Page 1

UM11524

First Field Verification Tool User manual

Rev. 1 — 24 February 2021 User manual

Document information

Information Content

Keywords SEN-SPI-BOX, FFV Tool

Abstract FFV Tool User manual

Page 2

NXP Semiconductors

Revision history

Rev Date Description

1 20210224 • Initial release

UM11524

First Field Verification Tool User manual

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

2 / 34

Page 3

NXP Semiconductors

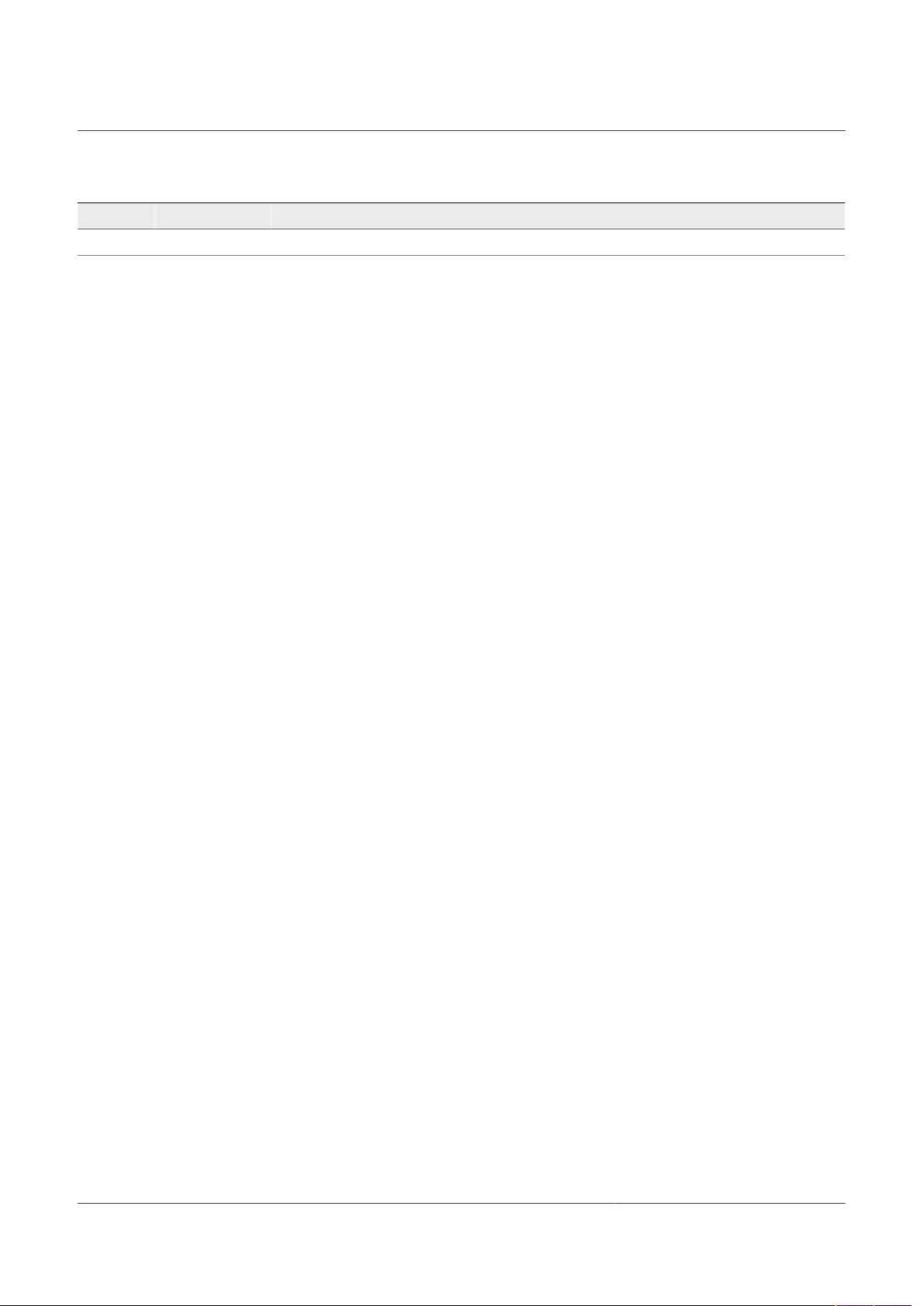

1 Introduction

This document describes how to use the SEN-SPI-BOX kit for NXP automotive sensor

evaluation with the “NXP First Field Verification Tool” software.

The intent of this document is to get started, from the hardware configuration to the

software manipulation, in order to communicate with NXP sensors and get interactive

data.

UM11524

First Field Verification Tool User manual

Figure 1. NXP Sensor SPI/I2C Master Kit - SEN-SPI-BOX

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

3 / 34

Page 4

NXP Semiconductors

2 Getting started

2.1 Kit contents/packing list

UM11524

First Field Verification Tool User manual

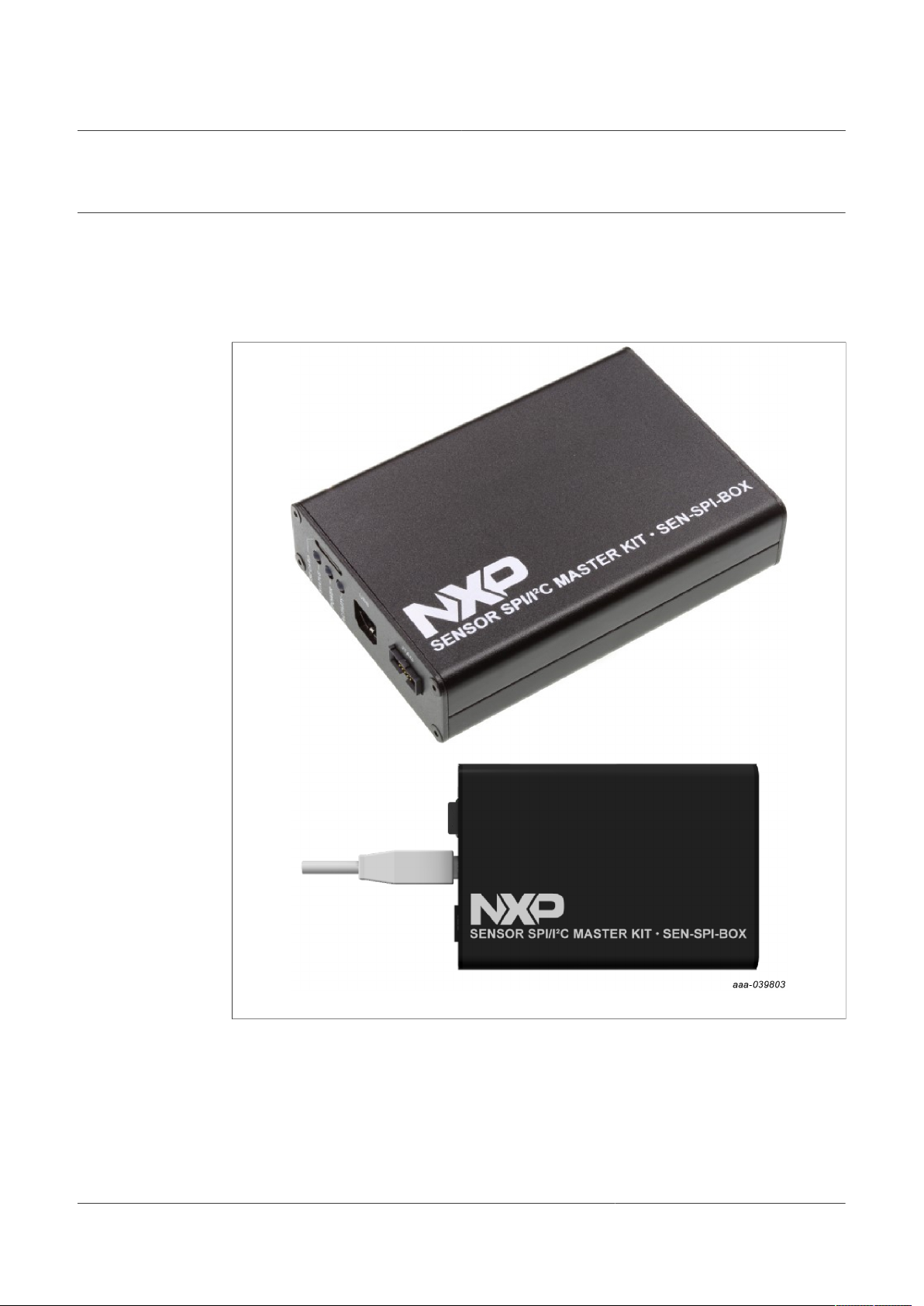

Figure 2. SEN-SPI-BOX kit contents

The SEN-SPI-BOX evaluation board contains:

• One Sensor SPI Master Kit (SEN-SPI-BOX)

• One USB Type A USB cable

• One NXP MDI ribbon cable (16-pin)

• One Beagle ribbon cable (10-pin)

• One debug cable

• One 8 GB microSD card

• One microSD to PC adapter

If DSI3 or PSI5 protocol is required, a SEN-DSI3-ADAPTER and a SEN-PSI5-ADAPTER

may be ordered separately.

SEN-xxxx-ADAPTER kit contains:

• One SEN-xxxx-ADAPTER

• Two, 2-wire twisted cables

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

4 / 34

Page 5

NXP Semiconductors

2.2 Finding kit resources and information on the NXP website

NXP Semiconductors provides online resources for this evaluation board and supported

devices on http://www.nxp.com. The information page for the SEN-SPI-BOX evaluation

board is at http://nxp.com/SEN-SPI-BOX. The information page provides overview

information, documentation, software and tools, parametrics, ordering information and

a Getting Started tab. The Getting Started tab provides quick-reference information

applicable to using the SEN-SPI-BOX evaluation board, including the downloadable

assets referenced in this document.

3 Hardware description

The NXP SEN-SPI-BOX kit provides a full-solution of built-in functionalities to

communicate with any SPI/I²C sensor. The kit graphs real-time data, executes custom

scripts and verifies sensor status. The board is a generic SPI/I²C evaluation board,

compatible with some of the NXP sensor families such as FXLS9xxxx automotive digital

accelerometers. The list of compatible sensors is non-exhaustive and may evolve in the

future.

Figure 3 shows how to couple the SEN-SPI-BOX with a SEN-GEN6-SKT board for the

FXLS9xxxx evaluation.

UM11524

First Field Verification Tool User manual

Figure 3. Attaching the SEN-GEN6-SKT board to the SEN-SPI-BOX

3.1 Kit overview

The kit contains an NXP SEN-SPI-BOX evaluation board, three different cables

compatible with dedicated NXP sensor boards, a microSD card for built-in boot loading

capability, and a USB Type-B cable to connect the kit to a computer.

The kit is powered by an NXP Kinetis® K64F Cortex M4 Microcontroller.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

5 / 34

Page 6

NXP Semiconductors

Figure 4. SEN-SPI-BOX overview

UM11524

First Field Verification Tool User manual

Figure 5. SEN-SPI-BOX interfaces

3.2 Pinout

The NXP MDI (16-pin) and Beagle (10-pin) connectors can be used with their own

dedicated ribbon cable or with breadboard jumper wires.

Figure 6. NXP MDI and Beagle connector pinout

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

6 / 34

Page 7

NXP Semiconductors

aaa- 0398 35

10

9

8

7

6

5

4

3

2

1

GND

/CS

MOSI

SCK

VCC

MISO

VCC

SDA

SCL

GND

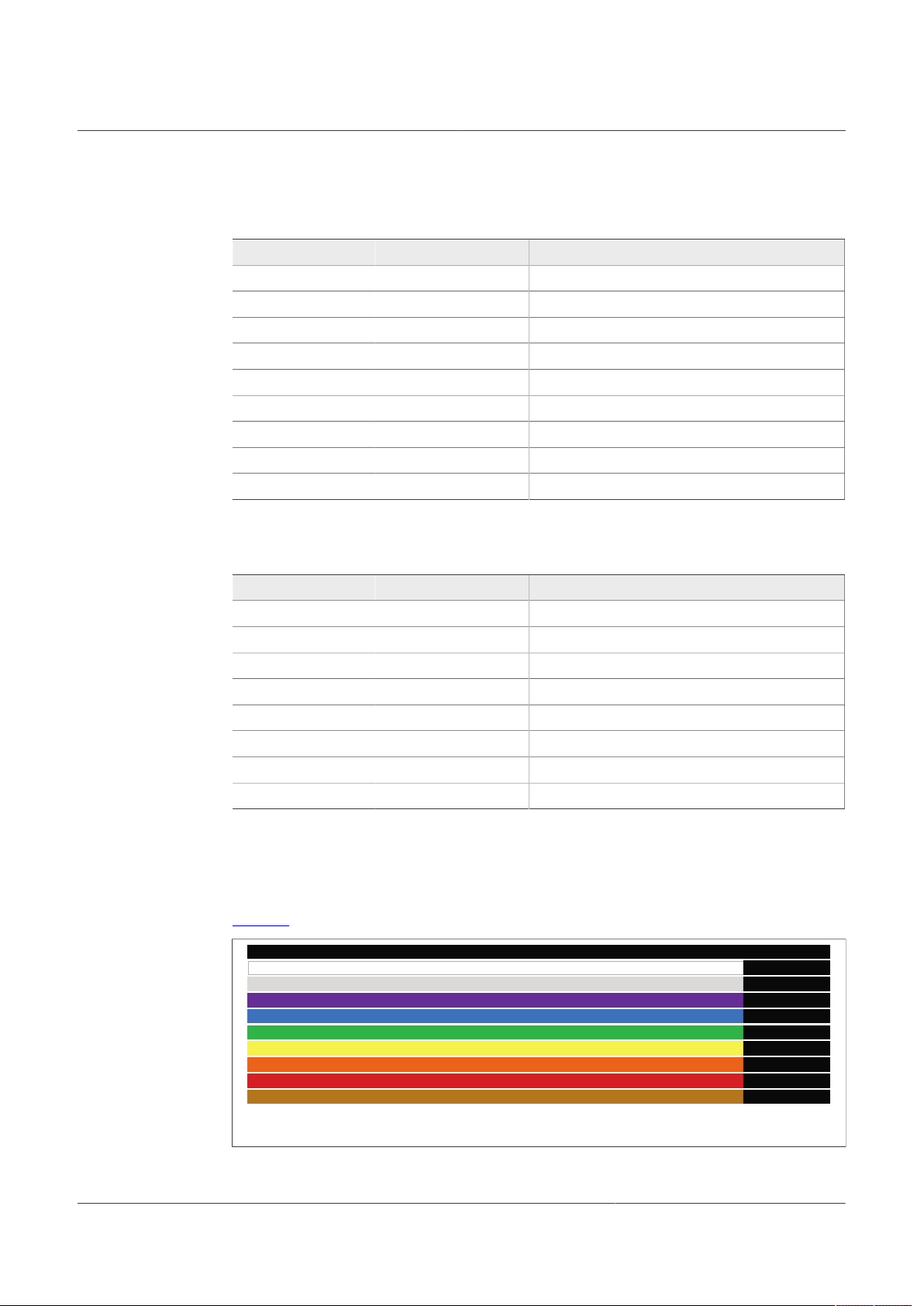

3.2.1 NXP MDI connector

Table 1. NXP MDI connector pinout

3.2.2 Beagle connector

UM11524

First Field Verification Tool User manual

Pin Label Description

6 VCC Power supply: off, 3.3 V or 5 V

2 VPP High-voltage supply: off, 10.5 V or 13.5 V

4,8,10,12 GND Ground

1 /CS SPI chip select

3 SCK/SCL SPI serial clock / I²C serial clock

5 MOSI SPI output

7 MISO/SDA SPI input / I²C serial data

9, 11, 13, 15 I/Ox Configurable input/output

14, 16 Ax Analog input

Table 2. Beagle connector pinout

Pin Label Description

4, 6 VCC Power supply: off, 3.3 V or 5 V

2, 10 GND Ground

9 /CS SPI chip select

7 SCK SPI serial clock

8 MOSI SPI output

5 MISO SPI input

1 SCL I²C serial clock

3 SDA I²C serial data

3.2.3 Beagle debug cable

To directly connect any sensor, use the debug cable (to be plugged into the Beagle

connector).

Figure 7 identifies the debug cable pinout connections.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

Figure 7. Debug cable pinouts

7 / 34

Page 8

NXP Semiconductors

3.3 LED indicators

3.3.1 Rear view

Figure 8. Status indicators

• Status: Blinks green if running, if red, something is wrong

• Power: Red when board is powered

• Activity: Fast blink when communicating with the software (red for input, green for

output, orange when directional)

UM11524

First Field Verification Tool User manual

3.3.2 Front view

Figure 9. Front LED indicators

• VCCIO: Green if VCCIO is turned on

• VCC: Green if VCC is turned on

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

8 / 34

Page 9

NXP Semiconductors

2

K64F_I2C1

2

I2C1

P3V3_ FRDM VCCIO

aaa- 039810

LEVE L SHIFTER

TCA9406

30 mA

E-FUSE

TPS22946

30-155 mA

E-FUSE

TPS22946

VCCIO

LDO 13.5 V

LM317LCPWR

BOOST 15 V

MAX8572

LDO 3.3 V

LMO317MPX-3.3/NCFB

FILTER

P5V_USB

NXP Part

Other part

Population option

Supply related

Supply nameLABEL

BUCK-BOOST 5 V

ADP2504

P5V_USB P3V3_ FTDIV_USB

USB

P15V P13V5

VPP

P10V5

P5V

P3V3_ KL46Z

P3V3_ KL46Z

USB CONTROLLER

FT230XQ

BEAGLE

CONNECTOR

MDI

CONNECTOR

P3V3_ FRDM

UART

MCU

MK64FN1M0VLQ12

6

K64F_SNIF_SPIO_x

4

BGE_SPIO_ x (CSI)

P3V3_ FRDM VCCIO

LEVE L SHIFTER

CD40109B

4

K64F_IOx

4

IO_x

P3V3_ FRDM VCCIO

LEVE L SHIFTER

MAX14611ETD

2

KL46_ADC_ Ax

2

A_ x

P5V

VOLTAGE FOLLOWER

MCP6022-1/SN

K64F_SPIO_CS1

K64F_SPIO_x

4

BGE_SPIO_ x (CSI)

P3V3_ FRDM VCCIO

LEVE L SHIFTER

74LVC 4T3144

K64F_SPIO_CS0

3

4

MDI_SPIO_ x (CS0)

P3V3_ FRDM VCCIO

LEVE L SHIFTER

74LVC 4T3144

4

STATUS LED

USB TYPE B

Hard reset

PUSH BUT TON

50 MHz CLOCK

4

JTAG/SWD

SWD/JTAG

CONNECTOR

6

SDHC

uSD CARD SOCKET

VCC

LDO 10.5 V

LM317LCPWR

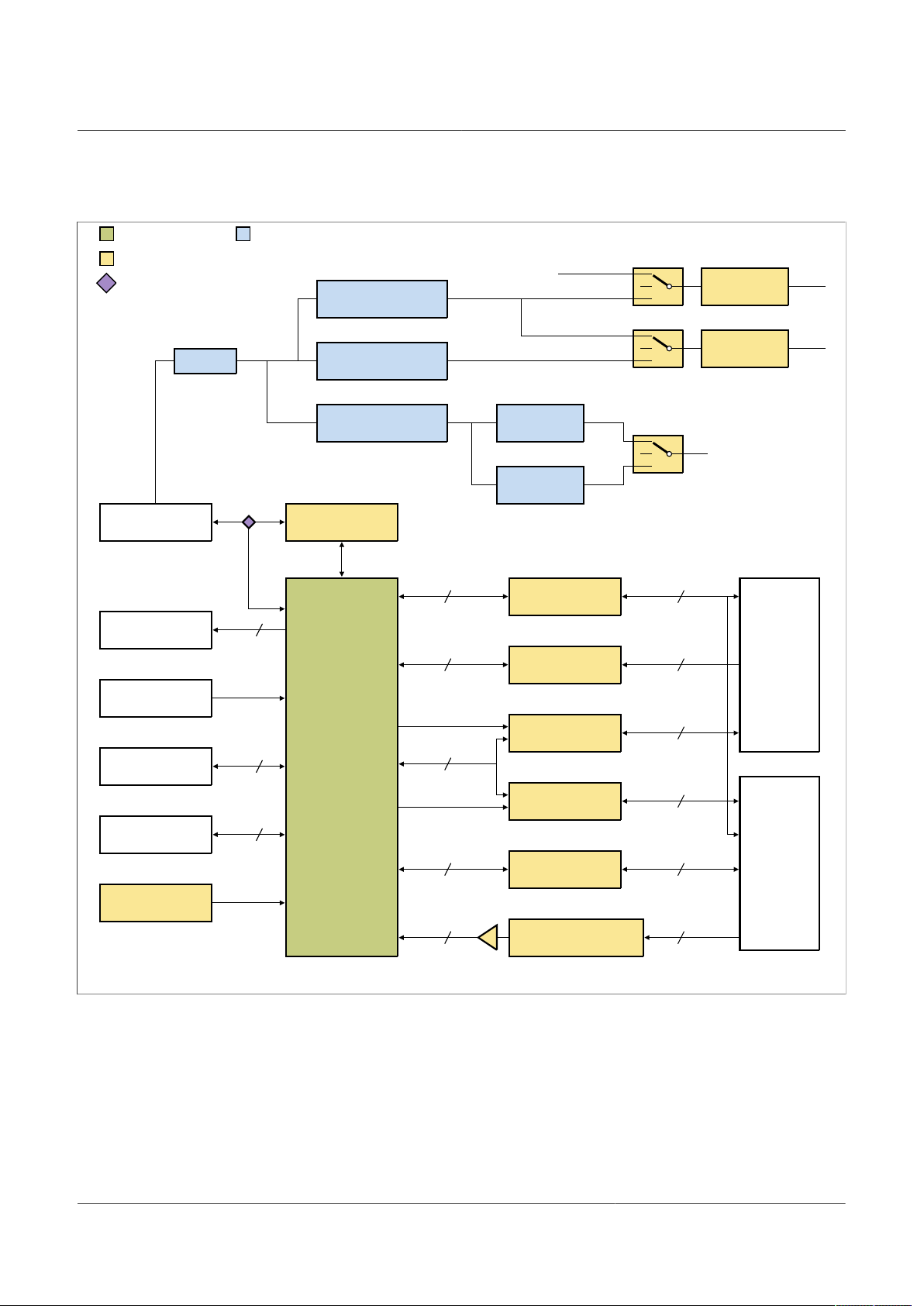

3.4 Block diagram

UM11524

First Field Verification Tool User manual

Figure 10. Block diagram

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

9 / 34

Page 10

NXP Semiconductors

4 Setting up the FFV Tool kit

4.1 Software installation

4.1.1 Download software

Go to http://www.nxp.com/SEN-SPI-BOX to download the software.

4.1.2 System requirements

The computer system hosting the Sensor FFV Tool software and SEN-SPI-BOX

hardware must meet the following requirements:

• Windows 10 (x86, x64). Although Windows Vista, 7 are anticipated to work as well,

these systems have not been tested and are not supported.

• For each SEN-SPI-BOX, a USB (V3.0) port must be available on the host PC. NXP

anticipates the SEN-SPI-BOX will work with USB V1.1 or V2.0 ports. However, NXP

has not tested the SEN-SPI-BOX with USB V1.1 or V2.0 ports.

• The screen size shall be at least 1024 x 768 pixels. NXP does not recommend using

screens with resolution smaller than 1024 x 768 pixels. Although the software runs on

screens with lower resolution, the GUI and forms are less convenient to use.

• Software to display Adobe PDF documents is required to read the documentation and

the data sheets.

UM11524

First Field Verification Tool User manual

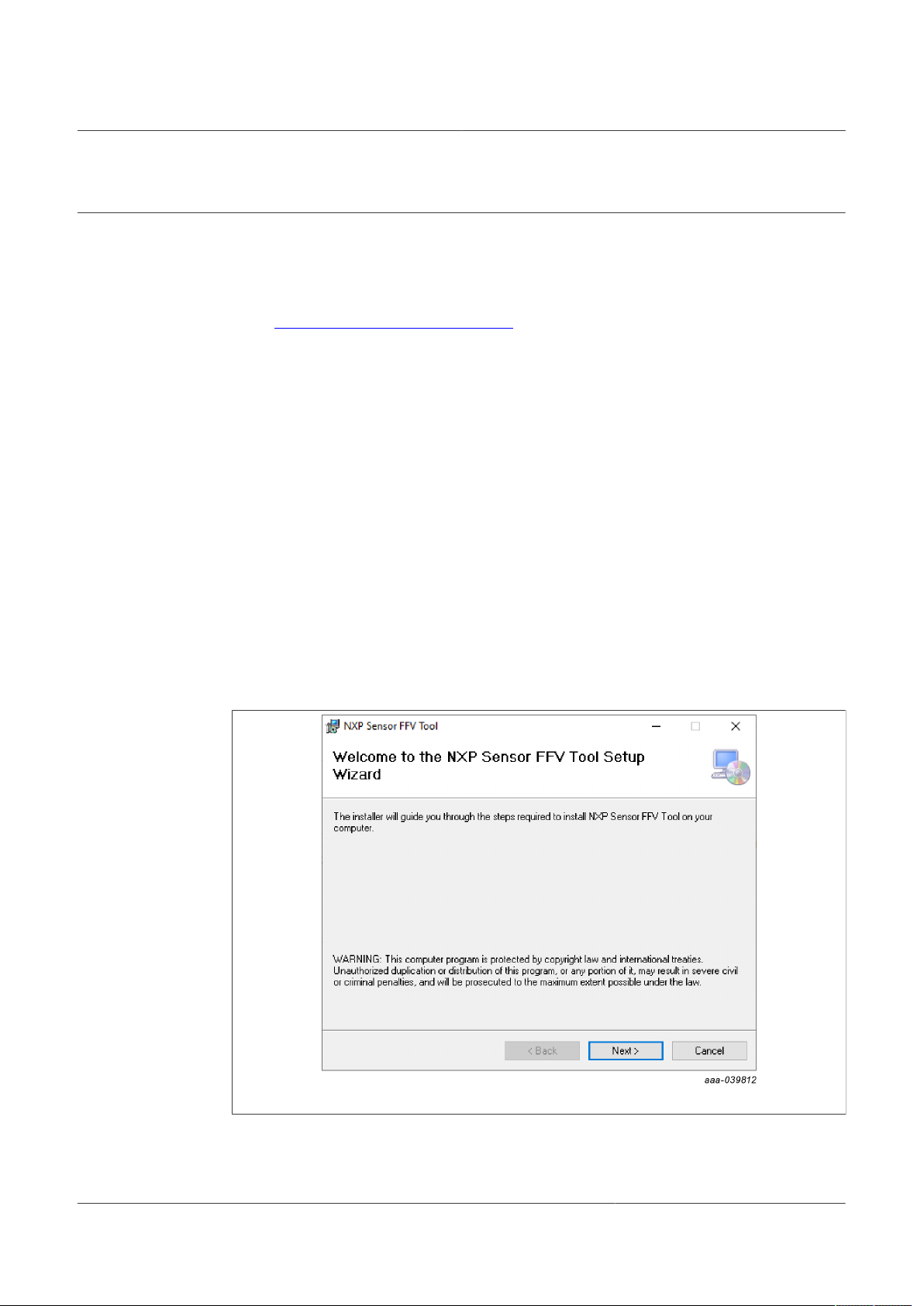

4.1.3 Setup

Double-click the downloaded .msi file and follow the instructions.

Figure 11. NXP Sensor FFV tool setup

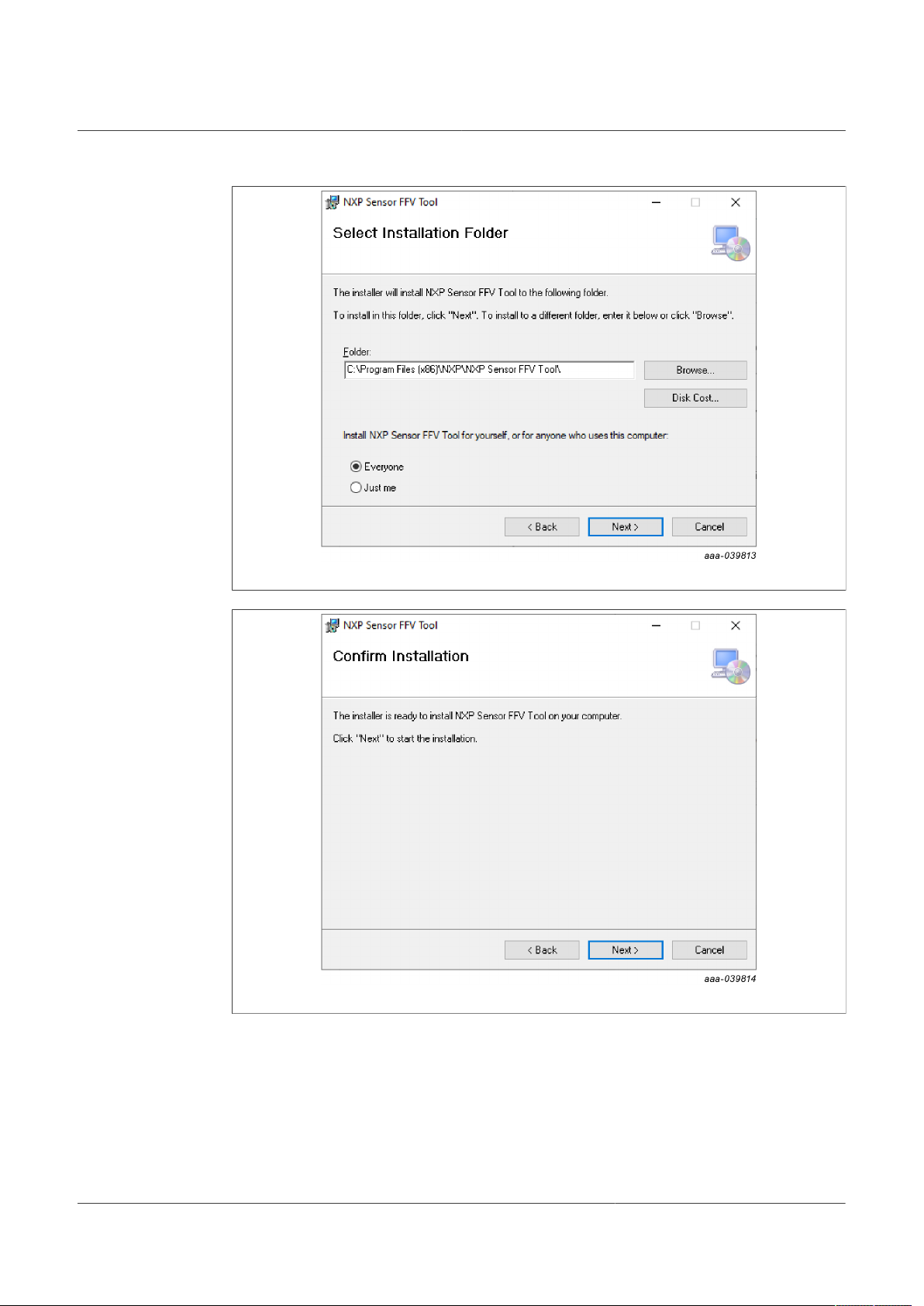

NXP recommends using the default installation folder, however the installation location

can be customized.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

10 / 34

Page 11

NXP Semiconductors

UM11524

First Field Verification Tool User manual

Figure 12. NXP Sensor FFV installation folder

Figure 13. NXP Sensor FFV tool installation confirmation

4.2 Prepare the kit

4.2.1 Connect the kit

Connect the FFV kit via the USB Type-B cable included in the kit.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

11 / 34

Page 12

NXP Semiconductors

Figure 14. Connecting the kit via USB Type-B cable

A new USB design should appear in the Windows device manager as shown in

Figure 15. There is no need to install a specific driver because the FFV kit uses standard

Window COM port drivers (usbser.sys, hhdserial64.sys) already present in Windowsbased computers.

UM11524

First Field Verification Tool User manual

Figure 15. Compatible COM Port drivers

4.2.2 Launch the software

4.2.2.1 Start

Start the GUI through the launcher or double-click a .ffvpkg file (if .ffvpkg is used, skip

Section 4.2.2.2 and jump directly to step Section 4.2.2.3)

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

12 / 34

Page 13

NXP Semiconductors

4.2.2.2 Select a project

UM11524

First Field Verification Tool User manual

Figure 16. Select a script in the First Field Verification tool

There are several ways to open projects.

Previously Opened Project: Previously opened projects are listed in “Recent projects”.

Double-click the "recent project" to reopen the project. To learn more, refer to Section 6.

Figure 17. Open an existing project

NXP Compatible sensor without dedicated package file: The user has an NXP

compatible sensor but does not have a dedicated package file. Click the menu bar and

review the existing “Predefined sensor packages”. To learn more, refer to Section 6.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

13 / 34

Page 14

NXP Semiconductors

UM11524

First Field Verification Tool User manual

Figure 18. Open a compatible sensor without a dedicated package file

NXP .ffvpkg file: The user has an NXP-provided .ffvpkg file. Click the “Browse” button,

select the file and open it. Alternately, drag and drop the file in “Recent projects” adding

the file to the "recent projects" list. To learn more, refer to Section 6.

Unsupported device or missing package to communicate with the device: The

user has an unsupported device or lacks the necessary package to communicate with

the sensor. In this case, use the “Standard communication protocols”. These protocols

provide basic functions to communicate with SPI, I2C, PSI5, or DSI3 sensors. To learn

more, refer to Section 5.

Figure 19. Open an unsupported device or missing a package

Note: PSI5 and DSI3 protocols necessitate special hardware which is sold separately

from the SEN-SPI-BOX kit. (SEN-PSI5-ADAPTER and SEN-DSI3-ADAPTER).

4.2.2.3 FFV kit search

The software scans all the compatible devices. If this operation fails, ensure that

everything is properly connected and retry.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

14 / 34

Page 15

NXP Semiconductors

Figure 20. FFV compatible device scan

UM11524

First Field Verification Tool User manual

4.2.2.4 Enable the power supplies

After the software detects the kit, enable and select the voltage for the power supplies as

needed.

Figure 21. FFV power supply voltage selection

4.2.2.4.1 VCC

When using the FFV kit standalone (no MCU attached to the sensor nor external supply),

enable the VCC supply.

If the sensor is already powered by an external source, disable the option.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

15 / 34

Page 16

NXP Semiconductors

4.2.2.4.2 VCCIO

VCCIO is the logic voltage of the SPI and I²C interfaces. It must be set to a value

compatible with the sensor VCC supply.

4.2.2.4.3 VPP

VPP is the high-voltage supply which could be used in specific cases. It must be carefully

used and may damage the sensor if not used correctly.

5 Using standard communication protocols

The SEN-SPI-BOX supports natively SPI and I2C protocols.

To add PSI5 and/or DSI3 automotive protocol interfaces to the SEN-SPI-BOX, adapter

boards may be purchased separately.

5.1 Native protocols

When SPI or I2C protocol is selected from the “Standard communication protocol” block,

it opens as shown in Figure 22.

UM11524

First Field Verification Tool User manual

Figure 22. Example of custom GUI selection for SPI interface

Choose the power supplies as explained Section 4.2.2.4. Select the SEN-SPI-BOX kit

(green button bottom right).

Use the debug cable provided in the kit to connect the sensor with the SEN-SPI-BOX

board.

Click on the "Select" button once erverything is configured. The software opens the

form corresponding to the selected protocol (SPI or I2C) as detailed in Section 5.1.1 and

Section 5.1.2.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

16 / 34

Page 17

NXP Semiconductors

5.1.1 SPI

The SPI menu offers the necessary functions to transfer data. It supports frequencies

up to 10 MHz and the four different SPÏ modes. Transfer width supports 8 to 32 bits data

transfers. There are two selections for Chip Select that correspond to the NXP MDI and

Beagle terminals.

UM11524

First Field Verification Tool User manual

Figure 23. SPI functions for data transfer

Once the configuration set, data can be easily transferred using the “Send” button.

5.1.2 I2C

This I2C interface supports up to 64 byte data transfers.

Configure the 7-bit sensor address and the frequency of the bus (up to 1 MHz).

Figure 24. I2C Interface

5.1.2.1 I2C scanner

The SEN-SPI-BOX is able to scan for I2C sensor addresses. To see all compatible

connected sensors, click the “Scan” button.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

17 / 34

Page 18

NXP Semiconductors

5.1.2.2 Read

Select a register start address and the number of data to read. The result is shown as an

array of 8-bit data.

5.1.2.3 Write

Select a start register and write the value in hexadecimal. Separate multiple values using

a semicolon (;).

5.2 Optional protocols

The selection of DSI3 or PSI5 protocol in the “Standard communication protocol” block

necessitates a special adapter board (SEN-PSI5-ADAPTER or SEN-DSI3-ADAPTER) for

each protocol.

1. Check and set the compatible power supply. Always refer to and set the power

2. Connect the adapter board on the SEN-SPI-BOX using the NXP MDI terminal.

3. Click the Scan button.

4. Select the PSI5/DSI3 transceiver listed.

UM11524

First Field Verification Tool User manual

settings using the value printed on the bottom of the board.Table 3 provides a

summary for convenience.

Table 3. DSI3/PSI5 adapter power settings summary

SEN-DSI3-ADAPTER SEN-PSI5-ADAPTER

VCC, VCCIO 5 V 3.3 V

VPP 13.5 V 10.5 V

Components are on the top. Check the connector coding to avoid mistakes.

Figure 25. Transceiver selection

5.2.1 DSI3

Two DSI3 interfaces are available on the SEN-DSI3-ADAPTER board: DSI3 channel 0

and DSI3 channel 1.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

18 / 34

Page 19

NXP Semiconductors

To enable or disable the interface for each channel, use the “DSI3 channel enable”

checkbox.

Enabling a channel automatically sends discovery pulses. Every compatible device

present on the bus is assigned a unique physical address.

Figure 26. Enable or disable the DSI3 channel

To exit PDCM mode, the corresponding DSI3 channel must be disabled.

5.2.1.1 Command and response mode (CRM)

By default the transceiver boots in CRM mode. If a sensor is connected to the bus and

owns a physical address, users may be able to send a CRM command.

The sensor manufacturer specifies the commands and the data to send.

UM11524

First Field Verification Tool User manual

Figure 27. CRM settings

5.2.1.2 Periodic data collection mode (PDCM)

Once the sensor is configured using CRM commands, the user must set the DSI3

receiver correctly for PDCM operations.

1. Selected chip time (transceiver chip time must be identical to the chip time of the DSI3

sensor).

2. Associate source ID to timeslot. If a mismatch occurs between the frame source ID

and the slot number, the mismatch raises an error.

3. Choose whether Broad Read Command (BRC) is sent every 500 µs or manually

(when the user clicks the "Update" button.

The user can then switch the DSI3 transceiver to PDCM mode by clicking the “Enter”

button. The transceiver stays in PCDM mode while the bus is powered.

To return to CRM mode, the user must power off, then power on, the associated channel

to return to CRM mode.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

19 / 34

Page 20

NXP Semiconductors

Figure 28. PDCM settings

5.2.1.3 Background diagnostic mode (BDM)

UM11524

First Field Verification Tool User manual

Background diagnostic mode is not supported.

5.2.2 PSI5

Two PSI5 interfaces are available on the SEN-PSI5-ADAPTER board: PSI5 channel 0

and PSI5 channel 1.

The interfaces are enabled/disabled using the “PSI5 channel enable” checkbox.

The interface only works for “Sensor to ECU” communication (ECU to Sensor

communication is not supported yet).

Figure 29. PSI5 transceiver interface

The operation mode must be selected according to the PSI5 sensor capability.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

20 / 34

Page 21

NXP Semiconductors

aaa- 041027

Communication Mode:

A / P / U / DPSI5 P / CRCdd L / Hntttt /

Nº of Data Bits

Error Detection

Cycle Time in µs

Nº of Time Slots per cycle

Bit Rate

Figure 30. Denomination of PSI5 operation modes

PSI5 supports both synchronous (P) and asynchronous (A) modes. Figure 30 provides a

visual summary of the PSI5 operation modes and Table 4 provides details for each field.

Table 4. PSI5 operation mode details

Field Possible values

Cycling time 200 µs to 8360 µs (32 µs step)

Number of slots per cycle 1 to 6

UM11524

First Field Verification Tool User manual

Synchronous: PCommunication mode

Asynchronous: A

16-bit: 16Number of data bits

10-bit: 10

CRC: CError detection

Parity: P

125 kbit/s: LBit rate

189 kbit/s: H

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

21 / 34

Page 22

NXP Semiconductors

First Field Verification Tool User manual

6 Using .ffvpkg or predefined sensor packages

6.1 Connect the sensor to the FFV kit

Plug the sensor to the Sensor FFV kit. If provided by NXP, use the NXP socket board, or

connect your own board. The pinout is described in Section 3.2.

6.2 Scan for sensor

In the software, press the “Scan” button.

UM11524

Figure 31. Sensor selection page

A list of the compatible sensors appears.

6.3 Configure the sensor

Select the sensor from the list and if available, configure the SPI/I²C settings.

Note: The new configuration is applied only when the "Select" button is activated.

6.3.1 Advanced window for advanced features

To open the advanced windows, right-click any compatible sensor.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

22 / 34

Page 23

NXP Semiconductors

Figure 32. Advanced features

Note: This feature should be used with special care and is not synchronized with

standard functions.

This capability means that users can overwrite the sensor register without seeing it in the

other window if it is not updated.

UM11524

First Field Verification Tool User manual

Currently, there are two advanced forms:

• Register table: Quick and easy way to read and modify the sensor memory.

• Scripting: To configure the sensor, automate actions with a command list.

6.3.1.1 Register table

Figure 33 presents the values found in the registers of the sensor.

Figure 33. Register sensor content

The data presented in the sensor table, shown in Figure 33, is not real time and a

mismatch could exist between the value in the table and the actual register value. The

value is displayed in hexadecimal format.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

23 / 34

Page 24

NXP Semiconductors

Use filters to reduce the number of visible registers (address, register name, bit field

name).

6.3.1.2 Custom script

In parallel, custom scripts can be executed if users want to automate some actions.

To learn how to write scripts, review Section 6.5.3.1.

UM11524

First Field Verification Tool User manual

Figure 34. FFV script editor

6.4 Open the package

Press the "select" button to open the package content.

There are two types of .ffvpkg files:

• Test File (See the magnifier icon in Figure 35.)

• Datalogger File (See the graphing icon in Figure 35.)

Depending on the file, the correct form automatically opens.

Figure 35. Types of .ffvpkg files

If using .ffvscript file, jump to Section 6.5.3.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

24 / 34

Page 25

NXP Semiconductors

6.5 Use the package files

6.5.1 Test file

6.5.1.1 Configure the test

If available, press the wrench icon to change the test settings. Users can skip some tests

by unchecking the test in the list.

UM11524

First Field Verification Tool User manual

Figure 36. Test of an FXLS90422AES inertial sensor

6.5.1.2 Run the test

Once everything is configured, press the “Run” button. Wait while the sequence is being

executed. To view the details of the selected test, click the folder icon.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

25 / 34

Page 26

NXP Semiconductors

UM11524

First Field Verification Tool User manual

Figure 37. FFV running the test

When complete, export the test results by clicking “Save”. A “.ffvreport” file and a .pdf is

generated. The results are visible later when opening the file.

Close the software.

6.5.1.3 Open a test report

Open a test report file by double-clicking a “.ffvreport” file or by launching the software

and selecting the file from the window browser.

Figure 38. FFV opening the test report

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

26 / 34

Page 27

NXP Semiconductors

This form is read-only. Re-executing any test from here is not possible.

6.5.1.4 Create a custom test file using C# .Net

Custom test files can be developed using Visual Studio IDE with C# .Net framework.

Special documentation is available from the FFV software by clicking “Create advanced

C# script” from the launcher.

6.5.2 Datalogger file

6.5.2.1 Configure the sensor

UM11524

First Field Verification Tool User manual

Figure 39. Example of configuration interface

The left panel offers many high-level settings the user may access to configure the

sensor. Do not forget to apply the settings before starting any data steam.

This panel may display differently depending on the selected file/sensor.

6.5.2.2 Configure the streaming settings

The streaming panel is split in 3 different sub panels.

6.5.2.2.1 Stream settings

The Stream settings panel allows users to select:

• “Sampling time” between two data (make sure that the communication frequency is

high enough to support the highest rate).

• “Count”: The number of samples to be collected (any non-number value is turned into

infinite).

• “Acquisition time”: Not selectable. It just gives the result of “Count” x “Sampling Time”.

• “Unit in LSB”: Unchecked. Shows the plot with the standard units, else shows in LSB.

• “Start” / “Stop”: Launch/stop the stream.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

27 / 34

Page 28

NXP Semiconductors

Figure 40. FFV configuring the stream settings

6.5.2.2.2 Stream info

The stream info panel displays status information about the data collection.

UM11524

First Field Verification Tool User manual

Figure 41. FFV stream information

6.5.2.2.3 Recording settings

The Recording settings panel allows the user to record the incoming data stream.

• Output file: The path of the record

• Status: Indicates whether a recording is taking place.

• Recording time: Displays how long the recording has been running.

• Record / Stop: Launches/Stops the record.

Figure 42. FFV recording the settings

6.5.2.2.4 Run the datalog

Once everything is configured, take advantage on the fast real-time data plotting.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

28 / 34

Page 29

NXP Semiconductors

Figure 43. Real-time graphing example

UM11524

First Field Verification Tool User manual

6.5.3 Script file

To automatically execute a list of commands, use script files to create customized scripts.

These scripts are editable using simple text keywords.

Figure 44. FFV creating customized scripts

To load the file content, drag and drop a text file into the editor area.

6.5.3.1 Create custom scripts

The available keywords are listed below and can be used to develop automatic line by

line sequences.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

29 / 34

Page 30

NXP Semiconductors

6.5.3.1.1 Generic sensor commands (high-level)

• RR <address> [options]: Read register command.

• WR <address> <data> [options]: Write register command.

• DR <source ID> [options]: Sensor Data Request command (Auto-Safety sensor).

6.5.3.1.2 Generic advanced sensor commands (high-level)

• MR <addess(es)> <multiplier> <delay> [options]: Multi read register command, real

time.

– address(es): Can be [@1, @2, @3] or range as [@1 - @3] (up to 1024 bytes).

– multiplier: Repeat the address sequence.

– delay: Time in µs between each command. (up to 100 ms, check the bus speed

• MD <source Id> <multiplier> <delay> [options]: Multi data-request register command,

real time).

– source Id: Can be [1, 2, 3] or range as [1 - 3].

– multiplier: Repeat the source Id sequence.

– delay: Time in µs between each command. (up to 100 ms, check the bus speed

UM11524

First Field Verification Tool User manual

compatibility).

compatibility).

6.5.3.1.3 Generic SPI commands (low level)

• S32 <data> [options]: 32-bit SPI transfer.

• S24 <data> [options]: 24-bit SPI transfer.

• S16 <data> [options]: 16-bit SPI transfer.

• S8 <data> [options]: 8-bit SPI transfer.

6.5.3.1.4 Generic I²C commands (low level)

Not supported yet.

6.5.3.1.5 Other commands (low level)

• SETV <channel> <voltage> [options]: Power supply command (Special care is required

when using this command. Applying an incorrect voltage may damage a sensor.).

– channel: VCC, VCCIO, or VPP.

– voltage: (VCC, VCCIO) OFF, 3.3, 5 - (VPP) OFF, 10.5, 13.5.

• DELAY <time> [options]: Software delay command in milliseconds, not real time, only

accurate for long timing.

• ': Comment.

6.5.3.1.6 Using [Options]

At the end of the command line, add a "-" followed by the option flag. The available flags

are:

• -D: Output result in decimal rather than hex.

• -T: Print timestamp.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

30 / 34

Page 31

NXP Semiconductors

6.5.3.1.7 Examples

Table 5. Example script commands

Command Command comment

rr 0x3e 'read address 3E in hexadecimal, result output is in hexadecimal.

rr 25 -t 'read register 25 (19 in hex), result output in hexadecimal, timestamp is

rr 0x12 -d 'read address 12 in hexadecimal, result output is in decimal.

wr 0x1A 0xAA 'write 0xAA in the register 0x1A.

wr 0x41 255 'write 0xFF in the register 0x41.

dr 0 -d -t 'data request channel 0 with timestamp and decimal output.

mr [0-5] 1 0 'read addresses from 0 to 5 once at the highest bus speed.

mr [0,1,2,3,4,5] 1 0 'same as above.

mr 0 20 100 -d 'read register at address 0 20 times every 100 μs with a decimal display.

md 0 5 100 'data request for channel 0, 5 times every 100 μs.

md [0,1] 10 200 -d 'data request channel 0 and 1, 20 times every 200 ms, decimal display.

UM11524

First Field Verification Tool User manual

displayed.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

31 / 34

Page 32

NXP Semiconductors

7 Legal information

7.1 Definitions

Draft — A draft status on a document indicates that the content is still

under internal review and subject to formal approval, which may result

in modifications or additions. NXP Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information included in a draft version of a document and shall have no

liability for the consequences of use of such information.

7.2 Disclaimers

Limited warranty and liability — Information in this document is believed

to be accurate and reliable. However, NXP Semiconductors does not

give any representations or warranties, expressed or implied, as to the

accuracy or completeness of such information and shall have no liability

for the consequences of use of such information. NXP Semiconductors

takes no responsibility for the content in this document if provided by an

information source outside of NXP Semiconductors. In no event shall NXP

Semiconductors be liable for any indirect, incidental, punitive, special or

consequential damages (including - without limitation - lost profits, lost

savings, business interruption, costs related to the removal or replacement

of any products or rework charges) whether or not such damages are based

on tort (including negligence), warranty, breach of contract or any other

legal theory. Notwithstanding any damages that customer might incur for

any reason whatsoever, NXP Semiconductors’ aggregate and cumulative

liability towards customer for the products described herein shall be limited

in accordance with the Terms and conditions of commercial sale of NXP

Semiconductors.

Right to make changes — NXP Semiconductors reserves the right to

make changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This document supersedes and replaces all information supplied prior

to the publication hereof.

Suitability for use — NXP Semiconductors products are not designed,

authorized or warranted to be suitable for use in life support, life-critical or

safety-critical systems or equipment, nor in applications where failure or

malfunction of an NXP Semiconductors product can reasonably be expected

to result in personal injury, death or severe property or environmental

damage. NXP Semiconductors and its suppliers accept no liability for

inclusion and/or use of NXP Semiconductors products in such equipment or

applications and therefore such inclusion and/or use is at the customer’s own

risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. NXP Semiconductors makes

no representation or warranty that such applications will be suitable

for the specified use without further testing or modification. Customers

are responsible for the design and operation of their applications and

products using NXP Semiconductors products, and NXP Semiconductors

accepts no liability for any assistance with applications or customer product

design. It is customer’s sole responsibility to determine whether the NXP

Semiconductors product is suitable and fit for the customer’s applications

and products planned, as well as for the planned application and use of

customer’s third party customer(s). Customers should provide appropriate

design and operating safeguards to minimize the risks associated with

their applications and products. NXP Semiconductors does not accept any

liability related to any default, damage, costs or problem which is based

on any weakness or default in the customer’s applications or products, or

UM11524

First Field Verification Tool User manual

the application or use by customer’s third party customer(s). Customer is

responsible for doing all necessary testing for the customer’s applications

and products using NXP Semiconductors products in order to avoid a

default of the applications and the products or of the application or use by

customer’s third party customer(s). NXP does not accept any liability in this

respect.

Export control — This document as well as the item(s) described herein

may be subject to export control regulations. Export might require a prior

authorization from competent authorities.

Evaluation products — This product is provided on an “as is” and “with all

faults” basis for evaluation purposes only. NXP Semiconductors, its affiliates

and their suppliers expressly disclaim all warranties, whether express,

implied or statutory, including but not limited to the implied warranties of

non-infringement, merchantability and fitness for a particular purpose. The

entire risk as to the quality, or arising out of the use or performance, of this

product remains with customer. In no event shall NXP Semiconductors, its

affiliates or their suppliers be liable to customer for any special, indirect,

consequential, punitive or incidental damages (including without limitation

damages for loss of business, business interruption, loss of use, loss of

data or information, and the like) arising out the use of or inability to use

the product, whether or not based on tort (including negligence), strict

liability, breach of contract, breach of warranty or any other theory, even if

advised of the possibility of such damages. Notwithstanding any damages

that customer might incur for any reason whatsoever (including without

limitation, all damages referenced above and all direct or general damages),

the entire liability of NXP Semiconductors, its affiliates and their suppliers

and customer’s exclusive remedy for all of the foregoing shall be limited to

actual damages incurred by customer based on reasonable reliance up to

the greater of the amount actually paid by customer for the product or five

dollars (US$5.00). The foregoing limitations, exclusions and disclaimers shall

apply to the maximum extent permitted by applicable law, even if any remedy

fails of its essential purpose.

Translations — A non-English (translated) version of a document is for

reference only. The English version shall prevail in case of any discrepancy

between the translated and English versions.

Security — Customer understands that all NXP products may be subject

to unidentified or documented vulnerabilities. Customer is responsible

for the design and operation of its applications and products throughout

their lifecycles to reduce the effect of these vulnerabilities on customer’s

applications and products. Customer’s responsibility also extends to other

open and/or proprietary technologies supported by NXP products for use

in customer’s applications. NXP accepts no liability for any vulnerability.

Customer should regularly check security updates from NXP and follow up

appropriately. Customer shall select products with security features that best

meet rules, regulations, and standards of the intended application and make

the ultimate design decisions regarding its products and is solely responsible

for compliance with all legal, regulatory, and security related requirements

concerning its products, regardless of any information or support that may

be provided by NXP. NXP has a Product Security Incident Response Team

(PSIRT) (reachable at PSIRT@nxp.com) that manages the investigation,

reporting, and solution release to security vulnerabilities of NXP products.

7.3 Trademarks

Notice: All referenced brands, product names, service names and

trademarks are the property of their respective owners.

NXP — wordmark and logo are trademarks of NXP B.V.

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

32 / 34

Page 33

NXP Semiconductors

Tables

UM11524

First Field Verification Tool User manual

Tab. 1. NXP MDI connector pinout ............................... 7

Tab. 2. Beagle connector pinout ................................... 7

Tab. 3. DSI3/PSI5 adapter power settings

summary ..........................................................18

Figures

Fig. 1. NXP Sensor SPI/I2C Master Kit - SEN-SPI-

BOX ................................................................... 3

Fig. 2. SEN-SPI-BOX kit contents ................................4

Fig. 3. Attaching the SEN-GEN6-SKT board to the

SEN-SPI-BOX ................................................... 5

Fig. 4. SEN-SPI-BOX overview .................................... 6

Fig. 5. SEN-SPI-BOX interfaces ...................................6

Fig. 6. NXP MDI and Beagle connector pinout .............6

Fig. 7. Debug cable pinouts ......................................... 7

Fig. 8. Status indicators ................................................8

Fig. 9. Front LED indicators ......................................... 8

Fig. 10. Block diagram ................................................... 9

Fig. 11. NXP Sensor FFV tool setup ............................10

Fig. 12. NXP Sensor FFV installation folder .................11

Fig. 13. NXP Sensor FFV tool installation

confirmation ..................................................... 11

Fig. 14. Connecting the kit via USB Type-B cable ........12

Fig. 15. Compatible COM Port drivers ......................... 12

Fig. 16. Select a script in the First Field Verification

tool ...................................................................13

Fig. 17. Open an existing project ................................. 13

Fig. 18. Open a compatible sensor without a

dedicated package file .................................... 14

Fig. 19. Open an unsupported device or missing a

package ........................................................... 14

Fig. 20. FFV compatible device scan ........................... 15

Tab. 4. PSI5 operation mode details ........................... 21

Tab. 5. Example script commands .............................. 31

Fig. 21. FFV power supply voltage selection ................15

Fig. 22. Example of custom GUI selection for SPI

interface ...........................................................16

Fig. 23. SPI functions for data transfer ........................ 17

Fig. 24. I2C Interface ....................................................17

Fig. 25. Transceiver selection ...................................... 18

Fig. 26. Enable or disable the DSI3 channel ................ 19

Fig. 27. CRM settings ...................................................19

Fig. 28. PDCM settings ................................................ 20

Fig. 29. PSI5 transceiver interface ............................... 20

Fig. 30. Denomination of PSI5 operation modes .......... 21

Fig. 31. Sensor selection page .....................................22

Fig. 32. Advanced features .......................................... 23

Fig. 33. Register sensor content .................................. 23

Fig. 34. FFV script editor ..............................................24

Fig. 35. Types of .ffvpkg files ........................................24

Fig. 36. Test of an FXLS90422AES inertial sensor .......25

Fig. 37. FFV running the test ....................................... 26

Fig. 38. FFV opening the test report ............................ 26

Fig. 39. Example of configuration interface .................. 27

Fig. 40. FFV configuring the stream settings ................28

Fig. 41. FFV stream information ...................................28

Fig. 42. FFV recording the settings .............................. 28

Fig. 43. Real-time graphing example ........................... 29

Fig. 44. FFV creating customized scripts ..................... 29

UM11524 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 24 February 2021

33 / 34

Page 34

NXP Semiconductors

Contents

UM11524

First Field Verification Tool User manual

1 Introduction ......................................................... 3

2 Getting started .................................................... 4

2.1 Kit contents/packing list ..................................... 4

2.2 Finding kit resources and information on

the NXP website ................................................5

3 Hardware description ......................................... 5

3.1 Kit overview ....................................................... 5

3.2 Pinout .................................................................6

3.2.1 NXP MDI connector ...........................................7

3.2.2 Beagle connector ...............................................7

3.2.3 Beagle debug cable ...........................................7

3.3 LED indicators ................................................... 8

3.3.1 Rear view ...........................................................8

3.3.2 Front view .......................................................... 8

3.4 Block diagram ....................................................9

4 Setting up the FFV Tool kit .............................. 10

4.1 Software installation .........................................10

4.1.1 Download software .......................................... 10

4.1.2 System requirements ....................................... 10

4.1.3 Setup ................................................................10

4.2 Prepare the kit ................................................. 11

4.2.1 Connect the kit ................................................ 11

4.2.2 Launch the software ........................................ 12

4.2.2.1 Start ................................................................. 12

4.2.2.2 Select a project ................................................13

4.2.2.3 FFV kit search ................................................. 14

4.2.2.4 Enable the power supplies .............................. 15

5 Using standard communication protocols ..... 16

5.1 Native protocols ............................................... 16

5.1.1 SPI ................................................................... 17

5.1.2 I2C ................................................................... 17

5.1.2.1 I2C scanner ..................................................... 17

5.1.2.2 Read ................................................................ 18

5.1.2.3 Write .................................................................18

5.2 Optional protocols ............................................18

5.2.1 DSI3 ................................................................. 18

5.2.1.1 Command and response mode (CRM) ............19

5.2.1.2 Periodic data collection mode (PDCM) ............19

5.2.1.3 Background diagnostic mode (BDM) ............... 20

5.2.2 PSI5 ................................................................. 20

6 Using .ffvpkg or predefined sensor

packages ............................................................ 22

6.1 Connect the sensor to the FFV kit ...................22

6.2 Scan for sensor ............................................... 22

6.3 Configure the sensor ....................................... 22

6.3.1 Advanced window for advanced features ........ 22

6.3.1.1 Register table .................................................. 23

6.3.1.2 Custom script ...................................................24

6.4 Open the package ........................................... 24

6.5 Use the package files ......................................25

6.5.1 Test file ............................................................ 25

6.5.1.1 Configure the test ............................................ 25

6.5.1.2 Run the test ..................................................... 25

6.5.1.3 Open a test report ........................................... 26

6.5.1.4 Create a custom test file using C# .Net ........... 27

6.5.2 Datalogger file ................................................. 27

6.5.2.1 Configure the sensor ....................................... 27

6.5.2.2 Configure the streaming settings ..................... 27

6.5.3 Script file ..........................................................29

6.5.3.1 Create custom scripts ......................................29

7 Legal information .............................................. 32

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section 'Legal information'.

© NXP B.V. 2021. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: 24 February 2021

Document identifier: UM11524

Loading...

Loading...