Page 1

UM11503

KITFS26AEEVM evaluation board

Rev. 1 — 29 January 2021 User manual

Figure 1. KITFS26AEEVM

Important Notice

NXP provides the enclosed product(s) under the following conditions:

This evaluation kit is intended for use of ENGINEERING DEVELOPMENT OR EVALUATION PURPOSES ONLY. It is provided as a

sample IC pre-soldered to a printed circuit board to make it easier to access inputs, outputs, and supply terminals. This evaluation board

may be used with any development system or other source of I/O signals by simply connecting it to the host MCU or computer board via

off-the-shelf cables. This evaluation board is not a Reference Design and is not intended to represent a final design recommendation for

any particular application. Final device in an application will be heavily dependent on proper printed circuit board layout and heat sinking

design as well as attention to supply filtering, transient suppression, and I/O signal quality.

The goods provided may not be complete in terms of required design, marketing, and or manufacturing related protective considerations,

including product safety measures typically found in the end product incorporating the goods. Due to the open construction of the product,

it is the user's responsibility to take any and all appropriate precautions with regard to electrostatic discharge. In order to minimize risks

associated with the customers applications, adequate design and operating safeguards must be provided by the customer to minimize

inherent or procedural hazards. For any safety concerns, contact NXP sales and technical support services.

Should this evaluation kit not meet the specifications indicated in the kit, it may be returned within 30 days from the date of delivery and will

be replaced by a new kit.

NXP reserves the right to make changes without further notice to any products herein. NXP makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does NXP assume any liability arising out of the

application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation consequential or

incidental damages. Typical parameters can and do vary in different applications and actual performance may vary over time. All operating

parameters, including Typical, must be validated for each customer application by customer’s technical experts.

NXP does not convey any license under its patent rights nor the rights of others. NXP products are not designed, intended, or authorized

for use as components in systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for

any other application in which the failure of the NXP product could create a situation where personal injury or death may occur.

Should the Buyer purchase or use NXP products for any such unintended or unauthorized application, the Buyer shall indemnify and hold

NXP and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and

reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or

unauthorized use, even if such claim alleges NXP was negligent regarding the design or manufacture of the part.

Page 2

NXP Semiconductors

KITFS26AEEVM evaluation board

1 Introduction

This document is the user guide for the KITFS26AEEVM evaluation board.

This document is intended for the engineers involved in the evaluation, design,

implementation, and validation of FS2600 Fail-safe system basis chip with multiple

SMPS and LDO.

The scope of this document is to provide the user with information to evaluate the

FS2600 Fail-safe system basis chip with multiple SMPS and LDO. This document covers

connecting the hardware, installing the software and tools, configuring the environment

and using the kit.

It is delivered with empty OTP content in order to leave the opportunity to the user to

burn the OTP configuration. The board contains a superset device (PFS2630AMDA0AD),

allowing tests on all the FS26 derivatives.

2 Finding kit resources and information on the NXP web site

NXP Semiconductors provides online resources for this evaluation board and its

supported device(s) on http://www.nxp.com.

UM11503

The information page for KITFS26AEEVM evaluation board is at http://www.nxp.com/

KITFS26AEEVM. The information page provides overview information, documentation,

software and tools, parametrics, ordering information and a Getting Started tab. The

Getting Started tab provides quick-reference information applicable to using the

KITFS26AEEVM evaluation board, including the downloadable assets referenced in this

document.

2.1 Collaborate in the NXP community

The NXP community is for sharing ideas and tips, ask and answer technical questions,

and receive input on just about any embedded design topic.

The NXP community is at http://community.nxp.com.

3 Getting ready

Working with the KITFS26AEEVM requires the kit contents, additional hardware and a

Windows PC workstation with installed software.

3.1 Kit contents

• Assembled and tested evaluation board and preprogrammed FRDM-KL25Z

• 3.0 ft USB-STD A to USB-B-mini cable

• Two connectors, terminal block plug, 2 pos., str. 3.81 mm

• Three connectors, terminal block plug, 3 pos., str. 3.81 mm

• Jumpers mounted on board

microcontroller board in an anti-static bag

3.2 Additional hardware

In addition to the kit contents, the following hardware is necessary or beneficial when

working with this kit.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

2 / 60

Page 3

NXP Semiconductors

• Power supply with a range of 8.0 V to 40 V and a current limit set initially to 1.0 A

3.3 Windows PC workstation

This evaluation board requires a Windows PC workstation. Meeting these minimum

specifications should produce great results when working with this evaluation board.

• USB-enabled computer with Windows 7 or Windows 10

3.4 Software

Installing software is necessary to work with this evaluation board.

• NXP GUI installation package

4 Getting to know the hardware

The KITFS26AEEVM provides flexibility to play with all the features of the device and

make measurements on the main part of the application. The FRDM-KL25Z connected

to the board, combined with the FS26 NXP GUI software allows full configuration and

control of the FS26 SBC.

UM11503

KITFS26AEEVM evaluation board

4.1 Kit overview

The FS26 family can be evaluated with this board as it is populated with a superset part.

The FS26xx part soldered on the board can be fused one time or it is possible to test as

many configurations as needed in Emulation mode.

This board was designed to sustain up to 2.0 A total on VPRE. Layout is done using sixlayer PCB stack up. Set initial current limitation of 1 A.

4.1.1 KITFS26AEEVM features

• VBAT power supply connectors (Jack and Phoenix)

• VPRE output capability up to 2.0 A

• VBOOST in independent mode or in front-end topology to support battery cranking

profiles

• VCORE up to 1.5 A peak

• LDO1 and LDO2 from 3.3 V or 5.0 V, up to 400 mA

• VTRK1 and VTRK2, from 3.3 V or 5.0 V, up to 125 mA

• VREF 1 % accuracy regulator for external ADC reference

• FS0B, FS1b external safety pins

• USB to SPI protocol for easy connection to software GUI

• LEDs that indicate signal or regulator status

• Manual or Automated OTP fuse programming

• Advance system monitoring via AMUX or external ADC

• Analog variable resistor to test external VMON

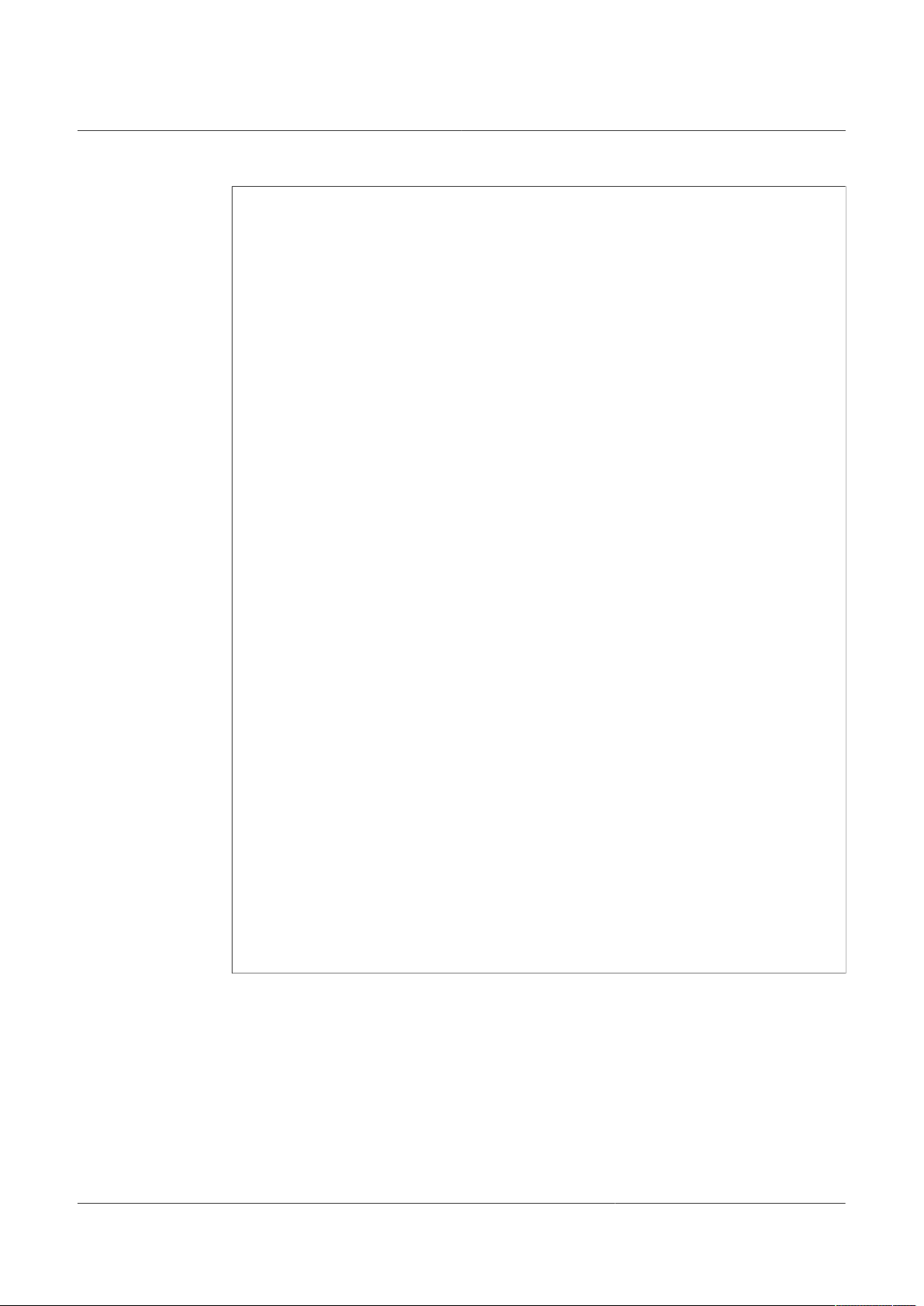

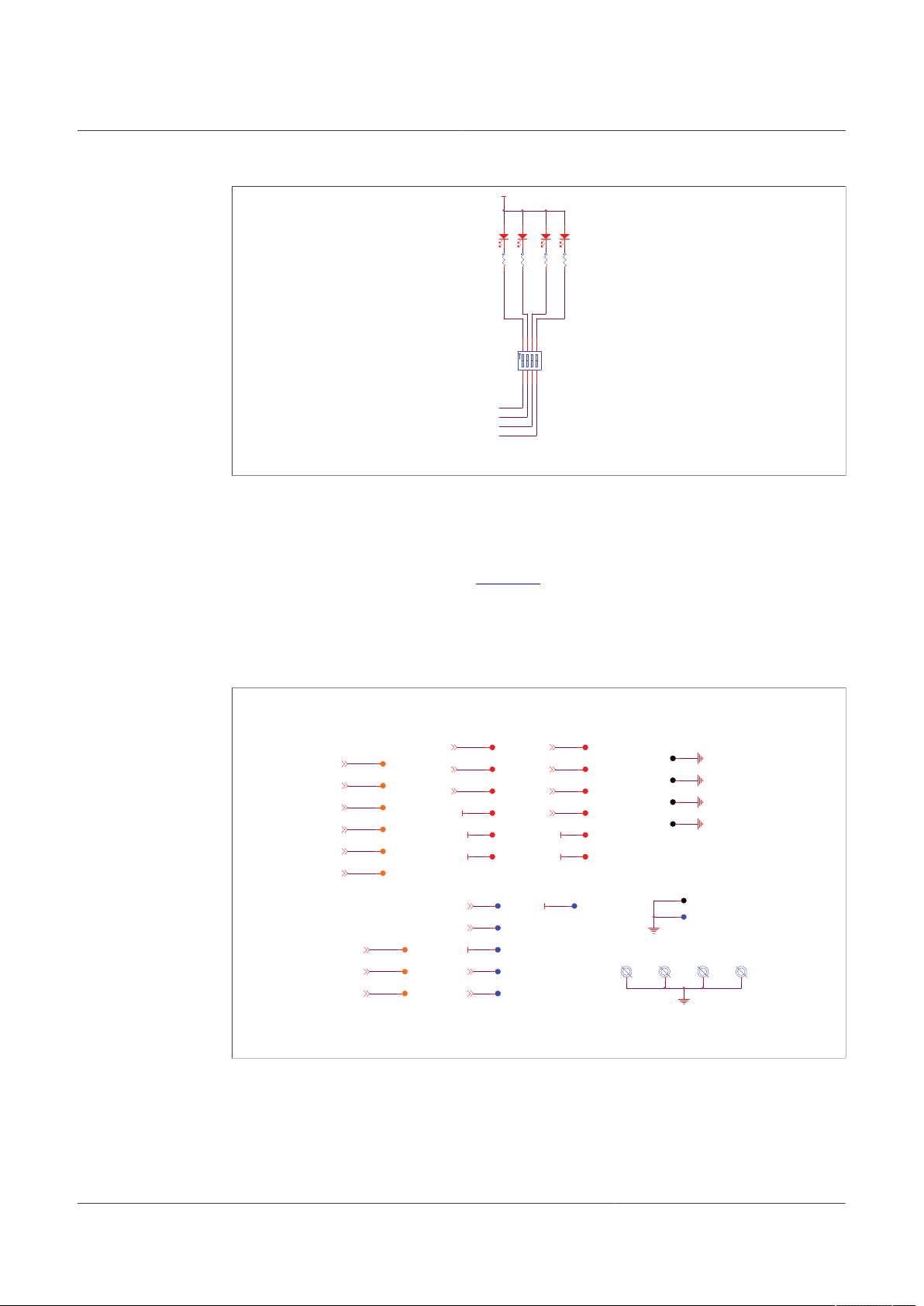

4.2 Kit featured components

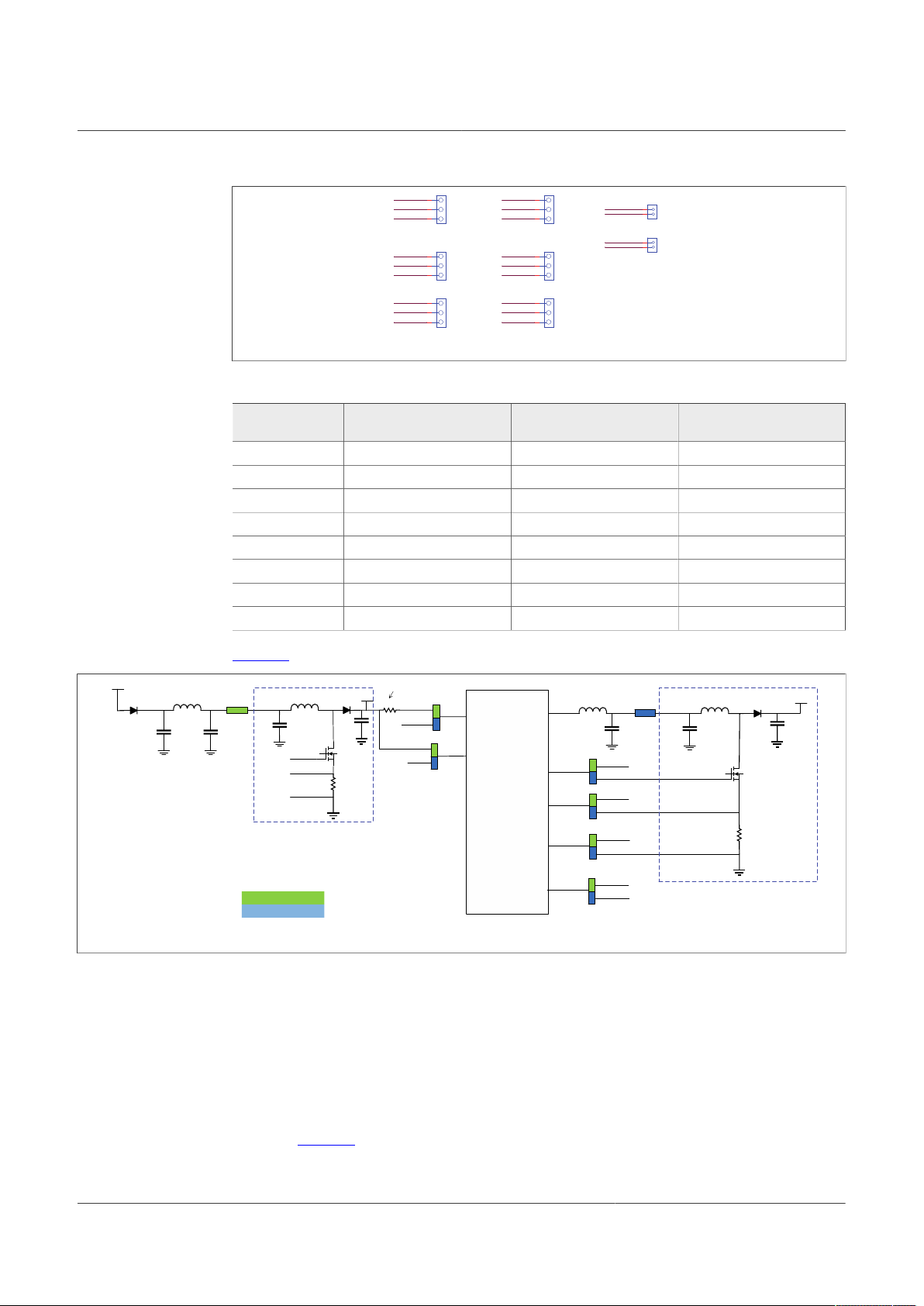

Figure 2 identifies important components on the board.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

3 / 60

Page 4

NXP Semiconductors

UM11503

KITFS26AEEVM evaluation board

1. VBAT Phoenix connector

2. VBAT3 position switch

3. VBAT Jack connector

4. VDDIO selection

5. Regulators outputs

6. WAKE1 and WAKE2 inputs switches

7. FS26 SBC

8. KL25Z Freedom headers (bottom)

9. VDEBUG pin source selection (switch or MCU)

10. VDEBUG pin voltage level switches

11. VDDIO USB voltage level selection

12. VMONEXT variable resistor

13. Signal connector

14. Program connector

15. Regulators output LED indicators

16. Program burning voltage LED indicator

17. Safety output LED indicators

Figure 2. Evaluation board featured component locations

4.2.1 FS26: Safety system basis chip with low power and fit for ASIL D

The FS26 is a family of automotive Safety SBC devices with multiple power supplies,

designed to support entry and mid-range safety microcontrollers like the S32K3 series

while maintaining flexibility to fit other microcontrollers targeting automotive electrification

such as power train, chassis, safety and low-end gateway applications.

This family of devices is composed of several versions, pin to pin and software

compatible, to support a wide range of applications, offering choice in number of output

rails, output voltage setting, operating frequency, power up sequencing, and integrated

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

4 / 60

Page 5

NXP Semiconductors

system level features to address multiple applications with Automotive Safety Integrity

Levels (ASIL) B or D.

It features multiple switch mode regulators as well as LDO voltage regulators to supply

the microcontroller, sensors, peripheral ICs, and communication interface. It offers a

high precision voltage reference available to the system as well as reference voltage for

two independent voltage tracking regulators as well as various functionalities for system

control and diagnostics such as Analog multiplexer, GPIOS and selectable wake up

events from I/O, long duration timer or SPI communication.

The FS26 is developed in compliance with the ISO 26262 standard, and it includes

enhanced safety features, with multiple fail-safe outputs, becoming a full part of a safetyoriented system partitioning, covering both ASIL B and ASIL D safety integrity level, with

the latest on-demand latent fault monitoring.

Operating range

• 40 V DC maximum input voltage

• Handles severe cranking operation (3.2 V battery) thanks to its BOOST controller

• Supports operating voltage range down to battery 6.0 V without BOOST

• Low-power Off mode with very low sleep current (50 µA typ)

• Low-power Standby mode, VPRE active

• LDO1 or LDO2 active selectable via OTP configuration (50 µA typ)

UM11503

KITFS26AEEVM evaluation board

4.2.2 VBAT connectors

There are two ways of supplying the board: either by a Phoenix Connector (J2) or a Jack

connector (J2). The selection of the supplying connector is done using a three-position

switch (SW1).

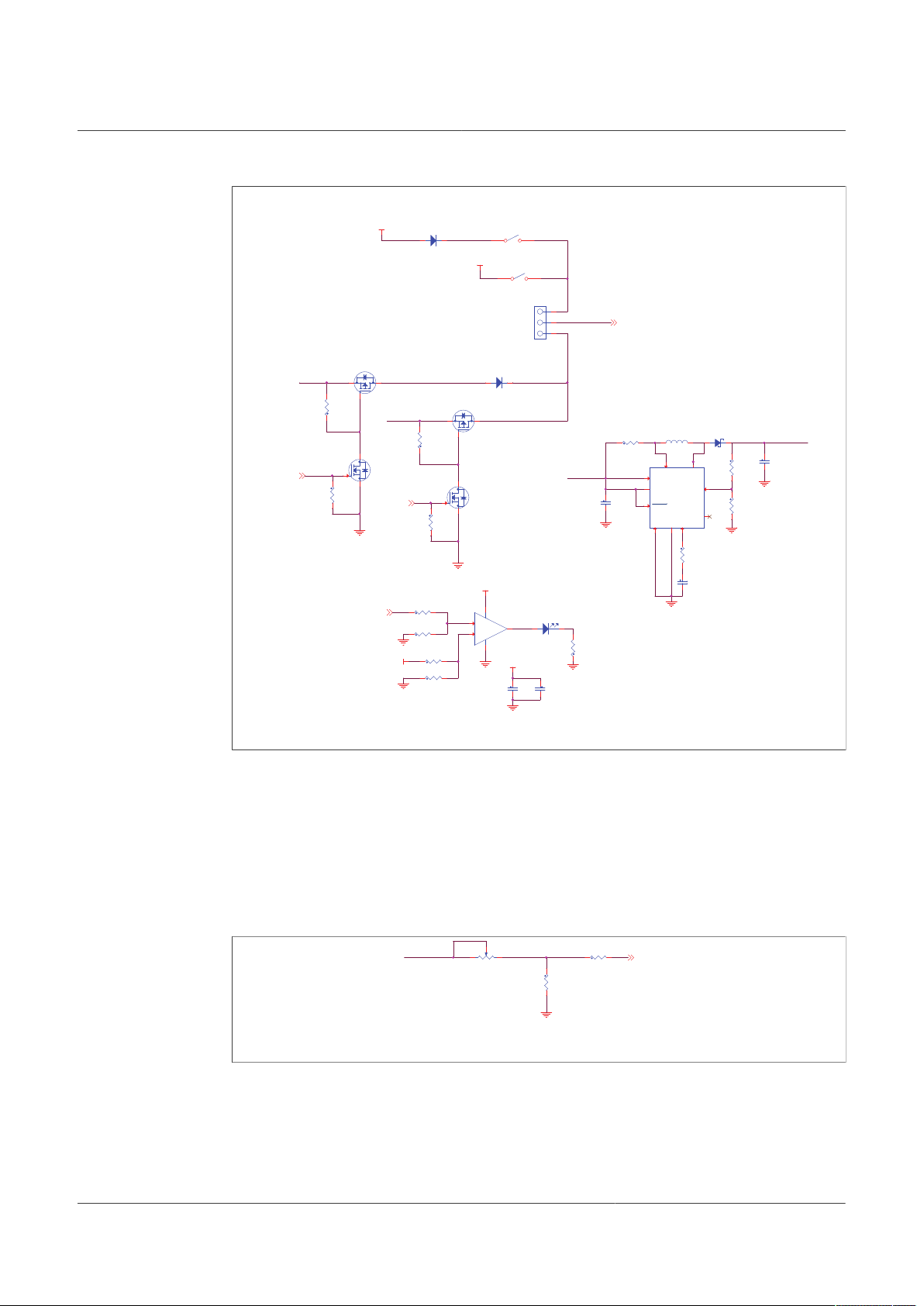

Figure 3 shows related schematic. Nominal VBAT voltage is 12 V and can support up to

40 V.

Table 1. VBAT Phoenix connector (J1)

Schematic label Signal name Description

J1-1 VBAT Battery voltage supply input

J1-2 GND Ground

Table 2. VBAT three position connector (SW1)

Schematic label Signal name Description

SW1 pin 2-3 VBAT Phoenix Board supplied by Phoenix connector

SW1 pin 2 (middle position) VBAT Board not supplied

SW1 pin 2-1 VBAT jack Board supplied by Jack connector

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

5 / 60

Page 6

NXP Semiconductors

aaa-039503

Vba

t

Vba

t

GND

GND

GND

GND

J21

1

2

3

SW1

1

2

3

S

1

S

2

J20

1

2

VBA

T

aaa-039505

For Boost

in

Back

En

d

For Boost

in Front

En

d (d

efa

ult)

VBST_PG_OUT

VBOOS

T

GND

GND

GND

GND

VBS

T

GND

GND

GND

VBST_BE_L

S

VBST_PG

VBST_FE_L

S

SJ7

Close

d

1

2

JP2

1

2

R11

1

0

C

1

10u

F

R

7

0.1

C12

22u

F

C

3

10u

F

Q18

NTR4101

DNP

1

3

2

SJ9

Close

d

1

2

D

1

PMEG045T100EP

D

1

2

3

L

6

4.7uH

LBST1

1

2

0.01u

F

DNPC103

R1080DN

P

Q19

BSS138LT1

G

DNP

1

2

3

R

2

0.0

2

JP5

1

2

C78

10u

F

C18

22u

F

R1090

R11

3

0

R10

2

510

K

DNP

0.01u

F

DNPC102

D

3

NRVTS245ESFT1

G

A

C

Q

1

NTD5C688N

L

1

3

4

C11

22u

F

G

S

D

Q

2

PMV30UN

2

C

2

10u

F

C

4

10u

F

C13

22u

F

R11

2

0

SJ8

Close

d

1

2

C94

10u

F

R10

1

510

K

DNP

SJ1

Close

d

1

2

R11

4

0

L

2

4.7uH

LBST2

1

2

VBST_BE_L

S

VBST_BE_I

N

VBST_G_BE

VBST_ISH_BE

VBST_ISL_BE

VBST_FE_I

N

VBST_OU

T

VBST_G_FE

VBST_ISH_FE

VBST_ISL_FE

VBOOST_SN

S

VBST_SN

S

Figure 3. VBAT connectors schematic

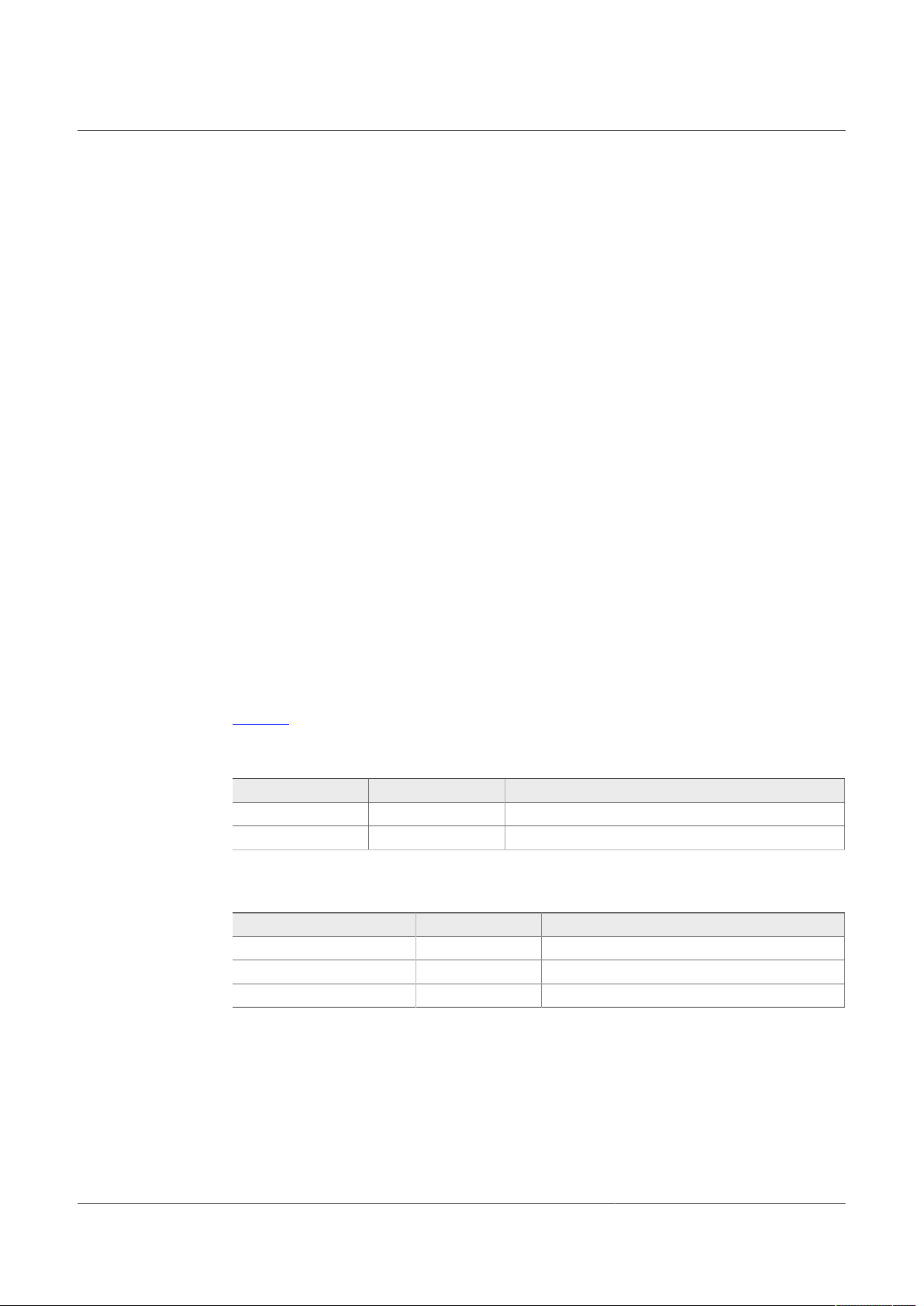

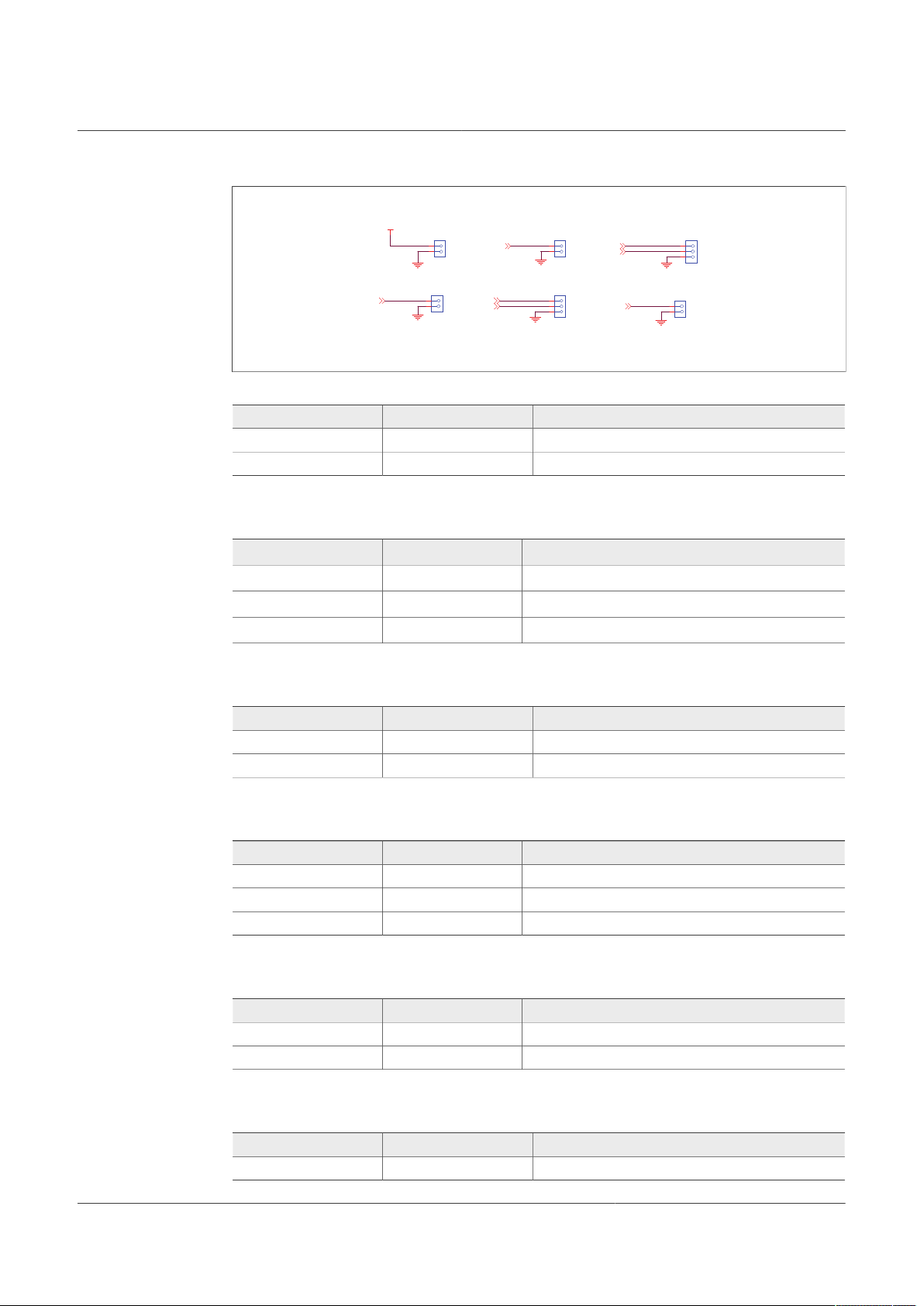

4.2.3 Power topology configuration

There are two power topologies available depending on the application and OTP

configuration. The device can be supplied directly by the battery after diode and pi filter;

on the other side, the boost regulator can be connected in front-end topology to support

cold cranking profiles.

It is possible to evaluate both power topologies with this board since external boost

components for each topology are soldered separately as shown in Figure 4.

A set of jumper configurations allows you to select between the two options. See Figure 5

and Table 3. Default jumper configuration is boost in front-end topology.

UM11503

KITFS26AEEVM evaluation board

In front-end topology boost is connected to the battery after reverse diode; the output

of the boost supplies the device during cold cranking profiles. Otherwise, boost stops

switching, and it is bypassed. See FS26 data sheet for more information.

In back-end topology or independent boost, the device is supplied by the battery, and the

boost is supplied by the buck regulator VPRE.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

Figure 4. Schematic of boost external components for front end and back-end topologies

6 / 60

Page 7

NXP Semiconductors

aaa-039511

ON:

BackEnd

OFF: FrontEnd

3-2: FrontEnd

1-2: BackEn

d

3-2: FrontEnd

1-2: BackEn

d

3-2: FrontEnd

1-2: BackEn

d

3-2: FrontEnd

1-2: BackEn

d

3-2: FrontEnd

1-2: BackEn

d

ON:

BackEnd

OFF: FrontEnd

3-2: FrontEnd

1-2: BackEn

d

J3VBST_BE_I

N

1

2

J5VSUP_PW

R

1

2

3

J6VBST_IS

H

1

2

3

J8VBST_IS

L

1

2

3

J7VSU

P

1

2

3

J26VBST_F

B

1

2

3

J25VBST_FE_IN

1

2

J4VBST_

G

1

2

3

VBST_

G

VBST_IS

H

VBST_IS

L

VSU

P

VBST_BE_I

N

VBST_G_FE

VBST_G_BE

VPR

E

VBST_OU

T

VBAT_

D

VSUP_PW

R

VPI

VBST_ISH_FE

VBST_ISH_BE

VBST_ISL_FE

VBST_ISL_BE

VBS

T

VPI

VBST_FE_I

N

VBST_SN

S

VBST_FB

VBOOST_SN

S

aaa-039512

VBA

T

Vsu

p

R

SNS_BST

C

OUT_BST

D

2

L

BST

1

D

1

C

IN_BS

T

FS26 SB

C

VBST_FE_I

N

VPI

Vsup_pw

r

Vpr

e

R

SNS_BST

C

OUT_BST

L

BST

2

D

3

C

IN_BS

T

R 0 Ohm

VBST_BE_I

N

VBS

T

VBST_OU

T

VBAT_

D

VBS

T

VPI

VBOOS

T

C

PRE_OUT

Vpre_SW

VBST_

G

VBST_IS

H

VBST_IS

L

VBST_G_BE

VBST_ISH_BE

VBST_ISL_BE

VBST_G_FE

VBST_ISH_FE

VBST_ISL_FE

VBST_G_FE

VBST_ISH_FE

VBST_ISL_FE

Cpi

1

Cpi

2

Lpi

J25

J

7

J

5

J

4

J

6

J

3

1

1

1

1

1

1

1

VBST_FB

VBS

T

1

VBOOS

T

Replace by

ferrite bead

if needed

Components for

BOOST in Front end

Components for

BOOST in Back end

Front end

topolog

y

Back end

topolog

y

L

1

VBAT_

D

J

8

J26

L

6

J

3

L

2

Q

2

Q

1

Figure 5. Boost configuration jumper section in the schematic

Table 3. Jumper configuration for front end and back-end power topologies

Schematic label Signal name BOOST front-end (default

J3 VBST_BE_IN OFF ON

J4 VBST_G 3-2 1-2

J5 VSUP_PWR 3-2 1-2

J6 VBST_ISH 3-2 1-2

J7 VSUP 3-2 1-2

J8 VBST_ISL 3-2 1-2

J25 VBST_FE_IN ON OFF

J26 VBST_FB 3-2 1-2

UM11503

KITFS26AEEVM evaluation board

BOOST back-end

positions)

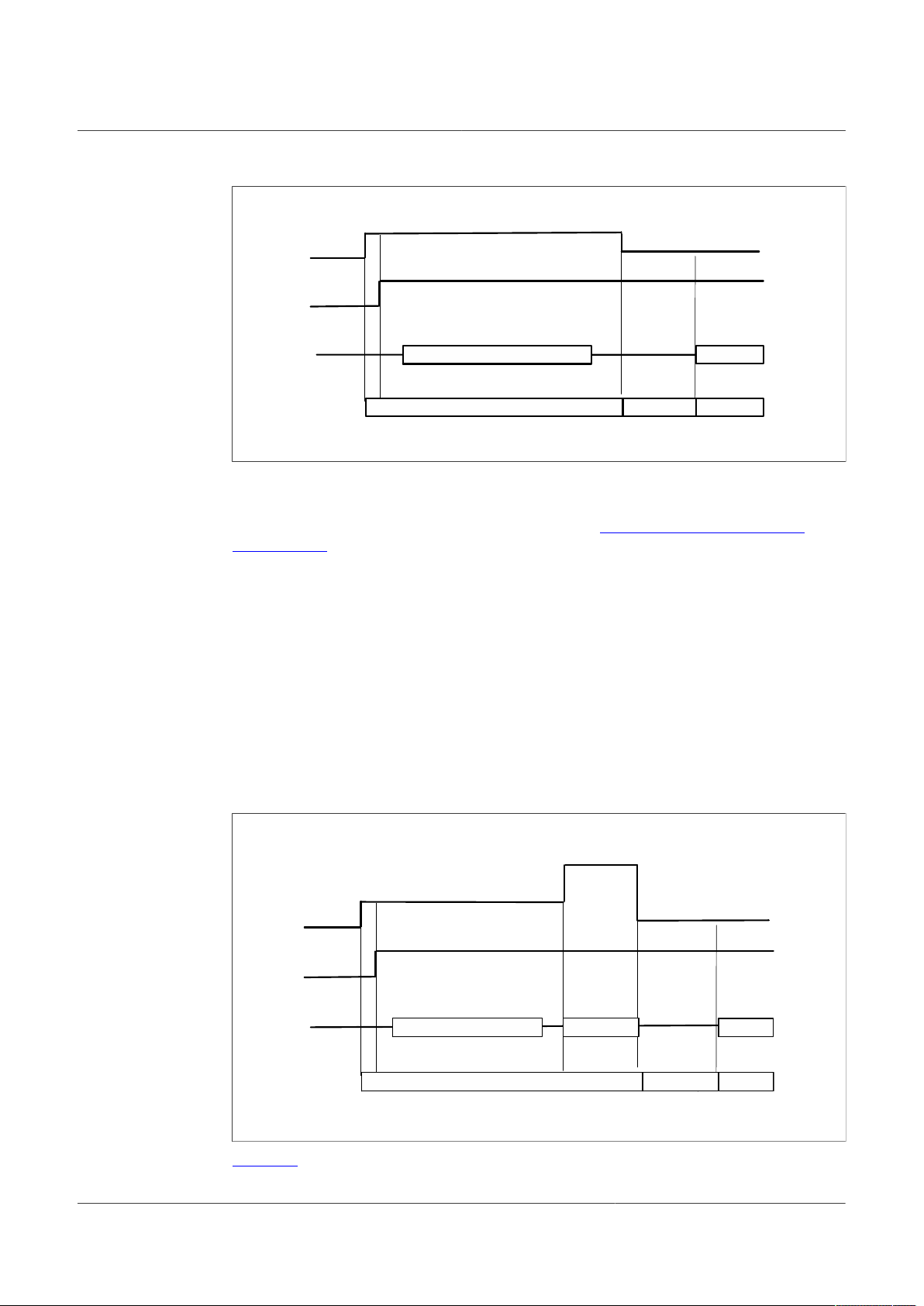

Figure 6 shows a simplified diagram of jumper configuration to associated device pins.

Figure 6. Simplified diagram of jumper configuration for front-end and back-end topologies

When testing the FS26 SBC with a front-end configuration at very low battery level and

loading product at its maximum rating, make sure that the power supply is capable of

providing at least 4.0 A.

4.2.4 Output power supply connectors

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

Output regulators are accessible through test points or Phoenix connectors in order to

make measurement or plug loads. Male connectors are included on this kit to plug or

unplug wires easily. All output regulators are located at the top edge of the board as

shown in Figure 2.

7 / 60

Page 8

NXP Semiconductors

aaa-039513

POWER OUTPUTS

VBOOS

T

GND

VCORE

GND

VTRK1

GND

VTRK2

VPRE

GND

VREF

GND

VLDO2

GND

VLDO1

GND

GND

GND

GND

GND

GND

VBOOS

T

VPR

E

VCORE

VLDO1

VLDO2

VTRK1

VTRK2

VRE

F

J15

1

2

3

J18

1

2

J19

1

2

J14

1

2

J17

1

2

3

J16

1

2

Figure 7. Power output Phoenix connectors

Table 4. VCORE connector (J14)

Schematic label Signal name Description

J16-1 VCORE VCORE power supply output

J16-2 GND Ground

Table 5. VTRK1/VTRK2 connector (J15)

Schematic label Signal name Description

J15-1 VTRK1 VTRK2 power supply output

J15-2 VTRK2 VTRK1 power supply output

J15-3 GND Ground

UM11503

KITFS26AEEVM evaluation board

Table 6. VPRE connector (J16)

Schematic label Signal name Description

J16-1 VPRE VPRE power supply output

J16-2 GND Ground

Table 7. VLDO1/VLDO2 connector (J17)

Schematic label Signal name Description

J17-1 LDO1 LDO1 power supply output

J17-2 LDO2 LDO2 power supply output

J17-3 GND Ground

Table 8. VREF connector (J18)

Schematic label Signal name Description

J18-1 VREF VREF reference output

J18-2 GND Ground

Table 9. VBOOST connector (J19)

Schematic label Signal name Description

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

J19-1 VBOOST VBOOST power supply output

8 / 60

Page 9

NXP Semiconductors

aaa-039514

Signal connecto

r

Program connector

GND

GND

VSU

P

VDDIO

VBA

T

DBG_OTP

MOS

I

MIS

O

SCL

K

CSB

WAKE1_I

N

WAKE2_I

N

VDEBU

G

RST

B

INT

B

FS0

B

FS1

B

AMU

X

GPIO1

GPIO2

FCCU1

FCCU2

VMONEXT_0.8

V

GPIO1_I

N

GPIO2_I

N

VBAT_Ctrl

MCU_DBG8V

MCU_DBG5V

J11

HDR_2X6

1

2

3

4

6

5

7

8

910

111

2

J23

1

2

3

4

6

5

7

8

910

111

2

131

4

151

6

171

8

192

0

VMONEXT

VDDIO_EXT

Table 9. VBOOST connector (J19)...continued

Schematic label Signal name Description

J19-2 GND Ground

4.2.5 Signal and program connectors

Signal and program connectors allow access to most of the device signals in order to

program the device externally or to perform debug and diagnosis.

Figure 8. Signal and debug headers connectors

Table 10. Program connector (J11)

Schematic label Signal name Description

J11_1 WAKE1_IN WAKE1 input access

J11_2 MOSI MOSI signal access

J11_3 MISO MOSI signal access

J11_4 WAKE2_IN WAKE2 input access

J11_5 VDEBUG VDEBUG pin

J11_6 SCLK SCLK signal access

J11_7 VBAT_Ctrl VBAT_Ctrl KL25Z output access; to control VBAT power by MCU,

J11_8 CSB CSB signal access

J11_9 MCU_DBG8V MCU_DBG8V KL25Z output access

J11_10 MCU_DBG5V MCU_DBG5V KL25Z output access

J11_11 GND GND

J11_12 GND GND

UM11503

KITFS26AEEVM evaluation board

JP1 must be OFF

Table 11. Signal connector (J23)

Schematic label Signal name Description

J23_1 VMONEXT External monitoring, resistor bridge side

J23_2 RSTB RSTB IC safety output

J23_3 VDDIO_EXT Optional external supply for VDDIO, make sure that there is a

J23_4 INTB INTB interruption output

J23_5 GPIO1 GPIO1 IC side, for signal access; disconnect R87 before use

J23_6 FS0B FS0B IC safety output

J23_7 GPIO2 GPIO2 IC side, for signal access; disconnect R87 before use

J23_8 FS1B FS1B IC safety output

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

jumper between J12 5-6 pins

as an output

as an output

9 / 60

Page 10

NXP Semiconductors

aaa-039515

LED SIGNALING

TRK

2

TRK

1

LDO

2

LDO

1

VRE

F

V

P

R

E

V

B

S

T

_

B

E

V

B

A

T

VCORE

GPIO1

GPIO2

V

B

S

T

_

F

E

VBA

T

GND

Vpr

e

Vpr

e

Vpr

e

Vpr

e

Vpr

e

VLDO1VLDO2VTRK1VTRK2VRE

F

GND

GND

GND

GND

GND

VBOOS

T

Vpr

e

GND

Vpr

e

GND

Vpr

e

GND

VBS

T

GPIO2

GPIO1

VPR

E

VCORE

R32510K

R23

1.3

K

R84

1.3

K

D14

A

C

D11

A

C

Q

3

1

2

3

R99510K

D24

A

C

R25

1.3

K

Q16

1

2

3

R31510K

D12

A

C

D23

A

C

R29

4.7

K

R27

4.7

K

R34510K

R95510K

D25

A

C

D13

A

C

R22

1.3

K

Q14

1

2

3

D10

A

C

R97510K

R30510K

Q15

1

2

3

R24

1.3

K

D22

A

C

D15

A

C

D

8

A

C

R85

1.3

K

R33510K

Q

4

1

2

3

R94

1.3

K

Q

5

1

2

3

SW4

SW_DIP-12/S

M

SWITCH(DEFAULT) = ALL O

N

12345109876

1516171819202122232

4

111

2

141

3

Q

6

1

2

3

R26

1.3

K

Q

7

1

2

3

R11

5

4.7

K

D

9

A

C

R28

1.3

K

V

B

A

T

_

L

E

D

VBST_FE

V

B

S

T

_

F

E

VBAT_LE

D

Table 11. Signal connector (J23)...continued

Schematic label Signal name Description

J23_9 FCCU1 FCCU1

J23_10 VMONEXT_0.8V VMONEXT IC side, for access or disconnect R39 to apply

J23_11 FCCU2 FCCU2

J23_12 AMUX AMUX pin read

J23_13 GPIO1_IN GPIO1 input side

J23_14 VDDIO VDDIO IC side access

J23_15 GPIO2_IN GPIO2 input side

J23_16 VSUP VSUP pin access

J23_17 DBG_OTP DBG_OTP power supply (8.0 V) access

J23_18 VBAT VBAT access

J23_19 GND GND

J23_20 GND GND

UM11503

KITFS26AEEVM evaluation board

0.8 V externally

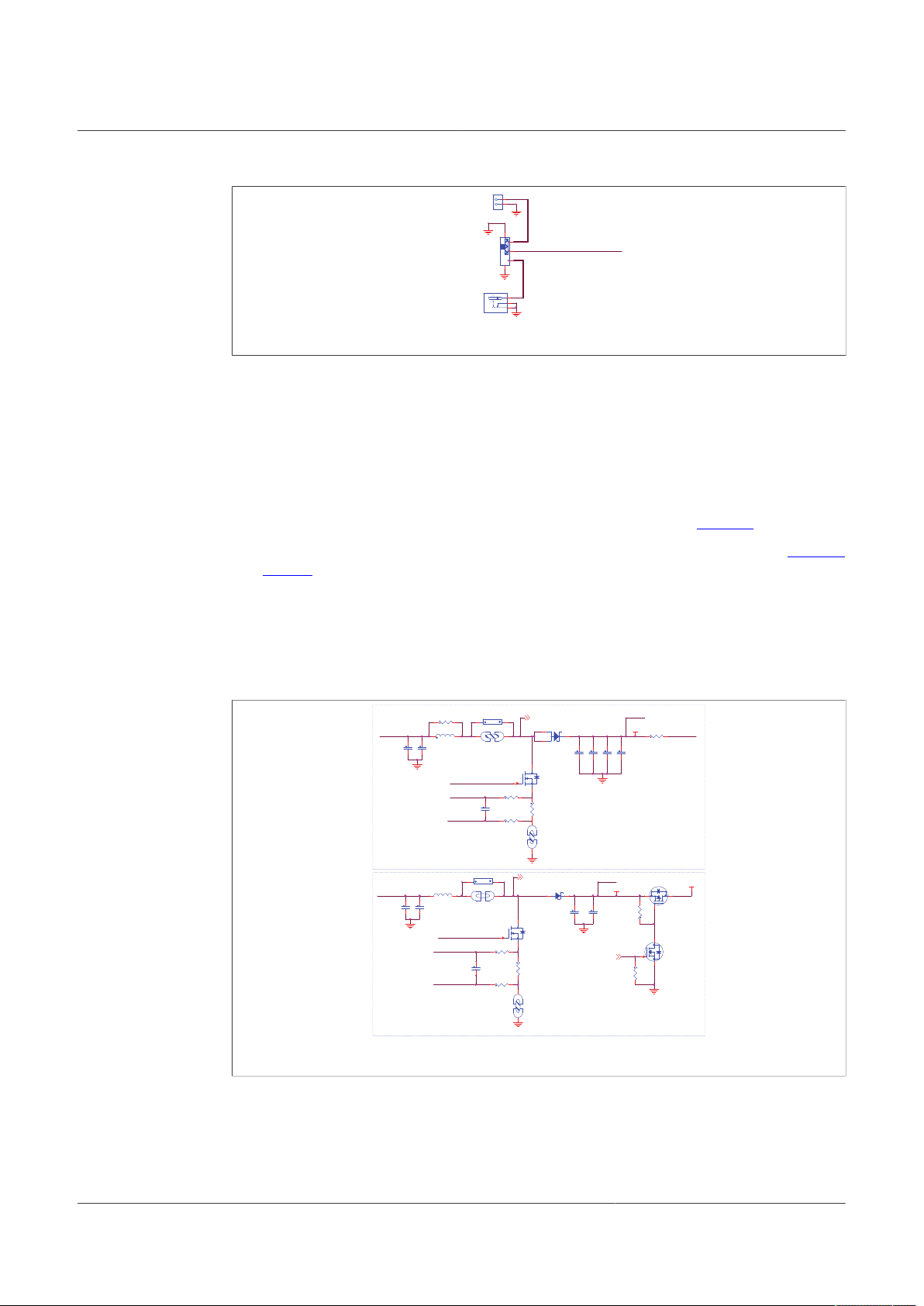

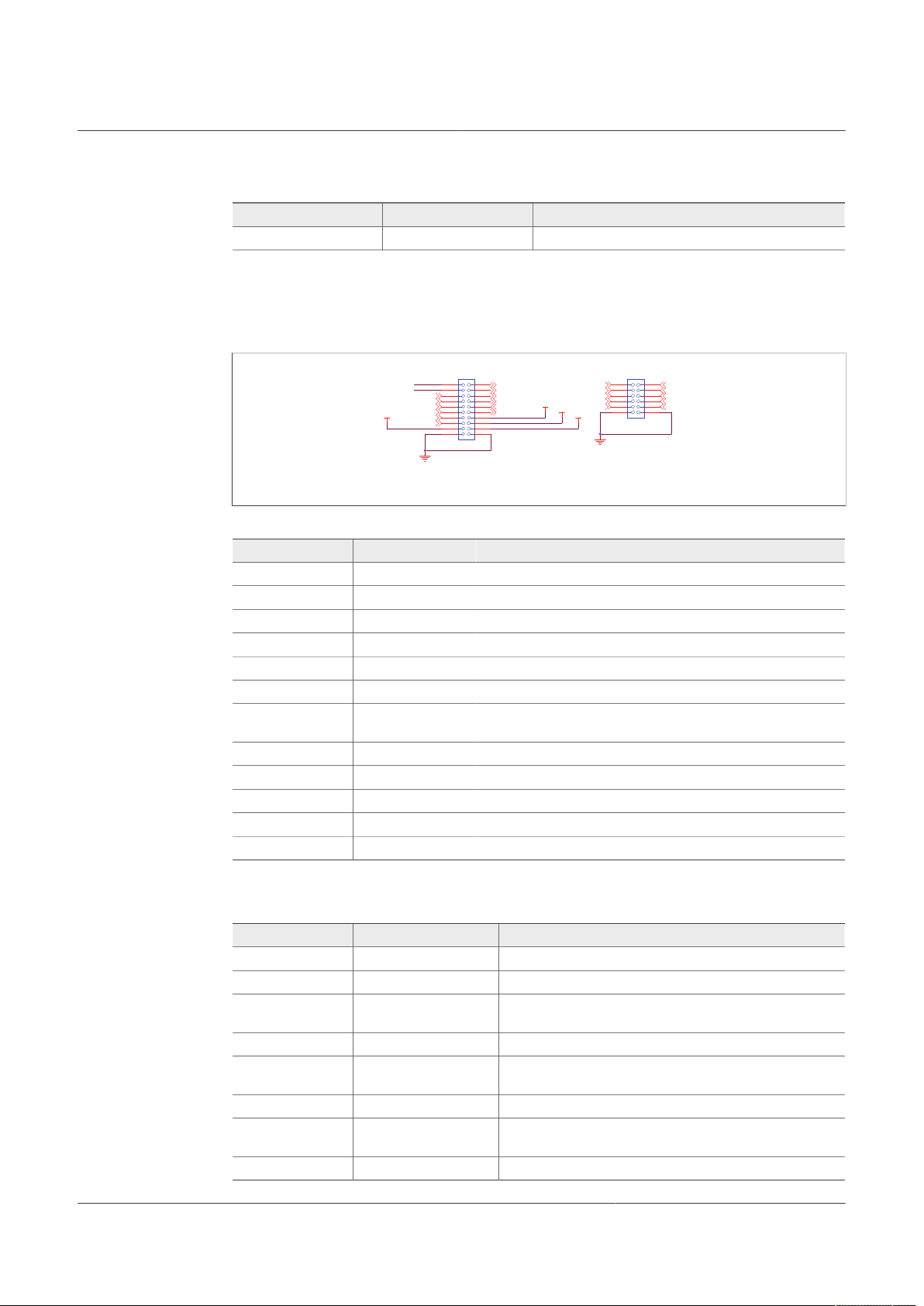

4.2.6 Indicators

The LED indicators on the board display VBAT regulators, safety outputs, and GPIO

status. For VBAT, regulators and GPIOs there are green LEDs indicating that the output

is powered on. The power supply of these indicators is usually VPRE, and it is controlled

by a low voltage MOSFET by the corresponding signal or regulator.

These regulators can be turned Off manually at any time with the switch SW4 in order to

avoid undesired losses and obtain more accurate current consumption measurements.

Figure 9. Power and regulator LED indicators

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

10 / 60

LED indicators are turned On and Off when the safety output is released. LEDs can also

be disabled using switch SW5.

The color of the safety output LED indicators is red. When the safety output is asserted,

Page 11

NXP Semiconductors

aaa-039516

VDDIO

D

4

RED

A

C

R18

1.5

K

D

6

RED

A

C

R20

1.5

K

SW5

SW DIP-4/SM

123

4

876

5

R21

1.5

K

D

5

RED

A

C

R19

1.5

K

D

7

RED

A

C

RST

b

INT

B

FS0

b

FS1

b

aaa-039528

Debug

Through hole test point

s

TEST POINTS

Groun

d

Power

GND

GND

VBA

T

VSU

P

VPI

GND

GND

VDDIO

VBS

T

VBST_PG_OUT

VBOOS

T

GND

GND

VRE

F

VLDO1

FS0

B

VCORE

VLDO2

FS1

B

VPR

E

VTRK1

RST

B

VTRK2

INT

B

AMU

X

VBST_FE_L

S

VBST_BE_L

S

VPRE_SW

VCORE_S

W

VDEBU

G

VMONEXT_0.8

V

VBST_PG

VBO

S

TP7

BH1

MTG

1

TP4

4

TP1

1

TP3

4

TP2

5

TP3

2

BH3

MTG

1

TP3

5

TP3

0

TP2

8

TP2

0

TP1

5

TP4

1

TP1

6

TP3

6

TP2

7

TP4

2

TP1

9

BH2

MTG

1

TP2

2

TP1

8

TP5

TP1

4

TP2

6

TP1

0

BH4

MTG

1

TP4

3

TP1

2

TP2

1

TP8

TP1

7

TP6

TP1

3

TP2

4

TP9

TP2

3

Figure 10. Safety output LED indicators

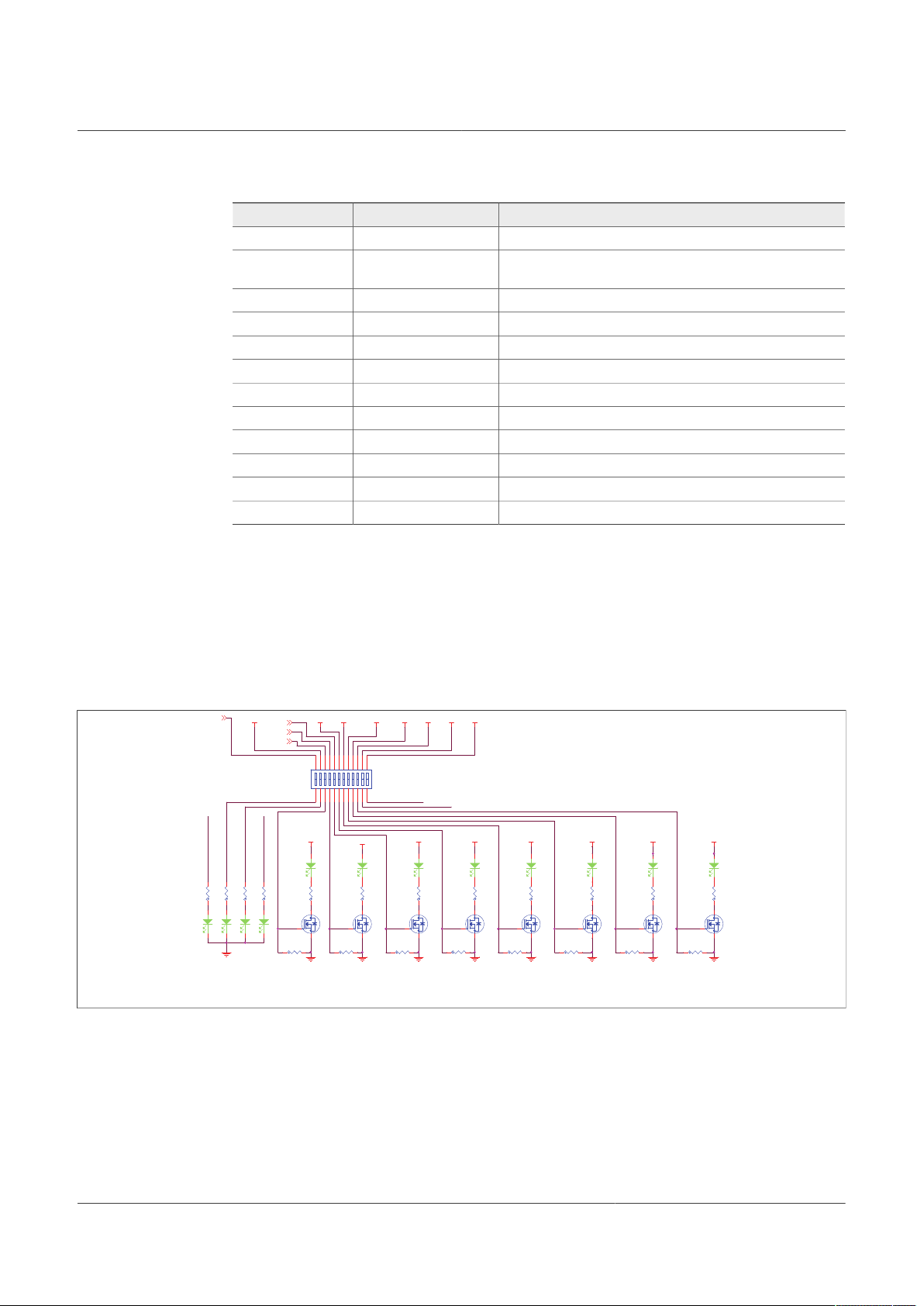

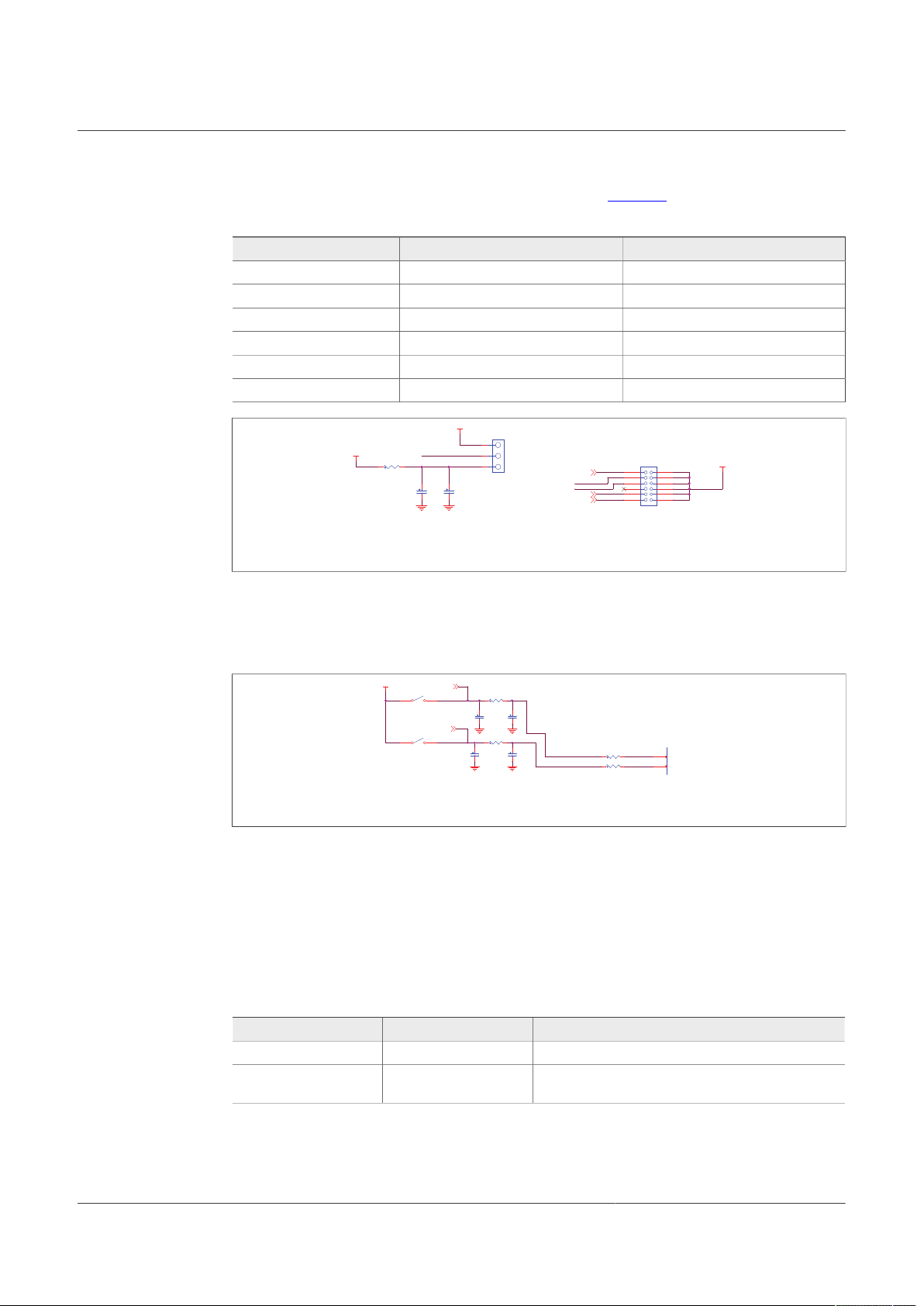

4.2.7 Test points

The KITFS26AEEVM evaluation board has several test points for easy access and

measurements. The test points are color coded, and can be different part numbers or

without a part number, as shown in Figure 11.

UM11503

KITFS26AEEVM evaluation board

• Orange: test loop access to safety outputs and analog signals

• Red: test loop access for power supplies

• Black: test loop access to GND

• Blue: not a part; through hole small test points on board close to the signal

4.2.8 VDDIO selection

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

Figure 11. KITFS26AEEVM test points

VDDIO reference can be supplied by 3.3 V or 5.0 V depending on the system. The

supply can be generated on the board, from a voltage regulator, or from an external

source.

11 / 60

Page 12

NXP Semiconductors

aaa-039529

GNDGN

D

VDDIO

P3V3_KL25

Z

P5V_KL25Z

VCORE

VLDO1

VLDO2

C30

1.0UF

DNP

R36

0

C31

1.0UF

DNP

J22

1

2

3

J12

HDR_2X6

1

2

3

4

6

5

7

8

910

111

2

VDDIO_USB

VDDIO_EXT

VDDIO_USB

aaa-039530

VBA

T

GNDGN

D

GND

GND

WAKE1_I

N

WAKE2_I

N

5.1

K

R

6

R55.1

K

0.01u

F

C15

DNP

0.01u

F

C17

SW2

1

2

SW3

1

2

WAKE2

2

WAKE1

4

7

0.022uF

C14

R86

0.022uF

C16

R35.1

K

5.1

K

R

4

WAKE1

WAKE2

WAKE1_I

N

WAKE2_I

N

J12 allows selection of the supply source, as shown in Table 12.

Table 12. VDDIO connector (J12)

Schematic label Signal name Description

J12_1-2 VCORE VDDIO supply is VCORE

J12_3-4 (default) VDDIO_USB VDDIO supply is VDDIO_USB (J22_2)

J12_5-6 VDDIO_EXT VDDIO supply is VDDIO_EXT (J23_3)

J12_7-8 NC VDDIO Not connected

J12_9-10 VLDO1 VDDIO supply is VLDO1

J12_11-12 VLDO2 VDDIO supply is VLDO2

UM11503

KITFS26AEEVM evaluation board

Figure 12. VDDIO source selector headers

4.2.9 Wake input switches

Wake inputs can be exercised by switches SW2 for WAKE1_IN and SW3 for WAKE2_IN.

These interrupts are supplied by the battery to VBAT signal.

Figure 13. WAKE pins control switches

4.2.10 VDEBUG pin voltage control

VDEBUG pin allows FS26 SBC to enter the different operating modes to perform debug

or programming by applying different voltage thresholds or sequences. These thresholds

can be generated on the board and debug pin can be controlled manually or fully

automated by KL25Z.

The selection for manual (default) or automatic is done by J13.

Table 13. Debug control selector (J13)

Schematic label Signal name Description

J13_1-2 Manual (default) Debug thresholds are control by SW6 and SW7

J13_2-3 Automatic (feature not

enabled)

Debug thresholds are controlled by KL25Z

Different voltage levels and sequences can be used to enter Debug mode; emulate an

OTP configuration, or burn an OTP configuration to the fuses. The threshold levels are:

12 / 60

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

Page 13

NXP Semiconductors

• VDEBUG < VDBG4TH (VDEBUG < 4.2 V): waive debug entry at power up or after low-

power modes exit.

• VDEBUG > VDBG4TH (VDEBUG > 4.2 V): enter debug mode at power up or after low

power modes exit.

• VDEBUG VDBG65TH (VDEBUG > 6.9 V): burning level for OTP programming.

The power supply to generate the debug entry voltage threshold comes from KL25Z

USB. This means that Freedom board and USB must be plugged in. Burning voltage for

OTP is generated by an onboard boost IC that is also powered by FRDM-KL25Z.

For manual mode, use SW6 to allow connection to 5.0 V power supply, and SW7 to

connect to 8.0 V power supply; when VDBG65TH is reached a blue LED (D19) turns On.

Table 14 shows the possible output voltage level to apply to VDebug pin depending on

SW6 and SW7 positions.

Table 14. SW6 and SW7 VDebug output configuration

SW6 SW7 VDebug (J13-2) voltage level

OFF OFF 0 V

OFF ON 7.8 V

ON OFF 4.5 V

ON ON 7.8 V

UM11503

KITFS26AEEVM evaluation board

When automatic mode is selected on connector J13 and KL25Z is plugged in and used,

5.0 V and 8.0 V thresholds can be controlled on the NXP GUI by KL25Z signals. It is also

possible to control VBAT by a MCU signal to generate automated sequences for program

and emulations; these signals are:

VBAT_Ctrl: Open or close VBAT power supply

MCU_DBG5V: 5.0 V on VDEBUG pin

MCU_DBG8V: 8.0 V on VDEBUG pin

Debug mode entry

To enter debug mode, follow the sequence:

1. VBAT Off (SW1)

2. VDebug (J13) > VDBG4TH

3. VBAT On (SW1)

4. At this step Debug mode is enabled and you can emulate an OTP configuration or

access the SPI register map. You can read FS_STATES register to verify you are in

Debug mode.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

13 / 60

Page 14

NXP Semiconductors

aaa-039531

VSU

P

>

V

SUP_UVH

DEBUG

V

Debug

= 5 V

SPI or OTP Emulatio

n

SPI

OFF

REG

x

O

N

PWR U

P

SPI

V

Debug

= 0

V

Debug entry/Emulation

V

Debug

= 5 V

V

Debug

= 0

V

V

Debug

= 8

V

VSU

P

>

V

SUP_UVH

DEBUG

SPI OTP program

SPI

OFF

REG

x

O

N

PWR U

P

SPI

OTP programming

Go CM

D

aaa-039532

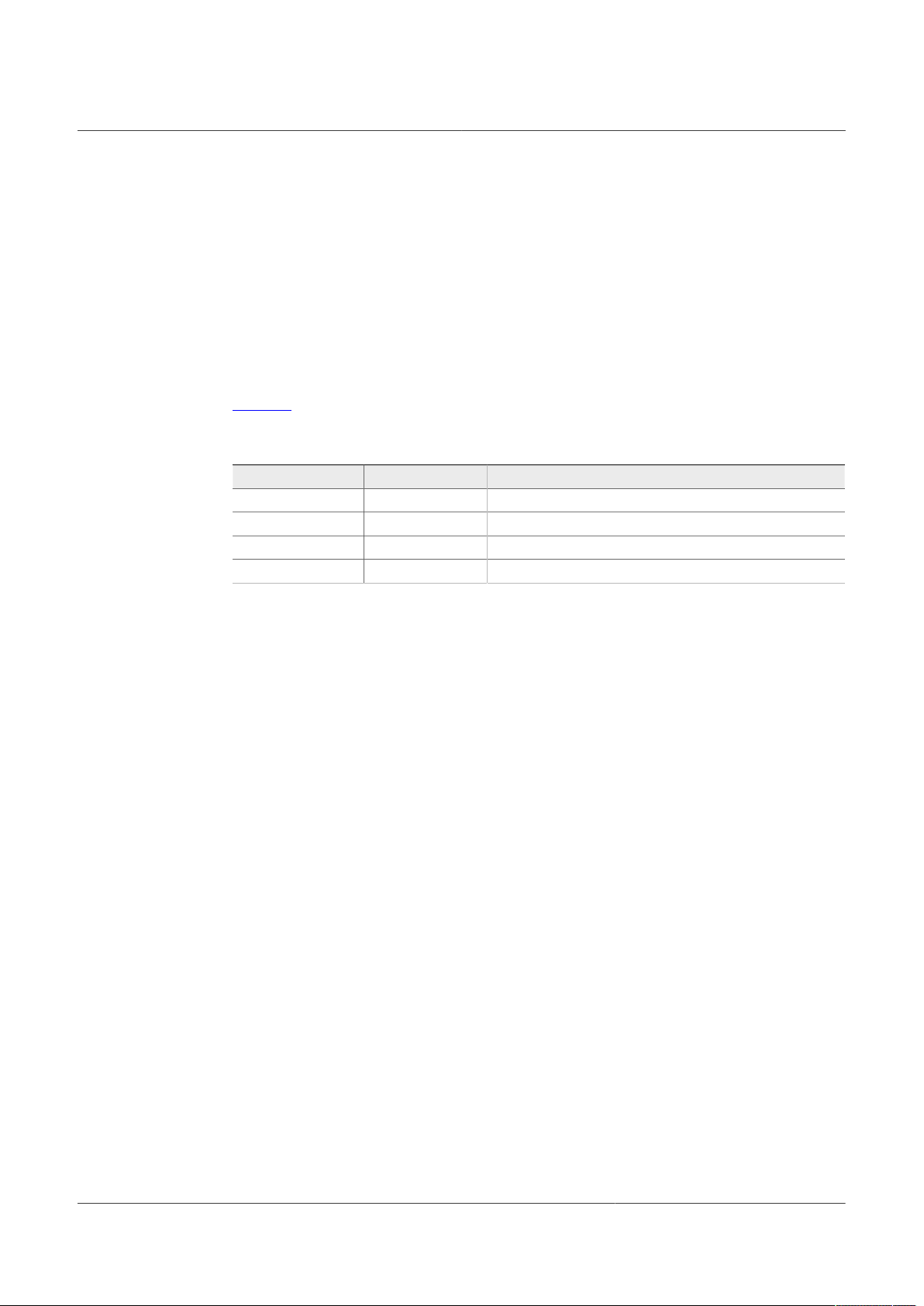

Figure 14. Debug entry voltage sequence

OTP programming

To burn an OTP configuration on the fuses permanently, the following sequence must

be applied. More detailed instructions are provided in Section 8.5 "Program an OTP

configuration".

UM11503

KITFS26AEEVM evaluation board

1. VBAT OFF (SW1)

2. VDebug (J13) > VDBG4TH (SW6 On).

3. VBAT On (SW1)

4. At this step, Debug mode is enabled and you can emulate an OTP configuration or

access the SPI register map. You can read FS_STATES register to verify you are in

Debug mode.

5. VDebug (J13) > VDBG65TH (SW7 On). If the threshold is applied, D19 blue LED

turns On.

6. Load an OTP configuration file and wait until all commands are sent.

7. Put VDebug (J13) to 0 V (first SW7, and then SW6).

8. The device should power up with selected OTP configuration or you can restart the

device power supply to load the burned OTP configuration from fuses.

Figure 15. OTP programming voltage sequence

Figure 16 shows the VDebug voltage sources and its selection.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

14 / 60

Page 15

NXP Semiconductors

aaa-039533

DEBUG & PROG VOLTAG

E

Burning

Volt

age

(on DBG pin)

RH1

to be replaced by 53.6k for DBG_OTP = 8V or solution to be replace

d

J13

1-2: Manual

3-2: Auto

GND

P3V3_KL25

Z

GND

GND

GND

GND

P3V3_KL25

Z

P3V3_KL25

Z

GND

GND

GND

GND

DBG_OTP

GND

GND

P5V_KL25Z

MCU_DBG5V

VDEBU

G

MCU_DBG8V

VDEBU

G

LT1618EMS

U

2

F

B

1

I

S

N

2

ISP

3

I

A

D

J

4

G

N

D

5

N

C

6

S

W

7

VIN

8

SHD

N

9

V

C

1

0

D16

BAT46ZFIL

M

A

C

-

+

VDD

VSS

U

4

MCP6001T-E/OT

3

1

4

5

2

C34

4.7uF

R4710

K

R35

510

K

C37

1.0UF

Q10

FDN360P

1

3

2

R4480.6

K

C36

10n

F

R4810

K

Q11

BSS138LT1

G

1

2

3

C32

4.7uF

R410.

1

D19BLUE

A

C

J13

1

2

3

R45

3.3

K

R82

510

K

Q

8

BSS138LT1

G

1

2

3

R43

19.6K

R83

47K

D17PMEG2005AE

L

A

C

Q

9

FDN360P

1

3

2

R38

47K

R4622.1

K

R91

10K

RL1

D18

BAT46ZFIL

M

A

C

C38

0.1uF

SW6

1

2

R90

52.3K

1

%

RH1

L310u

H

1

2

SW7

1

2

P5V_KL25Z

DBG_OTP

P5V_KL25Z

DBG_OTP

aaa-039534

GND

VMONEXT_0.8

V

R37

100

K

1

3

2

R40

22.1K

R39

0

VMONEXT

UM11503

KITFS26AEEVM evaluation board

Figure 16. VDEBUG pin source selection schematic

4.2.11 VMONEXT monitoring

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

4.2.12 GPIO1 and GPIO2

FS26 VMONEXT monitoring pin can be accessed in different ways. If used, VMONEXT

value should always be 0.8 V. VMONEXT signal can be supplied by any source or

regulator and VMONEXT_0.8V value can be adjusted by using a screwdriver on R37

potentiometer. Default bridge resistor is 22.2 kΩ.

To apply 0.8 V directly to VMONEXT_0.8V, remove R39 and apply 0.8 V to connector

J23_1.

Figure 17. VMONEXT voltage resistor bridge schematic

GPIO1 and GPIO2 FS26 pins are connected by default as outputs, and can be accessed

by J23 connector.

• J23_5 for GPIO1

15 / 60

Page 16

NXP Semiconductors

aaa-039535

GNDGN

D

GND

GND

GND

GND

GPIO1_I

N

GPIO2_I

N

0.01u

F

C80

0.01u

F

C82

5.1

K

R88

R875.1K

DNP

0.022uF

C79

0.022uF

C81

GPIO1

3

GPIO2

6

R89

5.1KDNP

5.1

K

R86

GPIO1

GPIO2

• J23_7 for GPIO2

To exercise GPIO pins as inputs, R87 and R89 must be populated in order to apply

voltage before RC filter. GPIO input supply can be applied through J23 header.

• GPIO1_IN can be accessed through J23_13; R87 must be populated.

• GPIO2_IN can be accessed through J23_15; R89 must be populated.

Figure 18. GPIO1 and GPIO2 schematics

Note: There are no external pull-ups or pull-downs for the GPIO. If the internal pull-ups

or pull-downs are not enabled by OTP, external PU/PD can be added through J23.

4.3 Schematic, board layout and bill of materials

The schematic, board layout and bill of materials for the KITFS26AEEVM evaluation

board are available at http://www.nxp.com/KITFS26AEEVM.

UM11503

KITFS26AEEVM evaluation board

5 Installing and configuring software and tools

5.1 Flashing or updating the GUI firmware

The KITFS26AEEVM is delivered with the GUI firmware flashed. If MCU firmware is

flashed, ignore this section. If it is specified to update the firmware or it is malfunctioning,

follow the instructions in Section 5.1.1 "Flashing Freedom board firmware for Windows 7"

and Section 5.1.2 "Flashing Freedom board firmware from Windows 10".

5.1.1 Flashing Freedom board firmware for Windows 7

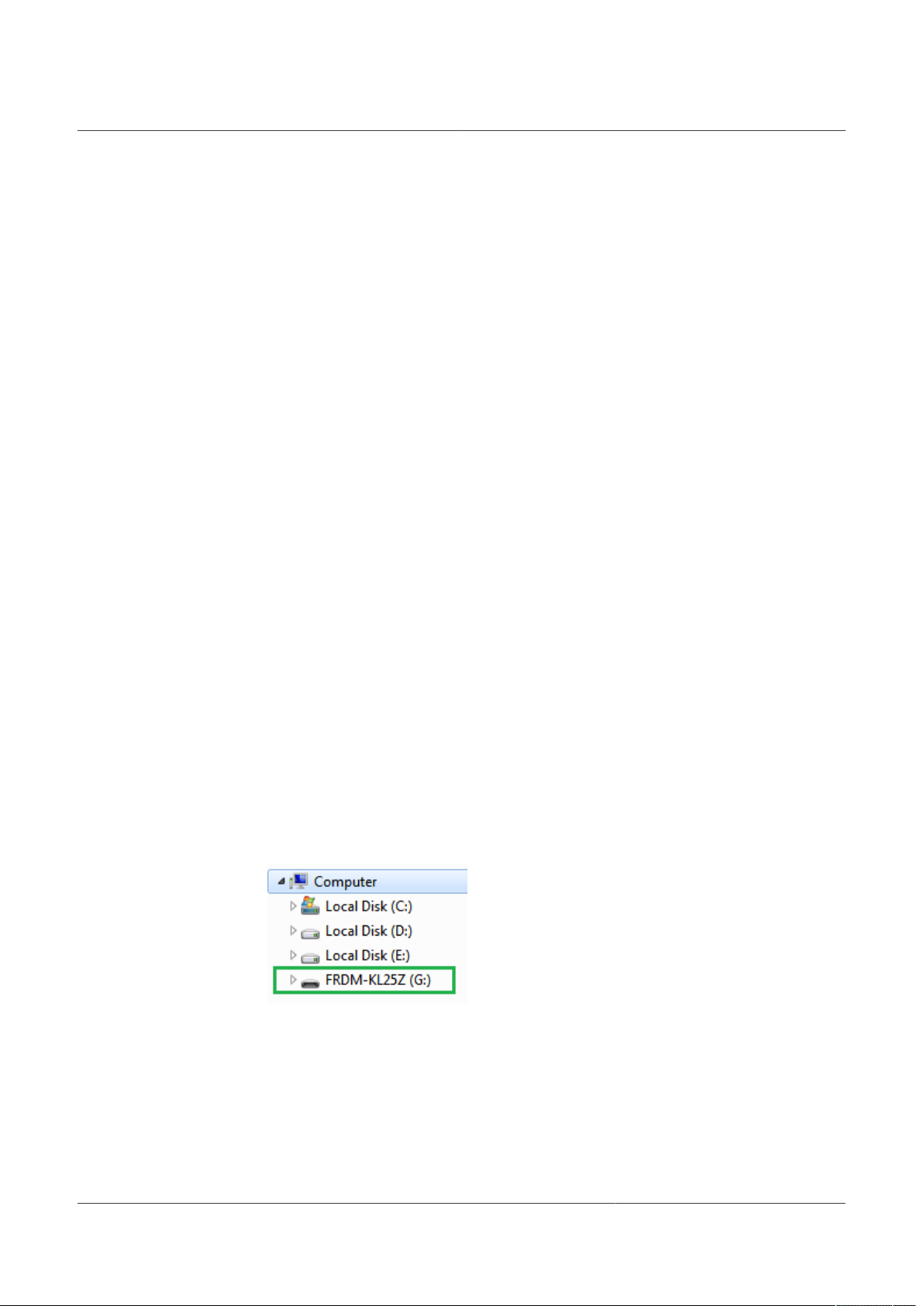

Steps 1 and 2 are not required if BOOTLOADER is already loaded in the Freedom board.

1. Press the RST push-button and connect the USB cable into the SDA port on the

Freedom board.

• A new “BOOTLOADER” device should appear on the left pane of the File explorer.

2. Drag and drop the file “MSD-DEBUG-FRDM-KL25Z_Pemicro_v118.SDA” into the

BOOTLOADER drive.

Note: Make sure to allow enough time for the firmware to be saved in the Bootloader.

3. Disconnect and reconnect the USB cable into the SDA port.

• This time without pressing the RST push-button, FRDM_KL25Z device should

appear on the left pane of the File explorer.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

16 / 60

Page 17

NXP Semiconductors

4. Locate the file “nxp-gui-fw-frdmkl25z-usb_hid-fs2630_vX.Y.bin” from the package and

drag and drop the file into the FRDM_KL25Z device.

Note: Make sure to allow enough time for the firmware to be saved.

5. Freedom board firmware is successfully loaded. Disconnect and reconnect the USB

cable into the KL25Z USB port.

5.1.2 Flashing Freedom board firmware from Windows 10

1. Disable the storage services: run the services, double-click on the storage service

from the list and press STOP.

UM11503

KITFS26AEEVM evaluation board

Steps 2 and 3 are not required if BOOTLOADER is already loaded in the Freedom

board.

2. Press the RST push-button and connect the USB cable into the SDA port on the

Freedom board.

a. A new “BOOTLOADER” device should appear on the left pane of the File explorer.

3. Drag and drop the file “MSD-DEBUG-FRDM-KL25Z_Pemicro_v118.SDA” into the

BOOTLOADER drive.

Note: Make sure to allow enough time for the firmware to be saved in the

BOOTLOADER.

4. Disconnect and reconnect the USB cable into the SDA port.

• This time without pressing the RST push-button, FRDM_KL25Z device should

appear on the left pane of the File explorer.

5. Locate the file “nxp-gui-fw-frdmkl25z-usb_hid-fs2630_vX.Y.bin” from the package and

drag and drop the file into the FRDM_KL25Z device.

Note: Make sure to allow enough time for the firmware to be saved.

6. Freedom board Firmware is successfully loaded. Disconnect and reconnect the USB

cable into the KL25Z USB port.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

17 / 60

Page 18

NXP Semiconductors

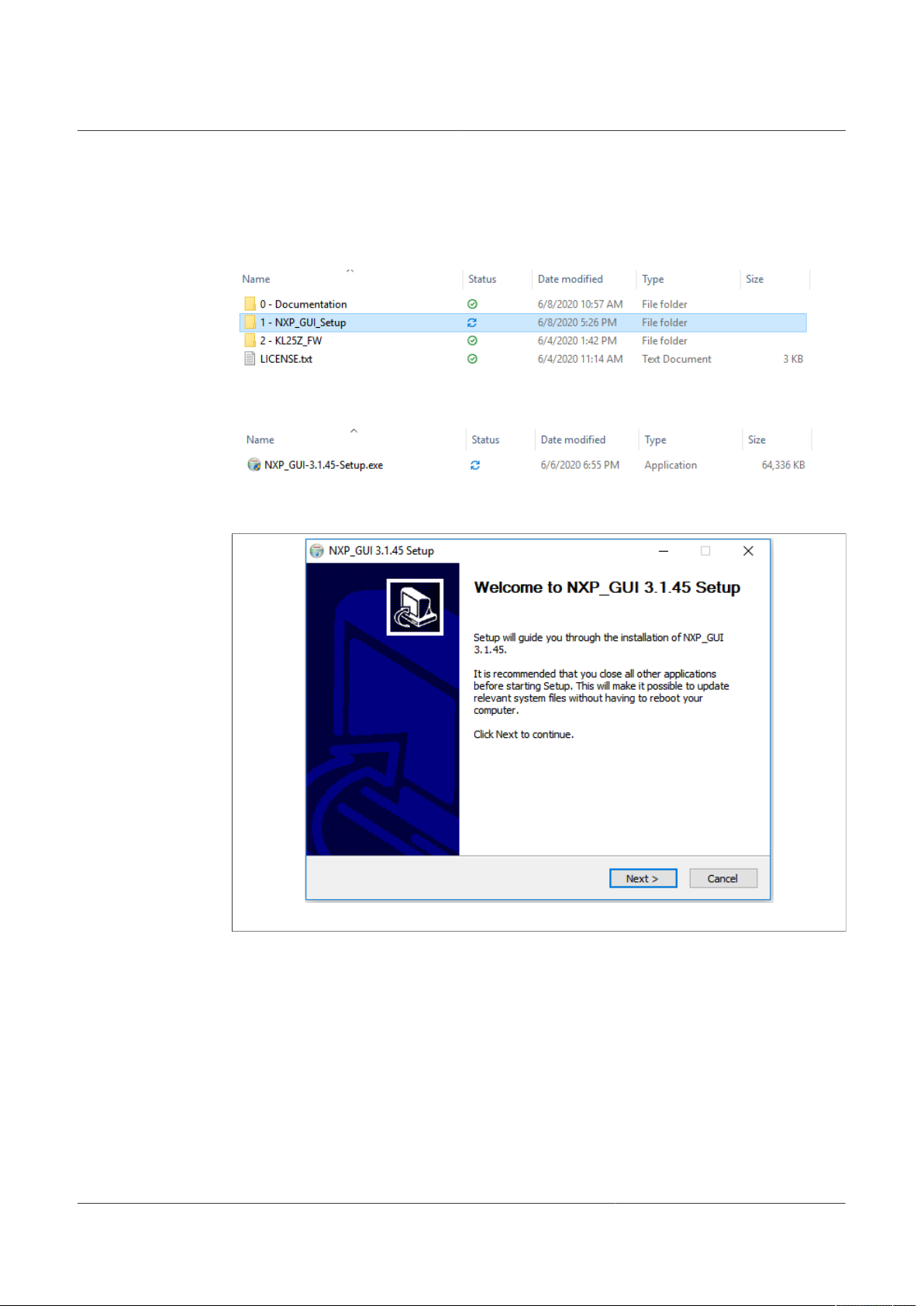

5.2 Installing GUI software package

To install the FS26 NXP GUI, download or obtain the NXP GUI package, unzip 1NXP_GUI_Setup folder:

Double-click NXP_GUI_version-Setup.exe and follow the instructions.

Proceed with the following pop-up windows to install the application on Windows PC:

UM11503

KITFS26AEEVM evaluation board

Figure 19. Application setup

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

18 / 60

Page 19

NXP Semiconductors

UM11503

KITFS26AEEVM evaluation board

Figure 20. License agreement

Figure 21. Select FS2630_GUI feature

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

19 / 60

Page 20

NXP Semiconductors

UM11503

KITFS26AEEVM evaluation board

Figure 22. Choose the folder to install

Select the following options before completing the installation of the setup:

• Run NXP_GUI

• Show Readme

Select Finish to complete the installation.

Figure 23. Run NXP_GUI

When installation is finished the application can be found in the windows search bar as

“NXPGUI”.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

20 / 60

Page 21

NXP Semiconductors

6 Configuring the hardware

UM11503

KITFS26AEEVM evaluation board

Figure 24. Typical initial configuration

To configure the hardware and workstation, complete the following procedure:

1. With SW1 in middle position, set DC power supply to 12 V and current limit to 1.0 A.

Attach the DC power supply positive and negative output to KITFS26AEEVM VBAT

Phoenix connector(J1). Or connect 12 V power supply to VBAT Jack (J2).

Table 15. VBAT Phoenix connector (J1)

Schematic label Signal name Description

J1-1 VBAT Battery voltage supply input

J1-2 GND Ground

Table 16. VBAT three position connector (SW1)

Schematic label Signal name Description

SW1 pin 2-3 VBAT Phoenix Board supplied by Phoenix connector

SW1 pin 2 (middle position) VBAT Board not supplied

SW1 pin 2-1 VBAT jack Board supplied by Jack connector

2. Connect the Windows PC USB port to the KL25Z USB side of the freedom board

included in the kit, using the provided USB 2.0 cable.

3. Turn On SW6 to apply 5.0 V to the VDebug pin.

4. Turn On the power supply.

5. Close SW1.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

21 / 60

Page 22

NXP Semiconductors

Note: At this step, the product is in debug mode and all regulators are turned Off. The

user can then power up with OTP configuration or configure the mirror registers before

power up. Power up is effective as soon as SW6 is turned Off.

7 FS26 NXP GUI

Once the kit is ready and the NXP GUI is installed, launch the kit from the Windows

search bar.

Launching FS26_GUI application

1. When the NXP GUI is launched, the Kit Selection window is displayed. Check for the

following settings and then select OK.

UM11503

KITFS26AEEVM evaluation board

2. To avoid the kit selection window on every launch, select the box “Use this

configuration and do not ask again”.

The following window is displayed.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

22 / 60

Page 23

NXP Semiconductors

7.1 Framework

UM11503

KITFS26AEEVM evaluation board

Device manager: Start communication with device. Enter or exit test mode. Quick

access to execute system scripts.

Framework settings: Import or export files, configure framework.

Window log: USB and Device communication events.

USB and device status: Displays if USB or Device is connected or disconnected.

Displays firmware and GUI version. Display current state of FS state machine; click

Display to refresh.

Tool access bar: Quick access to the FS26 evaluation tools and features.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

23 / 60

Page 24

NXP Semiconductors

Tab content: Content of each tool or tab; there can be more tabs, boxes, or windows

inside.

7.1.1 Framework settings

The NXP GUI main menu has five GUI elements: File, View, Export, NXP, and Help.

7.1.1.1 File

Load or save a configuration or exit the application. Load and save are only enabled

when OTP tool tab is active.

UM11503

KITFS26AEEVM evaluation board

• Load: Loads an existing configuration file previously exported from OTP tool to

continue to modify it on the OTP tool. This file has a .cfg extension. It is identified as:

FS26_ProgIDASILlevel_CONFIG.cfg.

Example: FS26_A0D_CONFIG.cfg.

• Save: Saves the current configuration of the OTP tool as a .cfg file.

• Use default configuration: Loads default values into the OTP tool.

• Exit: Exits NXP GUI application

7.1.1.2 View

This main menu has options related to GUI display.

• Display

• Show

• Naming Conventions

Display: It consists of Connection Tool Bar (enabled by default) option. To show or hide,

go to View → Display, and then select Connection Tool Bar.

Figure 25. Display options

Show: This option can be used to access various sections of the GUI.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

24 / 60

Page 25

NXP Semiconductors

Figure 26. Show options

Naming Conventions: Select Friendly or Register name display for OTP tool. Option

enabled only when OTP tool is active.

UM11503

KITFS26AEEVM evaluation board

Figure 27. Naming conventions options

Friendly: Go to View → Naming Conventions → Friendly. This mode helps to view the

registers names as user-friendly names throughout the OTP tool.

Figure 28. Friendly mode

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

25 / 60

Page 26

NXP Semiconductors

Register: Go to View → Naming Conventions → Register. This mode helps to view the

register names as register's technical names throughout the OTP Tool.

Example: VSUP UV threshold → VSUP_UVTH_OTP

7.1.1.3 Export

This option allows user to export the current OTP from the OTP tool into different script

formats.

• OTP: Exports OTP configuration into OTP script file for programming.

• TBB: Exports OTP configuration into a TBB script file for emulation

• I-HEX: Exports to Intel Hex script file

• S-HEX: Exports to Simple Hex script file

UM11503

KITFS26AEEVM evaluation board

Figure 29. Export options

This option is enabled only in OTP Tool and remains disabled in other sections of the

GUI.

7.2 Device manager

The device manager allows start/stop of communication with device as well as enter/exit

of the test mode; it also allows quick access to execute useful system scripts.

Figure 30. Device manager

7.2.1 Device connection

If USB is detected from USB and device status bar, the USB status changes from NOT

DETECTED to DISCONNECTED. Start button is enabled.

Click Start to initiate communication with FS26 device.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

26 / 60

Page 27

NXP Semiconductors

When connected successfully, FS26 color changes to green and other buttons are

enabled. USB status changes to CONNECTED.

Apply test mode to send Main and Fail-safe Test mode entry keys. If test mode is entered

correctly, button changes to “Exit test mode”.

When test mode is entered, options requiring test mode are enabled, such as Mirrors and

device programming.

UM11503

KITFS26AEEVM evaluation board

Click Polling to do a continuous check of test mode entry.

If the device versioning bits are already programmed with an existing part number, the

NXP GUI decodes and displays the assigned Device ID. The following example displays

FS2633D.

7.2.2 Script shortcuts

To find a section with system script shortcuts, select the script and click execute. This

does not warrant the entry or acknowledge of the device. Device must be in INIT FS

state in most cases.

7.3 Access

7.3.1 Register map

The register access tab allows read/write to the FS26 Main and Fail-safe register maps

and is divided into following sections:

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

27 / 60

Page 28

NXP Semiconductors

• Functional: Main functional SPI registers (diagnostics, configuration, and controls)

• Safety: Safety SPI registers (diagnostics and configuration)

• Write_INIT_Safety: Safety registers that can be configured during INIT FS state (for

example, WD configuration and WD window).

UM11503

KITFS26AEEVM evaluation board

There are three types of registers: read only (only read button), write only (only write

button) or read/write (read and write buttons).

7.3.1.1 Register read only

To read the values of a register, click READ; the value is read from the device and

displayed on label near READ button, and is displayed on the log window.

Figure 31. Read only register

To view the values of all the bits from a register after read operation, click Edit button.

Bits are read with their corresponding values displayed as a pop-up window.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

28 / 60

Page 29

NXP Semiconductors

Figure 32. Register read with values and description

7.3.1.2 Register read/write

To read or write the bit values individually, click each bit button; the value is read from the

bit or written to the bit based on its properties and displayed on the log window and in the

label near READ and text box near WRITE button correspondingly. The bit button color

changes accordingly.

7.3.1.3 Global read/write

UM11503

KITFS26AEEVM evaluation board

The global read/write and reset option is located at the bottom left section of the register

tab.

The SELECT ALL option selects all the registers on the tab.

Figure 33. Global read/write

WRITE: Writes data to all selected registers at once

READ: Reads data back from the selected register at once

RESET: Resets all the input textbox to 0x00. Write bits are set to 0 and change register

bit buttons to default setting

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

29 / 60

Page 30

NXP Semiconductors

7.3.2 INIT Safety

Configure reaction of safety outputs for VMON, FCCU, ERRMON, and configure Fault

Monitor. It is required to be in INIT FS to configure registers. Click Read All to get current

configuration, then modify it.

Click the combo box controls to select configuration, then click Write.

Click Read or Read All to get configuration; read values appear to the right of controls.

UM11503

KITFS26AEEVM evaluation board

Figure 34. INIT Safety

To get current state, click FS_STATES display from USB and Device status bar on the

bottom.

7.3.3 FS Config

This tab helps to configure safety features such as Watchdog and fault error counter.

Click Read All to get current configuration.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

30 / 60

Page 31

NXP Semiconductors

Figure 35. FS Config

UM11503

KITFS26AEEVM evaluation board

7.3.4 Regulators

Enable or disable FS26 regulators. Check enable or disable box, then click Write button.

These registers do not provide regulator status; it writes ‘1’ to apply the command then

restart to 0. Write ‘0’ has no effect. VPRE can be only enabled or disabled in test mode.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

31 / 60

Page 32

NXP Semiconductors

UM11503

KITFS26AEEVM evaluation board

Figure 36. Regulators

7.3.5 AMUX

This tab can be accessed from Toolbar → REG ACCESS or View → Show → Registry

Map → AMUX Registers.

This tab allows selection of AMUX pin channel and gets its current value by using KL25Z

AMUX ADC pin. The voltage or temperature graph can do a single read or dynamically

display various channels.

The displayed values apply to the divider and temperature formulas.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

32 / 60

Page 33

NXP Semiconductors

UM11503

KITFS26AEEVM evaluation board

Figure 37. AMUX

To do a single read of all channels click Read.

To use the dynamic graph, select the channel then click + button to add to the graph and

then start polling with Poll button.

Click Poll again to stop measurements.

7.4 Script editor

The script editor allows you to create or send existing sequences to the device. You can

read/write individually to a register, to an I/O, or to an analog pin. You can emulate an

OTP configuration as well with this tab.

This tab can be accessed from Toolbar → SCRIPT or View → Show → Script Editor.

Figure 38. Script editor

The script can be written by selecting and configuring the pins and registers that are

available on the script commands section, or by loading a previously exported .txt file.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

33 / 60

Page 34

NXP Semiconductors

Click one type of command to access more options, until the command to build the

sequence is found.

• Digital pins: Select the pin name, then pin value (High or Low). Command is

automatically added to the script.

UM11503

KITFS26AEEVM evaluation board

• Analog pins: Select the pin name, and then write the pin value. If the pin is read only,

pin value is not enabled and it gets added to script editor automatically.

• Registers: Select the Operation (Read/Write).

– Read: Select the register group then the register name. Register is added to script

editor automatically.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

34 / 60

Page 35

NXP Semiconductors

• Write: Select the register group then the register name. Write value and click enter key.

Value must be written in HEX. Press Enter key to add to the editor.

• Mode: Write command to exit or enter different device modes.

– Test mode: Send Main and Fail-safe test mode entry keys

– User mode: Exit test mode if device is in test mode.

• Generator: Select an existing script to add to the script editor. Some options may

require to be in a specific mode or state.

UM11503

KITFS26AEEVM evaluation board

The script operations can be found at the bottom of the script editor window. This section

is responsible for:

• Execution of script

• Script management: Create, Open, Save, Run

• Logging feature: Load, Save, Clear

Figure 39. Script editor options

Run: Runs the script once

Loop: Runs the script continuously in loop

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

35 / 60

Page 36

NXP Semiconductors

Save: Saves the script that is present in the script command window in a text file

Open: Opens a saved script from the desired location

ATE: Saves the script in ATE format

Clear: Clears the script command window

Script Editor Help Window: This section describes the commands available in Script

editor and their formats. This option can be accessed from Menu → SCRIPT → Help or

View → Show → Script Editor → Help.

7.5 OTP Mirror

To enable this option, test mode must be applied. This tab is divided in Main and Failsafe OTP registers.

Each bit group box can be read or written, or the whole page can be read. OTP

configuration can be imported or exported from this tab.

UM11503

KITFS26AEEVM evaluation board

Figure 40. OTP Mirror registers

7.5.1 Read/write operation

To read a bit group, click Read from a box. Read values are displayed to the right of each

register.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

36 / 60

Page 37

NXP Semiconductors

Figure 41. Read bit group

To write to a bit group, modify the controls of each register, then click Write.

UM11503

KITFS26AEEVM evaluation board

Figure 42. Write bit group

7.5.2 Read/write all and write all operation

Read All reads the bits of each block from all mirror registers.

Read values appear at the right of each register as well on the window log.

Figure 43. Read All

To write all OTP bit groups configuration, click Write All.

7.5.3 Mirror registers export option

This operation generates a configuration file and this file is saved as a text file in local

device which can be imported later into this tab. Figure 44 shows the generated .txt

configuration file.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

37 / 60

Page 38

NXP Semiconductors

UM11503

KITFS26AEEVM evaluation board

Figure 44. Export option for reference

7.5.4 OTP import to mirror registers

This option is used to import the configuration file previously saved. Click OTP Import

and select the the.txt configuration file previously saved from this tab.

Figure 45. OTP Import for reference

7.6 INT

This option allows access to monitor the regulators and safety events. To access the

Interrupt Editor window, click Menu → INT or View → Show → Interrupt Editor.

It is separated in two tabs: Interrupt Configuration and Safety Diagnostic.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

38 / 60

Page 39

NXP Semiconductors

UM11503

KITFS26AEEVM evaluation board

Figure 46. Interrupt Configuration tab

The below legend and functions apply to both tabs:

• Blue means Low or not activated

• Yellow means High or activated.

• To clear flags, click each check box from clear column or click Clear All.

• To mask the interruption, check the box of each interruption from mask column.

• Click Read on each box to read the current status or Read all to update the whole tab.

• Use Poll button to read each box periodically.

Sense status can be read only.

7.6.1 Interrupt Configuration

This tab allows the user to monitor the regulators, Wake inputs, I/O and communication

events or status. It allows read, write and poll over/under voltage, over temperature and

over current of device. You can read, clear or mask an interruption.

If an event occurs flag changes to red. When regulators are red or ‘1’ they are turned ON.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

39 / 60

Page 40

NXP Semiconductors

Figure 47. Interrupt Configuration

UM11503

KITFS26AEEVM evaluation board

7.6.2 Safety Diagnostics

Safety Diagnostics tab allows the monitoring of safety events such as VMON status, bad

WD, SPI communication errors, FCCU pins, safety outputs, ABIST1 and ABIST2 status.

Figure 48. Safety diagnostics tab

ABIST1_PASS Yellow means that it is done and PASS, since we can read ‘1’ from its

register. 0 or blue after execution means fail.

7.7 Device programming

This section is used to burn permanently an OTP configuration on the OTP fuses. To

enable this window device must be in test mode.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

40 / 60

Page 41

NXP Semiconductors

Figure 49. Device programming

To program an OTP configuration Vdebug pin must be higher than VDBG65TH. To apply

this voltage, turn on SW7 (Apply 8.0 V to Vdebug).

Click on Browse to select an OTP script file, then click on program button to run the

script. If Vdebug not set to 8.0 V, a pop-up appears asking to turn on SW7, or it turns On

automatically if jumper J13 is on Automatic mode J13 3-2.

UM11503

KITFS26AEEVM evaluation board

If the required conditions are met (sectors available), the programming starts. Otherwise

the execution is cancelled. To verify sectors are available, click Read from Fuse Box

Status.

OTP is programmed into SECTBE2 of Main and Fail-safe. SECTBE1 and SECTBE0 are

reserved for NXP users only.

Blue or ‘0’: Available

Yellow or ‘1’: Not available

When programming is complete, a pop-up appears to request to turn Off SW7 and SW6

(set Vdebug to 0 V).

If the device was programmed correctly the power-up sequence starts. Fuse box status

can be read to verify if sectors are burned. In some conditions a power up could be

required.

7.8 OTP tool

This option allows user to configure OTP registers, save configurations, and generate

scripts in different file formats which can be burnt (OTP script) or emulated (TBB script)

into the FS26 SBC. See Section 7.1.1.3 "Export".

To access the FS26 OTP tool, launch NXP GUI application and navigate to OTP. To

access OTP Tool from menu, go to View → Show/Hide → OTP Tool.

It is possible to save a configuration to visualize or modify it later. Click Save Config to

export or go to File and then select Save. To import, click Import or go to File and then

select Load.

7.8.1 OTP tool application

All blocks in the OTP tool use default values configured on launch. It consists of the

following configuration sections:

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

41 / 60

Page 42

NXP Semiconductors

• System Configuration

• Switching Regulators

• Regulators

• Voltage Monitoring

• System Safety Configuration

UM11503

KITFS26AEEVM evaluation board

Figure 50. OTP tool configuration tabs for FS26

7.8.2 OTP configuration sections

7.8.2.1 System Configuration

This block consists of the parameter (bits) settings that are related to the system

configuration registers of FS26. It displays block diagram with the selected regulators

output values from Regulators section. It contains the power up sequence configuration

which is displayed in the sequence diagram. You can configure the I/O and wake inputs

as well.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

42 / 60

Page 43

NXP Semiconductors

UM11503

KITFS26AEEVM evaluation board

Figure 51. System Configuration

7.8.2.2 Regulators

The FS26 regulators are separated in two tabs: Switching regulators and Regulators

(LDOs).

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

43 / 60

Page 44

NXP Semiconductors

UM11503

KITFS26AEEVM evaluation board

Figure 52. Regulators Tabs

The switching regulators can configure VPRE, VBST and VCORE output values and its

internal parameters. Select the Power topology by configuring the VBST_CFG_OTP bit

group.

Figure 53. VBST configuration

The Regulators tab consists of VLDO1, VLDO2, VTRK1, VTRK2, VREF output values

and its TSD behavior.

7.8.2.3 System Safety Configuration

This tab allows user to configure ABIST1 for each regulator, configure system reaction in

case of Fault or enable and disable Watchdog timer.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

44 / 60

Page 45

NXP Semiconductors

Figure 54. System Safety Configuration

7.8.2.4 Voltage Monitoring

This tab allows user to configure FS26 voltage monitoring and consists of the following:

UM11503

KITFS26AEEVM evaluation board

• VMONPRE configuration

• VMONLDO1 configuration

• VMONCORE configuration

• VMONLDO2 configuration

• VMONEXT configuration

• VMONREF configuration

Make sure that each VMON is assigned with the same voltage output value configured

on Regulators tab, then select its fault OV/UV threshold and filtering time.

Figure 55. Voltage Monitoring

7.8.2.5 OTP ID

Displays OTP ID. Only NXP users can create a new OTP ID.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

45 / 60

Page 46

NXP Semiconductors

Figure 56. OTP ID

7.9 I/O pins

This section can control some I/Os connected to the KL25Z plugged-in Freedom. It can

read the device safety outputs externally or control different voltage sources in order to

apply sequences to apply debug mode without moving any switches.

The input pins are the pins that can be read from the MCU; they are input pins from MCU

point of view. This section contains the safety outputs FS0B, FS1B and RSTB. It can be

read once with Read button, or you can select at which frequency you want to the read

the pins. Select the duration then start polling with Poll button.

UM11503

KITFS26AEEVM evaluation board

Figure 57. I/O pins

The output pins are thresholds that can be controlled with MCU. These pins are

described in Section 4.2.10 "VDEBUG pin voltage control"

VBAT_Ctrl: Open or close VBAT power supply

MCU_DBG5V: 5 V on VDebug pin

MCU_DBG8V: 8 V on VDebug pin

They can be used instead of the Manual switches SW6 and SW7. In order to use

MCU_DBG5V and MCU_DBG8V for debug pin control, J13 must be on ‘’Auto mode’’ J13

position 3-2. Select high or low to control the pins, default is low.

To use VBAT_Ctrl the red jumper JP1 next to the VBAT switch must be OFF. Once JP1 is

removed, use VBAT_Ctrl instead of SW1 to turn the power supply on or off.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

46 / 60

Page 47

NXP Semiconductors

These pins are also accessible from script editor and be used to create script sequences.

8 Using FS26 NXP GUI

UM11503

KITFS26AEEVM evaluation board

Once the NXP GUI (Section 5.2 "Installing GUI software package") is installed, follow

these instructions for a quick power up, debug, programming, or entering the different

operating modes of the FS26 SBC.

8.1 Power up

If the FS26 device contains an OTP configuration, connect a power supply to the VBAT

Phoenix connector or the VBAT jack connector. See Section 4.2.2 "VBAT connectors".

It is recommended to set the power supply to an initial value of 12 V and limit current to

1.0 A.

Make sure the board has the correct jumper configuration. Every kit is delivered with a

default configuration shown in the following figure. This configuration is enabled for a

boost in front-end topology.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

47 / 60

Page 48

NXP Semiconductors

UM11503

KITFS26AEEVM evaluation board

Verify that the KL25Z Freedom is plugged in, as well as the USB cable on KL25Z USB

connector side. It is important that the USB cable is connected since in addition to

enabling the communication with the NXP GUI, it provides voltages and references to

some circuits on board as well as generates the VDDIO reference for the IC.

Since all the previous statements are valid or considered, switch SW1 can be used to

power on the board.

If the OTP configuration has many safety features enabled, the device may restart or

power Off after a few seconds. To prevent this, enter debug mode to waive some of those

features.

UM11503 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2021. All rights reserved.

User manual Rev. 1 — 29 January 2021

48 / 60

Page 49

NXP Semiconductors

8.2 Debug mode entry

To modify any parameters or to communicate with the IC, enter debug mode. Refer to the

power and connection statements from Section 8.1 "Power up".

Once the kit is ready, follow the next steps:

1. Make sure the device is powered Off (SW1 middle position).

2. Turn On SW6 to apply 5.0 V to the VDebug pin. Make sure the jumper of J13 has

the right configuration, default is Manual. See Section 4.2.10 "VDEBUG pin voltage

control" for more details.

UM11503

KITFS26AEEVM evaluation board

3. Power on VBAT, and the device enters debug mode, this allows access to the register