NXP Semiconductors Digital DNA MSC8102 User Manual And Hardware Detailed Design Description

Page 1

MSC8102PFCUG/D

Rev. 1.3

MSC8102 - Packet Telephony Farm Card (PFC)

User Guide and Hardware Detailed Design

Description

PFC_DDD_v1.3.doc

Author: Colin McEwan Mark Knox

Email: colin.mcewan@motorola.com mark.knox@motorola.com

Phone: +44 1355 356061 +44 1355 356034

Networking and Computing Systems Group (NCSG)

Colvilles Road, Kelvin Industrial Estate, East Kilbride, Glasgow G75 OTG. 44 (0) 1355 355000. Fax:

44 (0) 1355 260780

Reg. Office: Motorola Ltd., Jays Close, Viables Industrial Estate, Basingstoke, Hants., RG22 4PD

(registration No. 912182 England)

Page 2

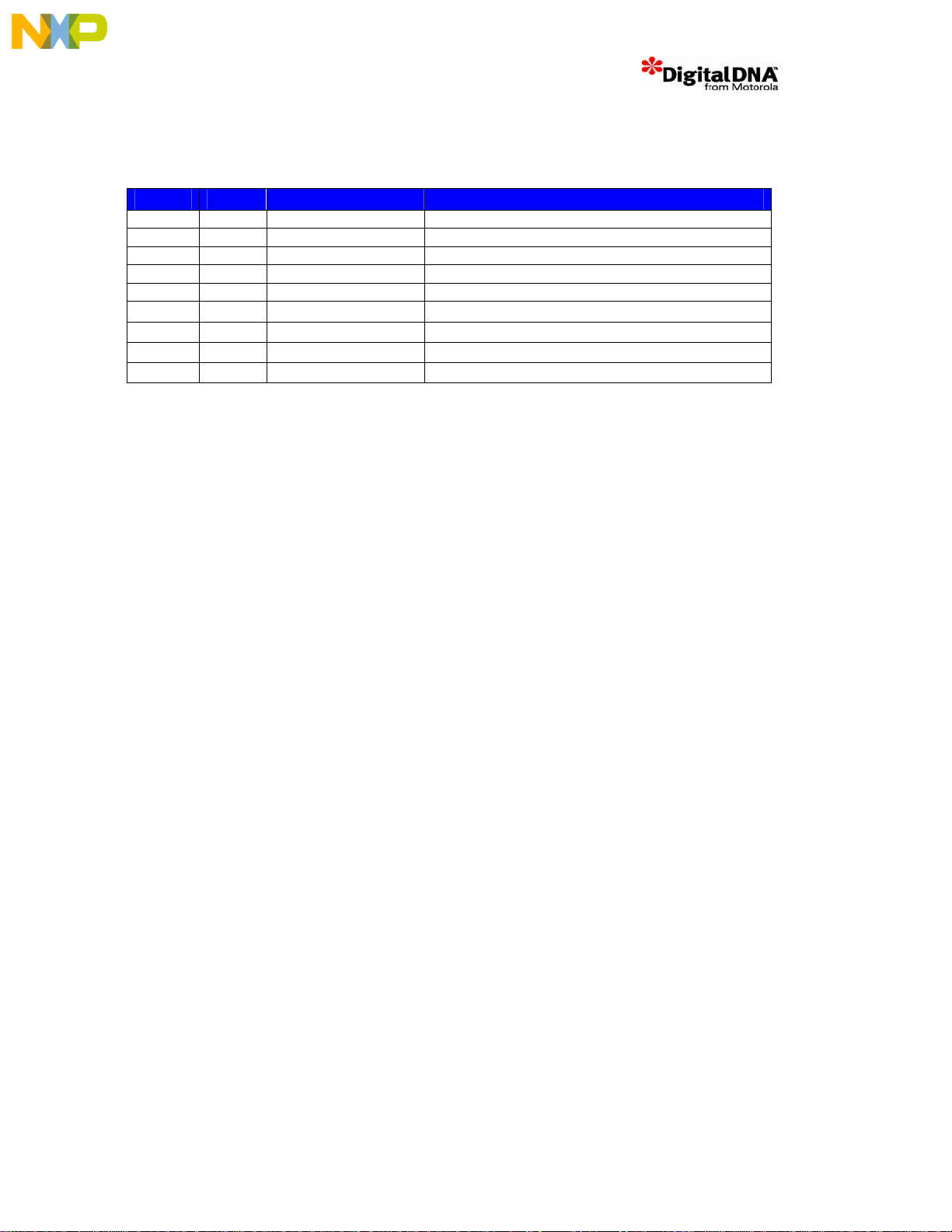

Revision History

Revision By Date Descri p ti o n of Change

1.0 CM 24/1/3 First Issue

1.1 CM 7/3/3 Updated to reflect Pilot Production Boards

1.2 CM 27/3/3 MSC8102 SDRAM increased to 16MB

1.3 CM 21/4/3 Pilot Production Releas e (with quick start guide)

i PFC_DDD_v1.3.doc

Page 3

CONTENTS

1 OVERVIEW......................................................................................................................................................................1

1.1 SCOPE..............................................................................................................................................................................1

1.2 REFERENCE DOCUMENTS................................................................................................................................................1

2 PFC OVERVIEW.............................................................................................................................................................2

3 PFC FEATURE LIST.......................................................................................................................................................3

4 USER GUIDE....................................................................................................................................................................4

4.1 QUICK START ..................................................................................................................................................................4

4.2 BOARD CONFIGURATION OPTIONS.................................................................................................................................. 5

4.2.1 Single MSC8101 with Default Configuration..........................................................................................................5

4.2.2 MSC8101 Boot thro ug h HD I1 6..................................................................................................... ..........................6

4.2.3 MSC8101 Ethernet /U t op i a Op t i on s .................. .......................................................................................................6

4.2.4 MSC8102 DSI Optio n s............................................................................................................................................6

4.2.5 JTAG options..........................................................................................................................................................6

4.3 PROGRAMMING FLASH....................................................................................................................................................7

5 HARDWARE DESCRIPTION........................................................................................................................................8

5.1 BOARD ARCHITECTURE................................................................................................................................................... 8

5.2 MSC8101 AGGREGATOR & 60X BUS INTERFACE............................................................................................................ 8

5.2.1 MSC8101 SDRAM Interface ................................................................................................................................... 9

5.2.1.1 SDRAM Initialization Command Sequence.................................................................................................. 10

5.2.1.2 SDRAM Refresh........................................................................................................................................... 11

5.2.2 MSC8101 FLA SH Inte rf ace..................................................................................................................................11

5.2.3 MSC8101 60x to DSI Interface.............................................................................................................................12

5.2.3.1 MSC8101 60x to DSI Interface: Synchronous mode.....................................................................................12

5.2.3.2 MSC8101 60x to DSI Interface: Asynchronous mode...................................................................................13

5.2.4 MSC8101 to MSC8102 Interrupt Connectivity......................................................................................................13

5.2.5 MSC8101 FCC Interf ac e.................................. ................................................... ..................... .............................15

5.2.6 RMII Interface.......................................................................................................................................................16

5.2.7 MSC8101 I2C Controlle r......................................................................................................................................16

5.2.8 MSC8101 RS232 Inter fa ce....................................................................................................................................16

5.2.9 MSC8101 Host Interf ace (H D I 16)........................................................................................................................16

5.3 MSC8102 DSP PROCESSING ARRAY.............................................................................................................................17

5.3.1 DSP Array SDRAM Configuration........................................................................................................................17

5.3.1.1 SDRAM Initialization Command Sequence.................................................................................................. 19

5.3.1.2 SDRAM Refresh........................................................................................................................................... 19

5.3.2 MSC8102 Array DSI Interface.............................................................................................................................. 19

5.3.3 MSC8102 Array TDM Interface............................................................................................................................19

5.3.4 MSC8102 RS232 Inter fa ce....................................................................................................................................21

5.4 GENERAL BOARD CONFIGURATION...............................................................................................................................21

5.4.1 Reset......................................................................................................................................................................21

5.4.2 Clock Distribution.................................................................................................................................................22

5.4.3 Power....................................................................................................................................................................24

5.4.4 FPGA Configuration.............................................................................................................................................24

5.4.5 PTMC Connectors.................................................................................................................................................24

5.4.6 JTAG Connectivity................................................................................................................................................29

5.4.7 LEDs.....................................................................................................................................................................30

5.5 PFC BOARD CONFIGURATION.......................................................................................................................................30

6 FIRMWARE IMPL E MEN TA TION.............................................................................................................................32

6.1 MSC8101 HOST MEMORY CONTROLLER SETTINGS......................................................................................................32

6.2 MSC8102 MEMORY CONTROLLER SETTINGS ............................................................................................................... 33

6.3 PFC RESET CONFIGURATION WORD (MSC8101).......................................................................................................... 34

6.4 PFC RESET CONFIGURATION WORD (MSC8102).......................................................................................................... 35

6.5 PFC BOOTSTRAP...........................................................................................................................................................35

7 PFC BASE CARD...........................................................................................................................................................37

7.1 UTOPIA INTERFACE.....................................................................................................................................................37

7.2 I2C INTERFACE ............................................................................................................................................................. 38

7.3 HDI16 INTERFACE ........................................................................................................................................................38

7.4 CT BUS INTERFACE.......................................................................................................................................................39

7.5 ETHERNET INTERFACE ..................................................................................................................................................39

APPENDIX A PFC PARTS..................................................................................................................................................... 41

ii PFC_DDD_v1.3.doc

Page 4

APPENDIX B PFC BASE CARD PARTS..............................................................................................................................43

APPENDIX C JTAG CONFIGURATION FILE (21 CORES).............................................................................................44

APPENDIX D PFC LAYOUT.................................................................................................................................................45

FIGURES

FIGURE 1. MSC8102 - PACKET TELEPHONY FARM CARD .............................................................................................................. 2

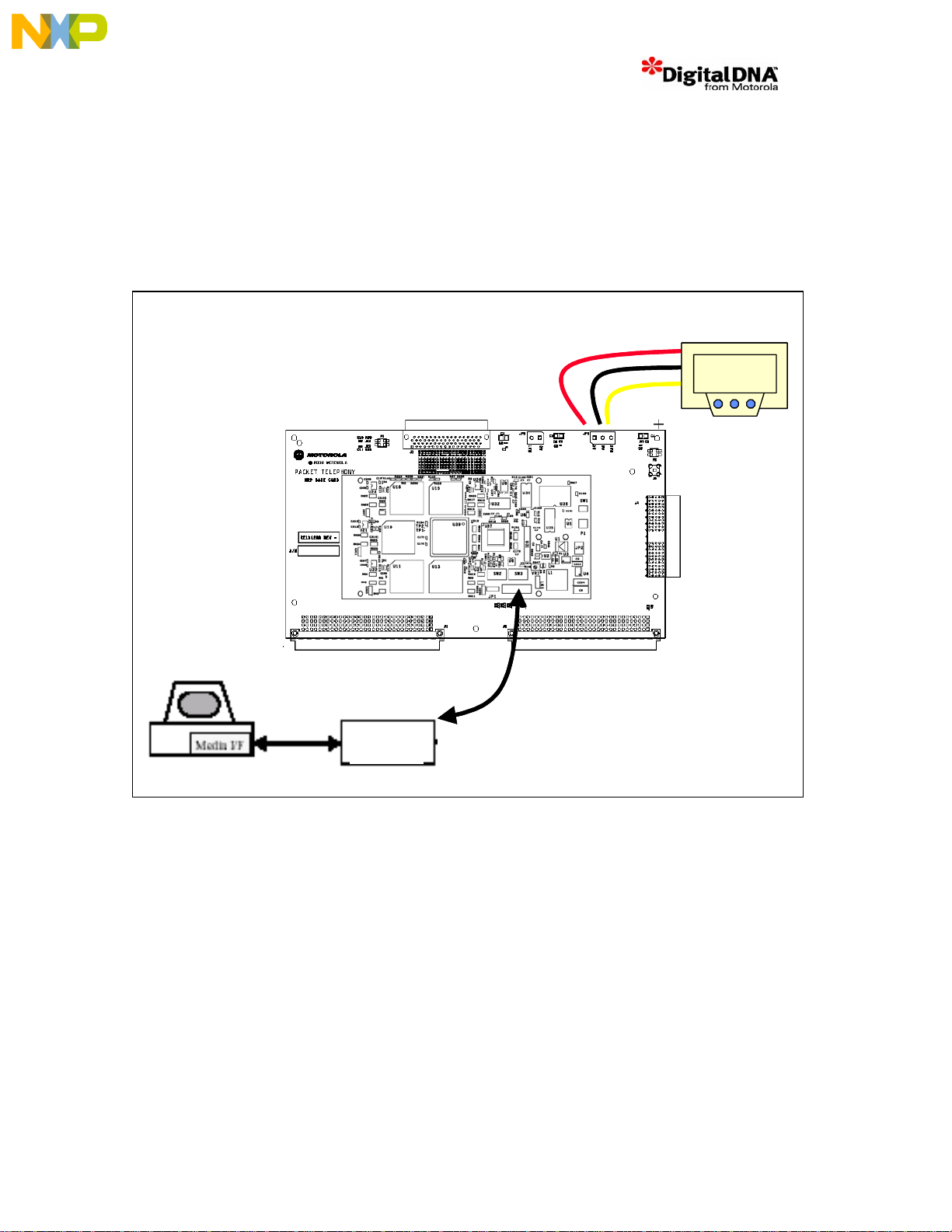

FIGURE 2. PFC SETUP ....................................................................................................................................................................4

FIGURE 3. PACKET TELEPHONY FARM CARD ARCHITECTURE........................................................................................................8

FIGURE 4. SDRAM MODE REGISTER SETTINGS...........................................................................................................................11

FIGURE 5. REFRESH CALCULATIONS ............................................................................................................................................11

FIGURE 6. PFC TO DSI INTERFACE...............................................................................................................................................13

FIGURE 7. AGGREGATOR MSC8102 INTERRUPT CONNECTIVITY OPTIONS...................................................................................14

FIGURE 8. STANDARD INTERRUPT ROUTING ................................................................................................................................14

FIGURE 9. SDRAM MODE REGISTER SETTINGS...........................................................................................................................19

FIGURE 10. REFRESH CALCULATIONS ........................................................................................................................................... 19

FIGURE 11. TDM TO CT ROUTING ............................................................................................................................................... 20

FIGURE 12. PORESET SCHEME ...................................................................................................................................................22

FIGURE 13. HRESET SCHEME .....................................................................................................................................................22

FIGURE 14. MSC8101 AGGREGATOR CLOCKING SCHEME ...........................................................................................................23

FIGURE 15. MSC8102 AND SDRAM CLOCKING .......................................................................................................................... 23

FIGURE 16. SETTING VOUT WITH RESISTOR-DIVIDER..................................................................................................................24

FIGURE 17. JTAG CHAIN .............................................................................................................................................................30

FIGURE 18. MSC8101 HOST MEMORY MAP ................................................................................................................................33

FIGURE 19. MSC8102 MEMORY MAP ..........................................................................................................................................34

FIGURE 20. PFC BOOTSTRAP METHOD ........................................................................................................................................36

FIGURE 21. PFC & BASE CARD LAYOUT......................................................................................................................................37

FIGURE 22. PFC LAYOUT - TOP.................................................................................................................................................... 45

FIGURE 23. PFC LAYOUT - BOTTOM ............................................................................................................................................45

TABLES

TABLE 1. REFERENCE DOCUMENTS................................................................................................................................................1

TABLE 2. MSC8101 BOOT FROM FLASH ........................................................................................................................................ 5

TABLE 3. MSC8102 BOOT THROUGH DSI......................................................................................................................................5

TABLE 4. FULL CHAIN (JTAG OF 21)..............................................................................................................................................5

TABLE 5. MSC8101 DEFAULT RESET CONFIGURATION WORD......................................................................................................5

TABLE 6. MSC8101 HDI16 BOOT..................................................................................................................................................6

TABLE 7. JTAG OPTIONS...............................................................................................................................................................6

TABLE 8. MSC8101 MEMORY CONTROLLER RESOURCES..............................................................................................................9

TABLE 9. PSDMR SETTINGS ..........................................................................................................................................................9

TABLE 10. OR & BR SETTINGS....................................................................................................................................................10

TABLE 11. MSC8102 DSI ADDRESSES.........................................................................................................................................11

TABLE 12. MSC8102 DSI ADDRESSES.........................................................................................................................................12

TABLE 13. DSI ASYNCHRONOUS SIGNALS ................................................................................................................................... 1 3

TABLE 14. FCC1 INTERFACE........................................................................................................................................................15

TABLE 15. MSC8101 AGGREGATOR FCC2 PTMC CONNECTIVITY ............................................................................................. 16

TABLE 16. HDI6 CONFIGURATION...............................................................................................................................................17

TABLE 17. PSDMR SETTINGS ......................................................................................................................................................18

TABLE 18. OR SETTINGS ..............................................................................................................................................................18

TABLE 19. TDM TO CT STREAM ROUTING..................................................................................................................................21

TABLE 20. MSC8101 CLOCK FREQUENCIES .................................................................................................................................22

TABLE 21. MSC8102 CLOCK FREQUENCIES .................................................................................................................................22

TABLE 22. PN1/JN1 CONNECTOR PIN OUT (CPORT INTERFACE).................................................................................................25

TABLE 23. PN2/JN2 CONNECTOR PIN OUT (HOST PORT INTERFACE)...........................................................................................26

TABLE 24. PN3/JN3 CONNECTOR PIN OUT (CT BUS & RMII)......................................................................................................27

TABLE 25. PN4/JN4 CONNECTOR PIN OUT (UTOPIA) .................................................................................................................28

TABLE 26. PN5/JN5 CONNECTOR PIN OUT (ETHERNET)............................................................................................................... 29

TABLE 27. SWITCH 3 DESCRIPTIONS ............................................................................................................................................ 30

TABLE 28. SWITCH 2 DESCRIPTIONS ............................................................................................................................................ 30

TABLE 29. MSC8101 MEMORY CONTROLLER RESOURCES.......................................................................................................... 32

TABLE 30. MSC8102 MEMORY CONTROLLER RESOURCES.......................................................................................................... 33

TABLE 31. MSC8101 HARD RESET CONFIGURATION WORD .......................................................................................................34

TABLE 32. MSC8102 HARD RESET CONFIGURATION WORD .......................................................................................................35

TABLE 33. UTOPIA INTERFACE...................................................................................................................................................37

TABLE 34. I2C INTERFACE ...........................................................................................................................................................38

TABLE 35. HDI16 INTERFACE ......................................................................................................................................................38

iii PFC_DDD_v1.3.doc

Page 5

TABLE 36. CT BUS .......................................................................................................................................................................39

TABLE 37. ETHERNET INTERFACE ................................................................................................................................................40

TABLE 38. MISCELLANEOUS SIGNALS.......................................................................................................................................... 40

iv PFC_DDD_v1.3.doc

Page 6

1 Overview

1.1 Scope

This document provides user guide information and a detailed design description of the MSC8102

Packet Telephony Farm Card.

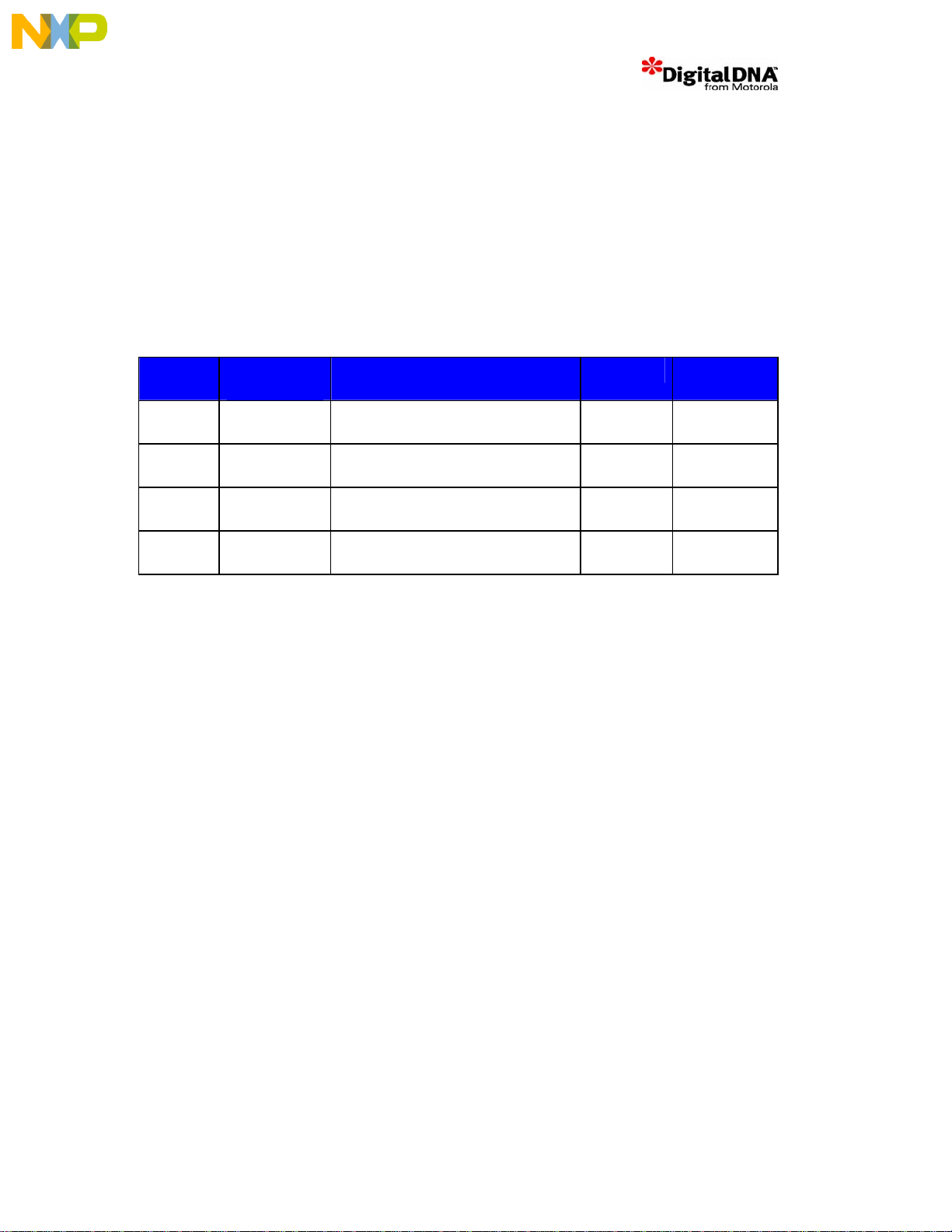

1.2 Reference Documents

The documents listed in the table below are referenced in this document.

Table 1. Reference Documents

Reference Document

Number

1 IEEE P1386.1 Standard Physical and Environmental

2 IEEE P1386 Standard for a Common Mezzanine

3 PICMG 2.15 CompactPCI PCI Telecom

4 H.100 H.100 Hardware Compatability

Description Revision Date

Layers for PCI Mezzanine Cards: PMC

Card Fa mi l y: CMC

Mezzanine/Card Card Specification

Specification : CT Bus

Draft 2.4 January 12,

2001

Draft 2.4a March 21,

2001

R1.0 April 11, 2001

1.0

1 PFC_DDD_v1.3.doc

Page 7

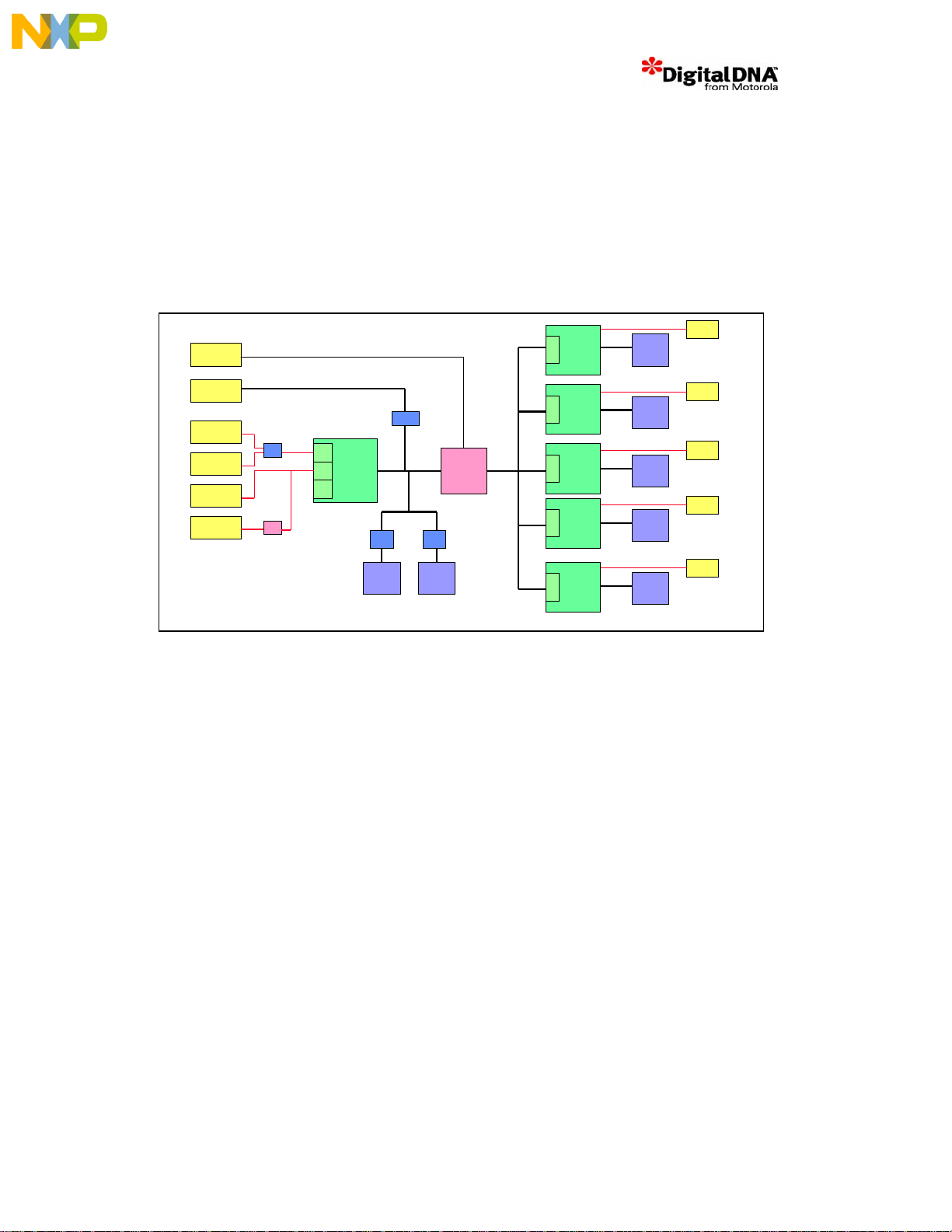

2 PFC Overview

The Packet Telephony Farm Card is a PCI Telephony Mezzanine Card (PTMC) designed primarily as

an MSC8102 upgrade and Media Gateway evaluation product for Media Gateway Systems. It is

designed around the Star-Core MSC8102 16 bit fixed point DSP device from Motorola Semiconductor.

The PFC DSP farm card utilizes five MSC8102 devices and a MSC8101 to aggregate the data to/from

the DSP farm. Each MSC8102 DSP has an associated 4M x 32 (16MB) SDRAM. The aggregator has

a separate 2M x32 (8MB) SDRAM.

The PFC interfaces with a baseboard platform via its PTMC site. A PTMC is a PMC module, which

conforms to the PMC standard for Jn1 and Jn2, but uses Jn3 and Jn4 to support a variety of telecom

interfaces. The PTMC site on the Media Gateway is configured as PT3MC, a subset of the PTMC

specification, which supports UTOPIA, RMII and CT bus interfaces on Jn3/4. An optional fifth

connector (Jn5) has been added to support the two MII interfaces available from the MSC8101; Jn5 is

a proprietary connector, effectively supporting an enhanced PTMC, which is backward compatible

with existing PTMCs.

Data movement around the board is primarily through the use of 10/100 Mb/s Ethernet (single RMII or

dual MII interfaces) or UTOPIA and a Computer Telephony local bus through the PTMC connectors.

Additionally an I2C management interface is facilitated through PTMC J3 connect or. Additional I/O

includes HDI16, RS232 and OnCE JTAG ports for Debug.

The PFC is targeted to interface with Motorola Packet Telephony enhanced PTMC baseboards such as

the PDK demonstration system, as well as interfacing with standard customer PTMC Type III

baseboards.

Figure 1. MSC8102 - Packet Telephony Farm Card

2 PFC_DDD_v1.3.doc

Page 8

3 PFC Feature List

PFC Platfor m

Digital Support for up to 672 chan nels

PTMC Type 3 form card for interfacing to standard subsystems

MSC8101 Aggregator

One MSC8101 DSP communications processor with:

10/100BaseT Fast Ethernet via PTMC Interface

RMII Ethernet via PTMC Interface

UTOPIA interface via PTMC Interface

Host Interface to enable Host control of Aggregator via PTMC Interface

64-bit/32-bit PPC interface to the MSC8102 DSI port for on board data

distribution to DSP Farm

RS232 interface on board

4MByte of Flash for System Bootstrap

8MByte of SDRAM

MSC810 2 Farm

Five MSC8102s DSPs each with

TDM interface (CT Bus) via PTMC interface

64-bit/32-bit DSI Slave port interfacing to the MSC8101 PPC (via FPGA) for data

distribution

DSI-Asynchronous mode of ope ration

DSI-Synchronous mode of operation

16MByte of SDRAM

MSC8102 DSP1 has RS232 interface on board

FPGA

PPC to DSI translation for synchronous DSI

Transparent mode for asynchronous DSI

Routing of MSC8102 to MSC8101 interrupts

CPORT cluster interface

MII to RMII conversion

Debug

Chained DSP EONCE port with option to configure the full 5 MSC8102s and

MSC8101 chain or only the MSC8101 DSP.

SMC2 RS232 Connection to the MSC8101

UART connection to one MSC8102

Break out card allows access to Utopia interfaces via connectors

Power Supply

For stand al one ope rat i on 5V / 3.3V su ppl ie d e xte rn ally via bas e ca rd w it h opti on t o

supply 1.6V externally or via on board PFC 5V to 1.6V step down.

3 PFC_DDD_v1.3.doc

Page 9

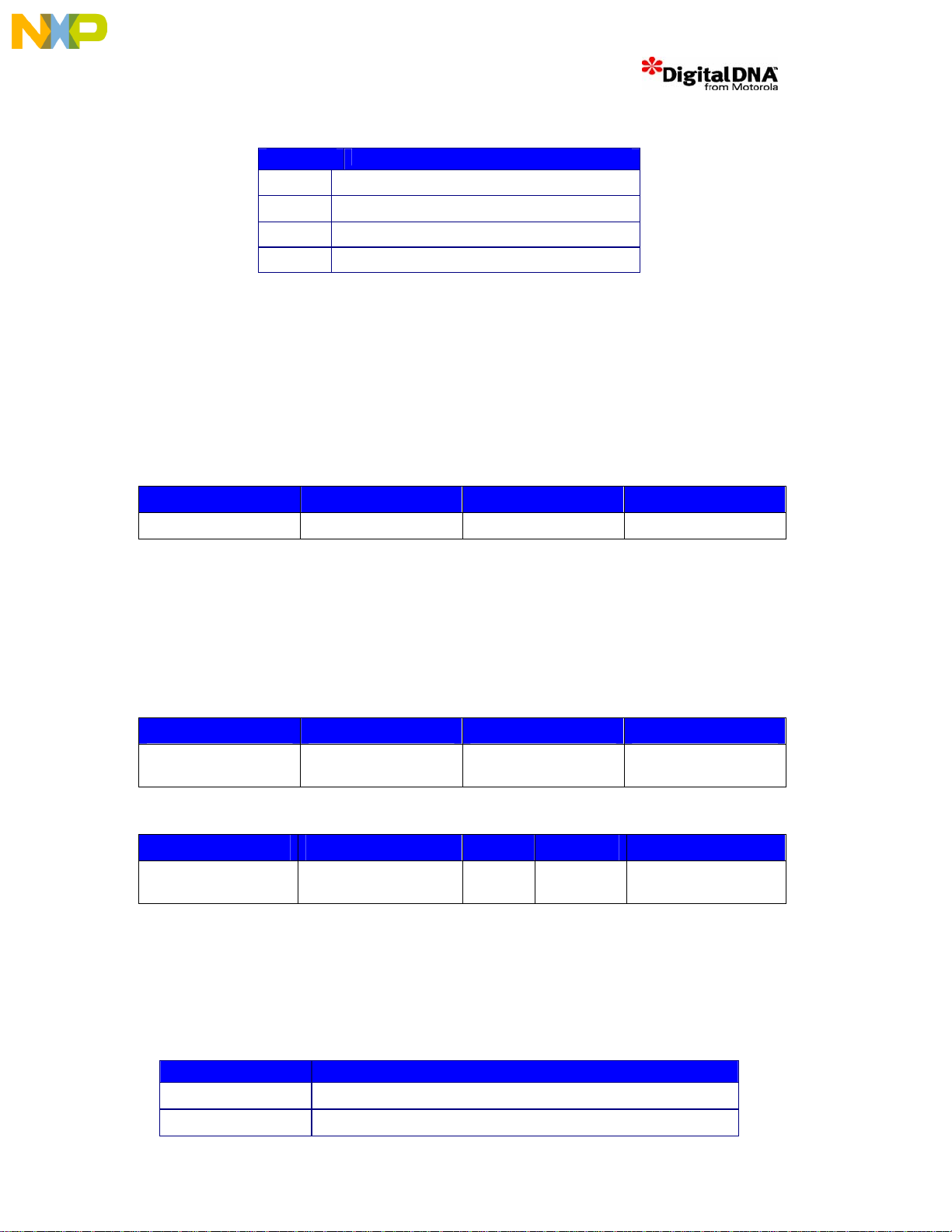

4 User Guide

4.1 Quick Start

1. Start the Start the Codewarrior tools and ensure that the command converter is running

2. Connect a dual supply to the 5V, 3.3V and 0V on the JP1 connector of the Base Card.

3. The parallel command converter should also be connected to P 3 on the P FC to enable JTAG

access, reference Figure 2.

3.3V

0V

0V

3.3V

5V

5V

Host

Host

Host

Computer

Computer

Computer

Command

Command

Command

Converter

Converter

Converter

Figure 2. PFC Setup

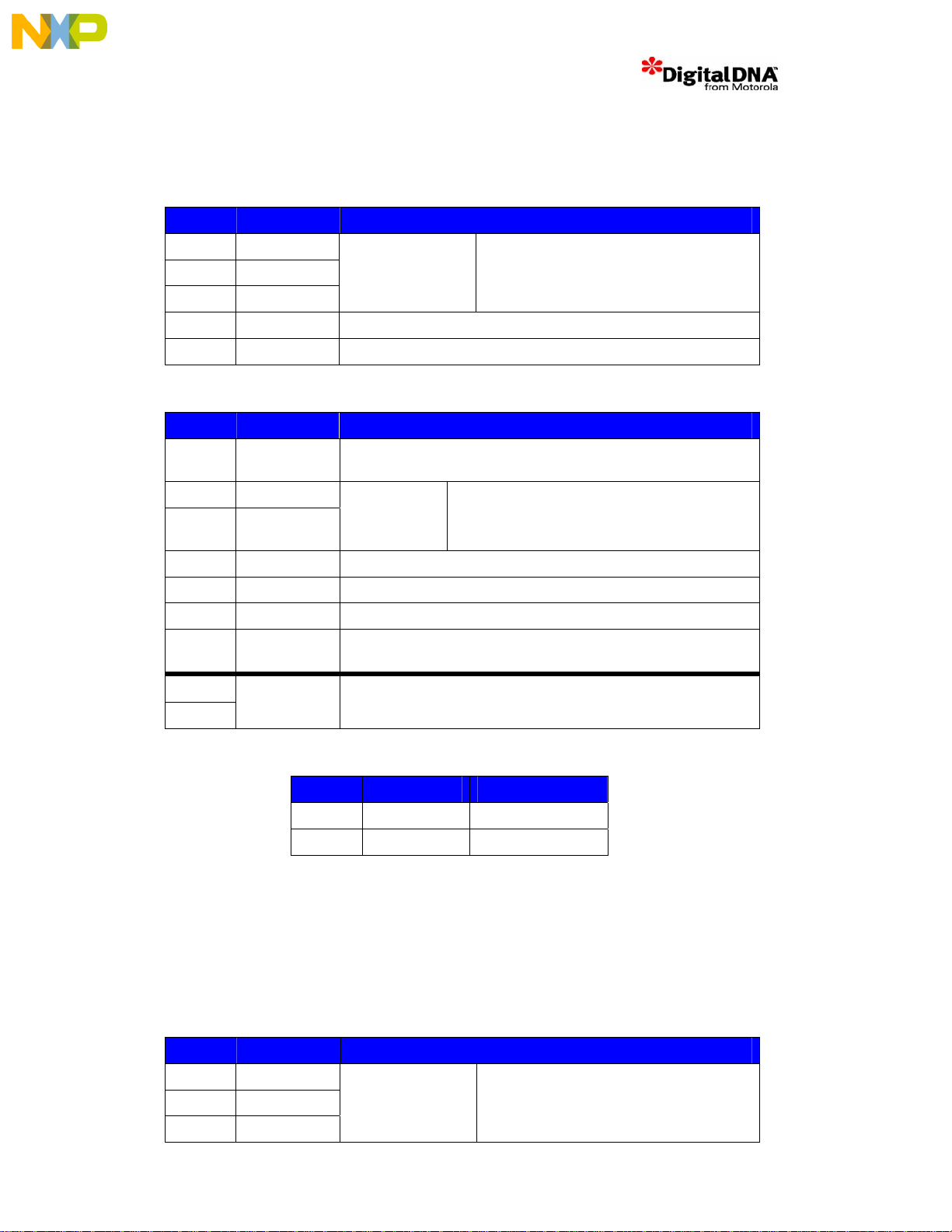

4. Set the switch settings as per Table 2, Table 3 and Table 4.

5. Power up the PFC, which will now automatically bootstrap in the following modes:

• MSC8101 Boot from Flash

o Operating frequency: 275 MHz Core/ 138 MHz CPM / 69MHz system bus

• MSC8102 Boot through DSI

o Operating frequency: 250MHz core/ 83MHz system bus

o 32-bit asynchronous DSI

• JTAG of 21 cores

Each DSP LED will light after approximately 4 seconds (delay due to FPGA programming)

indicating a successful bootstrap.

6. The user can now use the StarCore Codewarrior tools to access the DSPs. Note that the user

should ensure the following:

o That reset on connect is NOT selected (a tools reset will restart the boot process,

preventing MSC8102 DSP JTAG access)

4 PFC_DDD_v1.3.doc

Page 10

o The JTAG file “PFCjtag21.cfg” is selected. The file listing and core JTAG

numbering is detailed in Appendix C.

Table 2. MSC8101 Boot from Flash

Feature Settings Comments

SW3.1 OFF

SW3.2 OFF

SW3.3 ON

SW3.4 ON Boot=0, Host Port disabled, Boot from external memory.

SW3.8 ON RSTCONF=0, Reset Configuration Master

Feature Settings Comm ents

SW2.1 OFF CNFGS=1 [MSC8102 Boot Over DSI]. Keeps MSC8102s in reset

SW2.2 ON

SW2.3 OFF

SW2.4 ON DSI64 =0, DSI is 32-bit

SW2.5 ON DSISYNC=0, DSI operates in asynchronous mode

SW2.6 ON SWTE=0, Software WDT disabled

SW2.7 ON RSTCONF=0 [MSC8102 Boot over DSI]. Keeps MSC8102s in reset

A_MODCK1 = 1

A_MODCK2= 1

A_MODCK3= 0

Table 3. MSC8102 Boot through DSI

until RCW received

MODCK2=0

MODCK1=1

until RCW received

MODCK 46 [101-110].

CLKIN=34.5MHz

Core/CPM/Bus= 275/138/69 MHz

MODCK 10 [010-10].

CLKIN=41.6MHz

Core/Bus= 250/83 MHz

SW3.6

SW3.7

OFF

ON

BM2: MSC8102 Boot Sequence through DSI

BM1

Table 4. Full chain (JTAG of 21)

Feature Settings Comments

JP1 Pos 1-2 Full Cha in

SW2.8 ON Full Chain

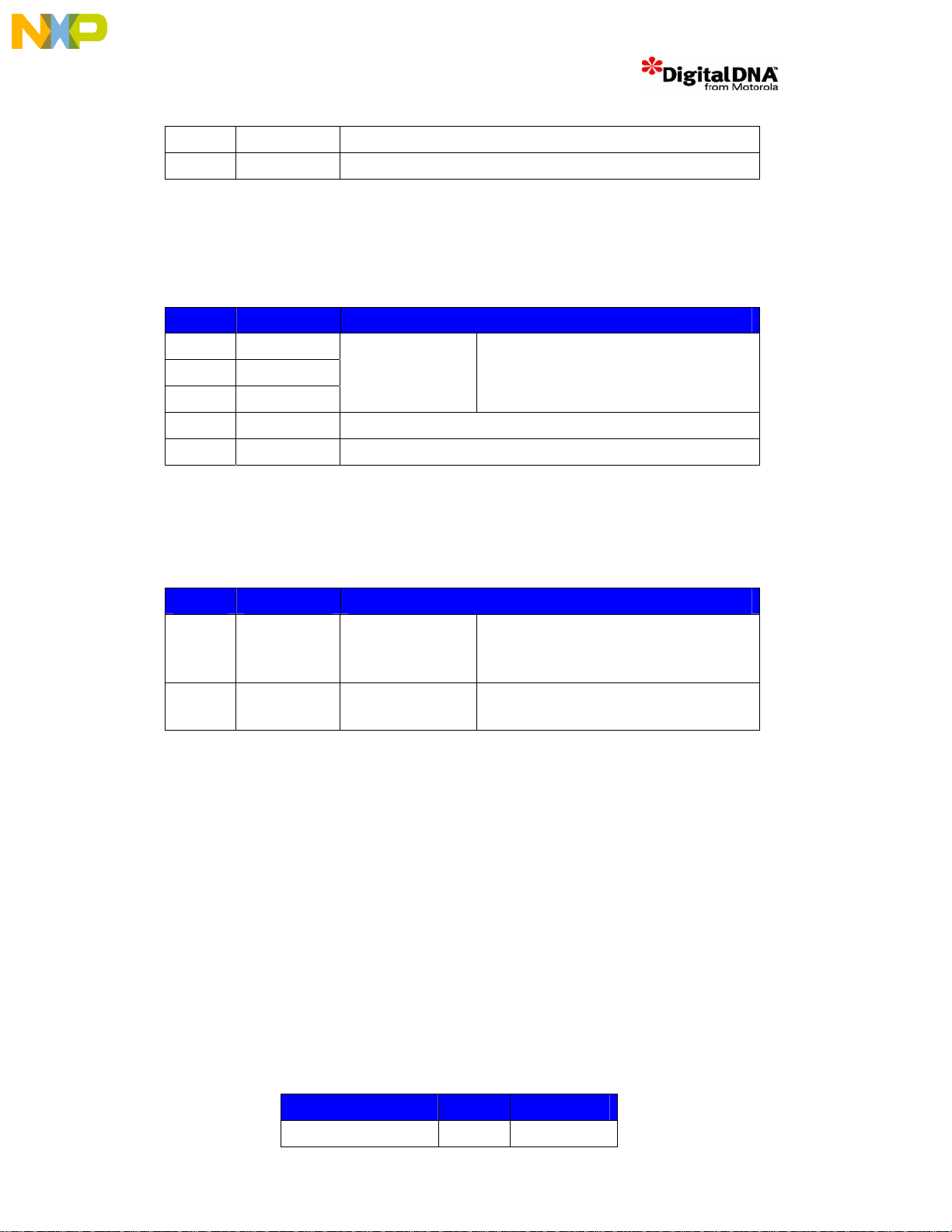

4.2 Board Configuration Options

4.2.1 Single MSC8101 with Default Configuration

To initialize the MSC8101 with its default Reset Configuration Word, set the switch settings detailed

in Table 5 and Table 8 (MSC8101 only). Note that this mode allow tools access to the MSC8101 only

(the MSC8102s will remain in reset), and should be used when the flash is blank or corrupted.

Table 5. MSC8101 Default Reset Configuration Word

Feature Settings Comments

SW3.1 OFF

SW3.2 OFF

SW3.3 ON

A_MODCK1 = 1

A_MODCK2= 1

A_MODCK3= 0

MODCK 6 [000-110].

CLKIN=34.5MHz

Core/CPM/Bus= 138/69/34.5 MHz

5 PFC_DDD_v1.3.doc

Page 11

SW3.4 ON Boot=0, Host Port disabled, Boot from external memory

SW3.8 OFF RSTCONF=1, Reset Configuration Slave

4.2.2 MSC8101 Boot through HDI16

To bootstrap the PFC through the MSC8101 HDI16 interface, set the switch settings detailed in Table

6 and Table 3.

Table 6. MSC8101 HDI16 Boot

Feature Settings Comments

SW3.1 OFF

SW3.2 OFF

SW3.3 ON

SW3.4 OFF Boot=1, Host Port enabled, MSC8101 boot from HDI16

SW3.8 OFF RSTCONF=1, Reset Configuration Slave

A_MODCK1 = 1

A_MODCK2= 1

A_MODCK3= 0

4.2.3 MSC8101 Ethernet/Utopia Options

Switch SW3.5 can be used to select the required MSC8101 CPM options as detailed below

Table 7. MSC8101 Ethernet/Utopia Options

Feature Settings Comments

SW3.5 ON FCC1

UTOPIA

SW3.5 OFF FCC1

Ethernet MII1

MODCK 46 [101-110].

CLKIN=34.5MHz

Core/CPM/Bus= 275/138/69 MHz

FCC2

Ethernet (MII2)

FCC2

Ethernet (MII2)

4.2.4 MSC8102 DSI Options

The MSC8102 DSI port cam be configured into 1 of 4 modes

• 32-bit wide Asynchronous Mode

• 64-bit wide Asynchronous Mode

• 32-bit wide Synchronous Mode

• 64-bit wide Synchronous Mode

The PFC is delivered with 32-bit wide asynchronous mode as standard, which is preprogrammed in

Flash memory. To implement a different mode the user should contact Motorola to obtain the required

firmware.

4.2.5 JTAG options

There are 2 JTAG options available as detailed in Table 8:

Table 8. JTAG Options

Description Feature Settings

MSC8101 only JP1 P os 2-3

6 PFC_DDD_v1.3.doc

Page 12

SW2.8 OFF

JP1 Pos 1-2 Full Chain (21 cores)

The JTAG configuration file for 21 cores is listed in Appendix C.

4.3 Programming Flash

The PFC uses the same Flash (AM29LV320DB) as the MSC8102ADS so the option exists to use

either the Metrowerks Code-warrior or PFC specific Flash Programmer (consult Motorola for

additi onal details on program ming Flash).

SW2.8 ON

7 PFC_DDD_v1.3.doc

Page 13

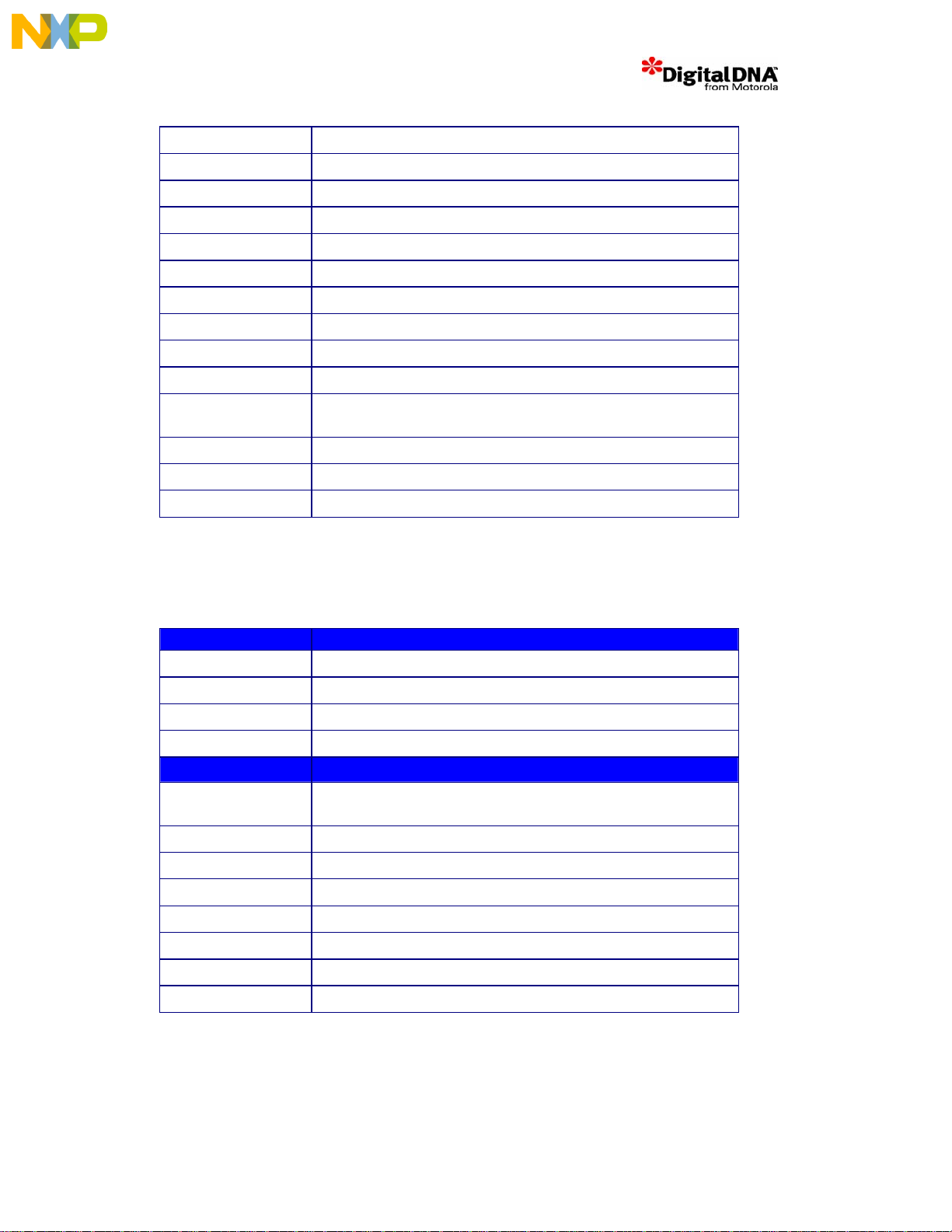

5 Hardware Description

This section describes the Packet Telephony Farm Card Hardware. The Hardware architecture has

been partitioned into the following logical sections: Aggregator, DSP Processing Array, General Board

Config ur at i o n, Fi r mware and P FC Ba s e Ca rd.

5.1 Board Architecture

The board architecture of the Packet Telephony Farm Card is shown in Figure 3.

CT Bus

CT Bus

PN2

CT Bus

CT Bus

CT Bus

CT Bus

CT Bus

CT Bus

CT Bus

CT Bus

PN2

PN2

PN2

PN2

PN2

PN2

PN2

PN2

PN2

PN1

PN1

PN2

PN2

PN4

PN4

PN5

PN5

PN5

PN5

PN3

PN3

CPORT GMII

CPORT GMII

Interface

Interface

Host

Host

UTOPIA

UTOPIA

Ethernet

Ethernet

(MII 1)

(MII 1)

Ethernet

Ethernet

(MII 2)

(MII 2)

Ethernet

Ethernet

(RMII)

(RMII)

MUX

MUX

FPGA

FPGA

FCC1

FCC1

FCC2

FCC2

SMC2

SMC2

MSC8101

MSC8101

LATCH

LATCH

MUX

MUX

8MB

8MB

SDRAM

SDRAM

Buffer

Buffer

64/32-bit

64/32-bit

60x

60x

LATCH

LATCH

FLASH

FLASH

4MB

4MB

FPGA

FPGA

8-bit32-bit

8-bit32-bit

32/64-bit

32/64-bit

DSI

DSI

DSI

DSI

DSI

DSI

DSI

DSI

DSI

DSI

DSI

DSI

DSI

DSI

DSI

DSI

DSI

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

32-bit

32-bit

32-bit

32-bit

32-bit

32-bit

32-bit

32-bit

32-bit

32-bit

16MB

16MB

SDRAM

SDRAM

16MB

16MB

SDRAM

SDRAM

16MB

16MB

SDRAM

SDRAM

16MB

16MB

SDRAM

SDRAM

16MB

16MB

SDRAM

SDRAM

Figure 3. Packet Telephony Farm Card Architecture

This can be split into 2 main blocks

1. MSC8101 Aggregator Processor

2. MSC8102 Farm

Under typical operating conditions the MSC8101 is used to terminate ATM or 10/100BaseT Ethernet

packet traffic from a host card via its PTMC interface, with the subsequent data placed in the

MSC8101’s internal SRAM or external SDRAM. The data is then distributed to the MSC8102 farm for

processing via the MSC8102 DSI port with the FPGA performing the 60x bus to DSI translation

(NOTE: the FPGA has been incorporated to allow synchronous DSI transfer – it is not required for

asynchronous DSI transfers). After MSC8102 processing the data is dispatched through the MSC8102

TDM interfaces to the PTMC CT Bus.

5.2 MSC8101 Aggregator & 60x Bus Interface

The Aggregator terminates the packet protocol and transfers Media Data to and from the DSP Array

through its 60x bus. The 60x interface to the MSC8102 DSI can be configured as 32 or 64-bit wide.

When configured for 32-bit operation an external host can access the host port (HDI16) of the

MSC8101 aggregator for bootstrap and ongoing data exchange and control. 4 MB of 8-bit wide Flash

is connected to the MSC8101 60x bus for configuration, boot and execution code (for all 6 DSPs). 8

MBytes of 32-bit wide SDRAM also hangs off this bus to provide adequate storage during real time

operation. It should be noted that the address bus is latched to the SDRAM and Flash memories due to

the 60x compatible mode used (when running in DSI Synchronous mode). The data bus is un-buffered

to the memories and FPGA but buffered for the HDI16 port. The SDRAM is not required for normal

Aggregation functions and has been incorporated purely for maximum flexibility.

Table 9 details the MSC8101 Chip selects used for the 60x bus devices.

8 PFC_DDD_v1.3.doc

Page 14

Table 9. MSC8101 Memory Controller Resources

Chip Select

CS0 Flash (Boot)

CS2

CS3 DSI Asynchronous (Individual Chip Selects)

CS4 DSI Asynchronous (Broadcast mode)

SDRAM

5.2.1 MSC8101 SDRAM Interface

The Aggregator 60x bus incorporates 64M-bit x32-bit wide x4 bank Micron MT48LC2M32B2

SDRAM surface mounted onto the board providing 8 MBytes of general-purpose system RAM. The

MSC8101’s Chip Select 2 is used to select the SDRAM devices through the SDRAM controller, which

is capable of interfacing to JEDEC compatible SDRAM, the settings of which are now described.

• SDRAM size is 512k x 32 x 4 Ba nks = 8MBytes, which requires 2 3 a ddress lines.

• Device has 8 column and 11 Row lines, 2 Bank Selects. The 32-bit port size means addresses

30 and 31 are not used.

For Page based Interleaving the 60x bus is arranged as follows:

A[9:19] A[20:21] A[22:29] A[30:31]

Row (x11) Bank Select Column (x8) LSB

This gives the following MSC8101 Registers settings:

• PSDMR[PBI] = 1, Page Based Interleaving

• ORx[BPD] = 01, 4 Ba nks per device

• ORx[ROWST] = 1001, Row Starts at A9

• ORx[NUMR]= 010, SDRAM has 11 Row lines

From the SDRAM perspective during an ACTIVATE command it’s address port will look like:

A9:A19 A17:A18 A19:A29 A30:A31

--- Internal Bank Select

(A[20:21])

Peripheral

Row(A[9:19]) LSB

While a Read/Write will look like:

A9:A19 A17:A18 A[19:21] A[22:29] A30:A31

--- Internal Bank Select

(A[20:21])

Which gives the following regist er settings:

• PSDMR[SDAM] = 010, A[9:19] muxed to A[19:29]

• PSMDR[BSMA] = 100, A[17-18] are used as Bank Selects Signals

• PSMDR[SDA10] = 001, A9 maps to A10/AP pin

The full PSDMR settings are described in table

Table 10. MSC8101 PSDMR settings

Register Setting Description

PBI = 1 Paged Based Interleaving

RFEN = 1 Refresh services required

9 PFC_DDD_v1.3.doc

Don’t

care

Column

(A[22:29])

LSB

Page 15

OP = 000 Normal Operation

SDAM = 010 A[9:19] multiplexed to A[19:29]

BSMA = 100 A17-A18 are used as Bank Selects Signals

SDA10 = 001 A9 maps to A10/AP pin

RFRC = 110 8 Clock Cycles Refresh Recovery

PRETOACT = 011 Pre-charge to Activate 3 cycle interval

ACTTORW= 011 Activate to Read/Write 3 clock cycles

BL 23 = 1 Burst Length is 8

LDOTOPRE = 10 Precharge can be set 2 cycles before last data is read from SDRAM

WRC = 00 Precharge is set 4 cycles after the last data is written to SDRAM

EAMUX= 1 External Address Multiplexing, Fastest timing (set to 0 for MSC8102

SDRAM)

BUFCMD = 0 Normal Timing for the control lines

CL = 10 Cycle CA S Lat e ncy=2

These SDRAM settings are conservative and can be optimized for future configurations.

The OR & BR settings are described below:

Register Setting Description

BA=0x2000_0 Base Addre ss = 0x20000000

PS=11 32-bit port size

MSEL =010 SDRAM machine

Register Setting Description

SDAM = 1111 1111

1000

LSDAM = 0000 0 8MB SDRAM

BPD= 01 4 Banks Per Device

ROWST = 1001 R ow Star ts at A9

NUMR = 010 SDRAM has 11 Row lines

PMSEL = 0 Back to Back Page Mode (Normal Operation)

PSDMR = 0xC287378A: MSC8101 SDRAM

Table 11. MSC8101 BR & OR settings

0x20001841

IBID = 1 Bank Interleaving Disabled

After Power On a JEDEC standard initialization sequence is performed to configure the SDRAM. This

is carried out in Software utilizing the SDRAM controller PSDMR register:

OR = 0xFF803290

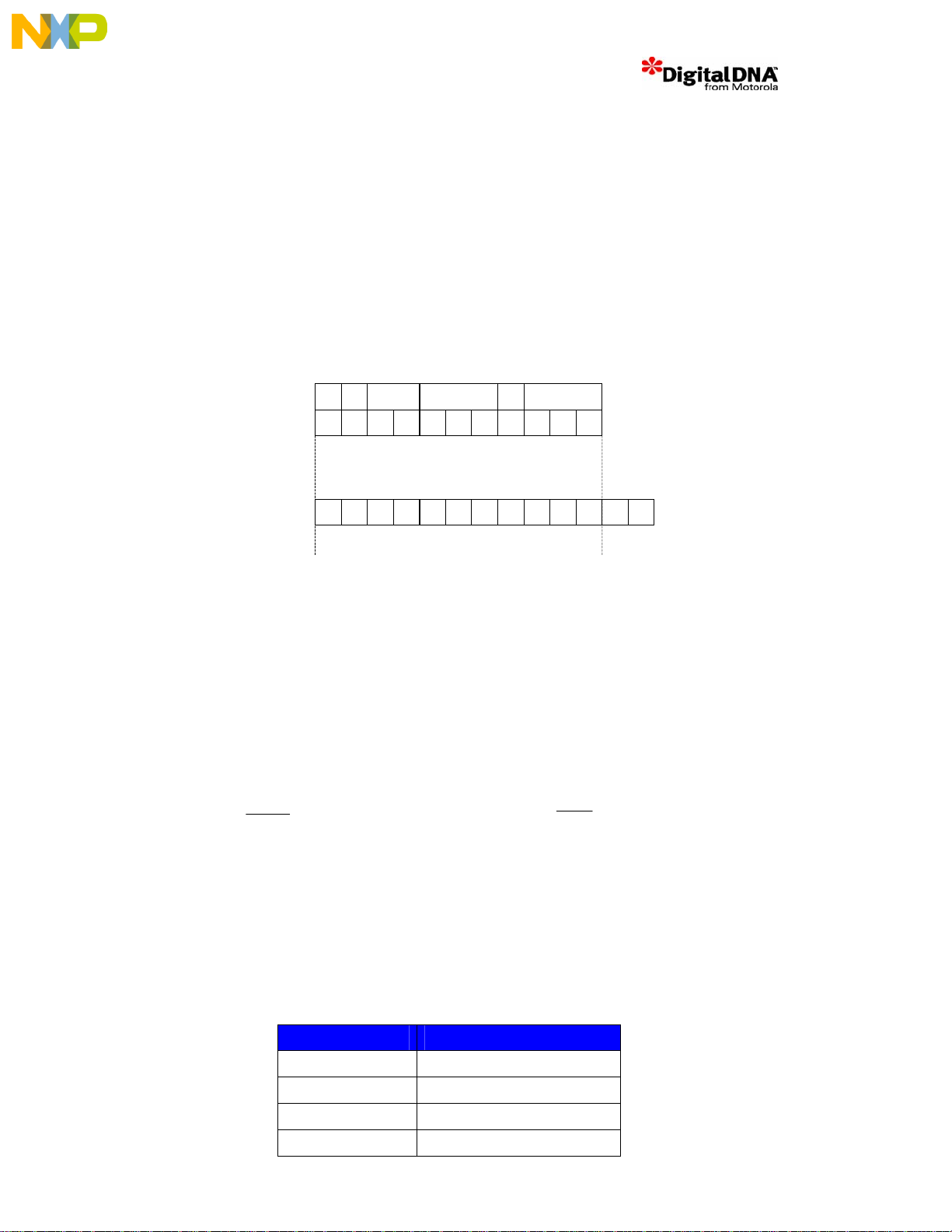

5.2.1.1 SDRAM Initialization Command Sequence

Step 1. Apply power and start clock. Maintain No Operation (NOP) condition at the inputs.

Step 2. Maintain stable power, stable clock and NOP input conditions at the inputs.

10 PFC_DDD_v1.3.doc

Page 16

Step 3. Issue Precharge All command (PALL) to all banks of the device. Program PSDMR[OP] bits to

[101] and then perform an access to the SDRAM bank.

Step 4. Issue 8 or more CBR Refresh (REF) commands. Program PSDMR[OP] bits to [001] and then

perform 8 accesses to the SDRAM bank.

Step 5. Issue Mode Register Set (MRS) command to initialise the mode register. Program

PSDMR[OP] bits to [011] and then performing an access to the SDRAM bank at an address offset to

0x08Csee figure below.

BL = Burst Length 8 for 32 Bit b us.

BT = 0 Sequential B ur s t s

CAS Latency = 2

OP MODE = Standard Operation

WB = 0 Programmed Burst Length

A10/

A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

AP

SDRAM

Address

Lines

RSVD Burst Length

0 0 0 0 1 0 0 0 1 1

0

BTCAS LatencyWB Op Mode

MSC8101

Address

Lines

A19 A20 A21 A22 A23 A24 A25 A26 A27 A28 A29 A30 A31

0 0 0 0 1 0 0 0 1 10 0 0

SDRAM Only sees this part of the Bus

NC

Figure 4. MSC8101 SDRAM Mode Reg ister Settings

5.2.1.2 SDRAM Refresh

The SDRAM requires 4096 refresh cycles per 64ms or one refresh cycle per 15.625µs. The MSC8101

can be programmed to carry out the refresh cycle periodically using the SDRAM Refresh Timer

(PSRT). By setting the memory refresh timer prescaler register, MPTPR[PTP] to divide by 32, and the

PSRT to 0x30 a timer period of 15.625µs is realized for a 100MHz system clock . For a 69MHz

System clock PSRT = 0x17.

odxTimerPeriFPSRT

1625.15

usx

−=

PSRT

PSRT

=

MPTC

69

MHz

32

200

xPSRT

=

=

MPTC

100

MHz

32

300

=

xPSRT

odxTimerPeriFPSRT

1625.15

−=

usx

Figure 5. Refresh Calculations

5.2.2 MSC8101 FLASH Interface

The Aggregator incorporates an AM29LV320DB-120E 4Mx8-bit FLASH for Stand-alone reset

configuration and boot. To enable bootstrapping from reset the Flash is mapped to GPCM CS0 and

utilizes the following signals

Table 12. MSC8102 DSI Ad dresses

MSC8102 GPCM Signal

A_CS_FLASH CS0

A_PSDRAS POE

A_PSDDQMO WE

A_BADDR[27:30] A[3:0]

11 PFC_DDD_v1.3.doc

Page 17

A_BADDR[31] A-1

On the flash the BYTE signal is pulled down for byte mode which enables DQ[0:7] but tri-states

DQ[8:14], with D DQ15/A-1 used as an input for the LSB address bit, A _BADDR31. The memory

controller uses the BADDR[27-31] signals to interface to the memories when operating in multimaster mo de.

5.2.3 MSC8101 60x to DSI Interface

The 60x-DSI interface is the main means of communications between the Aggregator and the DSP

Farm. The DSI interface is configurable, and can be set to either 32 or 64bit wide, as well as

synchronous or asynchronous modes

• Asynchronous Mode: SRAM-like interface enabling the host single accesses (with no external

clock). Data is transfer red usi ng the MSC8101 Memory Co ntrolle r’s UPM.

• Synchronous Mode: SSRAM-like interface enabling host single or burst accesses of 256 bits

(8 accesses of 32 bits or 4 accesses of 64 bits) with its external clock decoupled from the

MSC8102 internal bus clock. Data transferred in this mode is passed onto the external 60x

bus to be handled by the FPGA

The DSI gives external hosts direct access to the MSC8102 internal memory space, including on-chip

memories and the registers of the on-chip modules. The DSI write buffer stores the address and the

data of the accesses until they are performed. The external host can therefore perform multiple writes

without waiting for those accesses to complete. Latencies that are typical during accesses to on-chip

memories are greatly reduced by the DSI read prefetch mechanism. The host addresses each of the

MSC8102 devices using a single chip-select with the most significant bits on the address bus

identifying the addressed MSC8102 device. The 4-bit MSC8102 DSI address is hardwired via

CHIP_ID [0:3], Table 13

Table 13. MSC8102 DSI Ad dresses

MSC8102 CHIP_ID[0:3]

1 0000

2 0001

3 0010

4 0011

5 0100

The host can also write the same data to multiple MSC8102 devices simultaneously by asserting a

dedica ted broad cast chi p s elect.

5.2.3.1 MSC8101 60x to DSI Interface: Synchronous mode

In synchronous mode an FPGA is required to interface between the MSC8101 60x bus and the

MSC8102 DSI port. The connectivity is detailed in Figure 6.

12 PFC_DDD_v1.3.doc

Page 18

Dh[0:63]

Dh[0:63]

Ah[0:31]

Ah[0:31]

A_TSIZ[0:3]

A_TSIZ[0:3]

A_PUPMWAIT

A_PUPMWAIT

A_TS

A_TS

A_TBST

MSC8101

MSC8101

Note: All unused PPC

Note: All unused PPC

signals on host side pulled

signals on host side pulled

high

high

A_TBST

A_PSDVAL

A_PSDVAL

A_TT[0:4]

A_TT[0:4]

A_BADDR[27:31]

A_BADDR[27:31]

A_AACK

A_AACK

A_TA

A_TA

A_ALE

A_ALE

A_PSDQM[0:7]

A_PSDQM[0:7]

A_BCTL[0:1]

A_BCTL[0:1]

A_CS_HCS

A_CS_HCS

A_CS_HBCS

A_CS_HBCS

PGPL2

PGPL2

A_CLK_OUT

A_CLK_OUT

FPGA_CK

FPGA_CK

HCK_D[1:5]

HCK_D[1:5]

ICS9112

ICS9112

(Zero delay buffer)

(Zero delay buffer)

GRP_Ds[0:63]

GRP_Ds[0:63]

GRP_Ah[7:29]

GRP_Ah[7:29]

FPG

FPGA

Xilinix XC2S300E - 7F - G456C

Xilinix XC2S300E - 7F - G456C

Figure 6. PFC to DSI Interface

HBRST

HBRST

HTA

HTA

HWBS[0:7]

HWBS[0:7]

HRW

HRW

HCS

HCS

HBCS

HBCS

MSC8102 – CHIP_ID[0:3]

MSC8102 – CHIP_ID[0:3]

--------------------------

-------------------------DSP1 0000

DSP1 0000

DSP2 0001

DSP2 0001

DSP3 0010

DSP3 0010

DSP4 0011

DSP4 0011

DSP5 0100

DSP5 0100

GRP_Ah[11:29]

GRP_Ah[11:29]

GRP_Ah[7:10]

GRP_Ah[7:10]

HCK_D1

HCK_D1

HCK_D2

HCK_D2

HCK_D3

HCK_D3

HCK_D4

HCK_D4

HCK_D5

HCK_D5

3V3

3V3

HD[0:63]

HD[0:63]

HA[11:29]

HA[11:29]

HCID[0:3]

HCID[0:3]

MSC8102

MSC8102

[x5]

[x5]

HDST[0:1]

HDST[0:1]

CHIP_ID[0:3]

CHIP_ID[0:3]

HCLKIN

HCLKIN

5.2.3.2 MSC8101 60x to DSI Interface: Asynchronous mode

The DSI can be asynchronously controlled via the following UPM signals:

Table 14. DSI Asynchronous signals

UPM Signal Description

CS3 Broadcast Chip Select

CS4 Chip Select

PBS[0:7] Byte Strobe

PGPL2 General Purpose

PGPL4/UPMWAIT UPMWAIT

These signals are routed through the FPGA, which operates in transparent mode.

5.2.4 MSC8101 to MSC8102 Interrupt Connectivity

The FPGA is used to route the interrupts/GPIO lines between the MSC8101 and MSC8102s. For

flexibility the MSC8101 has 5 GPIO lines (PC4, PC5, PC24, PC25 & PC30) connected to the FPGA

and in turn receives 7 IRQ inputs from the FPGA. Each MSC8102 has GPIO30 and INT_OUT

connected to the FPGA, with their respective IRQ1 and IRQ2 also connected, Figure 7. The standard

pre-programmed FPGA interrupt routing is shown in Figure 8.

13 PFC_DDD_v1.3.doc

Page 19

IRQ1_D1

MSC

8101

A_IRQ[1:7]

DSP_IRQ_GPIO[1:5]

FPGA

IRQ2_D1

GPIO30_D1

INT_OUT_D1

IRQ1_D2

IRQ2_D2

GPIO30_D2

INT_OUT_D2

IRQ1_D3

IRQ2_D3

GPIO30_D3

INT_OUT_D3

IRQ1_D4

IRQ2_D4

GPIO30_D4

INT_OUT_D4

IRQ1_D5

IRQ2_D5

GPIO30_D5

INT_OUT_D5

MSC8102

#1

MSC8102

#2

MSC8102

#3

MSC8102

#4

MSC8102

#5

Figure 7. Aggregator MSC8102 Interrupt Connectivity Options

MSC 8101

FPGA

A_IR Q1

DSP_IRQ_ GP IO1 (P C4 )

A_IR Q4

DSP_IRQ_ GP IO2 (P C5 )

A_IR Q5

DSP_IRQ_GPIO3 (PC24)

A_IR Q6

DSP_IRQ_GPIO4 (PC25 )

A_IR Q7

DSP_IRQ_GPIO5 (PC30 )

INT_OUT_D1

GPIO30_D1

INT_OUT_D2

GPIO30_D2

INT_OUT_D3

GPIO30_D3

INT_OUT_D4

GPIO30_D4

INT_OUT_D5

GPIO30_D5

MSC8102

#1

MSC8102

#2

MSC8102

#3

MSC8102

#4

MSC8102

#5

Figure 8. Standard Interrupt Routing

14 PFC_DDD_v1.3.doc

Page 20

5.2.5 MSC8101 FCC Interface

The MSC8101 incorporates two FCC interfaces for packet transfers. The packet interfaces are

configur a bl e t o pe rf or m 2 xM II port s (F CC1 & FCC 2) or an M II ( FC C1 ) pl us a U TOP I A (FC C2) por t.

Both configurations are routed out to the PTMC connector as detailed in Table 15. Signals that are

common between UTOPIA FCC1 and MII FCC1 are routed to their connector positions via a

PERICOM P13B16233 bus switch.

Table 15. FCC1 Interface

PIN Function Signal Connects to

PA10 FCC1 Utopia II RxD0 Pn4-60

PA11 FCC1 Utopia II RxD1 Pn4-58

PA12 FCC1 Utopia II RxD2 Pn4-54

PA13 FCC1 Utopia II RxD3 Pn4-52

PA14 FCC1 Utopia II Rx4 / MII1 RxD3 Pn4-48 / Pn5-54

PA15 FCC1 Utopia II Rx5 / MII1 RxD2 Pn4-46 / Pn5-50

PA16 FCC1 Utopia II Rx6 / MII1 RxD1 Pn4-42 / Pn5-48

PA17 FCC1 Utopia II Rx7 / MII1 RxD0 Pn4-40 / Pn5-46

PA18 FCC1 Utopia II Tx7 / MII1 TxD0 Pn4-35 / Pn5-41

PA19 FCC1 Utopia II Tx6 / MII1 TxD1 Pn4-37 / Pn5-43

PA20 FCC1 Utopia II Tx5 / MII1 TxD2 Pn4-47 / Pn5-45

PA21 FCC1 Utopia II Tx4 / MII1 TxD3 Pn4-49 / Pn5-47

PA22 FCC1 Utopia II Tx3 Pn4-53

PA23 FCC1 Utopia II Tx2 Pn4-55

PA24 FCC1 Utopia II Tx1 Pn4-59

PA25 FCC1 Utopia II Tx0 Pn4-61

PA26 FCC1 Utopia II RxCLAV / MII1 RX_ER Pn4-18 / Pn5-56

PA27 FCC1 Utopia II RxSOC / MII1 RX_DV Pn4-49 / Pn5-64

PA28 FCC1 Utopia II RXENB/ MII1 TX_EN Pn4-16 / Pn5-53

PA29 FCC1 Utopia II TXSOC/ MII1 TX_ER Pn4-1 / Pn5-55

PA30 FCC1 Utopia II TXCLAV / MII1 CRS Pn4-5 / Pn5-58

PA31 FCC1 Utopia II TXENB / MII1 COL Pn4-49 / Pn5-22

PC6 FCC1 Utopia II RXADDR2 Pn4-24

PC7 FCC1 Utopia II TXADDR2 Pn4-19

PC12 FCC 1 Utopia II RXADDR1 Pn4-30

PC13 FCC1 Utopia II TXADDR Pn4-28

PC14 FCC 1 Utopia II RXADDR0 Pn4-34

PC15 FCC1 Utopia II TXADDR0 Pn4-29

PC30 FCC1 Utopia II TXCLK / MII1 TCLK Pn4-25 / Pn5-64

PC31 FCC1 Utopia II RXCLK / MII1 RCLK Pn4-43 / Pn5-60

PD7 FCC1 Utopia II TXADDR3 Pn4-17

15 PFC_DDD_v1.3.doc

Page 21

PD16 FCC1 Utopia II TXPRTY Pn4-31

PD17 FCC1 Utopia II RXPRTY Pn4-36

PD18 FCC1 Utopia II RXADDR4 Pn4-4

PD19 FCC1 Utopia II TXADDR4 Pn4-6

PD29 FCC1 Utopia II RXADDR3 Pn4-7

Table 16. MSC8101 Aggregator FCC2 PTMC Connectivity

PIN Function Signal Connects to

PB18 FCC2 MII2 RXD3 Pn5-34

PB19 FCC2 MII2 RXD2 Pn5-30

PB20 FCC2 MII2 RXD1 Pn5-28

PB21 FCC2 MII2 RXD0 Pn5-26

PB22 FCC2 MII2 TXD0 Pn5-21

PB23 FCC2 MII2 TXD1 Pn5-23

PB24 FCC2 MII2 TXD2 Pn5-25

PB25 FCC2 MII2 TXD3 Pn5-27

PB26 FCC2 MII2 CRS Pn5-38

PB27 FCC2 MII2 COL Pn5-37

PB28 FCC2 MII2 RX_ER Pn5-36

PB29 FCC2 MII2 TX_EN Pn5-33

PB30 FCC2 MII2 RX_DV Pn5-24

PB31 FCC2 MII2 TX_ER Pn5-35

5.2.6 RMII Interface

The MSC8101 FCC2 signals are routed to the FPGA to allow conversion of FCC2’s MII interface to

RMII enabling connection to the PTMC Type III RMII port on connector PN3.

5.2.7 MSC8101 I2C Controller

An I2C Management for customer specific application.is incorporated on the MSC8101 via J14 Pin 57

[SDA] and J1 4 Pi n 9 [ SC L] . Th e o pti on (vi a 0 oh m re si st or s) t o pr ovi de a st an dar d P TM C I2C is a ls o

provided for on Jn1 Pin 41 [SCL] and Pin 42 [SDA].

5.2.8 MSC8101 RS232 Interface

A simple RS232 UART is provided through the MSC8101’s Serial Management Channel interface

(SMC2) t o gi ve program ma ble debu g or co m m un ic a t io n s c a pa bi l ity. A Max im M AX 3241 pr ovides the

level conversion for the interface.

5.2.9 MSC8101 Host Interface (HDI16)

The 16-bit Host port on the MSC8101 can be used for bootstrapping and ongoing data and control flow

from a Host processor if desired. The port connects to PTMC connector PN2 via an IDTQ34XV245Q3

bus switch controllable by the host signal PTENB, by default the switch is open whish isolates any

host data signals.

A host processor accessing the MSC8101 aggregator should do so in the following mode

16 PFC_DDD_v1.3.doc

Page 22

Table 17. HDI6 Conf igur ation

60x signal HDI16 Signal Description

Dh57 HDSP=0 Sing le data strobe mode

Dh58 HDDS=0 Negative data strobe polarity

Dh59 H8BIT=0 16-bit mode enabled

Dh60 HCS2=1 Not used, pulled high

Note that when using the host port the DSI interface must be configured for 32-bits

5.3 MSC8102 DSP Processing Array

The DSP farm contains 5 MSC8102 DSPs connected to the MSC8101 via a shared DSI 60x bus

interface. Each DSP has access to 16MB of SDRAM. The DSPs interface to the PSTN world through

the PTMC connector via their TDM links. In addition MSC8102 DSP1 (U19) has an SMC U ART

connection to an onboard connector.

5.3.1 DSP Array SDRAM Configuration

Each DSP incorporates 128M-bit x32-bit wide x4 bank Micron MT48LC4M32B2 SDRAM surface

mounted onto the board providing 16 MBytes of general-purpose system RAM. The MSC8102’s Chip

Select 2 is used to select the SDRAM devices through the SDRAM controller, which is capable of

interfacing to JEDEC compatible SDRAM, the settings of which are now described.

• SDRAM size is 1M x 32 x 4 Banks = 16MBytes, which requires 24 address lines.

• Device has 8 column and 12 Row lines, 2 Bank Selects. The 32-bit port size means addresse s

30 and 31 are not used.

For Page based interleaving the 60x bus is arranged as follows:

A[8:19] A[20:21] A[22:29] A[30:31]

Row (x12) Bank Select Column (x8) LSB

This gives the following MSC8101 Registers settings:

• PSDMR[PBI] = 1, Page Based Interleaving

• ORx[BPD] = 01, 4 Ba nks per device

• ORx[ROWST] = 1000, Row Starts at A8

• ORx[NUMR]= 011, SDRAM has 12 Row lines

From the SDRAM perspective during an ACTIVATE command it’s address port will look like:

A9:A19 A16:A17 A18:A29 A30:A31

--- Internal Bank Select

(A[20:21])

Row(A[8:19]) LSB

While a Read/Write will look like:

A9:A19 A16:A17 A[18:21] A[22:29] A30:A31

--- Internal Bank Select

(A[20:21])

This gives the following register settings:

• PSDMR[SDAM] = 010, A[9:19] multiplexed to A[19:29]

• PSMDR[BSMA] = 011, A[16-17] are used as Bank Selects Signals

• PSMDR[SDA10] = 001, A9 maps to A10/AP pin

The full PSDMR settings are described in table

17 PFC_DDD_v1.3.doc

Don’t

care

Column

(A[22:29])

LSB

Page 23

Table 18. MSC8102 PSDMR settings

Register Setting Description

PBI = 1 Paged Based Interleaving

RFEN = 1 Refresh services required

OP = 000 Normal Operation

SDAM = 010 A[9:19] muxed to A[19:29]

BSMA = 011 A16-A17 are used as Bank Selects Signals

SDA10 = 001 A9 maps to A10/AP pin

RFRC = 110 8 Clock Cycles Refresh Recovery

PRETOACT = 011 Pre-charge to Activate 3 cycle interval

ACTTORW= 011 Activate to Read/Write 3 clock cycles

BL 23 = 1 Burst Length is 8

LDOTOPRE = 10 Precharge can be set 2 cycles before last data is read from SDRAM

WRC = 00 Precharge is set 4 cycles after the last data is written to SDRAM

EAMUX= 1 SDAMUX asserted for an extra cycle

BUFCMD = 0 Normal Timing for the control lines

CL = 10 Cycle CA S Lat e ncy=2

These SDRAM settings are conservative and can be optimized for future configurations.

The OR settings are described below:

BR Register Setting Description

BA=0x2000_0 Base Addre ss = 0x20000000

PS=11 32-bit port size

MSEL =010 SDRAM machine

OR Register Setting Description

SDAM = 1111 1111

0000

LSDAM = 0000 0 16MB SDRAM

BPD= 01 4 Banks Per Device

ROWST = 1000 R ow Star ts at A8

NUMR = 010 SDRAM has 12 Row lines

PSDMR = 0xC267378A: MSC8102 SDR AM

Table 19. MSC8102 BR & OR Settings

BR = 0x20001841

PMSEL = 0 Back to Back Page Mode (Normal Operation)

IBID = 1 Bank Interleaving Disabled

After Power On a JEDEC standard initialization sequence is performed to configure the SDRAM. This

is carried out in Software utilizing the SDRAM controller PSDMR register:

18 PFC_DDD_v1.3.doc

OR = 0xFF003090

Page 24

27

0

x

PSRT

5.3.1.1 SDRAM Initialization Command Sequence

Step 1. Apply power and start clock. Maintain No Operation (NOP) condition at the inputs.

Step 2. Maintain stable power, stable clock and NOP input conditions at the inputs.

Step 3. Issue Precharge All command (PALL) to all banks of the device. Program PSDMR[OP] bits to

[101] and then perform an access to the SDRAM bank.

Step 4. Issue 8 or more CBR Refresh (REF) commands. Program PSDMR[OP] bits to [001] and then

perform 8 accesses to the SDRAM bank.

Step 5. Issue Mode Register Set (MRS) command to initialise the mode register. Program

PSDMR[OP] bits to [011] and then performing an access to the SDRAM bank at an address offset to

0x08Csee figure below.

BL = Burst Length 8 for 32 Bit b us.

BT = 0 Sequential B ur s t s

CAS Latency = 2

OP MODE = Standard Operation

WB = 0 Programmed Burst Length

A10/

A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

AP

SDRAM

Address

Lines

RSVD Burst Length

0 0 0 0 1 0 0 0 1 1

0

BTCAS LatencyWB Op Mode

MSC8101

Address

Lines

A19 A20 A21 A22 A23 A24 A25 A26 A27 A28 A29 A30 A31

0 0 0 0 1 0 0 0 1 10 0 0

SDRAM Only sees this part of the Bus

NC

Figure 9. SDRAM M ode Regis ter Settings

5.3.1.2 SDRAM Refresh

The SDRAM requires 4096 refresh cycles per 64ms or one refresh cycle per 15.625µs. The MSC8101

can be programmed to carry out the refresh cycle periodically using the SDRAM Refresh Timer

(PSRT). By setting the memory refresh timer prescaler register , MPTPR[PTP] to divide by 32, and the

PSRT to 0x30 a timer period of 15.625µs is realised for a 100MHz system clock . For a 83MHz

System clock PSRT = 0x17.

PSRT

PSRT

=

MPTC

83

MHz

32

=

=

MPTC

100

MHz

32

300

xPSRT

=

odxTimerPeriFPSRT

1625.15

usx

−=

odxTimerPeriFPSRT

−=

1625.15

usx

Figure 10. Refresh Calculations

5.3.2 MSC8102 Array DSI Interface

The MSC8102’s DSI interface is the main means of packet media transfers to and from the DSP Array.

The DSI is configurable between 32 and 64 bit modes of operation using Dip Switch SW2.

5.3.3 MSC8102 Array TDM Interface

The CT bus is split into 32 streams of 128 timeslots each, giving 4096 timeslots. Each MSC8102

TDM link is uni-directional, meaning two CT Streams are required to interf ace with the MSC8102

19 PFC_DDD_v1.3.doc

Page 25

TDM0TCLK

TDM0 T

DAT

MSC8102

TDM0TCLK

TDM0 T

DAT

TDM3 TDAT

MSC8102

TDM0TCLK

TDM0 T

DAT

MSC8102

CT_D0

CT_D12

TDM0TCLK

TD

M0T

DAT

MSC8102

TDM0TCLK

TDM0 T

DAT

MSC8102

CT_D14

TDM. With the P3TMC specification implemented the number of CT lines is further restricted to 20

streams.

Each MSC8102 has four TDM interfaces. The TDM Streams are routed as follows:

CT_C8_

CT_FRAME_

CT_C8_A_B

CT_FRAME_A_B

CT_C8_A_B

CT_FRAME_A_B

CT_C8_A_B

CT_FRAME_A_B

TDM0TSYN

TDM1TCLK

TDM1TSYN

TDM2TCLK

TDM2TSYN

TDM3TCLK

TDM3TSYN

TDM0TSYN

TDM1TCLK

TDM1TSYN

TDM2TCLK

TDM2TSYN

TDM3TCLK

TDM3TSYN

TDM0TSYN

TDM1TCLK

TDM1TSYN

TDM2TCLK

TDM2TSYN

TDM3TCLK

TDM3TSYN

TDM0TSYN

TDM1TCLK

TDM1TSYN

TDM2TCLK

TDM2TSYN

TDM3TCLK

TDM3TSYN

TDM0TSYN

TDM1TCLK

TDM1TSYN

TDM2TCLK

TDM2TSYN

TDM3TCLK

TDM3TSYN

TDM0RDAT

TDM1TDAT

TDM1RDAT

TDM2TDAT

TDM2RDAT

TDM3TDAT

TDM3RDAT

TDM0RDAT

TDM1 TDAT

TDM1RDAT

TDM2 TDAT

TDM2RDAT

TDM3 TDAT

TDM3RDAT

TDM0RDAT

TDM1 TDAT

TDM1RDAT

TDM2 TDAT

TDM2RDAT

TDM3 TDAT

TDM3RDAT

TDM0RDAT

TDM1 TDAT

TDM1RDAT

TDM2 TDAT

TDM2RDAT

TDM3RDAT

TDM0RDAT

TDM1 TDAT

TDM1RDAT

TDM2 TDAT

TDM2RDAT

TDM3 TDAT

TDM3RDAT

Figure 11. TDM to CT Rout ing

MSC8102 TDM Ref. MSC8 102 Signal CT Stream Signal

MSC8102 #1 TDM0 TDM0TDAT

TDM0RDAT

TDM1 TDM1TDAT

TDM1RDAT

TDM2 TDM2TDAT

TDM2RDAT

TDM3 TDM3TDAT

TDM3RDAT

MSC8102 #2 TDM0 TDM0TDAT

TDM0RDAT

TDM1 TDM1TDAT

TDM1RDAT

TDM2 TDM2TDAT

TDM2RDAT

TDM3 TDM3TDAT

TDM3RDAT

MSC8102 #3 TDM0 TDM0TDAT

TDM0RDAT

TDM1 TDM1TDAT

TDM1RDAT

CT_D0

CT_D1

CT_D2

CT_D3

CT_D4

CT_D5

CT_D6

CT_D7

CT_D0

CT_D1

CT_D2

CT_D3

CT_D4

CT_D5

CT_D6

CT_D7

CT_D12

CT_D13

CT_D18

CT_D19

CT_D1

CT_D2

CT_D3

CT_D4

CT_D5

CT_D6

CT_D7

CT_D13

CT_D18

CT_D19

CT_D15

CT_D10

CT_D11

CT_D16

CT_D17

CT_D8

CT_D9

20 PFC_DDD_v1.3.doc

Page 26

12

R

TDM2 TDM2TDAT

TDM2RDAT

TDM3 TDM3TDAT

TDM3RDAT

MSC8102 #4 TDM0 TDM0TDAT

TDM0RDAT

TDM1 TDM1TDAT

TDM1RDAT

TDM2 TDM2TDAT

TDM2RDAT

TDM3 TDM3TDAT

TDM3RDAT

MSC8102 #5 TDM0 TDM0TDAT

TDM0RDAT

TDM1 TDM1TDAT

TDM1RDAT

TDM2 TDM2TDAT

TDM2RDAT

TDM3 TDM3TDAT

TDM3RDAT

Table 20. TDM to CT Stream Ro uting

The MSC8102s are configured in their four-pin setup with common clock and frame syncs for receive

and transmit. The clock and Frame Sync signals routed from the PTMC CT Bus are CT_8_A and

CT_FRAME_A respectively.

CT_D12

CT_D13

CT_D18

CT_D19

CT_D14

CT_D15

CT_D10

CT_D11

CT_D16

CT_D17

CT_D8

CT_D9

CT_D14

CT_D15

CT_D10

CT_D11

CT_D16

CT_D17

CT_D8

CT_D9

5.3.4 MSC8102 RS232 Interface

A simple RS232 UART is provided through the MSC8102’s serial communications interface (SCI) to

give programmable debug or communications capability. A Maxim MAX3232CUE provides the level

conversion for the interface. Note that the receiver inputs are pulled low internally while the

transmitter inputs have external pull-ups.

5.4 General Board Configuration

5.4.1

Reset

Figure 12 illustrates the reset scheme. The MAXIM MAX6828 generates the primary reset for the PFC

(PORESET), which is supplied to the MSC8101, MSC8102s (AND with MSC8101 GPIO: PA7),

FPGA and Flash memory. The Open drain output (RESET_N) is pulled low (for a minimum time out

period of 140ms) when any of the f ollowin g conditions occur:

• MR_N is pulled low via the pushbutton switch SW1

• The 1V6 voltage monitor trip voltage is reached (1.23Von Reset In pin),

1210

RR

+

tripVmonitor

(63.0_

=

• The threshold voltage on 3V3 is reached (MIN = 2.85V, MAX = 3.00V, TYP = 2.93V)

)

21 PFC_DDD_v1.3.doc

Page 27

1V6

R10

R12

Reset In

MR

3V3

VCC

A_PORESET

RESET

PORESET_M1

PORESET_FPGA

Figure 12. PORESET Sc heme

The MSC8101 controls the generation of individually buffered HRESET signals to the MSC8102s

through the AND gating of its own HRESET signal and its HRESET GPIO control line PD31. Note

that for f lexibility the MSC8102 HRESETS have been routed to the FPGA via 0ohm resistors.

The PMCC signal PTMC_RESET can be used by a prospective PFC base card host to control the

HRESET of the PFC.

The SRESET signals for the MSC8101 and MSC8102s have all been pulled high.

PTMC Connector

Pn2 pin 13

FLASH

MSC8101

GPIO[PA7]

FPGA

A_PORESET_M1

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

PTMC_RESET

MSC8101

HRESET

PD31

A_HRESET

A_M_HRESET

HRESET signals

(pulled up)

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

Figure 13. HRESET Scheme

5.4.2 Cloc k Distribution

The PFC has two clock regions

1. MSC8101 Aggregator and MSC8102 DSI interface clocking, Figure 14

2. MSC8102 and associated SDRAM clocking, Figure 15

In the first clock region the MSC8101 Aggregator and MSC8102 DSI interface clocks (HCK) are

generated via a single oscillator, which is distributed via an ICS9112-17 low skew buffer.

In the second clock region the MSC8102 CLKIN signals are generated from a single oscillator, which

is distributed via the ICS9112-16 low skew output buffer to the MSC8102 farm. Each MSC8102

CLKOUT s i gn al is in turn fed ba c k as the D L LIN signal via an addit i on a l l ow s ke w bu f fe r . This buffer

also generates the MSC8102’s associated SDRAM clock

To accommodate debug and board set up the following clock frequencies are used on the MSC8101

and MSC8102.

Table 21. MSC8101 Clock frequencies

Clock Mode CLKIN Core CPM Bus

46 34.5 MHz 275 MHz 138 MHz 69 MHz

Table 22. MSC8102 Clock frequencies

Clock Mode CLKIN Core Bus DSI

10 41.6 MHz 250 MHz 83 MHz 69 MHz

22 PFC_DDD_v1.3.doc

Page 28

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

MSC8102

Oscillator.

MSC8102

MSC8102

MSC8102

MSC8102

The frequency of operation will depend on the revision of silicon used and the required application.

Consult Motorola Ltd for the latest operating frequency characteristics of the MSC8101 and

MSC8102.

Note that to ensure synchronous operation the following layout constraints are placed:

• The MSC8102 CLKIN_D[1:5] are of equal length

• The MSC8101 derived clocks: FPGA _CK, SDRAMCKA, A_DLLIN, HCK_D[1:5]

are of equal length.

• On the MSC8102s the signals D1_DLLINx, SDRMCKx are of equal length

FPGA_CK

FPGA

MSC8101

Oscillator

MSC8102

CLKIN

MSC8101

A_DLLIN

CLKOUT

Figure 14. MSC8101 Aggregator Clocking Sc heme

CLKIN_D1

#1

DLLIN

CLKIN_D2

#2

SDRAMCKA

HCK_D1

HCK_D2

HCK_D3

HCK_D4

HCK_D5

CLKOUT

SDRAMCK

SDRAM

#1

#2

#3

#4

#5

SDRAM

SDRAM

ICS9112-16

CLKIN_D3

CLKIN_D4

CLKIN_D5

#3

SDRAM

SDRAM

#4

SDRAM

#5

Figure 15. MSC8102 and SDRAM Clocking

23 PFC_DDD_v1.3.doc

Page 29

1

5

VR

R

Vout

5.4.3 Power

The PICMG 2.15 standard currently stipulates that 5V, 3.3V and GND are provided through the PTMC

connectors. The optional connector, Pn5/Jn5 has the capabilities to supply the core voltage, 1.6V to the

card. In this configuration, there is no need for additional regulation on the card. However, in order to

interface with standard PTMC cards Pn5/Jn5 may not be populated – therefore in this scenario the core

voltage cannot be obtained through the PTMC connectors. To compensate for this the PFC uses a

Maxim MAX1714 Buck Controller to step down from 5V (Supplied via Jn1/Pn1) to 1.6V, capable of

supplying 8A. A link is provided to isolate this 1V6 suppl y when required. Pulling the MAX1714 pin

SHDN low can also disable the 1V6. (a resistor pad is provided for this).

The 1V6 output voltage can be adjusted from 1.3V to 2.0V as per Figure 16. The equation for

adjusting the output voltage is:

4

1(

VfbVout

R

+=

)

: Vfb =1.0V, R4=R5=1K and VR=2K

+

R4

Vfb

R5

VR1

Figure 16. Setting Vout with Resistor-Divider

The FPGA requires 1V8 supply and a minimum 500mA (for a few millisecs) on power up. Note that

the operating power requirements of the FPGA are application specific. A Maxim MAX8869EU18

linear regulator, which can give a guaranteed 1A, is used to supply the 1V8.

5.4.4 FPG A Co nf i gu ra ti o n

The FPGA is configured with the following:

• M[0:2] = 110, Slave Serial Mode with pre-configuration pull ups

• CCLK: Input clock in slave mode

• PROGRAM_N: initiates a configuration sequence when low.

5.4.5 PT M C Conne c tor s

The PFC is designed to interface with the PTMC connectors implemented on a Media Gateway

Platform. The PFC implements an enhanced PTMC Type III or P3 TMC c onfi gura tion, in corp orati ng

an additional optional connector, Pn5 to allow the inclusion of 2x MII capabilities. In general the 5

connectors interface is:

• Pn1 - CPORT interface

• Pn2 - Host Port Interface

• Pn3 - CT Bus, Ethernet-RMII

• Pn4 - UTOPIA Interface

• Pn5 - Ethernet (MII1 & MII2)

The connector pin out uti lized is listed in Table 23 t o Table 27:

24 PFC_DDD_v1.3.doc

Page 30

Color Meaning

N ot C onnected

Ground

Voltage

C T (TDM) Bus

Host Interface Signals

General Data I/O

PIN SIGNAL SIGNAL PIN

1NC NC2

3 GND NC 4

5NC NC6

7NC +5V8

9NC NC10

11 GND NC 12

13 GMII_CK GND 14

15 GND NC 16

17 NC +5V 18

19 VIO NC 20

21 NC CP14_D0 22

23 CP13_D6 GND 24

25 GND CP14_D1 26

27 CP13_D5 CP14_D2 28

29 CP13_D4 +5V 30

31 CP13_D3 CP14_D3 32

33 CP13_D2 GND 34

35 GND CP14_D4 36

37 CP13_D1 +5V 38

39 GND CP14_D5 40

41 CP13_D0 CP14_D6 42

43 CP12_D6 GND 44

45 VIO CP15_D0 46

47 CP12_D5 CP15_D1 48

49 CP12_D4 +5V 50

51 GND CP15_D2 52

53 CP12_D3 CP15_D3 54

55 CP12_D2 GND 56

57 VIO CP15_D4 58

59 CP12_D1 CP15_D5 60

61 CP12_D0 +5V 62

63 GND CP15_D6 64

Table 23. Pn1/Jn1 Connector Pin Out (CPORT Interface)

25 PFC_DDD_v1.3.doc

Page 31

PIN SIGNAL SIGNAL PIN

1NC NC2

3NC NC4

5NC GND6

7 GND NC 8

9HD0 HA110

11 HD1 +3.3V 12

13 PTMC_RESET HA2 14

15 +3.3V HA3 16

17 HD2 GND 18

19 HD3 HRW 20

21 GND HDS 22

23 HD4 +3.3V 24

25 HD5 HTREQ 26

27 +3.3V HRREQ 28

29 HD6 GND 30

31 HD7 A_IRQ7 32

33 GND HCS 34

35 HD8 +3.3V 36

37 GND NC 38

39 HD9 GND 40

41 +3.3V NC 42

43 HD10 GND 44

45 HD11 NC 46

47 GND NC 48

49 HD12 +3.3V 50

51 HD13 NC 52

53 +3.3V NC 54

55 HD14 GND 56

57 HD15 NC 58

59 GND NC 60

61 HA0 +3.3V 62

63 GND NC 64

Table 24. Pn2/Jn2 Connector Pin Out (Host Port Interface)

26 PFC_DDD_v1.3.doc

Page 32

PIN SIGNAL SIGNAL PIN

1 MII_MDIO GND 2

3 GND NC 4

5 MII_ MDC NC 6

7RMII_RX_ER0 GND 8

9NCRMII_TXD010

11 NC RM II_T XD1 12

13 REF_CLK GND 14

15 GND RMII_RXD0 16

17 CT_FRA ME_A RMII_RXD1 18

19 NC GND 20

21 NC RMII_TXEN0 22

23 NC RMII_CRS_DV0 24

25 CT_C8_A GND 26

27 GND CT_D19 28

29 CT_D18 CT_D17 30

31 CT_D16 GND 32

33 GND NC 34

35 CT_D14 NC 36

37 CT_D12 GND 38

39 PTENB NC 40

41 NC NC 42

43 NC GND 44

45 GND CT_D15 46

47 CT_D10 CT_D13 48

49 CT_D8 CT_D11 50

51 GND CT_D9 52

53 CT_D6 CT_D7 54

55 CT_D4 GND 56

57 NC CT_D5 58

59 CT_D2 CT_D3 60

61 CT_D0 GND 62

63 GND CT_D1 64

Table 25. Pn3/Jn3 Connector Pin Out (CT Bus & RMII)

27 PFC_DDD_v1.3.doc

Page 33

PIN SIGNAL SIGNAL PIN

1TxSOC GND 2

3GNDRXADR44

5 TxCLAV T XADR4 6

7 RXADR3 GND 8

9I2C_SCL GND 10

11 GND 5V 12

13 5V GND 14

15 GND RXENB# 16

17 TXADR3 RXCLAV 18

19 TXADR2 GND 20

21 5V TXENB# 22

23 GND RXADR2 24

25 TXCLK GND 26

27 GND TXA DR1 28

29 TXADR0 RXAD R1 30

31 TXPRTY GND 32

33 GND RXADR0 34

35 TXD7 RXPRTY 36

37 TXD6 GND 38

39 5V RXD7 40

41 GND RXD6 42

43 RX CLK GND 44

45 GND RXD5 46

47 T XD5 RXD4 48

49 TXD4 GND 50

51 GND RXD3 52

53 T XD3 RXD2 54

55 TXD2 GND 56

57 I2C_SDA RXD1 58

59 T XD1 RXD0 60

61 TXD0 GND 62

63 GND RxSOC 64

Table 26. Pn4/Jn4 Connector Pin Out (UTOPIA)

28 PFC_DDD_v1.3.doc

Page 34

PIN SIGNAL SIGNAL PIN

1NC 1V62

3NC NC4

5NC NC6

7NC NC8

91V6 NC10

11 1V6 GND 12

13 NC NC 14

15 NC NC 16

17 NC NC 18

19 GND MII2_TCLK 20

21 MII2_TXD0 1V6 22

23 MII2_TXD1 MII2_RXDV 24

25 MII2_TXD2 MII2_RXD0 26

27 MII2_TXD3 MII2_RXD1 28

29 1V6 MII2_RXD2 30

31 1V6 GND 32

33 MII2_TXEN MII2_RXD3 34

35 MII2_TXER MII2_RXER 36

37 MII2_COL MII2_CRS 38

39 GND MII2_RCLK 40

41 MII1_TXD0 VCC_CORE 42

43 MII1_TXD1 MII1_RXDV 44

45 MII1_TXD2 MII1_RXD0 46

47 MII1_TXD3 MII1_RXD1 48

49 1V6 MII1_RXD2 50

51 1V6 GND 52

53 MII1_TXEN MII1_RXD3 54

55 MII1_TXER MII1_RXER 56

57 MII1_COL MII1_CRS 58

59 GND MII1_RCLK 60

61 1V6 GND 62

63 1V6 MII1_TCLK 64

Table 27. Pn5/Jn5 Connector Pin Out (Ethernet)

5.4.6 JTAG Connectivity

The MSC810x’s EONCE module allows non-intrusive interaction with the SC140 core allowing

examination/analysis of registers, memory and on-chip peripherals. The EONCE module interfaces

with the debugging system through on-chip JTAG TAP controller pins.

The DSP’s EONCE JTAG debug ports are connected in a chain configuration to allow simultaneous

debug of the complete DSP Array and Aggregator. There are a number of configurations:

• Setting JP1 jumper to position 1-2 and switch 2_8 to ON (short) enables the debug of the full

chain.

• Setting JP 1 jumper to p osition 2- 3 and switc h 2_8 to OFF (op en) enable s the debug of only

the MSC8101.

• MSC8102s can be removed/added to the chain as r equired b y the removal/addition of various

0 ohm resist o rs .

An EONCE connector is provided on P3. The signals available on the connector are:

• TMS: This signal is pulled up so that after reset 5 TCK clocks will put the TAP into the

Test Logic Reset State,

• TSRT: The Reset signal is pulled low to force the JTAG into reset by default.

• TCK: The clock signal is pulled low (pulled high is also OK for this signal) to save power

in low power stop mode.

29 PFC_DDD_v1.3.doc

Page 35

• TDI: The input signal is pulled high to save power in low power stop mode. All JTAG

ports have a weak internal TDI pull up.

• TDO: The output signal is pulled high

MSC8101

MSC8101

MSC8101

U37

U37

U37

5.4.7 LEDs

Surface mount 0603 footprints LEDs are provided on each of the MSC8102s, the MSC8101 and the

FPGA.

• MSC8101 port line PA6 controls MSC8101 LED

• MSC8102 port line GPIO31 controls MSC8102 LED

• FPGA pin D3 (IO_82) controls FPGA LED

5.5 PFC Board Configuration

The PFC incorporates 2 banks of switches to enable configuration of the MSC8101 and MSC8102.

The Configuration switch options are detailed below, consult the user guide section for further details

on switch setti ngs. When setting the switches ON =

Feature Description

SW3.1

SW3.2

SW3.3

SW3.4 MSC810 1 Boot Option:

SW3.5 IO SEL for MSC8101 UTOPIA/Ethernet multiplexed Selection

SW3.6

SW3.7

SW3.8 Reset Configuration

MSC8102(1)

MSC8102(1)

MSC8102(1)

U19

U19

U19

3 2 1 0 3 2 1 0 3 2 1 0 3 2 1 0 3 2 1 0

3 2 1 0 3 2 1 0 3 2 1 0 3 2 1 0 3 2 1 0

3 2 1 0 3 2 1 0 3 2 1 0 3 2 1 0 3 2 1 0

Core ref.

Core ref.

Core ref.

MSC8102(2)

MSC8102(2)

MSC8102(2)

U18

U18

U18

MSC8102(3)

MSC8102(3)

MSC8102(3)

U15

U15

U15

MSC8102(4)

MSC8102(4)

MSC8102(4)

U13

U13

U13

MSC8102(5)

MSC8102(5)

MSC8102(5)

U11

U11

U11

Figure 17. JTAG Chain

logic 0 and OFF = logic 1.

Table 28. Switch 3 Desc riptions

A_MODCK1

A_MODCK2

A_MODCK3

This sets MSC8101 MODCLK [1:3] and works in