Page 1

P82B96

Dual bidirectional bus buffer

Rev. 08 — 10 November 2009 Product data sheet

1. General description

The P82B96 is a bipolar IC that creates a non-latching, bidirectional, logic interface

between the normal I2C-bus and a range of other bus configurations. It can interface

I2C-bus logic signals to similar buses having different voltage and current levels.

For example, it can interface to the 350 µA SMBus, to 3.3 V logic devices, and to 15 V

levels and/or low-impedance lines to improve noise immunity on longer bus lengths.

It achieves this interface without any restrictions on the normal I2C-bus protocols or clock

speed. The IC adds minimal loading to the I2C-bus node, and loadings of the new bus or

remote I2C-bus nodes are not transmitted or transformed to the local node. Restrictions

on the number of I2C-bus devices in a system, or the physical separation between them,

are virtually eliminated. Transmitting SDA and SCL signals via balanced transmission

lines (twisted pairs) or with galvanic isolation (opto-coupling) is simple because separate

directional Tx and Rx signals are provided. The Tx and Rx signals may be directly

connected, without causing latching, to provide an alternative bidirectional signal line with

I2C-bus properties.

2. Features

n Bidirectional data transfer of I2C-bus signals

n Isolates capacitance allowing 400 pF on Sx/Sy side and 4000 pF on Tx/Ty side

n Tx/Ty outputs have 60 mA sink capability for driving low-impedance or high capacitive

buses

n 400 kHz operation over at least 20 meters of wire (see

n Supply voltage range of 2 V to 15 V with I2C-bus logic levels on Sx/Sy side

independent of supply voltage

n Splits I2C-bus signal into pairs of forward/reverse Tx/Rx, Ty/Ry signals for interface

with opto-electrical isolators and similar devices that need unidirectional input and

output signal paths.

n Low power supply current

n ESD protection exceeds 3500 V HBM per JESD22-A114, 250 V DIP package, 400 V

SO package MM per JESD22-A115, and 1000 V CDM per JESD22-C101

n Latch-up free (bipolar process with no latching structures)

n Packages offered: DIP8, SO8 and TSSOP8

AN10148

)

Page 2

NXP Semiconductors

3. Applications

n Interface between I2C-buses operating at different logic levels (for example, 5 V and

3 V or 15 V)

n Interface between I2C-bus and SMBus (350 µA) standard

n Simple conversion of I2C-bus SDA or SCL signals to multi-drop differential bus

hardware, for example, via compatible PCA82C250

n Interfaces with opto-couplers to provide opto-isolation between I2C-bus nodes up to

400 kHz

4. Ordering information

Table 1. Ordering information

Type number Package

P82B96DP TSSOP8 plastic thin shrink small outline package; 8 leads;

P82B96PN DIP8 plastic dual in-line package; 8 leads (300 mil) SOT97-1

P82B96TD SO8 plastic small outline package; 8 leads;

P82B96TD/S900 SO8 plastic small outline package; 8 leads;

P82B96

Dual bidirectional bus buffer

Name Description Version

SOT505-1

body width 3 mm

SOT96-1

body width 3.9 mm

SOT96-1

body width 3.9 mm

4.1 Ordering options

Table 2. Ordering options

Type number Topside mark Temperature range

P82B96DP 82B96 −40 °C to +85 °C

P82B96PN P82B96PN −40 °C to +85 °C

P82B96TD P82B96T −40 °C to +85 °C

P82B96TD/S900 P82B96T −40 °C to +125 °C

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 2 of 32

Page 3

NXP Semiconductors

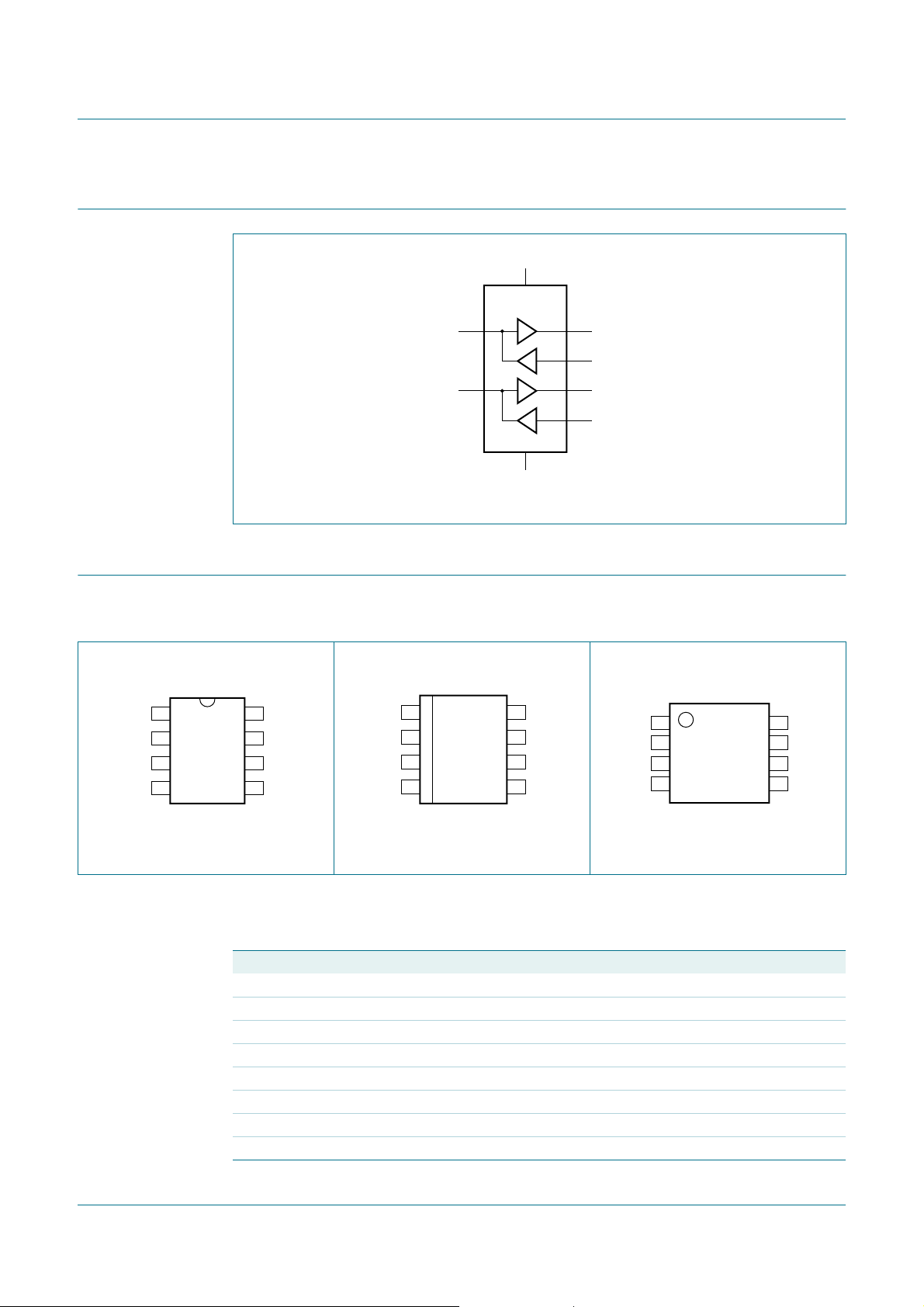

5. Block diagram

Sx (SDA)

Sy (SCL)

VCC (2 V to 15 V)

8

P82B96

1

7

4

3

2

5

6

P82B96

Dual bidirectional bus buffer

Tx (TxD, SDA)

Rx (RxD, SDA)

Ty (TxD, SCL)

Ry (RxD, SCL)

GND

002aab976

Fig 1. Block diagram of P82B96

6. Pinning information

6.1 Pinning

P82B96TD

P82B96TD/S900

1

1

Sx V

2

Rx Sy

P82B96PN

3

Tx Ry

4

GND Ty

002aab977

8

7

6

5

CC

Sx V

2

Rx Sy

3

Tx Ry

4

GND Ty

002aab978

Fig 2. Pin configuration for DIP8 Fig 3. Pin configuration for SO8 Fig 4. Pin configuration for

6.2 Pin description

8

CC

7

6

5

1

Sx V

2

Rx Sy

Tx Ry

GND Ty

3

4

P82B96DP

002aab979

TSSOP8

8

CC

7

6

5

Table 3. Pin description

Symbol Pin Description

2

Sx 1 I

C-bus (SDA or SCL)

Rx 2 receive signal

Tx 3 transmit signal

GND 4 negative supply

Ty 5 transmit signal

Ry 6 receive signal

2

Sy 7 I

V

CC

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 3 of 32

8 positive supply voltage

C-bus (SDA or SCL)

Page 4

NXP Semiconductors

7. Functional description

Refer to Figure 1 “Block diagram of P82B96”.

The P82B96 has two identical buffers allowing buffering of both of the I2C-bus (SDA and

SCL) signals. Each buffer is made up of two logic signal paths, a forward path from the

I2C-bus interface pin which drives the buffered bus, and a reverse signal path from the

buffered bus input to drive the I2C-bus interface. Thus these paths are:

P82B96

Dual bidirectional bus buffer

• sense the voltage state of the I

Tx (Ty respectively), and

• sense the state of the pin Rx (Ry) and pull the I

LOW.

The rest of this discussion will address only the ‘x’ side of the buffer; the ‘y’ side is

identical.

The I2C-bus pin (Sx) is designed to interface with a normal I2C-bus.

The logic threshold voltage levels on the I2C-bus are independent of the IC supply VCC.

The maximum I2C-bus supply voltage is 15 V and the guaranteed static sink current is

3 mA.

The logic level of Rx is determined from the power supply voltage VCC of the chip. Logic

LOW is below 42 % of VCC, and logic HIGH is above 58 % of VCC(with a typical switching

threshold of half VCC).

Tx is an open-collector output without ESD protection diodes to VCC. It may be connected

via a pull-up resistor to a supply voltage in excess of VCC, as long as the 15 V rating is not

exceeded. It has a larger current sinking capability than a normal I2C-bus device, being

able to sink a static current of greater than 30 mA, and typical 100 mA dynamic pull-down

capability as well.

A logic LOW is only transmitted to Tx when the voltage at the I2C-bus pin (Sx) is below

0.6 V. A logic LOW at Rx will cause the I2C-bus (Sx) to be pulled to a logic LOW level in

accordance with I2C-bus requirements (maximum 1.5 V in 5 V applications) but not low

enough to be looped back to the Tx output and cause the buffer to latch LOW.

2

C-bus pin Sx (or Sy) and transmit this state to the pin

2

C-bus pin LOW whenever Rx (Ry) is

The minimum LOW level this chip can achieve on the I2C-bus by a LOW at Rx is typically

0.8 V.

If the supply voltageVCCfails,thenneithertheI2C-bus nor the Tx output willbeheldLOW.

Their open-collector configuration allows them to be pulled up to the rated maximum of

15 V even without VCC present. The input configuration on Sx and Rx also present no

loading of external signals even when VCC is not present.

The effectiveinput capacitance of any signal pin, measured by its effectonbusrise times,

is less than 7 pF for all bus voltages and supply voltages including VCC=0V.

Remark: Two or more Sx or Sy I/Os must not be interconnected. The P82B96 design

does not support this configuration. Bidirectional I2C-bus signals do not allow any

direction control pin so,instead,slightlydifferent logic low voltage levels are used at Sx/Sy

to avoid latching of this buffer. A ‘regular I2C-bus LOW’ applied at the Rx/Ry of a P82B96

will be propagated to Sx/Sy as a ‘buffered LOW’ with a slightly higher voltage level. If this

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 4 of 32

Page 5

NXP Semiconductors

special ‘buffered LOW’ is applied to the Sx/Sy of another P82B96 that second P82B96 will

not recognize it as a ‘regular I2C-bus LOW’ and will not propagate it to its Tx/Ty output.

The Sx/Sy side of P82B96 may not be connected to similar buffers that rely on special

logic thresholds for their operation, for example PCA9511, PCA9515, or PCA9518. The

Sx/Sy side is only intended for, and compatible with, the normal I2C-bus logic voltage

levels of I2C-bus master and slave chips, or even Tx/Rx signals of a second P82B96 if

required. The Tx/Rx and Ty/Ry I/O pins use the standard I2C-bus logic voltage levels of all

I2C-bus parts. There are no restrictions on the interconnection of the Tx/Rx and Ty/Ry I/O

pins to other P82B96s, for example in a star or multipoint configuration with the Tx/Rx and

Ty/Ry I/O pins on the common bus and the Sx/Sy side connected to the line card slave

devices. For more details see

8. Limiting values

Table 4. Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Voltages with respect to pin GND.

Symbol Parameter Conditions Min Max Unit

V

CC

V

Sx

V

Tx

V

Rx

I

n

P

tot

T

j

T

stg

T

amb

[1] See also Section 10.2 “Negative undershoot below absolute minimum value”.

P82B96

Dual bidirectional bus buffer

Application Note AN255

supply voltage VCC to GND −0.3 +18 V

voltage on pin Sx I2C-bus SDA or SCL −0.3 +18 V

voltage on pin Tx buffered output

voltage on pin Rx receive input

current on any pin - 250 mA

total power dissipation - 300 mW

junction temperature operating range

P82B96TD/S900

storage temperature −55 +125 °C

ambient temperature operating −40 +85 °C

.

[1]

−0.3 +18 V

[1]

−0.3 +18 V

−40 +125 °C

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 5 of 32

Page 6

NXP Semiconductors

9. Characteristics

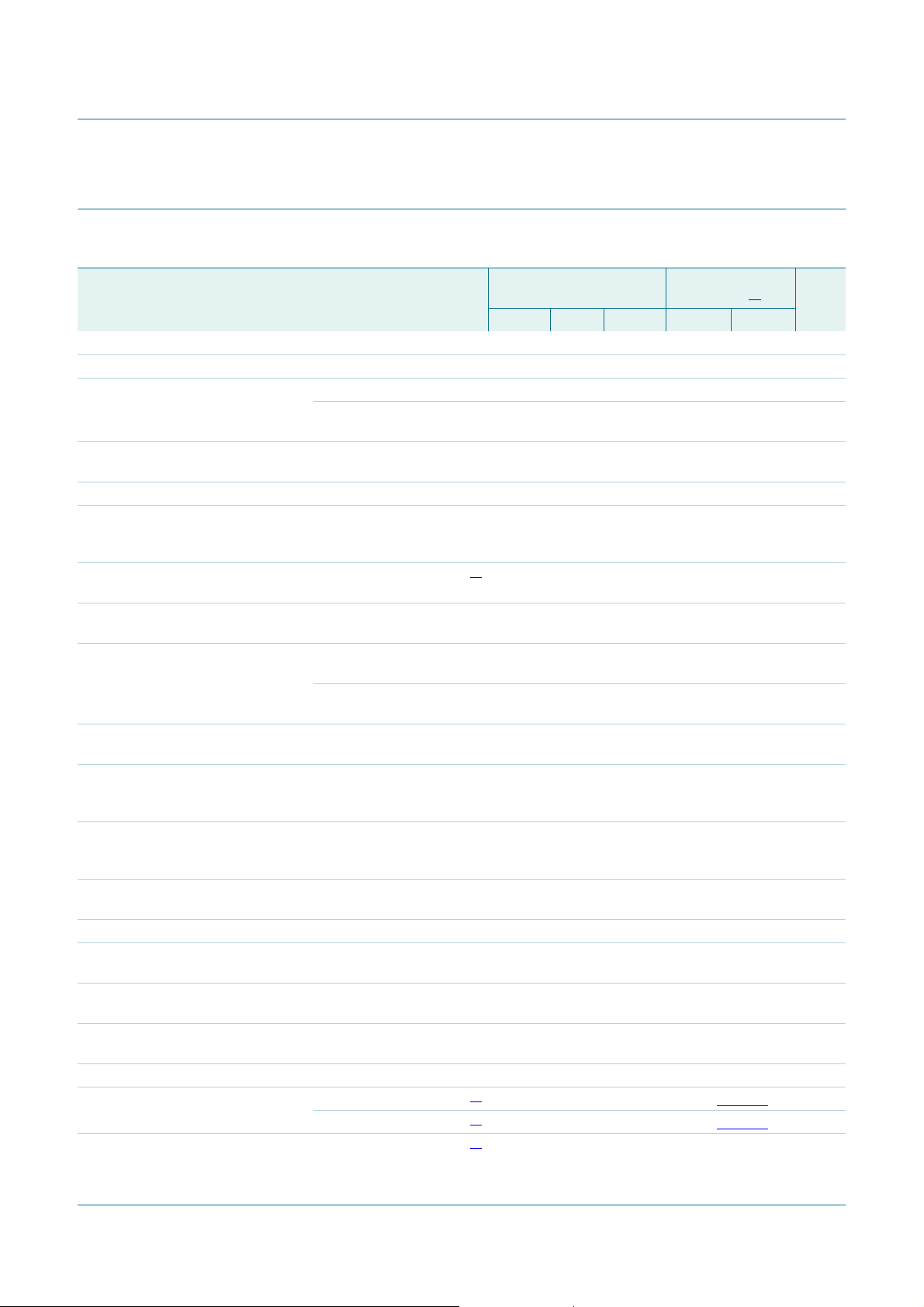

Table 5. Characteristics

T

= +25°C; voltages are specified with respect to GND with VCC= 5 V, unless otherwise specified.

amb

Symbol Parameter Conditions T

Min Typ Max Min Max

Power supply

V

CC

I

CC

supply voltage operating 2.0 - 15 2.0 15 V

supply current buses HIGH - 0.9 1.8 - 3 mA

=15V;

V

CC

buses HIGH

∆I

CC

additional quiescent

per Tx or Ty LOW - 1.7 3.5 - 3.5 mA

supply current

Bus pull-up (load) voltages and currents

, V

V

Sx

maximum input/output

Sy

voltage

open-collector;

2

I

C-busandVRx,VRy=

HIGH

, I

I

Sx

Sy

, I

I

Sx

Sy

, I

I

Sx

Sy

, V

V

Tx

static output loading on

2

I

C-bus

dynamic output sink

capability on I

leakage current on

2

I

C-bus

maximumoutputvoltage

Ty

2

C-bus

, VSy= 1.0 V;

V

Sx

V

Rx,VRy

V

Sx

V

Rx,VRy

V

Sx

V

Rx,VRy

V

Sx

V

Rx,VRy

=LOW

, VSy=2V;

=LOW

, VSy=5V;

= HIGH

, VSy=15V;

= HIGH

open-collector - - 15 - 15 V

[2]

0.2 - 3 0.2 3 mA

718- 7 -mA

level

, I

I

Tx

Ty

, I

I

Tx

Ty

, I

I

Tx

Ty

static output loading on

buffered bus

dynamic output sink

capability, buffered bus

leakage current on

buffered bus

VTx, VTy= 0.4 V;

V

2

I

= LOW on

Sx,VSy

C-bus = 0.4 V

VTx, VTy>1V;

V

2

I

= LOW on

Sx,VSy

C-bus = 0.4 V

VTx, VTy=VCC=15V;

V

, VSy= HIGH

Sx

60 100 - 60 - mA

Input currents

, I

I

Sx

Sy

, I

I

Rx

Ry

, I

I

Rx

Ry

input current from

2

I

C-bus

input current from

buffered bus

leakage current on

bus LOW;

VRx,VRy= HIGH

bus LOW;

V

Rx,VRy

VRx, VRy=V

= 0.4 V

CC

buffered bus input

Output logic LOW level

V

dV

dV

, V

Sx

Sx

Sy

output logic level LOW

Sy

on normal I

/dT,

temperature coefficient

/dT

of output LOW levels

2

C-bus

, ISy=3mA

I

Sx

, ISy= 0.2 mA

I

Sx

, ISy= 0.2 mA

I

Sx

[3]

0.8 0.88 1.0 (see Figure 6)V

[3]

670 730 790 (see Figure 5)mV

[3]

= +25 °C T

amb

- 1.1 2.5 - 4 mA

--15-15V

--1 -10µA

-1- - 10µA

- - 30 - 30 mA

-1- - 10µA

- −1- - −10 µA

- −1- - −10 µA

-1- - 10µA

- −1.8 - - - mV/K

P82B96

Dual bidirectional bus buffer

= −40 °C to

amb

+125 °C

[1]

Unit

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 6 of 32

Page 7

NXP Semiconductors

P82B96

Dual bidirectional bus buffer

Table 5. Characteristics

T

= +25°C; voltages are specified with respect to GND with VCC= 5 V, unless otherwise specified.

amb

Symbol Parameter Conditions T

…continued

= +25 °C T

amb

Min Typ Max Min Max

Input logic switching threshold voltages

, V

V

Sx

, V

V

Sx

input logic voltage LOW on normal I2C-bus

Sy

input logic level HIGH

Sy

on normal I2C-bus

[4]

- 640 600 (see Figure 7)mV

[4]

700 650 - (see Figure 8)mV

threshold

/dT,

dV

dV

V

V

V

Rx

Rx

Rx

Sx

Sy

, V

, V

, V

temperature coefficient

/dT

of input thresholds

input logic HIGH level fraction of applied V

Ry

input threshold fraction of applied V

Ry

input logic LOW level fraction of applied V

Ry

CC

CC

CC

- −2 - - - mV/K

0.58V

- 0.5V

- - 0.58V

CC

CC

- - 0.42V

Logic level threshold difference

, V

V

Sx

input/output logic level

Sy

difference

VSx output LOW at

0.2 mA − V

Sx

input

[2]

50 85 - 50 - mV

HIGH maximum

Thermal resistance

R

th(j-pcb)

thermal resistance from

junctiontoprinted-circuit

board

SOT96-1 (SO8);

average lead

temperature at board

- 127 - - - K/W

interface

Bus release on V

V

V

Sx

Tx

, VSy,

, V

VCC voltage at which all

busesare guaranteed to

Ty

failure

CC

- - 1 (see Figure 9)V

be released

dV/dT temperature coefficient

- −4 - - - mV/K

of guaranteed release

voltage

Buffer response time

T

fall delay

VSxtoVTx,

V

to V

Sy

buffer time delay on

falling input between

V

Ty

Sx

threshold, and V

[5]

= input switching

Tx

R

pull-up = 160 Ω;

Tx

no capacitive load;

V

=5V

CC

-70- - -ns

output falling 50 %

T

rise delay

VSxtoVTx,

V

to V

Sy

Ty

buffer time delay on

rising input between

V

= input switching

Sx

threshold, and V

Tx

RTx pull-up = 160 Ω;

no capacitive load;

V

=5V

CC

-90- - -ns

output reaching 50 %

V

CC

= −40 °C to

amb

+125 °C

CC

[1]

Unit

-V

---V

CC

- 0.42VCCV

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 7 of 32

Page 8

NXP Semiconductors

P82B96

Dual bidirectional bus buffer

Table 5. Characteristics

T

= +25°C; voltages are specified with respect to GND with VCC= 5 V, unless otherwise specified.

amb

Symbol Parameter Conditions T

…continued

= +25 °C T

amb

= −40 °C to

amb

+125 °C

[1]

Unit

Min Typ Max Min Max

T

fall delay

VRx to

V

, V

Sx

to V

Sy

buffer time delay on

falling input between

V

Ry

= input switching

Rx

threshold, and V

Sx

R

pull-up = 1500 Ω;

Sx

no capacitive load;

V

=5V

CC

- 250 - - - ns

output falling 50 %

T

rise delay

VRx to

V

, V

Sx

to V

Sy

buffer time delay on

rising input between

V

Ry

= input switching

Rx

threshold, and V

RSx pull-up = 1500 Ω;

- 270 - - - ns

no capacitive load;

V

=5V

CC

Sx

output reaching 50 %

V

CC

Input capacitance

C

i

input capacitance effective input

--7 - 7pF

capacitance of any

signal pin measured

by incremental bus

rise times

[1] Limit data for +125 °C applies to P82B96TD/S900 version. It is guaranteed by design/characterization, but not by 100 % test.

[2] The minimum value requirement for pull-up current, 200 µA, guarantees that the minimum value for VSxoutput LOW will always exceed

the minimum VSxinput HIGH level to eliminate any possibility of latching. The specified difference is guaranteed by design within any IC.

While the tolerances on absolute levels allow a small probability the LOW from one Sx output is recognized by an Sx input of another

P82B96, this has no consequences for normal applications. In any design the Sx pins of different ICs should never be linked because

the resulting system would be very susceptible to induced noise and would not support all I2C-bus operating modes.

[3] The output logic LOW depends on the sink current. For scaling, see

[4] The input logic threshold is independent of the supply voltage.

[5] The fall time of VTx from 5 V to 2.5 V in the test is approximately 15 ns.

The fall time of VSx from 5 V to 2.5 V in the test is approximately 50 ns.

The rise time of VTx from 0 V to 2.5 V in the test is approximately 20 ns.

The rise time of VSx from 0.9 V to 2.5 V in the test is approximately 70 ns.

Application Note AN255

.

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 8 of 32

Page 9

NXP Semiconductors

P82B96

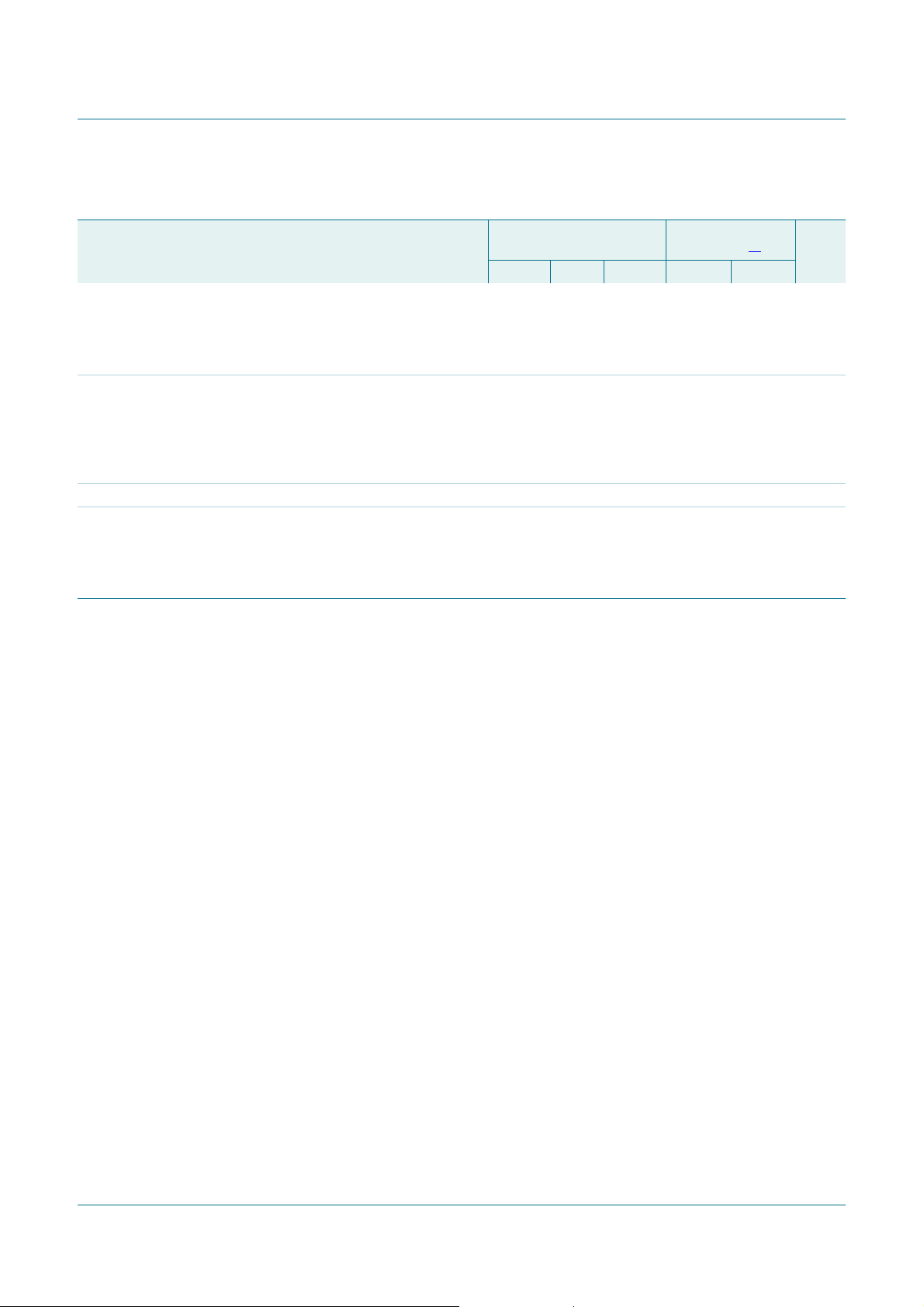

Dual bidirectional bus buffer

1000

V

OL

(mV)

800

600

400

−50 1251007550250−25

002aac069

(1)

(2)

(3)

T

(°C)

j

VOL at Sx typical and limits over temperature

(1) Maximum

(2) Typical

(3) Minimum

Fig 5. VOL as a function of junction temperature

(I

= 0.2 mA)

OL

1000

V

IL(max)

(mV)

800

002aac071

1200

V

OL

(mV)

1000

800

600

400

−50 1251007550250−25

(1) Maximum

(2) Typical

(3) Minimum

Fig 6. V

1000

V

IH(min)

(mV)

800

002aac070

T

(°C)

j

VOL at Sx typical and limits over temperature

as a function of junction temperature

OL

(I

= 3 mA)

OL

002aac072

(1)

(2)

(3)

600

400

200

−50 1251007550250−25

Fig 7. V

T

(°C)

j

V

at Sx changes over temperature range V

IL(max)

as a function of junction temperature Fig 8. V

IL(max)

1400

V

CC(max)

(mV)

1200

1000

800

600

400

−50 1251007550250−25

600

400

200

−50 1251007550250−25

at Sx changes over temperature range

IH(min)

as a function of junction temperature

IH(min)

002aac075

T

(°C)

j

T

(°C)

j

Fig 9. V

P82B96_8 © NXP B.V. 2009. All rights reserved.

that guarantees bus release limit over temperature

CC(max)

Product data sheet Rev. 08 — 10 November 2009 9 of 32

Page 10

NXP Semiconductors

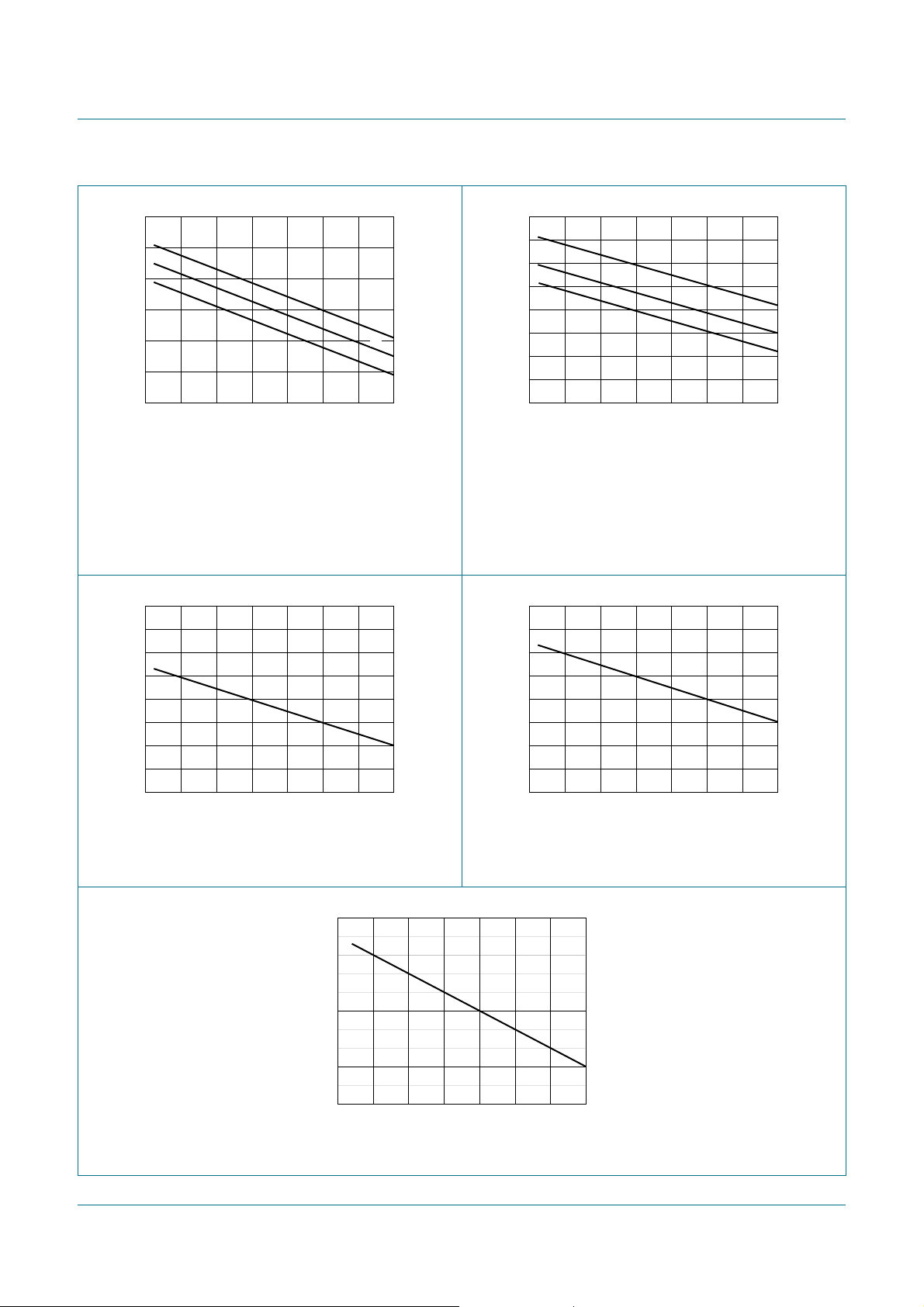

10. Application information

P82B96

Dual bidirectional bus buffer

Refer to

AN460

and

AN255

I2C-bus

SDA

for more application detail.

+VCC (2 V to 15 V)

+5 V

Tx

(SDA)

Rx

(SDA)

1

/

P82B96

2

R1

'SDA' (new levels)

Fig 10. Interfacing an ‘I2C’ type of bus with different logic levels

I2C-bus

SDA

R1

+5 V

1

/

P82B96

2

R2

Rx

(SDA)

Tx

(SDA)

+V

CC

R3

+V

R4

002aab986

CC1

R5

I2C-bus

SDA

002aab987

2

Fig 11. Galvanic isolation of I

main enclosure

3.3 V to 5 V

SDA

SCL

Fig 12. Long distance I

P82B96_8 © NXP B.V. 2009. All rights reserved.

12 V

P82B96

2

C-bus nodes via opto-couplers

long cables

12 V3.3 V to 5 V

C-bus communications

remote control enclosure

3.3 V to 5 V

12 V

3.3 V to 5 V

P82B96

SDA

SCL

002aab988

Product data sheet Rev. 08 — 10 November 2009 10 of 32

Page 11

NXP Semiconductors

Figure 13 shows how a master I2C-bus can be protected against short circuits or failures

in applications that involve plug and socket connections and long cables that may become

damaged. A simple circuit is added to monitor the SDA bus, and if its LOW time exceeds

the design value, then the master bus is disconnected. P82B96 will free all its I/Os if its

supply is removed, so one option is to connect its VCC to the output of a logic gate from,

say, the 74LVC family. The SDA and SCL lines could be timed and VCC disabled via the

gate if one or other lines exceeds a design value of ‘LOW’ period as in

AN255

low-cost discrete circuit in Figure 13 can be used. If the SDA line is held LOW, the 100 nF

capacitor will charge and the Ry input will be pulled towards VCC. When it exceeds 0.5V

the Ry input will set the Sy input HIGH, which in practice means simply releasing it.

In this example the SCL line is made unidirectional by tying the Rx pin to VCC. The state of

the buffered SCL line cannot affect the master clock line which is allowed when

clock-stretching is not required. It is simple to add an additional transistor or diode to

control the Rx input in the same way as Ry when necessary. The +V cable drive can be

any voltage up to 15 V and the bus may be run at a lower impedance by selecting pull-up

resistors for a static sink current up to 30 mA. V

connected devices. Because DDC uses relatively low speeds (< 100 kHz), the cable

length is not restricted to 20 m by the I2C-bus signalling, but it may be limited by the video

signalling.

P82B96

Dual bidirectional bus buffer

Figure 28 of

. If the supply voltage of logic gates restricts the choice of VCC supply then the

CC1

and V

may be chosen to suit the

CC2

CC

V

CC1

V

CC

Rx

SCL

I2C-bus/DDC

master

SDA

GND

Sx

Sy

P82B96

PC/TV receiver/decoder box

Tx

Ry

Ty

470 kΩ

470 kΩ

Fig 13. Extending a DDC bus

100 nF

BC

847B

4.7 kΩ

+V cable drive

100

kΩ

BC

847B

3 m to 20 m

cables

I2C-bus/DDC

R

G

B

video signals

+V cable drive

Rx

Tx

Ry

Ty

P82B96

monitor/flat TV

V

CC2

V

CC

Sx

Sy

SCL

2

I

C-bus/DDC

slave

SDA

GND

002aab989

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 11 of 32

Page 12

NXP Semiconductors

Figure 14 shows that P82B96 can achieve high clock rates over long cables. While

calculating with lumped wiring capacitance yields reasonable approximations to actual

timing, even 25 meters of cable is better treated using transmission line theory.Flat ribbon

cables connected as shown, with the bus signals on the outer edge, will have a

characteristic impedance in the range 100 Ω to 200 Ω. For simplicity they cannot be

terminated in their characteristic impedance but a practical compromise is to use the

minimum pull-up allowed for P82B96 and place half this termination at each end of the

cable. When each pull-up is below 330 Ω, the rising edge waveforms have their first

voltage ‘step’ level above the logic threshold at Rx and cable timing calculations can be

based on the fast rise/fall times of resistive loading plus simple one-way propagation

delays. When the pull-up is larger, but below 750 Ω, the threshold at Rx will be crossed

after one signal reflection. So at the sending end it is crossed after 2 times the one-way

propagation delay and at the receiving end after 3 times that propagation delay. For flat

cables with partial plastic dielectric insulation (by using outer cores) the one-way

propagation delays will be about 5 ns per meter. The 10 % to 90 % rise and fall times on

the cable will be between 20 ns and 50 ns, so their delay contributions are small. There

will be ringing on falling edges that can be damped, if required, by using Schottky diodes

as shown.

P82B96

Dual bidirectional bus buffer

When the Master SCL HIGH and LOW periods can be programmed separately, for

example using control registers I2SCLH and I2SCLL of 89LPC932, the timings can allow

for bus delays. The LOW period should be programmed to achieve the minimum 1300 ns

plus the net delay in the slave's response data signal caused by bus and buffer delays.

The longest data delay is the sum of the delay of the falling edge of SCL from master to

slave and the delay of the rising edge of SDA from slave data to master. Because the

buffer will ‘stretch’ the programmed SCL LOW period, the actual SCL frequency will be

lower than calculated from the programmed clock periods. In the example for 25 meters

the clock is stretched 400 ns, the falling edge of SCL is delayed 490 ns and the SDA rising

edge is delayed 570 ns. The required additional LOW period is

(490 ns + 570 ns) = 1060 ns and the I2C-bus specifications already include an allowance

for a worst case bus rise time 0 % to 70 % of 425 ns. (The bus rise time can be 300 ns

30 % to 70 %, which means it can be 425 ns 0 % to 70 %. The 25 meter cable delay times

as quoted already include all rise and fall times.) Therefore, the microcontroller only needs

to be programmed with an additional (1060 ns − 400 ns − 425 ns) = 235 ns, making a

total programmed LOW period 1535 ns. The programmed LOW will the be stretched by

400 ns to yield an actual bus LOW time of 1935 ns, which, allowing the minimum HIGH

period of 600 ns, yields a cycle period of 2535 ns or 394 kHz.

Note that in both the 100 meter and 250 meter examples, the capacitive loading on the

I2C-buses at each end is within the maximum allowed Standard mode loading of 400 pF,

but exceeds the Fast mode limit. This is an example of a ‘hybrid’ mode because it relies on

the response delays of Fast mode parts but uses (allowable) Standard mode bus loadings

with rise times that contribute significantly to the system delays. The cables cause large

propagation delays, so these systems need to operate well below the 400 kHz limit, but

illustrate how they can still exceed the 100 kHz limit provided all parts are capable of

Fast mode operation. The fastest example illustrates how the 400 kHz limit can be

exceeded, provided masters and slaves have the required timings, namely smaller than

the maximum allowed for Fast mode. Many NXP slaves have delays shorter than 600 ns

and all Fm+ devices must be < 450 ns.

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 12 of 32

Page 13

NXP Semiconductors

P82B96

Dual bidirectional bus buffer

CC

+V cable drive

Rx

Tx

Ry

Ty

R1 R1

V

CC1

I2C-BUS

MASTER

SCL

SDA

R2

R2

Sx

Sy

V

P82B96

C2C2

GND

BAT54A

Fig 14. Driving ribbon or flat telephone cables

cable

propagation

delay ≈ 5 ns/m

R1 R1

BAT54A

Rx

Tx

Ry

Ty

V

P82B96

CC

Sx

Sy

V

CC2

R2

R2

SCL

2

I

C-BUS

SLAVE(S)

SDA

C2C2

GND

002aab990

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 13 of 32

Page 14

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx x x x xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xx xx

xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxx x x

xxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxx

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 14 of 32

Table 6. Examples of bus capability

Refer to Figure 14.

+V

CC1

5 V 12 V 5 V 750 2.2 k 400 250 m n/a

5 V 12 V 5 V 750 2.2 k 220 100 m n/a

3.3 V 5 V 3.3 V 330 1 k 220 25 m 1 nF 125 ns 600 ns 1500 ns 390 kHz Normal spec.

3.3 V 5 V 3.3 V 330 1 k 100 3 m 120 pF 15 ns 600 ns 1000 ns 500 kHz 600 ns

xxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx xxx

+V

cable

+V

R1

CC2

(Ω)R2(Ω)C2(pF)

Cable

length

Cable

capacitance

(delay based)

(delay based)

Cable

delay

1.25 µs 600 ns 4000 ns 120 kHz Normal spec.

500 ns 600 ns 2600 ns 185 kHz Normal spec.

Set master nominal SCL Effective

HIGH period LOW period

bus clock

speed

NXP Semiconductors

Maximum slave

response delay

400 kHz parts

400 kHz parts

400 kHz parts

Dual bidirectional bus buffer

P82B96

Page 15

NXP Semiconductors

10.1 Calculating system delays and bus clock frequency for a Fast mode

system

P82B96

Dual bidirectional bus buffer

local master bus

V

CCM

Rm

MASTER

2

I

C-BUS

SCL

GND (0 V)

Effective delay of SCL at slave: 255 + 17V

V

CCB

Sx

Cm

master bus

capacitance

P82B96 P82B96

CCM

buffered expansion bus

Rb Rs

Tx/Rx

Tx/Rx Sx

Cb

buffered bus

wiring capacitance

+ (2.5 + 4 × 109 Cb)V

CCB

+ 10V

CCS

ns.

C = F; V = volts.

Fig 15. Falling edge of SCL at master is delayed by the buffers and bus fall times

V

CCM

local master bus

V

CCB

buffered expansion bus

remote slave bus

SCL

Cs

slave bus

capacitance

SLAVE

I2C-BUS

V

CCS

002aab991

MASTER

2

I

C-BUS

SCL

GND (0 V)

Rm

Sx

Cm

master bus

capacitance

P82B96

Tx/Rx

Rb

Tx/Rx

Cb

buffered bus

wiring capacitance

002aab992

Effective delay of SCL at master: 270 + RmCm + 0.7RbCb ns.

C = F; R = Ω.

Fig 16. Rising edge of SCL at master is delayed (clock stretch) by buffer and bus rise times

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 15 of 32

Page 16

NXP Semiconductors

P82B96

Dual bidirectional bus buffer

local master bus

V

CCM

MASTER

2

I

C-BUS

Effective delay of SDA at master = 270 + 0.2RsCs + 0.7 (RbCb + RmCm) ns.

C = F; R = Ω.

SDA

GND (0 V)

V

CCB

Rm

Sx

Cm

master bus

capacitance

P82B96 P82B96

buffered expansion bus

Rb Rs

Tx/Rx

Tx/Rx Sx

Cb

buffered bus

wiring capacitance

Fig 17. Rising edge of SDA at slave is delayed by the buffers and bus rise times

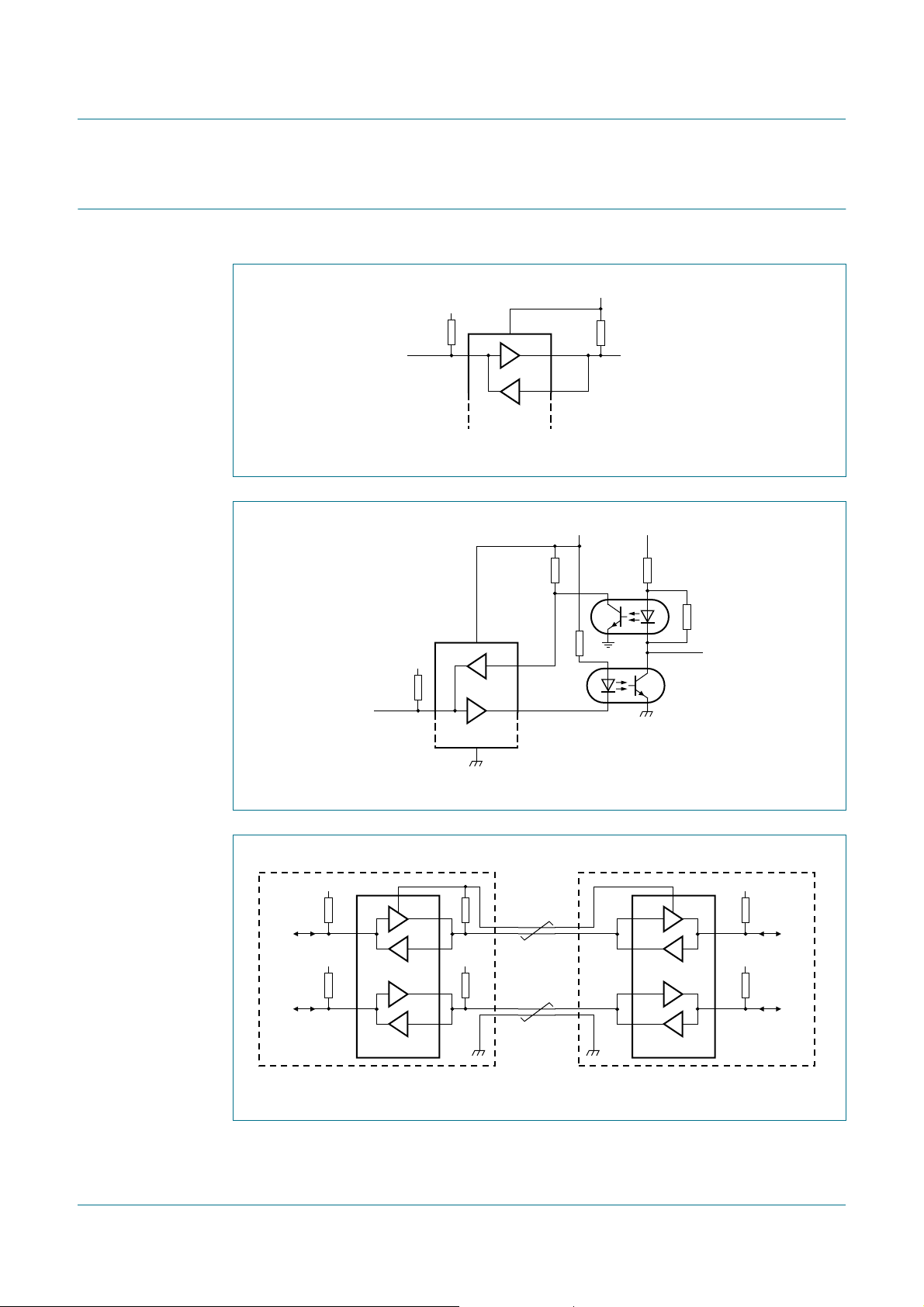

Figure 15, Figure 16, and Figure 17 show the P82B96 used to drive extended bus wiring,

with relatively large capacitance, linking two Fast mode I2C-bus nodes. It includes

simplified expressions for making the relevant timing calculations for 3.3 V or 5 V

operation. Because the buffers and the wiring introduce timing delays, it may be

necessary to decrease the nominal SCL frequency below 400 kHz. In most cases the

actual bus frequency will be lower than the nominal Master timing due to bit-wise

stretching of the clock periods.

remote slave bus

SDA

Cs

slave bus

capacitance

SLAVE

I2C-BUS

V

CCS

002aab993

The delay factors involved in calculation of the allowed bus speed are:

A — The propagation delay of the master signal through the buffers and wiring to the

slave. The important delay is that of the falling edge of SCL because this edge ‘requests’

the data or acknowledge from a slave. See Figure 15.

B — The effective stretching of the nominal LOW period of SCL at the master caused by

the buffer and bus rise times. See Figure 16.

C — The propagation delay of the slave's response signal through the buffers and wiring

back to the master. The important delay is that of a rising edge in the SDA signal. Rising

edges are always slower and are therefore delayed by a longer time than falling edges.

(The rising edges are limited by the passive pull-up while falling edges are actively driven).

See Figure 17.

The timing requirement in any I2C-bus system is that a slave's data response (which is

provided in response to a falling edge of SCL) must be received at the master before the

end of the corresponding LOW period of SCL as appears on the bus wiring at the master.

Since all slaves will, as a minimum, satisfy the worst case timing requirements of a

400 kHz part, they must provide their response within the minimum allowed clock LOW

period of 1300 ns. Therefore in systems that introduce additional delays it is only

necessary to extend that minimum clock LOW period by any ‘effective’ delay of the slave's

response. The effectivedelay of the slaves response equals the total delays in SCL falling

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 16 of 32

Page 17

NXP Semiconductors

edge from the master reaching the slave (Figure 15) minus the effective delay (stretch) of

the SCL rising edge (Figure 16) plus total delays in the slave's response data, carried on

SDA, reaching the master (Figure 17).

The master microcontroller should be programmed to produce a nominal SCL LOW

period = (1300 + A − B + C) ns, and should be programmed to produce the nominal

minimum SCL HIGH period of 600 ns. Then a check should be made to ensure the cycle

time is not shorter than the minimum 2500 ns. If found necessary, just increase either

clock period.

Due to clock stretching, the SCL cycle time will always be longer than

(600+1300+A+C)ns.

Example:

P82B96

Dual bidirectional bus buffer

SDA

SCL

3.3 V to 5 V

3.3 V to 5 V

The master bus has an RmCm product of 100 ns and V

CCM

=5V.

The bufferedbus has a capacitance of 1 nF and a pull-up resistor of 160 Ω to 5 V giving

an RbCb product of 160 ns. The slave bus also has an RsCs product of 100 ns.

The microcontroller LOW period should be programmed to

≥ (1300 + 372.5 − 482 + 472) ns, that is ≥ 1662.5 ns.

Its HIGH period may be programmed to the minimum 600 ns.

The nominal microcontroller clock period will be ≥ (1662.5 + 600) ns = 2262.5 ns,

equivalent to a frequency of 442 kHz.

The actual bus clock period, including the 482 ns clock stretch effect, will be below

(nominal + stretch) = (2262.5 + 482) ns or ≥ 2745 ns, equivalent to an allowable

frequency of 364 kHz.

12 V

Sx

Sy

P82B96

Tx

Rx

Ty

Ry

12 V

12 V

P82B96

Sx Sy

SCL/SDA

no limit to the number of connected bus devices

P82B96

Sx Sy

SCL/SDA

P82B96

Sx Sy

SCL/SDA

P82B96

twitsted-pair telephone wires,

USB, or flat ribbon cables;

up to 15 V logic levels,

include V

3.3 V 3.3 V

and GND

CC

Sy SDA

Sx SCL

002aab994

Fig 18. I2C-bus multipoint application

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 17 of 32

Page 18

NXP Semiconductors

P82B96

Dual bidirectional bus buffer

14

V

10

6

2

−2

0 20001600800 1200400

Frequency = 624 kHz Ch1 frequency = 624 kHz

Tx

Sx

002aab995

ns

Fig 19. Propagation Sx to Tx (Sx pull-up to 5 V;

Tx pull-up to V

CC

=10V)

10.2 Negative undershoot below absolute minimum value

The reason why the IC pin reverse voltage on pins Tx and Rx in Table 4 “Limiting values”

is specified at such a low value, −0.3 V, is not that applying larger voltages is likely to

cause damage but that it is expected that, in normal applications, there is no reason why

larger DC voltages will be applied. This ‘absolute maximum’ specification is intended to be

a DC or continuous ratings and the nominal DC I2C-bus voltage LOW usually does not

even reach 0 V. Inside P82B96 at every pin there is a large protective diode connected to

the GND pin and that diode will start to conduct when the pin voltage is more than about

−0.55 V with respect to GND at 25 °C ambient.

14

V

10

6

2

−2

Rx

Sx

0 20001600800 1200400

002aab996

ns

Fig 20. Propagation Rx to Sx (Sx pull-up to 5 V;

Rx pull-up to VCC=10V)

Figure 21 shows the measured characteristic for one of those diodes inside P82B96. The

plot was made using a curve tracer that applies 50 Hz mains voltage via a series resistor,

so the pulse durations are long duration (several milliseconds) and are reaching peaks of

over 2 A when more than −1.5 V is applied. The IC becomes very hot during this testing

but it was not damaged. Whenever there is current flowing in any of these diodes it is

possible that there can be faulty operation of any IC. For that reason we put a specification

on the negative voltage that is allowed to be applied. It is selected so that, at the highest

allowed junction temperature, there will be a big safety factor that guarantees the diode

will not conduct and then we do not need to make any 100 % production tests to

guarantee the published specification.

For the P82B96, in specific applications, there will always be transient overshoot and

ringing on the wiring that can cause these diodes to conduct. Therefore we designed the

IC to withstand those transients and as a part of the qualification procedure we made

tests, using DC currents to more than twice the normal bus sink currents, to be sure that

the IC was not affected by those currents. For example, the Tx/Ty and Rx/Ry pins were

tested to at least −80 mA which, from Figure 21, would be more than −0.8 V. The correct

functioning of the P82B96 is not affected even by those large currents. The Absolute

Maximum (DC) ratings are not intended to apply to transients but to steady state

conditions. This explains why you will never see any problems in practice even if, during

transients, more than −0.3 V is applied to the bus interface pins of P82B96.

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 18 of 32

Page 19

NXP Semiconductors

Figure 21 “Diode characteristic curve” also explains how the general Absolute Maximum

DC specification was selected. The current at 25 °C is near zero at −0.55 V. The P82B96

is allowed to operate with +125 °C junction and that would cause this diode voltage to

decrease by 100 × 2 mV = 200 mV. So for zero current we need to specify −0.35 V and we

publish −0.3 V just to have some extra margin.

Remark: You should not be concerned about the transients generated on the wiring by a

P82B96 in normal applications and that is input to the Tx/Rx or Ty/Ry pins of another

P82B96. Because not all ICs that may be driven by P82B96 are designed to tolerate

negative transients, in Section 10.2.1 “Example with questions and answers” we show

they can be managed if required.

P82B96

Dual bidirectional bus buffer

0

diode current

(mA)

−1

−10

−1

−10

2

−10

3

−10

4

−10

−2.0 0−0.5−1.5 −1.0

Fig 21. Diode characteristic curve

002aaf063

voltage (V)

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 19 of 32

Page 20

NXP Semiconductors

10.2.1 Example with questions and answers

Question: On a falling edge of Tx we measure undershoot at −800 mV at the linked Tx,

Rx pins of the P82B96 that is generating the LOW,but the P82B96 data sheet specifies

minimum −0.3 V. Does this mean that we violate the data sheet absolute value?

Answer: For P82B96 the −0.3 V Absolute Maximum rating is not intended to apply to

transients, it is a DC rating. As shown in Figure 22, there is no theoretical reason for any

undershoot at the IC that is driving the bus LOW and no significant undershoot should

be observed when using reasonable care with the ground connection of the ‘scope. It is

more likely that undershoot observed at a driving P82B96 is caused by local stray

inductance and capacitance in the circuit and by the oscilloscope connections. As

shown, undershoot will be generated by PCB traces, wiring, or cables driven by a

P82B96 because the allowed value of the I2C-bus pull-up resistor generally is larger

than that required to correctly terminate the wiring. In this example, with no IC

connected at the end of the wiring, the undershoot is about 2 V.

voltage

(V)

P82B96

Dual bidirectional bus buffer

6

4

send

2

0

−2

horizontal scale = 62.5 ns/div

Sx

5 V

Rx

Tx

P82B96

5 V

300 Ω

send

Fig 22. Transients generated by the bus wiring

receive

2 meter

cable

time (ns)

5 V

300 Ω

receive

GND

002aaf064

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 20 of 32

Page 21

NXP Semiconductors

Question: We have 2 meters of cable in a bus that joins the Tx/Rx sides of two P82B96

devices. When one Tx drives LOW the other P82B96 Tx/Rx is driven to −0.8 V for over

50 ns. What is the expected value and the theoretically allowed value of undershoot?

Answer: Because the cable joining the two P82B96s is a ‘transmission line’ that will

have a characteristic impedance around 100 Ω and it will be terminated by pull-up

resistors that are larger than that characteristic impedance there will always be negative

undershoot generated. The duration of the undershoot is a function of the cable length

and the input impedance of the connected IC. As shown in Figure 23, the transient

undershoot will be limited, by the diodes inside P82B96, to around −0.8 V and that will

not cause problems for P82B96. Those transients will not be passed inside the IC to the

Sx/Sy side of the IC.

P82B96

Dual bidirectional bus buffer

6

voltage

(V)

4

2

cable

receive

5 V

time (ns)

300 Ω

receive

GND

5 V

Rx

Sx

Tx

002aaf065

send

0

−2

horizontal scale = 62.5 ns/div

5 V

Sx

Rx

Tx

P82B96

5 V

300 Ω

send

2 meter

Fig 23. Wiring transients limited by the diodes in P82B96

Question: If we input 800 mV undershoot at Tx, Rx pins, what kind of problem is

expected?

Answer: When that undershoot is generated by another P82B96 and is simply the

result of the system wiring, then there will be no problems.

Question: Will we have any functional problem or reliability problem?

Answer: No.

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 21 of 32

Page 22

NXP Semiconductors

Question: If we add 100 Ω to 200 Ω at signal line, the overshoot becomes slightly

smaller. Is this a good idea?

Answer: No, it is not necessary to add any resistance. When the logic signal generated

by Tx or Ty of P82B96 drives long traces or wiring with ICs other than P82B96 being

driven, then adding a Schottky diode (BAT54A) as shown in Figure 24 will clamp the

wiring undershoot to a value that will not cause conduction of the IC’s internal diodes.

P82B96

Dual bidirectional bus buffer

6

voltage

(V)

4

2

send

0

receive

−2

horizontal scale = 62.5 ns/div

Sx

5 V

Rx

Tx

P82B96

send

5 V

300 Ω

2 meter

cable

5 V

300 Ω

receive

1

/2 BAT54A

Fig 24. Wiring transients limited by a Schottky diode

time (ns)

5 V

Rx

Tx

GND

002aaf066

Sx

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 22 of 32

Page 23

NXP Semiconductors

11. Package outline

P82B96

Dual bidirectional bus buffer

DIP8: plastic dual in-line package; 8 leads (300 mil)

D

seating plane

A

L

Z

e

b

8

pin 1 index

1

w M

b

1

b

2

5

SOT97-1

M

E

A

2

A

c

(e )

1

M

H

E

1

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

12

min.

max.

050G01 MO-001 SC-504-8

b

1.73

1.14

0.068

0.021

0.045

0.015

IEC JEDEC JEITA

mm

OUTLINE

VERSION

SOT97-1

A

max.

UNIT

inches

Note

1. Plastic or metal protrusions of 0.25 mm (0.01 inch) maximum per side are not included.

b

0.53

0.38

4

0 5 10 mm

scale

1

1.07

0.89

0.042

0.035

b

2

0.36

0.23

0.014

0.009

REFERENCES

(1) (1)

cD E e M

9.8

9.2

0.39

0.36

6.48

6.20

0.26

0.24

1

3.60

3.05

0.14

0.12

E

8.25

7.80

0.32

0.31

EUROPEAN

PROJECTION

10.0

0.39

0.33

M

L

e

H

8.3

w

max.

0.2542.54 7.62

0.010.1 0.3

0.0450.17 0.02 0.13

ISSUE DATE

99-12-27

03-02-13

1.154.2 0.51 3.2

(1)

Z

Fig 25. Package outline SOT97-1 (DIP8)

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 23 of 32

Page 24

NXP Semiconductors

P82B96

Dual bidirectional bus buffer

SO8: plastic small outline package; 8 leads; body width 3.9 mm

D

c

y

Z

8

pin 1 index

1

e

5

A

2

A

4

w M

b

p

SOT96-1

E

H

E

1

detail X

A

X

v M

A

Q

(A )

L

p

L

A

3

θ

0 2.5 5 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT96-1

A

max.

1.75

0.069

A1A2A

0.25

1.45

0.10

1.25

0.010

0.057

0.004

0.049

IEC JEDEC JEITA

076E03 MS-012

0.25

0.01

b

3

p

0.49

0.25

0.36

0.19

0.019

0.0100

0.014

0.0075

UNIT

inches

Notes

1. Plastic or metal protrusions of 0.15 mm (0.006 inch) maximum per side are not included.

2. Plastic or metal protrusions of 0.25 mm (0.01 inch) maximum per side are not included.

(1)E(2)

cD

5.0

4.8

0.20

0.19

REFERENCES

eHELLpQZywv θ

4.0

3.8

0.16

0.15

1.27

0.05

6.2

5.8

0.244

0.228

1.05

1.0

0.4

0.039

0.016

0.7

0.6

0.028

0.024

0.25 0.10.25

0.010.010.041 0.004

EUROPEAN

PROJECTION

(1)

0.7

0.3

0.028

0.012

ISSUE DATE

99-12-27

03-02-18

o

8

o

0

Fig 26. Package outline SOT96-1 (SO8)

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 24 of 32

Page 25

NXP Semiconductors

P82B96

Dual bidirectional bus buffer

TSSOP8: plastic thin shrink small outline package; 8 leads; body width 3 mm

D

y

Z

8

pin 1 index

5

14

e

w M

b

p

c

A

2

A

1

E

H

E

detail X

SOT505-1

A

X

v M

A

(A3)

L

p

L

A

θ

2.5 5 mm0

scale

DIMENSIONS (mm are the original dimensions)

A

A

UNIT

max.

mm

1.1

Notes

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

2. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

OUTLINE

VERSION

SOT505-1

1

0.15

0.05

A2A3b

0.95

0.25

0.80

IEC JEDEC JEITA

p

0.45

0.25

ceD

0.28

0.15

(1)E(2)

3.1

3.1

2.9

2.9

REFERENCES

0.65

5.1

4.7

LH

E

L

0.7

0.4

p

wyv

0.1 0.10.10.94

EUROPEAN

PROJECTION

(1)

Z

0.70

0.35

ISSUE DATE

θ

6°

0°

99-04-09

03-02-18

Fig 27. Package outline SOT505-1 (TSSOP8)

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 25 of 32

Page 26

NXP Semiconductors

12. Soldering of SMD packages

This text provides a very brief insight into a complex technology. A more in-depth account

of soldering ICs can be found in Application Note

soldering description”

12.1 Introduction to soldering

Soldering is one of the most common methods through which packages are attached to

Printed Circuit Boards (PCBs), to form electrical circuits. The soldered joint provides both

the mechanical and the electrical connection. There is no single soldering method that is

ideal for all IC packages. Wave soldering is often preferred when through-hole and

Surface Mount Devices (SMDs) are mixed on one printed wiring board; however, it is not

suitable for fine pitch SMDs. Reflow soldering is ideal for the small pitches and high

densities that come with increased miniaturization.

12.2 Wave and reflow soldering

Wave soldering is a joining technology in which the joints are made by solder coming from

a standing wave of liquid solder. The wave soldering process is suitable for the following:

.

P82B96

Dual bidirectional bus buffer

AN10365 “Surface mount reflow

• Through-hole components

• Leaded or leadless SMDs, which are glued to the surface of the printed circuit board

Not all SMDs can be wave soldered. Packages with solder balls, and some leadless

packages which have solder lands underneath the body, cannot be wave soldered. Also,

leaded SMDs with leads having a pitch smaller than ~0.6 mm cannot be wave soldered,

due to an increased probability of bridging.

The reflow soldering process involves applying solder paste to a board, followed by

component placement and exposure to a temperature profile. Leaded packages,

packages with solder balls, and leadless packages are all reflow solderable.

Key characteristics in both wave and reflow soldering are:

• Board specifications, including the board finish, solder masks and vias

• Package footprints, including solder thieves and orientation

• The moisture sensitivity level of the packages

• Package placement

• Inspection and repair

• Lead-free soldering versus SnPb soldering

12.3 Wave soldering

Key characteristics in wave soldering are:

• Process issues, such as application of adhesive and flux, clinching of leads, board

transport, the solder wave parameters, and the time during which components are

exposed to the wave

• Solder bath specifications, including temperature and impurities

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 26 of 32

Page 27

NXP Semiconductors

12.4 Reflow soldering

Key characteristics in reflow soldering are:

• Lead-freeversus SnPb soldering; note that a lead-free reflow process usually leads to

• Solder paste printing issues including smearing, release, and adjusting the process

• Reflow temperature profile; this profile includes preheat, reflow (in which the board is

Table 7. SnPb eutectic process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (°C)

< 2.5 235 220

≥ 2.5 220 220

P82B96

Dual bidirectional bus buffer

higher minimum peak temperatures (see Figure 28) than a SnPb process, thus

reducing the process window

window for a mix of large and small components on one board

heated to the peak temperature) and cooling down. It is imperative that the peak

temperature is high enough for the solder to make reliable solder joints (a solder paste

characteristic). In addition, the peak temperature must be low enough that the

packages and/or boards are not damaged. The peak temperature of the package

depends on package thickness and volume and is classified in accordance with

Table 7 and 8

Volume (mm3)

< 350 ≥ 350

Table 8. Lead-free process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (°C)

Volume (mm3)

< 350 350 to 2000 > 2000

< 1.6 260 260 260

1.6 to 2.5 260 250 245

> 2.5 250 245 245

Moisture sensitivity precautions, as indicated on the packing, must be respected at all

times.

Studies have shown that small packages reach higher temperatures during reflow

soldering, see Figure 28.

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 27 of 32

Page 28

NXP Semiconductors

Fig 28. Temperature profiles for large and small components

maximum peak temperature

temperature

MSL: Moisture Sensitivity Level

= MSL limit, damage level

minimum peak temperature

= minimum soldering temperature

P82B96

Dual bidirectional bus buffer

peak

temperature

time

001aac844

For further information on temperature profiles, refer to Application Note

“Surface mount reflow soldering description”

.

13. Soldering of through-hole mount packages

13.1 Introduction to soldering through-hole mount packages

This text gives a very brief insight into wave, dip and manual soldering.

Wave soldering is the preferred method for mounting of through-hole mount IC packages

on a printed-circuit board.

13.2 Soldering by dipping or by solder wave

Driven by legislation and environmental forces the worldwide use of lead-free solder

pastes is increasing. Typical dwell time of the leads in the wave ranges from

3 seconds to 4 seconds at 250 °C or 265 °C, depending on solder material applied, SnPb

or Pb-free respectively.

The total contact time of successive solder waves must not exceed 5 seconds.

The device may be mounted up to the seating plane, but the temperature of the plastic

body must not exceed the specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling may be necessary immediately

after soldering to keep the temperature within the permissible limit.

AN10365

stg(max)

). If the

13.3 Manual soldering

Apply the soldering iron (24 V or less) to the lead(s) of the package, either below the

seating plane or not more than 2 mm above it. If the temperature of the soldering iron bit is

less than 300 °C it may remain in contact for up to 10 seconds. If the bit temperature is

between 300 °C and 400 °C, contact may be up to 5 seconds.

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 28 of 32

Page 29

NXP Semiconductors

13.4 Package related soldering information

Table 9. Suitability of through-hole mount IC packages for dipping and wave soldering

Package Soldering method

CPGA, HCPGA - suitable

DBS, DIP, HDIP, RDBS, SDIP, SIL suitable suitable

PMFP

[1] For SDIP packages, the longitudinal axis must be parallel to the transport direction of the printed-circuit

[2] For PMFP packages hot bar soldering or manual soldering is suitable.

14. Abbreviations

Table 10. Abbreviations

Acronym Description

CDM Charged Device Model

DDC Display Data Channel

ESD ElectroStatic Discharge

HBM Human Body Model

IC Integrated Circuit

2

C-bus Inter IC bus

I

MM Machine Model

SMBus System Management Bus

[2]

board.

P82B96

Dual bidirectional bus buffer

Dipping Wave

[1]

- not suitable

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 29 of 32

Page 30

NXP Semiconductors

Dual bidirectional bus buffer

15. Revision history

Table 11. Revision history

Document ID Release date Data sheet status Change notice Supersedes

P82B96_8 20091110 Product data sheet - P82B96_7

Modifications:

P82B96_7 20090212 Product data sheet - P82B96_6

P82B96_6 20080131 Product data sheet - P82B96_5

P82B96_5 20060127 Product data sheet - P82B96_4

P82B96_4

(9397 750 12932)

P82B96_3

(9397 750 11351)

P82B96_2

(9397 750 11093)

P82B96_1

(9397 750 08122)

• Table 4 “Limiting values”: added Table note [1].

• Added Section 10.2 “Negative undershoot below absolute minimum value”.

20040329 Product data - P82B96_3

20030402 Product data 853-2241 29602

of 2003 Feb 28

20030220 Product data 853-2241 29410

of 2003 Jan 22

20010306 Product data 853-2241 25758

of 2001 Mar 06

P82B96_2

P82B96_1

-

P82B96

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 30 of 32

Page 31

NXP Semiconductors

16. Legal information

16.1 Data sheet status

P82B96

Dual bidirectional bus buffer

Document status

Objective [short] data sheet Development This document contains data from the objective specification for product development.

Preliminary [short] data sheet Qualification This document contains data from the preliminary specification.

Product [short] data sheet Production This document contains the product specification.

[1] Please consult the most recently issued document before initiating or completing a design.

[2] The term ‘short data sheet’ is explained in section “Definitions”.

[3] The product status of device(s) described in this document may have changed since this document was published and may differ in case of multiple devices.The latest product status

information is available on the Internet at URL

[1][2]

Product status

16.2 Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. NXP Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information included hereinand shall have no liabilityfor the consequences of

use of such information.

Short data sheet — A short data sheet is an extract from a full data sheet

with the sameproduct type number(s) and title. Ashort data sheetis intended

for quickreference only and should not be relied upon to contain detailed and

full information. For detailed and full information see the relevant full data

sheet, which is available on request via the local NXP Semiconductors sales

office. In case of any inconsistency or conflict with the short data sheet, the

full data sheet shall prevail.

16.3 Disclaimers

General — Information in this document is believed to be accurate and

reliable. However,NXP Semiconductors does not give any representations or

warranties, expressedor implied, as to the accuracy or completeness of such

information and shall have no liability for the consequences of use of such

information.

Right to make changes — NXP Semiconductors reserves the right to make

changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This document supersedes and replaces all information supplied prior

to the publication hereof.

Suitability for use — NXP Semiconductors products are not designed,

authorized or warranted to be suitable for use in medical, military, aircraft,

space or life support equipment, nor in applications where failure or

malfunction of an NXP Semiconductors product can reasonably be expected

to result in personal injury, death or severe property or environmental

[3]

http://www.nxp.com.

Definition

damage. NXP Semiconductors accepts no liability for inclusion and/or use of

NXP Semiconductors products in such equipment or applications and

therefore such inclusion and/or use is at the customer’s own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. NXP Semiconductors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

Limiting values — Stress above one or more limiting values (as defined in

the Absolute Maximum Ratings System of IEC 60134) maycause permanent

damage to the device.Limiting values are stress ratings onlyand operation of

the device at these or any other conditions above those given in the

Characteristics sections of this document is not implied. Exposure to limiting

values for extended periods may affect device reliability.

Terms and conditions of sale — NXP Semiconductors products are sold

subject to the general terms and conditions of commercial sale, as published

at

http://www.nxp.com/profile/terms, including those pertaining to warranty,

intellectual property rights infringement and limitation of liability, unless

explicitly otherwise agreed to in writing by NXP Semiconductors. In case of

any inconsistency or conflict between information in this document and such

terms and conditions, the latter will prevail.

No offer to sell or license — Nothing in this document may be interpreted

or construed as an offer to sell products that is open for acceptance or the

grant, conveyance or implication of any license under any copyrights, patents

or other industrial or intellectual property rights.

Export control — This document as well as the item(s) described herein

may be subject to export control regulations. Export might require a prior

authorization from national authorities.

16.4 Trademarks

Notice: Allreferenced brands, product names,service names and trademarks

are the property of their respective owners.

I2C-bus — logo is a trademark of NXP B.V.

17. Contact information

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

P82B96_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 10 November 2009 31 of 32

Page 32

NXP Semiconductors

18. Contents

1 General description . . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4 Ordering information. . . . . . . . . . . . . . . . . . . . . 2

4.1 Ordering options. . . . . . . . . . . . . . . . . . . . . . . . 2

5 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6 Pinning information. . . . . . . . . . . . . . . . . . . . . . 3

6.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 3

7 Functional description . . . . . . . . . . . . . . . . . . . 4

8 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . . 5

9 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . 6

10 Application information. . . . . . . . . . . . . . . . . . 10

10.1 Calculating system delays and bus clock

frequency for a Fast mode system . . . . . . . . . 15

10.2 Negative undershoot below absolute minimum

value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.2.1 Example with questions and answers. . . . . . . 20

11 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 23

12 Soldering of SMD packages . . . . . . . . . . . . . . 26

12.1 Introduction to soldering . . . . . . . . . . . . . . . . . 26

12.2 Wave and reflow soldering . . . . . . . . . . . . . . . 26

12.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 26

12.4 Reflow soldering. . . . . . . . . . . . . . . . . . . . . . . 27

13 Soldering of through-hole mount packages . 28

13.1 Introduction to soldering through-hole mount

packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

13.2 Soldering by dipping or by solder wave . . . . . 28

13.3 Manual soldering . . . . . . . . . . . . . . . . . . . . . . 28

13.4 Package related soldering information . . . . . . 29

14 Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . 29

15 Revision history. . . . . . . . . . . . . . . . . . . . . . . . 30

16 Legal information. . . . . . . . . . . . . . . . . . . . . . . 31

16.1 Data sheet status . . . . . . . . . . . . . . . . . . . . . . 31

16.2 Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

16.3 Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

16.4 Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

17 Contact information. . . . . . . . . . . . . . . . . . . . . 31

18 Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

P82B96

Dual bidirectional bus buffer

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section ‘Legal information’.

© NXP B.V. 2009. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: 10 November 2009

Document identifier: P82B96_8

Loading...

Loading...