Nuwe OT 020 Service manual

NÜVE SANAYİ MALZEMELERİ İMALAT VE TİCARET A.Ş.

BENCH TOP STEAM STERILIZERS

OT 020 / OT 020V

SERVICE MANUAL

CONTENTS

SECTION 1 INTRODUCTION

1.1. Purpose of the Service Manual 2

1.2. General Purpose 3

SECTION 2 OPERATING PRINCIPLES

2.1. General Overview 4

2.2. Explanations of Functions 4

2.2.1. Power Supply Values 4

2.2.2. Main PCB 4

2.2.3. Clontrol Panel

2.2.4. Water and Steam Unit

SECTION 3 SERVICING

3.1. General Overview 8

3.2. General Failure 9

3.3. Temperature Control Failure

SECTION 4 CALIBRATION PROCEDURE

4.1. How to Measure the Actual Temperature

4.2. Calibration

4.2.1. OT 020

4.2.2. OT 020 V

SECTION 5 SPARE PART REPLACING

4.1. Access to Command and Control 14

4.2. Replacing Main PCB 14

4.3. Replacing Display PCB 14

4.4. Replacing Temperature Sensor 14

4.5. Replacing Condense Selonoid Valve 14

4.6. Replacing Water Filling Solenoid Valve 15

4.7. Replacing Steam Discharge Solenoid Valve 15

4.8. Replacing Vacuum Line Solenoid Valve 15

4.9. Replacing Check Valve 15

4.10. Replacing Vacuum Pump 15

4.11. Replacing Water Pump

4.12. Replacing Safety Valve

4.13. Replacing Water Level Sensor

4.14. Replacing Heater

4.15. Replacing Plastic Panel

4.16. Replacing Locking Bobbin

4.17. Replacing Locking Switch

4.18. Cleaning the Sterilizator Chamber Filter

4.19. Replacing Pressure Switch

SECTION 6 DRAWINGS AND DIAGRAMS

6.1. Electric Circuit Diagram (OT 020)

6.2. Electrical Circuit Diagram (OT 020V)

6.3. Water and Steam Unit Diagrams

SECTION 7 SPARE PART LIST

Spare Parts List 29

5

7

11

13

13

13

13

13

16

16

16

16

16

17

17

17

17

19

20

21

1

SECTION 1

INTRODUCTION

1.1. PURPOSE OF THE SERVICE MANUAL

This manual includes servicing and maintenance information for OT 020 and OT 020V Bench Top

Steam Sterilizers. It is prepared to be used by technicians who were formerly trained by Nuve. This

manual informs the technicians about the operating principles, diagnosing and repairing methods and

spare part replacing.

If any problem determined which is not identified in this manual, please contact to Nuve Servicing

Team.

Factory

Esenboğa Yolu 22 km

Akyurt - ANKARA / TURKEY

Tel : (00 90 312) 399 28 30 ( 3 lines )

Fax : (00 90 312) 399 21 97

e-mail: service@nuve.com.tr

2

1.2. GENERAL PURPOSE

The heating function is provided by means of the stainless heater placed inside the sterilization

chamber. The sterilization cycle consists of the water filling, heating, sterilization, steam discharge and

drying phases.

Water filling: Distilled water is taken from the distilled water tank and pumped into the sterilization

chamber by means of a vacuum pump.

Heating: The distilled water in the sterilization chamber is heated to generate steam at the required

temperature and pressure. During heating, the condense solenoid valve is opened and discharges the

unsaturated steam periodically.

Sterilization: When the sterilization chamber temperature reaches the set temperature sterilization

starts. The sterilization chamber is kept at the required temperature and pressure during the set time.

During sterilization, the condense solenoid valve keeps the pressure in the chamber constant

according to the set temperature.

Steam discharge and drying (OT 020): During the steam discharge phase, the steam in the

sterilization chamber is discharged and after the pressure has dropped to zero, moisture in the

sterilizator chamber is discharged according to driying time set on the OT 020.

Steam discharge and drying (OT 020V): During the steam discharge phase, the steam in the

sterilization chamber is discharged and after the pressure has dropped to zero, the vacuum pump is

operated for drying. During drying, the air intake is ensured by opening the air intake solenoid valve

and taking in fresh air after it has been passed through 0,2 µm biological filter.

3

SECTION 2

OPERATING PRINCIPLES

2.1. GENERAL OVERVIEW

The OT 020 and OT 020V can be split into 4 main groups,

• Power supply values

• Control unit

• Heating unit

• Water and steam unit

2.2. EXPLANATIONS FOR THE FUNCTIONS

2.2.1. Power Supply

The power supply values are listed below.

Glass Fuse Power Supply Power inlet Heater Supply

OT 020 10 A 1500 W 230 V, 50 Hz Stainless tube type

(1450 W)

OT 020V 10 A 1550 W 230 V, 50 Hz Stainless tube type

(1450 W)

2.2.2. Main PCB

The microprocessor controlled main PCB operates on “proportional” heating system. The main PCB

first prepares steam at the required temperature and pressure in the sterilization chamber. Then, it

carries out the sterilization, steam discharge and drying phases as explained in the section 1.2 At the

end of the phases, the sterilizer warns the users with an audible alarm that the cycle has ended.

4

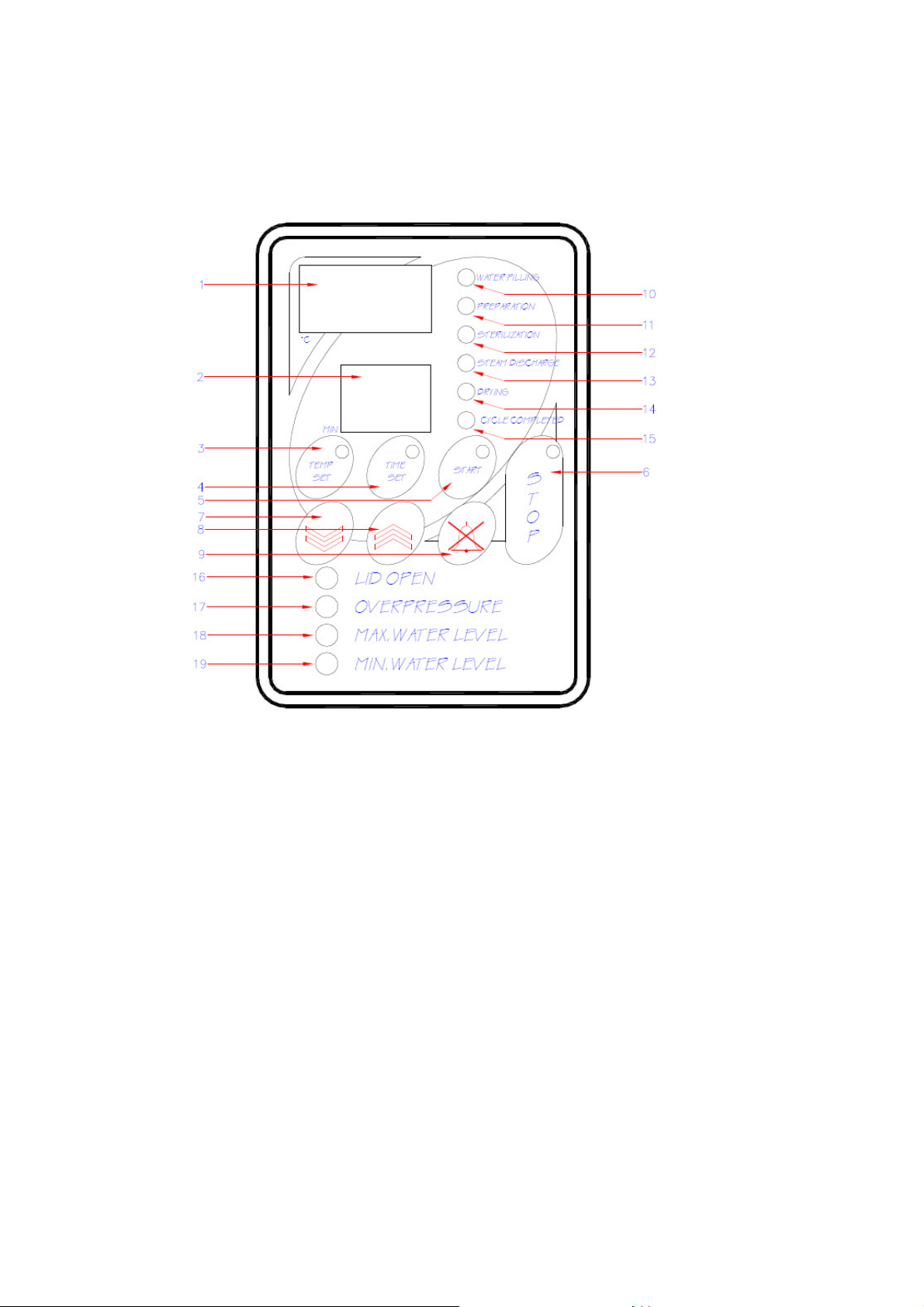

2.2.3. Control Panel

The illustration below shows the functions of the display board. For more information, please see the

OT 020 or OT 020V user’s manual.

Figure 1- OT 020

1. Temperature display 11. Preperation led

2. Time display 12. Sterilization led

3. Temperature setting key 13. Steam discharge led

4. Time setting key 14. Drying led

5.

Start key

6.

Stop key

7. Value decrease key 17. Overpressure led

8. Value increase key 18. Maximum water level led

9. Alarm mute key 19. Minimum water level led

10. Water filling led

15.

Cycle completed led

16.

Lid open led

5

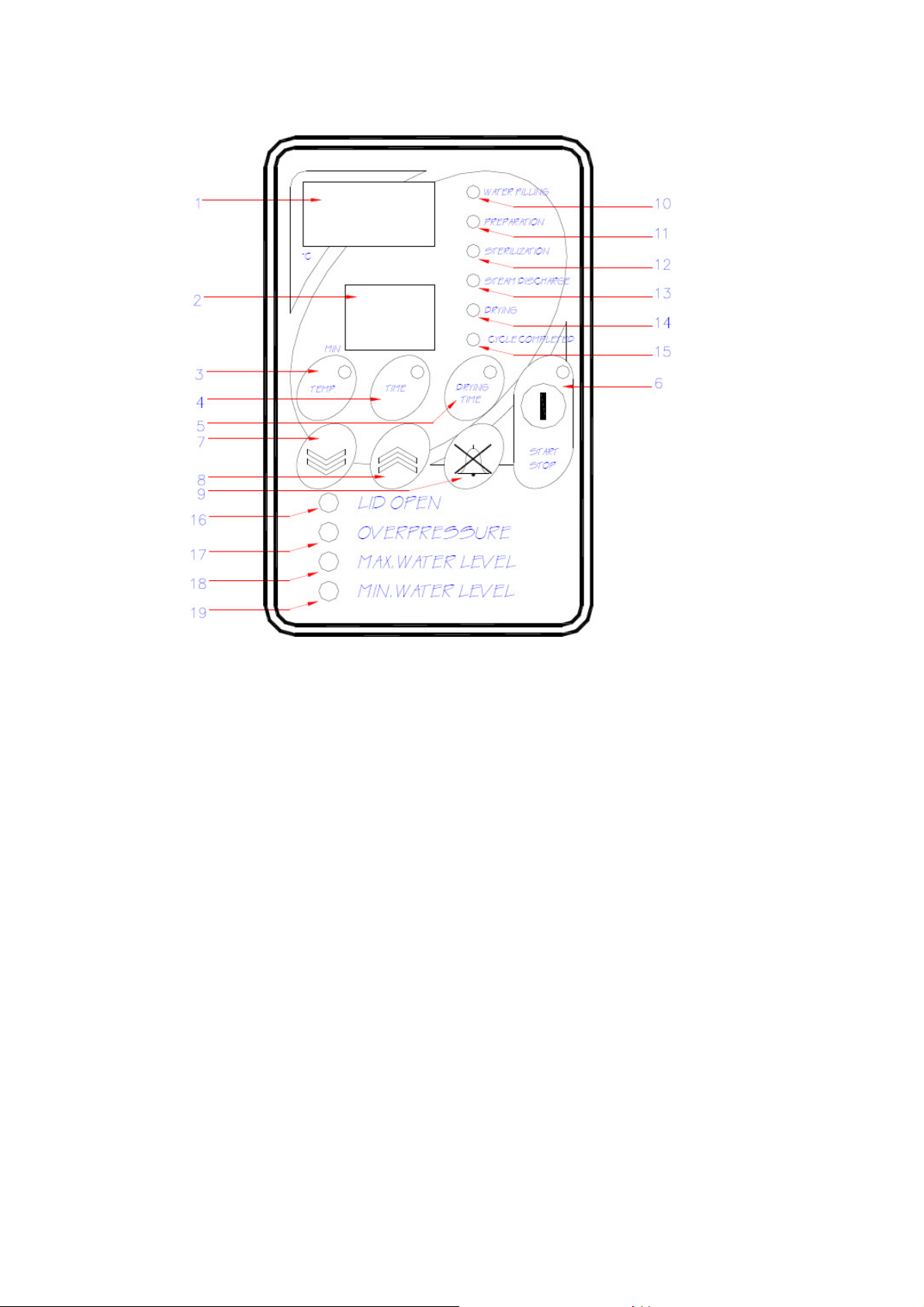

Figure 2- OT 020V

1. Temperature display 11. Preperation led

2. Time display 12. Sterilization led

3. Temperature setting key 13. Steam discharge led

4. Time setting key 14. Drying led

5.

Drying time

6.

Start/Stop key

7. Value decrease key 17. Overpressure led

8. Value increase key 18. Maximum water level led

9. Alarm mute key 19. Minimum water level led

10. Water filling led

15.

Cycle completed led

16.

Lid open led

6

2.2.4. Water and Steam Unit

The steam needed for the sterilization is generated by boiling the distilled water which is taken from the

water tank to the sterilization chamber.

The pressure in the sterilization chamber is followed on the manometer.

The steam charge, steam discharge, air intake♣, condense and vacuum line solenoid valves♣ are

operated as explained in the section 1.2 by the main PCB.

The sterilization chamber safety valve operates if the pressure inside the chamber exceeds 3,5 Bar and

it discharges the excess steam which leads to over-pressure.

The maximum pressure switch cuts the power of heaters when the pressure inside the chamber

exceeds 3 bar to protect the device and user. The minimum pressure switch also prevents door to open

if there is a pressure other than zero (over zero) in the chamber after the sterilization cycle and

provides safe operation. The second minimum pressure switch equipped in OT 020V is used to start

the vacuum pump after the pressure inside the sterilizator chamber drops to zero.

The components of the water and steam unit are listed below,

• Reserve tank

• Manometer

• Water charge solenoid valve

• Steam discharge solenoid valve

• Condense solenoid valve

• Vacuum line solenoid valve♣

• Water pump

• Vacuum pump♣

• Check valve

• Sterilization chamber safety valve (3,5 Bar)

♣

This feature is valid for only OT 020V.

7

SECTION 3

SERVICING

Caution: Before servicing the instrument, please take the necessary precautions for your

health. Please respect to the warnings on the unit!!

Please make sure that you have disconnected the unit before you service it.

3.1. GENERAL OVERVIEW

The failures can be diagnosed according to the following tables.

Most of the arising problems can be determined by the help of a multimeter.

The components on the main PCB must not be replaced even the failure is caused by one of the

components on the main PCB. In this case, please send the failed PCB to factory service along with a

note on which the failure explanations are written.

Before replacing the PCB or any control element, please make sure that the failure is not caused by

weak wire and terminal connections.

8

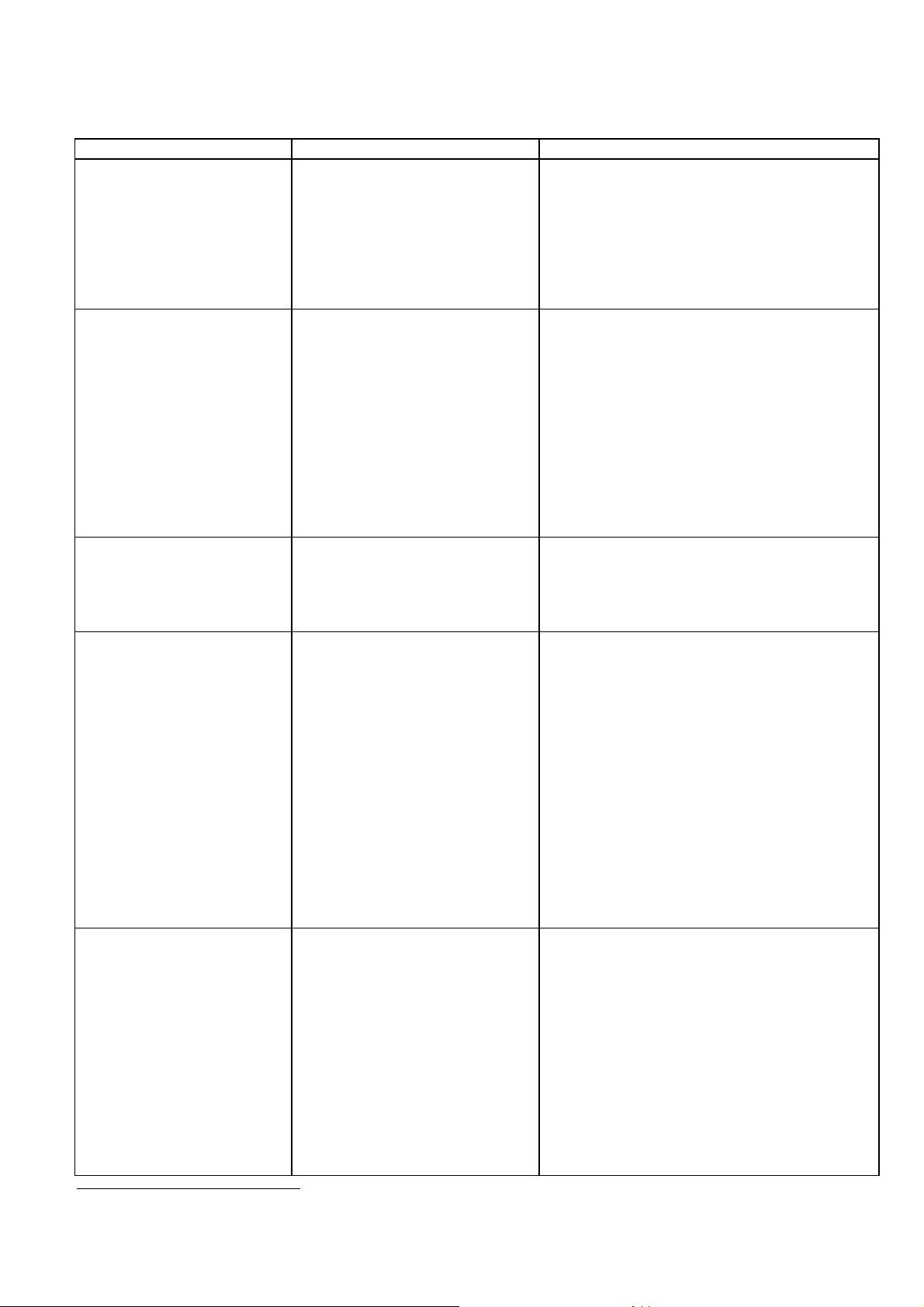

3.2. GENERAL FAILURES

The fuse blows frequently.

Check with a multimeter that there is short circuit

FAILURE PROBABLE CAUSES SOLUTION

1 The on / off switch is ON Power supply inlet failure Check that mains voltage is supplied to the unit.

but it does not lighten,

the display is blank.

The glass fuse is blown. Replace the glass fuse and check the short

2 The on / off switch is ON The main PCB / display PCB Disconnect the connection cable and re-connect

and lightens but the connection cable is not it carefully.

display is blank or some well connected.

segments do not lighten.

The cable with socket is Replace the cable.

defective.

The display PCB is defective. Replace the display PCB.

The main PCB is defective. Replace the main PCB.

Check that the terminal connections and power

supply socket connections are well connected.

circuit that causes the blowing of the fuse.

3 The on / off switch is The on / off switch cable Check the connections and correct them.

OFF but it lightens. connections are connected in

reverse.

4

Short circuit exists. Check the heater with a multimeter. If short-

circuit

exists, replace the heater.

Check all solenoid valve bobbins for short-circuit

with a multimeter. If short-circuit exits in any

bobbin, replace it.

Check the vacuum pump♣ and water pump for

short-circuit. If there is short-circuit, replace that

pump.

Check all other electrical terminals and cables

for short-circuit.

5 The pressure in the The safety valve is open. Close the valve by turning it to the counter

sterilization chamber does clockwise direction.

not increase.

One of the steam charge, Take the capsule of the solenoid valve out and

condense or vacuum line solenoid

valves♣ is open or defective.

clean the core of it. If you cannot solve the

problem replace the solenoid valve.

The heater is defective. Check the heater. Replace it if it is defective.

The safety thermostat does not

outlet for heating. in the safety thermostat terminals. If there is

no short-circuit, replace the safety thermostat.

♣

This feature is valid only for OT 020V.

9

Loading...

Loading...