Page 1

P82B715

I2C-bus extender

Rev. 08 — 9 November 2009 Product data sheet

1. General description

The P82B715 is a bipolar IC intended for application in I2C-bus and derivative bus

systems. While retaining all the operating modes and features of the I2C-bus it permits

extension of the practical separation distance between components on the I2C-bus by

buffering both the data (SDA) and the clock (SCL) lines.

The I2C-bus capacitance limit of 400 pF restricts practical communication distances to a

few meters. Using one P82B715 at each end of a long cable (connecting Lx/Ly to Lx/Ly)

reduces that cable’s loading on the linked I2C-buses by a factor of 10 and allows the total

system capacitance load (all devices,cable, connectors,andtracesor wires connected to

the I2C-bus) to be around 3000 pF while the loading on each I2C-bus on the Sx/Sy sides

remains below 400 pF. Longer cables or low-cost, general-purpose wiring may be used to

link I2C-bus based modules without degrading noise margins. Multiple P82B715s can be

connected together, linking their Lx/Ly ports, in a star or multi-point architecture as long as

the total capacitance of the system is less than about 3000 pF and each bus at an Sx/Sy

connection is well below 400 pF. This configuration, with the master and/or slave devices

attached to the Sx/Sy port of each P82B715, has full multi-master communication

capability. The P82B715 alone does not support voltage level translation, but it can be

simply implemented using low cost transistors when required. There is no restriction on

interconnecting the Sx/Sy I/Os, and, because the device output levels are always held

within 100 mV of input drive levels, P82B715 is compatible with bus buffers that use

voltage level offsets, e.g., PCA9511A, PCA9517, Sx/Sy side of P82B96.

2. Features

The lower VOL level and ability to operate with any master, slave or bus buffer is the

primary advantage of the using the P82B715 for long distance buses at the disadvantage

of not isolating bus capacitance like the P82B96 or PCA9600 are able to do. The primary

disadvantage of the P82B96 and PCA9600 is that the static level offset needed to isolate

bus capacitance does not allow these devices to operate with other bus buffers with

special offset levels or with master/slaves that require a VIL lower than 0.8 V with noise

margin. A proven quick design-in point-to-point/multi-point circuit (Figure 9) is included in

Section 8.2 to allow rapid use of the P82B715 along with comparison waveforms so that

the designer can clearly see the trade-offs between the P82B715 and the

P82B96/PCA9600 and choose the type of device that is best for their application.

n Dual, bidirectional, unity voltage gain buffer with no external directional control

required

n Compatible with I2C-bus and its derivatives SMBus, PMBus, DDC, etc.

n Logic signal levels may include (but not exceed) both supply and ground

n Logic signal input voltage levelsare output without change and are independent of V

n ×10 impedance transformation, but does not change logic voltage levels

CC

Page 2

NXP Semiconductors

n Supply voltage range 3 V to 12 V

n Clock speeds to at least 100 kHz and 400 kHz when other system delays permit

n ESD protection exceeds 2500 V HBM per Mil. Std 883C-3015.7 and 400 V MM per

JESD22-A115 (I/Os have diodes to VCC and GND)

n Latch-up testing is done to JEDEC Standard JESD78 which exceeds 100 mA

3. Applications

n Increase the total connected capacitance of an I2C-bus system to around 3000 pF

n Drive I2C-bus signals over long cables to approximately 50 meters or 3000 pF

n Drives ×10 lower impedance bus wiring for improved noise immunity

n Multi-drop distribution of I2C-bus signals using low cost twisted-pair cables

n AdvancedTCA radial IPMB architecture

n Driving 30 mA Fm+ devices from standard 3 mA parts

4. Ordering information

P82B715

I2C-bus extender

Table 1. Ordering information

Type number Package

Name Description Version

P82B715PN DIP8 plastic dual in-line package; 8leads (300 mil) SOT97-1

P82B715TD SO8 plastic small outline package; 8 leads; body width 3.9 mm SOT96-1

[1] For applications requiring lower voltage operation, or additional buffer performance, see application notes

AN255, “I2C/SMBus repeaters, hubs and expanders”

P82B715 I2C-bus extender”

[1]

and

AN10710, “Features and applications of the

.

4.1 Ordering options

Table 2. Ordering options

Type number Topside mark Temperature range

P82B715PN P82B715PN −40 °C to +85 °C

P82B715TD P82B715 −40 °C to +85 °C

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 2 of 23

Page 3

NXP Semiconductors

5. Block diagram

P82B715

P82B715

I2C-bus extender

V

CC

Fig 1. Block diagram of P82B715

6. Pinning information

6.1 Pinning

n.c. V

GND n.c.

SDA LDA

SCL

P82B715PN

1

2

Lx Ly

3

Sx Sy

4

002aad686

8

CC

7

6

5

BUFFER

BUFFER

GND

002aad689

P82B715TD

1

n.c. V

2

Lx Ly

3

Sx Sy

4

GND n.c.

002aad687

LCL

8

7

6

5

CC

Fig 2. Pin configuration for DIP8 Fig 3. Pin configuration for SO8

6.2 Pin description

Table 3. Pin description

Symbol Pin Description

n.c. 1 not connected

Lx 2 buffered bus, LDA or LCL

2

Sx 3 I

GND 4 negative supply

n.c. 5 not connected

Sy 6 I

Ly 7 buffered bus, LCL or LDA

V

CC

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 3 of 23

8 positive supply

C-bus, SDA or SCL

2

C-bus, SCL or SDA

Page 4

NXP Semiconductors

7. Functional description

The P82B715 is a dual bidirectional logic signal device having unity voltage gain in both

directions, but ×10 current amplification in one direction that allows increasing the

allowableI2C-bus system capacitance. It contains identical circuits for each I2C-bus signal

and requires no external directional control. It uses unidirectional analog current

amplification to increase the current sink capability of I2C-bus chips by a factor of 10 and

to change the I2C-bus specification limit of 400 pF to a 4 nF system limit. This allows

I2C-bus, or similar bus systems, to be extended over long distances using conventional

cables and without degradation of system performance.

P82B715 provides current amplification from its I2C-bus to its low-impedance or buffered

bus. Whenever current is flowing out of Sx, into an I2C-bus chip driving the I2C-bus LOW,

P82B715 will sink ten times that current into Lx to drive the buffered bus LOW (see

Figure 4).

To minimize interference and ensure stability, the current rise and fall times of the Lx drive

amplifier are internally controlled.

The P82B715 does not amplify signal currents flowing in the other direction, i.e., into Sx

from the I2C-bus.The Sx pin is driven LOW by current flowing out of Lx to the driver of that

buffered side.

P82B715

I2C-bus extender

The buffered bus logic LOW voltage at Lx simply drives the I2C-bus at Sx LOW via the

internal 30 Ω resistor. The buffer’s offset voltage (the difference between Sx and Lx)

depends on the current flowing in the sense resistor so it will be very small when the bus

currents are small, but it is guaranteed not to exceed 100 mV in either direction with full

static I2C-bus loading.

The unity voltage gain, with signal current amplification dependent on direction, preserves

the multi-master, bidirectional, open-collector/open-drain, characteristic of any connected

I2C-bus lines and provides these characteristics to the new low-impedance bus. Bus logic

signal voltage levels will be clamped at (VCC+ 0.7 V), but otherwise are independent of

the supply voltage VCC.

= I

I

Sx

Lx

I

Sx

9 × I

I

= 10 × I

Lx

Sx

Sx

Lx buffered bus

002aad688

I2C-bus Sx

V

CC

GND

I

Sx

CURRENT

SENSE

30 Ω

Fig 4. Equivalent circuit: one-half P82B715

7.1 Sx, Sy: I2C-bus SDA or SCL

On the normal side, because the two buffer circuits in the P82B715 are identical, either

the Sx or Sy input pins can be used as the I2C-bus SDA data line, or the SCL clock line.

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 4 of 23

Page 5

NXP Semiconductors

7.2 Lx, Ly: buffered bus LDA or LCL

On the special low-impedance or buffered line side, the corresponding output at the Lx or

Ly pins becomes the LDA data line or LCL clock line.

7.3 VCC, GND: positive and negative supply pins

The power supply voltages at each P82B715 used in a system are normally nominally the

same. If they differ by a significant amount, noise margin may be sacrificed as the bus

HIGH level should not exceed the lowest of those supplies.

8. Application design-in information

By using two (or more) P82B715 ICs, a sub-system can be built that retains the interface

characteristics of a normal I2C-bus device so that the sub-system may be included in, or

added onto, any I2C-bus or related system.

The sub-system shown in Figure 5 features a low-impedance or buffered bus, capable of

driving large wiring capacitance.

P82B715

I2C-bus extender

The P82B715 will operate with a supply voltage from 3 V to 12.5 V but the logic signal

levels at Sx/Lx are independent of the chip’s supply. They remain at the levels presented

to the chip by the attached ICs. The maximum static I2C-bus sink current, 3 mA, flowing in

either direction in the internal current sense resistor,causes a difference, or offset voltage,

less than 100 mV between the bus logic LOW levels at Sx and Lx. This makes P82B715

fully compatible with all logic signal drivers, including TTL. The P82B715 cannot modify

the bus logic signal voltage levelsbut it contains internal diodes connected between Lx/Sx

and VCC that will conduct and limit the logic signal swing if the applied logic levels would

have exceeded the supply voltage by more than 0.7 V. In normal applications external

pull-up resistors will pull the connected buses up to the desired voltage HIGH level.

Usually this will be the chip supply, VCC, but for very low logic voltages it is necessary to

use a VCC of at least 3.3 V and preferably even higher. Note that full performance over

temperature is only guaranteed from 4.5 V. Specification de-ratings apply when its supply

voltage is reduced below 4.5 V. The absolute minimum VCC is 3 V.

SDA

SCL

P82B715

1/2

1/2

V

CC

V

CC

long

cable

LDA

LCL

V

V

CC

CC

P82B715

SDA

1/2

I2C-BUS

DEVICE

SCL

1/2

standard

2

C-bus

I

special

buffered bus

special

buffered bus

standard

2

C-bus

I

002aad690

Fig 5. Minimum sub-system with P82B715

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 5 of 23

Page 6

NXP Semiconductors

8.1 I2C-bus systems

As in standard I2C-bus systems, pull-up resistors are required to provide the logic HIGH

levels on the buffered bus. (The standard open-collector configuration is retained.) The

value and number of pull-up resistors used is flexible and depends on the system

requirements and designer preferences.

If P82B715 ICs are to be permanently connected into a system it could be configured with

only one pull-up resistor on the buffered bus and none on the I2C-buses, but the system

design will be simplified, and performance improved, by fitting separate pull-ups on each

section of the bus. When a sub-system using P82B715 may be optionally connected to an

existing I2C-bus system that already has a pull-up, then the effects of the sub-system

pull-ups acting in parallel with the existing I2C-bus pull-up must be considered.

8.1.1 Pull-up resistance calculation

When calculating the pull-up resistance values, the gain of the buffer introduces scaling

factors which must be applied to the system components. In practical systems the pull-up

resistance value is usually calculated to achieve the rise time requirement of the system.

As an approximation, this requirement will be satisfied for a standard 100 kHz system if

the time constant of the total system (product of the net resistance and net capacitance) is

set to 1 microsecond or less.

P82B715

I2C-bus extender

In systems using P82B715s, the most convenient way to achieve the total system

rise time requirement is by considering each bus node separately. Each of the I2C-bus

nodes, and the buffered bus node, is designed by selecting its pull-up resistor to provide

the required rise time by setting its time constant (product of the pull-up resistance and

load capacitance) equal to the I2C-bus rise time requirement. If each node complies, then

the system requirement will also be met with a small safety margin.

This arrangement, using multiple pull-ups as in Figure 6, provides the best system

performance and allows stand-alone operation of individual I2C-buses if parts of the

extended system are disconnected or re-connected. For each bus section the pull-up

resistor for a Standard-mode system is calculated as shown in Equation 1:

R

=

-----------------------------------------------------

C device C wiring+

Where: C device = sum of any connected device capacitances, and C wiring = total wiring

and stray capacitance on the bus section.

Remark: The 1 µs is an approximation, with a safety factor, to the theoretical

time-constant necessary to meet the Standard-mode 1 µs bus rise time specification in a

system with variable logic thresholds where the CMOS limits of 30 % and 70 % of V

apply. The actual RC requirement can be shown to be 1.18 µs. For a Fast-mode system,

and the same safety margin, replace the 1 µs with its 300 ns requirement.

If these capacitances cannot be measured or calculated then an approximation can be

made by assuming that each device presents 10 pF of load capacitance and 10 pF of

trace capacitance and that cables range from 50 pF to 100 pF per meter.

1 µs

(1)

CC

If only a single pull-up must be used then it must be placed on the buffered bus (as R2 in

Figure 6) and the associated total system capacitance calculated by combining the

individual bus capacitances into an equivalent capacitive loading on the buffered bus.

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 6 of 23

Page 7

NXP Semiconductors

This equivalent capacitance is the sum of the capacitance on the buffered bus plus

10 times the sum of the capacitances on all the connected I2C-bus nodes. The calculated

value should not exceed 4 nF. The single buffered bus pull-up resistor is then calculated to

achievethe rise time requirement and it then provides the pull-up for the buffered bus and

for all other connected I2C-bus nodes included in the calculation.

2

C-bus 1

I

P82B715

I2C-bus extender

V

= 5 V

CC

R3

SDA

I2C-bus 2

SCL

VCC = 5 V

R4

SDA

I2C-bus 3

SCL

SDA

SCL

R1

Sx

Sy

Lx

Ly

R2

buffered bus

Lx

Ly

Lx

Ly

Sx

Sy

Sx

Sy

Fig 6. Single pull-up on buffered bus and multiple pull-up option

8.1.2 Calculating static bus drive currents

Figure 6 shows three P82B715s connected to a common buffered bus. The associated

bus capacitances are omitted for clarity and we assume the pull-up resistors have been

selected to give RC products equal to the bus rise time requirement. An I2C-bus chip

connected at I2C-bus 1 and holding the SDA bus LOW must sink the current flowing in its

local pull-up R1 plus, with assistance from the P82B715, the currents in R2, R3 and R4.

When I2C-bus 1 is LOW, the resistors R3 and R4 act to pull the bus nodes I2C-bus 2 and

I2C-bus 3, and their corresponding Sx pins, to a voltage higher than the voltage at their Lx

pins (which are LOW) so their buffer amplifiers will be inactive.The SDA at Sx of I2C-bus 2

and I2C-bus 3 is pulled LOW by the LOW at Lx via the internal 30 Ω resistor that links Lx

to Sx. So the effective current that must be sunk by the P82B715 bufferon I2C-bus 1, at its

Lx pin, is the sum of the currents in R2, R3 and R4. The Sx current that must be sunk by

an I2C-bus chip at I2C-bus 1, due to the buffer gain action, is1⁄10of the Lx current. So the

effectivepull-up, determining the current to be sunk by an I2C-bus chip at I2C-bus 1, is R1

in parallel with resistors 10 times the values of R2, R3 and R4. If R1 = R3 = R4 = 10 kΩ,

and R2=1kΩ, the effective pull-up load at I2C-bus 1 is

10 kΩ||10 kΩ||100 kΩ||100 kΩ = 4.55 kΩ. (‘||’ means ‘in parallel with’.)

The same calculation applies for I2C-bus 2 or I2C-bus 3.

002aad691

To calculate the current sunk by the Lx pin of the buffer at I2C-bus 1, note that the current

in R1 is sunk directly by the IC at I2C-bus 1. The buffer therefore sinks only the currents

flowing in R2, R3, and R4 so the effective pull-up is R2 in parallel with R3 and R4.

In this example that is 1 kΩ||10 kΩ||10 kΩ = 833 Ω. For a 5.5 V supply and 0.4 V LOW,

that means the buffer is sinking 16.3 mA.

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 7 of 23

Page 8

NXP Semiconductors

The P82B715 has a static sink rating of 30 mA at Lx. The requirement is that the pull-up

on the buffered bus, in parallel with all other pull-ups that it is indirectly pulling LOW on Sx

pins of other P82B715 ICs, will not cause this 30 mA limit to be exceeded.

The minimum pull-up resistance in a 5 V ± 10 % system is 170 Ω.

The general requirement is given in Equation 2:

P82B715

I2C-bus extender

V

CC max()

------------------------------------------

0.4 V–

R

PU

30 mA<

Where: RPU= parallel combination of all pull-up resistors driven by the Lx pin of the

P82B715.

Figure 7 shows calculations for an expanded Standard-mode I2C-bus with 3 nF of cable

capacitance.

V

CC

I2C-BUS

I2C-BUS

effective capacitance

2

local bus I

2 × I

total capacitance

C-bus devices

2

C-bus devices

strays

P82B715

SDA

SDA

local bus

20 pF

20 pF

10 pF

50 pF

R1

wiring capacitance

total capacitance

proposed bus expansion

LxSx

LDA

effective capacitance

at common Lx node

3000 pF

3000 pF

R3R2

Lx Sx SDA

3 nF = cable wiring capacitance

effective capacitance

remote I

2

C-bus devices

1 × I

total capacitance

I2C-BUS

2

C-bus devices

strays

P82B715

5 V

0 VGND

10 pF

10 pF

10 pF

30 pF

(2)

2

C-bus pull-up

local I

1 µs

R1 = = 20 kΩ

50 pF

buffered bus pull-up

1 µs

R2 = = 330 Ω

3000 pF

2

C-bus pull-up

remote I

1 µs

R3 = = 33 kΩ

30 pF

002aad692

Fig 7. Typical loading calculation: adding an extension bus with P82B715

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 8 of 23

Page 9

NXP Semiconductors

3.3 V

P82B715

I2C-bus extender

R1

BUFFERShMM

C1

R2

LxSx

C2

Lx Sx

1

R3

C3

FRU 1

BUFFER µC

R3

common Lx node

Calculations to ensure rise time is met on each bus section:

effective capacitance

at ShMM buffer

ShMM buffer

P82B715

total capacitance C1

ShMM buffer pull-up

1 µs

R1 = = 25 kΩ

40 pF

strays

10 pF

20 pF

10 pF

40 pF

total capacitance C2

Lx Sx

2

Lx Sx

16

effective capacitance

at common Lx node

17 × P82B715

trace capacitance

Lx common pull-up

R2 = = 5 kΩ

1 µs

200 pF

C3

R3

C3

170 pF

30 pF

200 pF

radial traces

radial trace/connector

total capacitance C3

BUFFER µC

BUFFER µC

effective capacitance

at average radial trace

1 × FRU

P82B715

radial trace pull-up

1 µs

R3 = = 6.2 kΩ

160 pF

Calculation of static loading at ShMM buffer and each FRU:

Loading on ShMM buffer = R1 || {10 (R2 || R3/16)} = 3.5 kΩ

Loading on each FRU = R3 || {10 (R1 || R2 || R3/15)} = 3.76 kΩ

Fig 8. Typical arrangement and calculations for an IPMB analog radial shelf

FRU 2

FRU 16

25 pF

125 pF

10 pF

160 pF

002aad708

Figure 8 shows P82B715 in an analog radial IPMB shelf application.

In this example the total system capacitance is 2800 pF, but it is distributed over 18

different bus sections and no section has a capacitance greater than 200 pF.

If every individual bus section is designed to rise at least as fast as the IPMB requirement,

then when any driver releases the bus, all bus sections will rise together and no amplifiers

in the P82B715s will be activated or, if one is activated, it can only slow the system bus

rise to its own rate and that has been designed to meet the requirement.

It is then only necessary to calculate the equivalent static bus pull-up loading and to

ensure that it exceeds the specification requirement. The calculated loadings meet the

requirements.

Note that in this example only one of the four IPMB lines is shown and the usual switching

arrangements for isolating or cross-connecting bus lines are not shown. The typical offset

(increase in the bus LOW level) measured between any two Sx points in this system is

below 100 mV.

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 9 of 23

Page 10

NXP Semiconductors

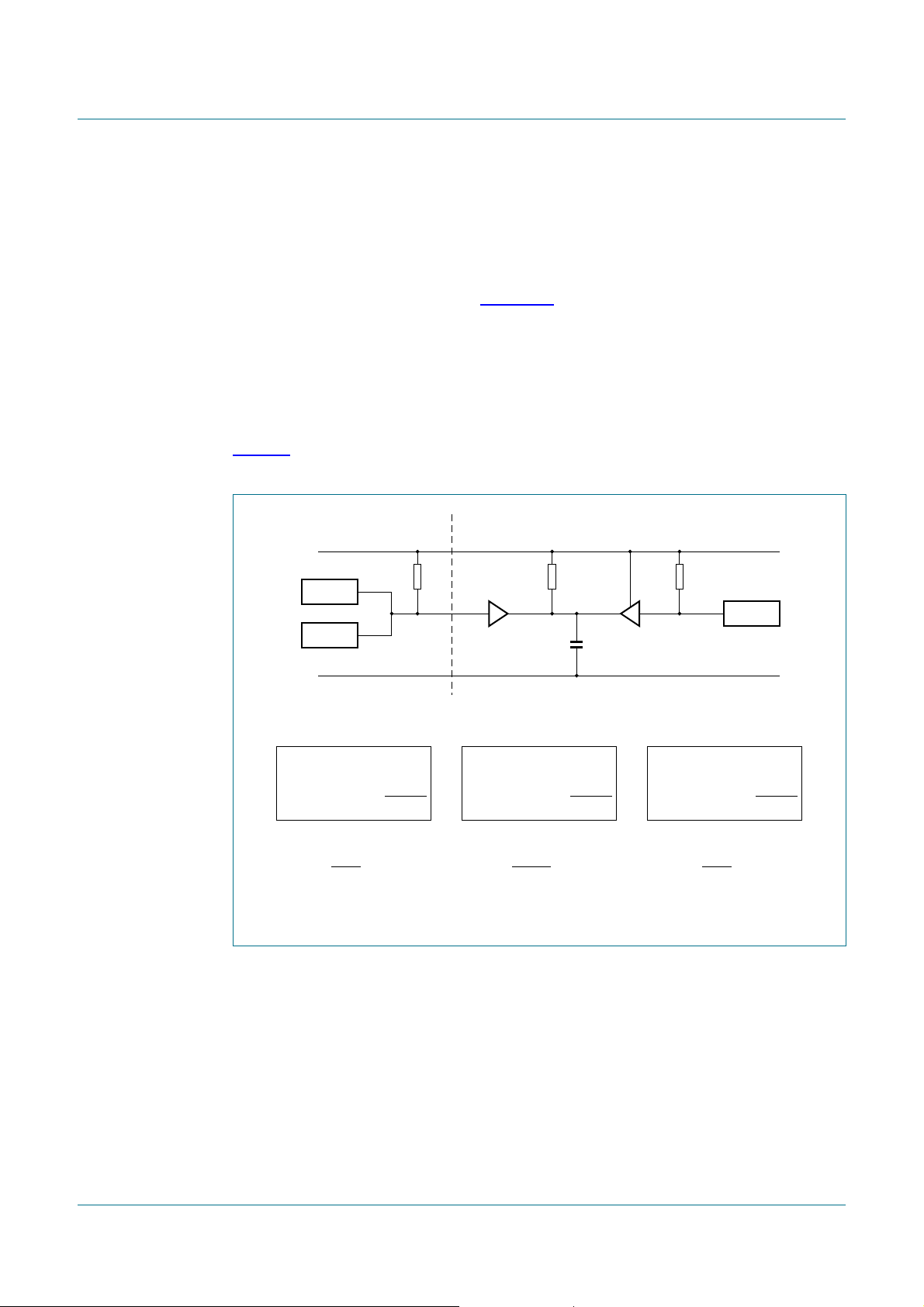

8.2 Quick design-in point-to-point/multi-point circuit information for 5 V

bus

With many variables (cable length/capacitance, local capacitive loading on each I2C-bus,

bus voltages, and bus speed), optimizing a design can be complex and requires

significant study of the application note information. The following circuit and simplified

approach has been checked to provide adequate performance in the typical 100 kHz

application and can be easily implemented by just using the values and circuit shown for

either point-to-point application, up to 30 meters long, or in multiple point applications if

additional nodes need to be added along the way.

P82B715

I2C-bus extender

5 V

4.7 kΩ 4.7 kΩ

2

I

MASTER

SDA

C-BUS

SCL

µC

Remark: Cable bus pull-ups only fitted at the cable ends, not fitted to modules connected along cable.

Sx

Sy

P82B715

470 Ω 470 Ω

Lx

Ly

5V1

optional

ESD protection

20 meter Cat5e

twisted pair cable

optional

ESD protection

optional

ESD

protection

Fig 9. Quick design-in point-to-point/multi-point circuit for 5 V bus

470 Ω 470 Ω

5V1

Lx

P82B715

Ly

5V1

4.7 kΩ 4.7 kΩ

Lx

P82B715

Ly

4.7 kΩ 4.7 kΩ

Sx

Sy

Sx

Sy

SDA

SCL

SDA

SCL

5 V

I2C-BUS

SLAVE

5 V

I2C-BUS

SLAVE

002aad817

Specific information on this circuit implementation:

• The pull-up on each I

2

C-bus is (VCC− 0.4V)/1mA=4.6kΩ, using 4.7 kΩ as the

nearest usual value.

• The net pull-up on the cable bus can be (V

− 0.5 V) / (21 − n) mA where

CC

n = total number of P82B715 modules on the cable. When there are only two

modules, one each end of the cable, the pull-up = (4.5 / 19) = 237 Ω. Make the

pull-ups at each end of the cable equal. Signalling is bidirectional so there is no

advantage optimizing for any one direction. The pull-up at each end will be 474 Ω,

using 470 Ω as the nearest usual value.

• The 100 kHz rise time requirement is 1 µs. Meeting this requires the product of the

bus capacitance and pull-up resistor on each bus section to be less than 1.18 µs. That

provides one capacitance limit. With 4.7 kΩ pull-ups the I2C-bus limit is 250 pF each,

while the 235 Ω sets a cable bus limit at 5000 pF.

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 10 of 23

Page 11

NXP Semiconductors

P82B715

I2C-bus extender

• The 300 ns bus fall time, and the Standard-mode I

2

C-bus limit specification limit of

400 pF, must also be observed. If the 400 pF limit is observed the fall time limit will be

met. Allocate about1⁄3 of this 400 pF limit, or 133 pF, to each I2C-bus leaving2⁄3, or

266 pF, for the cable bus loading as it will appear at the Sx/Sy pins. The ×10 gain of

P82B715 allows the loading at Lx/Ly to be 10 times the load at Sx/Sy, so 2660 pF

maximum. The loading at Lx/Ly due to the other standard buses is 133 pF each. For

just one remote module the cable capacitance may then be up to

(2660 − 133) = 2530 pF. For typical twisted pair or flat cables, as used for telephony or

Ethernet (Cat5e) wiring, that capacitance is around 50 pF to 70 pF / meter so the

cable could, in theory, be up to 50 m long. From practical experience, 30 m has

proven a safe cable length to be driven in this simple way, up to 100 kHz, with the

values shown. Longer distances and higher speeds are possible but require more

careful design.

• If there are severeEMI/ESD tests to be passed then large clamp diodes can be fitted

on the cable bus at each module to VCCand to ground. They may be diodes rated for

this ESD application, or simply large rectifiers (1N4000). The low-impedance bus

easily accommodates their relatively large capacitance. The P82B715 does not

provide any isolation between Lx and Sx, so this clamping method provides the best

protection for the lower voltage I2C-bus parts. The VCC supply should be bypassed

using low-impedance capacitors. Zeners may be fitted to preventthe supply rising due

to rectification during very large interference.

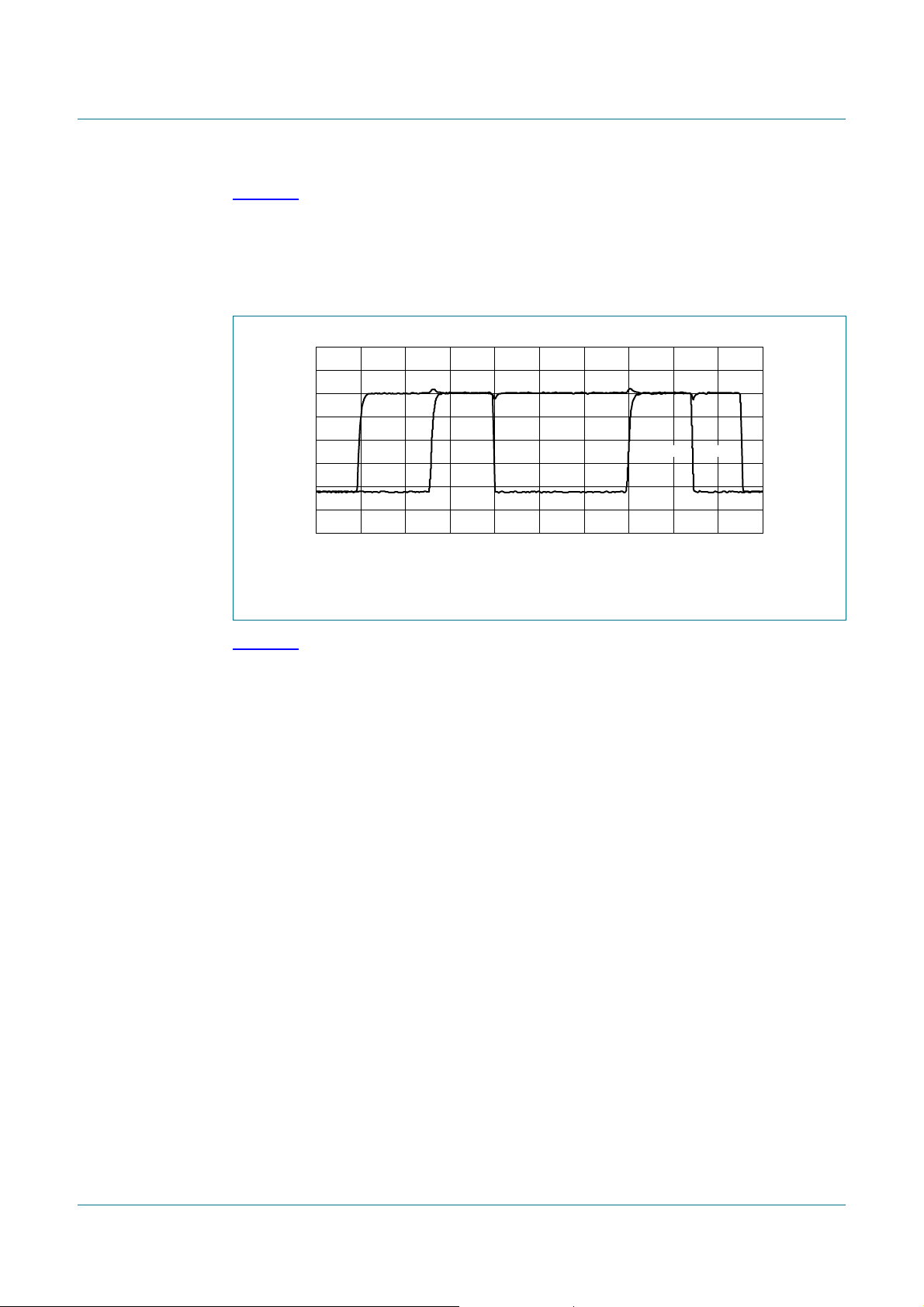

8.3 Comparison of P82B715 versus P82B96 in the quick design-in point-to-point/multi-point circuit

The lower VOL level and ability to operate with any master, slave or bus buffer is the

primary advantage of the using the P82B715 for long distance buses at the disadvantage

of not isolating bus capacitance like the P82B96 or PCA9600 are able to do. The primary

disadvantage of the P82B96 and PCA9600 is that the static level offset needed to isolate

bus capacitance does not allow these devices to operate with other bus buffers with

special offset levels or with master/slaves that require a VIL lower than 0.8 V with noise

margin. Waveforms using the circuit shown in Figure 9 are shown in Figure 10 using the

P82B715 and Figure 11 using the P82B96 so that the designer can clearly see these

trade-offs and choose the type of device that is best for their application.

7

voltage

(V)

5

3

1

−1

0 20168124

SDA

SDA

SCL

SCL

002aad818

SDA

SCL

time (µs)

Fig 10. Clock and data signal output at Sx/Sy from a system with P82B715 at each end of

a 20 m cable

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 11 of 23

Page 12

NXP Semiconductors

Figure 10 shows the I2C-bus waveforms from the long distance line as seen by the slave

on the P82B715 Sx/Sy I/O. Notice that the offset is small and the static levels remain

under 0.4 V. Coupling of SDA to SCL is negligible when SCL is LOW but slight

cross-coupling of SCL to SDA is visible when SDA is HIGH and therefore higher

impedance. The waveforms are very clean and will easily support all available I2C-bus

masters and slaves.

P82B715

I2C-bus extender

7

voltage

(V)

5

3

1

−1

0 20168124

SDA

SCL

SCL

SDA

SCL

SCL

002aad819

SDA

time (µs)

Fig 11. Clock and data signal output to a slave from Sx/Sy of a P82B96 replacing one of

the P82B715s

Figure 11 shows the waveforms on the Sx/Sy I/O as seen by the slave when a P82B96 is

substituted. P82B96 uses a static level offset on the slave side to isolate noise and

loadings on either side of this device. The nominal offset is 0.8 V and that VOLmay create

worst-case design tolerance problems with slave devices that do not use I2C-bus

switching levels, for example TTL levels. It also precludes operation with other bus buffers

using special non-compliant I2C-bus levels.

The P82B96 does not actually interfere with the operation of compliant I2C-bus devices

down to at least 2.7 V supply or even with TTL devices (that switch around 1.4 V). It only

causes a theoretical worst case design tolerance problem because TTL devices have a

worst case 0.8 V requirement. A TTL designer must center the actual switch point

between the two specified limits, 0.8 V and 2.1 V, so in reality it cannot ever approach the

problem 0.8 V theoretical limit.

The PCA9600 is an improved version of the P82B96 offering 1 MHz operation and lower,

more closely controlled VOL on the Sx and Sy pins.

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 12 of 23

Page 13

NXP Semiconductors

9. Limiting values

Table 4. Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

CC

V

bus

V

buff

I DC current (any pin) - 60 mA

P

tot

T

stg

T

amb

[1] Voltages with respect to GND.

The bus voltages quoted are DC voltages and are allowed to be exceeded during any negative transient

undershoot that may be generated by normal operation of P82B715, P82B96 or PCA9600 when any of

those parts are driving long PCB traces, wiring or cables. The Lx/Sx pins have internal protective diodes to

GND that will conduct when the applied bus voltage exceeds approximately −0.6 V and these diodes will

limit the amplitude of the negative undershoot. If required, fitting additional Schottky diodes such as

BAT54A at Sx/Sy may be used to further ensure any undershoot at these pins does not cause conduction of

the diodes inside other ICs connected to Sx/Sy.

P82B715

I2C-bus extender

supply voltage

voltage range I2C-bus, SCL or SDA

voltage range buffered bus

total power dissipation - 300 mW

storage temperature −55 +125 °C

ambient temperature operating −40 +85 °C

[1]

−0.3 +12 V

[1]

0VCCV

[1]

0VCCV

10. Characteristics

Table 5. Characteristics

T

=25°C; VCC= 5 V; unless otherwise specified.

amb

Symbol Parameter Conditions Min Typ Max Unit

Power supply

V

CC

I

CC

supply voltage operating

supply current - 14 - mA

Drive currents

, I

I

Sx

Sy

I

, I

Lx

Ly

output sink on I2C-bus VCC>3V; VSx,VSyLOW = 0.4 V;

output sink on buffered bus VLx, VLy LOW = 0.4 V;

Derated dynamic drive currents for V

ILx, I

Ly

output sink on buffered bus VCC>3V;

=12V - 15 - mA

V

CC

2

C-bus inputs LOW; both

both I

buffered outputs sinking 30 mA

CC

V

I

Lx

V

< 4.5 V

V

I

Sx,ISy

V

V

I

Sx,ISy

LOW on buffered bus = 0.3 V;

Lx,VLy

, ILy= −3mA

LOW on I2C-bus = 0.3 V

Sx,VSy

[1]

LOW = 0.4 V to 1.5 V;

Lx,VLy

sinking on I2C-bus < −4mA

>3V;

CC

LOW = 1.5 V to VCC;

Lx,VLy

sinking on I2C-bus = −7mA

[1]

4.5 - 12 V

-22-mA

[2]

3- - mA

30 - - mA

24 - - mA

24 - - mA

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 13 of 23

Page 14

NXP Semiconductors

P82B715

I2C-bus extender

Table 5. Characteristics

T

=25°C; VCC= 5 V; unless otherwise specified.

amb

…continued

Symbol Parameter Conditions Min Typ Max Unit

Input currents

, I

I

Sx

Sy

, I

I

Lx

Ly

, I

I

Lx

Ly

input current from I2C-bus ILx, ILy sink on buffered bus = 30mA - - −3mA

input current from buffered bus VCC>3V; ISx, ISy sink on

2

I

C-bus = 3 mA

leakage current on buffered bus VCC= 3 V to 12 V; VLx, VLy=VCC and

V

, VSy=V

Sx

CC

[2]

--−3mA

- - 200 µA

Impedance transformation

Z

in/Zout

input/output impedance VSx<VLx and the buffer is active;

I

sinking 30 mA on buffered bus

Lx

81013

Buffer delay times

t

rise/fall delay

ISxto V

ISyto V

t

rise/fall delay

VLxto V

VLyto V

[1] Operation with reduced performance is possible down to 3 V.Typical static sinking performance is not degraded at 3 V, but the dynamic

sink currents while the output is being driven through 0.5VCC are reduced and can increase fall times. Timing-critical designs should

accommodate the guaranteed minimums.

[2] Buffer is passive in this test. The Sx/Sy sink current flows via an internal resistor to the driver connected at the Lx/Ly I/O.

[3] A conventional input-output delay will not be observed in the Sx/Lx voltage waveforms because the input and output pins are internally

tied with a 30 Ω resistor so they show equal logic voltage levels, to within 100 mV. When connected in an I2C-bus system, an Sx/Sy

input pin cannot rise/fall until the buffered busload at the output pin has been driven by the internal amplifier. This test measures the bus

propagation delay caused to falling or rising voltages at the Lx/Ly output (as well as the Sx/Sy input) by the amplifier’s response time.

The figure given is measured with a drive current as shown in Figure 12. Because this is a dynamic bus test in which a corresponding

bus driving IC has an output voltage well above 0.4V, 6 mA is used instead of the static 3 mA.

[4] The signal path Lx to Sx and Ly to Sy is passive via the internal 30 Ω resistor. There is no amplifier involved and essentially no signal

propagation delay.

time delay to VLx voltage

crossing 0.5V

Lx

current step I

Ly

for input drive

CC

at Sx

Sx

buffer time delay of switching

edges between V

Sx

V

Sy

output

Sx

input and

Lx

Figure 12; RLx pull-up = 270 Ω;

see

no capacitive load; V

pull-up = 4700 Ω;

R

Sx

no capacitive load; V

CC

CC

=5V

=5V

[3]

- 250 - ns

[4]

-0-ns

11. Test information

5 V

input

current

input and

voltage

output

t

delay

t

delay

5 V

0 V

002aad693

input

I = 6 mA

4.7 kΩ

Sx Lx

P82B715

V V V

270 Ω

Lx Sx

P82B715

4.7 kΩ

output

Fig 12. Test circuit for delay times

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 14 of 23

Page 15

NXP Semiconductors

12. Package outline

P82B715

I2C-bus extender

DIP8: plastic dual in-line package; 8 leads (300 mil)

D

seating plane

A

L

Z

e

b

8

pin 1 index

1

w M

b

1

b

2

5

SOT97-1

M

E

A

2

A

c

(e )

1

M

H

E

1

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

UNIT

mm

inches

Note

1. Plastic or metal protrusions of 0.25 mm (0.01 inch) maximum per side are not included.

A

max.

OUTLINE

VERSION

SOT97-1

A

12

min.

max.

050G01 MO-001 SC-504-8

b

1.73

0.53

1.14

0.38

0.068

0.021

0.045

0.015

IEC JEDEC JEITA

b

1

4

0 5 10 mm

scale

b

2

0.36

1.07

0.23

0.89

0.014

0.042

0.009

0.035

REFERENCES

(1) (1)

cD E e M

9.8

6.48

9.2

6.20

0.39

0.26

0.36

0.24

1

3.60

3.05

0.14

0.12

E

8.25

7.80

0.32

0.31

EUROPEAN

PROJECTION

10.0

0.39

0.33

M

L

e

H

8.3

w

max.

0.2542.54 7.62

1.154.2 0.51 3.2

0.010.1 0.3

0.0450.17 0.02 0.13

ISSUE DATE

99-12-27

03-02-13

(1)

Z

Fig 13. Package outline SOT97-1 (DIP8)

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 15 of 23

Page 16

NXP Semiconductors

P82B715

I2C-bus extender

SO8: plastic small outline package; 8 leads; body width 3.9 mm

D

c

y

Z

8

pin 1 index

1

e

5

A

2

A

4

w M

b

p

SOT96-1

E

H

E

1

detail X

A

X

v M

A

Q

(A )

L

p

L

A

3

θ

0 2.5 5 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT96-1

A

A1A2A3b

max.

0.25

1.75

0.10

0.010

0.069

0.004

p

1.45

1.25

0.057

0.049

IEC JEDEC JEITA

076E03 MS-012

0.25

0.01

0.49

0.36

0.019

0.014

0.25

0.19

0.0100

0.0075

UNIT

inches

Notes

1. Plastic or metal protrusions of 0.15 mm (0.006 inch) maximum per side are not included.

2. Plastic or metal protrusions of 0.25 mm (0.01 inch) maximum per side are not included.

(1)E(2)

cD

5.0

4.8

0.20

0.19

REFERENCES

eHELLpQZywv θ

4.0

3.8

0.16

0.15

1.27

0.05

6.2

5.8

0.244

0.228

1.05

1.0

0.4

0.039

0.016

0.7

0.6

0.028

0.024

0.25 0.10.25

0.010.010.041 0.004

EUROPEAN

PROJECTION

(1)

0.7

0.3

0.028

0.012

ISSUE DATE

99-12-27

03-02-18

o

8

o

0

Fig 14. Package outline SOT96-1 (SO8)

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 16 of 23

Page 17

NXP Semiconductors

13. Soldering of SMD packages

This text provides a very brief insight into a complex technology. A more in-depth account

of soldering ICs can be found in Application Note

soldering description”

13.1 Introduction to soldering

Soldering is one of the most common methods through which packages are attached to

Printed Circuit Boards (PCBs), to form electrical circuits. The soldered joint provides both

the mechanical and the electrical connection. There is no single soldering method that is

ideal for all IC packages. Wave soldering is often preferred when through-hole and

Surface Mount Devices (SMDs) are mixed on one printed wiring board; however, it is not

suitable for fine pitch SMDs. Reflow soldering is ideal for the small pitches and high

densities that come with increased miniaturization.

13.2 Wave and reflow soldering

Wave soldering is a joining technology in which the joints are made by solder coming from

a standing wave of liquid solder. The wave soldering process is suitable for the following:

.

P82B715

I2C-bus extender

AN10365 “Surface mount reflow

• Through-hole components

• Leaded or leadless SMDs, which are glued to the surface of the printed circuit board

Not all SMDs can be wave soldered. Packages with solder balls, and some leadless

packages which have solder lands underneath the body, cannot be wave soldered. Also,

leaded SMDs with leads having a pitch smaller than ~0.6 mm cannot be wave soldered,

due to an increased probability of bridging.

The reflow soldering process involves applying solder paste to a board, followed by

component placement and exposure to a temperature profile. Leaded packages,

packages with solder balls, and leadless packages are all reflow solderable.

Key characteristics in both wave and reflow soldering are:

• Board specifications, including the board finish, solder masks and vias

• Package footprints, including solder thieves and orientation

• The moisture sensitivity level of the packages

• Package placement

• Inspection and repair

• Lead-free soldering versus SnPb soldering

13.3 Wave soldering

Key characteristics in wave soldering are:

• Process issues, such as application of adhesive and flux, clinching of leads, board

transport, the solder wave parameters, and the time during which components are

exposed to the wave

• Solder bath specifications, including temperature and impurities

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 17 of 23

Page 18

NXP Semiconductors

13.4 Reflow soldering

Key characteristics in reflow soldering are:

• Lead-freeversusSnPb soldering; note that a lead-free reflow process usually leads to

• Solder paste printing issues including smearing, release, and adjusting the process

• Reflow temperature profile; this profile includes preheat, reflow (in which the board is

Table 6. SnPb eutectic process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (°C)

< 2.5 235 220

≥ 2.5 220 220

P82B715

I2C-bus extender

higher minimum peak temperatures (see Figure 15) than a SnPb process, thus

reducing the process window

window for a mix of large and small components on one board

heated to the peak temperature) and cooling down. It is imperative that the peak

temperature is high enough for the solder to make reliable solder joints (a solder paste

characteristic). In addition, the peak temperature must be low enough that the

packages and/or boards are not damaged. The peak temperature of the package

depends on package thickness and volume and is classified in accordance with

Table 6 and 7

Volume (mm3)

< 350 ≥ 350

Table 7. Lead-free process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (°C)

Volume (mm3)

< 350 350 to 2000 > 2000

< 1.6 260 260 260

1.6 to 2.5 260 250 245

> 2.5 250 245 245

Moisture sensitivity precautions, as indicated on the packing, must be respected at all

times.

Studies have shown that small packages reach higher temperatures during reflow

soldering, see Figure 15.

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 18 of 23

Page 19

NXP Semiconductors

Fig 15. Temperature profiles for large and small components

maximum peak temperature

temperature

MSL: Moisture Sensitivity Level

= MSL limit, damage level

minimum peak temperature

= minimum soldering temperature

P82B715

I2C-bus extender

peak

temperature

time

001aac844

For further information on temperature profiles, refer to Application Note

“Surface mount reflow soldering description”

.

14. Soldering of through-hole mount packages

14.1 Introduction to soldering through-hole mount packages

This text gives a very brief insight into wave, dip and manual soldering.

Wave soldering is the preferred method for mounting of through-hole mount IC packages

on a printed-circuit board.

14.2 Soldering by dipping or by solder wave

Driven by legislation and environmental forces the worldwide use of lead-free solder

pastes is increasing. Typical dwell time of the leads in the wave ranges from

3 seconds to 4 seconds at 250 °C or 265 °C, depending on solder material applied, SnPb

or Pb-free respectively.

The total contact time of successive solder waves must not exceed 5 seconds.

The device may be mounted up to the seating plane, but the temperature of the plastic

body must not exceed the specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling may be necessary immediately

after soldering to keep the temperature within the permissible limit.

AN10365

stg(max)

). If the

14.3 Manual soldering

Apply the soldering iron (24 V or less) to the lead(s) of the package, either below the

seating plane or not more than 2 mm aboveit. If the temperature of the soldering iron bit is

less than 300 °C it may remain in contact for up to 10 seconds. If the bit temperature is

between 300 °C and 400 °C, contact may be up to 5 seconds.

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 19 of 23

Page 20

NXP Semiconductors

14.4 Package related soldering information

Table 8. Suitability of through-hole mount IC packages for dipping and wave soldering

Package Soldering method

CPGA, HCPGA - suitable

DBS, DIP, HDIP, RDBS, SDIP, SIL suitable suitable

PMFP

[1] For SDIP packages, the longitudinal axis must be parallel to the transport direction of the printed-circuit

[2] For PMFP packages hot bar soldering or manual soldering is suitable.

15. Abbreviations

Table 9. Abbreviations

Acronym Description

AdvancedTCA Advanced Telecom Computing Architecture

CMOS Complementary Metal-Oxide Semiconductor

DDC Data Display Channel

EMI ElectroMagnetic Interference

ESD ElectroStatic Discharge

FRU Field Replaceable Unit

HBM Human Body Model

2

C-bus Inter-Integrated Circuit bus

I

I/O Input/Output

IC Integrated Circuit

IPMB Intelligent Platform Management Bus

MM Machine Model

PMBus Power Management Bus

RC Resistor-Capacitor network

ShMM Shelf Management Module

SMBus System Management Bus

TTL Transistor-Transistor Logic

[2]

board.

P82B715

I2C-bus extender

Dipping Wave

[1]

- not suitable

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 20 of 23

Page 21

NXP Semiconductors

P82B715

I2C-bus extender

16. Revision history

Table 10. Revision history

Document ID Release date Data sheet status Change notice Supersedes

P82B715_8 20091109 Product data sheet - P82B715_7

Modifications:

P82B715_7 20080529 Product data sheet - P82B715_6

P82B715_6

(9397 750 12452)

P82B715_5

(9397 750 11094)

P82B715_4

(9397 750 08163)

• Table 4 “Limiting values”, Table note [1]: added 2

20031202 Product data ECN 853-2240 01-A14516

20030220 Product data ECN 853-2240 29410

20010306 Product data ECN 853-2240 25757

nd

paragraph.

of 14 Nov 2003

of 22 Jan 2003

of 06 Mar 2001

P82B715_5

P82B715_4

P82B715_3

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 21 of 23

Page 22

NXP Semiconductors

17. Legal information

17.1 Data sheet status

P82B715

I2C-bus extender

Document status

Objective [short] data sheet Development This document contains data from the objective specification for product development.

Preliminary [short] data sheet Qualification This document contains data from the preliminary specification.

Product [short] data sheet Production This document contains the product specification.

[1] Please consult the most recently issued document before initiating or completing a design.

[2] The term ‘short data sheet’ is explained in section “Definitions”.

[3] The product statusof device(s) described inthis document mayhave changed sincethis document waspublished and maydiffer incase of multipledevices. The latestproduct status

information is available on the Internet at URL

[1][2]

Product status

17.2 Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. NXP Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information includedhereinand shall havenoliability for theconsequencesof

use of such information.

Short data sheet — A short data sheet is an extract from a full data sheet

with thesameproduct type number(s) andtitle. A short data sheet isintended

for quickreference only and should not be relied upontocontain detailed and

full information. For detailed and full information see the relevant full data

sheet, which is available on request via the local NXP Semiconductors sales

office. In case of any inconsistency or conflict with the short data sheet, the

full data sheet shall prevail.

17.3 Disclaimers

General — Information in this document is believed to be accurate and

reliable. However,NXP Semiconductors does not give anyrepresentationsor

warranties, expressedor implied, as to the accuracyorcompleteness of such

information and shall have no liability for the consequences of use of such

information.

Right to make changes — NXP Semiconductors reserves the right to make

changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This documentsupersedesandreplaces all information supplied prior

to the publication hereof.

Suitability for use — NXP Semiconductors products are not designed,

authorized or warranted to be suitable for use in medical, military, aircraft,

space or life support equipment, nor in applications where failure or

malfunction of an NXP Semiconductors product can reasonably be expected

to result in personal injury, death or severe property or environmental

[3]

http://www.nxp.com.

Definition

damage. NXP Semiconductors accepts no liability for inclusion and/or use of

NXP Semiconductors products in such equipment or applications and

therefore such inclusion and/or use is at the customer’s own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. NXP Semiconductors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

Limiting values — Stress above one or more limiting values (as defined in

the Absolute MaximumRatingsSystem of IEC 60134) may cause permanent

damage to thedevice. Limitingvalues are stressratingsonly and operation of

the device at these or any other conditions above those given in the

Characteristics sections of this document is not implied. Exposure to limiting

values for extended periods may affect device reliability.

Terms and conditions of sale — NXP Semiconductors products are sold

subject to the general terms and conditions of commercial sale, as published

at

http://www.nxp.com/profile/terms, including those pertaining to warranty,

intellectual property rights infringement and limitation of liability, unless

explicitly otherwise agreed to in writing by NXP Semiconductors. In case of

any inconsistency or conflict between information in this document and such

terms and conditions, the latter will prevail.

No offer to sell or license — Nothing in this document may be interpreted

or construed as an offer to sell products that is open for acceptance or the

grant, conveyance or implication of anylicenseunder any copyrights, patents

or other industrial or intellectual property rights.

Export control — This document as well as the item(s) described herein

may be subject to export control regulations. Export might require a prior

authorization from national authorities.

17.4 Trademarks

Notice: Allreferenced brands, productnames, service names and trademarks

are the property of their respective owners.

I2C-bus — logo is a trademark of NXP B.V.

18. Contact information

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

P82B715_8 © NXP B.V. 2009. All rights reserved.

Product data sheet Rev. 08 — 9 November 2009 22 of 23

Page 23

NXP Semiconductors

19. Contents

P82B715

I2C-bus extender

1 General description . . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4 Ordering information. . . . . . . . . . . . . . . . . . . . . 2

4.1 Ordering options. . . . . . . . . . . . . . . . . . . . . . . . 2

5 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6 Pinning information. . . . . . . . . . . . . . . . . . . . . . 3

6.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 3

7 Functional description . . . . . . . . . . . . . . . . . . . 4

7.1 Sx, Sy: I

2

C-bus SDA or SCL. . . . . . . . . . . . . . . 4

7.2 Lx, Ly: buffered bus LDA or LCL. . . . . . . . . . . . 5

7.3 V

, GND: positive and negative supply pins. . 5

CC

8 Application design-in information . . . . . . . . . . 5

8.1 I

2

C-bus systems . . . . . . . . . . . . . . . . . . . . . . . . 6

8.1.1 Pull-up resistance calculation. . . . . . . . . . . . . . 6

8.1.2 Calculating static bus drive currents. . . . . . . . . 7

8.2 Quick design-in point-to-point/multi-point

circuit information for 5 V bus . . . . . . . . . . . . . 10

8.3 Comparison of P82B715 versus P82B96

in the quick design-in point-to-point/

multi-point circuit. . . . . . . . . . . . . . . . . . . . . . . 11

9 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . 13

10 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . 13

11 Test information. . . . . . . . . . . . . . . . . . . . . . . . 14

12 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 15

13 Soldering of SMD packages . . . . . . . . . . . . . . 17

13.1 Introduction to soldering . . . . . . . . . . . . . . . . . 17

13.2 Wave and reflow soldering . . . . . . . . . . . . . . . 17

13.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 17

13.4 Reflow soldering . . . . . . . . . . . . . . . . . . . . . . . 18

14 Soldering of through-hole mount packages . 19

14.1 Introduction to soldering through-hole mount

packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

14.2 Soldering by dipping or by solder wave . . . . . 19

14.3 Manual soldering . . . . . . . . . . . . . . . . . . . . . . 19

14.4 Package related soldering information . . . . . . 20

15 Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . 20

16 Revision history. . . . . . . . . . . . . . . . . . . . . . . . 21

17 Legal information. . . . . . . . . . . . . . . . . . . . . . . 22

17.1 Data sheet status . . . . . . . . . . . . . . . . . . . . . . 22

17.2 Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

17.3 Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

17.4 Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

18 Contact information . . . . . . . . . . . . . . . . . . . . 22

19 Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section ‘Legal information’.

© NXP B.V. 2009. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: 9 November 2009

Document identifier: P82B715_8

Loading...

Loading...