Page 1

PCA9646

Buffered 4-channel 2-wire bus switch

Rev. 1 — 1 March 2011 Product data sheet

1. General description

The PCA9646 is a monolithic CMOS integrated circuit for 2-wire bus buffering and

switching in applications including I

similar principles.

Each of the four outputs may be inde pendently enabled i n any combination as d etermined

by the contents of the programmable control register. Each I/O is impedance isolated from

all others, thus allowing a total of five branches of 2-wire bus with the maximum specified

load (e.g., 5 400 pF for Fm+ I

(Ref. 1

). More than one PCA9646 may be used in series, providing a substantial fan-o ut

capability.

As per the PCA9525 and PCA9605 simple bus buffers, the PCA9646 includes a

unidirectional buffer for the clock signal, and a bidirectional buffer for the data signal. The

direction of the clock signal may also be set by the contents of the programmable control

register. Clock stretching and timing must always be under control of the master device.

The PCA9646 has excellent application to 2-wire bus address expansion and increasing

of maximum load capacitance. Very large LED displays are a perfect example.

2. Features and benefits

Drop-in pin compatible with PCA9546A, etc.

Each I/O is impedance isolated from all others allowing maximum capacitance on all

branches

30 mA static sink capability on all ports

Works with I

SMBus (standard and high power mode) , and PMBus

Fast switching times allow operation in excess of 1 MHz

Allows driving of large loads (e.g., 5 4nF)

Hysteresis on I/O increases noise immunity

Operating voltages from 2.7 V to 5.5 V

Uncomplicated characteristics suitable for quick implementation in most common

2-wire bus applications

2

C-bus, SMBus, PMBus, and other systems based on

2

C-bus at 1 MHz, or 5 4 nF at lower frequencies)

2

C-bus (Standard-mode, Fast-mode, and Fast-mode Plus (Fm+)),

3. Applications

Large arrays of I2C-bus components, e.g., LED displays

Power management systems

Game consoles, computers, RAID systems

Page 2

NXP Semiconductors

R4

002aaf367

I2C-BUS

CONTROL

5

7

10

12

4

6

9

11

SC0

SC1

SC2

SC3

SD0

SD1

SD2

SD3

R3 R5 R6 R7 R8 R9 R10

V

DD

16

FILTER

1 A0

2 A1

13 A2

14

15

3

SCL

SDA

RESET

R2R1

2.7 V to 5.5 V

PCA9646

V

SS

8

4. Ordering information

PCA9646

Buffered 4-channel 2-wire bus switch

mark

Package

Name Description Version

Table 1. Ordering information

Type number Topside

PCA9646D PCA9646 SO16 plastic small outline package; 16 leads; body width3.9 mm SOT109-1

PCA9646PW PCA9646 TSSOP16 plastic thin shrink small outline package; 16 leads;

SOT403-1

body width 4.4 mm

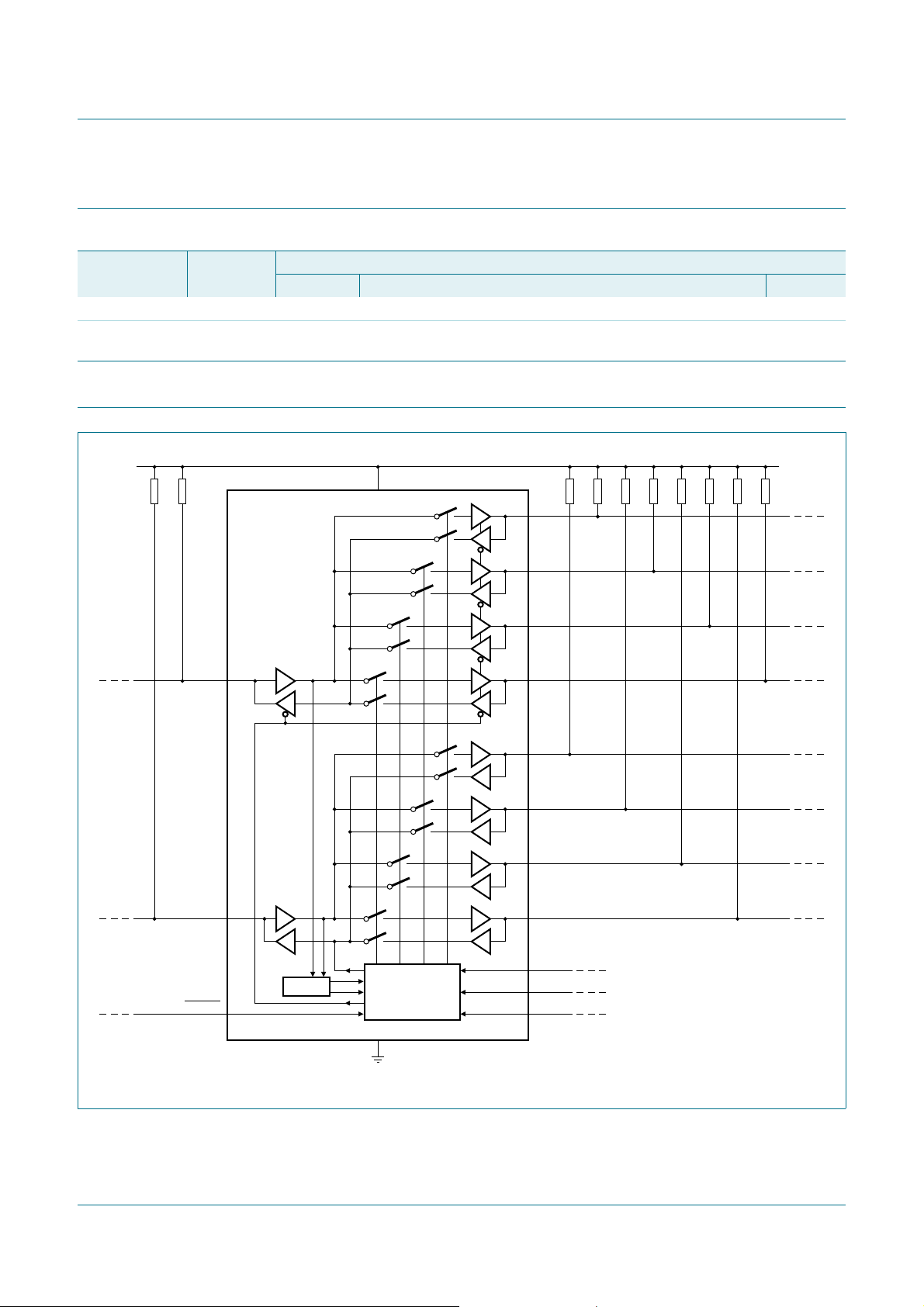

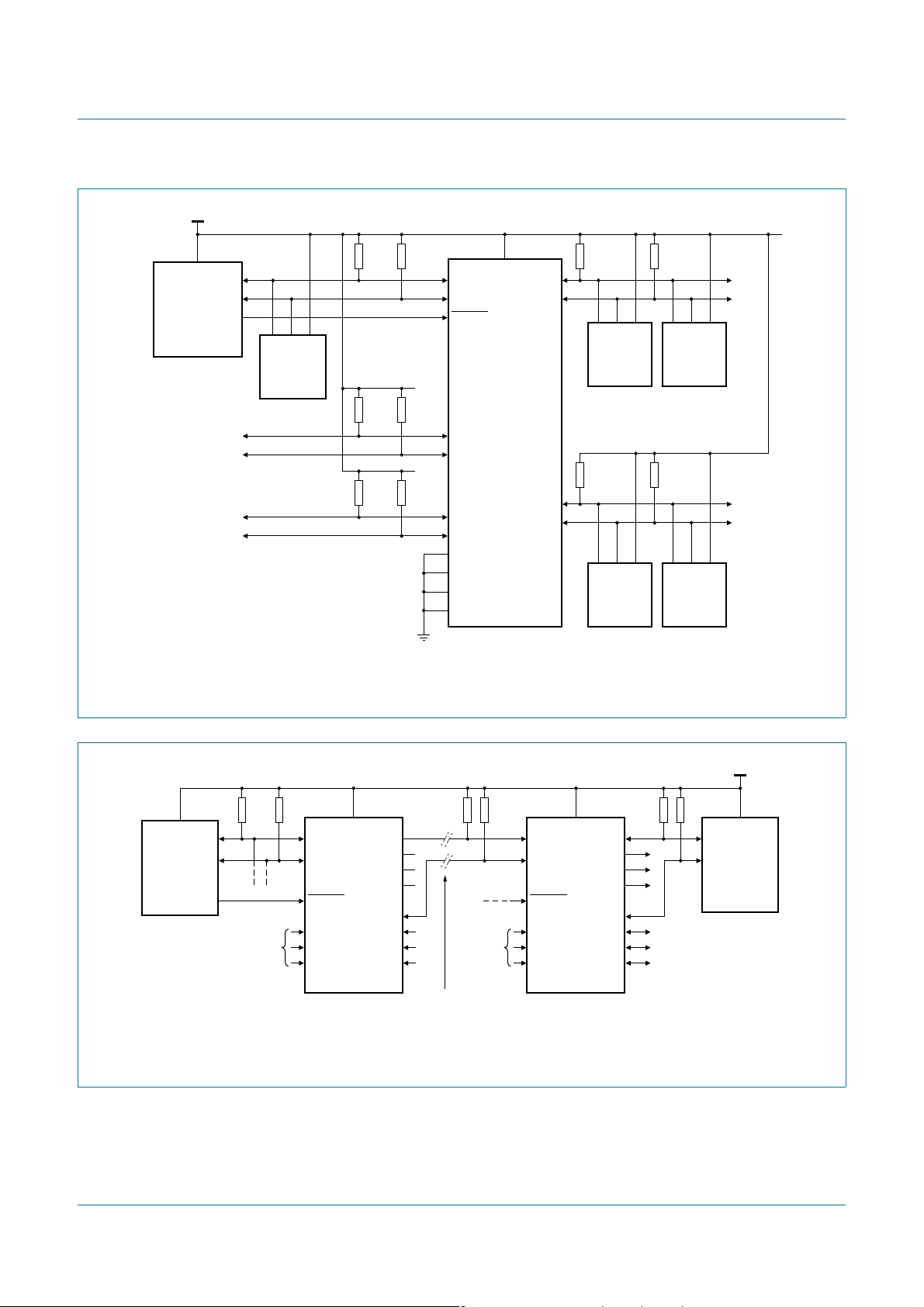

5. Block diagram

Fig 1. Simplified block diagram of PCA9646

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 2 of 22

Page 3

NXP Semiconductors

PCA9646D

A0 V

DD

A1 SDA

RESET SCL

SD0 A2

SC0 SC3

SD1 SD3

SC1 SC2

V

SS

SD2

002aaf364

1

2

3

4

5

6

7

8

10

9

12

11

14

13

16

15

PCA9646PW

002aaf366

1

2

3

4

5

6

7

8

10

9

12

11

14

13

16

15

A0 V

DD

A1 SDA

RESET SCL

SD0 A2

SC0 SC3

SD1 SD3

SC1 SC2

V

SS

SD2

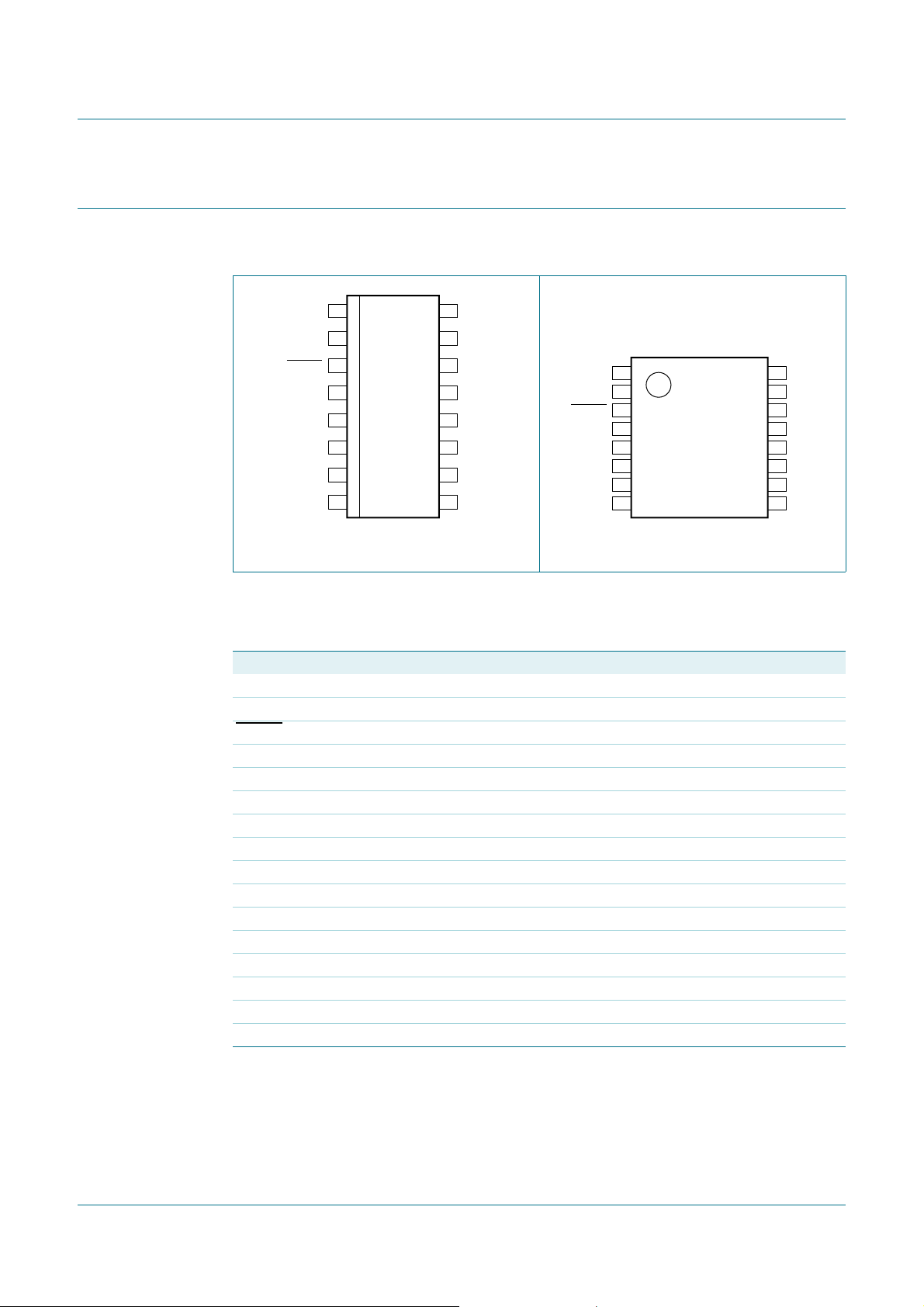

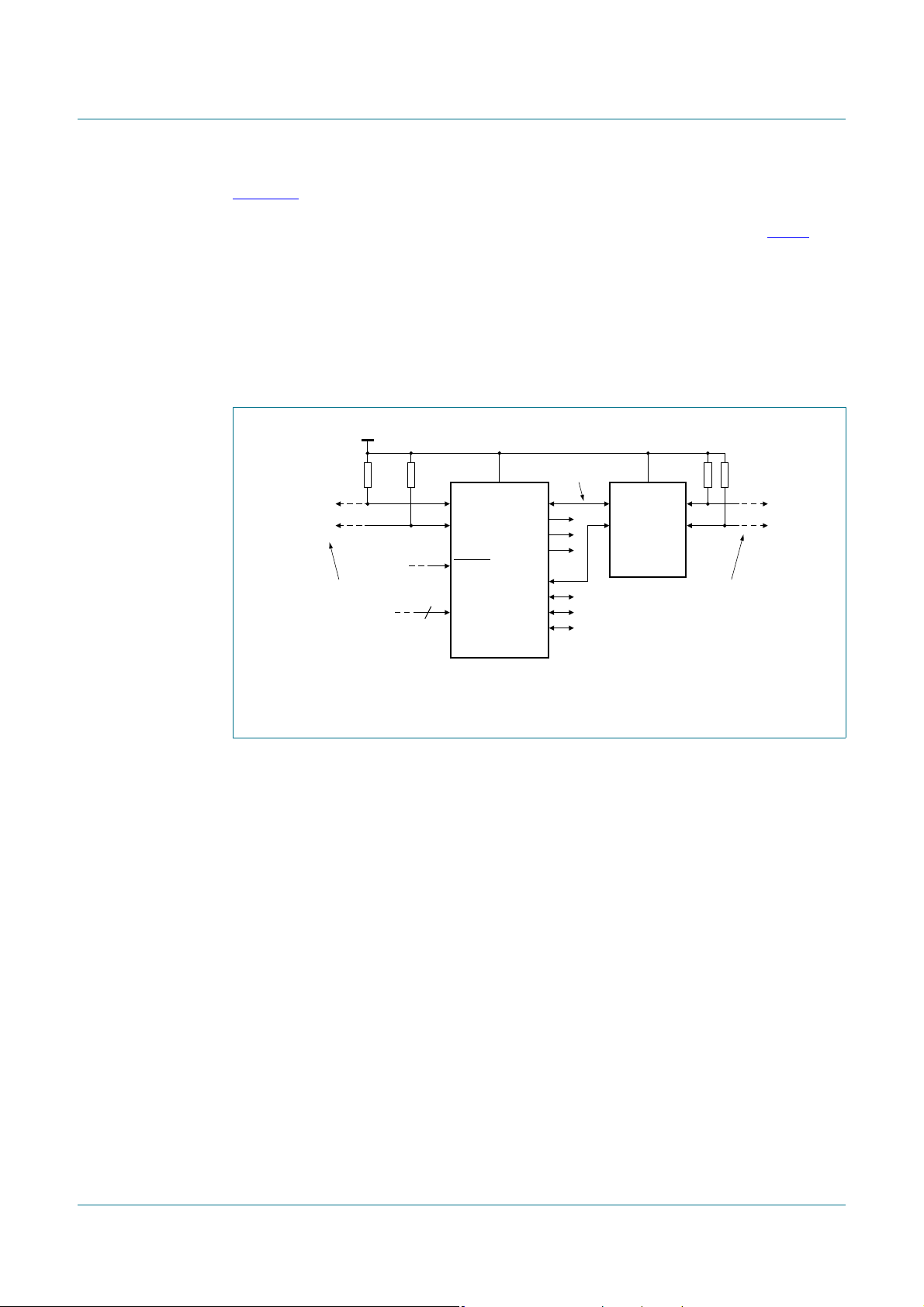

6. Pinning information

6.1 Pinning

PCA9646

Buffered 4-channel 2-wire bus switch

Fig 2. Pin configuration for SO16 Fig 3. Pin configuration for TSSOP16

6.2 Pin description

Table 2. Pin description

Symbol Pin Description

A0 1 address input 0

A1 2 address input 1

RESET

SD0 4 serial data 0

SC0 5 serial clock 0

SD1 6 serial data 1

SC1 7 serial clock 1

V

SS

SD2 9 serial data 2

SC2 10 serial clock 2

SD3 11 serial data 3

SC3 12 serial clock 3

A2 13 address input 2

SCL 14 serial clock line (normally input)

SDA 15 serial data line

V

DD

3 active LOW reset input

8 negative supply (ground)

16 positive supply

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 3 of 22

Page 4

NXP Semiconductors

7. Functional description

Refer to Figure 1 “Simplified block diagram of PCA9646”.

7.1 VDD, VSS — DC supply pins

The power supply voltage for the PCA9646 may be any voltage in the range 2.7 V to

5.5 V. The IC supply must be common with the supply for the bus. Hysteresis on the port s

are a percentage of the IC’s power supply, hence noise margin considerations should be

taken into account when selecting an operating voltage.

7.2 SCL — clock signal input

The clock signal buffer is unidirectional, with this pin acting as the default input. However,

the clock signal direction may be reversed by setting the MSB of the Control register

HIGH. In normal I

signal to the slave. For lowest cost the PCA9646 combines unidirectional buffering of the

clock signal with a bidirectional buffer for the data signal. Clock stretching is therefore not

supported and slave devices that may require clock stretching must be accommodated by

the master adopting an appropriate clocking when communicating with them.

PCA9646

Buffered 4-channel 2-wire bus switch

2

C-bus operations the master device generates a unidirectional clock

The buffer includes hysteresis to ensure clean switching signals are output, especially

with slow rise times on high capacitively loaded buses.

7.3 SC0, SC1, SC2 , SC3 — clock signal outputs

The clock signal from SCL is buffered through four independent buffers, and the signal is

presented at the four SC0 to SC3 ports. Ports are open-drain type and require external

pull-up resistors.

When the MSB of the control register is set HIGH, the port direction is reversed. The

ANDed result of the selected SC0 to SC3 lines is then used to drive the open-dr ain output

of the SCL pin.

7.4 SDA, SD0, SD1, SD2, SD3 — data signal inputs/outputs

The data signal buffers are bidir ectional. The port ( SDA, or any one of SD0 to SD3) which

first falls LOW, will decide the direction of this buf fer and ‘lock out’ signals coming from the

opposite side. As the ‘input’ signal continues to fall, it will then drive the open-drain of the

‘output’ side LOW. Again, hysteresis is applied to the buffer to minimize the effects of

noise. Ports are open-drain type and require external pull-up resistors.

At some points during the communication, the data direction will reverse—for example,

when the slave transmits an acknowledge (ACK) or responds with its register contents.

During these times, the controlling ‘input’ side will have to rise to V

the ‘lock’, which then allows the ‘output’ side to gain control, and pull (what was) the ‘input’

side LOW again. This will cause a ‘pulse’ on the ‘input’ side, which can be quite long

duration in high capacitance buses. However, this pulse will not interfere with the actual

data transmission, as it should not occur during times of clock line transition (during

normal I

still met.

2

C-bus and SMBus protocols), and thus data signal set-up time requ irem ents are

before it releases

unlock

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 4 of 22

Page 5

NXP Semiconductors

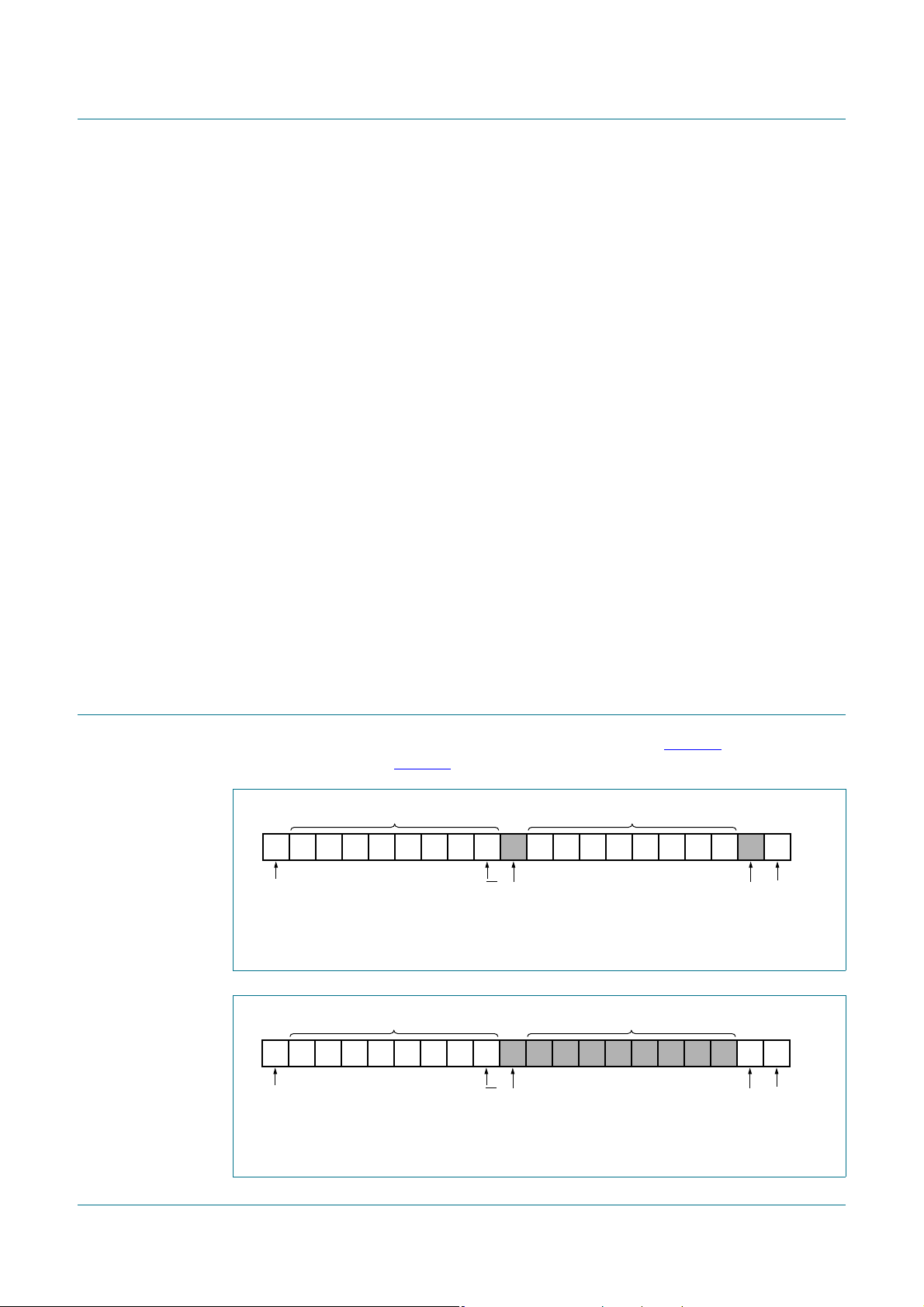

002aaf368

1 1 1 0 A2 A1 A0 R/W

fixed externally

selectable

read = 1

write = 0

002aaf369

B7 X X X B3 B2 B1 B0

output channel

enable bits

MSB LSB

SCL direction

0: SCL → SC0 to SC3

1: SC0 to SC3 → SCL

SC0/SD0 enable

SC1/SD1 enable

SC2/SD2 enable

SC3/SD3 enable

7.5 RESET — reset IC to default state

The active LOW RESET input is used to disable the buffer, and reset it to its default state.

The IC should only be disabled when the bus is idle to avoid truncation of commands

which may confuse other devices on the bus.

PCA9646

Buffered 4-channel 2-wire bus switch

The RESET

disabling all output lines SC[0:3] and SD[0:3]. It is the nature of the I

signal will clear the contents of the Control register, which has the effect of

2

C-bus protocol that

devices may become ‘stuck’. T o help in the clearin g of this condition, the PCA9646 can be

reset, and each port brought on-line successively to find the component holding the bus

LOW.

7.6 Power-On Reset (POR)

During power-on, the PCA9646 is internally held in the reset condition for a maximum of

t

= 500 ns. The default condition after reset is for the Control register to be erased

rst

(all zeros), resulting in all output channels being disabled.

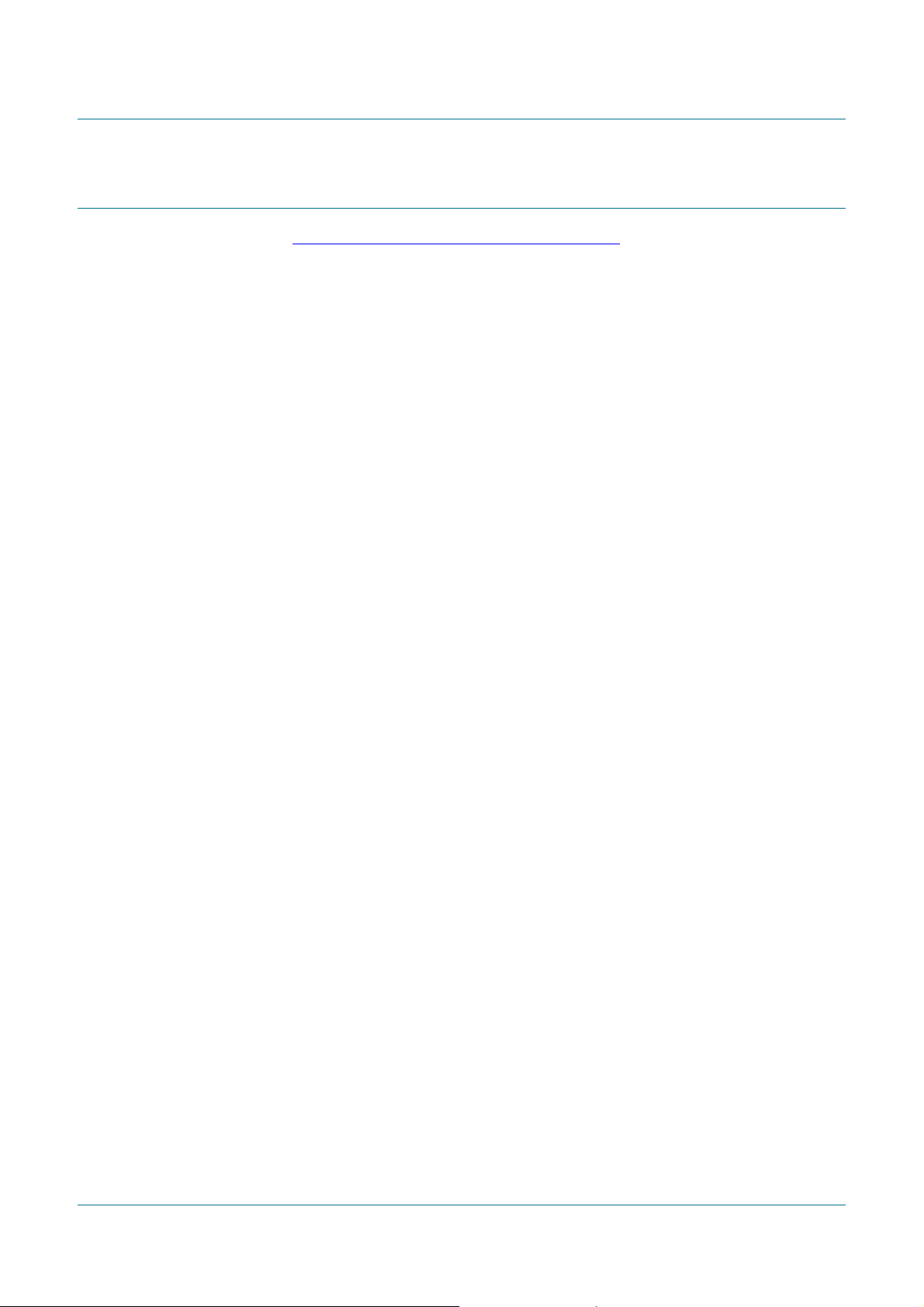

7.7 A0, A1, A2 — address lines

The slave address of the PCA9646 is shown in Figure 4. The address pins (A2, A1, A0)

must be driven to a HIGH or LOW level—they are not internally pulled to a default state.

Fig 4. Slave address

The read/write bit must be set LOW to enable a write to the Control register, or HIGH to

read from the Control register.

7.8 Control register

The Control register of the PCA9646 is shown in Figure 5. Each of the four output

channels (SCn/SDn pairs) can be enabled independently, and the direction of the clock

signal can be reversed.

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 5 of 22

Fig 5. Control register

Page 6

NXP Semiconductors

002aaf370

S 1 1 1 0 A2 A1 A0

slave address

0 A B7 X X X B3 B2 B1 B0 A P

Control register

START

condition

R/W acknowledge

from slave

acknowledge

from slave

STOP

condition

002aaf371

S 1 1 1 0 A2 A1 A0

slave address

1 A B7 0 0 0 B3 B2 B1 B0 NA P

Control register

START

condition

R/W acknowledge

from slave

not acknowledge

from master

STOP

condition

A LOW or ‘zero’ bit (B[3:0]) indicates that the respective channel (SC[3:0], SD[3:0]) is

disabled. The default reset condition of the register is all zeros, all channels disabled,

forward direction. A HIGH or ‘one’ bit indicates the respective channel is enabled.

Example: B3 = 1, B2 = 0, B1 = 1, B0 = 0 means channel 3 (SC3/SD3) and channel 1

(SC1/SD1) are enabled, and channel 2 (SC2/SD2) and channel 0 (SC0/SD0) are

disabled.

As each channel is individually buffered, the loads on each are isolated, and therefore

there is no special requirement to keep the sum of the collective capacitances below the

maximum bus capacitance. Instead, each line may have up to the maximum bus

capacitance and be enabled or disabled without affecting the performance of the other

channels.

The Most Significant Bit (MSB) B7 is used to set the direction of the SCL (clock) signal.

The default state is LOW (zero). In this state, the SCL port will act as the input, and the IC

will supply a buffered signal to any of the four output channels (SC0 to SC3) which are

enabled. When B7 is set HIGH (one), the clock signal direction is reversed. The ports

SC0 to SC3 act as inputs, the ANDed combination of the selected signals is buffered and

output on the SCL pin.

PCA9646

Buffered 4-channel 2-wire bus switch

The PCA9646 is always addressable from the SCL/SDA side, regardless of the state of

B7. Any device which can communicate data to the SCL/SDA pins, either by being directly

attached to those pins or by transmitting through the PCA9646 (when B7 = 1), may

address the device and change the control register’s contents. The Control register is only

updated upon receipt of the STOP condition.

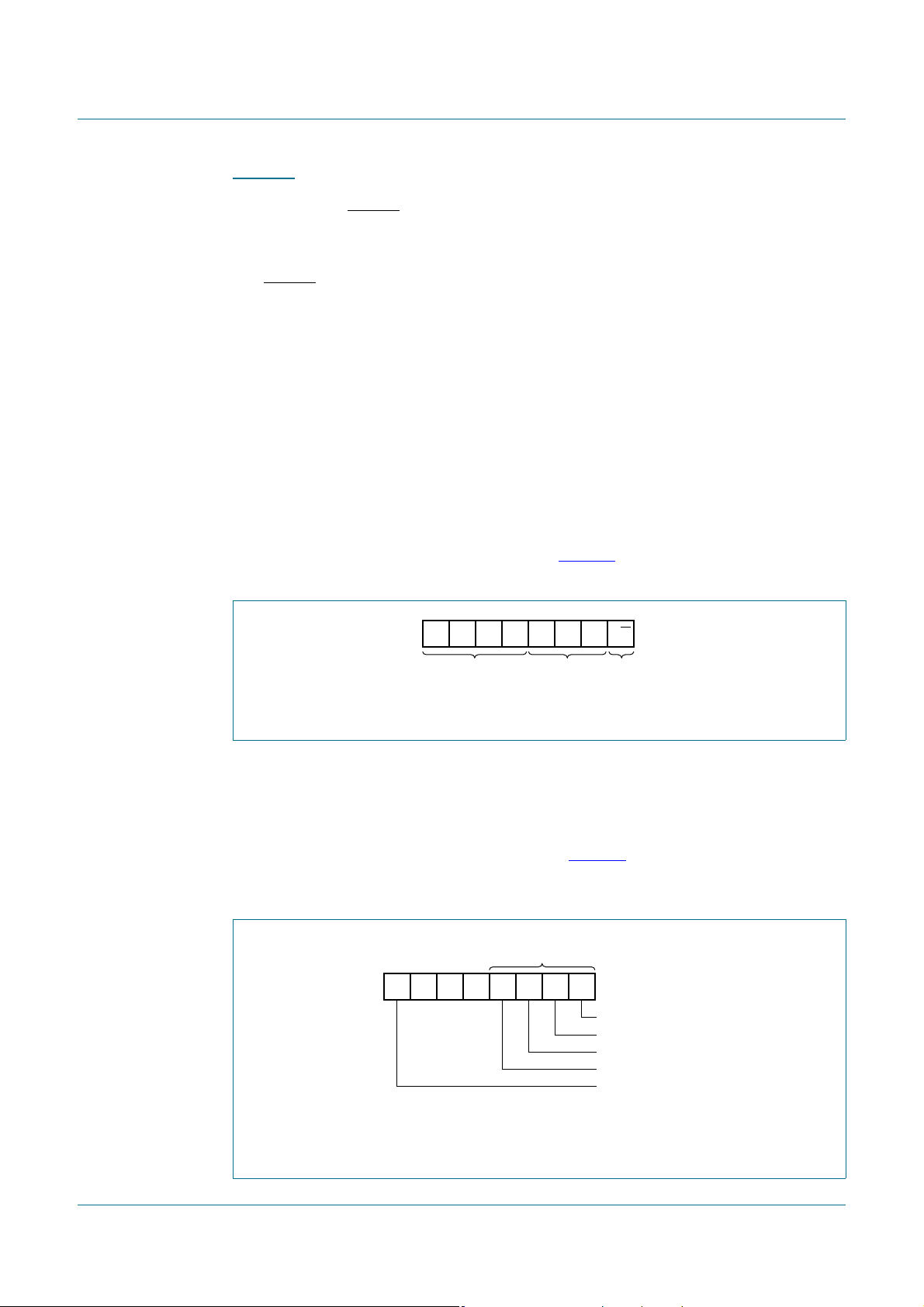

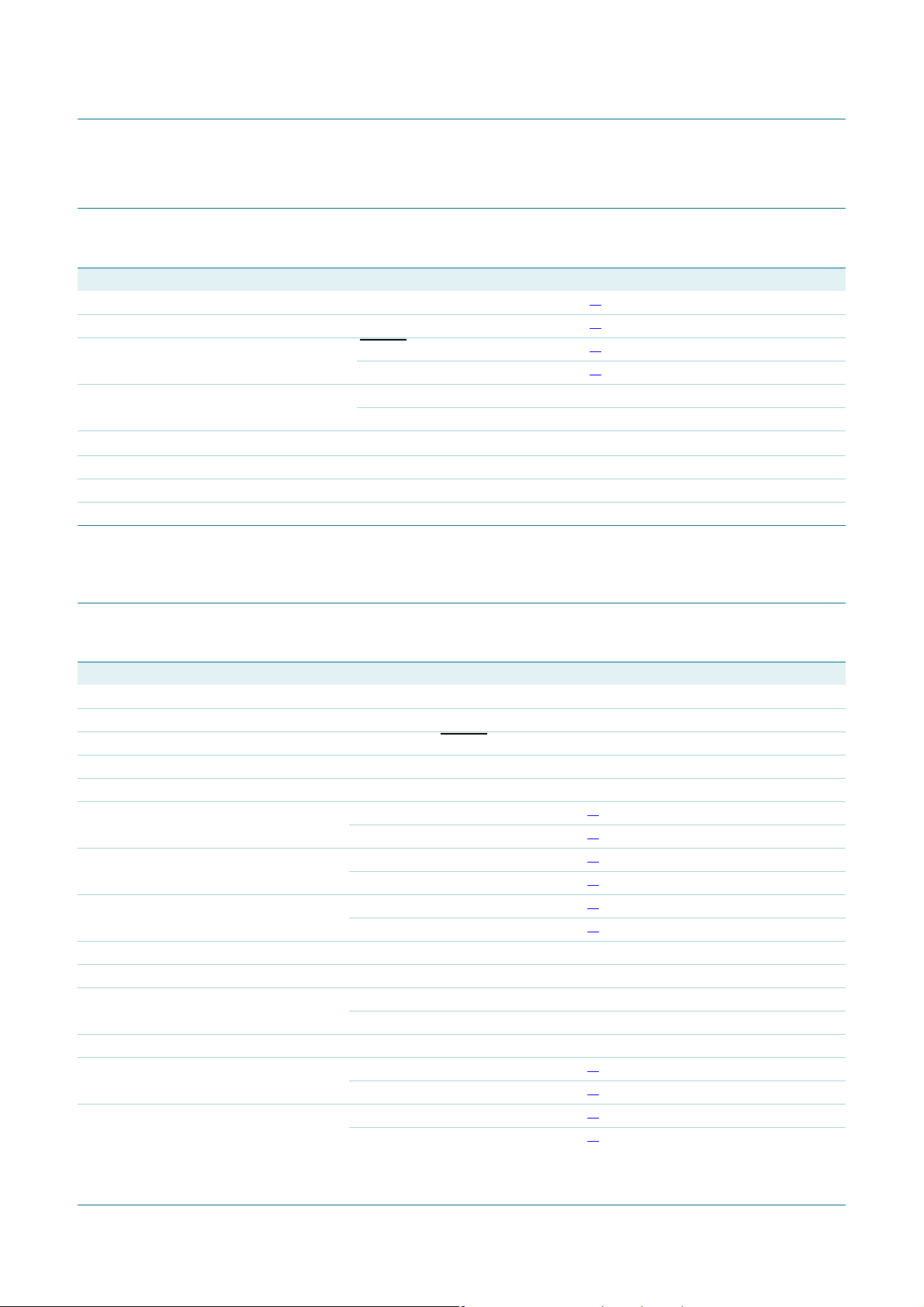

8. Bus transaction

A typical I2C-bus write transaction to the PCA9646 is shown in Figure 6. A typical read

transaction is shown in Figure 7

Fig 6. PCA9646 write transaction to Control register

.

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 6 of 22

Fig 7. PCA9646 read transaction from Control register

Page 7

NXP Semiconductors

9. Limiting values

PCA9646

Buffered 4-channel 2-wire bus switch

Table 3. Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

DD

V

I/O

V

I

supply voltage

voltage on an input/output pin pins SDx, SCx

input voltage RESET pin

address pins A2, A1, A0

I

I

input current pins other than SCx/SDx - 20 mA

[1]

0.3 +7 V

[1]

VSS 0.5 +7 V

[1]

VSS 0.5 VDD+0.5 V

[1]

VSS 0.5 VDD+0.5 V

all SCx and SDx - 40 mA

I

SS

P

tot

T

stg

T

amb

[1] Voltages are specified with respect to pin 8 (VSS).

ground supply current - 280 mA

total power dissipation - 300 mW

storage temperature 55 +125 C

ambient temperature operating 40 +85 C

10. Characteristics

Table 4. Characteristics

=40C to +85C; voltages are specified with respect to ground (VSS); VDD= 5.5 V unl ess oth erwise specified.

T

amb

Symbol Parameter Conditions Min Typ Max Unit

Power supply

V

DD

I

DD

2

C-bus ports (SCL, SDA, SC[3:0], SD[3:0])

I

V

I2C-bus

V

IL

V

IH

V

I(hys)

I

LI

I

O(sink)

V

OL

supply voltage operating 2.7 - 5.5 V

supply current quiescent; VI(RESET pin)=0V--1 A

I2C-bus voltage SDx, SCx - - 5.5 V

LOW-level input voltage VDD=2.7V

HIGH-level input voltage VDD=2.7V

hysteresis of input voltage VDD=2.7V

input leakage current pin at VDDor V

output sink current LOW-level; V

LOW-level output voltage IOL=30mA; VDD= 2.7 V - 260 450 mV

Pins SDA, SD0, SD1, SD2, SD3

V

V

lock

unlock

direction lock voltage VDD=2.7V

direction unlock voltage VDD=2.7V

[1]

--0.4V

=5.5V

V

DD

=5.5V

V

DD

=5.5V

V

DD

SS

input < V

Sxx

=30mA; VDD= 5.5 V - 140 275 mV

I

OL

=5.5V

V

DD

=5.5V

V

DD

IL

[1]

--0.5V

[1]

1.2 - - V

[1]

2.0 - - V

[1]

80 - - mV

[1]

200 - - mV

1- +1 A

30 - - mA

[1]

--1.3V

[1]

--3.0V

[1]

2.0 - - V

[1]

4.8 - - V

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 7 of 22

Page 8

NXP Semiconductors

002aaf438

t

f

t

d

V

I2C-bus

time

70 % V

DD

30 % V

DD

SDx, SCx input

SDx, SCx output

V

IL

PCA9646

Buffered 4-channel 2-wire bus switch

Table 4. Characteristics

T

=40C to +85C; voltages are specified with respect to ground (VSS); VDD= 5.5 V unl ess oth erwise specified.

amb

…continued

Symbol Parameter Conditions Min Typ Max Unit

RESET

V

IH

V

IL

V

hys

I

LI

t

w(rst)L

t

rst

t

POR

HIGH-level input voltage VDD= 2.7 V 2.0 - - V

= 5.5 V 4.8 - - V

V

DD

LOW-level input voltage VDD= 2.7 V - - 650 mV

= 5.5 V - - 900 mV

V

DD

hysteresis voltage VDD=2.7V 100 - - mV

=5.5V 200 - - mV

V

DD

input leakage current pin at VDDor V

LOW-level reset time VI<V

IL

SS

reset time RESET pin; from VI > V

power-on reset pulse time RESET pin; from VI > V

IH

IH

1- +1 A

[2]

-25- ns

- 250 500 ns

- 250 500 ns

Address pins (A0, A1, A2)

V

IH

V

IL

I

LI

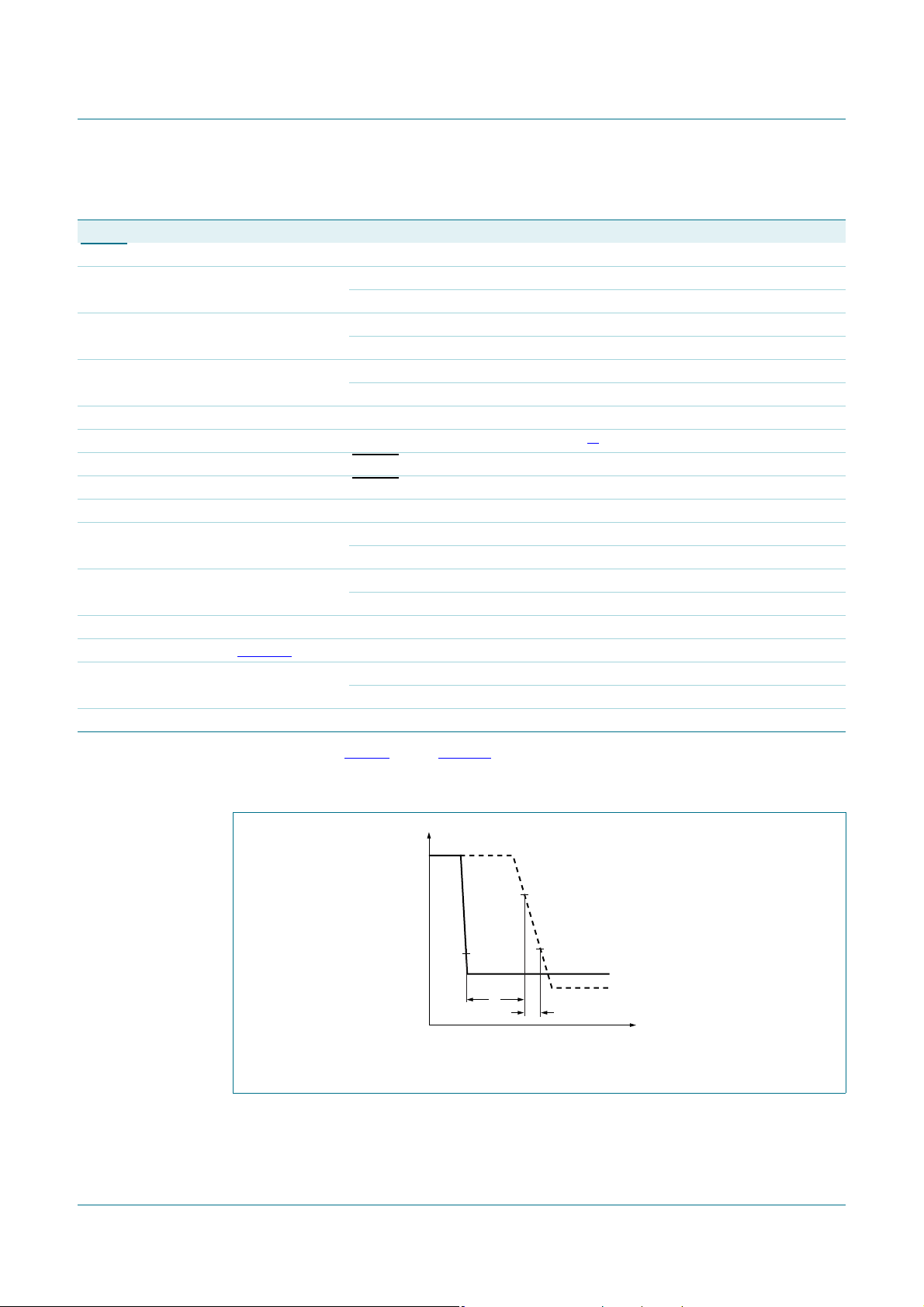

Timing characteristics (Figure 8

t

d

t

f

HIGH-level input voltage VDD= 2.7 V 1.7 - - V

= 5.5 V 3.5 - - V

V

DD

LOW-level input voltage VDD=2.7V --0.7V

=5.5V --1.5V

V

DD

input leakage current pin at VDDor V

SS

1- +1 A

)

delay time RPU = 200 ; VDD= 2.7 V - 100 - ns

= 200 ; VDD=5.5V - 70 - ns

R

PU

fall time RPU = 200 -16- ns

[1] Supply voltage dependent; refer to graphs (Figure 9 through Figure 12) for typical trend.

[2] Guaranteed by design, not subject to test.

Fig 8. Timing diagram

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 8 of 22

Page 9

NXP Semiconductors

2

3

1

4

5

V

I

(V)

0

V

DD

(V)

26534

002aaf333

V

lock

V

IH

V

IL

400

600

200

800

1000

V

I(hys)

(V)

0

V

DD

(V)

26534

002aaf334

T

amb

= +85 °C

+25 °C

−40 °C

100

150

50

200

250

V

OL

(mV)

0

R

PU

(Ω)

0 1000800400 600200

002aaf372

VDD = 5.5 V

2.7 V

100

300

400

V

OL

(mV)

0

T

amb

(C)

−50 150100050

002aaf373

200

VDD = 2.7 V

5.5 V

PCA9646

Buffered 4-channel 2-wire bus switch

T

=25C

amb

Fig 9. Typical input levels versus supply voltage Fig 10. Typical VIH VIL hysteresis versus supply

voltage

Fig 11. Typical LOW-level output voltage versus

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 9 of 22

T

=25CI

amb

=30mA

OL

Fig 12. Typical LOW-level output voltage versus

pull-up resistance

ambient temperature

Page 10

NXP Semiconductors

002aaf374

S

START

sequence

SCL

(clock)

SDA

(data)

A0

(master)A1(master)A2(master)

master side of PCA9646

slave side of PCA9646

purpose of bit (address bit 5)

device asserting data line (master/slave)

A3

(master)

A4

(master)A5(master)

A6

(master)

SDA direction

'hand over' pulses upon change

of device asserting the data line

W

(master)

ACK

(slave)

P

STOP

sequence

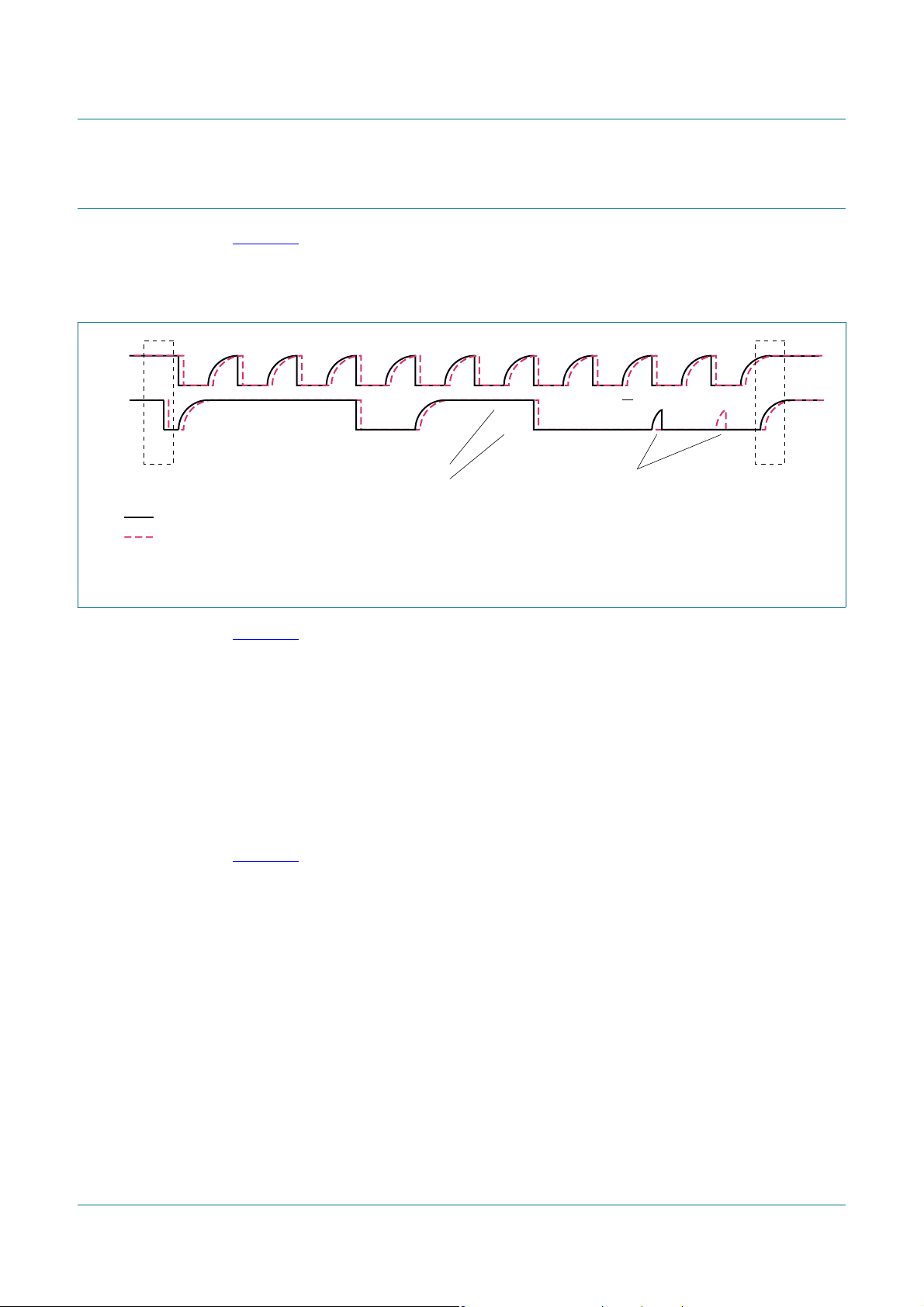

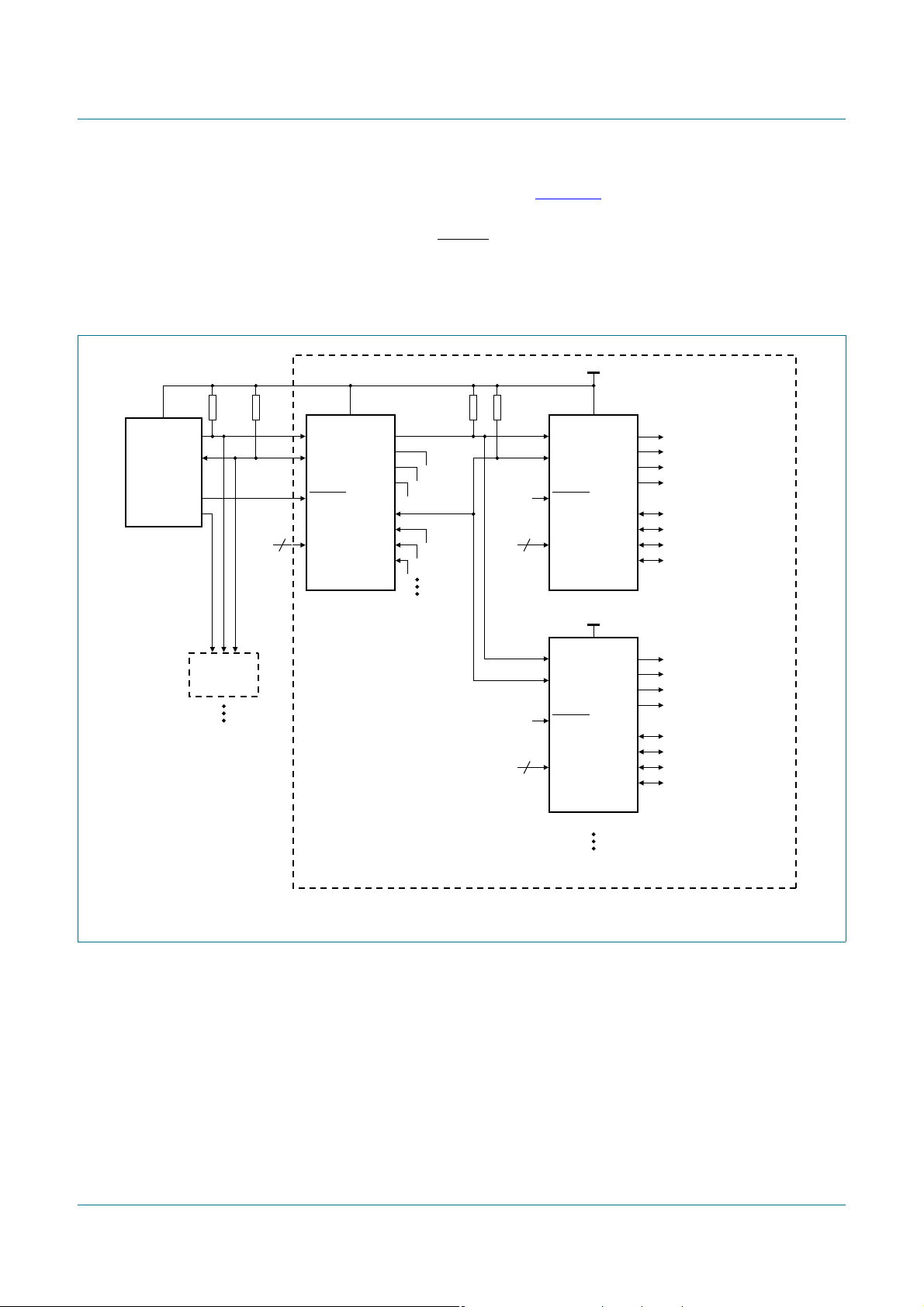

11. Application information

Figure 13 shows a typical data transfer through the PCA9646. The PCA9646 has

excellent application to extending loads and expanding the address space of slave

devices. Rise times are determined simply by the side of the buffer with the slowest RC

time constant.

PCA9646

Buffered 4-channel 2-wire bus switch

Remark: Input to output delay exaggerated for clarity.

Fig 13. Typical communication sequence through the PCA9646

Figure 14 shows a typical application for the PCA9646. Each channel can support up to

the maximum permissible capacitance load, thus the maximum loading of the system can

be 5 times that which could be achieved without buffering.

The channel enable function can be used to interface buses of different operating

frequencies. When certain bus sections are enabled, the system frequency may be limited

by a bus section having a slave device specified only to 100 kHz. When that bus section is

disabled, the slow slave is isolated and the remaining bus can be run at 400 kHz. The

timing performance and current sinking capability will allow the PCA9646 to run in excess

2

of the 1 MHz maximum limit of the I

C-bus Fast-mode Plus (Fm+), or to run a huge 4 nF

load at 100 kHz.

Figure 15

shows the PCA9646 used as a line driver . Fou r such lines (only one shown) can

be run from the same device. The receiving end may then again be used as a 4-way bus

switch, radiating out into another four lines.

Using the address pins, this entire structure may be repeated. Thus a total of eight

PCA9646 ‘line drivers’ may be connected to a single bus master (U1), allowing for

32 (8 4) long distance bus pairs to be driven from the one I

2

C-bus port.

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 10 of 22

Page 11

NXP Semiconductors

002aaf375

BUS MASTER

U3

V

DD

SCL

SDA

R8

1.1 kΩ

SC0

SD0

SCL

SDA

PCA9646

V

DD

SC0

SD0

U1

RESET

3.3 V

SCL

SDA

V

DD

MASTER/

SLAVE

U4

SCL

SDA

V

DD

SLAVE

U5

SCL

SDA

V

DD

SLAVE

U6

R7

1.1 kΩ

R1

1.1 kΩ

R2

1.1 kΩ

SC2

SD2

SC2

SD2

R3

1.1 kΩR41.1 kΩ

SC3

SD3

SC3

SD3

R5

1.1 kΩR61.1 kΩ

400 pF load at 1 MHz

or 4 nF load at 100 kHz

400 pF load at 1 MHz

or 4 nF load at 100 kHz

400 pF load at 1 MHz

or 4 nF load at 100 kHz

A0

A1

A2

V

SS

R10

1.1 kΩ

SC1

SD1

SC1

SD1

SCL

SDA

V

DD

SLAVE

U7

SCL

SDA

V

DD

SLAVE

U8

R9

1.1 kΩ

400 pF load at 1 MHz

or 4 nF load at 100 kHz

400 pF load at 1 MHz

or 4 nF load at 100 kHz

002aaf376

BUS

MASTER

U1

V

DD

SCL

SDA

R4

180 Ω

SCL

SDA

PCA9646

V

DD

SC0

SC1

U2

RESET

5 V

R3

180 Ω

R1 R2

A0

A1

e.g., PC/TV

receiver or

decoder box

SD0

SD1

etc.

SC2

SC3

A2

SD2

SD3

SCL

SDA

PCA9646

V

DD

SC0

SC1

U3

RESET

A0

A1

SD0

SD1

SC2

SC3

A2

SD2

SD3

address address

backplane or

long cable run

with 30 mA

pull-up current

SLAVE

U4

V

DD

SCL

SDA

R6R5

e.g., monitor,

flat TV, LED array

PCA9646

Buffered 4-channel 2-wire bus switch

Fig 14. PCA9646 typical buffer application

Fig 15. PCA9646 as a 30 mA line driver

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 11 of 22

Page 12

NXP Semiconductors

002aaf377

SCL

SDA

SCL

SDA

PCA9646

V

DD

SC0

SC1

U1

RESET

5 V

R1

1.8 kΩR21.8 kΩ

A[2:0]

SD0

SD1

SC2

SC3

SD2

SD3

P82B715

U2

V

CC

SX

SY

R4R3

3

LX

LY

long cable runisolated I2C-bus

no pull-up

required

PCA9646

Buffered 4-channel 2-wire bus switch

Figure 16 shows how PCA9646 can be used to combine or extend existing long cable

systems using P82B715 I

capacitance limit. P82B715 alone provides a ‘10 impedance transformation’ (Ref. 2

2

C-bus extenders when they have reached their maximum

) but

no isolation of the loadings on either side. P82B715 systems have a finite capacitance

limit and its system calculations can be relatively complex. The buffering action of

PCA9646 simplifies calculations and allows the isolated bus rise time to meet the

Fast-mode requirement even when that is not possible on the long cable section.

Of course it is possible to create a much larger system by connecting existing long

P82B715 cable systems to each of the four channels and driving all of them from one

isolated Master.

PCA9646 provides bus isolation and simplifies calculation of bus RC components.

Fig 16. PCA9646 isolating the standard I2C-bus from a P82B715 used as a line driver

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 12 of 22

Page 13

NXP Semiconductors

002aaf378

SCL

SCL

SDA

PCA9646

V

DD

SC0

SC1

U2

RESET

5 V

R1

180 ΩR2180 Ω

A[2:0]

SD0

SD1

SC2

SC3

SD2

SD3

3

BUS

MASTER

U1

V

DD

SCL

SDA

000b

up to seven PCA9646s

on each output pair

(address: 001b to 111b)

structure in

dashed box

repeated

etc.

R4

180 Ω

R3

180 Ω

SCL

SDA

PCA9646

V

DD

SC0

SC1

U3

RESET

SD0

SD1

SC2

SC3

SD2

SD3

A[2:0]

3

001b

total output of

4 × 7 × 4 = 112

individually enabled

fully isolated buses,

each with full

capacitance load

(e.g., 400 pF at 1 MHz)

5 V

SCL

SDA

PCA9646

V

DD

SC0

SC1

U4

RESET

SD0

SD1

SC2

SC3

SD2

SD3

A[2:0]

3

010b

connect, for example,

8 LED driver ICs,

each with 8 LED

outputs = 7168 LEDs

up to seven devices

(address: 001b to 111b)

The PCA9646 may also be driven in series. Figure 17 shows this configuration. In this

scenario, each of the four outputs of the first device (U2) has six more PCA9646’s

connected to it. Each of those six devices has four outputs, thus giving

4 7 4 = 112 outputs. If the RESET

be possible to reproduce this entire structure multiple times, giving a truly massive

address space capability. Such a configuration may be applied to situations such as

display drivers.

PCA9646

Buffered 4-channel 2-wire bus switch

pin on U2 was also driven from the master, it would

Fig 17. PCA9646 series implementation for large I/O fan-out

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 13 of 22

Page 14

NXP Semiconductors

X

w M

θ

A

A

1

A

2

b

p

D

H

E

L

p

Q

detail X

E

Z

e

c

L

v M

A

(A )

3

A

8

9

1

16

y

pin 1 index

UNIT

A

max.

A

1

A2A3b

p

cD

(1)E(1) (1)

eHELLpQZywv θ

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC JEITA

mm

inches

1.75

0.25

0.10

1.45

1.25

0.25

0.49

0.36

0.25

0.19

10.0

9.8

4.0

3.8

1.27

6.2

5.8

0.7

0.6

0.7

0.3

8

0

o

o

0.25 0.1

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

Note

1. Plastic or metal protrusions of 0.15 mm (0.006 inch) maximum per side are not included.

1.0

0.4

SOT109-1

99-12-27

03-02-19

076E07 MS-012

0.069

0.010

0.004

0.057

0.049

0.01

0.019

0.014

0.0100

0.0075

0.39

0.38

0.16

0.15

0.05

1.05

0.041

0.244

0.228

0.028

0.020

0.028

0.012

0.01

0.25

0.01 0.004

0.039

0.016

0 2.5 5 mm

scale

SO16: plastic small outline package; 16 leads; body width 3.9 mm

SOT109-1

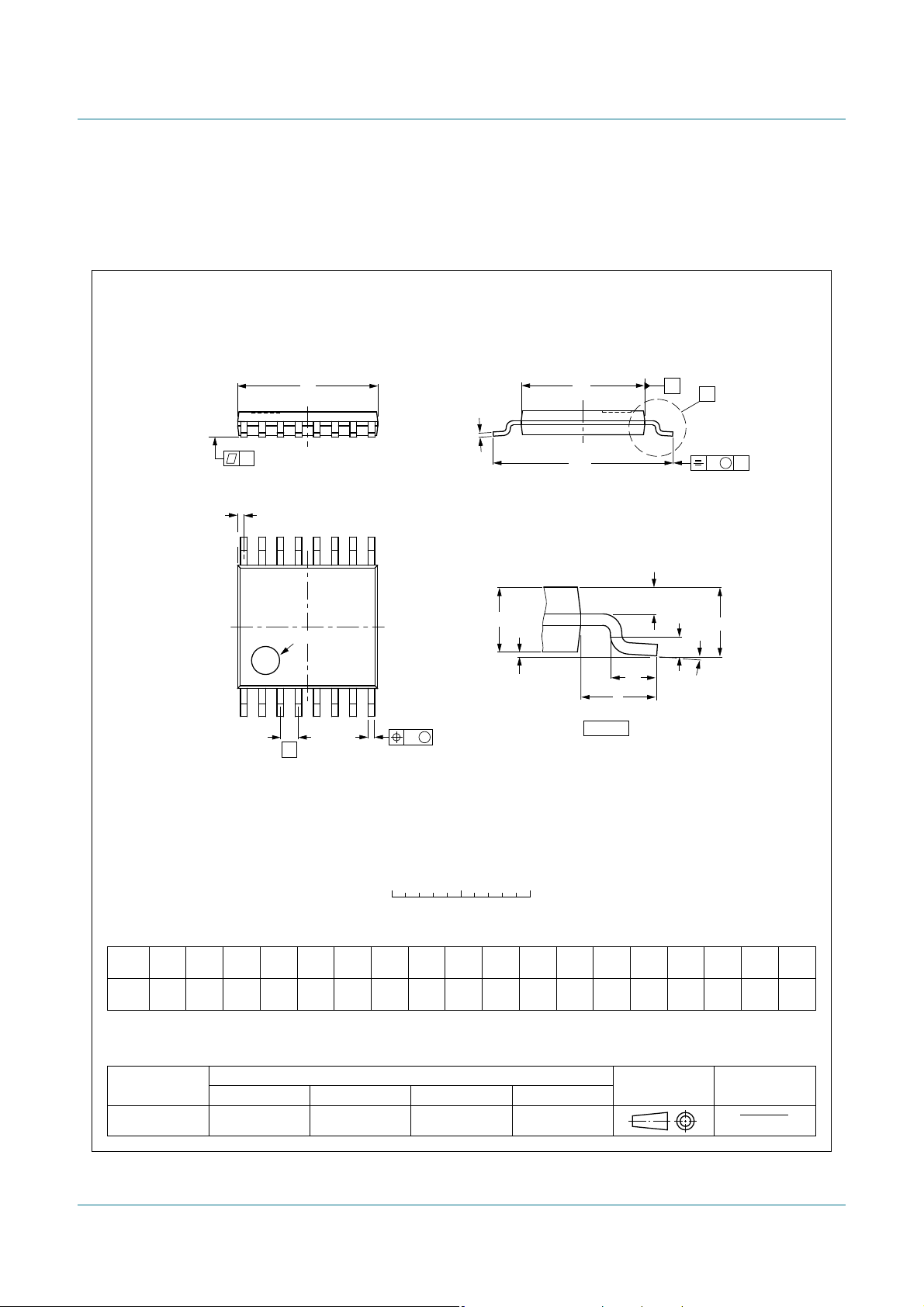

12. Package outline

PCA9646

Buffered 4-channel 2-wire bus switch

Fig 18. Package outline SOT109-1 (SO16)

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 14 of 22

Page 15

NXP Semiconductors

UNIT A1A2A3b

p

cD

(1)E(2) (1)

eHELLpQZywv θ

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC JEITA

mm

0.15

0.05

0.95

0.80

0.30

0.19

0.2

0.1

5.1

4.9

4.5

4.3

0.65

6.6

6.2

0.4

0.3

0.40

0.06

8

0

o

o

0.13 0.10.21

DIMENSIONS (mm are the original dimensions)

Notes

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

2. Plastic interlead protrusions of 0.25 mm maximum per side are not included.

0.75

0.50

SOT403-1 MO-153

99-12-27

03-02-18

w M

b

p

D

Z

e

0.25

18

16

9

θ

A

A

1

A

2

L

p

Q

detail X

L

(A )

3

H

E

E

c

v M

A

X

A

y

0 2.5 5 mm

scale

TSSOP16: plastic thin shrink small outline package; 16 leads; body width 4.4 mm

SOT403-1

A

max.

1.1

pin 1 index

PCA9646

Buffered 4-channel 2-wire bus switch

Fig 19. Package outline SOT403-1 (TSSOP16)

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 15 of 22

Page 16

NXP Semiconductors

13. Handling information

CAUTION

This device is sensitive to ElectroStatic Discharge (ESD). Observe precautions for handling

electrostatic sensitive devices.

Such precautions are described in the ANSI/ESD S20.20, IEC/ST 61340-5, JESD625-A or

equivalent standards.

14. Soldering of SMD packages

This text provides a very brief insight into a complex technology . A more in-depth account

of soldering ICs can be found in Application Note AN10365 “Surface mount reflow

soldering description”.

14.1 Introduction to soldering

Soldering is one of the most common methods through which packages are attached to

Printed Circuit Boards (PCBs), to form electrical circuits. The soldered joint provides both

the mechanical and the electrical connection. There is no single soldering method that is

ideal for all IC packages. Wave soldering is often preferred when through-hole and

Surface Mount Devices (SMDs) are mixed on one printed wiring board; however, it is not

suitable for fine pitch SMDs. Reflow soldering is ideal for the small pitches and high

densities that come with increased miniaturization.

PCA9646

Buffered 4-channel 2-wire bus switch

14.2 Wave and reflow soldering

Wave soldering is a joining technology in which the joints are made by solder coming from

a standing wave of liquid solder. The wave soldering process is suitable for the following:

• Through-hole components

• Leaded or leadless SMDs, which are glued to the surface of the printed circuit board

Not all SMDs can be wave soldered. Packages with solder balls, and some leadless

packages which have solder lands underneath the body, cannot be wave soldered. Also,

leaded SMDs with leads having a pitch smaller than ~0.6 mm cannot be wave soldered,

due to an increased probability of bridging.

The reflow soldering process involves applying solder paste to a board, followed by

component placement and exposure to a temperature profile. Leaded packages,

packages with solder balls, and leadless packages are all reflow solderable.

Key characteristics in both wave and reflow soldering are:

• Board specifications, including the board finish, solder masks and vias

• Package footprints, including solder thieves and orientation

• The moisture sensitivity level of the packages

• Package placement

• Inspection and repair

• Lead-free soldering versus SnPb soldering

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 16 of 22

Page 17

NXP Semiconductors

14.3 Wave soldering

Key characteristics in wave soldering are:

• Process issues, such as application of adhesive and flux, clinching of leads, board

• Solder bath specifications, including temperature and impurities

14.4 Reflow soldering

Key characteristics in reflow soldering are:

• L ead-free versus SnPb sold ering; note that a lead-fr ee reflow process usually leads to

• Solder paste printing issues including smearing, release, and adjusting the process

• Reflow temperature profile; this profile includes preheat, reflow (in which the board is

Table 5. SnPb eutectic process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (C)

< 2.5 235 220

2.5 220 220

PCA9646

Buffered 4-channel 2-wire bus switch

transport, the solder wave parameters, and the time during which components are

exposed to the wave

higher minimum peak temperatures (see Figure 20

reducing the process window

window for a mix of large and small components on one board

heated to the peak temperature) and cooling down. It is imperative that the peak

temperature is high enough for the solder to make reliable solder joint s (a solder paste

characteristic). In addition, the peak temperature must be low enough that the

packages and/or boards are not damaged. The peak temperature of the package

depends on package thickness and volume and is classified in accordance with

Table 5

and 6

Volume (mm3)

< 350 350

) than a SnPb process, thus

Table 6. Lead-free process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (C)

Volume (mm3)

< 350 350 to 2000 > 2000

< 1.6 260 260 260

1.6 to 2.5 260 250 245

> 2.5 250 245 245

Moisture sensitivity precautions, as indicated on the packing, must be respected at all

times.

Studies have shown that small packages reach higher temperatures during reflow

soldering, see Figure 20

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 17 of 22

.

Page 18

NXP Semiconductors

001aac844

temperature

time

minimum peak temperature

= minimum soldering temperature

maximum peak temperature

= MSL limit, damage level

peak

temperature

Fig 20. Temperature profiles for large and small components

PCA9646

Buffered 4-channel 2-wire bus switch

MSL: Moisture Sensitivity Level

For further information on temperature profiles, refer to Application Note AN10365

“Surface mount reflow soldering description”.

15. Abbreviations

Table 7. Abbreviations

Acronym Description

CMOS Complementary Metal-Oxide Semiconductor

2

C-bus Inter-Integrated Circuit bus

I

I/O Input/Output

IC Integrated Circuit

LED Light-Emitting Diode

MSB Most Significant Bit

PMBus Power Management Bus

RAID Redundant Array of Independent Discs

RC Resistor-Capacitor network

SMBus System Management Bus

16. References

[1] UM10204, “I2C-bus specification and user manual” — NXP Semiconductors;

[2] P82B715, I2C-bus extender — NXP Semiconducto rs; Product data sheet;

www.nxp.com/documents/user_manual/UM10204.pdf

www.nxp.com/documents/data_sheet/P82B715.pdf

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 18 of 22

Page 19

NXP Semiconductors

PCA9646

Buffered 4-channel 2-wire bus switch

17. Revision history

Table 8. Revision history

Document ID Release date Data sheet status Change notice Supersedes

PCA9646 v.1 20110301 Product data sheet - -

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 19 of 22

Page 20

NXP Semiconductors

PCA9646

Buffered 4-channel 2-wire bus switch

18. Legal information

18.1 Data sheet status

Document status

Objective [short] data sheet Development This document contains data from the objective specification for product development.

Preliminary [short] data sheet Qualification This document contains data from the preliminary specification.

Product [short] data sheet Production This document contains the product specification.

[1] Please consult the most recently issued document before initiating or completing a design.

[2] The term ‘short data sheet’ is explained in section “Definitions”.

[3] The product status of device(s) d escribed i n this docu ment may have changed si nce this d ocument was p ublished and may dif fer in case of multiple devices. The latest product statu s

information is available on the Internet at URL http://www.nxp.com.

[1][2]

Product status

[3]

Definition

18.2 Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. NXP Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information included herein and shall have no liability for the consequences of

use of such information.

Short data sheet — A short data sheet is an extract from a full data sheet

with the same product type number(s) and title. A short data sheet is intended

for quick reference only and should not be relied upon to co nt ain det ailed and

full information. For detailed and full information see the relevant full data

sheet, which is available on request via the local NXP Semiconductors sales

office. In case of any inconsistency or conflict with the short data sheet, the

full data sheet shall prevail.

Product specification — The information and data provided in a Product

data sheet shall define the specification of the product as agreed between

NXP Semiconductors and its customer, unless NXP Semiconductors and

customer have explicitly agreed otherwise in writing. In no event however,

shall an agreement be valid in which the NXP Semiconductors product is

deemed to offer functions and qualities beyond those described in the

Product data sheet.

18.3 Disclaimers

Limited warranty and liability — Information in this document is believed to

be accurate and reliable. However, NXP Semiconductors does not give any

representations or warranties, expressed or implied, as to the accuracy or

completeness of such information and shall have no liability for the

consequences of use of such information.

In no event shall NXP Semiconductors be liable for any indirect, incidental,

punitive, special or consequential damages (including - without limitation - lost

profits, lost savings, business interruption, costs related to the removal or

replacement of any products or rework charges) whether or not such

damages are based on tort (including negligence), warranty, breach of

contract or any other legal theory.

Notwithstanding any damages that customer might incur for any reason

whatsoever, NXP Semi conductors’ aggregat e and cumulative liabil ity towards

customer for the products described herein shall be limited in accordance

with the Terms and conditions of commercial sale of NXP Semiconductors.

Right to make changes — NXP Semiconductors reserves the right to make

changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This document supersedes and replaces all information supplied prior

to the publication hereof.

Suitability for use — NXP Semiconductors products are not designed,

authorized or warranted to be suitable for use in life support, life-critical or

safety-critical systems or equipment, nor in applications where failure or

malfunction of an NXP Semiconductors product can reasonably be expected

to result in personal injury, death or severe property or environmental

damage. NXP Semiconductors accepts no liability for inclusion and/or use of

NXP Semiconductors products in such equipment or applications and

therefore such inclusion and/or use is at the customer’s own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. NXP Semiconductors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

Customers are responsible for the design and operation of their applications

and products using NXP Semiconductors products, and NXP Semiconductors

accepts no liability for any assistance with applications or customer product

design. It is customer’s sole responsibility to determine whether the NXP

Semiconductors product is suitable and fit for the customer’s applications and

products planned, as well as for the planned application and use of

customer’s third party customer(s). Customers should provide appropriate

design and operating safeguards to minimize the risks associated with their

applications and products.

NXP Semiconductors does not accept any liability related to any default ,

damage, costs or problem which is based on any weakness or default in the

customer’s applications or products, or the application or use by customer’s

third party customer(s). Customer is responsible for doing all necessary

testing for the customer’s applications and products using NXP

Semiconductors products in order to avoid a default of the applications and

the products or of the application or use by customer’s third part y

customer(s). NXP does not accept any liability in this respect.

Limiting values — Stress above one or more limiting values (as defined in

the Absolute Maximum Ratings System of IEC 60134) will cause permanent

damage to the device. Limiting values are stress ratings only and (proper)

operation of the device at these or any other conditions above those given in

the Recommended operating conditions section (if present) or the

Characteristics sections of this document is not warranted. Constant or

repeated exposure to limiting values will permanently and irreversibly affect

the quality and reliability of the device.

Terms and conditions of commercial sale — NXP Semiconductors

products are sold subject to the general terms and conditions of commercial

sale, as published at http://www.nxp.com/profile/terms

agreed in a valid written individual agreement. In case an individual

agreement is concluded only the terms and conditions of the respective

agreement shall apply. NXP Semiconductors hereby expressly objects to

applying the customer’s general terms and conditions with regard to the

purchase of NXP Semiconductors products by customer.

No offer to sell or license — Nothing in this document may be interpreted or

construed as an offer to sell product s that is open for accept ance or the gr ant,

conveyance or implication of any license under any copyrights, patents or

other industrial or intellectual property rights.

Export control — This document as well as the item(s) described herein

may be subject to export control regulations. Export might require a prior

authorization from national authorities.

, unless otherwise

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 20 of 22

Page 21

NXP Semiconductors

PCA9646

Buffered 4-channel 2-wire bus switch

Non-automotive qualified products — Unless this data sheet expressly

states that this specific NXP Semiconductors product is automotive qualified,

the product is not suitable for automotive use. It i s neit her qua lif ied nor tested

in accordance with automotive testing or application requirements. NXP

Semiconductors accepts no liability for inclusion and/or use of

non-automotive qualified products in automotive equipment or applications.

In the event that customer uses the product for design-in and use in

automotive applications to automotive specifications and standards, custome r

(a) shall use the product without NXP Semiconductors’ warranty of the

product for such automotive applications, use and specifications, and (b)

whenever customer uses the product for automotive applications beyond

NXP Semiconductors’ specifications such use shall be solely at customer’s

own risk, and (c) customer fully indemnifies NXP Semiconductors for any

liability, da mages or failed produ ct claims result ing from custome r design and

use of the product for automotive applications beyond NXP Semiconductors’

standard warranty and NXP Semiconductors’ product specifications.

18.4 Trademarks

Notice: All referenced brands, prod uct names, service names and trademarks

are the property of their respective owners.

2

I

C-bus — logo is a trademark of NXP B.V.

19. Contact information

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

PCA9646 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 1 — 1 March 2011 21 of 22

Page 22

NXP Semiconductors

20. Contents

1 General description. . . . . . . . . . . . . . . . . . . . . . 1

2 Features and benefits . . . . . . . . . . . . . . . . . . . . 1

3 Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 Ordering information. . . . . . . . . . . . . . . . . . . . . 2

5 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6 Pinning information. . . . . . . . . . . . . . . . . . . . . . 3

6.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 3

7 Functional description . . . . . . . . . . . . . . . . . . . 4

7.1 V

7.2 SCL — clock signal input . . . . . . . . . . . . . . . . . 4

7.3 SC0, SC1, SC2, SC3 — clock signal outputs. . 4

7.4 SDA, SD0, SD1, SD2, SD3 — data signal

7.5 RESET

7.6 Power-On Reset (POR) . . . . . . . . . . . . . . . . . . 5

7.7 A0, A1, A2 — address lines . . . . . . . . . . . . . . . 5

7.8 Control register. . . . . . . . . . . . . . . . . . . . . . . . . 5

8 Bus transaction . . . . . . . . . . . . . . . . . . . . . . . . . 6

9 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . . 7

10 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . 7

11 Application information. . . . . . . . . . . . . . . . . . 10

12 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 14

13 Handling information. . . . . . . . . . . . . . . . . . . . 16

14 Soldering of SMD packages . . . . . . . . . . . . . . 16

14.1 Introduction to soldering. . . . . . . . . . . . . . . . . 16

14.2 Wave and reflow soldering . . . . . . . . . . . . . . . 16

14.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 17

14.4 Reflow soldering. . . . . . . . . . . . . . . . . . . . . . . 17

15 Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . 18

16 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

17 Revision history. . . . . . . . . . . . . . . . . . . . . . . . 19

18 Legal information. . . . . . . . . . . . . . . . . . . . . . . 20

18.1 Data sheet status . . . . . . . . . . . . . . . . . . . . . . 20

18.2 Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

18.3 Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

18.4 Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

19 Contact information. . . . . . . . . . . . . . . . . . . . . 21

20 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

, VSS — DC supply pins . . . . . . . . . . . . . . . 4

DD

inputs/outputs. . . . . . . . . . . . . . . . . . . . . . . . . . 4

— reset IC to default state. . . . . . . . . . 5

PCA9646

Buffered 4-channel 2-wire bus switch

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section ‘Legal information’.

© NXP B.V. 2011. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: 1 March 2011

Document identifier: PCA9646

Loading...

Loading...