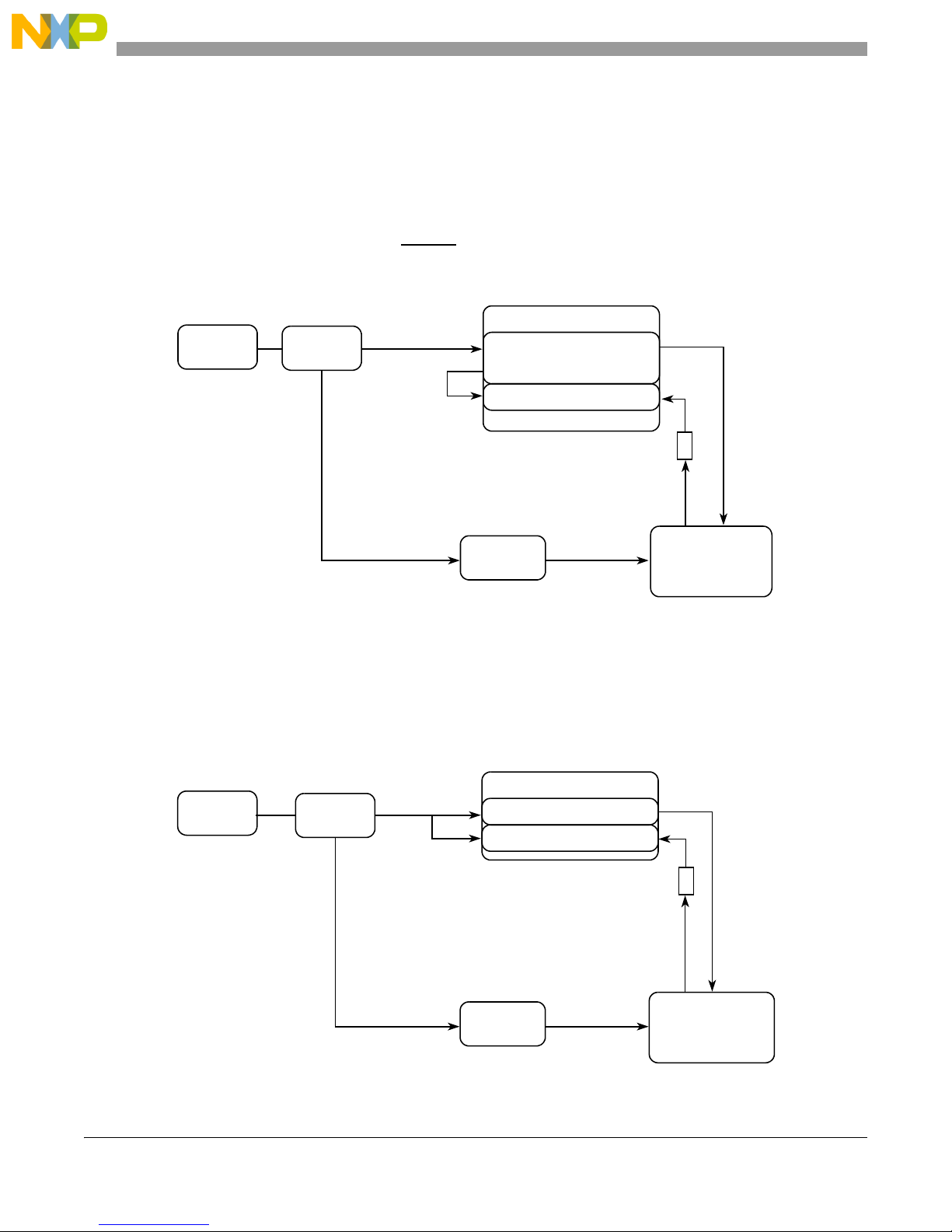

Figure 1-1 shows the MC92602 design verification board block diagram.

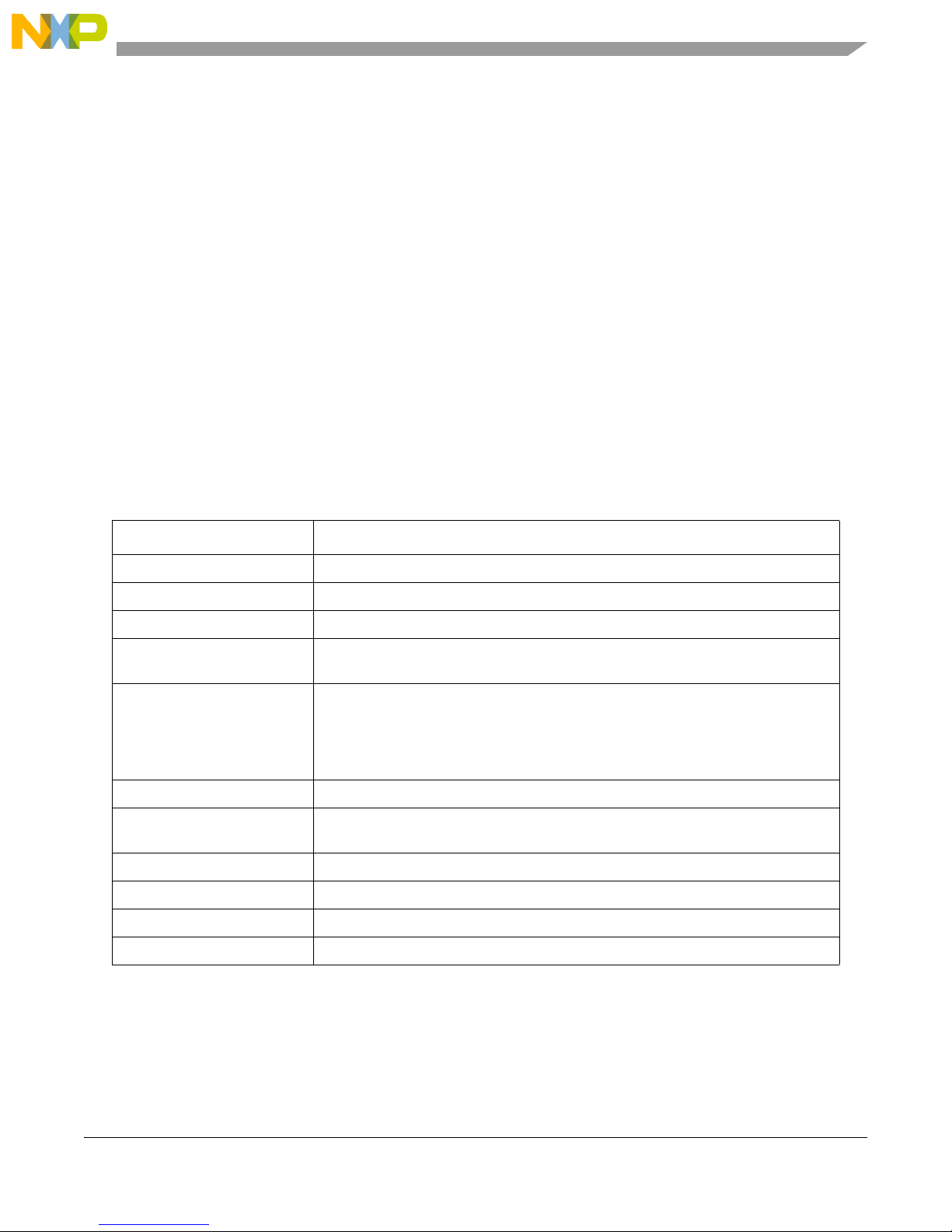

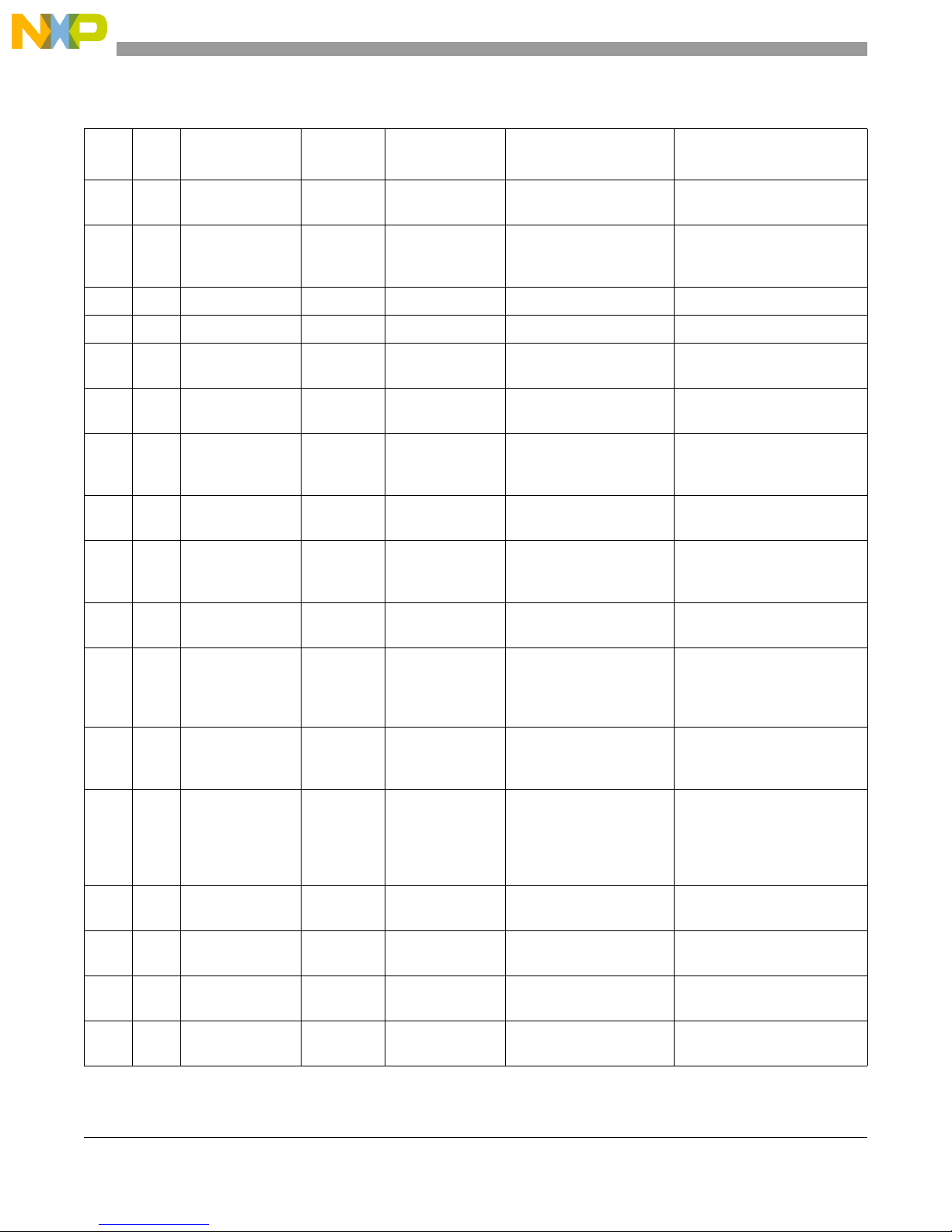

1.7 Board Components

Table 1-3 is a list of major components of the MC92602 design verification board. A complete parts listing

can be found in Appendix B, “Parts List.”

Tabl e 1-3. Major Board Components

Component Description

MC92602ZT Freescale Quad 1.25 Gbaud Reduced Interface SerDes

2 × 10, 0.100" connectors PG1–PG11, and PG13 provide access to the parallel inputs and control signals

2 × 20, 0.100" connectors LA1–LA4 provide access to the parallel outputs

2 × 8, 0.100" connectors PG12 and PG14 provide access to the SFP connector and +VDD/ground planes,

respectively.

SMA connectors SMA1–SMA16: Serial transmit and receive connections

TST1–TST8: Impedance test trace connections

CLK_OUT1–CLK_OUT6: Reference clock outputs

CLK_IN: External reference clock input

CLK_A_PG - CLK_D_PG: Input clock connectors

LT1587 voltage regulators VR33, VR18, and VR1: +3.3 V, +1.8 V, and +1.5 (V

Potentiometers R12V, R22V, R22V1, and R22V2: Potentiometers for setting +3.3 V, +1.8 V,

V

+1.5

XTAL oscillator Y1, Y2: Onboard 250-MHz crystal oscillator

MC100ES6222 clock buffer U2: Divide-by-1 or divide-by-2 clock buffer

MPC9456 clock buffer U3: +3.3-V LVCMOS clock buffer

MC100ES8111 clock buffer U4: Level shift and clock buffer

, and HSTL reference voltage levels

DDQ

) voltage regulators

DDQ

1.8 Contact Information

For questions concerning the MC92602 design verification kit or to place an order for a kit, contact your

local Freescale field applications engineer.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 1-3

Page 10

General Information

+1.5 V/GND

0.100" Connector

CLK_IN

X-TAL

Osc

MC100

ES6222

MPC9456

3.3V_CLK_OUT1

3.3V_CLK_OUT2

3.3V_CLK_OUT3

3.3V_CLK_OUT4

R12V

GND

1.5V_CLK_OUT5

1.5V_CLK_OUT6

TST1 TST2

Vertical 50-Ω

Te s t Tr a c e s

TST5 TST6

2 × 20, 0.100"

Connectors

LA4

LA3

LA2

MC100

ES8111

SW1

CLK_C_PG

CLK_D_PG

2×10, 0.100" Connectors

PG1

Control

RECV_D

RECV_C

RECV_B

PG7

PG6

XMIT_C XMIT_D

Reduced Interface

+3.3 V

MC92602

SerDes

PG4

+1.5 V

PG5

+3.3-V

Regulator

Regulator

Regulator

+5 V

R22V1

+1.5-V

R22V

+1.8-V

+1.8 V

RLINK_D0

XLINK_D0

RLINK_C0

XLINK_C0

RLINK_B0

XLINK_B0

LA1

HSTL_VREF

R22V2

TST3 TST7

TST4 TST8

Horizontal 50-

Te s t Tr a c e s

Ω

Figure 1-1. MC92602 Design Verification Board Block Diagram

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

1-4 Freescale Semiconductor

PG8PG8

RECV_A

HSTL_VREF

XMIT_A

PG9

XMIT_B Ctrl/Tst

PG11

PG10

2×10, 0.100" Connectors

RLINK_A0

XLINK_A0

TPA

CLK_A_PG

CLK_B_PG

PG13PG2

PG3

Page 11

Chapter 2

Hardware Preparation and Installation

This chapter provides unpacking, hardware preparation, configuration-installation instructions, and

description of the interface components for the MC92602DVB.

2.1 Unpacking Instructions

Unpack the board from the shipping carton. Refer to the packing list and verify that all items are present.

Save the packing material for storing and reshipping of the equipment.

2.2 MC92602DVB Package Contents

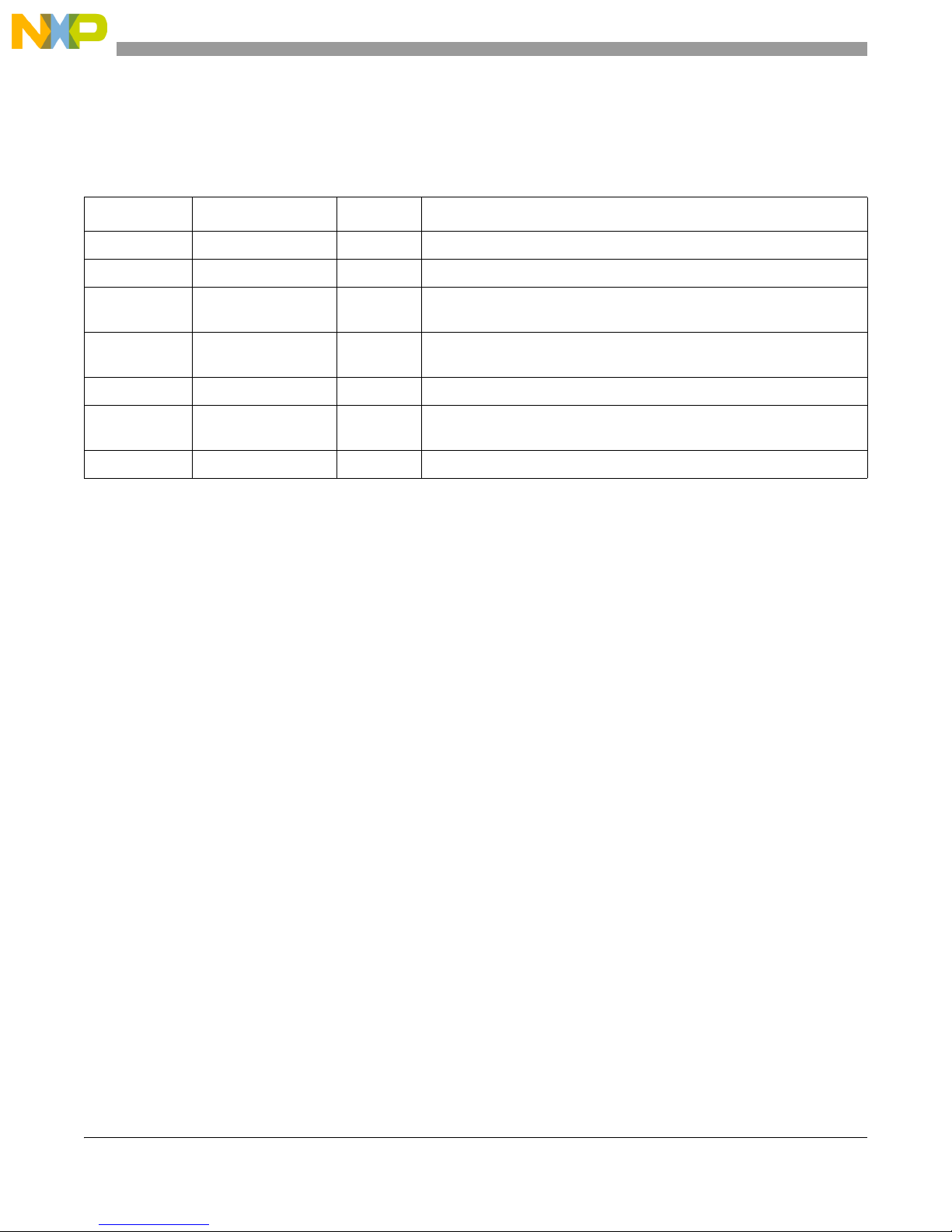

Table 2-1 describes the contents of the MC92602DVB kit.

Tabl e 2-1. MC92602DVB Kit Contents

Quantity Item

1 MC92602DVB design verification board

1 MC92602DVB Reduced Interface SerDes Design Verification Board User’s Guide

1 MC92602 Quad 1.25 Gbaud Reduced Interface SerDes Reference Guide

1 Complete set of MC92602DVB design verification board schematics

45 0.100" shunts

10 Square pin receptacle patch cords

2.3 Hardware Preparation

Operation of the MC92602DVB requires proper setup of the power supply and voltage regulators as well

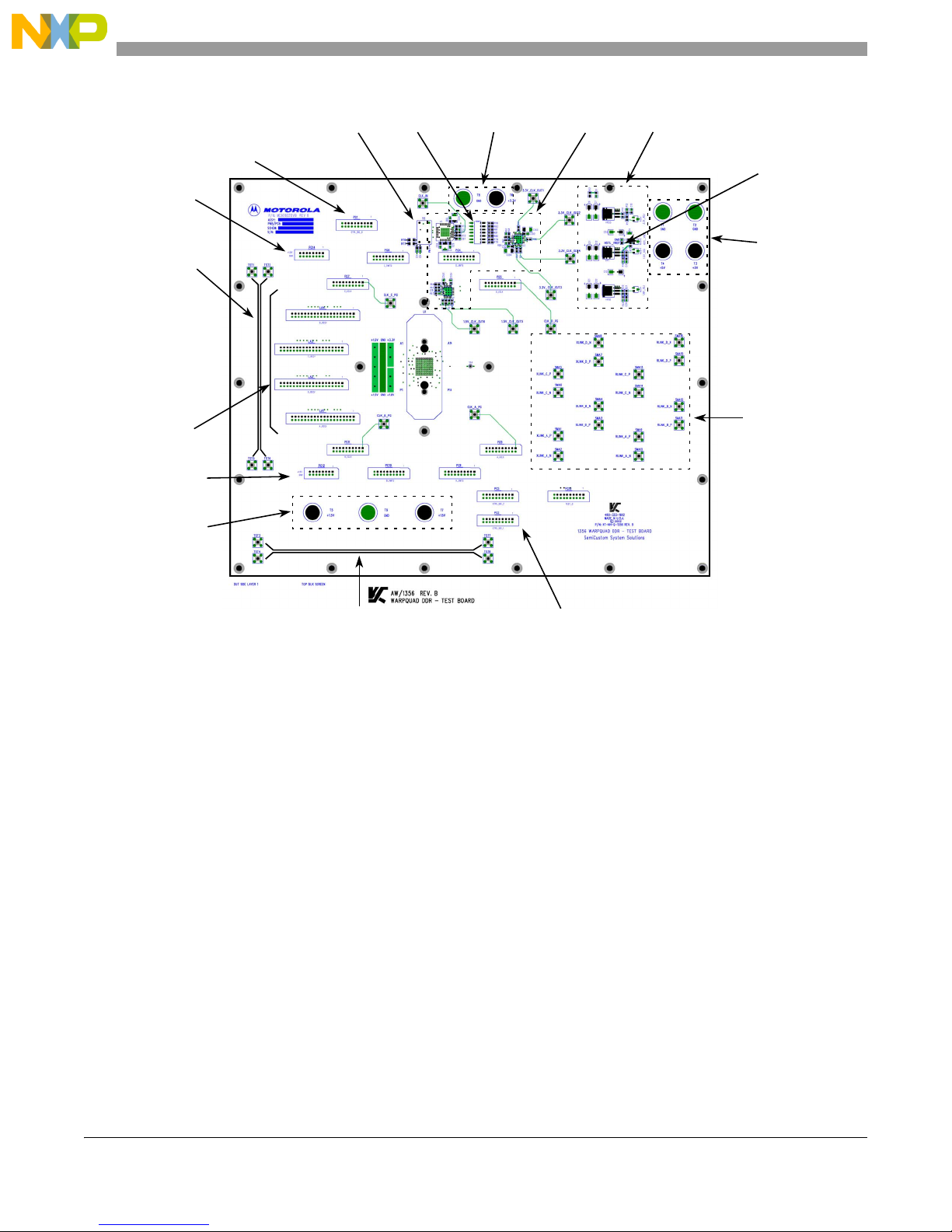

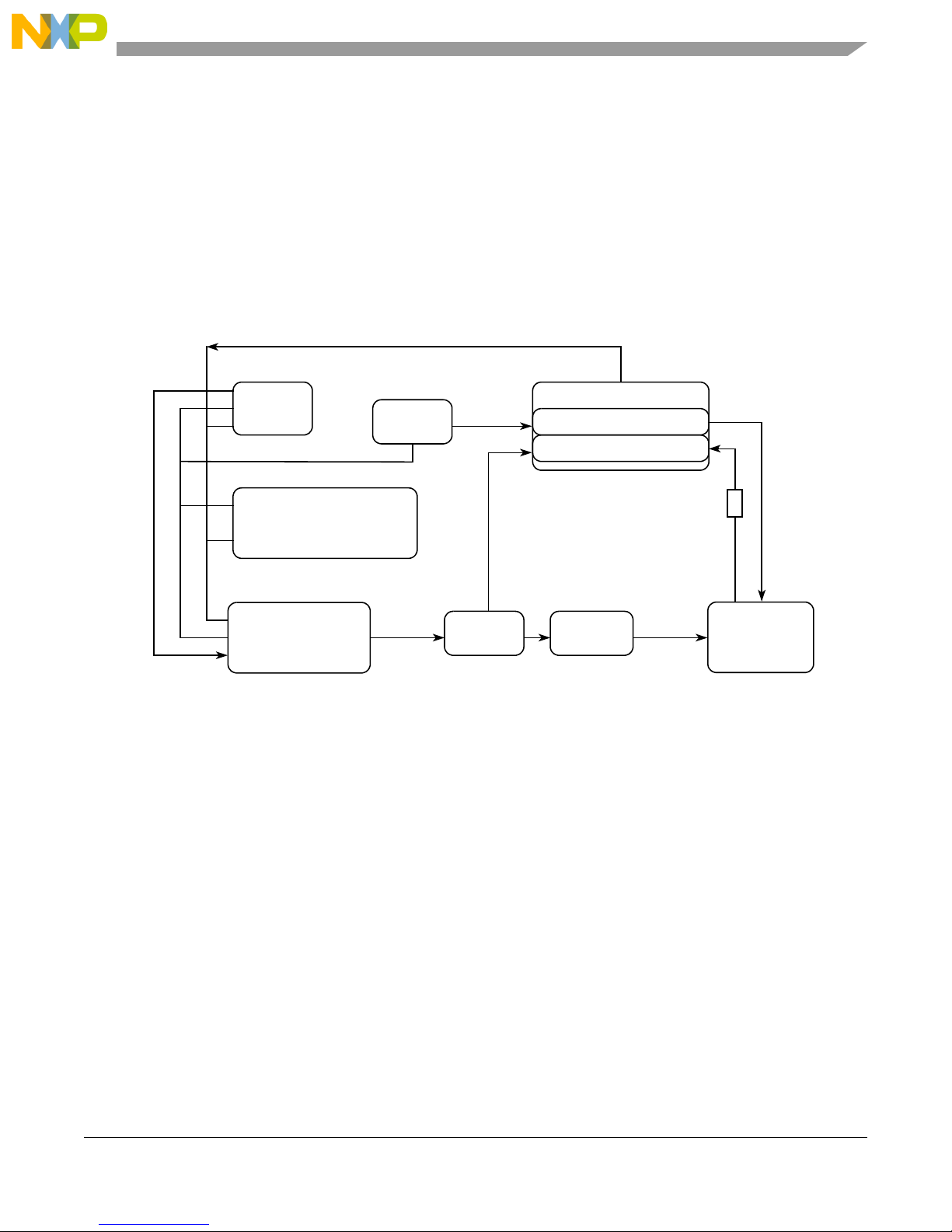

as the reference clock. Figure 2-1 depicts the location of the major components on the board. The

following sections describe proper setup of the MC92602DVB.

2.3.1 Setting the Power Supply and Voltage Regulators

The MC92602DVB requires a single +5.0-V supply. Fully operational, the board will draw a maximum

current less than 2.0 amps from the +5.0-V supply. Actual current consumption depends on the user set

voltage levels, clock frequencies, and the MC92602 operating mode. The board contains two +5.0-V

connection posts and two ground connection posts. These duplicate connections simplify using a four-wire

supply: supply and ground, force and sense.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 2-1

Page 12

Hardware Preparation and Installation

2 × 8

Connector

50-Ω

Ver ti ca l

Te st Tra ce s

2 × 20

Connectors

2 × 8

Connector

+1.5- and +1.8-V

Powe r

Connectors

2 × 10

Connectors

Crystal

Oscillator

DIP

Switch

MC92602

+3.3-V Power

Connection

Clock

Buffers

Vol tag e

Regulators

HSTL

Reference

Test Point

+5-V Power

Connectors

Serial

Differential

SMA

Connectors

Horizontal

50-Ω

Te st Tra ce s

2 × 10

Connectors

NOTE:

Freescale has begun the transition of marking Printed Circuit Boards (PCBs) with the Freescale

Semiconductor signature/logo. PCBs may have either Motorola or Freescale markings during the

transition period. These changes will have no impact on form, fit, or function of the current product.

Figure 2-1. Top Side Part Location Diagram

2.3.2 Setting the Voltage Regulators

The +5.0-V supply is used to power 3 onboard voltage regulators, VR33, VR18, and VR15. These

regulators generate +3.3, +1.8, and +1.5/1.8 V (V

to the oscillator and clock buffer chips. This supply can be varied over the range +3.3

R12V potentiometer.

The +1.8-V supply is used to power the MC92602 core logic, transceivers, and on-chip phase-locked loop

(PLL). This regulator can be adjusted over the range +1.8 V

The +1.5-V (HSTL) V

supply powers the MC92602 control signal, parallel input, and output interface

DDQ

circuitry. This voltage level is determined by the desired logic interface. The +1.5-V supply can be adjusted

using a R22V1 potentiometer from +1.5 V + 0.45 V/– 0.15 V. If desired, the +1.5-V regulator can be

adjusted to match the +1.8-V range for evaluation in those systems that do not contain a separate +1.5-V

supply.

), respectively. The +3.3-V supply provides power

DDQ

V ± 0.3 V using the

± 0.15 V using R22V.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

2-2 Freescale Semiconductor

Page 13

Hardware Preparation and Installation

The +3.3-V, +1.8-V, and +V

supplies are accessible via connection posts. Note that these regulators

DDQ

should be set to voltage limits within the operating ranges described in the MC92602 Quad 1.25 Gbaud

Reduced Interface SerDes Reference Guide. Failure to operate within these ranges could cause damage to

the MC92602. Freescale will not guarantee MC92602 operation beyond the ranges specified. The R12V,

R22V, and R22V1 potentiometers will be factory set for +3.3, +1.8, and +1.5

V, respectively.

2.3.3 HSTL Voltage Reference Regulator

The HSTL I/O has a voltage reference that must be adjusted to set the logic high/low switch point. For a

nominal +1.5 V on the +1.5-V, V

supply, R22V2 should be set such that the voltage at the

DDQ

HSTL_VREF test point is +0.75 V. For those systems whose HSTL voltage will be +1.8 V, t h i s

potentiometer should be set to +0.9 V. The R22V2 potentiometer is typically factory set for +0.8 V.

2.4 Reference Clock Source

Through a combination of clock buffers, a reference clock is supplied to the MC92602 and several SMA

output connectors. The input reference clock for the MC92602 can be supplied using either an onboard

crystal oscillator, or by directly driving an external reference clock into the board’s clock buffer circuit via

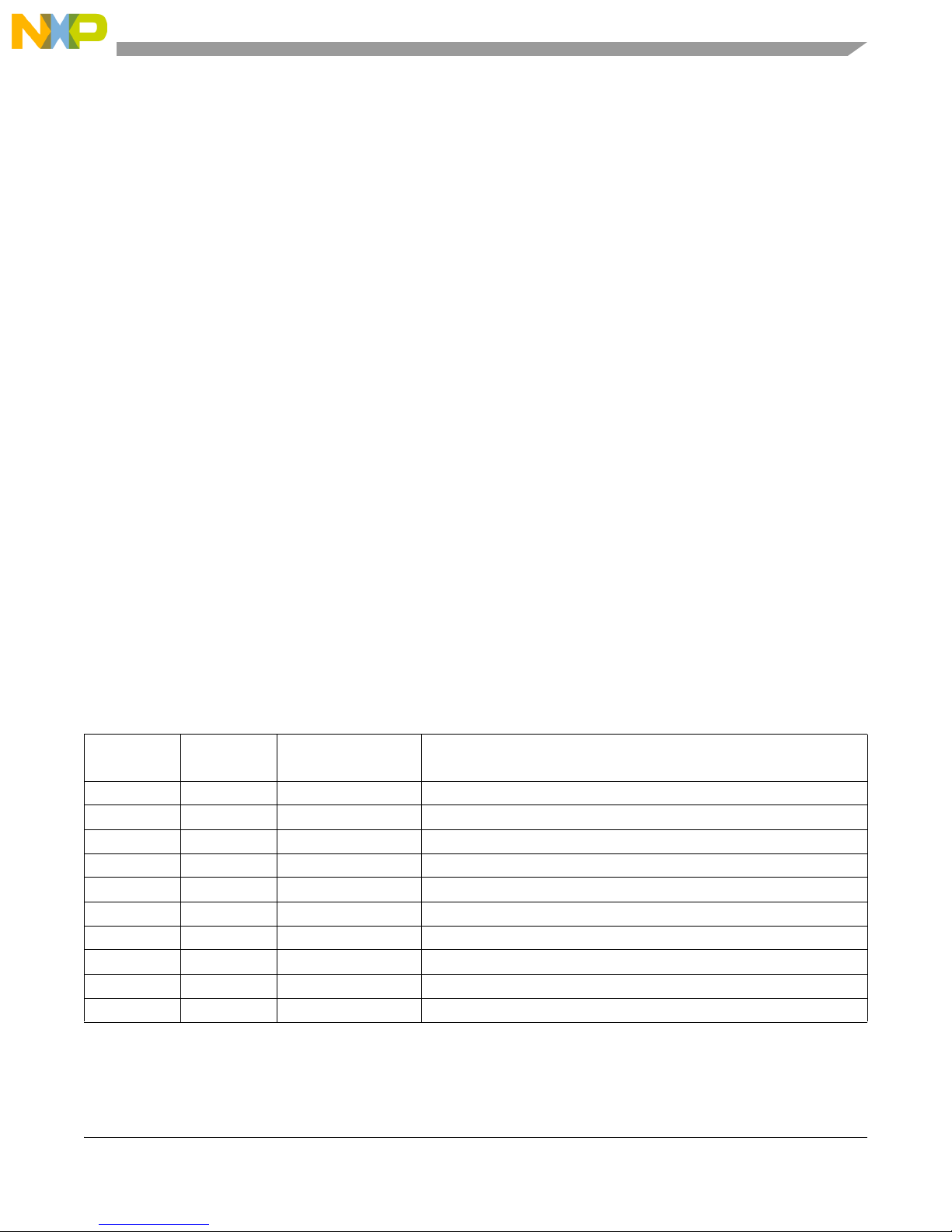

SMA connector, CLK_IN. The clock circuitry for the MC92602DVB is shown in Figure 2-2.

Y1

250-MHz

CLK_IN

Oscillator

Y2

EN

+

U2

CLK_0

CLK_1

CSEL

MC100ES6222

DIV 1/2

DIV by 1

EN

U4 MC100ES8111

PECL

to

HSTL

Buffer

U3

MPC9456

REF_CLK_P

REF_CLK_N

1.5V_CLK_OUT5

1.5V_CLK_OUT6

3.3V_CLK_OUT1

3.3V_CLK_OUT2

3.3V_CLK_OUT3

3.3V_CLK_OUT4

SW1

1

2

3

4

5

6

7

+

CLK

CLK

DIV 1/2

DIV 1/2

EN

Figure 2-2. MC92602DVB Clock Circuitry

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 2-3

Page 14

Hardware Preparation and Installation

2.4.1 Using the Onboard Oscillator

There are two available positions for using onboard oscillators. A standard 14-pin DIP socket is available

on the board to allow the user to easily change frequencies by swapping in crystal oscillators with other

values. The onboard oscillators must be two times (2×) the desired MVC92602 reference clock frequency.

The default reference clock frequency oscillator supplied with the board is 250 MHz.

Crystal oscillators used with this board should have +3.3-V complementary PECL outputs capable of

driving a line terminated with 50 Ω . Oscillators conforming to these specifications are also available in

J-lead SMT packages and can be soldered onto the underside of the MC92602DVB at location Y2. This

oscillator, Y2, can then be enabled by placing SW1 switch 1 in the ‘off’ position. Both types of crystal

oscillators are available from external vendors in a variety of frequencies. Once either type of oscillator is

installed, SW1 switch 2 must be placed in the ‘on’ position to select the onboard oscillator.

2.4.2 External Reference Clock Source

The input reference clock can also be supplied by using an external reference clock into the clock buffer

circuit on the board via the CLK_IN SMA connector. To supply an external reference clock, switch

number 2 on SW1 must be set to the ‘off’ position. The user must then supply a 1.0-Vp-p input clock via

the SMA connector. The CLK_IN input is AC coupled on the board and, therefore, does not require any

DC biasing of the input signal. This external clock input is also terminated with a 50-Ω impedance.

2.4.3 Supplying a Clock to the MC92602

The input reference clock, from either the onboard oscillator or an external source, is applied to a

MC100ES6222 clock buffer. This buffer has an input clock select multiplexer, and a programmable

divide-by-one/divide-by-two function. The buffer also contains a master reset (Enable). It is recommended

that this reset, found on SW1 switch 4, be activated, then deactivated after changing the divide-by-xx

switch. This will ensure proper frequency generation.

Between the MC100ES6222 output and the MC92602 reference clock inputs, REF_CLK_P and

REF_CLK_N, is an MC100ES8111 which performs a PECL to HSTL level shift. It also drives two SMA

connectors, 1.5V_CLK_OUT5 and 1.5V_CLK_OUT6, with HSTL level clock signals.

NOTE

The outputs of the MCP100ES8111 expect to see a DC 50-Ω path to ground.

Therefore, if a DC blocker is being used with the 1.5V_CLK_OUT5 or

1.5V_CLK_OUT6 outputs as a trigger or signal to an oscilloscope, a 50-Ω

feed through termination must be placed in line before the DC blocker and

before the attachment to the oscilloscope. A 3dB attenuator may be used in

place of the 50-Ω feed through termination.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

2-4 Freescale Semiconductor

Page 15

Hardware Preparation and Installation

2.4.4 3.3V_CLK_OUTn SMA Connectors

Four single-ended, 3.3-V level, clock signals are available on SMA connectors to drive other instruments.

Between the MC100ES8111 output and the 4 SMAs, is an MPC9456 which performs a differential PECL

to single-ended +3.3-V LVTTL/CMOS level shift. These CMOS outputs are series terminated on the

board, then connect to the SMA connectors labeled 3.3V_CLK_OUT1, 3.3V_CLK_OUT2,

3.3V_CLK_OUT3, and 3.3V_CLK_OUT4. All of the outputs of the MPC9456 can be disabled by setting

the DIP switch SW1, switch 7 to the ‘off’ position.

2.4.5 Clock Frequency Selection

To accommodate the fact that the MC92602 can receive data on both edges of the reference clock (DDR),

of which many pieces of test equipment are single-edge triggered (SDR), the MC92602DVB clock outputs

can be programmed to be either the same as the supplied frequency or half the supplied frequency by

setting SW1, switches 3, 5, and 6 to either ‘on’ (divide-by-one) or to ‘off’ (divide-by-2). This allows the

interface between the board and the bench to be either single data rate (SDR) with a double speed clock,

or double data rate (DDR) with a single speed clock.

The 1.5V_CLK_OUTn SMA outputs will always follow the clock supplied to the MC92602 and the

frequency is programmed via SW1, switch 3. SMA outputs 3.3V_CLK_OUT1 and 3.3V_CLK_OUT2 can

be programmed by setting SW1, switch 5 and 3.3V_CLK_OUT3 and 3.3V_CLK_OUT4 can be

programmed by setting SW1, switch 6. Table 2-2 lists the switch positions and output frequencies. The

input frequency, CLK_IN refers to either the onboard oscillator frequency or the externally applied clock

source frequency.

NOTE

Only those frequencies listed in the MC92602 Quad 1.25 Gbaud Reduced

Interface SerDes Reference Guide are considered valid. Freescale does not

guarantee operation of the MC92602 at frequencies other than those listed

in the reference Guide.

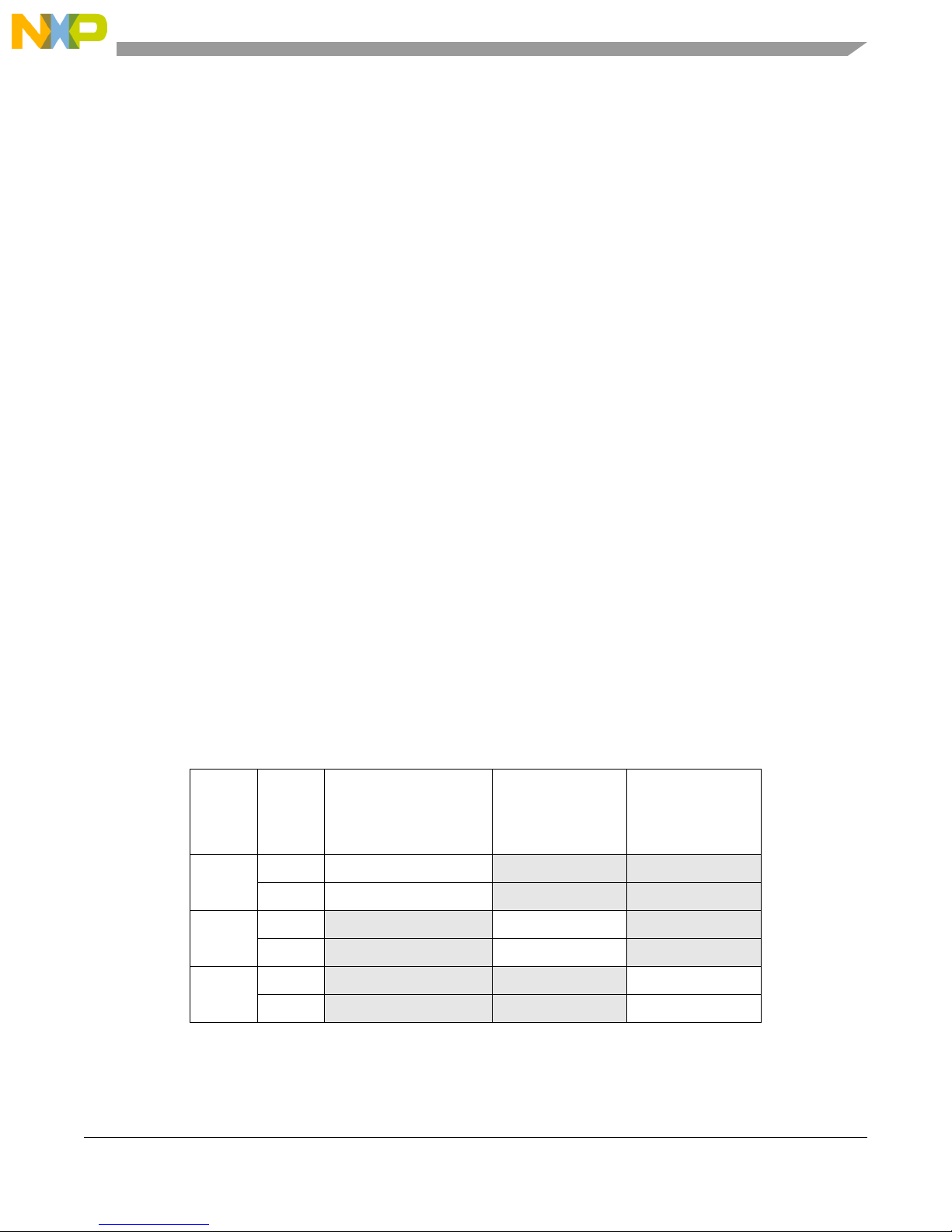

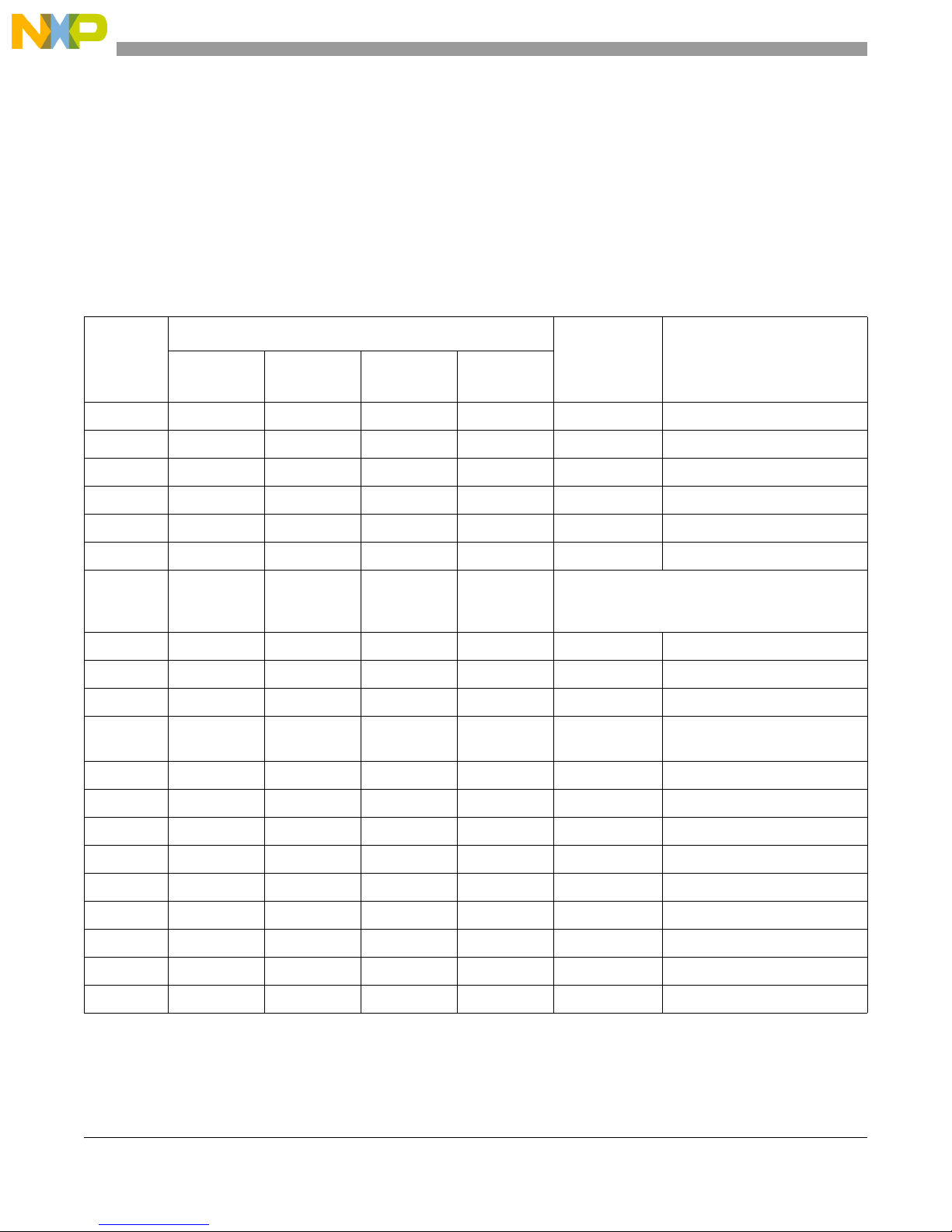

Tabl e 2-2. SW1 Settings and Output Frequencies

MC92602

SW1

Switch

3 On CLK_IN N/A N/A

5 On N/A CLK_IN N/A

6 On N/A N/A CLK_IN

Switch

Position

Off CLK_IN/2 N/A N/A

Off N/A CLK_IN/2 N/A

Off N/A N/A CLK_IN/2

REF_CLK_P,

REF_CLK_N,

and 1.5V_CLK_OUTn

3.3V_CLK_OUT1,

3.3V_CLK_OUT2

3.3V_CLK_OUT,

3.3V_CLK_OUT4

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 2-5

Page 16

Hardware Preparation and Installation

Figure 2-3 depicts SW1 settings for using an onboard oscillator with the divide-by-two function set for the

MC92602 and 3.3V_CLK_OUTn SMA outputs. The 3.3V_CLK_OUT1 and 3.3V_CLK_OUT2 SMA

outputs are enabled and set to the divide-by-one function. The 3.3V_CLK_OUT3 and 3.3V_CLK_OUT4

SMA outputs are also enabled and are set to the divide-by-two function.

SW1

ON

Y2

Onboard

Clk_In

Enabled

Clk_In

Clk_In

Enabled

Alternate Oscillator ENABLEY1

Onboard/External CLK_IN Select

MC92602 REF_CLK Frequency Select

MC100ES6222 Reset

3.3V_CLK_OUT1, _OUT2 Frequency Select

3.3V_CLK_OUT3, _OUT4 Frequency Select

MPC9456 (3.3V_CLKS) OUTPUT ENABLE_B

External

Clk_In/2

Reset

Clk_In/2

Clk_In/2

Reset

1

2

3

4

5

6

7

Figure 2-3. Reference Clock Selection Example Switch Settings

2.5 Interface Components

The following sections list the descriptions of the MC92602DVB interface connector components.

2.5.1 Parallel Inputs and Outputs

The MC92602 parallel I/O is supplied by the +1.5-V (HSTL) V

V) and has a rail-to-rail signal swing. There are no bi-directional signals on the MC92602 or on the design

verification board.

voltage regulator (set for 1.5 or 1.8

DDQ

2.5.1.1 Parallel Inputs

The parallel inputs, both data and control, are accessible via 2 × 10, 0.100" connectors. Figure 2-4 depicts

the 2 × 10, 0.100" connector numbering scheme, with pin 1 being labeled on the board. A complete

mapping of the MC92602 inputs to the 2 × 10, 0.100" connectors is listed in Appendix A, “Connector

Signals.” Note that all even number pins are connected to ground.

Figure 2-4. 2 × 10, 0.100" Input Connector Numbering Scheme

For a description of the input functionality of the MC92602, refer to the MC92602 Quad 1.25 Gbaud

Reduced Interface SerDes Reference Guide.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

2-6 Freescale Semiconductor

910

1112

1314

1516

1718

1920

(Top View)

345678

1

2

Page 17

Hardware Preparation and Installation

2.5.1.2 Parallel Outputs

All parallel outputs, both data and status bits, are present at four 2 × 20, 0.100" connectors. Figure 2-5

depicts the 2 × 20, 0.100" output connector numbering scheme, with pin 1 labeled on the board. The parallel

output signals of the MC92602 are 1.5- or 1.8-V HSTL compatible depending on the setting of the V

regulator. A complete mapping of the MC92602 outputs to the 2

× 20, 0.100" connectors is listed in

Appendix A, “Connector Signals.” Note that all even number pins are connected to ground.

1920

2122

2324

2526

2728

2930

3132

3334

3536

3738

3940

Figure 2-5. 2 × 20, 0.100" Output Connector Number Scheme

(Top View)

1

2

345678

910

1112

1314

1516

1718

For information regarding the MC92602 outputs, refer to the MC92602 Quad 1.25 Gbaud Reduced

Interface SerDes Reference Guide.

DDQ

2.5.2 +V

and Ground (GND) Access Connections

DDQ

The MC92602DVB also has two 2 × 8, 0.100" connectors, PG12 and PG14, with dedicated connections to

the +1.5-V V

cables. All of the odd number pins (1, 3, 5, and 7) are connected to the V

and ground planes. These are useful for biasing parallel input signals using jumper

DDQ

plane. All of the even number

DDQ

pins (2, 4, 6, and 8) are connected to the ground (0.0 V) plane.

2.5.3 Serial Inputs and Outputs

All MC92602 high-speed serial differential inputs and differential outputs are connected to appropriately

labeled pairs of SMA connectors through board traces with a characteristic impedance of 50 Ω (100-Ω

differential). The output driver requires a 50-Ω parallel termination to mid-rail (+0.9 V nominal for +1.8-V

supply). If the termination voltage is not +0.9 V, the signal must be AC coupled. There is no AC coupling

(DC blocking) of the serial outputs on the board. If needed, AC coupling must be done in-line before any

termination.

During all testing, the serial transmitter outputs should be terminated with 50 Ω . This can be done by

connecting the serial transmitter outputs to serial receiver inputs, to any laboratory equipment with 50-Ω

input impedance through in-line AC coupling, or by terminating the outputs with 50-Ω SMA terminations.

2.6 Special Test Connection

The MC92602DVB also contains an oscilloscope PCB test socket, labeled TPA. When the MC92602 is

configured in a PLL factory test mode, this test socket enables special access to the PLL.

This test mode is for factory testing purposes only. There are no system

applications for this mode and test socket TPA should remain unconnected

at all times.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 2-7

NOTE

Page 18

Hardware Preparation and Installation

2.7 Test Traces

The MCS92602DVB design verification board has both vertical and horizontal 50-Ω test traces:

• Vertical: TST1–TST5 and TST2–TST6

• Horizontal: TST3–TST7 and TST4–TST8

These traces can be used to determine the impedance of the board using TDR measurement techniques.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

2-8 Freescale Semiconductor

Page 19

Chapter 3

Laboratory Equipment and Quick Setup Evaluation

This chapter begins with a listing of the recommended test equipment needed to perform complete

evaluations on the MC92602. Chapter 4, “Test Setups,” covers specific setup configurations for this

equipment depending on the desired feature under test.

The quick setup evaluation procedures outlined below describe how the MC92602DVB can be used to

evaluate the data ‘eye diagram’ and a simple error rate test using the internal test features of the MC92602

with a minimal amount of test equipment. Only a power supply and sampling oscilloscope are required.

Details of testing in specific systems is left to the user. For more information regarding the MC92602

feature set, refer to the MC92602 Quad 1.25 Gbaud Reduced Interface SerDes Reference Guide.

3.1 Recommended Laboratory Equipment

Evaluation of the MC92602 feature set is possible using the MC92602DVB evaluation kit in conjunction

with several pieces of test equipment. The quick setup evaluations and other tests listed in this guide utilize

the basic set of test equipment listed in Table 3-1. Equivalent instrumentation may be substituted. Not all

pieces of test equipment are necessary for all tests.

Tabl e 3-1. Recommended Test Equipment

Quantity Equipment

1 MC92602DVB evaluation kit

1 Tektronix TDS 8000 digital sampling oscilloscope

1 Tektronix 80E04 TDR/sampling head (20 GHz)

3 Tektronix 80E03 sampling heads (20 GHz)

1 Hewlett-Packard HP16700 logic analysis system

5 Hewlett-Packard HP16522A pattern generators

2 Hewlett-Packard HP16557D logic analyzers

1 Hewlett Packard HP6624A system DC power supply

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 3-1

Page 20

Laboratory Equipment and Quick Setup Evaluation

Table 3-2 lists the laboratory accessories.

Tabl e 3-2. Lab Accessories

• SMA male each end coax patch cords, lengths: various

• SMA 3dB attenuators

• SMA 6db attenuators

• SMA DC blockers (AC couplers)

• 50-Ω SMA terminations (to ground)

•SMA 50-Ω feed through terminations

• 5/16" torque wrench (fits SMA, 2.9- and 3.5-mm connectors)

•Bias-T networks

• Power splitters

• BNC to SMA adapters

• SMA female to SMA female adapters

• SMA male to SMA male adapters

In-depth testing of the MC92602 can be performed using a bit error rate tester and a jitter analysis system.

Table 3-3 provides a listing of test equipment that can be used for these types of tests.

Tabl e 3-3. Jitter Analysis Test Equipment

Quantity Equipment

1 Agilent 71500C jitter analysis system

1 HP 70820A microwave transition analyzer

1 HP 70004A display

1 HP 3325B synthesizer/function generator

1 HP 83752A synthesized sweeper

1 HP 86130A BitAlyzer (serial bit error rate tester)

1 HP 70874C jitter personality card

2 each Assorted bandpass filters

1 Rohde and Schwarz SMIQ-04B signal generator

1 Agilent HP 6624A system DC power supply

1 Agilent 11636B power splitter

1 Divide-by-xx prescalers

3.2 Quick Setup Data-Eye Diagram

The MC92602DVB design evaluation kit comes equipped to immediately demonstrate two of the

MC92602 functions:

• Data-eye signal generation and observation

• Bit error rate checking using internal built-in self-test (BIST) features.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

3-2 Freescale Semiconductor

Page 21

Laboratory Equipment and Quick Setup Evaluation

3.2.1 Quick Setup Data-Eye Generation and Observation

A transmitted data-eye can be observed at any of the serial outputs of the MC92602 using its integrated,

23rd order, pseudo-noise (PN) pattern generator. The implementation of the 23-bit PN generator uses the

following polynomial.

23

1x5x

++=

Stimulus from this generator is 8B/10B encoded and may also be used for further system testing. Refer to

the MC92602 Quad 1.25 Gbaud Reduced Interface SerDes Reference Guide, for more information.

3.2.1.1 Equipment Setup

Generation and observation of the data-eye produced by the on-chip PN generator requires only the

MC92602DVB, a power supply, a high-speed digital sampling scope, 0.100" shunts, and single pin

receptacle patch cords. The shunts and patch cords are provided with the MC92602DVB evaluation kit.

The MC92602DVB and test equipment should be connected as depicted in Figure 3-1. Configure clock

circuits with SW2 as shown in Figure 2-3.

NOTE

All unconnected serial transmitter outputs should be terminated to 50 Ω .

This can be done by connecting the serial transmitter outputs to the serial

receiver inputs or to 50 Ω SMA terminations through in-line AC coupling

(DC blocking).

DSO

50 Ω

Feed Through

Termination

1.5 V_CLK_OUT1

MC92602DVB

CH 1

CH 2

TRIG

DC

Blocker

XMIT_P

XMIT_N

Figure 3-1. Data-Eye Observation Setup

DC

Blockers

GND

+5 V

+5-V GND+5-V GND

Sense Force Sense Force

+5-V Supply

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 3-3

Page 22

Laboratory Equipment and Quick Setup Evaluation

3.2.1.2 Parallel Input Connections

The basic eye diagram will be generated by biasing the parallel inputs according to Table 3-4. Ground

connections can be made using the 0.100" shunts. Connections to +1.5 V V

square pin receptacle patch cords and jumpering to the odd numbered pins of headers PG12 and PG14. All

even number pins on the connector headers are connected to the board’s ground plane. All unlisted pins

are not connected.

Tabl e 3-4. Data-Eye Generation Parallel Input Biasing

can be made using the

DDQ

Connector Pin Signal

TEST_0 9 TDI GND A_XMIT0 1 XMIT_A_0 GND

11 TCK GND 3 XMIT_A_1 GND

13 TMS GND 5 XMIT_A_2 GND

15 TRST GND 7 XMIT_A_3 GND

CTRL_SIG_0 1 REPE GND 9 XMIT_A_K +1.5 V

3 RCCE +1.5 V 11 XCVR_A_DISABLE GND

5 WSE GND A_XCLK 15 XMIT_A_CLK GND

7 HSE GND B_XMIT0 1 XMIT_B_0 GND

9 ADIE GND 3 XMIT_B_1 GND

11 RESET GND 5 XMIT_B_2 GND

15 STNDBY GND 7 XMIT_B_3 GND

CTRL_SIG_1 1 LBOE GND 9 XMIT_B_K +1.5 V

3 LBE GND 11 XCVR_B_DISABLE GND

5 MEDIA GND B_XCLK 15 XMIT_B_CLK GND

7 TBIE GND C_XMIT0 1 XMIT_C_0 GND

9 COMPAT GND 3 XMIT_C_1 GND

13 RECV_REF_A +1.5 V 5 XMIT_C_2 GND

15 XMIT_REF_A +1.5 V 7 XMIT_C_3 GND

CTRL_SIG_2 1 BSYNC +1.5 V 9 XMIT_C_K +1.5 V

3 DROP_SYNC GND 11 XCVR_C_DISABLE GND

5 TST_1 GND C_XCLK 15 XMIT_C_CLK GND

7 TST_0 +1.5 V D_XMIT0 1 XMIT_D_0 GND

Bias

Level

Connector Pin Signal

3 XMIT_D_1 GND

5 XMIT_D_2 GND

7 XMIT_D_3 GND

9 XMIT_D_K +1.5 V

11 XCVR_D_DISABLE GND

D_XCLK 15 XMITD_CLK GND

Bias

Level

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

3-4 Freescale Semiconductor

Page 23

Laboratory Equipment and Quick Setup Evaluation

3.2.2 Basic Eye Observation—Test Procedure

1. Connect the MC92Q602DVB and test equipment as described in Figure 3-1 and Table 3-4. This

will place the MC92602 in PN generation mode with the MC92602 in reset.

Step 2 and 3 may be skipped if previously performed when setting up the DVB.

2. Apply +5.0 V to the evaluation board. Verify voltage levels of +3.3 V, +1.8 V, and +V

DDQ

(1.5 V)

regulators at connectors T10, T7, and T6, respectively. If necessary, adjust R12V, R22V, and

R22V1 to obtain desired voltage levels.

3. Verify that the reference clock frequency at CLK_OUT5 is 125 MHz

(period = 8 ns).

4. Observe XMIT_x_P or XMIT_x_N output. Since the chip is in reset, the transmitter should show

a constant output level at ground.

5. Connect the RESET (connector CTRL_SIG_0, Pin 11) to a V

access connection. This releases

DDQ

the RESET signal.

6. Observe XMIT_x_P or XMIT_x_N. The transmitter should now be outputting random data.

Setting the digital sampling oscilloscope to infinite persistence mode will display a data-eye. An

example of a data-eye is shown in Figure 3-2.

Figure 3-2. MC92602 Data-Eye Using Recommended Test Setup

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 3-5

Page 24

Laboratory Equipment and Quick Setup Evaluation

3.2.3 Quick Setup Bit Error Rate Checking

In addition to having an integrated PN generator, the MC92602 also has a bit error rate checker (BERC).

An integrated 23rd order signature analyzer, that is synchronized to the incoming PN stream is used to

count code group mismatch errors relative to the internal PN reference pattern. The following test

procedure will describe how to use this BIST feature. For more information concerning the MC92602

BIST, refer to the MC92602 Quad 1.25 Gbaud Reduced Interface SerDes Reference Guide.

3.2.3.1 Equipment Setup

Connect the MC92602DVB as shown in Figure 3-3, connecting the transmitter outputs of the link under

test (XLINK_x_P/N) to the receiver under test (RLINK_x_P/N).

NOTE

The receiver signature analyzers assume all four channels are being

exercised. If BIST testing is being performed between devices, or by means

of external loopback on selected channels, the unused channel receivers

must be disabled or the analyzers will not go into the PN Sync state. That is,

receivers not having a PN stimulus must have XCVR_x_DISABLE

asserted.

Logic

Analyzer

CH 1

CH 2

CH 3

CH 4

+5-V Supply

D_RECV

C_RECV

B_RECV

A_RECV

MC92602DVB

+5-V

Sense

XLINK_D_P

XLINK_D_N

XLINK_C_P

XLINK_C_N

XLINK_B_P

XLINK_B_N

XLINK_A_P

XLINK_A_N

Force Sense

+5 V GND

RLINK_D_P

RLINK_D_N

RLINK_C_P

RLINK_C_N

RLINK_B_P

RLINK_B_N

RLINK_A_P

RLINK_A_N

Figure 3-3. Bit Error Rate Check Test Setup

GND+5-V

GND

Force

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

3-6 Freescale Semiconductor

Page 25

Laboratory Equipment and Quick Setup Evaluation

3.2.3.2 Parallel I/O Connections

The bias connections for the parallel inputs to perform the quick setup BERC test are the same as those for

the quick setup eye-diagram and shown in Table 3-4.

The parallel outputs are connected to a data analysis system. The data analyzer may be used to observe the

start up sequence and the status and errors detected by the internal data analyzers.

3.2.3.3 Quick Setup BERC Test Procedure

1. Connect the MC92602DVB and test equipment as described in Section 3.2.3.1, “Equipment

Setup.” This will place the MC92602 in PN generation mode with the MC92602 held in reset and

set the receivers to BERC mode using the recovered clock.

Steps 2 and 3 may be skipped if previously performed when setting up the DVB.

2. Apply +5.0 V to the evaluation board. Verify voltage levels of +3.3 V, +1.8 V, and +V

DDQ

(1.5 V)

regulators at connectors T10, T7, and T6, respectively. If necessary, adjust R12V, R22V, and

R22V1 to obtain desired voltage levels.

3. Verify that the reference clock frequency at CLK_OUT1 is 156.25 MHz

(period = 6.4 ns).

4. Connect the RESET (connector CTRL_SIG_0, pin 11) to a +1.5 V V

access connection. This

DDQ

releases the RESET signal.

5. Observe the parallel outputs on the data analyzer. As described in the MC92602 Quad 1.25 Gbaud

Reduced Interface SerDes Reference Guide, the MC92602 will start and lock the PLL, initialize

the receivers, perform byte alignment, and reset the bit error counter.

6. When the receivers are locked and BIST is running, the recovered clock is observable on

RECV_x_RCLK. Refer to Table 3-5 for the receiver state sequence, which will occur on each

receiver’s status output. See Figure 3-4 for an example of a receiver start-up and error detection

sequence.

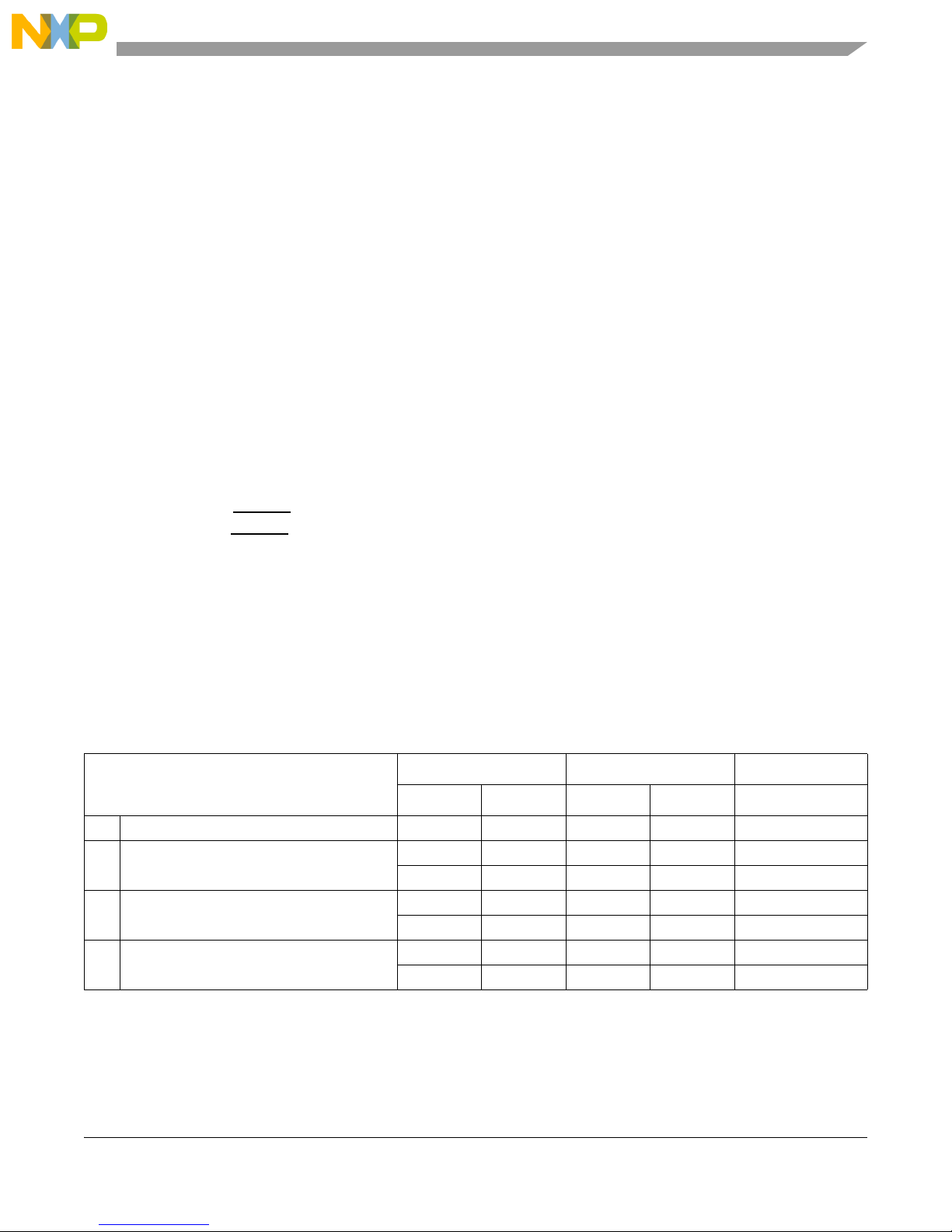

Tabl e 3-5. State Sequence of Receiver

Receiver State

1 MC92602 is in reset mode Low Low Low Low Low

2 Receiver in startup High — Don’t care — ¦

3. Receiver byte/word synchronized,

PN analyzer not locked

4 BIST running no PN mismatch this

character

RECV_x_ERR RECV_x_K RECV_x_RCLK

E

0

— Low — Don’t care Ø

Low — Low — ¦

— High — High Ø

Low — Don’t care — ¦

— Low — Don’t care Ø

E

1

K

0

K

1

Edge

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 3-7

Page 26

Laboratory Equipment and Quick Setup Evaluation

7. Once the receiver has initially locked all receiver data bits, RECV_x_[4:0], are set to zero (logic

low). Should an error occur, RECV_x_[4:0] will increment by one and RECV_x_ERR will flag the

error during that byte time. The value of RECV_x_[4:0] remains constant until another error is

detected or the system is reset. If the receiver counter fills with errors, all bits of RECV_x_[4:0]

stay a logic high (11111111) until the receiver is reset. Refer to the MC92602 Quad 1.25 Gbaud

Reduced Interface SerDes Reference Guide for more detail.

RESET

RECV_x_RCLK

RECV_x_ERR

RECV_x_K

RECV_x_3

RECV_x_2

RECV_x_1

RECV_x_0

MC92602

in Reset

Not Byte

Sync

RCVR in

Startup

RCVR BIST

Synced

PN Analyzer

Not Locked

No PN Mismatch

This Character

Figure 3-4. Receiver Startup and Error Detection Sequence

Running

BIST

Running

3 PN Mismatches

Counted

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

3-8 Freescale Semiconductor

Page 27

Chapter 4

Test Setups

This chapter outlines the laboratory test equipment setup and procedure to evaluate the features of the

MC92602 in more depth than those outlined in the previous chapter. These setups are meant to be

guidelines only and are not implied to be complete. Details of testing in specific system applications are

left to the user.

4.1 Serial Link Verification Using a Serial Bit Error Rate Tester

(BERT)

This test setup is used to observe the rate at which the MC92602 produces errors given either

pseudo-random (PRBS) patterns or user-defined pattern sets generated by the serial bit error rate tester

(BERT). The MC92602 is placed in repeater mode, REPE = high, thereby disabling the parallel receiver

and transmitter buses. Testing performed using the ten-bit interface mode does not require the insertion of

idle characters for word recognition or byte alignment. If verification using the 8B/10B encoder or other

MC92602 features is required, then appropriate idle insertion and timing requirements as outlined in the

MC92602 Quad 1.25 Gbaud Reduced Interface SerDes Reference Guide, must be followed.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 4-1

Page 28

Test Setups

4.1.1 Test Setup for Full-Speed Mode

Figure 4-1 depicts the test setup for MC92602 in full-speed mode (HSE = ‘0’). The control bits are set as

follows:

•REPE = ‘1’

•TBIE = ‘1’

All other control bits are set to ‘0,’ except RESET, which is initially set to ‘0,’ then transitioned to ‘1’ to

start the MC92602.

Bit Error Rate Tester

Pattern Generator

CK

CK_OUT

Error Detector

CK

Prescaler

Divide-by-10

DC Blocker

MC92602DVB

(Repeater Mode)

Reference

Clock

125 MHz

D

D

Serial Data

MC92602DVB

(Repeater Mode)

RF Source

Power

Splitter

Clean

Clock

1.25 GHz

Figure 4-1. Full Speed Serial Link Test Setup

4.1.2 Test Setup for Half-Speed Mode

Serial link testing may also be performed using half-speed mode (HSE = ‘1’). This reduces all frequencies

in the setup by a factor of two. Figure 4-2 depicts the serial link test setup for using HSE and using a

divide-by-10 prescaler.

RF Source

Power

Splitter

Figure 4-2. Half-Speed Serial Link Test Setup

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

4-2 Freescale Semiconductor

Clean

Clock

625 GHz

Bit Error Rate Tester

CK Pattern Generator

CK Error Detector D

Prescaler

Divide-by-10

Reference

Clock

62.5 MHz

D

DC Blocker

Serial Data

MC92602DVB

(Repeater Mode)

Page 29

Test Setups

4.2 Jitter Testing

The following tests are guidelines for verifying the performance of the MC92602 in ‘noisy’ conditions.

Results will vary depending on input reference frequencies, MC92602 mode of operation, test setup and

equipment, and test environment.

4.2.1 Jitter Test System Calibration

Before beginning any type of jitter measurements, the system must first be calibrated, as shown in

Figure 4-3, to produce the desired frequency and amplitude modulation of the jittered source. The

amplitude of modulation is then translated into jitter in units of peak-to-peak unit intervals (UIp-p).

Different synthesized sweepers have different characteristics at different frequencies. It is possible that

certain frequencies will produce spurious side lobes which will affect jitter characterization. It is strongly

advised that a bandpass filter centered on the carrier frequency be used at the input to the microwave

transition analyzer. Refer to the synthesized sweeper reference Guide for more details.

Function

Generator

70000 Mainframe

with Microwave

Transition Analyzer

HPIB

Modulation Signal

10-MHz Reference Clock

Synthesized

Sweeper

(Carrier Frequency)

Figure 4-3. Jitter Measurement System Calibration

Ch1

Ch2

Jittered

Clock

Filter

Power

Splitter

50 Ω

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 4-3

Page 30

Test Setups

4.2.2 Reference Clock Jitter Transfer Test

This test setup is used to observe the amount of jitter placed on the reference clock that is transferred to

the data outputs. Example frequencies were chosen to match narrow bandpass filters available with the

Agilent 71500C jitter analysis system. The control bits are set as follows:

•TBIE = ‘1’

All other control inputs are set to ‘0.’

The parallel data inputs must be set to the pattern shown in Figure 4-4. This data pattern appears as a

625-MHz clock signal at the serial outputs.

Function

Generator

DC Blocker

70000 Mainframe

with Microwave

Transition Analyzer

HPIB

Modulation Signal

10-MHz Reference Clock

Synthesized

Sweeper

(Carrier Frequency)

Ch1

Ch2

Jittered

1.25 GHz

Clock

Filter

Filter

Prescaler

Divide-by-2

Power

Splitter

DC Blocker

625 MHz

Divide-by-10

Serial Data

Prescaler

Jittered

Reference

Clock

125 MHz

MC92602DVB

Parallel

CLK

Data

1

10101

0

01010

1

10101

0

01010

1

10101

—

—

—

—

—

—

Figure 4-4. Reference Clock Jitter Transfer Test Setup

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

4-4 Freescale Semiconductor

Page 31

Test Setups

4.2.3 Reference Clock Jitter Tolerance Test

The test setup, as shown in Figure 4-5, is used to observe the amount of jitter placed on the reference clock

that does not produce errors on the serial data outputs as compared to the input serial data stream. The

MC92602 is placed in ten-bit interface mode (TBIE) and repeater mode (REPE). The serial data stream

can be set to either PRBS or user-defined data. The control bits are set as follows:

•REPE = ‘1’

•TBIE = ‘1’

All other control inputs are set to ‘0.’

Bit Error Rate Data over the HPIB

Function

Generator

70000 Mainframe

with Microwave

Transition Analyzer

HPIB

Modulation Signal

10-MHz Reference Clock

Synthesized

Sweeper

(Carrier Frequency)

RF Source

Ch1

Ch2

Jittered

Clock

1.25 GHz

Clean

Clock

1.25 GHz

Power

Splitter

Bit Error Rate Tester

CK Pattern Generator D

CK Error Detector D

DC Blocker

Jittered

Prescaler

Divide-by-10

Reference

Clock

125 MHz

Serial Data

MC92602DVB

Figure 4-5. Reference Clock Jitter Tolerance Test Setup

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor 4-5

Page 32

Test Setups

4.2.4 Data Jitter Tolerance Test

The test setup, as shown in Figure 4-6, is used to observe the amount of jitter placed on the serial data

inputs that does not produce errors on the serial data outputs. The MC92602 is placed in ten-bit interface

mode (TBIE) and repeater mode (REPE). The serial data stream can be set to either PRBS or user-defined

data. The control bits are set as follows:

•REPE = ‘1’

•TBIE = ‘1’

All other control inputs are set to ‘0.’

Bit Error Rate Data Over the HPIB

Clean

Function

Generator

Clock

RF Source

1.25 GHz

Power

Splitter

Bit Error Rate Tester

CK Pattern Generator D

CK Error Detector D

DC Blocker

70000 Mainframe

with Microwave

Transition Analyzer

HPIB

Modulation Signal

10-MHz Reference Clock

Synthesized

Sweeper

(Carrier Frequency)

Ch1

Ch2

Jittered Clock

1.25 GHz

Prescaler

Divide-by-10

Reference

Clock

125 MHz

Serial Data

MC92602DVB

(Repeater Mode)

Figure 4-6. Data Jitter Tolerance Test Setup

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

4-6 Freescale Semiconductor

Page 33

Appendix A

Connector Signals

The parallel data input and output signals of the MC92602DVB design verification board are listed in the

following tables. All the connection test points use the common 2 row 0.100" spaced 3-M type connectors.

A.1 Input: 2 × 10 (0.100") Connectors

The configuration, control, data, and test inputs to the MC92602 are via 2 row by 10 connectors. There are

a total of 12 input connectors on the DVB.

On each connector, the even pin numbers (2, 4, ..., to 20) are connected to the ground plane. The signal

inputs (on the odd pin numbers) do not have pull-up resistors on the DVB board. Therefore, if the

configuration requires a ‘high’ or logic 1, the pin must be jumper connected to +1.5 V (V

access connectors PG12 or PG14. If the input is required to be ‘low,’ a shorting jumper may be installed.

The signal name, description, and the MC92602 device ‘ball’ (pin) number are listed in the following

tables for each of the input connectors.

A.1.1 Control Signal Input Connectors

The signals on connectors CTRL_SIG_0, CTRL_SIG_1, and CTRL_SIG_2 (PG1–PG3, respectively) are

control input signals that set the basic configuration to the MC92602. These signals and corresponding

connector pins are listed in Table A-1, Table A-2, and Table A-3, respectively.

DDQ

) on the

Tabl e A-1. CTRL_SIG_0 Connector

Connector

Pin

1 B9 REPE Repeater mode enable

3 A13 RCCE Recovered clock enable

5 A10 WSE Word synchronization enable

7 C11 HSE Half-speed mode enable

9 B10 ADIE Add/drop idle enable

11 M4 RESET System reset bar

13 N/C — —

15 C10 STNDBY Standby mode enable

17 N/C — —

19 N/C GND Ground connection

Freescale Semiconductor A-1

MC92602

Pin

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Input Signal

Name

Description

Page 34

Connector Signals

Tabl e A-2. CTRL_SIG_1 Connector

Connector

Pin

1 P14 LBOE Loopback output enable

3 P13 LBE Loopback enable

5 M12 MEDIA Media impedance select

7 B12 TBIE Ten-bit interface enable

9 C12 C O MPAT IEEE 802.3 compatibility mode enable

11 N/C — —

13 P9 RECV_REF_A Receiver A, primary clock enable

15 N9 XMIT_REF_A Transmit A, primary clock enable

17 N/C — —

19 N/C GND Ground connection

MC92602

Pin

Input Signal

Name

Tabl e A-3. CTRL_SIG_2 Connector

Connector

Pin

1 A12 BSYNC Byte synchronization mode

3 A9 DROP_SYNC Drop synchronization

5 N13 TST_1 Test mode—select 1

7 N12 TST_0 Test mode—select 0

9 N/C — —

11 N/C — —

13 N/C — —

15 N/C — —

17 N/C — —

19 N/C GND Ground connection

MC92602

Pin

Input Signal

Name

Description

Description

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

A-2 Freescale Semiconductor

Page 35

Connector Signals

A.1.2 Transmitter Parallel Data Input Connectors

The MC92602 transmitter parallel data input signals for channels A through D are mapped to the 2 × 10

connectors as listed in the tables below. Table A-4 shows the 4-bit data (DDR) input for transmitter

channels A through D, respectively, on A_XMIT0 to D_XMIT0 (PG8, PG10, PG6, and PG4) connectors.

Tabl e A-4. A_XMIT0, B_XMIT0, C_XMIT0, and D_XMIT0 Connectors

MC92602 Ball No.

Connector

Pin No.

1 P5 N5 B5 A5 XMIT_x_0 Transmitter x, data input bit 0

3 N6 P4 A4 B6 XMIT_x_1 Transmitter x, data input bit 1

5 P6 N4 B4 A6 XMIT_x_2 Transmitter x, data input bit 2

7 N7 P3 A3 B7 XMIT_x_3 Transmitter x, data input bit 3

9 P7 N3 B3 A7 XMIT_x_K Transmitter x, special character

11 N8 M3 C3 B8 XCVR_x_D

13 N/C N/C N/C N/C — —

15 N/C N/C N/C N/C — —

17 N/C N/C N/C N/C — —

19 N/C N/C N/C N/C GND Ground connection

A_XMIT0,

(Channel A)

B_XMIT0,

(Channel B)

C_XMIT0,

(Channel C)

D_XMIT0,

(Channel D)

Input

Signal

Name

ISABLE

Description

Transmitter x, disable

Table A-5 lists the transmitter clock signals for the four channels on A_XCLK–D_XCLK (PG9, PG11,

PG7, and PG5) connectors, respectively.

Tabl e A-5. A_XCLK, B_XCLK, C_XCLK, and D_XCLK Connectors

Connector

Pin No.

A_XCLK,

(Channel A)

MC92602 Ball No.

B_XCLK,

(Channel B)

C_XCLK,

(Channel C)

D_XCLK,

(Channel D)

Input Signal

Name

Description

1 N/C N/C N/C N/C CLK_x_PG Clock connection via SMA

3 N/C N/C N/C N/C — —

5 N/C N/C N/C N/C — —

7 N/C N/C N/C N/C — —

9 N/C N/C N/C N/C — —

11 N/C N/C N/C N/C — —

13 N/C N/C N/C N/C — —

15 P8 P2 A2 A8 XMIT_x_CLK Tr a ns mi t te r x, interface clock

17 N/C N/C N/C N/C — —

19 N/C N/C N/C N/C GND Ground connection

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor A-3

Page 36

Connector Signals

A.2 Output: 2 × 20 (0.100") Connectors

The MC92602 receiver parallel data outputs are connected to 2 × 20, 0.100" connectors. A mapping of

these signals are contained in Table A-6.

Table A-6 lists the signals for the A_RECV–D_RECV (LA1–LA4, respectively) connectors. Note that the

receive data clock, RECV_x_RCLK, is brought out to two connector pins. Care should be exercised when

connecting to both these pins not to exceed the drive capacity of the chip output. Refer to the MC92602

Quad 1.25 Gbaud Reduced Interface SerDes Reference Guide, for more details.

Tabl e A-6. A_RECV and B_RECV Connectors

MC92602 Ball No.

Connector

Pin No.

1 N/C N/C N/C N/C — —

3 M2 K1 F1 C2 RECV_x_CLK XCVR_ x, receive data clock

5 N/C N/C N/C N/C — —

7 M2 K1 F1 C2 RECV_x_CLK XCVR_ x, receive data clock

A_RECV,

(Channel A)

B_RECV,

(Channel B)

C_RECV,

(Channel C)

D_RECV,

(Channel D)

Output Signal

Name

Description

9 N/C N/C N/C N/C GND Ground connection

11 N/C N/C N/C N/C GND Ground connection

13 N/C P10 N/C N/C For channels A, C, and D, this pin is ground.

For channel B, this pin is TDO (JTAG, test data

out)

15 P1 H2 G2 A1 RECV_x_ERR Receiver x, error detect

17 N/C N/C N/C N/C GND Ground connection

19 N/C N/C N/C N/C GND Ground connection

21 N2 J1 G1 B2 RECV_x_K Receiver x, special character

(status)

23 N/C N/C N/C N/C GND Ground connection

25 N/C N/C N/C N/C GND Ground connection

27 N/C N/C N/C N/C GND Ground connection

29 N/C N/C N/C N/C GND Ground connection

31 N1 J2 F2 B1 RECV_x_3 Receiver x, data bit 3

33 M1 H3 E1 C1 RECV_x_2 Receiver x, data bit 2

35 L2 K2 E3 D2 RECV_x_1 Receiver x, data bit 1

37 L1 J3 E2 D1 RECV_x_0 Receiver x, data bit 0

39 N/C N/C N/C N/C — —

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

A-4 Freescale Semiconductor

Page 37

Connector Signals

A.3 TEST_0 Connector

Table A-7 lists the signals for the connector TEST_0 (PG13). This is the MC92602 test access port, TAP,

interface for IEEE Std 1149 JTAG testing.

NOTE

There are 10-KΩ internal pull-ups on TMS, TDI, and TRST. If TRST is not

held low during power up or does not receive an active low preset after

power up, the test logic may assume an indeterminate state disabling some

of the normal transceiver functions. It is recommended that TRST be

terminated in one of the following ways:

• TRST be driven by a TAP controller that provides a reset after power up.

• Connect TRST to RESET.

• Terminate TRST with a 1-KΩ resistor (or hardwire) to ground.

It is important to use a shorting jumper on the TRST input to comply with the above note. For more

information on the test access port, see Section 5.1 in the MC92602 Quad 1.25 Gbaud Reduced Interface

SerDes Reference Guide, for more details.

Tabl e A-7. TEST_0 Connector

Connector

Pin

1 N/C — —

3 N/C — —

5 N/C — —

7 N/C — —

9 N10 TDI JTAG test data in

11 P11 TCK JTAG test clock

13 N11 TMS JTAG test mode select

15 P12 TRST JTAG test reset bar

17 N/C — —

19 N/C GND Ground connection

MC92602

Pin

Input Signal

Name

Description

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor A-5

Page 38

Connector Signals

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

A-6 Freescale Semiconductor

Page 39

Appendix B

Parts List

B.1 Design Verification Board Parts List

Table B-1 shows the parts used in constructing the MC92602DVB design verification board.

Tabl e B-1. MC92602DVB Design Verification Board Parts List (Sheet 1 of 3)

Item Qty. Reference Va lue

1 19 C1, C4,

C18–C19, C24,

C27, C30–C33,

C54–C57,

C208–C210,

C303–C304

2 3 C7, C11, C21 100 µF Kemet T495X107K010AS 100 µF solid tantalum chip

3 5 C5, C12–C13,

C22–C23

4 5 C3, C9, C10,

C14, C20

5 45 C2, C5–C6,

C15–C17,

C25–C26,

C28–C29,

C34–C53,

C58–C63,

C201–C207,

C301–302

1 µF Newark 99F3410 Ceramic chip capacitor,

10 µF Kemet T495X106K035AS 10 µF solid tantalum chip

0.1 µF Newark 93F8740 Ceramic chip capacitor,

0.01 µF Newark 93F2330 Ceramic chip capacitor, 0.01

Manufacturer/

Supplier

Manufacturer's

Part No.

Description

1 µF, size 1812

capacitor, low ESR, 10 V, size

7343H

capacitor, low ESR, 35

7343H

0.1 µF, size 0805

µF, size 0805

V, size

6 1 Y1 250 MHz MF Electronics M2988-250M 250 MHz + 3.3 V PECL

7 1 Y1 Socket N/A TTI 504-AG11D Socket, 14-pin DIP

8 1 SW1 N/A Newark 08C7815 7 pole DIP slide switches,

9 2 PG12, PG14 N/A 3M 2516-6002UB 2 × 8 keyed header with

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor B-1

crystal oscillator—14-pin DIP

position (open or closed),

2

surface mount

shroud, 0.1" pin spacing, low

profile

Page 40

Parts List

Table B-1. MC92602DVB Design Verification Board Parts List (Sheet 2 of 3)

Item Qty. Reference Value

10 12 PG1–PG11,

N/A 3M 2520-6002UB 2 × 10 keyed header with

PG13

Manufacturer/

Supplier

Manufacturer's

Part No.

Description

shroud, 0.1" pin spacing

11 4 LA1–LA4 N/A 3M 2540-6002UB 2 × 20 keyed header with

shroud, 0.1" pin spacing, low

profile

12 2 J1, J2 N/A HDR_100MIL

13 1 D1 N/A Dialight 597-5311-402 Green LED surface mount

14 3 VR1, VR18, VR33 N/A Linear

Technology

LT1587CM Linear voltage regulator,

3 amps, 3-lead DD pak

15 1 U3 N/A Freescale MPC9456S 3.3-V clock buffer,

32-pin gull wing LQFP

18 U2 N/A Freescale MC100ES6222 3.3 V/2.5 V 1:15 differential

ECL/PECL clock driver

52-lead LQFP

19 1 U4 N/A Freescale MC100ES8111S Level shift and clock buffer,

32-pin gull wing TQFP

20 9 T1–T9 N/A SPC

Technology

2304/2303/

9648/9649/9650

4 mm screw terminal binding

post, red/black/ yellow/

blue/green

21 1 R67 68 Ω Newark 50N1713 68-Ω chip resistor,

size 0603

22 10 R–-R6, R16, R23,

R62–R63,

82 Ω Newark 50N1715 82-Ω chip resistor,

size 0603

R70–R71,

R74–R75

23 37 R1, R2–-R32

R34–R56,

0 Ω Dale CR0805-10W-000T 0-Ω chip resistor,

size 0805

R92–R95

24 11 R3, R4, R10,

R14, R20,

124 Ω Dale CRCW08051240JT 124-Ω chip resistor,

size 0805

R60–R61,

R68–R69,

R72–R73

25 2 R11, R13 330 Ω Welwyn WCR0805330RG 330-Ω chip resistor,

size 0805

26 1 R21 68 Ω Newark 68-Ω chip resistor,

size 0805

27 1 R12 120 Ω Dale CRCW08051200JT 120-Ω chip resistor,

size 0805

28 1 R17, R64 100 Ω Dale CRCW08051000FT-X 100-Ω chip resistor,

size 0805

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

B-2 Freescale Semiconductor

Page 41

Table B-1. MC92602DVB Design Verification Board Parts List (Sheet 3 of 3)

Parts List

Item Qty. Reference Value

Manufacturer/

Supplier

Manufacturer's

Part No.

Description

29 3 R33, R76–R79 1 Ω Newark 95B6635 1.0-Ω chip resistor,

size 1206

30 1 TPA N/A Johnson 129-0701-202 Scope PCB test socket

31 35 CLK_A_PG,

CLK_B_PG,

N/A Amp 901-144-8-RFX SMA 50-Ω RF PCB jack

socket

CLK_C_PG,

CLK_D_PG,

CLK_IN,

CLK_OUT1–6,

SMA1–16,

TST1–8

32 1 R12V VRES,

1 KΩ

33 3 R22V, R22V1,

500 Ω BOURNS 3214W-1-502E Surface mount trimming

R22V2

BOURNS 3214W-1-102E Surface mount trimming

resistor, J lead

resistor, J lead

34 1 U1 N/A Freescale MC92602 Quad 1.25 Gbaud DDR

SerDes in 196 MAPBGA

35 45 N/A N/A 3M 929950-00 0.100" shunts

36 10 N/A N/A Pomona 4741-12-0/4741-12-2 Square pin receptacle patch

cord

37 10 R18–R19, R22,

R58, R78–R83

38 9 R2, R7–R9, R57,

R65,

10 KΩ Dale CR0805-10W-103J 10 KΩ chip resistor,

size 0805

50 Ω 50-Ω chip resistor,

size 0805

R85–R87

39 1 R15 12 Ω 12-Ω chip resistor,

size 0805

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor B-3

Page 42

Parts List

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

B-4 Freescale Semiconductor

Page 43

Appendix C

Prescaler for Jitter Measurement

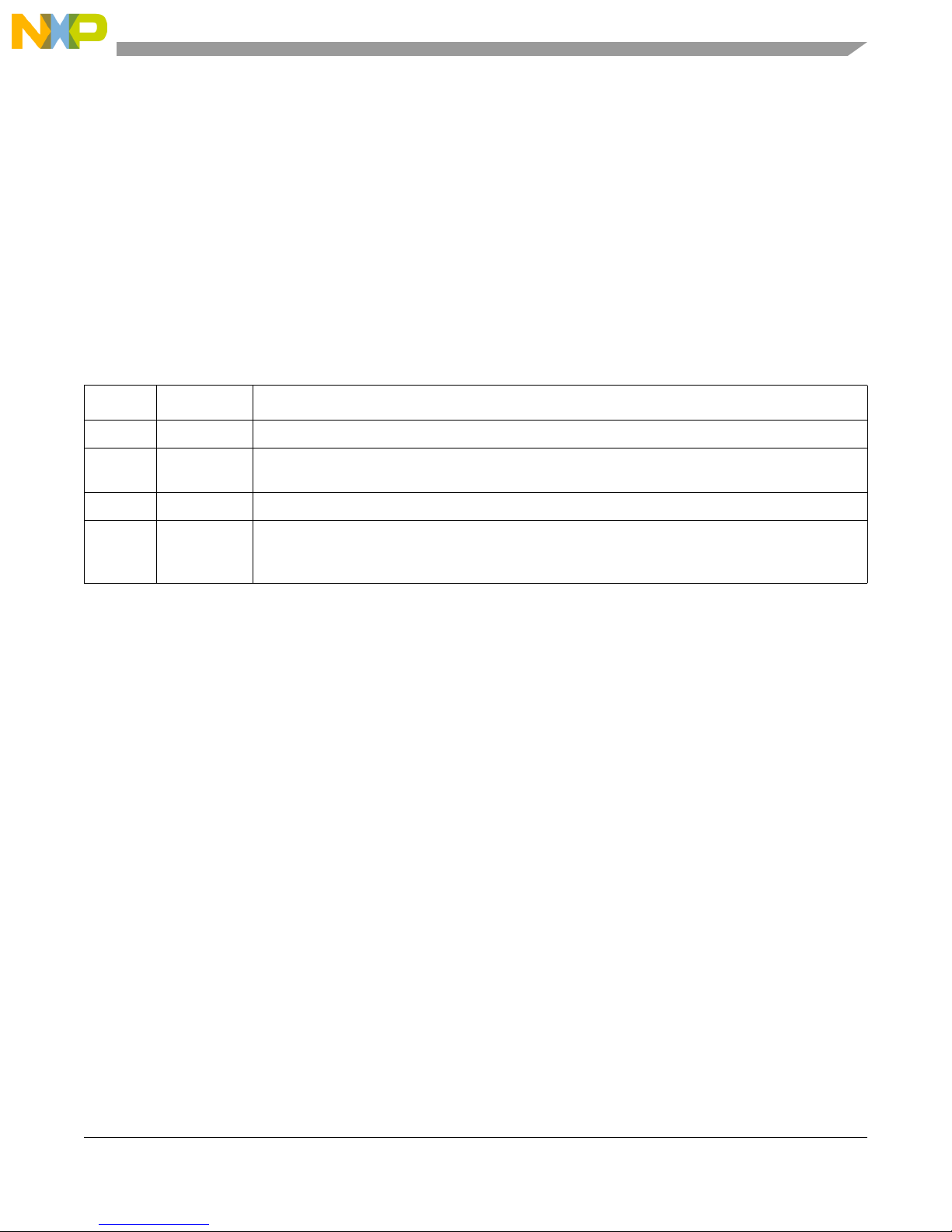

C.1 Divide-by-xx Prescaler Description

Evaluating jitter in a system requires that all clocks within the system be based on one common source.

For this reason, it is often necessary to use prescalers to derive the needed reference clock. Freescale has

developed a small programmable prescaler with a maximum input frequency of 4.4 GHz which can be

assembled using commercially available parts. Figure C-1 depicts the block diagram of this prescaler.

Clock

Clock

In

Divide

by 2

In_alt

5-Bit

Programmable

Counter

Divide by

2, 4, or 8

Prescaler

Level

Shift

Clock

Out

Bank 1 Switch

Figure C-1. Divide-by-xx Prescaler Block Diagram

Bank 2 Switch

The input to the prescaler can be either through a divide-by-2 or directly into the 5-bit programmable

counter. The bank 1 and bank 2 DIP switches can be used to select a variety of prescaler values based on

the following formula:

Modulus 2 A 1+()N⋅⋅=

where A = 1 to 31 and N = 2, 4, or 8.

For values commonly used in 1.0-Gbit systems refer to Table C-1.

Tabl e C-1. Switch Settings for 1.0-Gbit SERDES Prescalers

Bank 1 Bank 2

Input

SW5 SW4 SW3 SW2 SW1 SW2 SW1

Clock In_alt 0 0 1 0 0 1 1 5 × 2 = 10

Clock In 0 0 1 0 0 1 1 2 × 5 × 2 = 20

Clock In 0 0 1 0 0 0 1 2 × 5 × 4 = 40

Clock In 0 1 0 0 1 1 1 2 × 10 × 2 = 40

Modulus

Schematics for this prescaler are available from your Freescale field applications engineer.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor C-1

Page 44

Prescaler for Jitter Measurement

C.2 Prescaler Components

Table C-2 lists the major integrated circuit components needed for the prescaler.

Tabl e C-2. Major Components for Divide-by-xx Prescaler

Part No. Manufacturer Supplier Comments

MC12093 Freescale Newark 1.1-GHz prescaler (divide by 2, 4, or 8)

MC100ELT23 On Semiconductor Newark Dual differential PECL to TTL translator, with separate inputs.

MC100ELT21 On Semiconductor Newark Single differential PECL to TTL translator.

Alternative to above part.

MC100ELT26 On Semiconductor Newark Dual differential PECL to TTL translator, with common inputs.

Alternative to above part.

HMMC-3122 Agilent Arrow 12-GHz divide-by-2 prescaler, GaAs HBT MMIC.

HMC364S8G Hittite Microwave Hittite 12-GHz divide-by-2 prescaler, GaAs HBT MMIC.

Pin-for-pin alternative to above part.

HMC394LP4 Hittite Microwave Hittite 2.2-GHz programmable 5-bit counter, GaAs HBT MMIC.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

C-2 Freescale Semiconductor

Page 45

Appendix D

Revision History

This appendix provides a list of the major differences between revisions of the MC92602 Reduced

Interface SerDes Design Verification Board User’s Guide (MC92602DVBUG).

Table D-1 provides a revision history for this document.

Tabl e D-1. MC92602DVB Revision History

Rev. No. Date Substantive Change(s)

1 5/30/2002 Initial release.

1.1 10/1/2002 Editorial corrections.

Appendix A: Added note concerning loading of RECV_x_CLK.

2 2/2004 Reformatted for new release.

3 12/2004 Reformatted to Freescale with minor edits.

Added note to Figure 2-1. Top Side Part Location Diagram.

Corrected pin numbers in Ta bl e 3-4. Data-Eye Generation Parallel Input Biasing.

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

Freescale Semiconductor D-1

Page 46

Revision History

MC92602 Reduced Interface SerDes Design Verification Board User’s Guide, Rev. 3

D-2 Freescale Semiconductor

Page 47

BackCover

Page 48

How to Reach Us:

Home Page:

www.freescale.com

E-mail:

support@freescale.com

USA/Europe or Locations Not Listed:

Freescale Semiconductor

Technical Information Center, CH370

1300 N. Alma School Road

Chandler, Arizona 85224

+1-800-521-6274 or +1-480-768-2130

support@freescale.com

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

support@freescale.com

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-441-2447 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits based on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application or use of any

product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale Semiconductor data sheets and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer application by

customer’s technical experts. Freescale Semiconductor does not convey any license

under its patent rights nor the rights of others. Freescale Semiconductor products are

not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life,