Page 1

MC1322x Simple Media Access

Controller Demonstration

Applications

User's Guide

Document Number: 22xSMACDAUG

Rev. 1.3

09/2011

Page 2

How to Reach Us:

Home Page:

www.freescale.com

E-mail:

support@freescale.com

USA/Europe or Locations Not Listed:

Freescale Semiconductor

Technical Information Center, CH370

1300 N. Alma School Road

Chandler, Arizona 85224

+1-800-521-6274 or +1-480-768-2130

support@freescale.com

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

support@freescale.com

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1-8-1, Shimo-Meguro, Meguro-ku,

Tokyo 153-0064, Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1-800-521-6274 or 303-675-2140

Fax: 303-675-2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and software implementers to use

Freescale Semiconductor products. There are no express or implied copyright licenses granted

hereunder to design or fabricate any integrated circuits or integrated circuits based on the information

in this document.

Freescale Semiconductor reserves the right to make changes without further notice to any products

herein. Freescale Semiconductor makes no warranty, representation or guarantee regarding the

suitability of its products for any particular purpose, nor does Freescale Semiconductor assume any

liability arising out of the application or use of any product or circuit, and specifically disclaims any

and all liability, including without limitation consequential or incidental damages. “Typical” parameters

that may be provided in Freescale Semiconductor data sheets and/or specifications can and do vary

in different applications and actual performance may vary over time. All operating parameters,

including “Typicals”, must be validated for each customer application by customer’s technical

experts. Freescale Semiconductor does not convey any license under its patent rights nor the rights

of others. Freescale Semiconductor products are not designed, intended, or authorized for use as

components in systems intended for surgical implant into the body, or other applications intended to

support or sustain life, or for any other application in which the failure of the Freescale Semiconductor

product could create a situation where personal injury or death may occur. Should Buyer purchase

or use Freescale Semiconductor products for any such unintended or unauthorized application,

Buyer shall indemnify and hold Freescale Semiconductor and its officers, employees, subsidiaries,

affiliates, and distributors harmless against all claims, costs, damages, and expenses, and

reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Freescale

Semiconductor was negligent regarding the design or manufacture of the part.

IAR Systems, IAR Embedded Workbench, C-SPY, visualSTATE, From Idea to Target, IAR KickStart

Kit, IAR PowerPac, IAR YellowSuite, and IAR are trademarks or registered trademarks owned by IAR

Systems AB.

Copyright © 2007 IAR Systems AB.

ARM is the registered trademark of ARM Limited. ARM7TDMI-S is the trademark of ARM Limited.

Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc. All other

product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc. 2005, 2006, 2007, 2008, 2009, 2010, 2011. All rights reserved.

Page 3

Contents

About This Book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Available Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Definitions, Acronyms, and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Chapter 1

Generating an SMAC Application and Port Configuration

1.1 Loading Applications Into a Board Using the JTAG J-Link ARM Debugger . . . . . . . . . . . . . . 1-6

1.2 JTAG Debugging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3 UART/USB Virtual COM Port Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Chapter 2

Wireless UART Demonstration

2.1 Generating a Project From BeeKit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Open, Compile and Execute the Wireless UART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3

Connectivity Test

3.1 Loading the Connectivity Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 UART/USB Virtual Com Port Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Starting the Connectivity Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Connectivity Test Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.1 Test Mode Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.2 Spectrum Analyzer Captures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.5 Packet Error Rate (PER) Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.5.1 Starting the PER Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.5.2 PER operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.6 Range Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.7 Crystal Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Chapter 4

Accelerometer Demonstration

4.1 Loading the Accelerometer Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Board Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Board One Setup (PC_Radio Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.4 Board Two Setup (Accelerometer Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.5 PC Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.6 Verifying Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.7 Setting Up the Calibration Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor i

Page 4

Chapter 5

Low Power Bell Demonstration

5.1 Generating the Project From BeeKit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Open, Compile and Execute the Low Power Bell Application . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Chapter 6

Generic Application Demonstration

6.1 Generating a Project From BeeKit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Open, Compile and Execute the Generic Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Chapter 7

Simple ZigBee Test Client (SZTC) Demonstration

7.1 Generating a Project From BeeKit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Testing the SZTC with the WirelessUART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Chapter 8

Repeater Demonstration

8.1 Generating a Project From BeeKit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Open, Compile and Execute the Repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.3 Repeater Menu, Configuration and Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.4 Running the Repeater Demonstration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.4.1 Creating a Sniffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.4.2 Running a Dummy Repeater. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Chapter 9

Weather Station Demonstration

9.1 Generating a Project From BeeKit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Open, Compile, and Load the Weather Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.3 Weather Station PC Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.3.1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.3.2 Connecting to a Network Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.3.3 Data Packet Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.3.4 Loading a Pre-existing Log File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Chapter 10

Over The Air Programmer Demonstration

10.1 Generating a Project From BeeKit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.2 Open, Compile, and Load the OTAP Programmer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.3 Downloading an OTAP-enabled Image to the OTAP Programmer Board. . . . . . . . . . . . . . . . 10-4

10.4 Downloading an OTAP-enabled Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.5 Transmitting the New Image to the OTAP-enabled Board . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

ii Freescale Semiconductor

Page 5

10.5.1 Using the Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.5.2 Using The LCD Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.6 Verifying the Transmitted Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor iii

Page 6

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

iv Freescale Semiconductor

Page 7

About This Book

This guide provides a detailed description of the MC1322x Simple Media Access Controller (MC1322x

SMAC) demonstration applications. The demonstration applications are delivered as ANSI C source code

and are included in the MC1322x SMAC Codebase. The Codebase is incorporated into the Freescale

BeeKit Wireless Connectivity Toolkit. See the BeeKit Wireless Connectivity Toolkit User’s Guide

(BKWCTKUG) and the BeeKit on-line help for more information.

This guide explains how to run various MC1322x SMAC demonstration applications and provides

information that allows users to more easily take advantage of these demonstration applications or modify

the applications to fit their specific needs.

The demonstration applications shown in this guide are compatible with previous SMAC demonstrations

at the protocol level. However, the applications that employ security will be different because the

MC1322x SMAC takes advantage of the Advanced Security Module (ASM, AES based) security module

included in the MC122x Platform in a Package (PiP). The MC1322x device provides a more robust

security approach. For more information about security and the MC1322x, see the appropriate MC1322x

documentation available at www.freescale.com/zigbee.

The MC1322x SMAC API is similar to previous SMAC APIs. For more detail about the APIs, see the

MC1322x Simple Media Access Controller (SMAC) Reference Manual (22xSMACRM).

Available Devices

The MC1322x family is available as two part numbers. These device types differ only in their ROM

contents, all other device hardware, performance, and specifications are identical:

• MC13224V - this is the original version and is the generic part type.

— The MC13224V is intended for most IEEE 802.15.4 applications including MAC-based,

ZigBee-2007 Profile 1, and ZigBee RF4CE targets.

— It has a more complete set of peripheral drivers in ROM.

• MC13226V - this is a more recent version and is provided specifically for ZigBee-2007 Profile 2

(Pro) applications. Only the onboard ROM image has been changed to optimize ROM usage for

the ZigBee Pro profile and maximize the amount of available RAM for application use.

— The IEEE MAC/PHY functionality has been streamlined to include only that functionality

required by the ZigBee specification. The MAC functionality is 802.15.4 compatible.

— For a typical application, up to 20 kbytes more of RAM is available versus the M13224V

— Some drivers present in the MC13224 ROM have been removed and these include the ADC,

LCDfont, and SSI drivers. These drivers are still available as library functions, but now

compile into the RAM space.

— The Low Level Component (LLC) functionality has also been streamlined for the ZigBee

specification

NOTE

• When running the Freescale IEEE 802.15.4 MAC (or a related stack) on

the MC1322x platform, neither beaconing or GTS are supported.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor iii

Page 8

• See the MC1322x Reference Manual (Document No MC1322xRM), for

information on using applications on these devices.

Audience

This document is intended for application developers generating MC1322x SMAC demonstration

applications from the Freescale BeeKit Wireless Connectivity Toolkit or modifying these applications as

a starting point for proprietary applications.

Organization

This document is organized into ten chapters.

Chapter 1 Introduction — This chapter shows how to generate an SMAC demonstration

application using BeeKit.

Chapter 2 Wireless UART — Provides a detailed description of MC1322x SMAC Wireless

UART demonstration application.

Chapter 3 Connectivity Test — Provides an easy way to test the RF performance of the

transceiver for basic transmitter and receiver tests. It includes test mode

(continuous tx, modulated, unmodulated, etc.); Packet Error Rate and Range (LQI

measurements).

Chapter 4 Accelerometer Test — Provides an overview of the Accelerometer

Demonstration application, which shows various uses for the Freescale X, Y, and

Z axes accelerometers.

Chapter 5 Low Power Bell — Shows how to implement different low power options.

Chapter 6 Generic Application — Provides a start template for users what want to add their

own application.

Chapter 7 Simple ZTC — Allows users to test the SMAC primitives by sending special data

frames through the Serial/USB port.

Chapter 8 Repeater— Implements a simple repeater which extends the range between two

boards running an SMAC application demonstration.

Chapter 9 Weather Station— Simulates a Weather Station and shows the use of Freescale

sensors for acceleration and pressure.

Chapter 10 Over The Air Programmer (OTAP) — Allows users to update a board’s FLASH

remotely without a physical connection. Given an OTAP enabled application and

an OTAP programmer, users can replace an existing application with a new

application.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

iv Freescale Semiconductor

Page 9

Revision History

The following table summarizes revisions to this document since the previous release (Rev. 1.2).

Revision History

Location Revision

Chapters 3 and 6 Various software updates.

Definitions, Acronyms, and Abbreviations

The following list defines the acronyms and abbreviations used in this document.

AES Advanced Encryption Standard

API Application Program Interface

ASM Advanced Security Module

BDM Background Debug Module

BDM debugger A debugger using the BDM interface for communication with the MCU. An

example is the P&E BDM Multilink debugger for HCS08.

CBC Cipher Block Chaining.

CBC-MAC Cipher Block Chaining Message Authentication Code.

CCM Counter with CBC-MAC

CTR Counter.

dBm Decibels referred to one milliwatt.

ED Energy Detect.

EN End Node - Evaluation Board.

EVB Evaluation Boards.

EVK Evaluation Kit

EWW Embedded Workbench IDE work space file

GUI Graphical User Interface

IDE Integrated Development Environment

LP Low Power

MAC Media Access Control

MAC Message Authentication Code

MCU MicroController Unit

NCB Network Coordinator Board

NVM None-Volatile Memory

OTAP Over The Air Programming

PC Personal Computer

PCB Printed Circuit Board

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor v

Page 10

PiP Platform in Package

RX Reception

S19 S - Record. 'S19' is the file extension used for the Freescale binary image format.

The S19 file encapsulates the binary image as a list of ASCII records. Each record

contains a length -, address -, data - and checksum field. The 16 bit address field

allows a memory space for up to 64 KB. The S19 can be generated with

CodeWarrior IDE and is the product from the linking process. S19 does not

contain additional information to a debugger (where to look for source files).

Safe Mode Boot The Embedded Bootloader boots up using safe default system values.

SMAC Simple Media Access Control.

SN Sensor Node Evaluation Board.

TX Transmission.

References

The following sources were referenced to produce this book:

[1] Freescale 802.15.4 MAC/PHY Software Reference Manual (802154MPSRM)

[2] Freescale MC1322x Simple Media Access Controller (SMAC) Reference Manual (22xSMACRM)

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

vi Freescale Semiconductor

Page 11

Chapter 1

Generating an SMAC Application and Port Configuration

This chapter provides an overview of how to generate an SMAC demonstration application using BeeKit.

This chapter only provides an overview of how to generate an SMAC demonstration application. For more

details on installing BeeKit and BeeKit operation, see the BeeKit Wireless Connectivity Toolkit User’s

Guide (BKWCTKUG).

This chapter also shows how to set up a virtual UART/USB COM port. Once the ports are configured, refer

to the appropriate application chapter in this guide.

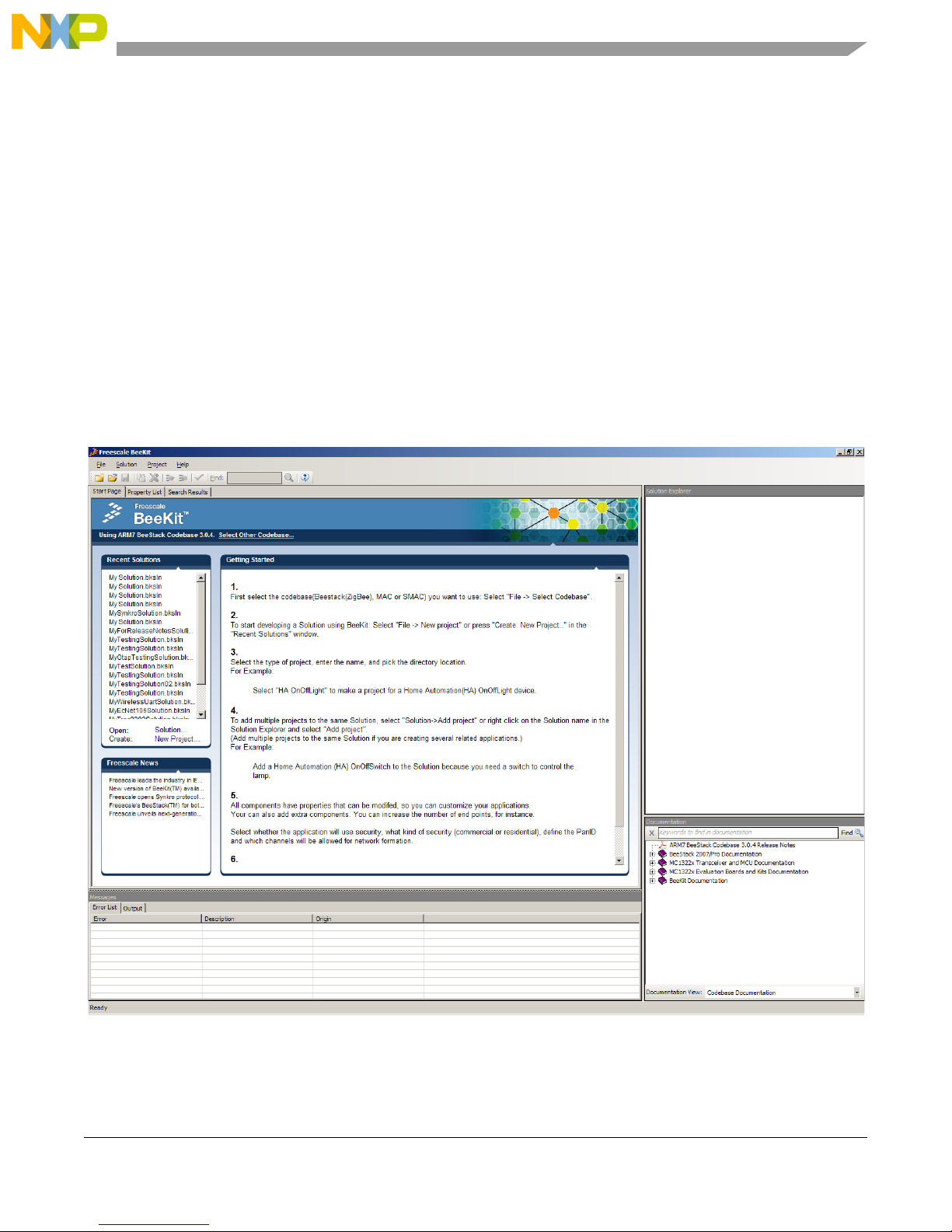

1. Install and then launch BeeKit and the BeeKit main window appears as shown in Figure 1-1.

Figure 1-1. BeeKit Graphical User Interface

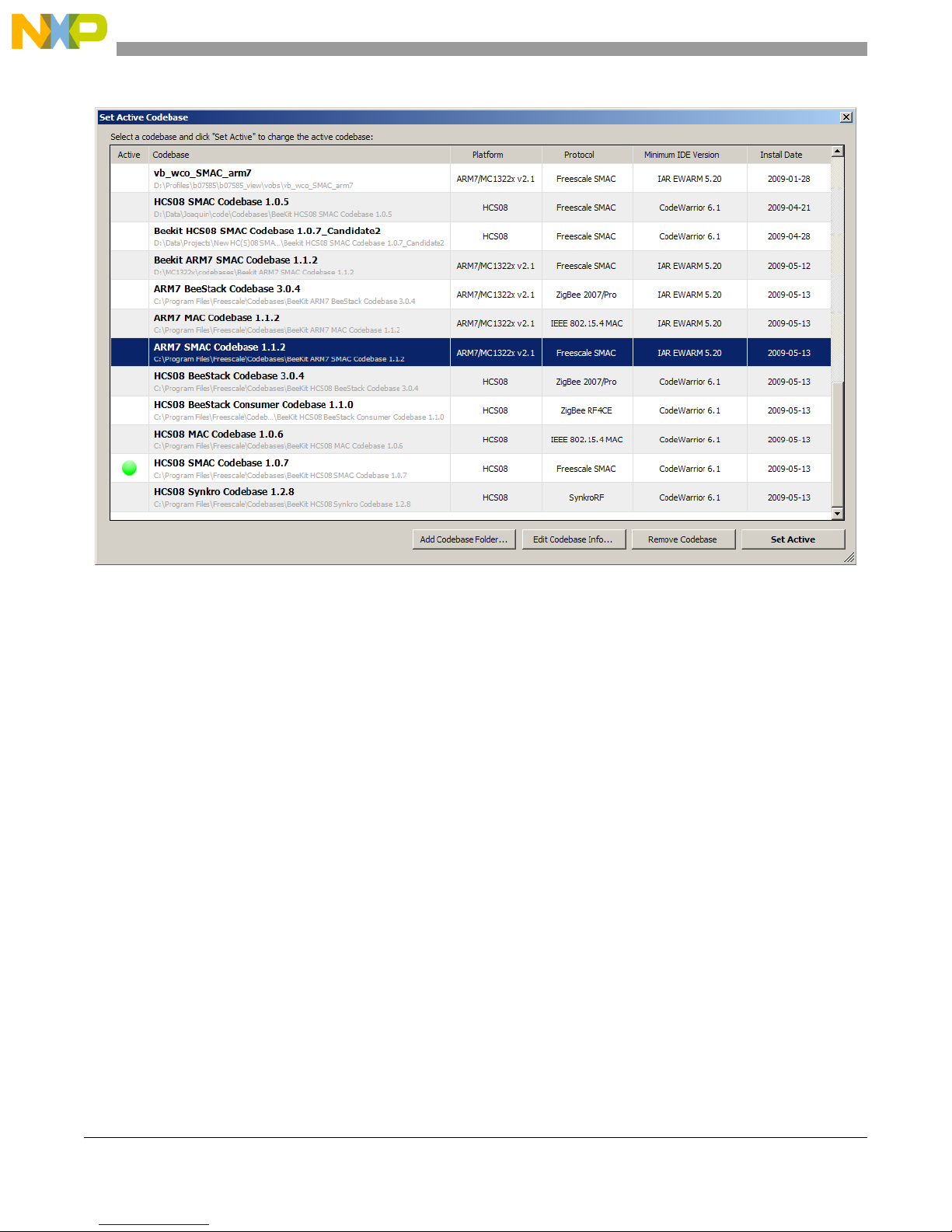

2. Select the SMAC Codebase as shown in Figure 1-2.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 1-1

Page 12

Generating an SMAC Application and Port Configuration

Figure 1-2. selecting SMAC Codebase

In BeeKit, a Codebase is a set of files and rules that permit users to generate the final applications. This

step is important, because the SMAC Codebase is different than the Codebase of MAC and BeeStack.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

1-2 Freescale Semiconductor

Page 13

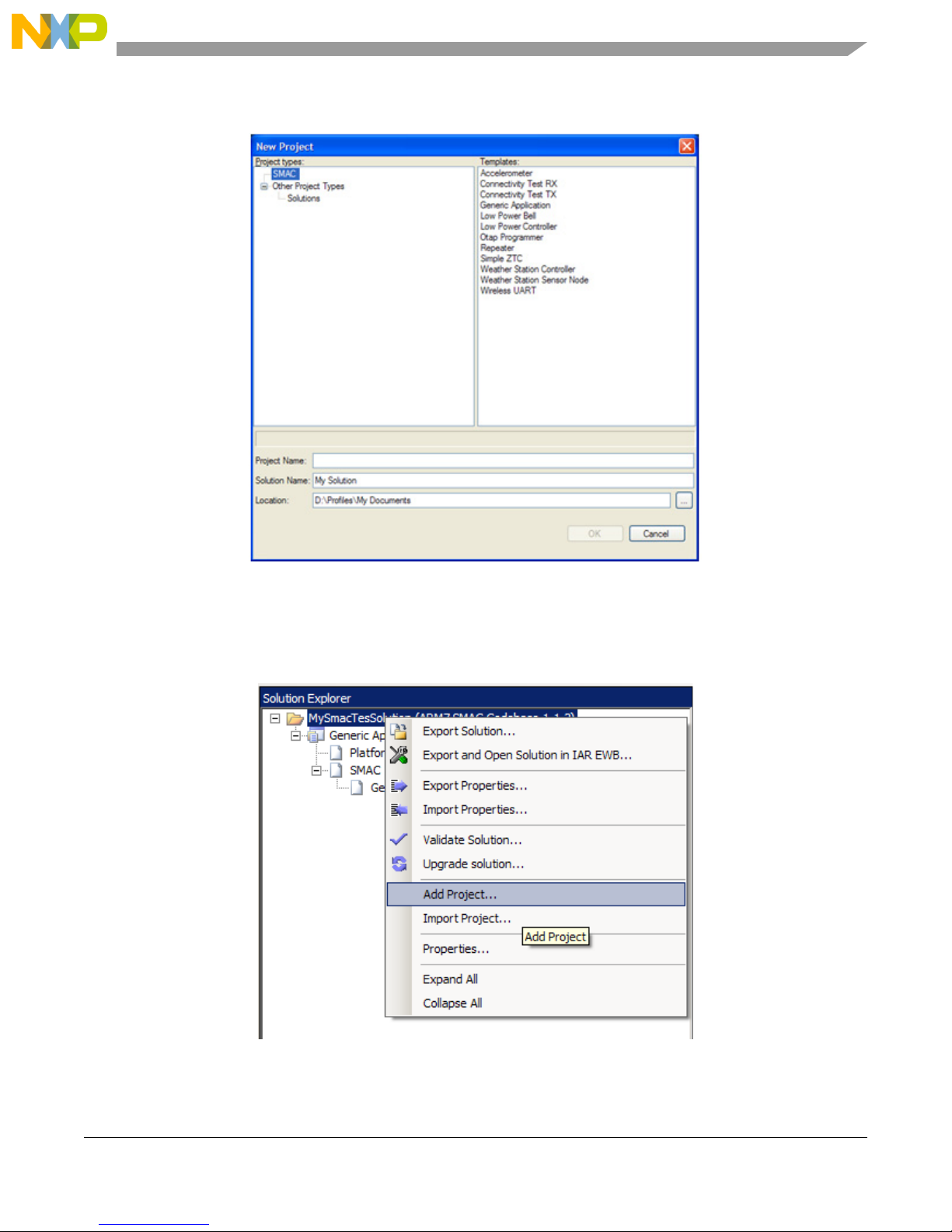

3. Create a new project as shown in Figure 1-3.

Generating an SMAC Application and Port Configuration

Figure 1-3. Creating a new project

If users create a new project and there is not a an existing solution, then users are also creating a solution.

The solution must have a name. Specify a name for the solution.

4. Add other required projects for the evaluation as shown in Figure 1-4.

Figure 1-4. Adding a New Project to a Existing Solution

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 1-3

Page 14

Generating an SMAC Application and Port Configuration

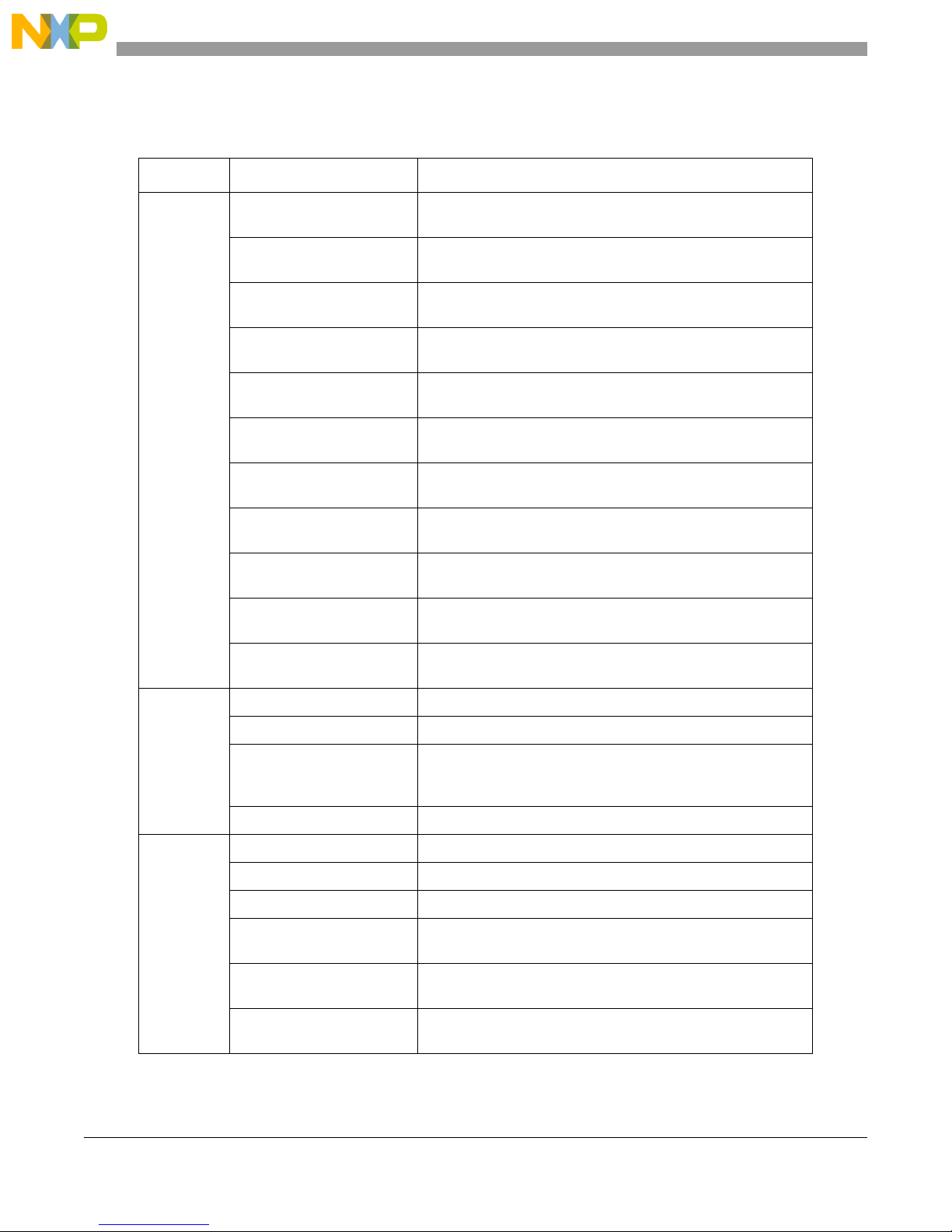

5. Modify the project properties as shown in Table 1-1.

Tab l e 1-1. Software Component Properties

Component Property Description

Security Enabled Enables the security Module to automatically encrypt the

information sent and received.

Promiscuous Mode If set to true, the SMAC Code Bytes are not sent prior to the

message.

Security Type This is the security engine used if the security enabled property

is true.

Security Default KEY0 Less Significative 32 bit Word of the 128 bits to be used as key

on the ciphering engine.

Security Default KEY1 Second Significative 32 bit Word of the 128 bits to be used as

key on the ciphering engine.

SMAC

PLM

Security Default KEY2 Third Significative 32 bit Word of the 128 bits to be used as key

on the ciphering engine.

Security Default KEY3 More Significative 32 bit Word of the 128 bits to be used as key

on the ciphering engine.

Security Default COUNTER0 Less Significative 32 bit Word of the 128 bits to be used as initial

counter on the ciphering engine.

Security Default COUNTER1 Second Significative 32 bit Word of the 128 bits to be used as

initial counter on the ciphering engine.

Security Default COUNTER2 Third Significative 32 bit Word of the 128 bits to be used as

initial counter on the ciphering engine.

Security Default COUNTER3 More Significative 32 bit Word of the 128 bits to be used as

initial counter on the ciphering engine.

Target hardware Allows board selection.

LCD Enabled Includes support for LCDs.

Default SCI Port Selects the SCI port. Freescale ZigBee boards usually have

SCI Port 1 connected to a DB9 connector and SCI port 2

connected to a USB connector.

MCU Version Can select either MC13224 or MC13226.

Default Channel Default starting channel in the application.

Output Power Initial power output configuration.

Baud Rate Baud rate to be set at the default SCI port for this application

App

1-4 Freescale Semiconductor

OTAP Enabled Enables the OTAP Module to allow over the air programming of

OTAP Request Code If the OTAP Module is enabled the application will switch to

OTAP Device Id This ID distinguishes between different devices identified by an

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

the application.

OTAP mode when this OTAP Request Code is received.

OTAP Programmer.

Page 15

Generating an SMAC Application and Port Configuration

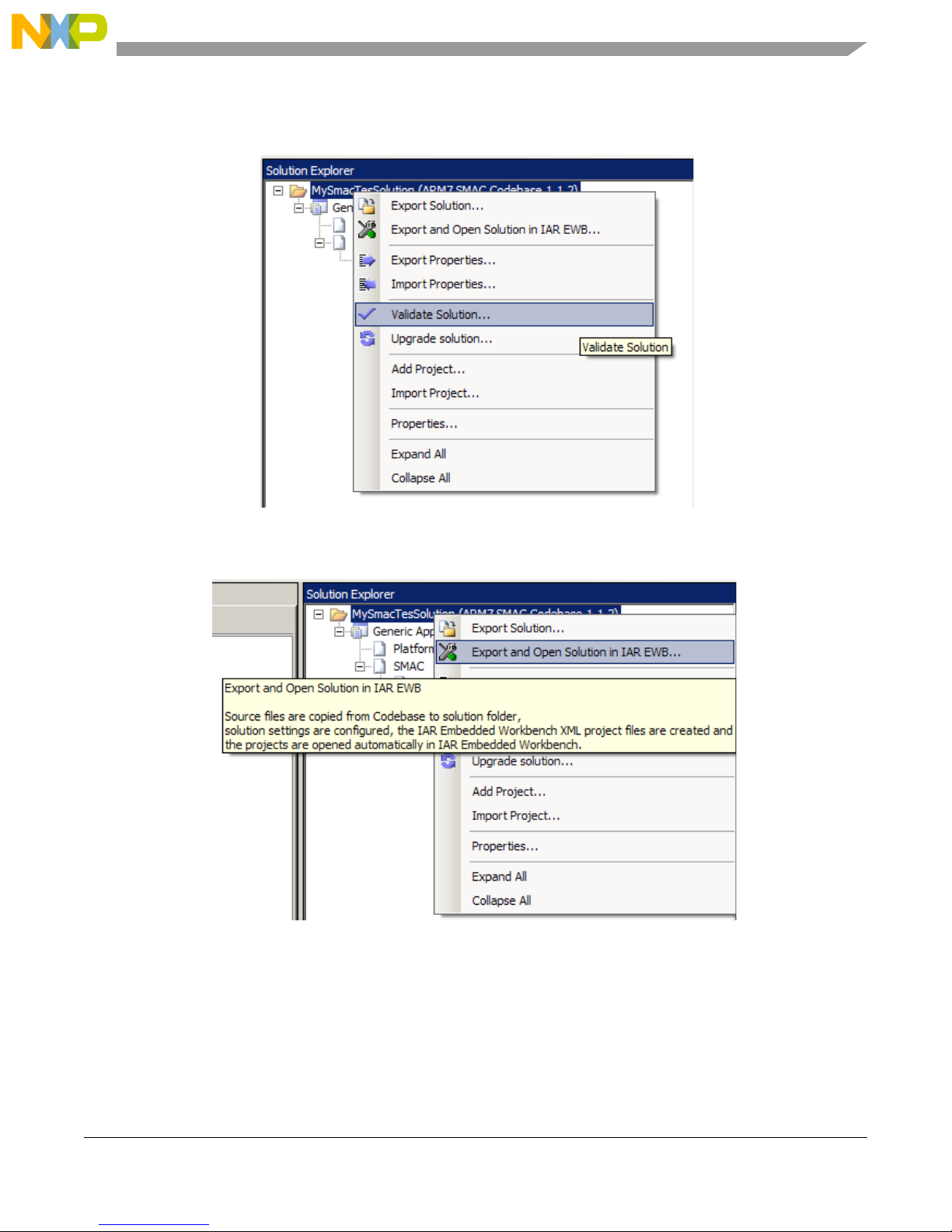

6. Users must now validate the solution as shown in Figure 1-5. The validation process helps users

find possible inconsistencies between the selected hardware and properties.

Figure 1-5. Validating a Solution

7. Users must now export the solution as shown in Figure 1-6.

Figure 1-6. Exporting a Solution

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 1-5

Page 16

Generating an SMAC Application and Port Configuration

1.1 Loading Applications Into a Board Using the JTAG J-Link ARM

Debugger

After exporting from BeeKit, the projects are generated as a .eww file. Perform the following tasks to load

the application to a board, using the IAR Embedded Workbench IDE. This example uses the repeater

application.

1. As shown in Figure 1-7, open the My Solution.eww file.

Figure 1-7. Opening a project

2. Make the project by clicking the Make button (Figure 1-8) which is located at the top of the IAR

Embedded Workbench main Window as shown in Figure 1-9.

Figure 1-8. Make Button

Figure 1-9. IAR Embedded Workbench Main Window

3. Connect the J-Link to the target board.

4. Click the Debug button Figure 1-10 which is located at the top of the IAR Embedded Workbench

main window as shown in Figure 1-9.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

1-6 Freescale Semiconductor

Figure 1-10. Debug

Page 17

Generating an SMAC Application and Port Configuration

5. The application will start to download, to run the application press F5 key or click the Go button

Figure 1-11

Figure 1-11. Go

1.2 JTAG Debugging

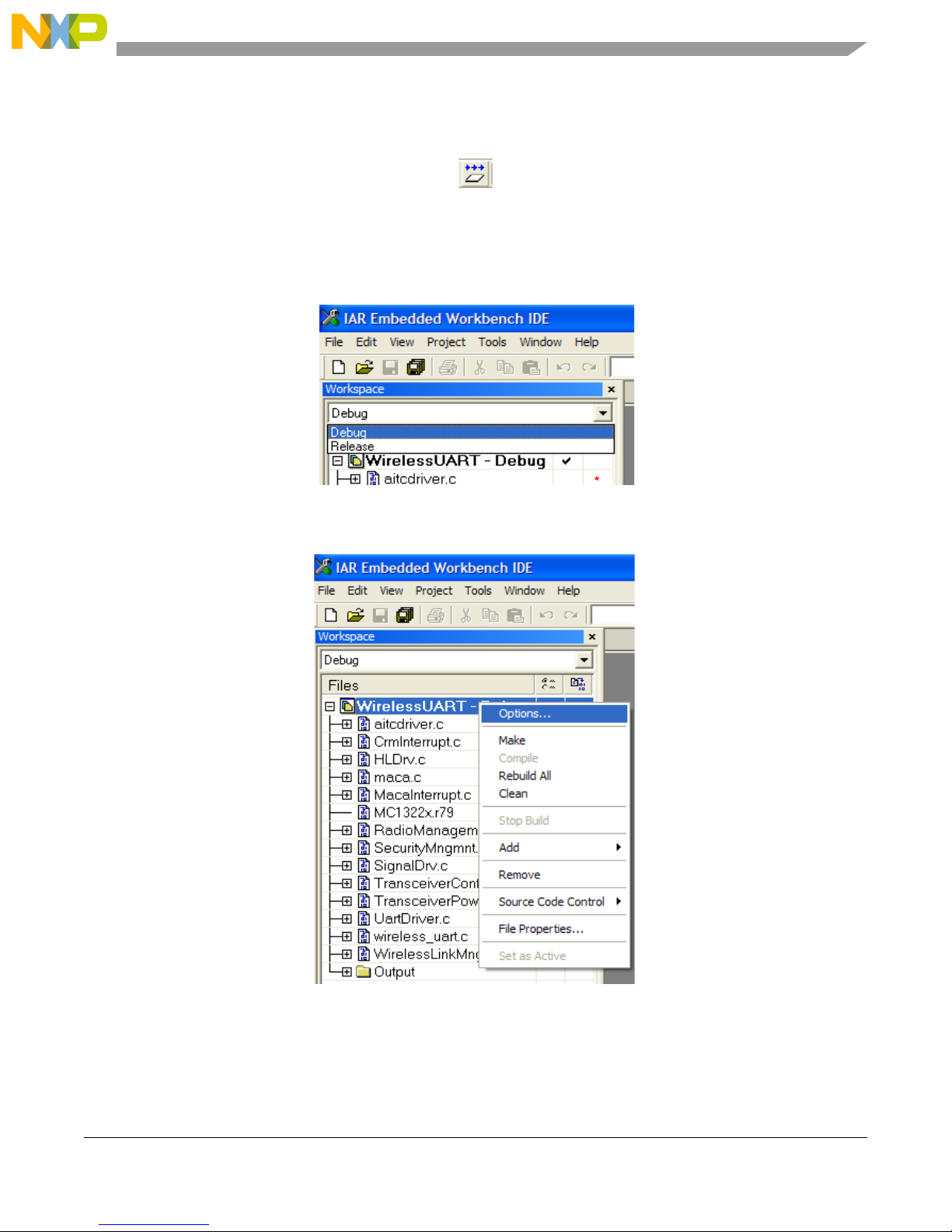

1. To debug an application select “Debug“ at the Work space window as shown in Figure 1-12.

Figure 1-12. IAR Embedded Workbench Work Space Debug and Release Window

2. Right click on the project name and select “Options“ as shown in Figure 1-13.

Figure 1-13. IAR Embedded Workbench Options Menu

3. At the debugger category on the Setup tab, select the “J-Link/J-Trace“ option as shown in

Figure 1-14.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 1-7

Page 18

Generating an SMAC Application and Port Configuration

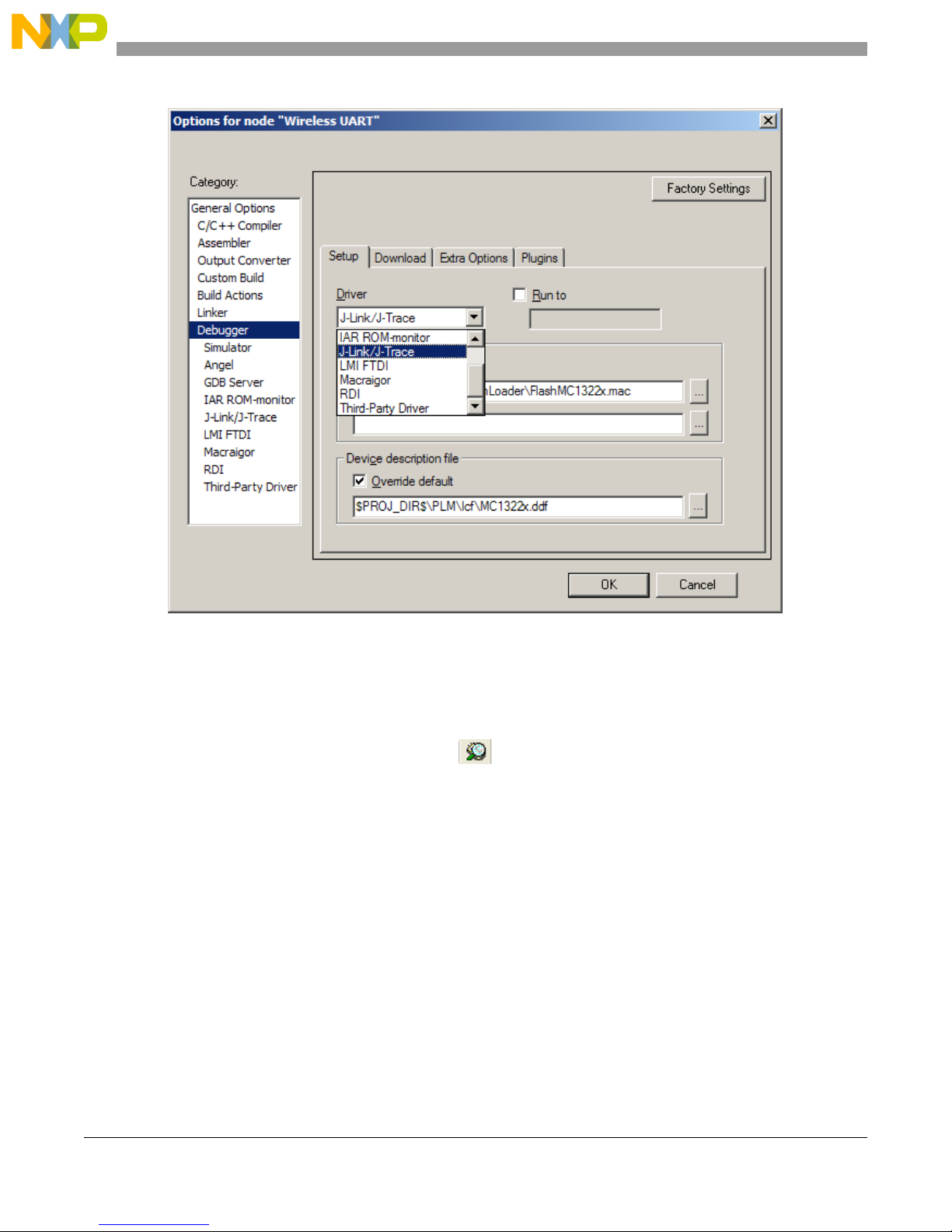

Figure 1-14. Debugger Setup

4. Ensure that the JTAG Debugger is connected to the PC and to the board.

5. On the Project window press the [CTRL]+[D] keys or just click the debug button shown in

Figure 1-15 to begin the debugging session.

Figure 1-15. Debug Button

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

1-8 Freescale Semiconductor

Page 19

Generating an SMAC Application and Port Configuration

1.3 UART/USB Virtual COM Port Setup

This section describes how to set up a virtual COM port for the following demonstration applications:

• Chapter 2, “Wireless UART Demonstration”

• Chapter 3, “Connectivity Test”

• Chapter 6, “Generic Application Demonstration”

• Chapter 7, “Simple ZigBee Test Client (SZTC) Demonstration”

• Chapter 8, “Repeater Demonstration”

• Chapter 9, “Weather Station Demonstration”

• Chapter 10, “Over The Air Programmer Demonstration”

Attach two boards to two PCs. This allows communication using a PC terminal communications program.

The two boards can be attached to two different serial ports of the same PC if needed, but Freescale

recommends using two PCs when possible.

1. Connect each of the boards to a separate PC either with an RS-232 cable or a USB cable. If using

a USB cable, a corresponding USB driver is required. Freescale recommends a direct USB

connection. Do not use a USB hub. This driver is located in the following directory:

<INSTALL DIR>\Freescale\Drivers

The BeeKit CD image is available from the Freescale ZigBee web site at

www.freescale.com/zigbee.

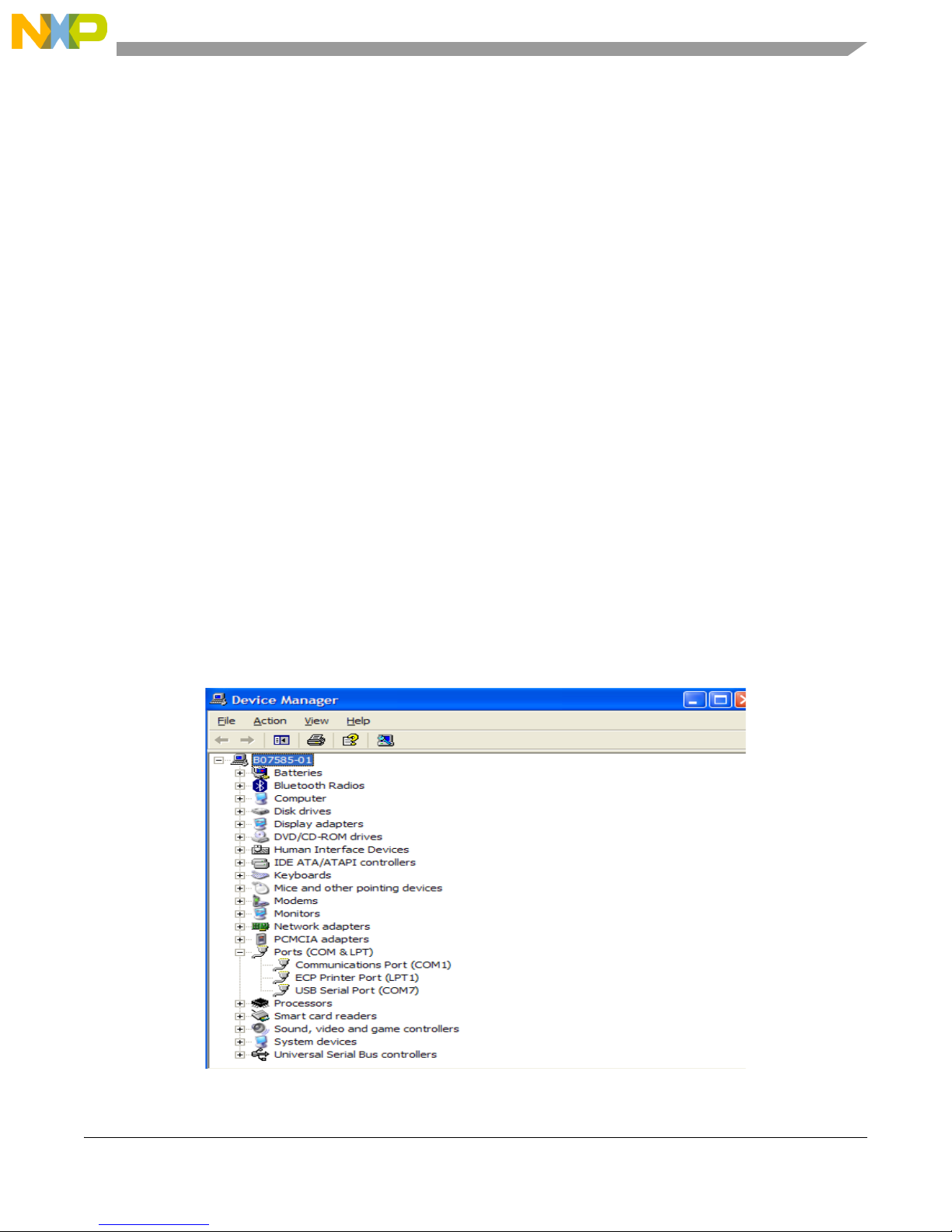

2. To check which COM port is being used by the USB, do the following:

a) Open the Windows System Properties window using Start->Settings->Control Panel->System.

b) Select the Hardware tab, and click the Device Manager button. The Device Manager window

appears as shown in Figure 1-16.

Figure 1-16. COM Port Determination in Device Manager

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 1-9

Page 20

Generating an SMAC Application and Port Configuration

c) Scroll to the Ports label and expand the tree by clicking the “+” sign. This shows the COM ports

in the system.

d) As shown in Figure 1-16, the COM Port chosen by the system is titled

USB Serial Port (COM7).

3. If the COM port chosen is not a port numbered between Ports 1-10, then perform the following

tasks:

a) Double click on USB Serial Port in the Device Manager window. The Properties window

appears.

b) Select the Port Settings tab, and then click on the Advanced button.

c) Go to the COM Port Number drop down menu and select a COM port between 1-10 that is not

already in use.

d) Open the Windows System Properties window using Start->Settings->Control Panel->System.

Select the Hardware tab, and click the Device Manager button. The Device Manager window

appears as shown in Figure 1-16.

e) Check to ensure the required port appears.

f) Close the Device Manager window.

4. Proceed to generating the project in BeeKit as described in the appropriate application chapter.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

1-10 Freescale Semiconductor

Page 21

Chapter 2

Wireless UART Demonstration

The Wireless UART application allows the Freescale ZigBee family of boards to communicate at

typematic rates from one board to another over RS-232 cables or USB virtual COM ports. In order to

execute this demonstration application the user will need a tool to send and receive characters over two

serial ports in addition to what Freescale supply.

This chapter provides a simplified example. Currently, the code cannot be used as a cable replacement. If

cable replacement is the ultimate goal, then queues, buffers, and other constructs must be added to increase

the reliability and efficiency of this demonstration.

Prior to loading the Wireless UART application, the application must be generated using BeeKit, as

described in the BeeKit Wireless Connectivity Toolkit User’s Guide.

The MC1322x SMAC Wireless UART demonstration application is protocol compatible with previous

SMAC Wireless UART applications (those that run on the MC1319x, MC1320x, and MC1321x boards).

However, if security is enabled, the MC1322x SMAC Wireless UART demonstration application is

incompatible with previous SMAC versions.

See Section 1.3, “UART/USB Virtual COM Port Setup” for information about how to set up a virtual COM

port for this application.

2.1 Generating a Project From BeeKit

Once the UART/USB virtual ports have been configured, continue with generating the project from

BeeKit as follows.

1. Open BeeKit (Start->Programs->Freescale BeeKit->Freescale BeeKit).

2. In BeeKit, select the MC1322x SMAC codebase (File menu -> Select Codebase...)

3. Click on File -> New Project and choose the Wireless UART template.

4. Follow the steps as displayed in the New Project wizard.

5. Configure the properties as needed.

6. Validate the solution.

7. Export the solution.

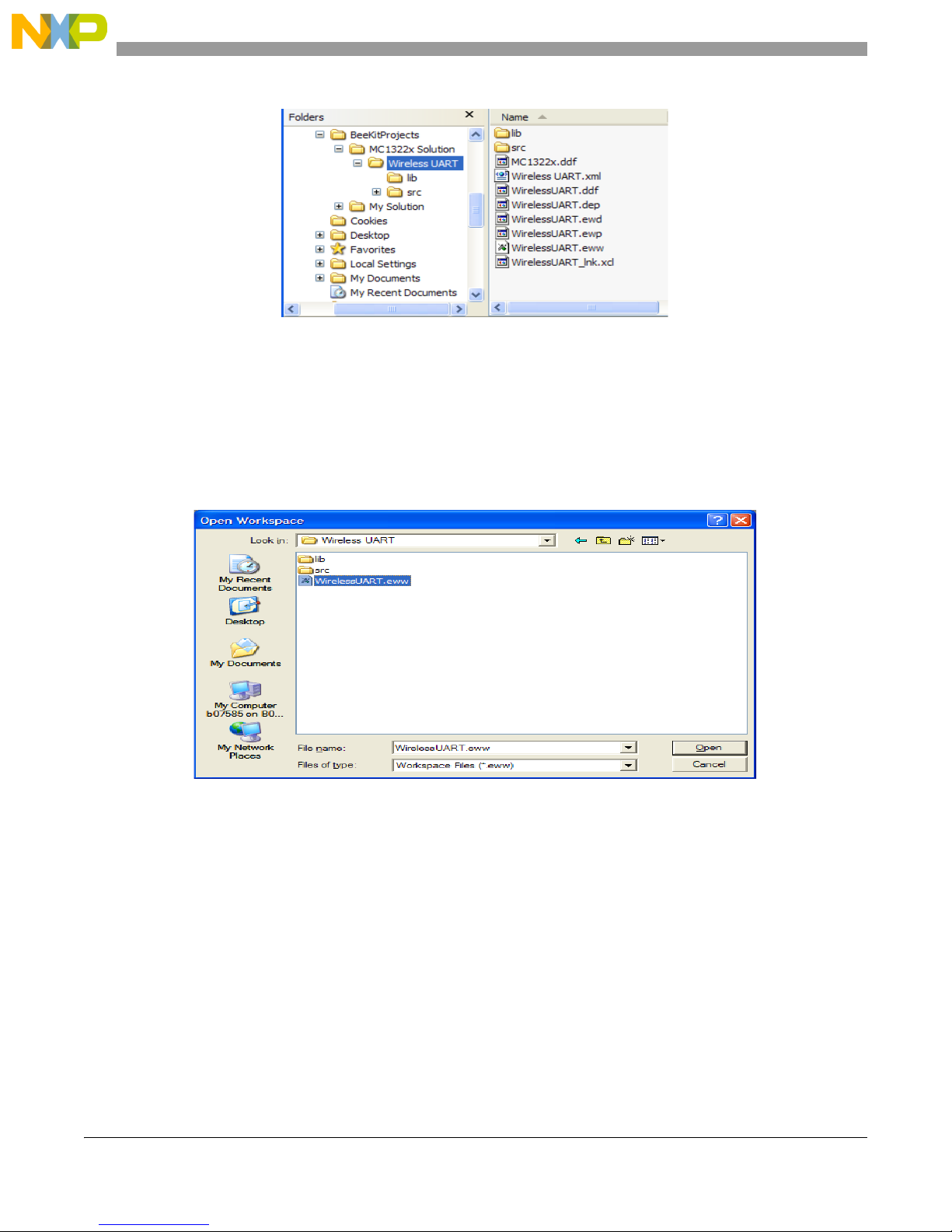

8. BeeKit creates the project folder with the structure as shown in Figure 2-1.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 2-1

Page 22

Wireless UART Demonstration

Figure 2-1. BeeKit Created, Wireless UART Directory Structure

For further details about how to use BeeKit, see the BeeKit Wireless Connectivity Toolkit User’s Guide

(BKWCTKUG).

2.2 Open, Compile and Execute the Wireless UART

1. Using the IAR Embedded Workbench, open the Wireless UART work space (Wireless UART.eww)

as shown in Figure 2-2.

Figure 2-2. Opening Wireless UART Work Space

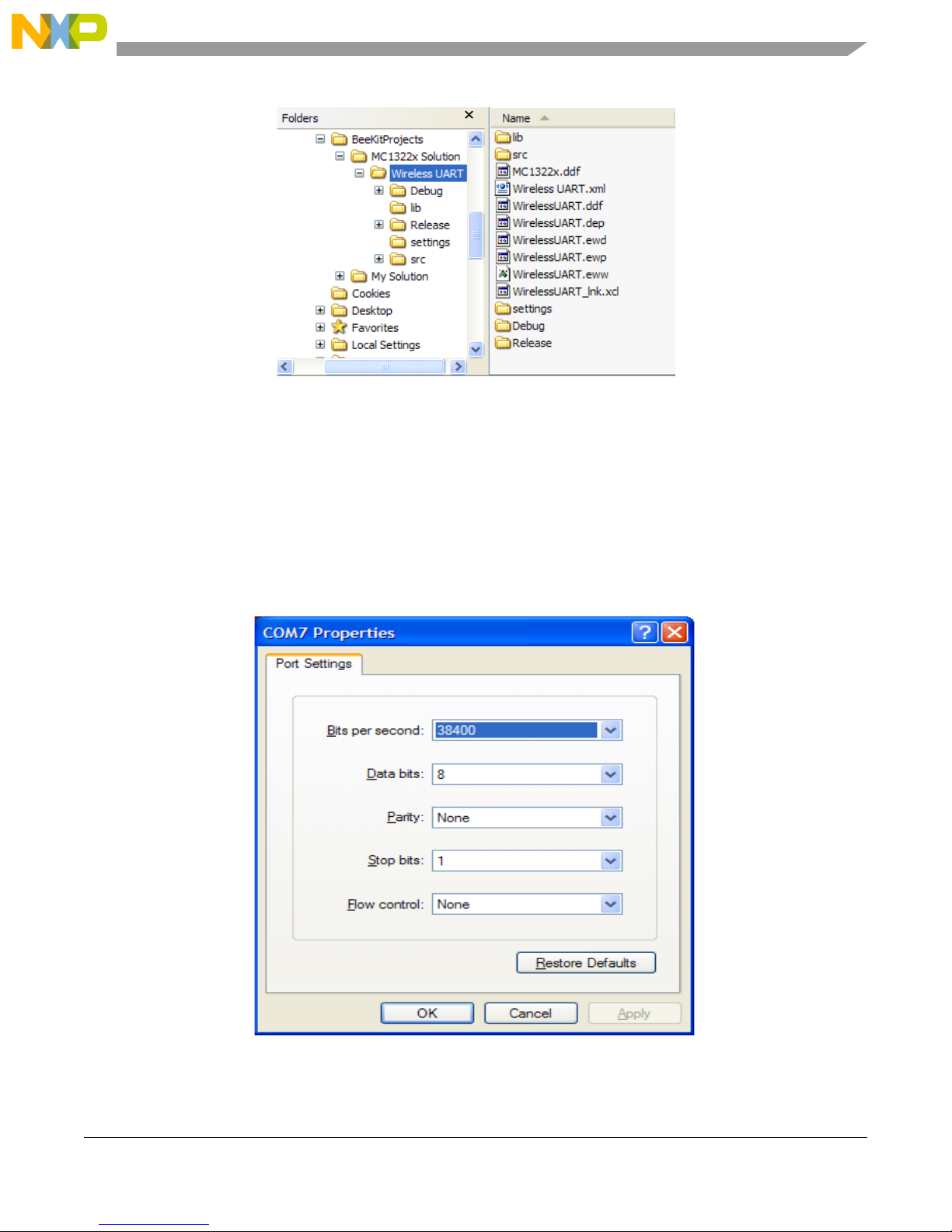

2. Select “Release” in the Workspace window.

3. Click on Project -> Rebuild All.

The folders Release, Debug, and the settings are now created in the project structure as shown in

Figure 2-3.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

2-2 Freescale Semiconductor

Page 23

Wireless UART Demonstration

Figure 2-3. Release, Debug, and Settings

The WirelessUART.bin file is placed at the following directory location:

[Project Directory]\Release\Exe\

4. Load the WirelessUART application to the boards. Connect the JTAG interface to the board, then

click the Debug button on the IAR Embedded Workbench IDE.

5. Use a PC terminal communications program, such as Hyper Terminal, and set the correct baud rate,

data bits, parity, COM port, and flow control. Figure 2-4 shows the default MC1322x SMAC

RS-232 settings.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 2-3

Figure 2-4. Default SMAC RS-232 Settings

Page 24

Wireless UART Demonstration

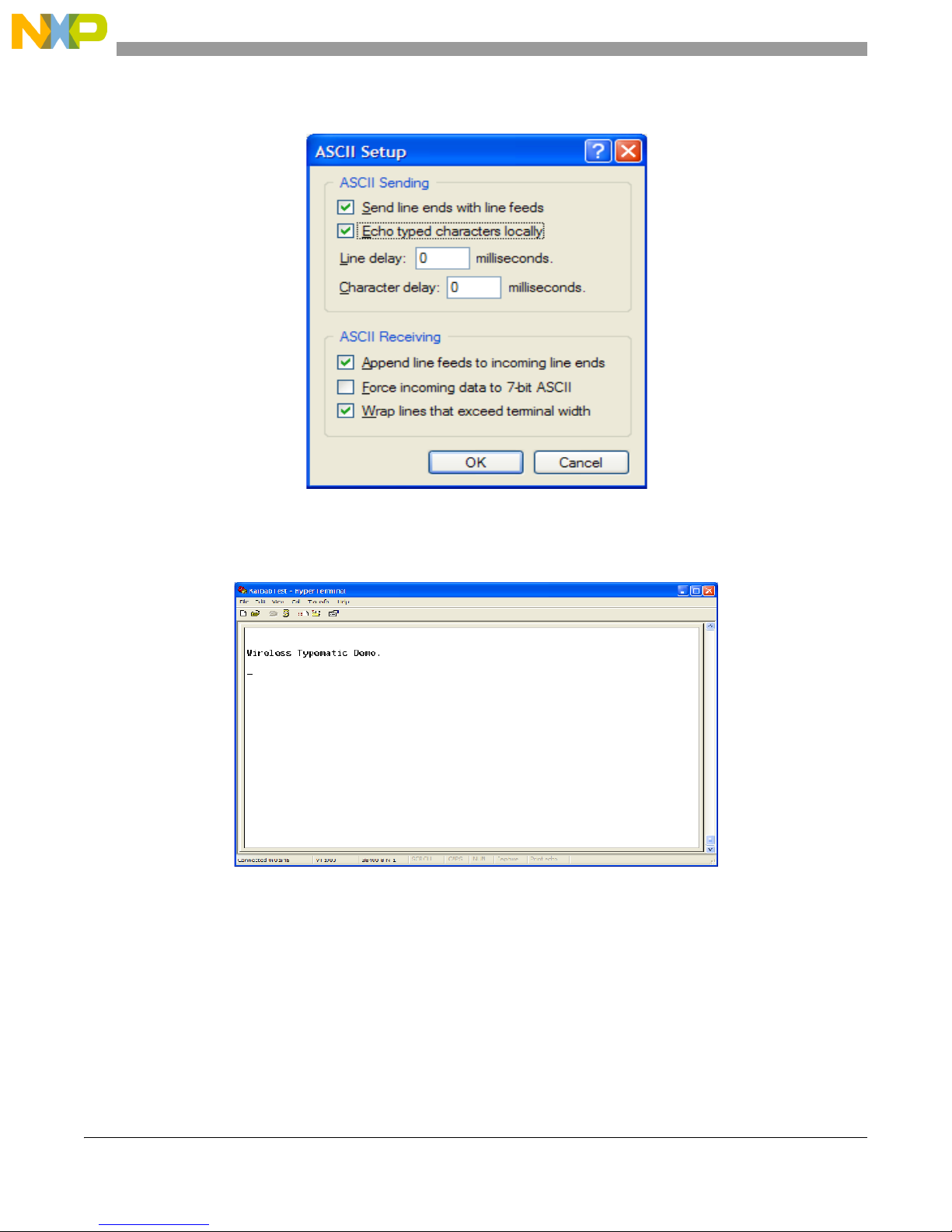

6. In the PC terminal program, set the properties in the optional settings as shown in Figure 2-5.

Figure 2-5. Additional Terminal Program Settings

7. Start the serial communication software and send any characters using the keyboard. The other

board answers with the “Wireless Typematic Demo.“ message as shown in Figure 2-6.

Figure 2-6. Wireless UART Welcome Message

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

2-4 Freescale Semiconductor

Page 25

Wireless UART Demonstration

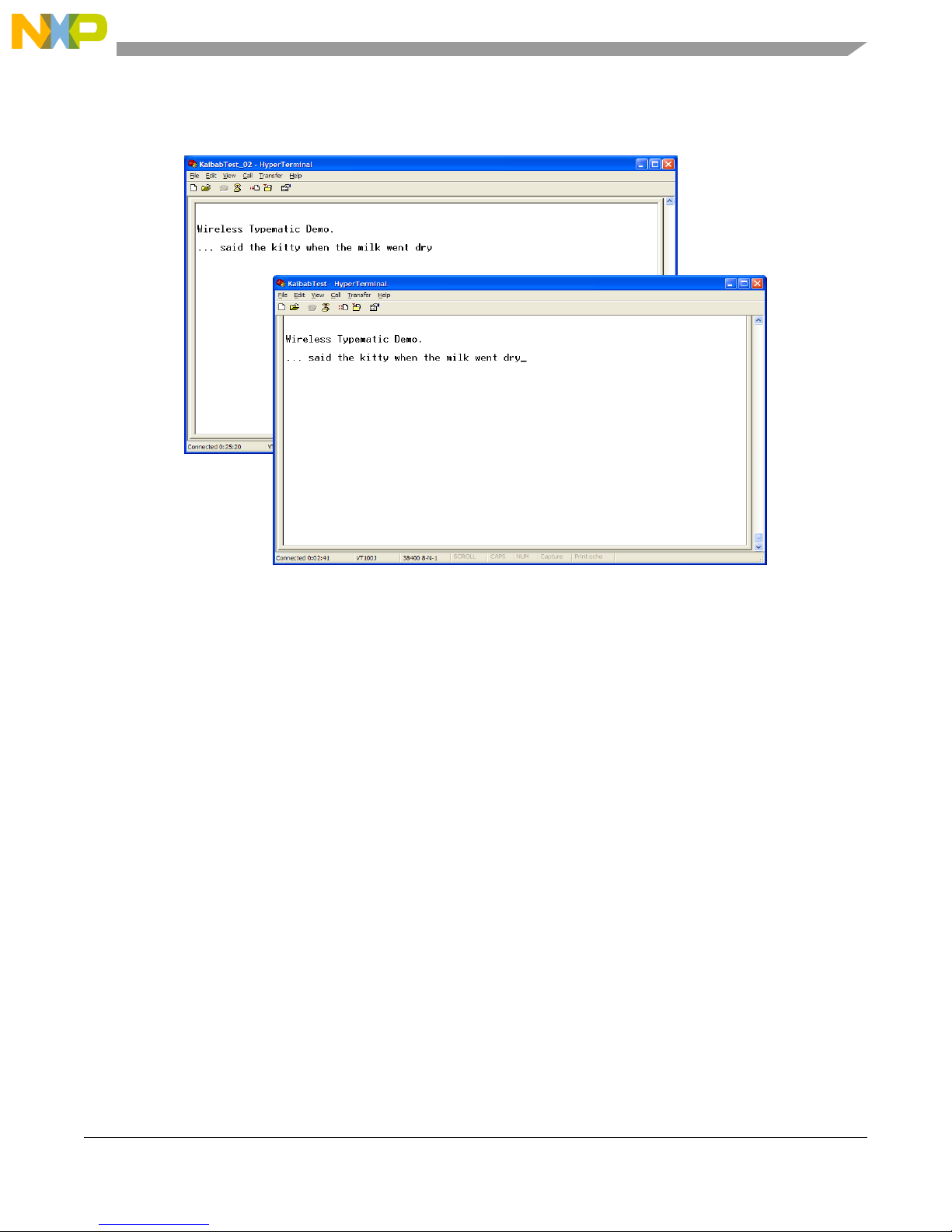

8. Type some characters in the Hyper Terminal Session (Board 1, shown in Figure 2-7) and the typed

message appears on the other PC Hyper Terminal Session (Board 2, also shown in Figure 2-7).

Figure 2-7. Wireless UART Board 1 (Sending) and Board 2 (Receiving)

This is a two-way communication protocol where the boards will retry their packets up to three times if an

acknowledgement is not received. This application highlights a very basic MC1322x SMAC Wireless

UART implementation and as already stated, because it is a basic demonstration application, it is not

intended for large file transfers.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 2-5

Page 26

Wireless UART Demonstration

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

2-6 Freescale Semiconductor

Page 27

Chapter 3

Connectivity Test

The connectivity test evaluates the basic connectivity between two transceivers. A transmitter and a

receiver application are required. The connectivity test supports the following functionality:

• Configure the transceiver in a specific test mode in order to test the transceiver RF performance.

These test mode are:

— Modulated Transmission

— Unmodulated Transmission

— Pulse PRBS Transmission

—IDLE

• Measure the percentage of packet losses over a certain channel as well as the Link Quality Indicator

of each packet received.

• Indicate the range of a signal using the Link Quality Indicator.

In both modes parameters such as the channel number and power level can be modified. This allows users

to execute all tests in every channel using different power values.

The application includes a reference oscillator frequency output at a pin useful for frequency measurement

and adjustment when required.

Two possible interfaces are implemented to use this application: a manual interface through push buttons

or menus for a serial interface. Only one interface can be selected, both interfaces can not been working at

the same time. The interface type is selected when creating the project with the Freescale BeeKit.

For manual interface, the function of each button is as follows:

• SW1: Selects the application mode. (Channel Change, Power Adjust, Test to perform, etc.) see

Figure 3-1.

• SW2: Increases a value.

— For TX the possible options are: IDLE (0), PSRB (1), PER (2), Range Test TX (3), Continuous

Modulated (4) and Continuous Unmodulated (5).

— For RX mode the possible options are: IDLE (0), Continuous reception (1), PER(2) and Range

Test RX (3).

— The values are momentarily shown at the LEDs then LEDs show current application mode.

• SW3: To decrease the value.

• SW4: To start the test (used only at PER test)

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 3-1

Page 28

Connectivity Test

Press SW1

Channel

Test

Bulk Capacitor

Fi ne Tune

Press SW1

Initial State

Reset

Power

Press SW1

Press SW1

Press SW1

Coarse Tun e

Press SW1

Channel

Test

Bulk Capacitor

Fi ne Tune

Press SW1

Initial State

Reset

Power

Press SW1

Press SW1

Press SW1

Coarse Tun e

Figure 3-1. Selecting the Application Mode

The functionality of the application could vary according with the selected board. Boards with the serial

port and push buttons support both interfaces, however for boards without serial port or without push

buttons only one interface is possible.

The following sections describe using the serial interface.

3.1 Loading the Connectivity Application

Prior to loading the Connectivity application, the Connectivity Test application must be generated using

BeeKit using the steps shown in Chapter 1, “Generating an SMAC Application and Port Configuration”:

1. Open the [Solution Name].eww file as shown in Figure 3-2.

2. Select Connectivity Test and load this application into two boards as shown in Section 1.1,

“Loading Applications Into a Board Using the JTAG J-Link ARM Debugger”.

Figure 3-2. My Solution EWW File Location

3-2 Freescale Semiconductor

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Page 29

Connectivity Test

3.2 UART/USB Virtual Com Port Setup

This section describes how to set up the UART/USB virtual Com port for the Connectivity application.

Figure 3-3 shows the default SMAC RS-232 settings.

Figure 3-3. Default SMAC RS-232 Setting

1. Use a PC terminal program and set the correct baud rate, data bits, parity, COM port, and flow

control as shown in .

2. In the PC terminal program, set the properties in the optional settings as shown in Figure 3-4.

Figure 3-4. Additional Terminal Program Settings

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 3-3

Page 30

Connectivity Test

3. Connect the Connectivity Test radio to a USB cable. The USB driver is required. Do not use a USB

hub. This driver can be found in the following directory:

<INSTALL DIR>\Freescale\Drivers

The BeeKit CD image is available from the Freescale ZigBee web site at

www.freescale.com/zigbee.

4. See Section 1.3, “UART/USB Virtual COM Port Setup” for information about how to set up a

virtual COM port for this application.

3.3 Starting the Connectivity Test

To start the connectivity test, perform the following tasks:

1. Configure the Com Port as shown in Section 3.2, “UART/USB Virtual Com Port Setup”.

2. Connect each board to a USB cable and a USB port (one PC for each board) and ensure it is enabled

as shown in Section 3.2, “UART/USB Virtual Com Port Setup”.

3. Reset both boards.

The terminal appears as shown in Figure 3-5.

1. Press any key and the following text appears.

_______________________________________

| |

| Connectivity Test Interface |

|______________________________________|

1 - CHANGE CHANNEL

2 - ADJUST OUTPUT POWER

3 - SELECT TEST MODE

4 - ADJUST CLOCK SETTINGS

Note: Case sensitive.

Please select an option:

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

3-4 Freescale Semiconductor

Figure 3-5. Starting the Connectivity Test

Page 31

Connectivity Test

2. Press the appropriate key to perform the associated task.

Users can set the desired channel or power through this menu. RX and TX mode must be operating on the

same channel.

When the “SELECT TEST MODE” (Option 3) is selected, users are routed to a menu to select the

operating mode in which the board is going to work (RX or TX) , this menu option is displayed as shown

in

Figure 3-6.

Figure 3-6. TX / RX Menu

After setting up the mode in which the board is going to work, the menu appears as shown in Figure 3-7.

The Connectivity test options are described in detail in Section 3.4, “Connectivity Test Applications”.

Figure 3-7. Test Mode Menu (Receive on Left, Transmit on Right)

3.4 Connectivity Test Applications

The Connectivity Test application combines the Test Mode application, Packet Error Rate (PER) tests, and

Range Test applications. The following sections describe each of these tests.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 3-5

Page 32

Connectivity Test

3.4.1 Test Mode Application

The Test Mode application allows users to test the RF performance of the transceiver for basic transmitter

and receiver tests. The test mode application is a collection of test modes consisting of the following tests:

• Idle

• Transmission 9th Order Binary Polynomial (PRBS9)

• Reception

• Link Quality Indication

• Transmission with modulation

• Transmission without modulation

3.4.1.1 Selecting the Transmit Mode

Figure 3-8 shows the Transmit Test Mode option that allows users to display the current transmit test mode

and all the possible tests. To select a test mode, press the appropriate key (S, M, U or P).

To test the receiver, the TX board must continuously transmit a packet on the same channel that the RX

application is running. The message received while in receive mode is displayed in the Hyper Terminal

window as shown in Figure 3-9. In this case, the TX board was transmitting the pulse pseudo random

binary sequence.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

3-6 Freescale Semiconductor

Figure 3-8. Transmission Test Mode Menu

Page 33

Connectivity Test

Figure 3-9. Receive Test Mode

3.4.2 Spectrum Analyzer Captures

The measurements shown in this section are example illustrations of the Test Modes and were captured

from a MC1322x-SRB using the F-antenna. These measurements are radiated measurement and not

conducted measurements.

3.4.2.1 Idle Mode

The Idle Mode captures the noise floor as shown in Figure 3-10.

Figure 3-10. Idle Mode Capture

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 3-7

Page 34

Connectivity Test

3.4.2.2 PRBS9Transmit Mode

The PRBS9 Transmit Mode captures the 9th Order Binary Polynomial as shown in Figure 3-11.

Figure 3-11. PRBS9 TX Mode Capture

3.4.2.3 Reception Mode

Figure 3-12 shows the Reception Test Mode. Because the radio is in receive mode, there is little or no

energy captured in the selected channel band.

Figure 3-12. Reception Mode Capture

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

3-8 Freescale Semiconductor

Page 35

3.4.2.4 Transmit with Modulation

Figure 3-13 shows transmitting with modulation.

Connectivity Test

Figure 3-13. TX with modulation Mode Capture

3.4.2.5 Transmit without Modulation (CW Mode)

Figure 3-14 shows Continuous Wave (CW) Mode.

Figure 3-14. TX without modulation Mode Capture

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 3-9

Page 36

Connectivity Test

3.5 Packet Error Rate (PER) Test

The Packet Error Rate (PER) test is a unidirectional test that sends a number of packets from a transmitter

to a receiver all on a single channel. The packet length is 18 bytes of data with 2 bytes of SMAC header

for a total of 20 bytes of payload. The results of the packets received by the receiver can be monitored in

two ways:

• Using a PC and a USB connection

• In a standalone mode by reading the count on the LEDs on the board

This test allows for PER testing using a PC.

3.5.1 Starting the PER Test

Ensure that both the Connectivity Test in TX mode board and the Connectivity Test in RX mode board are

on the desired channel. The PER-TX board and the PER-RX board are asynchronous to each other which

means that the PER-TX board does not know when the PER-RX board is on. Users must place the PER-RX

board into Listen Mode prior to setting the PER-TX board into Transmit Packet Mode. If this is done out

of order, the reported packet error rate may be incorrect.

Select Packet Error Rate option on both boards, the Connectivity Test TX and Connectivity Test RX

boards, and follow the instructions at the menus see Figure 3-15 for TX and for RX

Figure 3-15. Selection Packet Error Rate Test

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

3-10 Freescale Semiconductor

Page 37

Figure 3-16. Reception Mode

Connectivity Test

The PER-TX board setup follows a procedure similar to the PER-RX board setup. Place the PER-TX board

on the same channel as the PER-RX going through the Connectivity Test Menus. This ensures that the

PER-TX board is on the same channel as the PER-RX board. Set PER-TX board to place the application

into TX mode. The PER-TX application turns on LEDs 1 through 4 in order to show that the PER-TX

board is in Packet Transmit Mode and then it begins to transmit packets.

3.5.2 PER operation

Since the PER-TX board and the PER-RX board are on the same channel and the PER-RX board started

to listen before the PER-TX board sent any packets, the PER-RX board will toggle LED1 when a packet

is being received. Then the PER-TX board blinks LED1 on every packet that is transmitted. If both boards

are blinking, then both boards are on the same channel. If only the PER-TX board is toggling LED1, then

either the PER-RX board is not in Listen Mode or it is listening to the wrong channel. If this occurs, reset

both boards and try the procedure again without switching channels. If a packet is received, the radio

echoes data to the PC through the UART connection as shown in

• N represents the number of packets received

• L is the length of the packet

• LQI is the Link Quality Indicator (measured in dBm)

• CRC indicates if the Cyclical Redundancy Check (CRC) is good

• Data is the hex formatted payload

Figure 3-17.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 3-11

Page 38

Connectivity Test

Figure 3-17. The UART output during PER test

When the PER-TX board is done sending 1000 packets, the PER-TX board sends packets with the payload

“DONEDONE”. If the PER-RX board receives the “DONEDONE” packet, the application echoes the

total number of good packets received. The measured PER is echoed to the terminal in a 999/1000 format.

When using manual interface the PER value is echoed to the LEDs on the PER-RX board. For example,

if the measured packet received was 983/1000 then at the completion of the test, the value 1001b (9d),

1000b (8d), 0011b (3d) will blink. This example allows PER to be measured without the need for a PC.

3.6 Range Test

The range test uses the LQI in order to monitor the variation of distance between the transmitter and the

receiver in a normal transmission. This test uses two devices one configured as transmitter and the other

as receiver.

In the range test, the transmitter sends a message and waits for an acknowledge packet, then the receptor

calculates the LQI of the received packet and sent it to the transmitter into the acknowledge packet. In both

devices (transmitter and receiver) the LQI value is indicated through LEDs in the manual interface, when

serial interface is used the LQI value is sent to the serial terminal. This process is repeated until the user

finishes the test. See Figure 3-18

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

3-12 Freescale Semiconductor

Page 39

Figure 3-18. Range Test Stop and Start

Connectivity Test

3.7 Crystal Adjustment

The Connectivity Test application includes a utility to help adjust the onboard trim capacitance for the

MC1322x 24 MHz crystal reference oscillator. The trim capacitance can be changed to center the oscillator

frequency on the target 24 MHz, thus minimizing the error frequency (in ppm).

NOTE

For more information on tuning the oscillator, see the MC1322x Reference

Manual.

The reference frequency cannot be monitored directly via a GPIO pin, so as a substitute, the application

provides 2 MHz frequency derived from the reference oscillator and makes it available on the TMR1

signal pin.

To use this utility the “ADJUST CLOCK SETTINGS” option must be selected from the terminal main

menu.

When the “ADJUST CLOCK SETTINGS“ option is selected, the terminal displays the following menu.

_____________________

| |

| Clock Settings Menu |

|_____________________|

1 - Set Bulk 4 pF CAP.

2 - Adjust COARSE TUNE

3 - Adjust FINE TUNE

p - Previous Menu

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 3-13

Page 40

Connectivity Test

Please select an option:

There are only two options for the “Set Bulk 4 pF CAP” (bulk capacitor) option:

• Enable the 4 pF capacitor

• Disable the 4 pF capacitor

For the “Adjust COARSE TUNE” and the “Adjust FINE TUNE” options:

• Either the coarse tune or the fine tune is adjusted respectively.

• The user must enter a value for either parameter.

— The possible values are 0x00 to 0x0F for the coarse tune parameter

— The possible values are0x00 to 0x1F for the fine tune parameter.

— The application verifies that the value entered is between these ranges; if not the value is

rejected and the parameter value is not updated.

The crystal frequency adjustment is performed using the provided 2 MHz TMR1 reference signal. Use a

frequency counter to measure ppm. The trim should be adjusted typically to less than +/-5 to +/-10 ppm.

NOTE

The TMR1 pin on the Freescale Network Node Evaluation Board is also

used by the LCD control. The LCD cannot be used while the crystal

adjustment test is being utilized.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

3-14 Freescale Semiconductor

Page 41

Chapter 4

Accelerometer Demonstration

The Accelerometer Demonstration application shows various uses of the Freescale X, Y, and Z axes

accelerometers.

NOTE

When using the 13226-SRB, the Accelerometer Demonstration application

is not supported because the 13226-SRB does not have an accelerometer. If

users select and export this application in BeeKit, the results will not be

accurate.

4.1 Loading the Accelerometer Application

1. Flash the Accelerometer Demonstration into two boards. One board must be either a MC1322X

Sensor Node (also compatible with 13192-SARD or MC13213-SRB) to provide the X, Y, and Z

axes accelerometer data and the other board must have an available UART and be able to connect

to a PC. This example uses two MC1322x Sensor Node boards.

2. If users need to run the Accelerometer on different targets, those projects must be generated by

BeeKit as described in Chapter 1, “Generating an SMAC Application and Port Configuration”.

3. Download the appropriate target image by following the procedure in Section 1.1, “Loading

Applications Into a Board Using the JTAG J-Link ARM Debugger”.

4.2 Board Setup

To setup both boards for operation (transmit and receive), perform the steps shown in this section.

4.3 Board One Setup (PC_Radio Board)

1. Connect a Sensor Node Board to the PC using the USB cable included in the kit. (Do not use a hub.)

2. Power on the board by setting the Power Switch to the ON position.

3. Press the Reset Button once. The LEDs are off, but the PC_Radio application is running and in

receive mode.

4.4 Board Two Setup (Accelerometer Board)

1. Connect 9 VDC power to DC power connector with the 9 VDC wall transformer included in the

kit. Power on the board by setting the Power Switch (S100) to the ON position. Another board

power option is to use the batteries which provides the advantage of true wireless operation (no

cables) and allows users to easily move and manipulate the SRB.

2. Press the Reset Button once.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 4-1

Page 42

Accelerometer Demonstration

3. Press button SW1 once and LED3 will momentarily flash to indicate Application Two is running

(Accelerometer Mode).

4. The Accelerometer application sends a ping packet to the PC_Radio every two seconds. This is

indicated on the Accelerometer Board by a blinking LED2.

5. The Accelerometer application detects when the Accelerometer Board is moved and quickly

toggles LED1, then sends a packet to the PC_Radio Board with an updated reading.

4.5 PC Setup

1. If the Evaluation Kit tools are already installed, then users can run the Triax software by navigating

to the link using the Start menu.

2. From Windows, select Start->Programs->Freescale BeeKit->Triax.

a) If the Triax application does not exist, go to Step 3 to install it.

b) If the application is in the Start Menu, go to Step 4.

3. To run only the Triax application, insert the CD supplied with the kit into the PC CD-ROM drive.

4. Run the Triax.exe file from the selected install location on the PC hard drive.

5. The Triax application is set up to run on COM ports 1-10. To check which COM port is being used

by the USB, perform the following tasks:

a) Open the System Properties window by clicking on Start->Settings->Control Panel->System.

b) Select the Hardware tab, and click the Device Manager button. The Device Manager window

appears as shown in Figure 4-1.

c) Scroll to the “Ports” label and expand the tree by clicking the “+” sign to show the COM ports

in the system.

d) The COM Port selected by the system is titled USB Serial Port(COM24) as shown in Figure 4-1.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

4-2 Freescale Semiconductor

Page 43

Figure 4-1. COM Port Determination in Device Manager

Accelerometer Demonstration

6. If the COM port chosen for Freescale Zigbee/802.15.4 MAC COM Device is not a port within Ports

1-10, then perform the following tasks:

a) Double click on Freescale Zigbee/802.15.4 MAC COM Device in the Device Manager window

and the Properties window will appear.

b) Select the Port Settings tab and then click the Advanced button.

c) Go to the Com Port Number drop down menu and select a COM port between 1-10 that is not

in use.

4.6 Verifying Operation

1. Check for the ping packet. The Accelerometer application sends a ping packet to the PC_Radio

every two (2) seconds as indicated by LED2. The Accelerometer Board quickly blinks LED2

indicating that the ping packet is sent. The PC_Radio receives the ping and toggles LED2 upon

reception. Once connectivity between the PC_Radio and the Accelerometer Board is verified, go

to Step 2.

2. To check if the Accelerometer Board is working, move the Accelerometer Board. LED1 blinks,

which indicates that the Accelerometer Board has detected movement.

3. With the default application, data that represents movement of the Accelerometer Board is sent to

the PC_Radio. When the PC_Radio receives this data, LED2 toggles.

4. Select the Raw Data applet from the Triax application. The Raw Data applet shows the X, Y, and

Z axes A/D values as reported by the Accelerometer Board. When the board is laying flat, the raw

values should read approximately 0g for both the X and Y axes. However, the Z axis should read

approximately 1g. As shown in Figure 4-2, when the Accelerometer Board is moved, the values of

the X, Y, and Z axes are updated on the Raw Data applet.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 4-3

Page 44

Accelerometer Demonstration

Figure 4-2. Raw Data Demonstration

NOTE

To improve accuracy of the accelerometer readings, refer to Section 4.7,

“Setting Up the Calibration Application”.

The Triax main window appears as shown in Figure 4-3.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

4-4 Freescale Semiconductor

Figure 4-3. Triax Main Window

Page 45

Accelerometer Demonstration

When the accelerometer is moved, the Accelerometer Board sends data to the PC_Radio to update its data.

Data is only sent when it changes within a small tolerance.

The receiver receives these packets and updates its cached value of the accelerometer data. The PC

periodically sends a command string through the USB to the PC_Radio that requests the accelerometer

data. This data is interpreted by the Triax software to enable several applications and demonstrations.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 4-5

Page 46

Accelerometer Demonstration

4.7 Setting Up the Calibration Application

In order to verify and visualize the calibration procedure, the Triax.exe PC GUI must be running, but it is

not required.

1. Press the Reset button on the PC_Radio Board once. (Out of reset, the PC application is running.)

2. Press the Reset button on the Accelerometer Board once.

3. Place the Accelerometer Board on a flat surface. (component side up)

4. Press SW1 on the Accelerometer Board to advance the application to the Accelerometer Mode

(Application Two). LED3 momentarily lights to indicate that Application Two is running. The

Accelerometer Board sends out a ping packet every two (2) seconds and updates the data on the

XYZ Demo PC application each time the board is moved.

5. If the data points for the X, Y, and Z axes shown on the PC GUI are not near the origin of the graph,

then continue to Step 6.

6. Press SW4 on the Accelerometer Board once until all LEDs are lit. This shows that the calibration

is being performed.

7. Verify that the Accelerometer Board is calibrated by viewing the X, Y, and Z axes on the PC GUI.

The squares on the display should be approximately at axis point 0,0. If the calibration is still

incorrect, repeat the calibration process until the data points are nominally at axis point 0,0.

8. To quit, exit the application in the GUI and press reset on both boards. Press SW1 on the

Accelerometer Board once to return to main application functionality.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

4-6 Freescale Semiconductor

Page 47

Chapter 5

Low Power Bell Demonstration

The Low Power Bell Demonstration consists of a transmitter (TX) and receiver (RX). The Low Power Bell

TX application serves as the bell switch and demonstrates low power modes and how to implement them.

The Low Power Bell RX application serves as the bell and makes a sound when it receives a new packet

from the Low Power Bell TX application.

Freescale recommends using the 1322x-LPN Low Power Node to best demonstrate low power

capabilities.

5.1 Generating the Project From BeeKit

To generate the project from BeeKit.

1. Open BeeKit (Start->Programs->Freescale BeeKit->Freescale BeeKit).

2. In BeeKit, select the MC1322x SMAC codebase (File menu -> Select Codebase...)

3. Click on File -> New Project and choose the Low Power Bell TX template.

4. Follow the steps as displayed in the New Project wizard.

5. Add the Low Power Bell RX project to the current solution.

6. Configure the properties as needed.

7. Be sure to configure the Low Power Bell TX and Low Power Bell RX applications both on the

same channel.

8. Validate the solution.

9. Export the solution.

For further details about how to use BeeKit, see the BeeKit Wireless Connectivity Toolkit User’s Guide

(BKWCTKUG).

5.2 Open, Compile and Execute the Low Power Bell Application

1. Using the IAR Embedded Workbench, open the Generic Application work space (My

Solution.eww) as shown in Figure 5-1.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 5-1

Page 48

Low Power Bell Demonstration

Figure 5-1. Opening Generic Application Space

2. Chose the “Low Power Bell TX” tab.

3. Select “Release” in the Workspace window.

4. Click on Project -> Rebuild All.

The folders Release, Debug, and the settings are now created in the project structure as shown in

Figure 5-2.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

5-2 Freescale Semiconductor

Figure 5-2. Release, Debug, and Settings

Page 49

Low Power Bell Demonstration

The Low Power Bell Tx.bin file is located at the following directory location:

[Project Directory]\Release\Exe\

5. Use the JTAG interface to load the Low Power Bell TX application on the board being used as the

Low Power Bell TX. Connect the JTAG interface to the board, then click the Debug button at the

IAR Embedded Workbench IDE.

6. Choose the “Low Power Bell RX” tab.

7. Repeat Steps 3 and 4.

The Low Power Bell RX.bin file is located at the following directory location:

[Project Directory]\Release\Exe\

8. Use the JTAG interface to load the Low Power Bell RX application on the board being used as the

Low Power Bell RX. Click the IAR Debug button to download the application to the board.

9. Reset both boards.

Pressing SW1 on the Low Power TX board sounds the buzzer on the Low Power Bell RX board.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 5-3

Page 50

Low Power Bell Demonstration

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

5-4 Freescale Semiconductor

Page 51

Chapter 6

Generic Application Demonstration

The SMAC codebase includes a Generic Application Demonstration that can be used as template to

develop proprietary applications. This application shows all the initialization required to start the radio

and the commonly used peripherals such as UART and KBIs.

See Section 1.3, “UART/USB Virtual COM Port Setup” for information about how to set up a virtual COM

port for this application.

6.1 Generating a Project From BeeKit

Once the UART/USB virtual ports have been configured, generate the project from BeeKit.

1. Open BeeKit (Start->Programs->Freescale BeeKit->Freescale BeeKit).

2. In BeeKit, select the MC1322x SMAC codebase (File menu -> Select Codebase...)

3. Click on File -> New Project and choose the Generic Application template.

4. Follow the steps as displayed in the New Project wizard.

5. Configure the properties as needed. Choose the manual interface for the KBI.

6. Validate the solution

7. Export the solution.

For further details about how to use BeeKit, see the BeeKit Wireless Connectivity Toolkit User’s Guide

(BKWCTKUG).

6.2 Open, Compile and Execute the Generic Application

1. Using the IAR Embedded Workbench, open the Generic Application work space (My

Solution.eww

) as shown in Figure 6-1.

Figure 6-1. Opening Generic Application Space

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 6-1

Page 52

Generic Application Demonstration

2. Select “Release” in the Workspace window.

3. Click on Project -> Rebuild All.

The folders Release, Debug, and the settings are now created in the project structure as shown in

Figure 6-2.

Figure 6-2. Release, Debug, and Settings

The WirelessUART.bin file is placed at the following directory location:

[Project Directory]\Release\Exe\

4. Load the Generic Application file to a board using the JTAG interface. Connect the JTAG

interface to the board, then click the Debug button at the IAR Embedded Workbench IDE.

5. Use a PC terminal communications program, such as Hyper Terminal, and set the correct baud rate,

data bits, parity, COM port, and flow control. Figure 6-3 shows the default MC1322x SMAC

RS232 settings.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

6-2 Freescale Semiconductor

Figure 6-3. Default SMAC RS-232 Settings

Page 53

Generic Application Demonstration

6. In the PC terminal program, set the properties in the optional settings as shown in Figure 6-4.

Figure 6-4. Additional Terminal Program Settings

7. Start the serial communication software ant reset the board. Text is displayed in the Hyper Terminal

window as shown in the Figure 6-5,

At this point users have an empty project to start their own application.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 6-3

Figure 6-5. Generic Application Message

Page 54

Generic Application Demonstration

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

6-4 Freescale Semiconductor

Page 55

Chapter 7

Simple ZigBee Test Client (SZTC) Demonstration

The Simple ZigBee Test Client (SZTC) application allows users to test the SMAC primitives by sending

special data frames through the Serial/USB port. The SZTC application requires two boards and the

appropriate Python scripts to communicate with the boards or a serial port packet generator.

Prior to loading the SZTC application, the application must be generated using BeeKit as described in the

BeeKit Wireless Connectivity Toolkit User’s Guide.

See Section 1.3, “UART/USB Virtual COM Port Setup” for information about how to set up a virtual COM

port for this application.

7.1 Generating a Project From BeeKit

Once the UART/USB virtual ports have been configured proceed to generate the project from BeeKit.

1. Open BeeKit (Start->Programs->Freescale BeeKit->Freescale BeeKit).

2. In BeeKit, select the MC1322x SMAC codebase (File menu -> Select Codebase...)

3. Click on File -> New Project and choose the Simple ZTC template.

4. Follow the steps as displayed in the New Project wizard.

5. Configure the properties as needed.

6. Validate the solution

7. Export the solution.

For further details about how to use BeeKit, see the BeeKit Wireless Connectivity Toolkit User’s Guide

(BKWCTKUG).

7.2 Testing the SZTC with the WirelessUART

1. Download the SZTC application to the board that will be used as the tester.

2. Download the WirelessUART application to a board that will be used as the subject of the test.

3. Open a HyperTerminal session (or another compatible communications program) and configure it

for serial communications using the following parameters:

—8 Bits

—No Parity

— 1 Stop

— 38400 Baud

— No Flow control

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 7-1

Page 56

Simple ZigBee Test Client (SZTC) Demonstration

4. Connect the board that is running the WirelessUART application to the serial port of the PC and

press that board’s reset button. A message appears on the PC display as shown in Figure 7-1.

Figure 7-1. Wireless UART Application

5. Open the Freescale Test Tool located in the following directory:

Programs/Freescale BeeKit/Test Tool

6. As shown in Figure 7-2, from the Test Tool window, select Tools -> Communication Settings.

Figure 7-2. Test Tool Communication Settings

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

7-2 Freescale Semiconductor

Page 57

Simple ZigBee Test Client (SZTC) Demonstration

7. Create a new serial connection for the board running the SZTC application by clicking the “Add

Internal“ button in the “List Of Devices” window as shown in Figure 7-3.

Figure 7-3. List of Devices Window

8. Select the appropriate COM port and set the baud rate at 19200 as shown in Figure 7-4.

9. Click the OK button.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 7-3

Figure 7-4. Device Settings

Page 58

Simple ZigBee Test Client (SZTC) Demonstration

10. The List of Devices window appears again as shown in Figure 7-5. Disable all connections except

the SZTC connection that was just created by highlighting the connection to be disabled and

clicking on the Disable button. The disabled connections are should now be grayed out.

Figure 7-5. Disable Unused Devices

11. As shown in Figure 7-6, use the Test Tool main menu to open the Script Server application by

clicking on View -> Script Server. See the Freescale Test Tool User’s Guide for more details about

Test Tool.

Figure 7-6. Test Tool Launch Script Server

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

7-4 Freescale Semiconductor

Page 59

Simple ZigBee Test Client (SZTC) Demonstration

The Script Server window appears as shown in Figure 7-7. See the Freescale Test Tool User’s

Guide for more details about Script Server.

Figure 7-7. Test Tool Adding a Python (py) script

12. Load the Sending Letters To The Wireless Uart.py Python script, which is located in the

following directory:

~\Program Files\Freescale\BeeKit\Test Tool\Scripts\SMAC\Demo Scripts\

13. Click on the Execute button to run the script.

14. On the PC running the Serial Terminal application and is connected to the board running the

WirelessUART application, the expected end results are shown in Figure 7-8. If this is not the end

result, try running the WirelessUART application on the SZTC again.

Figure 7-8. Result at the Wireless UART Application

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 7-5

Page 60

Simple ZigBee Test Client (SZTC) Demonstration

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

7-6 Freescale Semiconductor

Page 61

Chapter 8

Repeater Demonstration

The Repeater application increases the range between two boards or monitors the activity on an SMAC

based communication system. To execute this demonstration application, user need a tool to send and

receive characters over two serial ports in addition to what Freescale supplies.

This chapter provides a simplified example. Currently, the code cannot be used as a generic repeater, this

application implements two modes of repeater and an SMAC sniffer.

Prior to loading the Repeater demonstration application, the application must be generated using BeeKit,

as described in the BeeKit Wireless Connectivity Toolkit User’s Guide.

The MC1322x SMAC Repeater demonstration application is consistent with previous SMAC Repeater

applications (those that run on the MC1319x, MC1320x, and MC1321x boards) but implements a new

SMAC sniffer which is a demonstration on how to monitor SMAC communication.

See Section 1.3, “UART/USB Virtual COM Port Setup” for information about how to set up a virtual COM

port for this application.

8.1 Generating a Project From BeeKit

Once the UART/USB virtual ports have been configured proceed to generate the project from BeeKit.

1. Open BeeKit (Start->Programs->Freescale BeeKit->Freescale BeeKit).

2. In BeeKit, select the MC1322x SMAC codebase (File menu -> Select Codebase...)

3. Click on File -> New Project and choose the Repeater template.

4. Follow the steps as displayed in the New Project wizard.

5. Configure the properties as needed.

6. Validate the solution

7. Export the solution.

Create the project folder with the structure as shown in Figure 8-1.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 8-1

Page 62

Repeater Demonstration

Figure 8-1. BeeKit Created, Wireless UART Directory Structure

For further details about how to use BeeKit, see the BeeKit Wireless Connectivity Toolkit User’s Guide

(BKWCTKUG).

8.2 Open, Compile and Execute the Repeater

1. Using the IAR Embedded Workbench, open the Repeater work space (My Solution.eww) as shown

in Figure 8-2.

Figure 8-2. Opening Repeater Work Space

2. Select “Release” in the Workspace window.

3. Click on Project -> Rebuild All.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

8-2 Freescale Semiconductor

Page 63

Repeater Demonstration

The folders Release, Debug, and the settings are now created in the project structure as shown in

Figure 8-3.

Figure 8-3. Release, Debug, and Settings

The Repeater.bin file is placed at the following directory location:

[Project Directory]\Release\Exe\

4. Load the Repeater file to the board. Click the IAR Debug button to download the application to the

board.

5. Use a PC terminal communications program, such as Hyper Terminal, and set the correct baud rate,

data bits, parity, COM port, and flow control. Figure 8-4 shows the default MC1322x SMAC

RS232 settings.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 8-3

Figure 8-4. Default SMAC RS-232 Settings

Page 64

Repeater Demonstration

6. In the PC terminal program, set the properties in the optional settings as shown in Figure 8-5.

Figure 8-5. Additional Terminal Program Settings

7. Start the serial communication software and reset the board. The start window appears as shown in

Figure 8-6.

Figure 8-6. Repeater Start Window

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

8-4 Freescale Semiconductor

Page 65

Repeater Demonstration

8. Type any key at the serial terminal software and the repeater menu appears as shown in Figure 8-7.

Figure 8-7. Repeater menu and configuration

8.3 Repeater Menu, Configuration and Settings

The Repeater menu displays eight options:

<s> Show Statistics

<0> Reset Statistics

<r> Repeat menu

<m> Switch Repeater mode

<p> Change Power

<d> Change Delay length

<c> Switch Channel

<z> EXECUTE

To select an option, type the character corresponding the desired option on the serial terminal. The options

are case sensitive.

1. Type “s” to show repeater statistics as shown in Figure 8-8.

Figure 8-8. Repeater Statistics

Received The number of frames that have been received.

Retransmitted The number of frames retransmitted.

Bad The number of packets received corrupted.

MC1322x SMAC Demonstration Application User’s Guide, Rev. 1.3

Freescale Semiconductor 8-5

Page 66

Repeater Demonstration

Dropped The number of frames that has been received but not retransmitted. This is used