Page 1

NX-MOUNT-ART-L

Large Full Motion Mount

INSTRUCTION MANUAL

V1

V1

CAUTION: DO NOT EXCEED MAXIMUM LISTED WEIGHT

CAPACITY. SERIOUS INJURY OR PROPERTY DAMAGE

MAY OCCUR!

Small Full Motion Mount

Max Screen Size: 70”

Max weight: 125lbs

P1

Page 2

Congratulations on the purchase of your new TV Mount. At NXG

Technology we design our products to be simple to use, durable, &

furnctional.

Like all NXG products, our mount line has evolved from hours of

rigorous testing by our engineers and customers and were

designed to provide you with years of enjoyment.

Please take a moment to review the installation instructions to

ensure that you get the most from your new mount.

support@nxgtechnology.com

DISCLAIMER – WARNING INFORMATION

Disclaimer – NXG™ has extended every effort to ensure to accuracy and completeness of this manual. However, NXG does not claim that the information

covers all installation and or operational variables. The information contained in this document is subject to change without notice or obligation of any kind.

Regarding the information contained herein, NXG makes no representation of warranty, expressed or implied, and assumes no responsibility for accuracy,

sufficiency, or completeness of the information contained in this document.

WARNING: FAILURE TO READ, THOROUGHLY UNDERSTAND, AND FOLLOW ALL INSTRUCTIONS CAN RESULT IN SERIOUS PERSONAL INJURY,

DAMAGE TO PERSONAL PROPERTY, OR VOIDING OF FACTORY WARRANTY!

It is the responsibility of the installer to ensure all components are properly assembled and installed using the instructions provided. If you do not understand these

instructions or have any questions or concerns, please send questions to support@nxgtechnology.com

Do not attempt to install or assemble this product if the product or hardware is damaged or missing. The included hardware is designed for use on vertical walls

constructed of wood studs or solid concrete. A wood stud wall is defined as consisting of a minimum of 2x4 wooden studs (2” wide by 4” deep) with a maximum of

5/8” drywall. The included hardware is not designed for use with metal studs or cinderblock walls. If you’re uncertain about the construction of your wall, then

please consult a qualified contractor or installer for assistance. For a safe installation, the wall you are mounting to must support 4 times the weight of the total load.

If not, then the surface must be reinforced to meet this standard. The installer is responsible for verifying that the wall structure and hardware used in any

installation method will safely support the total load.

TOOLS NEEDED

SYMBOLS

Drill

Level

Caution

Tighten Socket Wrench

7/32”

5.5 mm

3/8”

10 mm

Pencil Mark

Screwdriver

Heavy!

P2

Page 3

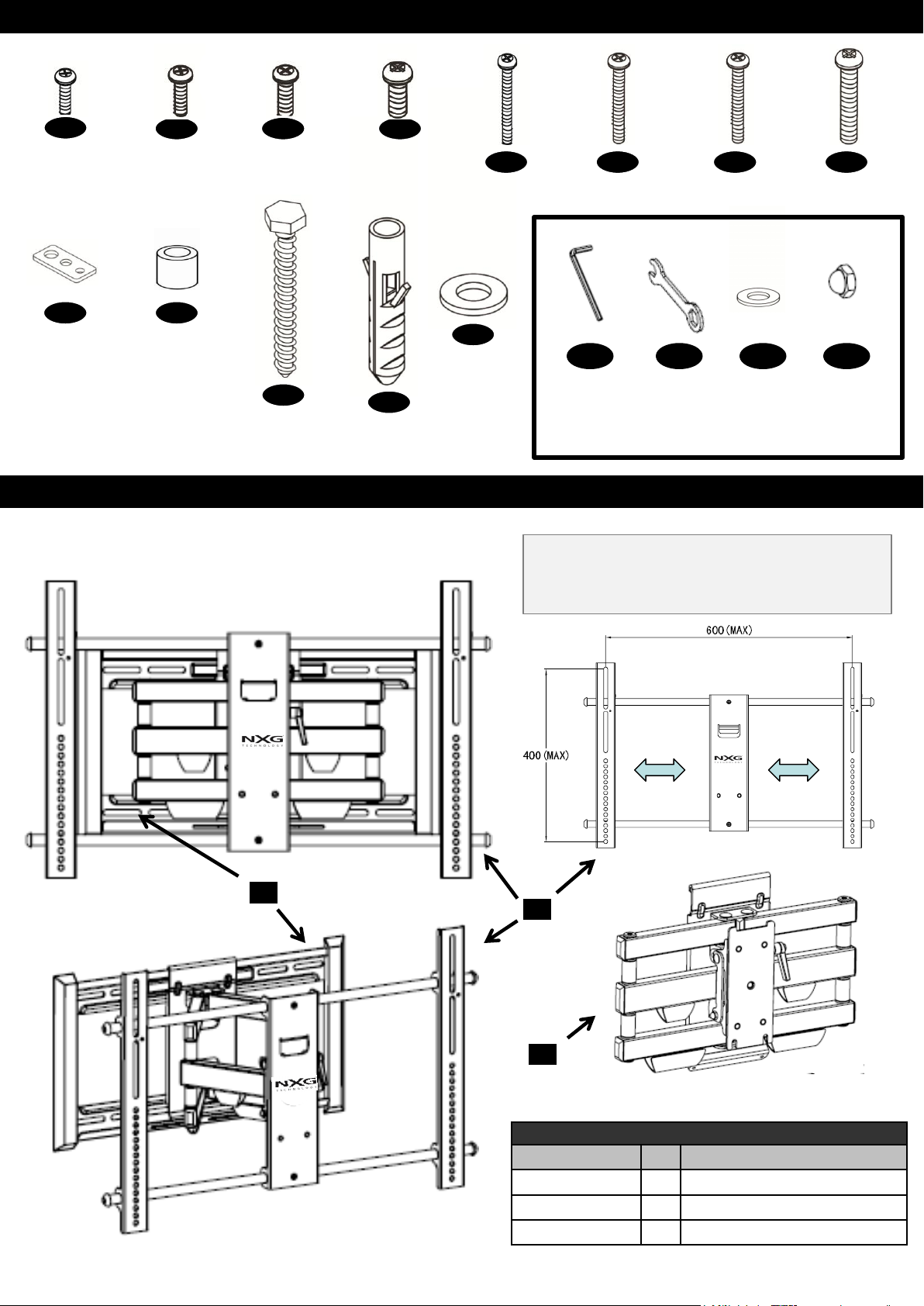

HARDWARE PRODUCT NUMBERS

1

M4 x 12

X 4

9

SQUARE

WASHER

X 4

2

M5 x 12

X 4

10

5mm

SPACER

X 8

3

M6 x 15

X 4

11

8 mm LAG

BOLT

X 4

PRODUCT COMPONENT PARTS

4

M8 x 15

X 4

12

ANCHOR

X 4

M4 x 25

13

STEEL

WASHER

X 4

X 4

6 5 7

M5 x 25

X 4

M6 x 25

X 4

8

M8 x 25

X 4

Adapter Hardware

A1

SECURITY

ALLEN

WRENCH

4 mm

A2

M6 X 5/8”

X 8

WRENCH

A3 A4

M6

WASHER

X 2

M6 ACORN

NUT

X 2

Universal Adapter Range

Minimum: 200mm x 100mm (W X H)

Maximum: 600mm x 400mm (W X H)

A

B

C

Product Components

Contents Qty

A 1 Wall Plate

B 1 Universal Monitor Plate

C 1 Arm Assembly

Description

P3

Page 4

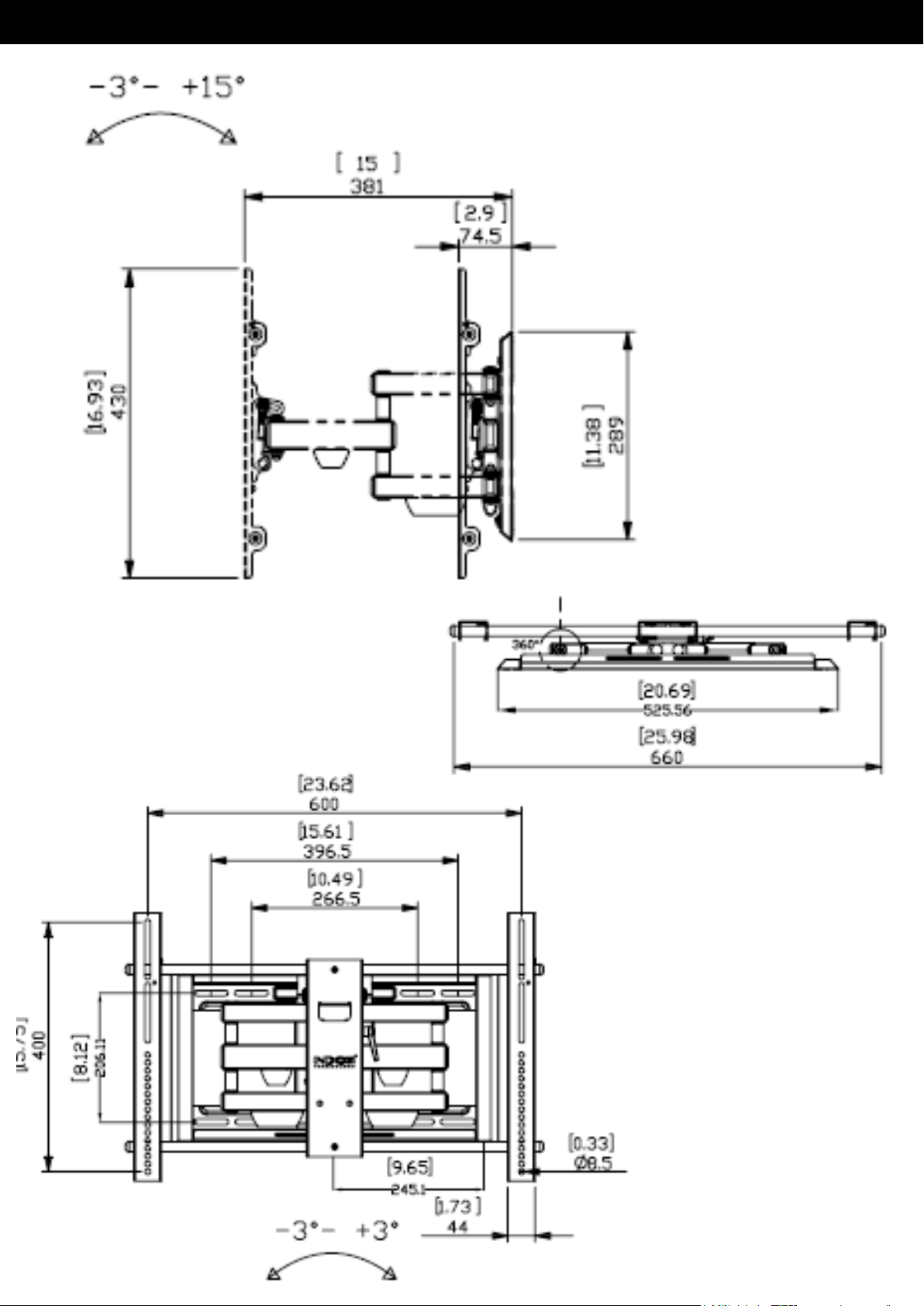

PRODUCT DIMENSIONS AND SPECIFICATIONS

60 lbs

MW60C44

P4

Page 5

CORNER MOUNTING INFORMATION

The Large Full Motion Mount can be

installed in a corner location when

needed. Prior to installing the

Mount it is important to determine

the appropriate corner wall to

install the mount. Please see

diagrams below to assist in

determining the appropriate wall

placement to use.

Drawings below show the Large Full Motion Mount attached to the left

and right of the corner. Depending on the desired angle for viewing,

please review to determine which wall to mount your panel.

Drawing shows panel mounted to left corner

wall

Drawing shows panel mounted to the right

corner wall

Maximum angle for corner placement decreases as panel size increases.

P5

Page 6

STEP 1- FLAT BACK FLAT PANEL (UNIVERSAL MONITOR PLATE)

Connect Universal Monitor Plate to flat panel

SQUARE

WASHER

X 4

1

2

3

4

9

9

B

X4

STEP 1- CURVED BACK FLAT PANEL (UNIVERSAL MONITOR PLATE)

Connect Universal Monitor Plate to flat panel

SQUARE

WASHER

X 4

5

6

7

8

9

10

9

10

Spacers can also be used

to provide clearance for

cables and connectors.

X4

10

B

P6

Page 7

STEP 1- CENTER UNIVERSAL MONITOR PLATE

Monitor Plate must be centered (horizontal plane) on back of flat panel

STEP 1- SECURE UNIVERSAL MONITOR PLATE VERTICAL RAILS

Secure vertical rails to horizontal

chrome rod on Monitor Plate with

pre-installed screws.

X2

P7

Page 8

STEP 2- PRIOR TO EXTENDING ARMS REMOVE ARM ASSEMBLY FROM WALL

PLATE

Prior to extending arms remove 2

security screws with security

Allen wrench to remove Arm

Assembly from Wall Plate. Note- 2

security screws will be used in Step 4 to

reattach arm assembly to wall mount.

Remove Arm Assembly by gently

lifting vertically off Wall Plate. Wall

Plate is now ready to attach to wall

surface (Step 3).

P8

Page 9

STEP 3A- WOOD STUD INSTALLATION (CONCRETE INSTALLATION SKIP TO 3B)

Find stud and mark edge and center locations

Ubique el panel y marque las ubicaciones de los bordes y el centro.

Repérez l'emplacement d'une poutre, puis marquez l'emplacement des bords et du centre de cette poutre.

LEVEL WALL PLATE

WITH INCLUDED

BUBBLE LEVEL AND

MARK HOLES FOR

DRILL BIT PILOT HOLE

STEP 3A – DRILL PILOT HOLE AND MOUNT WALL PLATE

Mount wall plate

Coloque la placa de pared

Montez la plaque murale

13

DRILL BIT

NOT INCLUDED

Secure lag bolts with

steel washer to Wall

Plate

13

11

11

13

X4

P9

Page 10

STEP 3B – SOLID CONCRETE INSTALLATION

Solid Concrete

Concreto sólido

Béton massif

Drill Bit

S. broca

Foret

DRILL BIT

NOT INCLUDED

Level

Nivelado

Level

LEVEL WALL PLATE

WITH INCLUDED

BUBBLE LEVEL AND

MARK HOLES FOR DRILL

BIT PILOT HOLE

STEP 3B – DRILL PILOT HOLES AND MOUNT WALL PLATE

Drill pilot hole

Realice el agujero piloto

Percez le trou de guidage

• Insert Wall Anchors into

Concrete Wall

•Secure Lag Bolts to Wall Plate

13

11

13

Wall Screws

Wall Anchors

1

12

X4

P10

Page 11

STEP 4- ATTACH MOUNT ASSEMBLY TO WALL PLATE

Position Arm Assembly to desired lateral

C

position on wall plate for optimum placement of

Flat Panel. Secure Arm Assembly to Wall plate

using 4mm Security Allen Key.

A

A1

STEP 5- ATTACH UNIVERSAL MOUNT PLATE TO ARM ASSEMBLY & WALL

PLATE

Heavy, Assistance

Required

TRES LOURD ! Cette etape

requiert deux personnes

!PESADO! Necesitara ayuda

para

realizar esta operacion

C

B

A

P11

Page 12

SECURE MONITOR PLATE TO ARM ASSEMBY

A3

Secure Acorn Nut

and Washer on

Monitor Plate to

Arm Assembly

(snug tension only)

B

A4

A3

A4

A2

M6 Washer

M6 Acorn Nut

M6 Wrench

X2

A2

ADJUST TILT TENSION/ POST INSTALLATION LEVEL

Adjust tilt mechanism tension with ratchet

handle

Ratchet handle

for tensioning

tilt mechanism.

Rotate

clockwise to

Tension Tilt

Mechanism. If

more tension is

required pull

lever laterally

and rotate

counter clock

wise and repeat

tension step.

Built-in level feature for post installation

correction

P12

Page 13

WARRANTY INFORMATION

Manufacturer warrants this product against defects in material or workmanship for the original

purchaser of the product with the following conditions:

WARRANTY PERIOD:

"The three-Year Limited Manufacturer’s Warranty” covers this product against defects in materials or

workmanship from the date of purchase by the original consumer for a period of three (3) years for

parts and labor.

SERVICE:

If the product fails under normal use due to a manufacturing defect within the warranty period, the

consumer will be responsible for the cost of shipping the product to an authorized service center NXG Technology will pay for the return shipment. Manufacturer will repair or replace the defective

item with a new or factory rebuilt replacement at Manufacturer’s discretion. The warranty will be

equal to the remainder of the original limited warranty period on the original product or for 90 days

after the date of repair / replacement, whichever is longer. All services must be performed by an

Authorized Service Center. All replaced parts will be the property of Manufacturer.

To obtain warranty service please send an email to support@nxgtechnology.com.

COVERAGE:

Manufacturer's liability under this limited warranty shall in no event exceed the cost of authorized

repairs, replacement with a similar product, reimbursement for authorized repairs or replacement, or

the original cost of the product at the time of purchase, whichever is less.

• This warranty is valid in the continental United States of America.

• Proof of purchase in the form of a bill of sale, invoice or sales receipt, which is evidence that the

unit is within the warranty period, must be presented to obtain warranty service

LIMITATION OF LIABILITY:

There are no other expressed warranties, whether written or oral, other than this printed limited

warranty. All implied warranties, including without limitation the implied warranties or merchantability

or fitness for a particular purpose, are limited to the durations of this limited warranty.

In no event shall NXG Technology be liable for incidental or consequential damages of any nature

whatsoever, including but not limited to lost profit or commercial loss, to the full extent those

damages can be disclaimed by law.

Some states do not allow the exclusion or limitation of incidental or consequential damage, or

limitation of the duration of implied warranties, so the preceding limitations or exclusions may not

apply to all purchasers. This warranty gives the original purchaser specific legal rights, and you may

also have other rights, which may vary from state to state.

P13

Loading...

Loading...