Page 1

1. Introduction

1.1 About this document

1.2 Intended audience

DRAFT

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

RAFT DRA

D

RAFT

DR

AFT

DRAFT

LPC2917/19

ARM9 microcontroller with CAN and LIN

Rev. 1.01 — 15 November 2007 Preliminary data sheet

This document lists detailed information about the LPC2917/19 device. It focuses on

factual information like pinning, characteristics etc. Short descriptions are used to outline

the concept of the features and functions. More details and background on developing

applications for this device are given in the LPC2917/19 User Manual (see Ref. 1

explicit references are made to the User Manual.

This document is written for engineers evaluating and/or developing systems, hardand/or software for the LPC2917/19. Some basic knowledge of ARM processors and

architecture and ARM968E-S in particular is assumed (see Ref. 2

).

F

T DRAFT DRAFT DRAFT DRA

DRA

). No

DR

AFT

DRAFT

DR

F

T DRAF

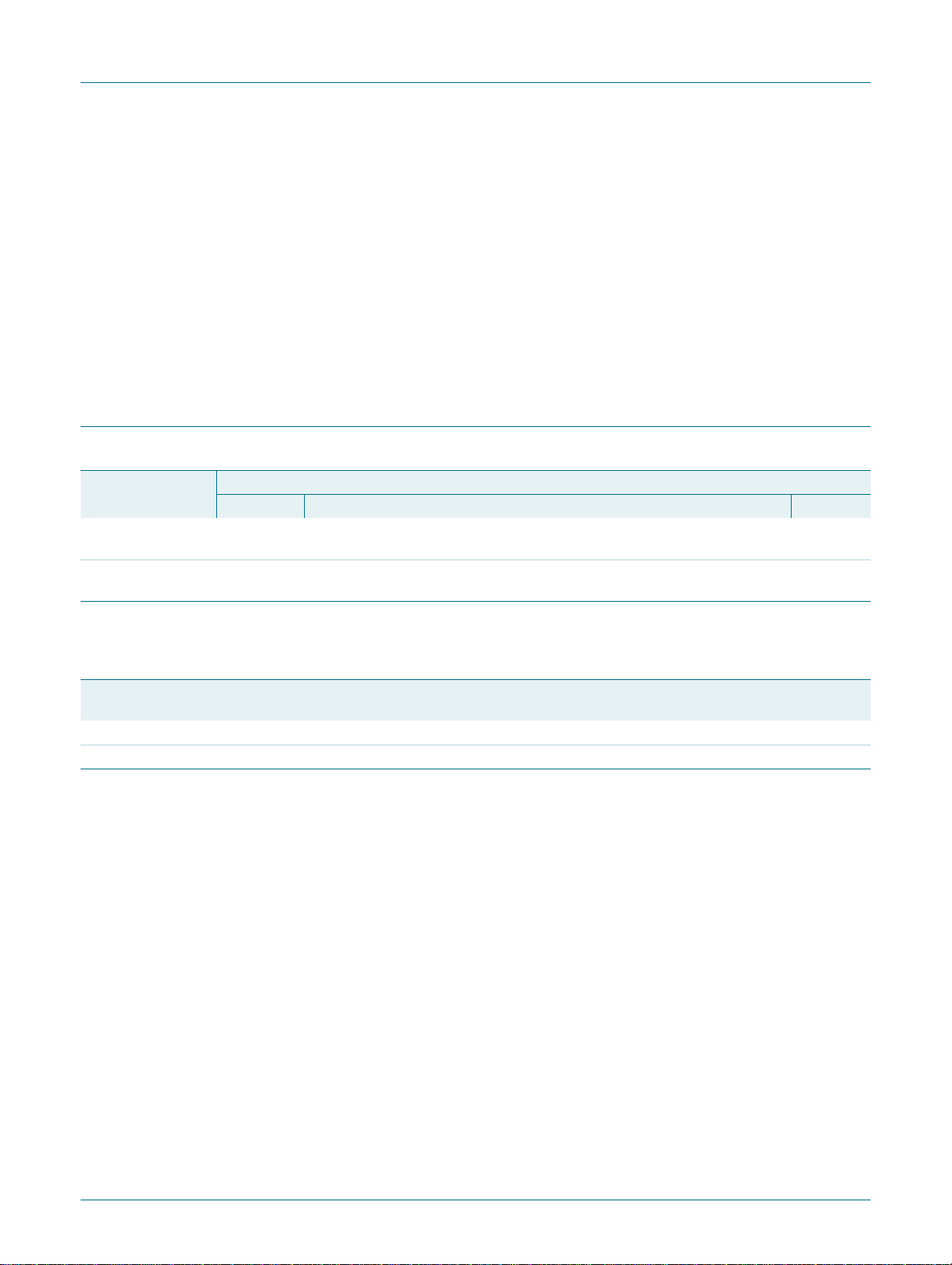

2. General description

2.1 Architectural overview

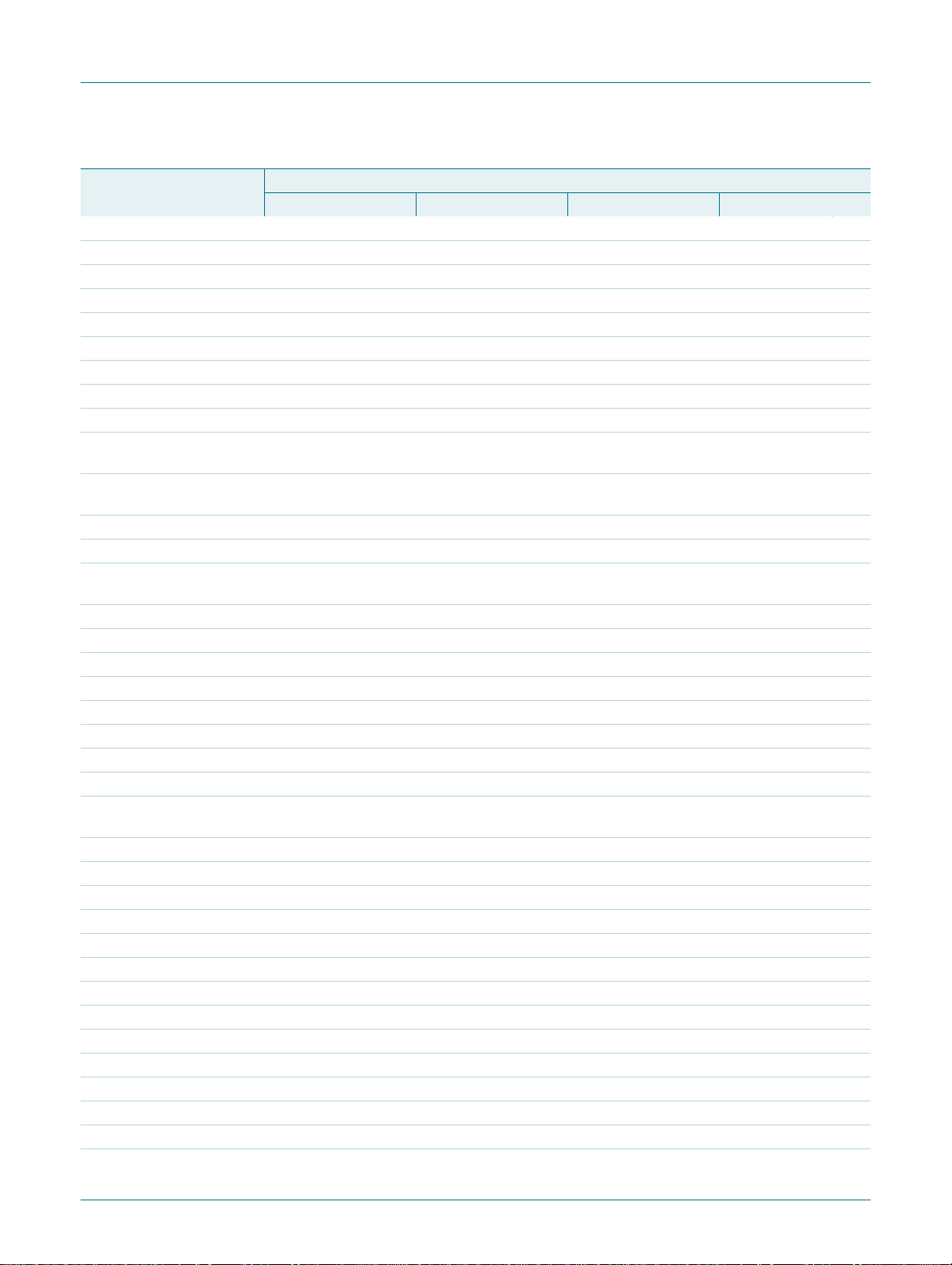

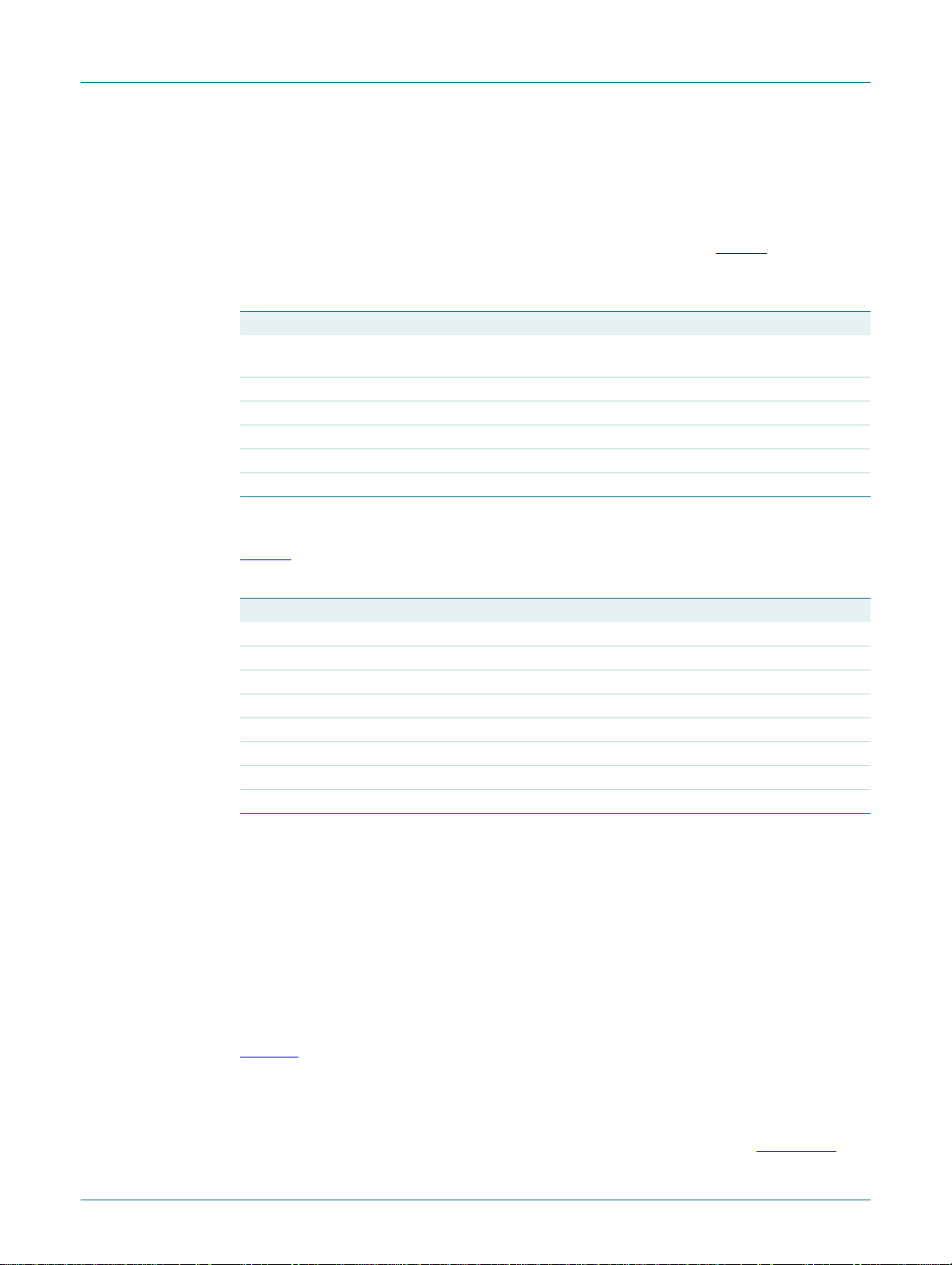

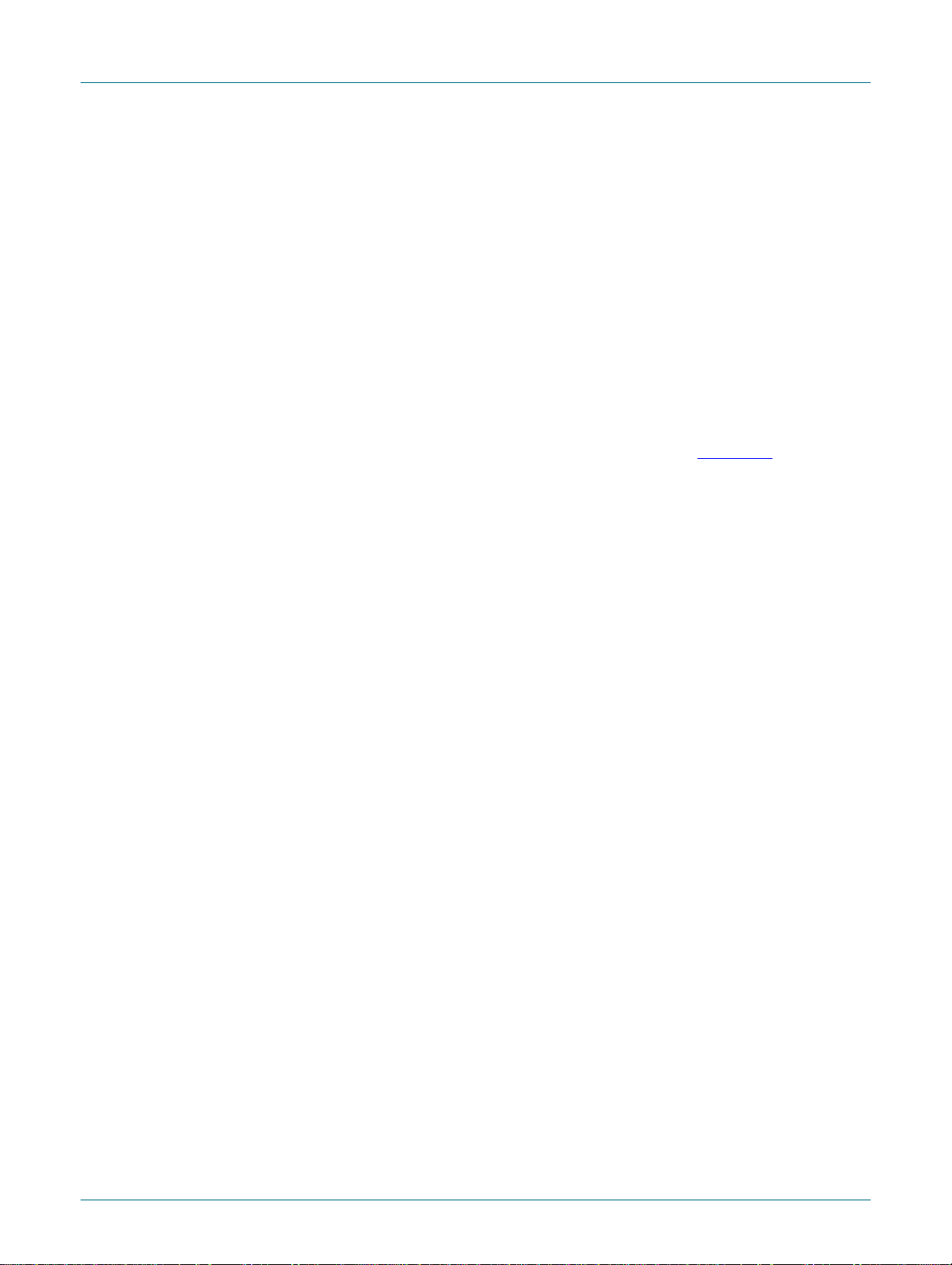

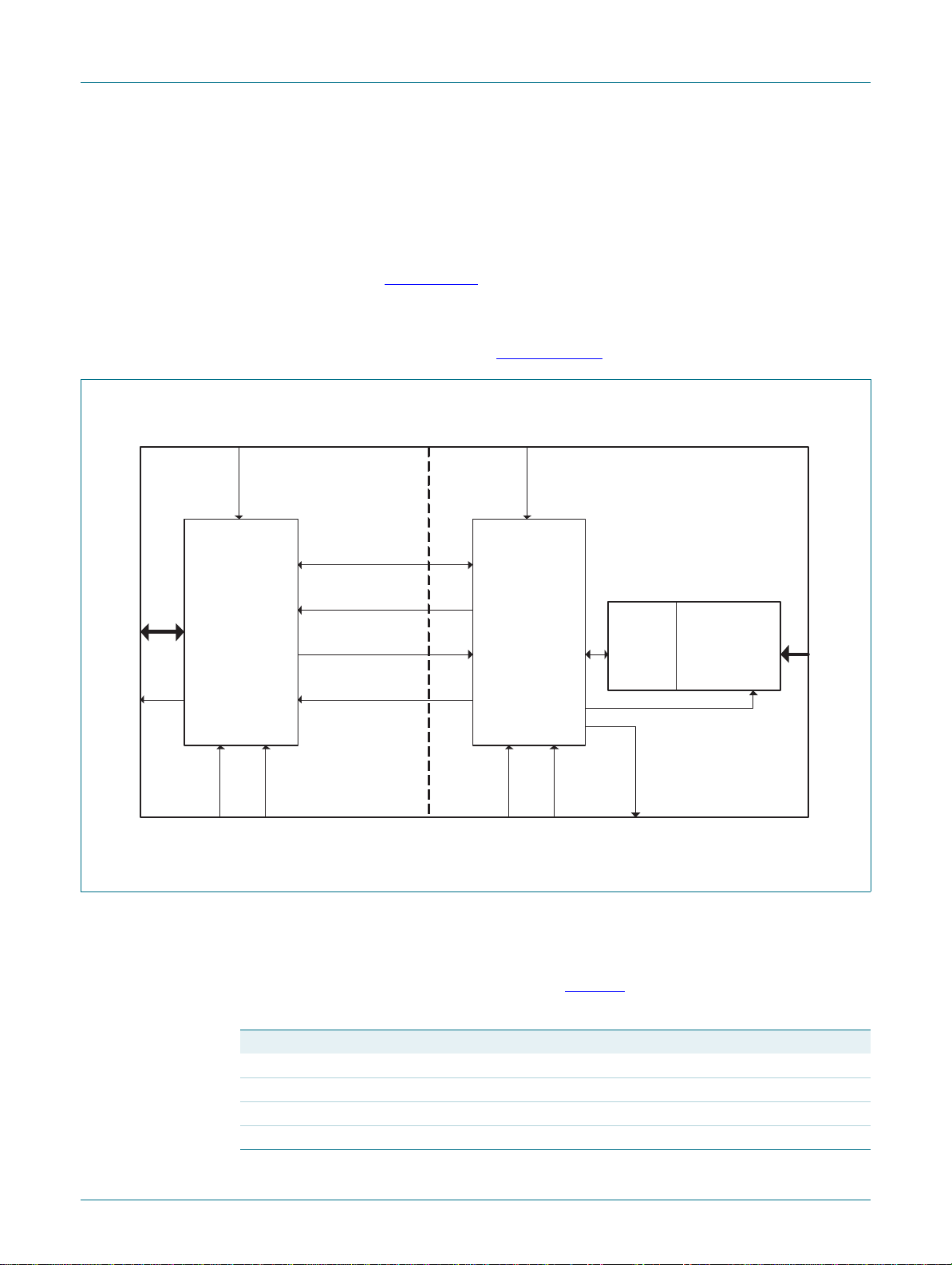

The LPC2917/19 consists of:

• An ARM968E-S processor with real-time emulation support

• An AMBA multi-layer Advanced High-performance Bus (AHB) for interfacing to the

on-chip memory controllers

• Two DTL buses (a universal NXP interface) for interfacing to the interrupt controller

and the Power, Clock and Reset Control cluster (also called subsystem)

• Three VLSI Peripheral Buses (VPB - a compatible superset of ARM's AMBA

advanced peripheral bus) for connection to on-chip peripherals clu stered in

subsystems.

The LPC2917/19 configures the ARM968E-S processor in little-endian byte order. All

peripherals run at their own clock frequency to optimize the total system power

consumption. The AHB2VPB bridge used in the subsystems contains a write-ahead buffer

one transaction deep. This implies that when the ARM968E-S issues a buffered write

action to a register located on the VPB side of the bridge, it continues even though the

actual write may not yet have taken place. Completion of a second write to the same

subsystem will not be executed until the first write is finished.

Page 2

NXP Semiconductors

2.2 ARM968E-S processor

The ARM968E-S is a general purpose 32-bit RISC processor, which offers high

performance and very low power consumption. The ARM architecture is based on

Reduced Instruction Set Computer (RISC) principles, and the instruction set and related

decode mechanism are much simpler than those of micro-programmed Complex

Instruction Set Computers (CISC). This simplicity results in a high instruction throughput

and impressive real-time interrupt respon se from a sm all an d co st- effective contr olle r

core.

Amongst the most compelling features of the ARM968E-S are:

• Separate directly connected instruction and data Tightly Coupled Memory (TCM)

• Write buffers for the AHB and TCM buses

• Enhanced 16 x 32 multiplier capable of single-cycle MAC operations and 16-bit fixed-

DRAFT

ARM9 microcontroller with CAN and LIN

interfaces

point DSP instructions to accelerate signal-processing algorithms and applications.

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DRAFT

DRA

F

DR

AFT

DR

T DRAF

Pipeline techniques are employed so that all part s of the pro cessing and memory systems

can operate continuously. The ARM968E-S is based on the ARMv5TE five-stage pipeline

architecture. Typically, in a three-stage pipeline architecture, while one instruction is being

executed its successor is being decoded and a third instruction is being fetched from

memory. In the five-stage pipeline additional stages are added for memory access and

write-back cycles.

The ARM968E-S processor also employs a unique architectural strategy known as

THUMB, which makes it ideally suited to high-volume applications with memory

restrictions or to applications where code density is an issue.

The key idea behind THUMB is that of a super-reduced instruction set. Essentially, the

ARM968E-S processor has two instruction sets:

• Standard 32-bit ARMv5TE set

• 16-bit THUMB set

The THUMB set's 16-bit instruction length allows it to approach twice the density of

standard ARM code while retaining most of the ARM's performance advantage over a

traditional 16-bit controller using 16-bit registers. This is possible because THUMB code

operates on the same 32-bit register set as ARM code.

THUMB code can provide up to 65 % of the code size of ARM, and 160 % of the

performance of an equivalent ARM controller connected to a 16-bit memory system.

The ARM968E-S processor is described in detail in the ARM968E-S data sheet Ref. 2

.

2.3 On-chip flash memory system

The LPC2917/19 includes a 512 kB or 768 kB flash memory system. This memory can be

used for both code and data storage. Programming of the flash memory can be

accomplished in several ways. It may be programmed in-system via a serial port; e.g.

CAN.

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 2 of 68

Page 3

NXP Semiconductors

2.4 On-chip static RAM

In addition to the two 16 kB TCMs the LPC2917/19 includes two static RAM memories:

one of 32 kB and one of 16 kB. Both may be used for code and/or data storage. Each

internal SRAM has its own controller, so both me mo r ies ca n be acce ssed simultaneously

from different AHB system bus layers.

3. Features

3.1 General

ARM968E-S processor at 80 MHz maximum

Multi-layer AHB system bus at 80 MHz with three separate layers

On-chip memory:

Two-channel CAN controller supporting Full-CAN and extensive message filtering

Two LIN master controllers with full hardware support for LIN communication

Two 550 UARTs with 16-byte Tx and Rx FIFO depths

Three full-duplex Q-SPIs with four slave-select lines; 16 bits wide; 8 locations deep; Tx

Four 32-bit timers each containing four capture-and-compare registers linked to I/Os

32 - bit wa tch d og with tim er cha nge pr ot ection, running on safe clock.

Up to 108 general-purpose I/O pins with programmable pull-up, pull-down or bus

Vectored Interrupt Controller (VIC) with 16 priority levels

Two 8-channel 10-bit ADCs provide a total of up to 16 analog inputs, with conversion

Up to 24 level-sensitive external interrupt pins, including CAN and LIN wake- up

External Static Memory Controller (SMC) with eight memory banks; up to 32-bit data

Processor wake-up from power-down via external interrupt pins; CAN or LIN activity

Flexible Reset Generator Unit (RGU) able to control resets of individual modules

Flexible Clock-Generation Unit (CGU) able to control clock frequency of individual

DRAFT

ARM9 microcontroller with CAN and LIN

Two Tightly Coupled Memories (TCM), 16 kB Instruction (ITCM), 16 kB Data TCM

(DTCM)

Two separate internal Static RAM (SRAM) instances; 32 kB SRAM and 16 kB

SRAM

Up to 768 kB flash-program memory

FIFO and Rx FIFO

keeper

times as low as 2.44 μs per channel. Each channel provides a compare function to

minimize interrupts

features

bus; up to 24-bit address bus

modules

On-chip very low-power ring oscillator; fixed frequency of 0.4 MHz; always on to

provide a Safe_Clock source for system monitoring

On-chip crystal oscillator with operating range from 10 MHz to 50 MHz - max. PLL

input 15 MHz

On-chip PLL allows CPU operation up to a maximum CPU rate of 80 MHz

Generation of up to 10 base clocks

Seven fractional dividers

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 3 of 68

Page 4

NXP Semiconductors

Highly configurable system Power Management Unit (PMU),

clock control of individual modules

allows minimization of system operating power consumption in any configuration

Standard ARM test and debug interface with real-time in-circuit emulator

Boundary-scan test supported

Du al po we r sup p ly:

CPU operating voltage: 1.8 V ± 5%

I/O operating voltage: 2.7 V to 3.6 V; inputs tolerant up to 5.5 V

14 4 -p i n LQ F P package

−40 °C to 85 °C ambient operating temperature range

4. Ordering information

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DR

F

T DRAF

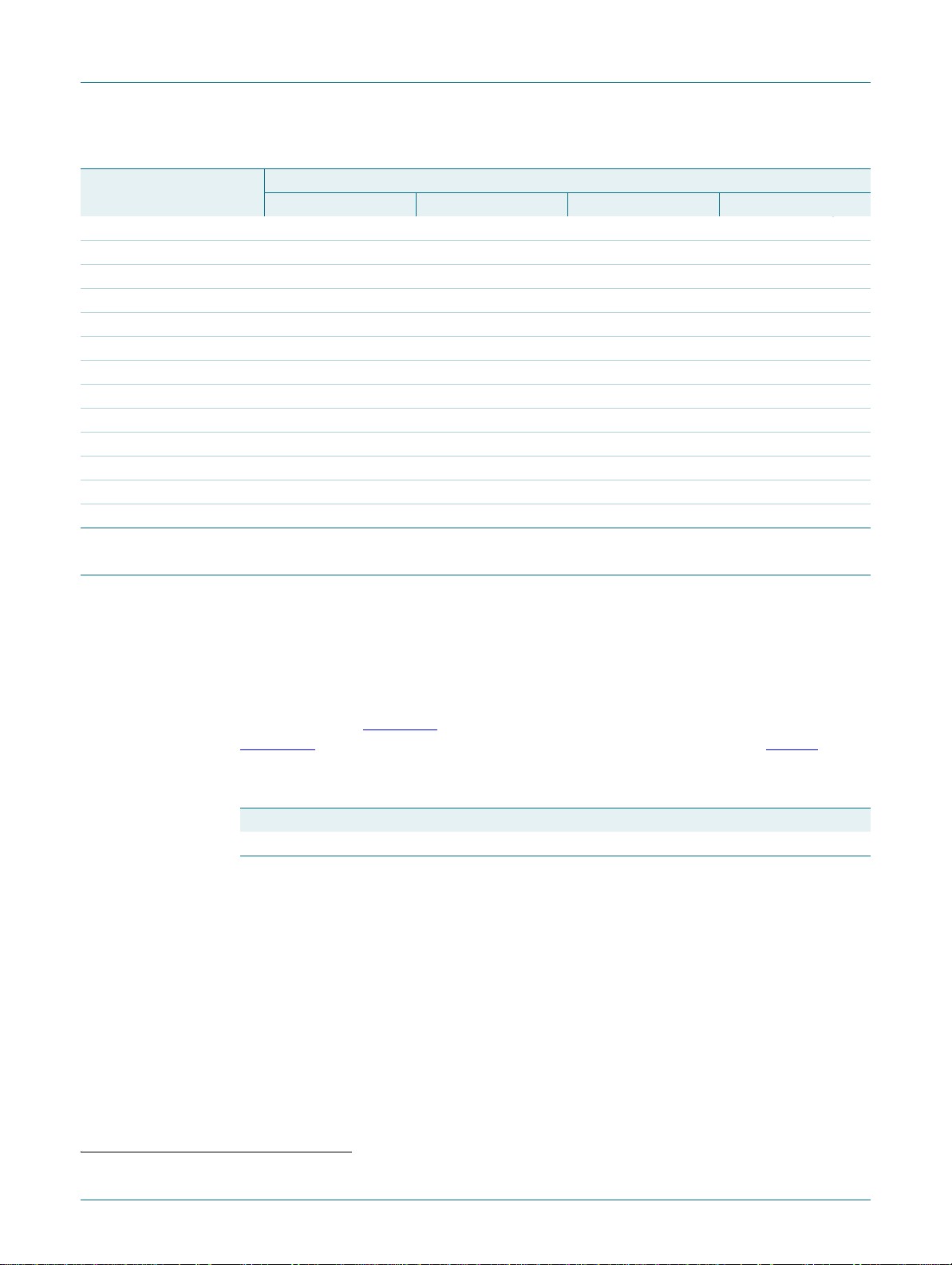

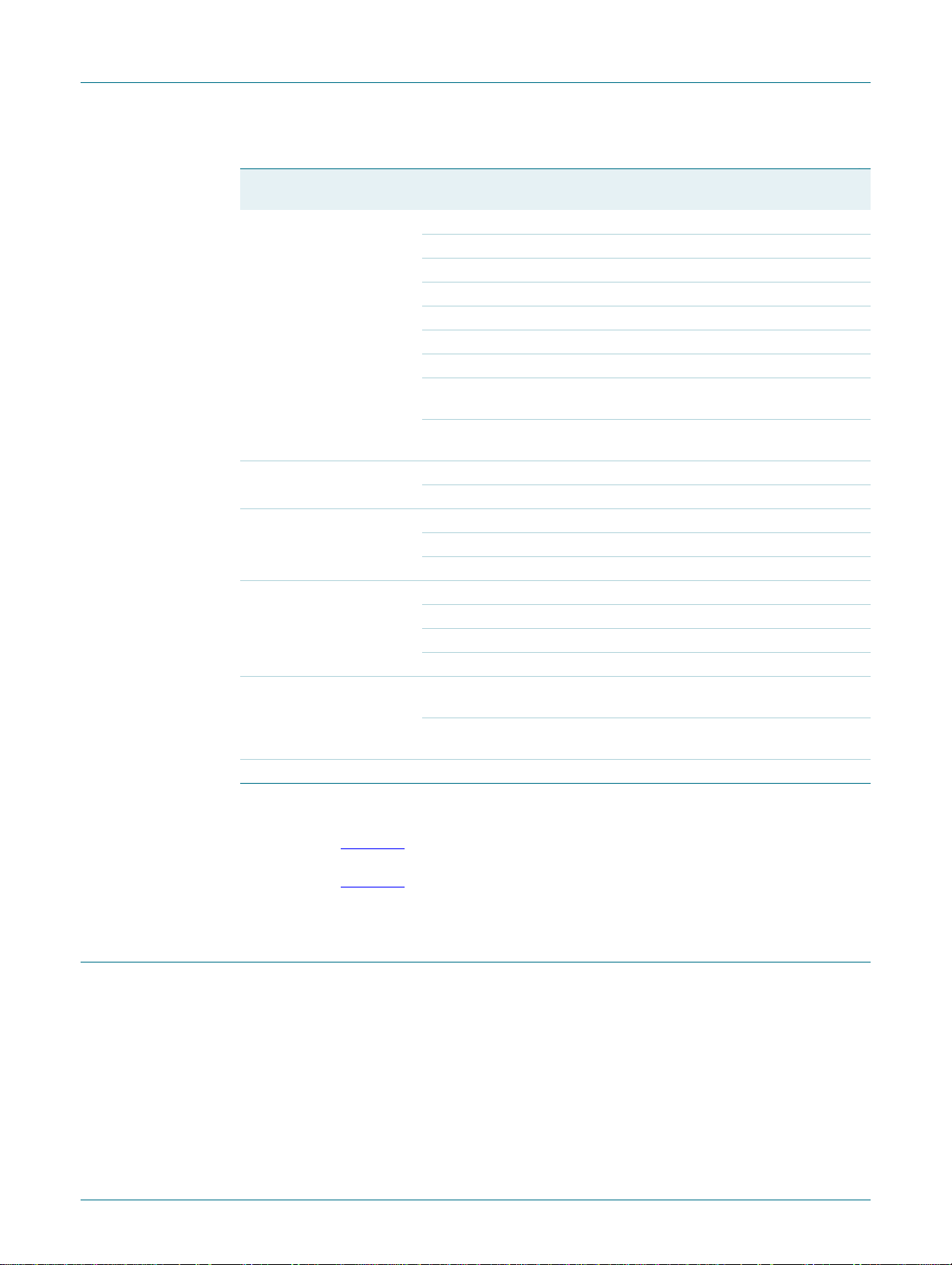

Table 1. Ordering information

Type number Package

LPC2917FBD144 LQFP144 plastic low profile quad flat package; 144 leads; body 20 × 20 × 1.4 mm, pin

LPC2919FBD144 LQFP144 plastic low profile quad flat package; 144 leads; body 20 × 20 × 1.4 mm, pin

Name Description Version

pitch 0.5 mm

pitch 0.5 mm

4.1 Ordering options

Table 2. Part options

Type number Flash memory

LPC2917FBD144 512 80 (incl TCMs) 32-bit 2 LQFP144

LPC2919FBD144 768 80 (incl TCMs) 32-bit 2 LQFP144

RAM (kB) SMC LIN 2.0 Package

(kB)

SOT486-1

SOT486-1

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 4 of 68

Page 5

NXP Semiconductors

IEEE 1149.1 JTAG TEST and

DEBUG INTERFACE

LPC2917/19

DTCM

16 Kb

ITCM

16 Kb

ARM968E-S

m

s

s

s

s

s

s

s

s

s

Multi-layer AHB

system bus

m = master port

s = slave port

External Static Memory

Controller (SMC)

Embedded

SRAM Memory 32 Kb

SRAM Controller #0

Embedded

FLASH Memory

512/768 Kb

FLASH Memory Controller (FMC)

Embedded

SRAM Memory 16 Kb

SRAM Controller #1

GLOBAL ACCEPTANCE

FILTER

2 Kbyte Static RAM

LIN MASTER 0/1

CAN Controller

0, 1

Vectored Interrupt

Controller (VIC)

AHB2VPB

Bridge

AHB2DTL

Bridge

Modulation and Sampling

Control Subsystem

PWM 0, 1, 2, 3

ADC 1, 2

Timer 0, 1 (MTMR)

AHB2VPB

Bridge

Power Clock Reset

Control Subsystem

Power Management Unit (PMU)

Reset Generation Unit (RGU)

Clock Generation Unit (CGU)

AHB2DTL

Bridge

s

General Subsystem

Event Router (ER)

System Control Unit (SCU)

Chip Feature ID (CFID)

AHB2VPB

Bridge

Peripheral Subsystem

General Purpose IO (GPIO)

0, 1, 2, 3

Timer (TMR)

0, 1, 2, 3

Watchdog Timer (WDT)

UART 0, 1

AHB2VPB

Bridge

SPI 0, 1, 2

s

5. Block diagram

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DR

F

T DRAF

Fig 1. LPC2917/19 block diagram

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 5 of 68

Page 6

NXP Semiconductors

LPC2917FBD144

LPC2919FBD144

108

37

72

144

109

73

1

36

144PINS

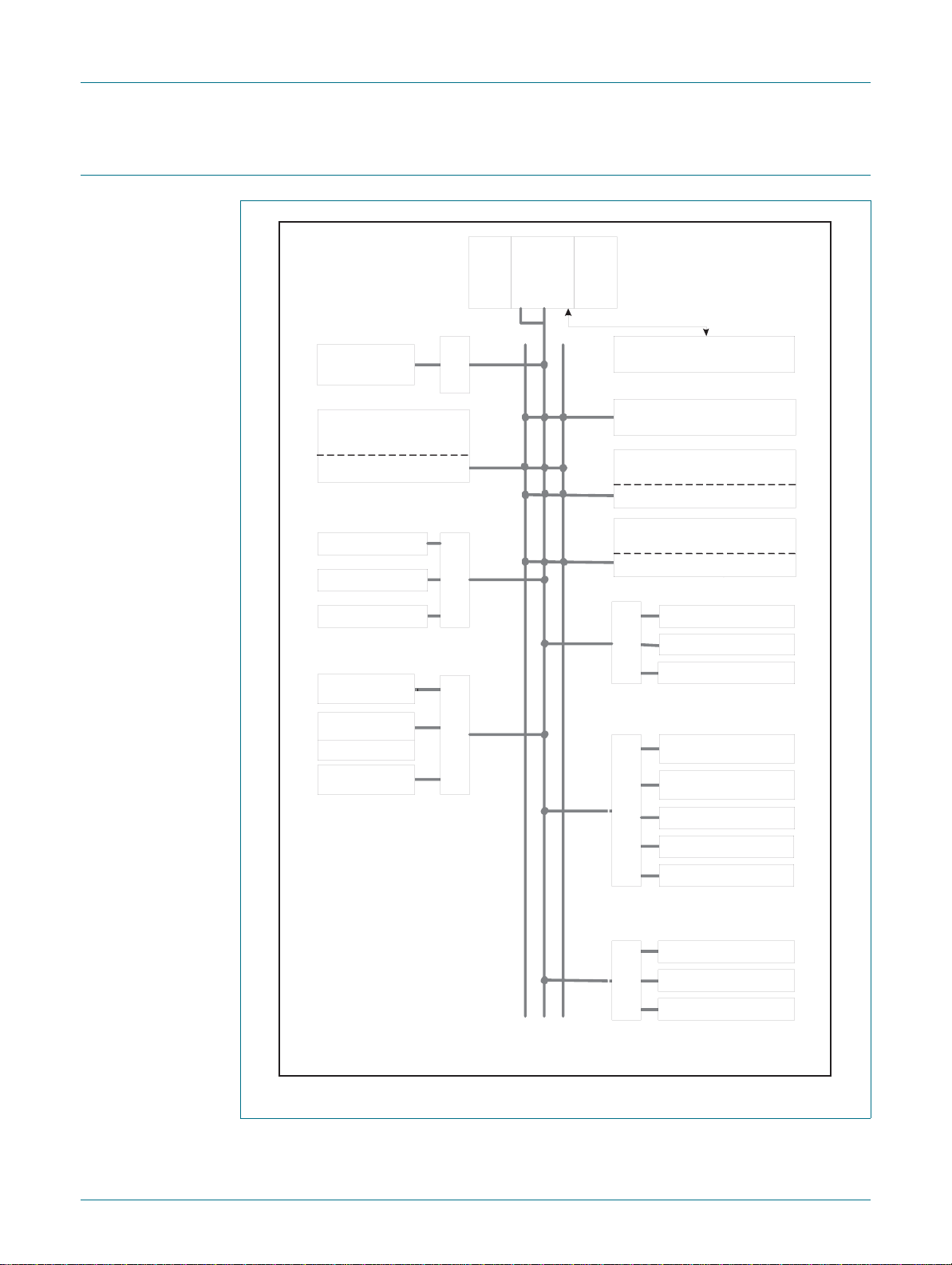

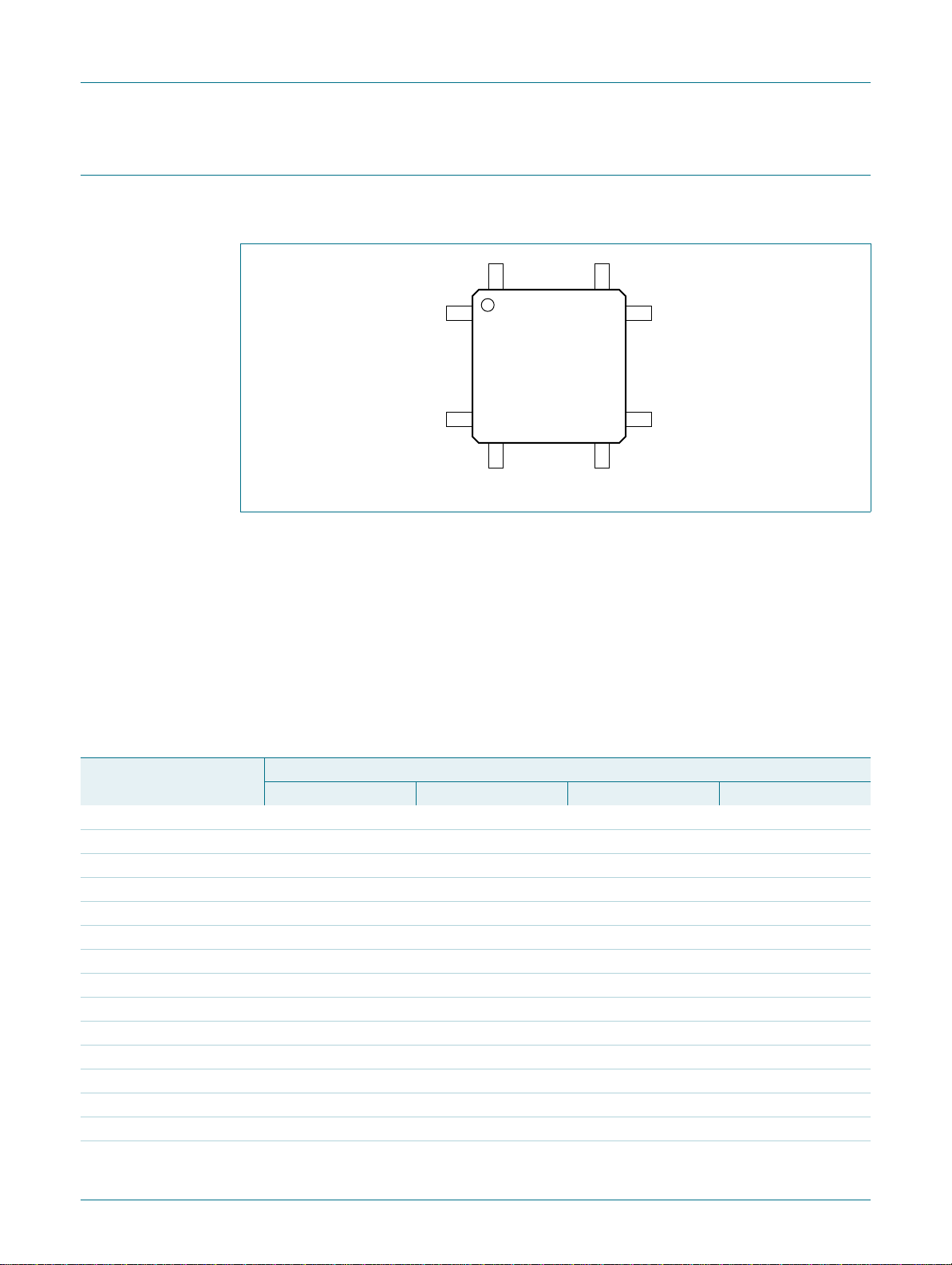

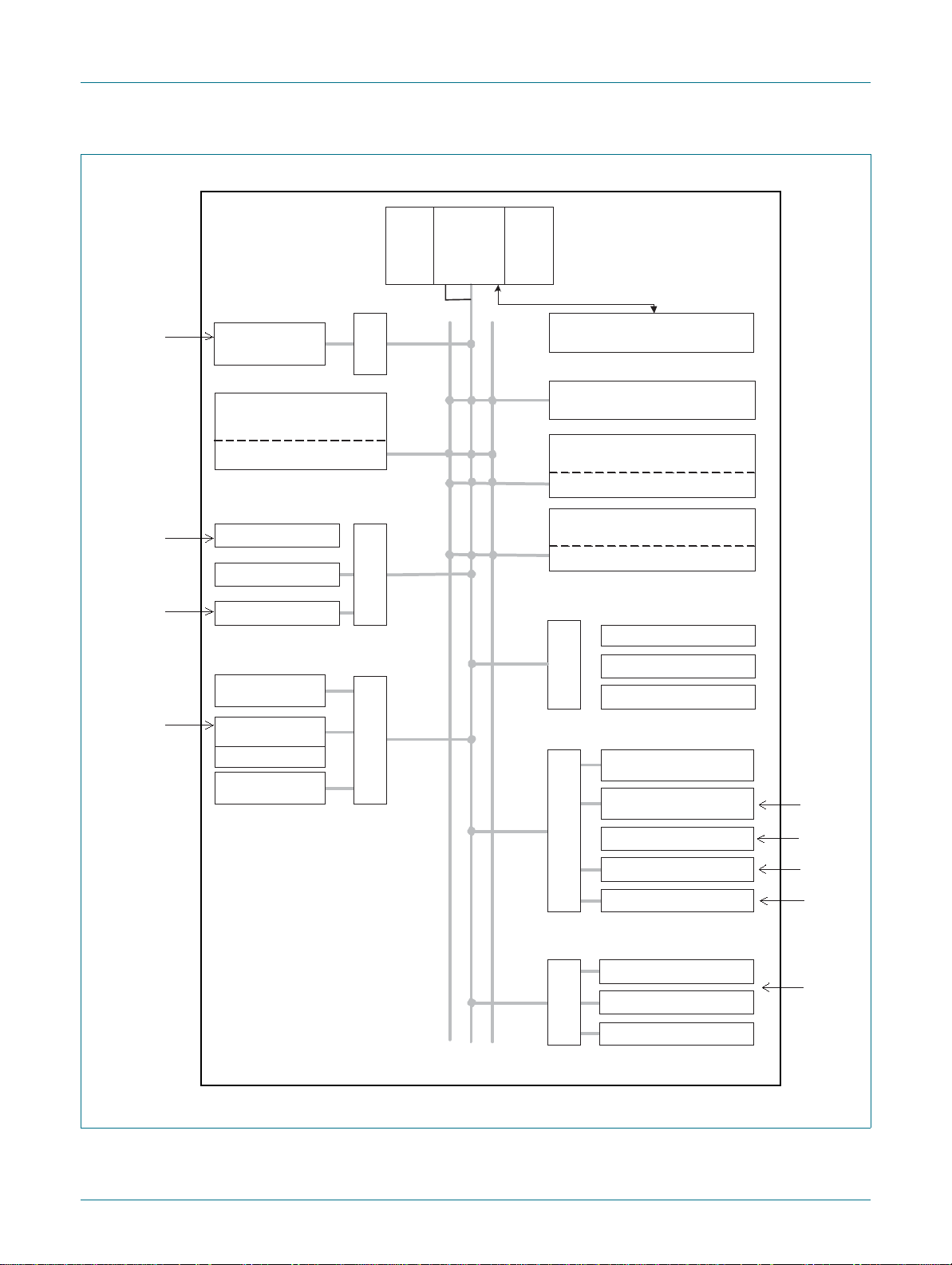

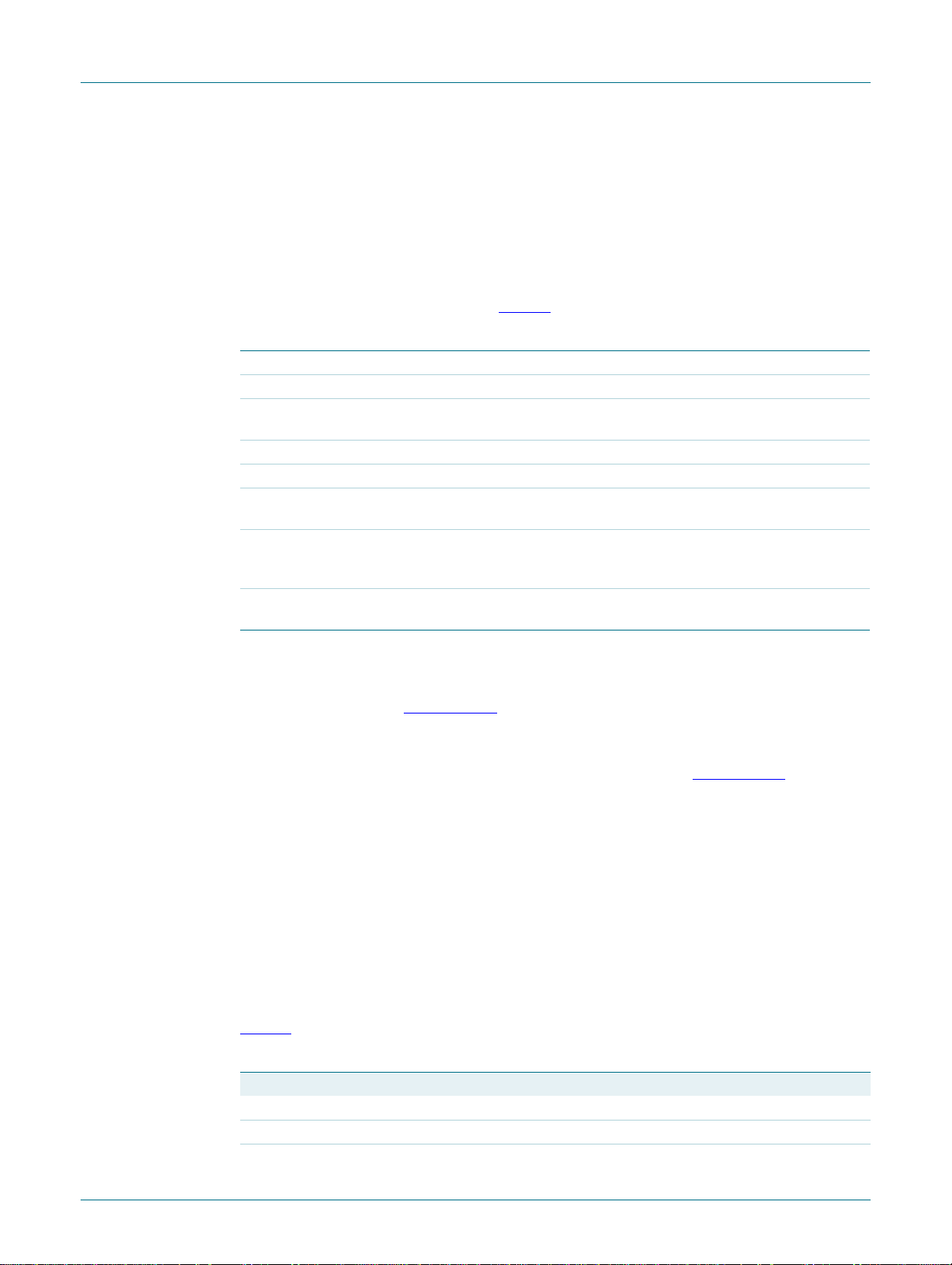

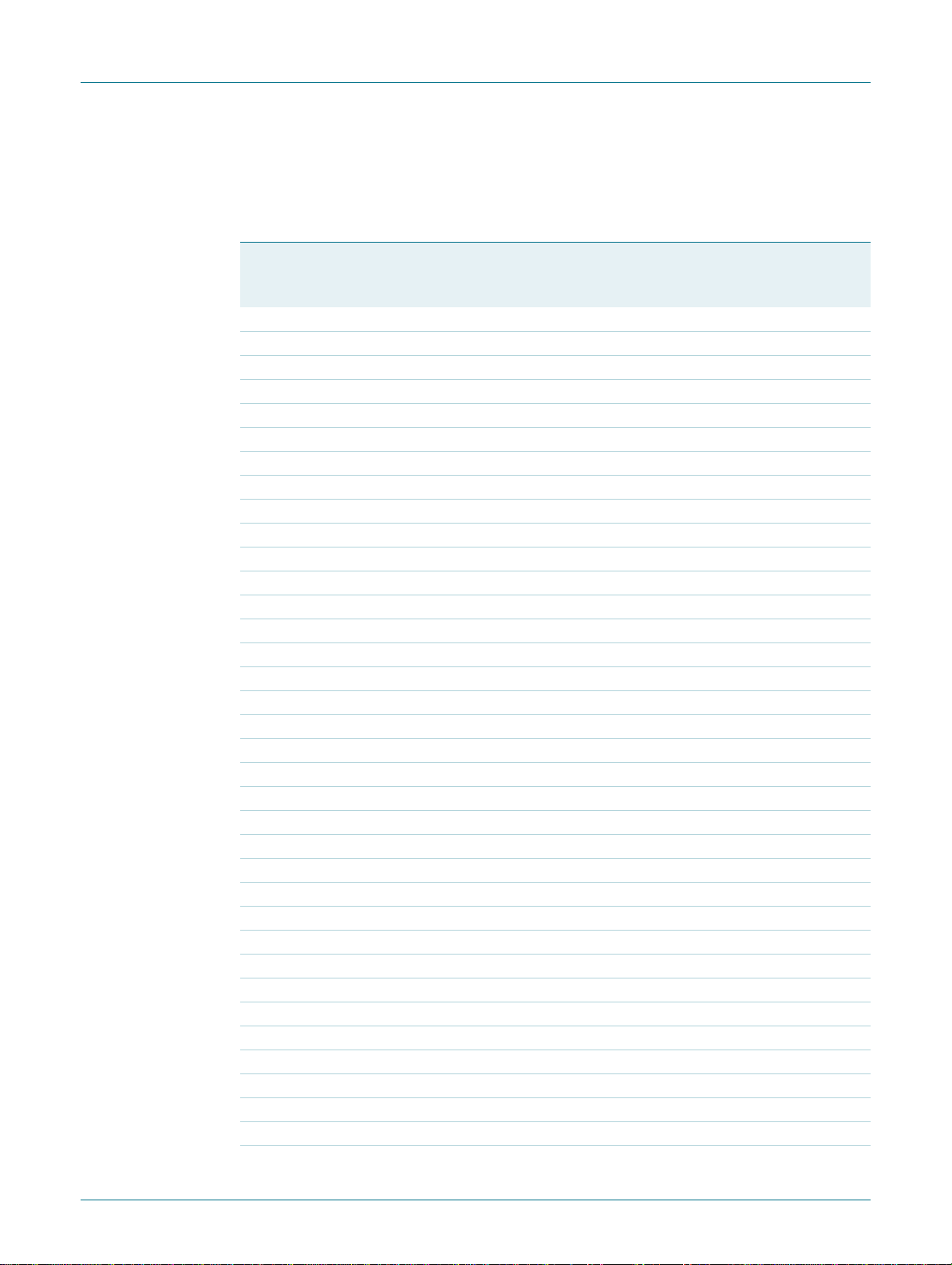

6. Pinning information

6.1 Pinning

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DR

F

T DRAF

Fig 2. Pin configuration for SOT486-1 (LQFP144)

6.2 Pin description

6.2.1 General description

The LPC2917/19 has up to four ports: two of 32 pins each, one of 28 pins and one of 16

pins. The pin to which each function is assigned is controlled by the SFSP registers in the

SCU. The functions combined on each port pin are shown in the pin description tables in

this section.

6.2.2 LQFP144 pin assignment

Table 3. LQFP144 pin assignment

Symbol Pin Description

TDO 1 IEEE 11 49.1 test data out

P2.21 2 GPIO 2, pin 21 - PWM2 CAP1 EXTBUS D19

P0.24 3 GPIO 0, pin 24 UART1 TxD CAN1 TxD SPI2 SCS0

P0.25 4 GPIO 0, pin 25 UART1 RxD CAN1 RxD SPI2 SDO

P0.26 5 GPIO 0, pin 26 - - SPI2 SDI

P0.27 6 GPIO 0, pin 27 - - SPI2 SCK

P0.28 7 GPIO 0, pin 28 - TIMER0 CAP0 TIMER0 MAT0

P0.29 8 GPIO 0, pin 29 - TIMER0 CAP1 TIMER0 MAT1

V

DD(IO)

P2.22 10 GPIO 2, pin 22 - PWM2 CAP2 EXTBUS D20

P2.23 11 GPIO 2, pin 23 - PWM3 CAP0 EXTBUS D21

P3.6 12 GPIO 3, pin 6 SPI0 SCS3 PWM1 MAT0 LIN1 TxD

P3.7 13 GPIO 3, pin 7 SPI2 SCS1 PWM1 MAT1 LIN1 RxD

P0.30 14 GPIO 0, pin 30 - TIMER0 CAP2 TIMER0 MAT2

P0.31 15 GPIO 0, pin 31 - TIMER0 CAP3 TIMER0 MAT3

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 6 of 68

Function 0 (default) Function 1 Function 2 Function 3

9 3.3 V power supply for I/O

Page 7

DRAFT

NXP Semiconductors

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

ARM9 microcontroller with CAN and LIN

F

T DRAFT DRAFT DRAFT DRA

Table 3. LQFP144 pin assignment

Symbol Pin Description

Function 0 (default) Function 1 Function 2 Function 3

P2.24 16 GPIO 2, pin 24 - PWM3 CAP1 EXTBUS D22

P2.25 17 GPIO 2, pin 25 - PWM3 CAP2 EXTBUS D23

V

DD(CORE)

V

SS(CORE)

P1.31 20 GPIO 1, pin 31 TIMER0 CAP1 TIMER0 MAT1 EXTINT5

V

SS(IO)

P1.30 22 GPIO 1, pin 30 TIMER0 CAP0 TIMER0 MAT0 EXTINT4

P3.8 23 GPIO 3, pin 8 SPI2 SCS0 PWM1 MAT2 P3.9 24 GPIO 3, pin 9 SPI2 SDO PWM1 MAT3 P1.29 25 GPIO 1, pin 29 TIMER1 CAP0, EXT

P1.28 26 GPIO 1, pin 28 TIMER1 CAP1, ADC1

P2.26 27 GPIO 2, pin 26 TIMER0 CAP2 TIMER0 MAT2 EXTINT6

P2.27 28 GPIO 2, pin 27 TIMER0 CAP3 TIMER0 MAT3 EXTINT7

P1.27 29 GPIO 1, pin 27 TIMER1 CAP2, ADC2

P1.26 30 GPIO 1, pin 26 PWM2 MAT0 PWM TRAP3 PWM3 MAT2

V

DD(IO)

P1.25 32 GPIO 1, pin 25 PWM1 MAT0 - PWM3 MAT1

P1.24 33 GPIO 1, pin 24 PWM0 MAT0 - PWM3 MAT0

P1.23 34 GPIO 1, pin 23 UART0 RxD - EXTBUS CS5

P1.22 35 GPIO 1, pin 22 UART0 TxD - EXTBUS CS4

TMS 36 IEEE 1149.1 test mode select, pulled up internally.

TCK 37 IEEE 1149.1 test clock

P1.21 38 GPIO 1, pin 21 TIMER3 CAP3 TIMER1 CAP3,

P1.20 39 GPIO 1, pin 20 TIMER3 CAP2 SPI0 SCS1 EXTBUS D6

P1.19 40 GPIO 1, pin 19 TIMER3 CAP1 SPI0 SCS2 EXTBUS D5

P1.18 41 GPIO 1, pin 18 TIMER3 CAP0 SPI0 SDO EXTBUS D4

P1.17 42 GPIO 1, pin 17 TIMER2 CAP3 SPI0 SDI EXTBUS D3

V

SS(IO)

P1.16 44 GPIO 1, pin 16 TIMER2 CAP2 SPI0 SCK EXTBUS D2

P2.0 45 GPIO 2, pin 0 TIMER2 MAT0 PWM TRAP3 EXTBUS D8

P2.1 46 GPIO 2, pin 1 TIMER2 MAT1 PWM TRAP2 EXTBUS D9

P3.10 47 GPIO 3, pin 10 SPI2 SDI PWM1 MAT4 P3.11 48 GPIO 3, pin 11 SPI2 SCK PWM1 MAT5 P1.15 49 GPIO 1, pin 15 TIMER2 CAP1 SPI0 SCS0 EXTBUS D1

P1.14 50 GPIO 1, pin 14 TIMER2 CAP0 SPI0 SCS3 EXTBUS D0

P1.13 51 GPIO 1, pin 13 EXTINT3 - EXTBUS WEN

P1.12 52 GPIO 1, pin 12 EXTINT2 - EXTBUS OEN

18 1.8 V power supply for digital core

19 ground for digital core

21 ground for I/O

31 3.3 V power supply for I/O

43 ground for I/O

…continued

PWM TRAP0 PWM3 MAT5

START

PWM TRAP1 PWM3 MAT4

EXT START

PWM TRAP2 PWM3 MAT3

EXT START

EXTBUS D7

MSCSS PAUSE

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 7 of 68

Page 8

DRAFT

NXP Semiconductors

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

ARM9 microcontroller with CAN and LIN

F

T DRAFT DRAFT DRAFT DRA

Table 3. LQFP144 pin assignment

Symbol Pin Description

Function 0 (default) Function 1 Function 2 Function 3

V

DD(IO)

P2.2 54 GPIO 2, pin 2 TIMER2 MAT2 PWM TRAP1 EXTBUS D10

P2.3 55 GPIO 2, pin 3 TIMER2 MAT3 PWM TRAP0 EXTBUS D11

P1.11 56 GPIO 1, pin 11 SPI1 SCK - EXTBUS CS3

P1.10 57 GPIO 1, pin 10 SPI1 SDI - EXTBUS CS2

P3.12 58 GPIO 3, pin 12 SPI1 SCS0 EXTINT4 V

SS(CORE)

V

DD(CORE)

P3.13 61 GPIO 3, pin 13 SPI1 SDO EXTINT5 P2.4 62 GPIO 2, pin 4 TIMER1 MAT0 EXTINT0 EXTBUS D12

P2.5 63 GPIO 2, pin 5 TIMER1 MAT1 EXTINT1 EXTBUS D13

P1.9 64 GPIO 1, pin 9 SPI1 SDO LIN1 RxD EXTBUS CS1

V

SS(IO)

P1.8 66 GPIO 1, pin 8 SPI1 SCS0 LIN1 TxD EXTBUS CS0

P1.7 67 GPIO 1, pin 7 SPI1 SCS3 UART1 RxD EXTBUS A7

P1.6 68 GPIO 1, pin 6 SPI1 SCS2 UART1 TxD EXTBUS A6

P2.6 69 GPIO 2, pin 6 TIMER1 MAT2 EXTINT2 EXTBUS D14

P1.5 70 GPIO 1, pin 5 SPI1 SCS1 PWM3 MAT5 EXTBUS A5

P1.4 71 GPIO 1, pin 4 SPI2 SCS2 PWM3 MAT4 EXTBUS A4

TRSTN 72 I EEE 1149.1 test reset NOT; active LOW; pulled up internally

RSTN 73 asynchronous device reset; active LOW; pulled up internally

V

SS(OSC)

XOUT_OSC 75 crystal out for oscillator

XIN_OSC 76 crystal in for oscillator

V

DD(OSC)

V

SS(PLL)

P2.7 79 GPIO 2, pin 7 TIMER1 MAT3 EXTINT3 EXTBUS D15

P3.14 80 GPIO 3, pin 14 SPI1 SDI EXTINT6 CAN0 TxD

P3.15 81 GPIO 3, pin 15 SPI1 SCK EXTINT7 CAN0 RxD

V

DD(IO)

P2.8 83 GPIO 2, pin 8 - PWM0 MAT0 SPI0 SCS2

P2.9 84 GPIO 2, pin 9 - PWM0 MAT1 SPI0 SCS1

P1.3 85 GPIO 1, pin 3 SPI2 SCS1 PWM3 MAT3 EXTBUS A3

P1.2 86 GPIO 1, pin 2 SPI2 SCS3 PWM3 MAT2 EXTBUS A2

P1.1 87 GPIO 1, pin 1 EXTINT1 PWM3 MAT1 EXTBUS A1

V

SS(CORE)

V

DD(CORE)

P1.0 90 GPIO 1, pin 0 EXTINT0 PWM3 MAT0 EXTBUS A0

P2.10 91 GPIO 2, pin 10 - PWM0 MAT2 SPI0 SCS0

P2.11 92 GPIO 2, pin 11 - PWM0 MAT3 SPI0 SCK

53 3.3 V power supply for I/O

59 ground for digital core

60 1.8 V power supply for digital core

65 ground for I/O

74 ground for oscillator

77 1.8 V supply for oscillator

78 ground for PLL

82 3.3 V power supply for I/O

88 ground for digital core

89 1.8 V power supply for digital core

…continued

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 8 of 68

Page 9

DRAFT

NXP Semiconductors

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DRAFT

ARM9 microcontroller with CAN and LIN

F

T DRAFT DRAFT DRAFT DRA

Table 3. LQFP144 pin assignment

Symbol Pin Description

Function 0 (default) Function 1 Function 2 Function 3

P0.0 93 GPIO 0, pin 0 - CAN0 TxD EXTBUS D24

V

SS(IO)

P0.1 95 GPIO 0, pin 1 - CAN0 RxD EXTBUS D25

P0.2 96 GPIO 0, pin 2 - PWM0 MAT0 EXTBUS D26

P0.3 97 GPIO 0, pin 3 - PWM0 MAT1 EXTBUS D27

P3.0 98 GPIO 3, pin 0 - PWM2 MAT0 EXTBUS CS6

P3.1 99 GPIO 3, pin 1 - PWM2 MAT1 EXTBUS CS7

P2.12 100 GPIO 2, pin 12 - PWM0 MAT4 SPI0 SDI

P2.13 101 GPIO 2, pin 13 - PWM0 MAT5 SPI0 SDO

P0.4 102 GPIO 0, pin 4 - PWM0 MAT2 EXTBUS D28

P0.5 103 GPIO 0, pin 5 - PWM0 MAT3 EXTBUS D29

V

DD(IO)

P0.6 105 GPIO 0, pin 6 - PWM0 MAT4 EXTBUS D30

P0.7 106 GPIO 0, pin 7 - PWM0 MAT5 EXTBUS D31

V

DD(A3V3)

JTAGSEL 108 TAP controller select input; LOW-level selects the ARM debug mode; HIGH-level selects

NC 109 VREFP 1 10 HIGH reference for AD Converters

VREFN 111 LOW reference for AD Converters

P0.8 112 GPIO 0, pin 8 ADC1 IN0 LIN0 TxD EXTBUS A20

P0.9 113 GPIO 0, pin 9 ADC1 IN1 LIN0 RxD EXTBUS A21

P0.10 114 GPIO 0, pin 10 ADC1 IN2 PWM1 MAT0 EXTBUS A8

P0.11 115 GPIO 0, pin 11 ADC1 IN3 PWM1 MAT1 EXTBUS A9

P2.14 1 16 GPIO 2, pin 14 - PWM0 CAP0 EXTBUS BLS0

P2.15 1 17 GPIO 2, pin 15 - PWM0 CAP1 EXTBUS BLS1

P3.2 118 GPIO 3, pin 2 TIMER3 MAT0 PWM2 MAT2 V

SS(IO)

P3.3 120 GPIO 3, pin 3 TIMER3 MAT1 PWM2 MAT3 P0.12 121 GPIO 0, pin 12 ADC1 IN4 PWM1 MAT2 EXTBUS A10

P0.13 122 GPIO 0, pin 13 ADC1 IN5 PWM1 MAT3 EXTBUS A11

P0.14 123 GPIO 0, pin 14 ADC1 IN6 PWM1 MAT4 EXTBUS A12

P0.15 124 GPIO 0, pin 15 ADC1 IN7 PWM1 MAT5 EXTBUS A13

P0.16 125 GPIO 0, pin 16 ADC2 IN0 UART0 TXD EXTBUS A22

P0.17 126 GPIO 0, pin 17 ADC2 IN1 UART0 RXD EXTBUS A23

V

DD(CORE)

V

SS(CORE)

P2.16 129 GPIO 2, pin 16 UART1 TxD PWM0 CAP2 EXTBUS BLS2

P2.17 130 GPIO 2, pin 17 UART1 RxD PWM1 CAP0 EXTBUS BLS3

V

DD(IO)

94 ground for I/O

104 3.3 V power supply for I/O

107 3.3 V power supply for AD Converters

boundary scan and flash programming; pulled up internally

1 19 ground for I/O

127 1.8 V power supply for digital core

128 ground for digital core

131 3.3 V power supply for I/O

…continued

DR

AFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 9 of 68

Page 10

DRAFT

NXP Semiconductors

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

ARM9 microcontroller with CAN and LIN

F

T DRAFT DRAFT DRAFT DRA

Table 3. LQFP144 pin assignment

Symbol Pin Description

Function 0 (default) Function 1 Function 2 Function 3

P0.18 132 GPIO 0, pin 18 ADC2 IN2 PWM2 MAT0 EXTBUS A14

P0.19 133 GPIO 0, pin 19 ADC2 IN3 PWM2 MAT1 EXTBUS A15

P3.4 134 GPIO 3, pin 4 TIMER3 MAT2 PWM2 MAT4 CAN1 TxD

P3.5 135 GPIO 3, pin 5 TIMER3 MAT3 PWM2 MAT5 CAN1 RxD

P2.18 136 GPIO 2, pin 18 - PWM1 CAP1 EXTBUS D16

P2.19 137 GPIO 2, pin 19 - PWM1 CAP2 EXTBUS D17

P0.20 138 GPIO 0, pin 20 ADC2 IN4 PWM2 MAT2 EXTBUS A16

P0.21 139 GPIO 0, pin 21 ADC2 IN5 PWM2 MAT3 EXTBUS A17

P0.22 140 GPIO 0, pin 22 ADC2 IN6 PWM2 MAT4 EXTBUS A18

V

SS(IO)

P0.23 142 GPIO 0, pin 23 ADC2 IN7 PWM2 MAT5 EXTBUS A19

P2.20 143 GPIO 2, pin 20 - PWM2 CAP0 EXTBUS D18

TDI 144 IEEE 1149.1 data in, pulled up internally.

141 ground for I/O

…continued

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

7. Functional description

7.1 Reset, debug, test and power description

7.1.1 Reset and power-up behavior

The LPC2917/19 contains external reset input and internal power-up reset circuits. This

ensures that a reset is extended internally until the oscillators and flash have reached a

stable state. See Section 11

Section 12

the reset pin.

Table 4. Reset pin

Symbol Direction Description

RSTN in external reset input, active LOW; pulled up internally

At activation of the RSTN pin the JTAGSEL pin is sensed as logic LOW. If this is the case

the LPC2917/19 is assumed to be connected to debug hardware, and internal circuits

re-program the source for the BASE_SYS_CLK to be the crystal oscillator instead of the

Low-Power Ring Oscillator (LP_OSC). This is required because the clock rate when

running at LP_OSC speed is too low for the external debugging environment.

7.1.2 Reset strategy

The LPC2917/19 contains a central module, the Reset Generator Unit (RGU) in the

Power, Clock and Reset Control Subsystem (PCRSS), which controls all internal reset

signals towards the peripheral modules. The RGU provides individua l reset control as well

as the monitoring functions needed for tracing a reset back to source.

for characteristics of the several start-up and initialization times. Table 4 shows

for trip levels of the internal power-up reset circuit1. See

1. Only for 1.8 V power sources

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 10 of 68

Page 11

NXP Semiconductors

7.1.3 IEEE 1149.1 interface pins (JTAG boundary-scan test)

The LPC2917/19 contains boundary-scan test logic according to IEEE 1149.1, also

referred to in this document as Joint Test Action Group (JTAG). The boundary-scan test

pins can be used to connect a debugger probe for the embedded ARM processor. Pin

JTAGSEL selects between boundary-scan mode and debug mode. Table 5

boundary- scan test pins.

Table 5. IEEE 1149.1 boundary-scan test and debug interfa ce

Symbol Description

JTAGSEL TAP controller select input. LOW level selects ARM debug mode and HIGH level

TRSTN test reset input; pulled up internally (active LOW)

TMS test-mode select input; pulled up internally

TDI test data input, pulled up internally

TDO test data output

TCK test clock input

DRAFT

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

ARM9 microcontroller with CAN and LIN

F

selects boundary scan and flash programming; pulled up internally

D

RAFT

DR

DRAFT

T DRAFT DRAFT DRAFT DRA

AFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

shows the

7.1.4 Power supply pins description

Table 6 shows the power supply pins.

Table 6. Power supplies

Symbol Description

V

DD(CORE)

V

SS(CORE)

V

DD(IO)

V

SS(IO)

V

DD(OSC)

V

SS(OSC)

V

DD(A3V3)

V

SS(PLL)

digital core supply 1.8 V

digital core ground (digital core, ADC 1)

I/O pins supply 3.3 V

I/O pins ground

oscillator and PLL supply

oscillator ground

ADC 3.3 V supply

PLL ground

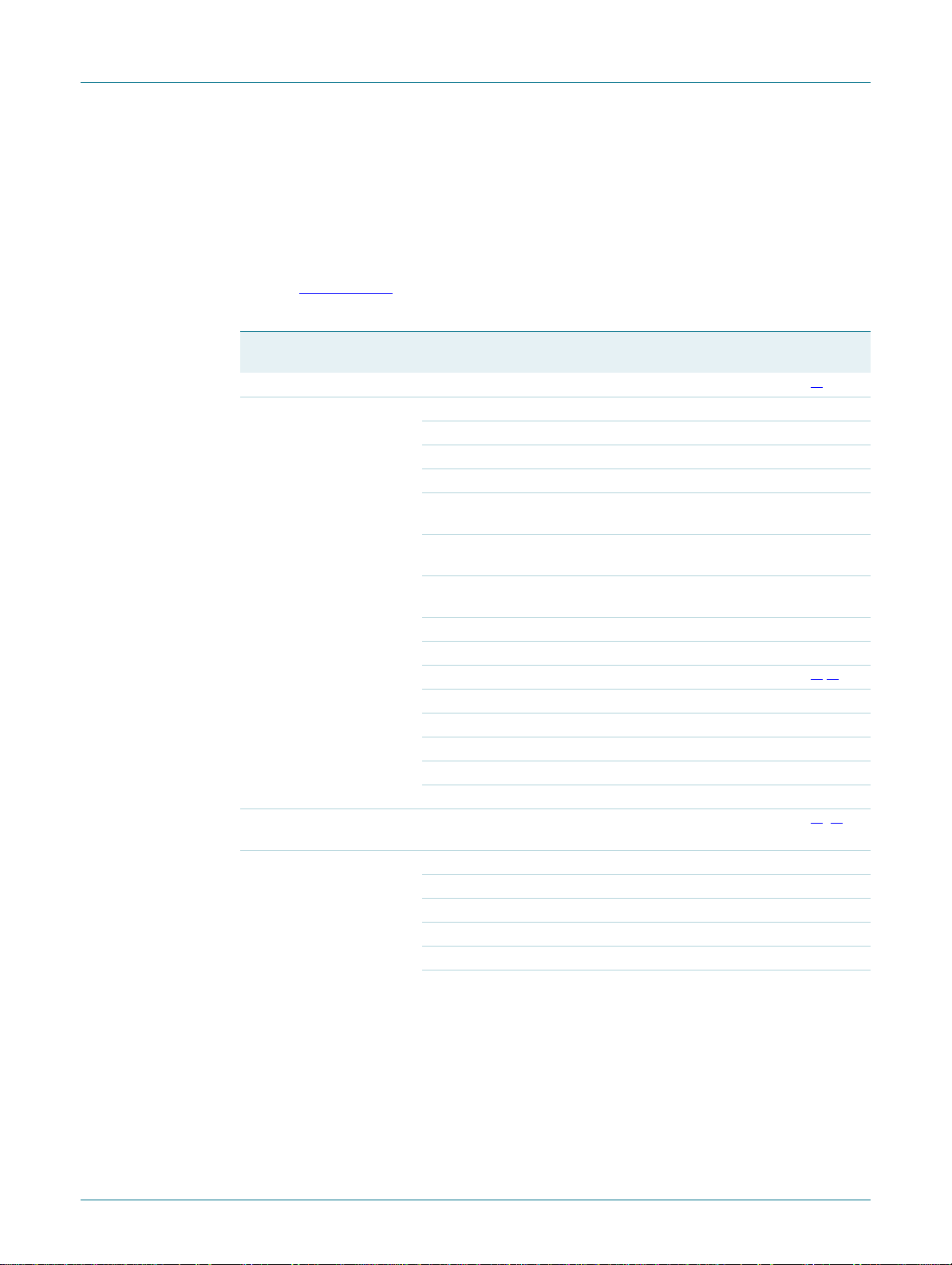

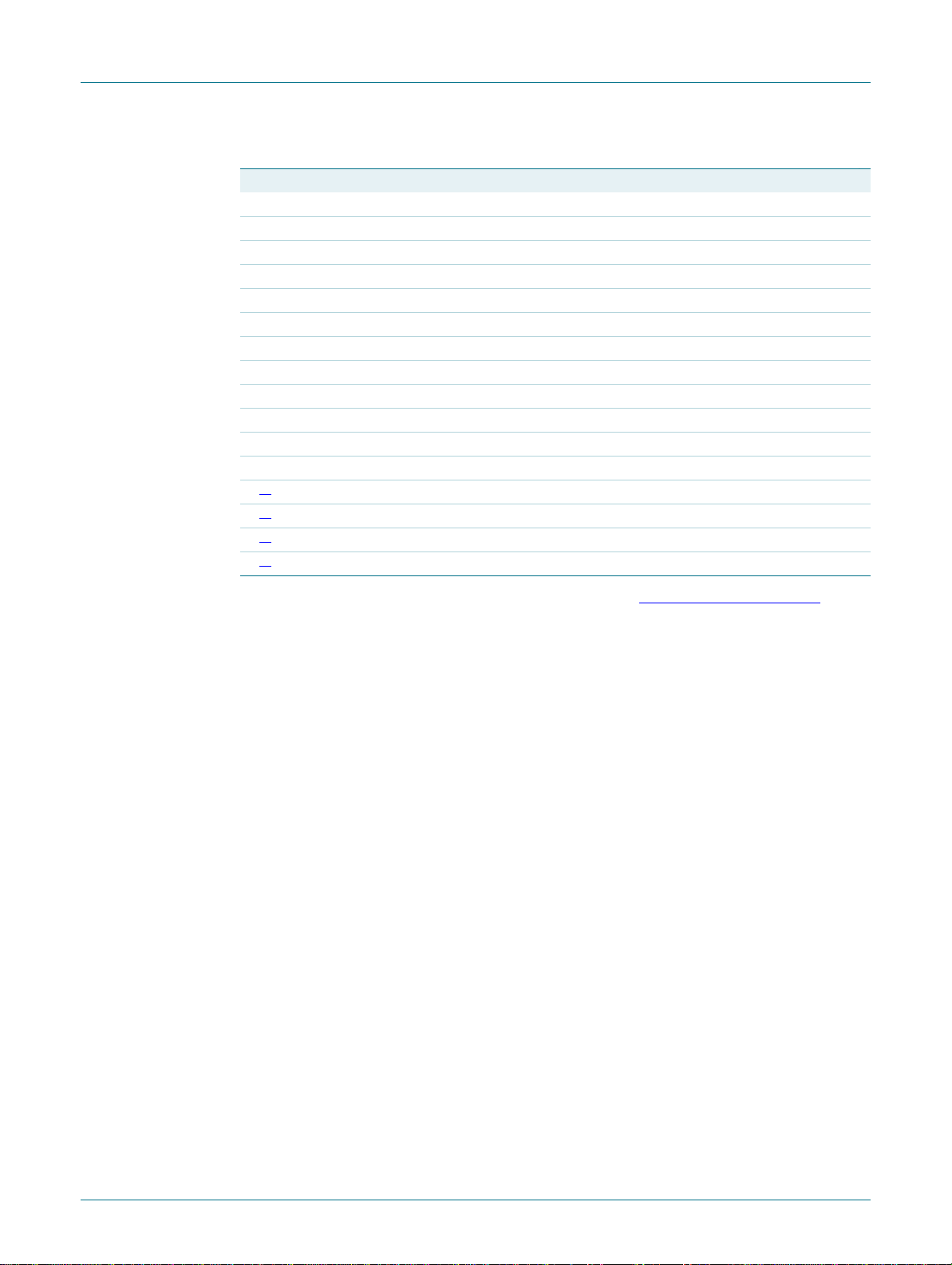

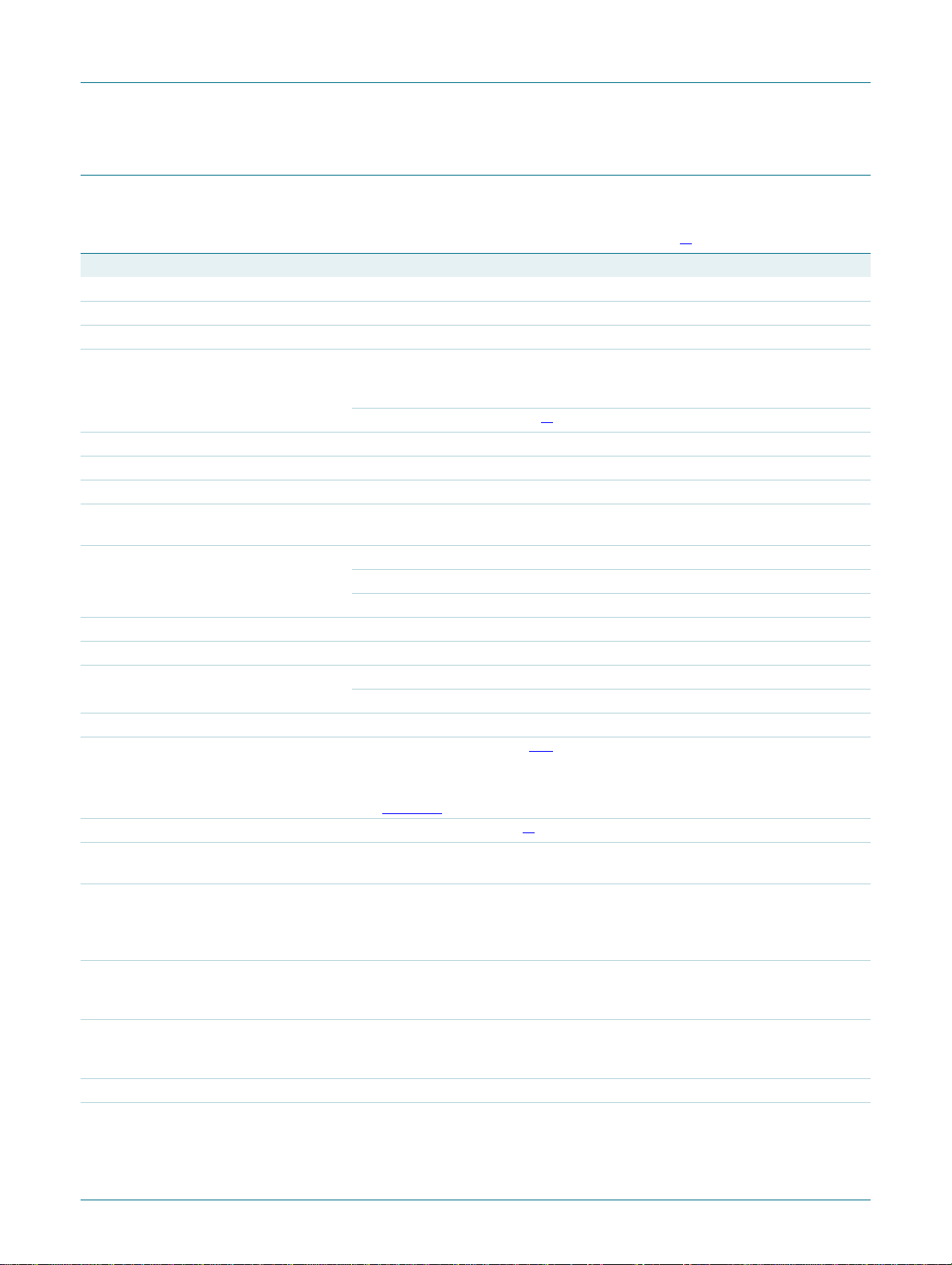

7.2 Clocking strategy

7.2.1 Clock architecture

The LPC2917/19 contains several different internal clock areas. Peripherals like Timers,

SPI, UART, CAN and LIN have their own individual clock sources called Base Clocks. All

base clocks are generated by the Clock Generator Unit (CGU). They may b e unre lated in

frequency and phase and can have different clock sources within the CGU.

The system clock for the CPU and AHB Multilayer Bus infrastructure has its own base

clock. This means most peripherals are clocked independently from the system clock. See

Figure 3

for an overview of the clock areas within the device.

Within each clock area there may be multiple branch clocks, which offers very flexible

control for power-management purposes. All branch clocks are outputs of the Power

Management Unit (PMU) and can be controlled independently. Branch clocks derived

from the same base clock are synchronous in frequency and phase. See Section 8.8

for

more details of clock and power control within the device.

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 11 of 68

Page 12

NXP Semiconductors

General Subsystem

Event Router (ER)

System Control Unit (SCU)

Chip Feature ID (CFID)

AHB2VPB

Bridge

s

IEEE 1149.1 JTAG TEST and

DEBUG INTERFACE

LPC2917/19

DTCM

16 Kb

ITCM

16 Kb

ARM968E-S

m

s

s

s

s

s

s

s

s

s

External Static Memory

Controller (SMC)

Embedded

SRAM Memory 32 Kb

SRAM Controller #0

Embedded

FLASH Memory

512 - 768 Kb

FLASH Memory Controller (FMC)

Embedded

SRAM Memory 16 Kb

SRAM Controller #1

GLOBAL ACCEPTANCE

FILTER

2 Kbyte Static RAM

LIN MASTER 0/1

CAN Controller

0, 1

Vectored Interrupt

Controller (VIC)

AHB2VPB

Bridge

AHB2DTL

Bridge

Modulation and Sampling

Control Subsystem

PWM 0, 1, 2, 3

ADC 1, 2

Timer 0, 1 (MTMR)

AHB2VPB

Bridge

Power Clock Reset

Control Subsystem

Power Management Unit (PMU)

Reset Generation Unit (RGU)

Clock Generation Unit (CGU)

AHB2DTL

Bridge

Peripheral Subsystem

General Purpose IO (GPIO)

0, 1, 2, 3

Timer (TMR)

0, 1, 2, 3

Watchdog Timer (WDT)

UART 0, 1

AHB2VPB

Bridge

TMR_CLK

SAFE_CLK

UART_CLK

SPI_CLK

PCR_CLK

IVNSS_CLK

ADC_CLK

MSCSS_CLK

SYS_CLK

SPI 0, 1, 2

s

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DR

F

T DRAF

Fig 3. LPC2917/19 block diagram, overview of clock areas

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 12 of 68

Page 13

NXP Semiconductors

7.2.2 Base clock and branch clock relationship

The next table contains an overview of all the base blocks in the LPC2917/19 and their

derived branch clocks. A short description is given of the hardware parts that are clocked

with the individual branch clocks. In relevant cases more detailed information can be

found in the specific subsystem description. Some branch clocks have special protection

since they clock vital system parts of the device and shou ld (for example) not be switched

off. See Section 8.8.6

T able 7. Base clock and branch clock overview

Base clock Branch clock name Parts of the device clocked by

BASE_SAFE_CLK CLK_SAFE Watchdog Timer

BASE_SYS_CLK CLK_SYS_CPU ARM968E-S and TCMs

BASE_PCR_CLK CLK_PCR_SLOW PCRSS, CGU, RGU and PMU

BASE_IVNSS_CLK CLK_IVNSS_VPB VPB side of the IVNSS

DRAFT

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

DRAFT

ARM9 microcontroller with CAN and LIN

F

T DRAFT DRAFT DRAFT DRA

for more details of how to control the individual branch clocks.

Remark

this branch clock

[1]

CLK_SYS_SYS AHB Bus infrastructure

CLK_SYS_PCRSS AHB side of bridge in PCRSS

CLK_SYS_FMC Flash-Memory Controller

CLK_SYS_RAM0 Embedded SRAM Controller 0

(32 KByte)

CLK_SYS_RAM1 Embedded SRAM Controller 1

(16 KByte)

CLK_SYS_SMC External Static-Memory

Controller

CLK_SYS_GESS General Subsystem

CLK_SYS_VIC Vectored Interrupt Controller

CLK_SYS_PESS Peripheral Subsystem

CLK_SYS_GPIO0 GPIO bank 0

CLK_SYS_GPIO1 GPIO bank 1

CLK_SYS_GPIO2 GPIO bank 2

CLK_SYS_GPIO3 GPIO bank 3

CLK_SYS_IVNSS_A AHB side of bridge of IVNSS

logic clock

CLK_IVNSS_CANCA CAN controller Acceptance Filter

CLK_IVNSS_CANC0 CAN channel 0

CLK_IVNSS_CANC1 CAN channel 1

CLK_IVNSS_LIN0 LIN channel 0

CLK_IVNSS_LIN1 LIN channel 1

[2] [4]

[1], [3]

AFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 13 of 68

Page 14

NXP Semiconductors

T able 7. Base clock and branch clock overview

Base clock Branch clock name Parts of the device clocked by

BASE_MSCSS_CLK CLK_MSCSS_VPB VPB side of the MSCSS

BASE_UART_CLK CLK_UART0 UART 0 interface clock

BASE_SPI_CLK CLK_SPI0 SPI 0 interface clock

BASE_TMR_CLK CLK_TMR0 Timer 0 clock for counter part

BASE_ADC_CLK CLK_ADC1 Control of ADC 1, capture sample

BASE_CLK_TESTSHELL CLK_TESTSHELL_IP

DRAFT

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

ARM9 microcontroller with CAN and LIN

F

T DRAFT DRAFT DRAFT DRA

…continued

this branch clock

CLK_MSCSS_MTMR0 Timer 0 in the MSCSS

CLK_MSCSS_MTMR1 Timer 1 in the MSCSS

CLK_MSCSS_PWM0 PWM 0

CLK_MSCSS_PWM1 PWM 0

CLK_MSCSS_PWM2 PWM 0

CLK_MSCSS_PWM3 PWM 0

CLK_MSCSS_ADC1_VPBVPB side of ADC 1

CLK_MSCSS_ADC2_VPBVPB side of ADC 2

CLK_UART1 UART 1 interface clock

CLK_SPI1 SPI 1 interface clock

CLK_SPI2 SPI 2 interface clock

CLK_TMR1 Timer 1 clock for counter part

CLK_TMR2 Timer 2 clock for counter part

CLK_TMR3 Timer 3 clock for counter part

result

CLK_ADC2 Control of ADC 2, capture sample

result

DR

AFT

DRAFT

DRA

Remark

DR

AFT

DRAFT

DR

F

T DRAF

[1] This clock is always on (cannot be switched off for system safety reasons)

[2] In the peripheral subsystem parts of the Timers, Watchdog Timer, SPI and UART have their own clock

source. See Section 8.4

[3] In the Power Clock and Reset Control subsystem parts of the CGU, RGU PMU have their own clock

source. See Section 8.8

[4] The clock should remain activated w hen system wake-up on timer or UART is required.

for details.

for details.

8. Block description

8.1 Flash memory controller

8.1.1 Overview

The Flash Memory Controller (FMC) interfaces to the embedded flash memory for two

tasks:

• Providing memory data transfer

• Memory configuration via triggering, programming and erasing

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 14 of 68

Page 15

NXP Semiconductors

The flash memory has a 128-bit wide data interface and the flash controller offers two

128-bit buffer lines to improve system performance. The flash has to be programmed

initially via JTAG. In-system programming must be supported by the boot loader.

In-application programming is possible. Flash memory contents can be protected by

disabling JTAG access. Suspension of burning or erasing is not supported.

The key features are:

• Programming by CPU via AHB

• Programming by external programmer via JTAG

• JTAG access protection

• Burn-finished and erase-finished interr up t

8.1.2 Description

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

After reset flash initialization is started, which takes t

initialization flash access is not possible and AHB transfers to flash are stalled, blocking

the AHB bus.

During flash initialization the index sector is read to identify the status of the JTAG access

protection and sector security. If JTAG access protection is active the flash is not

accessible via JTAG. ARM debug facilities are disabled to protect the flash-memory

contents against unwanted reading out externally. If sector security is active only the

concerned sections are read.

Flash can be read synchronously or asynchronously to the system clock. In synchronous

operation the flash goes into standby after returning the read data. Started reads cannot

be stopped, and speculative reading and dual buff ering are therefore not supported.

With asynchronous reading, transfer of the address to the flash and of read da ta from the

flash is done asynchronously , giving the fastest possib le response time. S t arted reads can

be stopped, so speculative reading and dual buffering are supported.

Buffering is offered because the flash has a 128-bit wide data interface while the AHB

interface has only 32 bits. With buffering a buffer line holds the complete 128-bit flash

word, from which four words can be read. Without buffering every AHB data port read

starts a flash read. A flash read is a slow process compare d to the minimum AHB cycle

time, so with buffering the average read time is reduced. This can improve system

performance.

time, see Section 12. During this

init

With single buffering the most recently read flash word remains availabl e until the next

flash read. When an AHB data-port read transfer requires data from the same flash word

as the previous read transfer , no ne w flash read is done and the read dat a is given without

wait cycles.

When an AHB data-port read transfer requires data from a different flash word to that

involved in the previous read transfer, a new flash read is done and wait states are given

until the new read data is available.

With dual buffering a secondary buffer line is used, the output of the flash being

considered as the primary buffer. On a primary buffer hit data can be copied to the

secondary buffer line, which allows the flash to start a speculative read of the next flash

word.

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 15 of 68

Page 16

NXP Semiconductors

Both buffer lines are invalidated after:

• Initialization

• Configuration-register access

• Data-latch reading

• Index-sector reading

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DR

F

T DRAF

The modes of operation are listed in Table 8

Table 8. Flash read modes

Synchronous timing

No buffer line for single (non-linear) reads; one flash-word read per word read

Single buffer line default mo de of operation; most recently read flash word is kept until

another flash word is required

Asynchronous timing

No buffer line one flash-word read per word read

Single buffer line most recently read flash word is kept until another flash word is

required

Dual buffer line, single

speculative

Dual buffer line, always

speculative

on a buffer miss a flash read is done, followed by at most one

speculative read; optimized for execution of code with small loops

(less than eight words) from flash

most recently used flash word is copied into second buffer line; next

flash-word read is started; highest performance for linear reads

.

8.1.3 Flash memory controller pin description

The flash memory controller has no extern al pins. However, the flash can be programmed

via the JTAG pins, see Section 7.1.3

.

8.1.4 Flash memory controller clock description

The flash memory controller is clocked by CLK_SYS_FMC, see Section 7.2.2.

8.1.5 Flash layout

The ARM processor can program the flash for ISP (In-System Programming) a nd IAP (InApplication Programming). Note that the flash always has to be programmed by ‘flash

words’ of 128 bits (four 32-bit AHB bus words, hence 16 bytes).

The flash memory is organized into eight ‘small’ sectors of 8 kB each and up to 11 ‘large’

sectors of 64 kB each. The number of large sectors depends on the device type. A sector

must be erased before data can be written to it. The flash memory also has sector-wise

protection. Writing occurs per page which consists of 4096 bits (32 flash words). A small

sector contains 16 pages; a large sector contains 128 pages.

Table 9

Table 9. Flas h sector overview

Sector number Sector size (kB) Sector base address

0 8 0000 0000h

1 8 0000 2000h

2 8 0000 4000h

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 16 of 68

gives an overview of the flash-sector base addresses.

Page 17

NXP Semiconductors

WST

t

acc clk()

t

t

tclk sys()

------------------

> 1–

WST

t

acc addr()

t

tclk sys()

--------------------- -

> 1–

Table 9. Flas h sector overview

Sector number Sector size (kB) Sector base address

3 8 0000 6000h

4 8 0000 8000h

5 8 0000 A000h

6 8 0000 C000h

7 8 0000 E000h

8 64 0001 0000h

9 64 0002 0000h

10 64 0003 0000h

11 64 0004 0000h

12 64 0005 0000h

13 64 0006 0000h

14 64 0007 0000h

[1]

15

[1]

16

[1]

17

[1]

18

ARM9 microcontroller with CAN and LIN

…continued

64 0008 0000h

64 0009 0000h

64 000A 0000h

64 000B 0000h

DRAFT

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

F

T DRAFT DRAFT DRAFT DRA

RAFT

DRAFT

DR

AFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

[1] Availability of sector 15 to sector 18 depends on device type, see Section 4 “Ordering information”.

The index sector is a special sector in which the JTAG access protection and sector

security are located. The address space becomes visible by setting the FS_ISS bit and

overlaps the regular flash sector’s address space.

Note that the index sector cannot be erased, and that acce ss to it ha s to be pe rformed via

code outside the flash.

8.1.6 Flash bridge wait-states

To eliminate the delay associated with synchronizing flash-read data, a predefined

number of wait-states must be programmed. These depend on flash-memory response

time and system clock period. The minimum wait-states value can be calculated with the

following formulas:

Synchronous reading:

Asynchronous reading:

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 17 of 68

Page 18

NXP Semiconductors

Remark: If the programmed number of wait-states is more than three, flash-data reading

cannot be performed at full speed (i.e. with zero wait-states at the AHB bus) if speculative

reading is active.

8.2 External static memory controller

8.2.1 Overview

The LPC2917/19 contains an external Static Memory Controller (SMC) which provides an

interface for external (off-chip) memory devices.

Key features are:

• Supports static memory-mapped devices including RAM, ROM, flash, burst ROM and

• Asynchronous page-mode read operation in non-clocked memory subsystems

• Asynchronous burst-mode read access to burst-mode ROM devices

• Independent configuration for up to eight banks, each up to 16 MB

• Programmable bus-turnaround (idle) cycles (one to 16)

• Programmable read and write wait states (up to 32), for static RAM devices

• Programmable initial and subsequent burst-read wait state for burst-ROM devices

• Programmable write protection

• Programmable burst-mode operation

• Programmable external data width: 8-bit, 16-bit or 32-bit

• Programmable read-byte lane enable control

external I/O devices

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

8.2.2 Description

The SMC simultaneously supports up to eigh t independently configurable memory banks.

Each memory bank can be 8, 16 or 32 bits wide and is capable of supporting SRAM,

ROM, burst-ROM memory or external I/O devices.

A separate chip-select output is available for each bank. The chip-select lines are

configurable to be active HIGH or LOW. Memory-bank selection is controlled by memory

addressing. Table 10

memory base addresses, chip selects and bank internal addresses.

Table 10. External memory-bank address bit description

32 bit

System

Address Bit

field

31 to 29 BA[2:0] external static-memory base address (three most significant bits);

28 to 26 CS[2:0] chip-select address space for eight memory banks; see

25 and 24 - always ’00’; other values are ’mirrors’ of the 16 MByte bank address

23 to 0 A[23:0] 16-MByte memory banks address space

shows how the 32-bit system address is mapped to the external bus

Symbol Description

the base address can be found in the memory map; see Ref. 1

field contains ’010’ when addressing an external memory bank.

. This

[1]

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 18 of 68

Page 19

NXP Semiconductors

Table 11. External static-memory controller banks

CS[2:0] Bank

000 bank 0

001 bank 1

010 bank 2

011 bank 3

100 bank 4

101 bank 5

110 bank 6

111 bank 7

8.2.3 External static-memory controller pin description

The external static-memory controller module in the LPC2917/19 has the following pins,

which are combined with other functions on the port pins of the LPC2917/19. Table 12

shows the external memory controller pins.

Table 12. External memory controller pins

Symbol Direction Description

EXTBUS CSx out memory-bank x select, x runs from 0 to 7

EXTBUS BLSy out byte-lane select input y, y runs from 0 to 3

EXTBUS WE_N out write enable (active LOW)

EXTBUS OE_N out output enable (active LOW)

EXTBUS A[23:0] out address bus

EXTBUS D[31:0] in/out data bus

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DR

F

T DRAF

8.2.4 External static-memory controller clock description

The External Static-Memory Controller is clocked by CLK_SYS_SMC, see Section 7.2.2.

8.2.5 External memory timing diagrams

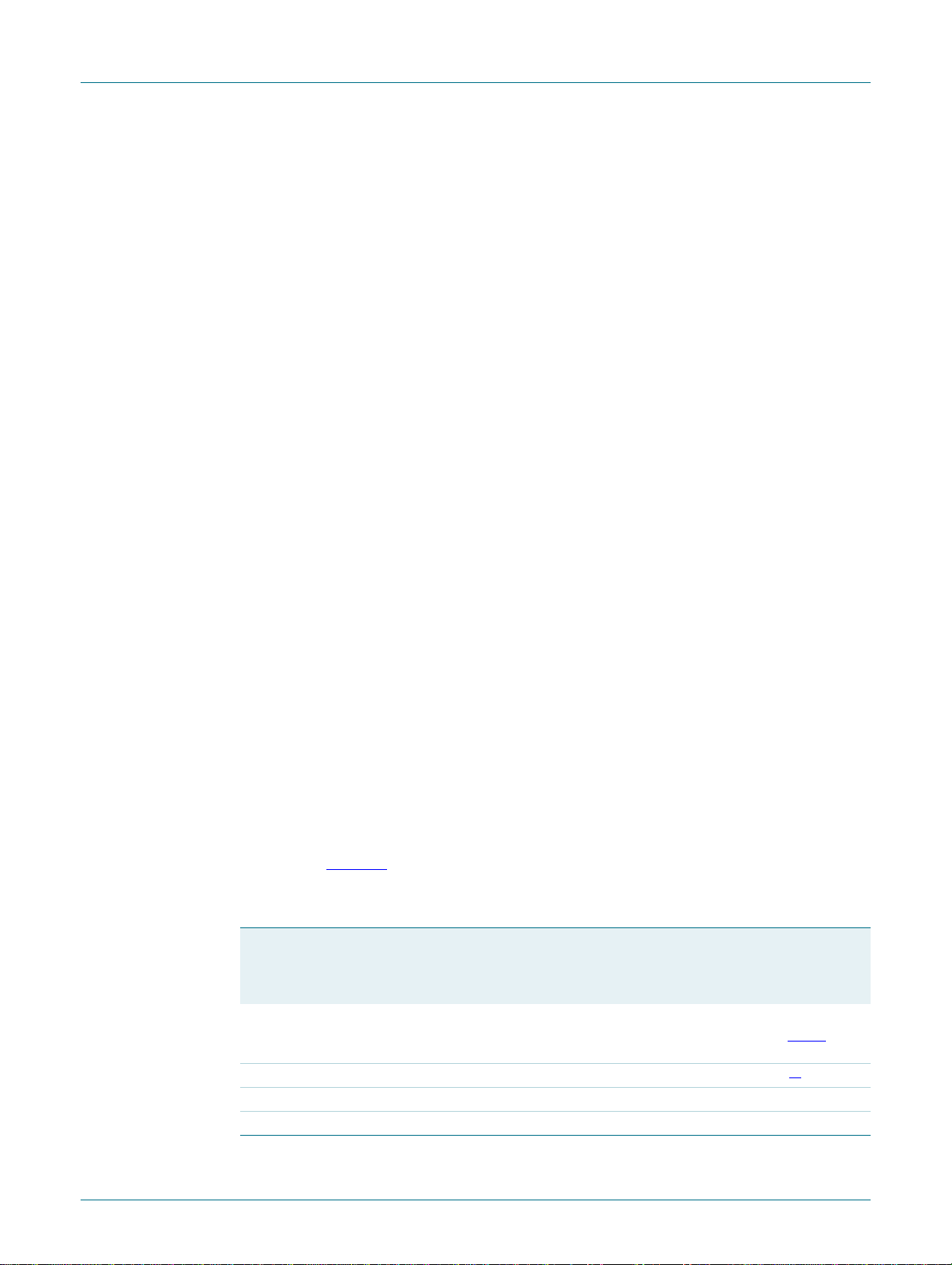

A timing diagram for reading from external memory is shown in Figure 4. The relationship

between the wait-state settings is indicated with arrows.

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 19 of 68

Page 20

NXP Semiconductors

OE_N

CLK(SYS)

CS

ADDR

DATA

WSTOEN

WST1

CLK(SYS)

CS

ADDR

DATA

WSTWEN

WST2

WE_N / BLS

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DR

F

T DRAF

WSTOEN=3, WST1=7

Fig 4. Reading from external memory

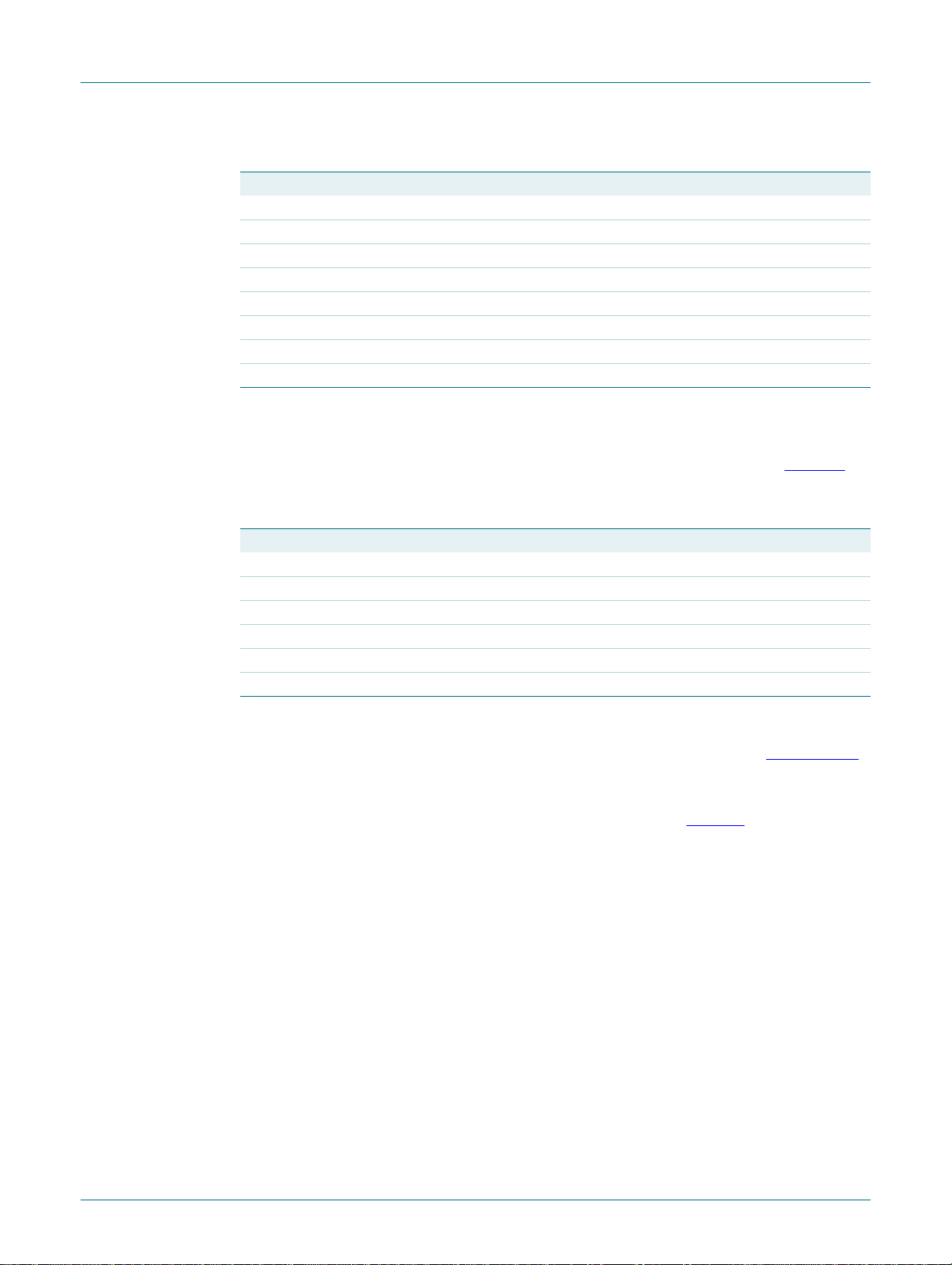

A timing diagram for writing to external memory is shown In Figure 5. The relationship

between wait-state settings is indicated with arrows.

WSTWEN=3, WST2=7

Fig 5. Writing to external memory

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 20 of 68

Page 21

NXP Semiconductors

OE_N

CLK(SYS)

CS

ADDR

DATA

WSTOEN

WST1

WSTWEN

WST2

WE_N / BLS

IDCY

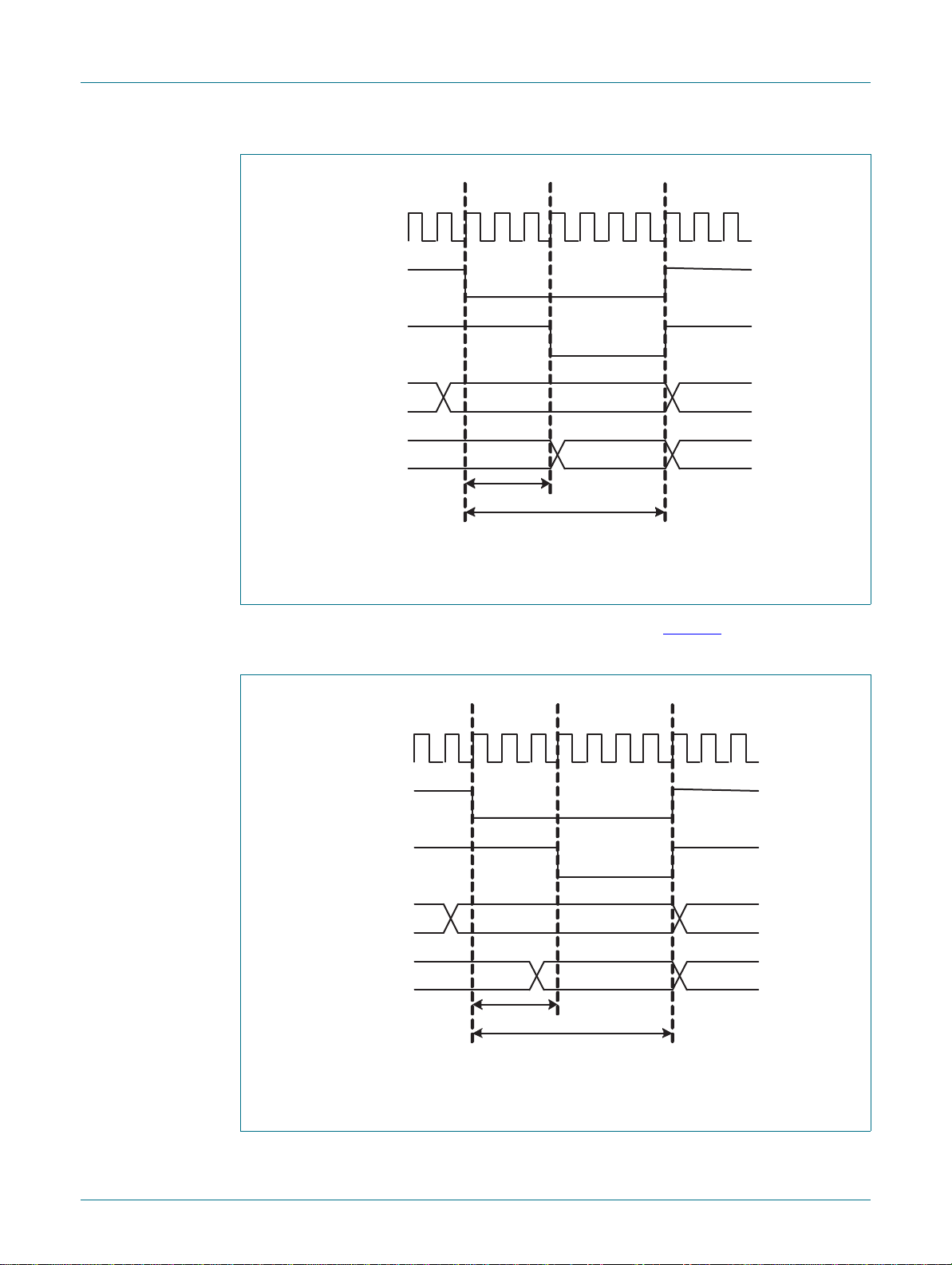

Usage of the idle/turn-around time (IDCY) is de mon str ated In Figure 6. Extra wait states

are added between a read and a write cycle in the same external memory device.

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DR

F

T DRAF

WSTOEN=5, WSTWEN=5, WST1=7, WST2=6, IDCY=5

Fig 6. Reading/writing external memory

Address pins on the device are shared with other functions. When connecting external

memories, check that the I/O pin is programmed for the correct function. Control of these

settings is handled by the SCU.

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 21 of 68

Page 22

NXP Semiconductors

8.3 General subsystem

8.3.1 General subsystem clock description

The general subsystem is clocked by CLK_SYS_GESS, see Section 7.2.2.

8.3.2 Chip and feature identification

8.3.2.1 Overview

The key features are:

• Identification of product

• Identification of features enabled

8.3.2.2 Description

The Chip/Feature ID (CFID) module contains registers which show and control the

functionality of the chip. It contains an ID to identify the silicon, and also registers

containing information about the features enabled or disabled on the chip.

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

8.3.2.3 CFID pin description

The CFID has no external pins.

8.3.3 System Control Unit (SCU)

8.3.3.1 Overview

The system control unit takes care of system-related functions.The key feature is

configuration of the I/O port-pins multiplexer.

8.3.3.2 Description

The system control unit defines the function of each I/O pin of the LPC2917/19. The I/O

pin configuration should be consistent with peripheral function usage.

8.3.3.3 SCU pin description

The SCU has no external pins.

8.3.4 Event router

8.3.4.1 Overview

The event router provides bus-controlled routing of input events to the vectored interrupt

controller for use as interrupt or wake-up signals.

Key features:

• Up to 24 level-sensitive external interrupt pins, including CAN, LIN and RxD wake-up

features plus three internal event sources

• Input events can be used as interrupt source either directly or latched (edge-detected)

• Direct events disappear when the event becomes inactive

• Latched events remain active until they are explicitly cleared

• Programmable input level and edge polarity

• Event detection maskable

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 22 of 68

Page 23

NXP Semiconductors

• Event detection is fully asynchronous, so no clock is required

8.3.4.2 Description

The event router allows the event source to be defined, its polarity and activation type to

be selected and the interrupt to be masked or enabled. The event router can be used to

start a clock on an external event.

The vectored interrupt-controller inputs are active HIGH.

8.3.4.3 Event-router pin description and mapping to register bit positions

The event router module in the LPC2917/19 is connected to the pins listed below. The

pins are combined with other functions on the port pins of the LPC2917/19. Table 13

shows the pins connected to the event router, and also the corresponding bit position in

the event-router registers and the default polarity.

Table 13. Event-router pin connections

Symbol Direction Bit position Description Default

EXTINT0 in 0 external interrupt input 0 1

EXTINT1 in 1 external interrupt input 1 1

EXTINT2 in 2 external interrupt input 2 1

EXTINT3 in 3 external interrupt input 3 1

EXTINT4 in 4 external interrupt input 4 1

EXTINT5 in 5 external interrupt input 5 1

EXTINT6 in 6 external interrupt input 6 1

EXTINT7 in 7 external interrupt input 7 1

CAN0 RXD in 8 CAN0 receive data input wake-up 0

CAN1 RXD in 9 CAN1 receive data input wake-up 0

- - 13 - 10 reserved LIN0 RXD in 14 LIN0 receive data input wake-up 0

LIN1 RXD in 15 LIN1 receive data input wake-up 0

- - 21 - 16 reserved -

- na 22 CAN interrupt (internal) 1

- na 23 VIC FIQ (internal) 1

- na 24 VIC IRQ (internal) 1

- - 26 - 25 reserved -

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

polarity

DR

AFT

DRAFT

DR

F

T DRAF

8.4 Peripheral subsystem

8.4.1 Peripheral subsystem clock description

The peripheral subsystem is clocked by a number of different clocks:

• CLK_SYS_PESS

• CLK_UART0/1

• CLK_SPI0/1/2

• CLK_TMR0/1/2/3

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 23 of 68

Page 24

NXP Semiconductors

• CLK_SAFE see Section 7.2.2

8.4.2 Watchdog timer

8.4.2.1 Overview

The purpose of the watchdog timer is to reset the ARM9 processor within a reasonable

amount of time if the processor enters an error state. The watchdog generates a system

reset if the user program fails to trigger it correctly within a predetermined amount of time.

Key features:

• Internal chip reset if not periodically triggered

• Timer counter register runs on always-on safe clock

• Optional interrupt generation on watchdog timeout

• Debug mode with disabling of reset

• Watchdog control register change-protected with key

• Programmable 32-bit watchdog timer period with programmable 32-bit prescaler.

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

8.4.2.2 Description

The watchdog timer consists of a 32-bit counter with a 32-bit prescaler.

The watchdog should be programmed with a time-out value and then periodically

restarted. When the watchdog times out it generates a reset through the RGU.

To generate watchdog interrupts in watchdog debug mode the interr upt has to be enable d

via the interrupt enable register. A watchdog-overflow interrupt can be cleared by writing

to the clear-interrupt register.

Another way to prevent resets during debug mod e is via the Pause feature of the

Watchdog Timer. The watchdog is stalled when the ARM9 is in debug mode and the

PAUSE_ENABLE bit in the Watchdog Timer Control register is set.

The Watchdog Reset output is fed to the Reset Gener ator Unit (RGU). The RGU cont ains

a reset source register to identify the reset source when the device has gone through a

reset. See Section 8.8.5

8.4.2.3 Pin description

The watchdog has no external pins.

8.4.2.4 Watchdog timer clock description

The Watchdog Timer is clocked by two different clocks; CLK_SYS_PESS and

CLK_SAFE, see Section 7.2.2

by CLK_SYS_PESS. The timer and prescale counters are clocked by CLK_SAFE which

is always on.

.

. The register interface towards the system bus is clocked

8.4.3 Timer

8.4.3.1 Overview

The LPC2917/19 contains six identical timers: four in the peripheral subsystem and two in

the Modulation and Sampling Control SubSystem (MSCSS) located at d iffer ent peripher al

base addresses. This section describes the four timers in the peripheral subsystem. Each

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 24 of 68

Page 25

NXP Semiconductors

timer has four capture inputs and/or match output s. Connection to device pins depends on

the configuration programmed into the port function-select registers. The two timers

located in the MSCSS have no external capture or match pins, but the memory map is

identical, see Section 8.7.7

function.

The key features are:

• 32-bit timer/counter with programm ab le 32 -b it pr es ca ler

• Up to four 32-bit capture channels per timer . These ta ke a snapshot of the time r value

• Four 32-bit match registers per timer that allow:

• Up to four external outputs per timer corresponding to match registers, with the

• Pause input pin (MSCSS timers only)

DRAFT

ARM9 microcontroller with CAN and LIN

. One of these timers has an external input for a pause

when an external signal connected to the TIMERx CAPn input changes state. A

capture event may also optionally generate an interrupt

– Continuous operation with optional interrupt generation on match

– Stop timer on match with optional interrupt generation

– Reset timer on match with optional interrupt generation

following capabilities:

– Set LOW on match

– Set HIGH on match

– Toggle on match

– Do nothing on match

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

DRAFT

AFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

8.4.3.2 Description

The timers are designed to count cycles of the clock and optionally generate interr upts or

perform other actions at specified timer values, based on four match registers. They also

include capture inputs to trap the timer value when an input sign al changes state,

optionally generating an interrupt. The core function of the timers consists of a 32 bit

‘prescale counter’ trig g er ing the 32 bit ‘timer cou nt er’. Both counters run on cl oc k

CLK_TMRx (x runs from 0 to 3) and all time references are related to the period of this

clock. Note that each timer has its individual clock source within the Peripheral

SubSystem. In the Modulation and Sampling SubSystem each timer also has its own

individual clock source. See section Section 8.8.6

clocks.

8.4.3.3 Pin description

The four timers in the peripheral subsystem of the LPC2917/19 have the pins described

below. The two timers in the modulation and sampling subsystem have no external pins

except for the pause pin on MSCSS timer 1. See Section 8.7.7

timers and their associated pins. The timer pins are combined with other functions on the

port pins of the LPC2917/19, see Section 8.3.3

runs from 0 to 3).

for information on generation of these

for a description of these

. Table Table 14 shows the timer pins (x

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 25 of 68

Page 26

NXP Semiconductors

Table 14. Timer pins

Symbol Direction Description

TIMERx CAP[0] IN TIMER x capture input 0

TIMERx CAP[1] IN TIMER x capture input 1

TIMERx CAP[2] IN TIMER x capture input 2

TIMERx CAP[3] IN TIMER x capture input 3

TIMERx MAT[0] OUT TIMER x match output 0

TIMERx MAT[1] OUT TIMER x match output 1

TIMERx MAT[2] OUT TIMER x match output 2

TIMERx MAT[3] OUT TIMER x match output 3

8.4.3.4 Timer clock description

The timer modules are clocked by two different clocks; CLK_SYS_PESS and CLK_TMRx

(x = 0-3), see Section 7.2.2

power management. The frequency of all these clocks is identical as they are derived

from the same base clock BASE_CLK_TMR. The register interface towards the system

bus is clocked by CLK_SYS_PESS. The timer and prescale counters are clocked by

CLK_TMRx.

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

. Note that each timer has its own CLK_TMRx branch clock for

DR

AFT

DRAFT

DR

F

T DRAF

8.4.4 UARTs

8.4.4.1 Overview

The LPC2917/19 contains two identical UARTs located at different peripheral base

addresses. The key features are:

• 16-byte receive and transmit FIFOs

• Registers conform to industry standard 550

• Receiver FIFO trigger points at 1 byte, 4 bytes, 8 bytes and 14 bytes

• Built-in baud-rate generator

8.4.4.2 Description

The UART is commonly used to implement a serial interface such as RS232. The

LPC2917/19 contains two industry-st andard 550 UAR Ts with 16-byte transmit and receive

FIFOs, but they can also be put into 450 mode without FIFOs.

8.4.4.3 UART pin description

The two UARTs in the LPC2917/19 have the following pins. The UAR T p ins are combine d

with other functions on the port pins of the LPC2917/19. Table 15

runs from 0 to 1).

Table 15. UART pins

Symbol Direction Description

UARTx TXD out UART channel x transmit data output

UARTx RXD in UART channel x receive data input

shows the UART pins (x

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 26 of 68

Page 27

NXP Semiconductors

8.4.4.4 UART clock descrip tio n

The UART modules are clocked by two different clocks; CLK_SYS_PESS and

CLK_UARTx (x = 0-1), see Section 7.2.2

branch clock for power management. The frequency of all CLK_UAR Tx clocks is identical

since they are derived from the same base clock BASE_CLK_UART. The register

interface towards the system bus is clocked by CLK_SYS_PESS. The baud generator is

clocked by the CLK_UARTx.

8.4.5 Serial peripheral interface

8.4.5.1 Overview

The LPC2917/19 contains three Serial Peripheral Interface modules (SPIs) to allow

synchronous serial communication with slave or master peripherals.

The key features are:

• Master or slave operation

• Supports up to four slaves in sequential multi-slave operation

• Supports timer-triggered operation

• Programmable clock bit rate and prescale based on SPI source clock

• Separate transmit and receive FIFO memory buffers; 16 bits wide, 32 locations deep

• Programmable choice of interface operation: Motorola SPI or Texas Instruments

• Programmable data-frame size from 4 to 16 bits

• Independent masking of transmit FIFO, receive FIFO and receive overrun interrupts

• Serial clock-rate master mode: fserial_clk ≤ f

• Serial clock-rate slave mode: fserial_clk = f

• Internal loopback test mode

ARM9 microcontroller with CAN and LIN

. Note that each UART has its own CLK_UARTx

(BASE_SPI_CLK), independent of system clock

Synchronous Serial Interfaces

CLK(SPI)*

CLK(SPI)*

DRAFT

/2

/4

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

DRAFT

AFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

8.4.5.2 Functional description

The SPI module is a master or slave interface for synchronous serial communication with

peripheral devices that have either Motorola SPI or Texas Instruments Synchronous

Serial Interfaces.

The SPI module performs serial-to-parallel conversion on data received from a peripheral

device. The transmit and receive paths are buffered with FIFO memories (16 bits wide x

32 words deep). Serial data is transmitted on SPI_TxD and received on SPI_RxD.

The SPI module includes a programmable bit-rate clock divider and pre scaler to ge nerate

the SPI serial clock from the input clock CLK_SPIx.

The SPI module’s operating mode, frame format, and word size are programmed thr ough

the SLVn_S ETTINGS registers.

A single combined interrupt request SPI_INTREQ output is asserted if any of the

interrupts are asserted and unmasked.

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 27 of 68

Page 28

NXP Semiconductors

Depending on the operating mode selected, the SPI_CS_OUT outputs operate as an

active-HIGH frame synchronization output for Texas Instruments synchronous serial

frame format or an active-LOW chip select for SPI.

Each data frame is between four and 16 bits long, depending on the size of words

programmed, and is transmitted starting with the MSB.

There are two basic frame types that can be selected:

• Texas Instruments synchronous serial

• Motorola Serial Peripheral Interface

8.4.5.3 Modes of operation

The SPI module can operate in:

• Master mode:

• Slave mode

– Normal transmission mode

– Sequential slave mode

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

DR

AFT

DRAFT

DRA

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DR

F

T DRAF

8.4.5.4 SPI pin description

The three SPI modules in the LPC2917/19 have the pins listed below. The pins are

combined with other functions on the port pins of the LPC2917/19, see Section 8.3.3

Table 16

Table 16. SPI pins

Symbol Direction Description

SPIx SCSy in/out SPIx chip select

SPIx SCK in/out SPIx clock

SPIx SDI in SPIx data input

SPIx SDO out SPIx data output

[1] Direction of SPIx SCS and SPIx SCK pins depends on master or slave mode. These pins are output in

[2] In slave mode there is only one chip-select input pin, SPIx SCS0. The other chip selects have no function in

shows the SPI pins (x runs from 0 to 2; y runs from 0 to 3).

master mode, input in slave mode.

slave mode.

8.4.5.5 SPI clock description

The SPI modules are clocked by two different clocks; CLK_SYS_PESS and CLK_SPIx (x

= 0-2), see Section 7.2.2

power management. The frequency of all clocks CLK_SPIx is identical as they ar e derived

from the same base clock BASE_CLK_SPI. The register interface towards the system bus

is clocked by CLK_SYS_PESS. The serial-clock rate divisor is clocked by CLK_SPIx.

.

[1][2]

[1]

. Note that each SPI has its own CLK_SPIx branch clock for

The SPI clock frequency can be controlled by the CGU. In master mode the SPI clock

frequency (CLK_SPIx) must be set to at least twice the SPI serial clock rate on the

interface. In slave mode CLK_SPIx must be set to four times the SPI serial clock rate on

the interface.

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 28 of 68

Page 29

NXP Semiconductors

8.4.6 General-purpose I/O

8.4.6.1 Overview

The LPC2917/19 contains four general-purpose I/O ports located at different peripheral

base addresses. In the 144-pin package all four ports are av ailable. All I/O pins are

bi-directional, and the direction can be programmed individually. The I/O pad behavior

depends on the configuration programmed in the port function-select registers.

The key features are:

• General-purpose parallel inputs and outputs

• Direction control of individual bits

• Synchronized input sampling for stable input-data values

• All I/O defaults to input at reset to avoid any possible bus conflicts

8.4.6.2 Description

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

The general-purpose I/O provides individual control over each bi-directio nal port pin.

There are two registers to control I/O direction and output level. The inputs are

synchronized to achieve stable read-levels.

To generate an open-drain output, set the bit in the output register to the desired value.

Use the direction register to control the signal. When set to output, the output driver

actively drives the value on the output: when set to input the signal floats and can be

pulled up internally or externally.

8.4.6.3 GPIO pin description

The five GPIO ports in the LPC2917/19 have the pins listed below. The GPIO pins are

combined with other functions on the port pins of the LPC2917/19. Table 17

GPIO pins.

Table 17. GPIO pins

Symbol Direction Description

GPIO0 pin[31:0] in/out GPIO port x pins 31 to 0

GPIO1 pin[31:0] in/out GPIO port x pins 31 to 0

GPIO2 pin[27:0] in/out GPIO port x pins 27 to 0

GPIO3 pin[15:0] in/out GPIO port x pins 15 to 0

8.4.6.4 GPIO clock descri p tio n

The GPIO modules are clocked by several clocks, all of which are derived from

BASE_SYS_CLK; CLK_SYS_PESS and CLK_SYS_GPIOx (x = 0-3), see Section 7.2.2

Note that each GPIO has its own CLK__SYS_GPIOx branch clock for power

management. The frequency of all clocks CLK_SYS_GPIOx is identical to

CLK_SYS_PESS since they are derived from the same base clock BASE_SYS_CLK.

shows the

.

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 29 of 68

Page 30

NXP Semiconductors

8.5 CAN gateway

8.5.1 Overview

Controller Area Network (CAN) is the definition of a high-performance communication

protocol for serial data communication. The two CAN controllers in the LPC2917/19

provide a full implementation of the CAN protocol according to the CAN specification

version 2.0B. The gateway concept is fully scalable with the number of CAN controllers,

and always operates together with a separate powerful and flexible hardware acce ptance

filter.

The key features are:

• Supports 11-bit as well as 29-bit identifiers

• Double receive buffer and triple transmit buffer

• Programmable error-warning limit and error counters with read/write access

• Arbitration-lost capture and error-code capture with detailed bit position

• Single-shot transmission (i.e. no re-transmission)

• Listen-only mode (no acknowledge; no active error flags)

• Reception of ‘own’ messages (self-reception request)

• Full CAN mode for message reception

DRAFT

ARM9 microcontroller with CAN and LIN

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

8.5.2 Global acceptance filter

The global acceptance filter provides look-up of received identifiers - called acceptance

filtering in CAN terminology - for all the CAN controllers. It includes a CAN ID look-up table

memory, in which software maintains one to five sections of identifiers. The CAN ID

look-up table memory is 2 kB large (512 words, each of 32 bit s). It can contain up to 1024

standard frame identifiers (SFF) or 512 extended frame identifiers (EFF) or a mixture of

both types. It is also possible to define identifier groups for standard and extended

message formats.

8.5.3 CAN pin description

The two CAN controllers in the LPC2917/19 have the p ins listed below. The CAN pins are

combined with other functions on the port pins of the LPC2917/19. Table 18

CAN pins (x runs from 0 to 1).

Table 18. CAN pins

Symbol Direction Description

CANx TXDC out CAN channel x transmit data output

CANx RXDC in CAN channel x receive data input

8.6 LIN

8.6.1 Overview

shows the

The LPC2917/19 contain two LIN 2.0 master con trollers. These can be used as dedicated

LIN 2.0 master controllers with additional support for sync break generation and with

hardware implementation of the LIN protocol according to spec 2.0.

The key features are:

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 30 of 68

Page 31

NXP Semiconductors

• Complete LIN 2.0 message handling and transfer

• One interrupt per LIN message

• Slave response time-out detection

• Programmable sync-break length

• Automatic sync-field and sync-break generation

• Programmable inter-byte space

• Hardware or software parity generation

• Automatic checksum generation

• Fault confinement

• Fractional baud-rate generator

8.6.2 LIN pin description

The two LIN 2.0 master controllers in the LPC2917/19 have the pins listed be low. The LIN

pins are combined with other functions on the port pins of the LPC2917/19. Table 19

shows the LIN pins. For more information see Ref. 1

controller.

Table 19. LIN controller pins

Symbol Direction Description

LIN0/1 TXDL out LIN channel 0/1 transmit data output

LIN0/1 RXDL in LIN channel 0/1 receive data input

DRAFT

ARM9 microcontroller with CAN and LIN

subsection 3.43, LIN master

D

RAFT DRAFT DRAFT DRAFT DRAFT D

D

LPC2917/19

RAFT DRA

D

RAFT

F

T DRAFT DRAFT DRAFT DRA

DR

AFT

DRAFT

DRA

DR

AFT

DRAFT

DR

F

T DRAF

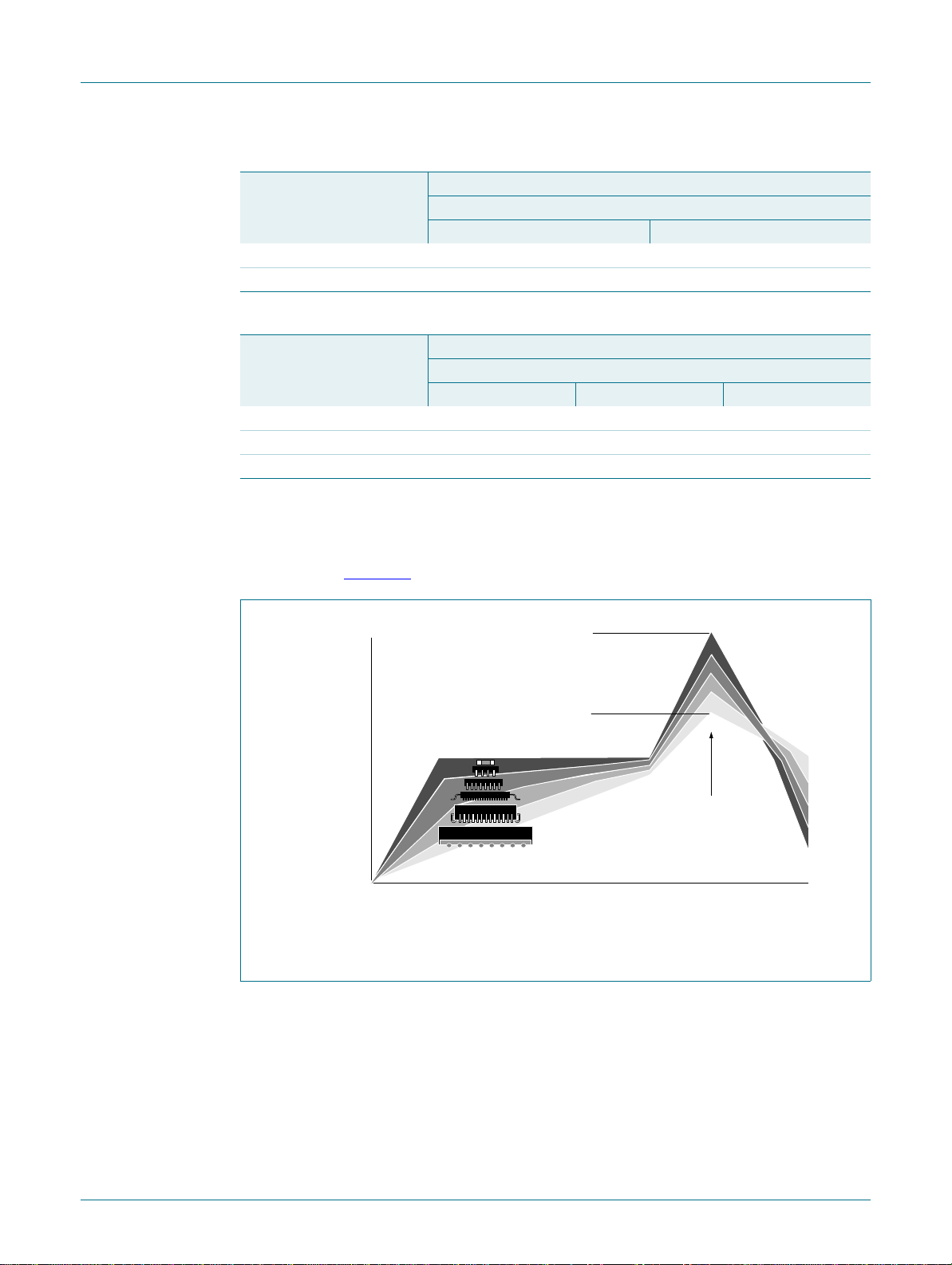

8.7 Modulation and sampling control subsystem

8.7.1 Overview

The Modulation and Sampling Control Subsystem (MSCSS) in the LPC2917/19 includes

four Pulse-Width Modulators (PWMs), three10-bit successi ve approximation

Analog-to-Digital Converters (ADCs) and two timers.

The key features of the MSCSS are:

• Two 10-bit, 400 ksamples/s, 8-channel ADCs with 3.3 V inputs and various trigger-

start options

• Four 6-channel PWMs (Pulse-Width Modulators) with capture and trap functionality

• Two dedicated timers to schedule and synchronize the PWMs and ADCs

8.7.2 Description

The MSCSS contains Pulse-Width Modulators (PWMs), Analog-to-Digital Converters

(ADCs) and timers.

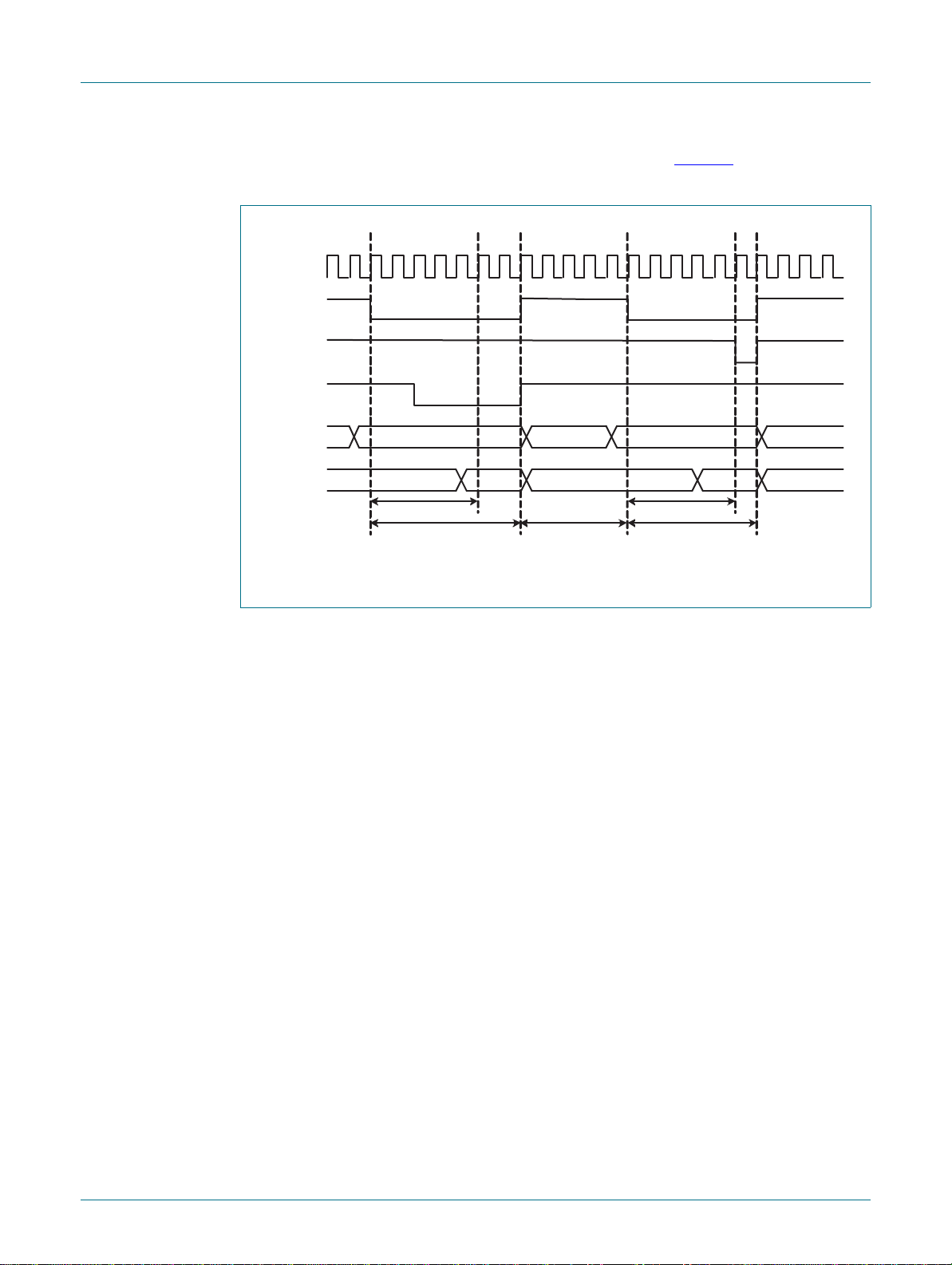

Figure 7

communication with the AHB system bus. Two internal timers are dedicated to this

subsystem. MSCSS timer 0 can be used to generate start pulses for the ADCs and the

first PWM. The second timer (MSCSS timer 1) is used to generate ‘carrier’ signals for the

PWMs. These carrier patterns can be used, for example, in applications requiring current

provides an overview of the MSCSS. An AHB-to-VPB bus bridge takes care of

LPC2917_19_1 © NXP B.V. 2007. All rights reserved.

Preliminary data sheet Rev. 1.01 — 15 November 2007 31 of 68

Page 32

NXP Semiconductors

002aad348

PWM0 MAT[5:0]

PWM1 MAT[5:0]

PWM2 MAT[5:0]

PWM3 MAT[5:0]

ADC

1

3.3 V

ADC

2

3.3 V

PWM

0

MSCSS

TIMER 1

PWM

CONTROL

CARRIERS

MSCSS

TIMER 0

ADC

CONTROL

SYNCS

AHB2VPB

BRIDGE

PWM

1

PWM

2

PWM

3

AHB

system bus

VPB sub system bus

(to all sub blocks)

ADC2 IN[7:0]

ADC2_EXT_START

ADC1 IN[7:0]

ADC1_EXT_START

ADC clock

PWM0 TRAP

PWM0 CAP[2:0]

PWM1 TRAP

PWM1 CAP[2:0]

PWM2 TRAP

PWM2 CAP[2:0]

PWM3 TRAP

PWM3 CAP[2:0]

control. Several other trigger possibilities are provided for the ADCs (external, cascaded

or following a PWM). The capture inputs of both timers can also be used to capture the

start pulse of the ADCs.

The PWMs can be used to generate waveforms in which the frequency, duty cycle and

rising and falling edges can be controlled very precisely. Capture inputs are provided to